Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB50820066

MX-C55J,MX-C55C

ECO DISC SKIP

SP-MXC55 SP-MXC55CA-MXC55

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.MB508

2006/6

Page 2

SPECIFICATION

Amplifier section

CA-MXC55

Tuner FM tuning range 87.50 MHz - 108.00 MHz

CD player CD Capacity 3 CDs

General Power requirement AC 120 V , 60 Hz

Speaker section

SP-MXC55

Output Power SUBWOOFERS 170 W per channel, min. RMS, driven into 3 Ω at

63 Hz with no more than 10% total harmonic distortion

MAIN SPEAKERS 80 W per channel, min. RMS, driven into 6 Ω at 1

kHz with no more than 10% total harmonic distortion

Audio input sensitivity/Impedance

(at 1 kHz, measured at MAIN SPEAKERS)

Speakers/Impedance Subwoofers 3 Ω - 6 Ω

AM tuning range 530 kHz - 1 710 kHz

Dynamic range 85 dB

Signal-to-noise ratio 85 dB

Power consumption 80 W /136 VA (at operation)

Dimensions (approx.) 270 mm × 317 mm × 402 mm (W/H/D)

Mass (approx.) 5.9 kg (13 lbs)

Type 3-way bass-reflex type

Speaker units Subwoofer 16 cm (6 5/16 in.) cone ×1

Power handling capacity Subwoofer 170 W

Impedance Subwoofer 3 Ω

Frequency range Subwoofer 30 Hz - 1 000 Hz

Sound pressure level Subwoofer 74 dB/W·m

Dimensions (approx.) 220 mm × 435 mm × 316 mm (W/H/D)

Mass (approx.) 5.7 kg (12.6 lbs) each

AUX 400 mV/47 kΩ

USB USB Version 1.1

Main speakers 6 Ω - 16 Ω

7.3 W (on standby)

1 W (in ECO mode)

(10 11/16 in. × 12 1/2 in. × 15 7/8 in.)

Main Woofer 10 cm (3 15/16 in.) cone ×1

Tweeter 5 cm (2 in.) cone ×1

Main speaker 80 W

Main speaker 6 Ω

Main speaker 100 Hz - 20 000 Hz

Main speaker 81 dB/W·m

(8 11/16 in. × 17 13/16 in. × 12 1/2 in.)

Design and specifications are subject to change without notice.

1-2 (No.MB508)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

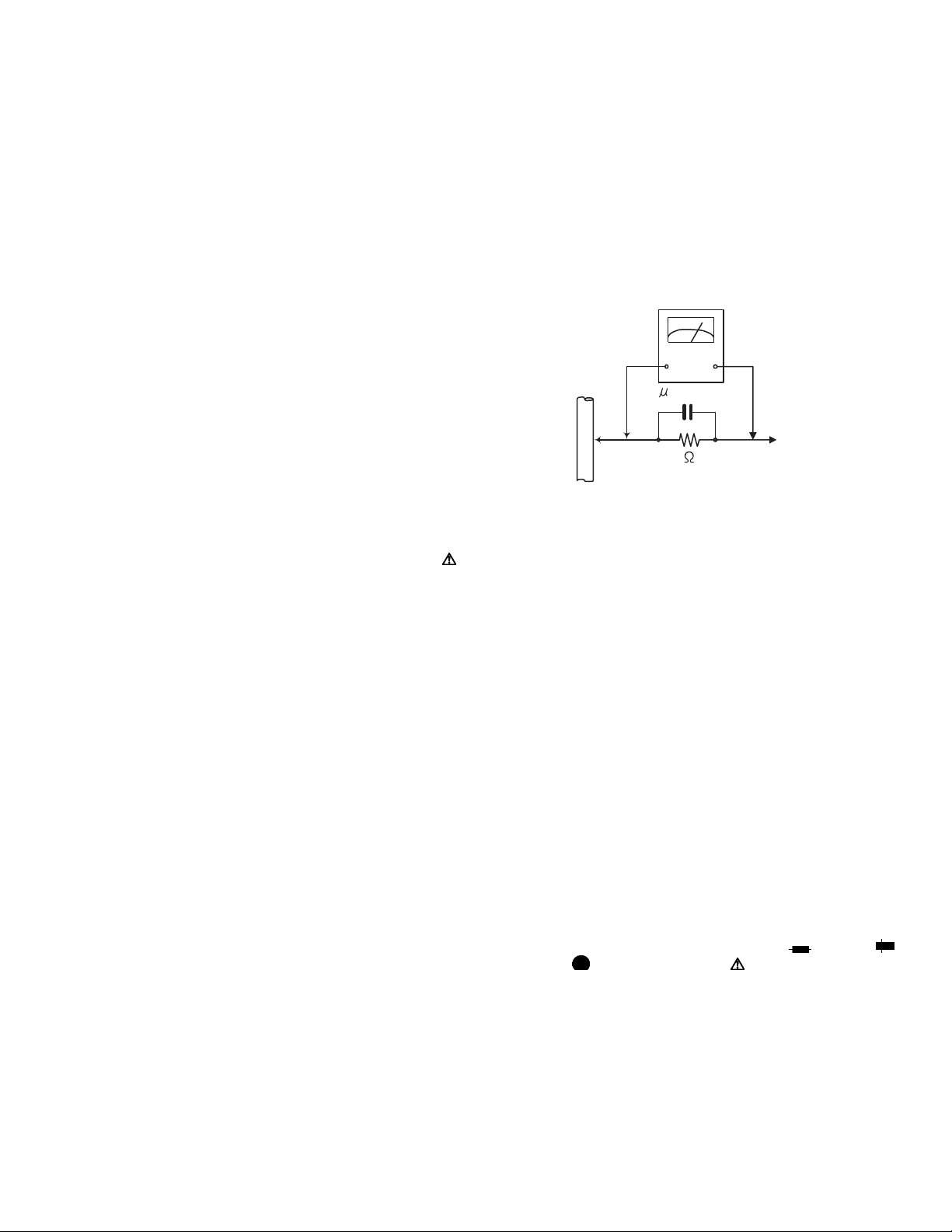

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB508)1-3

Page 4

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

1-4 (No.MB508)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB508)1-5

Page 6

SECTION 3

r

DISASSEMBLY

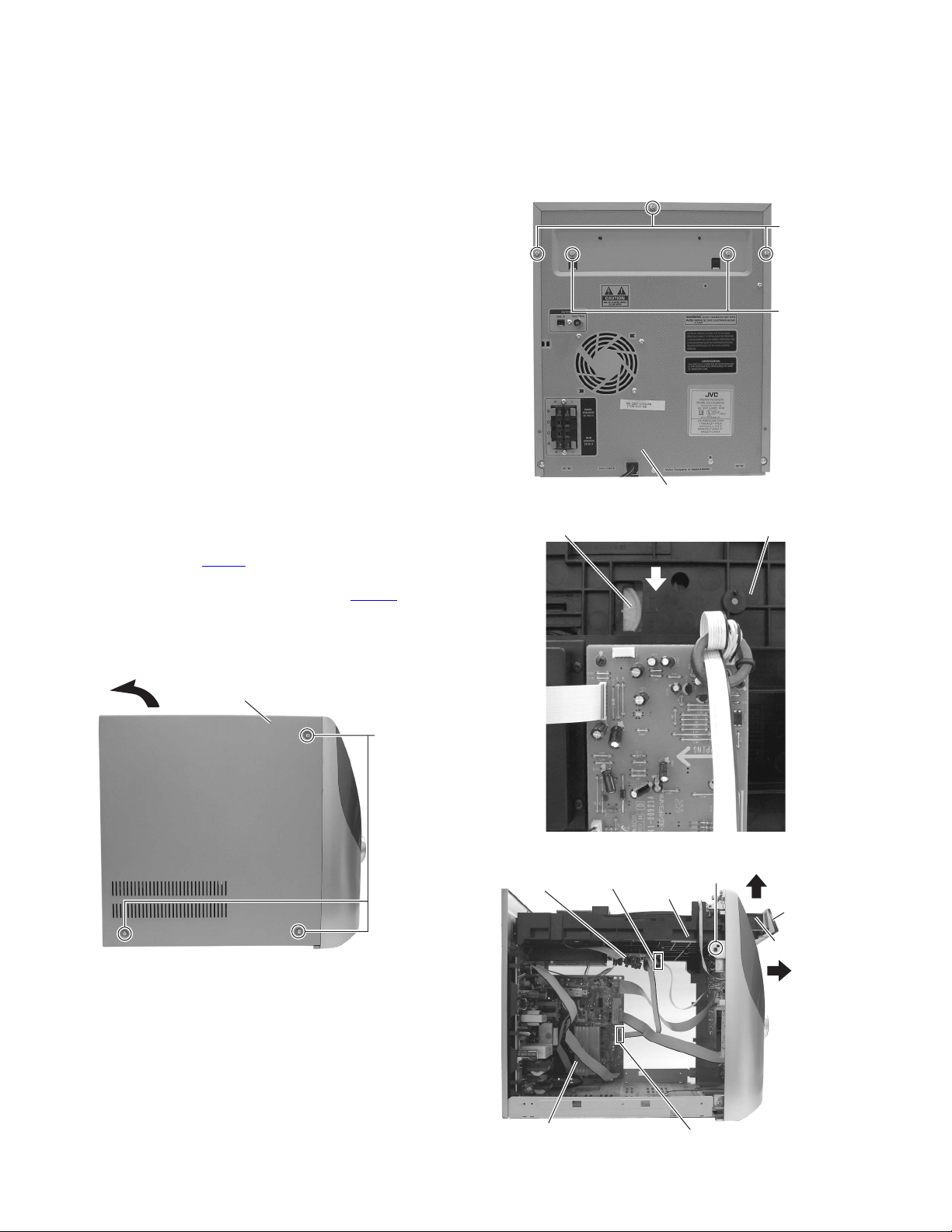

3.1 Main body section

3.1.1 Removing the top cabinet

(See Figs.1 and 2)

(1) From the both sides of the main body, remove the six

screws A attaching the top cabinet. (See Fig.1.)

(2) From the back side of the main body, remove the three

screws B attaching the top cabinet. (See Fig.2.)

(3) Take out the top cabinet from the main body while lifting the

rear section of the top cabinet in the direction of the arrow.

(See Fig.1.)

3.1.2 Removing the CD deck assembly

(See Figs.2 to 4)

• Remove the top cabinet.

(1) From the back side of the main body, remove the two

screws B attaching the CD deck assembly to the rear cabinet. (See Fig.2.)

(2) From the bottom side of the CD deck assembly, turn the

gear cam in the direction of the arrow and draw the tray

disc out of the CD deck assembly in the direction of the arrow 1. (See Figs.3 and 4.)

(3) Remove the CD door from the tray disc in the direction of

the arrow 2. (See Fig.4.)

