Page 1

R

SERVICE MANUAL

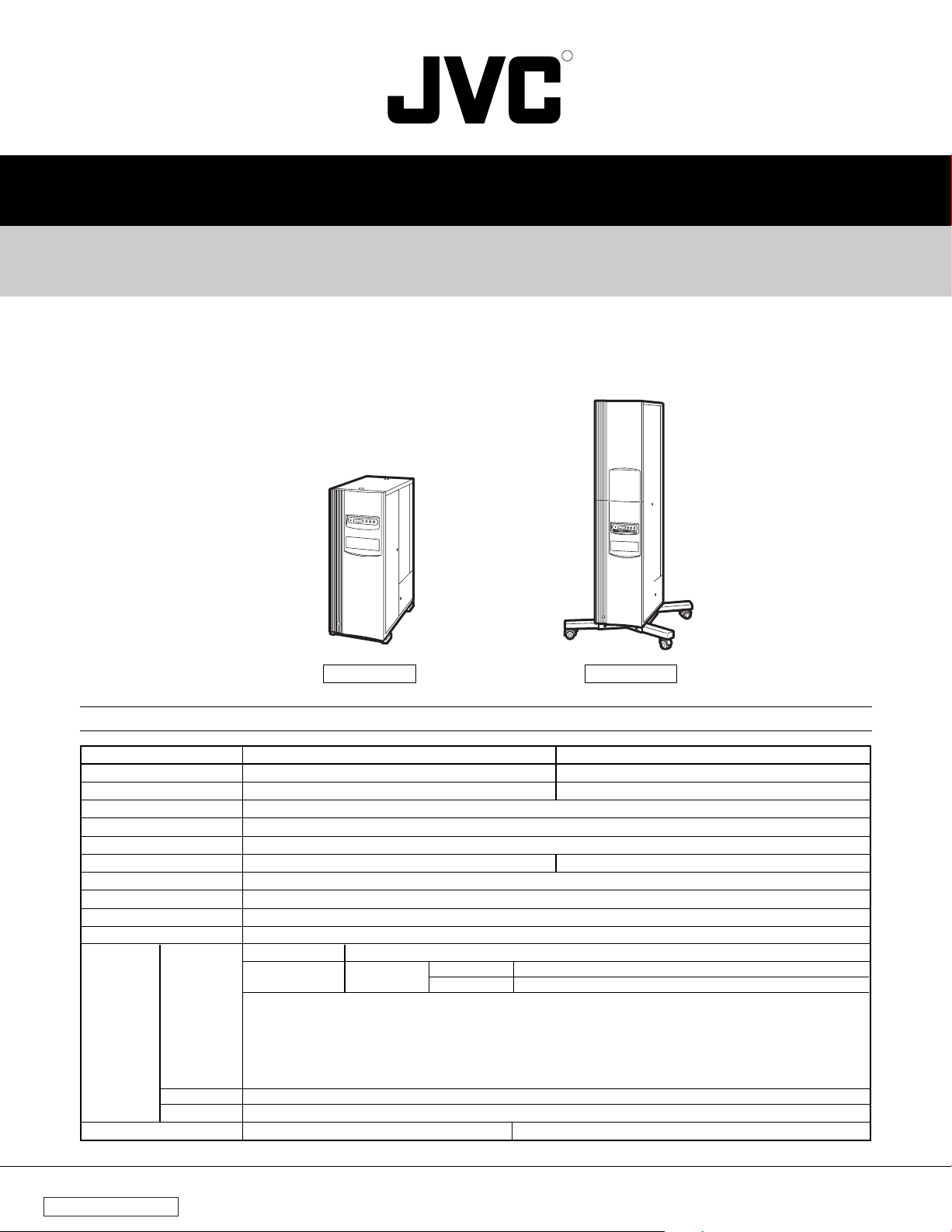

CD/DVD LIBRARY

MC-8200LU/MC-8600LU

SPECIFICATIONS

Item

Number of stored discs

Number of magazines

Operating environment

Rated power voltage

Rated power frequency

Rated current

Power consumption

Interface

Drive slots rack bays

Media size

Applicable

options

Weight

Drives

Carrier

Magazine

MC-8200LU

MC-8200LU

200

4

Temperature: 5°C to 35°C (41°F to 95°F) (Note 1) Humidity: 10% to 80% (no condensation)

AC 120 V to 240 V

50 Hz/60 Hz

2.4 A to 1.4 A (max. value), 1.4 A to 0.8 A (6 Drives are loaded)

140 W (Reference value, 6 DVD-RAM drives are loaded)

68-pin external SCSI connector

6

12 cm discs

Available drives

DVD-RAM/R

drive

• The relevant specifications for the drives can be found in the appropriate instruction manual.

• Concerning the Availability/Compatibility of the drives that are not listed, please contact your dealer

or nearest JVC service centre.

• The production of a particular drive may be discontinued without prior notice. Therefore,

a replacement drive may be changed to a different model.

• JVC does not provide a warranty in the case of software not functioning correctly as a result of a

drive being replaced or added.

Single-sided / Double-sided compatible disc carrier: MC-CF10U

Magazine set: MC-M25U (B)

(Excluding the discs and optional equipment)

58kg

MC-R434U Write/Read

Read

DVD-RAM (Ver. 2.1), DVD-R (for General), CD-R, CD-RW

DVD-ROM, CD-ROM

104kg

MC-8600LU

MC-8600LU

600

12

3.2 A to 1.8 A (max. value), 1.4 A to 0.8 A (6 Drives are loaded)

Compatible discs

(Excluding the discs and optional equipment)

100% recycled paper

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No. HM003

Dec. 2003

Page 2

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

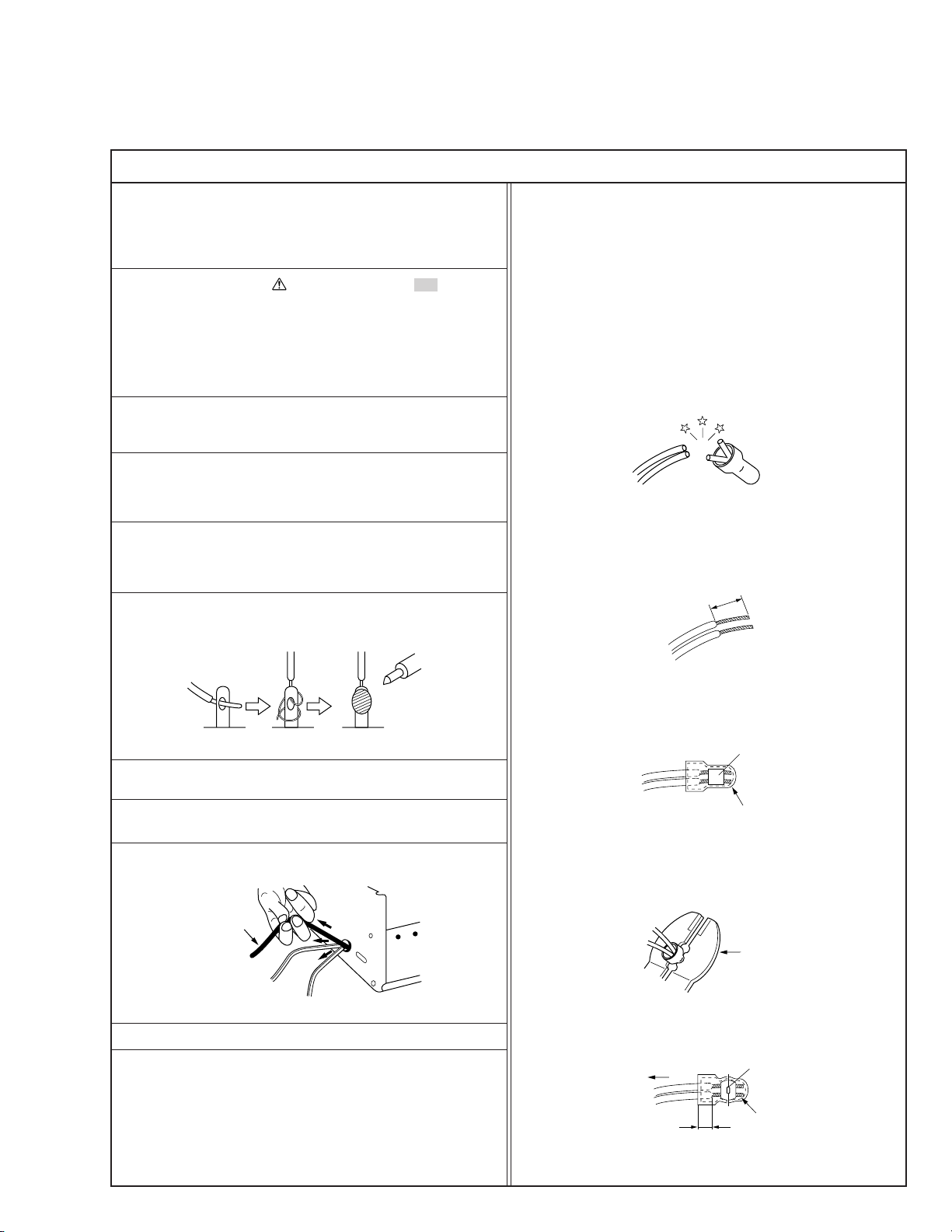

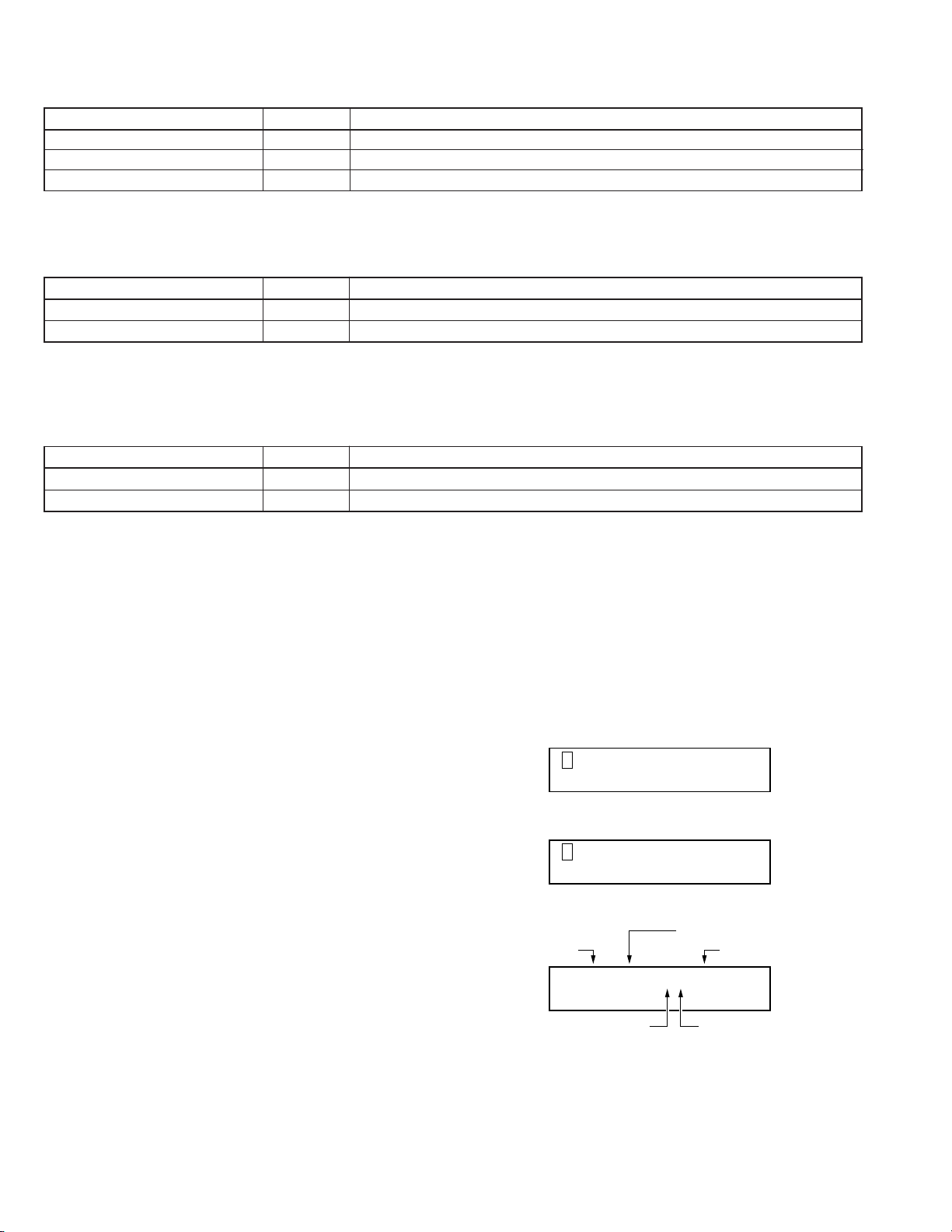

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 3

p

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

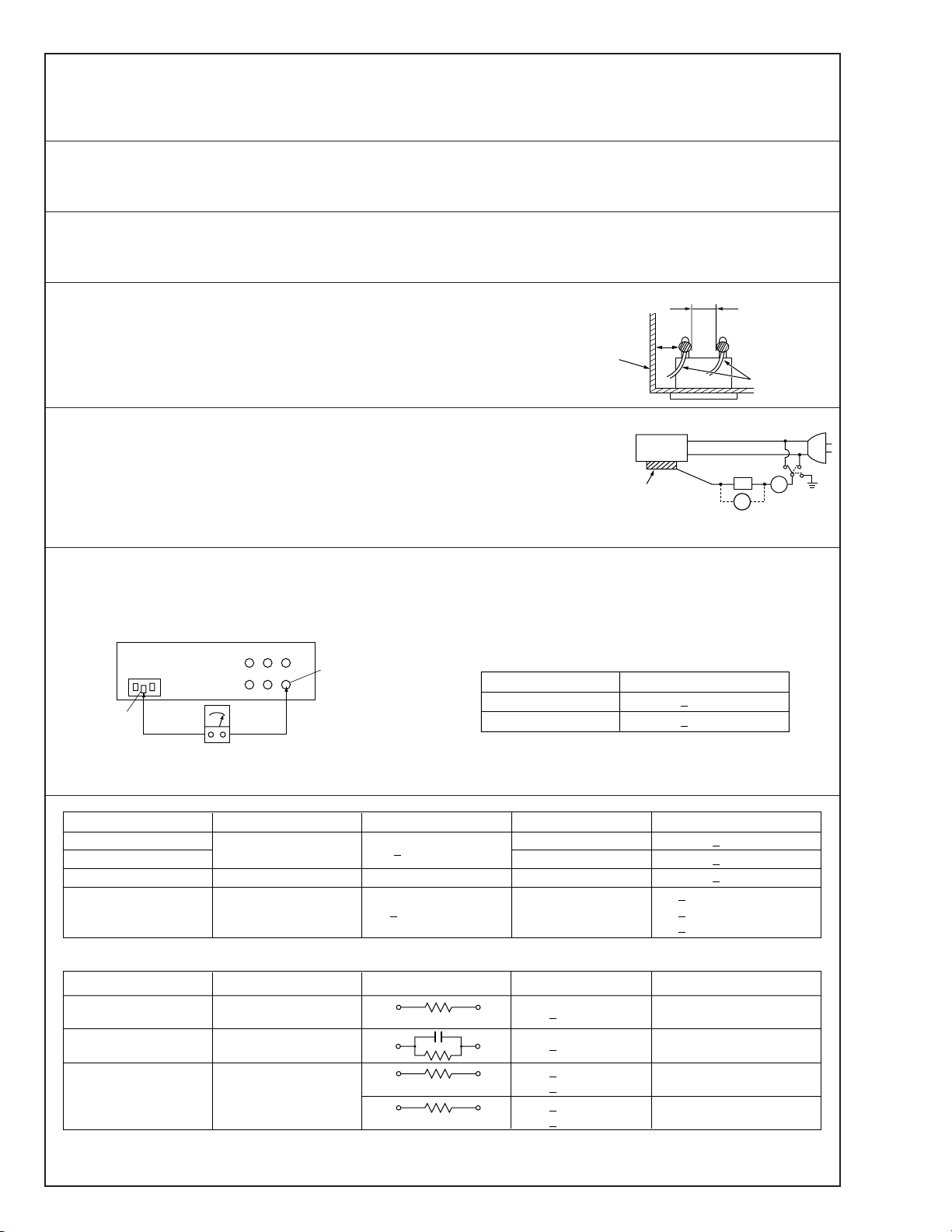

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible

Grounding Impedance (Z)

d

d'

art

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

A

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan R 1 MΩ/500 V DC

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

–

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 900 V 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i2 mA dc

