Page 1

MA209200510

SERVICE MANUAL

IN-DASH 7-INCH WIDESCREEN MONITOR

KV-M705,KV-M706

KV-M705

Area suffix

E ------------- Southern Europe

UT ------------------------- Taiwan

UN --------------------- Indonesia

HUN ------------------ Indonesia

U -------------------- Other Areas

KV-M706

Area suffix

J ------------- Northern America

E ------------- Southern Europe

UT ------------------------- Taiwan

UN --------------------- Indonesia

U -------------------- Other Areas

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA209

2005/10

Page 2

SPECIFICATION

Screen 7 inch liquid crystal panel

Number of pixel 336 960 pixels (480 vertical × 234 horizontal × 3)

Drive method TFT (Thin Film Transistor) active matrix format

Color system NTSC/PAL

Input Video RCA pin × 2 circuits 1 V(p-p), 75 Ω

Audio RCA pin × 2 circuits 1.5 V(rms)

Output Video RCA pin × 1 circuit 1 V(p-p), 75 Ω

Audio RCA pin × 1 circuit 1.5 V(rms)

Other terminal AV bus (AV BUS)

Power requirement Operating voltage DC 14.4 V (11 V to 16 V allowance)

Grounding system Negative ground

Allowable operating temperature 0°C to +40°C (32°F to 104°F)

Allowable storage temperature -10°C to +60°C (14°F to 140°F)

Dimensions (W × H × D) Installation size (approx.) With sleeve-mounting plate Type B (standard)

: 182 mm × 52 mm × 165 mm (7-3/16 in. × 2-1/16 in. × 6-1/2 in.)

With sleeve-mounting plate Type A

: 182 mm × 52 mm × 160 mm (7-3/16 in. × 2-1/16 in. × 6-5/16 in.)

Panel size (approx.) 188 mm × 58 mm × 14 mm (7-7/16 in. × 2-5/16 in. × 5/8 in.)

Mass (approx.) 1.6 kg (3.6 lbs)

Design and specifications are subject to change without notice.

1-2 (No.MA209)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MA209)1-3

Page 4

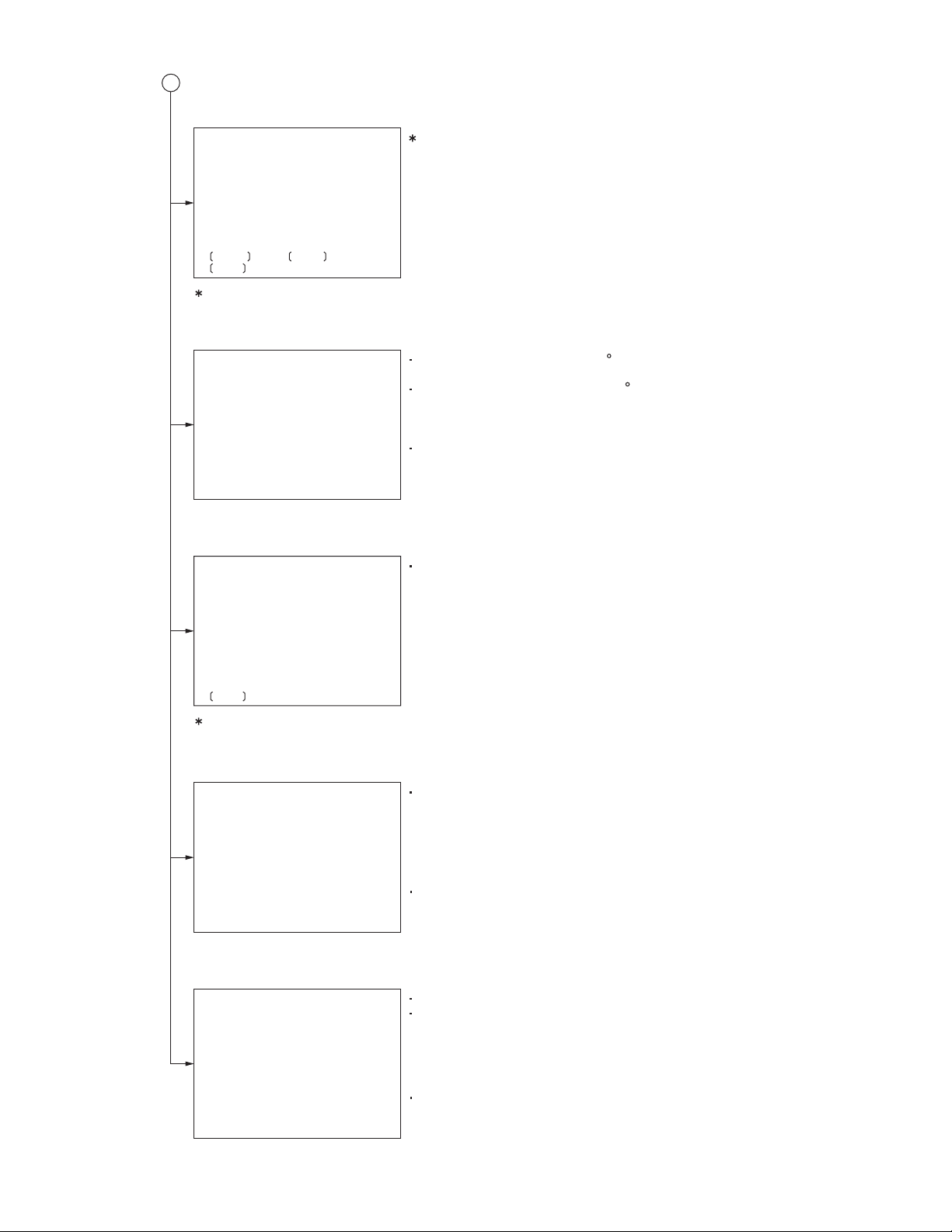

SECTION 3

DISASSEMBLY

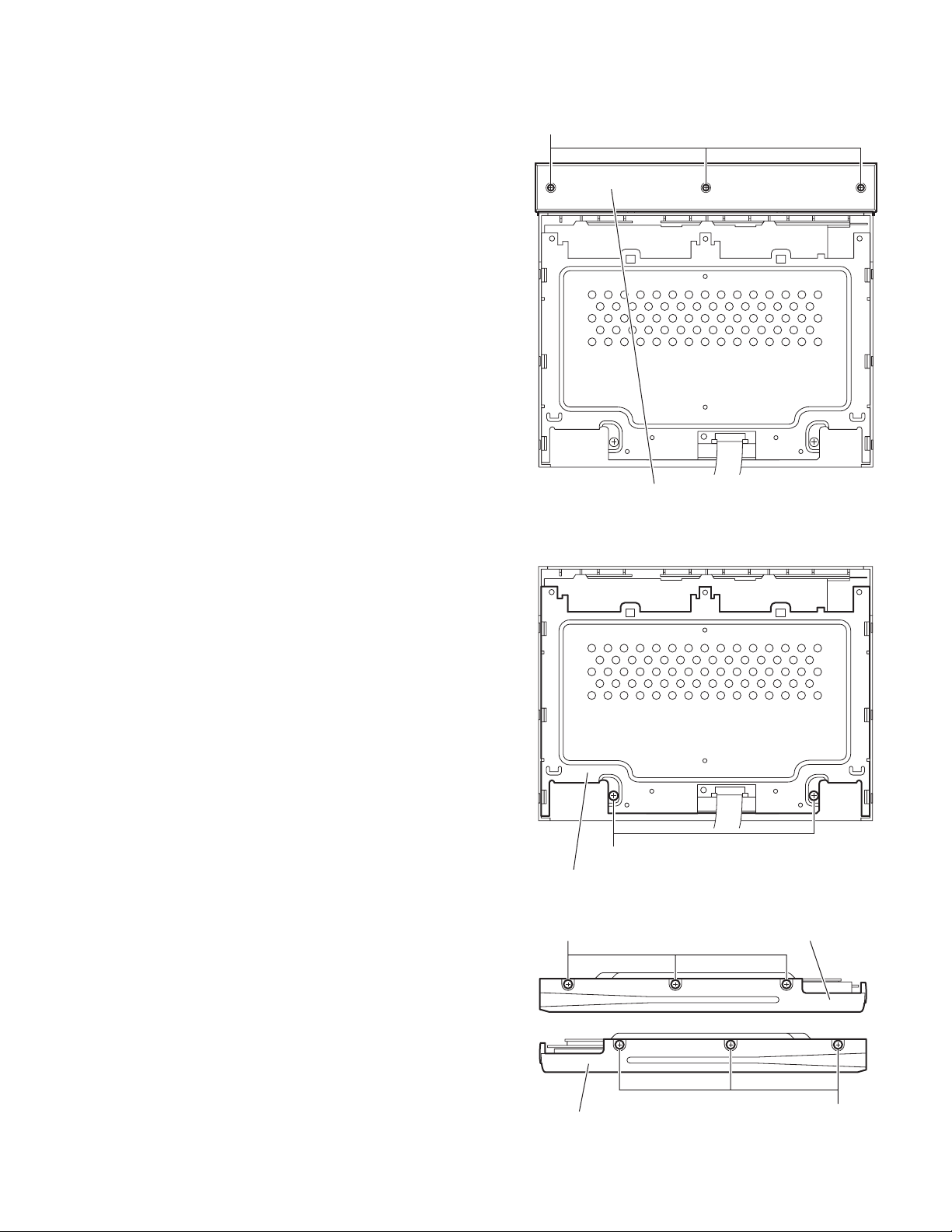

3.1 Main body section

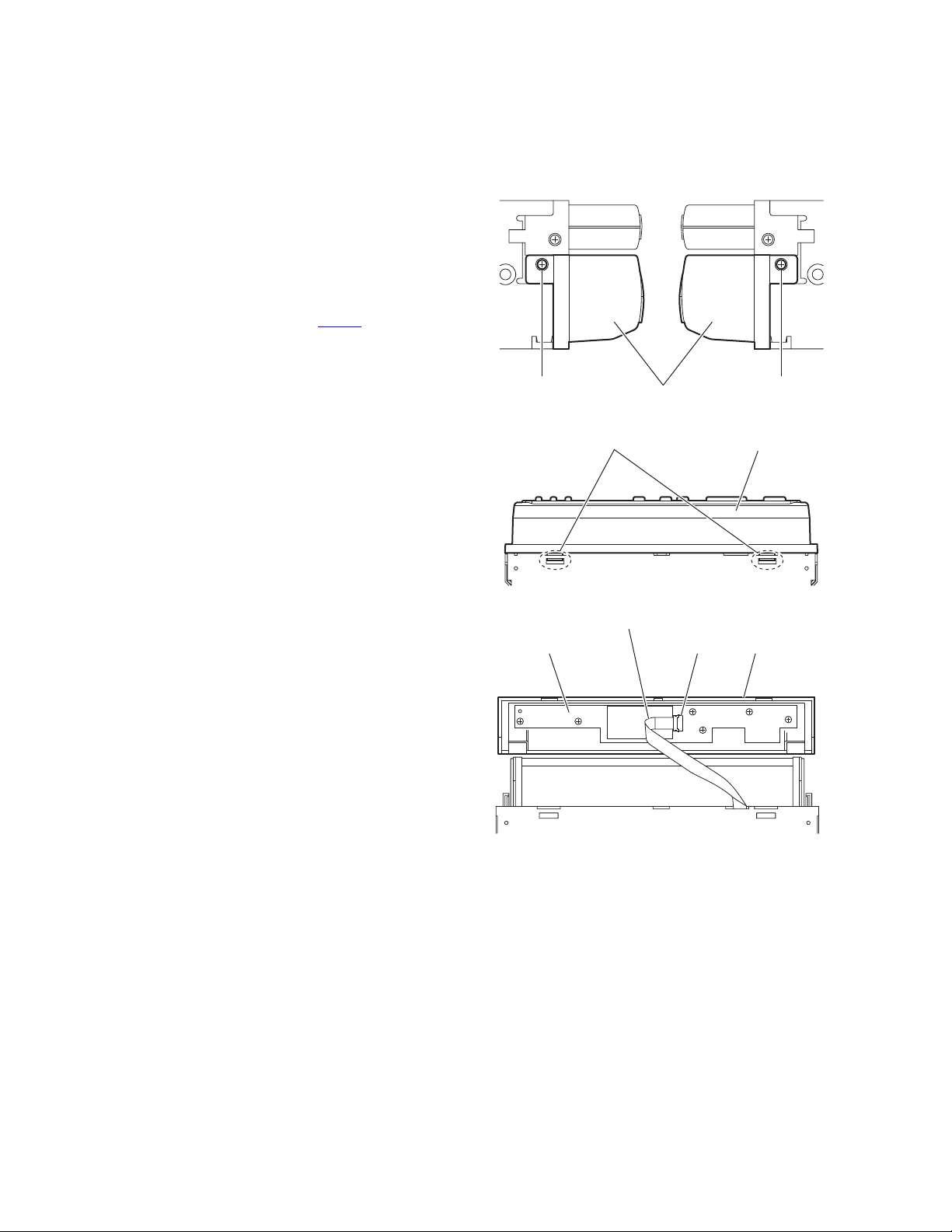

3.1.1 Removing the front assembly

(See Figs.1 to 3)

(1) From the both sides of the main body, remove the two

screws A attaching the front assembly to the main body.