(4) From the left side of the main body, disconnect the wire

from the connector CN103

Fig.4)

(5) Disconnect the card wire from the connector CW105

CD board. (See Fig.4)

(6) From the both sides of the main body, remove the two

screws D and then take out the CD deck assembly from the

main body. (See Fig.4.)

on the main AMP board. (See

on the

Gear cam

B

C

Rear cabinet

Fig.2

CD deck

OPEN

Top cabinet

Fig.1

A

Fig.3

2

CD board

Main AMP board

CW105

CD deck

Fig.4

D

CD doo

Tray disk

1

CN103

1-6 (No.MB508)

Page 7

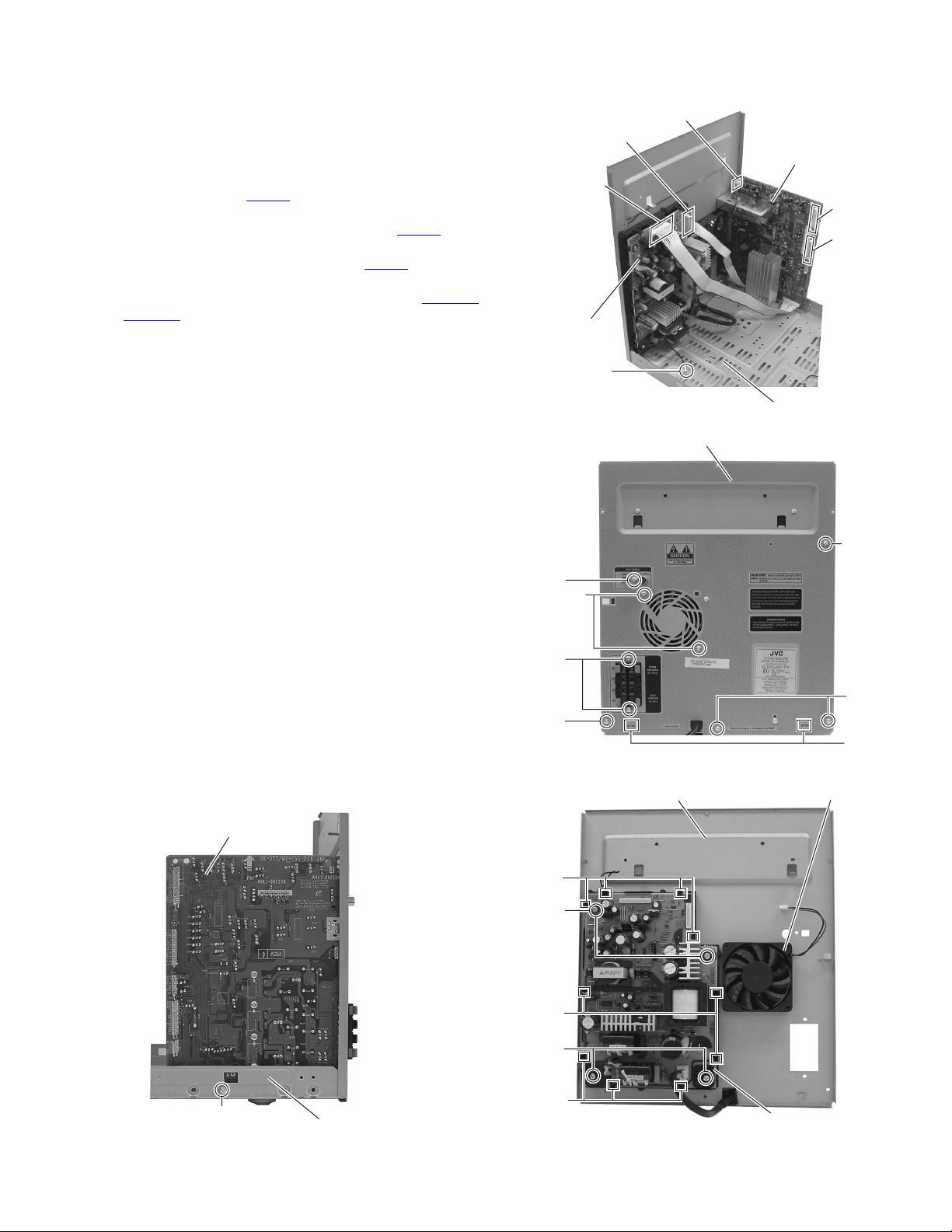

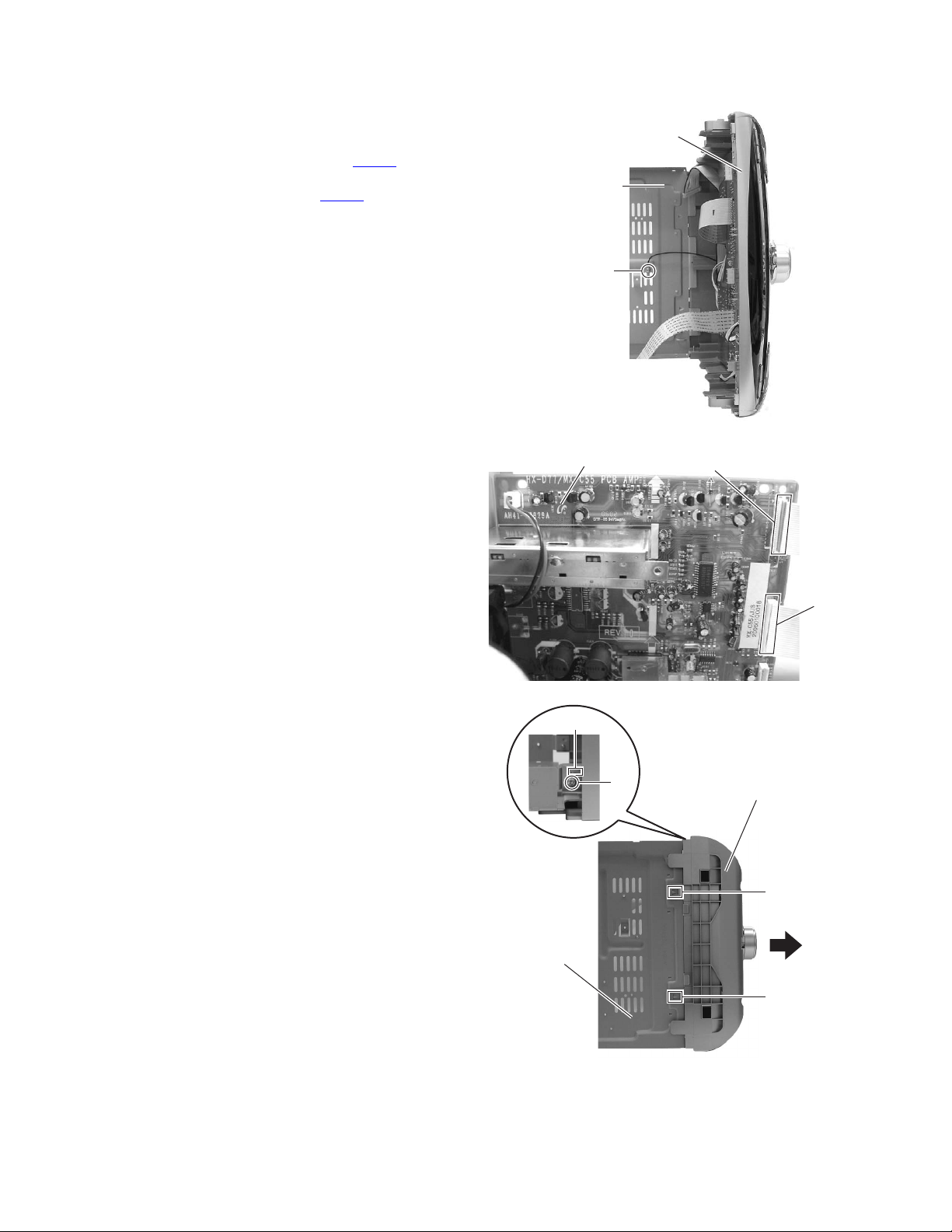

3.1.3 Removing the main AMP board

r

(See Figs.5 to 7)

• Remove the top cabinet and CD deck assembly.

(1) From the right side of the main body, remove the screw E

attaching the main AMP board to the main body. (See

Fig.5)

(2) From the top side of the main body, disconnect the wire

from the connector CN108

Fig.6.)

(3) Disconnect the card wire from the connector CN101

main AMP board. (See Fig.6.)

(4) Disconnect the wire from the connector CN102

AMP board. (See Fig.6.)

(5) Disconnect the wires from the connectors (SMCN01

SMCN02

(6) From the back side of the main body, remove the three

screws G attaching the main AMP board to the rear cabinet. (See Fig.7.)

(7) Take out the main AMP board from the bottom cabinet.

3.1.4 Removing the SMPS board and rear cabinet

(See Figs.6 to 8)

• Remove the top cabinet, CD deck assembly and main AMP

board.

(1) From the top side of the main body, remove the screw F at-

taching the earth wire on the bottom cabinet. (See Fig.6.)

(2) From the back side of the main body, remove the three

screws H attaching the rear cabinet. (See Fig.7.)

(3) Remove the sections a toward this side and take out the

rear cabinet. (See Fig.7.)

(4) From the inside of the rear cabinet, remove the four screws

M attaching the SMPS board. (See Fig.8.)

(5) Release the claw b and take out the SMPS board from the

rear cabinet assembly. (See Fig.8.)

3.1.5 Removing the fan motor

(See Figs.7 and 8)

• Remove the top cabinet, CD deck assembly and main AMP

board.

(1) From the back side of the main body, remove the two

screws K attaching the fan motor to the rear cabinet. (See

Fig.7.)

(2) Take out the fan motor from the rear cabinet. (See Fig.8.)

) on the SMPS board. (See Fig.6.)

on the main AMP board. (See

on the

on the main

CN108

SMCN101

SMCN102

,

SMPS board

Main AMP board

CN101

CN102

F

Bottom cabinet

Fig.6

Rear cabinet

J

G

K

G

H

H

a

Fig.7

Rear cabinet

FAN moto

Main AMP board

E

Fig.5

Bottom cabinet

b

M

b

M

b

SMPS board

Fig.8

(No.MB508)1-7

Page 8

3.1.6 Removing the front cabinet assembly

(See Figs.9 to 11)

• Remove the top cabinet and CD deck assembly.

(1) From the top side of the main body, remove the screw N at-

taching the earth wire on the bottom cabinet. (See Fig.9.)

(2) Disconnect the card wire from the connector CN101

main AMP board. (See Fig.10.)

(3) Disconnect the wire from the connector CN102

AMP board. (See Fig.10.)

(4) From the both sides of the main body, remove the two

screws P attaching the front cabinet assembly. (See

Fig.11.)

(5) From the both and bottom sides of the main body, release

the joints (c, d) and then take out the front cabinet assembly from the main body in the direction of the arrow. (See

Figs.11.)

on the

on the main

Front cabinet assembly

Bottom cabinet

N

Fig.9

Main AMP board

CN101

c

Bottom cabinet

P

CN102

Fig.10

Front cabinet assembly

d

d

1-8 (No.MB508)

Fig.11

Page 9

3.1.7 Removing the VFD board

(See Figs.12 and 13)

• Remove the top cabinet, CD deck assembly and front cabinet

assembly.

(1) From the front side of the front cabinet assembly, pull out

the two knobs. (See Fig.12.)

(2) From the inside of the front cabinet assembly, remove the

seven screws Q attaching the VFD board. (See Fig.13.)

(3) Take out the VFD board from the front cabinet assembly

and then disconnect the wires from the connectors

(UW101

(See Fig.13.)

