Page 1

R

SERVICE MANUAL

CD/DVD LIBRARY

MC-8100U

MC-8100U

SPECIFICATIONS

Number of stored discs

Number of magazines

Operating environment

Rated power voltage

Rated power frequency

Rated current

Power Consumption

Interface

Drive slots rack bays

Media size

100% recycled paper

: 100

: 2

: Temperature: 5°C-35°C (41°F-95°F)

Humidity: 10%-80% (no condensation)

: AC120 V - 240 V

: 50 Hz / 60 Hz

: 1.4 A - 0.8 A (max. value),

1.1 A - 0.6 A (4 Drives are loaded)

: 105 W (Reference value,

4 DVD-RAM drives are loaded)

: SCSI-2 (Amphenol 50-pin full size)

: 4

: 12 cm discs

Applicable options

Drives

Carrier

Magazine

Printer

Weight

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

Availabel drives Compatible discs

: DVD-RAM drive

MC-R400U Rec/Play DVD-RAM with4.7 GBytes/side

Play DVD-ROM, CD-ROM/R, etc.

MC-R200U Rec/Play DVD-RAM with 2.6 GBytes/side

Play DVD-ROM, CD-ROM/R, etc.

DVD-ROM drive

MC-D104U Play DVD-ROM, CD-ROM/R, etc.

CD-ROM drive

MC-D32U Play CD-ROM/R, etc.

MC-D18U

CD-R drive

MC-R18U Rec/Play

MC-R14U CD-ROM/R, etc.

MC-R12U Play

For the specifications of the drives, refer to their relevant instruction manuals.

For other drives, consult your dealer or nearest JVC service center.

: Double-sided disc compatible carrier: MC-CF10U

: Magazine set: MC-M25U (B)

: Compatible with color disc printer (MC-AP30U)

: 42 kg (Excluding the discs and optional equipment)

and 2.6 GBytes/side

CD-R, CD-RW (Records with MC-R18U only)

No. 6124

Jan. 2001

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. CIRCUIT BOARD COMPATIBILITY ............................. 1-1

2. PRODUCT SPECIFIC SERVICE ITEMS

2.1 REMOVAL OF MAJOR PARTS ............................. 2-1

2.1.1 REPLACEMENT OF FUSES AND BATTERIES ...... 2-1

OPENING/CLOSING THE DOOR AND PANEL REMOVAL .......

2.1.2

2.1.3 REMOVING THE MAGAZINE ............................... 2-3

2.1.4 REMOVING THE DRIVE ....................................... 2-4

2.1.5 REMOVING THE SIDE STAY R ............................. 2-4

2.1.6 REMOVING THE CARRIER MECHANISM ........... 2-5

2.1.7 REMOVING THE SIDE PANEL L .......................... 2-6

2.1.8 REMOVING THE SIDE PANEL R .......................... 2-6

2.1.9 REMOVING THE REAR PANEL ............................ 2-6

2.1.10 REMOVING THE POWER SUPPLY UNIT ............. 2-6

2.1.11 REMOVING THE CHASSIS PCB ........................... 2-7

2.1.12 REMOVING THE SCSI PCB .................................. 2-7

2.1.13 REMOVING THE MAIL SLOT ............................... 2-8

2.1.14 REMOVING THE TOP PANEL .............................. 2-8

2.1.15 REMOVING THE U/D MOTOR .............................. 2-9

HOW TO OPERATE WITH THE DOOR OPEN (FOR SERVICING) ...

2.1.16

2.2 SPECIAL OPERATION MODE ............................ 2-10

2.2.1 RUNNING MODES ............................................. 2-10

2.2.2 ACCESS COUNTER CLEARANCE ...................... 2-12

2.2.3 MANUAL OPERATION ....................................... 2-12

2.2.4 PACKING MODE ................................................ 2-14

2.2.5 TRAY AUTO RETURN MODE ............................. 2-14

2.2.6 MEMORY CLEAR MODE ................................... 2-14

2.2.7 DISC/TRAY CHECK MODE ................................. 2-15

2.2.8 AUTO CHECK MODE ......................................... 2-15

2.2.9 DRIVE DETECTION MODE ................................. 2-15

2.2.10 AUTO DISC/TRAY CHECK ON/OFF SETTING ..... 2-16

2.3 SELF-DIAGNOSTIC DISPLAY .............................. 2-16

2.3.1 DISPLAYING TROUBLE HISTORY ...................... 2-16

2.3.2 DISPLAY WHEN TROUBLE OCCURS ................ 2-17

2.3.3 ERASING THE TROUBLE HISTORY ................... 2-18

2.3.4 ERROR CODE LIST ............................................ 2-18

2.4 MAINTENANCE MODE ...................................... 2-19

2.4.1 OUTLINE ............................................................. 2-19

2.4.2 ELECTRICAL SPECIFICATIONS .......................... 2-19

2.4.3 MAINTENANCE TYPES AND CONDITIONS ....... 2-19

2.4.4 ACTIVATING THE MAINTENANCE MODE ......... 2-19

2.4.5 MAINTENANCE PROGRAM ............................... 2-19

2.5 MAINTENANCE AND PERIODICAL CHECK ....... 2-20

2.6 COUNTERMEASURES AGAINST

MECHANICAL TROUBLE (FOR MC-R400U) ...... 2-21

2.7 COUNTERMEASURES AGAINST

MECHANICAL TROUBLE (FOR MC-R200U) ...... 2-22

3. DIAGRAMS AND CIRCUIT BOARDS

3.1 CD/DVD LIBRARY BLOCK DIAGRAM .................. 3-1

3.2 CHASSIS BLOCK DIAGRAM ................................ 3-2

2-2

2-9

3.3 OVERALL WIRING DIAGRAM .............................. 3-3

3.4 CHASSIS SCHEMATIC DIAGRAM ........................ 3-4

3.5 CHASSIS CIRCUIT BOARD .................................. 3-5

3.6 SCSI SCHEMATIC DIAGRAM ............................... 3-6

3.7 SCSI CIRCUIT BOARD .......................................... 3-7

3.8 CARRIER SCHEMATIC DIAGRAM ....................... 3-8

3.9 CARRIER CIRCUIT BOARD .................................. 3-9

3.10 MAIL SLOT SCHEMATIC DIAGRAM .................. 3-10

3.11 MAIL SLOT CIRCUIT BOARD............................. 3-11

3.12 S. MOT SCHEMATIC DIAGRAM ........................ 3-12

3.13 S. MOT CIRCUIT BOARD ................................... 3-13

3.14 DISPLAY SCHEMATIC DIAGRAM ...................... 3-14

DISPLAY CIRCUIT BOARD AND OTHER BOARD .......

3.15

3.16 BLOCK DIAGRAMS OF IC’S............................... 3-16

4. EXPLODED VIEW AND PARTS LIST

4.1 FINAL ASSEMBLY M1......................................... 4-1

4.2 FINAL ASSEMBLY PARTS LIST M1..................... 4-2

4.3 CARRIER MECHANISM ASSEMBLY M2 ............ 4-5

CARRIER MECHANISM ASSEMBLY PARTS LIST

4.4

4.5 MAIL SLOT ASSEMBLY M3 ................................ 4-7

4.6 MAIL SLOT ASSEMBLY PARTS LIST M3............ 4-8

4.7 MAGAZINE ASSEMBLY M4 ................................ 4-9

4.8 MAGAZINE ASSEMBLY PARTS LIST M4............ 4-9

4.9 IL BRACKET ASSEMBLY M5............................. 4-10

4.10 IL BRACKET ASSEMBLY PARTS LIST M5......... 4-10

4.11 U/D MECHANISM ASSEMBLY M6 .................. 4-11

U/D MECHANISM ASSEMBLY PARTS LIST

4.12

5. ELECTRICAL PARTS LIST

5.1

CHASSIS BOARD ASSEMBLY PARTS LIST

CONNECTOR BOARD ASSEMBLY PARTS LIST

5.2

5.3 RS232C BOARD ASSEMBLY PARTS LIST 03.... 5-5

S.MOT BOARD ASSEMBLY PARTS LIST

5.4

5.5 SCSI BOARD ASSEMBLY PARTS LIST 05 ......... 5-6

5.6 DISPLAY BOARD ASSEMBLY PARTS LIST 06... 5-7

MAIL CN BOARD ASSEMBLY PARTS LIST

5.7

ROT SENSOR BOARD ASSEMBLY PARTS LIST

5.8

5.9

MG SENSOR BOARD ASSEMBLY PARTS LIST

CARRIER MEC BOARD ASSEMBLY PARTS LIST 10

5.10

5.11

R CATCH BOARD ASSEMBLY PARTS LIST 11

L CATCH BOARD ASSEMBLY PARTS LIST 12

5.12

LOADING BOARD ASSEMBLY PARTS LIST 13

5.13

5.14

TRAY LOCK BOARD ASSEMBLY PARTS LIST 14

LANE2 SEN BOARD ASSEMBLY PARTS LIST 15

5.15

5.16

L ADD SEN BOARD ASSEMBLY PARTS LIST 16

R ADD SEN BOARD ASSEMBLY PARTS LIST 17

5.17

DISK SEN R BOARD ASSEMBLY PARTS LIST 18

5.18

5.19

DISK SEN T BOARD ASSEMBLY PARTS LIST 19

MAIL SLOT BOARD ASSEMBLY PARTS LIST 20

5.20

5.21

SENSOR BOARD ASSEMBLY PARTS LIST 21

POSI IN BOARD ASSEMBLY PARTS LIST 22

5.22

6. PACKING ..................................................................... 6-1

M6 ..... 4-12

01

04 .......... 5-5

3-15

M2.... 4-6

...........

5-2

02

....

5-5

07 ... 5-7

08

...

5-7

09

....

5-7

...

5-8

...........

5-8

...........

5-8

..........

5-9

.......

5-9

.......

5-9

.......

5-9

.......

5-9

.......

5-9

....

5-10

....

5-10

.........

5-10

..........

5-10

Page 3

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 4

p

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible

Grounding Impedance (Z)

d

d'

art

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

A

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan R 1 MΩ/500 V DC

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

–

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 900 V 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i 1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

2

Page 5

CD/DVD LIBRARY

BEDIENUGSANLEITUNG : CD/DVD-BIBLIOTHEK

MANUEL D’INSTRUCTIONS : BIBLIOTHEQUE CD/DVD

CD/DVD

MC-8100U

ENGLISHDEUTSCHFRANÇAIS

INSTRUCTIONS

For Customer Use:

Enter below the Model No. and Serial

No. which is located on the side of the

cabinet. Retain this information for

future reference.

Model No.

Serial No.

MC-8100U

MC-8100U

This instruction book is made from 100% recycled paper.

