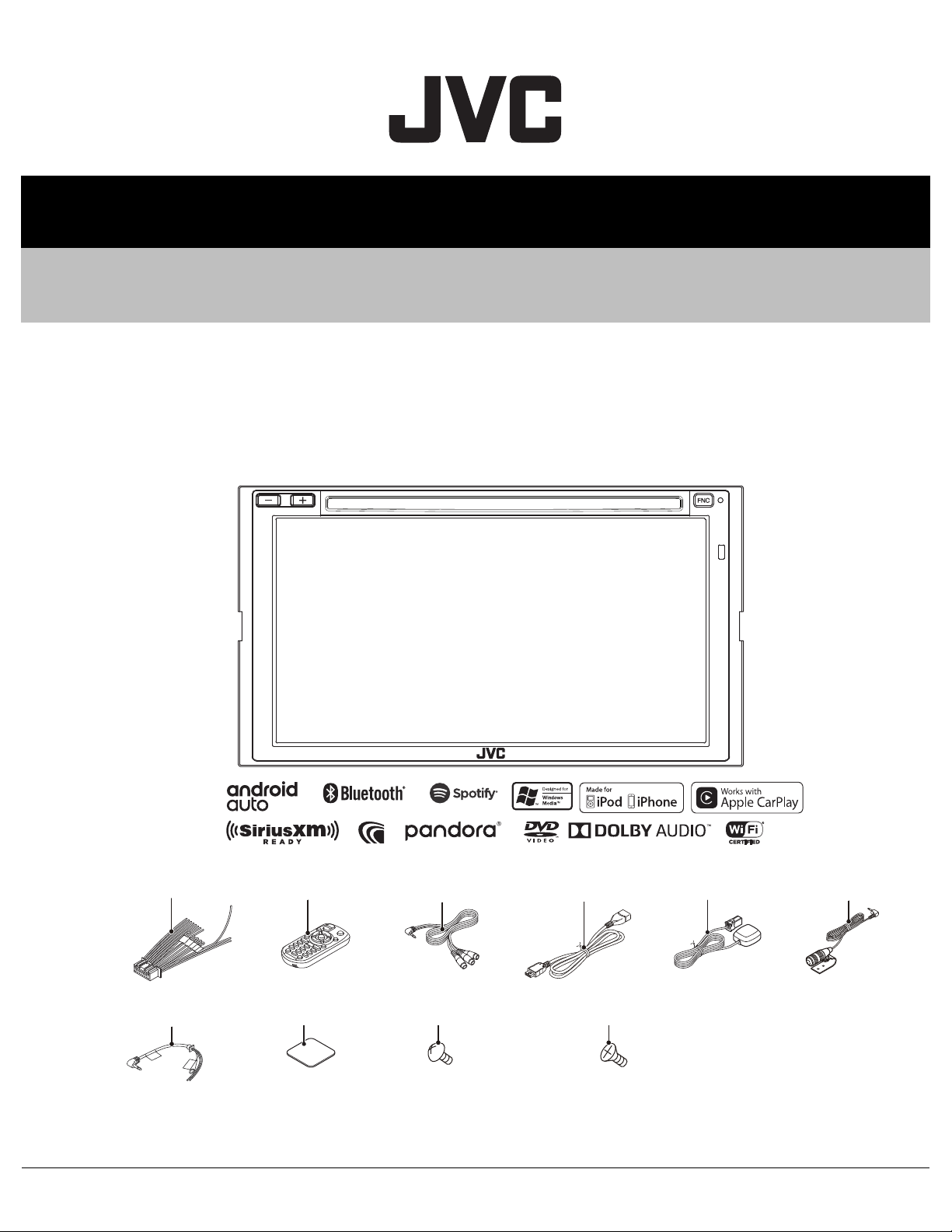

Page 1

SERVICE MANUAL

KW-V930BW (Australia) : X1

KW-V930BW (Other Areas) : M1

(3.5m)

Antenna

(QAL1550-001)

GPS Bracket

(LV45939-001A)

Screw (M5x8)

(QYSTSP5008ZA) x6

Screw (M5x8)

(QYSSSP5008ZA) x6

USB cord

(E3A-036x-00)

Car cable

(QAM1419-001)

(3m)

Microphone

(QAN0137-001)

Cord w.pinjack

(E3A-0274-00)

DC cord

(E3A-0214-00)

Remote control

(A7A-0006-00)

MA656<Rev.001>20174SERVICE MANUAL

KW-V830BT, KW-V930BW,

KW-V930BWM

MONITOR WITH DVD RECEIVER

COPYRIGHT © 2017 JVC KENWOOD Corporation

Lead free solder used in the board (material: Sn-Ag-Cu, melting point: 219 Centigrade)

Lead free solder used in the board (material: Sn-Cu, melting point: 230 Centigrade)