3.1.8 Removing the front board

• Remove the top cabinet, CD deck assembly, front cabinet as-

sembly and VFD board.

(1) From the inside of the front cabinet assembly, remove the

four screws R attaching the front board.

(2) Take out the front board from the front cabinet assembly.

, UW201, FW102, FW104) on the VFD board. .

(See Fig.12)

Fig.12

Front board

Knob

Front cabinet assembly

RR

Q

FW104

VFD board

FW102UW201UW101

Fig.13

(No.MB508)1-9

Page 10

3.1.9 Removing the USB board

(See Fig.14)

• Remove the top cabinet, CD deck assembly, front cabinet as-

sembly, Knobs and VFD board.

(1) From the inside of the front cabinet assembly, remove the

three screws S attaching the USB board.

(2) Take out the USB board from the front cabinet assembly.

3.1.10 Removing the LED1 board, LED2 board and LED3

board

(See Fig.14)

• Remove the top cabinet, CD deck assembly, front cabinet as-

sembly, knobs and VFD board.

(1) From the inside of the front cabinet assembly, release the

claws e and then take out the LED1 board from the front

cabinet assembly.

(2) Remove the screw T attaching the LED2 board.

(3) Release the claw f and then take out the LED2 board from

the front cabinet assembly.

(4) Take out the LED3 board from the front cabinet assembly.

LED1 board

e

LED2 board

f

T

USB board

SSS

LED3 board

Fig.14

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

1-10 (No.MB508)

Page 11

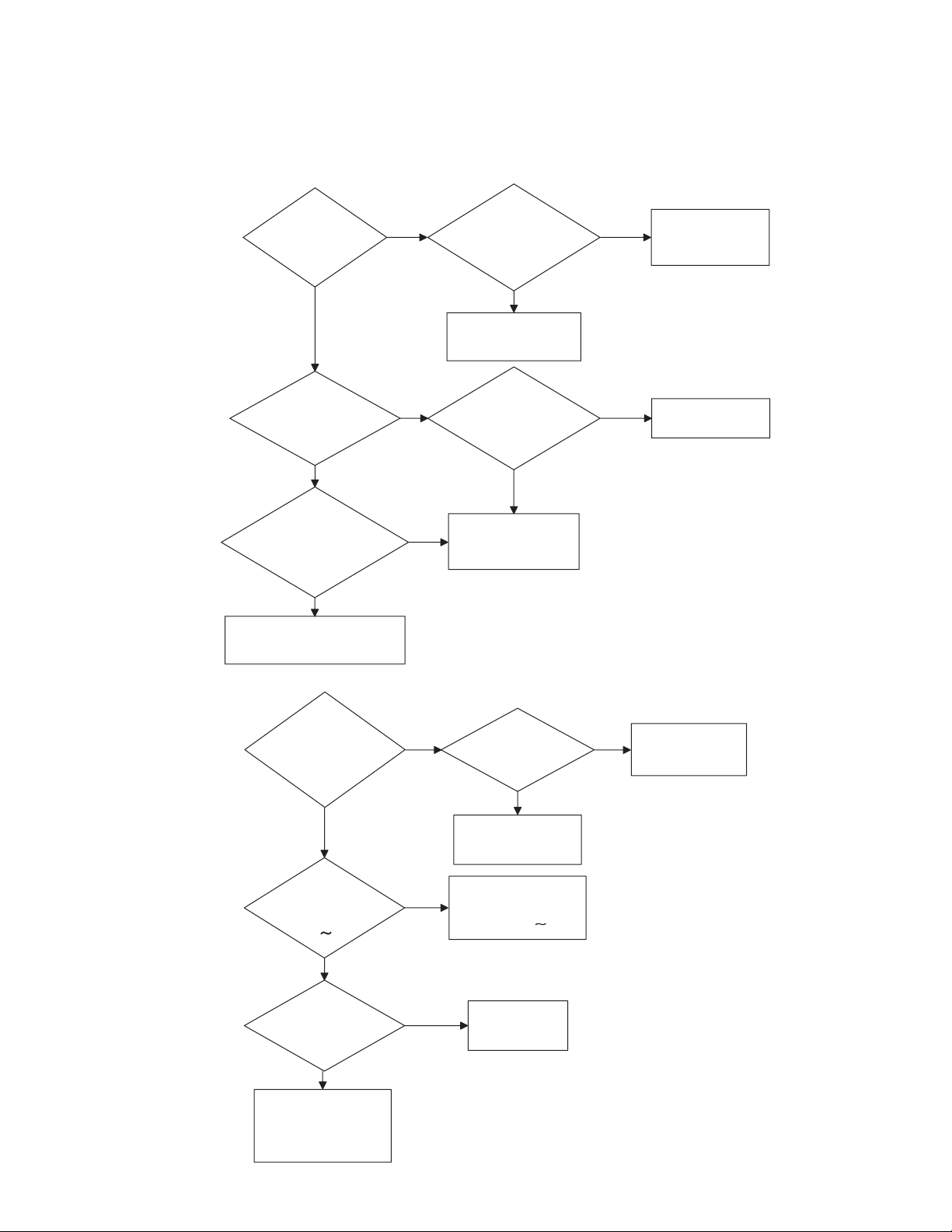

5.1 Amplifier

5.1.1 Power Malfunction

SECTION 5

TROUBLESHOOTING

Front pcb

u-com Vdd

normal?

YES

Front pcb dose

UX101(10MHz)

oscillate?

YES

Front pcb

When the power on

"H" pin

no.94(UIC01)

YES

CHECK the AMP PCB

AIC01,FIC01,WIC01,WIC02

NO

NO

SMIC42 input

voltage normal?

Check amp PCS

wire CN107

Front pcb psense voltage

normal?(#82)

Replace u-COM IC

NO

SMPS pcb

YES

YES

(UIC01)

SMIC01,SMD43

NO

Check the SMPS

NO

check the

SMD44

5.1.2 No Output

Amp pcb

AIC01,WIC01,02

pin No.4,7,12,15

B+ normal?

YES

Amp pcb

AIC01,pin No.51

normal?

(2.5 5V)

YES

Amp pcb

BIC01, pin No14

normal?(3.3V)

YES

Check the

master clock

(12.288MHz)

Check the FIC01

NO

NO

NO

Check

the SMPS

pcb SMIC02

YES

Check amp pcb

wire CN107

Check amp pcb

BIC02 pin #3,6,7

voltage(3.0 5V)

Replace of

BIC02

SMIC01,SMd43

NO

check the

(No.MB508)1-11

Page 12

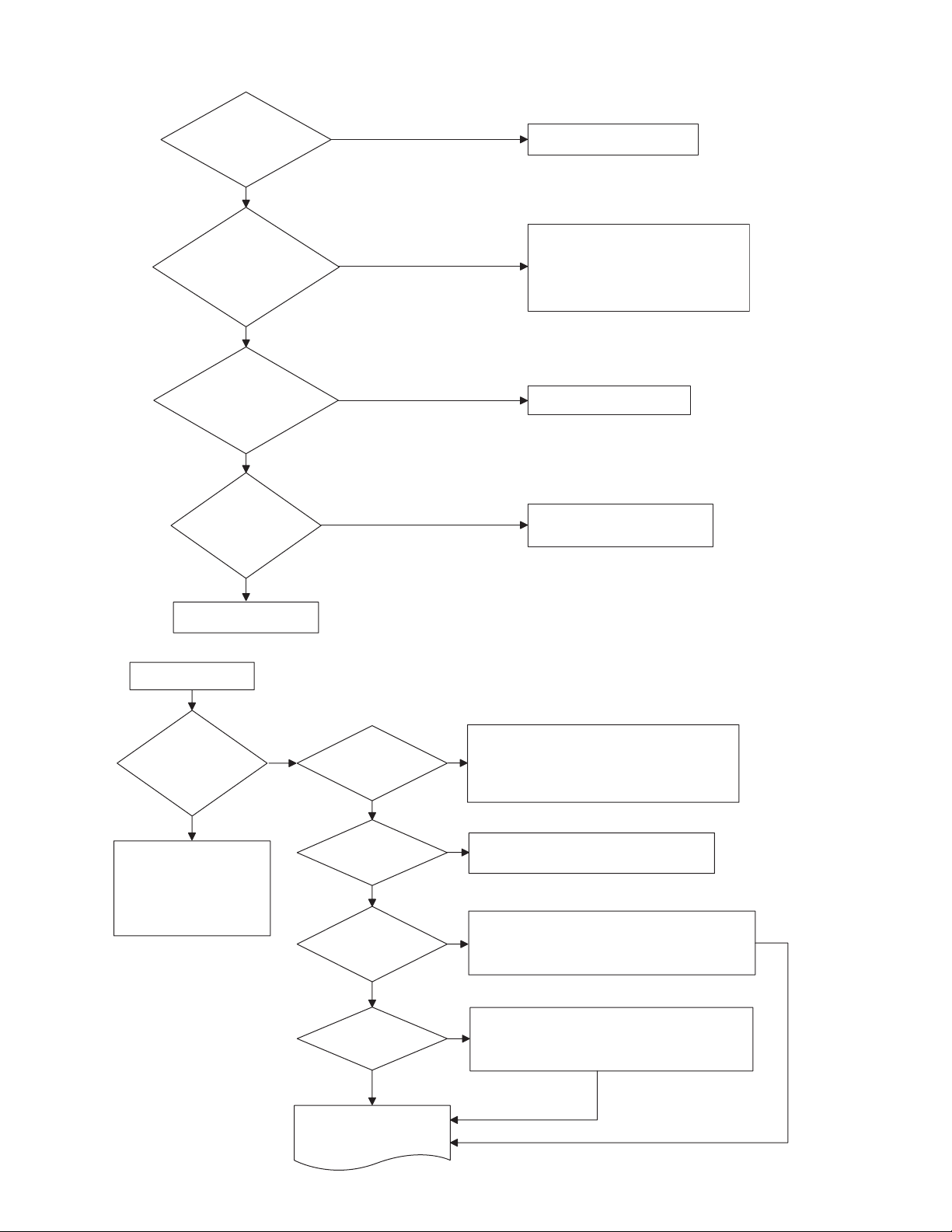

5.1.3 USB Malfunction

Front Jack

pcb UIC03 pin#10

voltage 5V

normal?

YES

NO

Check the USB cable

Front Jack

pcb UIC03 pin #7

voltage more than

2.5V? or normal?

Front jack pcb

JIC01 pin #14,15

analog signal

UIC02 pin #14

voltage 5V

Check the amp pcb

5.1.4 Compact Disc Player

CD playing N.G

YES

normal?

YES

Front pcb

normal?

YES

NO

NO

NO

Check the front pcb JIC01

pin #4 voltage

Check the oscillator

frequency 12MHz

Replace of JIC01

Check the amp pcb

EIC01 function IC

CD pack

5V,8V(motor)

normal?

1. CD pack to amp pcb

8 pin wire check

(CW106)

2. Amp pcb 5V,8V

supply check

Roulette

operating?

Check

pickup LD

LD and sied

operating?

Spindle

operationg?