(See Fig.1.)

(2) From the bottom side of the main body, release the two

claws a attaching the front assembly to the main body.

(See Fig.2.)

(3) Take out the front assembly forward from the main body.

(4) Lift up the lock lever of the connector CN471

key board and disconnect the card wire from it. (See Fig.3.)

on the front

A A

Front assembly

Fig.1

Fig.2

Card wire

Fig.3

CN471

Front assemblyClaws a

Front assemblyFront key board

1-4 (No.MA209)

Page 5

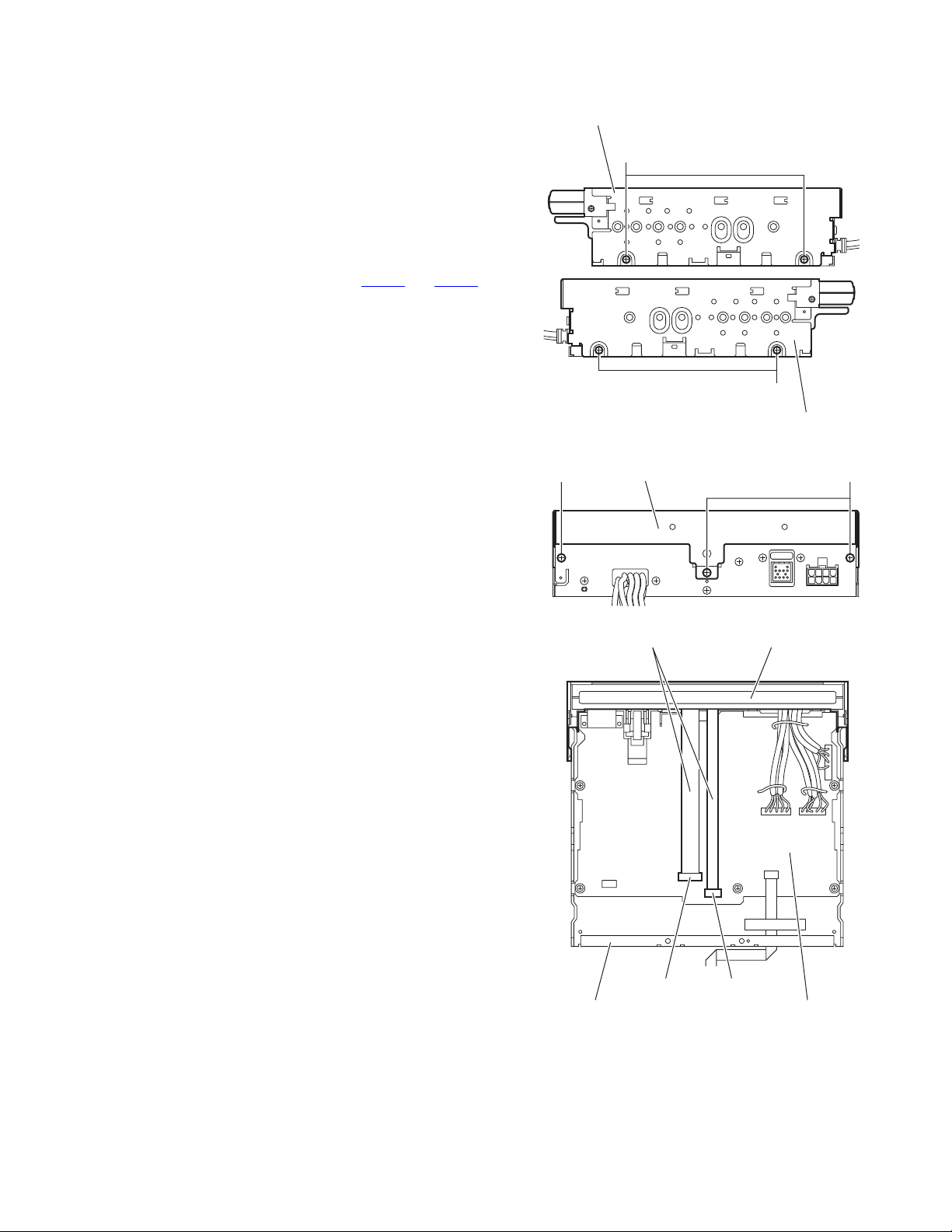

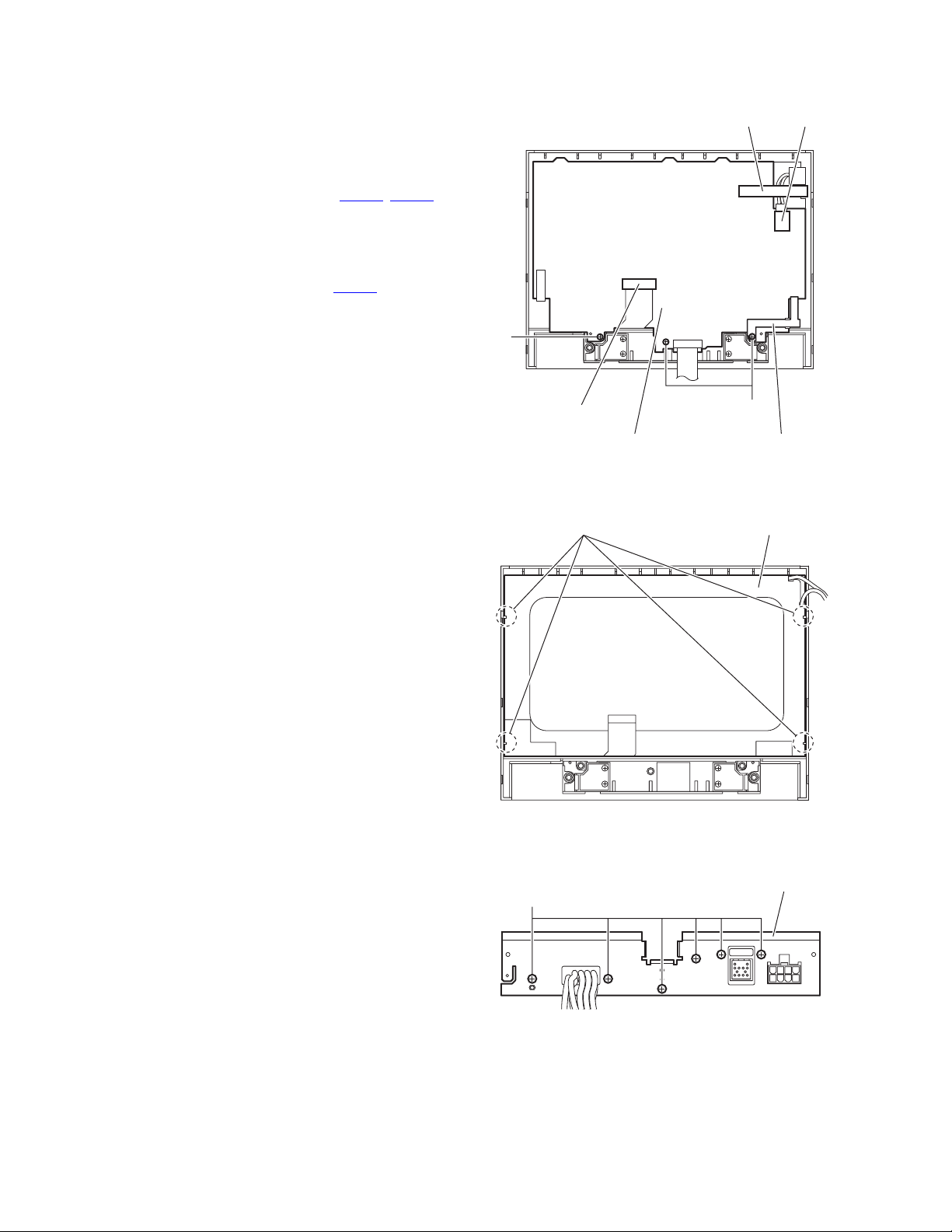

3.1.2 Removing the top drive unit

(See Figs.4 to 6)

• Prior to performing the following procedure, remove the front

assembly.

(1) From the both sides of the main body, remove the four

screws B attaching the top drive unit to the main body. (See

Fig.4.)

(2) From the back side of the main body, remove the three

screws C attaching the top drive unit to the main body. (See

Fig.5.)

(3) From the top side of the main body, lift the top drive unit

from the bottom case assembly.

(4) Lift up the lock lever of the connectors (CN391

on the system control board and disconnect the flexible

wires from it. (See Fig.6.)

(5) Take out the top drive unit from the bottom case assembly.

and CN392)

Top drive unit

B

B

Top case assembly

Fig.4

Top drive unit

Flexible wires

CC

Fig.5

Top drive unit

Fig.6

CN391CN392

System control boardBottom case assembly

(No.MA209)1-5

Page 6

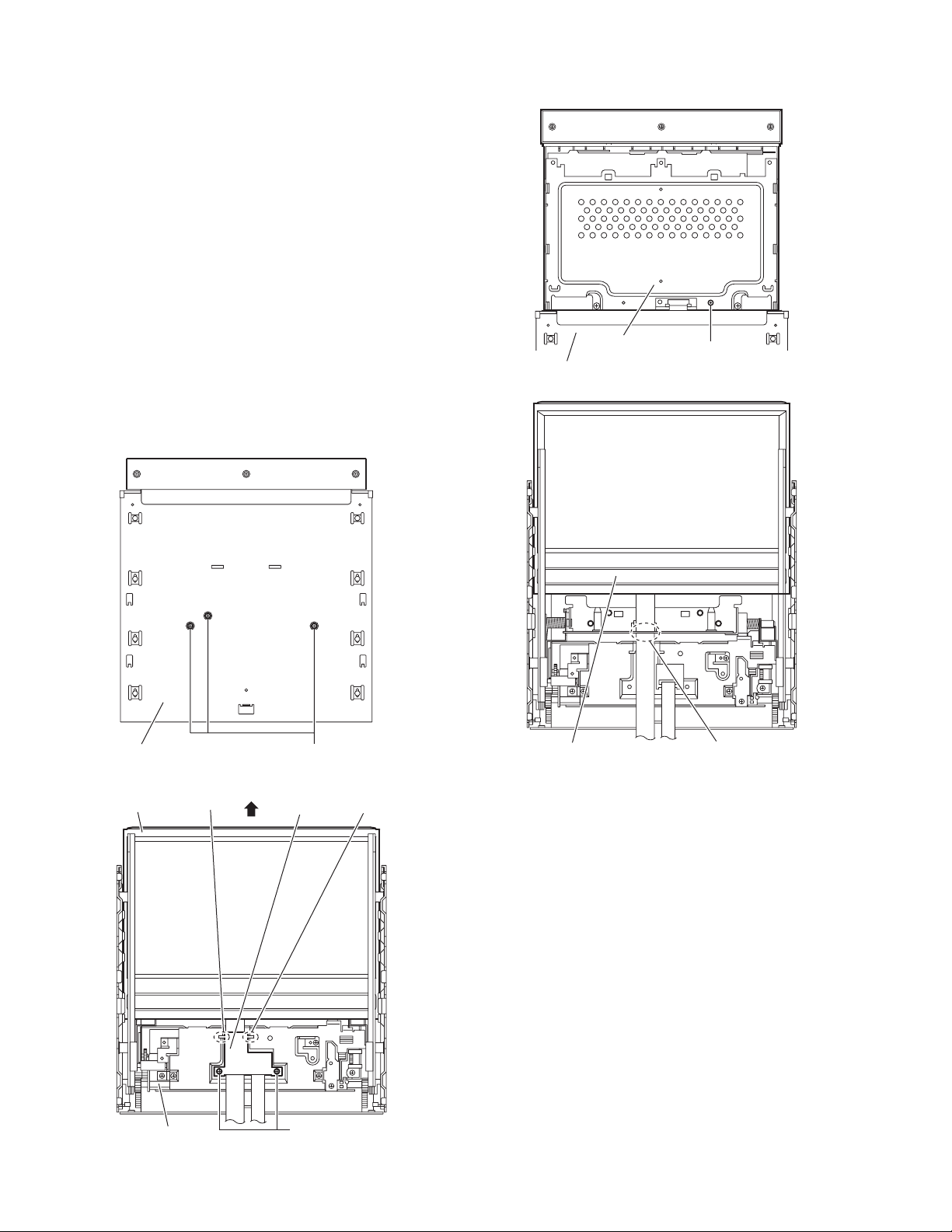

3.1.3 Removing the LCD assembly

(See Figs.7 to 10)

• Prior to performing the following procedures, remove the front

assembly and top drive unit.

(1) From the top side of the top drive unit, remove the three

screws D attaching the LCD assembly to the top drive unit.

(See Fig.7.)

(2) From the bottom side of the top drive unit, remove the two

screws E attaching the FPC guide and take out it. (See

Fig.8.)