i 0.7 mA peak

i2 mA dc

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

2

Page 4

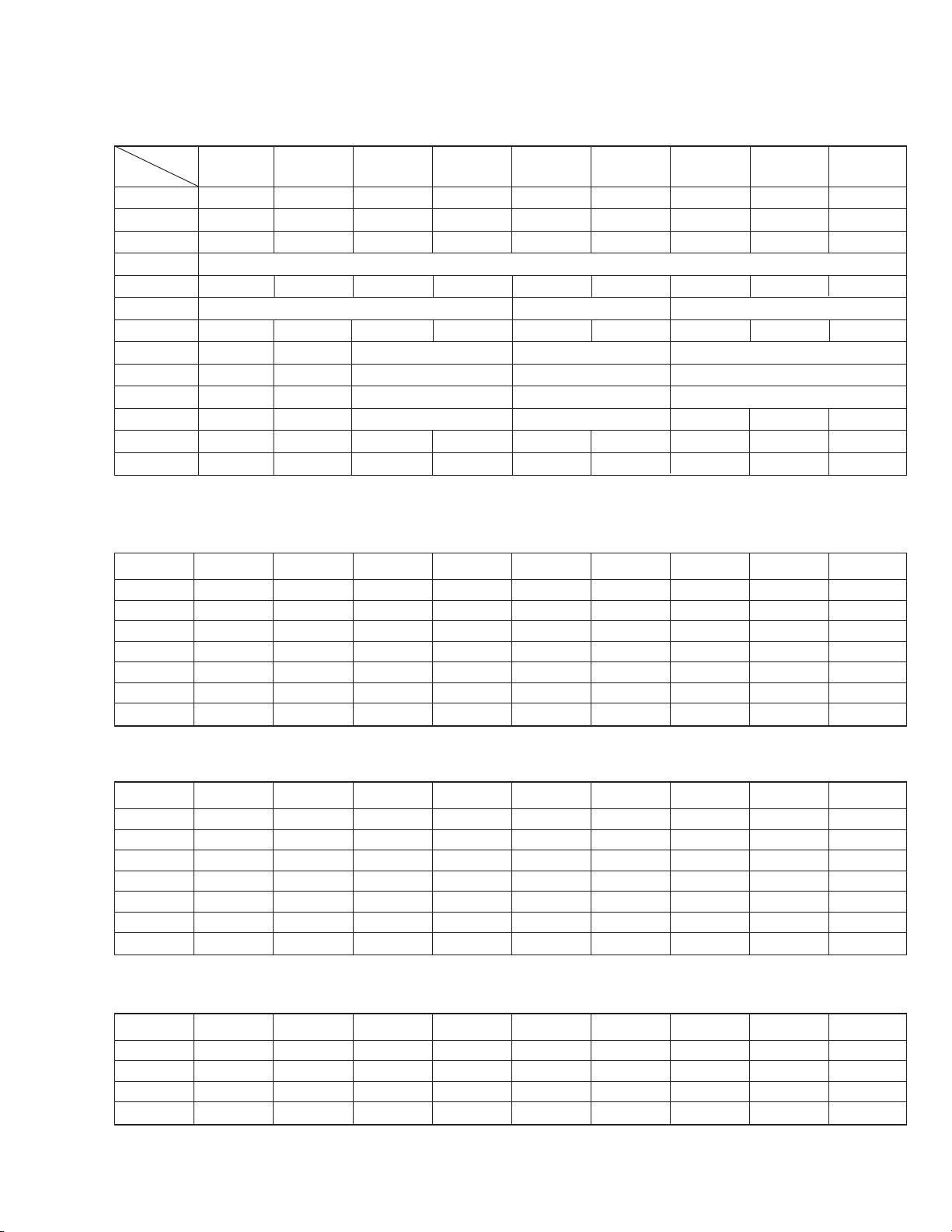

SECTION 1

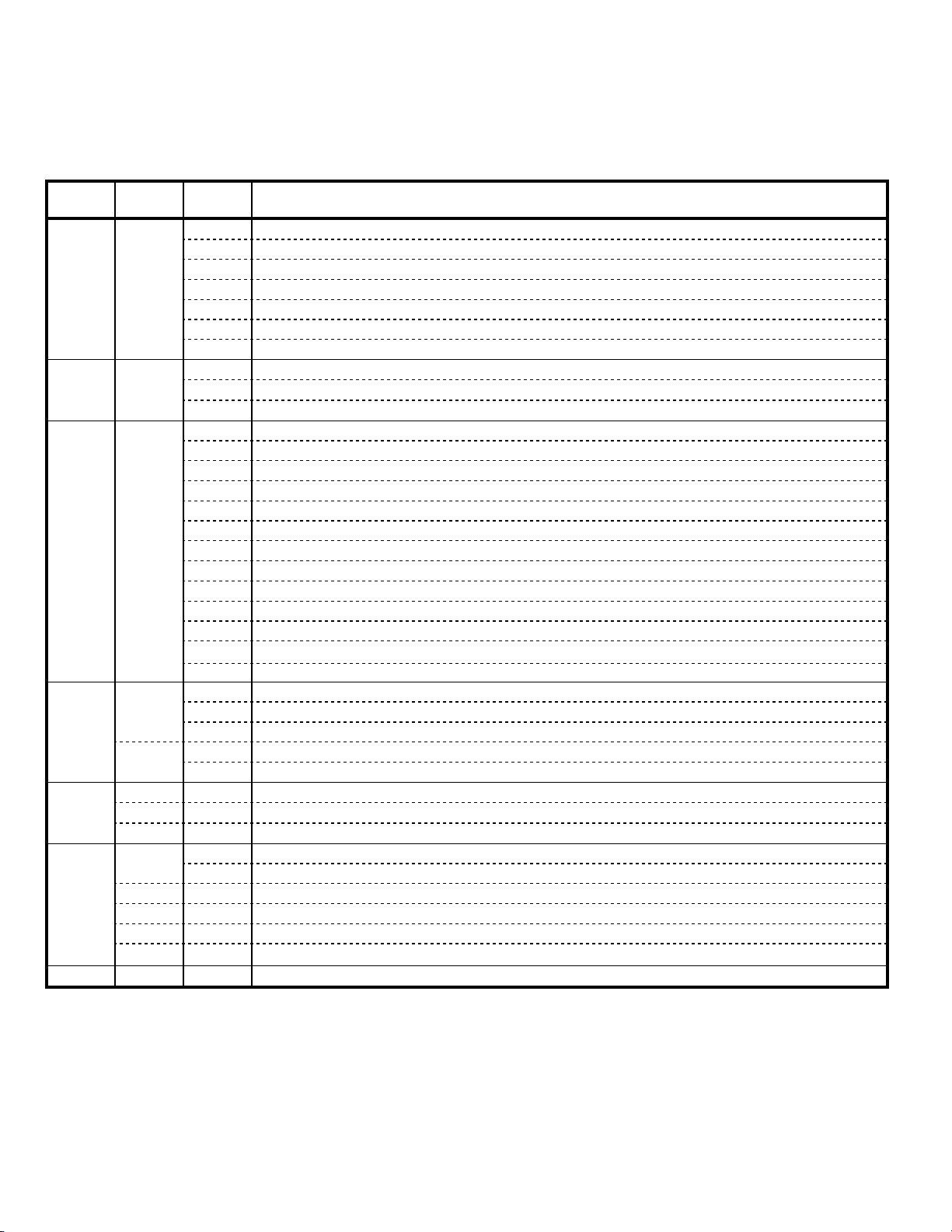

CIRCUIT BOARD COMPATIBILITY

Model

Unit Name

SCSI PCB ASS'Y

CHASSIS PCB ASS'Y

CARRIER MECHA ASS'Y

MAIL SLOT ASS'Y

U/D MOTOR ASS'Y

MAGAZINE SET

POWER UNIT ASS'Y

CD-ROM DRIVE

CD-R DRIVE — — MC-R18/MC-R14/MC-R12 — — MC-R18/MC-R14/MC-R12

DVD-ROM DRIVE

DVD-RAM DRIVE

DVD-R DRIVE — — MC-R421 MC-R421 — — — — —

DVD-RAM/R DRIVE

MC-8100LU

MC81-SCSI MC82-SCSI MC81-SCSI MC82-SCSI MC71-SCSI MC72-SCSI MC21-SCSI MC22-SCSI MC12-SCSI

MC81-CHAS MC82-CHAS MC81-CHAS MC82-CHAS MC71-CHAS MC72-CHAS MC21-CHAS MC22-CHAS MC12-CHAS

MC21-CARR MC22-CARR MC21-CARR MC22-CARR MC21-CARR MC22-CARR MC21-CARR MC22-CARR MC12-CARR

MC21-UD-M MC12-UD-M MC21-UD-M MC12-UD-M MC21-UD-M MC12-UD-M MC21-UD-M MC12-UD-M MC12-UD-M

QALD141-001

—— MC-D32/MC-D18 — — MC-D32/MC-D18

——MC-D307/MC-D104/MC-D207 — — MC-D307/MC-D104/MC-D207

——MC-R400/MC-R200 MC-R200 — — —

MC-R434 MC-R434 MC-R433 MC-R433 — — — — —

MC-8200LU/8600LU

MC-M25 (B) MC-M25 MC-M15

QAL0538-001 QAL0141-001 QAL0112-001 QAL0141-001 QAL0112-001 QAL0141-001 QAL0112-001 MC12-POWR

MC-8100 MC-8200/8600 MC-7100 MC-7200/7600 MC-2100 MC-1200/1600

MC12-MAIL

MC-2200/2200P

MC-2600/2600P

*1: The CARRIER MECHA ASS’Y has upward compatibility. (The MC21-CARR can be used with all models.)

SCSI PCB Compatibility Table R: Usable. ^: Usable by replacing ROM. ×: Unusable.

MC81-SCSI

MC82-SCSI

MC71-SCSI

MC72-SCSI

MC21-SCSI

MC22-SCSI

MC12-SCSI

MC-8100LU

R × R × ^ × ^ ××

× R × R × ^ × ^ ×

^ × ^ × R × ^ ××

× ^ × ^ × R × ^ ×

^ × ^ × ^ × R ××

× ^ × ^ × ^ × R Ч

ЧЧЧЧЧЧЧЧR

MC-8200LU/8600LU

MC-8100

MC-8200/8600

MC-7100

MC-7200/7600

MC-2100

MC-2200/2600 MC-1200/1600

CHASSIS PCB Compatibility Table R: Usable. ^: Usable by replacing ROM. ×: Unusable.

MC81-CHAS

MC82-CHAS

MC71-CHAS

MC72-CHAS

MC21-CHAS

MC22-CHAS

MC12-CHAS

MC-8100LU

R × R × ^ × ^ ××

× R × R ЧЧЧЧЧ

^ × ^ × R × ^ ××

ЧЧЧЧЧR × ^^

^ × ^ × ^ × R ××

ЧЧЧЧЧ^ × R^

ЧЧЧЧЧ^ × ^R

MC-8200LU/8600LU

MC-8100

MC-8200/8600

MC-7100

MC-7200/7600

MC-2100

MC-2200/2600 MC-1200/1600

CARRIER MECHA ASS’Y Compatibility Table R: Usable. ×: Unusable.

MC21-MCRR

MC22-MCRR

MC12-MCRR

MC-8100LU

RRRRRRRRR

× R × R × R × RR

ЧЧЧЧЧЧЧЧR

MC-8200LU/8600LU

MC-8100

MC-8200/8600

MC-7100

MC-7200/7600

MC-2100

MC-2200/2600 MC-1200/1600

MC-CF10 RRRR ЧЧЧЧЧ

1-1

Page 5

SECTION 2

PRODUCT SPECIFIC SERVICE ITEMS

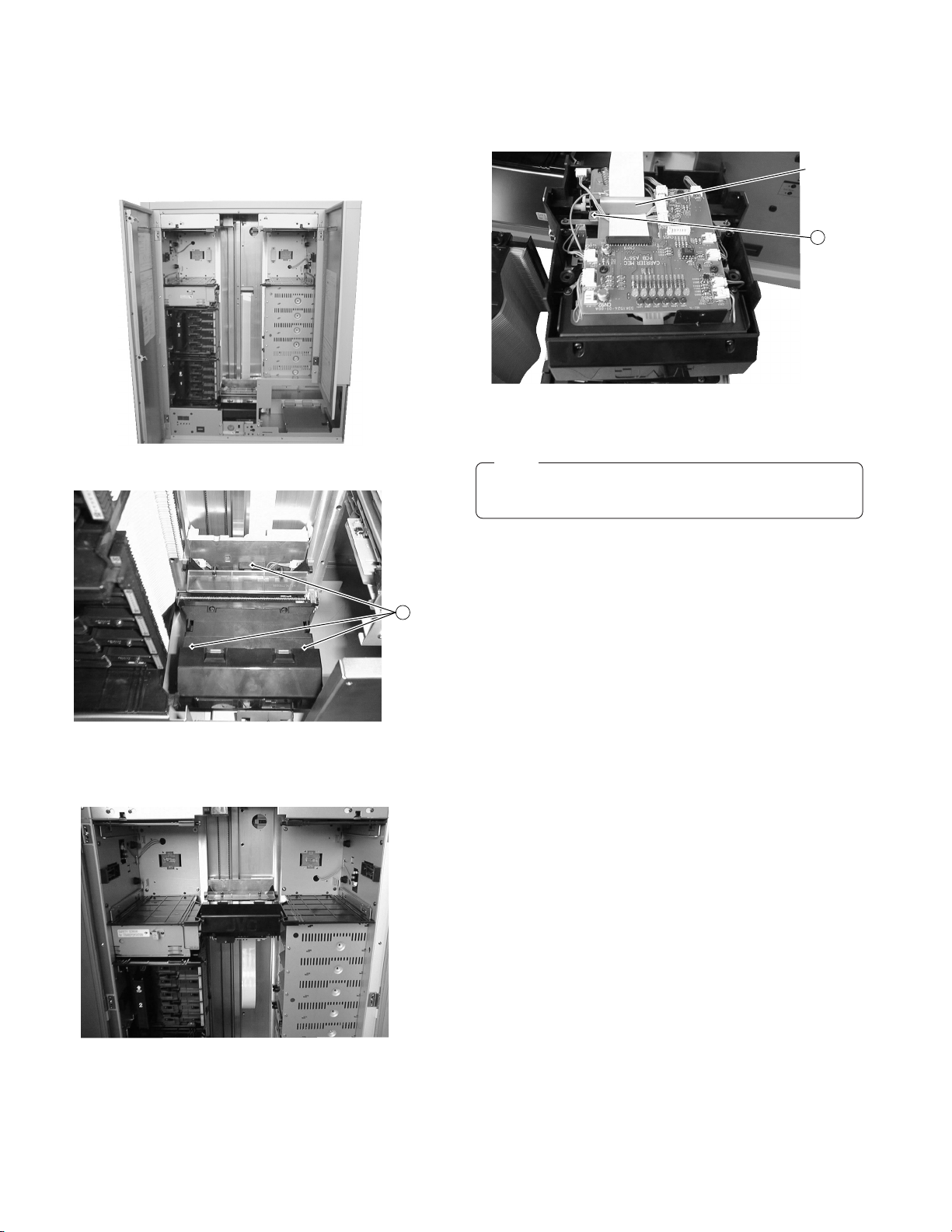

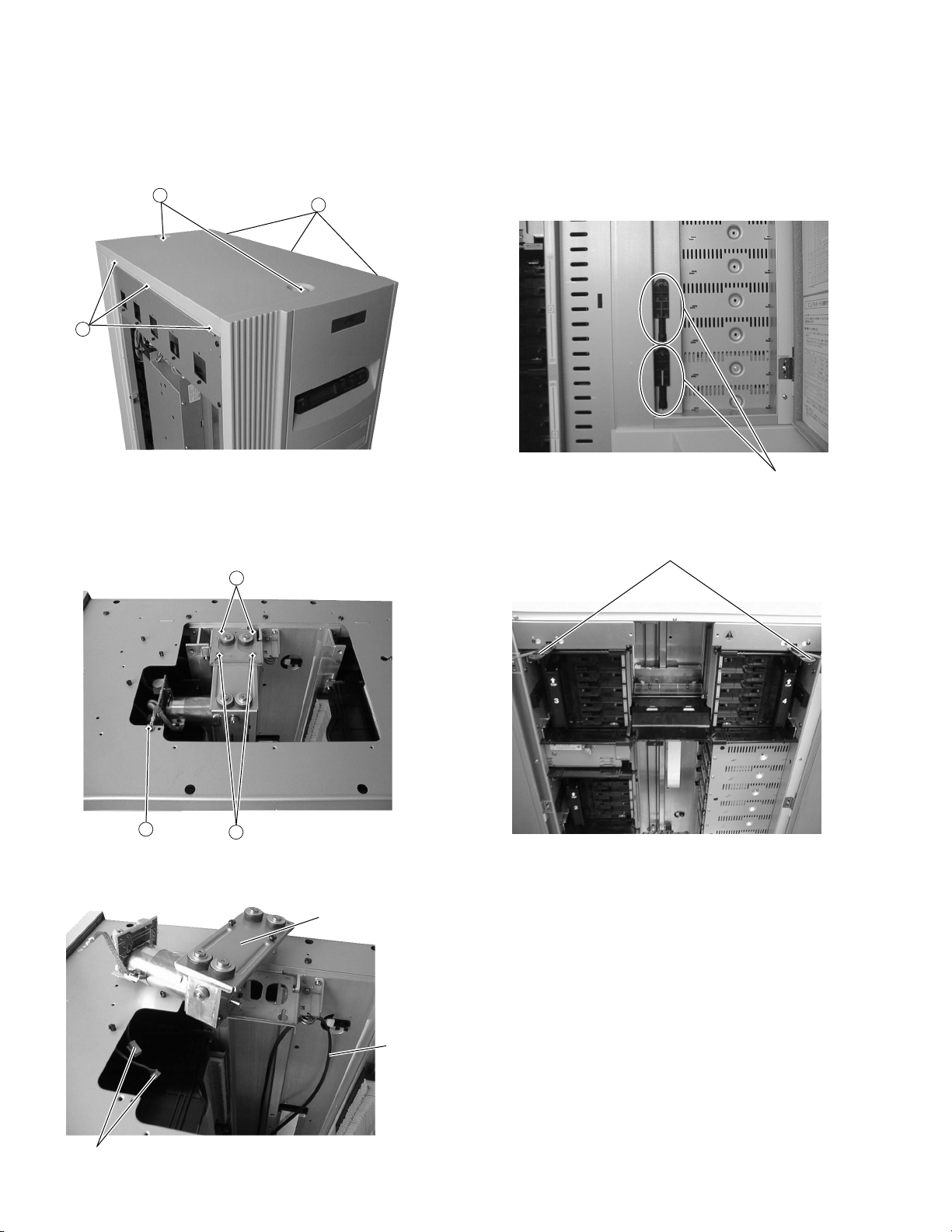

2.1 Removal of Major Parts

2.1.1 Replacement of Fuses and Batteries

1. Fuses

Note:

Perform fuse replacements correctly.