1. Replace IC101

2. Replace IC201

1. Mecha reset

2. IC401 8V check

3. Mecha to CD pcb 8 pin cable check

4. CD pcb to front pcb 22 pin cable check

1. Pickup to CD pcb 6 pin wire check

2. Replace pickup

1. Check the Q302 output 3.3V

2. Check the IC101 pin No.6 voltage 3.3V

3. Check the IC301 pin No.21,22 voltage 8V

1. Check the IC201, JW11 voltage 1.2V

2. Check the Q303 output 2.0V

3. Check the IC201 pin No.87 reset normal?

1-12 (No.MB508)

Page 13

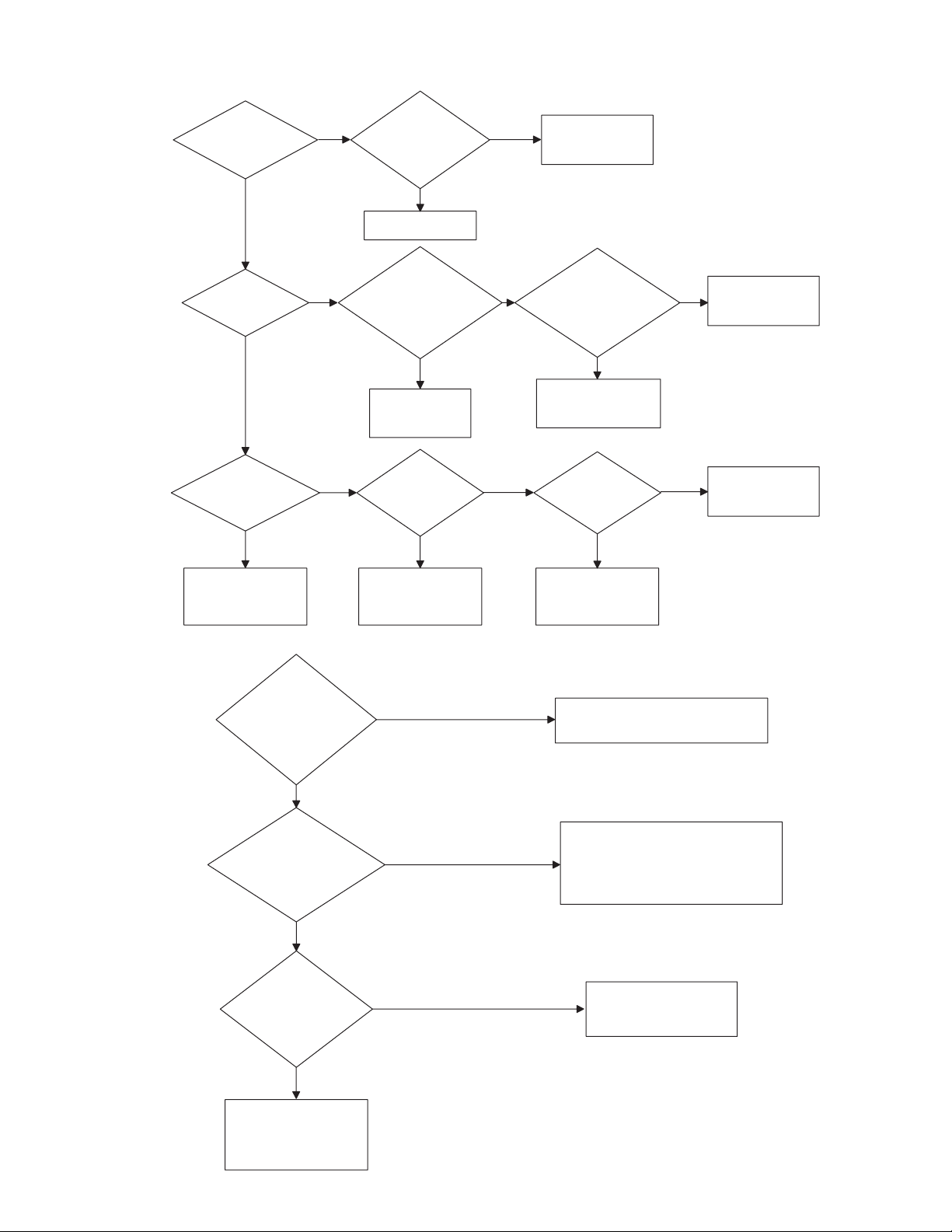

5.1.5 SMPS

Standby LED

normal?

YES

Check

P-SENSE

NO NO

(smCN02

pin 9)

YES

Check amp pcb

Replace SMPS

Set play is

O.K.?

YES

Sound output

O.K.?

YES

Check

display circuit at

amp pcb

5.1.6 Tuner Malfunction (FM/AM)

Amp pcb t

tuner pack

pin No.4

voltage12V

normal?

Check

3V,5V,12V

(SMCN02 pin

NO NO

3,4,5,6 SMCN01

pin 9)

YES

Check AIC01

at amp pcb

Check

SMCN01

NO NO NO

pin 1 to 3

YES

Check

SMIC42,SMIC43

SMIC44 input

(pin No.1)

YES

Replace

SMIC42,43 or 44

SMNC01

pin 1, pin 4

short?

YES

Check amp pcb Check amp pcb

Check the Amp PCB SZ105

NO

Check the SMPS PCB SMIC44

Replace SMPS

NO

Replace SMPS

YES

Amp pcb

check the by-pass

condenser

EE01L,EE01R

YES

Amp pcb

check the

EIC02

pin #1,2

YES

Check the arround

EIC02, ER02R/L

EE10R/L

NO

Check the amp pcb ER01R,

ER01L open?

Check the amp pcb EIC1, EIC02

Rreplace tuner pack

Replace of EIC02

NO

(No.MB508)1-13

Page 14

Victor Company of Japan, Limited

Audio/Video Systems Category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB508)

Printed in Japan

VPT

Page 15

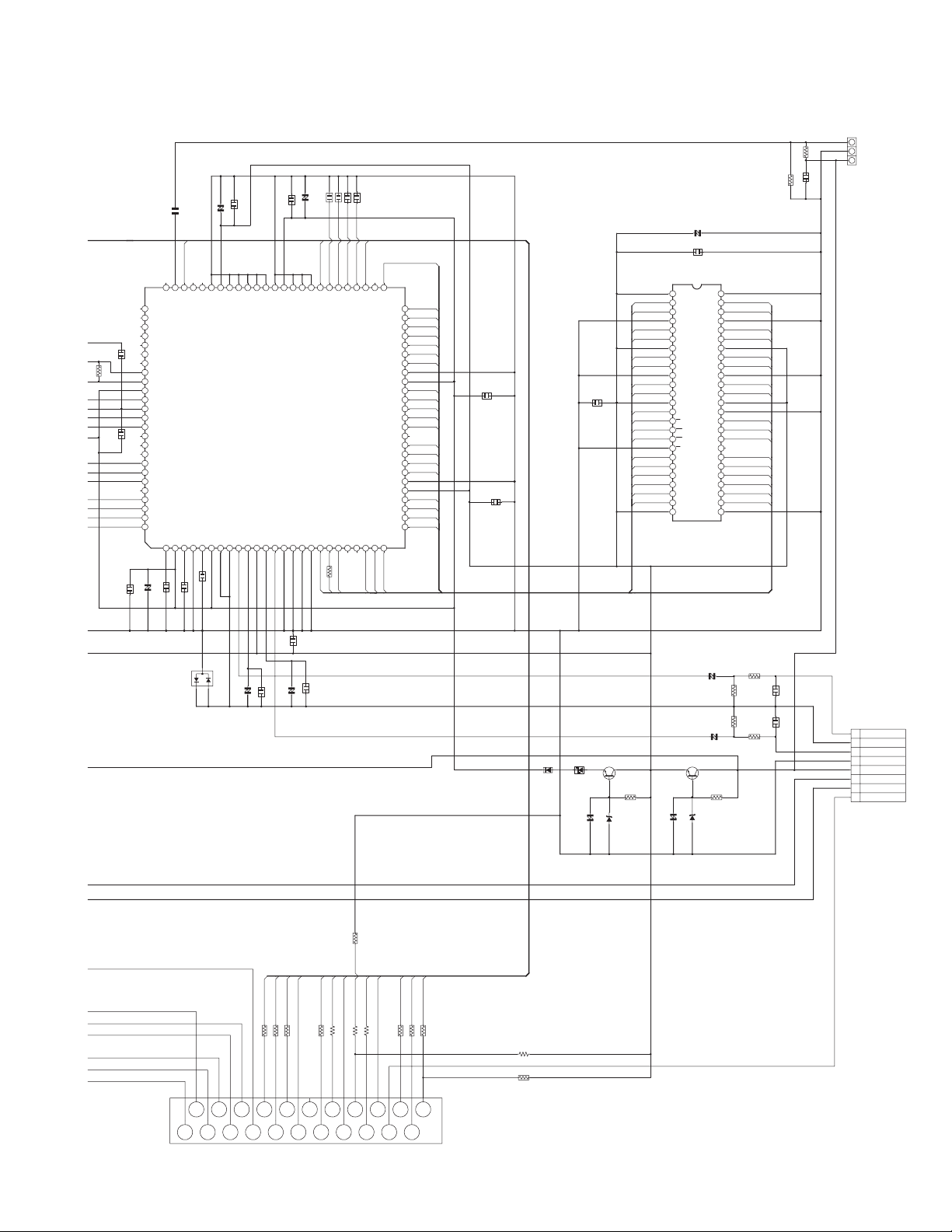

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

MX-C55J,MX-C55C

CD-ROM No.SML200606

ECO DISC SKIP

SP-MXC55 SP-MXC55CA-MXC55

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2006 Victor Company of Japan, Limited.

2-1

2-3

2-11 to 17

No.MB508SCH

2006/6

Page 16

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 17

< MEMO >

Page 18

Block diagram

C

R

N

FM / AM

CD / CD-R

AUX / GAME

V-IN

H/PHONE

USB

R-CH[RED]

L

-

CH[WHITE]

DIGITAL SIG.