COPYRIGHT © 2017 JVC KENWOOD Corporation

No.MA656<Rev.001>

2017/4

Page 2

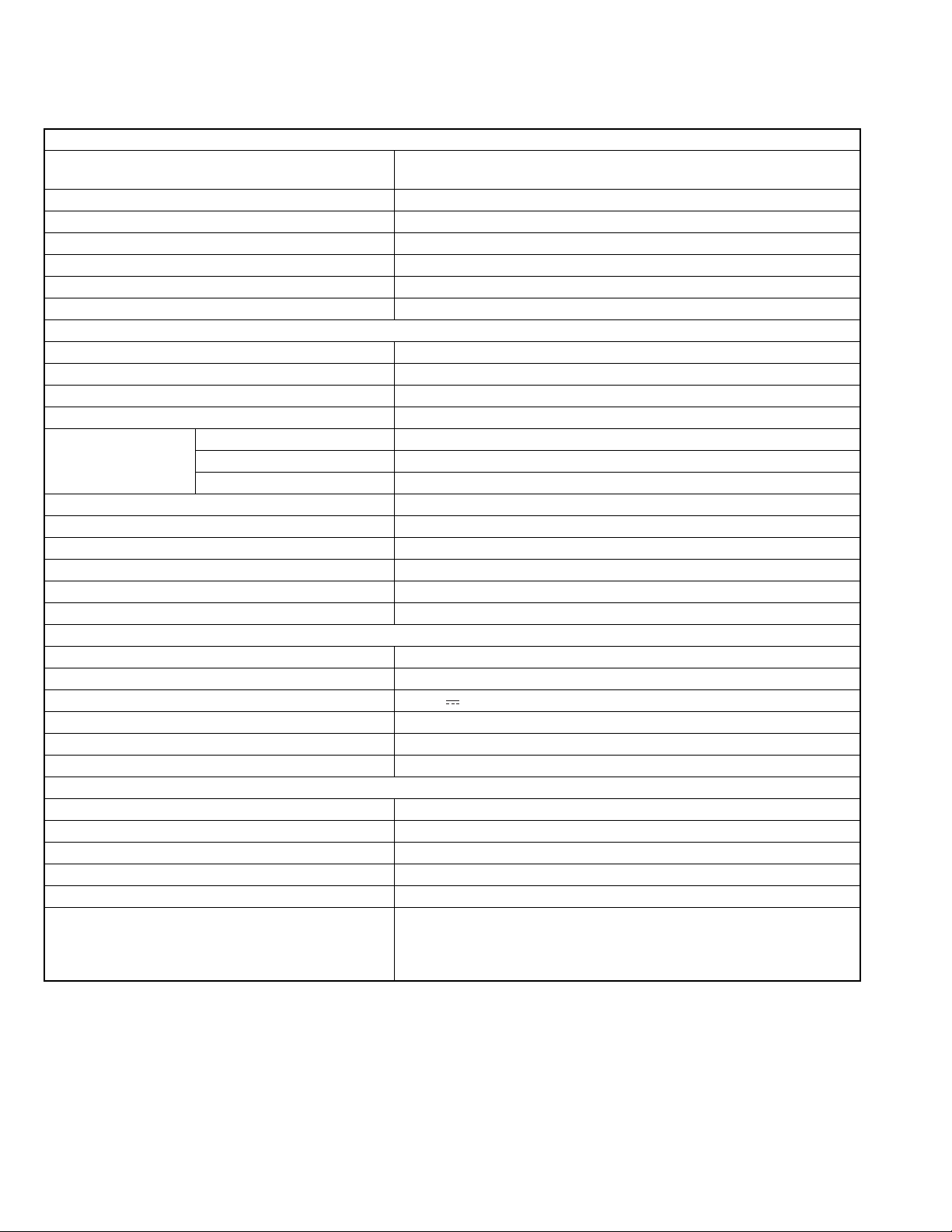

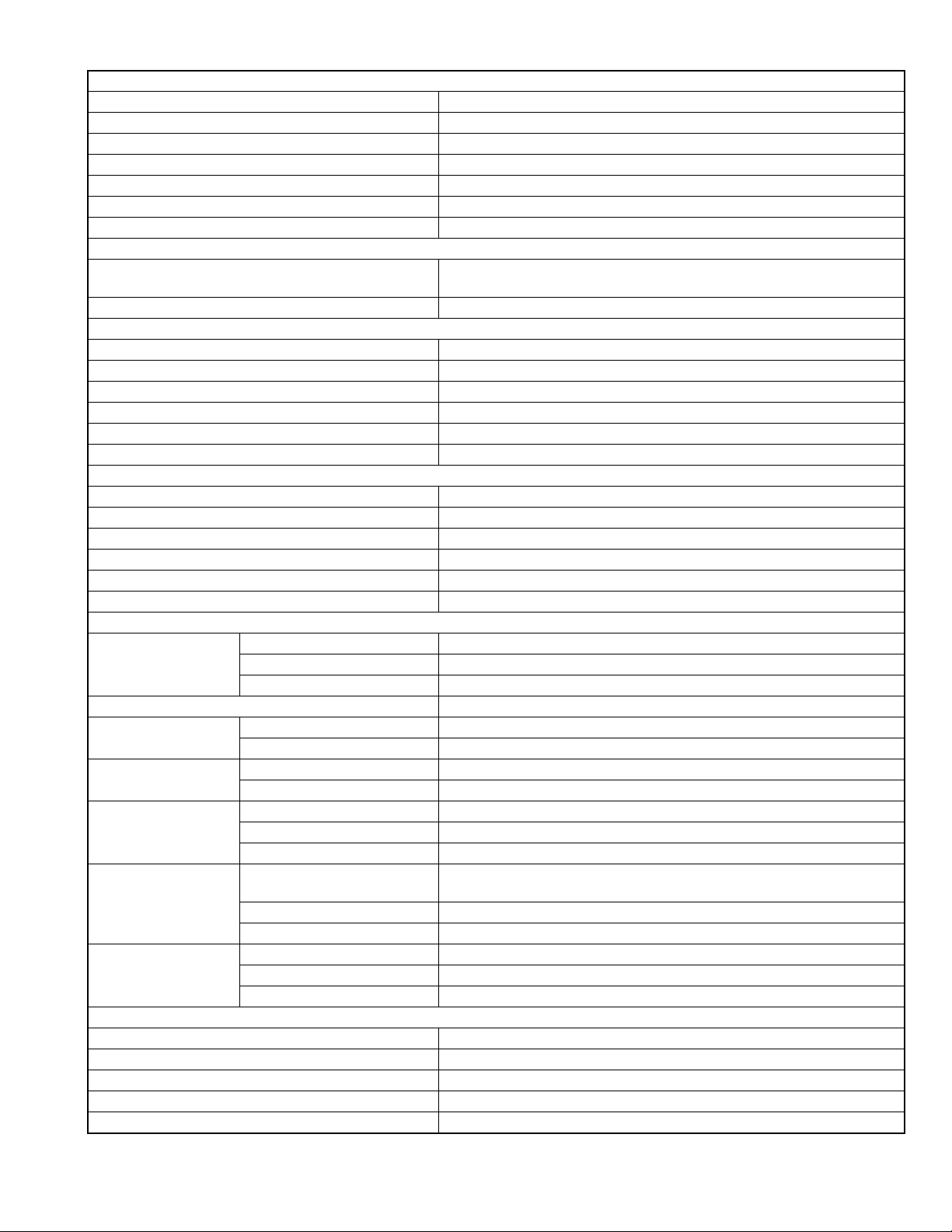

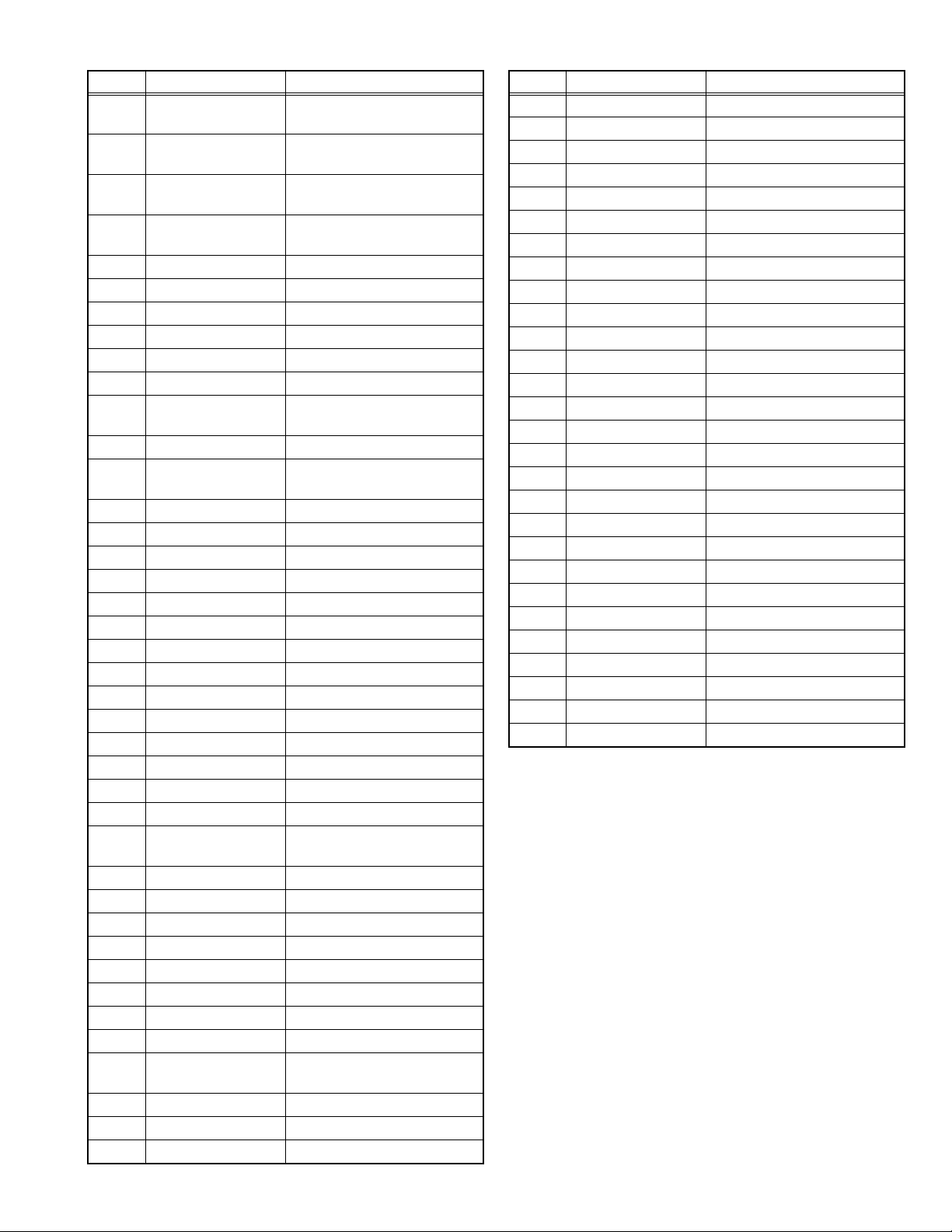

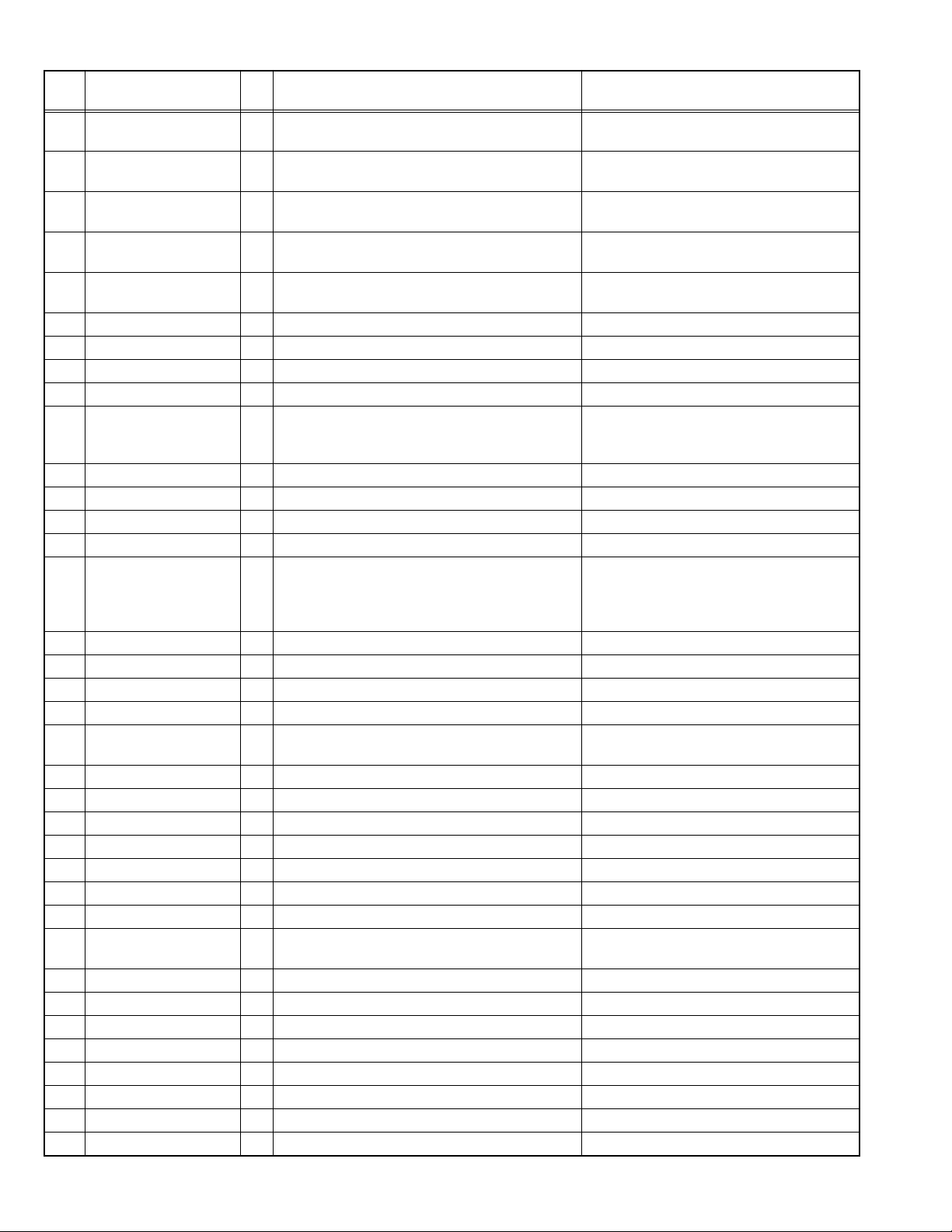

SPECIFICATION

Model for destination "K" (KW-V830BT)

Monitor section

Picture Size 6.75 inches (diagonal) wide

151.8 mm (W) 79.68 mm (H) (5-31/32 3-1/8 inch)

Display System TN LCD panel

Drive System TFT active matrix system

Number of Pixels 1 152 000 (800H 480V RGB)

Effective Pixels 99.99%

Pixel Arrangement RGB striped arrangement

Back Lighting LED

DVD player section

D/A Converter 24/32 bit

Audio Decoder Linear PCM/Dolby Digital/MP3/WMA/AAC/WAV/FLAC/Vorbis

Video Decoder MPEG1/MPEG2/MPEG4/WMV/H.264/MKV

Wow & Flutter Below Measurable Limit

Frequency

Response

Total Harmonic Distortion 0.010% (1 kHz)

S/N Ratio (dB) 90.5 dB

Dynamic Range 89 dB

Disc Format DVD-Video/VIDEO-CD/CD-DA/DVD-R/DVD-RW/DVD+R/DVD+RW

Sampling frequency 44.1/48/96 kHz

Quantifying Bit Number 16/20/24 bit

USB interface section

USB Standard USB 2.0 High Speed

File System FAT 16/ 32, exFAT, NTFS

Maximum Power Supply Current DC 5 V 1.5 A x 2

D/A Converter 24/32 bit

Audio Decoder MP3/ WMA/ AAC/ WAV/ FLAC/ Vorbis/ DSD

Video Decoder MPEG1/ MPEG2/ MPEG4/ WMV/ H.264/ MKV

Bluetooth section

Technology Bluetooth Ver.3.0

Frequency 2.402 GHz to 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE), Power Class2

Maximum Communication range Line of sight approx. 10 m (32.8 ft)

Audio Codec SBC/AAC

Profile (Multi Profile support) HFP (V1.6) (Hands Free Profile), SPP (Serial Port Profile), A2DP (Ad-

96 kHz 20 Hz to 44 000 Hz

48 kHz 20 Hz to 22 000 Hz

44.1 kHz 20 Hz to 20 000 Hz

vanced Audio Distribution Profile), AVRCP (V1.5) (Audio/Video Remote

Control Profile), HID (Human Interface Device Profile), PBAP (Phonebook

Access Profile)

(No.MA656<Rev.001>)2/61

Page 3

FM tuner section

Frequency Range (step) 87.9 MHz to 107.9 MHz (200 kHz)

Usable Sensitivity (S/N: 30 dB) 9.3 dBf (0.8 V/75 )

Quieting Sensitivity (S/N: 50 dB) 15.2 dBf (1.6 V/75 )

Frequency Response 30 Hz to 15 kHz

S/N Ratio (dB) 75 dB (MONO)

Selectivity (± 400 kHz) Over 80 dB

Stereo Separation 45 dB (1 kHz)

AM tuner section

Frequency Range (step) 530 kHz to 1700 kHz (10 kHz)

Usable Sensitivity 29 dB

Video section

Color System of External Video Input NTSC

External Video Input Level (RCA jacks) 1 Vp-p/ 75

External Video Input Level (mini jack) 1 Vp-p/ 75

External Audio Max Input Level (mini jack) 2 V/ 25 k

Video Output Level (RCA jacks) 1 Vp-p/ 75

Audio Output Level (mini jack) 1.2 V/ 10 k

Audio section

Maximum Power (Front & Rear) 50 W 4

Full Bandwidth Power (Front & Rear) 22 W 4 (4, 14.4 V, at less than 1% THD)

Output frequency band 20 Hz to 88,000 Hz

Preout Level (V) 4 V/10 k

Preout Impedance 600

Speaker Impedance 4 to 8

DSP section

Graphics equalizer BAND 13 Band

Frequency (BAND1 to 13) 62.5/100/160/250/400/630/1k/1.6k/2.5k/4k/6.3k/10k/16k Hz

Q 1.35/1.5/2.0

Gain -9/-8/-7/-6/-5/-4/-3/-2/-1/0/1/2/3/4/5/6/7/8/9 dB

2 Way X'Over

High pass filter

2 Way X'Over

Low pass filter

3 Way X'Over

High pass filter

3 Way X'Over

Band pass filter

3 Way X'Over

Low pass filter

General

Operating Voltage 14.4 V (10.5 V to 16 V allowable)

Maximum Current Consumption 15 A

Installation Dimensions (W H D) 178 mm 100 mm 155 mm (7 3-15/16 6-1/8 inch)

Operational Temperature Range -10C to +60C

Weight 2.1 kg (4.63 lbs)

Frequency (Hz) Through, 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz

Slope -6/-12/-18/-24 dB/Oct.

Frequency (Hz) 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz, Through

Slope -6/-12/-18/-24 dB/Oct.

Frequency (Hz) 1k/1.6k/2.5k/4k/5k/6.3k/8k/10k/12.5k Hz

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

Frequency (Hz) Through, 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz

1k/1.6k/2.5k/4k/5k/6.3k/8k/10k/12.5kHz, Through

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

Frequency (Hz) 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz, Through

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

• Design and specifications are subject to change without notice.

