Page 1

SERVICE MANUAL

LCD VIDEO MONITOR

LM-17G

LM-17G

LM-17G

MENU/ENTER

/U

/E

/C

INPUT SELECT

POWER

PCVIDEOBA

TABLE OF CONTENTS

1. PRECAUTIONS .......................................................................................................................................... 1-3

2. SPECIFIC SERVICE INSTRUCTIONS ....................................................................................................... 1-6

3. DISASSEMBLY ........................................................................................................................................... 1-7

4. ADJUSTEMNT ...........................................................................................................................................1-11

5. TROUBLE SHOOTING .............................................................................................................................. 1-12

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.52164

2003/11

Page 2

Items Contents

Type

Dimensions (W × H × D)

Mass

Color system

Scanning frequency

Power Input

Power consumption

LCD Panel

Display area

Display Pixels

Input/Output VIDEO A

terminals

VIDEO B

PC input

REMOTE INPUT

ASPECT

SPECIFICATION

LCD Video Monitor

40.2cm × 34.8cm × 6.9cm (Monitor only)

40.2cm × 34.9cm × 16.2cm (With supplied stand)

5kg (Monitor only)

5.8kg (with stand)

PAL / NTSC

H : 31.5kHz ~ 80kHz(PC) / 15.734kHz(NTSC) / 15.625kHz(PAL)

V : 56Hz

AC100V/AC240V, 50Hz/60Hz

45W

17-in, active matrix TFT

Visible size : 43.3cm(Diagonal) / 33.8cm × 27.0cm(H × V)

Horizontal : 1280 pixel × Vertical : 1024 pixel

Composite video, BNC connector ×2, 1V(p-p), 75Ω negative sync

(bridge connection possible, auto termination)

Composite video, BNC connector

(bridge connection possible, auto termination)

Analog RGB : D-sub(15 pin) ×1, positive 0.7 (p-p)

RCA pin ×1

RCA pin ×1

~ 75Hz(PC) / 59.94(NTSC) / 50Hz(PAL)

×

2, 1V(p-p), 75Ω negative sync

NOTE: Design & specifications are subject to change without notice.

1-2 (No. 52164)

Page 3

SECTION 1

PRECAUTION

1. 1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should

be made to the original design unless authorized in writing

by the manufacturer. Replacement parts must be identical

to those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by (!) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list

of Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : (

GND, the ISOLATED (NEUTRAL) : (

EARTH : (

) side GND. Don't short between the LIVE

) side GND and

side GND and ISOLATED (NEUTRAL) side GND or EARTH

side GND and never measure the LIVE side GND and

ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope

etc.).

If above note will not be kept, a fuse or any parts will be

broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See ADJUSTMENT OF B1 POWER SUPPLY).

(6) The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept

to a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

) side

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence

of overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output

terminals, Control knobs, metal cabinet, screw heads,

earphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand

a voltage of 3000V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

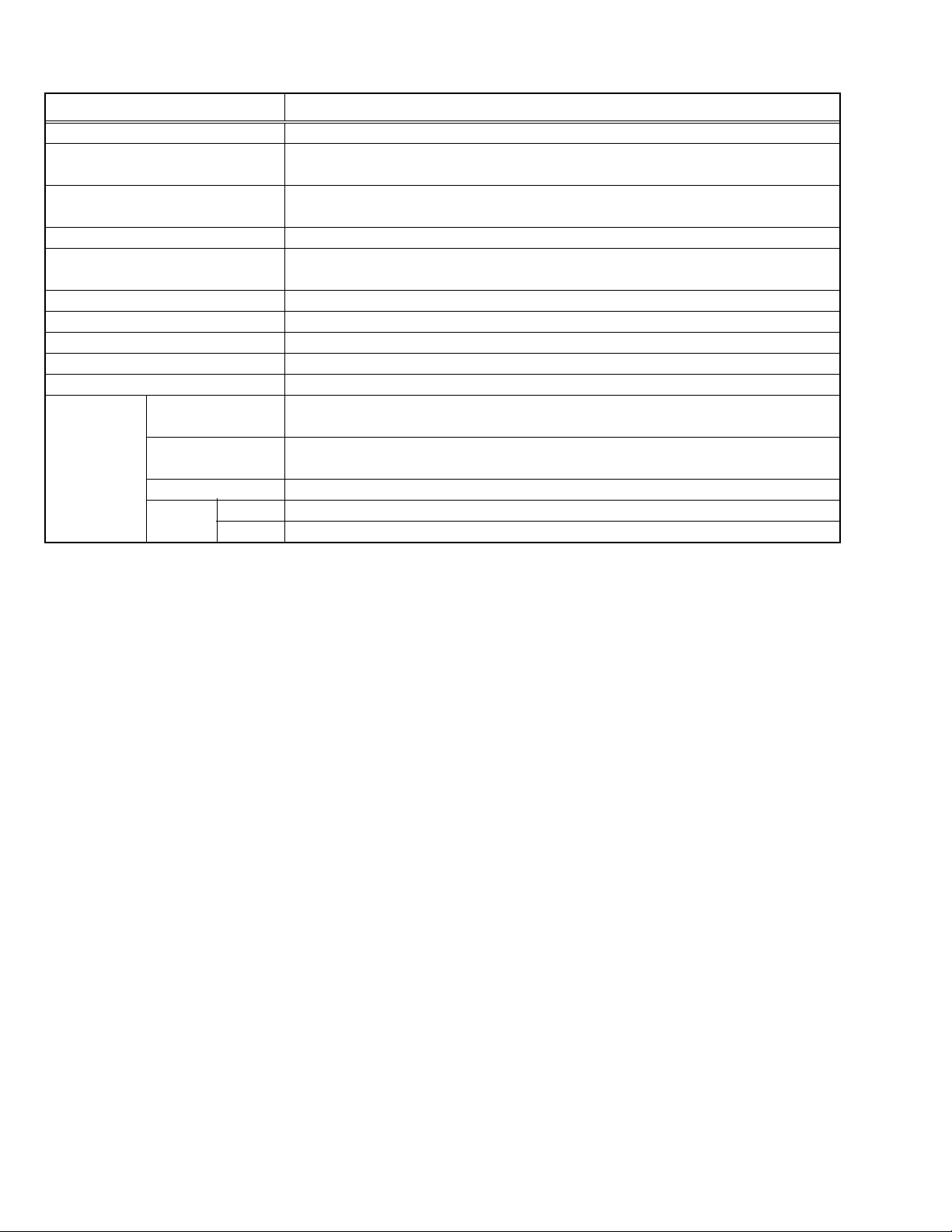

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.).

Use an AC voltmeter having 1000 ohms per volt or

more sensitivity in the following manner. Connect a

1500Ω 10W resistor paralleled by a 0.15µF AC-type

capacitor between an exposed metal part and a known

good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move

the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds

to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000Ω/V,

OR MORE SENSITIVITY)

0.15µF AC-TYPE

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

GOOD EARTH GROUND

1500Ω 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PA RT

(No. 52164) 1-3

Page 4

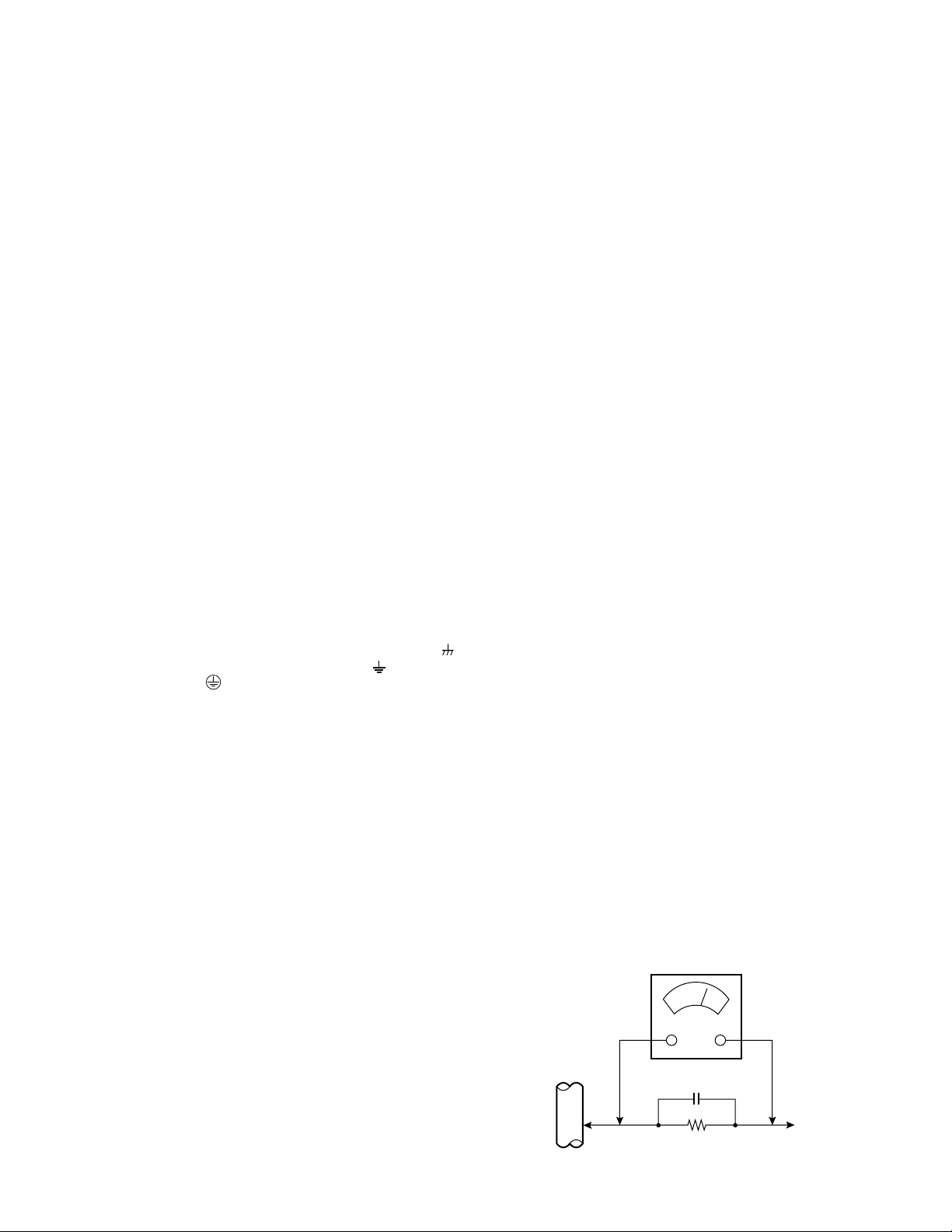

1. 2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise.

Therefore, please make sure pay attention not to block the

heat dissipation vent as well as the ventilation outlet behind

the unit and ensure that there is room for ventilation around it.

front side Note

wall

20cm

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as

well as the floor etc.

Install the unit on stable flooring or stands.

Take precautionary measures to prevent the unit from tipping

in order to protect against accidents and earthquakes.

Use the metal fittings

of the exclusive use

option.

1.Hang

on the

wall

2.Hang

from the

ceiling

3.Put

on the

table

10cm

10cm

10cm

10cm

front

wall

20cm

10cm

10cm

10cm

front wall

10cm

front

wall

10cm

front

wall

Install has to be

done by professional

construction trader

Please confirm the

structure and the

strength of the wall to

install beforehand.

It attempts accident

prevention and safe

securing .

Install on the fixed

floor and the stand.

To prevent from an

accident and for the

safe securing of an

earthquake and so on,

please process for

tumble prevention.

15cm

5cm

15cm

1.2.3 FALL TIP PREVENTION MEASURES

Take precautionary measures to prevent the unit from falling

or tipping to protect against emergencies such as

earthquakes as well as accidents.

Attach the supplied stand to the monitor as shown, and then

fix it with the screws. Please fix the stand with the

supplied screw (A) first, and then fix it with the screws (B).

1-4 (No. 52164)

10cm

BB

A

Page 5

1.3 PRECAUTIONS

(1) Depending on the around temperature, the brightness leaning occurs. Be careful of the environment in the product

installation place and so on sufficiently.

(2) Don't hinder radiation from the back, the heaven and the side. Please refer to the next page that explains about the

condition of the installation.

The inside becomes hot if hindering radiation and there is fear, which the inner circuit damages.

(3) Install in the place with good ventilation. Use in the condition that around temperature is in the 0~35°C range.

(4) Avoid preservation and use at the high temperature or high humidity place. If you behave like this, leaning sometimes

happens in the screen when the set actives.

(5) Depending on the condition and the environment of display, the slight fleck of the light and leaning of the screen and so on

is sometimes conspicuous. This is the characteristic which is peculiar to liquid crystal display. It is not set trouble.

(6) This monitor has cool cathode pipe as the backlight. The time change and the use time sometimes change brightness

and condition of display.

1.4 THE ATTENTION IN TRANSPORTATION

When transporting a set, if the load handling is bad (throwing, falling and so on) however it is using a solid box, pressure inside

liquid crystal display.