(3) Move the LCD assembly in the direction of the arrow by

turning the feed gear. (See Fig.8.)

(4) From the top side of the top drive unit, remove the screw D

attaching the LCD assembly to the top drive unit. (See

Fig.9.)

(5) Take out the LCD assembly from the top drive unit.

Reference:

• When reattaching the LCD assembly, pass the flexible wire

through the slot c of the mecha assembly as before. (See

Fig.10.)

• When reattaching the FPC guide, pass it through the section

b as before. (See Fig.8.)

LCD assembly

D

Bottom case assembly

Fig.9

Bottom case assembly

LCD assembly Section b

Feed gear

1-6 (No.MA209)

Fig.7

Fig.8

D

FPC guide

E

Section b

LCD assembly

Slot c

Fig.10

Page 7

3.1.4 Removing the display rear cover

(See Fig.11)

• Prior to performing the following procedures, remove the front

assembly, top drive unit and LCD assembly.

(1) From the back side of the LCD assembly, remove the three

screws F attaching the display rear cover to the LCD assembly.

(2) Take out the display rear cover from the LCD assembly.

3.1.5 Removing the display back panel

(See Figs.12 and 13)

• Prior to performing the following procedures, remove the front

assembly, top drive unit, LCD assembly and display rear cover.

(1) From the back side of the LCD assembly, remove the two

screws G attaching the display back panel to the LCD assembly. (See Fig.12.)

(2) From the both sides of the LCD assembly, remove the six

screws H attaching the display back panel to the LCD assembly. (See Fig.13.)

(3) Take out the display back panel from the LCD assembly.

F

Display rear cover

Fig.11

G

Display back panel

H

Display back panel

Fig.12

Display back panel

H

Fig.13

(No.MA209)1-7

Page 8

3.1.6 Removing the monitor board

(See Fig.14)

• Prior to performing the following procedures, remove the front

assembly, top drive unit, LCD assembly, display rear cover

and display back panel.

(1) From the back side of the LCD assembly, remove the three

screws J attaching the monitor board to the LCD assembly.

(2) Disconnect the wires from the connectors (CN791

on the monitor board.

(3) Take out the monitor board with the insulator.

Reference:

• When attaching the screw J, attach it with the ground spring.

• After connecting the wire to the connector CN851

the new tape.

, CN851)

, fix it with

Ta pe

CN851

J

3.1.7 Removing the LCD module

(See Fig.15)

• Prior to performing the following procedures, remove the front

assembly, top drive unit, LCD assembly, display rear cover,

display back panel and monitor board.

(1) From the back side of the LCD assembly, release the four

section d attaching the LCD module while lifting up the LCD

module.

(2) Take out the LCD module from the LCD assembly.

Reference:

When releasing the LCD module, take care not to break it.

3.1.8 Removing the rear bracket

(See Fig.16)

• Prior to performing the following procedures, remove the front

assembly and top drive unit.

(1) From the back side of the bottom case assembly, remove

the six screws K attaching the rear bracket to the bottom

case assembly.

(2) Take out the rear bracket from the bottom case assembly.

K

CN791

Monitor board

Fig.14

Fig.15

J

Ground spring

LCD moduleSection d

Rear bracket

1-8 (No.MA209)

Fig.16

Page 9

3.1.9 Removing the system control board

(See Fig.17)

• Prior to performing the following procedures, remove the front

assembly, top drive unit and rear bracket.

(1) From the top side of the bottom case assembly, remove the

five screws M attaching the system control board to the bottom case assembly.

(2) Disconnect the wire from the connector CN351

tem control board.

(3) Take out the system control board from the bottom case

assembly.

3.1.10 Removing the front key board

(See Fig.18)

• Prior to performing the following procedure, remove the front

assembly.

(1) From the back side of the front assembly, remove the spac-

er from the front key board.

(2) Remove the eight screws N attaching the front key board

to the front assembly.

(3) Take out the front key board from the front assembly.

Reference:

After reattaching the front key board, cover it with the new

spacer.

on the sys-

M System control boardCN351 MM

Fig.17

N

Front key board Spacer

Fig.18

(No.MA209)1-9

Page 10

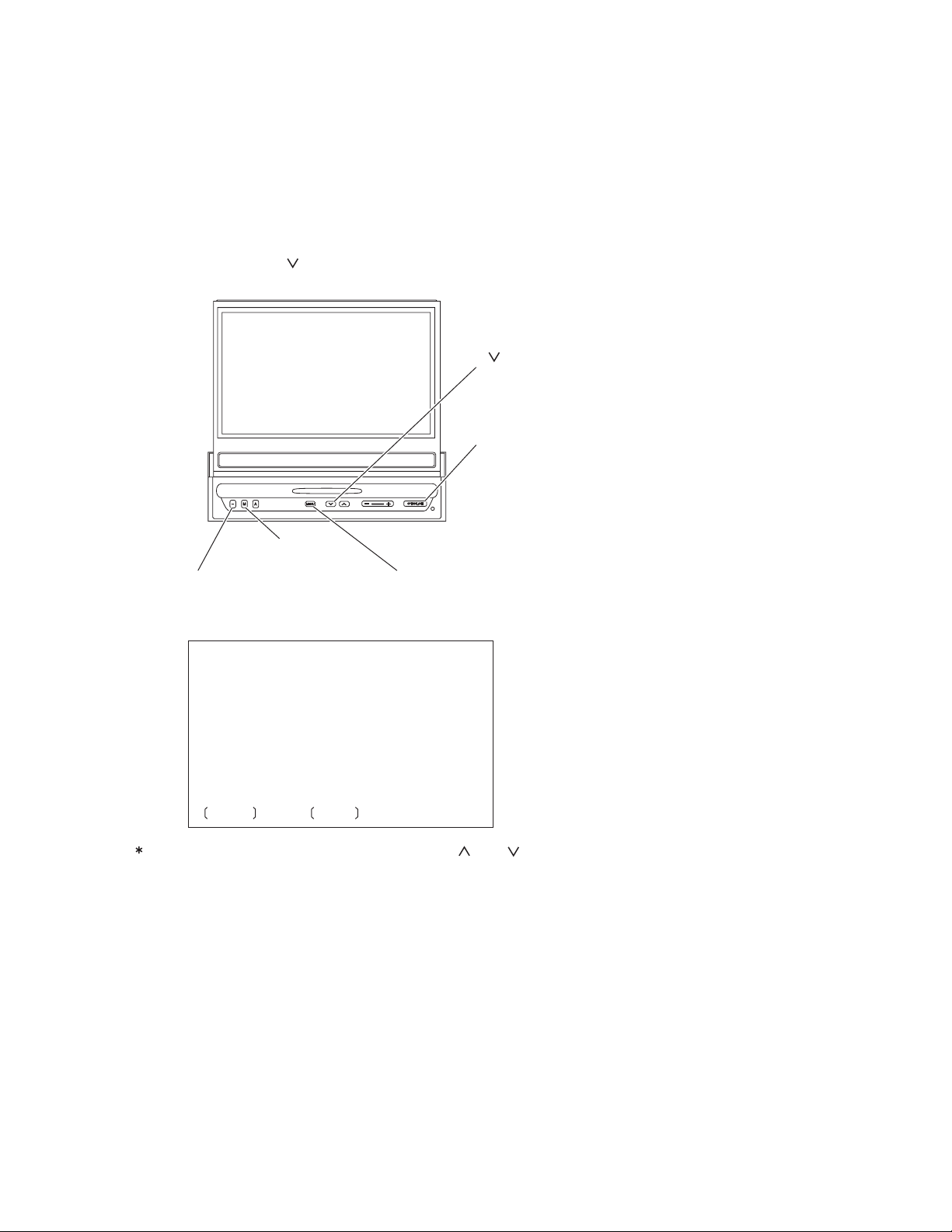

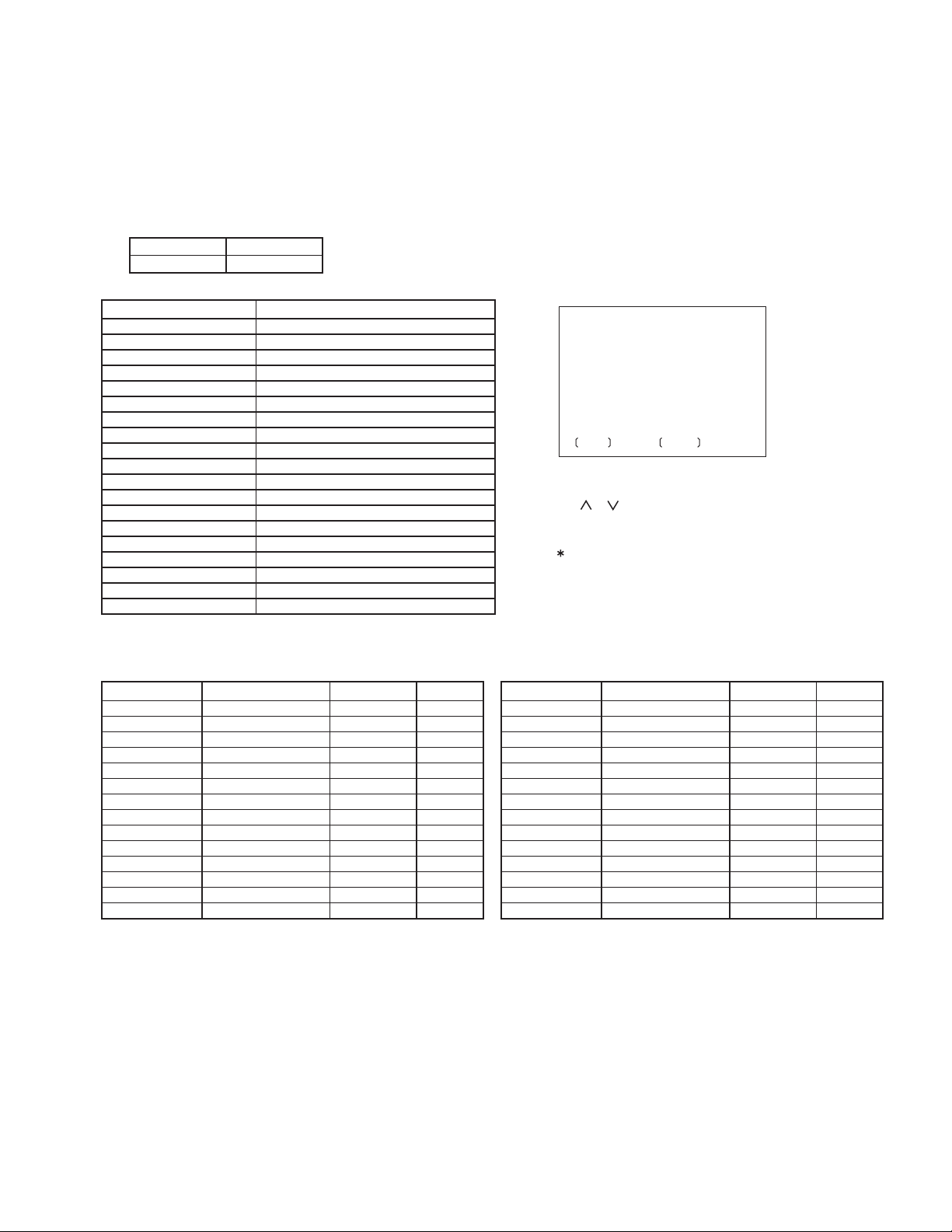

4.1 Service mode

4.1.1 Standard conditions

Power supply voltage:DC14.4V (11V to 16V)

4.1.2 Service mode setting procedure

1. Press the [POWER] button, and the display panel will come out and stand upright.

2. Press the [POWER], [ ] and [OPEN/CLOSE] buttons in this order, and keep them

pressed for 3 seconds or more.

SECTION 4

ADJUSTMENT

[ ] button

[OPEN/CLOSE] button

[MODE] button

[POWER] button [MENU] button

3. The service mode menu is displayed in the monitor.

Service Mode Menu

>

INITIALIZE ALL

INFORMATION

LCD SETTING MODE

MONITOR MECHA RUNNING

MONITOR MECHA CHECK

READ MECHA ERROR

CLEAR MECHA ERROR

INITIALIZE

DW/UP : SEL MODE : ENT

The service mode menu is selected with the [ ] or [ ] button on the main unit,

and the service mode menu is entered with the [MODE] button on the main unit.