SS961554-002

Page 6

For Europe

For North America

IMPORTANT

The wires in this mains lead are coloured in accordance with

the following code:

GREEN - and - YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

As the colours of the wires in the mains lead of this apparatus

may not correspond with the coloured markings identifying

the terminals in your plug. proceed as follows. The wire which

is coloured GREEN-AND-YELLOW must be connected to the

terminal in the plug which is marked with the letter E or the

safety earth symbol

YELLOW. The wire which is coloured BLUE must be connected

to the terminal which is marked with the letter N or which is

coloured BLACK. The wire which is coloured BROWN must

be connected to the terminal which is marked with the letter L

or coloured RED.

or coloured GREEN or GREEN-AND

WARNING–THIS APPARATUS

MUST BE EARTHED

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT

EXPOSE THIS UNIT TO RAIN OR MOISTURE.

The lightning flash with arrowhead symbol, within

an equilateral triangle is intended to alert the

user to the presence of uninsulated “dangerous

voltage” within the product's enclosure that may

be of sufficient magnitude to constitute a risk of

electric shock to persons.

Information for Canada

This product complies with D.O.C limits (C.R.C., C. 1374)

pertaining to class A digital apparatus.

Informations pour le Canada

Ce produit est en conformité avec les normes D.O.C (C.R.C.,

C. 1374) concernant les appareils numériques de classe A.

Information for USA

NOTE: This equipment has been tested and found to comply

with the limits for a Class A digital device,pursuant to

Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates,uses,and can radiate radio

frequency energy and,if not installed and used in accordance with the instruction manual,may cause harmful

interference to radio communications.Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Warning

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

REPRODUCTION OF LABELS

CLASSIFICATION LABEL, PLACED ON

REAR ENCLOSURE.

(Except for the U.S.A. and Canada)

CLASS 1

LASER PRODUCT

Note : Classaification Label is placed on rear panel.

IMPORTANT FOR LASER PRODUCT

1. CLASS 1 LASER PRODUCT

2. DANGER : Invisible laser radiation when open and interlock

failed or defeated. Avoid direct exposure to beam.

3. CAUTION : Do not open the top cover. There are no user serviceable parts inside the unit: leave all servicing to qualified

service personnel.

CAUTION

Do not put your hand in. The hand may be trapped and injured as a result.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Note

Place a cover on the terminal when not in use.

Static may cause a malfunction or failure of the unit.

2

Page 7

Thank you for purchasing the JVC MC-8100U CD/DVD Library

Special Features

The MC-8100U CD/DVD Library is a highly reliable and durable disc changer equipped with large capacity and high

access speed to cope with the ever-changing needs of the rapidly developing information network age. This model is

suitable for business as well as home use.

• Large capacity

Up to 100 optical discs*

modated.

1

(12 cm discs) can be accom-

• Four drive bay slots

Four drive bay slots are provided so up to 4 drives*

can be installed.

• Double-sided disc compatibility

DVD-RAM double-sided discs may also be accommodated, by adding an optional carrier*

*1

Media compatible with the library varies depending on the installed drive types. For details, refer to the instruction

3

.

manuals of the relevant drives.

*2

For the compatible optional drives, see Specifications on page 31.

*3

MC-CF10U: Optional Carrier.

CAUTION

This product does not include drives. Optional drives should be purchased and installed before using the product. After installing, adding or replacing drives, be sure to execute the automatic drive detection mode as described on page 22. Malfunctions may occur if this procedure is not performed.

ENGLISH

2

CAUTION

This equipment is supplied with an internal mechanism lock and protective materials. The lock should be opened

and the protective materials removed before use.

Be sure to perform the unlocking and removal operations in accordance with the corresponding information in

this manual. (APage 10,11,12)

CAUTION

The magazines and trays used with the MC-1000/2000 series CD-ROM Library (MC-M15U) and MC-7000 series

DVD-RAM (MC-M25U) are not compatible with those used with the MC-8000 series CD/DVD Library. Do not interchange the magazines and trays between these models, as this will damage the equipment.

CAUTION

If a media that is not compatible with any of the installed drives is used in the library, malfunctions will result. To

prevent this happening, be sure to check the instruction manuals of the optional drives in order to confirm that

the media to be accommodated is compatible with the drive.

PACKAGED ITEMS

The following table shows the items provided in the package. Always check thoroughly that all the items are present when

unpacking.

Item Qty

Main unit 1

Door opening/closing keys 2

Main unit power cord (2.5 m) 2

Clamp filters (with belt) 2

Instructions (this manual) 1

3

Page 8

CONTENTS

1. PRECAUTIONS ..................................................................................................................................................... 5

Installation and handling precautions ................................................................................................................. 5

Disc handling precautions .................................................................................................................................. 5

2. NAMES AND FUNCTIONS OF PARTS ................................................................................................................. 6

2-1. Front panel, right side panel, rear panel ........................................................................................................ 6

2-2. Interior ............................................................................................................................................................ 7

2-3. Magazine numbers, tray numbers, disc numbers .......................................................................................... 8

2-4. Internal SCSI cable ........................................................................................................................................ 8

3. SETUP ................................................................................................................................................................... 9

3-1. Opening the transport lock ........................................................................................................................... 10

3-2. Removing the transport protective materials ............................................................................................... 11

3-3. Removing the optional carrier transport lock screw ..................................................................................... 12

3-4. Installing drives and settings SCSI-ID No., etc. ........................................................................................... 12

3-5. Connecting the power cord and cables........................................................................................................13

4. CONTROL PANEL OPERATIONS AND LCD DISPLAY ..................................................................................... 14

4-1. Normal display ............................................................................................................................................. 14

4-2. Menu display ................................................................................................................................................ 14

4-3. Event display................................................................................................................................................15

4-4. Display and operation sequence ................................................................................................................. 16

5. DOOR OPENING/CLOSING ................................................................................................................................ 17

6. MAIL SLOT .......................................................................................................................................................... 18

6-1. Disc loading ................................................................................................................................................. 18

6-2. Import/export operation ............................................................................................................................... 19

7. DRIVE UNITS ....................................................................................................................................................... 21

7-1. Removing the panels ................................................................................................................................... 21

7-2. Installing the drive units ............................................................................................................................... 21

7-3. Setting the SCSI-ID numbers, etc. ............................................................................................................... 22

7-4. Connecting the cables ................................................................................................................................. 22

7-5. Installing the panels ..................................................................................................................................... 22

7-6. Automatic drive detection mode .................................................................................................................. 22

7-7. Drive type display.........................................................................................................................................22

8. SETUP OF SCSI ID NUMBER OF THE MAIN UNIT ........................................................................................... 23

8-1. Display for checking the SCSI ID numbers .................................................................................................. 23

9. MAGAZINES ........................................................................................................................................................ 24

9-1. Ejecting/loading the magazines ................................................................................................................... 24

9-2. Loading/replacing the discs ......................................................................................................................... 25

9-3. Automatic disc checking function ................................................................................................................. 26

10. ERROR CODES ................................................................................................................................................... 27

10-1. Error code explanation................................................................................................................................. 27

10-2. Error code list............................................................................................................................................... 28

10-3. How to cancel the Error "64" ........................................................................................................................ 28

10-4. Error history display .....................................................................................................................................29

10-5. Troubleshooting ........................................................................................................................................... 29

11. ACCESS COUNTS .............................................................................................................................................. 30

SPECIFICATIONS ..................................................................................................................................................... 31

4

Page 9

1. PRECAUTIONS

Installation and handling precautions

(1) Opening the transport lock

• Make sure that the transport lock is released and all transport protective materials are removed before turning on the

power. Failure to do so will result in equipment malfunction.

(2) Location of installation

• Do not install the equipment near a source of vibration such

as motor, engine or loudspeaker. They may adversely affect

the equipment performance.

• If the equipment is to have a fixed installation, we advise

you to give sufficient allowance for space so that extension

and replacement of optional units and other operations such

as replacement and maintenance can be easily performed.

For details, please consult your dealer or nearest JVC-authorized service agent.

(3) Condensation

• If the equipment which has been left in a cold room for a

long period of time and is moved to a warm room or if the

temperature of the room suddenly increases, condensation

may occur on a mobile part, optical pickup or a disc inside

the equipment with a disabling effect. If this occurs, do not

use the equipment for a few hours before starting it again.

(4) Interference with reception of other devices

• When this equipment is used near a radio receiver such as

a radio, television or BS tuner, reception of radio waves on

these devices may experience interference.

(5) Use in a strong radio wave environment

The equipment may not function properly if it is used in a

strong radio wave environment, for example near an illegal

radio station or a broadcasting station. If this happens, please

consult your dealer or nearest JVC-authorized service agent.

(6) Compatible media

Media compatible with the MC-8100U varies depending on

the drive in which it is accommodated. For details, refer to

the instruction manual of the relevant drive.

(7) Installation environment

• This equipment has been designed with consideration for

dust protection, but its structure is not dust-proof. Therefore, if it is used in an environment where cigarette smoke

and/or dust are present, the lens of the drive or a disc will

become dirty and stop functioning correctly. Using the equipment in these conditions should be avoided. If, however, you

have to use it in a dusty environment, make sure to carry

out ‘maintenance & regular inspection’ at an earlier interval.

• If the equipment is used outside of the suitable temperature

and humidity range, the drive life may become greatly shortened. Please make sure to use the equipment in an appropriate environment.

(8) Backup

• JVC cannot accept responsibility for any loss of data and/or

any other direct and indirect damage caused by the use or

malfunctioning of this equipment. We therefore strongly advise that all important data should be fully backed up in case

of unexpected loss.

• When this equipment is used with a system which runs continually for 24 hours or which cannot be turned off at all, we

recommend a redundancy design such as [a] back-up system on the system.

(9) Never take the equipment apart.

• Fire and electric shock may result. Do not try to take apart

or modify this equipment or the drive units inside.

(10) Cleaning

• Do not use solvents (paint thinner, benzene, etc.), cleaning

products containing abrasives, anti-static agent, cloth soaked

in detergent and silicon cloth. They can cause discoloration.

• Wipe-clean using a well-squeezed cloth which has been

soaked in a neutral detergent.

ENGLISH

Disc handling precautions

A disc is made of plastic material which can be easily damaged. If the discs are damaged or become dirty, it may lead to

malfunction such as incorrect data readout. To prevent this handle the discs with care so that they will stay free of damage,

stain, dust/dirt adhesion, warping, etc.

(1) Do not touch the reflective surface (data surface) of a

disc directly with your hand. Be sure to use special care

when handling double-sided discs.

(2) Use commercially available cleaning kits such as a CD

cleaner to remove dust and/or dirt from the disc surface.

• Gently wipe-clean the disc surface without scratching it.

(Make sure to wipe from the centre of the disc towards the

outer edge. Never use a circular motion.)

• Always wipe from the centre to the outer edge.

(3) Do not use chemicals for disc cleaning.

• Never use any solvents other than those included in the

cleaning kits.