(No.MA656<Rev.001>)3/61

Page 4

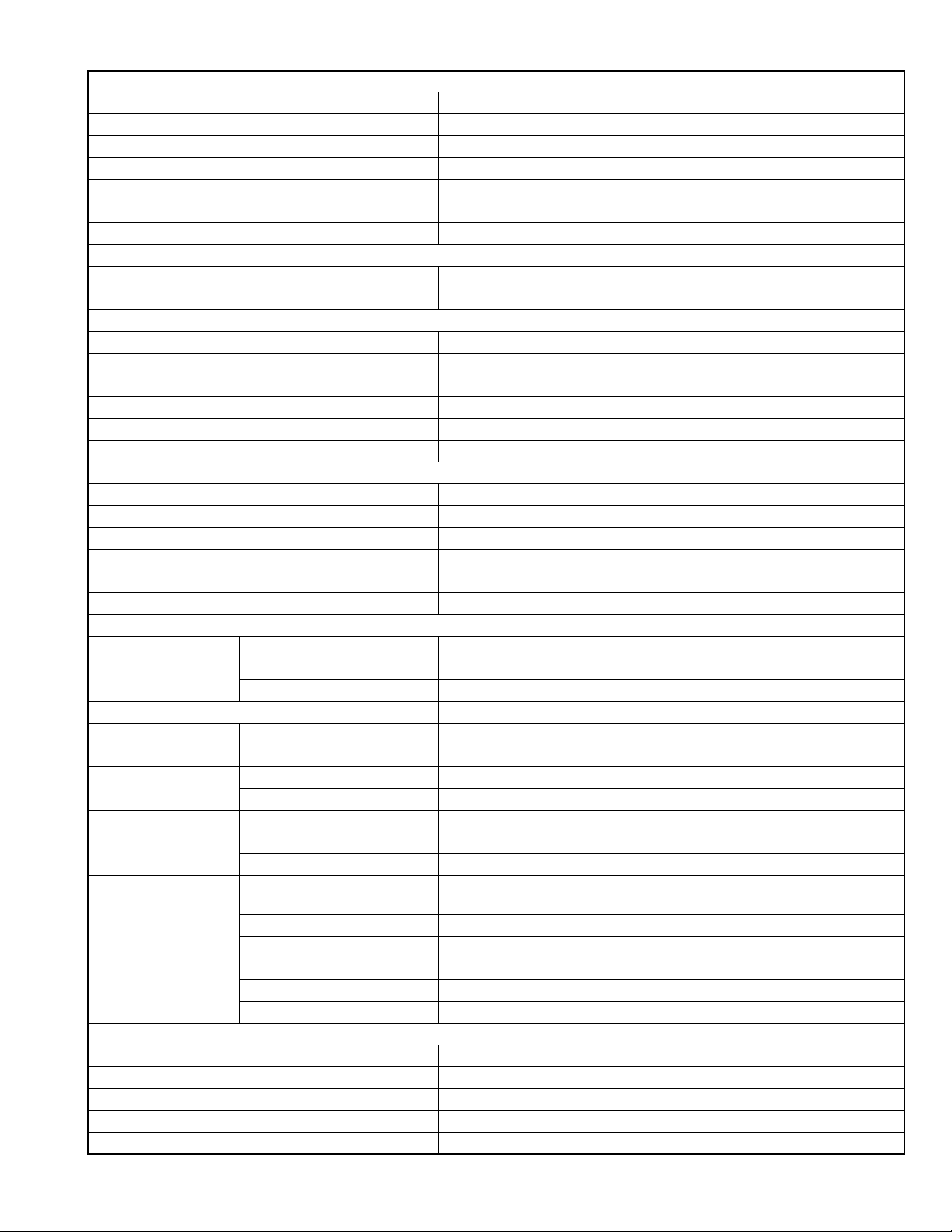

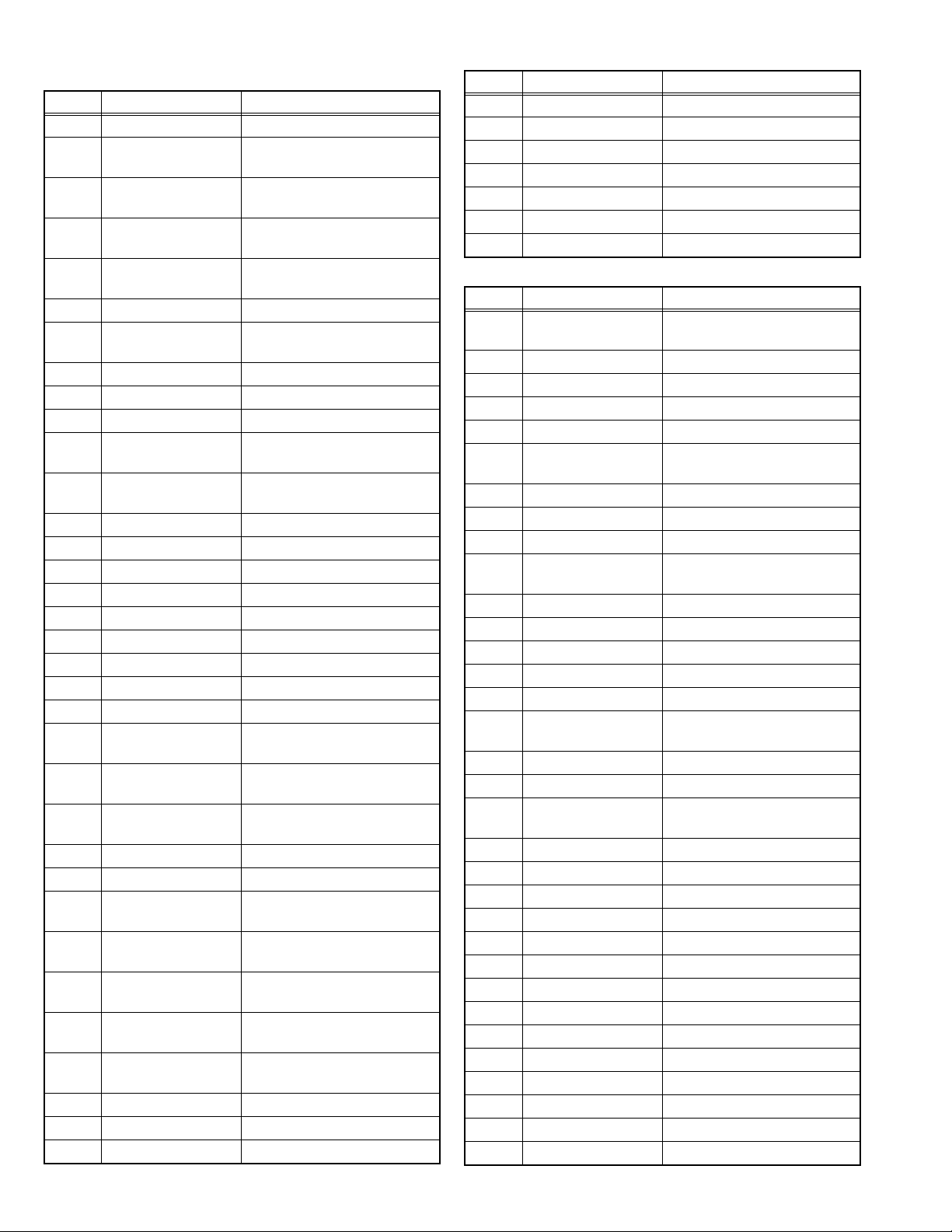

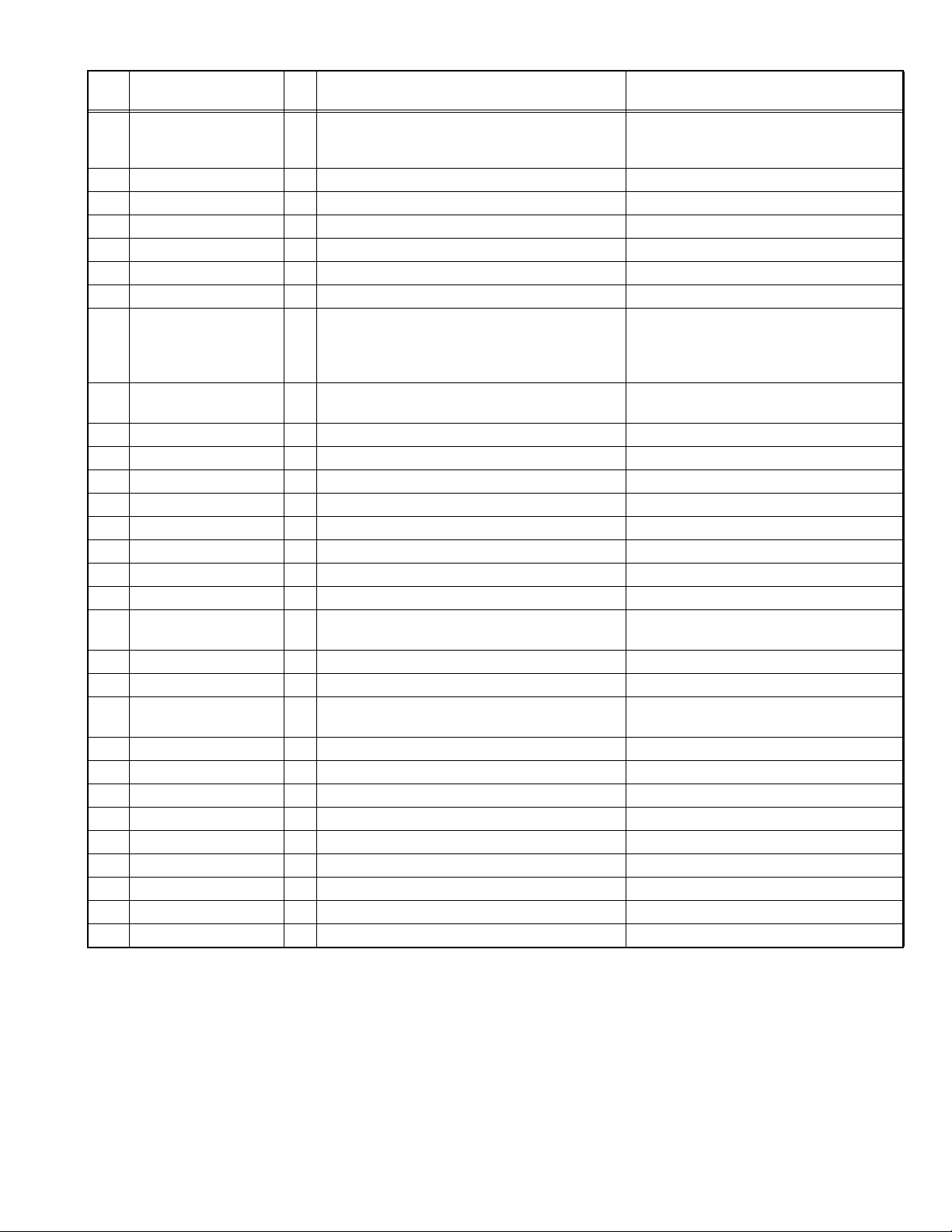

SPECIFICATION

Models for destinations "M" & "X" (KW-V930BW, KW-V930BWM)

Monitor section

Picture Size 6.75 inches (diagonal) wide

151.8 mm (W) 79.68 mm (H)

Display System TN LCD panel

Drive System TFT active matrix system

Number of Pixels 1 152 000 (800H 480V RGB)

Effective Pixels 99.99%

Pixel Arrangement RGB striped arrangement

Back Lighting LED

DVD player section

D/A Converter 24/32 bit

Audio Decoder Linear PCM/Dolby Digital/MP3/WMA/AAC/WAV/FLAC/Vorbis

Video Decoder MPEG1/MPEG2/MPEG4/WMV/H.264/MKV

Wow & Flutter Below Measurable Limit

Frequency

Response

Total Harmonic Distortion 0.010% (1 kHz)

S/N Ratio (dB) 90.5 dB

Dynamic Range 89 dB

Disc Format DVD-Video/VIDEO-CD/CD-DA/DVD-R/DVD-RW/DVD+R/DVD+RW

Sampling frequency 44.1/48/96 kHz

Quantifying Bit Number 16/20/24 bit

USB interface section

USB Standard USB 2.0 High Speed

File System FAT 16/ 32, exFAT, NTFS

Maximum Power Supply Current DC 5 V 1.5 A x 2

D/A Converter 24/32 bit

Audio Decoder MP3/ WMA/ AAC/ WAV/ FLAC/ Vorbis/ DSD

Video Decoder MPEG1/ MPEG2/ MPEG4/ WMV/ H.264/ MKV

Miracast section

Mode Sink

Copyright protection HDCP2.2

Touch Control UIBC

Wi-Fi section

IEEE Standard Region 3/4: 802.11a/b/g/n, Region 2: 802.11b/g/n

Frequency Range Region 3/4: Dual Band (2.4GHz / 5GHz), Region 2: 2.4GHz

Channels Region 3/ 4: Auto (1-11ch), Auto (149,153,157,161ch), Region 2: Auto (1-

Transfer rates (MAX) 11a: 54 Mbps (Region 3/ 4), 11b: 11 Mbps, 11g: 54 Mbps, 11n: 150 Mbps

Output Power 11a: 14 dBm ± 2 dB (Region 3/ 4), 11b: 17 dBm ± 2 dB, 11g: 15 dBm ± 2

Bluetooth section

Technology Bluetooth Ver.3.0

Frequency 2.402 GHz to 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE), Power Class2

Maximum Communication range Line of sight approx. 10 m (32.8 ft)

Audio Codec SBC/AAC

Profile (Multi Profile support) HFP (V1.6) (Hands Free Profile), SPP (Serial Port Profile), A2DP (Ad-

96 kHz 20 Hz to 44 000 Hz

48 kHz 20 Hz to 22 000 Hz

44.1 kHz 20 Hz to 20 000 Hz

11ch)

dB, 11n: 14 dBm ± 2 dB

vanced Audio Distribution Profile), AVRCP (V1.5) (Audio/Video Remote

Control Profile), PBAP (Phonebook Access Profile)

(No.MA656<Rev.001>)4/61

Page 5

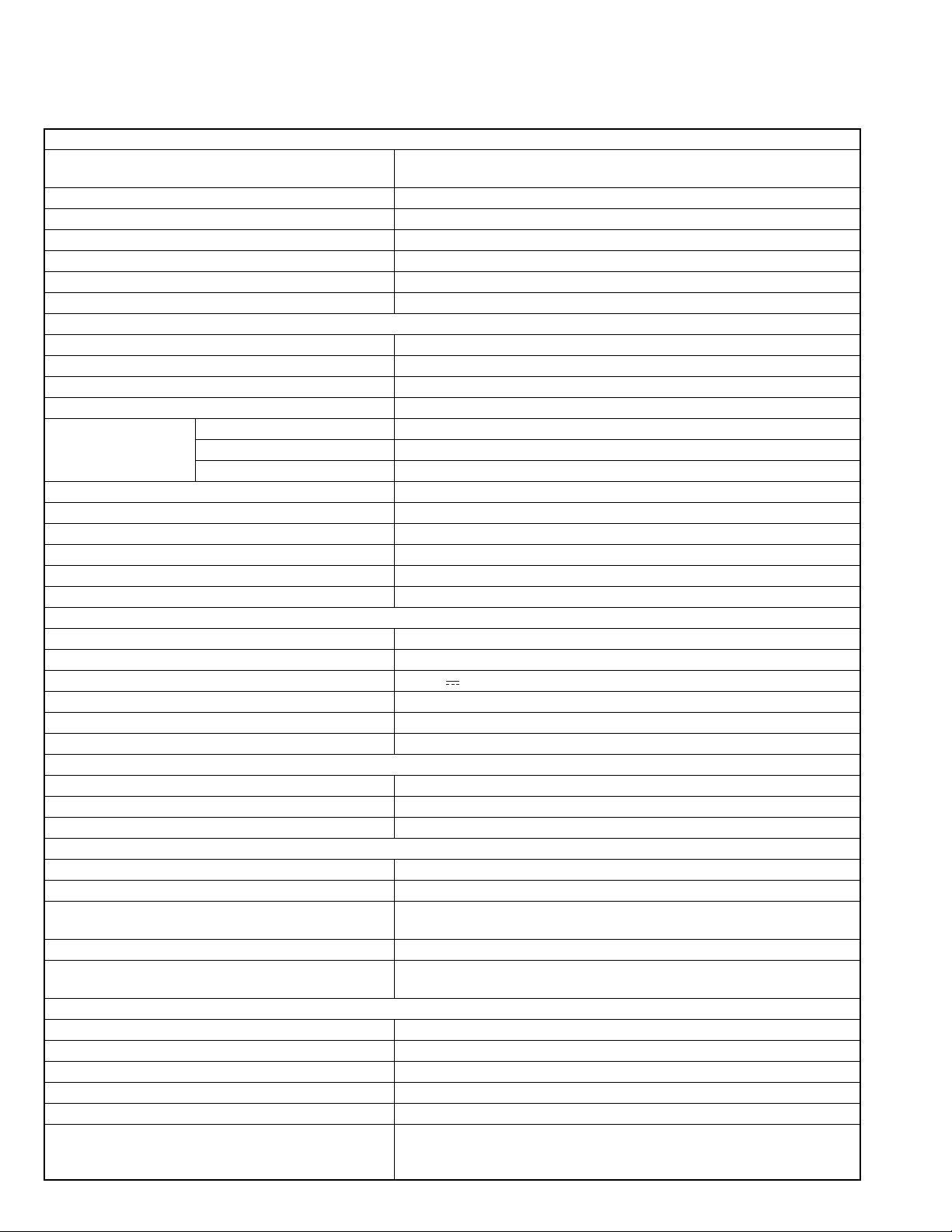

FM tuner section

Frequency Range (step) 87.5 MHz to 108.0 MHz (50 kHz)

Usable Sensitivity (S/N: 30 dB) 9.3 dBf (0.8 V/75 )

Quieting Sensitivity (S/N: 46 dB) 15.2 dBf (1.6 V/75 )

Frequency Response 30 Hz to 15 kHz

Signal to Noise Ratio (dB) 75 dB (MONO)

Selectivity (± 400 kHz) Over 80 dB

Stereo Separation 45 dB (1 kHz)

AM tuner section

Frequency Range (step) Region 3/ 4: 531 kHz to 1611 kHz (9 kHz), Region 2: 531 kHz to1602 kHz

(9 kHz)

Usable Sensitivity Region 3/ 4: 28 dB, Region 2: 25 V

Video section

Color System of External Video Input NTSC/PAL

External Video Input Level (RCA jacks) 1 Vp-p/ 75

External Video Input Level (mini jack) 1 Vp-p/ 75

External Audio Max Input Level (mini jack) 2 V/ 25 k

Video Output Level (RCA jacks) 1 Vp-p/ 75

Audio Output Level (mini jack) 1.2 V/ 10 k

Audio section

Maximum Power (Front & Rear) 50 W 4

Full Bandwidth Power (Front & Rear) 22 W 4 (4, 14.4 V, at less than 1% THD)

Output frequency band 20 Hz to 88,000 Hz

Preout Level (V) 4 V/10 k

Preout Impedance 600

Speaker Impedance 4 to 8

DSP section

Graphics equalizer BAND 13 Band

Frequency (BAND1 to 13) 62.5/100/160/250/400/630/1k/1.6k/2.5k/4k/6.3k/10k/16k Hz

Q factor 1.35/1.5/2.0

Gain -9/-8/-7/-6/-5/-4/-3/-2/-1/0/1/2/3/4/5/6/7/8/9 dB

2 Way X'Over

High pass filter

2 Way X'Over

Low pass filter

3 Way X'Over

High pass filter

3 Way X'Over

Band pass filter

3 Way X'Over

Low pass filter

General

Operating Voltage 14.4 V (10.5 V to 16 V allowable)

Maximum Current Consumption 15 A

Installation Dimensions (W H D) 178 mm 100 mm 155 mm

Operational Temperature Range -10C to +60C

Weight 2.1 kg

• Design and specifications are subject to change without notice.

Frequency (Hz) Through, 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz

Slope -6/-12/-18/-24 dB/Oct.

Frequency (Hz) 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz, Through

Slope -6/-12/-18/-24 dB/Oct.

Frequency (Hz) 1k/1.6k/2.5k/4k/5k/6.3k/8k/10k/12.5k Hz

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

Frequency (Hz) Through, 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz

1k/1.6k/2.5k/4k/5k/6.3k/8k/10k/12.5kHz, Through

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

Frequency (Hz) 30/40/50/60/70/80/90/100/120/150/180/220/250 Hz, Through

Slope -6/-12 dB/Oct.

Gain -8/-7/-6/-5/-4/-3/-2/-1/0 dB

(No.MA656<Rev.001>)5/61

Page 6

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

1.5 Remote control

The Lithium battery is in danger of explosion if replaced incorrectly. Replace it only with the same or equivalent type.

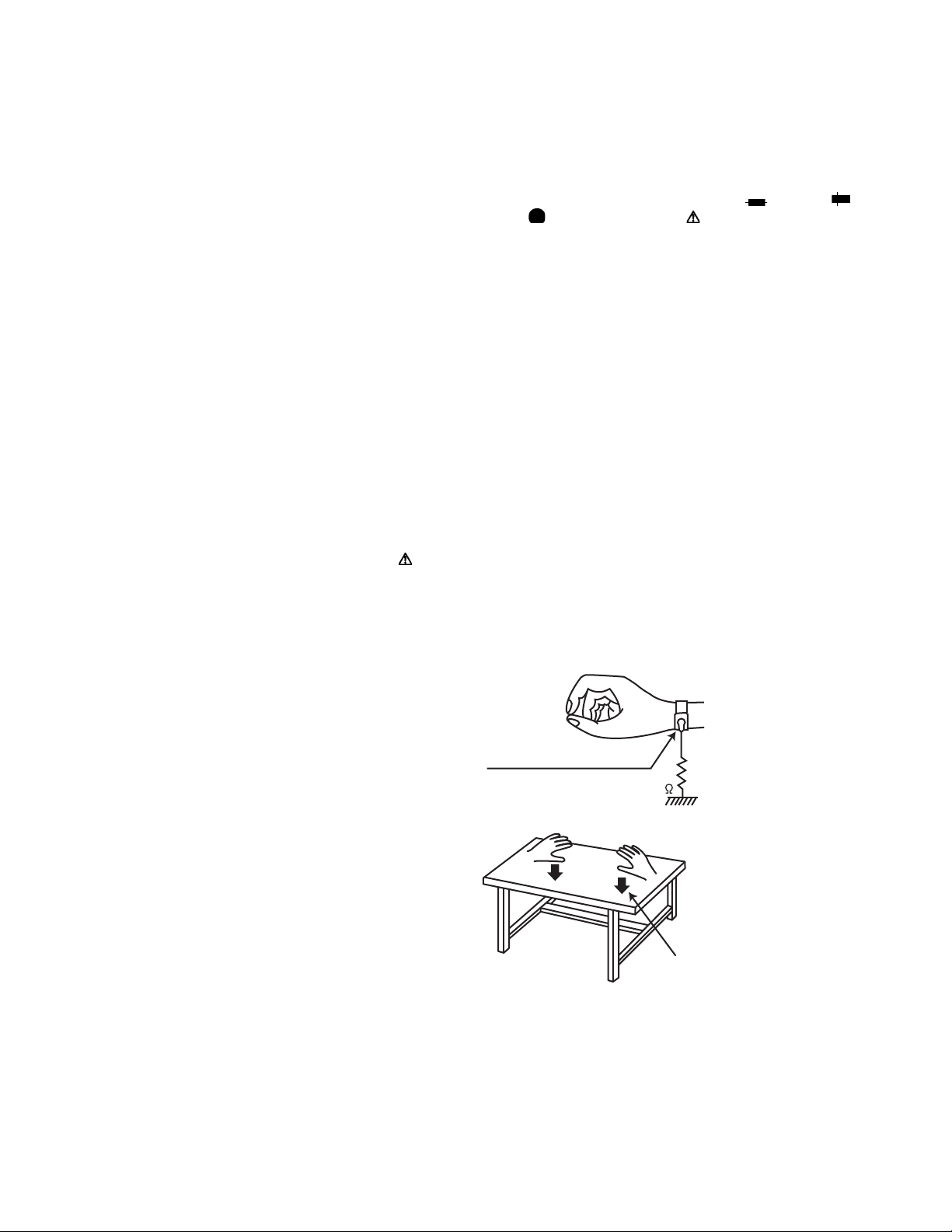

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the

laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup

(laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are

being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such

as a conductive sheet) or an iron plate over it before placing the traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity

built up in your body.