Never use a fuse other than that specified by the manufacturer (same model number or its equivalent).

There are four fuses on the chassis PCB and one fuse on the SCSI PCB. When replacing a fuse, be sure to use one having the

specified parts number. For the parts number, refer to “5. PCB Ass’y Parts List”.

Chassis PCB : F120, F900, F400, F500

SCSI PCB : F2

2. Batteries

Note:

If the battery is not replaced correctly, it could cause an explosion.

Never use a battery other than one specified by the manufacturer (same model number or its equivalent). After replacement,

dispose of the expired battery according to the instructions of the manufacturer.

There are two batteries; one on the chassis PCB and the other on the SCSI PCB. When replacing a battery, be sure to use one having

the specified parts number. For the parts number, refer to “5. PCB Ass’y Parts List”.

Chassis PCB : BT300

SCSI PCB : BT1

2-1

Page 6

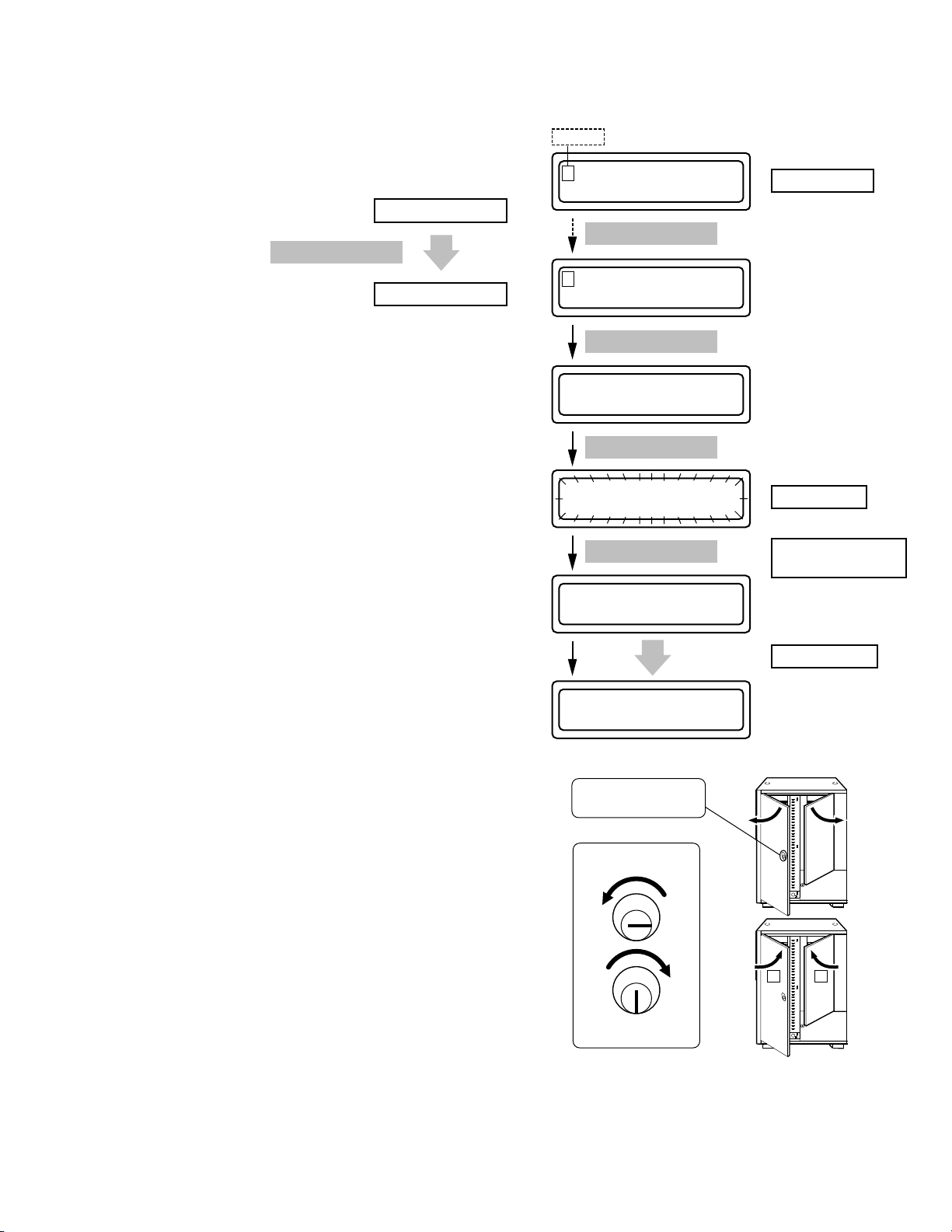

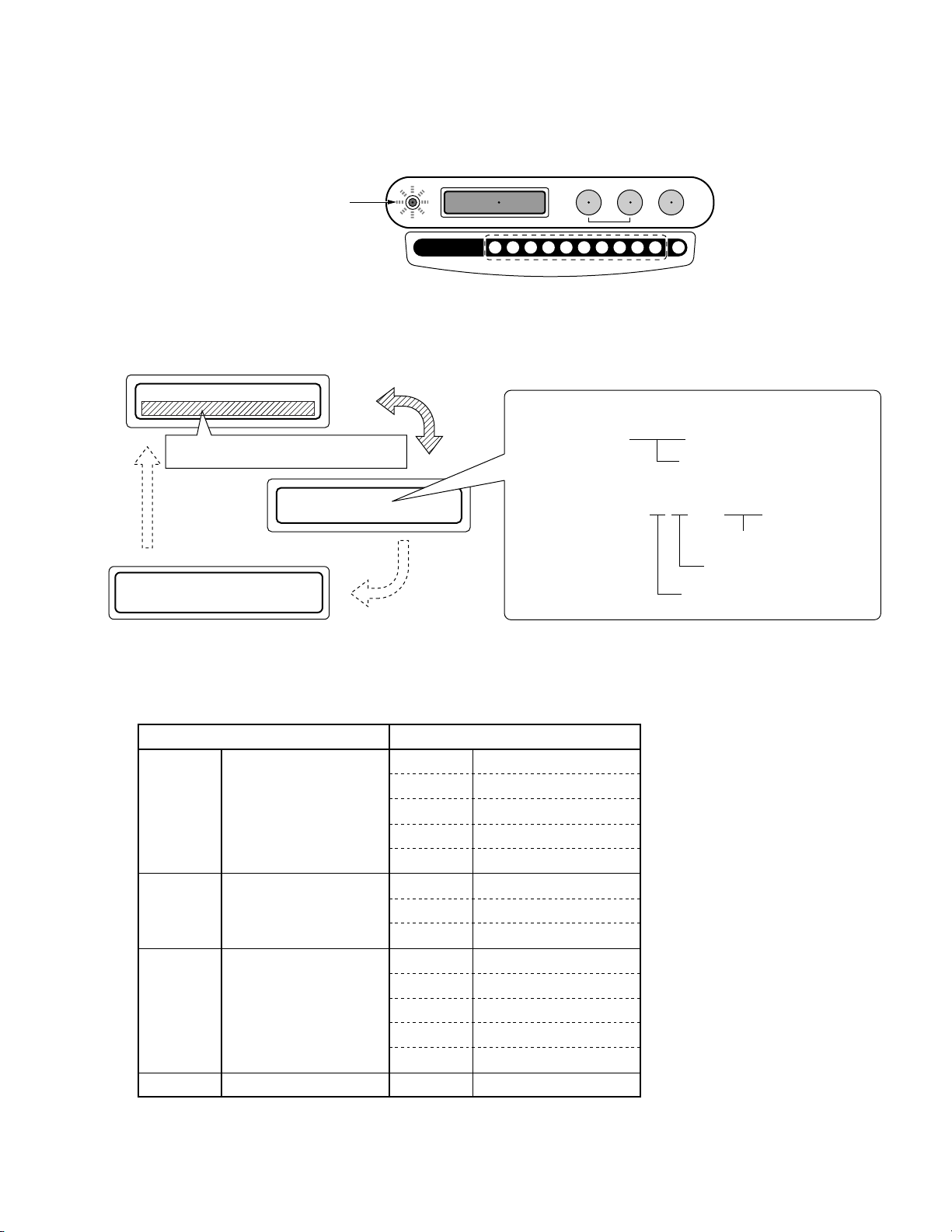

2.1.2 Opening/Closing the Door and Panel Removal

Opening the Door

<In normal condition>

When the power of the main unit is OFF, first turn it to ON.

1. Press the MODE switch on the control panel to display the

MENU display.

NORMAL display

MODE switch

Cursor

1 . NORMAL DISPLAY

2 . ERROR DISPLAY

SELECT switch

MENU display

MENU display

2. Use the SELECT switch to move the cursor to “5. DOOR

OPEN MODE” and select with the MODE switch.

3. When the SELECT switch is pressed, the LCD display starts

blinking. Hold down the switch for more than 5 seconds,

the unit enters the door open mode.

4. When the door open mode operation completes, the message “YOU MAY OPEN THE DOOR” is displayed accompanied by a click sound.

In this condition, when the MODE switch is pressed without

opening the door, the “NORMAL display” (normal operation

status) resumes.

5 . DOOR OPEN MODE

6 . ID No. SET MODE

MODE switch

PUSH SELECT SW

TO OPEN THE DOOR

SELECT switch

PUSH SELECT SW

TO OPEN THE DOOR

SELECT switch

EXECUTING DOOR

OPEN PROCESS

YOU MAY

OPEN THE DOOR

Display blinks

Hold down for more

than 5 sec.

Wait for a while

5. Turn the power of the main unit to OFF.

Door open/close key

cylinder (lock key)

Unlocked

6. Insert the key and turn it counterclockwise (by 90°) to re-

(release)

lease the lock. Now the doors are opened toward you.

7. When closing the door, first close the [L] door then close the

[R] door.

L R

While holding the door gently, turn the key clockwise (by 90°)

to lock it, then pull out the key.

Locked

(lock)

<When trouble occurs>

When the power is not turned on or when electrical or mechanical trouble occurs, the unit will not enter the door open mode with the

above operations, and inserting the key cannot open the door. In this case, proceed in the following manner to open the door.

1. Turn the power of the main unit to OFF.

2. Insert a pin having a diameter of approx. 2 mm (or extended spike or clip, etc.) into the emergency hole to release the key lock. With

this, you can turn the key to perform the door opening operation.

2-2

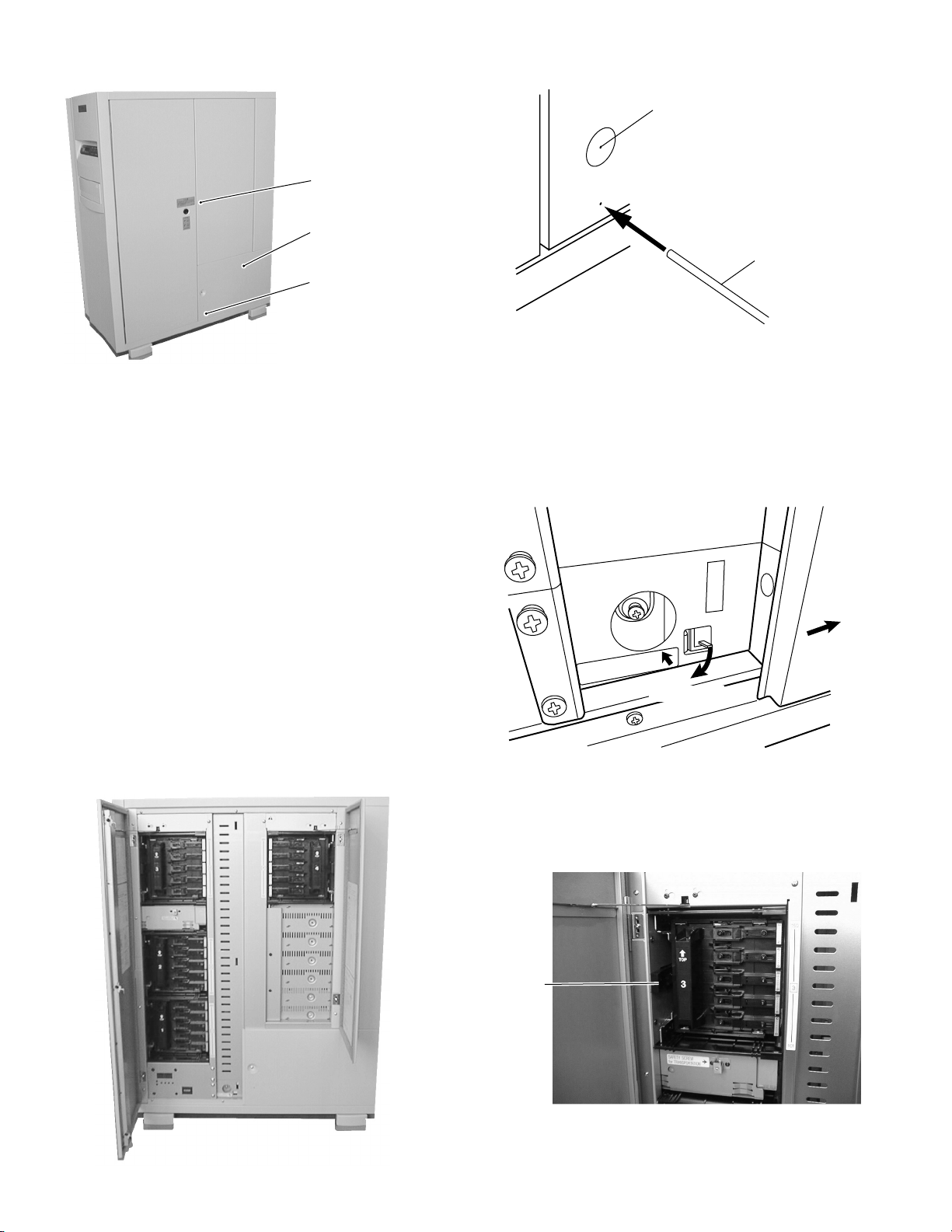

Page 7

Key Cylinder

Panel

Emergency Hole

Panel mounting

screw

Pin (2 mm dia.)

Removing the Panel

<In normal condition>

Turn the power OFF in standby mode, insert a pin into the emergency hole on the panel, and open the door using the key. Then

remove the screw enabling the panel to be removed by sliding

it to the right.

2.1.3 Removing the Magazine

1. Open the door. (Refer to 2.1.2.)

Removing the Panel

<When trouble occurs>

When trouble occurs with the carrier stopped at the lower section, remove the panel while release the lock by pressing down

the lever shown in the diagram.

Panel

Slide

SAFETY SCREW for

TRANSPORTATION

Release lock

2. Pull the release lever which locks the magazine toward you.

The magazine is slightly protruded toward the front.

