Page 1

SERVICE

MANUAL

Model 100 Projector

2310 Camino Vida Roble

Carlsbad, California 92009

Phone: (760) 929-5300

Fax: (760) 929-5410

Page 2

DECLARATION OF CONFORMITY

PER ISO/IEC GUIDE 22 AND EN 45014

Manufacturer: Hughes JVC

2310 Camino Vida Roble

Carlsbad, Ca 92009

USA

Hughes-JVC declares that this product conforms to the following Product

Specifications (Directive/Standard):

Safety:EN 60950

IEC 950 (1992)

EMC: EN 55022 (1988) / CISPR-22 (1986) Class "A"

EN 50082-1 (1992) / IEC 801-2(1991)

EN 50082-1 (1992) / IEC 801-3(1984)

EN 50082-1 (1992) / IEC 801-4(1988)

ANSI C63.4-1992, FCC, Part 15, Class A

In addition, the above product complies with the requirements of the Low Voltage Directive 73/23 EEC and

the EMC Directive 89/336/EEC.

105827 First Edition February 1999

Revision A July 1999

© Copyright 1998 by Hughes-JVC Technology Corporation.

All worldwide rights reserved.

This manual was produced by Hughes-JVC Technology Corporation and may be

revised without prior notice.

No part of this manual may be reproduced in any form without the express written

permission of Hughes-JVC Technology Corporation.

®

is a registered trademark of Hughes-JVC Technology Corporation.

ILA

ii

Model 100 Service Manual

Page 3

Table of Contents

Safety Information

...............................................................................

Chapter 1 Introduction

1.1 Safety...............................................................................................1-1

1.2 Updates............................................................................................1-1

1.3 Tool List..........................................................................................1-2

1.4 Acronyms Used in this Manual......................................................1-2

Chapter 2 Functional Description

2.1 Introduction....................................................................................2-1

2.2 Optical Section...............................................................................2-2

2.3 Electronics System.........................................................................2-9

Chapter 3 Service Adjustments

3.1 Introduction....................................................................................3-1

3.2 Arc Lamp Adjustment....................................................................3-5

3.2 ILA® Back Focus............................................................................3-9

3.3 CRT Electronic Focus....................................................................3-11

3.4 ILA® Overlap..................................................................................3-12

3.5 Front/Rear or Inverted Projection Jumper Settings........................3-13

3.8 Horizontal Size Settings.................................................................3-15

3.9 Software Updating..........................................................................3-17

3.11 Graphic Enhancement Adjustment.................................................3-21

3.12 Cleaning Lenses, ILA® Assemblies and Mirrors............................3-22

v

Chapter 4 Maintenance (Removal/Replacement)

4.1 Introduction....................................................................................4-1

4.2 Projector Covers.............................................................................4-4

4.3 Air Filters .......................................................................................4-4

4.4 Arc Lamp Assembly.......................................................................4-5

4.5 Ignitor Assembly............................................................................4-7

4.6 Arc Lamp Power Supply................................................................4-8

4.7 Low Voltage Power Supply............................................................4-9

4.8 High Voltage Power Supply...........................................................4-9

4.9 System Controller \ Raster Timing Generator................................4-10

4.10 Video Processor PCBs ...................................................................4-11

4.11 Deflection Processor PCB..............................................................4-12

4.12 Vertical Convergence Deflection PCB...........................................4-12

4.13 Horizontal Deflection PCB ............................................................4-13

4.14 Video Input Cards ..........................................................................4-13

4.15 Regulator PCB................................................................................4-13

4.16 Video Amplifier PCBs...................................................................4-14

4.17 CRT/ILA® Assembly.....................................................................4-15

4.18 Projection Lens...............................................................................4-17

4.19 Recommended Spares....................................................................4-19

Model 100 Service Manual

iii

Page 4

Chapter 5 Troubleshooting

5.1 PCB Status LEDs.............................................................................. 5-1

5.2 Error Codes .......................................................................................5-5

5.3 Troubleshooting Guide...................................................................... 5-8

Chapter 6 Parts List

............................................................................

Appendix A Import/Export

Appendix B Glossary

...........................................................................

6-1

............................................................A-1

B-1

iv

Model 100 Service Manual

Page 5

Safety Information

Introduction

Read entire Safety Chapter thoroughly before performing any maintenance or

service on the projector. Only qualified service personnel should perform

procedures and adjustments.

Safety Equipment: Use safety equipment specified in the projector’s

maintenance training and certification program.

Warnings and Cautions!

Warnings and Cautions in this manual should be read thoroughly and strictly

adhered to. Warning and Caution definitions and symbols are as follows:

Safety Information

WARNING SYMBOL!!!

potential electric shock hazard in a procedure or situation that could

result in personal injury if improperly performed.

CAUTION SYMBOL!

safety hazard or potential light hazard from ultraviolet, infrared or

bright light that could cause severe eye injury or a situation that could

result in damage to the equipment if improperly used.

Installation Safeguards

WARNING!!!

require removing the projector’s covers to access internal component

to remove, replace, service and adjust the projector. Only HughesJVC Certified Technicians are qualified to perform these procedures.

Before removing or replacing any internal components or

subassemblies, verify that the circuit breaker on the back panel is in

the Off position

and

remove the power plug. Any adjustments

Warns user of a

Warns user of a potential

Procedures in this service manual

Model 100 Service Manual v

Page 6

Safety Information

performed that require covers off and power on should be performed

with extreme care. Be especially aware of all hazardous areas

indicated by warning and caution labels.

without using a safe shipping pallet. Lifting the projector without

supporting the weight at the foot locations can cause severe damage

to the projector.

If there is any visible damage to the power cable, disconnect power to

the projector until the damaged cable is replaced. Install the projector

on a smooth, vibration-resistant level surface, or ceiling mount, in an

area free from dust and moisture. Do not place the equipment in

direct sunlight or near heat-radiating appliances. Smoke, steam and

exposure to direct sunlight could adversely affect the internal

components.

CAUTION!

Do not use a forklift to lift the projector

If mounting the projector, use hardware that can handle a minimum of three

(3) times the projector weight.

Heat Safeguards

Fans and Ventilation: The projector has multiple fans to cool the system. Do

not block the intake or outflow of any fans. Heat is emitted within the

system and must be properly dissipated to keep the system running correctly.

Blocking air intake or exhaust ports can lead to projector overheating. Do

not enclose the unit in a restricted space (refer to the physical access and

thermal clearance illustration guidelines).

CAUTION!

the arc lamp fan has stopped running. This fan protects the arc lamp

from overheating. Disconnecting power before the cooling fans have

stopped running can shorten Arc Lamp life.

Light Safeguards

Dangerous high voltage, bright light, ultraviolet, and infrared radiation can be

hazardous to personnel. Access must remain restricted to certified engineers

and technicians.

Do not unplug the power cord until after

Ultra Violet and Infrared Li ght

Protect eyes and face from ultra violet light and infrared light by using the

following protective eyewear:

vi Model 100 Service Manual

Page 7

Safety Information

1. X3 (up to 375 nanometers), ANSI approved, shade goggles must be

worn by anyone near the projector when it is lit and the cover is off.

2. X5 (375 to 700 nanometers), ANSI approved, shade goggles when

actually working on the projector near the arc lamp source.

WARNING, BRIGHT LIGHT!!!

Never look directly at the Arc Lamp, the lighted Projection Lens or into

the lamp housing, from any distance, when the projector is on. Direct

exposure to light of this brightness can cause severe eye injury.

Dangerous levels of ultraviolet and infrared radiation, dangerous

glare, very high temperatures and high internal gas pressure are

present at the Xenon Arc Lamp. The lamp is contained in a protective

reflector housing module and should not be operated outside this

housing or outside of the projector. When replacement is needed, the

arc lamp must be replaced as an entire module, as shown in this

manual. Do not open the lamp housing or attempt to replace the Arc

Lamp inside its module! Do not touch the Arc Lamp, or any

connections, when the lamp is ignited or is arcing. Any servicing of

the Arc Lamp must remain restricted to Hughes-JVC certified

maintenance personnel.

Electrical Safeguards

High voltage access. The front cover

contains a safety interlock. Defeat

restricted to certified service

personnel

WARNING!!!

exposed inside the covers. Allow at least one minute for the high

voltage to bleed off, even after power is turned off.

Due to high voltage danger,

!

CRT cables. These cables can cause severe shock from a tiny,

invisible crack or hole and should never be touched while projector

power is on.

!

CRT anodes.

!

Main power ± supply posts.

!

Arc Lamp main power ± posts

!

CRT yoke assemblies and other proximity electrical assemblies,

components and wiring. If performing the ILA® Back Focus, Overlap

High Voltage points up to 40,000 volts are

!

DO NOT TOUCH

Model 100 Service Manual vii

Page 8

Safety Information

adjustment, always use an ANSI/ASTM 10,000 volt rated glove.

Periodically check the condition of the gloves for cracks.

Power Supply

The Model 100 projector operates from a 90V - 264V, 20 Amp, single-phase,

50/60 Hz AC power source. Verify that local power source matches these

requirements before operating! Installation should be performed by an

electrician with current knowledge of electrical codes in the country of use.

For continued safe and reliable operation, only use cables supplied by the

manufacturer for power and signal connections.

Ventilation and Foreign Object Retrieval

CAUTION!

free from obstructions and operating properly. Air filters are located at

vent ports on the cover. Air filters require periodic cleaning to ensure

adequate cooling of the projector (

ports are clear of obstructions.

Ensure the projector’s multiple fans are

Section 4.4

). Ensure that all vent

Keep the inside of the projector free from foreign objects, such as

hairpins, nails, paper, etc. Do not attempt to retrieve any object or

insert metal objects such as wire and screwdrivers inside the unit. If

an object falls inside the projector, immediately unplug the projector

and call a certified technician to remove object.

viii Model 100 Service Manual

Page 9

1.0 Introduction

Contents

1.1 Safety........................................................................................................1-1

1.2 Updates.....................................................................................................1-1

1.3 Tool List...................................................................................................1-2

1.4 Acronyms Used in this manual ................................................................1-2

This Service Manual is designed to be used with the Model 100 User’s Guide.

This Service Manual provides information on the:

!

Projector functional description;

!

Service adjustments

!

Removal and replacement of subassemblies;

!

Troubleshooting.

Chapter 1---Introduction

The User’s Guide covers the projector’s installation, operation, setup

adjustments, and specifications. Together the Service Manual and User’s Guide

provide a qualified service person with information to operate and maintain the

projector.

1.1 Safety

This projector contains high voltages and high intensity light sources in its

internal system and power supplies. Read the entire Safety Chapter at the front

of this manual before performing any adjustments or maintenance.

When performing procedures that call for the projector’s power to be on,

always wear high voltage gloves (ANSI/ASTM 10,000 volt rated) when

working around the CRTs, Arc Lamp or power supplies. Wear safety goggles

(rated X5) when working anywhere near the light path from the Arc Lamp or

the projection lens at all times.

1.2 Updates

Hughes-JVC will periodically provide Service Bulletins and /or manual

supplements to ensure the accuracy of this service manual.

Model 100 Service Manual 1-1

Page 10

Chapter 1---Introduction

1.3 Tool List

The following tools are required to perform service adjustments:

All Purpose Tools=Diagonal Sidecutters, Wirestrippers, Slot Adjustment

Screwdriver (Tweeker), Mirror/Magnet Pick-Up Tool, Flashlight, 6” Crescent

Wrench, Needlenose pliers, 6” Vise Grips

Balldriver, 1.5mm

Balldriver, 3mm

Balldriver, 3mm, Long

Balldriver, 4mm

Balldriver, 5mm, Long, T-handle

Balldriver, 6mm

Balldriver, 8mm

Ballpoint L-Wrench Set, 1.5-5mm

Delrin .100 Hex Alignment Tool

Gloves, ANSI/ASTM 10,000 volt rated, Safety

Goggles, Safety, x3(covers on) and x5(covers off)

Hex Ballpoint Driver, 3mm

Hex Ballpoint Driver, 5mm

Nutdriver, 10mm

Nutdriver, 11mm (or 7/16”)

Nutdriver, 5mm

Nutdriver, 7mm

Nutdriver, 8mm

Screwdriver, Phillips, #1

Screwdriver, Phillips, #2

Screwdriver, Pozidrive, #1

Screwdriver, Pozidrive, #2

Screwdriver, Slot ¼”

Screwdriver, Slot, ½”

Screwdriver, Slot, 3/16”