In the case there is fear to break the liquid crystal display while transporting. To prevent from the accident or trouble while

transporting, pay attention to choice of the transportation company sufficiently and also arrange for it in the delivery after the

attention of the load handling is explained to the transportation company.

This set is used glass for composing liquid crystal display. When carrying, pay attention not to add over vibration and impact

sufficiently.

Ensure that it is placed upright and not horizontally during transportation and storage as the LCD panel is very vulnerable to

lateral impacts and may break. During transportation, ensure that the unit is loaded along the traveling direction of the vehicle,

and avoid stacking them on one another. For storage, ensure that they are stacked in 2 layers or less even when placed upright.

(No. 52164) 1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DESCRIPTION ABOUT LIQUID CRYSTAL PANEL

2.2.1 STRUCTURE OF LIGUID CRYSTAL PANEL

The Liquid Crystal Panel of this model is TFT Panel. The Print circuit board that consist of TFT array and the print circuit board

adopted stripe shaped image element alignment are used. These two boards are mixed. The Liquid crystal is enclosed between

two boards.

2.1.2 LONG RANGE AFTERIMAGE OF LIQUID CRYSTAL

The small amount of ion material has mixed a liquid crystal panel with the liquid crystal material in the manufacturing process.

If ion material is piled up partially among the poles when the voltage is impressed among the poles, the brightness difference

occurs and becomes a long-range afterimage If same picture is reflected for long time, such a long-range afterimage occurs. If

the long-range afterimage occurs, we recommend that you reflect the single color image or moving picture and so on to restore.

2.1.3 THE DISPLAY REPLYING SPEED OF LIQUID CRYSTAL

Because the speed to display of Liquid crystal panel is slower than the speed of the CRT monitor, some of the moving picture

cannot overtake to the speed to display and the image looks flowing is sometimes displayed. This is not trouble, but efficiency

of Liquid Crystal.

2.1.4 THE EYESIGHT CORNER OF LIQUID CRYSTAL

The liquid crystal panel has the wide eyesight corner for which it is difficult to reverse brightness. The tint changes depending on

the direction to see a screen. This is not trouble, but efficiency of Liquid Crystal.

2.1.5 THE PICTURE ELEMENT FAULT OF LIQUID CRYSTAL

The liquid crystal panel is composed of precise technique but all devices don't always work right.

2.2 ATTENTION ITEMS WHEN REPLACING PARTS

2.2.1 ATTENTION TO EXCHANGE THE LIQUID CRYSTAL PANEL

(1) The stillness electricity sometimes makes damage a liquid crystal panel. In liquid crystal panel exchange, do a measure

of the stillness electricity such as the earth band.

(2) A liquid crystal panel and back-light are made from glass. If you gain an impact to these materials, there is fear to damage.

So in case of treatment, be careful sufficiently.

(3) Fix with the screw after confirming that there is not a float to chassis base when exchanging liquid crystal panel.

After that reflect all the black signals and confirm that brightness leaning doesn't occur near the screw fixation part.

When brightness leaning occurs, slacken a screw in the neighborhood until the brightness leaning is running-out.

(4) Fix the torque that installs a screw below 0.294Nm.

If you install at any more torque, the liquid crystal panel is transformed and sometimes damages.

(5) If you pull out or insert each connector when power is ON, it causes the trouble.

So pull out or insert each connector in the condition to have pulled out a power supply plug.

2.2.2 ATTENTION WHEN EXCHANGING THE MAIN PWB

To show the original efficiency of the MAIN PWB, pull out a heat think from the previous MAIN PWB and install it in the new PWB

surely.

2.2.3 ATTENTION WHEN EXCHANGING THE FUSE

When exchanging the fuse, please use specified parts. After fuse exchange, confirm that insulater is set to the shield and

insulate surely.

1-6 (No. 52164)

Page 7

SECTION 3

DISASSEMBLY

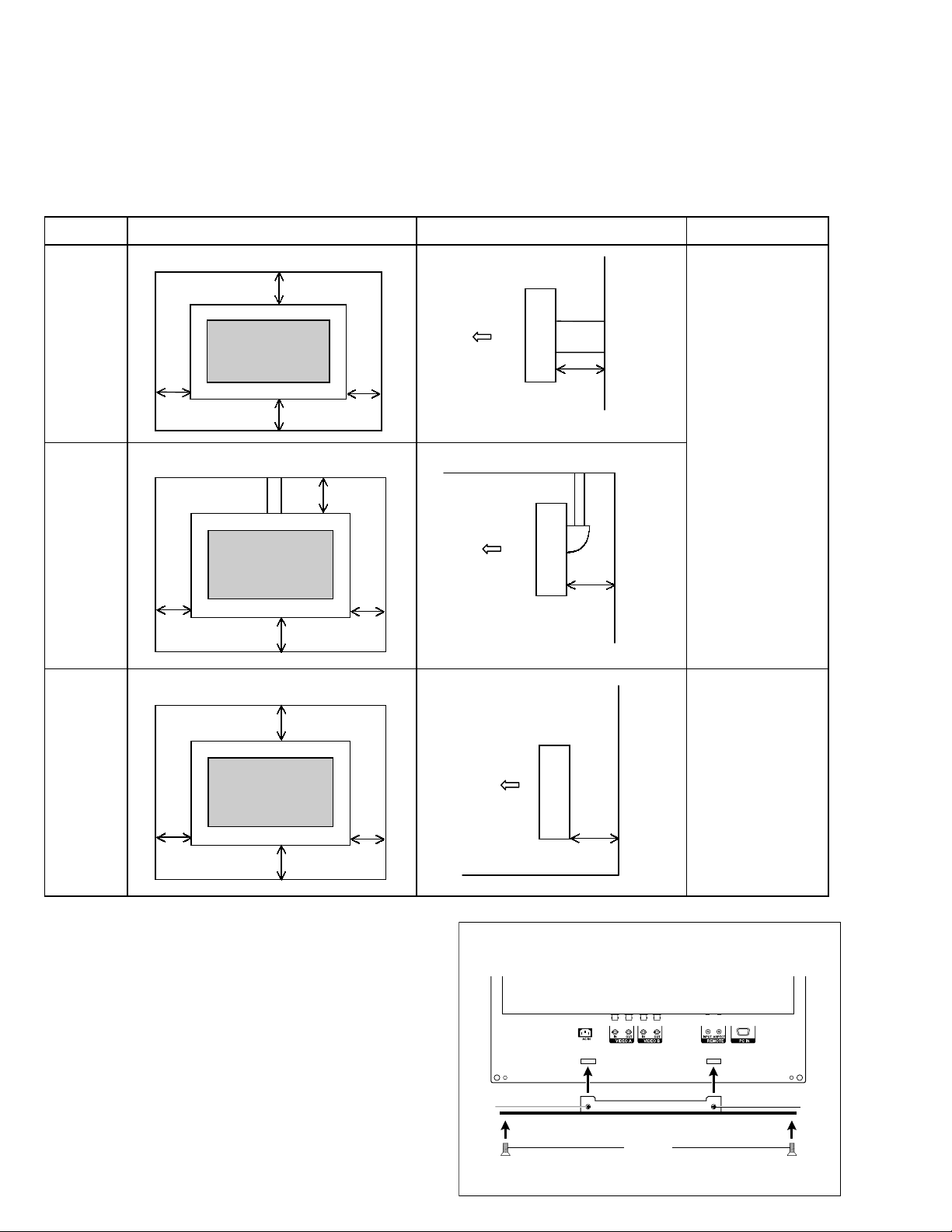

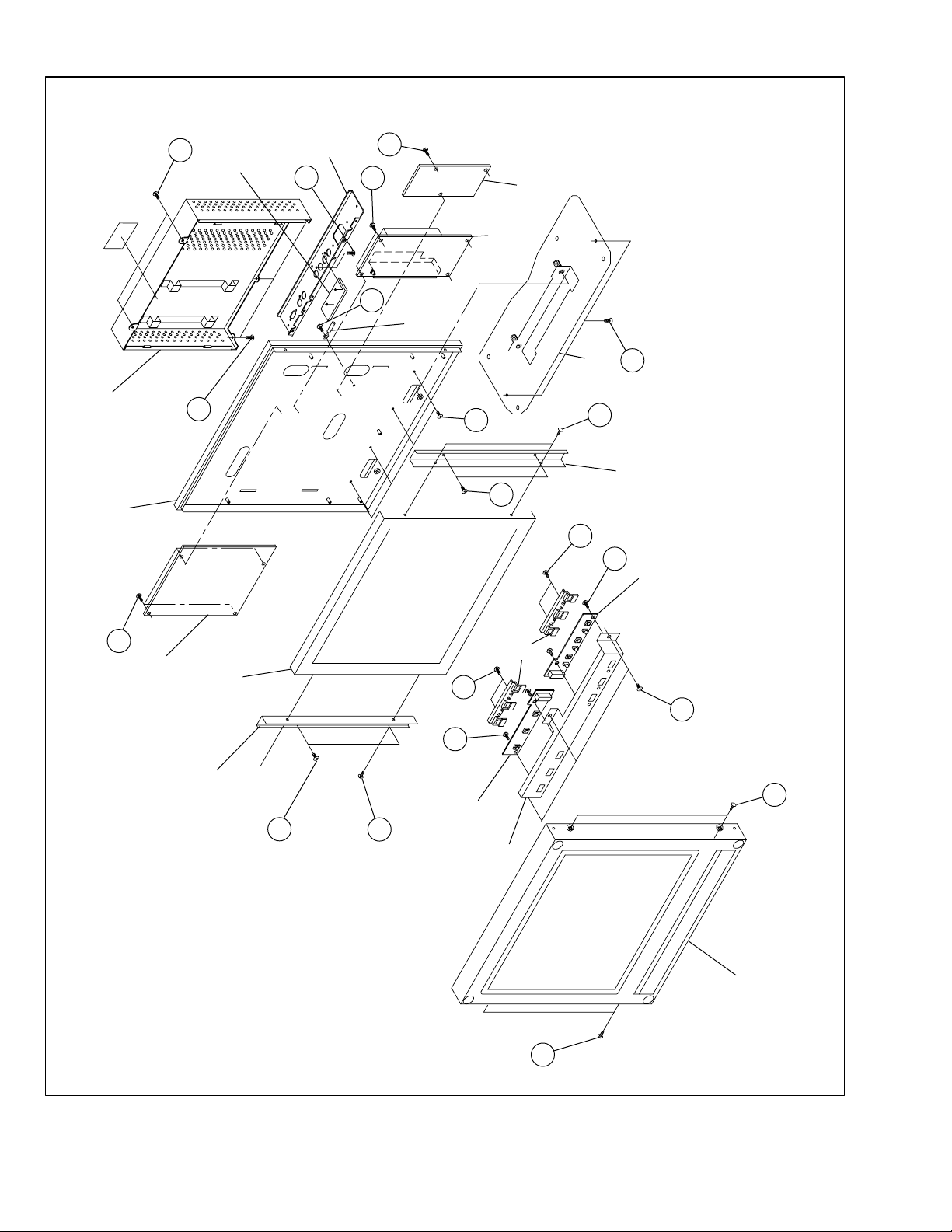

3.1 DISASSEMBLY PROCEDURE

CAUTION:

• Even with the power switch off, some parts of the unit

are live. Be sure to disconnect the power plug from the

AC outlet before disassembly and reassembly.

• Remove the power cord.

3.1.1 REMOVING THE BASE

(1) Lie down the unit and let panel downward.

(2) As shown in Fig.1, remove 2 screws [A] and loosen the

two spring screws on BASE.

(3) Slightly remove the BASE.

3.1.2 REMOVING THE FUNCTION COVER

• Remove the BASE.

(1) As shown in Fig.1, remove 5 screws [B].

(2) Shift the FUNCTION COVER toward BASE and raise

upward.

3.1.3 REMOVING THE MAIN PWB

• Remove the FUNCTION COVER.

(1) As shown in Fig.1, remove 4 screws [C].

(2) Slightly remove the MAIN PWB upward.

3.1.4 REMOVING THE POWER PWB

• Remove the FUNCTION COVER.

(1) As shown in Fig.1, remove 1 screw [D].

(2) As shown in Fig.1, remove 4 screws [E], and remove the

earth wire.

(3) Slightly remove the POWER PWB upward.

3.1.9 REMOVING THE CONTROL BRACKET

• Remove the FRONT COVER.

(1) As shown in Fig.1, remove 3 screws [M].

(3) Remove the CONTROL BRACKET upward.

3.1.10 REMOVING THE CONTROL BUTTON

• Remove the CONTROL BRACKET.

(1) As shown in Fig.1, remove 4 screws [N].

(2) Remove two CONTROL BUTTON downward.

3.1.11 REMOVING THE FRONT CONTROL 1 PWB AND THE

FRONT CONTROL 2 PWB

• Remove the CONTROL BRACKET.

(1) As shown in Fig.1, remove 2 screws [P].

(2) Remove the FRONT CONTROL 1 PWB upward.

(3) As shown in Fig.1, remove 2 screws [Q].

(4) Remove the FRONT CONTROL 2 PWB upward.

3.1.12 REMOVING THE BACK COVER AND THE TERMINAL

BRACKET

• Remove the FUNCTION COVER.