2-3

Release Lever

Page 8

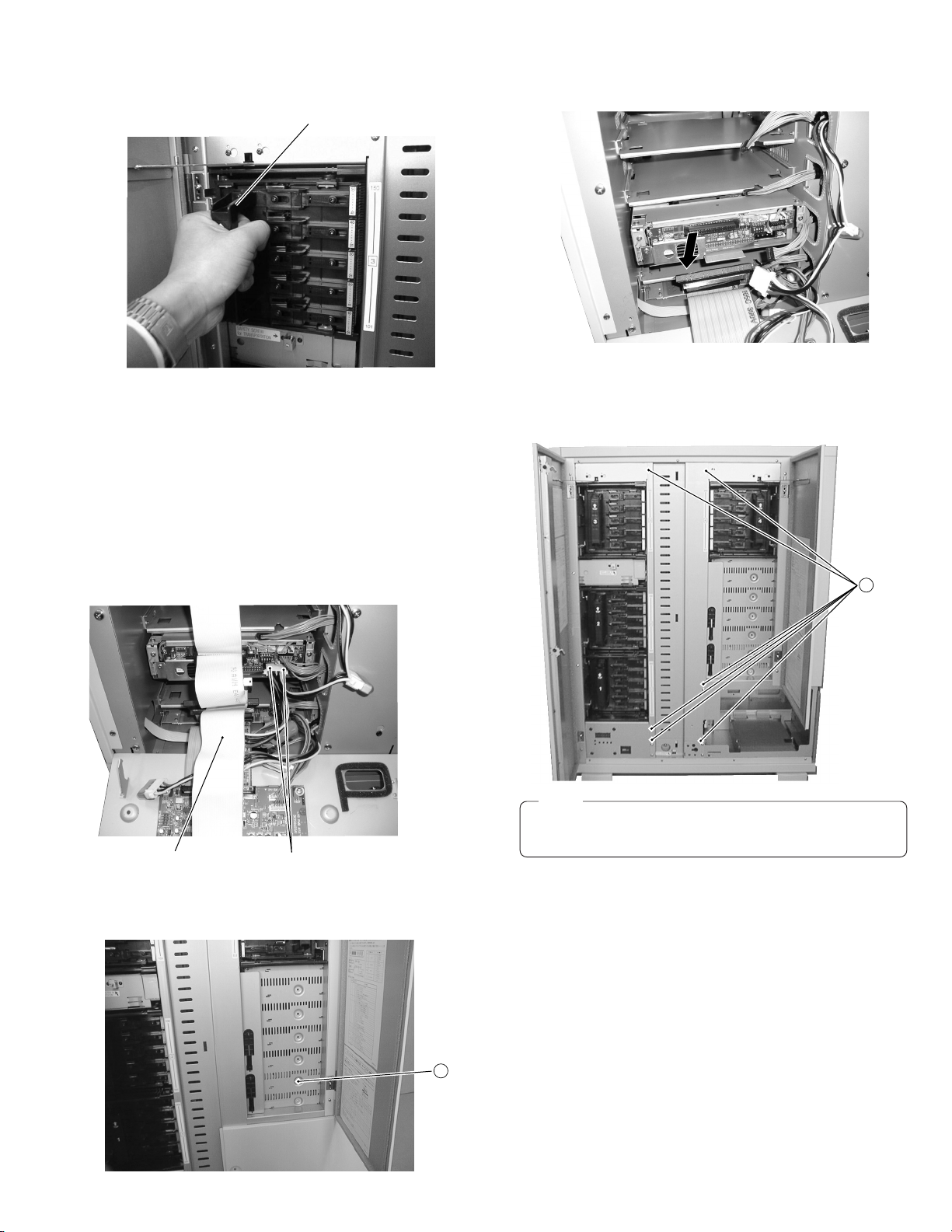

3. Grasp the grip to remove the magazine toward you. 6. Remove the drive from the rear.

2

6 screws

Grip

2.1.5 Removing the Center Panel

4. When loading the magazine, insert the magazine gently until

it clicks.

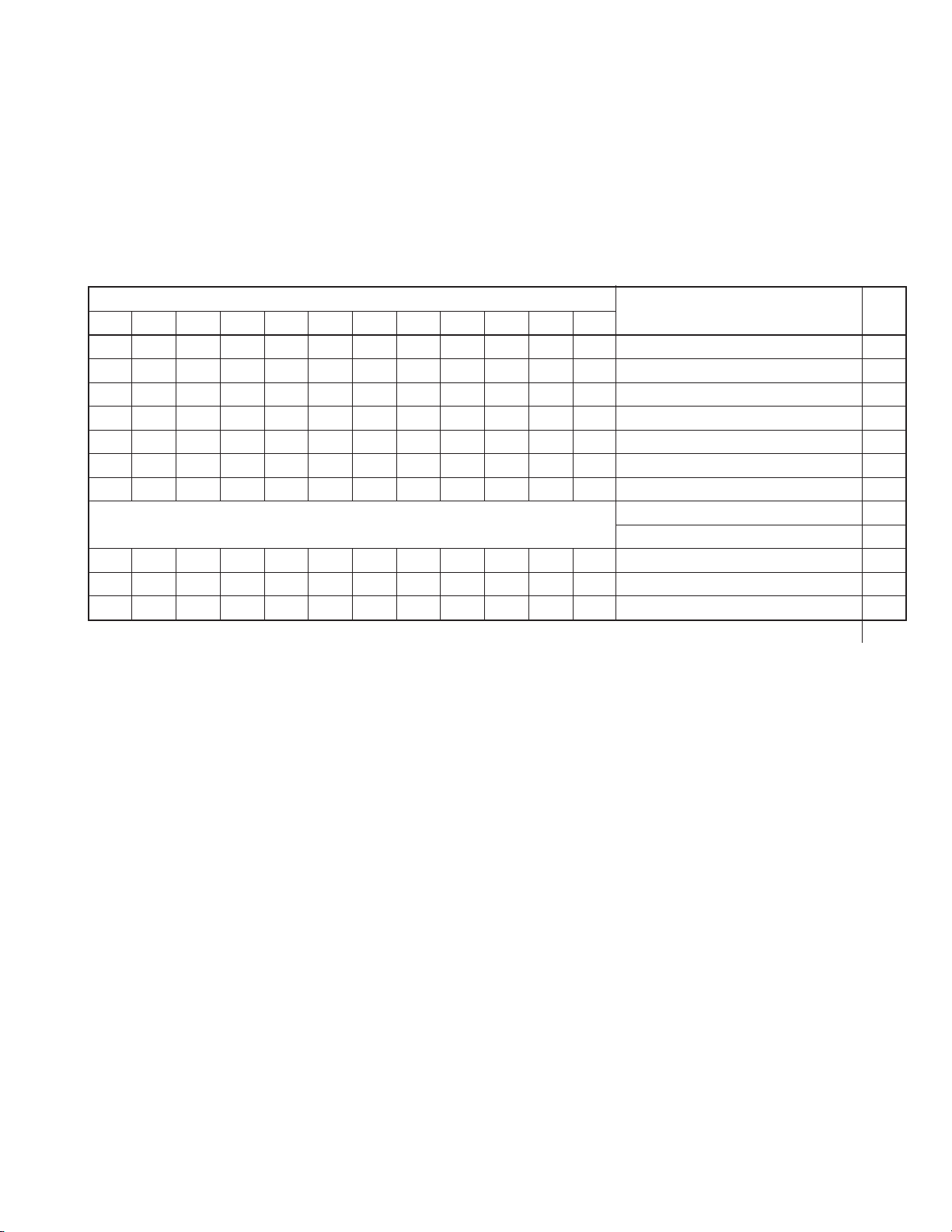

2.1.4 Removing the Drive

1. Open the door. (Refer to 2.1.2.)

2. Remove the panel. (Refer to 2.1.2.)

3. Remove the six screws

to remove the center panel.

2

1. Open the door. (Refer to 2.1.2.)

2. Remove the rear panel (DH). (Refer to 2.1.8.)

3. Disconnect the two connector cables from the drive.

4. Disconnect all the SCSI cables from all the drives and the

SCSI PCB. (When removing the drive in the uppermost slot

among the currently mounted drives, disconnect the cable

connected to the uppermost drive only.)

Photo shows situation when removing the Drive 2

SCSI cable

5. Remove the screw

Connector cable

located on the side of the drive (door

1

panel side).

Photo shows situation when removing the Drive 2

Note:

Center panel must be removed when removing the carrier mechanism.

1

2-4

Page 9

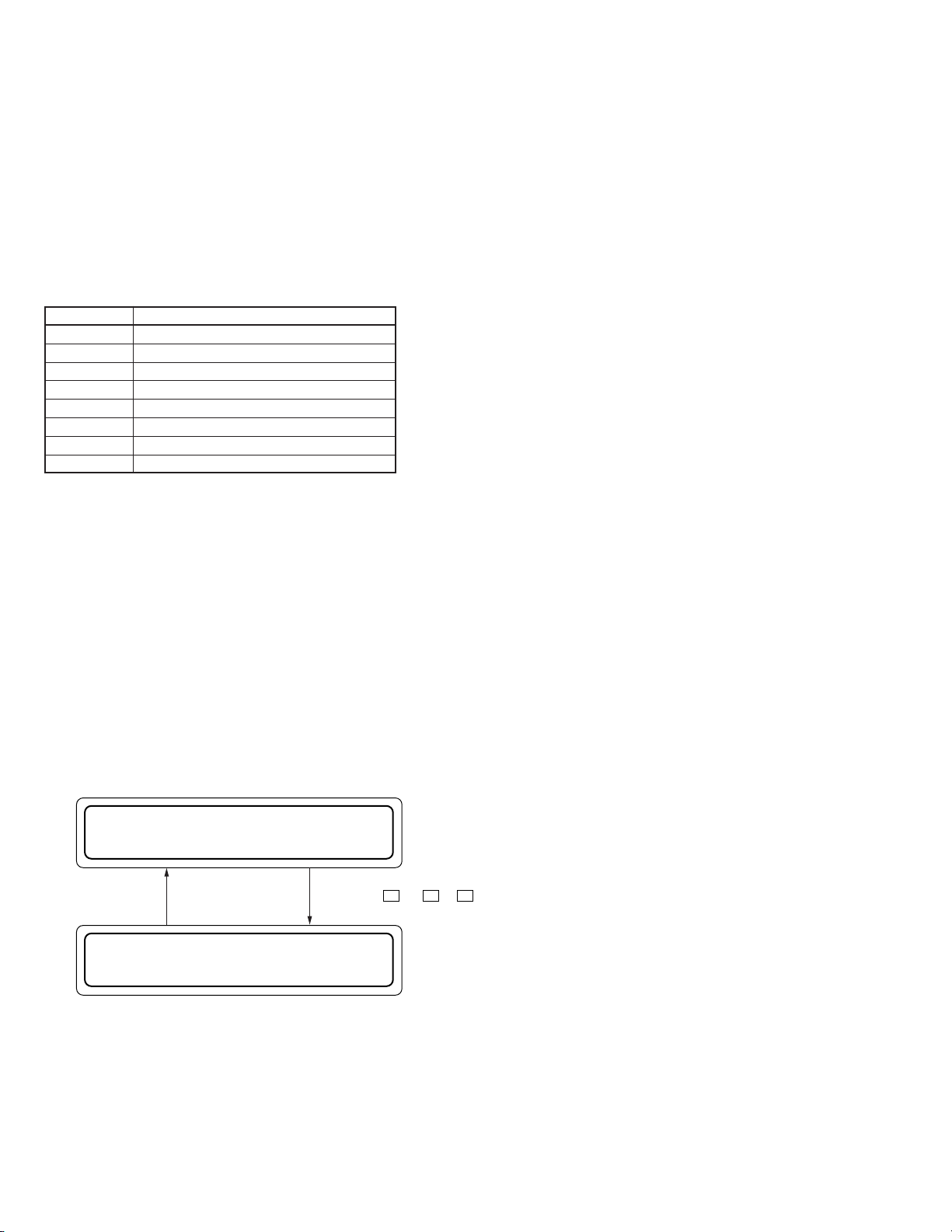

2.1.6 Removing the Carrier Mechanism

1. Open the door. (Refer to 2.1.2.)

2. Remove the center panel. (Refer to 2.1.5.)

3. Remove the #3 and #4 magazines. (Refer to 2.1.3.)

For the MC-8600U, remove the #3 and #4 magazines in the

same way.

6. Remove the carrier mechanism upward.

7. Turn the carrier mechanism upside down, and remove the

screws

retaining the flat cable mounting bracket.

4

Bracket

4

8. Release the flat cable connector lock and disconnect the flat

cable to remove the carrier mechanism.

4. Remove the three screws 3.

3

5. While holding the lower section of the carrier mechanism,

rotate the shaft of the U/D motor by hand to shift the carrier

mechanism to the #3/#4 magazine position.

Note:

Pay attention not to damage the lock of the flat cable connector .

2-5

Page 10

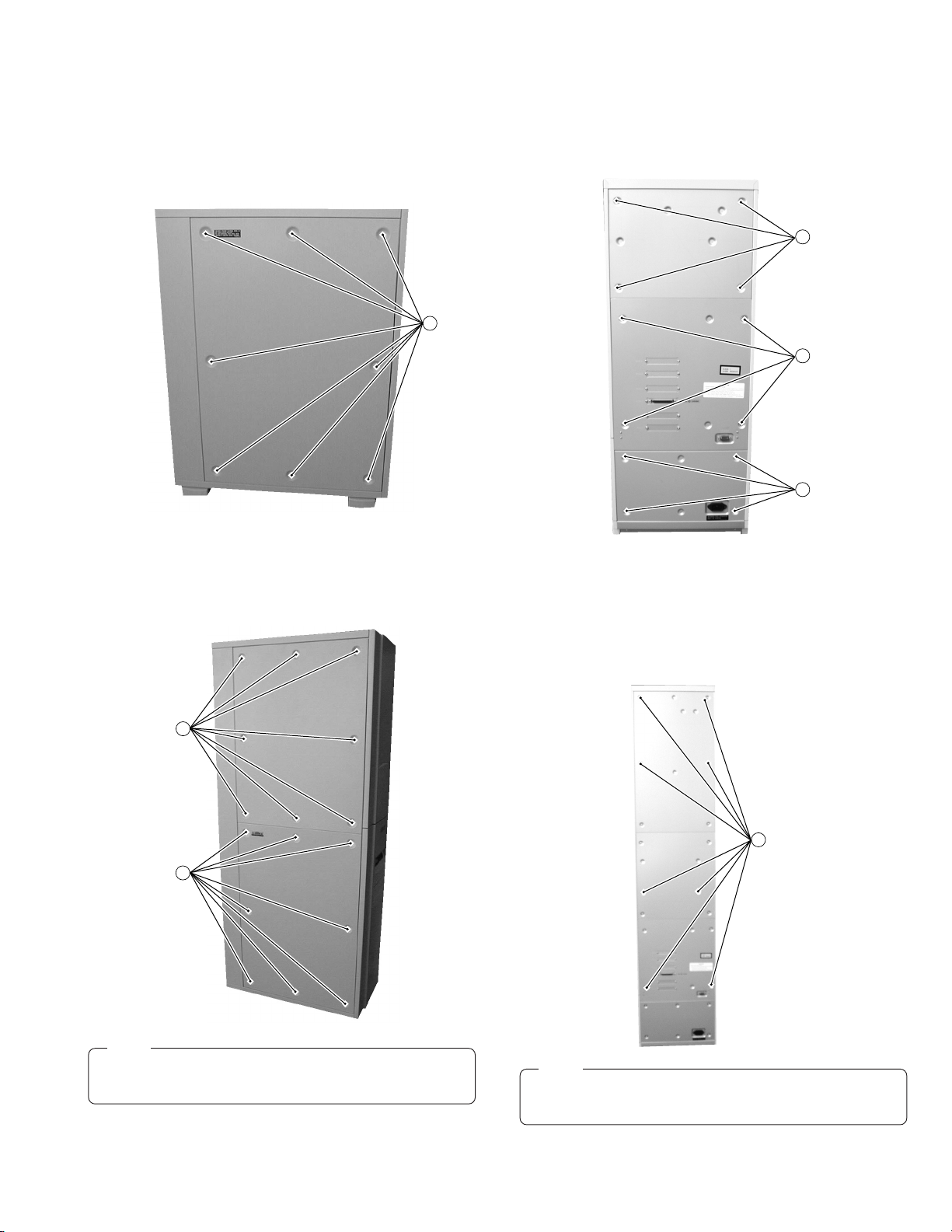

2.1.7 Removing the Side Panel

7

(T6)

8 screws

<MC-8200U>

1. Remove the eight screws 6 to remove the side panel.

When removing the side panel, unscrew while holding the

side panel with your hands. (To prevent the panel from dropping.)

2.1.8 Removing the Rear Panel

<MC-8200U>

1. Remove the three rear panels (T), (DH) and (B) by removing

the four screws 7 for each.

(T)

7

4 screws

6

<MC-8600U>

1. Remove the 16 screws

to remove the side panels.

6

When removing the side panel, unscrew while holding the

side panel by hand. Pay special attention to the upper side

panel. (in order to prevent the panel from being dropped.)

6

(DH)

7

4 screws

(B)

7

4 screws

<MC-8600U>

1. In the same way as MC-8200U, remove the two rear panels

(DH) and (B).

2. Remove the eight screws

to remove the upper rear panel

7

(T6).

6

Note:

When removing the U/D motor and magazine sensor PCB,

remove the upper side panel.

Note:

When removing the power supply unit, chassis PCB or

SCSI PCB, you don’t have to remove the rear panels.

2-6

Page 11

2.1.9 Removing the Exterior Side Panel

1. Remove the rear panel. (Refer to 2.1.8.)

2. Remove the side panel. (Refer to 2.1.7.)

3. Remove the six screws 8 (ten screws for MC-8600U), to

remove the exterior side panel.