Socket, ¼” drive, 7mm-deep

1.4 Acronyms Used in this manual

ALPS Arc Lamp Power Supply

CDB Convergence/Deflection Board

CH Channel

CPU Central Processing Unit

CRT Cathode Ray Tube

DP PCB Deflection Processor Printed Circuit Board

EMI Electromagnetic Interference

EPROM Erasable Programmable Read-Only Memory

FPGA Field Programmable Gate Array

F to V Frequency to Voltage

G

1

1-2 Model 100 Service Manual

CRT Grid 1

Page 11

Chapter 1---Introduction

G

2

CRT Grid 2

HD PCB Horizontal Deflection Printed Circuit Board

Hz Hertz

HSYNC Horizontal Sync

VCD PCB Vertical Convergence Deflection Printed Circuit Board

HVPS High Voltage Power Supply

IIC Inter-Integrated Circuit

®

ILA

Image Light Amplifier

I/O Input/Output

I/R Infrared

kHz Kilohertz

LED Light Emitting Diode

LVPS Low Voltage Power Supply

PC Personal Computer

PCB Printed Circuit Board

PLL P hase Lock Loop

RAM Random Access Memory

REG PCB Regulator Printed Circuit Board

RGB Red, Green and Blue

RGBHV Red, Green, Blue, Horizontal, Vertical

ROM Read Only Memory

SC/RTG PCB System Controller/ Raster Timing Generator Printed

Circuit Board

SYNC Synchronization

TTL Transistor-Transistor Logic

UL Underwriter Laboratories

UV Ultraviolet

VA PCB Video Amplifier Printed Circuit Board

VCO Voltage Controlled Oscillator

VIC Video Input Card

VIN Video Input

VP PCB Video Processor Printed Circuit Board

VSYNC Vertical Sync

Model 100 Service Manual 1-3

Page 12

Chapter 1---Introduction

1-4 Model 100 Service Manual

Page 13

2.0 System Description

Contents

2.1 Introduction.................................................................................................. 2-1

2.2 Optical System ............................................................................................. 2-2

The Arc Lamp Module............................................................................... 2-2

The Illumination Path................................................................................. 2-2

CRT \ ILA

Front Projection Lens................................................................................. 2-8

2.3 Electronics System....................................................................................... 2-9

General Description.................................................................................... 2-9

Power Supplies........................................................................................... 2-10

Video Input Cards (VIC)............................................................................2-15

Video Processor PCB................................................................................. 2-24

System Controller/ Raster Timing Generator PCB.................................... 2-28

Deflection Processor PCB.......................................................................... 2-35

Vertical Convergence Deflection PCB.......................................................2-38

Horizontal Deflection PCB ........................................................................ 2-41

Regulator for three CRTs........................................................................... 2-44

Video Amplifier PCBs............................................................................... 2-46

Backplane PCB .......................................................................................... 2-49

®

Module................................................................................... 2-6

Chapter 2---System Description

2.1 Introduction

The Model 100 Projector consists of assemblies and components, which are

grouped into the three main sections listed below. Included in each of the sections

is a list of the main components found in that section and a brief description of

their function (see Figure 4-1 for physical locations of assemblies and

components).

!

The Optics Assembly Section sits toward the front of the projector. It

consists of an Arc Lamp Module, the Illumination Path, the CRT/ILA

Modules and the Front Lens. The Arc Lamp Module provides the 750

Watt high intensity light source for the projected image. The illumination

path consists of optics that filter, polarize, separate the beam into red,

green, and blue light and direct it to the ILA® and then to the Front Lens

Assembly. The ILA® \CRT Modules supply the image and modulate the

light to create the projected image. The Front Lens sends the image to the

screen.

Model 100 Service Manual 2-1

®

Page 14

Chapter 2---System Description

!

The Power Supply Section consists of three power supplies: the Arc Lamp

Power Supply, the Low Voltage Power Supply and the High Voltage

Power Supply. The Arc Lamp Power Supply supplies constant adjustable

current to the arc lamp. The High Voltage Power Supply drives the CRTs

with anode voltage, G

Low Voltage Power Supply provides the standby voltages and bias voltage

for all the digital and analog circuits. It also supplies the CRT filament

voltage and some supply voltages for the Horizontal Deflection PCB, and

the Video Amp PCBs.

!

The Projector Electronics Section is located mainly in the back half of the

projector. It consists of the Electronics Module that houses 6 of the

electronics printed circuit boards used in the projector, and their associated

cabling. It also contains the Backplane PCB which is used to electrically

interconnect the printed circuit boards, power supplies and other units in

the projector, the Video Amp PCBs and Regulator PCB, and the Video

Input Cards that interface with different kinds of input signals.

2.2 Optical System

voltage, the focus voltage and the G1 voltage. The

2

The Arc Lamp Module

The Arc Lamp Module includes a 750-Watt Xenon Arc Lamp that is located

directly below the Front Projector Lens in the front of the projector. The Arc

Lamp is driven by the Arc Lamp Power Supply, which sits in the front of the

projector opposite the Arc Lamp Module.

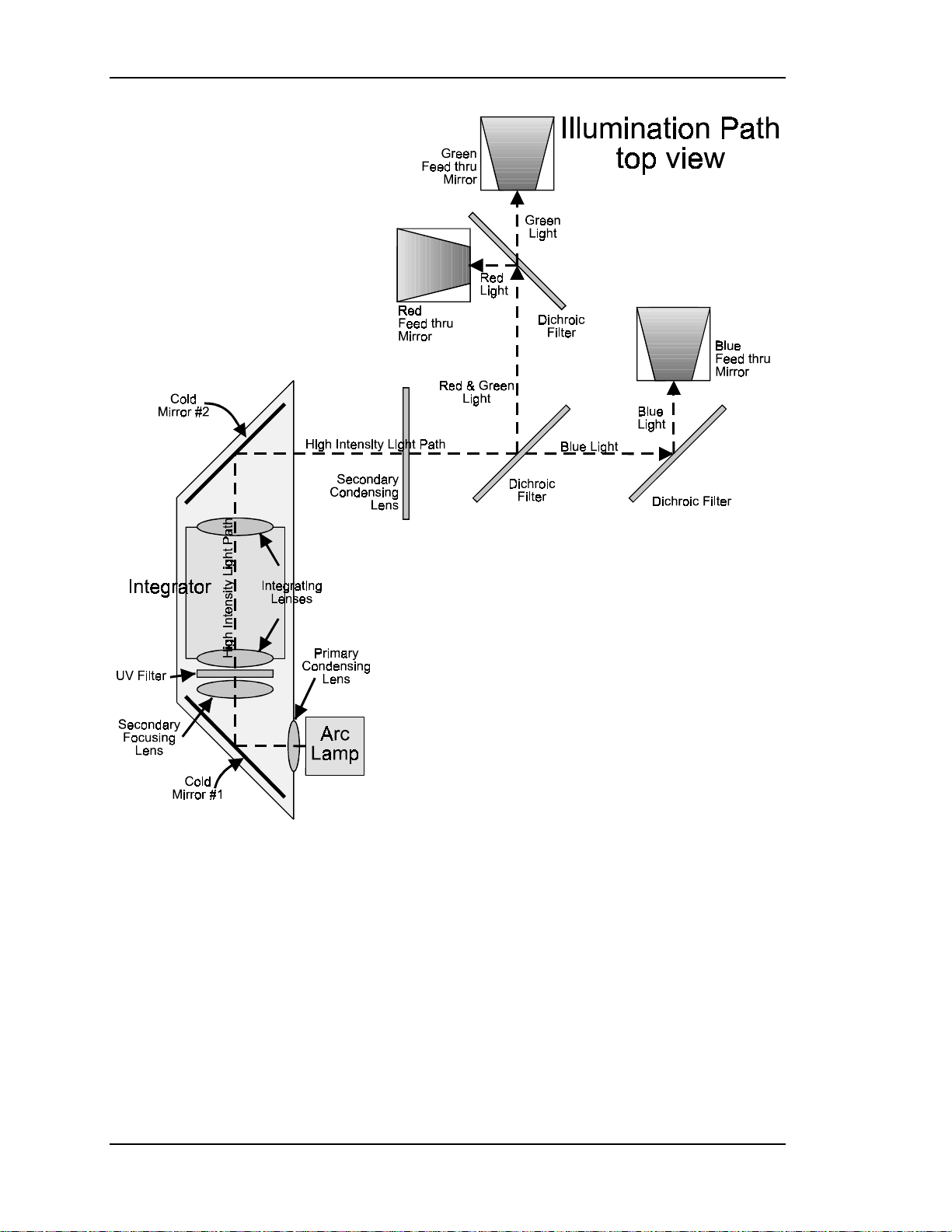

The Illumination Path

The illumination path is a very complex optical system of condensing lenses and

integrator lenses, reflective steering mirrors and Dichroic Filters, polarizing

optics, beamsplitters and combining prisms (see Figure 2-1 for physical layout).

The illumination path actually consists of two sections: the light path and the

image path. The light path begins with a light source, the Arc Lamp, then passes

through Primary Condensing Lens and is reflected off the #1IR Filter/Cold Mirror

where the infrared heat radiation is filtered out.

CAUTION!

mirror passes infrared light and its reflection contains only "cold' light that

does not transmit appreciable heat. As a result of the absorption of

infrared heat radiation, "cold" mirrors can get very hot.

The term "cold mirror" is used because the

From the #1 Cold Mirror the high intensity light passes through the Secondary

Focusing Lens, a UV Filter and into the Integrator, which consists of two “fly’s

eye” integrating lenses. The Primary Condensing Lens collects all the light from

2-2 Model 100 Service Manual

Page 15

Chapter 2---System Description

the Arc Lamp and begins to bend the light rays into a straight path. The Secondary

Focusing Lens works with the Primary Condensing Lens to collimate or

“straighten” the light path before it enters the Integrator. The UV Filter filters out

unwanted ultravioltet light.

After leaving the UV Filter the light passes through the Integrator. The function of

the Integrator is to spread out the beam so that it will have a more uniform

distribution of light across the face of the ILA®. This will result in a more

uniform image on the screen. After leaving the Integrator the white light is

reflected off the #2 IR Filter/Cold Mirror where more IR light is removed. The

white light then travels out to the Secondary Condensing lens and onto the

Dichroic Filters.

The Dichroic Filters divide the white light from the Arc Lamp into its three color

components, Red, Green and Blue. The first filter reflects the green and red light

and allows the blue light to pass through the beamsplitter and continue on to the

Blue Dichroic filter. The red and green light travel on to a second Dichroic Filter

where the red light is separated from the green light. The Blue Dichroic Filter

Mirror reflects the blue light into a Feedthru Beamsplitter. The red light is also

reflected from a Dichroic Filter into a Feedthru Steering Mirror and the green light

is transmitted through the beamsplitter into its respective Feedthru Beamsplitter.

All three light beams are reflected up into the Polarizing Beam Splitter.

Model 100 Service Manual 2-3

Page 16

Chapter 2---System Description

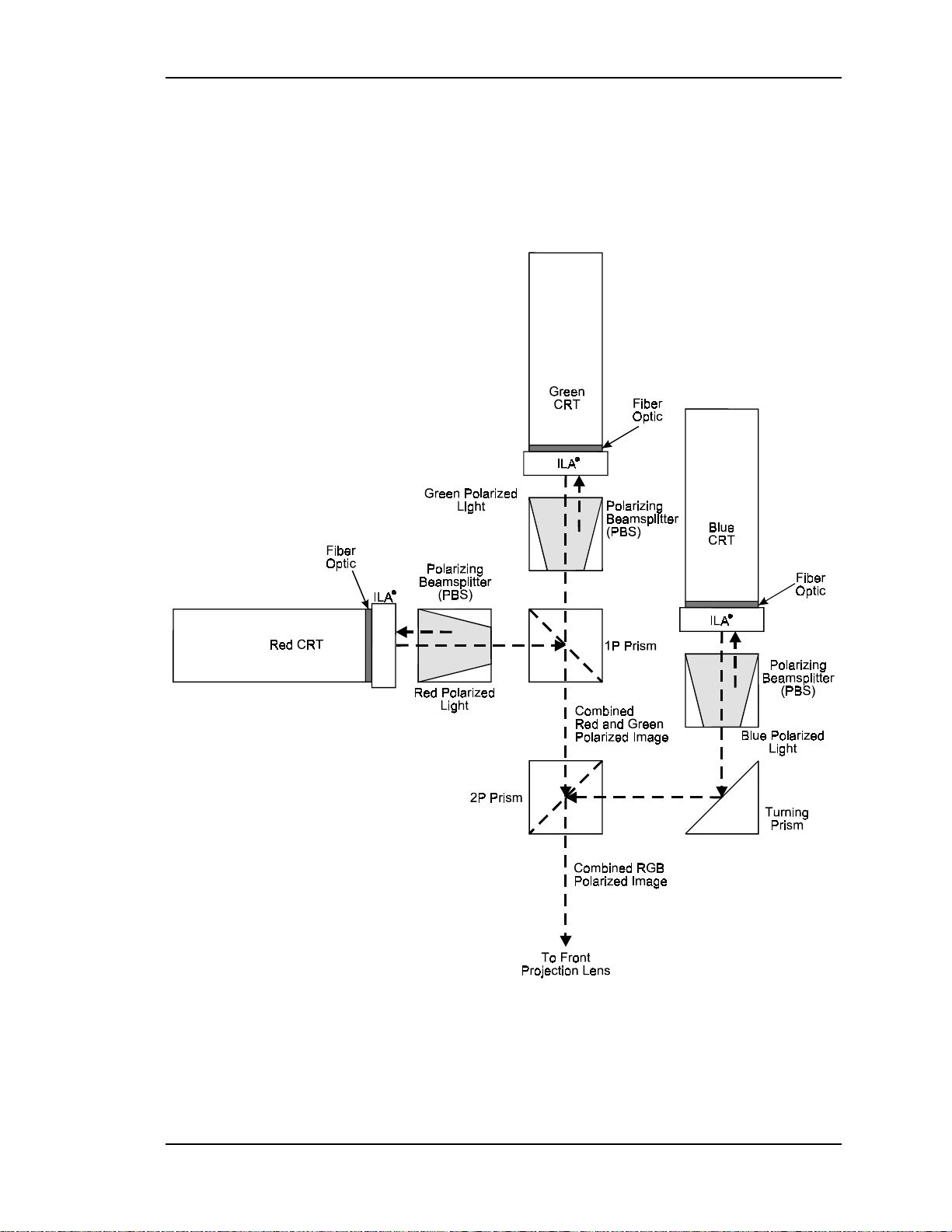

Figure 2-1

2-4 Model 100 Service Manual

Top View of lower level of Illumination Path for the Model 100.

