Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MX-GC5

MX-GC5

SP-MXGC

5

CA-MXGC

Contents

Safety precautions ---------------------------- 1- 2

Preventing static electricity ----------------- 1- 3

Important for laser products ---------------- 1- 4

Disassembly method ------------------------ 1- 5

Adjustment method -------------------------- 1- 18

COPYRIGHT © 2005 Victor Company of Japan,Limited

5

Flow of functional

operation until TOC read -------------- 1- 20

Maintenance of laser pickup -------------- 1- 21

Replacement of laser pickup -------------- 1- 21

Description of major ICs ------------------- 1- 22

SP-MXGC

5

Area Suffix

J ........................ U.S.A.

C ........................ Canada

Page 2

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacture of responsibility for personal injury or property damage

resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are identified in the Parts List of

Service Manual. Electrical components having such features are identified by shading on the

schematics and by (

which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention

of electric shock and fire hazard. When service is required, the original lead routing and dress should

be observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock. Do not use a line isolation

transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each exposed metal parts of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground. Any leakage current must not

exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or

more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F ACtype capacitor between an exposed metal part

and a known good earth ground. Measure the AC

voltage across the resistor with the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and meausre

the AC voltage across the resistor. Now, reverse

the plug in the AC outlet and repeat each

measurement. Voltage measured Any must not

exceed 0.75 V AC(r.m.s.). This corresponds to 0.5

mA AC(r.m.s.).

! ) on the Parts List in the Service Manual. The use of a substitute replacement

AC VOLTMETER

(Having 1000

ohms/v

olts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

each exposed

metal part.

Good earth ground

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

Preventing static electricity

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is

discharged, can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when

performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity

of the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The testers internal power

source can easily destroy the laser diode.

4. Handling the CD changer unit (optical pickup)

1. Do not subject the CD changer unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text.

Remove the anti-static pin when replacing the CD changer

unit. Be careful not to take too long a time when attaching it

to the connector.

CD changer

unit

3. Handle the flexible cable carefully as it may break when

subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that

adjusts the laser power. Do not turn it.

Attention when traverse unit is decomposed

Please refer to “Disassembly method” in the text for

*

pick up and how to detach the CD changer mechanism.

1. Remove the CD changer unit.

2. Disconnect the harness from connector on the CD motor

board.

3. Solder is put up before the card wire is removed from connector

Cn601on the main board as shown in Fig.A and Fig. B.

(When the wire is removed without putting up solder, the

CD pick-up assembly might destroy.)

4. Please remove solder after connecting the card wire with

CN601 when you install picking up in the substrate.

Flexible cable

Fig.A

Soldering

Fig.B

Page 4

Important for laser products

1. CLASS 1 LASER PRODUCT

2. DANGER :

lock failed or defeated. Avoid direct exposure to beam.

3. CAUTION :

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4. CAUTION :

laser radiation and is equipped with safety switches

which prevent emission of radiation when the drawer is

open and the safety interlocks have failed or are

defeated. It is dangerous to defeat the safety switches.

Invisible laser radiation when open and inter

There are no serviceable parts inside the

The compact disc player uses invisible

5. CAUTION : If safety switches malfunction, the laser is able

to function.

6. CAUTION :

of procedures other than those specified herein may

result in hazardous radiation exposure.

!

CAUTION Please use enough caution not

Use of controls, adjustments or performance

to see the beam directly or touch

it in case of an adjustment or

operation check.

FUSE CAUTION

CAUTION:

REPLACE WITH SAME TYPE

AND RATING FUSE (S).

ATTENTION:

REMPLACER PAR UN(LES)

FUSIBLE(S) DE MEME TYPE

ET DE MEME VALEUR

Page 5

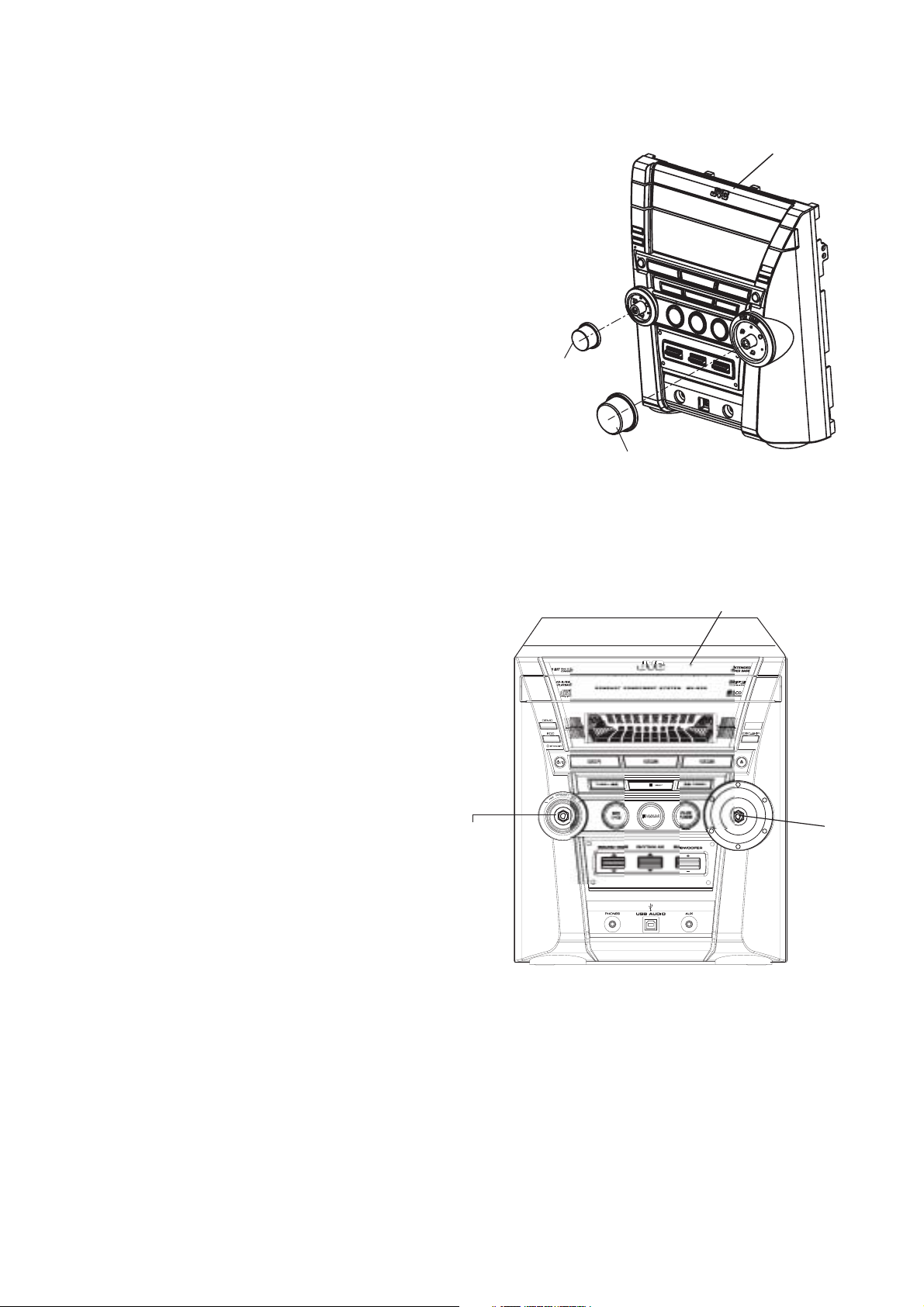

Disassembly method

Commence disassembly of the set by removing the main units and then proceed to the components

and assemblies inside the units.

Replacement of the fuses and the power IC

Top cover

CD changer unit

Front panel assembly

CD changer unit

Removing the main PCB

Removing the CD changer mechanism assembly

Removing the CD pickup

Replacing the loading motor and belt of the CD changer tray

Replacing the CD tray rotor belt of CD changer, and removing the motor

Front panel assembly

Removing the (USB, AUX jack) earphone jack PCB

Removing the control/FL PCB

Removing the volume, preset and CD Function switch PCB

Removing the remote sensor PCB

Removing the standby Led PCB

Removing jack Led backlight PCB

Removing Sound mode PCB

1-5

Page 6

<Disassembly of the main blocks of the set>

Replacement of the fuses and the power IC

Replacing the fuses (See Fig.1)

Prior to performing the following procedure, remove

the left side BOARD.

1. Replace the fuses inside.

Replacing the heat sink cover (See Fig.3)

1. Remove four screws B from the rear panel.

2. Remove four screws

E

from the heat cover.

3. Pull the heat sink cover outward.

[Caution]

Be sure to use fuses with the specified

ratings.

Fuse (F901)

Fuse (F902)

1.6A 250V

3.5A 125V

Fig.1

Replacing the power IC (See Fig.2)

Prior to performing the following procedure, remove

the top cover.

1. Remove the two screws A from the heat sink between

the power IC(STK412-430)

2. Remove the four screws B from the heat sink the

between the power IC (D1889,B1340)

3. Remove the solder fixing the power IC.

E

B

Fig.3

AA

Fig.2

B

Page 7

Top cover

C

Removing the top cover

(See Fig.4 and 5)

1. Remove six screws C that retain the top cover from

the panel rear of the body.

2.

Remove six screws D that retain the top cover from

the two sides of the body.

3. Remove the top cover from the body by lifting it

toward the rear.

Fig.4

Right Front panel assembly Left Front panel assembly

D

D D

D

Fig.5

Page 8

Removing the CD changer unit

(See Fig.6 to 9)

Prior to performing the following procedures, remove

the top cover.