8

3 screws

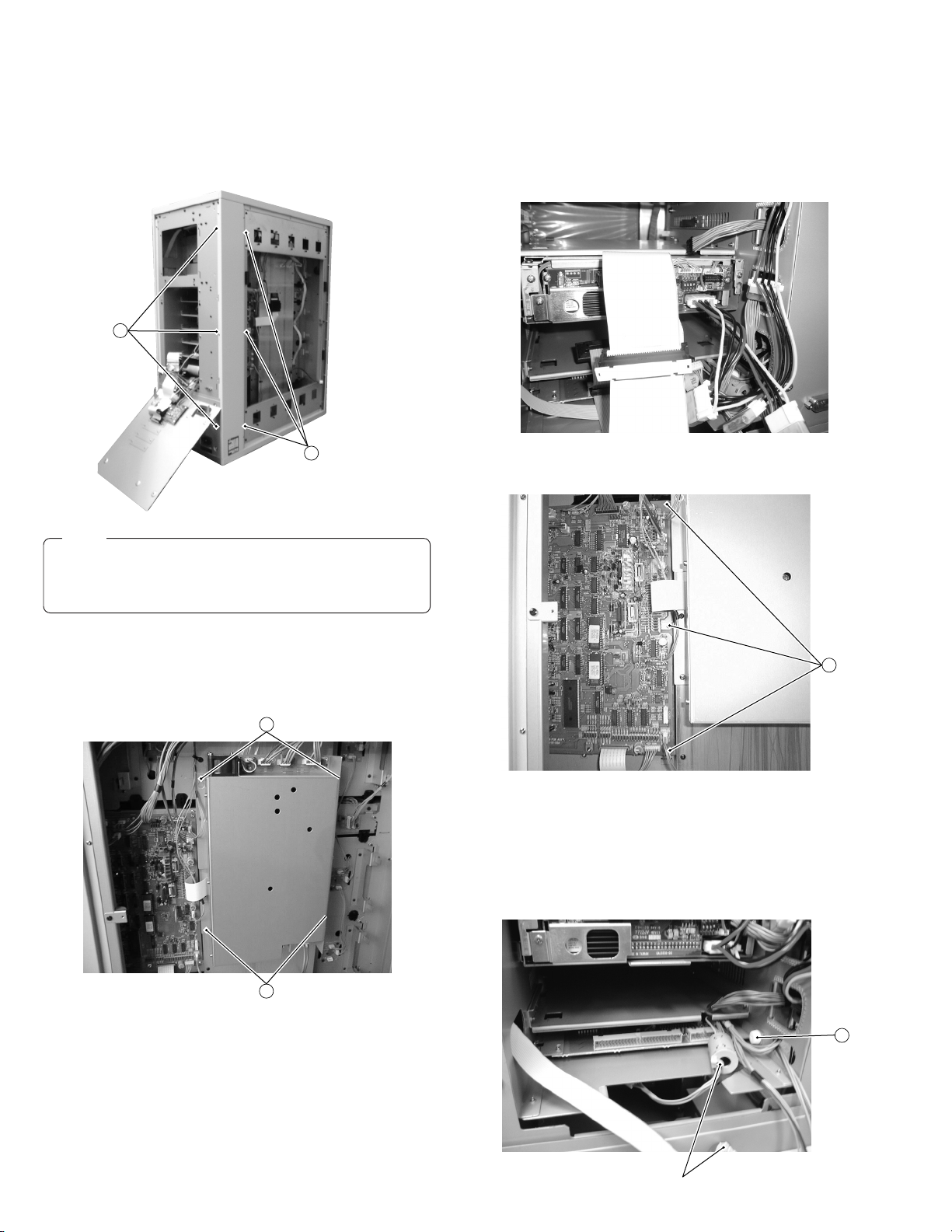

2.1.11 Removing the Chassis PCB

1. Remove the rear panel (DH). (Refer to 2.1.8.)

2. Remove the side panel. (Refer to 2.1.7.)

3. Remove the chassis PCB and connector cables from the drive

at the drive side. (Leave the cables connected to the drive

power supply as they are.)

8

3 screws

Note:

When removing the power supply unit, chassis PCB or

SCSI PCB, there is no need to remove the exterior side

panel.

2.1.10 Removing the Power Supply Unit

1. Remove the side panel. (Refer to 2.1.7.)

2. Disconnect the connector cables connected to the power supply unit.

10

4. Disconnect the connector cables from the chassis PCB.

5. Remove the three screws

!

.

11

6. Slide the chassis PCB toward the left and pull it out from the

right side.

2.1.12 Removing the SCSI PCB

1. Remove the rear panel (DH). (Refer to 2.1.8.)

2. Disconnect the two connector cables and all the SCSI cables connected to the SCSI PCB and the drives.

3. Remove the two screws 9.

4. Slightly loosen the two screws

supply unit by sliding it upward.

2-7

9

, and remove the power

0

12

Connector cable

Page 12

3. Remove the screw @ and pull the SCSI PCB toward you

Connector cable

15

until the connector at the right sides are exposed, then disconnect the two connectors from the chassis side.

4. Remove the SCSI PCB by pulling it toward you.

5. When mounting the SCSI PCB, insert it so that the PCB

bracket passes under the guide rails.

Connector cableBracket

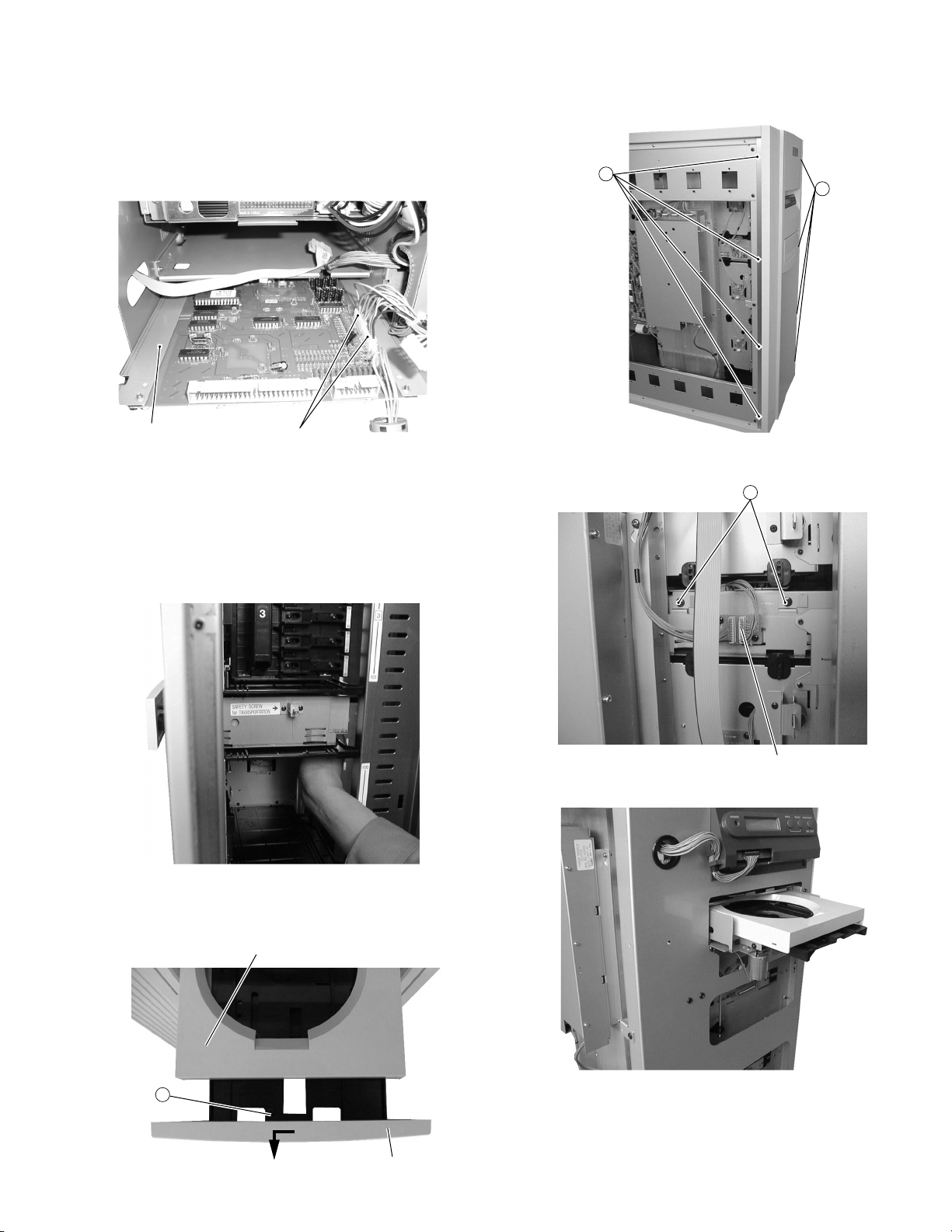

2.1.13 Removing the Mail Slot

1. Open the door. (Refer to 1.1.2.)

2. Remove the side panel. (Refer to 1.1.7.)

3. Remove the #2 magazine. (Refer to 1.1.3.)

4. Insert your hand into the #2 slot and gently push the tray of

the mail slot. Pay attention not to push the tray forcibly for it

could damage the gear teeth.

6. Remove the eight screws

to remove the front panel of

$

the main unit.

14

14

7. Disconnect the connector cable on the mail CN PCB, and

remove the two screws

%

.

5. Gently pull out the mail slot tray toward you and push the

guide to the main unit side. Remove the screws

and pull

#

out the mail slot panel by sliding it toward the left.

13

Guide

Mail slot panel

8. Remove the mail slot from the front of the main unit.

2-8

Page 13

2.1.14 Removing the Top Panel

1. Open the door. (Refer to 2.1.2.)

2. Remove the side panel. (Refer to 2.1.7.)

3. Remove the two blind bolts ^ using a coin, etc.

4. Remove the six screws

16

17

to remove the top panel.

&

17

2.1.16 How to Operate with the Door Open (for Servicing)

For safety this unit is designed so as not to be operated with

the door open. When operating the unit with the door open for

maintenance or servicing, proceed in the following manner.

1. Open the door. (Refer to 2.1.2.)

2. Remove the two interlock release bars on the center panel

which turns the interlock switch to ON.

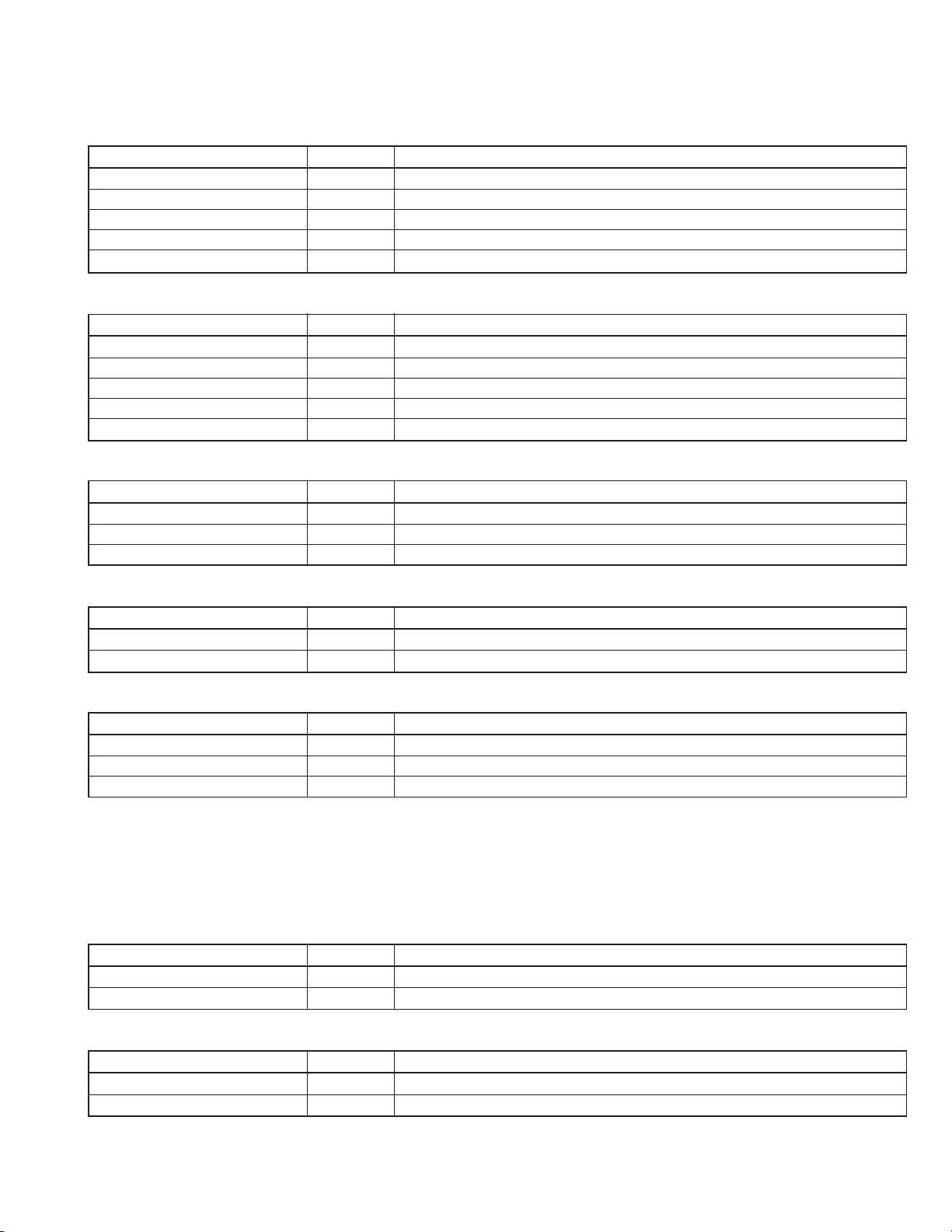

2.1.15 Removing the U/D Motor

1. Remove the top panel. (Refer to 2.1.14.)

2. Remove the screws

3. Loosen the two screws

and two screws (.

*

, and pull out the U/D motor by

)

sliding it toward the door side.

19

18

20

4. Disconnect the two connector cables from the U/D motor.

5. Remove the U/D belt to remove the U/D motor.

U/D Motor Ass'y

Release bars

3. With the door open, insert the interlock release bars into the

interlock switch holes located at both the left and right sides.

Interlock Release Bar

4. With this operation, the unit enters the mode in the same

way as with the doors closed, and you can operate the unit

as normally.

Connector cable

2-9

Belt

Page 14

2.2 Special Operation Mode

• Operating Condition

The external control equipment must not be connected to the SCSI connector. (That is the CD/DVD Library is not operated as a

part of the system.) If the special operation mode is activated in the system operating condition, the correct operation will not be

guaranteed.

• Mode Setting

As shown in the table below, the operation mode is determined depending on the status of each switch at the moment when the

CD/DVD Library's power is turned ON.

("–" in the table below is the conventional symbol for OFF. )

M: Mode S: Select L/E: Load/Eject E: Enter 0-9: Numeric keypad

SW Status

MSL/E E 01234589

————————————Normal mode —

—————ON——————Package mode 2-16

——————ON—————Disc return mode 2-16

———————ON————Memory clear mode 2-16

—————ON——ON———Auto check mode 2-16

ON —ON—————————Disc tray check mode 2-16

—ONON —————————Auto tray check ON/OFF switching 2-17

Running modes for use in factory production.

Cannot be used in servicing.

———ON———ON————

———ON———————ONManual mode 2-11

——————————ON—Drive detection mode 2-17

Other than the above, a self-check mode for use during maintenance is also available (by turning the power ON while pressing the

MODE key).

* In the Disc Return, Memory Clear, Disc Tray Check or Auto Tray Check ON/OFF Select mode, the CD-ROM Library operates in the

normal mode after the corresponding operation is completed.

* Since each operation mode other than normal mode (including Disc Return, Memory Clear, Disc Tray Check and Auto Tray Check

ON/OFF Select modes) is performed with the door open, the interlock release lever must be inserted into the interlock switch hole.

(Each of the mode will not operate correctly with the door open but without the interlock release bar because the 15V power is

turned OFF.)

* Also if the printer panel is open, the 15V power is OFF and the Library operation is not available.)

Running mode (5) (Production running)

Running mode (1) (Mechanism running)

Running mode (3) (Demonstration running)

Operation Mode

Page

2-11

2.2.1 Running Modes

1. Details of Running

* During running mode, the "RUNNING MODE" warning and the number of times appear on the LCD display. During demonstration

mode, the "DEMONSTRATION MODE" warning and the number of times appear.

* All the magazines must be installed. (However the demonstration mode automatically detects the presence of magazines, and only

the installed magazines are accessed.)

2-10

Page 15

Demonstration Mode

1

(1) Purpose

This mode is used to perform a demonstration of the CD/DVD changer operation.

(2) Start

While pressing the “ENTER” key and the numeric key “3” simultaneously, turn the power ON.

* It is not necessary to set the discs on each tray. (A disc presence check is not performed.)

(3) Operation

Repetition of crossing operation.

Disc Access (MC-8200U: when drives 1 and 2 are connected)

• Crossing Operation

Count Access Address

0001 “200” → DR1 → “200”

0002 “001” → DR2 → “001”

0003 “199” → Mail slot → “199”

0004 “002” → DR1 → “002”

0005 “198” → DR2 → “198”

0006 “003” → Mail slot → “003”

0099 “101” → DR1 → “101”

0100 “100” → DR2 → “100”

(4) Operation Stop

When the numeric key “3” is pressed during demonstration, the operation stops after the disc being accessed is returned to the

original magazine.

(5) Operation Restart

When the “ENTER” key is pressed in the demonstration-stop mode, the operation restarts from the tray next to the one being

accessed the previous time.

2.2.2 Access Counter Clearance

1.Set to display the contents shown on page 29 of the instruction manual.

2.Hold the SELECT key until the unit to be cleared appears in the 1st line.

3.With the unit counter to be cleared shown on the 1st line, hold the ENTER key for more than 5 seconds.

2.2.3 Manual Operation

MANUA L MODE

S ELECT : 00

Select SUBMODE using the numeric keys

ENTER

(00 - 07, 0 - 1; : 1 - 4)

After selecting, press ENTER key

MANUA L MODE

00

Pressing numeric key 1 - 5 activates the corresponding operation

(refer to the table on the next page).