• Never use analogue record cleaning fluid, benzene, alcohol

or anti-static agent.

(4) Do not damage the label surface

• Damage to the label surface also affects the data surface

immediately underneath it.

• Do not attach pieces of paper or adhesive tape to either

side of the disc.

• When you need to write on the label surface, please use a

permanent ink felt-tip pen.

Writing implements with hard tips such as ball-point pens

and pencils should not be used as they will damage the

surface.

(5) Periodical cleaning of the discs is recommended.

• Periodical disc cleaning may be required depending on the

equipment installation environment and disc handling

method.

* Always from the centre to outer edge

5

Page 10

2. NAMES AND FUNCTIONS OF PARTS

2-1. Front panel, right side panel, rear panel

POWER switch ................... Turns the main unit power on/off. "I": On. "O": Off.

1

Power indicator ................. Lights up when the POWER switch is on. Blinks in case of error during operation.

2

LCD display ....................... Shows information using alphanumeric characters.

3

MODE key .......................... Used for LCD page selection and other operations.

4

SELECT key ....................... Used for switching mode displays and other operations.

5

LOAD/EJECT key .............. Opens or close the mail slot.

6

ENTER key ......................... Used for LCD page selection and other operations.

7

10-key ................................. Used for selecting tray Nos. and changer SCSI ID Nos. for import/export operations.

8

Mail Slot ............................. Used for disc insertion/ejection.

9

Key cylinder ....................... After completing the door opening mode, insert a key in the cylinder and turn it counterclockwise.

0

Rear panel .......................... Opened and closed when installing or replacing drive units.

!

SCSI connectors ............... One SCSI-2 connector port system (A: IN, B: OUT) is provided as standard.

@

RS-232C connector ........... 9-pin D-sub connector (plug) for use in maintenance.

#

AC inlet (main unit) ........... Insert the provided power cord in the AC inlet and plug the other end to a 120 V - 240 V,

$

50 Hz/60 Hz AC power outlet.

Side panel (Drive) .............. Open and close when installing or replacing drive units.

%

Side panel (Printer) ..... To be removed when incorporating the optional MC-AP30U color disc printer.

^, &

Control panel :

2

3

the display section and the keys (

referred to as the control panel.

POWER

MODE SELECT LOAD/EJECT

5 6 7

4

1 2 3

4 5 6

7 8 9

0

ENTER

2-8

) will be

SCSI-B

8

SCSI-A

%

Front panel Right side panel Rear panel

9

@

0

^

!

#

1

6

$

&

Page 11

Names and Functions of Parts

2-2. Interior

Mail slot .............................. Used for disc insertion/ejection.

9

Mail slot transport lock ..... Locks the mail slot during transport.

*

Magazines .......................... Each magazine has 50 trays accommodating up to 50 discs.

(

Drive bays .......................... Accommodation for up to 4 drive units is compatible with this product. The bays are num-

)

Carrier ................................ Transports the trays (discs) between the magazines and the mail slot, drive units or printer.

⁄

Carrier transport lock ....... Locks the carrier during transport.

¤

Optional carrier transport lock

‹

Transport lock screw storage hole

›

(for optional carrier) .......... Attach the transport lock screw provided with the MC-CF10U Optional Carrier to this hole.

Center panel ...................... To be removed only for maintenance, etc. Do not normally remove this panel, as it provides

fi

● The system for transporting trays (discs) between the magazines and the mail slot, drive unit or printer using the carrier

is generically referred to as the "changer".

bered 1, 2, 3 and 4 from the bottom.

... To be locked before transport when the MC-CF10U Optional Carrier is installed.

hazard protection to the parts inside.

ENGLISH

(

*

9

(

Right side panel

(when the door and panels are removed)

2

1

fi

⁄

)

›

‹

¤

7

Page 12

Names and Functions of Parts

2-3. Magazine numbers, tray numbers, disc numbers

The internal layout of the magazine and the numbers assigned to the magazines, trays and discs are as shown below.

Magazine number...... This is the number assigned to each of the 2 sets of magazines. The error message displayed

when a magazine is inserted incompletely refers to the magazine number.(AP.24)

Tray number............... This is the 2-digit number assigned to each of the 50 trays in each magazine. The combination of

a tray number and magazine number corresponds to a disc number. For example, disc number

070 can also be represented as the disc in tray number 20 of magazine number 2. In this way, the

disc can be located in the 20th slot from the bottom of magazine 2.

Disc number .............. This is the 3-digit number assigned serially to every disc in all magazines and trays, starting from

disc number 001 in tray 01 of magazine 1 up to disc number 100. The error messages usually refer

to the disc numbers. (AP.27)

50

Magazine No. : 2

Tray No. : 20

41

2

40

Disc No. : 070

31

30

21

20

11

10

Tray No.

01

100

2

051

050

1

001

Magazine No.

Disc No.

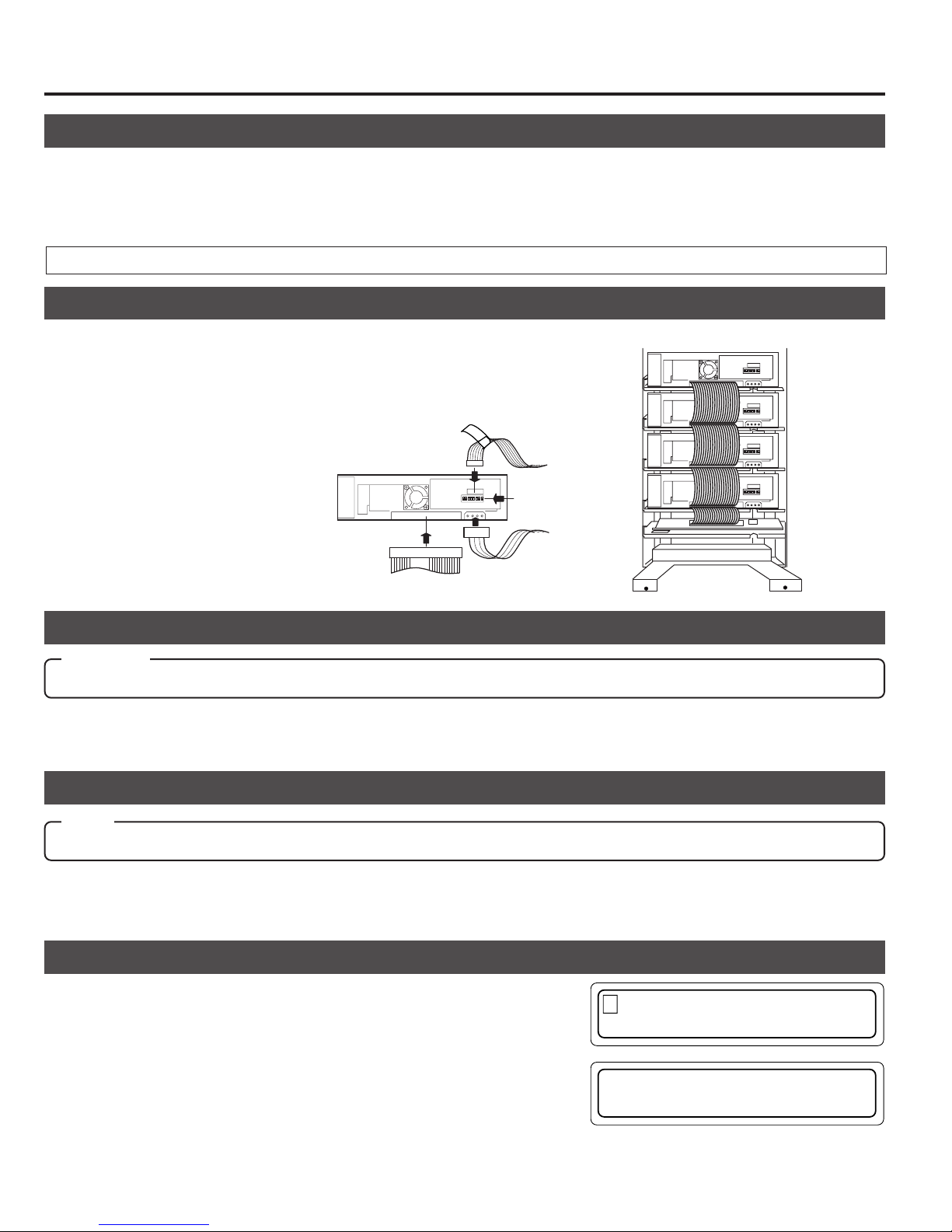

2-4. Internal SCSI cable

The SCSI connections inside the main unit (the Changer) are explained below:

The SCSI board which controls the changer and the drive units are daisy-chain (connected by the internal SCSI cable). This

cable is approximately 1.2 m (4.9 ft)long.

Interior

Drive 4

Drive 3

Drive 2

Drive 1

Changer SCSI board

● Terminate the physical end of the SCSI bus. When using the terminator provided with one of the installed drives, read

the relevant drive instruction manual before termination.

● In order to improve the communications stability via the SCSI bus, it is recommended to use an external active terminator.

Internal SCSI cable

SCSI connectors

SCSI-F (OUT)

SCSI-E (IN)

SCSI-D (OUT)

SCSI-C (IN)

SCSI-B (OUT)

SCSI-A (IN)