[Caution]

Although the CD mechanism unit can be

removed without removing the CD tray

panel, it is still recommended to remove it

in order to prevent damage.

a. From the front panel side of this set, push in the

sections marked with arrows and pull out the CD

tray toward the front.

b. Remove the CD tray panel by pushing both of

its extremities upward in the direction of the

arrows.

c. Push the CD tray deep into the set.

1.Disconnect the cord wires from the main PCB

CN401,CN601,CN501 and CN203.

2. From the rear of the set, remove two screws E, two

screws F and four screws G on the front panel left

and right side.

3. Handle the CD changer unit rear, take out the unit.

CD tray panel

CD tray panel

Fig.7

E

F

Antenna

terminal

F

Fig.6

Fig.8

G

Fig.9

Page 9

Removing the front panel assembly

(See Fig.10 to 11)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Disconnect the parallel wire and the cord wire from

the connectors CN201, CN401 on the main PCB.

2. Remove one screws H retaining the front panel

assembly onto the bottom of the body.

3. Remove two screws I on the left and right side of the set

retaining the panel front from the bottom and then

remove then GND lug b that comes from the power

amp and supply PCB.

4. Disengage the claws c on both sides of the front

panel assembly and then remove the assembly.

Fig.10

H

Fig.11

GND lug

Claw

b

c

Page 10

<Disassembly of units and assembly

inside this set>

Removing the MAIN PCB

(See Fig.12 to 13)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Disconnect the wires from CN701, CN702 and

CN703 on the CD PACK PCB, which is located on

the down side of the CD changer unit.

2. The four screws J that retain the CD PCB should

be removed.

3. Remove the CD PCB by pulling it toward the side

where the CN701 is located.

4. Using solder, short the CD pickup to connect to

short round.

J

CD PCB

J

Fig.12

J

[Caution]

After re-connecting the wires, be sure to

remove the shorting solder from the GND

connection.

5. Disconnect the card wire from the connector CN701

on the main PCB and then remove the main PCB.

CD PCB

CN601

Short round

Fig.13

Page 11

Removing the CD changer mechanism

assembly (See Fig.14 to 15)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

1. Turn the CD changer mechanism cover base and

remove the screws d connecting the unit to the CD

changer mechanism assembly.

2. Removing four screws e retaining the CD mechanism

holder assembly.

CD changer

unit

[Caution]

CD changer

mechanism

assemb

ly

When replacing the CD changer mechanism

assembly, be sure not to mistake the positions

of the silver color and copper color spring.

e

e

( Green color )

( Red color )

d

Fig.14

e

( Green color )

Fig.15

e

( Red color )

Page 12

Removing the CD pickup (See Fig.16)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the CD changer mechanism.

f

1. Widen the section

.

2. While keeping the section f wide open, push the

section g in the direction of the arrow to remove

the shaft, and then remove the CD pickup.

Replacing the loading motor and rotor

belt of the CD changer (See Fig .17)

Prior to performing the following procedures, remove

the top cover.

Also open the CD changer tray.

CD pickup

f

Shaft

g

1. Remove the two screws L retaining the CD changer

tray loading motor.

2. Remove the two screws M retaining the gear plate

and take it out, after remove the rotor belt from the

pulley.

Replacing the CD turn table and remov-

ing the motor (See Fig. 18 )

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

N

1. Remove the one screws

table).

2. Remove the two screws O retaining the stopper

brackets on both sides of the CD changer unit.

3. Remove the stopper brackets from both sides of

the CD changer unit.

4. Pull out the CD tray from the CD changer unit, all

the way and lift the tray (u/~ ward) to remove.

5. Remove the gear and after push out the tray motor

locker and pull out the tray motor from the CD tray.

retaining the CD (Turn

Fig.16

M

L

Fig.17

Turn table motor

, and then remove the CD tray

Fig.18

Motor locker

Obligue gear

Page 13

Removing the USB,AUX,earphone PCB

(See Fig.19)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

Remove six screws

earphone PCB.

Z

retaining the USB,AUX,

Front panel

assembly

R( 17PCS)

S

T

Z

Fig.19

Q

Removing the remote sensor PCB & the

standby PCB

(See Fig.20)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Remove four screws

P

that retains the

remote sensor PCB.

L

2. Remove four screws

that retains the

standby Led PCB.

Removing the display PCB

(See Fig.21)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

Remote sensor

PCB

P

Display PCB

Q

Fig.20

Front panel

assembly

Standby Led

L

PCB

Q

1. Remove four screws Q that retain the display PCB

from the back of the front panel unit.

Fig.21

Page 14

Removing sound mode and volume , pre-

set and CD function switch PCB

(See Fig.20 to 23)

Prior to performing the following procedures, remove

the top cover.

Also remove the CD changer unit.

Also remove the front panel assembly.

1. Pull out the volume control knob from the front of

the front panel assembly.(Fig.22)

2. Pull out the preset knob from the front of the front

panel assembly (Fig.22)

3. Remove four screws Q retaining the front panel

assembly.

4. Remove the control/FL PCB.

5. Remove eight screws S retaining the sound mode

switch PCB.(Fig.21)

6. Remove seventeen screws R retaining the volume ,

preset and CD founction switch PCB.(Fig.20)

7. Remove two screws T retaining the jack Led

Backlight PCB.

Front panel assembly

Preset Knob

Volume knob

Fig.22

Preset shaft

Front panel

assembly

Volume

shaft

Fig.23

Page 15

Removing the bridge diode

(See D214, D215 and Fig.28)

Prior to performing the following procedures, remove

the top cover and both sides board.

1. Remove two screws W that connect the heat sink.

2. Remove the solder fixing the 4-pin bridge diode

(D214, D215).

Removing the power amp and supply PCB

and the power trans PCB

(See Fig. 2, 29 to 31)

Prior to performing the following procedures, remove

the top cover and CD changer unit.

1. Remove four screws B from the rear panel. (Fig.3)

2. Pull the heat sink cover outward.

3. Remove four screws

the heat sink holder.

4. Remove four screws

and then remove the rear panel.

5. Disconnect the parallel wires from the connectors

FW951 on the power trans PCB.

6. Remove screws Z that retain the power amp and

supply PCB and then remove the assembly.

7. Remove four screws that retain the power trans PCB

and then remove the assembly.

AA

from the rear panel between

YY

that retains the rear panel,

Fuse (F902)

1.6A 250V

Rear panel

W

Fig.28

Fuse (F901)

3.5A 125V

Fig.29

Power amp and

supply PCB

AA

Z(4PCS)

Fig.31

Clamp

YY

Fig.30

Page 16

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check Point

Confirm that the voltage at the pin5

of CN702 is "H"\"L"\"H".

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 20 of

IC611(TE)

Approx

0.3V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig-1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin10 of IC701 is + 0V?

Confirm that the Focus error

S-cuve signal at the pin31 of

IC701 is approx.2Vp-p

Confirm that the signal from

pin26 IC701 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 29 of IC701 (R729)

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of Pin 2 of IC 701

Page 17

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean

the lens with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the

following symptoms will appear.

1. The level of RF output (EFM output : ampli tude of

eye pattern) will below.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the AC OUTLET.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Is the level of

RFOUT under

0.48V 0.1Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the

laser power.Since this adjustment should be performed to match the characteristics of the whole optical

block, do not touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup

should be replaced.

If the semi-fixed resistor would be adjusted when the pickup operates normally, the laser pickup may be

damaged due to excessive current.

NO

Replace it.

Play a disc.

Check the eye-pattern at

Finish.

Pin 2 of IC 701

Page 18

W

W

F

F

W

W

F

F

F

F

0

0

/10V

F

/10V

0

F

F

/50V

/50V

W

W

F

F

4

5

5

r

r

5

4

9

0

8

2

8

6

5

2

4

3

7

3

4

5

6

3

4

5

6

3

4

5

6

3

4

5R16

Description of major ICs STK412-430 (IC201) : Dual low noise operational

1. Equivalent Block Diagram

1

TR41

1

R41

R

TR1

D2

TR2

1

TR

1

C2 C11

C1

R1

TR

TR

TR9

R

R

TR8

TR10

TR19

TR20

TR18

R1

TR1

D12

C12

R1

R1

TR1

R11

TR1

TR11TR12

Comparato

D

D

R

R2

TR

TR7

R7

D1

R17

TR17

TR1

R12

TR51

Comparato

R51

1

1

11

2. Test Circuit

+VH

+VL

GND

-VL

-VH

100uF

/50V

100uF

/50V

100uF

/100V

100uF

/100V

2 3 4

1

GZA

1

1.5kohm

/1

X

5

GZA

X

1

1.5kohm

/1

6

891011 12

7

*1

56kohm

3p

100ohm/1

100u

/100V

100u

/100V

100ohm/1

SUB.GND

(*1)Metal Plate Cement Resistor 0.22ohm+-10%(5W)

*1

56kohm

13

14

3p

100u

16

ohm

33kohm

56

17

100p

ohm

56

100uF

3uH

4.7ohm

4.7ohm/1

4.7ohm/1

3uH

4.7ohm

18 15

100p

2.2uF

56kohm 56kohm

2.2uF

SUB

1kohm

1kohm

0.1u

0.1u

470p

p

47

D

D52

1

Ch2 IN

GND

Ch1 IN

Ch2 OUT

GND

Ch1 OUT

Page 19

CD DRIVE ICS BA5927FM(IC702)

Page 20

BA4558F (IC503) : Dual low noise operational amp.