2-11

Page 16

Carrier Manual Operation

1

· Carrier upward operation (SUBMODE = 00)

Function Numeric key

Upward normal move

Upward low-speed move

Upward 1-slit move toward left

Upward 1-slit move toward right

Upward 1-step advance

1

2

3

4

5

· Carrier downward operation (SUBMODE = 01)

Function Numeric key

Downward normal move

Downward low-speed move

Downward 1-slit move toward left

Downward 1-slit move toward right

Downward 1-step advance

1

2

3

4

5

· Tray lock/release operation (SUBMODE = 02)

Function Numeric key

Left tray lock release

Tray lock initial

Right tray lock release

1

2

3

Details

During key is ON (Condition: Tray lock initial position)

During key is ON (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Details

During key ON, until lower limit sensor is reached (Condition: Tray lock initial position)

During key ON, until lower limit sensor is reached (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Each time key is ON (Condition: Tray lock initial position)

Details

During key ON, until left tray lock is released

Each time key is ON

During key ON, until right tray lock is released

· Catcher operation (SUBMODE = 03)

Function Numeric key

Catcher leftward move

Catcher rightward move

1

2

During key is ON

During key is ON

Details

· Tray pickup/return operation (SUBMODE = 04)

Function Numeric key

Left tray auto loading

Right tray auto loading

Tray auto return

1

2

3

Each time key is ON (Condition: Tray lock initial, Catcher position right)

Each time key is ON (Condition: Tray lock initial, Catcher position left)

Each time key is ON (Condition: Tray lock initial, Catcher position left or right)

Details

* Left (Right) Tray Auto Loading Operation

1. Catcher moves toward left (right) → 2. Left (right) tray lock release → 3. Tray pickup

* Tray auto return operation

1. Catcher moves toward the direction of the tray lock pin (Tray return) → 2. Tray lock initial When the printer operation is performed,

set the disc-in tray on the printer beforehand.

· Mail slot operation (SUBMODE = 05)

Mail slot ejecting

Mail slot loading

Function Numeric key

1

2

During key is ON, until eject position is reached

During key is ON, until loading position is reached

Details

· Optional printer operation (SUBMODE = 06)

Printer ejecting

Printer loading

Function Numeric key

1

2

Each time key is ON, until ejecting position is reached

Each time key is ON, until loading position is reached

Details

2-12

Page 17

· Disc inversion operation when an inversion carrier is installed (SUBMODE = 07)

Function Numeric key Details

Arm upward movement 1 During key is ON (Condition: Tray lock initial)

Arm downward movement 2 During key is ON (Condition: Tray lock initial)

Disc inversion 3 Every time key is ON (Condition: Tray lock initial)

Drive Manual Operation

2

· Clamping & Clamping release operation (SUBMODE = □ 0) □ : Drive No. 1 - 4

Function Numeric key

Drive clamping

Drive clamping release

1

2

During key is ON, until clamping position is reached

Each time key is ON

Details

When the MC-R200U drive is used and the tray is in the drive, the clamping release operation is activated 3.5 seconds later (however,

the 1st operation for each drive starts after 7 seconds) the key is turned ON (the motor starts rotating) to wait until the disc revolution

stops.

· Play operation (SUBMODE = □ 1) □ : Drive No. 1 - 4

Play ON

Play OFF

Function Numeric key

1

2

Each time key is ON (Condition: CD-ROM disc must be clamped)

Each time key is ON (Condition: CD-ROM disc must be clamped)

Details

2.3 Self-Diagnostic Display

When a trouble occurs, this unit repeats the required process and then stops operation. In case of the trouble on a drive, the defective

drive is cut by the host PC and the operation continues with the other drives. When the trouble occurs on all drives, this unit enters the

mechanism stop operation. (The power indicator blinks when trouble occurs in all cases and the error massage is displayed on the

LCD screen.)

The trouble codes of the last eight times are stored in the memory and maintained even when the power is turned off.

2.3.1 Displaying Trouble History

(Operate with front panel switch to display on the LCD)

How to display trouble history

Press the MODE switch to show the MENU display.

1

Press the SELECT switch to select the trouble history dis-

2

play mode.

Press the MODE switch to display the trouble history.

3

When an error occurs continuously in a single trouble history, the detailed information is displayed in the second row.

Each time the SELECT switch is pressed, the trouble history

4

is changed in sequence.

MENU display

Trouble No.

Troubled Unit

C: Carrier

M: Mail Slot

D1 - D6 : Drive

NORMAL DISPLAY

1.

2.

ERROR DISPLAY

ERROR DISPLAY

2.

ID NO. DISPLAY3.

Disc No.

ER1 : 107–CU08

–CC20

Unit Detailed Code

Trouble Code

2-13

Page 18

2.3.2 Display When Trouble Occurs

In case of an error, the front panel indicator blinks and the LCD shows the error details by overriding any other information.

The indicator blinks.

LCD displays in case of error

ERROR OCCURRED !

If the transport lock of the carrier has not been unlocked,

this section shows “CHECK CAR. SCREW”.

DISC = 024

CODE = CU–04

E RORMAGAZINE

R

No. : –2

POWER

Display when

CODE = CC-31

MODE SELECT

1 2 3 4 5 6 7 8 9 0 E

LOAD/EJECT

MAIL SLOT

DISC = 024

Disc No.

CODE = CU – 04

Error code

Unit detail code

Unit in error

Disc No. : Shows the disc No. being accessed at the moment of error

occurrence. "---" is displayed if no disc is accessed at the moment

of error occurrence.

Units in error and unit detail codes

Unit in error Unit detail code

C

M

D1 to D4

P Color Disc Printer

Carrier

Mail slot

Drive

U

L

C

D

Up/down

Tray lock

Catcher

Disc

F Flip

E

L

T

T

C

E

D

S

Ejection

Loading

Tray

Tray

Clamp

Ejection

Disc

Spindle

T Tray

2-14

Page 19

2.3.3 Erasing the Trouble History

The error history can be cleared by pressing ENTER key for more then 5 seconds during displayed error history.

2.3.4 Error code list

Device

Device

part

Error

code

01 UP/DOWN rotary sensor does not change

02 Left slit sensor does not change

03 Right slit sensor does not change

CU 04 UP/DOWN motor does not function

07 UP/DOWN motor drive short-circuits and over-current is detected

08 UP/DOWN operation exceeds the predetermined duration

09 Lower limit sensor turn on during UP/DOWN operation

10 Tray lock release not possible

CL 11 Tray lock impossible, or lane change not possible

12 Tray lock does not exist at the initial position during carrier movement

20 Catcher (right → left) movement operation exceeds the predetermined duration

21 Catcher (left → right) movement operation exceeds the predetermined duration

22 Catcher (right → left) convergence operation exceeds the predetermined duration

23 Catcher (left → right) convergence operation exceeds the predetermined duration

24 Catcher (right → left) tray rotary sensor does not change

25 Catcher (left → right) tray rotary sensor does not change

CC 26 Right catcher sensor does not turn on

27 Left catcher sensor does not turn on

28 Catcher motor (right → left) does not function

29 Catcher motor (left → right) does not function

30 Tray does not exist

2

31*

Magazine insertion incomplete, or sensor defective

32 Over-current is detected during catcher motor operation

CD

41 Destination-unknown tray exists on the carrier

42 No disc in the tray

43 Flip tray does not exist

F

80 During the flip raise operation, the expected time required is over

81 During the flip descent operation, the expected time required is over

E50Mail Slot ejecting is not possible

ML 51 Mail Slot loading is not possible

T52Destination-unknown tray exists in the Mail Slot

60 Destination-unknown tray exists in the Drive and the control cable of the Drive is disconnected.

61 Tray removal is not possible at the drive position

(D#)*

1

T

C62Disc clamp of the drive does not function

E63Drive ejection is not possible

D64Failure to remove the disc from the drive

S65Spindle motor fails to stop

PT72 Destination-unknown tray exists in the Label Printer

*1: # represents the drive number.

*2: Check the magazine loading condition.

Description

2-15

Page 20

2.4 Auto Check Mode

2.6 Tray Auto Return Mode

(1) Purpose:

Simply checks the tray transfer operation for all units.

(2) Control:

Set the release bars, then turn the power to ON while pressing the key “1” and “4”on the 10-key Pad.

Check that there is no tray in the drive or mail slot. If this is

not sure, first perform the tray auto return mode operation

described in 2.6.

(3) Operation:

Accesses to the 2nd address (Tray No. 49 in the magazine)

from the top and the 2nd address (Tray No. 02 in the magazine) positions, drive and mail slot positions.

Operation Sequence

(MC-8200LU : when drive 1and 2 are connected)

Address 199 → Drive 1 → Address 199

1

Address 152 → Drive 2 → Address 152

2

Address 149 → Mail Slot → Address 149

3

Address 102 → Address 102

4

Address 99 → Address 99

5

Address 52 → Address 52

6

Address 49 → Address 49

7

Address 2 → Address 2

8

(4) Display during auto check mode

R UNN I NG MODE

4–099

Tray No. being accessed.

However, “END” appears when finished.

(1) Purpose:

If the tray is left in the drive or the mail slot, performs the

operation to return the tray to the original magazine.

(2) Control:

Set the release bars, then turn the power to ON while pressing the key “2”on the 10-key Pad.

(3) Operation:

Performs carrier initial operation.

1

Check whether the tray is left in the drive 1 or not. If the

2

tray is left in, it is returned to the memorized magazine.

The same operation as (2) is performed for drives 2 to 6

3

respectively.

Checks whether the tray is left in the mail slot or not. If

4

the tray is left in, it is returned to the memorized magazine.

Operation completed.

5

2.7 Disc/Tray Check Mode

(1) Purpose:

Checks the presence/absence of the tray/disc in the magazine and stores the information in the CPU as the mapping

data.

(2) Control:

While pressing the MODE switch and LOAD/EJECT switch

simultaneously, turn the power ON.

(3) Operation:

Performs carrier initial operation.

1

Takes up the tray in the address “001” on the carrier and

2

checks the tray and disc, then returns it to the original

position.

Performs the operation described in (2) for addresses till

3

“200” (address “600” for MC-8600LU).

Operation completed.

4

2.5 Packaging Mode

(1) Purpose:

For shipping the library’s main unit, the carrier mechanism is

moved to the fixing position located at the lower end of the

unit and the drive is clamped.

(2) Activation:

Set the release bars, then turn the power to ON while pressing the key “1” on the 10-key Pad.

(3) Operation: (when Drives 1 and 2 are connected)

Performs carrier initial operation.

1

Checks whether the tray is left in the mail slot or not. If

2

the tray is left, it is returned to the magazine.

Checks whether the tray is left in the drive 1 or not. If the

3

tray is left, it is returned to the magazine.

Checks whether the tray is left in the drive 2 or not. If the

4

tray is left, it is returned to the magazine. (The same

operation is performed when drives 3 to 6 are installed.)

Moves the carrier mechanism to the shipping position.

5

Performs clamping operation for the drive 1.

6

Performs clamping operation for the drive 2. (The same

7

operation is performed when the drive 3 to 6 are installed.)

2.8 Memory Clear Mode

(1) Purpose:

Clears the backup memory for the mechanism CPU and SCSI

CPU, including to reset the disc/tray mapping data and SCSI

ID of the main unit, etc.

(2) Control:

While pressing the key “3”on the 10-key Pad., turn the power

ON.

(3) Operation:

Performs the tray auto return mode operation.

1

Clears the backup memory for the mechanism CPU and

2

SCSI CPU.

* Be sure not to turn the power OFF until the mechanism

operation is completed because the memory is cleared

after the trays left in the drive/mail slot are returned.

Operation completed.

3

2-16

Page 21

2.9 Drive Detection Mode

(1)Purpose

Drives are detected in order to prevent simultaneous installation of different drives.

(2)Start

While pressing the “8” key, turn the power ON.

(3)Operation

After the initial operation, each of the installed drives performs the ejection operation for identification.

LCD display during drive detection LCD display after drive detection

DETECTING DRIVES

. . . . PLEASE WAIT

Note: Whenever a drive is added, replaced or removed after the last drive

detection, be sure to repeat drive detection.

* If this is omitted, a mechanism malfunction may result.

* Be sure to turn the power OFF and then ON again after drive detection.

DRIVE DETECTION

COMPLETED

2-17

Page 22

2.10 Maintenance Mode

1234

6

7

89

5

2.10.1 Outline

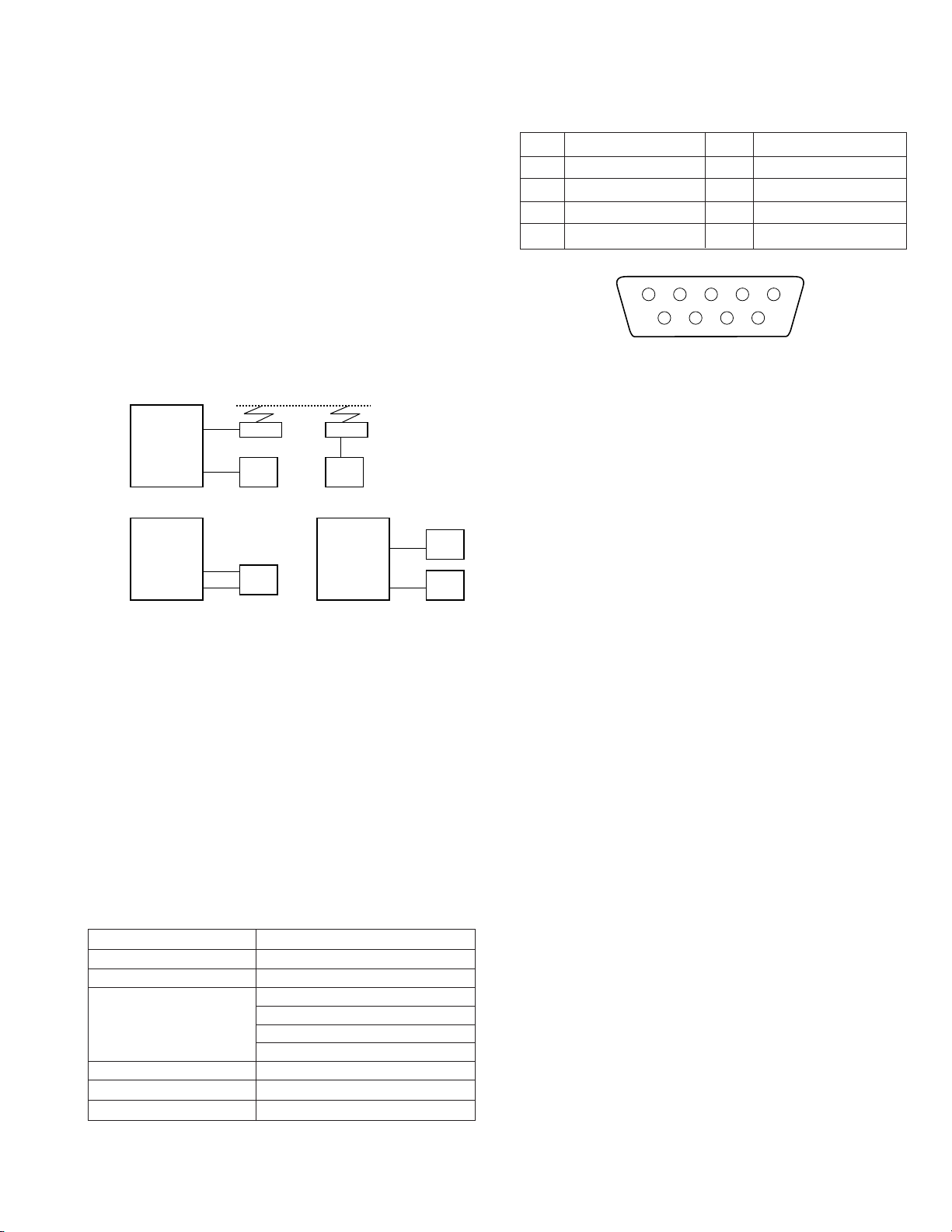

This unit is also equipped with an RS-232C port as an interface

for external equipment other than the SCSI interface which is

used for connection to the host computer. The RS-232C port is

used mainly for the following two purposes:

(a) Remote Maintenance:

It can be used for remote diagnostic operation by connecting

to the public telephone line via a modem.

(b) Direct Maintenance:

It can be used for diagnostic operation by direct connection

to a computer, etc.

In either way, while this unit is operated in the system the mechanical operation checking, which is one of the checking functions of the self-diagnosis operation, is not available.

(a) Remote maintenance

RS-232C

Modem

Library

SCSI

HOST

(b) Direct maintenance

●Maintenance by

Library

the same host

RS-232C

HOST

SCSI

*Judgment whether remote or direct maintenance Checks

whether the modem is connected or not when the power is

turned ON, and judges the unit is in the “remote maintenance”

or “direct maintenance” mode.

· The modem control AT command (Z: Reset) is transmitted to

the RS-232C port. And if there is a response, the unit is operated as the “remote maintenance” mode, and if there is no

response, the unit is operated as the “direct maintenance”

mode.

NOTES:

In the “direct maintenance” mode, the host computer must

not respond to an AT command.