Page 17

Chapter 2---System Description

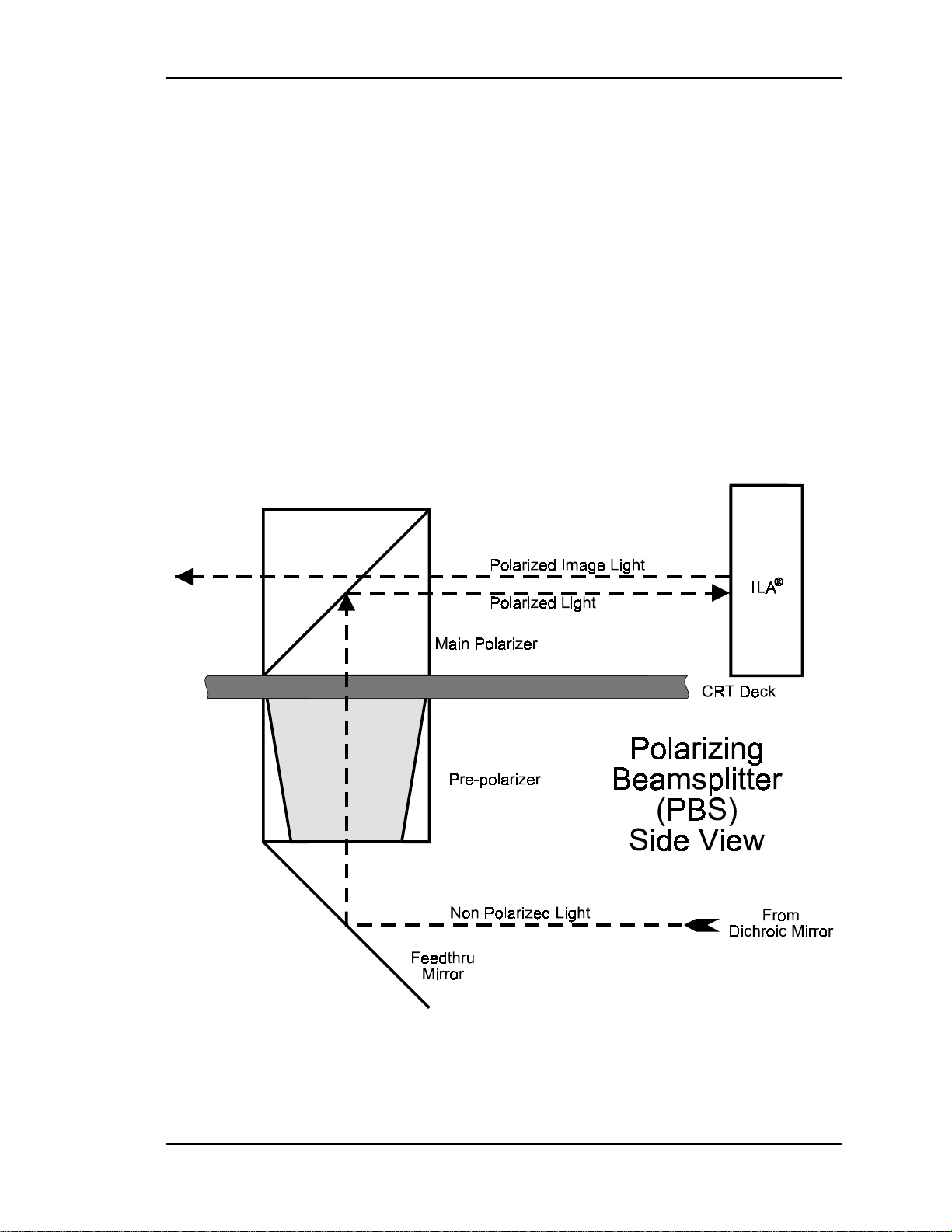

The Polarizing Beam Splitter (PBS) actually consists of a Pre-Polarizer and a

main Polarizer. The process of polarizing light is discussed in the following

paragraph.

Light can be viewed as having two electromagnetic components: a S-electric field

and a P-electric field. These fields are perpendicular to each other. When

unpolarized light travels through a polarizing beamsplitter one of these fields is

reflected and one is transmitted or passes through the beamsplitter. Upon striking

the Pre-Polarizer, the S-electric field is reflected and is wasted, the P-electric field

is passed through the Pre-Polarizing Beamsplitter and continues on to the Main

°

Polarizer. The Main Polarizing Beamsplitter is rotated 90

from the Pre-Polarizing

Beamsplitter so the P-electric field that was transmitted through the Pre-Polarizer

becomes the S-electric field and is reflected by the Main Polarizer. The reflected

polarized light, either red, green or blue, leaves the PBS and goes directly into the

®

ILA

device.

Figure 2-2

Side view of a Feedthru Beamsplitter and the Polarizing

Beamsplitter (PBS).

Model 100 Service Manual 2-5

Page 18

Chapter 2---System Description

The polarized light from each of the PBS’s enters the ILA® and is rotated and

modulated with the image signal. The amount the polarized light is rotated is

controlled by the ILA® bias and the amount of CRT light hitting the input side of

the ILA®, and translates directly to the brightness of the image on the screen.

The image light from each of the ILA®s is then sent back through the Main

Polarizer portion of the PBS. The polarized blue image light continues on to a

Turning Prism where it is reflected into the 2P Combining Prism. The red and

green light come from their respective PBSs and are combined in the1P

Combining Prism. From the 1P Combining Prism, the red and green image light

go into the 2P Combining Prism to combine with the blue image light, where the

RGB image light goes through the Front Projection Lens and out onto the screen.

This completes the Illumination Path.

CAUTION!

critical. Replacement of individual mirrors or prisms requires removing the

projector cover and must be performed only by Hughes-JVC Certified

technicians. Consult the factory before removing or aligning any mirrors or

prisms.

The alignment of system optical components is

CRT \ ILA® Module

The three CRT/ILA® assemblies are located in the main body of the projector

above the Dichroic Filters and in front of the Electronics Module card cage. The

red CRT is separated and perpendicular to the green and blue CRT. Two exhaust

fans at the rear help cool the green and blue CRT assemblies. Each CRT is sent a

red, green, or blue image signal, but they do not emit a red, green, or blue color, as

in traditional CRT projectors. The CRTs are not used as a primary light source.

The light output to the screen is the function of the Arc Lamp, ILA® bias, and

CRT output. The purpose of the CRT is to generate an image and to control the

amount of modulation the ILA® assemblies introduce on the light coming from

the Arc Lamp. The Red, Green, and Blue image signals are routed to the CRTs

The

from the Video Amplifier Board through the CRT socket connectors.

image passes through a thin fiber-optic coating on the CRT face and another fiberoptic on the back surface of the ILA

®.

There is a thin layer of optical fluid

between the two fiber optic coatings. The input and output sides of the ILA

assembly are isolated from each other electrically and optically but are coupled

electrostatically.

At the same time the image is received at the input side of the ILA

®

side of the ILA® is receiving high intensity polarized light from the arc lamp

through the PBS. This high intensity polarized light is modulated by the image

from the CRT and the light polarization is rotated (90° at 100% CRT output) by

the liquid crystal on the output side of the ILA®. The light is then reflected back

CRT

®

, the output

2-6 Model 100 Service Manual

Page 19

Chapter 2---System Description

from the output side of the ILA®, and travels through the 1 and 2 Combining

Prisms (red and green). The blue polarized image light goes through the Turning

Mirror and combines with the red and green light in the #2 Combining Prism to be

picked up by the projection lens.

Figure 2-3

Model 100 Service Manual 2-7

Overhead view of top-level optical path.

Page 20

Chapter 2---System Description

Front Projection Lens

The Front Projection Lens picks up the high intensity image from the 2P

Combining Prism and transmits it to the projector screen. The Front Lens options

are:

!

Zoom Lens with a 3:1 to 8:1 range

!

1.5:1 Fixed Range Lens with a variable offset that can be set to 50% of

screen height above or below the centerline of the screen

!

1.1:1 Fixed Range Lens

WARNING!!!

The Xenon Arc Lamp produces high

intensity white, ultraviolet and infrared light capable of severe eye injury.

Never look directly at or touch the Xenon Arc Lamp. Service should

be performed by Hughes-JVC certified

technicians only.

2-8 Model 100 Service Manual

Page 21

Chapter 2---System Description

2.3 Electronics System

General Description

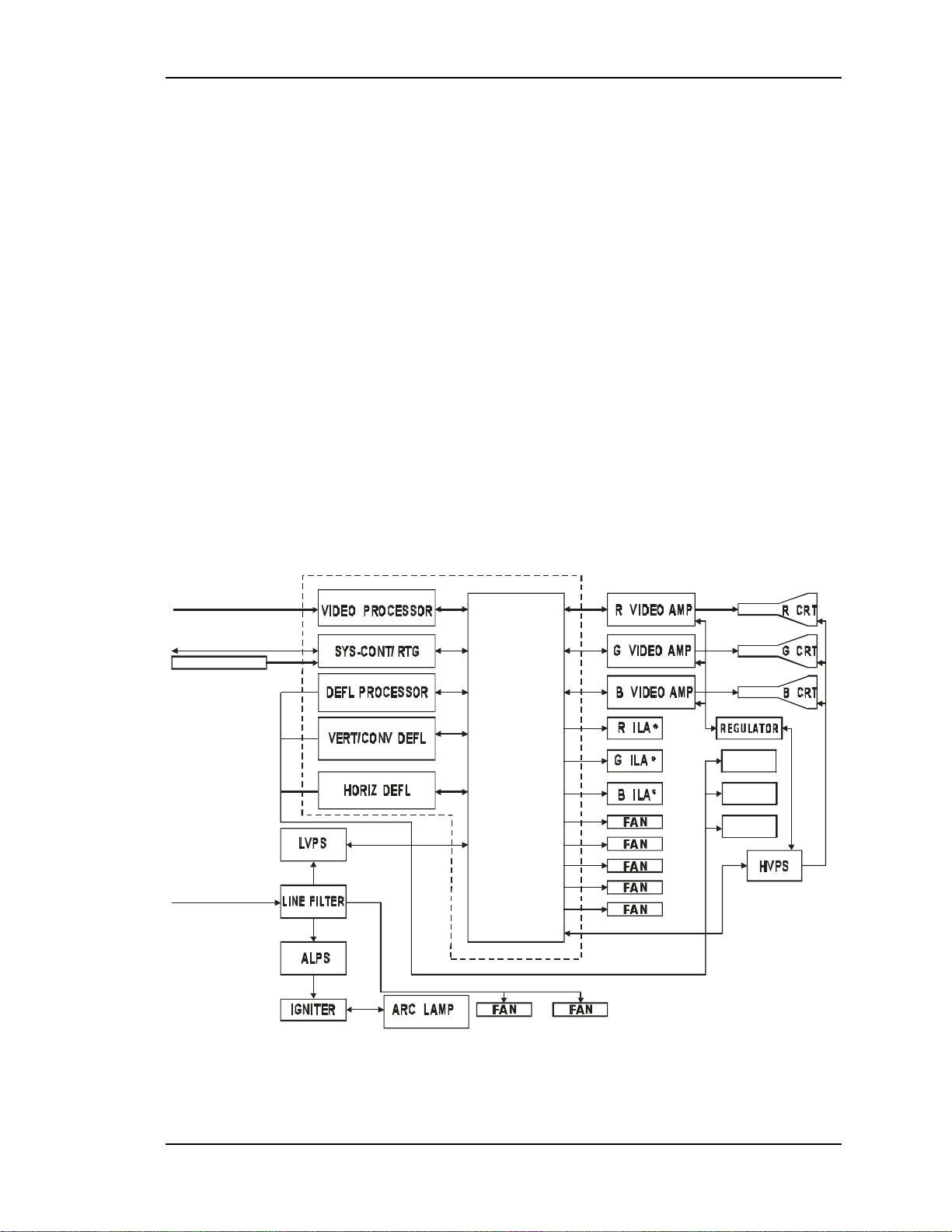

The Model 100 Electronics System includes nine printed circuit assemblies. They

provide all the controlling voltages and signals to adjust and correct picture

settings, geometry, convergence, and shading (see Chapter 4 of the User’s Guide).

The Electronics System also controls video and sync input signals, LED displays

on PCBs on the side of the projector, two RS-232 communications ports, and two

IR receivers for remote control of the projector.

The descriptions in this portion of the manual are based on an overall Electronics

System block diagram and simplified block diagrams for each of the nine printed

circuit assemblies. The diagrams and descriptions serve two purposes; first, to

provide the technician with an overall grasp of how the system works and how

each assembly works with other assemblies in the system, second, to provide the

technician with enough information to troubleshoot to the assembly level, if

needed.