1. Terminal layout

1. Pin descriptions

OUT1

- IN1

+IN1

VEE

1chip AM/FM, MPX tuner system

+-

Vcc

OUT2

- IN2

-+

+IN2

1. Block diagram

24

FM

RF

23

GND2

22

VCC2

21

20

FM

OSC

FM

MIX

MUTE

ST SW

17 16

DECODER

VCO FF FF

TRIG

15

PHASE

COMP

14

PILOT

DET

FF

1319 18

FM

DET

AM

RF

REG VCC1 GND1

1 2 4 5 10 11 126 7 8 93

AM

MIX

AM

OSC

OSC

BUFFER

2. Pin function

Pin

No.

Symbol

I/O

1 AM_RFIN I AMRF signal input

2 REG. -

3 AM_OSC - AM local oscillation circuit

4 VCC_1 - Power supply terminal

FM_MIXOUT

5

O Output terminal for FM mixer

6 GND_1 - Ground

7

IF_BUFFER

O IF buffer output

8 ST_IND O Stereo indicator output

AM_MIXOUT

9

O Output terminal for AM mixer

10 FM_IF IN I Input of FMIF signal

11 AM_IF IN I Input of AMIF signal

12 AGC I AGC voltage input terminal

Function

FM

S-METERAMDET

FM

IF

AM

IF

Function

IF

BUFFER

Pin

No.

STSD

Symbol

I/O

13 FM_DET O FM detection signal output

ST/MON_SW

14

15

AM/FM_SW

I Stereo/Monaural switching signal input

I AM/FM switching signal input

16 L_OUT O Output L-channel

17 R_OUT O Output R-channel

18 MPX_IN I Multiplex signal input

19 DET_OUT O AM/FM detection output

20 FM_OSC - FM local oscillation circuit

21 VCC_2 - Power supply terminal

22

FM_RFOUT

O Output of FMRF signal

23 GND_2 - Ground

24 FM_RFIN I Input of FMRF signal

AGC

Page 21

RHYTHM AX (IC502) JCV8011 : Block diagram

Page 22

RF AMP & SERVO SIGNAL PROCESSOR (IC701): S1L9226X

1. Application diagram

F

Pick-up

LD

PD

A

C

B

D

F

E

VR

VCC

GND

33

F

55k

55k

55k

55k

82k

82k

333

100 F

103

103

683

10

104

F220

47

37

38

39

40

41

42

43

44

45

46

47

48

2pF

104

333

36 35 34 33 32 31 30 29 28 27 26 25

LD

ATSC

PD

PDAC

PDBD

PDF

PDE

DCB

MCP

DCCI

DCCO

VREF

EQC

RFM

1 2 3 4 5 6 7 8 9 10 11 12

2pF

22k

100k

150k

LPFT

RFO

682

272

from pick-up

222

TEIO

TZC/SSTOP

S1L9226X

EQO

EQI

821

GND

EFMI

120k

FEM

FRSH

104

39k

100k120k

TEO

430k

FSET

104

391

FEO

VCC

47

F

47k

104

TEM

FLB

104

683

SLP

FGD

102

103

88k

SLO

FSI

SLM

RESET

MDATA

TGU

10k

22k

SPO

SPM

ASY

EFM

LOCK

WDCK

CLVI

MLT

MCK

ISTAT

104

24

23

22

21

20

19

18

From Micom

17

From Micom

16

From Micom

15

From Micom

14

To Micom

13

100k

10k

10k

103

474

From DSP

From DSP

333

1M

474

20k

8.2k

to DSP

10k

SMDP

SMDS

SMEF

Page 23

2. Block diagram

EQI

RFO

RFM

EQC

VREF

PDE

41 40424748123

PDF

PDBD

PDAC

39

EQO

EFMI

DCCI

DCC0

MCP

DCB

VCC/

VDD

FRSH

FSET

FLB

FGD

FSI

TGU

45

46

44

43

10

11

12

4

5

6

7

8

9

RF AGC & EQ

Control

Focus OK Detect

Defect Detect Mirror

Gen

Focus Servo Loop

- Gain & Phase

Compensation

- Focus Search

- Offset Adjust

- FZC Gen.

Micom Data Interface Logic Decoder

Center

Voltage

APC. Laser

Control &

LPC

Tracking Servo Loop

- Gain & Phase

Compensation

- Track Jump

- Offset Adjust

- TZC Gen.

Hardware Logic

- Auto-Sequencer

- Fast Search

- Febias, Focus Servo,

Tracking Offset ADJ.

- Tracking Balance & Gain

Adjust

- Interruption Detect

- EFM Muting System

Tracking Error

(RW)

I/V AMP

EFM

Comparator

RF & Focus

Error (CD-RW)

I/V AMP

Sled Servo &

Kick Gen

Spindle

Servo LPF

38

37

35

34

33

36

29

28

27

26

25

29

30

23

24

PD

LD

LPFT

TEIO

TZC&

SSTOP

ATSC

TEO

TEM

SLP

SLO

SLM

FEO

FEM

SPDLO

SPDLM

1413 15 16 17 19 18 20 22 21

ISTAT

MCK

MDATA

MLT

RESET

WDCK

CLVI

LOCK

ASY

EFM

Page 24

3. Pin description

Table 1. Pin Description

Pin No. Symbol I/O Description

1 RFM I RF summing amp. inverting input

2 RFO O RF summing amp. output

3 EQI I RFO DC eliminating input(use by MIRROR, FOK ,AGC & EQ terminal)

4 EQO O RF equalizer output

5 EFMI I EFM slice input. (input impedance 47K)

6 VCC P Main power supply

7 FRSH I Capcitor connection to focus search

8 FSET I Filter bias for focus,tracking,spindle

9 FLB I Capacitor connection to make focus loop rising band

10 FGD I Terminal to change the hign frequency gain of focus loop

11 FSI I Focus servo input

12 TGU I Connect the component to change the high frequency of tracking Loop

13 ISTAT O Internal status output

14 MCK I Micom clock

15 MDATA I Data input

16 MLT I Data latch input

17 RESET I Reset input

18 CLVI I Input the spindle control output from DSP

19 WDCK I 88.2KHz input terminal from DSP

20 LOCK I Sled run away inhibit pin (L: sled off & tracking gain up)

21 EFM O EFM output for RFO slice(to DSP)

22 ASY I Auto asymmetry control input

23 SPM I Spindle amp. inverting input

24 SPO O Spindle amp. output

25 SLM I Sled servo inverting input

26 SLO O Sled servo output

27 SLP I Sled servo noninverting input

28 TEM I Tracking servo amp.inverting input

29 TEO O Tracking servo amp. output

30 FEM I Focus servo amp. inverting input

31 FEO O Focus servo amp. output pin

Page 25

Table 1. Pin Description (Continued)

Pin No. Symbol I/O Description

32 GND P Main ground

33 TZC/

SSTOP

I Tracking zero crossing input & Check the position of pick-up

not

wherther inside or

34 TEIO B Tracking error output & Tracking servo input

35 LPFT I Tracking error integration input (to automatic control)

36 ATSC I Anti-shock input

37 LD O APC amp. output

38 PD I APC amp. input

39 PDAC I Photo diode A & C RF I/V amp. inverting input

40 PDBD I Photo diode B & D RF I/V amp. inverting input

41 PDF I Photo diode F & tracking(F) I/V amp. inverting input

42 PDE I Photo diode E & tracking(E) I/V amp. inverting input

43 DCB I Capacitor connection to limit the defect detection

44 MCP I Capacitor connection to mirror hold

45 DCCI O Output pin to connect the component for defect detect

46 DCCO I Input pin to connect the component for defect detect

47 VREF O (VCC+GND)/2 Voltage reference output

48 EQC I AGC_equalize level control terminal & capacitor terminal to input in to VCA

Item Symbol Rating Unit

Power supply voltage V

Absolute Ratings V

Operating temperature T

OPR

Storage temperature T

DD

I

STG

2.7 3.3 V

4.5 V

-20 75 °C

-40 125 °C

Page 26

5. Electrical characteristics

Table 2. Electrical Characteristics

No. Characteristics Symbols Test Block

1

Supply current 2.7V ICCTY 5 10 20 mA

2 RF AMP offset voltage Vrfo RF AMP -100 0 100 mV

3 RF AMP offset voltage 2 Vrfo2 -300 -200 -100 mV

4 RF AMP oscillation voltage Vrfosc 0 50 100 mV

5

RF AMP voltage gain AC Grf 15.5 18.5 23.5 dB

6

RF THD characteristic Rfthd - - 5 %

7

RF AMP maximum output voltage Vrfh 2.35 - - V

8 RF AMP minimum output voltage Vrfl - - 0.85 V

9 RF CDRW gain AC1 GRWAC1 1.05 1.30 1.55 -

10 RF CDRW gain AC2 GRWAC2 1.05 1.30 1.55 -

11

RF CDRW gain AC3 GRWAC3 1.05 1.30 1.55 -

12

Focus error offset voltage VFEO1

13

Focus error auto voltage VFEO2 -50 0 50 mV

14 ISTAT state after FEBIAS control VISTAT1 2.2 - - V

15 Focus positive offset 1 Vfep1 0 40 80 mV

16 Focus positive offset 2 Vfep2 10 60 100 mV

17

Focus positive offset 3 Vfep3 50 120 180 mV

18

4. Maximum absolute ratings

Focus negative offset 1 Vfen1 -80 -40 0 mV

19

Focus negative offset 2 Vfen2 -100 -60 -10 mV

20 Focus negative offset 3 Vfen3 -180 -120 -50 mV

21 Focus Error voltage gain 1 GFEAC 19 23 27 dB

22 Focus Error voltage gain 2 GFEBD 19 23 27 dB

23

Focus Error voltage gain difference

24

Focus Error RW down GFERWD 0.4 0.7 1.0 -

25 Focus Error AC difference VFEACP 0 50 100 mV

26 FERR maximum output voltage H VFEPPH 2.3 - - V

27 FERR minimum output voltage L VFEPPL - - 0.4 V

28 AGC max gain GAGC AGC_EQ 15 19 22 dB

29

AGC EQ gain GEQ -3 1 2.5 dB

30

AGC normal gain GAGC2 3 6 9 dB

31

AGC compress ratio CAGC 0 2.5 5 dB

∆GFE

Focus Error

Min. Typ. Max.