Public Tel line

Modem

PC

●Maintenance using

Library

exclusive PC

RS-232C

SCSI

HOST

PC

• Connector: D-Sub 9-pin (male)

• Pin Layout

1

2

3

4

5

DCD (IN)

RXD (IN)

TXD (OUT)

DTR (OUT)

S-GND

6

7

8

9

DSR

RTS (OUT)

CTS (IN)

NC

2.10.3 Maintenance Types and Conditions

Operating environment status

1

Outputs the environmental conditions including the type of

this unit (Model No.), status of connected drives, SCSI ID

No. setting and ROM version, etc.

Trouble contents check

2

Outputs the trouble information stored in this unit.

Self diagnostic function

3

Performs the preset specific operations and outputs the results as the status. Operations 1 and 2 are available at any

time. The operation

is available only when this unit is in

3

the maintenance mode. Regardless of the currently selected

maintenance mode (remote or direct), all the peripheral components must be turned on before turning on the power to

this unit.

2.10.4 Activating the Maintenance Mode

To activate the maintenance mode with this unit...

Set the maintenance disc in the address 1 before turning the

1

power ON.

While pressing the MODE switch on the front panel, turn the

2

power switch to ON.

2.10.5 Maintenance Program

To perform maintenance on this unit, the maintenance program

software must be installed on the PC connected.

2.10.2 Electrical Specifications

• Signal Format

Signal Level RS232C

Communication System Asynchronous half-duplex

Transfer Rate 9600 bps

Character Start bit: 1

Codes used ASCII character code

Modem Control Command Compliant to Hayes AT command

Compatible Modem ITU-T V.32

Data: 8 bits

Parity: None

Stop bit: 1

2-18

Page 23

2.11 Auto Disc/Tray Check ON/OFF Setting

On shipping, auto disc/tray checking function is set to ON which automatically checks the discs loaded in the magazine after the

magazine is loaded or unloaded with the power ON. This setting can be switched OFF in the following manner.

1. Changing the setting

While pressing the SELECT switch and the LOAD/EJECT switch located at the side of the LCD, turn the power ON. The operation

mode is alternated between ON and OFF. The default setting is ON (auto check function is activated). With the above operation,

the setting is changed to OFF (auto check function is deactivated).

2. How to check the current setting

· Hold down the MODE switch beside the LCD for more than 5 seconds. The current setting is displayed on the LCD.

AUTO DISC CHECK :

ON

AUTO DISC CHECK :

OFF

3. Others

· This setting is maintained after the power is turned off. Changing the setting requires the operation described in 1.

2.12 Maintenance and Periodical Check

The following shows an example of a maintenance reference chart when this unit is used with two drives for 50,000 times a year.

Maintenance period differs depending on the using conditions, etc.

Item Maintenance Contents

Carrier

U/D Motor Unit

Mail slot

Drives

Air filter unit

Magazine

: Replacement. ^ : Maintenance. : Operation check.

1yr 2yrs 3yrs 4yrs 5yrs 6yrs

^

–––––

––^ ––

––^ –– ^

Operation check contents

Item Check Contents

Carrier

U/D motor assembly

Mail slot

Drives

Magazines

Presence/absence of abnormal sound or backlash, Roller defect/wear, No defect on carrier FCC cable

Presence/absence of abnormal sound or backlash

Presence/absence of abnormal sound or backlash

Readout speed check using exclusive software

Cleaning of tray in the position where frequently used (wipe off dust)

Maintenance Intervals

Grease (See Disassembly view.)

Clean filter

Clean tray

NOTES:

1) The maintenance and replacement intervals for the CD/DVD library are variable depending on the operating conditions such as the

number of additional optional drives and the frequency of use. It is recommended to replace each drive after every 30,000 disc

loading cycles. To check the operation of the CD/DVD drive, perform recording and playback of the exclusively designed CD/DVD

disc.

2) The service life of the CD/DVD drive is variable depending on the write count (the total time spent in the write mode).

3) Each disc carrier tray should be replaced after every operation count of 10,000 cycles.

An operation refers to each operation cycle of the carrier. When the carrier has pulled out a magazine tray, inserted a disc in it and

then returned it to its original magazine, the operation count becomes 2.

4) When an MC-CF10 optional carrier is used, it is recommended that it should be replaced after 300,000 inversion operations.

The inversion count can be checked as describe in section “11. Access Count” of the instruction manual.

2-19

Page 24

R

VICTOR COMPANY OF JAPAN, LIMITED

R

is a registered Trademark owned by VICTOR COMPANY OF JAPAN, LTD.

R

is a registered Trademark in Japan, the U.S.A., the U.K. and many other countries.

Printed in Japan

Page 25

SECTION 4

S34

CARRIER MECHA

ASSEMBLY

29

30

31

28

128

33

34

33

26

13

14

23

58

8600 only

8600

only

12

14

13

15

16

17

1

147

148

125

126

146

22

19

27

21

22

25

20

3a

2

126

127

126

29

38

33

29

33

39

64

S5

S7

S2

S2

S2

S15

S2

S1

S2

S4

S6

S8

18

120

119

122

7

8

149

150

166

6

4

7

3b

18

11

10

9

4

S1

S3

S3

S4

S4

2

S2

W3

52

52

53

54

87

55

S12

S7

S11

S12

S11

S7

33

29

35

36

37

129

29

130

33

33

32

41

42

44

83

82

85

140

86

88

79

78

91

84

30

21

27

45

21

21

51

43

29

33

29

38

S9

S11

S10

S12

S10

S13

S13

S4

S34

S26

S27 S2

S20

DISPLAY

PCB ASSEMBLY

S32

48

A

49

50

66

138

65

47

46

131

72

64

62

133

63

67

55

79

78

80

55

61

59

60

134

167

156

S11

S12

S11

S13

S12

S4

S19

S2

S2

S19

S13

S20

W1

W2

MAIL CN

PCB ASSEMBLY

MAIL SLOT

ASSEMBLY

MAGAZINE HOUSE

ASSEMBLY

CENTER PANEL (B)

ASSEMBLY

52

52

113

68

136

102

135

138

24

69

S12

S7

S2

S21

S2

S21

S11

S7

S11

103

S11

CHASSIS

PCB ASSEMBLY

POWER

UNIT ASSEMBLY

CONNECTOR

PCB ASSEMBLY

100

142

71

55

A

89

55

71

124

91

40

92

93

94

145

143

145

90

74

75

106

73

132

101

S2

S2

S4

S12

S35

S28

S2

S2

S2

S4

S4

S3

S22

S3

97

95

98

99

98

95

96

161

168

95

96

141

95

S2

S2

S2

S2

S31

123

152

151

155

173

S2

S11

MAGAZINE HOUSE

ASSEMBLY

FAN

FAN CN

PCB ASSEMBLY

55

S12

U/D MECHA

PCB ASSEMBLY

S4

S7

137

11

11

155

156A

156B

S16

S16

S7

S21

S29

144

158

159

S35

108

164

70

110

S4

S2

S30

RS232C

PCB ASSEMBLY

165

111

167

167

153

S33

SCSI PCB

ASSEMBLY

56

57

S29

163

S17

105

5

8600

only

S4

163

104

S25

81

Apply grease

on the inside.

118

S2

121

154

117

118

175

176

116

S37

115

173

S2

174

S36

114

4.1 FINAL ASSEMBLY

M1

EXPLODED VIEW AND PARTS LIST

4-1

4-1

Page 26

4.2 FINAL ASSEMBLY LIST

Symbol

No.

1 SS22761-00C DOOR PANEL (L6) MC-8600

1 SS22759-00C DOOR PANEL (L2) MC-8200

2 SS411847-00A HINGE MC-8200: x 4

03a SS412126-F0A DOOR STAY (L)

03b SS412126-R0A DOOR STAY (R)

4 SS411853-D07 SPONGE TAPE

5 SSV3871 FFC MC-8200

5 SSV3872 FFC MC-8600

6 SS411853-D10 SPONGE TAPE MC-8600

6 SS411853-D09 SPONGE TAPE MC-8200

7 SS411853-D08 SPONGE TAPE

8 SS22916-00C DOOR PANEL (R6) MC-8600

8 SS22915-00C DOOR PANEL (R2) MC-8200

9 SS22765-002 D-LOCK BASE (6) MC-8600

9 SS22764-002 D-LOCK BASE (2) MC-8200

10 SS35376-001 D-LOCK BAR (6) MC-8600

10 SS35377-001 D-LOCK BAR (2) MC-8200

11 SS35732-00A D-LOCK HOOK

12 SS22744 FRONT PANEL (M)

13 SS411853-F07 SPONGE TAPE

14 SS411853-F08 SPONGE TAPE

15 SS411931 FP-BKT

16 SS411842-010 PLATE

! 17 SS11621-003 MAIN PANEL

18 SS411853-D11 SPONGE TAPE MC-8200

18 SS411853-D12 SPONGE TAPE MC-8600

19 SS35727-001 MP ANGLE (R6) MC-8600

19 SS35725-001 MP ANGLE (R2) MC-8200

20 SS35726-001 MP ANGLE (L2) MC-8200

20 SS35728-001 MP ANGLE (L6) MC-8600

21 SS411853-F06 SPONGE TAPE MC-8200: x 2

22 SS411853-F02 SPONGE TAPE

! 23 SS11622-001 SUB PANEL MC-8600

24 SS35994-00A C-PANEL (RRB)

25 SS35729-001 SP ANGLE (R6) MC-8600

26 SS35730-001 SP ANGLE (L6) MC-8600

27 SS411853-F01 SPONGE TAPE MC-8600

28 SM3921-001 BLANK LABEL

29 SS410270 R.SHAFT

30 SS410277 R.B.SHAFT

31 SS411900-0L1 SR.BRACKET

32 SS411900-0R1 SR.BRACKET

33 SS410268-00A ROLLER

34 SS35352-00B C.BASE ASSY

35 SS410274 SP.SCREW

36 SS411895-00A R.HOLDER ASSY

37 SS411884-001 SPRING

38 SS410275-002 SPRING

39 SS411899 BELT BRACKET

40 SS412031-001 BLIND BOLT

41 SS22476-002 FILTER CASE A

42 SS34931-00A AIR FILTER

43 SS22477-002 FILTER CASE B

44 QAR0068-001 FAN MOTOR

45 SS35408 U/D BASE

46 SS411883 SP BRACKET

47 SS411884-003 SPRING

48 SS11629 MAIL BASE

49 SS411923-002 SPRING

50 SS411959-002 MTB SHAFT

M1

M1MM````

DescriptionPart No. Part Name

4-2

Page 27

Symbol

No.

51 SS411961 BRACKET

52 SS22737 SQ PLATE MC-8200: x 7

53 SS22917-00B DRIVE HOUSE ASSY

54

55 SS411880-003 WIRE CLAMP

56 SS412434-001 S-PCB BKT(B)

57 SS412433-001 S-PCB BKT(A)

58 SS413399 SWITCH SHEET

59 SS48947-002 SHAFT PIN

60 SS411886 PULLY(B) BKT

61 SS411882 PULLEY(B)HOLDER

62 SS411884-002 SPRING

63 SSV3334 PULLEY(B) ASSY

64 SSV3221 BELT MC-8200

64 SSV3220 BELT MC-8600

65 SS412134 STOPPER

66 SS413387 C-PCB BKT

67 SS22907-002 C-PANEL(RR2) MC-8200

67 SS22909-002 C-PANEL(RR6) MC-8600

68 SS22903-003 CENTER PANEL(2) MC-8200

68 SS22904-002 CENTER PANEL(6) MC-8600

69 SS22905-002 C-PANEL(BR)

70 SS35734-001 AC BARRIER

71 SS413570 C. B BLOCK

72 SS11827 GUIDE RAIL(86) MC-8600

72 SS23202 GUIDE RAIL(82) MC-8200

73 SS35349-001 CAR-TP HOOK

74 SS411085-001 SPRING(RH)

75 SS48507-002 WASHER

78 SS412015-001 SENSOR BKT

79 GP1A61LC SENSOR

80 SS412006-001 P-SW BKT

! 81 QSW0520-001 POWER SWITCH

82 SS412002-001 FCF BKT

83 HGT19-188UL-NT TAPE

84 SS35086-001 C&C FASTENER

85 SSV2622-30144B FFC CABLE MC-8600

85 SSV2622-3084B FFC CABLE MC-8200

! 86 SS11623-00D CONT.PANEL ASSY

87 SS413012 F.BKT

88 RCM2060M-B L.C.DISPLAY

89 SS411880-006 WIRE CLAMP

90 SS11638-002 C-PANEL(T)

91

92 SS412005-001 P.CN-PCB BKT

! 93 QAL0538-001 POWER SUPPLY

94 SS35437-001 C-PCB HOOK

95 SS412012-S03 CUSHION MC-8200: x 2

96 SS412012-S02 CUSHION MC-8600

97 SS22793-002 SIDE PANEL(T6) MC-8600

98 SS412012-S01 CUSHION

99 SS22792-002 SIDE PANEL

100 SS22908-002 C-PANEL(RL2) MC-8200

100 SS22910-002 C-PANEL(RL6) MC-8600

101 SS411149-005 PCB HOLDER

102 SS413617-001 C. LABEL-001

103 QNZ0676-001 CONN ACCESSORY

104 SS412017-012 EDGING

105 SS413010-002 FINGER

106 SS22906-002 C-PANEL(BL)

DescriptionPart No. Part Name

MC-12-UD-PULLY (No. 59 and No. 63) will be sup-

plied as it can not be disassembled.

4-3

Page 28

Symbol

No.

107 SS412013-001 AC PANEL

! 108 QNC0048-001 AC INLET

109 SS412001-001 D-SUB PANEL

110 SS411956 STUD

111 SSV2459-09 DUSTER COVER

112 SS35436-001 DH-COVER

113 WJS0037-001A E-FL/RE WIRE

114 SS412019-002 BLIND PANEL

115 SS36280 REAR PANEL (DH)

116 SSV2458-050 D-SUB CAP

117 SS412012-R07 CUSHION

118 SS412012-R08 CUSHION

119 QAR0261-001 FAN MOTOR

120 SS36338 FAN BKT

121 SS35720-002 REAR PANEL(B)

122 SSV3695 FAN GUARD

123 SS36284 REAR PANEL(T2) MC-8200

123 SS23206 REAR PANEL(T6) MC-8600

124 SS35478-00G CABI ASSY(8600)+D.HOUSE MC-8600

124 SS35477-00G CABI ASSY(8200)+D.HOUSE MC-8200

125 SS412123-001 C.LABEL

126 SS32387-00D LOCK KEY ASSY

127 SS411843-001 D LOCK CAM

128 MC22-CARR CARRIER MECHA ASSY

129 SS412157 EARTH

130 SS412138-002 CUSHION

131 MC12-UD-M U/D MOTOR ASSY

132 SS412017-012 EDGING

133 MC12-MAIL MAIL SLOT ASSY

134 SS412138-001 CUSHION

135 SS412139-001 IL RELEASE BAR

136 SS412038-001 No. LABEL(1 50)

136 SS412038-002 No. LABEL(51 100)

136 SS412038-003 No. LABEL(101 150)

136 SS412038-004 No. LABEL(151 200)

136 SS412038-005 No. LABEL(201 250) MC-8600

136 SS412038-006 No. LABEL(251 300) MC-8600

136 SS412038-007 No. LABEL(300 350) MC-8600

136 SS412038-008 No. LABEL(351 400) MC-8600

136 SS412038-009 No. LABEL(401 450) MC-8600

136 SS412038-010 No. LABEL(451 500) MC-8600

136 SS412038-011 No. LABEL(501 550) MC-8600

136 SS412038-012 No. LABEL(551 600) MC-8600

137 SS412043-001 CAUTION LABEL

138 SS412352-001 CAUTION LABEL

140 SSV2923 FLAT CORE

141 MC82-CHAS CHASSIS PCB ASS’Y

142 SS411880-004 WIRE CLAMP

143 SS412125-001 IL RULER

144 SS412125-002 IL RULER

145 QSW0540-001 SW

146 SS412039-001 KEY LABEL

147 SS35506-002 C. LABEL(TPS/JP)

148 SS35448-002 C. LABEL(TRY/JP)

151 SS412562-001 RATING LABEL

152 SS412084-002 FCC LABEL

153 SS48287-002 CAUTION. LABEL

154 SC40865-001 WARNING. LABEL

155 SS412043-001 CAUTION. LABEL

156A SS412047-001 UL LABEL

DescriptionPart No. Part Name

Symbol

No.