INPUT1

INPUT2

INPUT3

USB AUDIO IC

FUNCTION

INPUT4

DATA/CLK COMMAND

ECO CONTROL

A / D

W

P

MUL

PRO

M

USB ON

u

-

KEY COMMAND

COM

V.F. DISPLAY

FRONT PCB ASS'Y

REMOCON

-

VP

VFD

5. 6

V

5V REG

P. S E

POWE

2-1

Page 19

M AUDIO

LTI

-

OCESSOR

POWER STAGE

FRONT

POWER STAGE

S-WOOFER

POWER STAGE

S-WOOFER

MAIN

SUBWOOFER

REG. IC

. SENS

W

ER ON

CD8. 5V

MOTOR12V

SIGNAL12V

SMPS

VFD

AC

ECO P/T

AC INPUT

2-2

Page 20

Standard schematic diagrams

0

0

0

A

T

Amplifier section

CN101

V

AUX_L

A. GND

USB_L

USB_R

USB_SSPND

H/P_L

H/P_SENSE

+1. 2V

+1. 2V

5VforPICKUP

COMPOSITE

C_OUT

Y/G_OUT

A. GND

A. GND

CN106

9P, WIRE

M. GND

D.GND

D.GND

P

-

SENSE

P

-

U. GND

HT4. 3V(+)

15P

-

D4V

Y/B

Y/R

CD_L

CD_R

CD

OPTION

PVdd

+12V

+3. 3V

+3. 3V

CNTL

+5. 6V

IN

A6V

A6V

A6V

A6V

N. C

A6V

A. GND

+5V

+5V

FL

-

32P, ST

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

CN102

15, ST

MUTE

-

V

P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CN103

28P, ST

11

13

15

17

19

21

23

25

27

CN104

10P, ST

1

3

5

7

9

CN105

8P, ST

1

3

5

7

9

CN107

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

22

24

26

28

10

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2

4

6

8

2

4

6

8

CR101

56K

CR102

56K

100uF

10V

CD101

1SS355 1SS355

CE102

M9V

U91/DISPRST

U27/DISPBUSY

U95/DISPD2S

U96/DISPS2D

EE008

220uF

CR01L

27K

CR01R

27K

100nF

EMC04

EMC01

EMC02

PROTECT

-

ON/OFF

P

RESET

H/P_SENSE

+5. 6V

EQ_IN

U. GND

D. GND

M. MUTE

P

-

SENSE

USB_SSPND

T_DO

TUNED

STEREO

V

U92/DISPCS

U96/DISPS2D

U95/DISPD2S

U97/DISPCK

U27/DISPBUSY

U91/DISPRST

-

MUTE

V

H/P_R

U92/DISPCS

U97/DISPCK

+3. 3V

M. GND

10V

+5V

D. GND

CD_L

CD_R

CR02L

4. 7K

CR02R

4. 7K

CR103

18K

CR104

18K

M. GND

CE101

CD102

M. GND

100uF

D. GND

+12V

M. GND

+3. 3V

100nF

D. GND

D. GND

100nF

FL+

FL

-

V

FAN

SCL

SDA

+5V

T_CE

-

F

-

OFF

M9V

+5V

+5V

10V

EMC03

+12V

EQ_IN

EE011

-

PP

+

220nF50V

ER112

820K

ED102

ER111

1SS355

uF

330K

50V

EE010

4. 7

+

AUX_R

ER109

10K

50V

470K

ER108

4. 7uF

EE009

120

EE01L

+

EE01R

2. 2uF

+

EE03L

1uF

+

EE03R

1uF

+

EE02R

1uF

+

EE02L

1uF

+

EE04L

1uF

+

EE04R

1uF

+

U.GND

EQ101

KTD1304

DA

TU_L

TU_R

I/P

CD_L

CD_R

+5V

+3. 3V

ER110

+

2. 2uF

16V

47uF

100nF

EC101

+

EE110

ER105

47

1uF

50V

+

+

EE07L

28272625242322212019181716

@pinLa

@pinLa

@pinLa

FIC01

R2S15904SP

@pinLa

@pinLa

@pinLa

123456789

D. GND

TX

M9VM9V

3. 3

2

W

ER107

ED101

M. MUTE

1SR154-400

+5V

FL+

FL

-

V

PP

RESET

CQ102

KTD1304

CQ103

KTD1304

KSR2101

CR105

MR107

V

D.GND

CQ101

1K

10K

10K

MR108

SD102

SR001

2. 7K

DR104

DR102

560

270

SR002

10K

KTC3199

DR103

KTC3199-Y

SR104

SQ107

KTA1268

390

SQ104

330K

SQ105

-

Y

SQ106

KSR

M9V

V-OFF

SDA

SCL

1SS355

+5. 6

100nF

-

V

P

HT4. 3V(+)