• Remove the MAIN PWB

• Remove the POWER PWB

• Remove the INVERTER PWB

• Remove the BNC INPUT PWB

• Remove the FRONT COVER

• Remove the LCD PANEL.

• Remove the CONTROL BRACKET

(1) As shown in Fig.1, remove 4 screws [S].

(2) Remove the BACK COVER and the TERMINAL BRACKET.

3.1.5 REMOVING THE INVERTER PWB

• Remove the FUNCTION COVER.

(1) As shown in Fig.1, remove 3 screws [F].

(2) Slightly remove the INVERTER PWB upward.

3.1.6 REMOVING THE BNC INPUT PWB

• Remove the FUNCTION COVER.

(1) As shown in Fig.1, remove 2 screws [G].

(2) Slightly remove the BNC INPUT PWB upward.

3.1.7 REMOVING THE FRONT COVER

• Remove the BASE.

(1) Lie down the unit and let panel upward.

(2) As shown in Fig.1, remove 4 screws [H].

(3) Slightly remove the FRONT COVER.

3.1.8 REMOVING THE LCD PANEL, THE LCD BRACKET (R)

AND THE LCD BRACKET (L)

• Remove the FRONT COVER.

(1) As shown in Fig.1, remove 4 screws [J].

(2) Raise LCD PANEL upward.

(3) As shown in Fig.1, remove 4 screws [K].

(4) Remove the LCD BRACKET (R) and the LCD BRACKET

(L).

(No. 52164) 1-7

Page 8

B

PWB

BNC INPUT

BRACKET

TERMINAL

G

F

E

INVERTER PWB

POWER PWB

D

WIRE

EARTH

A

BASE

FUNCTION COVER

BACK COVER

C

MAIN PWB

B

LCD PANEL

LCD BRACKET

S

K

J

LCD BRACKET

N

P

PWB

FRONT CONTROL1

BUTTON

CONTROL

N

M

Q

H

J

K

PWB

1-8 (No. 52164)

FRONT CONTROL2

Fig. 1

BRACKET

CONTROL

FRONT COVER

H

Page 9

3. 2 REPLACEMENT OF MEMORY IC

3.2.1 MEMORY IC

The memory is in the MAIN PWB. The MAIN PWB is only for reference. Avoid replacing individual parts. Replace entire unit only.

When the microcomputer or the memory are out of order, exchange a MAIN PWB.

3. 3 USER SETTING

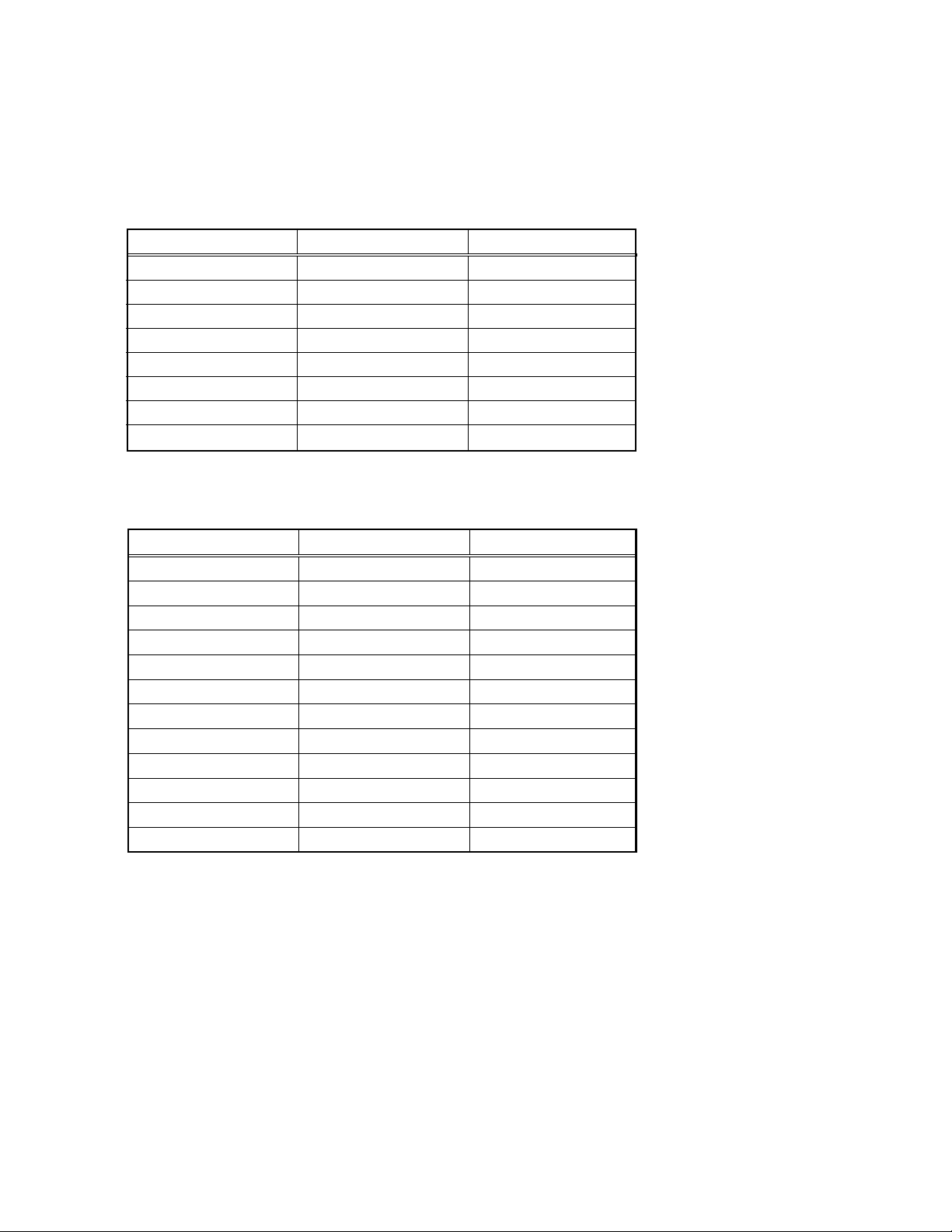

! PC mode

Setting item Setting range Setting value

BACK LIGHT 0 ~ 100 100

CONTRAST 0 ~ 100 50

H. POSITION 0 ~ 100 50

V. POSITION 0 ~ 100 50

COLOR TEMP.

H. OSD POSITION 0 ~ 100 50

V. OSD POSITION 0 ~ 100 50

REMOTE ON/OFF OFF

! Video mode (VIDEO A,B)

HIGH/NATURAL/LOW/USER

NATURAL

Setting item Setting range Setting value

BACK LIGHT 0 ~ 100 100

PICTURE 0 ~ 100 0

PHASE 0 ~ 45 23

CHROMA 0 ~ 100 80

ASPECT 4 : 3 / 16 : 9 4 : 3

COLOR TEMP.

LOW LIGHT ADJ. 0 ~ 255 20

SIGNAL LEVEL STD/AMP STD

H. OSD POSITION 0 ~ 100 5 0

V. OSD POSITION 0 ~ 100 50

AGC ON/OFF ON

REMOTE ON/OFF OFF

HIGH/NATURAL/LOW/USER

NATURAL

(No. 52164) 1-9

Page 10

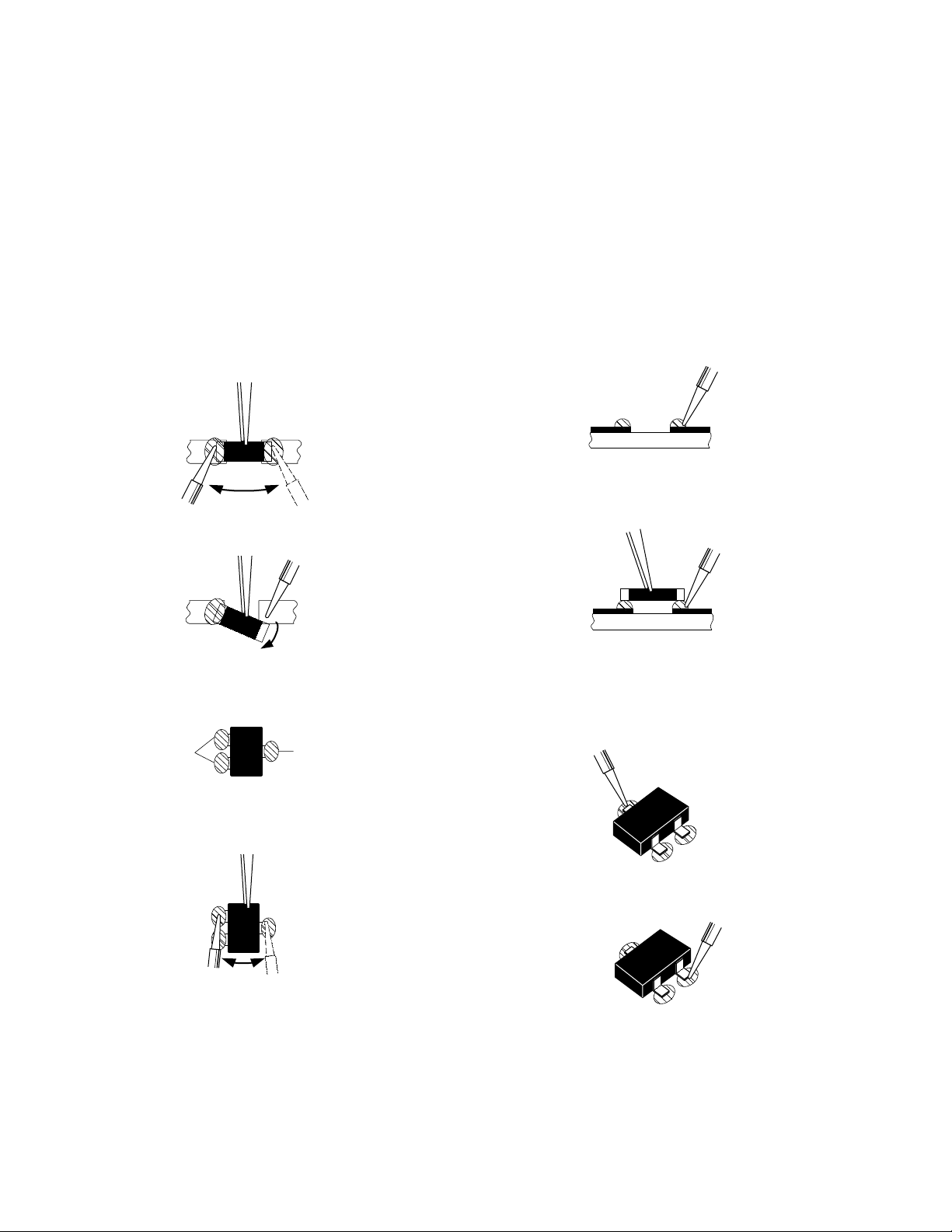

3.4 REPLACEMENT OF CHIP COMPONENT

A

B

C

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with tweezers and remove the chip part.

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of

the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

Note :

After removing the part, remove remaining solder from

the pattern.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(4) Then solder leads B and C.

A

B

C

1-10 (No. 52164)

Page 11

SECTION 4

ADJUSTMENT

The service manual does not describe ADJUSTMENT.

(No. 52164) 1-11

Page 12

SECTION 5

TROUBLE SHOOTING

The service manual does not describe TROUBLE SHOOTING.