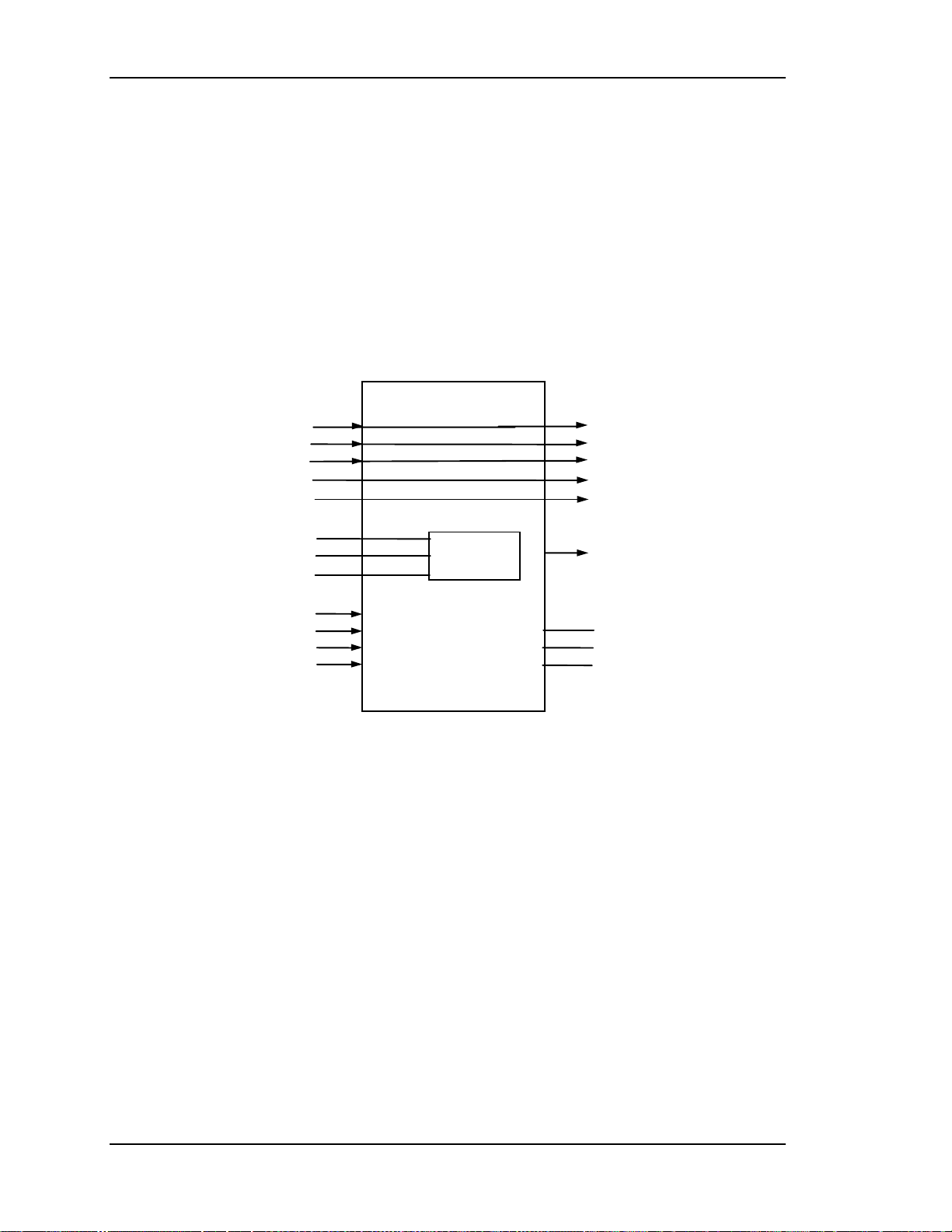

Figure 2-2 provides an overall System Block Diagram to show how the Optical

System, Arc Lamp, and Electronics System combine to provide the bright screen

image.

RGBVH

RS-232C / 422

IR RECEIVE

90-264 AC

50 / 60 Hz

BACKPLANE

R YOKE

G YOK E

FOCUS

B YOKE

RGB / HV

Figure 2-4

Model 100 Electronics System Block Diagram.

Model 100 Service Manual 2-9

Page 22

Chapter 2---System Description

Power Supplies

The Model 100 includes three power supply assemblies.

Low Voltage Power Supply

!

Arc Lamp Power Supply

!

High Voltage Power Supply

!

Low Voltage Power Supply (LVPS)

Main Functions:

!

Provides all of the analog, digital, and voltages needed by the projector.

!

Provides standby power when the projector is OFF.

!

Provides power for all cooling fans.

Operation:

The main power is filtered via the input filter to prevent radiation from escaping

back to the power line. From the line filter, AC power is fed into the Low Voltage

Power Supply module where AC is rectified, filtered, and compensated for power

factor correction.

The +5.1V Standby is on whenever AC power is connected to the projector and

the circuit breaker, next to AC power connection, is in the On position. The +24V

standby power for the fans turns on when the /FAN_ENA signal is received from

the System Controller (this turns off in 5-8 minutes if power is not turned on by

the remote control or a PC). All other voltages supplied by the LVPS are activated

when power is turned on at the remote or PC. These include +5.1V for digital

components, +6.2V for CRT filaments, ±15V for analog circuits, and the +80V

supply which is used by the High Voltage Power Supply, Video Amplifier PCB,

and the Horizontal Deflection PCB.

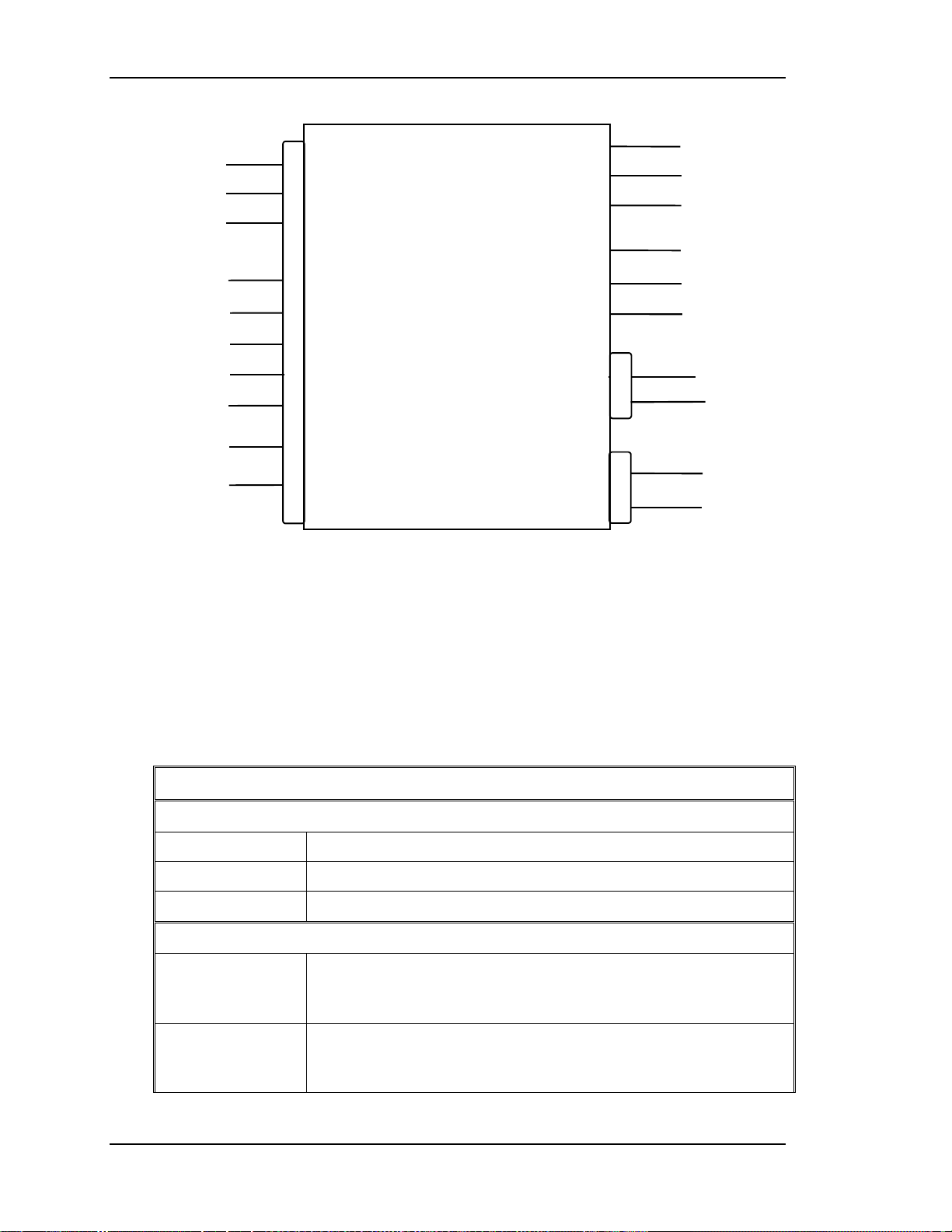

P76

AC

INPUT

P75

1

3

5

Line

Earth

Neutral

LV Ret

/LV_ENA

/LV_OK

+24v Fans

+5.1v STBY

+5.1v

+6.2v

+15V

-15v

+60V

/COVER_ON

/FAN_ENA

1-7

8

9

10

11

12

13

14

15

16

17

18

To P8 on

Backplane

Figure 2-5

LVPS Input/Output Diagram.

2-10 Model 100 Service Manual

Page 23

Chapter 2---System Description

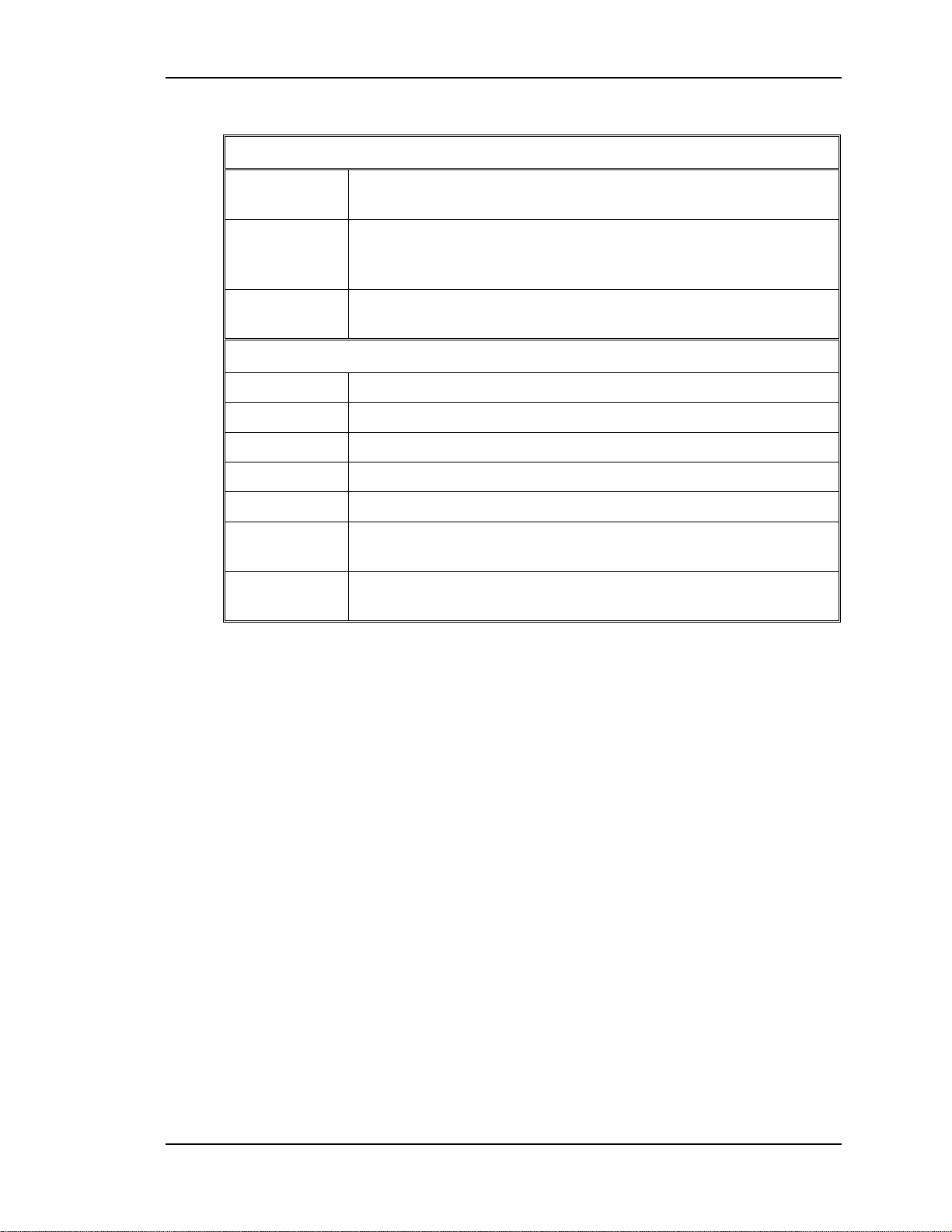

Table 2-1

Inputs and Outputs for the LVPS

Inputs

/ LV_ENA From System Controller/ RTG PCB - enables the LVPS when

the System Controller receives a Power-On command.