+5. 6V

P-ON/OFF

50V

1uF

EE07R

@pinLa

@pinLa

560

SR003

SZ106

UZP33B

KSC2331-Y

2103

SZ105

1N4739A

@pinLa

@pinLa

SR103

SQ102

SCL

DA

F

47

100nF

5. 6nF

5. 6nF

10uF16V

+

EC103

EC03R

SR004

@pinLa

@pinLa

10K

82

EE005

KSC2331

SR105

SR106

ER103 47

@pinLa

@pinLa

SD101

ER104

@pinLa

@pinLa

@pinLa

@pinLa

1uF

+

50V

EE06L

150K

ER101

ML104

Vpp

-

SE102

-

Y

330K

22K

1SS355

EC03L

@pinLa

@pinLa

@pinLa

@pinLa

1011121314

50V

+

1uF

150K

3. 3K

ER01R

ER102 EE06R

600

50V

27K

SR005

22uF

SZ102

RLZ5. 6A

SQ103

SE103

16V

SZ104

220uF

RLZ7. 5B

@pinLa

@pinLa

EL102

EC01R 220nF

600

SZ103

ER02R

ER02L

1. 2nF

@pinLa

@pinLa

EC102

EC104

15

@pinLa

@pinLa

EC01L 220nF

3. 3K

ER01L

100nF

RLZ5. 6A

220nF

EC02R

HR014

10K

10uF

16V

EE006

+

FL

220nF

EC02L

220

220

47K

ER03L

V

12

+

HR013

47K

ER03R

10V

220uF

100nF

EC105

EE007

8765432

VD

DGND

SDTO

LRCK

9

10111213141516

100

R102

M

0. 047nF

M

C105

0. 022nF

M

C104

47K

002

Q

H

KTD1304

600

EL101

VA

MCLK

0. 022nF

0. 022nF

XC102

AGND

SCLK

XC101

12. 288

XT101

VCOM

PDN

50V

EC106

1K

2. 2uF

R002

M

MHz

EE10L

CKS1

DIF

HL01L

22K

10K

FIC02

SDO_12

VDD_3

HR11L

10K

HR11R

10K

HC05R

0. 1nF

LRCKO

CKOUT

C110

M

HC05L

GND

HR05L

HR06L

HR05R

HR06R

AE101

OUT2B_1

OUT2B_2

GND2B

GND2A

OUT2A_1

OUT2A_2

OUT1B_1

OUT1B_2

GND1B

GND1A

OUT1A_1

OUT1A_2

4. 7K

4. 7K

4. 7K

4. 7K

Vcc2B

Vcc2A

Vcc1B

Vcc1A

BICKO

NC_3

100nF

-

C109

M

SUB

NC

47uF16V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

NC_6

GND_4

C111

M

100nF

HC02L

HC02R

AR102

GND_7

VDD_4

E101

M

HR04L

HR03R

HR04R

HR03L

AR103

2. 2K

C114

M

4. 7K

0. 22nF

4. 7K

4. 7K

0. 22nF

4. 7K

100nF

VDD_7

OUT8_B

M

L1

600

V

16

22uF

ML1

60

K

Y

-

AQ101

KSC2331

FE101

100nF

51

EAPD

OUT8_A

30

HC01L

HC01R

MC

100nF

C106

M

M

100nF

+12V

FC011

FC012

FC015

100

V

AR101

STA508

100nF

36

VccSign_2

35

VccSign_1

34

Vss_2

100nF

Vss_1

33

IN2B

32

IN2A

31

IN1B

30

IN1A

29

TH_WAR

28

FAULT

27

-

STATE

TRI

26

10K

FR004

PWRDN

25

CONFIG

24

VL

23

VDD_2

22

VDD_1

21

100nF

-

Reg

GND

20

-

Clean

GND

19

C115

M

100nF

NC_7

VDD_8

GND_8

SDO_34

AIC01

STA308A

XTI

FIL TER_PLL

VDDA

GNDA

R111

C108

3. 3K

M

M

C117

C107

1. 2nF

M

0. 1nF

M

HC03L

0. 22nF

HR07L

4. 7K

4560

2

HIC01

1

3

HR10L

10K

0. 22nF

HC03R

0. 22nF

HR07R

4. 7K

6

HIC01

7

4560

5

HR10R

10K

0. 22nF

FAN

PROTECT

1K

FR005

2. 2uF

FC013

600

FL003

FC014

100nF

M

C116

1. 2nF

M

R101

10K

C102

103

100nF

64636261605958575655545352

PWDN

SDO_78

SDO_56

MVO

1

GND_1

2

VDD_1

3

GND_2

4

NC_1

5

SDI_78

6

SDI_56

7

SDI_34

8

SDI_12

9

LRCKI

10

BICKI

11

VDD_2

12

GND_3

13

NC_2

14

RESET

15

PLLB

16

SA

SDA

SCL

17181920212223242526272829

M

L103

600

R105

R106

V

M

M

16

HC04L

8

HE002

100

XC103

100nF

10uF

HE01L

HR08L

10

100uF16

10K

HR09L

0. 1nF

V

16

HC006

100nF

47uF

HE01R

HR08R

10

100uF

V

16

10K

HR09R

0. 1nF

XE101

4

HC04R

ON/OFF

P

1K

1K

ER08R

ER08L

10uF

10uF

EE10R

1

AINL

AINR

CKS2

CKS0

EC107

100nF

M

R104

47

XR101

XR102

470

ER106

330

R110

M

600

HR001

47

HL01R

600

EIC02

AK5358

OUT

M

1

330

HR12R

KIA7029

GND

1

A1

2

Y1

3

A2

4

Y2

5

A3

6

Y3

7

GND

HR12L

1K

KTD1304

HQ01R

M

R001

M

R103

47

AIC02

XIC01

M

74HCU04

1K

KTD1304

H

10K

R112

M

C101

M

100nF

47

VCC

123

14

VCC

13

A6

12

Y6

11

A5

10

Y5

9

A4

8

Y4

Q

01L

4560

HIC01

2-3

Page 21

HR09R

HR09L

22K

AR103

2. 2K

AR102

AR101

10K

FC011

FC012

FC015

V

NC_7

XTI

FR004

HR10L

HR10R

R111

M

C117

M

10K

10K

100nF

100nF

10K

100nF

GND_8

FIL TER_PLL

HC03L

0. 22nF

HR07L

1

HC03R

0. 22nF

HR07R

7

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

C115

M

VDD_8

VDDA

3. 3K

1. 2nF

4. 7K

4. 7K

FIC02

STA508

VccSign_2

VccSign_1

Vss_2

Vss_1

IN2B

IN2A

IN1B

IN1A

TH_WAR

FAULT

-

STATE

TRI

PWRDN

CONFIG

VL

VDD_2

VDD_1

-

Reg

GND

-

Clean

GND

100nF

SDO_34

SDO_12

AIC01

STA308A

GNDA

VDD_3

C108

M

C107

0. 1nF

M

4560

2

HIC01

3

10K

0. 22nF

6

HIC01

4560

5

HC05R

0. 22nF

HR11L

HR11R

10K

C110

M

0. 1nF

LRCKO

CKOUT

HC05L

PROTECT

1K

FR005

2. 2uF

FC013

600

FC014

100nF

646362616059585756555453525150

PWDN

SDO_78

SDO_56

SA

SDA

SCL

171819202122232425262728293031

03

0

R105

R106

100

M

M

100

HE01L

100uF16

10K

100nF

HE01R

100uF

V

16

10K

GND

HR05L

HR06L

HR05R

HR06R

AE101

OUT2B_1

OUT2B_2

OUT2A_1

OUT2A_2

OUT1B_1

OUT1B_2

OUT1A_1

OUT1A_2

4. 7K

4. 7K

4. 7K

4. 7K

GND2B

GND2A

GND1B

GND1A

BICKO

NC_3

-

Vcc2B

Vcc2A

Vcc1B

Vcc1A

100nF

C109

M

SUB

NC

47uF16V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

NC_6

GND_4

C111

M

100nF

HC02L

HC02R

E101

M

GND_7

VDD_4

HR03L

HR04L

HR03R

HR04R

C114

M

100nF

4. 7K

0. 22nF

4. 7K

4. 7K

0. 22nF

4. 7K

VDD_7

OUT8_B

M

600

V

16

22uF

ML102

Y

-

KSC2331

L101

600

HC01L

HC01R

AQ102

KTA1273

AQ101

FE101

100nF

EAPD

OUT8_A

HR01L

HR02L

4. 7K

HR01R

HR02R

4. 7K

118

C

M

4. 7K

0. 27nF

4. 7K

0. 27nF

2. 2uF

FC14L

FC10L

100nF

FC11L

2. 2uF

2. 2uF

FC14R

FC10R

100nF

FC11R

2. 2uF

50V

1000uF

OUT1_A

OUT7_B

AR105

FC010

AR104

22

AE102

49

OUT1_B

OUT2_A

OUT2_B

NC_5

GND_6

VDD_6

OUT3_A

OUT3_B

OUT4_A

OUT4_B

OUT5_A

OUT5_B

NC_4

GND_5

VDD_5

OUT6_A

OUT6_B

OUT7_A

32

100nF

HPL_CH1

HPL_CH2

75

100nF

V

25

47uF

W

1/4

0. 33nF

FC01L

FR01L

W

22

1/4

0. 33nF

FC01R

FR01R

HPR_CH2

22

FL02L

22

FL02R

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

HPR_CH1

2P, ST

CN108

FR04L

FC13L

0. 33nF

15uH

FR04R

FC13R

0. 33nF

W

1/4

100nF

M

2. 2uF

22

M

W

1/4

E102

M

100nF

FAN

FC06L

FC06R

C113

C112

2

1

FL01L

FL01R

15uH

470nF [M]

15uH

470nF [M]

15uH

50

63V

5. 0uH

63V

5. 0uH

V

FL03L

FL03R

100nF [M]

FC12L

100nF [M]

FL12R

FC09L

FC09R

TR01L

TR02L

10K 18K

TR02R

TR01R

10K

18K

TE101

47uF

16

V

-

SM1-15PM

FMU-SM1-25PM

FMU

BASIC D77

[HX-D7] [HX-D77]

VR101, 102

330 ohm

+12V

TU_L

TU_R

TUNED

STEREO

T_DO

SCL

SDA

T_CE

+5V

FC05L

FC03L

100nF

10nF

FC07L

10nF

10nF

FC08L

10nF

FC07R

10nF

10nF

FC08R

100nF

FC02R

100nF

FC03R

100nF

FC02L

100nF

FR03L

4. 7 1/4

FC04L

100nF

FR02L

4. 7

1/4

FC05R

100nF

FR03R

1/4

W

4. 7

FC04R

100nF

FR02R

4. 7

1/4

W

-

FRONT_R

C_OUT

VR101

-

IN

V

V

-

OFF

COMPOSITE

I/P

VR102

VR121

VR104

VR103

390

390

75

VC110

100nF

VR120

390

390

W

W

D. GND

D. GND

V

-

MUTE

+

+

-

FRONT_L

FRONT_L

FRONT_R

VR107

VR103, 104

VR105, 106

VR108, 109

VR110, 111

16V

100nF

VC101

VE101

100uF

VC102

100nF

100

VR112

100

VE102

1uF

VE103

47uF16V

100

TX

330 ohm

330 ohm

200/ 120 ohm

200/ 120 ohm

1

2

3

4

5

6

50V

7

8

9

10

11

12

13

14

MM1623XFBE

VCC1

in

C_

MUTE1

CVBS

YC_MIX

Y_in

GND_1

BIAS

I / P

CY_in

CLP

Cb_in

MUTE2

Cr_in

VIC01

_in

390 ohm

390 ohm

390 ohm

200/ 180 ohm

200/ 180 ohm

VCC_2

S-DC_

C_

CVBS_

GND_5

Y_

CY_

GND_4

Cb_

GND_3

Cr_

GND_2

28

out

27

VC108

330uF

100nF

VE110

VE111

330uF

16

VR118

75

VR117

75

V

16

VR119

75

V

VR113

100

out

26

S1

25

S2

24

out

23

22

out

21

out

20

19

out

18

17

out

16

15

123456789

L_OUT

0-E50LFCC

GND_1

MV

R_OUT

TU101

000

VCC

MW

TUNED

STEREO

KST-

DO

CLK

DI

CE

10111213

GND_2

NC_1

NC_2

VJ102

2

5

1

3

4

1P

6

7

0. 22nF

0. 22nF

0. 18nF

VC106

VC109

VC107

2

C05

M

100nF

E

LED

Driver

1

IC

2. 5PI

3

VJ103

W

IC01

STA508

C15R

W

100nF

36

VccSign_2

VccSign_1

35

C16R

Vss_2

34

W

100nF

Vss_1

33

IN2B

32

IN2A

31

IN1B

30

IN1A

29

TH_WAR

28

FAULT

27

TRI-STATE

26

C17R

R07R

2. 2uF

W

W

10K

PWRDN

25

CONFIG

W

L05R

600

C18R

W

W

L05L

600

24

VL

23

VDD_2

22

VDD_1

21

100nF

C19R

W

100nF

GND-Reg

20

GND-Clean

19

C15L

W

100nF

36

VccSign_2

35

VccSign_1

C16L

34

Vss_2

W

100nF

33

Vss_1

32

IN2B

31

IN2A

30

IN1B

29

IN1A

28

TH_WAR

27

FAULT

26

TRI-STATE

10K

C17L

R07L

2. 2uF

W

W

25

PWRDN

24

CONFIG

23

VL

22

VDD_2

21

100nF

VDD_1

C19L

W

100nF

20

GND-Reg

19

GND-Clean

C18L

W

W

STA508

1

GND-SUB

OUT2B_1

2

OUT2B_2

3

Vcc2B

4

GND2B

5

GND2A

6

Vcc2A

7

OUT2A_1

8

OUT2A_2

9

OUT1B_1

10

OUT1B_2

11

Vcc1B

12

GND1B

13

14

GND1A

15

Vcc1A

16

OUT1A_1

17

OUT1A_2

E01R

W

18

NC

IC02

1

GND-SUB

2

OUT2B_1

3

OUT2B_2

4

Vcc2B

5

GND2B

6

GND2A

7

Vcc2A

8

OUT2A_1

9

OUT2A_2

10

OUT1B_1

11

OUT1B_2

12

Vcc1B

13

GND1B

14

GND1A

15

Vcc1A

16

OUT1A_1

17

OUT1A_2

E01L

W

18

NC

2. 2uF

WC25R

2. 2uF

WC24R

WC09R

100nF

WC11R

2. 2uF

WC10R

100nF

WC12R

2. 2uF

V

50

1000uF

WC25L

2. 2uF

14R

C

W

WC24L

2. 2uF

WC09L

100nF

WC11L

2. 2uF

WC10L

100nF

WC12L

2. 2uF

V

50

1000uF

22uH

W

L01R

10

1 / 4W

R10R

W

C23R

W

0. 68nF

C13R

W

0. 68nF

W

1 / 4W

R01R

W

10

W

L03R

22uH

10

R09R

W

22R

C

W

0. 68nF

21R

C

W

R08R

100nF

W

W

10

1 / 4W

0. 68nF

C13L

W

1 / 4W

R01L

10

W

W

10

R09L

W

C22L

W

0. 68nF

C21L

W

C14L

W

100nF

R08L

W

L02R

22uH

0. 68nF

10

22uH

L04R

R10L

W

C23L

W

0. 68nF

W

L03L

22uH

WL04L

22uH

22uH

W

L01L

L02L

22uH

0. 68nF

10

220nF

220nF

WC01R

WC02R

WC01L

220nF

220nF

WC02L

220nF

WR03R

220nF

WC03R

WR02R

6. 8

6. 8

WC04R

WR04R

WR05R

220nF

WR02L

WR03L

220nF

6. 8

6. 8

WC03L

6. 8

6. 8

W

WR04L

WR05L

]

06R

]

M

C

M

W

470nF [

20R

C

W

C20L

W

470nF [M]

470nF [

07R

C

W

470nF [M]

100nF

08R

C

10nF

W

100nF

SP101

SOLDER

FRONT_R

+

1

FRONT_L

+

2

FRONT_R

-

3

FRONT_L

-

W

C06L

W

100nF

C08L

W

C07L

W

100nF

OOFER_R

W

10nF

OOFER_R

W

OOFER_L

4

-

5

W

OOFER_L

-

6

+

7

+

8

05R

C

W

C05L

W

C04L

6. 8

6. 8

2-4

Page 22

Front section

T

E

E

E

I

P

C

9

2

0

K

BEAD2

3. 6 1. 2 5. 7

7

7

123456

305

1

W

4P/ 1P

F

2

3

4

5

6

8

8

AJACK1

HJACK1

7P

FL302

3. 6 1. 2 5. 7

FC01L

7

220pF(A)

6

2

3

4

5

1

7P

FC01R

220pF(A)

H/P-SENS

7

6

2

3

4

5

1

mm

FL301

mm

FE302

FR01L

FR01R

10uH

18K

18K

DIODE MATRIX OP

UD01

1M

FR323

UX103

12MHz/12pF

10K

100uF

FE30R

18

FR32R

25V

FE30L

100uF

+

FC02R

+

PCB3

USB SENS

FR30R

FC03R

18K

220pF [A]

4. 7K

FR31R

0. 027nF [A]

FR30L

4. 7K

FR31L

18K

25V

FC03L

FW301

14P, WIRE

FC305

1nF

220pF [A]

1

A.GND A.GND

2

3

A.GND

4

-

L USB-L

USB

5

A.GND

6

SIGN1217

7

USB_SSPND

8

A.GND

9

H/PL

10

A.GND

11

H/PR

12

A.GND

13

-

SENS

H/P

14

AUXL -CH

-

CH

-

CH

AUXR

V-IN

AUX-L

-

CH

AUX-R

A.GND

A.GND

-

R

USB

-

R

USB

USB-SSPND

A.GND

H/P

-

L

A.GND

-

R

H/P

A.GND

-

SENS

H/P

FC303

FC304

UIC03

18pF[A]

18pF[A]

FE303

FC02L

FR32L

PCM2704DBR

XTO

1

CK

2

DT

3

PSEL

4

+

DOUT

5

DGND

6

VDD

7

D

8

D+

9

VBUS

10

ZGND

11

AGNDL

12

VCCL

13

+

VOUTL

14

18

0. 027nF [A]

XTI

28

SSPND

27

TEST0

26

TEST1

25

HID2/MD

24

HID1/MC

23

HID0/MS

22

HOST

VCOM

ANGDR

VOUTR

21

FE306

+

VCCP

20

1uF

PGND

19

FE304

+

18

10uF

16V

17

FE305

+

VCCR

16

1uF

15

FR33R

10K

FR33L

-

mm

BEAD1

FR324

3. 6 1. 2 5. 7

FR320

1. 5K

FR322

22

FR321

22

+

10M

1uF

FR325

50

V

18K

FR800L

18K

FR800R

FC301

470pF

FC800L

1. 5K

FE301

1uF

1uF

FC302

0. 1nF[A]

0. 1nF[A]