8

Page 13

3. SETUP

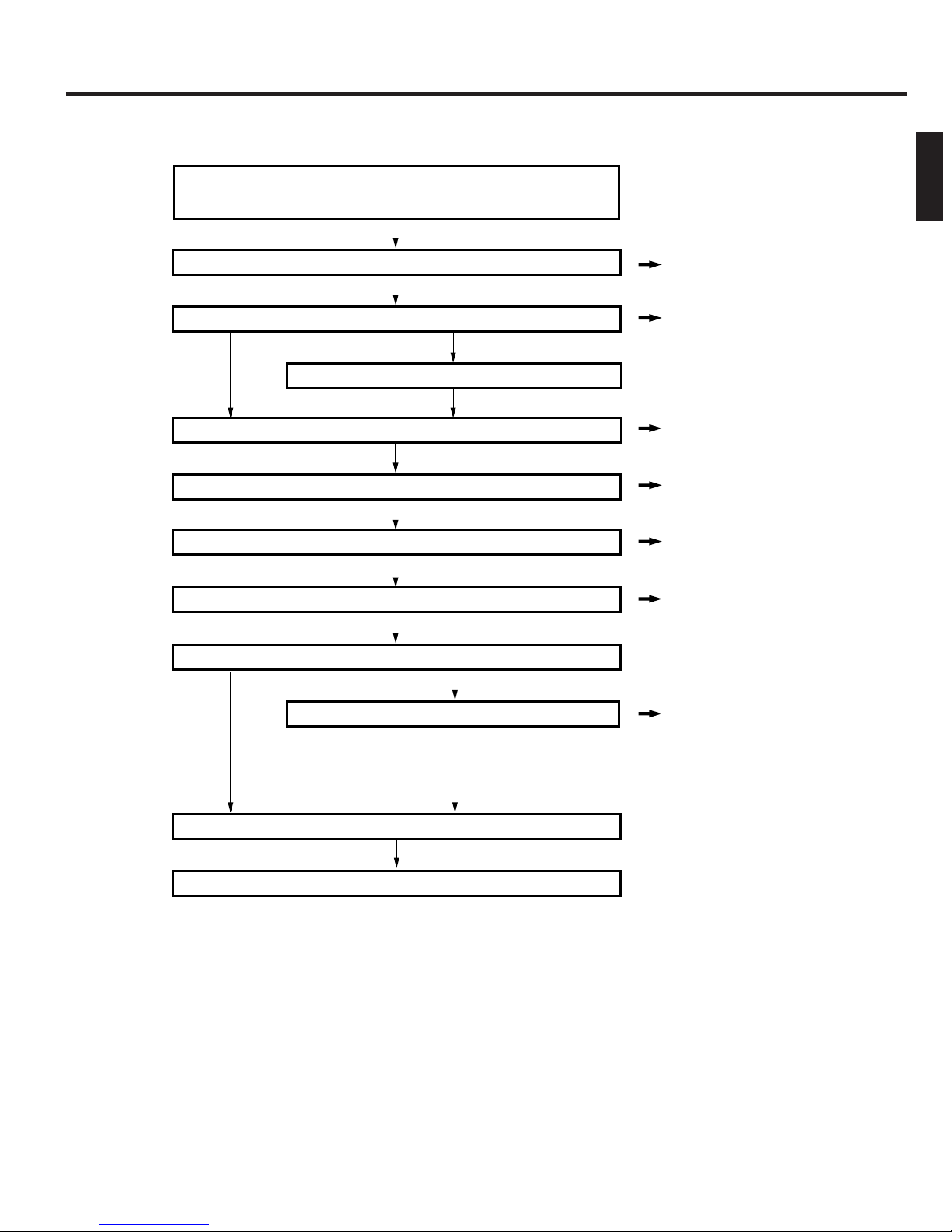

The standard setup procedure is shown below. Set up the equipment accordingly.

Start

Unpack and check that all the attachments are included.

Open the transport lock

Remove the transport protective materials (2 places.)

Mount the optional carrier *2.

Install the drive units

Initial setup of SCSI-ID No., etc.

Connect the power cord and cables

Execute the automatic drive detection mode.

ENGLISH

P.10

P.11

P.21

P.12

P.13

P.22

Load discs in the magazines *

Turn the power switch on.

Completion

Proceed to the host computer setup

1

A large number of discs can be loaded quickly(bulk load).

*

2

Please have your dealer or nearest JVC service center perform this task.

*

1

P.18, 25

9

Page 14

Setup

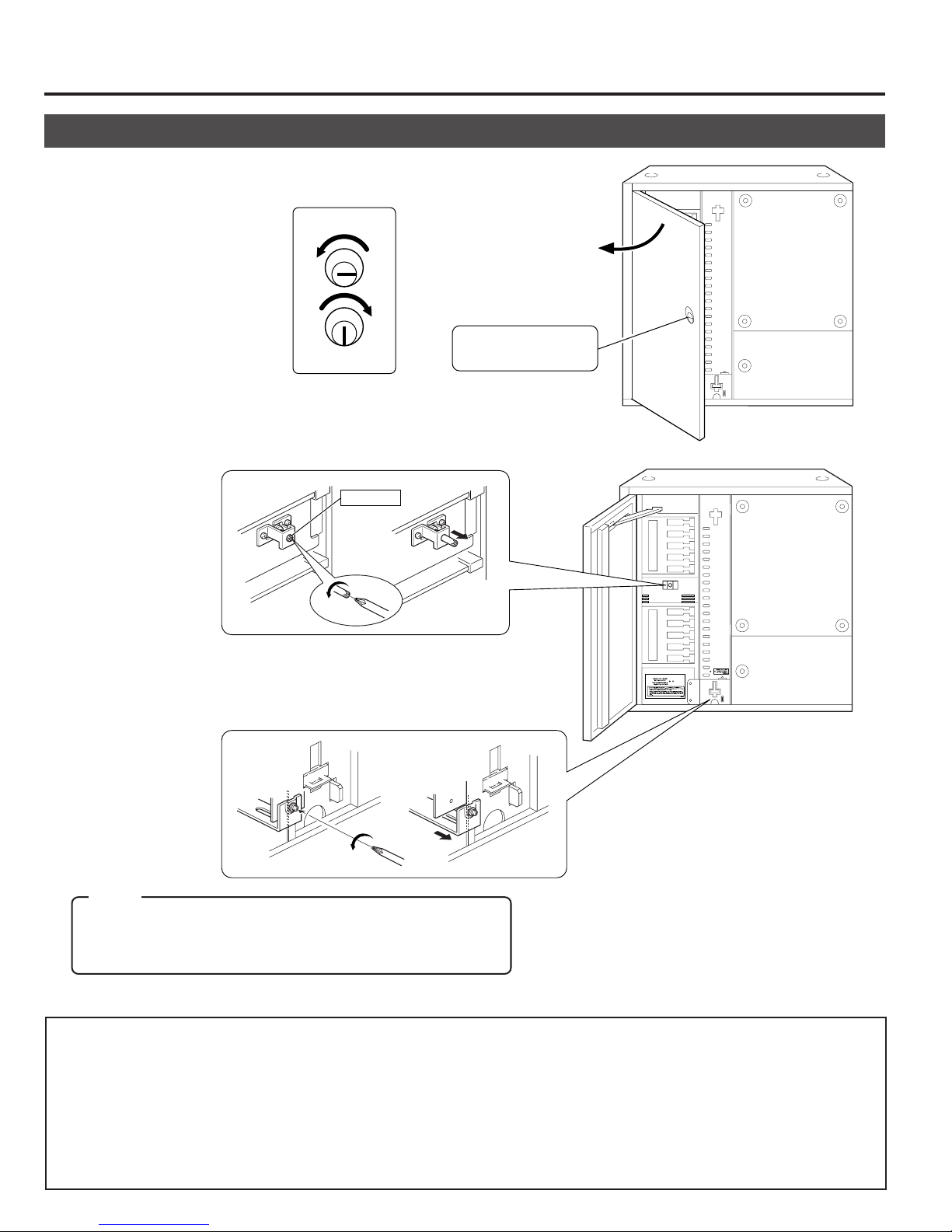

3-1. Opening the transport lock

1.

Open the door by inserting the key and turning it

counterclockwise (90°) to unlock the door.

Unlocked

Locked

2.

Open the transport lock of the mail slot.

• Using a philips screwdriver, continue to turn the lock

counterclockwise until the lock is completely disengaged and moves outwards.

Lock pin

Door opening/closing

key cylinder

3.

Unlock the transport lock of the carrier.

• Continue to turn the screw counterclockwise to loosen

it until the metal device retaining it is disengaged and

moves outwards.

Note:

When using the MC-CF10U Optional Carrier, read "3-3. Removing the optional carrier transport lock screw" on page

12 before continuing on.

Proceed to the operation in the next page without closing the door.

• In the case of re-transporting, lock the transport lock as follows:

1) Remove all the discs and turn off the power.

2) Turn on the power while pressing the “1” of the 10-key pad and enter the PACKING mode.

3) Turn off the power as soon as the “END” display appears on the LCD screen.

2

4) Fix the transport lock as described in

5) When using the MC-CF10U Optional Carrier, read "3-3. Removing the optional carrier transport lock screw" on

page 12 before continuing on.

6) Re-attach the protective transport materials. (a See page 11.)

and 3 above.

10

Page 15

3-2. Removing the transport protective materials

After opening the transport lock, proceed to the following steps without closing the door.

1.

Remove magazine No. 1.

(a See “9-1. Ejecting/loading the magazines” on page 24.)

TOP

2.

Pull out the protective material forwards.

Setup

ENGLISH

2

Protective material

3.

Load magazine No. 1.

(a See “9-1. Ejecting/loading the magazines” on page 24.)

TO

P

4.

Repeat the same operation for magazine No. 2.

• In the case of re-transporting, it is necessary to remove all the discs and re-attach the protective transport materials

using the reverse procedure to the above. When this operation is required, please consult your dealer or nearest JVCauthorized service agent.

• Although the MC-8100U is compatible with the optional MC-AP30U color disc Printer, it should be removed from the

system before transporting it. Otherwise, the printer and its outer panel may get damaged during transport.

11

Page 16

Setup

3-3. Removing the optional carrier transport lock screw

When the MC-CF10U is installed, its special transport lock should be removed in addition to its being unlocked as detailed in "3-

1. Opening the transport lock" on page 10. Use the following procedure when unlocking the optional carrier transport lock.

1.

Remove the transport lock screw

(for optional carrier).

2.

Insert the removed screw into

the designated storage hole for

the transport lock screw.

• If the system is transported with the MC-CF10U Optional Carrier installed, refer to "3-1. Opening the transport lock",

execute the packing mode and clamp the above-mentioned transport lock screw.

3-4. Installing drives and settings SCSI-ID No., etc.

1.

Installing drives

Install the drives ( a See "7. DRIVE UNITS" on page 21).

2.

Initial setting of SCSI-ID No., etc.

The default setting of the SCSI-ID No. of the MC-8100U is "0".

Set the SCSI-ID No. according to your system.

• To change the SCSI-ID No. of the MC-8100Ua Read "8. SETUP OF SCSI ID NUMBER OF THE MAIN UNIT" on

page 23.

• To set the SCSI-ID Nos. and termination of drives a Read the instruction manuals of the installed drives.

• As the MC-8100U should be turned on to allow its SCSI-ID No. to be set, read "3-5. Connecting the power cord and

cables" on page 13 and connect the power cord before proceeding.

• When using an external active terminator, set the termination settings of the installed drives to OFF.

12

Page 17

3-5. Connecting the power cord and cables

CAUTION

Turn OFF the power of all equipment before starting connections.

Connecting the equipment while power is ON may lead to a malfunction.

To SCSI-A

Attach the provided clamp filters.

To AC IN

Setup

ENGLISH

To SCSI port of

host computer

To AC outlet

Always use the power cord provided by JVC. The library system has been designed to conform to

WARNING

“Insulation category Class 1”. In order to assure safety at all times, be sure to ground the system

before use. If other types of power cords other than the specified cord are used, they may overheat and

burn or cause a fire.

Attaching the clamp filters

Tighten until the tabs are

locked completely.

Attach a clamp filter to the end of the cable.

Pull strongly.

Pull hard

Push the clamp filter against the connector

and secure it by using the provided strap.

Cut any

surplus part.