/ COVER ON Indicates the front cover is in place or the Interlock is in the

Service Mode. Enables the non-standby outputs. Also includes

Arc Lamp Thermal Shutdown Sensor signal.

/ FAN_ENA From System Controller/ RTG PCB - enables the +24 V

Standby voltage for the projector cooling fans.

Outputs

+24V To cooling fans

+5.1V +5.1 Stdby for CPU and remote operation.

+6.2V For CRT Filaments

+15V For analog circuitry

-15V For analog circuitr y

+60V For Horizontal power Supply section of Horizontal Deflection

PCB and Video Amplifiers PCB.

/ LV_OK Feedback signal indicating to the System Cont r oller, the status

of the non-standby supply (working or not working ).

NOTE:

a “/”in front of signal name means “active low“. This means the signal

will enable a device such as the LVPS in / LV_ENA. A high = 5V and low = 0V.

The /COVER_ON signal from the cover interlock switch tells the Low Voltage

Power Supply that the front cover is in place and the interlock switch is pressed

in. The /COVER ON signal also includes the Thermal Shutdown signal that

comes from a thermocouple attached to the Arc Lamp. If the Arc Lamp exceeds

°

130 ± 5

C or the Interlock Switch is not pushed in (or pulled out) the Low

Voltage Power Supply shuts down the projector.

Model 100 Service Manual 2-11

Page 24

Chapter 2---System Description

Arc Lamp Power Supply (ALPS)

Main Functions:

!

Provides a boost voltage of 150 Volts to Igniter Assembly. The Igniter

then delivers a 32 kV pulse to turn the Xenon Arc Lamp on.

!

Provides steady state power to maintain the lamp ON (approx. 19V at 39

Amps)

!

Current adjustable power supply (located on top of the power supply).

Operation:

The System Controller sends the /LAMP_ENA signal to the ALPS. The

/LAMP_ENA signal turns on the ALPS. The Arc Lamp Power Supply then

provides the +150 VDC boost voltage to the Laser Power Supply The Laser

Power Supply provides the spark gap to the Igniter Transformer (Igniter). The

Igniter steps up the +150 VDC boost voltage to approximately 32KV and ignites

the Xenon Arc Lamp. After the Arc Lamp is lit, it is maintained on by the ALPS

at a constant 19 volts and 39 amps. The /LAMP_LIT output signal informs the

System Controller if the lamp is lit or not. The Arc Lamp Power Supply is

shielded electrically and magnetically to prevent noise or disturbances in the

CRTs or other circuitry.

The / Cover On signal goes to the Arc Lamp Power Supply as well as the Low

Voltage Power Supply. If the Arc Lamp exceeds 130 ± 5° C or the Interlock

Switch is not pushed in (or pulled out) the Arc Lamp Power Supply shuts down.

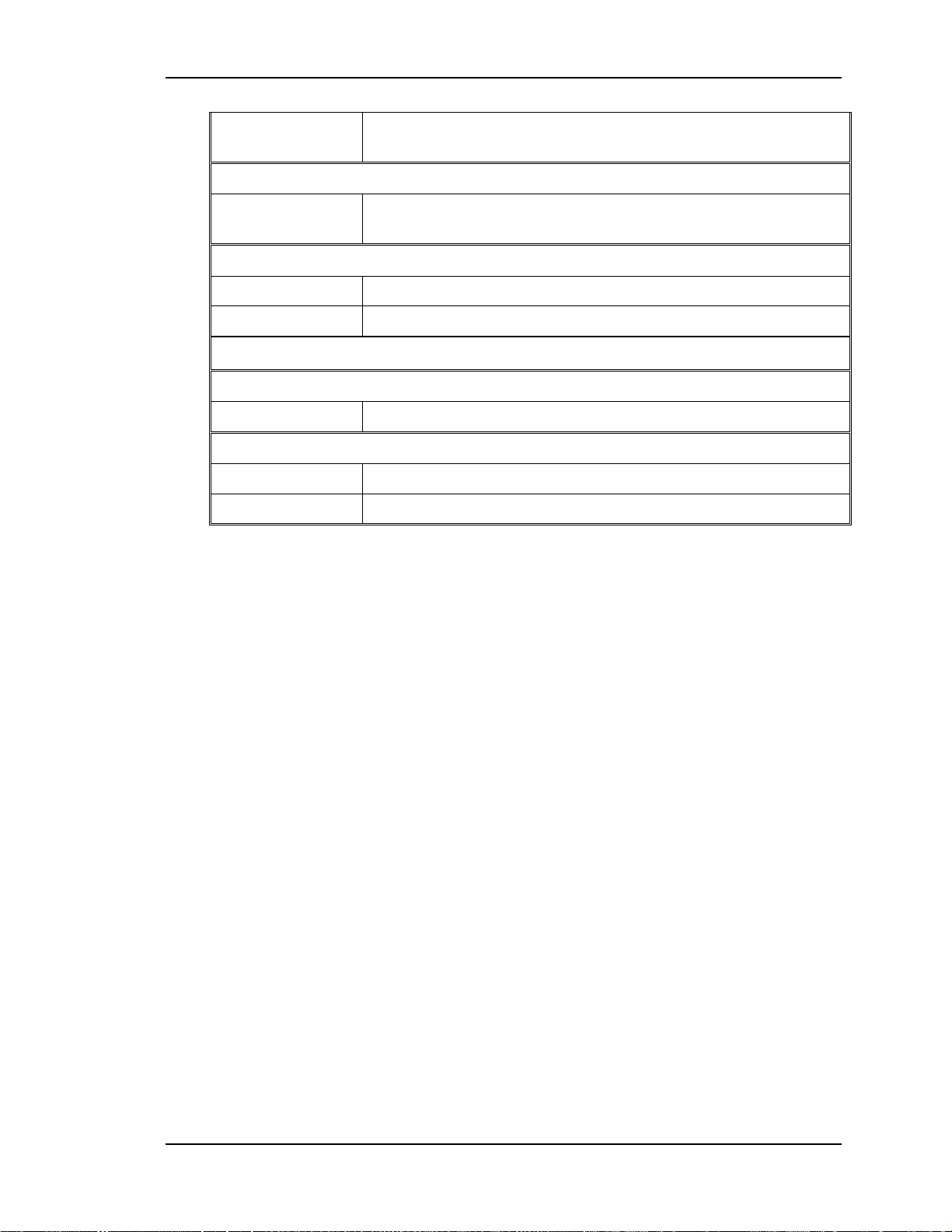

P74

1

2

To Arc

Lamp Igniter

To Arc Lamp

Igniter

P73

Jumper

Jumpered

1

2

A/C Input

To J106

Backplane

P71

AC

INPUT

1

3

5

P72

To J106

Backplane

1

2

3

4

5

6

Figure 2-6

Line

Earth

Neutral

GND

/LAMP_LIT

/LAMP_OK

/LAMP_ENA

/COVER_ON

GND

LAMP_OUT

LAMP_RET

LAMP_OK

GND

Arc Lamp Power Supply, Block Diagram.

2-12 Model 100 Service Manual

Page 25

Chapter 2---System Description

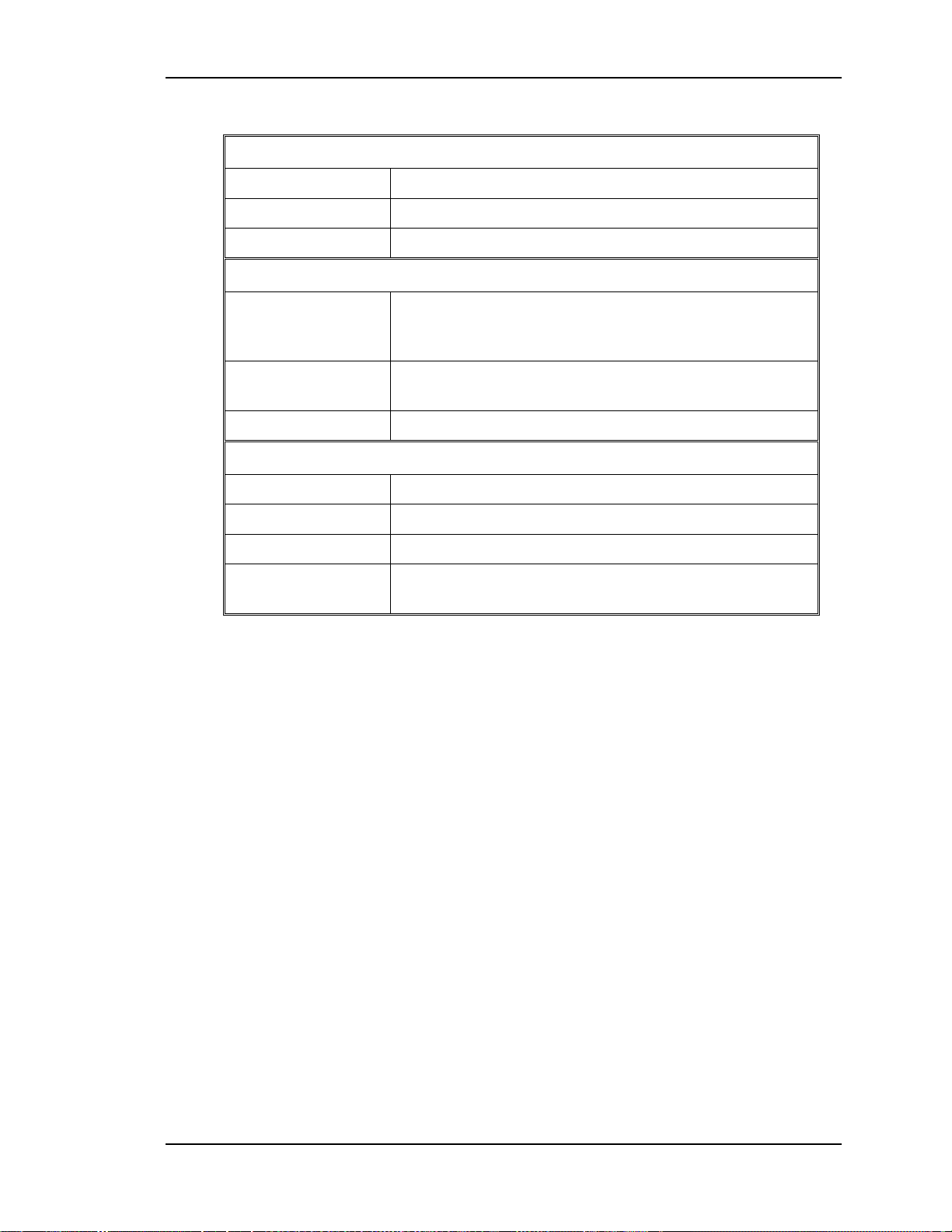

Table 2-2

Inputs and Outputs for the ALPS

A/C Inputs

LINE 90-132 Vac to 200-264 Vac at 50-60 Hz

EARTH Ground

NUETRAL Return

Inputs

/ COVER ON Indicates the front cover is in place or the Interlock is

in the Service Mode. Also includes Arc Lamp Thermal

Shutdown Sensor signal.

/ LAMP ENA Signal from System Controller/ RTG to turn on Arc

Lamp Power Supply

/ LAMP OK Jumpered to ground

Outputs

ARC LAMP OUT +150 V boost voltage to Igniter t o st ar t Arc Lamp

Normal Operation: +19 Volts at 39 Amps

ARC LAMP IN Arc Lamp return

/ LAMP LIT Feedback signal to System Controller / RTG that Arc

Lamp is lit

High Voltage Power Supply (HVPS)

The High Voltage Power Supply (HVPS) is located in front of the LVPS on the

left side of projector (as viewed from rear). This supply provides the anode, focus,

and screen voltages required for the three CRTs in the Model 100 projector.

The following functions are provided by HVPS:

!

Phase locked loop circuit for synchronization to the horizontal sync

!

Generation of anode voltages (15kV) for all three CRTs (RGB)

!

Generation of G3 focus voltage (3.5 to 4.5kV) for all three CRTs (RGB)

!

Generation of the G2 (supply-Black Level voltage for all three CRTs

!

Generation of G1 supply (Blanking) voltage

!

Dynamic focus amplifier using H and V parabolas

!

External ON/OFF and generation of /HV_OK signal

The High Voltage Power Supply I/O diagram (see Figure 2-7) and the list of

inputs and outputs (see Table 2-3), provide an understanding of the operation of

the HVPS to allow the technician to perform module level troubleshooting.

Model 100 Service Manual 2-13

Page 26

FROM SYSTEM

CONTROLLER

H VPS_SYNC

IIC CLK

IIC DATA

FROM LVPS

(VA_OK)

(

From VPB

/

+5V

+15V

+15V

-15

)

CN1

19

Chapter 2---System Description

R ANODE

5

9

11

12

13

17

20

HIGH

VOLTAGE

POWER

SUPPLY

G ANODE

B ANODE

R FOCUS

G FOCUS

B FOCUS

CN5

ARC GND

3

G2 SUPPLY

1

T

O

C

R

T

S

TO

REGULATOR

PCB

FROM

DEFLECTION

PROCESSOR

H FOCUS SIG

V FOCUS SIG

15

16

CN1 IS CONNECTED TO J104 BACKPLANE

CN5 IS CONNECTED TO CN201 REGULATOR PCB

CN1

14

18

G1 SUPPLY

/HV OK

TO

Figure 2-7

High Voltage Power Supply, I/O Diagram.