-525 -250 0 mV

Spec

-3 0 3 dB

Unit

Page 27

32X16 VFD DRIVER & CONTROLLER preliminary DATASHEET (IC402)

1. Sample application circuit

Panel : 11Grid & 29Seg

The value of control register

Display Mode Control Register(dsp) : 111 ( default)

Display Sub Time Control Register(tsub) : 101 ( -5 )

+5V VDD

S10

S7

S9

S8

S5G5128A

G3

G4

G5

S11

S9

S10

U3

S5G5128A

G6

G7

S6

S5

S4

D3

D1

D2

R9

R8

560

560

D4

R10

R11

560

560

SENB

SDIN

SCLK

D5

R12

560

D6

R13

560

+5V VDD

S3

S2

S1

R14

51k

646362616059585756555453525150

S4S5S6S7S8

1

S3

2

S2

3

S1

4

VSS

5

LED6

6

LED5

7

LED4

8

LED3

9

LED2

10

LED1

11

SENB

12

SDIN

13

SCLK

14

VSS

15

OSC

16

VDD

VEEG1G2G3G4G5G6G7G8G9S39/G10

171819202122232425262728293031

G2

G1

S15

S13

S12

S11

S12

S13

G8

G9

S18

S17

S16

S14

49

S14

S15

S16

S17

S18

VDD

VEE

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33/G16

S38/G11

S37/G12

S36/G13

S35/G14

S34/G15

32

G11

G10

F1

48

S19

47

S20

46

S21

45

S22

44

S23

43

S24

42

S25

41

S26

40

S27

39

S28

38

S29

37

36

35

34

33

S[29:1]

G[11:1]

-35V VEE

F2

U2

1

F1

2

F1

3

NP

4

NP

S1

5

P1

S2

6

P2

S3

7

P3

S4

8

P4

S5

9

P5

S6

10

P6

S7

11

P7

S8

12

P8

S9

13

P9

S10

14

P10

S11

15

P11

S12

16

P12

S13

17

P13

S14

18

P14

S15

19

VFD PANEL(11G * 29S)

P15

S16

20

P16

S17

21

P17

S18

22

P18

S19

23

P19

S20

24

P20

S21

25

P21

S22

26

P22

S23

27

P23

S24

28

P24

S25

29

P25

S26

30

P26

S27

31

P27

S28

32

P28

S29

33

P29

34

NX

35

NX

36

NX

37

NX

38

NX

39

NX

40

NX

41

NX

42

NX

43

NX

44

NX

45

NX

46

NX

47

NX

G11

48

11G

G10

49

10G

G9

50

9G

G8

51

8G

G7

52

7G

G6

53

6G

G5

54

5G

G4

55

4G

G3

56

3G

G2

57

2G

G1

58

1G

59

NP

60

NP

61

F2

62

F2

Page 28

2. Block diagram

S1 to S32

S33/G16

to

S39/G10

G9 to G1

SEG DRIVER

32

40-bit seg l atch 16-bit gr id atch

Dimming

Circuti

SEG RAM

6

6-bit led

latch

Serial I/F OSC

40

40X16

16

SEG/GRID

DRIVER

16

16X16

GRID RAM

GRID

DRIVER

888

Tim ing G enerator

POR

LED6

to

LED1

VSS

SENB

SDIN

SCLK

OSC

VDD

VEE

Page 29

3. Pin description

Pin No. Name Function IN/OUT

1 to 3 S3 to S1 Segment driver output pins (segment only). This is P-ch

open-drain output with pull-down resistor

5 to 10 LED6 to

6 LED driver output ports. This is a CMOS output pin. O

LED1

11 SENB Serial Interface Enable

All shifted data is latched into the corre sponding regist er

at the rising edge of SENB.

12 SDIN Serial Interfac e Data IN

Input serial data at the rising edge of the shift clock.

13 SCLK Serial Interface Clock

Reads serial data at the rising edge when SENB is low

15 OSC Connected to an external resistor or an RC oscillator

circuit.

18 to 26 G1 to G9 Grid driver output pins (Grid only). This is push-pull

cmos output.

27to 33 S39/G10

Segment or Grid driver output pins. These pins are

O

I

I

I

I/O

O

O

to

S33/G16

34 to 47 S32 to S19 Segment driver outpu t pin s (segment only). This is P-ch

selectabl e for segment or grid driving. This is P-ch open -

drain output with pull-down resistor

O

open-drain output with pull-down resistor

50 to 64 S18 to S4 Segment d river output pins (segment only). This P-ch

O

open-drain output with pull-down resistor

16,49 VDD Positive power ( Internally connected ) PWR

4,14 VSS Ground ( Internally connected ) GND

17,48 VEE Negative power for driving VFD Panel ( Internally

PWR

connected )

Page 30

CD-MP3 Decoder Specification (IC804)

1. PKG Type : 100 TQFP PKG

MNT0

MNT1

MNT2

MNT3

MNT4

MNT5

XIN

XOUT

INTVDD2

INTVSS2

RESETB

EFMI

ISTAT

MCLK/C4M

SDAT

WFCK

SBCK

S0S1

SMEF

SMON

SMDP

SMDS

WDCK

LOCK

LKFS

C2PO

DATXO

7574737271706968676665646362616

76RFCK

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DEMAND

/PCMCS

HIFSEL

MDATA7

MDATA5

PADVSS1

PADVDD1

MDATA6

S5L9279X

CD-MP3 1 Chip Data Processor

MDATA4

INTVDD1

INTVSS1

MDATA1

MDATA3

MDATA2

59585756555453525

0

/MRD

MDATA0

/MADDR

DECINT

DB4

FRAMSYNC

1

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

DB5

DB6

DB7

DB0

DB1

DB2

DB3

INT_DVSS0

INT_DVSS0

LDQM

/DRW

/CAS

/RAS

BA0

BA1

ADDR10

ADDR0

ADDR1

ADDR2

PADVSS0

PADVDD0

ADDR3

ADDR4

ADDR5

ADDR6

/MCS

/MWE

21 3 4 5 6 7 8 9

FIN

VCO2LF

VCO LF

PLLVDDA

PLLVSSA

DACVSSD

DACVDDD

DACVSSA

RCH_OUT

1

0

1

DACVREF

121

1314151

DACVDDA

DACHALF

17181920212223242

6

TEST3

TEST2

TEST0

TEST

LCH_OUT

CKE

UDQM

XSCLK

ADDR12

ADDR11

ADDR9

ADDR8

5

ADDR7

Page 31

2. CD-MP3 1 Chip Block Diagram

SDAT

SBCK

LKFS

EFMI

VCO1F

VCO2F

SMEF

SMDS

SMDP

SMON

DATX

Digital

Outp ut

Subc ode

Outp ut

EFM

Demod.

Digital

PLL

VCO

Digital

CLV

Servo

CDP

ECC

ADPCM

ENC/DEC

ESP

Contro l

CDP

Interpol .

16K

SRAM

Adress

Gen.

EDC

BLOCK

DATA

TRANS

BLOCK

CD- ROM

BLOCK

SYNC

PROT.

CD- ROM

ECC

CD- ROM

MICOM

REG.

MEMORY I/ F

PCM DATA

INTERFACE

FRAME

SYNC DET

Side Inf or.

PROCESS

DECODER

Contro ller

FRAME

Sync Outp ut

MEMORY

CONTROL

I/ O

MP3

INTERNAL

MEMORY

BANK1

MAIN DATA PROCERROR

MP3 Deco ding ( MULTIPLIER & A DDER )

ANCILLARY

REGISTER

TIMING

Generat or

DATA

REGISTER

HEADER

OUTPUT

HEAD

INTERNAL

MEMORY

BANK 2

DECODER

STATUS

REGISTER

Frequency

Synthesizer

FPLL

Interf ace

LPF

PWM

1 Bit

DAC

Digital

Filter

WRITE

REGISTER

MICOM

INTERFACE

MICOM

Interf ace

LCHOUT

RCHOUT

Page 32

SYSTEM IC (IC301) S3P825A

P0.6/SEG22

P0.5/SEG21

P0.4/SEG20

P0.3/SEG19

P0.2/SEG18

P0.1/SEG17

P0.0/SEG16

P8.3/SEG15

P8.2/SEG14

P8.1/SEG13

P8.0/SEG12

P7.7/SEG11

P7.6/SEG10

P7.5/SEG9

P7.4/SEG8

P7.3/SEG7

P0.7/SEG23

P1.0/SEG24

P1.1/SEG25

P1.2/SEG26

P1.3/SEG27

P1.4/SEG28

P1.5/SEG29

P1.6/SEG30

P1.7/SEG31

P2.0

P2.1

V

DD1

VSS1

XOUT

XIN

TEST

XT

XTOUT

RESET

P2.2/T2CLK

P2.3/T2OUT

P2.4/INT0/T0CLK

P2.5/INT1/T1CLK

P2.6/INT2/TAOUT

807978777675747372717069686766

1

2

3

4

5

6

7

8

9

10

11

12

S3P825A

13

14

(80-QFP-1420C)

15

16

17

IN

18

19

20

21

22

23

24

65

64

P7.2/SEG6

63

P7.1/SEG5

62

P7.0/SEG4

61

P6.7/SEG3/COM7

60

P6.6/SEG2/COM6

59

P6.5/SEG1/COM5

58

P6.4/SEG0/COM4

57

P6.3/COM3

56

P6.2/COM2

55

P6.1/COM1

54

P6.0/COM0

53

V

DD2

52

VSS2

51

VLC1

50

P5.6

49

P5.5/TXD

48

P5.4/RXD

47

P5.3/BUZ

46

P5.2/SO

45

P5.1/SI

44

P5.0/SCK

43

P4.7/INT11

42

P4.6/INT10

41

P4.5/INT9

252627282930313233343536373839

SS

P3.4

AVREF

P3.0/AD0

P3.1/AD1

AV

P3.2/AD2

P3.3/AD3

P4.0/INT4

P4.1/INT5

40

P4.2/INT6

P4.3/INT7

P4.4/INT8

P3.5/T3CLK

P2.7/INT3/TBOUT

P3.6/T3OUT/T3PWM/T3CAP

P3.7/T0OUT/T0PWM/T0CAP

Figure 1-3. S3C825A Pin Assignments (80-QFP-1420)

Page 33

2. PIN DESCRIPTIONS

Table 1-1. S3C825A Pin Descriptions

Pin

Names

Pin

Type

P0.0–P0.7 I/O 4-bit-programmable I/O port.