470pF

FC800R

UD02

UD03

UD04

UD05

UD06

UD07

UD09

AREA FREQ. STEP S

AREA FREQ. STEP S

AREA FREQ. STEP S

CLOCK SELECT

RDS OPTION

ECO OPTION

CLOCK BACK

-

UP OPT

AM FREQUENCY STE

TO

202

W

3P, ST

U

1 2 3

220

FR310

FR800

LD310

10K

BLUE

22nF [A] FC800

PCB2-A

PCB2

220

220

FR309

FR308

RED

RED

LD308

LD309

FW401

4P, WIRE

1

GND

KEY-A/D3

2

STANDBY-LED

3

LED +5. 6V

4

LD201

FR222

560

UI

218

W

S

-

KEY

DISC1

LC70

24

P00

23

P01

22

P02

21

P03

20

P04

19

P05

18

P06

17

P07

16

VDDP1

15

P10

14

P11

13

P12

FR

A/D1

82

201

W

S

SOUND MODE DOWN

217

216

W

W

STOP

S

S

PCB1-A

UW102

2P, WIRE

FW201

8P, WIRE

1

2

3

CONT

220

FR307

220

220

FR304

RED

LD307

1/4

W

220

FR306

FR305

LD305

LD306

LD304

ER

311

W

310

W

W

S

PO

S

820

FR311 FR312 FR313

ECO

VR101

312

W

S

1K

MAIN VR

313

W

S

DISC SKIP

1. 2K

OPEN/CLOSE

4

5

6

7

8

VR1

VR2

LED_GND

LED+5V

W

102

F

8P, ANGLE

1

2

3

4

5

6

7

8

UW201

3P, ANGLE

LED+5V

LED+5V

LED_GND

VR2

VR1

CONT

1

2

3

FQ303

PCB1

KTC8050

2

220

FR301

LD301

AUX_LENS_LED

4. 7K

FR317

FQ301

KTC8050

1

FR302

2P,

220

LD302

4. 7K

FR318

UW101

ANGLE

1

2

3

1

KTC8050

FQ302

220

FR218

PRESET LED

LD202

CENTER LED

AUX LENS(RED)

USB LENS(BLUE)

VOLUME LED

2

FR111

4. 7K

100NF

UC107

220

219

W

W

S

S

DISC2

DISC3

6. 8K 4. 7K 3. 3K 2. 2

FR108 FR107 FR106 FR105

PCB4

2-5

Page 23

ATRIX OPTION

E

DISC1

EA FREQ. STEP SELECT

EA FREQ. STEP SELECT

EA FREQ. STEP SELECT

OCK SELECT

S OPTION

O OPTION

OCK BACK-UP OPTION

FREQUENCY STEP

ISTAT

/MDATAO

/MADDR

/MRO

/MCS

/DECINT

/MWE

MUTE

LKFS

NC

XRST

U98

17

U100U6U97

ML T

11

1213141516

10

U24

U91

U94U2U1

SOSI

21

19

22

20

18

U96

U99

U95

U28

MODESW

DSKSW

CLOSE_M

OPEN_M

MDATA

MCK

OPENSW2

+5V

OPENSW1

9

1

34567

8

2

22P, ST

2

1

M

W

W

W

_

M

_

W

+5.0V

OPENS

CLOSE

OPEN

MODES

OPENS

DSKS

TO MAIN / AMP PCB

FW103

24P, ST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

UIC02

LC709004A

P00

24

23

D

22

ED

21

ED)

20

UE)

19

LED

18

17

16

15

14

13

EY-A/D1

217

W

S

DOUT

P01

P02

P03

P04

P05

P06

P07

VDDP1

P10

P11

P12

DIN

CLK#

CS#

VDD

RES#

VSS

P17

P16

P15

P14

P13

FR201 FR202 FR203 FR204 FR205

820

1K

205

201

W

W

S

S

SOUND MODE UP

SOUND MODE DOWN

216

W

STOP

PAUS E

S

3. 3K 2. 2K 1. 8K 1. 5K 1. 2K 1K 820

VFD AC1

VFD AC2

-

VP

AMP SCL

AMP SDA

PROTECT

PO

AMP RESET

H/P SENS

+5. 6V

LED +5V

EQ IN

LED GND

GND

MAIN MUTE

P-SENSE

USB ON

T CE

TUNE

STEREO

1

2

3

4

5

6

7

8

9

10

11

12

UR192

100

1. 2K

204

W

DEMO

OOFER+

S

W

S /

215

214

W

W

S

S

REWARD

FORWARD

W

ER ON

1. 5K 1. 8K

-

206

W

S / WOOFER

S

213

W

S

USB / AUX

470

FAN

FD301

1N4002

UR191

UR102

100

207

W

S

212

W

S

UR186

100

UR189

100

BSSS / TREBLE

FM / AM

PO

AMP

LED_GND

UR190

AMP

PO

208

W

S

211

W

S

T-CLK

T

-

DATA

PROTECT

WER-

-

RESET

H/P

5. 6V

LED+5V

EQ

-

M-MUTE

P

-

USB

T

T

-

STEREO

ZHUIJ

CD

-

100

CD-MUTE

STEREO

TUNE

USB

-

MUTE

M

-

RESET

WER-

PROTECT

KEY

-

ON

IN

SENS

-

ON

-

DI

CE

TUNE

MUTE

5. 6V

U91

U26

-

ON

ON

FAN

A / D1

CD / DVD

101

W

F

F1

F1

UPDATE

1N4002

P-SENS

ZHUIJ

CLOSE_M

U94

U95

U96

U97

U98

U99

U100

5. 6V

FD204

UR164

1K

+

3. 3uF 50V

5. 6V

FD205

UE107

1N 4002

UPDATE

5. 6V

6. 8K

DATE

UP

UE101

UR180

UR181

10uF

50V

100

100

100

+

F2

+

FC204

UR188

UR187

100

UW001

6P, ST

1

3

5

50V

2. 2uF

4. 7K 2. 2K

UR151

UR152

10K

UR185

UR174

SENS

P

UD101

6469

UE105

GND

47nF

UR150

100

UR165

UR166

UR167

2

4

6

1G

2G

3G

4G

5G

6G

7G

8G

47nF

G1G2G3G4G5G6G7G8G9

5VDC

PS102

PS1

81

DSK-SW

82

-

SENSE

P

83

PRESET 1

84

PRESET 2

85

709006 CS

86

709006 CLK

87

709006 DATA OUT

88

709006 RESET

89

GND

90

VDD2

91

FUNCTION DATA

92

CLOSE

93

BUZZER

94

D / LATCH

UR172

95

CD / MP3 O

96

CD / MP3 I

97

CD / MP3 CLK

98

MP3 C

99

CD / MP3 LATCH

CD / MP3

100

DECINT

10K

Fresh only

GND

220K

UD102

1N4148

UR183

+

10nF

UC101

UE102

220nF50V

GND

9G

-

M

-

ADDRESS

UR101

U1

+

UE103

63 6261 6059 58 57 5655 5453

UC105

10K

DSKSW

1K

100

100

100

UR168

100

UR173

UR182

1N4148

UQ101

KTC945B

10G

11G

12G

P35

P34

40 3938 37 3635 34 3332 3130 29

UR128

47K

127

UR

47K

UR

126

47K

UR

125

47K

UR

124

47K

UR

123

47K

UR

122

47K

UR

121

47K

UR

120

47K

UR

119

47K

UR

118

47K

UR

117

47K

UR

116

47K

UR

115

47K

4. 7K

UR103

4. 7K

UR104

4. 7K

UR105

4. 7K

UR106

4. 7K

UR107

4. 7K

UR108

4. 7K

UR109

4. 7K

UR110

4. 7K

UR111

4. 7K

UR112

4. 7K

UR113

4. 7K

UR114

SG35

SG34

SG2

SEG 2

M

-

OPEN

100

UR169

OPEN_M

SG3

SEG 3

SW1

-

OPEN

100

UR170

1

W

OPENS

BZ101

1N4002

SG4

SEG 4

LV2300 / CE

CE

T

SG33

SG5

SEG 5

P_ISTAT

U6

UR161

G10

G11

G12

SG1

8079787776757473727170696867666564636261605958575655545352

SEG 1

OPTION

-

DATA

-

DATA

DSP /

SSK CLK

DSP /

SSK DATA

123456789

U2

47

UE104

+

100uF10V

UD103

1000uF10V

R106 FR105 FR104 FR103 FR102 FR101 FR100

VFD1

P33

SG32

SG6

SEG 6

MX-C55

P32

P31

P30

P29

P28

P27

P26

P25

P24

P23

P22

P21

P20

P19

P18

P17

P16

P15

P14

P13

P12

P11

SG15

UR129

UR130

SG17

UR131

UR132

UR133

SG17

SG14

UD12

UD11

UD10

UD09

UD01

UD02

UD03

UD04

UD05

UD06

UD07

UC108

SEG 17

1nF

P10P9P8P7P6P5P4P3P2

SG13

SG12

SG11

SG10

47K

47K

47K

47K

47K

1N4148

UD08

47K

UR193

SEG 18

SEG 19

SEG 20

SG9

SG16

SG15

SG16

SG15

SG31

SG7

SG30

SEG 7

SG29

SG28

SG8

SEG 8

VFD_5V

28 2726 2524 23 22 2120 19 1817 16 1514 13 1211 10 9 8 7 6

SG21

SG20

SG19

SG18

SG17

SG16

SG19

SG18

SG21

SG20

SG27

SG26

SG25

SG24

SG23

SG22

SG21

SG20

SG19

SEG 13

SEG 14

SEG 15

SG18

SEG 16

SG9

SEG 9

SG10

SG11

SEG 10

SG12

SEG 11

SEG 12

UIC01

LC87F67C8A

SW

2 (VOLUME)

-

-

DATA

CLK

E

UR162

DATA

T

1K

RESET

-

-

EVR3

E

MODE

u

101112131415161718192021222324252627282930

100

1K

UR171

1K

32. 768KHz

UR163

UC103

CLK

T

MODESW

VR2

GND

10K

UR153

47nF

UC102

UD104

1N4002

CLK IN (32. 768KHz)

CLK OUT (32. 768KHz)

UR177

10M

UX101

UR178

UC104

0. 022nF

GND

4. 7K

UR184

GND

1M

UR179

UX102

(1)

10MHZ

560K

C1

0. 022nF

T IN (10MHz)

T OUT (10MHz)

-

X

X

(3)

C2

(2)

VDD1

UR154

KEY A / D1

A / D1

-

KEY

10K

KEY A / D2

100

UR176

A / D2

-

DI

-

KEY

T

10K

UR155

FW104

4P, ANGLE

1

2

3

4

LV2300 DATA IN

10K

UR157

KEY-A / D3

1 (VOLUME)