(caption)

Anti-static wrist strap

1M

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

(No.MA656<Rev.001>)6/61

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before

installation, both sides of the laser diode on the replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

Page 7

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong

shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers,

etc. after replacing the optical pickup. For specific details,

refer to the replacement procedure in the text. Remove the

anti-static pin when replacing the traverse unit. Be careful

not to take too long a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when

subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that ad-

justs the laser power. Do not turn it.

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the

pickup unit.

• Apply solder to the short land sections before the FPC wire is

disconnected from the connector on the DVD mecha board. (If

the FPC wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land

sections after connecting the FPC wire.

Short land section

(No.MA656<Rev.001>)7/61

Page 8

1.9 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

(No.MA656<Rev.001>)8/61

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 How to repair a fuse pattern

2.1.1 Purpose of fuse pattern

In order to prevent serious damage on the circuit, fuse pattern is prepared on the GND line of RCA Terminal. This damage may

take due to improper part replacement with a external equipment via RCA line.

2.1.2 Repair Procedure

(1) Check the shorted circuit at the meltdown point.

Need to clean up if the shorted circuit or carbonization happen at the fuse pattern.

(2) Add following part on the fuse pattern.

(3) Check output level.

Meltdown point

Part Number Part Name SPEC

F53-0513-08 PATTERN FUSE 4A

2.1.3 After finished repair

Due to improper part replacement, this meltdown occurs.

Thus please notice following information when the unit is returned to your customer.

Things to be checked before installing the unit.

(1) Check the GND line of external amplifier or other equipment which must connect properly.

(2) Check whether the GND line is not short-circuited with the battery terminal. (do not short-circuit these lines)

2.2 Precautions when replacing the IC

When A951(CIRCUIT MODULE) in MAIN PWB is defective, replace the whole MAIN PWB (CB-XJ1192***N).

2.3 Precautions when replacing the DIGITAL IO PWB

When DIGITAL IO PWB (DGB1/CB-XJA056***N) is replaced, it is necessary to set the region code.

2.4 Extension cable

• Purpose for this cable is checking the DIGITAL IO PWB and MAIN PWB.

• Parts number for this extension cable is "W3F-0291-00".

(No.MA656<Rev.001>)9/61

Page 10

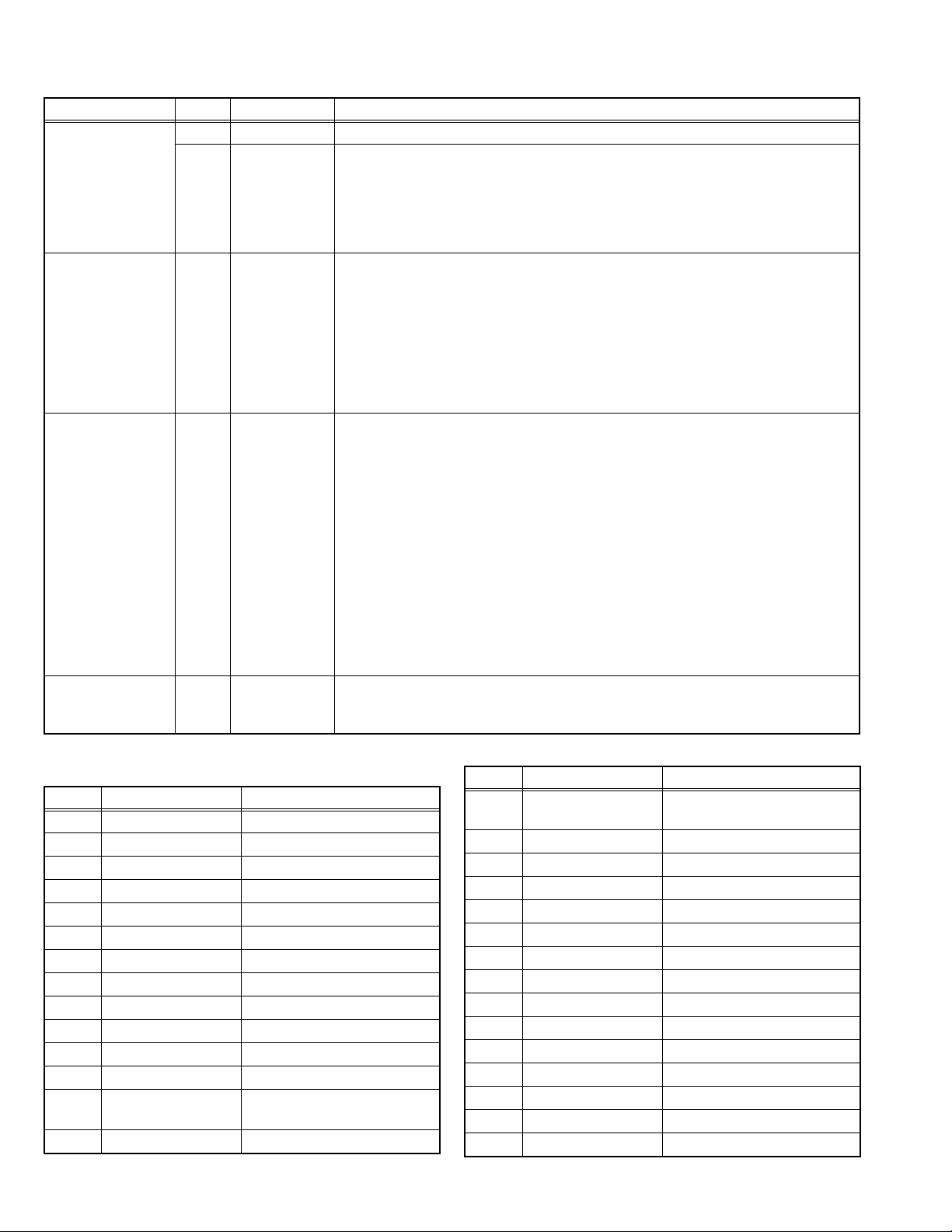

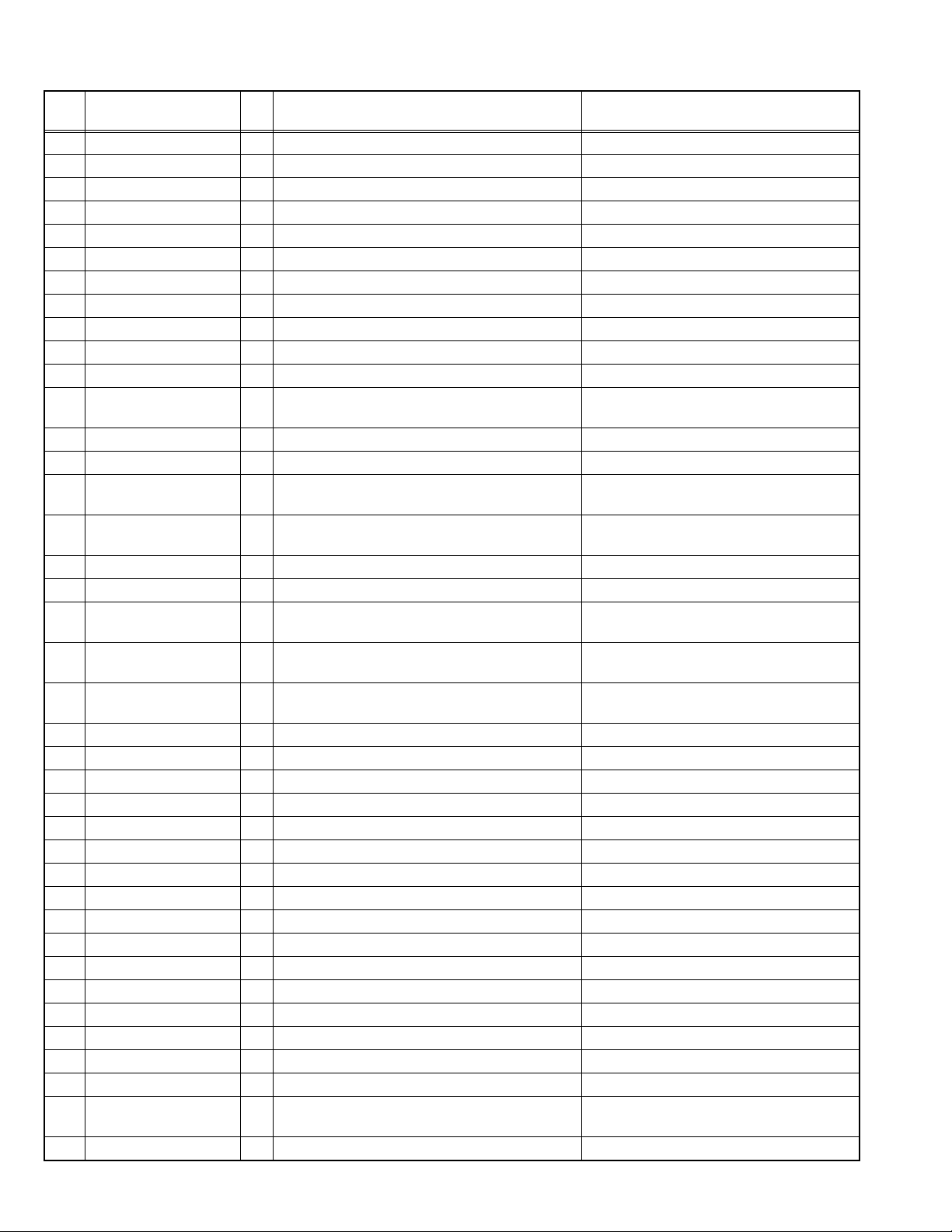

2.5 Data storage content of ICs

PWB Ref No. Part name Data preservation contents (*Need to setting to after the replacement of IC)

MAIN PWB IC301 MAIN uCOM Error information

IC304 EEPROM *White balance adjustment value

*Tilt mecha Open / Clese position adjustment value

TunerSpan (Area) information

Image quality adjustment values

DC offset information

Tuner information

DIGITAL IO PWB IC503 NAND FLASH User configuration data

Camera setting data

Sound various setting data

BtPhone setting data

Use history data of the mechanical system

Play history data

Car Play setting

iPod setting data

*File that Garmin is using (except DDX and KW models)

IC525 eMMC *Serial No.

*Region information

User configuration data

Audio setting data

Phone book data

Telephone number preset data

*Production mode test result data

*Gesture factory setting data

Wallpaper customize data for DOP

*File that Garmin is using (except DDX and KW models)

Pairing device information that A&W SDK is using

Pairing device information managed by the BtBackEnd

logfile

*Garmin license file (except DDX and KW models)

Custom opening image

VIDEO PWB IC100 PANEL uCOM *VCOM data

*Key illumination white color adjustment value

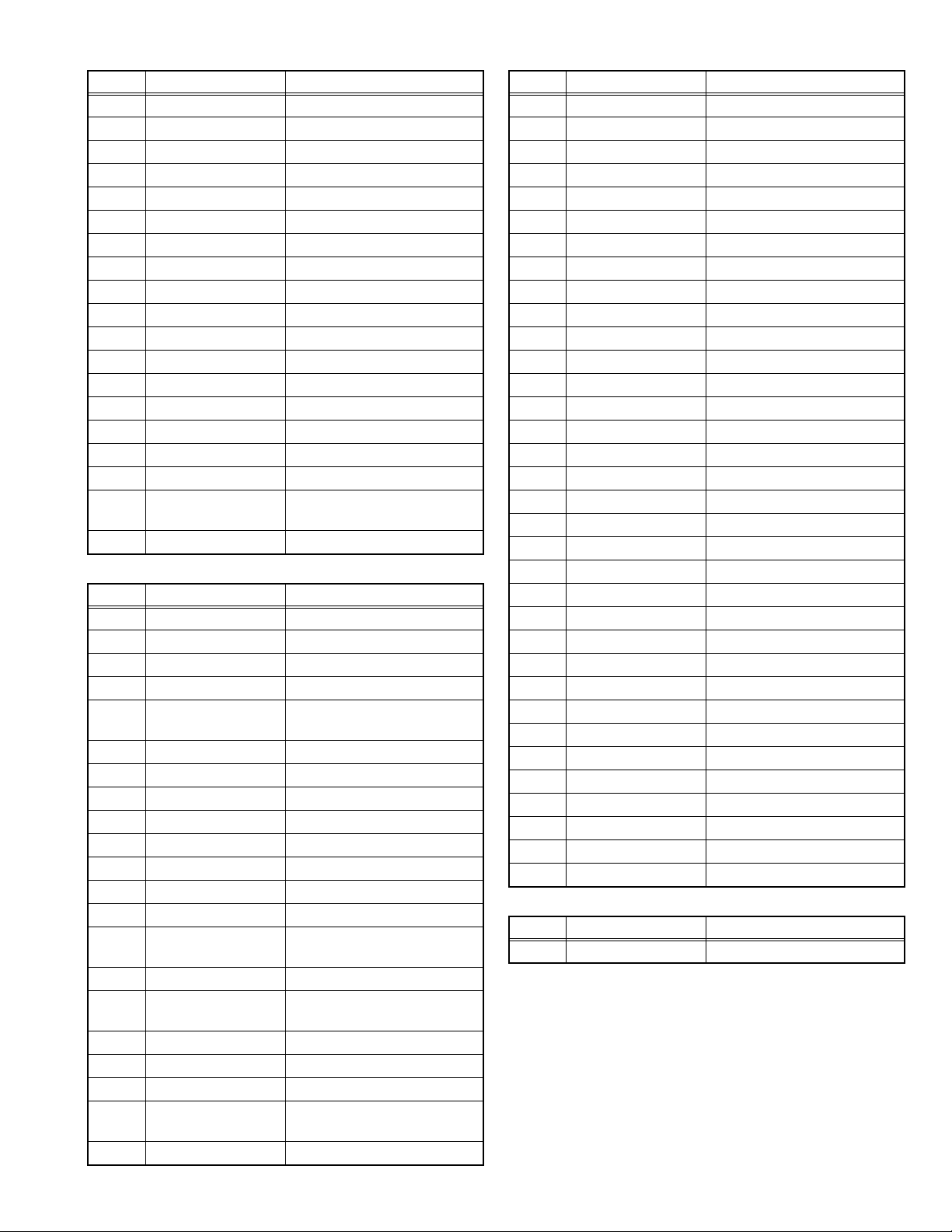

2.6 Components description

2.6.1 MAIN PWB (XJ1-192)

Ref. No. Application / Function

IC31 5.1V DCDC converter DCDC converter IC

IC51 5.1V DCDC converter DCDC controller IC

IC52 AND GATE IC IC51 control

IC71 5.1V DCDC converter DCDC controller IC

IC91 5.1V DCDC converter DCDC controller IC

IC92 AND GATE IC IC91 control

IC110 OP Amp USB VBUS current detect

IC131 5.1V DCDC converter DCDC controller IC

IC132 AND GATE IC IC131 control

IC150 OP Amp USB VBUS current detect

IC201 Regulator 3.3V Regulator IC for XJ6

IC205 Regulator Regulator IC for D3.3V

IC206 Hi side SW MHL5V ON/OFF and current

IC207 Regulator Regulator IC for FAN9V

Operation / Condition / Compatibility

limit

(No.MA656<Rev.001>)10/61

Ref. No. Application / Function

IC301 Micro Computer Slave CPU of Telechips

IC302 Voltage Detecte IC RESET control

IC303 AND GATE IC Remote control input

IC304 E2PROM u-COM memory

IC305 Comparator RESET control

IC307 AND GATE IC TV remote control out

IC501 DSP AUDIO DSP DAC

IC502 Audio DAC Subwoofer out

IC503 Audio DAC Alter / NAVI out

IC506 Audio DAC 2 zone out

IC507 Regulator Regulator IC for A5V

IC508 Regulator Regulator IC for A3.3V

IC601 OP Amp MIC Amp

IC602 Regulator Regulator IC for MIC5V

IC651 AD converter ADC for NAVI audio input

Operation / Condition / Compatibility

Control of Power XJ6 etc.