• The allowable length for the SCSI cable inside the equipment is about 1.2 meters. In the case of SCSI-2 10

Mbytes/sec. sync operation, if the total length of the SCSI cabling including those cables outside the equipment

exceeds 3 meters, a malfunction may result. However, if the SCSI-2 5 Mbytes/sec. async mode is used the total

length of the SCSI cabling should be no more than 6 meters.

• Use a shielded SCSI cable with high-impedance specifications and be sure to attach the provided clamp filter to

the cable. Using other type of cable or using a cable without a clamp filter may cause radio wave interference and

a malfunction.

13

Page 18

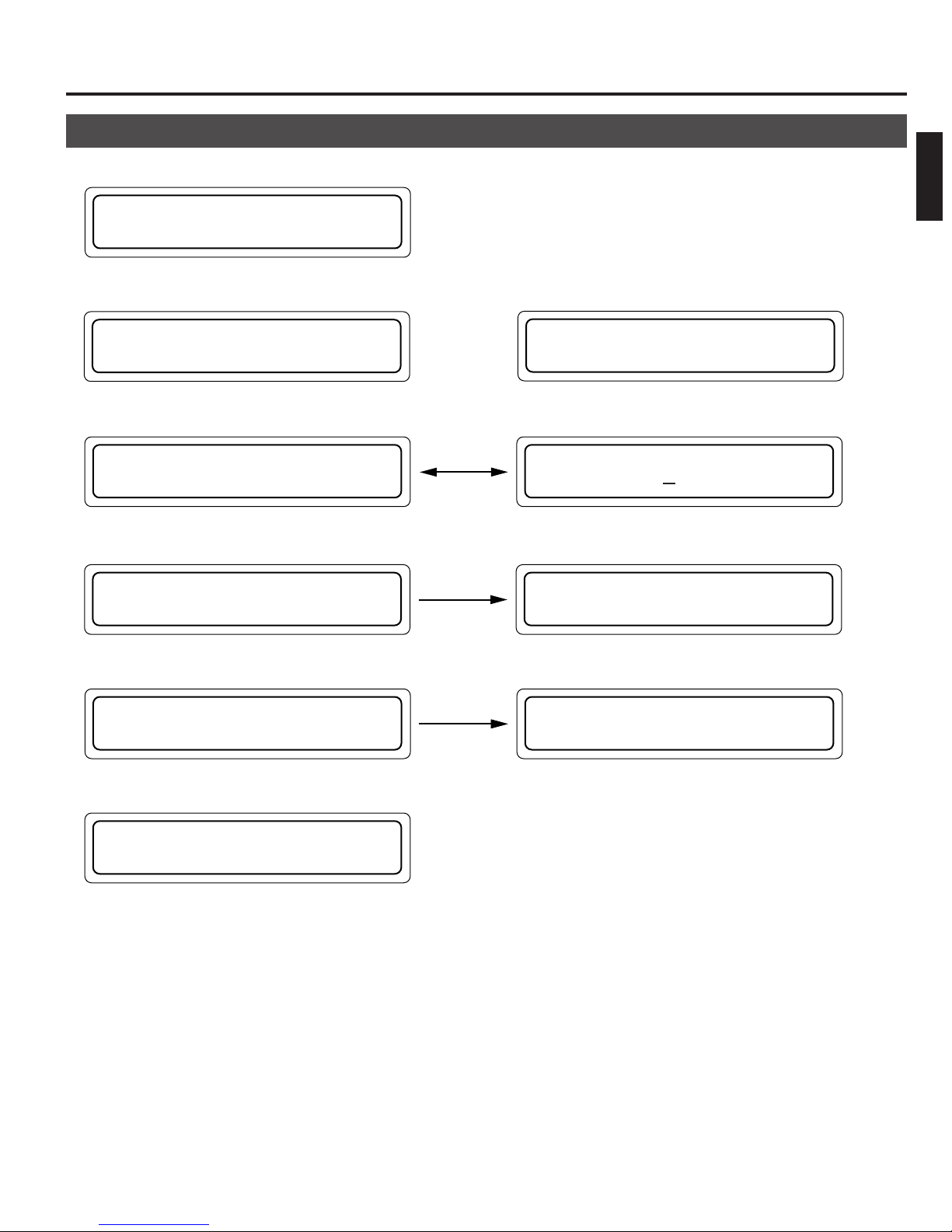

4.

CONTROL PANEL OPERATIONS AND LCD DISPLAY

The key operation and LCD display system has three main operation and display modes as described below.

Normal display ..... This mode includes two patterns, one of which is displayed automatically when the equipment starts

up normally. The disc numbers in the drive units are displayed in real time.

Menu display ........ This mode allows you to start user operations such as SCSI ID No. checking and setting, internal

history display, access count display, disc loading by the library only, door opening, etc.

Event display ........ This mode overrides other modes in case of an event such as initialization after startup, mail slot

operations, setting up the door/panel opening mode or appearance of errors.

4-1. Normal display

Pattern 1 is displayed automatically when the startup has succeeded normally. The display changes every time the SELECT

key is pressed.

[Pattern 1]

Carrier

Idle Mail slot

CR : – – – MS : – – –

D1 : 0 3 6 D2 : 0 7 5

Drive 1

Disc No.

SELECT

[Pattern 2]

D3 : NC D4 : NC

Drive 3

Drive 4

4-2. Menu display

Pressing the MODE key during normal display starts the menu display.

Select a menu by pressing the SELECT key and enter the selection by pressing the ENTER key.

NORMAL DISPLAY

1

(a See "4-1. Normal display" on this page.)

ERROR DISPLAY

2

(a See "10-4. Error history display" on page 29.)

ID No. DISPLAY

3

(a See "8-1. Display for checking the SCSI ID numbers" on page

23.)

PANEL OPEN

4

(a See the instruction manual of the optional MC-AP30U Color

Disc Printer.)

DOOR OPEN MODE

5

(a See "5. Door Opening/Closing" on page 17.)

ID No. SET MODE

6

(a See "8. Setup of SCSI ID number of the main unit" on page

23.)

COUNT DISPLAY

7

(a See "11. Access counts" on page 30.)

IMPORT/EXPORT

8

(a See "6-2. Import/export operation" on page 19.)

DRIVE DISPLAY

9

(a See "7.7. Drive type display" on page 22.)

PRINTER MODE

0

(a Display only when the optional MC-AP30U Color Disc Printer

is installed.)

14

Cursor: Currently selected menu

1 . NORMAL D I SP L AY

2.ERROR DISPLAY

.ERROR DISPLAY

2

3. ID No.DISPLAY

9

.DRIVE DISPLAY

1 . NORMAL DI SPLAY

Drive 2

SELECT

Unconnected

SELECT

SELECT

Page 19

4-3. Event display

Power on

1

POWER ON

Control Panel Operations and LCD Display

ENGLISH

During initialization

2

When the MC-CF10U Optional Carrier is installed

INITIALIZING

Error occurrence (a See “10-2. Error code list” on page 28.)

3

Displayed

E

RROR OCCURRED !

During door opening (a See “5. Door Opening/Closing” on page 17.)

4

alternately.

E X ECUT I NG DOOR

OPEN PROCESS

When door is open (a See “5. Door Opening/Closing” on page 17.)

5

D OOR OR PAN E L

Door closing

IS OPEN

INITIALIZING

FL I P CARR I ER

D ISC=024

CODE =CU

04

THE DOOR

CAN BE OPENED

P USH ENTER KEY

TO RESUME

During mail slot operation (a See “6. Mail Slot” on page 18.)