1-12 (No. 52164)

Page 13

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No. 52164)

Printed in Japan

WPC

Page 14

LM-17G /U,

LM-17G /E,

LM-17G

/C

STANDARD CIRCUIT DIAGRAMS

CONTENTS

USING P.W. BOARD ..................................................................................................................................................................... 2-1

SEMICONDUCTOR ........................................................................................................................................................................ 2-1

BLOCK DIAGRAM ......................................................................................................................................................................... 2-2

CIRCUIT DIAGRAMS ................................................................................................................................................................... 2-3

POWER PWB CIRCUIT DIAGRAM ...................................................................................................................................................... 2-3

MAIN PWB CIRCUIT DIAGRAM ........................................................................................................................................................... 2-5

FRONT CONTROL 1 PWB CIRCUIT DIAGRAM ................................................................................................................................ 2-17

FRONT CONTROL 2 PWB CIRCUIT DIAGRAM ................................................................................................................................ 2-17

BNC INPUT PWB CIRCUIT DIAGRAM ............................................................................................................................................... 2-17

INVERTER PWB CIRCUIT DIAGRAM ................................................................................................................................................ 2-19

PATTERN DIAGRAMS............................................................................................................................................................... 2-21

POWER PWB PATTERN .................................................................................................................................................................... 2-21

USING P.W. BOARD

POWER P.W. BOARD DA-5097613403

MAIN P.W. BOARD DA-5097624700

FRONT CONTROL1 P.W. BOARD DA-5098800661

FRONT CONTROL2 P.W. BOARD DA-5098800647

BNC INPUT P.W. BOARD DA-5098800646

INVERTER P.W. BOARD DA-5097672143

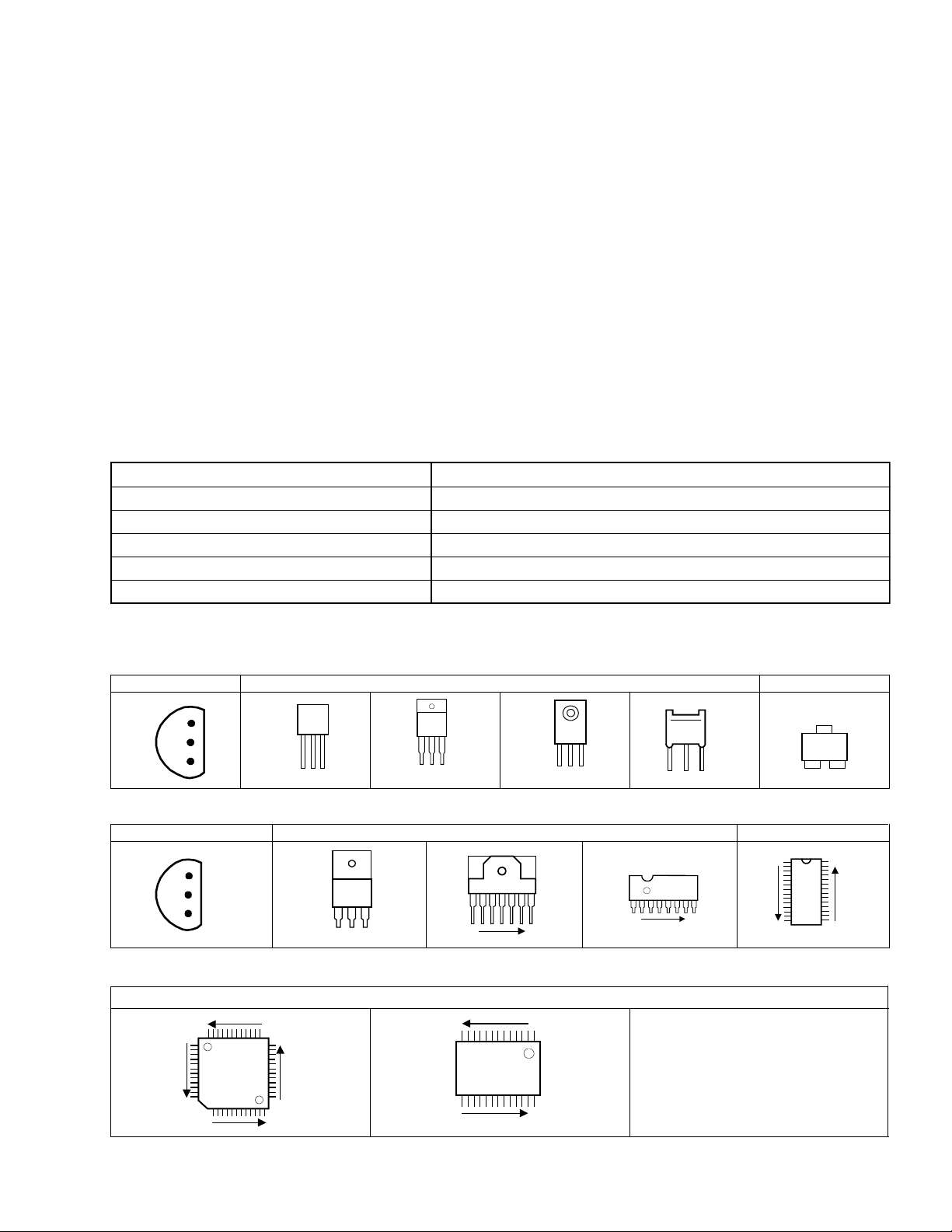

SEMICONDUCTOR SHAPES

TRANSISTOR

BOTTOM VIEW

E

C

B

ECB

(G)(D)(S )

IC

B OT TO M V I EW FR O NT V I EW T OP V I EW

OUT

E

IN

IN OUTE

CHIP IC

N

N

BCE

FRONT VI EW

1 N

TOP VIEW

ECB

1

ECB

1 N

TOP VIEW

CHIP TR

1

C

BE

N

N

1

N

N

(No. 52164) 2-1

Page 15

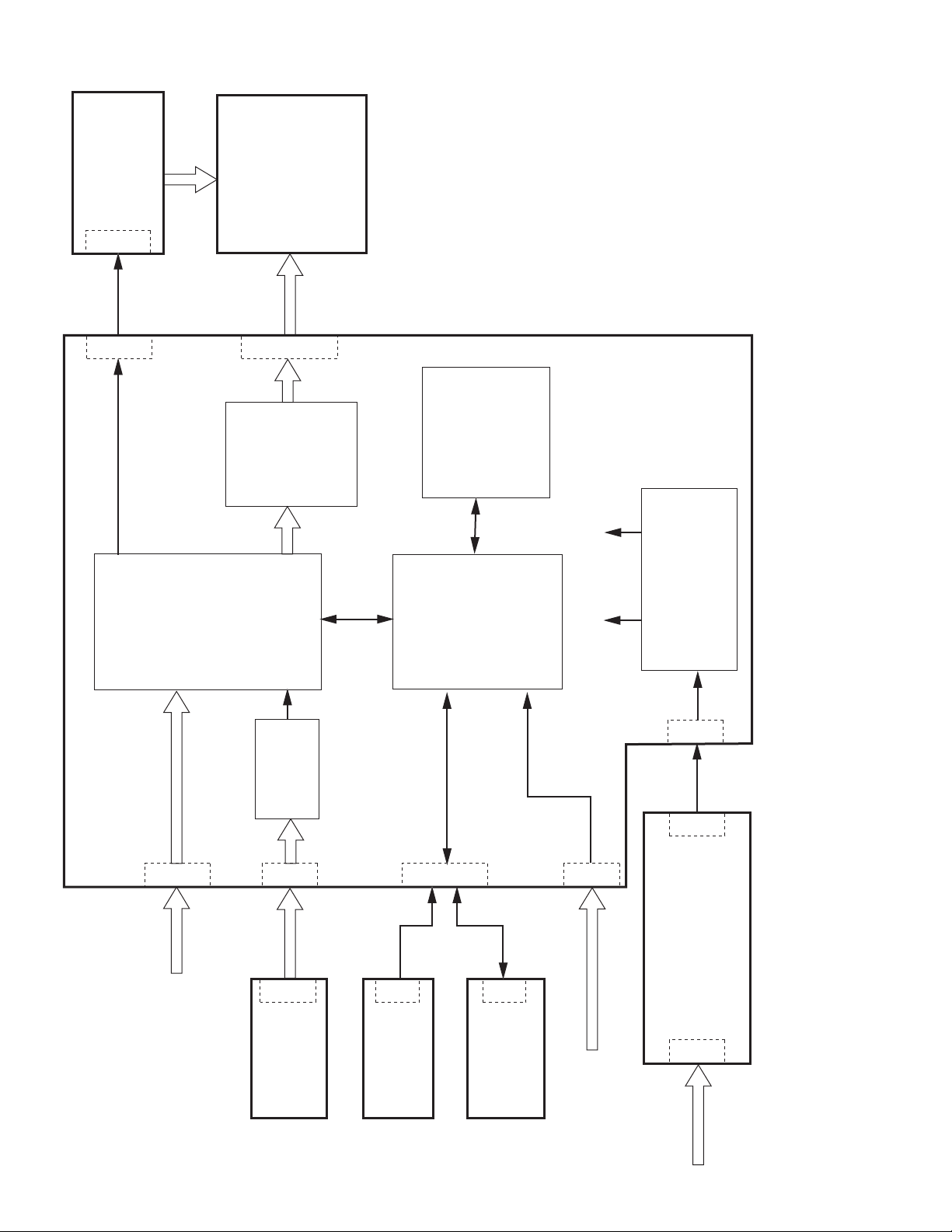

BLOCK DIAGRAM

Inverter

P1

PWB-0528-01

GM5020

Scaler

M170E6

LCD Panel

P010P004

THC63L

LVDS

VDM83A

24LC16B

EEPROM

Micro

W78E65P

Controller

3.3V

5V

Regulator

DC Power

PWB-0636-01

VGA

Video

SAA7118

Video

JP3

BNC

PWB-0584-03-1

P601

Key

PWB-0584-03-2

No. 521642-2

P002 P009P001

P602

Key

/LED

PWB-0584-03-3

12V

P802

P003

Remote input

PWB-0480-05

100~240Vac

P103

S.M.P.S

PWM Controller

P801

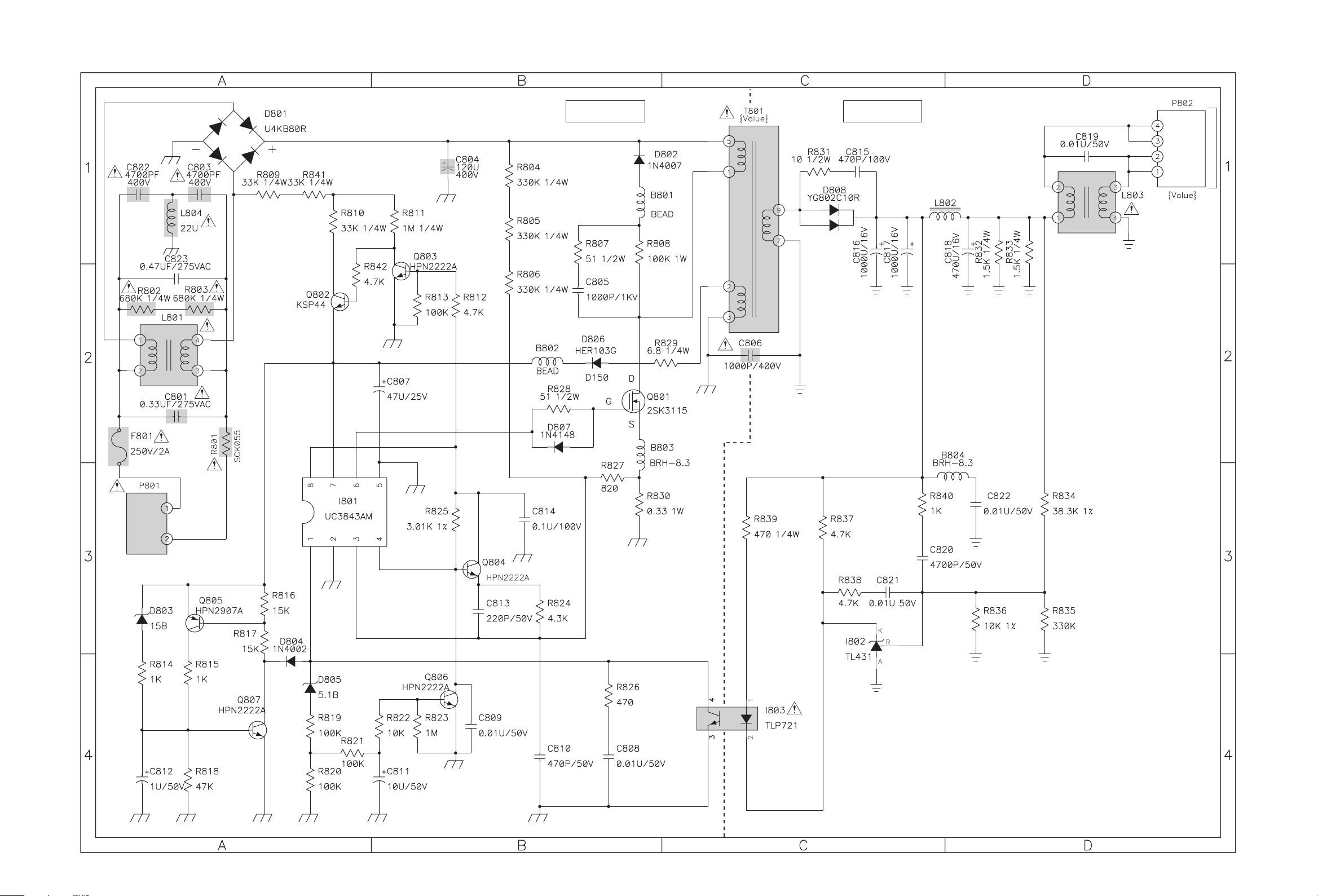

Page 16

ISOLATEDLIVE

MAIN PWB

(3/6)

P103

POWER PWB ASS'Y

DA-5097613403

POWER PWB CIRCUIT DIAGRAM

CIRCUIT DIAGRAMS

No. 52164 2-3 2-4

No. 52164

Page 17

PC

INPUT

MAIN PWB ASS'Y (1/6)

DA-5097624700

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

MAIN PWB CIRCUIT DIAGRAM (1/6)

No. 52164

2-5 2-6

No. 52164

Page 18

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

MAIN PWB ASS'Y (2/6)

DA-5097624700

REMOTE

FRONT

CONTROL2

PWB

P601

FRONT

CONTROL1

PWB

P602

INVERTER PWB

P1

MAIN PWB CIRCUIT DIAGRAM (2/6)

No. 52164 2-7 2-8

No. 52164

Page 19

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

POWER PWB

P802

MAIN PWB ASS'Y (3/6)

DA-5097624700

MAIN PWB CIRCUIT DIAGRAM (3/6)

No. 52164

2-9 2-10

No. 52164

Page 20

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

LCD

PAN EL

MAIN PWB ASS'Y (4/6)

DA-5097624700

MAIN PWB CIRCUIT DIAGRAM (4/6)

No. 52164

2-11 2-12

No. 52164

Page 21

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

MAIN PWB CIRCUIT DIAGRAM (5/6)

MAIN PWB ASS'Y (5/6)

DA-5097624700

No. 52164

2-13 2-14

No. 52164

Page 22

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

BNC INPUT

PWB

JP3

MAIN PWB AS'Y (6/6)

DA-5097624700

MAIN PWB CIRCUIT DIAGRAM (6/6)

No. 52164

2-15 2-16

No. 52164

Page 23

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

MAIN PWB (2/6)

P002

MAIN PWB (6/6)

P001

MAIN PWB (2/6)

P002

BNC INPUT PWB ASS'Y

DA-5098800646

FRONT CONTROL1 PWB ASS'Y

DA-5098800661

FRONT CONTROL2 PWB ASS'Y

DA-5098800647

FRONT CONTROL1 PWB, FRONT CONTROL2 PWB, BNC INPUT PWB CIRCUIT DIAGRAMS

No. 52164

2-17 2-18

No. 52164

Page 24

TP

TP

TP

TP

The schematic diagram is only for reference. Avoid replacing individual parts.