Page 11

Ref. No. Application / Function

IC721 AND GATE IC Transform 5V to 3.3V for DASH

IC722 3state Buffer IC Transform 3.3V to 5V for DASH

IC731 AND GATE IC Transform 5V to 3.3V for

IC732 3state Buffer IC Transform 3.3V to 5V for

IC733 4state Buffer IC Remote out buffer for NAVI I/F

IC871 Video SW IC Composite signal selector

IC872 Regulator Regulator IC for V5V

IC921 Low Noise Amp Amp for GPS signal

IC922 Regulator Regulator IC for G3.3V

IC923 Regulator Regulator IC for BU1.8V

IC951 Regulator Regulator IC for BT3.3V/

A921 GPS module

A951 WiFI / BT Combo

module

Q1 FET 14V ON/OFF

Q3 Transistor Q1 control

Q4 Transistor BU voltage detect (Hi voltage)

Q5 Transistor BU voltage detect (Hi voltage)

Q6 Transistor BU voltage detect (Hi voltage)

Q7 Transistor BU voltage detect (Low voltage)

Q8 Transistor BU voltage detect (Low voltage)

Q9 Transistor BU voltage detect (Hi voltage)

Q10 Transistor BU voltage detect (Low voltage)

Q11 Transistor BU voltage detect (8.5V)

Q12 Transistor BU voltage detect (8.5V)

Q51 Transistor IC51 EN control

Q52 Transistor IC51 EN control

Q110 Transistor QUICK CHARGE detect out

Q111 Transistor QUICK CHARGE detect

Q112 Transistor VBUS1 over current detect

Q113 Transistor VBUS1 over current detect

Q114 Transistor VBUS1 over current detect out

Q115 Transistor VBUS1 over current detect out

Q116 Transistor IC91 EN control

Q117 Transistor IC91 EN control

Q131 Transistor VBUS2 over voltage detect out

Q150 Transistor QUICK CHARGE detect out

Q151 Transistor QUICK CHARGE detect

Q152 Transistor VBUS2 over current detect

Q153 Transistor VBUS2 over current detect

Q154 Transistor VBUS2 over current detect out

Operation / Condition / Compatibility

CAM I/F

CAM I/F

iDATA LINK I/F or NAVI I/F

iDATA LINK I/F or NAVI I/F

WiFi3.6V

control

control

Ref. No. Application / Function

Q155 Transistor VBUS2 over current detect out

Q156 Transistor IC131 EN control

Q157 Transistor IC131 EN control

Q301 Transistor SW3.3V control

Q302 Transistor Q301 control

Q303 Transistor u-COM RESET control

Q304 Transistor u-COM RESET control

Q305 Transistor u-COM RESET control

Q306 Transistor DET_MUTE control

Q307 Transistor DET_MUTE control

Q308 Transistor SI control

Q309 Transistor SI control

Q312 Transistor PCON/ANT out

Q313 Transistor PCON/ANT voltage control

Q314 Transistor PCON/ANT voltage control

Q315 Transistor u-COM RESET control

Q316 Transistor u-COM RESET control

Q317 Transistor u-COM RESET control

Q318 Transistor u-COM RESET control

Q319 Transistor u-COM RESET control

Q501 Transistor DSP power down control

Q502 Transistor DAC RESET control

Q651 Transistor ADC power down control

Q801 FET STE REMO Pull up SW

Q802 FET STE REMO Pull up SW

Q803 Transistor STE REMO Pull up control

Q921 Transistor G3.3V control

Q922 Transistor BU1.8V control

Operation / Condition / Compatibility

(No.MA656<Rev.001>)11/61

Page 12

2.6.2 DIGITAL IO PWB (XJA-056)

Ref. No. Application / Function

IC501 SoC Processor for Digital Media

IC503 2Gb SLC NAND

Flash memory

IC525 16GB or 8GB or 4GB

eMMC memory

IC531 4Gb x16 DDR3

memory

IC532 4Gb x16 DDR3

memory

IC546 AND Logiv IC Rear camera control

IC541 LCD Controller Video scaler and timing

IC543 Dual Bus Switch I2C SW

IC544 AND Logiv IC Rear camera control

IC545 OR Logic IC Rear camera control

IC563 iPod Authentication

Coprocessor

IC571 USB Charging Port

Controller

IC573 2port USB Hub IC 2port USB Hub

IC574 Regulator D+1.2V_HUB Regulater IC

IC591 DCDC controller IC 3.3V DCDC converter

IC592 DCDC controller IC 1.17V DCDC converter

IC593 Regulator SD+3.3V Regulater IC

IC594 Regulator D+2.5V Regulater IC

IC595 Regulator D+1.8V Regulater IC

IC596 Regulator CPU+1.5V Regulater IC

IC597 Regulator TCON+1.5V Regulater IC

IC598 Hi side SW Over current protection of

IC599 Hi side SW Over current protection of

IC600 Hi side SW Over current protection of

IC601 DCDC controller IC 1.23V DCDC converter

IC602 AND Logiv IC IC591 control

IC631 Video Amp IC with

LPF

IC651 Differential serial

interface IC

Q5401 Transistor Emitter follower circuit of DVD

Q5402 Transistor Emitter follower circuit of DVD

Q5403 Transistor Emitter follower circuit of DVD

Q5603 Transistor IC563 control

Q5604 Transistor IC563 control

Q5605 Transistor IC563 control

Operation / Condition / Compatibility

SoC program memory

NAVI MAP memory

For SoC memory

For SoC memory

controller

iPod Authentication

USB charging port control

BL+5V

PANEL+5V

PANEL+3.3V

SoC Video amplifier and LPF

Serialize output of IC541(RGB)

line(Y)

line(Cb)

line(Cr).

Ref. No. Application / Function

Q5606 Transistor IC563 control

Q5607 Transistor IC563 control

Q5608 Transistor IC563 control

Q5801 Transistor MHL VBUS Control SW

Q5901 Transistor IC593 control

Q5902 Transistor IC593 control

Q6301 Transistor UPDATE Control SW

2.6.3 AUDIO PWB (XJ6-105)

Ref. No. Application / Function

IC1 Multi channel Voltage

Regulator

IC41 Voltage Regulator BU3.3V

IC42 Voltage Regulator A8.5V for XJ6

IC101 Power IC Power AMP

IC115 OR Logic IC PWIC_BEEP_Level_shift

IC201 Electoric Vol IC Audio Vol Control, Audio Signal

IC260 Analog IC Audio Select for SXM/ADS

IC261 Analog IC ISO Amp for DVD

IC301 Voltage Regulator RF3.3V

IC361 Microprocessor Microprocessor for DAB

IC401 FM & RDS Receiver Tuner for TMC

IC511 OR Logic IC SXi_TX Level shift

IC512 OR Logic IC SXi_RX Level shift

IC590 Bus Buffer IC Buffer for TV_Remote_Out

IC601 Line amp IC 5V Preout

IC781 Motor Drv Monitor mecha slide motor

IC790 Voltage Regulator TILT9.7V

IC801 speech synthesis LSI Audio for Emotional Beep

IC802 operational amplifier Change audio signal from

IC803 operational amplifier Mix Beep with audio for preout

IC900 Voltage Regulator DAB3.3V

IC1101 operational amplifier audio buffer to PWIC

IC1102 operational amplifier audio buffer to PWIC

Q31 Transistor ACC Detect

Q32 Transistor ACC Detect

Q51 DIGI Transistor Illumi Detect

Q60 DIGI Transistor Camera control

Q61 DIGI Transistor Camera control

Q62 DIGI Transistor Camera control

Q63 DIGI Transistor Camera control

Q80 DIGI Transistor Parking Detect

Q81 Transistor Parking Detect

Q82 Transistor Parking Detect

Operation / Condition / Compatibility

Operation / Condition / Compatibility

ILM8VCD8VA8.5VSW5VBU5V

P-CONP-ANT Power Supply

Select

module

control

differential to single end

(No.MA656<Rev.001>)12/61

Page 13

Ref. No. Application / Function

Q90 DIGI Transistor Reverse Detect

Q96 Transistor Update Detect

Q151 DIGI Transistor Preout mute drive

Q152 DIGI Transistor Preout mute drive

Q155 DIGI Transistor Preout mute drive

Q156 DIGI Transistor Preout mute drive

Q161 DIGI Transistor Preout FL mute

Q162 DIGI Transistor Preout FR mute

Q163 DIGI Transistor Preout RL mute

Q164 DIGI Transistor Preout RR mute

Q165 DIGI Transistor Preout SWL mute

Q191 DIGI Transistor AVOUT mute drive

Q193 DIGI Transistor AVOUT AL mute

Q194 DIGI Transistor AVOUT AR mute

Q391 DIGI Transistor DAB ANT POWER

Q392 DIGI Transistor DAB ANT POWER control

Q451 DIGI Transistor ANT Distributer

Q781 DIGI Transistor MOTOR Drv [IC781] Power

Q801 DIGI Transistor PDN for IC801

2.6.4 VIDEO PWB (XJ8-043)

Ref. No. Application / Function

IC100 MCU IC Panel uCOM

IC102 Analog IC RESET Voltage detedt 2.8V

IC103 IC 3.3V Regulator

IC106 MOS IC Inverter

IC200 IC LCD Backlight power LCD

IC201 MOS IC Inverter

IC202 MOS IC 3.3V Regulator

IC300 SV-analogue IC 10.5V Regulator

IC400 MOS IC LVDS Reciever

IC800 IR detect unit REMOCON IC

Q100 DIGI Transistor Reset Voltage Out

Q101 DIGI Transistor Reset Voltage Out

Q200 DIGI Transistor Backlight turn off by [V_OFF]

Q201 Transistor Luminance of Backlight

Q202 MOS FET SW control for Backlight Power

Q203 Transistor DCDC IC control by

Q204 Transistor Backlight LED Driver

Q205 Transistor Backlight LED Driver

Q206 Transistor Backlight LED Driver

Q207 Transistor Luminance of Backlight

Q208 Transistor Backlight LED Driver

Operation / Condition / Compatibility

Supply

Operation / Condition / Compatibility

power LED power supply

Contorol

[BOOST_H]

Contorol

Ref. No. Application / Function

Q209 Transistor Backlight LED Driver

Q210 Transistor Backlight LED Driver

Q211 Transistor Backlight LED Driver

Q212 Transistor Backlight LED Driver

Q213 DIGI Transistor Backlight turn off by [V_OFF]

Q214 DIGI Transistor Backlight turn off by [V_OFF]