4. To exit the service mode, press the [POWER] button on the main unit for more than 3 seconds.

1-10 (No.MA209)

Page 11

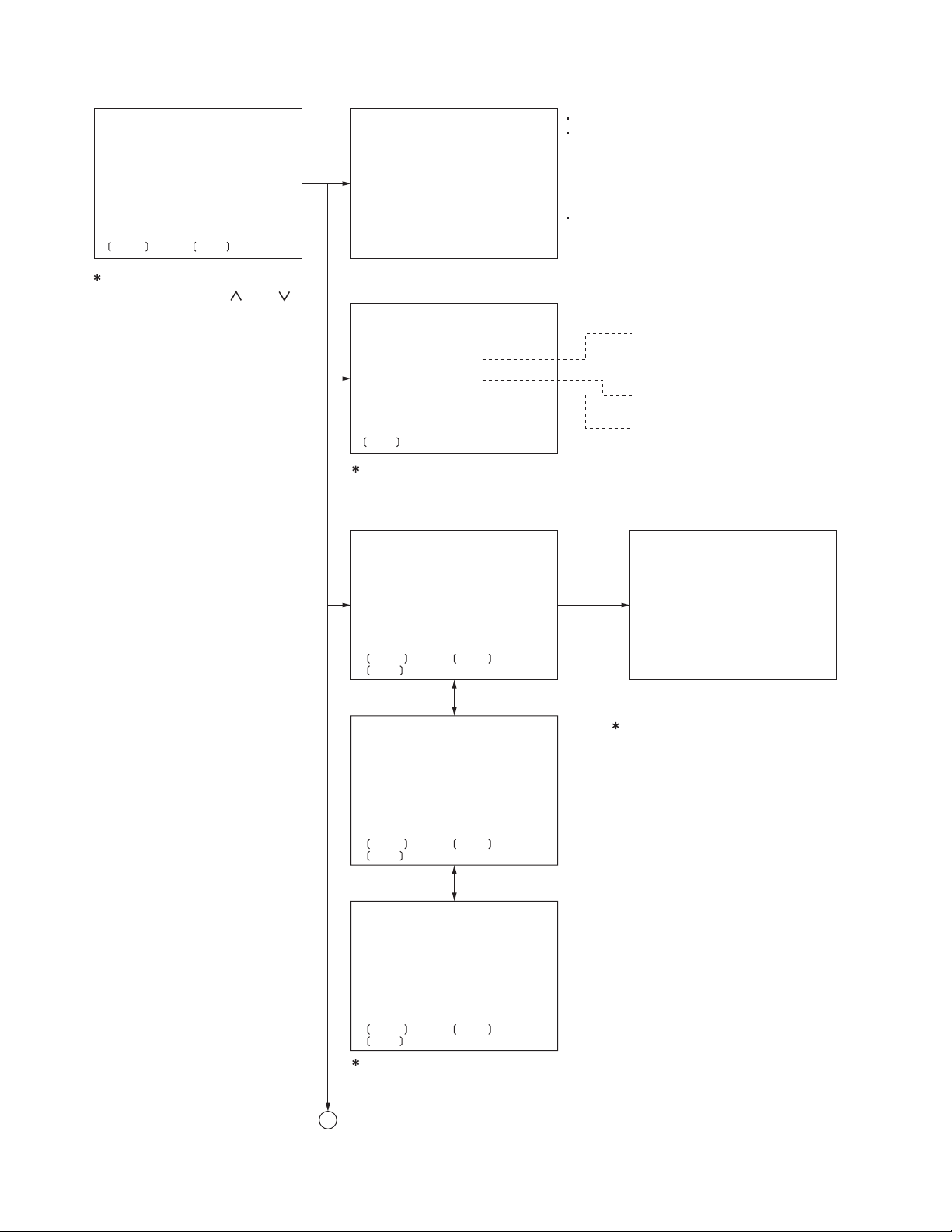

4.1.3 Operation procedures

Service Mode Menu

>

INITIALIZE ALL

INFORMATION

LCD SETTING MODE

MONITOR MECHA RUNNING

MONITOR MECHA CHECK

READ MECHA ERROR

CLEAR MECHA ERROR

INITIALIZE

DW/UP : SEL MODE : ENT

INITIALIZE ALL : All data are initialized to the factory default.

INITIALIZE ALL

"NOW EXECUTING" is displayed while the data is cleared.

After the data clear is completed, the screen returns to

NOW EXECUTING

COMPLETED

normal indication after "COMPLETED" is displayed for 3

seconds.

Data to be Initialized

All EEPROM data except the factory default of the system

micom and ROM collection data.

The service mode menu is

selected with the [ ] or [ ]

button on the main unit,

and the service mode menu

is entered with the [MODE]

button on the main unit.

INFORMATION : Area / Region indication / Version indication

INFORMATION

KV-M705

SYS VER XXXX XX

LCD INFO XX

TV TUNER VER XXXX

DOM

Version number of system micom and

ROM collection

This is used for technical support only.

Version number of TV tuner

(TV TUNER is connected.)

Area suffix of TV tuner

MENU : BACK

(TV TUNER is connected.)

Press the [MENU] button and the screen returns to the service mode menu.

LCD adjustment mode

LCD SETTING NTSC

COM AMPLITUDE

>

COM DC

DAC OUT

RGB AMPLITUDE

BRIGHT

GAMMA1

GAMMA2

SUB-BRIGHT R

SUB-BRIGHT B

DW/UP : SEL MODE : ENT

MENU : EEPROM WRITE

Indication

reshuffling

LCD SETTING NTSC

PHASE

>

CONTRAST

TINT

COLOR

PICTURE

INPUT MODE/SW

AGC SW ON

GAMMA TEST OFF

NTSC/PAL CHANGE

DW/UP : SEL MODE : ENT

MENU : EEPROM WRITE

Press the

[MENU]

button.

LCD SETTING NTSC

EEPROM WRITE

NOW EXECUTING

COMPLETED

Each setting value is written in EEPROM

by pressing the [MENU] button.

"NOW EXECUTING" is displayed while the data

is written.

After the data writing is completed, the screen

returns to service mode menu after

"COMPLETED" is displayed.

Indication

reshuffling

LCD SETTING NTSC

SETTING DISP ON>

DW/UP : SEL MODE : ENT

MENU : EEPROM WRITE

See "LCD adjustment" for details.

A

(No.MA209)1-11

Page 12

A

Monitor Mecha Running mode

MONITOR MECHA RUNNING

>

RUNNING MODE-1

RUNNING MODE-2

RUNNING MODE-3

RUNNING MODE-4

RUNNING MODE-5

RUNNING MODE-6

DW/UP : SEL MODE : ENT

MENU : BACK

This mode is not used for service.

To exit running mode, press the [POWER] button for

more than 3 seconds.

Then service mode is finished.

Press the [MENU] button and the screen returns to service mode menu.

Monitor Mecha Check mode

MONITOR MECHA CHECK

ANGLE SENSOR MIN : XXXX

ANGLE SENSOR MAX : XXXX

INITIALIZE OK

MIN : Value of the monitor angle 0 C entered by the

initialization processing.

MAX : Value of the monitor angle 105 C entered by the

initialization processing.

(The displayed value is the AD value, which is taken into

the system micom.)

"INITIALIZE OK/NG" indicates completion/incompletion

end of the initialization processing.

("NG" is displayed when mechanism initialization have

not been completed.)

Read Mecha Error history

READ MECHA ERROR

TOTAL ERROR : XXXXXX

E-1 : XXXXXX E01 : XXXXXX

E-2 : XXXXXX E02 : XXXXXX

E-3 : XXXXXX E03 : XXXXXX

E-4 : XXXXXX

E-5 : XXXXXX

MENU : BACK

Total number of errors, the first five and the latest three

errors are displayed.

Press the [MENU] button and the screen returns to service mode menu.

Clear Mecha Error history

CLEAR MECHA ERROR

NOW EXECUTING

COMPLETED

The Monitor Mecha Error history is cleared.

Data to be cleared

Monitor Mecha Error history stored in EEPROM.

Initialization of user setting data

INITIALIZE

"NOW EXECUTING" is displayed while the data is cleared.

After the data clear is completed, the screen returns to

NOW EXECUTING

COMPLETED

normal indication after "COMPLETED" is displayed

for 3 seconds.

Data to be Initialized

User setting data of the system micom

(All EEPROM data except the factory default of system

micom, ROM collection data and the Monitor Mecha

Error history.)

1-12 (No.MA209)

Page 13

4.1.4 LCD adjustment

LCD free run frequency adjustment

(1) Set the main unit in a service mode.

(2) Select "LCD SETTING" of the service mode.

(3) Connect the frequency counter to TP708 and TP761 (GND) on the monitor board.

(Not supplying a signal in the input.)

(4) Select "DAC OUT" of LCD SETTING menu to adjust.

(5) Carry out this adjustment with both modes of NTSC and PAL.

(Change "NTSC/PAL CHANGE" of LCD SETTING menu)

NTSC

15.734kHz

LCD SETTING MENU

Item Contents

COM AMPLITUDE

COM DC

DAC OUT

RGB AMPLITUDE

BRIGHT

GAMMA1

GAMMA2

SUB-BRIGHT R

SUB-BRIGHT B

PHASE

CONTRAST

TINT

COLOR

PICTURE

INPUT MODE/SW

AGC SW ON

GAMMA TEST OFF

NTSC/PAL CHANGE

SETTING DISP ON

PAL

15.625kHz

Amplitude of the common voltage

Center value of the LCD pulse

Free run frequency of the LCD

Amplitude of black-black

Brightness

GAMMA point 1

Difference with GAMMA point 1

Red brightness

Blue brightness

Phase of R-Y/B-Y

Contrast of video input

Hue

Deepness of a color

Picture

This mode not using it by service.

This mode not using it by service.

This mode not using it by service.

Reshuffling of NTSC/PAL

On/off for indication of adjustment value

LCD SETTING NTSC

COM AMPLITUDE XXH

MODE : BACK DW/UP : SET

Main unit operation in adjustment

[MODE] key : Return to LCD SETTING menu.

[ ], [ ] key : Change value, one step changes by one

time of input

Carry out this operation with both modes of NTSC and PAL.

When all the adjustment values are input, press the

[MENU] button to memorize the values in EEPROM.

When the power supply is turned off without pressing

the [MENU] button, the adjustment values are not

memorized.

Adjustment for all version (Carry out this adjustment with both modes of NTSC and PAL.)

NTSC adjustment

Item Production jig Def value

COM AMPLITUDE

COM DC

DAC OUT

RGB AMPLITUDE

BRIGHT

GAMMA1

GAMMA2

SUB-BRIGHT R

SUB-BRIGHT B

PHASE

CONTRAST

TINT

COLOR

PICTURE

Adjustment of frequency

3E

0A

DD

30

85

FF

80

85

30

A0

98

7B

10

Reference value

6D

28

CE

30

85

FF

84

8A

30

AB

98

7D

10

Adjustment

Adjustment

Adjustment

Adjustment

Fixed value

Fixed value

Fixed value

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Fixed value

PAL adjustment

Item Production jig Def value

COM AMPLITUDE

COM DC

DAC OUT

RGB AMPLITUDE

BRIGHT

GAMMA1

GAMMA2

SUB-BRIGHT R

SUB-BRIGHT B

PHASE

CONTRAST

TINT

COLOR

PICTURE

Adjustment of frequency

3F

1A

D0

30

85

FF

80

85

30

A0

92

7F

10

Reference value

72

25

D0

30

85

FF

84

8A

30

AB

91

84

10

Adjustment

Adjustment

Adjustment

Adjustment

Fixed value

Fixed value

Fixed value

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Fixed value

(No.MA209)1-13

Page 14

SECTION 5

TROUBLESHOOTING

5.1 Mechanism initialization

Operate the mechanism initialization when replacing the top drive unit.

5.1.1 Operation procedure of mechanism initialization

(1) Setup the service mode, and operate "INITIALIZE ALL".

(Refer to "4.1.2 Service mode setting procedure" and "4.1.3 Operation procedures")

(2) After the all data are initialized, press the [RESET] button of the main unit.

(3) After the display panel is closed, start the operating the mechanism initialization.

(4) After the operating mechanism initialization, press the [POWER] button of the main unit for more than 3 seconds.