Input or push-pull, open-drain output and

software assignable pull-ups.

P1.0–1.7 I/O 4-bit-programmable I/O port.

Input or push-pull, open-drain output and

software assignable pull-ups.

P2.0

P2.1

P2.2

P2.3

P2.4

P2.5

P2.6

P2.7

P3.0–P3.3 I/O F-16 25–28

I/O 1-bit-programmable I/O port.

Schmitt trigger input or push-pull, opendrain output and software assignable pullups.

P2.4–P2.7: Alternately used for external

interrupt input (Noise filters, interrupt

enable and pending control)

1-bit-programmable I/O port.

Schmitt trigger input or push-pull,

P3.4

P3.5

open-drain output, and software

assignable pull-ups.

P3.6

P3.7

P4.0–P4.7 I/O 1-bit-programmable I/O port.

Schmitt trigger input or push-pull, open-

Pin

Description

Circuit

Type

Pin

Numbers

H-32 72–79

(74-80, 1)

H-32 80, 1–7

(2-9)

E-4 8 (10)

9 (11)

18 (20)

19 (21)

20 (22)

21 (23)

22 (24)

23 (25)

(27–30)

E-4 30(32)

31(33)

32(34)

33(35)

E-4 34–41

(36–43)

Share

Pins

SEG16

–

SEG23

SEG24

–

SEG31

–

–

T2CLK

T2OUT

INT0/T0CLK

INT1/T1CLK

INT2/TAOUT

INT3/TBOUT

AD0–AD3

–

T3CLK

T3OUT/T3PWM/T3CAP

T0OUT/T0PWM/T0CAP

INT4–INT11

drain output and software assignable pullups.

P4.0–P4.7: Alternately used for external

interrupt input (Noise filters, interrupt

enable and pending control)

P5.0

P5.1

P5.2

P5.3

P5.4

P5.5

P5.6

P6.0-P6.3 I/O H-32 52-55(54-57) COM0–COM3

P6.4–P6.7 56-59(58-61) COM4–COM7/

I/O 1-bit-programmable I/O port.

Schmitt trigger input or push-pull, opendrain output and software assignable pullups.

4-bit programmable I/O port. Input or

push-pull, open-drain output and software

assignable pull-ups.

E-4 42 (44)

43 (45)

44 (46)

45 (47)

46 (48)

47 (49)

48 (50)

SCK

SI

SO

BUZ

RXD

TXD

–

SEG0–SEG3

P7.0–P7.7 I/O H-32 60-67(62-69) SEG4–SEG11

P8.0–P8.3 I/O H-32 68-71(70-73) SEG12–SEG15

NOTE: Parentheses indicate pin number for 80-QFP-1420 package.

Page 34

Table 1-1. S3C825A Pin Descriptions (Continued)

Share

Pins

V

X

SS1

OUT

Pin

Names

, V

DD1

X

,

IN

Pin

Type

Pin

Description

– Power input pins for core block – 10, 11 (12, 13) –

– Main oscillator pins – 12, 13 (14, 15) –

TEST – Test signal input pin (must be connected

)

to V

SS

XTIN, XT

RESET

OUT

– Sub oscillator pins – 15, 16 (17,18) –

I System reset pin B 17 (19) –

Circuit

Type

Pin

Numbers

(note)

–14 (16) –

INT0–INT3 I/O External interrupt input pins E-4 20–23 (22–25) P2.4–P2.7

T0CLK I/O Timer 0 external clock input. E-4 20 (22) P2.4

T0OUT I/O Timer 0 clock output E-4 33 (35) P3.7

T0PWM I/O Timer 0 PWM output E-4 33 (35) P3.7

T0CAP I/O Timer 0 capture input E-4 33 (35) P3.7

T1CLK I/O Timer 1/A external clock input. E-4 21 (23) P2.5

TAOUT I/O Timer 1/A clock output E-4 22 (24) P2.6

TBOUT I/O Timer B clock output E-4 23 (25) P2.7

T2CLK I/O Timer 2 external clock input. E-4 18 (20) P2.2

T2OUT I/O Timer 2 clock output E-4 19 (21) P2.3

T3CLK I/O Timer 3 external clock input. E-4 31 (33) P3.5

T3OUT I/O Timer 3 clock output E-4 32 (34) P3.6

T3PWM I/O Timer 3 PWM output E-4 32 (34) P3.6

T3CAP I/O Timer 3 capture input E-4 32 (34) P3.6

AD0–AD3 I/O Analog input pins for A/D convert module F-16 25–28 (27–30) P3.0–P3.3

AV

REF

, AV

SS

– A/D converter reference voltage and ground – 24, 29 (26, 31) –

INT4–INT11 I/O External interrupt input pins E-4 34–41 (36–43) P4.0–P4.7

BUZ I/O Buzzer signal output E-4 45 (47) P5.3

SCK, SI, SO I/O Serial clock, serial data input, serial data

E-4 42–44 (44–46) P5.0–P5.2

output

RXD, TXD I/O UART data input, output E-4 46-47 (48-49) P5.4-P5.5

V

V

LC1

SS2

, V

DD2

– LCD bias voltage input pins – 49 (51) –

– Power input pins for peripheral block – 50, 51 (52, 53) –

COM0–COM3 I/O LCD Common signal output H-32 52–55 (54–57) P6.0-P6.3

SEG0–SEG3

I/O LCD Common or Segment signal output H-32 56–59 (58–61) P6.4-P6.7

(COM4–COM7)

SEG4–SEG11 I/O LCD segment signal output H-32 60–67 (62–69) P7.0-P7.7

SEG12–SEG15 I/O LCD segment signal output H-32 68–71 (70–73) P8.0-P8.3

SEG16–SEG23 I/O LCD segment signal output H-32 72–79 (74–80, 1) P0.0–P0.7

SEG24–SEG31 I/O LCD segment signal output H-32 80, 1–7 (2–9) P1.0–P1.7

NOTE: Parentheses indicate pin number for 80-QFP-1420 package.

Page 35

Printed in Japan

Page 36

BLOCK DIAGRAM

Page 37

WIRE ASS'Y BLOCK DIAGRAN

Page 38

MAIN SCHEMATIC DIAGRAM(1/3)

Page 39

MAIN SCHEMATIC DIAGRAM(2/3)

Page 40

MAIN SCHEMATIC DIAGRAM(3/3)

Page 41

AMP SCHEMATIC DIAGRAM

Page 42

Power SCHEMATIC DIAGRAM

Page 43

FRONT SCHEMATIC DIAGRAM

Page 44

USB SCHEMATIC DIAGRAM

Page 45

AMP PCB BOTTOM

Page 46

AMP PCB TOP

Page 47

FRONT PCB BOTTOM

Page 48

FRONT PCB TOP

Page 49

MAIN PCB BOTTOM

Page 50

MAIN PCB TOP

Page 51

PT PCB TOP

Page 52

PARTS LIST

[ MX-GC5 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

MB361

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD changer mechanism assembly and parts list (Block No.MA)

Electrical parts list (Block No.01~05)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3- 7

3-16

3-1

Page 53

Exploded view of general assembly and parts list

Block No.