Q300 Transistor 13V Soft Start SW

Q301 Transistor 20V Soft Start SW

Q302 Transistor 20V Regulete

Q303 DIGI Transistor 13V Soft Start SW

Q304 DIGI Transistor 20V Soft Start SW

Q305 DIGI Transistor 13V Soft Start SW

Q306 DIGI Transistor 20V Soft Start SW

Q307 Transistor -7V Soft Start SW

Q308 Transistor -7V Soft Start SW

Q309 Transistor -7V Regulate

Q310 DIGI Transistor -7V Regulate

Q311 DIGI Transistor -7V Regulate

Q313 Transistor 15V Regulate

Q400 Transistor VCOM Voltage Driver

Q401 Transistor VCOM Voltage Driver

Q402 DIGI Transistor VCOM Voltage Driver

Q403 DIGI Transistor VCOM Voltage Driver

Q404 DIGI Transistor VCOM Voltage Driver

Q405 DIGI Transistor VCOM Voltage Driver

Q500 Transistor Touch Panel Control

Q501 Transistor Touch Panel Control

Q502 Transistor Touch Panel Control

Q503 Transistor Touch Panel Control

Q504 DIGI Transistor Touch Panel Control

Q505 Transistor Touch Panel Control

Q506 Transistor Touch Panel Control

Q800 Transistor White LED Driver

Q801 Transistor White LED Driver

2.6.5 BLUETOOTH PWB (XJ9-017)

Ref. No. Application / Function

A951 Cuicuit Module BT Module

Operation / Condition / Compatibility

Operation / Condition / Compatibility

(No.MA656<Rev.001>)13/61

Page 14

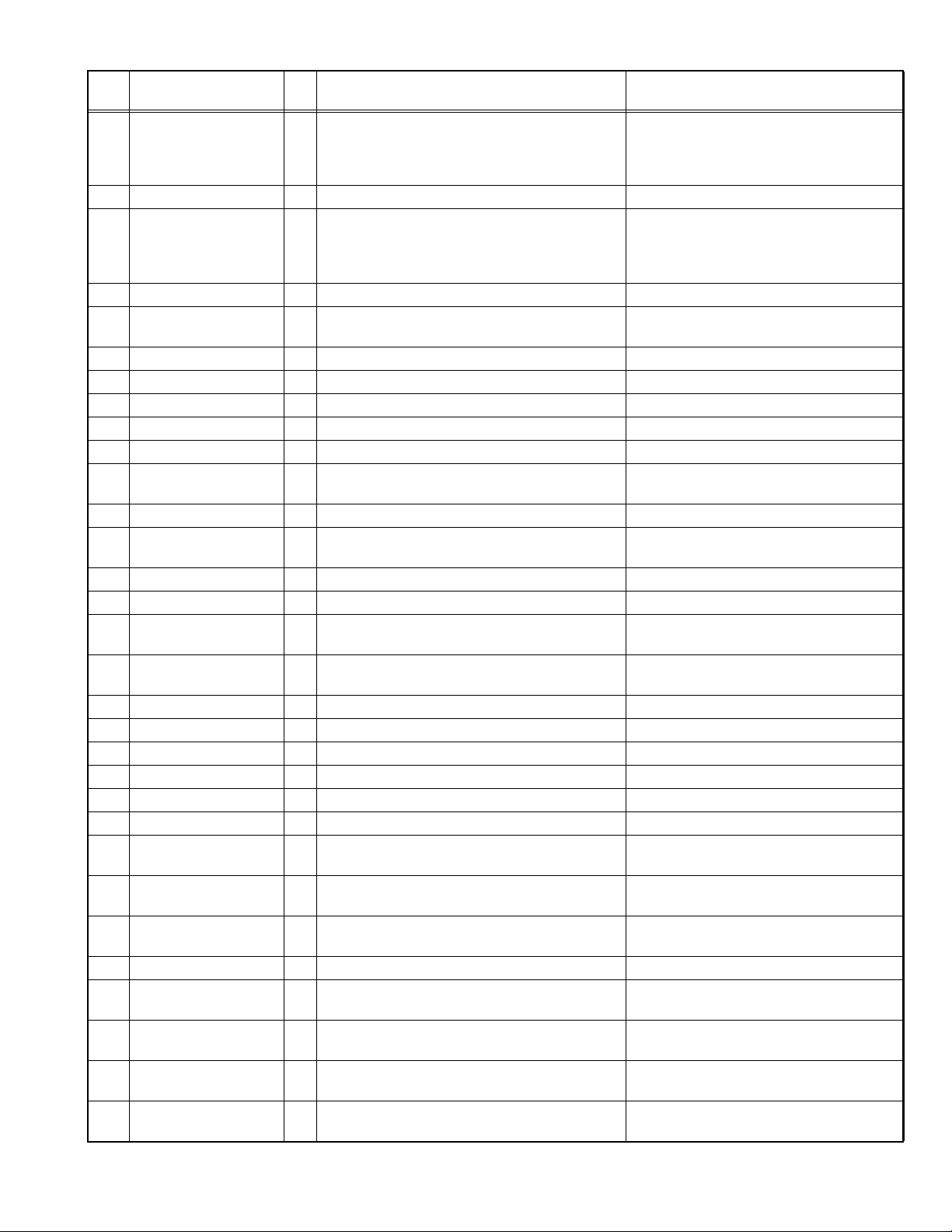

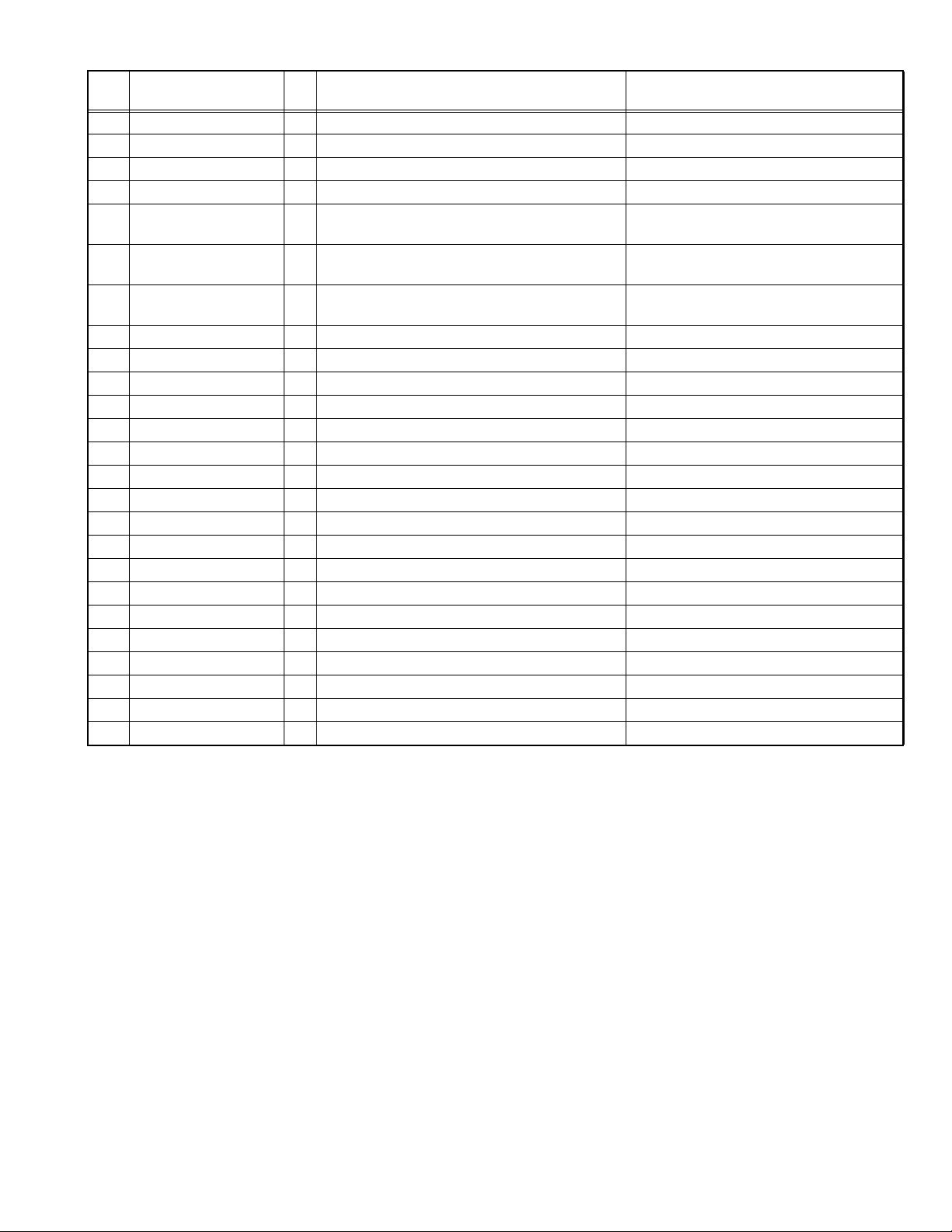

2.7 Microcomputer's terminal description

2.7.1 Main microcomputer (MAIN PWB : IC301)

Pin

No.

1VREF -

2 AVCC -

3 D_TO_M_DAT I DSP (AK7738) data communication (DSP to

4 M_TO_D_DAT O DSP (AK7738) data communication (MAIN to

5 M_TO_D_CLK O DSP (AK7738) clock communication (MAIN to

6 PWIC_BEEP O PWIC BEEP PWM output 1k/2 kHz duty 50%

7 REMO I Wired REMO data input For KWD models

8 M_TO_N_DAT O NAVI data communication (MAIN to NAVI)

9 N_TO_M_DAT I NAVI data communication (NAVI to MAIN)

10 M_TO_N_CLK O NAVI clock communication (MAIN to NAVI)

11 TOUCH_TV_REMO O REMO OUT of general-purpose TV CTRL touch

12 D3_3V_CTL O DIGITAL IO PWB D3.3 V control H: ON, L: OFF

13 BYTE - External data bus width switching input (In single

14 CNVSS - Processor mode switching terminal In microprocessor mode: Connected to

15 XCIN - Sub clock oscillation circuit input 32.768kHz (Crystal oscillator)

16 XCOUT - Sub clock oscillation circuit output 32.768kHz (Crystal oscillator)

17 /RESET I Reset input L: RESET on, H: Reset clear

18 XOUT - Main clock oscillation circuit output 16MHz (Crystal oscillator)

19 VSS -

20 XIN - Main clock oscillation circuit input 16MHz (Crystal oscillator)

21 VCC1 -

22 NMI I

23 DAB_SREQ I DAB ucom to Syscom REQ DAB model only

24 /N_TO_M_REQ I NAVI data receiving request (NAVI to MAIN)

25 /N_TO_M_RDY I NAVI data transmission and receiving enable sig-

26 /M_TO_N_REQ O NAVI data transmission request (MAIN to NAVI)

27 D_REC_RX I RX between SYS and drive recorder

28 /NAVI_RST O NAVI reset (MAIN to NAVI)

29 D_REC_TX O TX between SYS and drive recorder

30 NC I

31 VF_CTL+ O Frequency control of the DC-DC_IC, 180 degrees

32 NC I

33 A_POWER_PWM O Frequency control of XJ6_5V PREOUT_IC

34 WREMO_J I

35 VF_CTL- O Frequency control of the DC-DC_IC, 180 degrees

Pin Name I/O Application Processing/Operation/Description

MAIN)

DSP) Shared with ADC data communication

DSP) Shared with ADC data communication

H: Except REMO OUT

panel operation

In single chip mode: Connected to VSS

chip mode: Connected to VSS)

VCC1

In single chip mode: Connected to VSS

nal (NAVI to MAIN)

phase of VF_CTL-

phase of VF_CTL+

(No.MA656<Rev.001>)14/61

Page 15

Pin

No.

36 I2C_SDA_DISP

37 VCC1 -

38 I2C_SCL_DISP

39 VSS -

40 DEBUG_SCLK I Clock synchronous serial communication In standard serial I/O mode1: CLK

41 BUSY O BUSY signal output terminal In standard serial I/O mode1

42 TUN_SDA I/O DATA of between the SYS and HELIO

43 TUN_SCL O CLK of between the SYS and HELIO

44 NC O L fixed

45 NC O L fixed

46 SOC_RST

47 FAN_CTL O L fixed (FAN voltage changing standby terminal) H: high voltage, L: constant voltage

48 DAC_PDN O DAC power down H: Power down at the same timing as

49 /M_TO_AD_CSN O ADC control L: active

50 HOME I HOME KEY L: Depression of HOME KEY is detected

51 POW_REG

52 EPM I Standard serial I/O mode 1 Fixed connection to VSS

53 POW_ON O SW power supply ON/OFF control H: ON, L: OFF

54 EPROM_SCL O E2PROM SCL

55 EPROM_SDA I/O E2PROM SDA

56 EPROM_WC O E2PROM write protection H: Write prohibited, L: Write enable

57 Q_CHG I Quick charge detection L: Detected, H: Normal

58 DABUCOM_RST O DAB uCOM reset control L: RESET on, H: Reset clear

59 POW_AMP

60 REAR_CAM_PON O RCAM power enable L fixed

61 CE I Standard serial I/O mode 1 Fixed connection to VSS

62 LCD_MUTE2 O Insert black picture when rear camera switching

63 DABUCOM_POW O DAB uCOM startup request (DAB model only) H: Startup, L: Shutdown

64 CAYMAN_MREQ

64 CAYMAN_MREQ

65 CAYMAN_MDATA

Pin Name I/O Application Processing/Operation/Description

(VF_SW)

(VF_SW2)

(UPDATE_OUT)

(SW14V_PON)

(PWIC_STBY)

%CAYMAN_MREQ%

%HD_CS%

%DAB_MC_DATA%

O DATA of between the SYS and PANEL/decoder-

PANEL power PWM control

O CLK of between the SYS and PANEL/decoder-

PANEL power PWM control

O Forced write notification to Telechips When detecting L for more than 1 second at

O SW14V ON/OFF H: ON L: OFF

O Power IC standby control H: ON, L: OFF

O SYS to DAB uCOM REQ DAB model only

O SYS to CAYMAN REQ HD model only

O MCDATA of between the SYS and DAB DAB model only

Fast start: I2C communication

Normal operation: PWM control

In standard serial I/O mode 1: TX

For software rewriting

Fast start: I2C communication

Normal operation: PWM control

In standard serial I/O mode 1: RX

For software rewriting

For software rewriting

107 pin, H output

M_TO_D_PDN

For software rewriting

DOP model only

For rewriting software

DAB model only

(No.MA656<Rev.001>)15/61

Page 16

Pin

No.

65 CAYMAN_MDATA

66 CAYMAN_SDATA

66 CAYMAN_SDATA

67 CAYMAN_MCLK

67 CAYMAN_MCLK

68 EVOL_MUTE_M O EVOL MUTE control L:ON, H:OFF

69 EVOL_MUTE_S O EVOL MUTE control L:ON, H:OFF

70 GPS_RESET O GPS reset H: reset

71 EVOL_MUTE2 O E-VOL SW mute L:ON, H:OFF

72 SW_REVERSE_NAVI O Reverse detection notice (MAIN to NAVI) H: Fast startup, L: Reverse Detected

73 TILT_SPEED O Power supply voltage switching of tilt mechanism control start after PON

74 TMOTOR_P O Tilt control of tilt mecha control start after PON

75 TMOTOR_M O Tilt control of tilt mecha control start after PON

76 MUTE_AMP O Power IC audio mute control H: OFF, L: ON

77 PS3_BATLOW

78 NAVI_NMIPDN O NAVI power down L: Power down

79 TUN_RST O RESET of HELIO L: RESET on, H: Reset clear

80 BUZ_SCL O CLK of beep IC I2C communication

81 BUZ_SDA O DATA of beep IC I2C communication

82 BUZ_BUSY I Beep IC communication BUSY input (0=audio

83 EVOL_MUTE1 O E-VOL rear mute L: ON, H: OFF

84 EVOL_MUTE0 O E-VOL front mute L: ON, H: OFF

85 VCC2 -

86 PRE_MUTE_FR O Pre-out mute (for the front rear) L: OFF, H: ON

87 VSS -

88 NC (VSP_DA) O L fixed

89 PS1_ACC I ACC detection H: ACC power reduction detected, L: normal

90 PS2_BAT (BU_DET_7) I Backup power supply detection H: Backup power reduction detected, L: nor-

91 PANEL_DET_A I PANEL detachable detection

92 SECURE_CTL (SI) O SI control

93 SW_PARKING I Parking detection H: Detection L: Running

94 SW_REVERSE I Reverse detection L: Detected, H: Normal

95 SW_ILLMI I Illumi detection L: ON (detected), H: OFF (not detected)

96 PRE_MUTE_SW O Pre-out mute (for the subwoofer) L: ON, H: OFF

97 SI_ADJ O SI Dimmer control

98 SW_A I Panel release key detection

Pin Name I/O Application Processing/Operation/Description

O MCDATA of between the SYS and CAYMAN HD model only

%HD_MC_DATA%

I SCDATA of between the SYS and DAB DAB model only

%DAB_SC_DATA%

I SCDATA of between the SYS and CAYMAN HD model only

%HD_SC_DATA%

O CLK of between the SYS and DAB DAB model only

%DAB_MCLK%

O CLK of between the SYS and CAYMAN HD model only

%HD_MCLK%

L fixed when become to be able to communicate with Telechips

I Backup power detection H: backup power reduction detected

(BU_DET_9)

output/disconnection detected)

L: normal

Setting data retransmission to EVOL with HI

to LO return, Detecting PRE_MUTE ON

H: not in operation, L: in audio output

mal

(No.MA656<Rev.001>)16/61

Page 17

Pin

No.

99 STEREMO_SW O Select of STEREMO pull-up resistor H: 460 ohm (Toyota, Daihatsu, Nissan, Maz-

100 CAMERA_TXD O CMOS camera communication (UART TX)

101 CAMERA_RXD O CMOS camera communication (UART RX)

102 EVOL_SCL I/O CLK of between the SYS and EVOL

103 EVOL_SDA O DATA of between the SYS and EVOL

104 PWIC_CDET I PWIC short detection H: Normal, L: Abnormal

105 TYPE2 I Destination setting2

106 LINE_MUTE I LINE-MUTE input detection 1.6V: Normal

107 UPDATE_DET I SoC forced update mode detection When L is detected for 1 second or longer,

108 AD_TILT_DET I Panel mecha tilt detection

109 MODEL_1 I Model setting1

110 MODEL_0 I Model setting0

111 AD_DCERR I DC offset detection of SP output L: Detected

112 DSP_PDN O DSP power down H: Power down

113 PCON/ANT1 O PCON/ANT_CON/X34 power control

114 PCON/ANT2 O PCON/ANT_CON/X34 power control

115 PCON/ANT3 O PCON/ANT_CON/X34 power control

116 DSP_CSN O DSP chip selector (MAIN to DSP) L: between the microcomputer communica-

117 PANEL_VCC_OFF O ON/OFF control of power supply to PANEL H: ON, L: OFF

118 NC O L fixed

119 ILLMI_CTRL

120 ASEL O Audio selector CH switching

121 NC (PGOOD) O L fixed

122 NC O L fixed

123 NC(TYPE_OEM) O L fixed (reserved for DOP)

124 STE1 I Steering remote control KEY1 input

125 STE2 I Steering remote control KEY2 input

126 TYPE_1 I Destination setting1

127 AVSS -

128 TYPE_0 I Destination setting0

Pin Name I/O Application Processing/Operation/Description

da, Honda, Subaru), L: 4.7k ohm (Mitsubishi)

1V or less: AUDIO MUTE, Transition to Call

interrupt screen

2.0V or more: AUDIO ATT

46 pin to H output

tion

O ON/OFF control of DISC LED H: ON, L: OFF

(SLOT_ILL)

(No.MA656<Rev.001>)17/61

Page 18

2.7.2 Panel microcomputer (VIDEO PWB : IC100)

Pin

No.

1NC -

2NC -

3NC -

4 LCD_18V O LCD power supply control 2 LCD_ENA_18V

5 LCD_-6V O LCD power supply control 1 LCD_ENA_-6V

6 /RESET I System reset input

7VOFF OVOFF

8 FLMD0_CTRL O FLMD0 terminal control For self-programming

9 FLMD0 I Pull-in flash programming clock mode

10 EX_X2 O For flash programmer

11 NC -

12 REGC - Regulator output stabilization capacitor connec-

13 VSS - Ground for ports other than P121-P124

14 EVSS - Ground for ports other than P20-P27, P121-P124

15 VDD - Positive power supply for ports other than P121-

16 EVDD - Positive power supply for ports other than P20-

17 VF_SW2 I BOOST SYNC frequency for switching For rear camera quick start-up

18 VF_SW I BOOST SYNC frequency for switching For rear camera quick start-up

19 /P_TO_N_REQ O Transmission request to NAVI of communication

20 /N_TO_P_REQ I Clock output request from NAVI of communica-

21 BL_PWM O PWM output for brightness change of the LCD

22 NC -

23 NC -

24 LCD_9.2V O LCD power supply control 3 LCD_ENA_9.2V

25 V-COM1 O V-COM voltage adjustment 1

26 V-COM2 O V-COM voltage adjustment 2

27 V-COM3 O V-COM voltage adjustment 3

28 V-COM4 O V-COM voltage adjustment 4

29 BOOST_H O LCD backlight MST_BOOST_ENA

30 NC -

31 NC -

32 NC -

33 NC -

34 R_VOL+ I Rotary VOL

35 R_VOL- I Rotary VOL

36 MENU I MENU key

37 KEY_ILL O EJECT for Illumination red dimming

38 /N_TO_P_RDY I State notification from NAVI of communication

39 KEY_PWM_R O Key llumination PWM RED

Pin Name I/O Application Processing/Operation/Description

tion for internal operation

P124

P27, P121-P124

between the microcomputer

tion between the microcomputer

BL_PWM

backlight

between the microcomputer

(No.MA656<Rev.001>)18/61

Page 19

Pin

No.