6

E XPORT DONE

PUSH LOAD KEY

15

Page 20

Control Panel Operations and LCD Display

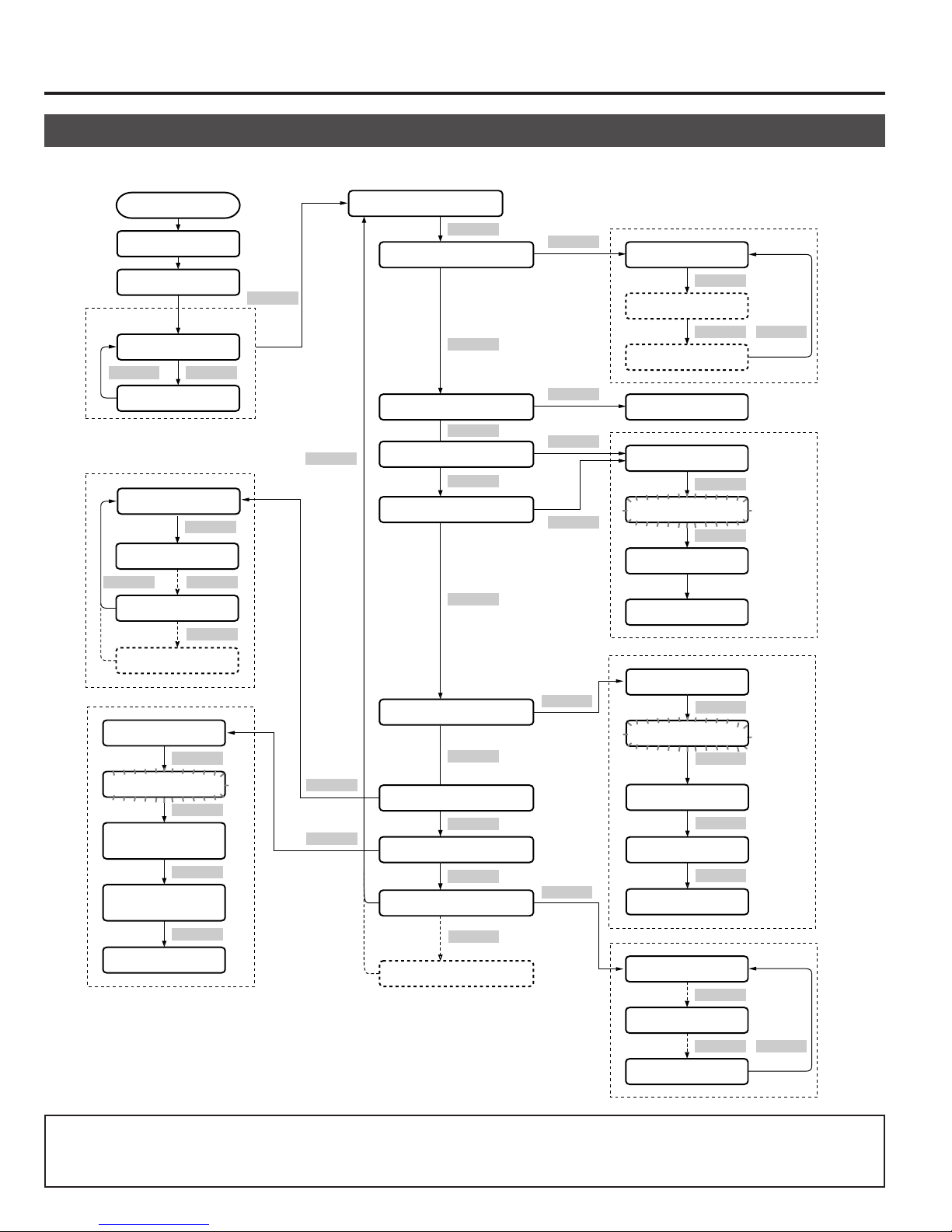

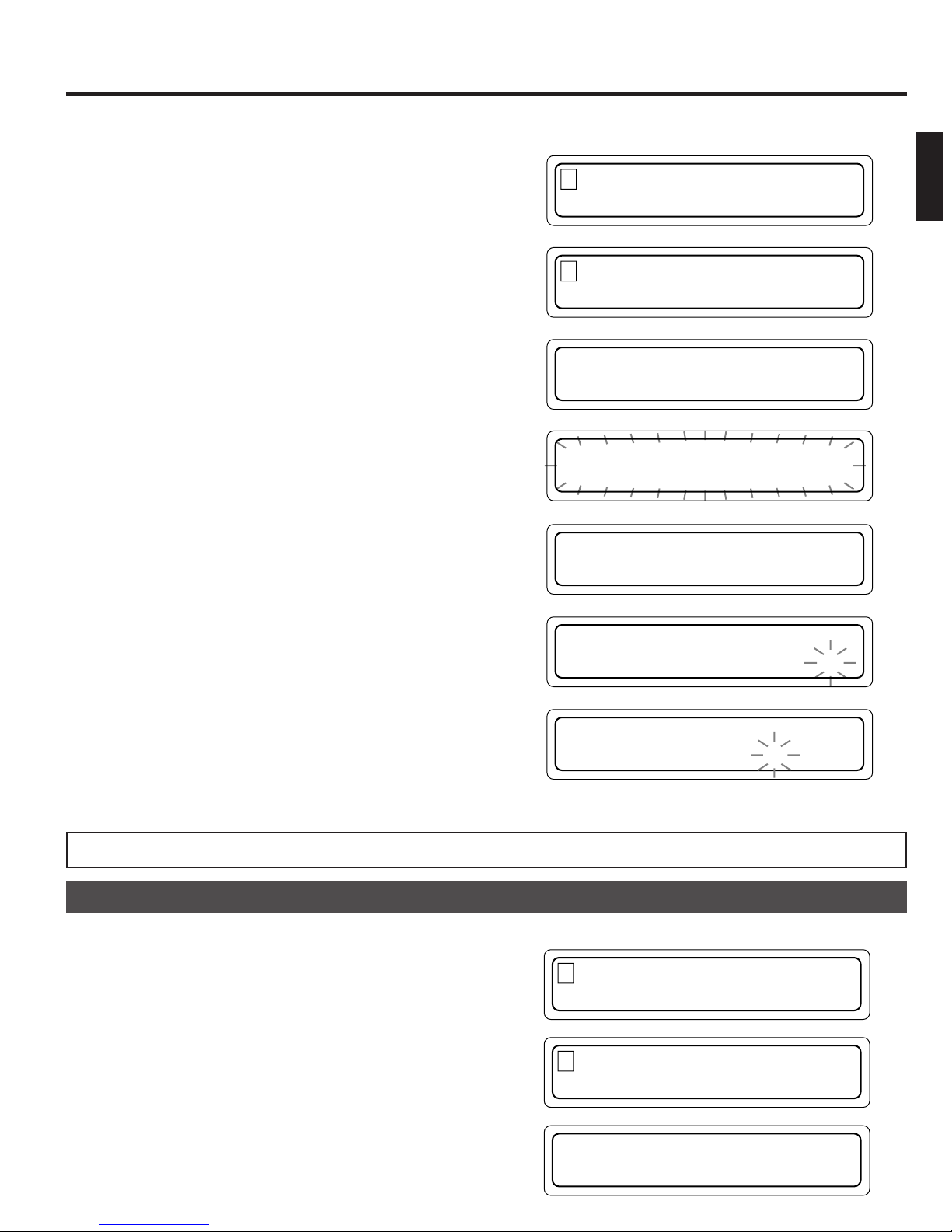

4-4. Display and operation sequence

The sequence of display and operation after turning the power on is as shown below.

Power On

POWER ON

INITIALIZING

Normal display

Pattern 1

SELECT SELECT

Pattern 2

1. TOTAL

2. CR

SELECT

7. DR4

1

*

8. FL

PUSH SEL. KEY

PUSH SEL. KEY

Input the start

tray No.

Input the end

tray No.

Start accessing

SELECT

SELECT

SELECT

SELECT

SELECT

ENTER

ENTER

MODE

SELECT

ENTER

ENTER

1. NORMAL DISPLAY

SELECT

2. ERROR DISPLAY

SELECT

3. ID No. DISPLAY

SELECT

4. PANEL OPEN MODE

SELECT

5. DOOR OPEN MODE

SELECT

6. ID No. SET MODE

SELECT

7. COUNT DISPLAY

SELECT

8. IMPORT/EXPORT

SELECT

9. DRIVE DISPLAY

SELECT

2

*

10. PRINTER MODE

*1. When the MC-CF10U Optional

Carrier is installed.

*2. When the optional MC-AP30U

Color Disc Printer is installed.

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Error display 1

SELECT

Error display 2

SELECT SELECT

Error display 8

SCSI-ID display

PUSH SELECT

SELECT

PUSH SELECT

SELECT

EXECUTING ...

... CAN BE OPENED

PUSH SELECT

SELECT

PUSH SELECT

SELECT

ID No. display

SELECT

Input ID No.

ENTER

ID No. entry

DR1 :

SELECT

DR2 :

SELECT SELECT

• If the MODE, SELECT or ENTER key has not been pressed within 10 seconds, the current display will return to “Normal

display - Pattern 1” (except in a situation when an event is displayed or the Import/Export Tray numbers and SCSI-ID

numbers are being input).

16

DR4 :

Page 21

5. DOOR OPENING/CLOSING

The door is closed.

The door is open.

P USH ENTER KEY

TO RESUME

D

OOR OR PANEL

I S OPENED

Once the transport locks have been opened and the power has been turned on for the first time (the optional MC-AP30U label

printer may also have been incorporated), the door is locked by the internal safety locking system in addition to locking by the

door opening/closing key, so that the door cannot be opened by the key alone.

To open the door under these conditions, keep the power on, or turn it on if it had been off, and then perform the following

operations before using the door opening/closing key.

ENGLISH

Door Opening

1.

In the normal display mode, press the MODE key.

(The menu display appears.)

2.

Press the SELECT key 4 times.

("5. DOOR OPEN MODE" appears.)

3.

Press the ENTER key.

(Select "5. DOOR OPEN MODE".)

4.

Press and hold the SELECT key for more than 5 seconds.

(Wait until the display starts to blink.)

5.

Release the SELECT key when the execution display

appears.

*When installing/removing drive units, turn off the power

after the completion display (THE DOOR CAN BE

OPENED) appears.

6.

Insert the door key in the cylinder and turn it

counterclockwise to release the lock and open the door.

1 . NORMAL D I SP L AY

2.ERROR DISPLAY

5

.DOOR OPEN MODE

6 . I D No . SET MODE

P

USH SELECT KEY

TO OPEN THE DOOR

P

USH SELECT KEY

TO OPEN THE DOOR

E

XECUT I NG DOOR

OPEN PROCESS

T

HE DOOR

CAN BE OPENED

Unlocked

Door opening/closing

key cylinder

Locked

Door Closing

1.

Close the door and lock it by turning the door key clockwise.

2.

Press the ENTER key when the display on the right

appears.

• The normal display returns after initialization.

• You cannot perform disc transport operations when the above door opening mode is being executed or the door is open.

17

Page 22

6. MAIL SLOT

Label surface

(With a single-sided disc)

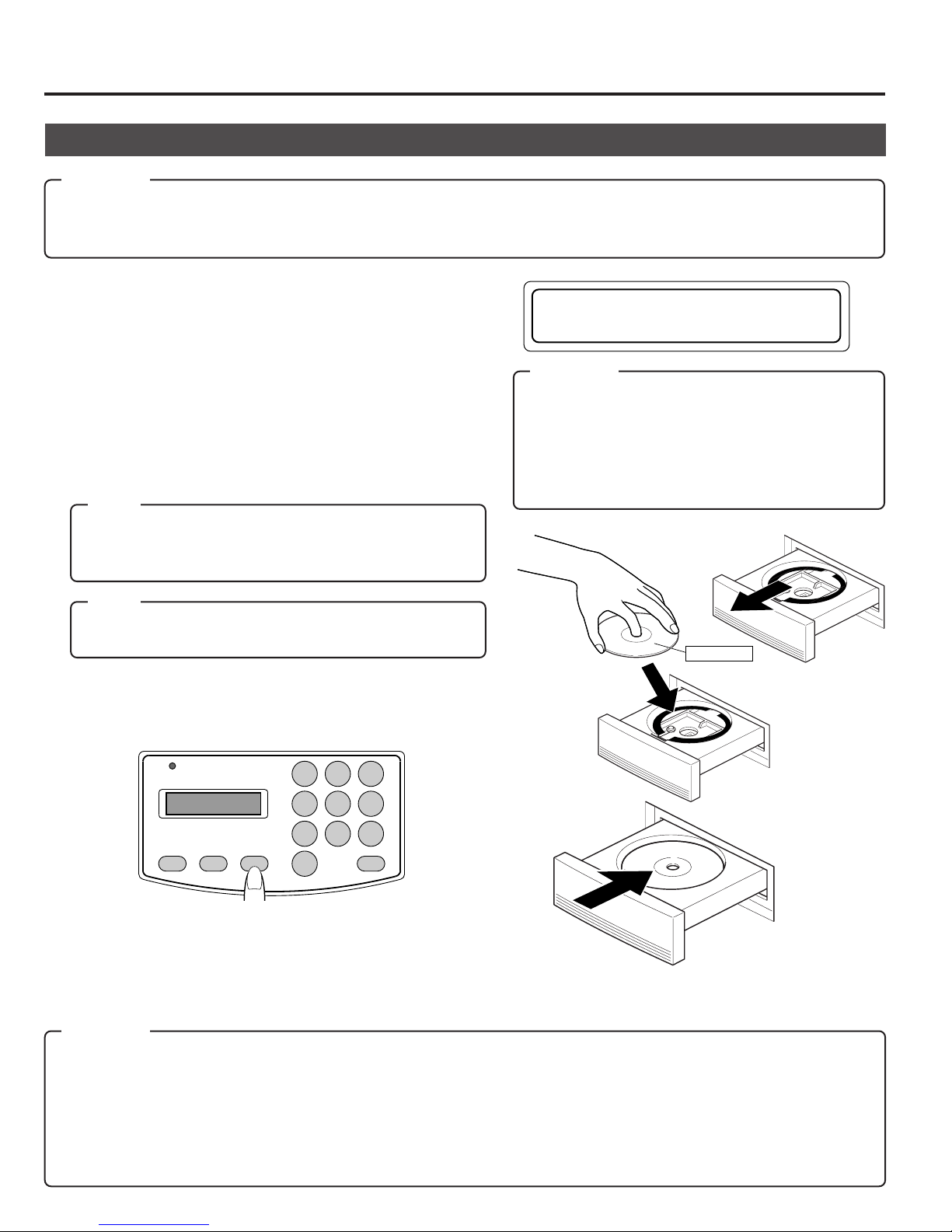

6-1. Disc loading

CAUTION

Do not load or eject a disc before the mail slot has stopped completely.