M

M

1

M

5

49

36

42

11

23

1

Main board

5

C

25

38

70

46

52

3

7

68

26

22

43

3

41

40

64

63

37

33

69

44

32

60

10

65

65

60

17

24

34

15

21

47

53

14

4

8

35

F902

71

4

45

31

3

54

16

3

C

30

39

36

12

59

3-2

Page 54

59

48

5

60

66

60

60

18

59

5

13

5

59

59

5

59

59

9

B

59

51

59

5

20

2

4

4

3

26

25

22

43

5

3

3

4

29

4

4

59

59

4

A

4

4

8

4

35

F902

71

45

31

31

3

4

4

4

4

55

62

Power trans.

board

61

28

19

67

F901

72

73

62

6

Amp. board

A

61

5

B

27

59

59

3-3

Page 55

General Assembly

Symbol No. Part No. Part Name Description Local

1 BI251030093100V 3CD MECHANISM

2 BIZ25094901VV TUNER PACK

3 BIBT000410S3 SCREW 6XL10(x11)

4 BIBT000418 SCREW 6XL18(x47)

5 BIBT000608 SCREW 3XL12(x14)

6 BIBT000654 SCREW 3XL16(x2)

7 BI1081740101X1 VFD BOX L

8 BI1081750101X1 VFD BOX R

9 BI2400261V FAN

10 BI1079689101X1 FRONT CABINET HIPS-8002

11 BI1079690101X1 CD DOOR HIPS470

12 BI2029220101W1 MAIN CHASSIS SECC THK=0.8mm

13 BI1080030101X1 HEAT SINK COVER PA777D

14 BI301779010101 CUSHION BACK FOAM(x2)

15 BI1079760101X1 FUNCTION KNOB AUX

16 BI1080120101X1 FUNCTION KNOB PMMA-CP-51 CD

17 BI1079750101X1 FUNCTION KNOB PMMA-CP-51 TUNER

18 BI202924010101 HEAT SINK PMMA-CP-51

19 BI2029230101W1 HEAT SINK

20 BI28GL3B0URP010 HIGH BRIGHT LED

21 BI1080000101X1 FUNC KEY HLDR AL

22 BI1080130101X1 LED HOLDER AL

23 BI2029500101W1 PLATE HOLDER ABS-700

24 BI1079980101X1 PRESET HLDR ABS-700

25 BI1080020101X1 PWB VFD HOLDER SECC THK=0.6mm

26 BI1080010101X1 VFD HOLDER ABS-700

27 BI2029200101W1 HEATSINK HLDR R ABS-700

28 BI2029190101W1 HEATSINK HLDR L ABS-700

29 BI2028690101W1 SENSOR HOLDER SECC

30 BI1080150101X1 LENS SECC

31 BIPMW001101S31 SCREW SECC(x4)

32 BI1079970101X1 JACK COVER SAN2495

33 BI109835010101 BADGE JVC

34 BI1080110101X1 KEY SAN2495 CD

35 BI1079810101X1 KEY ABS-700 FUNC SOUND

36 BIKT000627 SCREW ABS-700 3X-12(x4)

37 BI1079900101X1 KNOB ABS-700 BASE

38 BI1079910101X1 KNOB ABS470 DEMO ECO

39 BI1079920101X1 KNOB ABS470 DISC SKIP

40 BI1079940101X1 KNOB ABS470 PRESE

41 BI1079710101X1 KNOB ABS470 VOL

42 BI1079950101X1 LENS DOOR CD SAN2495

43 BI1080140101X1 LENS POWER SAN2495

44 BI1079960101X1 LENS TOP SAN2495

45 BI1080080101X1 LIGHT GUID JACK PMMA CP-51

46 BI1080050101X1 LIGHT GUID L PMMA CP-51

47 BI1080060101X1 LIGHT GUID R PMMA CP-51

48 BI2029670101W1 TOP COVER SECC THK-0.8mm

49 BI3021570101X1 MIRROR SHEET PC

51 BI2028680101W1 REAR PANEL SECC THK-0.8mm

52 BI302204010101 PET PLATE L PET THK=0.05mm

53 BI302201010101 PET PLATE R PET THK=0.05mm

54 BI1079990101X1 PRESET DRIVE ABS470

55 BI2029180101W1 BRACKET SECC

59 BIRM000603S3 SCREW 3XL6(x21)

60 BIRM000604S3 SCREW 3XL8(x6)

61 BIRT000617B3 SCREW 3XL10(x4)

62 BIRT000611B3 SCREW 3XL8(x4)

63 BI1079940101X1 PRESET RING ABS470

64 BI1079930101X1 VOL RING ABS470

65 BI3021970101V1 RUBBER FOOT RUBBER(x2)

66 BIBT000614P2 SCREW 3X14(x4)

67 BI211021025001W POWER TRANS

68 BI2702201V DISPLAY

69 BI1079700101X1 WINDOW DISPLAY SAN2495

70 BIWPT000601P31 SCREW 3XL8

71 BI402991 FUSE 1.6A 250V F902

72 BI403281 FUSE 3.5A 125V F901

73 BI1401701V POWER CORD

Block No. [M][1][M][M]

3-4

Page 56

CD loading mechanism assembly and parts list

Block No.

M

M

M

A

CMS-FR3BN

7

6

8

9

10

12

11

2

13

1

3

23

24

25

28

4

26

27

33

35

29

34

14

15

16

19

22

32

21

37

38B

17

18

20

36

5

37

38A

The parts without symbol number are not service.

37

38A

37

38B

39

3-5

Page 57

CD loading mechanism

Symbol No. Part No. Part Name Description Local

1 BIAJ7200601J BASE-MAIN 1X1

2 BIAJ6100601P BRKT-CHUCK

3 BI3302000158 MAGNET-FERRITE

4 BIAJ7200601L TABLE-CHUCK 1X4

5 BIAJ6300601A SHEET-CHUCK (x3)

6 BIAJ7300601B BELT-LOAD

7 BIAJ6600601N GEAR-SYNCRO 1X2

8 BIAJ6600601L GEAR-CONVERT 1X4

9 BIAJ6600601M GEAR-TRAY 1X4

10 BIAJ6600601R GEAR-CAM 1X2

11 BIAJ6600601K GEAR-LOAD 1X4

12 BIAJ6600601J GEAR-PULLEY 1X4

13 BIAJ7200601N SLIDER-CAM 1X4

14 BI3405000101 SWITCH-MICRO (x2)

15 BI3711003379 CONNECTOR-HEADE

16 BIAJ4100601K PCB-SW

17 BIAJ6100601K PULLEY-MOTOR 1X4

18 BIAJ3100601F MOTOR-DC

19 BI3710001248 CONNECTOR-SOCE

20 BI3711003692 CONNECTOR-HEADE

21 BI3708001163 CONNECTOR-FPC

22 BIAJ4100601L PCB-MECHA

23 BIAJ7200601P TRAY-ROULETTE 1X2

24 BIAJ7200601Q TRAY-DISC 1X2

25 BIAJ6600601Q GEAR-ROULETTE 1X4

26 BIAJ6600601P GEAR-WORM 1X2

27 BIAJ3100601K MOTOR-LOADING

28 BIAJ6300601B SHEET-MOTOR

29 BIAJ3900601A WIRE-ROULETTE

32 BIAJ3900601B WIRE-TRAY

33 BI3711000003 CONNECTOR-HEADE

34 BIAJ4100601J PCB-SENSOR

35 BIAJ3200601A SENSOR-ROULETTE

36 BIAJ9050605F CMS-B31NG6U

37 BIAJ6000601F SCREW (x4)

38A BIAJ7300601F RUBBER-B31Y (x2)

38B BIAJ7300601D RUBBER-B31 (x2)

39 BIAJ7200602F LEVER-LIFTER 1X2

Block No. [M][A][M][M]

3-6

Page 58

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC301 S3C825AX39-QWRA IC BI118501

IC401 BA4558F IC BI103952

IC402 NJM4580 D IC BI115511U

IC501 BD3873FS IC BI118231

IC502 JCV8011 IC BI116561

IC503 BA4558F IC BI103952

IC701 SIL9226 IC BI116431

IC702 ICBA5927 FM IC BI118221

IC801 BH18FB1WG IC BI118171

IC802 NJM7808FA IC BI110061

IC803 K4S161622H-UC60 IC BI117401V

IC804 S5L9279 IC BI116401

Q302 2SC3052 TRANSISTOR BI2SC3052FA013

Q303 DTA114YK TRANSISTOR BI2DTC114YKA01

Q304 2SC1815GR TRANSISTOR

Q361 DTA114YK TRANSISTOR BI2DTC114YKA01

Q401 DTC323TK TRANSISTOR BI2DTC323TKA01

Q402 DTC323TK TRANSISTOR BI2DTC323TKA01

Q403 DTA114YK TRANSISTOR BI2DTC114TKA01

Q404 DTA114YK TRANSISTOR BI2DTA114YKA01

Q405 DTA114YK TRANSISTOR BI2DTC114TKA01

Q406 DTA114YK TRANSISTOR BI2DTA114YKA01

Q407 DTA114YK TRANSISTOR BI2DTC114TKA01

Q408 2SC3052 TRANSISTOR BI2SC3052FA013

Q409 DTC323TK TRANSISTOR BI2DTC323TKA01

Q410 DTC323TK TRANSISTOR BI2DTC323TKA01

Q412 DTA114YK TRANSISTOR BI2DTC114TKA01

Q501 2SC3052 TRANSISTOR BI2SC3052FA013

Q502 2SC3052 TRANSISTOR BI2SC3052FA013

Q503 2SC3052 TRANSISTOR BI2SC3052FA013

Q504 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q505 DTA114YK TRANSISTOR BI2DTC114TKA01

Q506 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q507 DTA114YK TRANSISTOR BI2DTC114TKA01

Q508 2SC1815GR TRANSISTOR

Q509 DTA114YK TRANSISTOR BI2DTC114TKA01

Q510 DTA114YK TRANSISTOR BI2DTC114TKA01

Q571 KTA1267GR TRANSISTOR BI2KTA1267GP000

Q572 2SC3052 TRANSISTOR BI2SC3052FA013

Q701 KTA1266GR TRANSISTOR

Q703 KTC3205 TRANSISTOR BI2KTC3205P0008

Q704 2SC1815GR TRANSISTOR

D301 1SS133 FR DIODE

D302 1SS133 FR DIODE

D303 1SS133 FR DIODE

D304 1SS133 FR DIODE

D305 1SS133 FR DIODE

D306 UZ4.7BSA Z DIODE BI3UZ4.7BSAM000

D401 1SS133 FR DIODE BI31SS133N000V7

D413 1SS133 FR DIODE

D501 1SS133 FR DIODE

D503 1SS133 FR DIODE

D504 1SS133 FR DIODE

D505 1SS133 FR DIODE

D506 1SS133 FR DIODE

D507 UZ11BSC Z DIODE BI3UZ11BSCM000

Part No. Part Name Description Local

BI2SC1815GRP00

0

BI2SC1815GRP00

0

BI2KTA1266GP000

0

BI2SC1815GRP00

0

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

BI31SS133M000V

7

Symbol No.