[POWER] button [RESET] button

1-14 (No.MA209)

Page 15

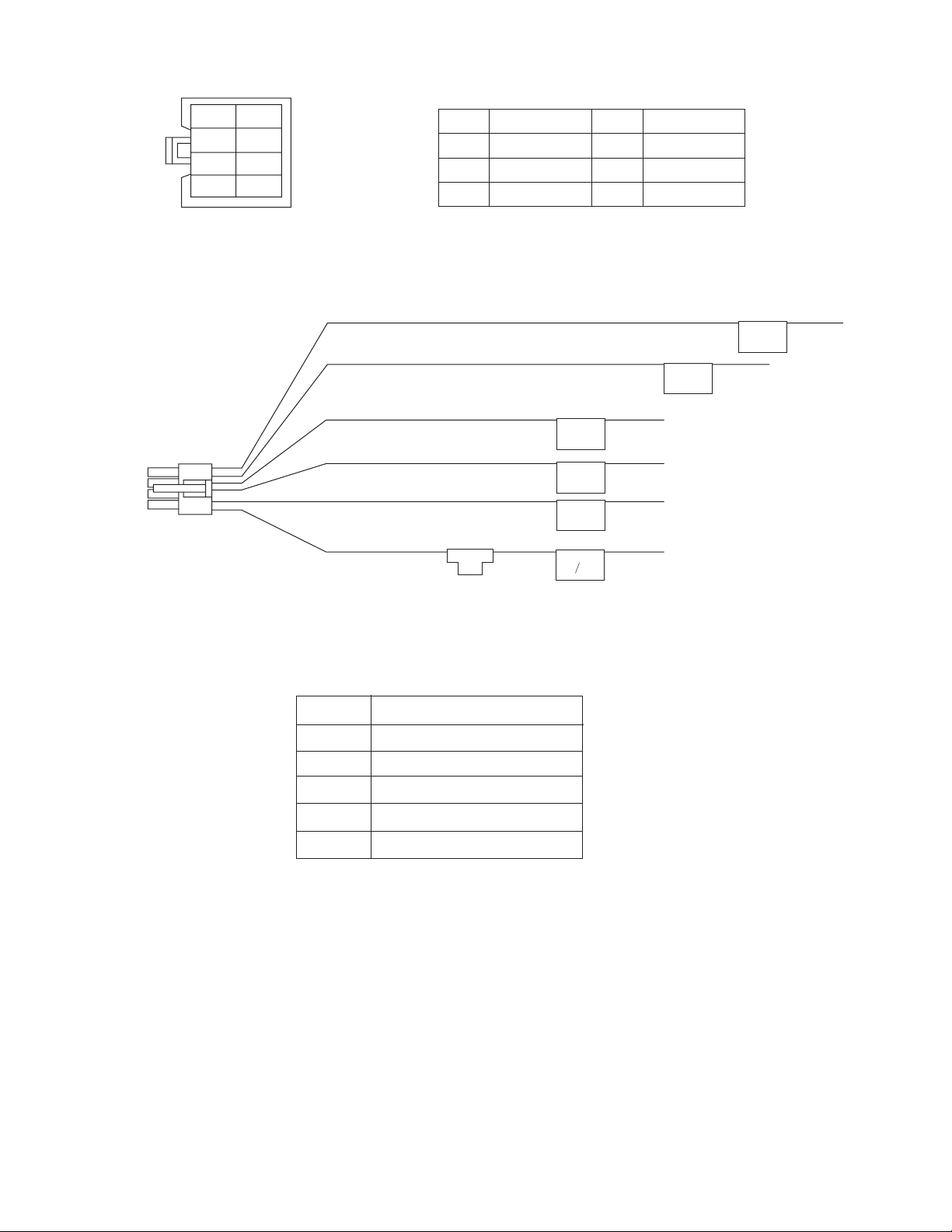

5.2 8 PIN CORD DIAGRAM

OR/WH

RD

VI/WH

L.GN

NC

NC

YL

BK

BK

RD

OR

L.GN

VI/WH REVERSE

Black

Red

Orange

Light Green

WH

YL

VI

White

Yellow

Violet

ACC

MEMORY

GND

ILL

PARKING

L.GN PARKING

OR/WH ILL

RD ACC

BK GND

YL MEMORY

ACC Line

Memory Backup Battery+

Ground

Illuminations Control

Parking Brake

3 A

ILLUMI

POWER

LEAD

GROUND

POWER MEMORY

LEAD BACKUP

REVERSE

PARKING

REVERSE

Reverse Gear Signal Lead

(No.MA209)1-15

Page 16

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA209)

Printed in Japan

VPT

Page 17

SCHEMATIC DIAGRAMS

IN-DASH 7-INCH WIDESCREEN MONITOR

KV-M705, KV-M706

CD-ROM No.SML200510

KV-M705

Area suffix

E ------------- Southern Europe

UT ------------------------- Taiwan

UN --------------------- Indonesia

HUN ------------------ Indonesia

U -------------------- Other Areas

KV-M706

Area suffix

J ------------- Northern America

E ------------- Southern Europe

UT ------------------------- Taiwan

UN --------------------- Indonesia

U -------------------- Other Areas

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2005 Victor Company of Japan, Limited.

2-1

2-3

2-11 to 14

No.MA209SCH

2005/10

Page 18

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 19

< MEMO >

Page 20

e

C

O

N

C

C

N

E

E

E

S

V

C

Y

G

Block diagram

TFT

LCD

MODULE

Monitor section

CN791 CN851

CONTROL

STH1, STH2

STV1, STV2

CLK1 to CLK3

OEV1 to OEV3

CPV, OEH

IC701

TFT

HSYNCIN

VDBIN

BLACK, POL

PD

POSSET

HPOS1

VPOS1

RESET

ROUT, GOUT, BOUT

VCOM

Q651 to Q654

VCOM

IC741

SYNC BUFF.

IC761

PLL

Q701, Q702

POSITION SET

IC702

RESET

COM_OUT

SYNC_OUT

DAC_OUT

NTSC/PAL_OUT

HSY_IN

R_IN2

G_IN2

B_IN2

SW1, SW2

IC601

VIDEO

PROCESSOR

CLK_LCD

TX_LCD

Mecha

VIDEO_IN

IC691

VIDEO IN

BUFFER

C_VIDEO(+)_IN

Main s

BACK

LIGHT

T851

TRANS.

IC811

B/L DRIVER

LTBOX, CPHSEL, QHSEL

HOUT

VOUT

IC703

INVERTER

12V

ENA

HSYNC

VSYNC

5V

IC911

17V 12V

REG.

CS

IC521

PORT

EXPANDER

CS

IC631

OSD

CONTROLLER

IC801

14V 5V

REG.

IC901

SW

REG.

EXP_DAT

EXP_CLK

EXP_STRB

EEP_DAT

EEP_CLK

IC511

LEVEL

TOLERANCE

TX_LCD

CLK_LCD

INV_PWR

SYS5V

CN501

CN392

I

S

RE

P

CON

2-1

Page 21

echa section

S3201

CLOSE SW

CLSW ANGSW

P3201

ANGLE SW

S3601

SLIDE PULSE

S361

HSW

CN332

HSW, PULSE

VR351

ANGLE SENSOR

CN331

ANGSENS

ain section

VOUT+

CCLK

CDATA

NTSC/PAL

EPSDATA, EPSCL

EXPDAT, EXPCLK

EXPSTRB

VIDEO5V

IC303

8V 5V

REG.

SW5V, A9V, 8V

IC301

SYSTEM

REGULATOR

ACC

CN301

POWER

CONNECTOR

SW+B, PWR

MVCNT

CNTL0, CNTL1, CNTL2

CN301

CN391

PULSE, HSW, ANGSW, CLSW

ANG_SENS, MO_PWR, MVCNTL

MO_CTL0, MO_CTL1, MO_CTL2

IC101

SYSTEM

CTL

ACCCHK

REVERSE

PARKING

FPKEY0

FPKEY1

FP_REM

OPEN/CLOSE

LED_CONT

RESET

IC102

RESET

IC301

REGULATOR

VMUTE

MONIMUTE

JBUSIO, JBUSSCK

JBUSSI, JBUSSO

IC103

JBUS BUFF.

RST

ASEL0

ASEL1

CN351

IC253

AUDIO

SELECT

IC202, IC203

Front section

REMOCON

CN471

S431 to S434

S441 to S444

IC312

MOTOR

VR

VOLTAGE

IC251

AUDIO

ISOLATION

IC252

AUDIO

ISOLATION

AMUTE

VSEL0

VSEL1

VIDEO

AMP

IC461

REMOCON LED_CONT

FPKEY0

FPKEY1

SWITCH

VIDEO SELECT

TV_L, TV_R

Q411, Q412

DIMMER

S435

OPEN/CLOSE

SWITCH

IC331

MOTOR

DRIVER

INP1L, INP1R, INP1_V

OUT_L, OUT_R

INP2_L, INP2_R, INP2_V

Q256 to Q258

AUDIO MUTE

IC201

ISO &

TV_V

OPEN/CLOSE

OUT_V

SI/SO, SCK

D401 to D421

CN312CN311

INPUT1

INPUT2

CN372CN371CN373

OUTPUT

CN361

AV_BUS

PAN EL

LIGHT

RESET

S451

RESET

SWITCH

2-2

Page 22

1

R

Standard schematic diagrams

Main section

LVA10619-1

TP353

TP351

TP352

TP354

TP355

TP303

PARKING

TP307

TP356

FP_REM

DGND

RST

FPKEY0

FPKEY1

OPEN/CLOSE

LED_CONT

R347

Q342

R345

Q341

47k

R342

R341

TP357

TP358

TP359

TP360

TP305

TP304

NI

C302

0.1/50

C303

NI

C301

47k

MA8062/M/-X

REVERSE

L301

QQR1620-001

NIC305

0.1/50

C304

L302

22

NQL79GM-220X

R311

NI

NI

C308

0.1/50

C309

UN2211-X

D341

C341

0.01

REMOTE_IN

REVE

R302

D302

10k

MA111-X

C310

47/16

100k

R301

0.01C307

3300/16C306

D301

1N5401-F64

PGND

47k

NI

REM_IN

4.7k

R348

5.1k

R346

10k

C343

10/16

PARKING

PARK

R303

47k

TP308

82k

R304

D303

TP309

MA8062/M/-X

100k

R306

33k

R305

R343

NI

D342

C342

NI

NI

Q301

2SD601A/QR/-X

REMOCON

TO_FP

OPEN/CLOSE

TO CN471

(SHEET 2)