It may not only damage the disc but also cause the equipment to malfunction because of excessive force being applied

during opening and closing.

Disc loading/ejection method

When a tray is transported to the mail slot under the control of

the host computer or the import/export operation

(a see page 19), the mail slot opens automatically when the

transportation has been completed.

1.

Place a disc gently on the tray with a label surface facing upwards.

(To remove a disc from the tray, hold the disc by the center

hole and the outer edge which is accessible near the notched

section on the front side of the tray.)

Note:

Media compatible with the MC-8100U varies depending on

the installed drive type. For details, refer to the instruction

manuals of the drives.

E XPORT DONE

PUSH LOAD KEY

CAUTION

• A disc may become impossible to write/read due

to dust, fingerprints, scratches, etc. adhering to the

disc surface. Please handle it carefully.

Take special care in handling the DVD-RAM discs

because they are extremely vulnerable to scratches

and contamination.

Note:

When using double-sided discs, handle them with special

care because they do not have a label on the surface.

2.

Press the LOAD/EJECT key.

(The mail slot closes.)

POWER

MODE SELECT LOAD/EJECT

1 2 3

4 5 6

7 8 9

0

ENTER

• Now you can repeat the open/close operations alternately

by pressing the LOAD/EJECT key provided that the mail slot

transportation operation has not started yet.

• While the carrier is in operation, pressing the LOAD/EJECT

key will not start the open/close operations.

CAUTION

• Never use a damaged and/or warped disc or a disc with an attached label. It will lead to a malfunction of the equipment.

• If you are going to use a disc from a different drive, please check the drive specifications carefully before using it.

(Some drives may not be able to read the disc.)

(At the same time, the equipment may not be able to read the disc which has been written and deleted in a different drive.)

• Note that some double-sided discs do not provide a distinction between the top and bottom sides. Take special care

when removing/loading these discs from/in the MC-8100U.

18

Page 23

6-2. Import/export operation

1 .NORMAL DISPLAY

2 . ERROR D I SPLAY

8

. I MPORT / EXPORT

9.DRIVE D ISPLAY

P

USH SEL . KEY FOR

IMPORT/EXPORT

I

NPUT START

TRAY No . : –––

I

NPUT START

TRAY N0o. : 15

I

NPUT END

TRAY No . : –––

I

NPUT END

TRAY N 0o. : 24

IMP ORT / EXPORT

TRAY No . : 015

P

USH SEL . KEY FOR

IMPORT/EXPORT

Mail Slot

When loading/ejecting discs from any chosen tray by the mail slot without the control of the host computer, follow the procedure shown below.

• During the import/export operation, the host computer commands which include the carrier operations cannnot be executed.

1.

In the normal display mode, press the MODE key.

(The menu display appears.)

2.

Press the SELECT key 7 times.

("8. IMPORT/EXPORT" appears.)

3.

Press the ENTER key.

(Select "8. IMPORT/EXPORT".)

4.

Press and hold the SELECT key for more than 5 seconds.

(Wait until the display starts to blink.)

ENGLISH

5.

Release the SELECT key when the input start tray

message is prompted.

6.

Enter the start tray number(001-100) using the 10-key

pad.

•If the number is wrong, input a new 3-digit tray No.(ex.

001) again.

7.

Press the ENTER key.

8.

Enter the end tray number(001-100) using the 10-key

pad.

•If you wish to use the import/export operation for single disc, either enter the same end tray number as the

start tray number or press the ENTER key without

entering any number.

9.

Press the ENTER key.

•You can cancel the following operations by pressing

and holding the ENTER key for 5 seconds during the

import/export operation. If the mail slot opens after

cancelling the operation, press the LOAD/EJECT

key.(The tray in operation will be returned to the magazine; then the import/export operation will be completed.)

19

Page 24

Mail Slot

10.

When the mail slot automatically opens, place the desired disc on the tray (number is displayed on the LCD).

(a See "6-1. Disc loading" on page 18.)

•To remove a disc, lift it out of the tray.

•When the following message appears on the LCD display, it is possible that the transport lock of the mail slot has not

been properly released. Please make sure that that lock pin has been removed completely. (a See "3-1. Opening the

transport lock" on page 10.)

CHECK THE LOCK

PIN!

Press the MODE key to return to the menu display.

11.

Press the LOAD/EJECT key. (The mail slot closes and the tray is returned to the magazine.)

12.

When continuous import/export operations are required, repeat steps 10 and 11.

(The tray number on the LCD display count will increment by one.)

•If the tray cannot be found in the magazine (including instances when the tray is in a drive or the color disc printer), this

tray No. will automatically show up on the LCD display and then the import/export operation will be completed.

NO T RAY

TRAY No. : 015

Press the MODE key to return to the menu display.

In the following instances, the import/export operation cannot be performed and the LCD display will indicate as shown

on the right.

Clear the following conditions on the host computer side first and

then input again.

• When a tray is in the mail slot.

• When the carrier operation is being executed.

• When the host computer control is prohibiting import/export

operations.

• If the disc positioning in the main unit (the changer) has been altered or the contents of a disc have changed bacause

of import/export operations, the disc positioning data on the host computer should, as a rule, be renewed.

(hardware and software must stay in sync to ensure proper system operation.)

IMPORT / EXPORT

I S PROH I B I T ED

20

Page 25

7. DRIVE UNITS

CAUTION

• Make sure that the power is turned off when installing/removing, connecting or setting any drive.

Performing these operations while the power is on will result in the equipment malfunctioning.

Be sure to read the instruction manuals of the drive units before proceeding to any of the following work.

• Note that certain device drivers are incompatible with the simultaneous use of more than one type of drive (mixed use).

Please consult your dealer or nearest JVC service center.

7-1. Removing the panels

1.

Open the door.

(a See "5. Door opening/closing" on page 17.)

Rear panel

2.

Turn off the power.

3.

Remove the rear panel.

• Remove the 6 screws.

• Carefully disconnect the SCSI cable from the drive.

(a See "7-4. Connecting the cables" on page 22.)

ENGLISH

4.

Remove the side panel.

• Remove the 4 screws.

Side panel

7-2. Installing the drive units

• When removing the drive units, be sure to disconnect the control cable and power cable beforehand.

(a See "7-4. Connecting the cables" on page 22.)

1.

Inserting a drive unit.

• Always insert it into a bay with the lowest available

bay No.(from bottom to top)

• Be careful not to snag any cables.

• Be careful not to damage the sensor slit.

2.

Secure the drive unit using the provided metric screws.

• The provided metric screws are attached to the optional drive unit.

* Be careful not

to damage the

sensor slit.

Sensor slit

CAUTION

Be sure to attach the screws securely. If the library system is operated without the screws, either the library or

the drives may be damaged.

21

Page 26

Drive Units

Internal SCSI cable(approx. 1.2 m)

Changer SCSI

board

Drive No. 4

4

Drive No. 3

3

Drive No. 2

2

Drive No. 1

1

9 .DRIVE DISPLAY

1 .NORMAL D I SPLAY

D R1 : DVD– RAM

DR2 : ROM / e t cR

7-3. Setting the SCSI ID numbers, etc.

s Procedure for the setting the SCSI ID Nos. and other jumpers, please refer to the specified section(s) of the corresponding

drive instruction manuals.

s Make sure to turn the power OFF before starting with the setting procedure. If the procedure is carried out with the power

ON, it will cause malfunction.

s The new ID Nos. will become effective from the moment the power is turned on.

s The new SCSI ID Nos. should not conflict with the ID Nos. of other SCSI equipment on the same SCSI bus.

7-4. Connecting the cables

Please refer to a relevant section of an optional drive unit's instruction manual for

the correct connector positions of the cables.

1.

Connect the control cable (14P).

• Connect the cable with the corresponding number to the drive bay No. If the

cable with the wrong number is connected, it will lead to the equipment malfunctioning.

2.

Connect the power cable (4P).(The figure shows the case with the MC-R200U.)

3.

Connect the SCSI cable

3

SCSI cable

1

1

2

Control cable

14p

Drive jumber settings

4p

Power cable

7-5. Installing the panels

CAUTION

Check the installation screws and cables before installing the panel. Insufficient connections may cause malfunctions.

s

1.

Attach rear and side panels.

• Screw the panels on, following the procedure in "7-1

Removing the panel" on page 21 in the reverse order.

7-6. Automatic drive detection mode

Note:

After installing, adding, exchanging or removing drives, be sure to execute the auto drive detection mode to prevent any malfunction.

1.

While holding key "8" on the control panel, turn on the

MC-8100U.

7-7. Drive type display

The types of the installed drives can be confirmed by the display.

1.

Press the MODE key while the LCD display is in normal display mode

(to display Menu display).

2.

Press the SELECT key 8 times (to display "9. DRIVE DISPLAY").

3.

Press the ENTER key (to select "9. DRIVE DISPLAY").

4.

The type of the drive in each drive bay will be displayed. (Each press of

the SELECT key displays the information on the next drive.)

Meaning of the display

"DVD-RAM" : DVD-RAM drive "ROM/R etc" :Non DVD-RAM drive (CD-ROM/R, DVD-ROM, etc.)

"NO DRIVE" : Drive is not connected or installed "UNKNOWN" : When drive detection mode has not been executed.

● If the automatic drive detection mode has not been executed, the LCD displays “UNKNOWN DRIVE DETECTED”.

22

2.

Close the door

(a See "5. Door Opening/Closing" on page 17.)

2.

When the LCD display shows "DRIVE DETECTION

COMPLETED", turn off the power of the MC-8100U.

3.

Turn the MC-8100U on again.

Page 27

8. SETUP OF SCSI ID NUMBER OF THE MAIN UNIT

The SCSI ID No. set for the main unit (changer) can be modified as described below.

1.

In the normal display mode, press the MODE key.

(The menu display appears.)

2.

Press the SELECT key 5 times.

("6. ID No. SET MODE” appears.)

3.

Press the ENTER key.

(Select “6. ID No. SET MODE".)

4.

Press and hold the SELECT key for more than 5 seconds.

(Wait until the display starts to blink.)