Replace the entire unit only.

LCD

PANEL

LCD

PANEL

MAIN PWB (2/6)

P004

INVERTER PWB ASS'Y

DA-5097672143

INVERTER PWB CIRCUIT DIAGRAM

No. 52164 2-19 2-20

No. 52164

Page 25

PATTERN DIAGRAM

POWER PWB PATTERN

()

TOP

()

No. 52164

2-21 2-22

No. 52164

Page 26

INSTRUCTIONS

LCD VIDEO MONITOR

LM-17G

LM-15G

Thank you for purchasing this JVC LCD video monitor. Before using it, read

and follow all instructions carefully to take full advantage of the monitor’s

capabilities.

ENGLISH

(* “LCD” stands for Liquid Crystal Display.)

For Customer Use:

Enter below the Serial No. which is located on the rear of the cabinet. Retain this

information for future reference.

Model No. : LM-17G, LM-15G Serial No. :

Page 27

Contents

Safety Precautions .................................................................................................... 3

Installation.................................................................................................................. 5

Unpacking the Monitor................................................................................................. 5

Controls and Features................................................................................................. 5

Using Your Monitor .................................................................................................. 7

Turning the Monitor On and Off ................................................................................. 7

Caring for and Cleaning the Monitor .......................................................................... 7

Using the Menu ........................................................................................................ 8

Summary of Control Buttons........................................................................................ 8

Menu Operations......................................................................................................... 8

Using the Monitor in the PC mode............................................................................... 13

Basic Connection Example ..................................................................................... 16

Troubleshooting ....................................................................................................... 17

Specifications ............................................................................................................ 18

2

Page 28

SAFETY PRECAUTIONS

In order to prevent any fatal accidents caused by disoperation or mishandling the monitor, be fully aware of all the

following precautions.

WARNINGS

To prevent fire or shock hazard, do not expose this monitor to rain or moisture. Dangerous high voltages are present

inside the unit. Do not remove the back cover of the cabinet. When servicing the monitor, consult qualified service

personnel. Never try to service it yourself.

WARNING: THIS APPARATUS MUST BE EARTHED.

This monitor is equipped with a 3-blade grounding-type plug to satisfy FCC rule. If you are unable to insert the

plug into the outlet, contact your electrician.

FCC NOTICE (U.S.A. only)

CAUTION: Changes or modifications not approved by JVC could void the user’s authority to operate the

equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

PRECAUTIONS

● Use only the power source specified on the unit.

● When not using this unit for a long period of time, or when cleaning it, be sure to disconnect the power plug from

the AC outlet.

● Do not allow anything to rest on the power cord. And do not place this unit where people will tread on the cord. Do

ENGLISH

not overload wall outlets or power cords as this can result in a fire or electric shock.

● Avoid using this unit under the following conditions:

– in extremely hot, cold or humid places,

– in dusty places,

– near appliances generating strong magnetic fields,

– in places subject to direct sunlight,

– in badly ventilated places,

– in automobiles with doors closed.

● Do not cover the ventilation slots while in operation as this could obstruct the required ventilation flow.

● When dust accumulates on the screen surface, clean it with a soft cloth.

3

Page 29

● Unplug this unit from the AC outlet and refer servicing to qualified service personnel under the following conditions:

– when the power cord is frayed or the plug is damaged,

– if liquid has been spilled into the unit,

– if the unit has been dropped or the cabinet has been damaged,

– when the unit exhibits a distinct change in performance.

● Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage or

other hazards. Always refer servicing to qualified service personnel.

● When replacement parts are required, have the service personnel verify in writing that the replacement parts

he/she uses have the same safety characteristics as the original parts. Use of manufacture’s specified

replacement parts can prevent fire, shock, or other hazards.

● Upon completion of any servicing or repair work to this unit, please ask the service personnel to perform the safety

check described in the manufacturer’s service literature.

● When this unit reaches the end of its useful life, improper disposal could result in a picture tube implosion. Ask

qualified service personnel to dispose of this unit.

POWER CONNECTION

The power supply voltage rating of this product is AC 120 V (For U.S.A. and Canada only) and AC 230 V (For

European countries or United Kingdom), the power cord attached conforms to the following power supply voltage

and countries. Use only the power cord designated to ensure Safety and EMC regulations of each countries.

Power cord

Power supply voltage : AC 120 V AC 230 V AC 230 V AC 220V

Countries : U.S.A. and Canada European countries United Kingdom China

Warning:

● Do not use the same Power Cord for AC 120 V as for AC 230 V. Doing so may cause malfunction, electric shock or

fire.

Note for the United Kingdom power cord only

The plug on the United Kingdom power cord has a built-in fuse. When replacing the fuse, be sure to use only a

correctly rated approved type, re-fit the fuse cover. (Consult your dealer or qualified service personnel.)

How to replace the fuse

Open the fuse compartment with the blade screw driver,

And replace the fuse.

(* An example is shown in the illustration.)

Fuse

4

Page 30

Installation

Please follow the instructions in this chapter to install your LCD Monitor.

Note: Before connecting your monitor, first read through the instructions in this chapter and the safety precautions in

the previous chapter.

Unpacking the Monitor

When you are unpacking the monitor, make sure that you have the following items:

Ö The LCD monitor

Ö AC power cord

Ö Stand and screw

Ö This instruction book

Note: Place the monitor on a flat, sturdy surface. Choose an area free from excessive heat, moisture, and sunlight.

<LM-17G> <LM-15G>

ENGLISH

Attach the supplied stand to the monitor as shown, and then fix it with the screws. Please fix the stand with the

supplied screw (A) first, and then fix it with the screws (B).

Controls and Features

5

Page 31

1

Down ( ) button

2

UP ( ) button

3

MENU/ENTER button

4

Video button

5

PC button

6

Power switch [POWER]

7

VIDEO A indicator

8

VIDEO B indicator

9

PC indicator

10

Power indicator

To AC outlet

(120 V AC,

50 Hz/60 Hz)

Use this button for menu operation. (See page 8)

Displays the “AUTO SET UP” menu in the PC mode. (See page 13)

Use this button for menu operation. (See page 8)

Displays the “AUTO SET UP” menu in the PC mode. (See page 13)

Use this button for menu operation. (See page 8)

Selects the VIDEO A or B input.

Selects the PC input.

Press this to turn the power on or off.

Lights when VIDEO A input is selected.

Lights when VIDEO B input is selected.

Lights when PC input is selected.

Lights in green when the power is on.

Unlit when the power is off.

Lights in amber when the monitor is in a reduced power mode, when there is

no signal or when the signal is out of range.

For U.S.A. and Canada

To AC outlet

(230 V AC,

50 Hz/60 Hz)

For Europe

To AC outlet

(220 V AC,

50 Hz/60 Hz)

For the United Kingdom

China

11

AC inlet

12

VIDEO A terminals

13

VIDEO B terminals

14

Remote (external

control) terminals

15

PC input terminal

16

AC power cord

(Provided)

Note: For more details about connections, see the "Basic Connection Example" on page 16.

Connect the provided AC power cord 16 to this inlet. Then connect the AC

power cord 16 to the AC outlet (120V AC/220V AC or 230V AC, 50Hz/60Hz)

Video signal input (IN) and output (OUT) terminals for VIDEO A input.

Video signal input (IN) and output (OUT) terminals for VIDEO B input.

Terminals for controlling the monitor from external unit.

You can select input signals, or change the ASPECT RETIO setting via the

Remote terminals.

You can connect this monitor to your PC.

Before using this terminal, please see the "Video Modes (Analog PC signal)”

and “Unknown Video Modes (Analog PC signal)” on page 20.

CAUTION:

In North America (USA and Canada), this monitor comes with one power cord.

In Europe and the United kingdom, two power cords are provided.

Be sure to use the power cable that is appropriate for the AC outlets used in your

region.

If none of the power cord provided is suitable, please contact your dealer or

qualified service personnel to obtain the correct type of power cord.

6

Page 32

Using Your Monitor

This chapter contains information about using your LCD Monitor.

Turning the Monitor On and Off

Use the power button located at the lower right side of the front panel of the monitor to turn the monitor on and off.

When the monitor is on, the Power indicator near the Power button lights green.

The monitor goes into the reduced power mode when there is no video signal input. And then the Power indicator

changes amber from green.

The Power indicator lights amber when the video signal input is out of range .

Note: Because of the technology used in LCD panels, screen savers will not prolong the life of your monitor . So if

the monitor will not be used for an extended period, be sure to turn it off.

Caring for and Cleaning the Monitor

To maximize screen life and prevent damage to the LCD panel, we recommend that you:

Ö Turn the monitor off when you are not using this monitor for a long period of time.

Ö Don’t press, rub, or poke the monitor with your finger or other object.

Ö Handle your monitor with care.

ENGLISH

Your LCD module is a high-quality optical device that requires special care when cleaning.

Warning

To clean the screen:

1. Turn off and unplug the monitor.

2. Gently dust the screen with a dry, soft, line-free cloth.

Note: If the screen is still dirty, you can dampen the cloth with several drops of distilled water. Make sure the LCD

panel is completely dry before you turn the monitor on.

Don’t use liquid, aerosol, or abrasive cleaning solutions to clean the screen.

Connecting the monitor to the PC

When you connect the monitor to a PC, you might be requested to install the specific driver. In this case do the

following:

-use the driver attached with the video card of the PC you use.

or

-set the monitor as standard monitor in the PC menu.Recommended mode, 1024x768 at 60Hz for LM-15G and

1280x1024 at 60Hz for LM-17G .

7

Page 33

Using the Menu

This chapter contains information about how to changing monitor settings for your LCD Monitor. It is designed with

an menu to help you easily adjust to its optimum performance.

Note: In the PC mode, do the “AUTO SET UP” setting first, before adjusting any settings. For details, see “AUTO

SET UP” on page 13.

Summary of Control Buttons

There are three control buttons located at the lower part of the front panel of your monitor:

MENU/ENTER: Display and select a menu. You can also exit a menu by pressing this button repeatedly.

UP( ): Move upward through the choice in the submenu. If an adjustment bar is displayed, this button increases

the setting value.

Down( ) : Move downward through the choice in the submenu. If an adjustment bar is displayed, this button

decreases the setting value.

Menu Operation

1. Press the ‘MENU/ENTER’ button to display the “BACK LIGHT” menu..

2. Press the ‘MENU/ENTER’ button repeatedly to display the menu you want to use.

100

PICTURE ADJ.

COLOR TEMP.

LOW LIGHT ADJ.

BACK LIGHT

Next page

PICTURE

PHASE

CHROMA

ASPECT

3. Press the ‘UP’ and ‘DOWN’ button to choose the item, and then press the ‘MENU/ENTER’ button to display the

sub-menu.

ASPECT

4 3

16 9

If the item do not have sub-menu, go to the step 4.

4. Press ‘UP’ and ‘DOWN’ button to adjust it, or choose a setting.

5. Press the ‘MENU/ENTER’ button repeatedly to exit the menu.

To return to the menu from the sub-menu, press the ‘MENU/ENTER’ button

The menu will disappear if no operation is performed for approximately 15 seconds.

8

Page 34

In the VIDEO A or B mode (composite video input):

Menu Items

BACK LIGHT You can adjust the light output of the backlight.

PICTURE ADJ. PICTURE, PHASE, CHROMA, ASPECT, COLOR TEMP., LOW LIGHT ADJ. .

SYSTEM SETTING SIGNAL LEVEL, DISPLAY, OSD POSITION, COLOR SYSTEM, AGC, REMOTE,

All reset

In the PC mode (analog RGB input):

Menu Items

BACK LIGHT You can adjust the light output of the backlight.

CONTRAST You can adjust the contrast of the picture.

POSITION ADJ. H.POSITION, V. POSITION

WHITE BALANCE

ADJ.