The HVPS Input/Output

This section provides a comprehensive description of the inputs to and outputs

from the HVPS. The I/O descriptions are arranged by the source/destination of the

signal. The format used is such that the assembly communicated with is used as

the primary heading of each output. Input refers to an input to the HVPS. Output

refers to an output from the HVPS. In each case the signals direction is noted.

Table 2-3

Inputs and Outputs for the HVPS

Inputs

LVPS

+15V Power for analog circuitry.

-15V Power for analog circuitry.

SYST

EM

CONT

+5.1V Power for digital circuitry.

SC/RTG

HVPS SYNC Synchronization pulse for the HVPS, synchronized with the

selected Horiz. Sync at either same, half or on t hir d the

frequency.

IIC DATA IIC data line. Bi- directional serial line for synchronous data

transfer between the SCB/RTG , the HVPS, video processing

and deflection processing PCBs.

2-14 Model 100 Service Manual

Page 27

Chapter 2---System Description

IIC CLK IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

Video Processor

/ VA OK (HV

Low enables HVPS

ENABLE)

Deflection Processor

H FOCUS SIG Horizontal focus parabola.

V FOCUS SIG Vertical Focus parabola.

Outputs

SC/RTG

/HV OK High Voltage status line. Low = HVPS operating normal.

Regulator

G1 SUPPLY -75V

G2 SUPPLY 1kV

Video Input Cards (VIC)

There is only one optional video input card slot on the Model 100. It is located

immediately to the right of the Video Processor PCB on the right side of the

projector. There are five Optional Video Input Cards that can be used with the

Model 100 Projector.

!

RGBHV Wide-Band VIC used as a second input card.

!

Graphics Enhancer RGB VIC

!

Four-Input RGB MUX VIC used in a similar manner as a switcher.

!

HDTV VIC used for High Definition Television.

!

Quad Standard Decoder/ Line Doubler VIC used for NTSC, PAL

SECAM and other composite sources.

RGBHV Wide-Band VIC

The RGBHV Wide-Band VIC has five BNC inputs. It provides the RGB and HV

sync interface for the projector. This RGB VIC provides a high bandwidth

interface for the three color video signals. The video signals are routed to the

Backplane Board. The sync signals (horizontal and vertical) are also directly

connected to the Backplane Board.

The following functions are provided by the RGB VIC:

!

Video and sync interface for red, green and blue

!

LED indication

!

IIC serial bus interface

Model 100 Service Manual 2-15

Page 28

Chapter 2---System Description

LED indication

The RGB VIC includes an LED which is illuminated when the board is selected

(i.e. when the /SEL_CH line is low) as the input for the Model 100 Projector.

IIC serial bus interface section

The RGBHV Wide Band VIC is controlled by the serial bus interface. The IIC bus

comes from the System Controller Board through the Backplane Board. The

information transferred over the IIC bus is indicated below (I = input to the RGB

VIC, and O = output from the RGB VIC). The RGB VIC does not use the

interrupt line of the IIC bus interface:

RED

GREEN

BLUE

HORIZ

VERT

IIC_CLK

IIC_DATA

IIC_INT

+5.1V_STBY

+5.1V

+15V

-15V

B13

A13

A12

A16

B16

B15

B14

IIC

B2

RED_VIC

B4

GRN_VIC

B6

BLU_VIC

H_VIC

B8

V_VIC

B10

/SEL_VIC

12*

A1 GND

A2 GND

A3 GND

Figure 2-8

RGBHV Wide-Band VIC I/O.

The RGBHV Wide-Band_VIC I/O

This section provides a description of the inputs to and outputs from the

RGB_VIC. The I/O descriptions are arranged by the source/destination of the

signal. The format used is such that the assembly communicated with is used as

the primary heading of each group of signals. Those signals are further subdivided

into inputs and outputs. Input refers to an Input to the RGB_VIC, output refers to

an output from the RGB_VIC.

2-16 Model 100 Service Manual

Page 29

Chapter 2---System Description

Table 2-4

Projector Inputs

Inputs

RED

GREEN

RGBHV Wide-Band VIC I/O signals

Description

Video input signals. about 0.7 to 1VPP

BLUE

HORIZ.

VERTICAL

Video Processor PCB

Outputs

/SEL_VIC

RED_VIC

Horizontal or composite sync signal

Vertical sync signal

Description

Select line for VIC. A low indicates the RGB_VI C is selected.

Video signals. about 0.7 to 1VPP

GRN_VIC

BLU_VIC

H_VIC

V_VIC

Horizontal or composite sync signals

Vertical sync signals

System Controller / RTG PCB

Description

Inputs

IIC_CLK

IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

IIC_DATA

IIC data line. Bi-directional serial line f or synchronous dat a

transfer between System Controller/ RTG PCB and the

RGB_VIC.

Description

Outputs

/IIC_INT

Low Voltage Power Supply

Inputs

+5.1V

+15V

-15V

+ 5.1

IIC interrupt line. RGB_VI C does not initiate an interrupt.

Description

+5.1V supply for use by RGB_VIC.

+ 15V supply for use by RGB_VIC.

-15V supply for use by RGB_VIC.

+ 5.1V standby supply for use by RGB_VIC.

V_STBY

Model 100 Service Manual 2-17

Page 30

Chapter 2---System Description

Graphics Enhancer RGB VIC

The Graphics Enhancer RGB VIC is the same as the RGBHV Wide-Band VIC

except that it has a Graphics Enhancer chip that allows some adjustment to

enhance small black text on a white background. This adjustment is discussed in

section 3.18 of this manual. Refer to the RGBHV Wide-Band VIC section for

inputs and outputs.

Four-Input RGB VIC

The Four-Input RGB VIC consists of four sets of RGBHV inputs and operates in

a manner similar to a switcher. The four inputs are multiplexed so that only one is

enabled at a specific time. Software selects the desired input channel through the

IIC bus and ensures that only one RGB VIC is enabled. When one of the channels

assigned to the Four-Input RGB VIC is selected, the /SEL_VIC line to the Video

Processor is enabled.

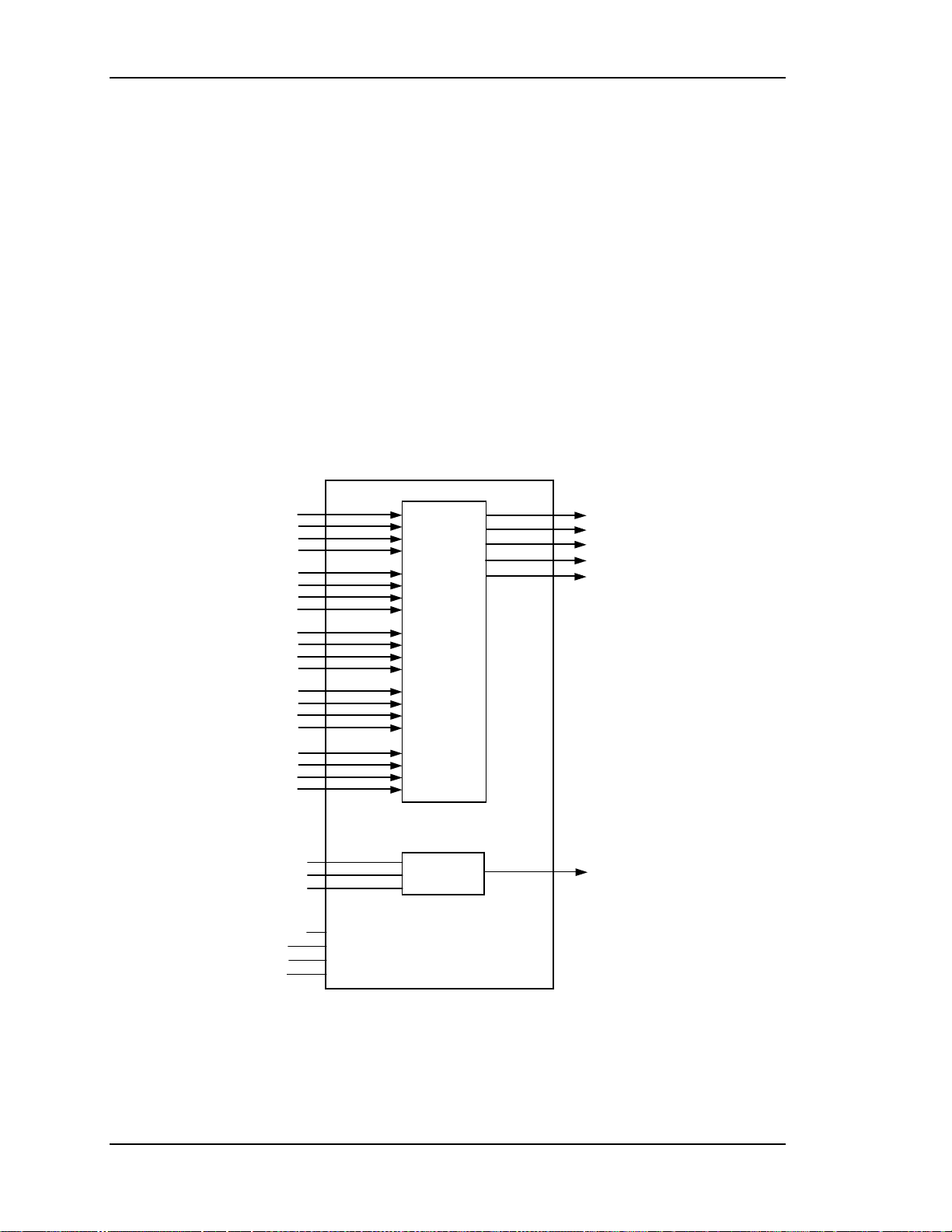

RED_CH1

RED_CH2

RED_CH3

RED_CH4

GRN_CH1

GRN_CH2

GRN_CH3

GRN_CH4

BLU_CH1

BLU_CH2

BLU_CH3

BLU_CH4

HOR_CH1

HOR_CH2

HOR_CH3

HOR_CH4

VER_CH1

VER_CH2

VER_CH3

VER_CH4

IIC_CLK

IIC_DATA

IIC_INT

+5.1Vstby

+5.1V

+15V

-15V

4:1

VIDEO

MUX

and

BUFFERS

IIC

RED_VIC

GREEN_VIC

BLUE_VIC

H_VIC

V_VIC

/SEL_VIC

Figure 2-9

Four-Input RGB VIC I.O Diagram.

The same functions performed by the RGB VIC are performed by the Four-Input

RGB VIC. The description of operation and pinouts are the same as the Graphics

2-18 Model 100 Service Manual

Page 31

Chapter 2---System Description

Enhancer RGB VIC. One of four LEDs indicates which of the four RGB inputs is

currently active.

YPbPr VIC

YPbPr is a high-end video signal standard. The HDTV YPbPr VIC converts the

YPbPr component signal to a RGBHV type video signal. It contains three BNC

input connectors that can be used for two different inputs, YPbPr or GBR.

The following functions are provided by YPbPr_VIC:

!

Video input and output buffers

!

Conversion of YPbPr signal format to RGB signals format

!

Separation of syncs from the Y/G input signal

!

Hue, sharpness, gamma, and color adjustment

!

Selection of RGB component input or YPbPr input

!

LED indication

!

IIC serial bus interface

This VIC accepts two types of video signals, color components (YPbPr) and RGB

signals. In either case, the output of this VIC is RGB type signal. If the inputs are

color components they will be converted to RGB type signals.

The selection between color component input mode and RGB input mode is

controlled by an input. This input is controlled by the System Controller/RTG

PCB via the IIC serial bus interface.

LED indication

There are two LEDs on this VIC. The RGB LED is illuminated when the

YPbPr_VIC is selected and is in RGB input mode. The YPbPr LED is illuminated

when the YPbPr_VIC is selected and is in YPbPr input mode. Both LEDs are off

when the YPbPr_VIC is not selected as the input to projector. Only one LED can

be on at one time.

IIC Interface

The YPbPr_VIC is controlled by the serial bus interface. The IIC bus comes from

the System Controller Board through the Backplane Board. All required

adjustments for this board are provided via the IIC serial bus interface. The

information transferred over the IIC bus is indicated below (I = input to

YPbPr_VIC, and O = output of YPbPr_VIC). The selection of this VIC is

accomplished through the IIC control bus which provides the /SEL_VIC signal.

Model 100 Service Manual 2-19

Page 32

Chapter 2---System Description

Y/G

Pb/B

Pr/R

IIC_CLK

IIC_DATA

+5.1V_STBY

+5.1V

+15V

-15V

B13

A13

A16

B16

B15

B14

B2

B4

B6

B8

B12

RED

GRN

BLU

HOR

/SELECT

Figure 2-10

YPbPr VIC I/O Diagram.

The YPbPr_VIC I/O

This section provides a comprehensive description of the inputs to and outputs

from the YPbPr_VIC. The I/O descriptions are arranged by the source/destination

of the signal. The format used is such that the assembly communicated with is

used as the primary heading of each group of signals. Those signals are further

subdivided into inputs and outputs. Input refers to an Input to the YPbPr_VIC,

output refers to an output from the YPbPr_VIC.