156B SS412174-002 CE/TUV LABEL

157 SSV2923 FLAT CORE

158 QSW0540-001 MICRO SWITCH

159 SS412476-001 CPL SW BASE

161 SS47383-001 C. LABEL

163 QQR0216-001 CLAMP FILTER CN13(for AP), CN900 (for CHAS),

164 SS412732-A0040 GASKET

165 SS412017-012 EDGING

166 SS412732-B0030 GASKET

167 SS412012-C01 CUSHION

168 SS412716-001 C. LABEL

169 SS413622-001 C. LABEL

171 SS413601 S. PCB BRACKET

173 SS413386 REAR PANEL HOOK

174 LS40403-001A CON. PLATE

175 LS30371-001A PWB BASE

176 SK250400A1 LVD PWB ASSY

S1 SS411848-001 SCREW

S2 QYSDSTY3006X SCREW

S3 SS411339-001 SCREW

S4 QYSDST3006M SCREW M3 x 6

S5 QYSDSP3006M SCREW M3 x 6

S6 QYSBSFG3006M SCREW

S7 QYSBSF3008M SCREW M3 x 8

S8 QYSDSF3006M SCREW

S9 QYSBSF3012M SCREW

S10 QYSBSF4035M SCREW

S11 QYSDST4008M SCREW M4 x 8

S12 QYSPSPD4008Z SCREW M4 x 8

S13 QYSPSPD3006Z SCREW

S14 QYSBST4008N SCREW M4 x 8

S15 QYSDSP3005M SCREW

S16 QYSPSP2604Z SCREW

S17 SS411759-002 SCREW

S18 QYSDST3006Z SCREW M3 x 6

S19 QYSDSP4008M SCREW

S20 QYSDST3010M SCREW M3 x 10

S21 SXST4008N SCREW

S22 QYSPSPD4010Z SCREW M4 x 10

S23 QYSDSTY3006N SCREW

S24 QYSBSTG3010M SCREW

S25 QYSDST3008M SCREW M3 x 8

S26 QYSBSFG3008M SCREW

S27 QYSDSP2004N SCREW M2 x 4

S28 QYAPSPL4010Z SCREW M4 x 10

S29 QYSBST3006X SCREW M3 x 6

S30 QYSSST3008M SCREW

S31 QYSPSP3008Z SCREW M3 x 8

S33 QYSDSTY3008X SCREW

S34 QYSBSTG3008M SCREW

S35 QYSPSPL2310Z SCREW

S36 LS40316-001A SCREW x 2

S37 QYSDST3006N SCREW M3 x 4

W1 QYWSS439008Z WASHER

W2 QYREE2500 E WASHER

W3 QYWFM31540 WASHER x 2 MC-8600

DescriptionPart No. Part Name

4-4

4-4

Page 29

15

16

17

18

25

24

26

23

17

20

31

89

90

30

29

33

39

87 88

35

36

32

38

69

70

73

74

75

76

77

78

81

82

68

67

65

64

63

62

66

84

61

59

60

48

47

45

43

42

40

41

44

41

40

51

50

52

45

55

58

57

56

53

54

49

83

5

6

3

2

42

46

85

79

80

72

71

34

27

28

22

19

21

14

13

12

11

8

86

9

10

7

12

4

S1

D.SEN T.PCB ASSEMBLY

DISC SEN R

PCB ASSEMBLY

L CATCH SEN

PCB ASSEMBLY

TRAY LOCK S

PCB ASSEMBLY

L ADD SEN PCB ASSEMBLY

R ADD SEN PCB ASSEMBLY

LOADING SEN PCB ASSEMBRY

LANE SEN PCB ASSEMBRY

CARRIER MEC PCB ASSEMBRY

R CATCH SEN

PCB ASSEMBRY

S1

S1

S1 S6

W3

W3

W1

S6

S7

S4

S1

S4

S1

S1

S1

S1

S10

W4

W5

S8

S8

S9

W5

S9

S11

S10

S9

S1

W1

S1

S1

S5

S1

S1

S3

S2

S1

S1

S1

W1

W6

S3

W1

S1

W2

W1

S4

W4

W4

S2

S13

S1

S12

W4

W7

Apply grease

on the back

side all over.

33 65

Motor pin

* and is solder to case.

4.3 CARRIER ASSEMBLY

Apply grease (G-31KAV)

M2

4-5

4-5

Page 30

4.4 CARRIER MECHANISM ASSEMBLY LIST

Symbol

No.

2 SS35406-002 ILL.BRACKET

3 SS412167 TL-BRACKET

4 SS35343-001 T.L HOLDER

5 SS411943 T-LINK

6 SS35343-002 T.L HOLDER

7 SS22745-00B C.CHASSIS ASSEMBLY

8 SS22739 TRAY GUIDE(F)

9 SS48906-003 STOPPER(1)

10 SS411807-002 PUSHER

11 SS411807-001 PUSHER

12 SS411908-001 SPRING

13 SS22740 DISK STOPPER(F)

14 PHY214PH02N WIRE ASSEMBLY

15 SS411912 H.RAIL

16 SS410979-004 S.SUPPORT

17 SS410982-002 C.H.S.BEARING

18 SS412600-002 C.SLIDER

19 SS412600-001 C.SLIDER

20 SS410978-00C S.SUPPORT ASSEMBLY

21 SS48874 J.GEAR

22 SS411806 J.GEAR

23 SS410295 C.H.S.GEAR

24 SS411904 C.H.W.GEAR

25 SS34908-00D C. HOLDER ASSEMBLY

26 SS411903 H.SHAFT

27 EHT309EH03N WIRE

28 EHT312EH03N WIRE

29 SS35405 T.G.HOLDER

30 SS22741 T.GUIDE(R)

31 SS35344-002 DISK STOPPER(R)

32 SS410976 S.BASE

33 SSV2793 DC MOTOR

34 SS411906-00A TLM BRA ASSEMBLY

35 SS48863-002 SL.GEAR

36 SS412601-00B SENSOR GEAR ASS’Y

38 PHY412PH04N WIRE

39 SM3921-001 LABEL

40 SS410973 LSP.SHAFT

41 SS410972-002 L.SPRING

42 SS410966 C.S.SHAFT

43 SS411915-00A LEVER(R) ASSEMBLY

44 SS411902-00A LEVER(L) ASSEMBLY

45 PHY307PH03N WIRE

46 SS411003-001 CS.BRACKET

47 SS411002-002 SPRING

48 SS411907-00B T.STOPPER ASSEMBLY

49 SS411003-002 CS.BRACKET

50 SS411002-001 SPRING

51 SS411907-00A T.STOPPER ASSEMBLY

52 EHT212EH02N WIRE

53 PHYD06PH05N WIRE ASSEMBLY

54 SS410991-00A TL.BRACKET ASSEMBLY

55 SS410993-00A T.L-LINK ASSEMBLY

56 SS411911 TLS.BRACKET

57 SS410997-002 SPRING

58 SS410996 TL SCREW

59 SS410999 SCREW

60 SS411918-00A CAM BRACKET

61 SS411008-002 BRACKET

62 SS411009-002 MOTOR BRACKET

M2

M2MM````

DescriptionPart No. Part Name

MC12-LOAD-M (LOADING M ASSY) will be sup-

plied as it can not be disassembled.(W4 and S10

is included)

Symbol

No.

63 SS411007 W.SHAFT

64 SS411006 WORM GEAR

65 SSV2793 DC MOTOR

66 SS411004-00A BASE ASSEMBLY

67 SS411025 R.PLATE

68 SS411010 GUIDE

69 SS411026-00A PLATE ASSEMBLY

70 SS411022-00A BRACKET ASSEMBLY

71 SS411011-00A WORM WHEEL ASSEMBLY

72 SS411017-003 PL BASE

73 SS411016 SLIDER

74 SS410961-002 SPRING

75 SS411015 S.BRACKET

76 SS411018-00A L.BRACKET ASSEMBLY

77 SS411021 PIN

78 EHT308EH03N WIRE

79 SS411044-002 CUSHION

80 SS411044-001 CUSHION

81 SS411035 WC BRACKET

82 SS411394-00B C.WIRE ASSEMBLY

83 SS411394-00A C.WIRE ASSEMBLY

84 SS411340 BUSH

85 SSV2622-3084B FLAT CABLE MC-8200

85 SSV2622-30144B FLAT CABLE MC-8600

86 QCFB1HZ-104YR C CAP

87 SS411415 S.BRACKET

88 SS411419-001 SPRING

89 SS412141-001 PROTECTOR

90 SS412141-002 PROTECTOR

S1 QYSDSF3008M SCREW M3 X 8

S2 QYSDSP2604M SCREW M2.6 X 4

S3 QYSBSFG3008M SCREW M3 X 8

S4 QYSDSP2004M SCREW M2 X 4

S5 QYSDSP2008M SCREW M2 X 8

S6 QYSDST2005Z SCREW M2 X 5

S7 QYSBSF2606Z SCREW M2.6 X 6

S8 QYSDSP2006M SCREW M2 X 6

S9 QYSDST3006M SCREW M3 X 6

S10 QYSPSP3003Z SCREW M3 X 3

S11 QYSPSPD3006M SCREW M3 X 6

S12 QYSDSF2004M SCREW M2 X 4

S13 QYSDSP3006M SCREW M3 X 6

S14 QYSDST3008M SCREW M3 X 8

W1 QYREE2000X E RING

W2 QYWSS327005Z WASHER

W3 QYWFM264750 POLY WASHER

W4 QYREE1500 E RING

W5 QYREE3000X E WASHER

W6 QYWFM315450 POLY WASHER

W7 QYWFM315425 WASHER

DescriptionPart No. Part Name

MC12-TR-M (TRAY LOCK M ASSY) will be sup-

plied as it can not be disassembled.

4-6

4-6

Page 31

4.5 MAIL SLOT ASSEMBLY

13

15

11

14

16

9

10

8

12

W1

W2

S3

S3

S1

S1

W1

W4

3

4

2

1

5

6

7

S1

S2

S1

S1

S1

S2

POSI PCB ASSEMBLY

SENSOR PCB ASSEMBLY

CN6

28

31

32

30

29

27

25

26

24

23

22

35

33

37

36

34

W2

W3

S2

S3

S6

S5

S4

S3

S7

39

From MOTOR

From SENSOR BOARD

From POSI BOARD

From SW

MAILSLOT PCB ASSEMBLY

19

17

18

20

21

S3

S3

S1

S3

S3

S1

S4

Motor pin

Apply grease (G-31KAV)

M3

4-7

4-7

Page 32

4.6 MAIL SLOT ASSEMBLY LIST

Symbol

No.

1 SS11616-002 GUIDE

2 SS411934 TGR BRACKET

3 SS35350 TRAY GUIDE(R)

4 SS22743-002 BASE

5 SS35349 T.RAIL(F)

6 SS411927-00B TGF BKT ASSEMBLY

7 SS411923-001 SPRING

8 SS35348 TL PUSHER

9 SS411938 TLG BRACKET

10 SS411920 TRAY LOCK

11 SS411919 SL SHAFT

12 SS411924-002 ST BRACKET

13 SS411925-002 STOPPER

14 SS411922 SPRING

15 SS411935 P.SPRING(UD)

16 SS22742 GEAR BASE

17 SS411929-002 S.GUIDE

18 SS35409 SEN.HOLDER

19 SS35347 BASE GUIDE(F)

20 SS35351 BASE GUIDE(R)

21 SS411936 BGR BRACKET

22 SS411942 P.SPRING

23 SS412048 PCB SPACER

24 SSV3280 PULLEY-GEAR

25 SSV3222 BELT

26 SSV1835 SW

27 SS411932-00C P.G.BKT ASSEMBLY

28 SS411929-001 S.GUIDE

29 SSV2793 DC MOTOR

30 SSV3279 PULLEY

31 SS411930 MOTOR BRACKET

32 SS411880-003 CLAMP

33 SS411811 GEAR-3

34 SS411812 GEAR-4

35 SS411926 STOPPER(B)

36 SS35410 TRAY GUIDE(S)

37 SS411937 TGS BRACKET

38 SS411941-00B B.BASE ASSEMBLY

39 QCFB1HZ-104Y C CAP

S1 QYSDSF3006M SCREW M3 X 6

S2 QYSBSFG3006M SCREW M3 X 6

S3 QYSDST3006M SCREW M3 X 8

S4 QYSDST3010M SCREW M3 X 10

S5 QYSDSP2610Z SCREW M2.6 X 10

S6 QYSDSP2008M SCREW M2 X 8

S7 QYSPSP3003Z SCREW M3 X 3

W1 QYREE2000 WASHER

W2 WDL260550-2 WASHER

W3 QYWDL2140254 WASHER

W4 QYWFM629513 WASHER

M3

M3MM````

DescriptionPart No. Part Name

MC12-RAIL-M (RAIL MOTOR ASSY) will be supplied

as it can not be disassembled.

4-8

Page 33

4.7 MAGAZINE ASSENBLY

M4

4

1

3

1

3

S1

5

4.8 MAGAZINE ASSENBLY LIST

S1

M4

S2

2

3

9

8

5

7

S1

S3

6

11

10

S3

Symbol

No.

1 SS22736-001 TB PLATE

2 SS11613-001 RAIL BOX

3 SS411080-001 NUT PLATE

4 SS22735-004 TRAY

5 SS412024-001 R-GUIDE BAR

6 SS35337-001 GRIP

7 SS35338-001 TRAY LOCK

8 SS411084-001 SPRING(TL)

9 SS35339-001 T.L.PUSHER

10 SS411851-001 LABEL(ADRS) (1—50)

11 SS411852-001 LABEL(No. 1—4)

S1 QYSDSP3008M SCREW M3 X 8

S2 QYSBSF3008M SCREW M3 X 8

S3 QYSBSFG3008M SCREW M3 X 8

4-9

M4MM````

DescriptionPart No. Part Name

Page 34

4.9 CENTER PANEL (B) ASSENBLY

S1

S2

S1

1

8

10

9

2

3

4

5

6

7

M5

4.10 CENTER PANEL (B) ASSENBLY LIST

Symbol

No.

1 SS35499-002 CENTER PANEL(B)

2 SS412116-003 SDL-HOOK

3 SS412120 SPRING

4 SS412118-001 SDL-SHAFT

5 SS412119 SPRING

6 SS412117-001 SDL-SHAFT. BKT

7 SS35500-002 SDL-LEVER

8 SS412481-002 SPRING

9 SS412474-003 CPL-HOOK

10 SS412475-003 CPLH-BASE

S1 QYSDST3006M SCREW

S2 SS411339-001 SCREW

M5

M5MM````

DescriptionPart No. Part Name

4-10

Page 35

4.11 U/D MECHANISM ASSENBLY

21

22

25

23

UD MOTOR

PCB ASSEMBLY

ROT SENSOR

PCB ASSEMBLY

2

4

5

3

1

S2

S2

S2

S1

17

10

18

15

19

20

21

22

25

23

11

12

13

8

9

10

6

7

15

24

16

14

10

S3

S2

S2

Apply grease (G-31KAV)

M6

4-11

Page 36

4.12 U/D MECHANISM ASSENBLY LIST

Symbol

No.

1 SS411891 SENSOR BASE

2 SS411944-00B SENSOR PLATE ASSEMBLY

3 SS412027 T PLATE

4 SS412026 N BAND

5 QAR0004-001 MOTOR

6 SS411889 PLATE

7 SS35346 GEAR BOX

8 SS410822-002 B.BEARING

9 SS411888-002 STOPPER

10 QYYASPR3006M S.SET SCREW

11 SS411813 SIDE COVER

12 SS45160-001 BALL BEARING

13 QYWFM629513 WASHER

14 SS411817-00A W.WHEEL ASSEMBLY

15 SS45160-006 BEARING

16 SS411892 SHAFT

17 SS411896 HOLDER

18 SS410813 B.HOLDER

19 SS49074-00B PULLEY (T) ASSEMBLY

20 SS410379-002 CUSHION

21 SS410319 BUSHING

22 SS410320 SPACER

23 SS410893 SP.SCREW

24 SS411901 TOP PLATE

25 QYWSS64C516N WASHER

S1 QYSDSF2005M SCREW M2 X 5

S2 QYSPSPL3008M SCREW M3 X 8

S3 QYSDSP3005M SCREW M3 X 5

M6

M6MM````

DescriptionPart No. Part Name

4-12

Page 37

4.13 MAGAZINE HOUSE ASSENBLY

11

2

3

5

6

4

1

7

1

S1

S1

S1

S2

S1

S1

MAGAZINEN SEN

PCB ASSEMBLY

W1

W2

10

12

13

9

8

S1

S2

M7

4-13

Page 38

4.14 MAGAZINE HOUSE ASSENBLY LIST

Symbol

No.

1 SS35442-001 GUIDE RAIL(P)

2 SS412022-001 ST-BAR

3 GP1A61LC SENSOR

4 SS35340-002 KNOB

5 SS35341-001 LOCK PIN

6 SS412036-002 SPRING

7 SS412025-001 STOPPER BASE

8 SS412036-003 SPRING

9 SS35342-002 L-PIN HOLDER

10 SS412035-001 JOINT SHAFT

11 SS35536-00A M-HOUSE ASS Y

12 SS35443-001 SLIDE BAR

13 SS411085-001 SPRING(RH)

14 SS412160-001 M-H-BRACKET

15 SS412962 SPACER

S1 QYSDST3006M SCREW M3 X 6

S2 SS411339-001 SCREW

W1 QYREE3000X E.WASHER

W2 Q03093-826 POLI SLIDER

M7

M7MM````

DescriptionPart No. Part Name

4-14

Page 39

SECTION 5

ELECTRICAL PARTS LIST

SAFETY PRECAUTION:

Parts identified by the ! symbol are criticaI for safety. Replace only with specified parts numbers.

For maximum reliability and performance, all other replacement parts should be identical to those specified.

NOTE:

● Parts not denoted by parts numbers are not supplied by JVC.

● Abbreviations in this list are as follows:

RESISTORS

In the Description column:

All resistance values are in ohms (Ω).

k expresses kilo-ohm (1 000 ohms, kΩ).

M expresses mega-ohm (10

6

ohms, MΩ).

CAPACITORS

In the Description column:

All capacitance values are in microfarad (µ F) unless