D508 1SS133 FR DIODE

D571 UZ9.1BSC Z DIODE

D572 1SS133 FR DIODE

D710 UZ3.6BSB Z DIODE BI3UZ3.6BSBM000

D711 UZ3.6BSB Z DIODE BI3UZ3.6BSBM000

D712 1SS133 FR DIODE

C301 BICC104500KA042 C CAPACITOR 0.1uF 50V

C302 BICC104500KA042 C CAPACITOR 0.1uF 50V

C303 BICC223500KA042 C CAPACITOR 0.022uF 50V

C304 BICE107100MP015 E CAPACITOR 100uF

C305 BICE108100MP015 E CAPACITOR 1000uF

C306 BICE476250MP015 E CAPACITOR 47uF

C307 BICC104500KA042 C CAPACITOR 0.1uF 50V

C311 BICC270500JA041 C CAPACITOR 27pF 50V

C312 BICC240500JA041 C CAPACITOR 24pF 50V

C313 BICC330500JA041 C CAPACITOR 33pF 50V

C314 BICC102500KA042 C CAPACITOR 1000pF 50V

C315 BICC220500JA041 C CAPACITOR 22pF 50V

C316 BICC220500JA041 C CAPACITOR 22pF 50V

C317 BICC104500KA042 C CAPACITOR 0.1uF 50V

C318 BICE105500MP015 E CAPACITOR 1uF 50V

C319 BICC104500KA042 C CAPACITOR 0.1uF 50V

C400 BICE226160MP015 E CAPACITOR 22uF

C401 BICE224500MP015 E CAPACITOR 0.22uF 50V

C402 BICE224500MP015 E CAPACITOR 0.22uF 50V

C403 BICE106250MP015 E CAPACITOR 10uF

C404 BICC102500KA042 C CAPACITOR 1000pF 50V

C405 BICC102500KA042 C CAPACITOR 1000pF 50V

C406 BICE106250MP015 E CAPACITOR 10uF

C407 BICE224500MP015 E CAPACITOR 0.22uF 50V

C408 BICE224500MP015 E CAPACITOR 0.22uF 50V

C409 BICE226160MP015 E CAPACITOR 22uF

C410 BICE476160MP015 E CAPACITOR 47uF

C411 BICC393500KA042 C CAPACITOR 0.039uF 50V

C412 BICE107160MP015 E CAPACITOR 100uF

C413 BICE106500MP015 E CAPACITOR 10uF

C414 BICM334500JP015 M CAPACITOR 0.33uF 50V

C415 BICM474500JP01 M CAPACITOR 0.47uF 50V

C416 BICM224101KP015 M CAPACITOR 0.22uF

C417 BICE107160MP015 E CAPACITOR 100uF

C418 BICE107160MP015 E CAPACITOR 100uF

C419 BICE106250MP015 E CAPACITOR 10uF

C420 BICC103500KA042 C CAPACITOR 0.01uF 50V

C421 BICE227160MP015 E CAPACITOR 220uF

C422 BICE475500MP015 E CAPACITOR 4.7uF

C423 BICC473500KA042 C CAPACITOR 0.047uF 50V

C424 BICC103500KA042 C CAPACITOR 0.01uF 50V

C425 BICC272500KA042 C CAPACITOR 2700pF 50V

C426 BICC472500KA042 C CAPACITOR 4700pF 50V

C427 BICE475500MP015 E CAPACITOR 4.7uF

C428 BICC473500KA042 C CAPACITOR 0.047uF 50V

C429 BICC103500KA042 C CAPACITOR 0.01uF 50V

C430 BICC272500KA042 C CAPACITOR 2700pF 50V

C431 BICE106250MP015 E CAPACITOR 10uF

C432 BICC472500KA042 C CAPACITOR 4700pF 50V

C451 BICE106500MP015 E CAPACITOR 10uF

C461 BICE107160MP015 E CAPACITOR 100uF

C500 BICM334500JP015 M CAPACITOR 0.33uF 50V

C501 BICC101500JA041 C CAPACITOR 100pF 50V

C502 BICC101500JA041 C CAPACITOR 100pF 50V

C503 BICM222101KP015 M CAPACITOR 2200pF

C504 BICM224101KP015 M CAPACITOR 0.22uF

C505 BICM224101KP015 M CAPACITOR 0.22uF

C506 BICE105500MP015 E CAPACITOR 1uF 50V

C507 BICE105500MP015 E CAPACITOR 1uF 50V

C509 BICE105500MP015 E CAPACITOR 1uF 50V

C510 BICE105500MP015 E CAPACITOR 1uF 50V

C511 BICE105500MP015 E CAPACITOR 1uF 50V

C513 BICE105500MP015 E CAPACITOR 1uF 50V

C514 BICM222101KP015 M CAPACITOR 2200pF

C515 BICM224101KP015 M CAPACITOR 0.22uF

Part No. Part Name Description Local

BI31SS133M000V

7

BI3UZ9.1BSCM00

0

BI31SS133M000V

7

BI31SS133M000V

7

3-7

Page 59

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C516 BICM224101KP015 M CAPACITOR 0.22uF