Table 2-5

Projector Inputs

Input

Y/G

Pb/B

YPbPr VIC Signals

Description

Video input signals-about 0.7 to 1 VPP

Pr/R

Video Processor PCB

Description

Output

/SELECT

Selection indicator for VIC. Low indicates the selected

YPbPr_VIC.

2-20 Model 100 Service Manual

Page 33

Chapter 2---System Description

RED

Video signals. about 0.7 to 1 VPP

GRN

BLU

HOR

System Controller Board / RTG PCB

Inputs

IIC_CLK

Composite horizontal / vertical sync signal

Description

IIC clock line. Unidirectional clock line for control of synchronous

data transfer over the IIC bus inter face.

IIC_DATA IIC data line. Bi-directional serial line f or synchronous data

transfer between system control board and the YPbPr _VIC.

Outputs

/IIC_INT

Low Voltage Power Supply

Inputs

+5.1V

Description

IIC interrupt line. YPbPr_VI C does not initiate any interrupt

Description

+5.1V supply for use by YPbPr_VIC.

+15V

-15V

+ 15V supply for use by YPbPr_VIC.

-15V supply for use by YPbPr_VIC.

Quad Standard Decoder/ Line Doubler VIC

The Quad Standard Decoder/ Line Doubler VIC has two basic functions. The

Quad Decoder accepts C-Vid and S-Vid signals in four different formats PAL,

SECAM NTSC and 4.43NTSC and converts them to a RGBHV signal. It contains

one BNC input connector for C-Video and two BNC connections for Luminance

(Y) and Chrominance (C) for S-Video. The Model 100 projector does not accept

sources with horizontal scan frequencies lower than 30 kHz. The Line Doubler

takes scan frequencies like NTSC (~15 kHz) and doubles it to ~31 kHz, which the

Model 100 can use.

The following functions are provided by the Quad Standard Decoder/ Line

Doubler VIC:

!

Select input source - Composite or S-video

!

Select standard-AUTO/NTSC/PAL/SECAM/4.43NTSC

!

Conversion of composite and S-video signals to RGB video signals

!

Separation of syncs from the input signal

!

Doubles the Horizontal Scan Frequency

!

Tint, sharpness, and color adjustment

Model 100 Service Manual 2-21

Page 34

!

LED indication of Composite or S-video

!

IIC serial bus interface

Chapter 2---System Description

Comp

Y in

C in

IIC_CLK

IIC_DATA

+5.1V

+15V

B16

Figure 2-11

B13

A13

B15

Quad Standard Decoder/ Line Doubler I/O Diagram.

B2

B4

B6

B8

B10

B12

R

G

B

/H

/V

/SELECT

LED Indication

There are two LEDs on this VIC. The LED on the right side of the board is

illuminated when Composite Video is selected and the LED on the left is

illuminated when S-Video is selected. Only one LED can be illuminated at one

time.

IIC Interface

The Quad Standard Decoder/ Line Doubler VIC is controlled by the serial bus

interface. The IIC bus comes from the System Controller Board through the

Backplane Board. All required adjustments for this board are provided via the IIC

serial bus interface. The information transferred over the IIC bus is indicated

below (I = input to YPbPr_VIC, and O = output of YPbPr_VIC). The selection of

this VIC is accomplished through the IIC control bus which provides the

/SEL_VIC signal.

Quad Standard Decoder/ Line Doubler VIC I/O

This section provides a description of the inputs to and outputs from the Quad

Standard Decoder VIC. The I/O descriptions are arranged by the

source/destination of the signal. The format used is such that the assembly

communicated with is used as the primary heading of each group of signals. Those

signals are further subdivided into inputs and outputs. Input refers to an Input to

the VIC, output refers to an output from the VIC.

2-22 Model 100 Service Manual

Page 35

Chapter 2---System Description

Table 2-6

Projector Inputs

Input

Composite

Quad Standard Decoder/ Line Doubler VIC Signals

Description

Video input signals-about 0.7 to 1VPP

Video

S-Video Y,

C,

System Controller Board

Inputs

IIC_CLK

Video input signal-about 0.7 to 1VPP f or Luminance and

about .3-.6 VPP for Chrominance (C)

Description

IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

IIC_DATA IIC data line. Bi-directional serial line f or synchronous dat a

transfer between SC/ RTG PCB and the VIC.

/ IIC_SINT IIC Interrupt (Output

Low Voltage Power Supply

Description

Inputs

+5.1V

+15V

-15V

GND

Video Processor Board

Output

/SELECT

+5.1V supply for use by The Quad Decoder VIC.

+ 15V supply for use by the Quad Decoder VIC.

- 15V supply for use by the Quad Decoder VIC.

Ground

Description

Selection indicator for VIC. Low indicates the Quad VIC is

selected.

RED

Video signals. about 0.7 to 1VPP

GRN

BLU

H / C

V_VIC

Horizontal Composite input signal, about 1-1. 25VPP

Vertical sync input signal to Video Processor.

Model 100 Service Manual 2-23

Page 36

Chapter 2---System Description

Video Processor PCB

The Video Processor PCB (VP PCB) is the bottom-most card (see Figure 4-10) in

the card cage. It is connected directly to the Backplane board through 2

connectors. When an external signal is being received, the VP-PCB provides

Horizontal Sync, Vertical Sync, and Green Sync signals to the System Controller /

Raster Timing Generator (SC/RTG) Printed Circuit Board (PCB). It also provides

three primary color signals, and G2 Control, and DC RESTORE signals to the

Video Amplifier PCBs (VA PCBs).

The following functions are provided by the VP PCB:

!

Video signal input and multiplexing

!

Sync signal stripping

!

Overlay signal multiplexing

!

Brightness and Contrast control, and DC RESTORE

!

On-screen Switching

!

Video signal gamma correction

!

Sensitivity and Threshold signal input and control

!

Automatic CRT Protection by limiting Contrast Amplifiers.

The Video Processor I/O diagram and the list of inputs and outputs provide

information to allow the technician to perform module-level troubleshooting.

2-24 Model 100 Service Manual

Page 37

Chapter 2---System Description

Figure 2-12

Video Processor I/O

This section provides a comprehensive description of the inputs to and outputs

from the Video Processor PCB. The I/O descriptions in Table 2-7 are arranged by

the source/destination of the signal. The format used is such that the assembly

communicated with is used as the primary heading of each group of signals. Those

signals are further subdivided into inputs and outputs. Inputs refers to an input to

the Video Processor PCB, while output refers to an output from the Video

Processor PCB.

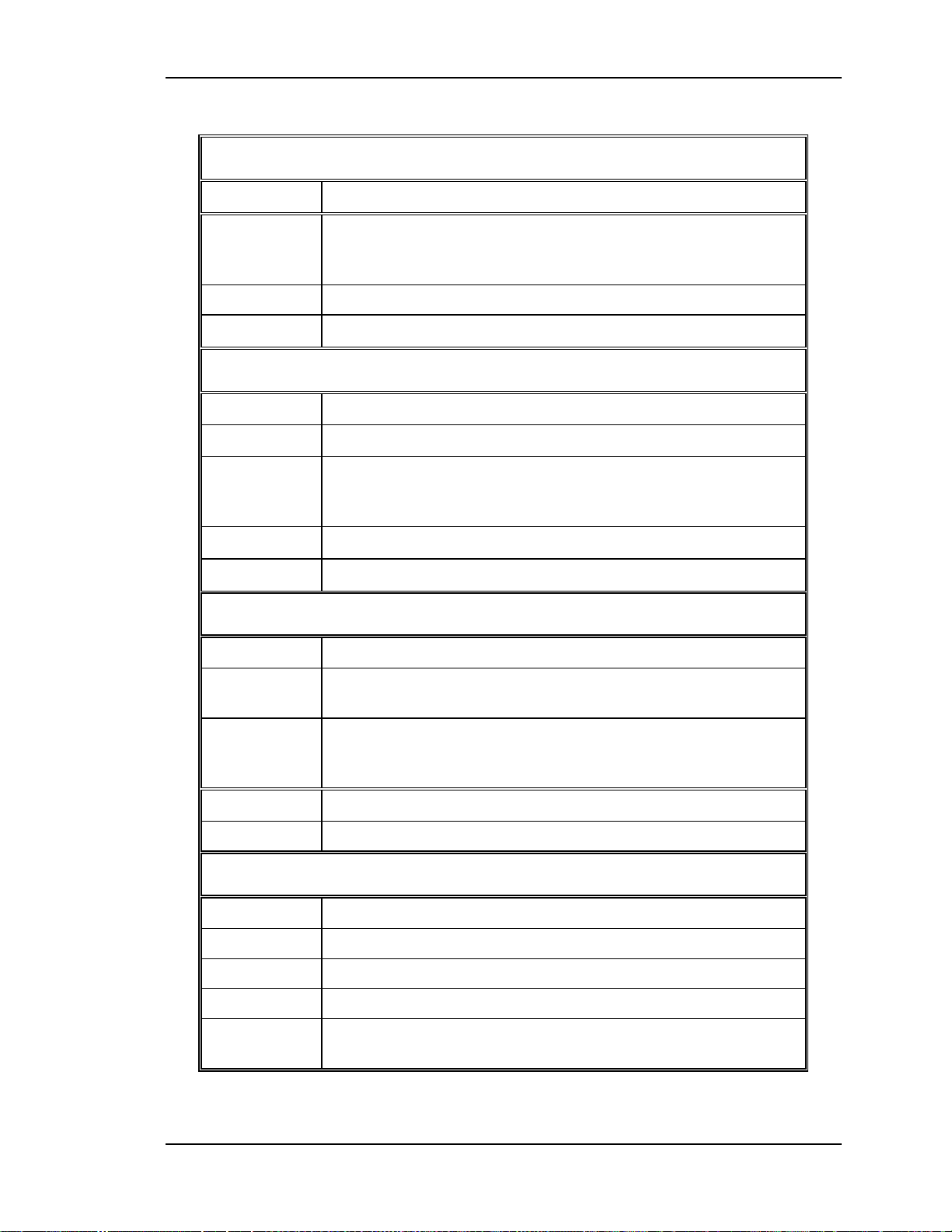

Table 2-7

Video Processor I/O signals

Video Processor I/O Diagram.

Video Processor PCB

2.4 Input

Description

s

+15V Power for analog circuitry.

Model 100 Service Manual 2-25

Page 38

Chapter 2---System Description

Video Processor PCB

-15V Power for analog circuitry.

+5.1V Power for digital circuitry.

SC/RTG

Red Sens. Sensitivity correction information for Blu. Real time data at

0 volt to 1 volt.

Grn Sens. Similar to Red Sens.

Blu Sens. Similar to Red Sens.

Red Thres. Threshold correction information for blue. Real time data at

0 volt to 1 volt.

Grn Thres. Similar to Red Thres.

Blu Thres. Similar to Red Thres.

Red Over Red signal of on-screen menu and/or internal test pat t er n.

Grn Over Similar to Red Over.

Blu Over Similar to Red Over.

Overlay Overlay control signal.

IIC DATA IIC data line. Bi- dir ectional serial line for synchronous data

transfer between the SCB/RTG , HVPS, video processing

and deflection processing PCBs.

IIC CLK IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

IICS IRQ Interrupt line.

Video Processor PCB

BLANKING Blanking signal composed of right, left, t op and bottom

blanking.

CLAMP A negative-going video clamp sig nal with about 3 % dut y

cycle.

Video Amplifier PCB

/Red VAMP_OK Signal from the Regulator that the Red Video Amplifier is

working.

/Grn VAMP_OK Similar to Red VA OK.

/Blu VAMP_OK Sim ilar to Red VA OK.

Red Beam Voltage signal proportional to cathode current averaged

over several horizontal lines in the red CRT. Voltage level

is + mV/mA.

2-26 Model 100 Service Manual

Page 39

Chapter 2---System Description

Video Processor PCB

Grn Beam Similar to Red Beam .

Blu Beam Similar to Red Beam.

Video Input Card

/Sel VIC Input signal from RGB VIC that is used to select input video

source.

V VIC Vertical sync input signal from VIC.

H/C VIC Horizontal Com posite input signal.

Red VIC Red video input from VIC.

Grn VIC Green video input from VIC.

Blu VIC Blue video input from VIC.

/VA OK (HV

ENABLE)

After signal is received that the Video Amplifiers are

functional, this signal is sent t o enable the HVPS.

Outputs

Video Amplifiers

Red Video Red video output . 0 Volt to 1 Volt.

Grn Video Similar to Red Video.

Blue Video Similar to Red Video.

Restore DC Restore control signal.

SC/RTG

Grn sync Input vertical sync.

H sync Input Horizontal or composite sync.

V sync Sync on green signal that is stripped from t he green video.

/IIC Sint IIC interrupt line.

Regulator

Red G

2

Red CRT G2 voltage adjust control signal.

Grn G

2

Similar to Red G2.

Blu G2 Similar to Red G2.

/ Video Ok Signal sent to Regulator and Video Amplifier that a video

signal is present at the VIC.

Model 100 Service Manual 2-27

Page 40

Chapter 2---System Description

System Controller/ Raster Timing Generator PCB

The System Controller/ Raster Timing Generator (SC/RTG) is located in the

electronic card cage (see Figure 4-1).