1 . NORMAL D I SPL A Y

2 . ERROR D I SPLAY

.IDNo.SETMODE

6

7 . COUNT D I SP L AY

USH SELECT KEY

P

TO CHANGE I D No .

P

USH SELECT KEY

TO CHANGE I D No .

ENGLISH

5.

Release the SELECT key when the current ID No. ap-

C

pears.

HANGER

SCS I I D No . =0

6.

Select a new ID No. using the keys 0 to 7.

HANGER

7.

Press the ENTER key. (The ID No. being displayed is

entered.)

• The set ID No. becomes effective from the next time

power is turned on.

C

SCS I I D No .=3.

C HANGER I D No .

IS SET TO 3

• The new SCSI ID No. should not conflict with the ID Nos. of other SCSI devices existing on the same SCSI bus.

8-1. Display for checking the SCSI ID numbers

The SCSI ID Nos. set for the main unit (changer) and installed drive units can be checked as described below.

1.

In the normal display mode, press the MODE key.

(The menu display appears.)

1 . NORMAL D I SPL A Y

2 . ERROR D I SPL AY

2.

Press the SELECT key twice.

("3. ID No. DISPLAY” appears.)

3.

Press the ENTER key.

(Select “3. ID No. DISPLAY".)

The following information is displayed.

CH: Changer

DR1 to 4: Drives 1 to 4 ("-” indicates “Not Connected".)

. ID No . D I SPLAY

3

4 . PANEL OPEN MODE

C

HDR1234

012––

23

Page 28

9. MAGAZINES

CAUTION

• Do not use a magazine which has been damaged (e.g. dropped), as normal operation cannot be accomplished with

such a magazine. In addition, the use of such a magazine may damage the internal mechanism.

• The magazines and trays used with the MC-1000/2000 series CD-ROM Library (MC-M15U) are not compatible with those

used with the MC-8000 series CD/DVD Library. Do not interchange the magazines and trays between these models, as this

will damage the equipment.

• If it is required to take out or attach a magazine during operation, be sure to perform optimum software processing at the host

in advance.

9-1. Ejecting/loading the magazines

Ejection

1.

Open the door. (a See “5. Door Opening/Closing” on page 17.)

*

Do not turn off the power switch.

2.

Pull the release lever toward the front.

• The magazine unlocks and comes out slightly toward the

front. Be careful not to get your finger caught between

the release lever and grip.

3.

Pull the magazine straight toward the front.

• Use care not to hit or drop the magazine.

• Be careful not to touch the tray lock by mistake.

A tray may spring out.

Release lever

2

3

Grip

Loading

1.

Check the orientation of the magazine.

• The [c TOP] marking is provided on the grip to indicate the

upper direction of the magazine.

2.

Align the magazine rails with the guide on the main unit

(changer) and insert it straight forward.

•

Insert the magazine slowly. Inserting it with a strong force

may damage the equipment.

•

Ensure that the magazine guides are fitted in the guides

located at the left side of the library (both at the top and

bottom of the sides).

3.

Push in the magazine completely until it stops.

•

Then, pull the magazines slightly toward the front to ensure that it is locked.

4.

Close the door (See "5. Door Opening/Closing" on page 17.)

* If a magazine was removed and installed and the door closed

after the power has been turned on, this function will automatically check the disc status inside the magazine.(provided that

the automatic disc checking function has been turned ON AP.26).

TOP

Tray lock

The magazine guides are fitted

in the guides located at the left

side of the library

TOP

Display in case of incomplete insertion

The front panel display will indicate an error if the door is closed while the magazine insertion is incomplete. Check the

incorrectly inserted magazines from the displayed message and re-insert them completely until they are locked.

E RROR OCCURRED !

DISC=–––

CODE = CC– 31

24

RORMAGAZINE

E

R

No . : – 2

Display when the insertion of magazine

No. 2 is unsatisfactory

Page 29

Magazines

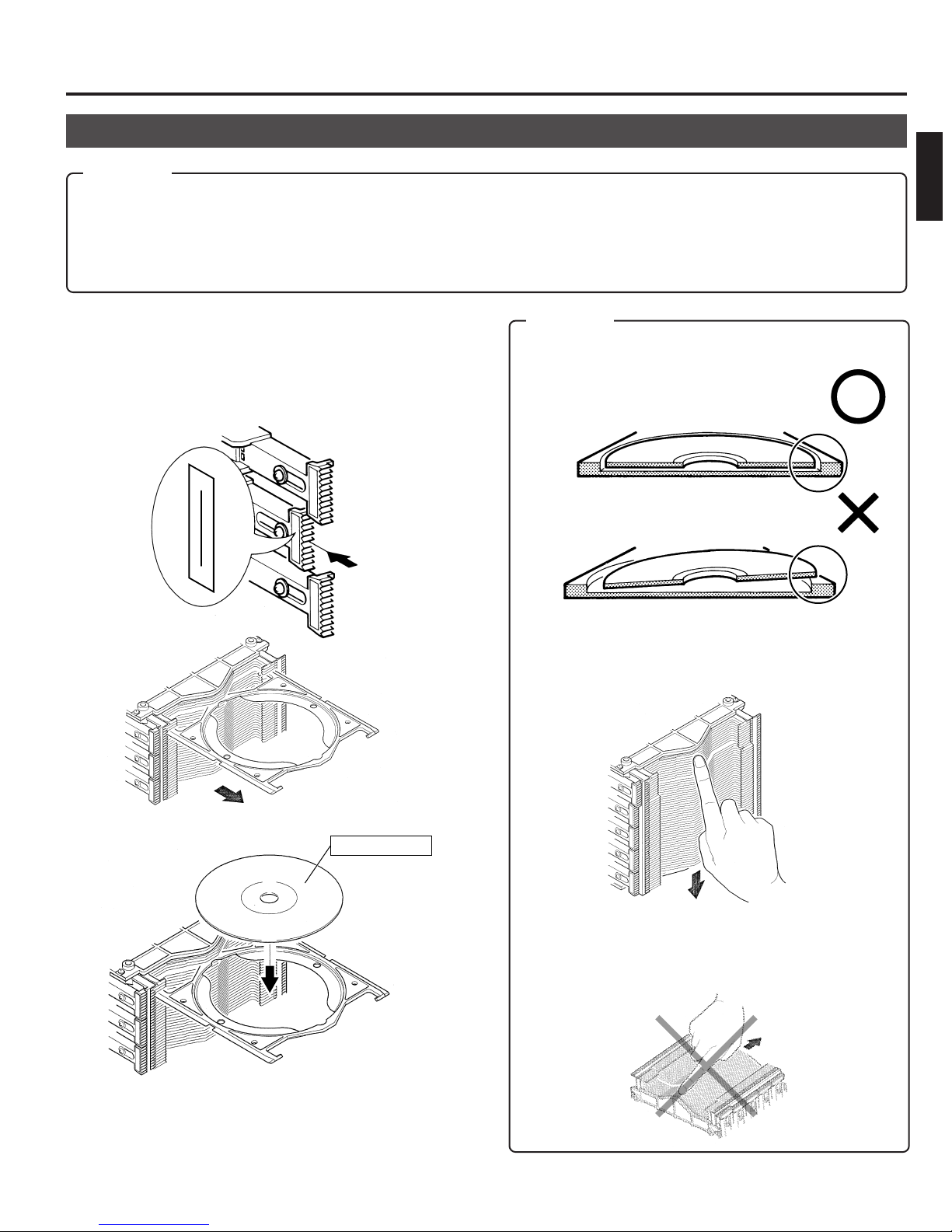

9-2. Loading/replacing the discs

CAUTION

• When loading discs directly into the magazine trays without using the mail slot, be careful not to damage the magazines

and trays.

• A disc may become impossible to write/read due to dust, fingerprints, scratches, etc. adhering to the disc surface. Please

handle it carefully.

• Take special care in handling the DVD-RAM discs because they are extremely vulnerable to scratches and contamination.

ENGLISH

1.

Eject a magazine. (a See “9-1. Ejecting/loading the

magazines” on page 24.)

2.

Unlock the tray lock corresponding to the tray to be used.

(a See “2-3. Magazine numbers, tray numbers, disc

numbers” on page 8.)

30

21

3.

Pull out the tray.

CAUTION

(1) Place the disc correctly on the disc tray so that it does

stay in the guide section of the disc tray.

(2) To prevent projection of a tray or incomplete locking

of the tray lock, align the edges of all the trays in the

magazine by slightly pushing them inward from.

4.

Place the disc on the tray.

5.

Push in the tray and lock the tray lock.

6.

Load the magazine in the changer. (a See “9-1. Ejecting/loading the magazines” on page 24.)

Label surface

(With a single-sided disc)

(3) Always handle the magazine the correct way.

Holding or placing a magazine upside down or on its

side may cause the discs to slip out of position and

result in malfunction.

25

Page 30

Magazines

Note:

• Media compatible with the MC-8100U varies depending on the drive configuration. For details, refer to the instruction

manuals of the drives.

• When using double-sided discs, handle them with special care because they do not have a label on the surface.

CAUTION

• Never use a damaged and/or warped disc. It will lead to malfunction of the equipment.

• If you are going to use a disc from the different drive, please check the drive specifications carefully before using it.

(Some drives may not be able to read the disc.)

(At the same time, the equipment may not be able to read the disc which has been written and deleted in a different

drive.)

• Note that some double-sided discs do not provide a distinction between the top and bottom sides. Take special care

when removing/loading these discs from/in the MC-8100U.

9-3. Automatic disc checking function

If a magazine was removed and reinstalled after the power has been turned on, this function will automatically check the disc

status inside the magazine.

Checking the operation modes.

Press and hold the MODE key for more than 5 seconds.

• The factory default setting for the automatic disc checking function is on.

Automatic disc checking function ON

A UTO DISC CHECK:

ON

Switching the operation modes

Operation modes will alternate (toggle) when you turn the power off, and then on while pressing both the SELECT key and

the LOAD/EJECT keys simultaneously.

sDepending on the management software used, you may still have to update the disc status data of the host computer

even after the automatic disc checking function has updated the disc status data of a magazine.

Automatic disc checking function OFF

A UTO DISC CHECK:

OFF

26

Page 31

10. ERROR CODES

In the event of an error, the control panel indicator blinks and the LCD shows the error details by overriding any other

information.

The indicator blinks.

POWER

MODE SELECT LOAD/EJECT

10-1. Error code explanation

LCD displays in the event of an error

ERROR OCCURRED !

If the transport lock of the carrier

has not been opened,

this section shows “CHECK

CAR. SCREW”.

DISC = 024

CODE = CU–04

E R OR MAGA Z I NE

R

No. : – 2

Display when

CODE = CC-31

1 2 3

4 5 6

7 8 9

0

ENTER

DISC = 024

Disc No.

CODE = CU – 04