LED_CONT

REVERSE

REMOTE_IN

POWER_CON

GND

5V

GND

RESET

FPKEY0

FPKEY1

ILL_B

ILL_GND

ILL10V

ILL_GND

CN301

QGA4201F1-08

ILLMI

ACC

PARKING

NC

GND

MEMORY

CN351

QGF0534F1-13X

13

R351 0

12

11

10

R352 0

9

R353 0

8

R354 0

7

R356 0

6

5

4

3

R355 0

2

1

1

2

3

4

5

6

7

8

C337

0.1/50

TP301

TP302

REVERSE

D317

MA111-X

TP306

Q343

UN2211-X

Q302

2SD601A/QR/-X

Q303

UN2213-X

TP310

Q304

2SB709A/QR/-X

R357

NI

R358

0

Q311

2SB709A/QR/-X

R324

22k

47k

C334

0.1

R325

2.2k

R326

Q312

UN2211-X

ILL

18k

R307

BAT_DET

82k

R308

R309

10k

ACCCHK

8.2kR310

R312

C311

0.01

C312

10/16

SYSTEM_REG

IC301

R2S25400DS-E

EXT

ANT

ACC

VDD

SW5V

ACC5V

ANTC

0V

5.0V

5.8V0V5.1V

D304

MA111-X

0.01C317

5.4V

14.2V

R328

10k

TP315

TP314

TP313

C319

0.1/16

10/16

C318

0.01

C320

R327

47k

13.6V

TP311

TP312

4.7k

0.1/16C314

100/10C316

47/16

0.01C315

C313

8V

CTRL

ILMI

VCC

0.4V

TP316

AJ

BAT

9V

9.1V

4.9V

8.1V

1.3V

8.8V

TP317

A9V

R313

5.6k

TP318

1k

R314

10/16

C323

C322

47/16

0.01

C324

0.01

C321

PWCONT

TP319

GND

151413121110987654321

0V

NI

R315

Q305

NI

Q306

NI

C325

47/16

INP2

OUT

INP1

QNZ0690-001

TV_V_GND

MEMORY

AV_BUS

REMOTE

TV_S_GND

QGA2501C1-05

INP2_VGND

INO2_AGND

QGA2501C1-07

OUTVGND

OUTAGND

OUTAGND

QGA2501C1-06

INP1VGND

INP1GND

INP1GND

INP2_R

CN372

VMUTE

VSEL1

VSEL0

C203

R231

10/16

100

C227

R232

150

R208

150

R207

10/16

100

C225

R226

10/16

100

C201

R225

10/16

6.8k

R202

180

R201

100

C226

R228

10/16

100

C202

INP1_VGND

INP2_VGND

C251

4.7/25

C252

4.7/25

C253

4.7/25

C254

4.7/25

C255

4.7/25

C256

4.7/25

INP1_V

150

R203

0R241

1kR242

1kR243

0R244

0R245

1kR246

R227

150

R204

100

IC251

NJM4565V-X

0V

4.5V

4321

VCC-

AUDIO_ISO1

2IN+

5678

4.5V

4.5V

0V

4.5V

4321

VCC-

AUDIO_ISO2

2IN+

5678

4.5V

4.5V

IC252

NJM4565V-X

10/16

C257

100p

R263

15k

4.5V

4.5V

1OUT1OUT

1IN-

1IN+

VCC+

2OUT

2IN-

4.5V

9.1V

R264

15k

C259

100p

C258

100p

R265

15k

4.5V

4.5V

1IN-

1IN+

VCC+

2OUT

2IN-

4.5V

9.1V

R266

15k

C260

100p

TP361

TP362

TP363

TP364

TP365

CN361

GND

1

C361

NC

2

NI

3

L361

TV_V

4

0

SCK

5

NC

6

D361

RB160M-30-X

7

8

9

R361

TV_L

10

100

SI/SO

11

TV_R

12

R362 NI

100p

C362

CN371

INP2_V

1

2

3

INP2_L

4

5

OUTV

1

2

OUTL

3

4

OUTR

5

6

NC

7

CN373

INP1_V

1

2

INP1L

3

4

INP1R

5

6

C384

TP366

SCK

AGND2

TV_L

SI/SO

TV_R

D364

NI

3

2

-

1

NI

NI

100p

C363

D362

C371

0.001

C372

0.001

C373

0.001

C374

0.001

PGND

TP370

TP371

100p

100p

C375

100p

C376

TP367

TP368

D363

TP372

TP373

100p

C377

TP369

TP380

TP379

TP381

TP382

TP374

TP375

TP376

TP377

TP378

C381

NI

INP2_V

INP2_VGND

C382

NI

OUT_V

VGND

R297

OUT_L

100

AGND1

R298

OUT_R

100

C383

NI

INP1_V

INP1_VGND

C380

100p

0.001

C378

0.001

C379

PGND

C331

0.01

C332

0.01

C333

0.01 NI

NI

NI

INP2_V

R255

15k

R256

100k

22k

R251

R257

15k

22k

R252

R258

15k

R259

15k

R260

100k

22k

R253

R261

15k

22k

R254

R262

15k

C231

0.1

C232

0.1

C206

0.01

47/16C261

1.7V

1.7V

1.7V

1.7V

1.7V

1.7V

1.7V

8.0V

47k

R267

47k

R268

47k

R269

0.1/16C266 0.1/16C262

47k

R270

ISO&VSEL

IC201

NJM2526V-X

VIN4 GND

VGND4

VOUT2

VIN3

MUTE

VGND3

SW2

VGND1

VOUT1

VIN1

SW3

VGND2

SW1

V+

VIN2

87654321

R273

22/16

C265

C263

0.1/16

15k

100p

C264

R271

R274

R275

22/16

C269

C267

0.1/16

R276

15k

100p

C268

R272

0V

161514131211109

1.0V

0V

R233

10k

0V

1.0V

R206

470

0V

4.8V

1.7V

R205

470

R277

0

1k

1k

1k

1k

TP201

D202

MA111-X

R234

NI

C207

0.1

47k

R238

C208

10/25

D201

MA111-X

21250R278

47kR279

47kR280

4.5V

9.1V

16 15 14 13 12 11 10 9

2X

VDD

0.1/16C271

47/16C270

0Y2YY3Y1Y

4.6V

4.5V

MONIMUTE

100k

R209

100k

R237

R235

0

4.5V

1X

CD4052BM-X

4.5V0V4.5V

R217

1M

C217

0.1

R221

1M

C221

0.1

C272

4.7/25

1k

R281

AUDIO_SEL

C209

0.1/16

IC202

MM1228XF-X

1.9V

IN

0V

0V

SW2 IN3

4321

R219

VIDEO_AMP_MONI

47k

C210

0.1/16

IC203

MM1228XF-X

1.9V

IN

0V

SW1

1.9V

IN1

0V

SW2

4321

VIDEO_AMP_OUT

R220

47k

TV_L

TV_R

C273

4.7/25

1k

R282

0.1V0V4.5V

4.5V

0XX3X

IC253

INH

0V0V0V 0V

C204

NQR0288-004X

100/10

K201

C205

0.1/16

R215

0

C211

470/16

0V

GND

8765

8.0V

OUTSW1

1.8V

VCCIN1

0V0V

0V

GND

8765

1.8V

OUT

8.0V

VCC

1.9V

IN3

47kR283

47kR284

100pC275

100pC274

A

B

VEE

VSS

87654321

R210

150

R218

C218

0.1

C213

470/16

R222

1M

C222

0.1

AGND2

VOUT+

R211

1M

150

R214

0

R212

150

R213

150

VGND

OUT_V

R285

10k

R286

10k

Q252

UN2211-X

C276

4.7/25

R290

R291

C277

4.7/25

VIDEO+5V

IC303

BA00ASFP-X

CNTL

VIN

GND

VOUT

ADJ

12345

4.7V

C344NIC347

Q251

UN2211-X

R287

1k

C278

100p

47k

C279

100p

47k

R288

1k

8.1V0V5.0V

C345

0.1

R295

NI

2.2kR289

R332

1.2V

1k

MONI5V

R333

6.8k

R334

2.2k

0.01

C346

10/16

D251

MA111-X

Q254

UN2111-X

AMUTE

Q253

C280

47/16

Q258

2SB709A/QR/-X

UN2211-X

ASEL0

ASEL1

C281

NI

R293

2.2k

D252

MA152WA-X

3

R294

2.2k

1

2

C282

NI

2-3

Page 23

R315

Q308

2

A

2

R

1

R318 47k

Q307

UN2211-X

C329 10/25

2SD601A/QR/-X

R317

10k

R323

22k

R322

47k

RSQ035P03-W

L303

4.7

C335 10/25

R321

47k

C328

0.1

C327

0.1

Q310

UN2211-X

IC302

14.2V

D

DDG

123

14.2V

14.2V

14.2V7.1V

456

D

S

R320

47k

14.2V

C330

0.1

47k

R319

Q309

UN2211-X

NTSC/PAL

VMUTE

AMUTE

MONIMUTE

PULSE

MO_PWR

MO_CNTL0

MO_CNTL1

MO_CNTL2

ANGSW

HSW

CLSW

OPEN/CLOSE

MVCNTL

CN101

QGA1002F1-07X

1

TX

FLHCLK

2

CLK

FLHDI

3

DI

FLHDO

4

DO

5

RESET

NI

6

VDD

7

GND

R153

CCFL_DIM

TX

NI

47kR154

R155

ANG_SENS

DGND

R157 NI

RST

FPKEY0

FPKEY1

R158 NI

LED_CONT

FP_REM

R159 470

4.9V

R144 470

R145

0V

470

R167

4.9V

470

R172

0V

470

0V

TP131

4.5V

R156

470

4.9V

R146

4.9V

470

0V

470R147

0V

470R148

R149

0V

470

4.7V

5.1V

5.1V

0V

TP132

0V

TP133

0V

TP134

0V

TP135

4.9V

0V

0.2V

470R150

0V

TP137

R151

2.8V

470

0.3V

TP138

C124

5.0V

0.1

C125

100p

47k

R103

470k

R152

R160

0

10kR101

10k

R102

10k

R171

ASEL1

VSEL0

VSEL1

470R143

470

470

470

TP129

R142

R141

R168

0V0V4.9V0V4.9V0V4.8V0V4.9V

ASEL1

VSEL0

VSEL1

DIMMER

76

NTSC/PAL

77

VMUTE

78

AMUTE

79

MONIMUTE

80

81

PULSE

82

FPPWR

83

MOTPWR

84

MOTCNT0

85

MOTCNT1

86

MOTCNT2

87

ANGSW

88

HSW

89

CLSW

90

91

92

93

94

OPEN/CLOSE

95

DAVSS

96

MOTVR

97

98

CCFL_DIM

99

100

DAVDD

VREF-

FP_KEY0

1 2 3 4 5 6 7 8 9 10111213141516171819202122232425

0V0V0V

C103

C102

C129

0.001

0.001

0.001

R163

10k

R161

10k

R162

10k

MON_PWR

PWCONT

C326

0.1

TP319

NI

Q305

NI

Q306

NI

C325

47/16

R316

NI

R335

0

NMFZ018-3R0X-E

F301

332

k

MONI5V

51

111-X

ILL

ACCCHK

PWCONT

MON_PWR

EPSCL

EPSDA

ASEL0

MONI5V

470R140

470

470R138

470R169

TP127

TP125

TP124

R137 470

ANGLE

4.4V0V5.0V

0.1

C104

4.9V

MONI5V

10k

R118

0V

5.3V0V5.0V

ACC

PWCONT

IC101

MN101C49KEF

VREF+

VDD

OSCO

5.0V

2.3V

0.1

0.1

C105

C106

3p

X101

C1073pC108

NAX0688-001X

OSCI

2.3V0V2.0V

470

R105

20MHz

5.1V

ILLUMI

VSSXIXO

22p

C127

R136 470

0V

EPSDA

2.4V0V5.0V

X102

32.768kHz

R139

ASEL0

MON_PWR

FP_KEY1

SENCK

5.0V0V5.0V

2.7V

470

R104

SENCK

TP123

TP122

TP121

TP120

0V0V0V0V0V0V0V

EPSCL

MMODTXRX

EXPCLK

0V

0V

4.9V

2.2kR176

2.2kR175

3.3kR107

22p

C128

NAX0244-001X

EXPCLK

TP119

FLHSDA

PARK

REVE

SI/SO

TP118

TP117

5.1V

0V

51525354555657585960616263646566676869707172737475

BACK

PARKING

JBUSSCK

CHROCLK

CHRODATA

EXPSTRB

EXPDATA

LED_CONT

BUZZER

FLHBSY

FLHCLK

0V0V0V

5.0V

330R108

TP141

FLHCLK

FLHDITXFLHDO

JBUSIO

JBUSSI

JBUSSO

JBUSINT

REM_IN

FP_REM

C109

100p

R123 100

R122 1k

0V

50

0V

49

0V

48

0V

47

0.1V

46

0.1V

R121

45

470

0V

44

0V

TP114

43

0V

42

470R120

0V

41

VPP

0V

TP113

40

0V

TP112

39

0V

38

3.3kR106

0V

37

0V

TP109

36

0V

R119

35

470

0V

TP108

34

5.0V

33

RESET

5.0V

R165

32

VDD2

0

0V

31

5.0V

30

5.0V

29

0V

28

0V

27

BATT

0V

26

TP105

100k

R117

TP101

0R109

NIR110

C110

100p

TP102

BZ101

QAN0023-001Z

TP142

Q101

UN2211-X

3.9k

3.9k

3.9k

3.9k

R114

R111

R113

R112

R126

100k

R125 100

R124 4.7k

R127

TP116

22k

TP115

CCLK

CDATA

EXPSTRB

EXPDATA

C118

0.1

C119

0.1

REM_IN

R177

10k

BAT_DET

R178

10k

330/6.3

C113

0.1

C112

C114

R115

47k

TP104

C111

BD4833FVE-W

NI

5.0V

123

OUT

0V

SUB

0V

NC

R130 10k

0V

5.0V

1OE

VDD

141312111098

0V

5.0V

4OE

1A

0V

0V

4A

1Y

R128

0V

0V

2OE

4Y

100

0V

0V

2A

3OE

5.0V

0V

2Y

3A

0V

0V

3Y

GND

7654321

NI

C120

NI

IC102

IC103

R129 47k

SN74AHCT126PW-X

L101

22

TP103

C116

0.1

220

R116

D101

MA111-X

5.0V

VCC

0V

45

GND

47/16

C117

Q102

C126

NI

UN2111-X

SCK

PGND

F391

R131

100k

R132

330

R133

100

C123

C121

0.047

NMFZ018-1R5X-E

TP321

TP322

TP323

TP324

MO_CNTL0

MO_CNTL1

MO_CNTL2

MVCNTL

MO_PWR

R134

NI

TP325

22k

ANG_SENS

CLSW

ANGSW

HSW

PULSE

R135

47k

TP327

TP328

TP331

TP333

TP332

NTSC/PAL

CDATA

CCLK

EXPSTRB

EXPDATA

EXPCLK

EPSDA

EPSCL

TP335

TP336

TP337

TP338

TP339

R396 NI

R395 NI

SENCK

CCFL_DIM

TP340

TP341

TO_MONITOR

CN391

C391

0.1

QGF0534F1-16X

1

SYS14

2

SYS14

3

GND

4

GND

5

CNTL0

6

CNTL1

7

CNTL2

8

MVCNT

9

PWR

C392 0.1

10

5V

11

TP329

TP330

TP334

R381 0

R382 0

R383 0

R384 0

R385 0

R386 0

R387 0

R388 0

R389 0

R390 0

R391 0

C393

0.1

C395

100/10

C394

0.1

L391

R3920

10

R3930

NQL49CM-100X

C396

10/25

C397

10/25

GND

12

ANGSENS

13

CLSW

14

ANGSW

15

HSW

16

PULSE

CN392

QGF0534F1-24X

1

NTSC/PAL

2

GND

3

VIDEO

4

GND

5

DATA

6

CLK

7

STROBE

8

DATA

9

CLK

10

DATA

11

CLK

12

VCC

13

GND

14

GND

15

+B

16

+B

17

SENCK

18

DIMMER

19

+B

20

+B

21

+B

22

GND

23

GND

24

GND

TO CN301

(SHEET 4)

TO CN501

(SHEET 3)

TP326

VGND

AMUTE

C280

47/16

Q258

UN2211-X

Q255

UN2111-X

R292

D253

10k

ASEL0

ASEL1

C281

NI

R293

2.2k

WA-X

3

R294

2.2k

2

C282

NI

C283

47/16

Q256

2SD1781K/QR/-X

Q257

2SD1781K/QR/-X

OUT_L

AGND1

OUT_R

MA8110/M/-X

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER.

CONDITION...DC SUPPLY 14.4V

2.UNLESS OTHERWISE SPECIFIED

ALL RESISTORS AER 1/10W 5% METAL GLAZE RESISTOR

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR

ALL RESISTANCE VALUES ARE IN OHM

ALL CAPACITANCE VALUES ARE IN uF(p=pF)

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE(V)

3.N.I STANDS FOR NOT MOUNTED PARTS.