The Electronics System is controlled by the SC/RTG PCB. The SC/RTG PCB

uses digital and analog circuits to direct the operation of image and raster

generation circuits and to control the input/output of power supply operation. The

SC/RTG can be viewed in two sections: the System Controller section and the

Raster Timing Generator section

The System Controller section sets the operating parameters of the image, such as

brightness and contrast. It also produces internal test patterns and generates onscreen display overlays. The SC/RTG PCB sets the timing for the raster

generation to adjust phase, geometric corrections, shading corrections, and

convergence. The program memory and the memory for all convergence and

shading maps are located on the SC/RTG PCB.

The following functions are performed or controlled by the System Controller

section of the System Controller / Raster Timing Generator PCB:

!

Enables control for the Low Voltage Power Supply, Arc Lamp and cooling

fans.

!

Fault monitors the HVPS, LVPS, Arc Lamp, and fans and most of the

other PCBs.

!

Provides interface communication via the IIC serial bus.

!

Controls Zoom and Focus of the Projection Lens.

!

IIC Interface control

!

Provides Video Overlays such as Menus and Internal Test Patterns

!

X and Y convergence control

!

Threshold and Sensitivity for shading

!

I/O control

!

Two RS-232 serial interface ports

!

Infrared (IR) remote control interface. Accepts input from front or rear IR

detectors.

!

A 5-wire JTAG interface port for CPU emulation support.

!

External 3 color system status LEDs. Green indicates normal, yellow is

standby and red indicates a fault condition.

!

External Service Mode Switch (see Figure 3-12). Pressing this switch

while turning on Circuit Breaker allows the technician to get into the

Buffer Memory. This allows the loading of new operation software and

boot manager.

2-28 Model 100 Service Manual

Page 41

Chapter 2---System Description

!

System Reset Switch. Resets the entire projector must be turned back on.

No data loss.

!

Front Lens control (Focus, Zoom, and Memory Position).

!

ILA® Shutter control.

!

CCD Camera control for Autoshading (future use).

The following functions are performed or controlled by the Raster Timing

Generator section of the System Controller / Raster Timing Generator PCB:

!

Provides the ability to handle sources with the following horizontal and

vertical scan frequencies

Horiz. (30-135 kHz)

"

Vert. (50-150 Hz)

"

!

Selects the proper sync from the source (Separate H&V, Comp sync, and

SOG).

!

Removes the serration and equalization pulses from the Composite. and

Sync On Green syncs.

!

Generates the back porch clamping signal.

!

Detects Non-interlaced and Interlaced sources.

!

Separates horizontal and vertical syncs and provides horizontal and

vertical phase adjustment.

!

Generates blanking signals (left, right, top, and bottom).

!

Provides internal sync generation

!

Provides timing signals used by the System Controller section, and the

Horizontal and Vertical Deflection areas.

Model 100 Service Manual 2-29

Page 42

Chapter 2---System Description

The SC/RTG I/O diagram (see Figure 2-13) and the list of Inputs and Outputs

(see Table 2-8) provide information for the technician to perform module-level

troubleshooting.

Figure 2-13

I/O Diagram of System Controller section of SC/RTG PCB.

IIC Interface

Communications are performed through the IIC bus to the other PCBs in the

system. This three-wire bus interface consists of clock line, data line and interrupt

line. The System Controller PCB controls the IIC bus and tells the other PCB

when to send and receive data over the IIC bus.

System Controller / Raster Timing Generator Input/Output

This section provides a description of the inputs to and outputs from the SC/RTG.

The I/O descriptions are arranged by the source/destination of the signal. The

format used is such that the assembly communicated with is used as the primary

heading of each output. Input refers to an input to the SC/RTG, output refers to an

output from the SC/RTG.

2-30 Model 100 Service Manual

Page 43

Chapter 2---System Description

Table 2-8

System

System Controller/ RTG PCB input/output signals

Controller

/Raster Timing Generator PCB

Inputs

LVPS

+5.1V Stdby Standby voltage for microprocessor contr ol and r emote

+15V Power for analog circuitry.

-15V Power for analog circuitry.

/LV OK Feedback signal from t he LVPS t hat it has powered up.

HVPS

HV OK High Voltage status line. Low = operation HVPS.

ALPS

/LAMP OK

/LAMP LIT Signal from ALPS that t h e Ar c Lamp is lit.

Video Processor

Description

operation.

Jumpered (not used).

V Sync Input vertical sync.

H Sync Input Hor izontal or com posit e sync.

Grn Sync Sync on grn signal that is stripped from the green video.

Misc.

/FRONT IR Input signal from Front IR Detector.

/REAR IR Input signal from Rear IR Detector.

LENS POS

CCD LINE Power to CCD AST camera.

CCD DATA Data from CCD AST camera.

Outputs

LVPS

/LV ENA Signal to enable the LVPS.

/FAN_ENA Signal to enable the 24V standby power.

Model 100 Service Manual 2-31

Page 44

Chapter 2---System Description

System Controller/Raster Timing Generator PCB

HVPS

Synchronization pulse for the HVPS, synchronized wit the

HVPS SYNC

ALPS

/LAMP ENA Enables the ALPS power.

Video Processor

OVERLAY Overlay control signal.

Red_Over Red signal of on-screen menu and/or internal t est pattern.

Grn_Over Similar to Red_Over.

Blu_Over Similar to Red_Over.

selected Horiz. Sync at either same, half or on t hir d the

frequency.

Blu_Thres

Grn_Thres Similar to Blu_Thres.

Red_Thres Similar to Blu_Thres.

Blu_Sens

Grn_Sens Similar to Blu_Sens.

Red_Sens Similar to Blu_Sens.

BLANKING Blanking signal composed of right, left , top and bottom

CLAMP A neg at ive-g oing video clamp signal wit about 3 % duty

Vertical Convergence Deflection

X_Red Conv

X_Red Conv

Threshold correction information for blue. Real time data at

0 volt to 1 volt.

Sensitivity correction information for Blu. Real time data at

0 volt to 1 volt.

blanking.

cycle.

Red X convergence waveform. The amplitude for full scale

correction is about 1 VPP.

Grn X convergence waveform. The am plitude for full scale

correction is about 1 VPP.

X_Red Conv

Y_Red Conv

Y_Grn Conv

2-32 Model 100 Service Manual

Blue X convergence waveform. The amplit ude for full scale

correction is about 1 VPP.

Red Y convergence waveform. The amplitude for full scale

correction is about 1 VPP.

Grn Y convergence waveform. The amplit ude for full scale

correction is about 1 VPP.

Page 45

Chapter 2---System Description

System Controller/Raster Timing Generator PCB

Y_Blu Conv

Deflection Processor

CORR SYNC

V DRIVE

Horizontal Deflection

H DRIVE

H BAND:0 Horizontal frequency band lines.

H BAND:1 Band A = 00, Band B = 01, Band C = 11.

/H ENABLE Low = enabled deflection and high = disabled deflection.

H_F2V A DC voltage proportional to horizontal frequency.

CCD Camera

CCD_EXP Signal to CCD Shading camera to control shutter

Blue Y convergence waveform. The amplitude for full-scale

correction is about 1 VPP.

Square wave HCT level synchronous signal for Horiz.

Axis.

Square wave negative going pulse synchronized to the

selected vertical sync with a pulse width of about 4

horizontal periods.

Square wave 50 % duty cycle synchronized to the

selected horizontal sync.

exposure time.

CCD_CLK Clock pulse for CCD Shading camera.

CCD_ZOOM Signal to CCD Shading camer a for zoom control.

CCD_FOCUS Signal to CCD Shading camera for focus control.

CCD_IRIS Signal to CCD Shading camera fo r aper ture control.

Front Lens

LENS_ZOOM Signal to lens zoom motor.

LENS_FOCUS Signal to lens focus motor.

Shutters

Red Shutter Signal to actuate the Red Shutter Motor.

Grn Shutter Signal t o act uat e the Green Shutter Motor.

Blue Shutter Signal to actuate t he Blue Shut ter Motor.

IIC

/IIC_SINT IIC interrupt line.

IIC data line. Bi-directional serial line f or synchronous dat a

IIC_DATA

transfer between the SCB/RTG and t he Horizontal

Deflection PCB.

Model 100 Service Manual 2-33

Page 46

Chapter 2---System Description

System Controller/Raster Timing Generator PCB

IIC_CLK

IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

Raster Timing Generator Section

Horizontal frequency band selection and LED logic.

The RTG section produces a voltage that is proportional to the horizontal

frequency, which is used by the Horizontal Deflection PCB, and the phase locked

loop (PLL) section of the RTG board. This DC voltage is used to create the

following frequency bands:

Band A: from 30 kHz to 45 kHz.

Band B: from 45 kHz to 90 kHz

Band C: from 90 kHz to 135 kHz

These bands are outputted through the IIC interface to be used by the System

Controller Board. Backplane Board. The Horizontal Deflection Board uses these

lines for proper selection of retrace times.

2-34 Model 100 Service Manual

Page 47

Chapter 2---System Description

Figure 2-14

Output

The RTG will disable the Horizontal Deflection Board by placing a high on the

/H_ENABLE line during any of following events:

Deflection Processor PCB

The Deflection Processor PCB is the circuit board directly above the System

Controller/ Raster Timing Generator in the Electronics Module card cage (see

figure 4-10). The following functions are performed by or controlled by the

Deflection PCB:

I/O diagram of Raster Timing Generator section of SC/RTG PCB.

!

A. During and about 2 seconds after the programming period of the

FPGA.

!

B. During frequency band change period.

!

C. During the period that the phase locked loop is out of lock.

!

Controls the ILA® Bias and Frequency

!

Combines Focus and Dynamic Focus signals to one signal (Focus_sig) for

both the horizontal and vertical for each color

!

L/R and T/B Pincushion

Model 100 Service Manual 2-35

Page 48

!

L/R and T/B Keystone

!

L/R and T/B Bow

!

Horizontal and Vertical Linearity

!

Horizontal and Vertical Edge Linearity

!

Red and Blue Horizontal Size

!

Red and Blue Vertical Size

Chapter 2---System Description

Figure 2-15

I/O diagram of Deflection Processor PCB.

The Deflection Processor PCB I/O diagram (see Figure 2-14) and the list of inputs

and outputs (see Table 2-9) provide information for the technician to perform

module level troubleshooting.

2-36 Model 100 Service Manual

Page 49

Chapter 2---System Description

Table 2-9

Deflection Processor input/outputs signals

Deflection Processor PCB

2.5 Input

s

+15V Power for analog circuitry.

-15V Power for analog circuitry.

+5.1V Power for digital circuitry.

SC/RTG

IIC_CLK IIC data line. Bi-directional serial line f or synchronous dat a

transfer between the SCB/RTG .

IIC_DATA IIC data line. Bi-directional serial line for synchronous data

transfer between the SCB/RTG .

IIC_CLK IIC clock line. Unidirectional clock line for control of

synchronous data transfer over the IIC bus interface.

CORR_SYNC Square wave HCT level synchronous signal for Hor iz. Axis.

V_DRIVE Square wave negative going pulse synchronized to the selected

vertical sync with a pulse width of about 4 horizontal periods.

Outputs

SC/RTG

IICS_IRQ Interrupt line.

BLANKING Blanking signal composed of right, left, top and bot tom

blanking.

CLAMP A negative-going video clamp sig nal wit about 3 % duty cycle.

V_Sync Input vertical sync.

H_Sync Input Horizontal or composit e sync.

Grn_Sync Sync on grn signal that is stripped from the green video.

Vertical Convergence Deflection

RED_ROTATE Signal to rotate the image for convergence alignment.

GRN_ROTATE Similar to RED ROTATE.

BLU_ROTATE Similar to RED ROTAT E.

X RED_SIG Red X-axis geomet r y corr ect ion data and also L/R Bow, L/R

Skew, Horiz. Edge Linearity, and width

X GRN_SIG Similar to X RED SI G except without the width signal.

Model 100 Service Manual 2-37

Page 50

Chapter 2---System Description

Deflection Processor PCB

X BLU_SIG Similar to X RED SIG.

Y RED_SIG Red Y-axis geometr y corr ection data.

Y GRN_SIG Similar to Y RED SI G.

Y BLU_SIG Similar to Y RED SIG.

VERT. SIG Vertical sync signal

Horizontal Deflection

H_PS_INFO Horizontal sweep feedback sig nal.

WIDT H Controls the green im age width.

H_GEO_SIG L/R Pincushion and Keystone combined into one signal.

HVPS

H_FOCUS_SIG Horizontal f ocus par abola.

V_FOCUS_SIG Vertical Focus parabola.

Vertical Convergence Deflection PCB

The Vertical Convergence Deflection PCB is the middle circuit board, above the

Deflection Processor PCB and below the shorter Horizontal Deflection PCB, in

the Electronics Module card cage (see Figure 4-10).

The Vertical Convergence Deflection PCB I/O diagram (see Figure 2-15) and the

list of inputs and outputs (see Table 2-10) provide information for the technician

to perform module level troubleshooting.

The following functions are provided by the Vertical Convergence Deflection

PCB:

!

Horizontal raster centering for all three colors

!

Combines Convergence data from the System Controller/ RTG PCB with

Geometry data signals (X_RGB_SIG and Y_RGB_SIG)

!

Scan reversal via jumper positioning

!

RGB Rotation

!

Drive for Vertical Deflection Coils

!