DISPLAY ADJ. AUTO SET UP, CLOCK, PHASE

SYSTEM SETTING DISPLAY, OSD POSITION, REMOTE, All reset

COLOR TEMP., LOW LIGHT ADJ.

BACK LIGHT menu

You can adjust the light output of the backlight.

BACK LIGHT

100

PICTURE ADJ. menu

PICTURE ADJ.

Next page

PICTURE

PHASE

CHROMA

ASPECT

COLOR TEMP.

LOW LIGHT ADJ.

PICTURE: You can adjust the levels of black and white on the screen, giving you a darker or brighter picture

overall.

.

ENGLISH

PHASE: You can adjust the picture hue. When the COLOR SYSTEM is BW60, BW50 or PAL, you cannot adjust

the PHASE.

CHOROMA: You can adjust the picture color density. When the COLOR SYSTEM is BW60 or BW50, you cannot

adjust the CHOROMA.

ASPECT: You can choose the screen aspect ratio between “4 3 ” and “ 16 9 ”.

COLOR TEMP.: If you select ‘COLOR TEMP.’ and press the ‘MENU/ENTER’ button, the “COLOR TEMP.” menu will

appear. For details, see the following “COLOR TEMP.” menu.

LOW LIGHT ADJ.: At the video mode: You can adjust the brightness of the dark part of picture.

At the PC mode: You can adjust the R.G.B. balance of the dark part of picture. For details of the

adjustments, see “HIGH LIGHT ADJ.” in page10

Next page: If you select ‘Next page’ and press the ‘MENU/ENTER’ button, the next menu will appear.

9

Page 35

COLOR TEMP. menu

1. Press the ‘UP’ and ‘DOWN’ button to choose the “COLOR TEMP.”, and then press the ‘MENU/ENTER’ button

to display the sub-menu.

COLOR TEMP.

HIGH

NATURAL

LOW

USER

2. Press ‘UP’ and ‘DOWN’ button to choose one of four Color temp settings: HIGH, NATURAL, LOW and USER.

“USER” setting:

You can store the adjustments of “HIGH LIGHT ADJ.” to the “USER” setting.

In “HIGH”, “NATURAL” and “LOW”, you cannot use “HIGH LIGHT ADJ.”.

1. Press the ‘UP’ or ‘DOWN’ button to choose the “USER” , and then press the ‘MENU/ENTER’ button to return to

the “HIGH LIGHT ADJ.” menu.

HIGH LIGHT ADJ.

Next page

RED

GREEN

BLUE

2. Press ‘UP’ and ‘DOWN’ button to choose “RED”, and then press ‘MENU/ENTER’ button to display the adjusting

menu.

3. Press ‘UP’ or ‘DOWN’ button to adjust the level, and then press ‘MENU/ENTER’ button to return to the

sub-menu

4. Repeat step 3 and 4 for other colors “GREEN” and “BLUE” to complete the “HIGH LIGHT ADJ.” setting.

RED

50

10

Page 36

SYSTEM SETTING menu

SYSTEM SETTING

Exit

SIGNAL LEVEL

DISPLAY

OSD POSITION

COLOR SYSTEM

AGC

REMOTE

All reset

SIGNAL LEVEL: You can choose the signal level from ”STD.” or “AMP.”.

STD.: Select this for normal operation.

AMP.: Select this to watch dark part of the picture better.

DISPLAY: If you select ‘DISPLAY’ and press the ‘MENU/ENTER’ button, you can confirm the current status;

resolution, Horizontal frequency and Vertical frequency.

COLOR SYSTEM: You can choose the color system from NTSC, PAL, BW60 or BW50. Choose the correct color

system when the color is abnormal or no color appears.

AGC: You can turn the AGC (Auto Gain Control) function on (ON) or off (OFF).If you select off(OFF), you can adjust

contrast bar.

REMOTE: If you select ON, you can only do remote control. If you select OFF, you can control only by using the

monitor’s buttons.

Exit: If you select “Exit” and press the ‘MENU/ENTER’ button, the menu will disappear.

All reset: If you select “All reset” and press the ‘MENU/ENTER’ button, the settings will be return to the factory

settings.

* “COLOR SYSTEM” and the input select will not be return to the factory settings.

OSD POSITION:

You can adjust the position of the menu on the screen as following procedure.

1. Select “OSD POSITION” and press the ‘MENU/ENTER’ button, the sub-menu will appear.

ENGLISH

OSD POSITION

Next page

H. POSITION

V. POSITION

2. Press ‘UP’ and ‘DOWN’ button to choose “H. POSITION” (horizontal position) or “V. POSITION” (vertical

position), and then press ‘MENU/ENTER’ button to display the adjusting menu

3. Press ‘UP’ and ‘DOWN’ button to adjust the position of the menu on the screen.

4. Press ‘MENU/ENTER’ button to return to the “OSD POSITION” menu.

Next page: If you select ‘Next page’ and press the ‘MENU/ENTER’ button, the next menu will appear.

CONTRAST menu

You can adjust the contrast of the image from the PC.

CONTRAST

50

11

Page 37

POSITION ADJ. menu

You can adjust the position of the image from the PC on the screen.

POSITION ADJ.

Next page

H. POSITION

V. POSITION

1. Press ‘UP’ and ‘DOWN’ button to choose “H. POSITION” (horizontal position) or “V. POSITION” (vertical

position), and then press ‘MENU/ENTER’ button to display the adjusting menu

2. Press ‘UP’ and ‘DOWN’ button to adjust the position of the picture on the screen.

3. Press ‘MENU/ENTER’ button to return to the “POSITION ADJ.” menu.

Next page: If you select ‘Next page’ and press the ‘MENU/ENTER’ button, the next menu will appear.

DISPLAY ADJ. menu

You can do the necessary adjustments to display the image from the PC.

DISPLAY ADJ.

Next page

AUTO SET UP

CLOCK

PHASE

AUTO SET UP:

We recommend you to do the AUTO SET UP first. And then adjust the CLOCK or PHASE if necessary.

To use the AUTO SET UP, select this item and press ‘MENU/ENTER’ button. And follow the step 2 of the description

“AUTO SET UP” on page13 .

CLOCK: You can adjust the Clock.

PHASE: You can adjust the Phase.

Next page: If you select ‘Next page’ and press the ‘MENU/ENTER’ button, the next menu will appear.

12

Page 38

Using the Monitor in the PC mode

Since the inherent format of this monitor is 1024 pixels by 768 lines, the monitor will perform best when your PC is

set to a screen resolution of 1024 x 768. If you use a lower resolution (such as 640 x 480), the image is expanded to

fill the screen

Your monitor supports many common video modes, as shown in “Video Modes” on page 20. Check the manuals

supplied with your PC and video adapter card to find out which modes they support. To see what the video mode in

your Microsoft Windows, please check Windows’settings in your PC.

Do the AUTO SET UP first when you use the monitor in the PC mode.

AUTO SET UP

You can setup this monitor to display the analog RGB signal from your PC. Please do the AUTO SET UP whenever

you apply a new video mode or change the refresh rate from the PC.

1. Press ‘UP’ or ‘DOWN’ button while no menu appears on the screen.

The “AUTO SET UP” menu appears on the screen

AUTO SET UP

YES NO

2. Press ‘UP’ or ‘DOWN’ button to choose “YES”, and then press ‘MENU/ENTER’ button to start the AUTO SET

UP.

The monitor will do the necessary settings for new PC input automatically.

AUTO SET UP

Please wait…

When you start the AUTO SET UP, do not display moving images (games, videos, etc) on the screen.

ENGLISH

3. After the AUTO SET UP is complete, you will be asked whether the image is displayed correctly or

not.

AUTO SET UP

Does this image

look correct?

YES NO

4. If the image looks correct, press ‘UP’ or ‘ DOWN’ button to choose “YES”.

The menu disappears.

If the image requires further adjustment, press ‘UP’ or ‘DOWN’ button to choose “NO”. “PHASE” menu will

appear and you can adjust the PHASE by ‘UP’ or ‘DOWN’ button.

When all text appears well focused and there is no instability in the image, press the ‘MENU/ENTER’ button.

The menu disappears.

Note: You can also start the AUTO SET UP with “DISPLAY ADJ.” menu.

13

Page 39

The menu flowchart of the VIDEO mode

*The menu can not be displayed when "No Sync" is displayed.

14

Page 40

The menu flowchart of the PC mode

ENGLISH

*The menu cannot be displayed when "No Sync" is displayed.

15

Page 41

)

Basic Connection Example

Notes:

Before connecting your system, make sure that all devices are turned off.

The illustration shows some examples of different connections. Terminal connections may differ depending on

the devices. Be sure to refer to the manuals provided with the devices.

Each pair of input (IN) and output (OUT) terminals are bridge-connected

If you’re not connecting any equipment to a bridged output (OUT) terminal, be sure not to connect any other

cables to the bridged output (OUT) terminal as this will cause the terminating resistance switch to open (auto

terminate function).

When making a bridge connection, connect the input (IN) and output (OUT) terminals on the monitor to separate

video components.(For example, if both terminals are connected to the same VCR, resonance may occur except

during playback. This is caused by the same video signal “looping” between the VCRs, and is not a malfunction.)

The ASPECT or INPUT A/B settings can be controlled via the ASPECT or INPUT jack in the REMOTE terminal.

When using REMOTE terminal, set REMOTE function ON . See “SYSTEM SETTING menu “ on page 11.

Video Camera

VCR

Video Monitor

VCR

Video Monitor

External control switch

open circuit (open)

RCA pin

closed circuit (short)

External control

functions n circuit

INPUT IN PUT A INPUT B

External control switch

Ope

(open)

Closed circuit

(short)

Video Camera

Video Monitor

VCR

REMOTE

(Remote cable)

Signal Flow

VCR

Video Monitor

REMOTE

(Remote cable)

RCA pin

External control

functions

ASPECT

RATIO

PC

External control switch

open circuit (open)

closed circuit (short

External control switch

Open circuit

(open)

4 – 3 (4 3) 16 – 9 (16 9)

Closed circuit

(short)

16

Page 42

Troubleshooting

Solutions to common problems related to your monitor are described here. If none of the solutions presented here

solove the problem, unplug the monitor and consult a JVC-authorised dealer or service centre for assistance.

A. My monitor doesn’t work.

Check that the power cable is securely plugged into the monitor.

Check that the monitor is turned on.

Turn the monitor off and pull the plug out, then put the plug in again and turn the monitor on.

B. My monitor shows no colors, wrong color, or dark pictures.

Check that the color system is selected correctly. See “SYSTEM SETTING menu” on page 11.

Check the BACK LIGHT and PICTURE ADJ. settings. See “BACK LIGHT menu” and “PICTURE ADJ.

menu” on page 9.

In the PC mode, check the CONTRAST setting. See “CONTRAST menu” on page 11.

C. Dark stripes appear at the top and bottom of the screen, picture vertically squeezed.

Set the ASPECT setting to “4:3”. See “PICTURE ADJ. menu” on page 9.

D. The message “No Sync” appears .

This message appears when there is no video signal. After few seconds, the monitor goes into the reduced

power mode.

Check the connection.

Select the required video signal input.

Connect the video signal cable firmly.

Check that your graphic card outputs the analog RGB signal.

E. The message “Signal Out of Range” appears on my monitor.

This message appears when the input signal is beyond the monitor capability.

Set your PC to a supported video mode; preferably 1024 x 768 at 60 Hz for LM-15G, 1280x1024 at

ENGLISH

60Hz for LM-17G.

F. The image is very unstable in the PC mode.

Set your PC to a supported video mode; preferably 1024 x 768 at 60 Hz for LM-15G, 1280x1024 at

60Hz for LM-17G.

Restore the original factory settings by “All reset”. See “SYSTEM SETTING menu” on page 11.

Do the “AUTO SET UP”. See “AUTO SET UP” on page 13.

G. When connecting to the PC,installation of the device is required. See "Connecting the monitor to the PC" on

page 7

Note: Even if your PC’s setting is out of the range of video modes that are supported by your LCD monitor, it

may still be displayed with reduced quality. This provides you with an opportunity to change your PC’s

setting to a correct one.

The following are not malfunctions:

The monitor emits a strange sound when the room temperature changes suddenly. This is only a problem if an

abnormality appears on the screen as well.

When a still image as been displayed for a long period, a faint residual image may remain on the screen for a short

time after the power has been turned off or when another image is displayed. The image will eventually

disappear.

When you see the monitor from the side, the color or brightness look different.

The LCD panel is made with high-precision technology and has more than 99.99% effective pixels.

Fewer than 0.01% of pixels may be chipped or always lit.