SHEET 1

2-4

Page 24

1

2

3

Front section

LVA10619-2

OUT

GND

123

4.9V0V4.9V

470

VCC

C461

10/25

R461

47

REMOCOM

IC461

RPM6938-V4

R462

R463

10k

R419

0

Q411

NI

R411

NI

R421

270

D421

SML-310VT/JK/-X

POWER

C411

NI

R412

R414

R418

NI

R416

R417

NI

D417

NI

C417

C421

NI

NI

R415

470

470

D415

NECBB205/WQR/-X

NI

R413

NI

D413

NI

C415

NI

C413

NI

NI

R405

R404

*

*

D403

UP

C405

NI

D404

**

ANGLE-

R403

R402

R401

*

*

*

D401

**

MENU

ASPECT

C403

NI

C401

NI

D402

MODE

DOWN

R444

10k

S444

NSW0206-001X

POWER

12

S434

NSW0206-001X

12

R407

R406

Q412

NI

R408

*

*

*

D407

D405

**

**

C407

NI

D406

D408

OPEN/CLOSE ANGLE+

2-5

Page 25

12

VCC

3

4.9V

C461

10/25

R461

47

CN471

QGF0534F1-13X

GND

1

S435

NSW0206-001X

R435

470

12

OPEN/CLOSE

R471 0

C471

0.1

R472 0

R473 0

C474

R474 0

NI

C472

0.1

C473

0.1

R475 0

R451

470

4

C452

NI

S451

NSW0220-001X

RESET

2

13

C451

0.01

R452

R441

0

0

2

3

4

5

6

7

8

9

10

11

12

13

REMOCON

5V

GND

RESET

FPKEY0

FPKEY1

OPEN/CLOSE

ILL_B

ILL_GND

ILL10V

LED_CONT

ILL_GND

TO CN351

(SHEET 1)

R443

4.7k

MODE

S443

NSW0206-001X

12

R434

10k

S433

ANGLE+

12

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER.

2.UNLESS OTHERWISE SPECIFIED

3.N.I STANDS FOR NOT MOUNTED PARTS.

NSW0206-001X

CONDITION...DC SUPPLY 14.4V

ALL RESISTORS AER 1/10W 5% METAL GLAZE RESISTOR

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR

ALL RESISTANCE VALUES ARE IN OHM

ALL CAPACITANCE VALUES ARE IN uF(p=pF)

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE(V)

POWER

R444

10k

S434

NSW0206-001X

S442

NSW0206-001X

R433

4.7k

ANGLE-

12

R442

2.2k

ASPECT

12

S432

NSW0206-001X

S441

NSW0206-001X

12

R432

2.2k

UP

12

MENU

C441

NI

S431

NSW0206-001X

DOWN

12

* MARK LIST

D401

D402

D403

D404

D405

D406

D407

D408

C431

NI

R401

R402

R403

R404

R405

R406

R407

R408

D U/UT/UN/A/J/E

SML-310PT/KL/-X SML-310VT/JL/-X

NRSA63J-102X NRSA63J-821X

SHEET 2

2-6

Page 26

Monitor section

LVA10620-1

FROM_PCB_POWER

CN501

QGF0522F1-24W

INV_GND

INV_GND

INV_GND

INV_PWR

INV_PWR

INV_PWR

DIMMER

SENCHK

SYS5V

SYS5V

LCD_GND

LCD_GND

M5V

EEP_CLK

EEP_DAT

EXP_CLK

TO CN392

(SHEET 1)

EXP_DAT

EXP_STRB

CLK_LCD

TX_LCD

VIDEO_GND

C_VIDEO(+)_IN

VIDEO_GND

NTSC/PAL

17V

C905

1/25

IC921

MM1563DF-X

TP921

0V

4321

0V

0V

0V

10k

R622

Q601

IC631

LC74772V-9015-X

0V

VSS

OSCIN

OSCOUT

0V

CTLR1

0V

TESTIN

CS

0V

SCLK

0V

SIN

0V

CKOUT

BLANK(BLK2)

0V

BLK4

0V

CHA4

0V

N.C.

12 11 10 9 8 7 6 5 4 3 2 1

TP902

RL

LTBOX

CPHSEL

QHSEL

UNR9212J-X

47

L601

HSYNC

VSYNC

OUTMCD

B(CHA1)

G(BLK1)

R(CHA2)

CHA3

BLK3

N.C.

L907

47

10/25

C912

L904

47

10/25

C906

33kR521

33kR522

C602

0.1/16

C603

100/10

4.9V

VCD

242322212019181716151413

C633

4.8V

1/6.3

RST

4.5V

4.8V

0V

0V

0V

0V

0V

0V

0V

0V

IC901

MM3203AF-X

R902

R903

R901

33k

100k

910k

4.9V0V1.3V

2.1V

5678

FB2

FB1

VREF

CNTRL

RSX201L-30-X

TP901

D901

0V

L901

C901

47

10/25

TP512

NNZ0009-001X

TP513

GND

TP516

TP515 TP514

TP517

TP519

TP518

10/25

C505

K501

NQR0251-004X

NQR0251-004X

IC691

0.47

C694

R692

0.1/25C506

NQR0251-004X

K508

NQR0251-004X

0.01

C501

0R503

K506

K505

K504

100

100R505

100R504

K502

0R502

4.9V

VCC

IN

MM1510XN-X

456

1.3V0V4.9V

C691

NI

150

TP511TP510 TP509TP508 TP507 TP506 TP505

TP521

NAD0025-223X

TH501

0.01

C502

0.1/16

C504

C503

0.1/16

0

R501

NQR0251-004X

NQR0251-004X

NQR0251-004X

NQR0251-004XK503

TP504 TP503 TP501

TP502

NNZ0009-001X

VIN

R693

NI

R694

0

1.2V

1.2V

123

OUT

SAG

GND

PS

C692

0.01

L691

22

0

R695

C693

47/10

R909 0

R910 0

R911 0

R912 0

R913 0

R914

R915 0

TP520

24

23

22

21

20

19

18

17

K507

16

NQR0251-004X

15

14

13

12

11

10

R506

9

8

7

6

5

NQR0251-004X

4

3

2

1

R691

150

0.1/16

C903

1/25

SW2

10kR511

0

C904

VIN

SW1

GND

4321

0V

4.9V

4.6V

L902

10

C902

10/25

1/6.3

C924

10k

R512

R696

0

R513

100

R514

100

D902

RSX201L-30-X

C921

0.01

BR24L02F-W-X

4.9V

5678

0.2V

0V

5.0V

C631

L631

4.9V0V4.9V

567

CONT

CN

GND

0V

3.3V

IC511

SDA

SCL

WP

VCC

22p

33

TP636

TP637

75k

R904

10k

R905

VIN

SUB

N.C.

VO

1234

0V

1.3V

C923

C922

47/10

0.1/16

GND

A2

A1

A0

0.1/16C511

2.4V

2.4V

27pC632

5.0V

33kR523

L908

47

C913

L905

47

C907

R525

33kR524

R601

100

C601

1/6.3

R602

270

R603

15k

1per

TP635

R640

NI

L909

47

C914

C915

C916

10/25

10/25

10/25

10/25

L906

47

10/25

C908

10/25

C909

10/25

C910

10/25

IC521

CD4094BPW-X

0V

VDD

STROBE

SERIAL_IN

0V

OUTPUT_ENABLE

0V

CLOCK

0V

Q1

0V

Q2

0V

Q3

22kR528

0V

7654321

Q4

0V

8

VSS

Q5

Q6

Q7

Q8

Q'S

QS

22k

22kR526

22kR527

MA111-X

5.0V0V0V

48

DI

CS

4.8V

HSY_IN

123456789101112

0.2V

SYNC_OUT

4.6V

SYNC_IN2

1.6V

SYNC_IN1

3.3V

HFIL_OUT

0V

SYNC_SW

0V

GND1

1.3V

F_ADJ

4.6V

VCC1

4.6V

P_SAVE

0V

SW2

0V

SW1

G_IN1

B_IN1

1314151617181920212223

0.7V

0.7V

R605

R604

470

0

L632

22

C635

C634

0.1/16

100/10

TP631

2SC4097/R/-X

3.3kR631

1kR632

C917

10/25

IC911

NJM78L12UA-X

C911

10/25

C931

10/25

1k

R534

5.0V

5.0V

15 16

R535

NI

5.0V

R531

0

4.9V

R532

1k

5.0V

R533

1k

5.0V

5.0V

5.0V

91011121314

C521

0.1/16

R621

10k

D601

RB521S-30-X

D602

C625

0

R619

0.1/16

4.8V

1.3V0V1.5V

CLK

FRP

BLK_IN

DAC_OUT

NTSC/PAL_OUT

IC601

RB5P0090M

R_IN1

B_IN2

G_IN2

R_IN2

HFIL_IN

0.8V

0.7V

0.7V

0.7V

0.7V

Q631

C636

0.033

C604

10kR633

0.1/16

C606

0.1/16

C605

R624NIR625

2SC4097/R/-X

TP632

0.22C607

R628 NI

0.1/16

470p

C608

NI

R623

3.3kR634

1k

R635

123

17.4V

C933

0.033

TP931

GND

VOUT

VIN

0V

12.0V

10/25

C934

0.1

C932

1/25

TP903

L651

47

C652

0.1/16

C651

10/25

C655

10/25

R651

NI

R653

R652

68k

15k

0.1/16

C656

C654

C653

R654

NI

0.1/16

10/25

L652

47

R626

15k

D603

MA8150/M/-X

47

L603

0

R618

C624

0.1/16

C630

C623

10/25

0.1/16

C626

10/25

1.5V

12.0V

5.9V0V0.5V0.1V

3738394041424344454647

VCC3

GND3

COM_DC

COM_FRP

COM_OUT

VCC2

B_OUT

G_OUT

R_OUT

GND2(RGB_OUT)

GN1

VC0_OUT(PAL)

VC0_IN(PAL)

APC_FIL

VC0_OUT(NTSC)

VC0_IN(NTSC)

TC1

VIDEO_IN

AGC_FIL

CLP

C_IN

ACC_FIL

24

0V

1.1V

2.2V

1.9V

1MR609

C611

0.0068

1M

TP633

2SC4097/R/-X

3.3kR637

0.1/16C613

TP601

Q633

C638

0.033

1kR638

C609

10/10

C612

1/6.3

R608

470R607

R620 390k

150R606

NI

Q632

C637

10kR636

R627NITP602

47

L602

C622

47/10

C621

4.9V

0.1/16

R617

2.3V

100

R616

2.3V

100

R615

2.3V

100

0V

0V

R614

2.6V

680

C618

8p

8.2k

0.01

C617

3.9V

X602

NAX0728-001X

NAX0728-001X

1.9V

2.6V

3.9V

X601

NAX0727-001X

NAX0727-001X

0.9V

25 26 27 28 29 30 31 32 33 34 35 36

C614

0.022

TP634

10kR639

R612

C616

0.47

2.2kR613

C615

5.6k

R611

8p

L633

22

C639

C640

47/10

0.1/16

2SB709A/QR/-X

R655

100

2SC4097/R/-X

Q652

Q651

10k

R656

R657

C725

0.01

39

R659

Q653

10k

2SC4097/R/-X

R663

1

R664

1

Q654

2SB709A/QR/-X

39

R658

SN74AHCT04PW-X

2.9V

0.4V

0.4V

2A

4.5V

2Y

0.1V

3A

4.8V

3Y

0V

7654321

GND

COM

NNZ0009-001X

TP651

C657

NI

R661

0

R662 NI

BOUT

GOUT

ROUT

NNZ0009-001X

IC703

TP708

4.9V

VCC

2.8V

6A1A1Y

C724

560p

0.4V

6Y

0.1V

5A

0V

5Y

3.0V

4A

0.1V

8 9 10 11 12 13 14

4Y

R735

2.7k

2-7

Page 27

T

k

3

F831

P

9

NMFZ018-2R5X-E

NMFZ018-2R5X-E

10/25

C823

0.001

R816

R817

47

R819

NI

45

C766

0.1/16

560pC765

100

R721

VPOS3

1kR701

47R813

47R814

47

4.9V

1.6V

CPH2RLCPH1

VPOS2

0V0V0V

NIR702

C834

C832

10/25

C833

10/25

C819

100p

C821

51kR815

100p

C822

0.047

C825

100p

C824

100p

MA357-X

R768

C768

C767 D762

1000p

NQR0321-001X

252627282930313233343536

CPH3

STV2

INEXT

VPOS1

LTBOX

1kR703

LTBOX

Q841

10/25

C836

10/25

C835

C841

0.047

C842

0.047

L762

NQR0288-004X

3.3k

R769

0.01

10kR771

1M

R773

100R717

12

LC703

3

0V

STH2

24

0V

STH1

23

0.4V

QH

22

0V

OEH

21

0V

STV1

20

0V

OEV1

19

0V

OEV2

18

0V

OEV3

17

0V

CPU

16

0V

15

1.5V

POL

14

3.1V

UD

13

100

R706

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER.