-

EVR3

H / P

H / P

VR1

10K

UR156

H / P SENSE

UR158

A / D3

-

KEY

SG8

SG14

SG14

SEG 21

KEY A / D3

10K

P1

F1

SG7

SG6

SG5

SG4

SG3

SG2

SG9

SG8

SG7

SG6

SG5

SG4

SG3

SG2

SG1

SG11

SG13

SG12

SG10

SG13

SG12

SG11

SG10

SG9

SG8

SG7

SG6

SG5

SG4

SG3

SG2

SG1

SEG 22

SEG 23

SEG 24

SEG 25

SW2

-

LKFS

EQ LENEL A /D

709006 DI

OPEN

100

UR175

2

W

IN

-

U24

EQ

OPENS

U26

10K

+5. 0V

UR159

SG1

UR134

47K

UR135

UR136

UR137

UR138

UR139

UR140

UR141

UR142

UR143

UR144

UR145

UR146

UR147

UR148

UR149

SEG 26

SEG 27

VFD_5V

SCORE (SOSI)

RMCON_IN

100

UR160

HORIZONTAL

U28

+

UE106

10uF

51

VPP

SEG 28

SEG 29

SEG 30

SEG 31

SEG 32

SEG 33

SEG 34

SEG 35

GRID12

GRID11

GRID10

GRID9

GRID8

GRID7

GRID6

GRID5

GRID4

GRID3

GRID2

GRID1

Vout

1 2 3

FD201

1N4002

1

REYE1

Vcc

5. 6V

47nF

100uF

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

50V

GND

10V

UC106

+

FE200

FC201

10nF

SG13

SG14

SG15

SG16

SG17

SG18

SG19

SG20

SG21

SG22

SG23

SG24

SG25

SG26

SG27

SG28

SG29

SG30

SG31

SG32

SG33

SG34

SG35

G12

G11

G10

G9

G8

G7

G6

G5

G4

G3

G2

G1

2-6

Page 24

CD section

A

0

FEO

10nF

C140 0. 1nF

TEO

SLO

SPO

C116

470nF

10K

R110

10K

R107

RESET

MLT

MDATA

MCK

ISTAT

20K

R106

8. 2K

RESET

ISTAT

SOS1

0. 027nF

0. 027nF

C222

1M

C223

R209

XT201

16. 93MHz

1K

R429

R217

470

C224

100nF

470

R216

R108

12K

76

77

78

79

80

81

C227

100nF

82

83

84

85

86

87

88

89

90

C226

100nF

91

92

93

94

95

96

97

98

99

10

50V10uF

C202

100nF

C203

C141 0. 1nF

C142 0. 1nF

R420

1K

C143 10nF

SPO

FEO

R118 82K

C122 0 .39nF

C126

10V

CW101

16P, ST

1

VC

2

VCC

3

E

4

D

5

6

B

C

7

8

F

GND

9

LD

10

VR

11

PD

12

F

+

13

T

-

14

T

+

15

F

-

16

CW102

6P, ST

1

2

3

4

5

6

R122

R123

R124

R125

R126

R127

R128 82

82K

56K

56K

56K

56K

82K

C134

220uF 10V

+

C135

+

220uF 10V

+

C128

R121 10

220uF

KSA812

Q101

37

C129

1nF

38

39

40

41

42

C130

10nF

43

C131

1. 5nF

44

45

C132

22nF

46

47

C133

68nF

48

2.2nF

C125

100nF

100nF

C1240.22nF

C123

R120 47K

R119

27K

C127

33nF

3635343332313029282726

ATSC

LD

PD

PDAC

PDBD

PDF

PDE

DCB

MCP

DCCI

DCCO

VREF

EQC

RFM

123456789

NC

18K

C101

R101

LPFT

RFO

TEIO

EQI

4. 7nF

C103

220uF 10V

GND

TZC / SSTOP

IC101

KB9226

EQO

EFMI

4. 7nF

C104

+

C105

R117 56K

120K

R116

C120100nF

FEO

TEO

FEM

TEM

VCC

FRSH

FSET

FLB

50V

C107

100nF

6. 8uF

180K

+

R102

C109

C110 100nF

R129

NC

56nF

C121

SLP

SLO

FGD

FSI

101112

1nF

C111

C119 68nF

R115 120K

C118

+

R114

50V

47K

25

SLM

SPO

SPM

ASY

EFM

LOCK

WDCK

CLVI

RESET

MLT

MDATA

MCK

ISTAT

TGU

68K

R103

C112 100nF

15K

10uF

R113

56K

C117

R112

24

R111

82K

23

22

21

20

19

18

17

16

15

14

13

C115

10nF

R109

R104

1K

+

C114

1uF

33nF

1M

C113

R105

15161718192021

)

)

-

+

DI3. 1

DI3. 2

DO3. 1

DO3. 2

OPIN(

OPIN(

OPOUT

GND_2

DO2. 2

DO2. 1

DI2. 2

DI2. 1

1413121110

9

FIN

22232425262728

VCC2

VCC1

MUTE

GND_1

7654321

8

FIN

VREF

REO

DI4. 1

REG

DI4. 2

DI1. 2

D401

MTZJ5. 6B

DO4. 1

DI1. 1

1

GND

2

VO1

3

VCTL

4

VIN1

DO4. 2

DO1. 2

IC401

FAN8082

GND_3

DO1. 1

PVCC

SVCC

IC301

KA9258D

D301

1N5392

C302

+

330uF

16V

TEO

SLO

C401

8

VO2

7

6

5

VIN2

100nF

47K

47K

47K

47K

R430

R431

R432

R433

2-7

103

W

C

8P, ANG

2 4 6

1 3 5

MTR-MTR

+

OP_SEN

TRAY_SEN

CL_SEN

MODE_SEN

8

7

5V

+

DGND

Page 25

CW107

z

7

3P, ANGLE

D. OUT

4. 7K

R411

4. 7K

C406

100nF

UDQ

ADDR

ADDR

ADDR

ADDR

ADDR

ADDR

R412

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

M

CLK

CKE

9

8

7

6

5

4

0.1nF

0.1nF

0.1nF

0.1nF

@pinLa

IC201

@pinLa

@pinLa

@pinLa

10V

C219

+

C218

100nF

100uF

C231

C233

C232

C230

C503

100uF

10V

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

MDATAO

@pinLa

@pinLa

UDQM

/MADDR

/ MADDR

@pinLa

@pinLa

220

R213

CLK

/MRD

/ MRD

@pinLa

@pinLa

CKE

/MWE

/ MWE

@pinLa

@pinLa

/MCS

/ MCS

@pinLa

@pinLa

/ DECINT

@pinLa

@pinLa

9

ADDR

ADDR8ADDR

@pinLa

@pinLa

DB4

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

25

DB5

50

DB6

49

DB7

48

DB0

47

DB1

46

DB2

45

DB3

44

43

42

M

LDQ

41

/ WE

40

/ CAS

39

/ RAS

38

BA

37

36

ADDR

10

35

ADDR

0

34

ADDR

1

33

ADDR

2

32

31

30

ADDR

3

29

ADDR

4

28

ADDR

5

27

ADDR

6

26

C216

100nF

C214

100nF

DB4

DB5

DB6

DB7

DB0

DB1

DB2

DB3

C502

100nF

UDQ

/ WE

/ CAS

/ RAS

BA

ADDR

ADDR

ADDR

ADDR

ADDR

M

10

0

1

2

3

7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

IC501

12L1616A

Vdd1

DQ0

DQ1

VSSQ1

DQ2

DQ3

VDDQ1

DQ4

DQ5

VSSQ2

DQ6

DQ7

VDDQ2

LDQM

WE

CAS

RAS

CS

BA

A10 / AP

A0

A1

A2

A3

Vdd2

+

C501

100nF

Vss2

50

DQ15

49

DQ14

48

VSSQ14

47

DQ13

46

DQ12

45

VDDQ4

44

DQ11

43

DQ10

42

VSSQ3

41

DQ9

40

DQ8

39

VDDQ3

38

N. C / RFU

37

UDQM

36

CLK

35

CKE

34

N. C

33

A9

32

A8

31

A7

30

A6

29

A5

28

A4

27

Vss1

26

10V

100uF

C220

100nF

C407

100nF

+

C221

LKFS

75747372717069686766656463626160595857565554535251

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

76

@pinLa

77

@pinLa

78

@pinLa

79

@pinLa

80

@pinLa

81

@pinLa

C227

100nF

82

1M

R209

0

0

@pinLa

83

@pinLa

84

@pinLa

85

@pinLa

86

@pinLa

87

@pinLa

88

@pinLa

89

@pinLa

90

@pinLa

C226

100nF

91

@pinLa

92

@pinLa

93

@pinLa

94

@pinLa

95

@pinLa

96

@pinLa

97

@pinLa

98

@pinLa

99

@pinLa

100

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

123456789

1nF

C205

1nF

C204

+

1nF

50V10uF

C201

C202

100nF

C203

@pinLa

S5L8310X

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

@pinLa

101112131415161718192021222324

1

GND

2

5

V

3

+

C215

100nF

C303

3. 3V

10V

100uF

Q302 KSC1008

+

D302

UZ3. 9B

C206R

4. 7uF

50V

R201R

+

C212L

4. 7uF

+

R302

100

C209R

R202R

2. 2nF

100K

R203L

C213L

100K

R204L 100

2. 2nF

8

R-CH

AGND

7

AGND

6

L

-

MGND

5

V

+

8

V

+

DRGND

CH

5

MGND

4

+5V

3

+8V

2

DGND

1

MUTE

8p

CW106

50V

82

3

D201

DAN217

1

+

2

10V

C207

100uF

+

10V

C211

100nF

C210

C208

100nF

100uF

D307

D306

SB01-05CP

C304

10V

100uF

+

Q303 KSC1008

D305

UZ2. 7BSA

R303

82

1SS355

47K

R409

LKFS

470

R421

/ MWE

470

R422

/ DECINT/ DECINT

SOS1

/ MCS

ISTAT

/ MRD

/ MADDR

/ MDATAO

470

470

R428

R423

470

470

470

R427

R425

R426

4. 7K

R210

R211

10K

MLT

MCK

RESET

MDATA

470

470

470

R407

R406

R408

2

1

3

OPEN_M

TRAY_SEN

MODE_SEN

4

6

5

CL_SEN

OP_SEN

CLOSE_M

7

+5V

8

MCK

10

12

14

16

18

20

9

11

13

15

LKFS

ISTAT

/ MWE

17 1921

SOS1

MUTE

/ MCS

/ DECINT

/ MRD

NC

MLT

XRST

MDATA

22

/ MADDR

/ MDATAO

CW105

22P, ANGLE

2-8

Page 26

SMPS section

50V

4

SMPN02

3P, ANGLE

1

2

3

JVC

SMC04

SMC05

SMC14

SMC15

100V AREA

JUMP WIRE

330uF 250V

JUMP WIRE

68uF 250V

200V AREA

330uF 250V

330uF 250V

68uF 250V

68uF 250V

JVC DELETE

SMD40

EU01W

SMC40

100uF

50V

7. 5K

SMR50

SMD47

1N4148

KSA2328A-Y

SMQ40

GBU6J

SMBD01

THERMISTOR

SMC02

470pF

SMTH01

0. 1uF[M]

3

2

D1 D2

D3 D4

3

2

SQE2930

SMLF02

SMCM02

SQE2930

SMLF01

SMR01

1. 5M

0. 1uF[M]

SMCM01

SMVR01

470pF

DFO6M

SMBD02

SMC03

470pF

L1 L2

?

SBC01

47uF

SMC07

56K

SMR02

SMD01

UF4007

SMR04

10

10

SMR03

SMD02

EU01W

SMD03

EU01W

8. 2nF