17

Page 43

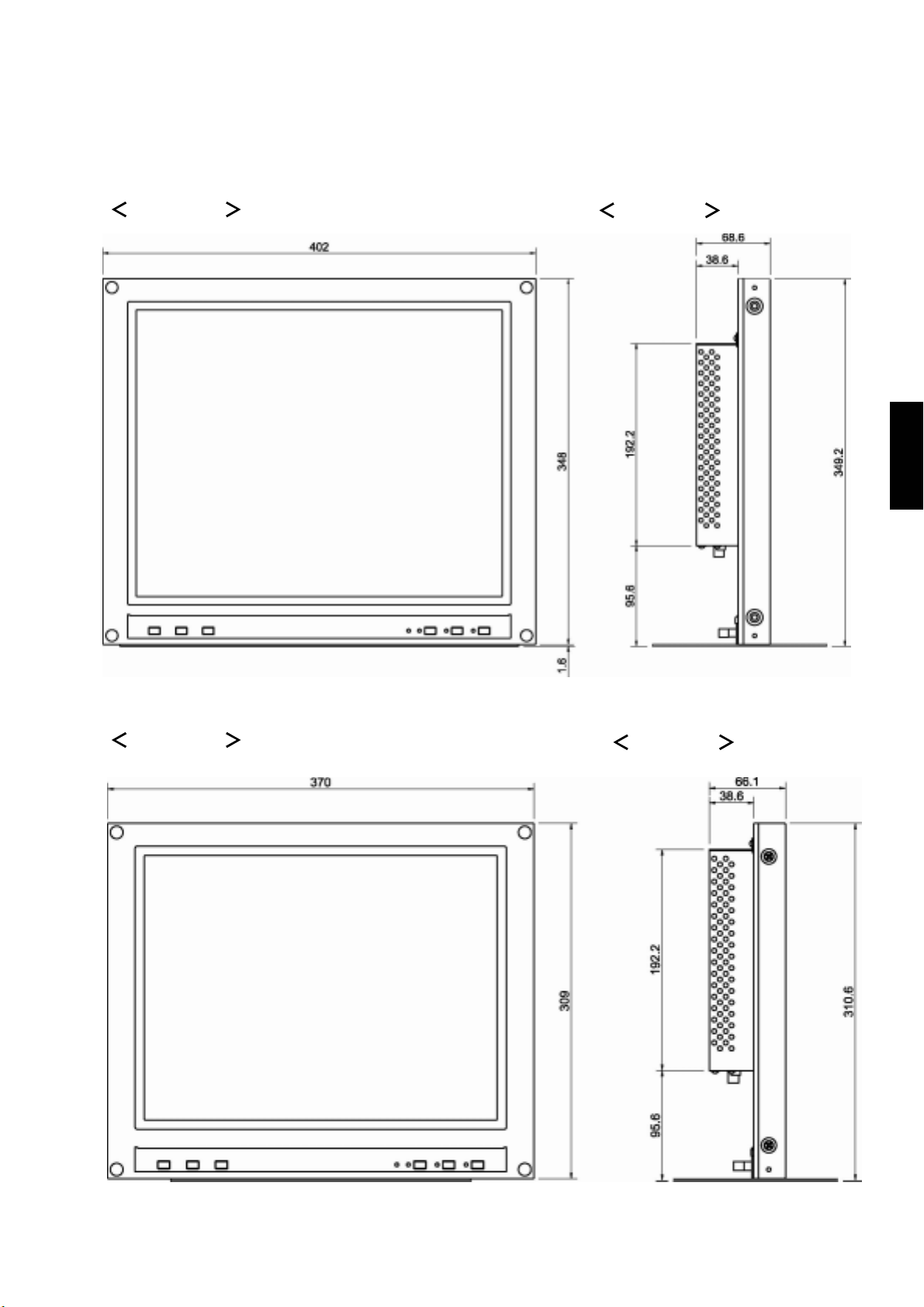

Specifications

Item

Type LCD Video Monitor

Color system PAL,NTSC, BW60,BW50

LCD panel

Display colors 16700000 colors 16700000 colors

Display area(W x H x D)

Scanning frequency

Viewing Angle

Power Input 100V~240V AC,50Hz/60Hz ,1.2A at 100V ,0.6A at 230V

Input terminals

Video A

Video B

PC input Analog RGB: D-sub (16 pins) x1, positive 0.7V

Model

LM-17G LM -15G

17-in(43.275cm),TFT active matrix

1280 x 1024 dot

337.92mmx270.34mmx432.75mm 304.1mmx228.1mmx380mm

(H) 31.5kHz~80kHz(Analog)

15.734kHz (NTSC)

15.625kHz (PAL)

(V)56Hz~75Hz (Analog)

59.94Hz (NTSC)

50Hz (PAL)

Left/Right 85/85,Up/Down 85/85 Left/Right 60/60,Up/Down 55/45

Composite video:

1line, BNC connector x 2, 1 V(p-p), 75 , bridge-connected (auto termination)

Composite video:

1line, BNC connector x 2, 1 V(p-p), 75 ,bridge-connected (auto termination)

15-in(38.1cm),TFT active matrix

1204 x 768 dot

(H) 31.5kHz~60kHz(Analog)

15.734kHz (NTSC)

15.625kHz (PAL)

(V)56Hz~70Hz (Analog)

59.94Hz (NTSC)

50Hz (PAL)

PP

Recommended mode

REMOTE For INPUT 1 line, RCA pin x 1

REMOTE For ASPECT 1 line, RCA pin x 1

Conditions Temperature 5 ~35 at altitude 0~2000m,5 ~30 at altitude 2000~3000m,

Humidity Altitude 20%~85%RH,non-condensing 3000m Max.

Storage Conditions

Temperature/Humidity/Altitude

Maximum power Consumption 45W 35W

Dimensions

Monitor only(W x H x D)

With supplied stand

(W x H x D)

Net weight

100mm mount based on VESA regulation is equipped.

1280 x 1024 at 60Hz (Analog) 1024 x 768 at 60Hz (Analog)

-20 ~60 / 5%~95% RH/ 10000m Max

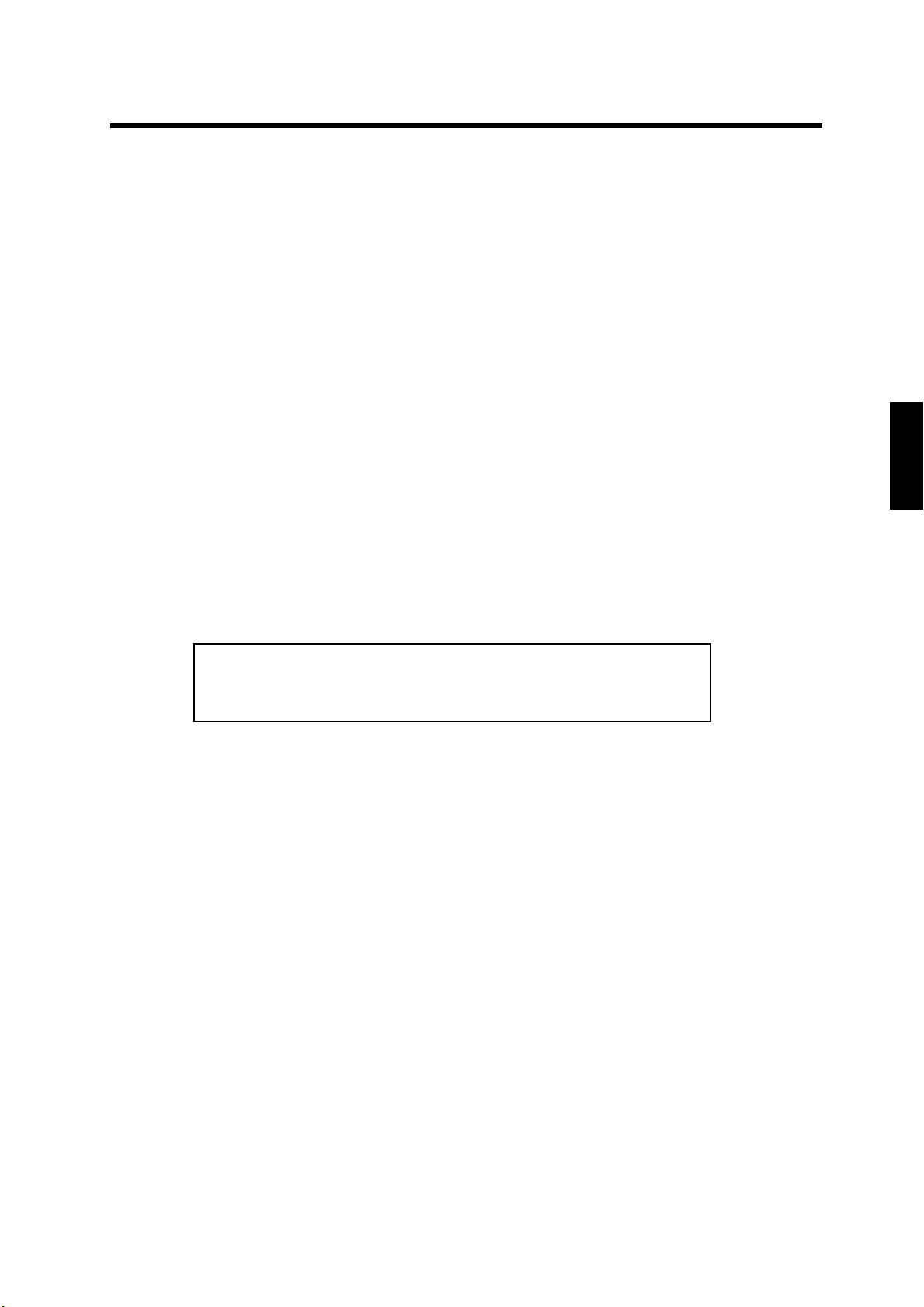

402mmx348mmx68.6mm

402mmx349.2mmx162mm

5kg / 5.8kg (with stand)

370mmx309mmx66.1mm

370 mmx310.6 mmx142 mm

3.75kg / 4.2 kg (with stand)

*Pictures may not appear on the some of PC even if frequencies are within this range.

*Design and specifications subject to change without notice

18

Page 44

Dimensions

<LM-17G>

Front View

Side View

ENGLISH

<LM-15G>

Front View

Side View

19

Page 45

Video Modes (Analog RGB Signal)

Your LCD monitor supports the following industry-standard combinations of screen resolution and refresh rates.

For optimum performance, set your PC to the screen resolution of 1024 x 768 at 60 Hz refresh rate.

<LM-17G> <LM-15G>

Supported Resolution

(dots x lines)

VGA

640 x 480

640 x 350

SVGA

XGA

SXGA

US TEXT 720 x 400 70 Hz

Power MAC

800 x 600

800 x 600

1024 x 768

1024 x 768

1280 x 1024 60 Hz

640 x 480 67 Hz

Vertical Frequency

(Refresh Rate)

60 Hz

70 Hz

56 Hz

60 Hz

60 Hz

70 Hz

Supported Resolution

(dots x lines)

VGA

SVGA

XGA

US TEXT

Power MAC

640 x 350

640 x 480

800 x 600

800 x 600

1024 x 768

1024 x 768

720 x 400

640 x 480

Unknown Video Modes (Analog RGB Signal)

Vertical Frequency

(Refresh Rate)

70 Hz

60 Hz

56 Hz

60 Hz

60 Hz

70 Hz

70 Hz

67 Hz

Like all other monitors, the your LCD monitor is designed to work with standard video modes. However, not all

video/graphic cards use only standard display modes.

Your LCD monitor uses state-of-the-art technology, which is designed to synchronize to any display mode. We

recommend choosing one of the supported modes listed above. If you want to use an unknown mode, do the AUTO

SET UP at first. If AUTO SET UP doesn’t make adjustments corrrectly, adjust the CLOCK, PHASE , horizontal

position and vertical position manually.

R

VICTOR COMPANY OF JAPAN, LIMITED

20

Page 46

PARTS LIST

CAUTION

!!

! The parts identified by the symbol are important for the safety . Whenever replacing these parts, be sure to use specified

!!

ones to secure thesafety.

!!

! The parts not indicated in this Parts List and those which are filled with lines

!!

supplied.

!!

! P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

!!

ABBREVIATIONS OF RESISTORS, CAPACITORS AND TOLERANCES

!!

! in the Parts No. columns will not be

!!