C517 BICE106500MP015 E CAPACITOR 10uF

C518 BICC103500KA042 C CAPACITOR 0.01uF 50V

C519 BICE476250MP015 E CAPACITOR 47uF

C520 BICC101500JA041 C CAPACITOR 100pF 50V

C521 BICC101500JA041 C CAPACITOR 100pF 50V

C522 BICM224101KP015 M CAPACITOR 0.22uF

C523 BICM224101KP015 M CAPACITOR 0.22uF

C524 BICC105160ZA023 C CAPACITOR 1uF 16V

C525 BICE475500MP015 E CAPACITOR 4.7uF

C526 BICE105500MP015 E CAPACITOR 1uF 50V

C527 BICE475500MP015 E CAPACITOR 4.7uF

C528 BICE475500MP015 E CAPACITOR 4.7uF

C529 BICE105500MP015 E CAPACITOR 1uF 50V

C530 BICE475500MP015 E CAPACITOR 4.7uF

C531 BICE475500MP015 E CAPACITOR 4.7uF

C532 BICM273101KP015 M CAPACITOR 0.027uF

C533 BICE225500MP015 E CAPACITOR 2.2uF

C534 BICE106250MP015 E CAPACITOR 10uF

C535 BICE476250MP015 E CAPACITOR 47uF

C536 BICE226250MP015 E CAPACITOR 22uF

C537 BICE226250MP015 E CAPACITOR 22uF

C538 BICE226250MP015 E CAPACITOR 22uF

C539 BICE106250MP015 E CAPACITOR 10uF

C540 BICE106250MP015 E CAPACITOR 10uF

C541 BICE475500MP015 E CAPACITOR 4.7uF

C542 BICE475500MP015 E CAPACITOR 4.7uF

C543 BICE106250MP015 E CAPACITOR 10uF

C544 BICE106250MP015 E CAPACITOR 10uF

C545 BICE475500MP015 E CAPACITOR 4.7uF

C546 BICE106250MP015 E CAPACITOR 10uF

C547 BICE224500MP015 E CAPACITOR 0.22uF 50V

C548 BICE105500MP015 E CAPACITOR 1uF 50V

C549 BICE105500MP015 E CAPACITOR 1uF 50V

C550 BICE476250MP015 E CAPACITOR 47uF

C551 BICE107100MP015 E CAPACITOR 100uF

C552 BICE475500MP015 E CAPACITOR 4.7uF

C553 BICE105500MP015 E CAPACITOR 1uF 50V

C554 BICE107100MP015 E CAPACITOR 100uF

C555 BICE476250MP015 E CAPACITOR 47uF

C556 BICE475500MP015 E CAPACITOR 4.7uF

C557 BICE107100MP015 E CAPACITOR 100uF

C558 BICC103500KA042 C CAPACITOR 0.01uF 50V

C559 BICE476160MP015 E CAPACITOR 47uF

C560 BICE476160MP015 E CAPACITOR 47uF

C561 BICC104500KA042 C CAPACITOR 0.1uF 50V

C562 BICC101500JA041 C CAPACITOR 100pF 50V

C563 BICC101500JA041 C CAPACITOR 100pF 50V

C570 BICE476160MP015 E CAPACITOR 47uF

C571 BICE476160MP015 E CAPACITOR 47uF

C701 BICC104500KA042 C CAPACITOR 0.1uF 50V

C702 BICC104500KA042 C CAPACITOR 0.1uF 50V

C703 BICC102500KA042 C CAPACITOR 1000pF 50V

C704 BICE476160MP015 E CAPACITOR 47uF

C705 BICC102500KA042 C CAPACITOR 1000pF 50V

C706 BICC102500KA042 C CAPACITOR 1000pF 50V

C707 BICC103500KA042 C CAPACITOR 0.01uF 50V

C708 BICC473500KA042 C CAPACITOR 0.047uF 50V

C709 BICE107100MP015 E CAPACITOR 100uF

C710 BICE107100MP015 E CAPACITOR 100uF

C711 BICC040500CA041 C CAPACITOR 4pF 50V

C712 BICC100500DA041 C CAPACITOR 10pF 50V

C713 BICC682500KA042 C CAPACITOR 6800pF 50V

C714 BICC103500KA042 C CAPACITOR 0.01uF 50V

C715 BICE475500MP010 E CAPACITOR 4.7uF

C716 BICC104500KA042 C CAPACITOR 0.1uF 50V

C717 BICC104500KA042 C CAPACITOR 0.1uF 50V

C718 BICC102500KA042 C CAPACITOR 1000pF 50V

C719 BICC104500KA042 C CAPACITOR 0.1uF 50V

C720 BICC333250KA042 C CAPACITOR 0.033uF 25V

C721 BICC474100KA042 C CAPACITOR 0.47uF 10V

C722 BICC332500KA042 C CAPACITOR 3300pF 50V

C723 BICC474100KA042 C CAPACITOR 0.47uF 10V

C724 BICC103500KA042 C CAPACITOR 0.01uF 50V

C725 BICC683160KA042 C CAPACITOR 0.068uF 16V

C726 BICE106160MP015 E CAPACITOR 10uF

C727 BICC683160KA042 C CAPACITOR 0.068uF 16V

C728 BICC331500KA042 C CAPACITOR 330pF 50V

C729 BICC102500KA042 C CAPACITOR 1000pF 50V

C730 BICC222500KA042 C CAPACITOR 2200pF 50V

C731 BICC333250KA042 C CAPACITOR 0.033uF 25V

C732 BICC104500KA042 C CAPACITOR 0.1uF 50V

C733 BICC104500KA042 C CAPACITOR 0.1uF 50V

C759 BICC104500KA042 C CAPACITOR 0.1uF 50V

C763 BICE107100MP015 E CAPACITOR 100uF

C764 BICC104500KA042 C CAPACITOR 0.1uF 50V

C765 BICE477100MP015 E CAPACITOR 470uF

C766 BICC104500KA042 C CAPACITOR 0.1uF 50V

C767 BICE107100MP015 E CAPACITOR 100uF

C768 BICC102500KA042 C CAPACITOR 1000pF 50V

C769 BICE476250MP015 E CAPACITOR 47uF

C770 BICC391500JA041 C CAPACITOR 390pF 50V

C771 BICC391500JA041 C CAPACITOR 390pF 50V

C772 BICC391500JA041 C CAPACITOR 390pF 50V

C773 BICC391500JA041 C CAPACITOR 390pF 50V

C774 BICC102500KA042 C CAPACITOR 1000pF 50V

C801 BICC104500KA042 C CAPACITOR 0.1uF 50V

C802 BICH104500KM019 CAPACITOR 0.1uF /50V

C803 BICE225500MP015 E CAPACITOR 2.2uF

C804 BICC104500KA042 C CAPACITOR 0.1uF 50V

C805 BICC270500JA041 C CAPACITOR 27pF 50V

C806 BICC270500JA041 C CAPACITOR 27pF 50V

C807 BICC104500KA042 C CAPACITOR 0.1uF 50V

C808 BICE107100MP015 E CAPACITOR 100uF

C809 BICC104500KA042 C CAPACITOR 0.1uF 50V

C810 BICC122500KA042 C CAPACITOR 1200pF 50V

C811 BICC122500KA042 C CAPACITOR 1200pF 50V

C812 BICC122500KA042 C CAPACITOR 1200pF 50V

C813 BICC104500KA042 C CAPACITOR 0.1uF 50V

C814 BICE107100MP015 E CAPACITOR 100uF

C815 BICE107100MP015 E CAPACITOR 100uF

C816 BICE475500MP015 E CAPACITOR 4.7uF

C817 BICE475500MP015 E CAPACITOR 4.7uF

C818 BICC102500KA042 C CAPACITOR 1000pF 50V

C819 BICC102500KA042 C CAPACITOR 1000pF 50V

C820 BICC104500KA042 C CAPACITOR 0.1uF 50V

C821 BICC104500KA042 C CAPACITOR 0.1uF 50V

C822 BICC104500KA042 C CAPACITOR 0.1uF 50V

C823 BICC104500KA042 C CAPACITOR 0.1uF 50V

C824 BICC104500KA042 C CAPACITOR 0.1uF 50V

C825 BICC104500KA042 C CAPACITOR 0.1uF 50V

C826 BICC104500KA042 C CAPACITOR 0.1uF 50V

C827 BICC104500KA042 C CAPACITOR 0.1uF 50V

C828 BICC104500KA042 C CAPACITOR 0.1uF 50V

C829 BICC104500KA042 C CAPACITOR 0.1uF 50V

C830 BICC104500KA042 C CAPACITOR 0.1uF 50V

C831 BICC104500KA042 C CAPACITOR 0.1uF 50V

C832 BICC100500DA041 C CAPACITOR 10pF 50V

C833 BICC330500JA041 C CAPACITOR 33pF 50V

C850 BICC104500KA042 C CAPACITOR 0.1uF 50V

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

R300 BIRC2230105A005 C RESISTOR 22K

R301 BIRC2230105A005 C RESISTOR 22K

R302 BIRC1010105A005 C RESISTOR 100

R303 BIRC1010085M000 C RESISTOR 100Ω 1/8W

R304 BIRC1010085M000 C RESISTOR 100

R305 BIRC1010085M000 C RESISTOR 100

R306 BIRC1010085M000 C RESISTOR 100

R307 BIRC1010085M000 C RESISTOR 100

R308 BIRC1010085M000 C RESISTOR 100

R309 BIRC1010085M000 C RESISTOR 100

R310 BIRC1010105A005 C RESISTOR 100

R311 BIRC1010105A005 C RESISTOR 100

R312 BIRC1010105A005 C RESISTOR 100

R313 BIRC1010105A005 C RESISTOR 100

R314 BIRC1020105A005 C RESISTOR 1K

R315 BIRC1010105A005 C RESISTOR 100

R316 BIRC1010105A005 C RESISTOR 100

R317 BIRC1010085N000 C RESISTOR 100Ω 1/8W

R318 BIRC1010105A005 C RESISTOR 100

R319 BIRC1010105A005 C RESISTOR 100

R320 BIRC1010105A005 C RESISTOR 100

R321 BIRC1010105A005 C RESISTOR 100

R322 BIRC1010105A005 C RESISTOR 100

R323 BIRC1010085M000 C RESISTOR 100Ω 1/8W

R324 BIRC1010105A005 C RESISTOR 100

3-8

Page 60

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R326 BIRC2230085M000 C RESISTOR 22K

R327 BIRC1020105A005 C RESISTOR 1K

R328 BIRC1010085N000 C RESISTOR 100Ω 1/8W

R329 BIRC4710085N000 C RESISTOR 470

R330 BIRC2220105A005 C RESISTOR 2.2K

R331 BIRC2220085M000 C RESISTOR 2.2K

R333 BIRC1820105A005 C RESISTOR 1.8K

R334 BIRC2230105A005 C RESISTOR 22K

R335 BIRC2230105A005 C RESISTOR 22K

R337 BIRC1010085N000 C RESISTOR 100Ω 1/8W

R338 BIRC1010105A005 C RESISTOR 100

R339 BIRC2230105A005 C RESISTOR 22K

R341 BIRC1010105A005 C RESISTOR 100

R342 BIRC1020085M000 C RESISTOR 1KΩ 1/8W

R343 BIRC2210085N000 C RESISTOR 220

R344 BIRC2210085N000 C RESISTOR 220

R345 BIRC1020085N000 C RESISTOR 1K

R346 BIRC1020085N000 C RESISTOR 1K

R347 BIRC1020085N000 C RESISTOR 1K

R348 BIRC1020105A005 C RESISTOR 1K

R349 BIRC1020085N000 C RESISTOR 1K

R350 BIRC1020105A005 C RESISTOR 1K

R351 BIRC1020105A005 C RESISTOR 1K

R353 BIRC1020105A005 C RESISTOR 1K

R354 BIRC1020105A005 C RESISTOR 1K

R363 BIRC4710085N000 C RESISTOR 470

R364 BIRC4710085N000 C RESISTOR 470

R365 BIRC1010105A005 C RESISTOR 100

R366 BIRC1010105A005 C RESISTOR 100

R367 BIRC1020085M000 C RESISTOR 1KΩ 1/8W

R369 BIRC1010105A005 C RESISTOR 100

R370 BIRC1030105A005 C RESISTOR 10K

R371 BIRC1030105A005 C RESISTOR 10K

R372 BIRC1030105A005 C RESISTOR 10K

R373 BIRC3320105A005 C RESISTOR 3.3K

R375 BIRC2230105A005 C RESISTOR 22K

R380 BIRC4710105A005 C RESISTOR 470

R381 BIRC4710105A005 C RESISTOR 470

R382 BIRC4710085N000 C RESISTOR 470

R383 BIRC4710045N000 C RESISTOR 470

R388 BIRC2220105A005 C RESISTOR 2.2K

R390 BIRC4730105A005 C RESISTOR 47K

R391 BIRC6840105A005 C RESISTOR 680K

R392 BIRC1030085M000 C RESISTOR 10KΩ 1/8W

R394 BIRC2220085M000 C RESISTOR 2.2K

R395 BIRC2220085M000 C RESISTOR 2.2K

R396 BIRC2220085M000 C RESISTOR 2.2K

R398 BIRC2230105A005 C RESISTOR 22K

R399 BIRC2230105A005 C RESISTOR 22K

R401 BIRC1540105A005 C RESISTOR 150K

R402 BIRC1030105A005 C RESISTOR 10K

R403 BIRC2220105A005 C RESISTOR 2.2K

R404 BIRC2720105A005 C RESISTOR 2.7K

R405 BIRC1030105A005 C RESISTOR 10K

R406 BIRC1040105A005 C RESISTOR 100K

R407 BIRC2220105A005 C RESISTOR 2.2K

R408 BIRC1540105A005 C RESISTOR 150K

R409 BIRC1030105A005 C RESISTOR 10K

R410 BIRC1030105A005 C RESISTOR 10K

R411 BIRC2220105A005 C RESISTOR 2.2K

R412 BIRC2720105A005 C RESISTOR 2.7K

R413 BIRC1040105A005 C RESISTOR 100K