40 KEY_PWM_G O Key llumination PWM GREEN/White LED DIMMER

41 KEY_PWM_B O Key llumination PWM BLUE/White LED ON

42 RXD O For communication with the flash writer

43 TXD O For communication with the flash writer

44 P_TO_N_DAT O Data transmission to the NAVI of communication

45 N_TO_P_DAT I Data received from NAVI of communication be-

46 P_TO_N_CLK O Clock signal to the NAVI of communication be-

47 AVREF - Analog reference voltage input

48 AVSS - Analog GND

49 NC -

50 KEY2 I Tact switch voltage input 2

51 KEY1 I Tact switch voltage input 1 EJECT Key

52 KEY3 I Tact switch voltage input 3 For VW

53 XDATA_U I Touch panel X-axis voltage input VDD side

54 XDATA_D I Touch panel X-axis voltage input GND side

55 YDATA_U I Touch panel Y-axis voltage input VDD side

56 YDATA_D I Touch panel Y-axis voltage input GND side

57 X0 O Touch panel X-axis control

58 X1 O Touch panel X-axis control

59 Y0 O Touch panel Y-axis control

60 Y1 O Touch panel Y-axis control

61 BOOST_SYNC O BOOST_SYNC

62 TP_PRESS O Touch panel control

63 PULL_UP_ON O Touch panel control

64 NC -

Pin Name I/O Application Processing/Operation/Description

between the microcomputer

tween the microcomputer

tween the microcomputer

(No.MA656<Rev.001>)19/61

Page 20

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the VIDEO PWB (See Fig.1 to 2)

(1) Remove the 5 screws (a,b). (See Fig.1)

(2) Remove 3 hooks, and remove the FRONT PANEL ASS'Y.

(See Fig.1)

(3) Disconnect the FFC wire from the connector. (See Fig.1)

b

FRONT PANEL ASS'Y

b

a

CN1

a

: Hook position

Fig.1

(4) Disconnect the each wires from connectors. (See Fig.2)

(5) Remove the 4 screws (a), and remove the VIDEO PWB (1/2).

(See Fig.2)

(6) Remove the 1 screw (b), and remove the VIDEO PWB (2/2).

(See Fig.2)

a

b

a

3.1.2 Removing the DVD MECHA ASS'Y (See Fig.3)

(1) Remove the 6 screws (a), and remove the TOP PLATE.

(2) Remove the DVD MECHA ASS'Y, and disconnect the each

wires from connectors.

(3) Remove the 4 screws (b), and remove the BRACKET.

a

a

a

a

a

BRACKET

b

CN572

b

CN751

TOP PLATE

a

a

b

BRACKET

DVD MECHA ASS'Y

b

CN800

VIDEO PWB (2/2)

VIDEO PWB (1/2)

CN400

Fig.2

a

a

CN500

(No.MA656<Rev.001>)20/61

Fig.3

Page 21

3.1.3 Removing the DIGITAL IO PWB (See Fig.4)

(1) Disconnect the each wires from connectors.

(2) Remove the 4 screws, and remove the HEAT SINK.

(3) Remove the DIGITAL IO PWB.

3.1.5 Removing the MAIN PWB (See Fig.6 and 7)

(1) Disconnect the each wires from connectors. (See Fig.6)

(2) Remove the 6 screws, and remove the REAR PANEL.

(See Fig.6)

HEAT SINK

CN562

CN571

DIGITAL IO PWB

Fig.4

3.1.4 Removing the BLUETOOTH PWB (See Fig.5)

(1) Disconnect the FFC wire from connector.

(2) Remove the 2 screws, and remove the BLUETOOTH

PWB.

REAR PANEL

CN251

CN201

CN802

Fig.6

(3) Disconnect the each wires from connectors. (See Fig.7)

(4) Remove the 3 screws (a), and remove the BRACKET. (See

Fig.7)

(5) Remove the 4 screws (b), and remove the MAIN PWB.

(See Fig.7)

a

BRACKET

CN952

BLUETOOTH PWB

Fig.5

b

CN1

CN301

CN201

b

a

MAIN PWB

Fig.7

a

b

b

(No.MA656<Rev.001>)21/61

Page 22

3.1.6 Removing the AUDIO PWB (See Fig.8 to 10)

(6) Remove the 9 screws, and remove the SIDE PLATE. (See

Fig.8)

SIDE PLATE

(8) Remove the 4 screws, and remove the AUDIO PWB. (See

Fig.10)

SIDE PLATE

Fig.8

(7) Remove the 3 screws, and remove CHASSIS. (See Fig.9)

CHASSIS

Fig.9

AUDIO PWB

Fig.10

(No.MA656<Rev.001>)22/61

Page 23

3.2 DVD mechanism assembly

TOP CHASSIS ASS'Y

3.2.1 Removing the PHOTO PWB (See Fig.1 to 3)

(1) Remove the 4 screws, and remove the TOP CHASSIS

ASS’Y. (See Fig.1)

Fig.1

(2) Remove the solder, and remove the wires. (See Fig.2)

3.2.2 Removing the Roller arm assy (See Fig4)

(1) Remove the ROLLER SPRING in the direction of the arrow.

(2) Remove the 1 screw, and remove the ROLLER ARM

ASS’Y.

ROLLER SPRING

ROLLER ARM ASS'Y

Fig.4

3.2.3 Removing the Clamp arm assy (See Fig.5)

(1) Remove the Clamp spring in the direction of the arrow.

(2) Remove the Clamp arm assy.

CLAMP ARM ASSY

BLACK WIRE

YELLOW WIRE

ORANGE WIRE

Fig.2

(3) Remove the 1 screw, and remove the PHOTO PWB.

(See Fig.3)

Note: When removing the PHOTO PWB,

be careful not to touch the photo sensor.

PHOTO PWB

CLAMP SPRING

Fig.5

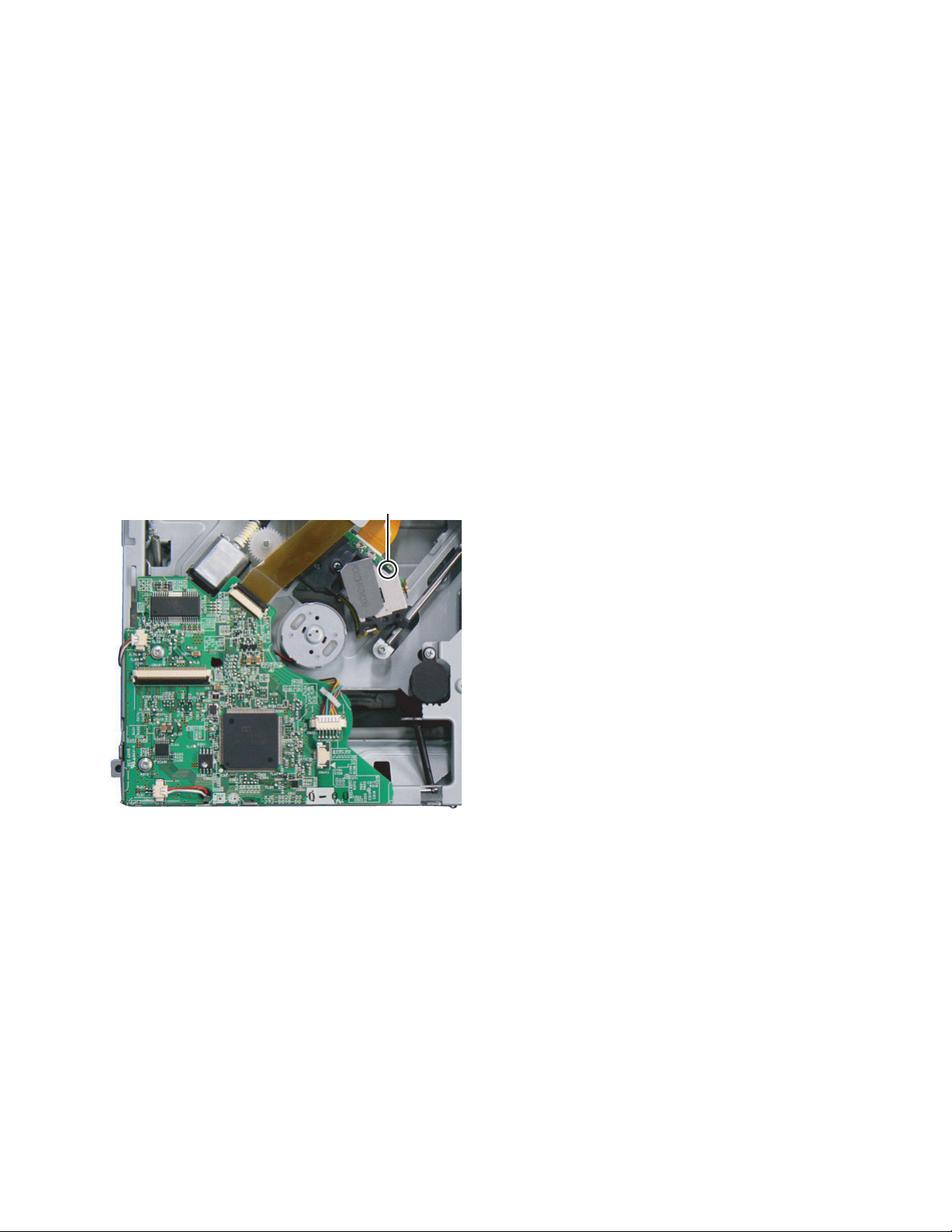

3.2.4 Removing the TM ASSY and DVD MECHA PWB

(See Fig.6,7)

(1) Remove the solder, and remove the wires. (See Fig.6)

(2) Remove the 4 screws, and remove TM ASS’Y. (See Fig.6)

(3) Remove the 2 screws, and remove the DVD MECHA PWB.

(See Fig.6)

TM ASS'Y

Fig.3

BLACK WIRE

RED WIRE

(No.MA656<Rev.001>)23/61

DVD MECHA PWB

Fig.6

Page 24

(4) Solder the short land on the FPC wire. (See Fig.7)

TM ASS'Y

SHORT LAND

DVD MECHA PWB

LOADING MOTOR BRACKET ASS'Y

(5) Disconnect the FPC wires form the connectors. (See Fig.7)

Fig.7

3.2.5 Removing the Loading motor (See Fig.8 to 11)

(1) Remove the 2 screws, and remove the LOADING MOTOR

BRACKET ASS’Y. (See Fig.8)

(4) Remove the 2 screws, and remove the GEARBOX ASS’Y.

(See Fig.10)

Fig.10

(5) Remove the 2 screws, and remove the LOADING MOTOR.

(See Fig.11)

LOADING MOTOR

Fig.8

(2) Remove the SLIDER SPRING in the direction of the arrow.

(See Fig.9)

(3) Remove the the SLIDER. (See Fig.9)

SLIDER SPRING

SLIDER

Fig.9

Fig.11

(No.MA656<Rev.001>)24/61

Page 25

SECTION 4

ADJUSTMENT

4.1 Special Mode and Specoal operation List

Mode Name Description Prerequisite Operation

Force EJECT Forced EJECT mode for when DISC

cannot be taken out.

TUNER span

switching

Opening screen /

wallpaper / initial

settings / steering

remote control set

rewrite mode

(Customize Menu)

Production Menu Special function menu for the

Service Menu Special function menu used by

Initialize Factory

Default

Forced Security

Release

For switching the frequency step /

span of TUNER

For rewriting the configurations of

the Opening screen / Wallpaper /

Parameter / Learning Remote via

USB.

production line.

(The production mode is turned on

when the menu is displayed.)

servicing personnel.

For initializing the setting values /

data to factory default.

For releasing the security forcibly

when the security code is not known.

While in the power

on.

While displaying the

STANBY(AV OFF)

screen.

While displaying the

STANBY(AV OFF)

screen.

While displaying the

SETUP top screen.

While displaying the

SETUP top screen.

While displaying the

Security Code input

screen.

Press OPEN key (or EJECT key) 2 seconds.

Touch the screen within 2 seconds in the following

order.

Upper left corner (1) Upper left corner (1)

Upper left corner (1) Lower left corner (2)

Lower left corner (2) Lower left corner (2)

Touch the screen within 2 seconds in the following

order.

Upper left corner (1) Upper left corner (1)

Lower left corner (2) Lower left corner (2)

Upper left corner (1) Lower left corner (2)

Touch the screen within 2 seconds in the following

order.

Upper left corner (1) Lower right corner (4)

Lower right corner (4) Lower right corner (4)

Upper left corner (1) Upper left corner (1)

Touch the screen within 2 seconds in the following

order.

Upper left corner (1) Upper left corner (1)

Lower right corner (4) Lower right corner (4)

Lower right corner (4) Upper left corner (1)

Operation in the Production Menu/Service Menu/

Developer Menu

Touch the screen within 2 seconds in the following

order.

Upper right corner (3) Upper left corner (1)

Upper left corner (1) Upper right corner (3)

Upper right corner (3) Upper left corner (1)

(1) (3)

(2) (4)

(No.MA656<Rev.001>)25/61

Page 26

4.2 Force EJECT

Forced EJECT mode for when DISC cannot be taken out.

(1) Press and hold the OPEN key (Fixed panel model EJECT

key) for 2 seconds.

(2) When the dialog is displayed, press the button according to

the purpose.

[Electric panel model]

Please press the DISC EJECT or OPEN.

The disc will be ejected forcefully or the panel

will be opened.

4.3 TUNER span switching

Switching frequency initial value of the Tuner, band and frequency range, frequency step, preset frequency initial value and the

seek threshold.

(1) Touch the screen within 2 seconds in the following order.

Upper left corner (1) Upper left corner (1) Upper left

corner (1) Lower left corner (2) Lower left corner (2)

Lower left corner (2)

(1)

DISC EJECT OPEN Cancel

Key Operation

DISC EJECT Opens the panel, starts forced ejection and clos-

es this dialog box.

If the panel is already opened, forced ejection

starts and this dialog box closes.

OPEN Full open the panel and closes this dialog box.

If the panel is already full open, this dialog box

closes.

Cancel Closes this dialog box.

[Fixed panel Model]

The disc will be ejected forcefully.

Is it OK?

Yes

No

Key Operation

Yes Starts forced ejection and closes this dialog box.

No Closes this dialog box.

(2)

(2) When the dialog is displayed, press the button according to

the purpose.

Flick up and down to scroll the screen.

Tuner Span Setup

NA

SA

EU

Close

Key Operation

NA Set to the North America (US).

SA Set to the South America (SA).

EU Set to the Europe (EU).

OTHERS Set to the Othets.

TUNISIA Set to the Tunisia.

AUS Set to the Australia.

Close Closes this dialog box.

(No.MA656<Rev.001>)26/61

Page 27

4.4 Customize Menu Specification

Customize Menu

Wallpaper Customize

Parameter Customize

Learning Remote Customize

Delete Base Map

Restore Base Map

Opening Customize

Back

4.5 Production Menu Specification

[Page 1/3]

Key Operation

Opening

Customizes the Opening Screen.

Customize

Wallpaper

Customizes the wallpaper.

Customize

Parameter

Customizes the parameter.

Customize

Learning

Remote

Customizes the key assignment of learning remote control.

Customize

Delete Base

Map

Restore Base

Map

Deletes the Base Map in the map database of

the system.

Restores the Base Map in the map database of

the system.

Back Exit the customize menu, return to the normal

screen.

4.4.1 Base Map delete (except DDX and KW models)

(1) Select the "Delete Base Map" in the Customize Menu.

(2) A confirmation dialog box appears, select "Yes" to delete

the base map.

Note: Do not press any hard keys on the unit while the process is ongoing.

4.4.2 Base Map restore (except DDX and KW models)

(1) Download the gmapbmap.zip file from CUSiS.

(2) Unzip the file and copy the gmapbmap.img file to the USB

root directory.

(3) Insert the USB memory.

(4) Select the "Restore Base Map" in the Customize Menu.

(5) A confirmation dialog box appears, select "Yes" to restores

the base map.

Note: Do not press any hard keys on the unit while the pro-

cess is ongoing.

Production Menu Syscom-Panel : OK(1/3)

System Info

Smeter & RDS Test

DAB Test

SXM Test

iDataLink Test

Illumi Adjust

Sensor Status

UnitID API Check

BT Device Search

BT Microphone

LCD Adjust

Serial ID Writing Mode

PREV NEXT

Back

Item Description

Syscom-Panel Displays the result (OK or NG) of the check on

the communication between Syscom and the

Panel CPU.

Key Operation

System Info Transition to the System Info screen.