RESISTORS

CR Carbon Resistor

FR Fusible Resistor

PR Plate Resistor

VR Variable Resistor

HV R High Voltage Resistor

MF R Metal Film Resistor

MG R Metal Glazed Resistor

MP R Metal Plate Resistor

OM R Metal Oxide Film Resistor

CMF R Coating Metal Film Resistor

UNF R Non-Flammable Resistor

CH V R Chip Variable Resistor

CH MG R Chip Metal Glazed Resistor

COMP. R Composition Resistor

LPTC R Linear Positive Temperature Coefficient Resistor

CAPACITORS

C CAP. Ceramic Capacitor

E CAP. Electrolytic Capacitor

M CAP. Mylar Capacitor

CH CAP. Chip Capacitor

HV CAP. High Voltage Capacitor

MF CAP. Metalized Film Capacitor

MM CAP. Metalized Mylar Capacitor

MP CAP. Metalized Polystyrol Capacitor

PP CAP. Polypropylene Capacitor

PS CAP. Polystyrol Capacitor

TF CAP. Thin Film Capacitor

MPP CAP. Metalized Polypropylene Capacitor

TAN. CAP. Tantalum Capacitor

CH C CAP. Chip Ceramic Capacitor

BP E CAP. Bi-Polar Electrolytic Capacitor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP. Chip Aluminum Bi-Polar Capacitor

CH TAN. E CAP. Chip Tantalum Electrolytic Capacitor

CH AL BP E CAP. Chip Tantalum Bi-Polar Electrolytic Capacitor

RESISTORS

FGJ K MNR HZ P

±1% ±2% ±5% ±10% ±20% ±30%

+30% +50% +80% +100%

-10% -10% -20% -0%

(No. 52164) 3-1

Page 47

CONTENTS

EXPLODED VIEW PARTS LIST .................................................................................................................................................... 3-2

EXPLODED VIEW ......................................................................................................................................................................... 3-3

PRINTED WIRING BOARD PARTS LIST ....................................................................................................................................... 3-4

MAIN PW BOARD ASS’Y ..................................................................................................................................................... 3-4

BNC INPUT PW BOARD ASS’Y .......................................................................................................................................... 3-4

FRONT CONTROL 1 PW BOARD ASS’Y............................................................................................................................ 3-4

FRONT CONTROL 2 PW BOARD ASS’Y............................................................................................................................ 3-4

INVERTER PW BOARD ASS’Y ........................................................................................................................................... 3-4

POWER PW BOARD ASS’Y ................................................................................................................................................ 3-4

PACKING ...................................................................................................................................................................................... 3-6

PACKING PARTS LIST ................................................................................................................................................................. 3-6

EXPLODED VIEW PARTS LIST

! Ref. No. Part No. Part Name Description

1 DA-5642725102 FRONT COVER LM-17G/U, LM-17G/C

1 DA-5642725103 FRONT COVER LM-17G/E

2 DA-5642678400 CLIP (x4)

3 DA-5642724601 CONTROL BRACKET

4 DA-5642848800 CONTROL BUTTON (x2)

5 DA-5642724410 LCD BRACKET (x2)

6 DA-5642724901 BACK COVER

7 DA-5646519201 INSULATOR (x2)

8 DA-5642725200 FUNCTION COVER

9 DA-5642724700 TERMINAL BRACKET

10 DA-5646425700 HEAT SINK(E)

11 DA-5646440601 HEAT SINK(P)

12 DA-5646425701 HEAT SINK(A)

13 DA-5642724401 BASE

14 DA-5642673100 LED HOLDER (x4)

! 15 DA-5051253648 LCD PANEL

16 DA-5030574201 MODEL LABEL LM-17G/U

16 DA-5030574202 MODEL LABEL LM-17G/E

16 DA-5030574204 MODEL LABEL LM-17G/C

S1 DA-7190562313 SCREW PPW M3X6 (x13)

S2 DA-7000311032 SCREW PPW M3X6 (x24)

S3 DA-7134161186 SCREW PZP 3X8 (x3)

S4 DA-7004171116 SCREW PFS M3X8 (x2)

S5 DA-7160250652 SCREW PZS+L 4X6

S6 DA-7190562304 SCREW PPF M3X0.4 (x8)

S7 DA-7006260616 SCREW M4X0.7x06 (x4)

3-2 (No. 52164)

Page 48

EXPLODED VIEW

S1

16

PWB

BNC INPUT

S3

8

S2

9

10

S5

WIRE

EARTH

12

11

INVERTER PWB

POWER PWB

S4

13

7

S1

S2

S6

5

S2

6

S1

S1

PWB

FRONT CONTROL1

14

S2

MAIN PWB

4

15

5

S2

S6

S1

S7

S1

S7

PWB

3

FRONT CONTROL2

2

1

S7

(No. 52164) 3-3

Page 49

PRINTED WIRING BOARD PARTS LIST

MAIN PWB ASS’Y

! Symbol Part No. Part Name Description ! Symbol Part No. Part Name Description

DA-5097624700 MAIN PWB ASS’Y

BNC INPUT PWB ASS’Y

! Symbol Part No. Part Name Description

DA-5098800646 BNC INPUT PWB ASS’Y

FRONT CONTROL1 PWB ASS’Y

! Symbol Part No. Part Name Description

DA-5098800661 FRONT CONTROL1 PWB ASS’Y

R814 DA-5142110295 C RESISTOR 1k 1/6W

R815 DA-5142110295 C RESISTOR 1k 1/6W

R816 DA-5142115395 C RESISTOR 15k 1/6W

R817 DA-5142115395 C RESISTOR 15k 1/6W

R818 DA-5142147395 C RESISTOR 47k 1/6W

R819 DA-5142110495 C RESISTOR 100k 1/6W

R820 DA-5142110495 C RESISTOR 56k 1/4W

R821 DA-5142110495 C RESISTOR 100k 1/6W

R822 DA-5142110395 C RESISTOR 10k 1/6W

R823 DA-5142110595 C RESISTOR 1k 1/6W

R824 DA-5142143295 C RESISTOR 4.3k 1/6W

R825 DA-5134730119 MF RESISTOR 3.01k 1/6W

R826 DA-5142147195 C RESISTOR 470 1/6W

R827 DA-5142182195 C RESISTOR 820 1/6W

R828 DA-5130251090 OM RESISTOR 51 1/2W

R829 DA-5142868995 C RESISTOR 6.8 1/4W

R830 DA-5130333890 OM RESISTOR 0.33 1 W

R831 DA-5130210095 OM RESISTOR 10 1/2W

R832 DA-5142815295 C RESISTOR 1.5k 1/4W

R833 DA-5142815295 C RESISTOR 1.5k 1/4W

R834 DA-5134738329 MF RESISTOR 38.4k 1/6W

R835 DA-5142133495 C RESISTOR 330k 1/6W

R836 DA-5134710028 MF RESISTOR 10k 1/6W

R837 DA-5142147295 C RESISTOR 4.7k 1/6W

R838 DA-5142847295 C RESISTOR 4.7k 1/4W

R839 DA-5142847195 C RESISTOR 470 1/4W

R840 DA-5142110295 C RESISTOR 1k 1/6W

R841 DA-5142833395 C RESISTOR 33k 1/4W

R842 DA-5142147295 C RESISTOR 4.7k 1/6W

FRONT CONTROL2 PWB ASS’Y

! Symbol Part No. Part Name Description

DA-5098800647 FRONT CONTROL2 PWB ASS’Y

INVERTER PWB ASS’Y

! Symbol Part No. Part Name Description

! DA-5097672143 INVERTER PWB ASS’Y

POWER PWB ASS’Y

! Symbol Part No. Part Name Description

RESISTORS

! R801 DA-5101111400 THERMISTOR 5 5A

! R802 DA-5142868490 C RESISTOR 650k 1/4W

! R803 DA-5142868490 C RESISTOR 680k 1/4W

R084 DA-5142833495 C RESISTOR 330k 1/4W

R805 DA-5142833495 C RESISTOR 330k 1/4W

R806 DA-5142833495 C RESISTOR 330k 1/4W

R807 DA-5130251090 OM RESISTOR 51 1/2W

R808 DA-5130310490 OM RESISTOR 100k 1W

R809 DA-5142833395 C RESISTOR 33k 1/4W

R810 DA-5142833395 C RESISTOR 33k 1/4W

R811 DA-5142810595 C RESISTOR 1M 1/4W

R812 DA-5142147295 C RESISTOR 4.7k 1/6W

R813 DA-5142110495 C RESISTOR 100k 1/6W

CAPCITORS

! C801 DA-5270113301 MF CAPACITOR 0.33µF 275V M

! C802 DA-5230108601 C CAPACITOR 4.7µF 250V M

DA-5230108701

DA-5230108101

! C803 DA-5230108601 C CAPACITOR 4.7µF 250V M

DA-5230108701

DA-5230108101

! C804 DA-5213019300 E CAPACITOR 120µF 400V M

C805 DA-5233310291 C CAPACITOR 1µF 1KV K

! C806 DA-5230108301 C CAPACITOR 1µF 250V M

DA-5230108501

DA-5230108401

C807 DA-5216021991 E LOW ESR CAP. 47µF 50V M

C808 DA-5231310391 C CAPACITOR 10µF 50V K

C809 DA-5221110391 POLYESTER CAP. 10µF 50V J

C810 DA-5231347191 C CAPACITOR 470pF 50V K

C811 DA-5216022191 E LOW ESR CAP. 10µF 50V M

C812 DA-5216022091 E LOW ESR CAP. 1µF 50V M

C813 DA-5231322191 C CAPACITOR 220pF 50V K

C814 DA-5222410491 POLYESTER CAP. 100µF 100V J

C815 DA-5232347191 C CAPACITOR 470pF 500V K

C816 DA-5216021891 E LOW ESR CAP. 1000µF 16V M

C817 DA-5216021891 E LOW ESR CAP. 1000µF 16V M

C818 DA-5216021791 E LOW ESR CAP. 470µF 16V M

C819 DA-5231310391 C CAPACITOR 1µF 50V K

C820 DA-5231347291 C CAPACITOR 4.7µF 50V K

C821 DA-5231310391 C CAPACITOR 10µF 50V K

C822 DA-5231310391 C CAPACITOR 10µF 50V K

! C823 DA-5270113701 MF CAPACITOR 470pF 275V M

DA-5270112401

TRANSFORMER

! T801 DA-5061377320 SWITCHING

INDUCTORS

! L801 DA-5061113700 EMI FILTER 14mH

L802 DA-5062142100 CHOKE COIL 1.5µH

! L803 DA-5061113800 EMI FILTER 260µH

! L804 DA-5062119802 CHOKE COIL 22µH

3-4 (No. 52164)

Page 50

! Symbol Part No. Part Name Description ! Symbol Part No. Part Name Description

BEADS

B801 DA-5062122946 FERRITE BEAD

B802 DA-5062122946 FERRITE BEAD

B803 DA-5062133201 FERRITE BEAD

B804 DA-5062133201 FERRITE BEAD

DIODES

D801 DA-6641000704 BRIDGE DIODE

D802 DA-6611007740 SI DIODE

D803 DA-6615023745 SI DIODE

D804 DA-6611007240 SI DIODE

D805 DA-6615007531 Z DIODE

D806 DA-6611020442 SI DIODE

D807 DA-6613003032 SI DIODE

D808 DA-6611010407 SI DIODE

DA-6611007741

DA-6615008441

DA-6611007244

DA-6611007243

DA-6611007245

DA-6615012436

DA-6615007833

DA-6611020443

DA-6613003034

TRANSISTORS

Q801 DA-6626005100 n-MOS FET

Q802 DA-6621032132 NPN TRANSISTOR

Q803 DA-6621025832 NPN TRANSISTOR

Q804 DA-6621025832 NPN TRANSISTOR

Q805 DA-6624000737 PNP TRANSISTOR

Q806 DA-6621025832 NPN TRANSISTOR

Q807 DA-6621025832 NPN TRANSISTOR

DA-6626008902

DA-6621025833

DA-6621025833

DA-6624000734

DA-6621025833

DA-6621025833

IC

I801 DA-6644063004 PWM CONTROLLER

I802 DA-6640007706 VOLTAGE REG.

! I803 DA-6642002904 PHOTO COUPLER

DA-6640007717

DA-6640007705

OTHERS

4E01 DA-5646425700 HEAT SINK(E)

4E02 DA-5646440601 HEAT SINK(P)

4E03 DA-5646425701 HEAT SINK(A)

! F801 DA-5054420084 FUSE 250V/2A

! P801 DA-5056415343 3P CONN. (#2 OFF)

P802 DA-5057404352 4P CONN. (w/WIRE)

(No. 52164) 3-5

Page 51

PACKING

9 10

6

5

8

2

12

7

4

2

13

11

3

13

1

PACKING PARTS LIST

! Ref. No. Part No. Part Name Description

1 DA-9513350156 BLANK CARTON

2 DA-9513355156 ANCHORSHEET (x2)

3 DA-9513355356 ANCHORSHEET-T

4 DA-9533280156 PE BAG for SET

5 DA-9554160800 PE BAG for BASE

6 DA-9533070556 ZIP LOCK PE BAG for MANUAL

7 DA-9530730657 ZIP LOCK PE BAG for SCREW

! 8 DA-5056706095 POWER CORD LM-17G/U

! 8 DA-5056705939 POWER CORD LM-17G/E

! 8 DA-5056706089 POWER CORD LM-17G/C

! 9 DA-5030053011 USER’S MANUAL LM-17G/U

! 9 DA-5030054005 USER’S MANUAL LM-17G/E

! 9 DA-5030053010 USER’S MANUAL LM-17G/C

10 BT-51010-2 WARRANTY CARD LM-17G/E

11 BT-51024-1 SERVICE CENTER LIST LM-17G/E

12 DA-5030409315 IDENTUFICATION LABEL(S) (x2) LM-17G/U

12 DA-5030409311 IDENTUFICATION LABEL(S) (x2) LM-17G/E

12 DA-5030409313 IDENTUFICATION LABEL(S) (x2) LM-17G/C

13 DA-5030409314 IDENTUFICATION LABEL(L) (x2) LM-17G/U

13 DA-5030409310 IDENTUFICATION LABEL(L) (x2) LM-17G/E

13 DA-5030409312 IDENTUFICATION LABEL(L) (x2) LM-17G/C

12

3-6 (No. 52164)

Loading...

Loading...