CONDITION...DC SUPPLY 14.4V

2.UNLESS OTHERWISE SPECIFIED

ALL RESISTORS AER 1/10W 5% METAL GLAZE RESISTOR

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR

ALL RESISTANCE VALUES ARE IN OHM

ALL CAPACITANCE VALUES ARE IN uF(p=pF)

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE(V)

3.N.I STANDS FOR NOT MOUNTED PARTS.

7.1V

D1

0V

S1

0V

S1

2.5V

4321

G1

UPA1890GR-9JG-X

Q842

6.7V

D1

0V

S1

0V1.3V

S1

2.6V

4321

G1

UPA1890GR-9JG-X

R772

1.2k

0.01C769

LC701 NQR0321-001X

12

LC702

12

3

NQR0321-001X

3

R715

100

R714

100

R713

100

R712

100

R711

100

R709

100

R708

100

R707

100

C701

TP703

0.1/16

D2

S2

S2

G2

MA8047/M/-X

D2

S2

S2

G2

MA8047/M/-X

RL

7.1V

8765

14.1V

14.1V

12.5V

10/25

5.1k

R841

C843

D841

6.7V

8765

14.1V

14.1V

12.6V

5.1k

R842

D842

R705

33k

Q703

UNR9212J-X

BACK LIGHT

T851

C851

10/25

2

10

3

4

5

NQR0596-001

10/25

C844

0.1C852

NID854

1MR851

C715

18p

C714

18p

C713

18p

C712

18p

C711

18p

C709

NNZ0009-001X

18p

TP706

C708

18p

ROUT

GOUT

BOUT

C707

18p

C706

18p

C703

18p

C702

18p

C704

18p

C705

18p

1

3

BAV99L-X

TP705

D851

-

47

L781

0.1/16C781

RGB

NNZ0009-001X

TP704

NNZ0009-001X

6

2

47/10C782

C854

0.015

R908NIR9070R906

5.1k

R781

4.7k

R782

C853

10p/3k

2

D852

1

3

BAV99L-X

R852

51k

470

R853

D853

NI

0

0

R784

0

R783

L783

C787

10/25

10/25

C795

0.1/16

C783

C794

NI

R704

33k

C791

0.1/16

C793

0.1/16

CN851

QGA3501F1-02X

QGA3501F1-02X

2

1

47

47

L785

47

L782

C785

10/25

47

L784

C784

47/10

C786

47/10

D782

RB521S-30-X

TO_TFT-LCD

D781

CN791

RB521S-30-X

VCOM

30

STH1

29

VB

28

RED

27

GREEN

26

BLUE

25

OEH

24

VDD

23

0.1/16C788

MODE

22

CLK1

21

CLK2

20

CLK3

19

RL

18

STH2

17

VEE

16

GND

C789

0.1/16

15

VCOM

14

STV2

13

OEV3

12

OEV2

11

OEV1

10

CPV

9

UD

8

STV1

7

N.C.

6

VSS

C792

0.1/16

5

GND

4

VDD

3

N.C.

2

VGON

1

QGF0523F3-30W

C831

NQR0450-001X

IC801

NJM78L05UA-X

5.0V

C802

C801

0.1/16

10/25

47

L702

K701

NQR0251-004X

R725

22kR731

5.6k

Q702

2SB709A/QR/-X

Q701

UNR9212J-X

33k

R734

R732

R733

27k

33k

0V0V3.0V

D701

123

MA111-X

NC

SUB

VOUT

0.01

T

T

-001X

708

5

45

0V

TP707

C722

VDD

GND

IC702

BD4827FVE-W

3.1V

C723

0.01

K702

NQR0251-004X

1k

TP741

R741

Q741

2SC4097/R/-X

R744

R750

NI

1k

R742

R745

R743

68k

68k

68k

820p

C742

220p

C741

123

C811

0.01

C812

1.0

R820

NI

C813

VIN

NNZ0009-001X

C744

NI

220p

0.47

C816

0.1

C804

10/25

L761

NQL085J-470X

47

0.1/16

C761

C762

47/10

GND

C719

0.22

2.2V

37

0V

38

C716

47p

2.9V

39

2.9V

40

0V

41

R726

0V

42

NI

R727

3.0V

43

1k

R728

3.0V

44

1k

R729

2.9V

45

1k

0V

46

3.1V

47

C721

0.22

0V

48

L741

47

10k

R747

47/10

C745

0.1/16

C747

Q742

1.5k

R746

2SC4097/R/-X

VOUT

GND

0V

14.1V

C803

0.1/16

TP761

C717

0.1/16

C718

47/10

R752560k

C743

IC811

NIR818

OZ961ISN-X

2.5V

0V

CTIMR

NDRB

20191817161514131211

0.5V

2.5V

OVP

PDRA

2.0V

5.0V

ENA

4.8V

SST

5.0V

C815

100p

0V

GNDA

0.1C814

2.6V

REF

1.4V

RT1

FB

1.8V

CMP

10987654321

C817

0.015

C855

1000p

R764

D761

68k

MA111-X

5.6k

R761

47k

R763

0.1/16

C763

3.3k

R762

470kR722

R724

1.5L701

1.7V

3.1V

2.8V

VDD

VCOI

QVD2MSEL

VCOO

VSS

RESET

HDOT1

WH

HPOS4

HPOS3

HPOS2

HPOS1

NP1

VDD

VSS

SYSCIN

HSYNCIN

CPHSEL

123456789101112

0V

0V

3.3V

CPHSEL

TP701

100

R749

3.3V

3.3V

2.5V

8765

1Y3A2Y

VCC

1A3Y2A

1234

0V0V0V

0.2V

0

R748

C746

PGNDVDDA

LPWM

PDRC

NDRD

R765

10k

1.6V

PD

TFT_CONTROL

IC701

MN5814

QHSEL

0V

QHSEL

R751

3.3V

GND

NI

CT

RT

LCT

DIM

33kR811

120kR812

C764

22k

1.5V

0V

2.0V

2.6V

1.4V

2.7V

2.6V

NJM2107F-X

1/6.3

1.5V

123

+

0V

V-

1.6V

-V+OUT

R767 10k

68k

1k

R723

3.0V0V3.0V

JUST

HDOT2

POSSET

VDBIN

HOUT

VOUT

3.3V

2.8V

3.0V0V3.0V

TP702

100

IC741

SN74LVC3G14U-X

C818

220p

IC761

R766

1M

1.2V0V1.2V0V1.2V

BLACK

SHEET 3

2-8

Page 28

S

N

k

A

Mecha section

TO

ANGLE_MOTOR

TO

SLIDE_MOTOR

CN311

QGA1002C1-02X

0.6V

2

0.6V

1

CN312

QGA1002C1-02X

0.6V

2

0.6V

1

C3107

C3106

0.1

0.1

C3103

0.1

C3104

0.1

C3105

R3107

0.01

11.4V

0.6V

0.6V

MOTOR DRIVER

470

0V

14

VR

NC

1516

VCC2

NC

17

18

OUT1

0V

19

GND

0V

27

GND

0V

20

GND

NC

21

22

OUT2

IC311

BA6247FP-Y

VCC1

IN3

GND

GND

IN2

IN1

MOTOR VOLT

NC

NC

NC

NC

10 11 12 13

11.4V

9

0.2V

8

0V

7

47/16

R3106

R3103

470

0.01

C3102

R3105

470

R3104

470

C3101

0V

26

0.2V

6

0.2V

NC

10k

R3102

R3108

22k

10k

R3101

10k

C3108

R3110

22p

33k

40V5

OUT

GND

VIN-

11.4V

+B

VIN+

1

0V20V30V

1k

R3109

232425

LVB10497-A1

SLIDE PULSE & HSW

15k

R3602

P3601

GP2S60B-X

R3601

180

C3601

0.1

S361

NSW0120-002X

OUT3

NC

TP312

TP313

2345

NC

0.6V

1

TP314

TP322

CLSW

R3

10

NC

NC

NC

CLOSE SW

TO

CN331

5V

PULSE

HPOSI

GND

TO

CN332

ANGLE SENS

VR351

NVQ0008-B14X

LVB10497-A3

C3501

0.1

5V

ANGSENS

GND

2-9

LVB10497-A2

Page 29

OLTAGE

11.4V

5

+B

VIN+

GND

10V2

0V

1k

R3109

IC312

NJM2125F

0.1

C3109

TP311

C3006

0.1

REGULATOR

IC301

BA00CC0WFP

CNTL

VIN

GND

VOUT

1

2

30V4

4.7V

13.9V

11.4V

0.01

C3008

C3007

C3005

10/16

10/16

ADJ

5

1.2V

R3003

1k

C3004

0.01

18kR3001

RB160M-30

R3002

2.2k

D3001

C3001

C3003

0.1

14.1V

0.1

C3002

100p

QGF0503C1-16V

0.2V

0.2V

0.2V

4.8V

4.6V

0.5V

1.2V

0.2V

CN301

TO MAIN

BOARD

16

SW+B

15

SW+B

0V

14

GND

13

GND

12

CNTL0

11

CNTL1

10

CNTL2

0V

9

MVCNT

8

PWR

7

5V

0V

6

GND

5

ANGSENS

0V

4

CLSW

3

ANGSW

0V

2

HSW

1

PULSE

TO CN391

(SHEET 1)

R3204

10k

S3201

NSW0120-002X

ANGLE SW

TP331

ANGSENS

R3202

22k

TP321

ANGSW

P3201

GP2S27T6J00F-X

1.VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER.

CONDITION...DC SUPPLY 14.4V , WITHOUT MONITOR

2.UNLESS OTHERWISE SPECIFIED

ALL RESISTORS AER 1/10W 5% METAL GLAZE RESISTOR

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR

ALL RESISTANCE VALUES ARE IN OHM

ALL CAPACITANCE VALUES ARE IN uF(p=pF)

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE(V)

3.N.I STANDS FOR NOT MOUNTED PARTS.

R3201

180

TP332

HSW

10k

R3302

C3302

0.1

C3303

0.01

C3301

0.1

4.6V

0.5V

QGA1002C1-03X

QGA1002C1-04X

CN331

CN332

4.6V

0.2V

5V

1

ANGSENS

2

0V

GND

3

1

5V

2

PULSE

0V

3

HSW

0V

4

GND

SHEET 4

2-10

Page 30

Printed circuit boards

Main board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Forward side

R384

R383

R382

R157

CN101

R159

C126

Q102

D101

R116

C111

IC102

BZ101

Q101

C117

CN392

R145

R150

TP340

R146

R147

R148

R149

R151

R156

R161

R162

R163

IC101

C395

R143

R108

C103

C102

R142

R101

R139

R102

C107

R137

R105

R169

TP123

R136

TP336

TP129

C108

X101

TP122

TP120

TP121

TP119

X102

R126

TP118

C114

R127

TP117

TP116

IC103

TP115

C119

C127

C128

C121

R115

TP101

C118

TP109

TP108

R122

R117

R123

C113

R124

TP106

TP107

R125

Q301

Q341

Q343

C329

C335

R178

R177

F301

L303

R303

R342

R348

R345

R361

D362

C347

C310

C346

C343

D363

L361

D364

C345

IC303

D302

D341

R362

C362

C363

L301

C307

CN361

D361

C323

D342

Q342

C316

R326

C334

R357

C306

C313

C305

C308

C361

C303

C301

C302

C304

C312

R327

C309

D317

C337

D301

R311

C318

R328

L302

R310

C319

CN301

C317

R312

C311

C321

C320

C324

IC301

C314

D417D415D413

IC461

R461

R462

C461

R463

S451

D408

D407

S434S435

S433

S432

D404D405D406

CN391

C391

F391

R323

R322

C327

R317

Q310 Q307

C328

R321

TP360

Q308

TP358

CN351

R214

R355

R215

C326

TP359

R351

C211

TP351

R234

C218

R238

C231

TP331

R218

IC202

R233

C232

C217

R206

R211

C207

R205

C202

C226

C201

C225

C227

C203

R217

R210

R220

R209

IC201

R237

C208

R232

R244

R208

R243

R231

D202

C221

C206

R207

IC203

R221

TP201

R225

R242

R201

R241

R226

R202

C213

R204

R222

R227

R246

R245

R228

R203

C222

R219

R172

C205

R235

D201

C373 C374

C383

C375

C384

C378C379

K201

CN373

C204

C377

C380

C381

R251 R252 R253 R254

R255

R257

R258

R256

R260

R259

R261

R262

CN371

R264

C258

C259

R265

IC252

C251

C252

C253

C254

C255

C256

R274 R275

C283

D253

IC251

PP3

R266

C260

C280

PP2

C257

R263

PP4

R273

C262

R276

Q255

C266

C265

C269

Q253

R292

D251

R289

C261

R295

IC253

C270

C382

C271

C325

Q254

Q258

C272

C273

Q251

C276

C279

R291

C277

C372

C371

R297

R288

CN372

R298

(System control board)

Q257