Sensor Status Transition to the Sensor Status screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Smeter & RDS

This mode is not used for service.

Test

DAB Test This mode is not used for service.

SXM Test This mode is not used for service.

iDataLink Test This mode is not used for service.

Illumi Adjust Transition to the Illumi Adjust screen.

*Displayed only for supporting models Illumi adjustment .

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

UnitID API

This mode is not used for service.

Check

BT Device

Search (*1

Transition to the BT Device Search screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

BT

This mode is not used for service.

Microphone

LCD Adjust Transition to the LCD Adjust screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Serial ID

This mode is not used for service.

Writing Mode

NEXT Switch the page from 1/3 to 2/3.

PREV Switch the page from 1/3 to 3/3.

Back Exit Production menu, and return to the normal

screen

*1: Test is performed automatically when the production menu

started.

(No.MA656<Rev.001>)27/61

Page 28

[Page 2/3]

Production Menu Syscom-Panel : OK(1/3)

System Info

Smeter & RDS Test

DAB Test

SXM Test

iDataLink Test

Illumi Adjust

Sensor Status

UnitID API Check

BT Device Search

BT Microphone

LCD Adjust

Serial ID Writing Mode

PREV NEXT

Back

Item Description

Syscom-Panel Displays the result (OK or NG) of the check on

the communication between Syscom and the

Panel CPU.

Key Operation

Region Code Transition to the Region Code screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Gesture Test Transition to the Gesture Test screen.

*Displayed only for supporting models Gesture

sensor.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Touch Panel

Test (*1

Transition to the Touch Panel Test screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Navigation

This mode is not used for service.

Test

Ext NaviBox

This mode is not used for service.

Test

Panel Mecha

Adjust Mode

Transition to the Panel Mecha Adjust Mode

screen.

*Displayed only for supporting models DDX Tilt

Mecha.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

iPod Test (*1 Transition to the iPod Test screen.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

Learning

Remote Test

(*1

Transition to the Learning Remote Test screen.

*Displayed only for models supporting Learning

Remote controller.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

SD Read/

Write Test

Transition to the SD Read/Write Test screen.

*Displayed only for models supporting SD card

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

HDMI / CEC

Test (*1

Transition to the HDMI / CEC Test screen.

*Displayed only for supporting models HDMI.

Button color is changed by the results.

(Not performed: Black/OK: Blue/NG: Red)

MHL Test This mode is not used for service.

NEXT Switch the page from 2/3 to 3/3.

PREV Switch the page from 2/3 to 1/3.

Key Operation

Back Exit Production menu, and return to the normal

screen

*1: Test is performed automatically when the production menu

started.

[Page 3/3]

Production Menu Syscom-Panel : OK(3/3)

2Zone Test

Siri Mic Test

Screen Check

Wi-Fi Device Search

Opening Customize

Wallpaper Customize

Parameter Customize

Learning Remote Customize

Initialize Factory Default

PREV NEXT

Back

Item Description

Syscom-Panel Displays the result (OK or NG) of the check on

the communication between Syscom and the

Panel CPU.

Key Operation

2Zone Test Switch the 2Zone of on/off.

On: button color is orange, Off: button color is

gray.

Front: "Tuner" and Rear: "USB" on when the

2Zone is "ON". *2Zone is "OFF" on when the

Production Mode is started.

Siri Mic Test This mode is not used for service.

Screen Check Transition to the Screen Check screen.

Wi-Fi Device

Transition to the Wi-Fi Device Search.

Search

Opening

Transition to the Opening Customize screen.

Customize

Wallpaper

Transition to the Wallpaper Customize screen.

Customize

Parameter

Transition to the Parameter Customize screen.

Customize

Learning

Remote

Transition to the Learning Remote Customize

screen.

Customize

Initialize

Factory

Transition to the Initialize Factory Default

screen.

Default

(No.MA656<Rev.001>)28/61

Page 29

System Info

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

*****

:0. 0. 0000. 0000

Back

4.5.1 SystemInfo

Mode for displaying the various versions of the system.

Flick up and down to scroll the screen.

Item Description

Model Name Model name

Destination "-" Fixed

Serial ID Serial number

Written condition: ********** (Alphanumeric)

Not Written: -

Y No Model number

Type Type information

K: North America

R: Latin America

E: Europe

Q: Russia

M: Asia (KWD: including A9/N)

M2: Middle East (JVC: including N)

X: Australia

???: Unknown

Span Tuner type information

Displaying Tuner span type (Tuner area)

NA: North America

EU: Europe

SA: Latin America

JP: Japan

ASIA: Others

BR: Brazil

TN: Tunisia

AUS: Australia

???: Unknown

SoC Image SoC firmware version

LKBOOT SoC LKBOOT version

FBIOS SoC FBIOS version

SBIOS SoC SBIOS version

Recovery

SoC recovery image version

Image

Syscom Syscom firmware version

Syscom Boot Syscom boot version

Panel CPU Panel CPU firmware version

Touch Cnt Touch Controller(ATMEL) version

FBIF FBIF version

Helio Helio version

eMMC eMMC firmware version

Cayman Cayman version

DAB DAB module version

(No.MA656<Rev.001>)29/61

Item Description

Disc Unit

Disc mecha module name

Name

Disc Version Disc mecha module firmware version

Disc Region DVD Region code

Disc CPRM Disc mecha CPRM check sum

Disc Serial No Disc mecha module serial no

Macrovision

Macrovision version(System)

(Sys)

Macrovision

Macrovision version(Disc mecha module)

(Disc)

Navigation software Version

Navigation

S/W

*DDX/KW models does not display

Base Map Navigation database version (Base Map)

*DDX/KW models does not display

Detail Map Navigation database version (Detail Map)

*DDX/KW models does not display

Junction View Navigation database version(Junction View)

*DDX/KW models does not display

DATA1 Opening data version

DATA2 Wallpaper version

DATA3 Steering Remote threshold version

Navi App Navigation application version

Version Check Perform the version check

After the version check is executed, items that are inconsistent

with the version check are displayed in red.

Key Operation

Back Return to the Production menu.

4.5.2 Version Check

Mode for checking the version of each software/data.

(1) Insert the USB memory that contains the version check da-

ta.

(2) Select the "System Info" in the Production Menu, and dis-

playing the System Info screen.

(3) Press "Version Check" to start the version check and dis-

play the result.

Checking...

System Version Check

Checking...

Back

Page 30

Result OK

System Version Check

OK

Back

Result NG

System Version Check

NG

Navi CPU/Main CPU/Panel CPU

Back

This is displayed when the version information within the system

is inconsistent with the version information of the version check

data in the USB memory.

An item that is inconsistent is displayed below "NG" and the version value of the corresponding item in the System Info screen is

displayed in red.

Result NG (no version check data)

System Version Check

No file.

Back

This is displayed when there is no version check data in the USB

memory.

Key Operation

Back Return to the Production menu.

4.5.2.1 For version check data

Store the following data in the root folder of the USB memory.

• File name:/VCheck_model_system.txt

• File format:

Version Check

[(item name 1)](version name 1)

[(item name 2)](version name 2)

:

[(item name n)](version name n)

~EN

item name list

Item Description

Model Name Model name

Serial ID Serial number

Type Type information

Span Tuner type information

SoC Image SoC firmware version

LKBOOT SoC LKBOOT version

FBIOS SoC FBIOS version

SBIOS SoC SBIOS version

Recovery Image SoC recovery image version

Syscom Syscom firmware version

Syscom Boot Syscom boot version

Panel CPU Panel CPU firmware version

Touch Cnt Touch Controller (ATMEL) version

eMMC FBIF version

FBIF Helio version

Helio eMMC firmware version

Cayman Cayman version

DAB DAB module version

Disc Unit Name Disc mecha module name

Disc Version Disc mecha module firmware version

Disc Region DVD Region code

Navigation S/W Navigation software version

Navigation S/W Dscrpt Navigation software description

HDCP Key HDCP Key Condition (-/OK)

Base Map Navigation database version

(Base Map)

Base Map Dscrpt Navigation database description

(Base Map)

Detail Map Navigation database version

(Detail Map)

Detail Map Dscrpt Navigation database description

(Detail Map)

Junction View Navigation database version

(Junction View)

Junction View Dscrpt Navigation database description

(Junction View)

DATA1 Opening data version

DATA2 Wallpaper version

DATA3 Steering Remote threshold version

(No.MA656<Rev.001>)30/61

Page 31

• Checks on items not included in the version check data are

Back

Sensor Status

Reverse Signal : Off

: Off

: OK.

Illumination

Camera

Parking Brake : On

: OK.

Dash-Cam

GPS Test

skipped.

• If the version name is "-", the absence of the corresponding

data is checked.

• If the version name is "!-", the presence of the corresponding

data is checked.

4.5.2.2 Adjustment / test flag check

The following items are checked (OK/NG) during the version

check. Items that are not applicable are not checked.

• LCD Adjust

• Panel Mecha Adjust

• GPS Test

• Serial ID

• key illumi adjustment

• Region Code writing

• Touch panel adjustment

• HD-Radio Test

• SXM Test

•DAB Test

• iDataLink Test

• Tuner Smeter Test

• BT Device Search

• Gesture Test

• Touch Panel Test

• iPod Test

• Learning Remote Test

• SD Card R/W Test @ SRS-92-3126

• HDMI/CEC Test @SRS-92-3141

• Unit ID API Check @SRS-92-3216

• TMC Tuner @SRS-92-3214

• Ext NaviBox Test @SRS-92-3143

4.5.3 Sensor Status

Mode for displaying the sensor information entered into the system.

The camera displays the result of checking with the CMOS-3xx

real machine connected.

Dash-Cam (drive recorder) displays the check result (OK / NG)

in the state where the loop back jig is connected.

4.5.3.1 GPS Test

Mode for testing the Smeter.

Mode for the Bluetooth module to check whether the electrically

normal operation.

(1) Turn on the power of the GPS SG, turn on the power of the

set after connecting it to the set.

(2) Select "Sensor Status" in the Production Menu

(3) When "GPS Test" is selected in the Sensor Status, the

GPS check starts and the result is displayed.

Checking...

GPS Test

C/NO

PGA

Doppler

RTC

POST

chnPLock

Processing...

Back

Check OK (When the result is "OK", the P.CONT output is "L".)

When exit the GPS Test screen by pressing [Back], P. CONT

output is "H".

GPS Test

C/NO

PGA

Doppler

RTC

POST

chnPLock

OK.

OK.

OK.

OK.

OK.

OK.

TEST OK

C/NO Max = 99.99

C/NO Min = 0.00

PGA = 9

Doppler Max = 9

Doppler Min = 0

Carr PhDev = 9.00000000

RTC Freq -= 99999

POST = 0X00000000

chnPLock = 99

Back

Check NG

GPS Test

C/NO

PGA

Doppler

RTC

POST

chnPLock

OK.

OK.

OK.

NG.

OK.

OK.

TEST NG

C/NO Max = 99.99

C/NO Min = 0.00

PGA = 9

Doppler Max = 9

Doppler Min = 0

Carr PhDev = 9.00000000

RTC Freq -= 99999

POST = 0X00000000

chnPLock = 99

Back

Item Description

Reverse

Displays the state of the reverse input (on/off)

Signal

Illumination Displays the state of Illumination Input (on/off)

Parking Brake Displays the state of Parking input (on/off)

Camera Display the communication check result (OK or

NG) of the camera (CMOS-3xx)

Dash-Cam Display the communication check result (OK or

NG) of Dash-Cam (drive recorder)

Key Operation

GPS Test Transition to the GPS Test screen.

Back Return to the Production menu.

(No.MA656<Rev.001>)31/61

Key Operation

Back Return to the Production menu.

The font color of the "Sensor Status" button on the first page of

the Production Menu changes depending on the result.

• Not performed: Black

•OK: Blue

• NG: Red

Page 32

4.5.4 Illumi Adjust

Mode for adjusting the white of Key iIllumi.

This function is used only DNX/DDX normal panel & 7inch model

(except VW). (200mm model, 6.2inch LCD model, VW model

does not correspond)

(1) Select the "Illumi Adjust" in the Production Menu.

(2) Make sure that as much as more "White color" key illumi-

nation condition by 10 kinds of option.

(3) Press the "OK" to save the value.

Illumination Adjust

pw05, pw09

pw12

pw11

pw17

pw04, pw20

pw10

pw01

pw08

pw02, pw06, pw07

pw03, pw18, pw19

OK

Back

Save OK

The font color of the "Illumi Adjust" button on the first page of the

Production Menu changes depending on the result.

• Not performed: Black

• OK: Blue

• NG: Red

4.5.5 BT Device Search

Mode for the Bluetooth module to check whether the electrically

normal operation.

(1) When "BT Device Search" is selected in the Production

Menu, the Blutooth device search starts and the result is

displayed.

Checking...

BT Device Search

Processing...

Illumination Adjust

pw05, pw09

pw12

pw11

pw17

pw04, pw20

- SAVE Success -

pw10

pw01

pw08

pw02, pw06, pw07

pw03, pw18, pw19

OK

Back

Save NG

Illumination Adjust

pw05, pw09

pw12

pw11

pw17

pw04, pw20

- SAVE Error -

pw10

pw01

pw08

pw02, pw06, pw07

pw03, pw18, pw19

OK

Back

Key Operation

(pw05,pw09) Switch the LED duty (R=71, G=50, B=30)

(pw10) Switch the LED duty (R=81, G=66, B=58)

(pw12) Return to the Production menu.

(pw01) Switch the LED duty (R=51, G=55, B=61)

(pw11) Switch the LED duty (R=71, G=71, B=68)

(pw08) Switch the LED duty (R=52, G=71, B=59)

(pw17) Switch the LED duty (R=71, G=69, B=25)

(pw02, pw06,

Switch the LED duty (R=71, G=71, B=48)

pw07)

(pw04, pw20) Switch the LED duty (R=42, G=71, B=49)

(pw03, pw18,

Switch the LED duty (R=52, G=71, B=39)

pw19)

Back Return to the Production menu.

Check OK (When the result is "OK", the P.CONT output is "L".)

BT Device Search

OK.

Back

Check NG

BT Device Search

NG.

Back

Key Operation

Back Return to the Production menu.

The font color of the "BT Device Search" button on the second

page of the Production Menu changes depending on the result.

• Not performed: Black

• OK: Blue

• NG: Red

(No.MA656<Rev.001>)32/61

Page 33

4.5.6 LCD Adjust

LCD VCOM Adjust

Back

Vcom 1 Vcom 2 Vcom 3 Vcom 4 Vcom 5 Vcom 6 Vcom 7 Vcom 8

OK

Mode for adjustting the image quality in the production line.

4.5.6.1 Flicker adjustment

(1) When "LCD Adjust" is selected in the Production Menu,

transition to the flicker adjustment screen.

(2) Select the key from "Vcom 1" to "Vcom 8" (8 options) to

seek out the Flicker amplitude level is minimum condition.

(Select best screen condition)

(3) Press "OK" to memory this condition and then move to

"LCD White Balance Adjust" mode, automatically.

Key Operation

Vcom1 Set Vcom1

Vcom2 Set Vcom2

Vcom3 Set Vcom3

Vcom4 Set Vcom4

Vcom5 Set Vcom5

Vcom6 Set Vcom6

Vcom7 Set Vcom7

Vcom8 Set Vcom8

Up Switch Vcom1 Vcom2 ---

Down Switch Vcom8 Vcom7 ---

OK Store

Back Return to to Production Menu

4.5.6.2 White balance adjustment

(1) After finished Flicker adjustment, automatically hange to

this mode.

(2) Change the adjustment values so that the screen is most

white.

(3) Press "OK" to memory the adjusted value.

XXX

XXX

Back

+1

+10

+1

+10

+1

+10

OK

LCD White Balance Adjust

-1BXXX

-10

R

-1

-10

-1

G

-10

After saving the data by pressing the OK button, transition to the

Production Menu screen.

Key Operation

Key Operation

B +1 Offset Gain B Gain Up

B -1 Offset Gain B Gain Down

B +10 Offset Gain B Gain Up +10

B -10 Offset Gain B Gain Down -10

R +1 Offset Gain R Gain Up

R -1 Offset Gain R Gain Down

R +10 Offset Gain R Gain Up +10

R -10 Offset Gain R Gain Down -10

G +1 Offset Gain G Gain Up

G -1 Offset Gain G Gain Down