Page 1

SERVICE MANUAL

CASSETTE RECEIVER

KS-FX772R

KS-FX772R

Contents

TP/PTY

SEL

DISP

7

CD CHANGER CONTROL

MO

8

10

9

11 12

RPT

Safety precaution

Disassembly method

Adjustment method

Description of major ICs

KS-FX772R

RND

MODE

TAP

E

DAB

FM/AM

¢

SSM

4

CDCH

SCM

Area Suffix

E Continental Europe

1-2

1-3

1-18

1-22

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.49694

Mar. 2002

Page 2

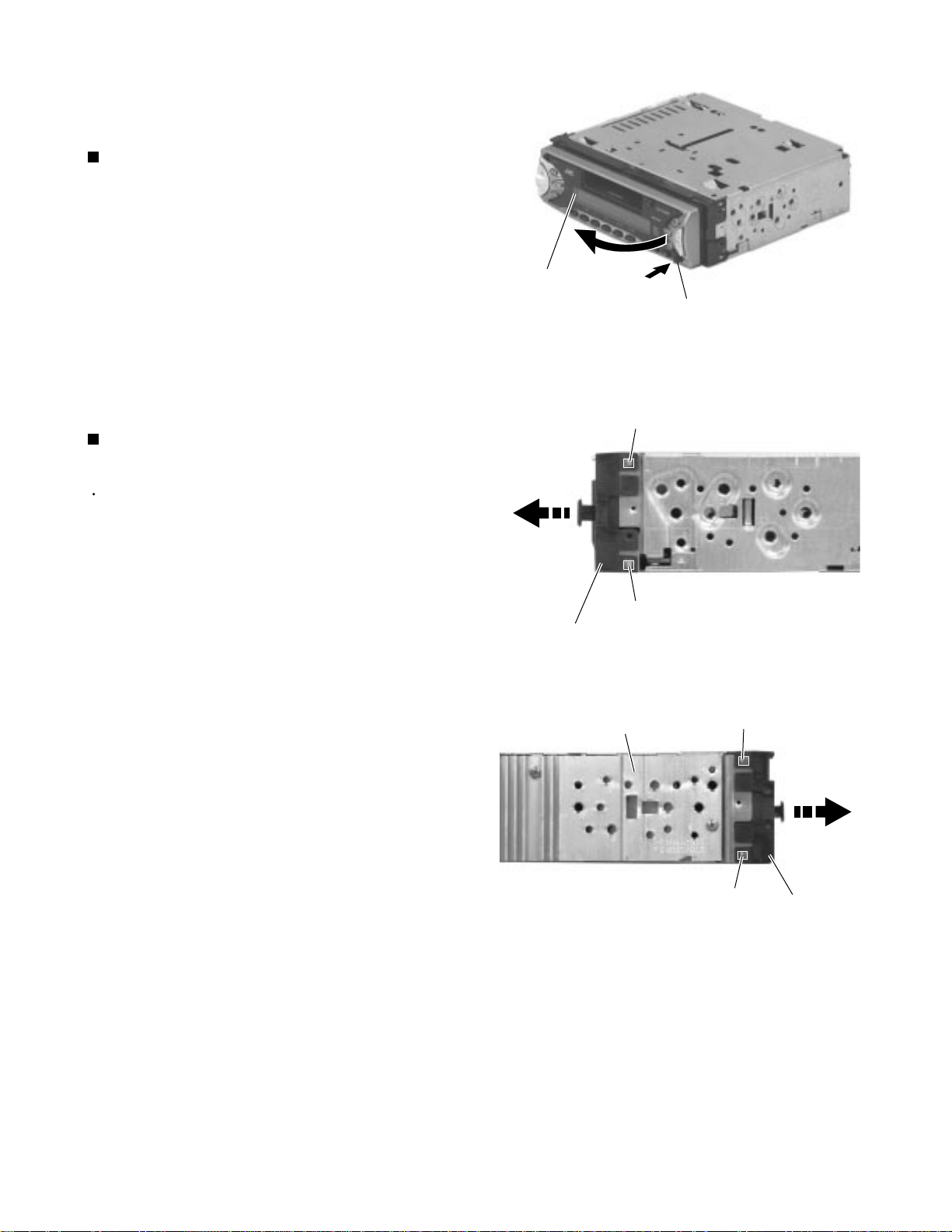

Disassembly method

<Main body>

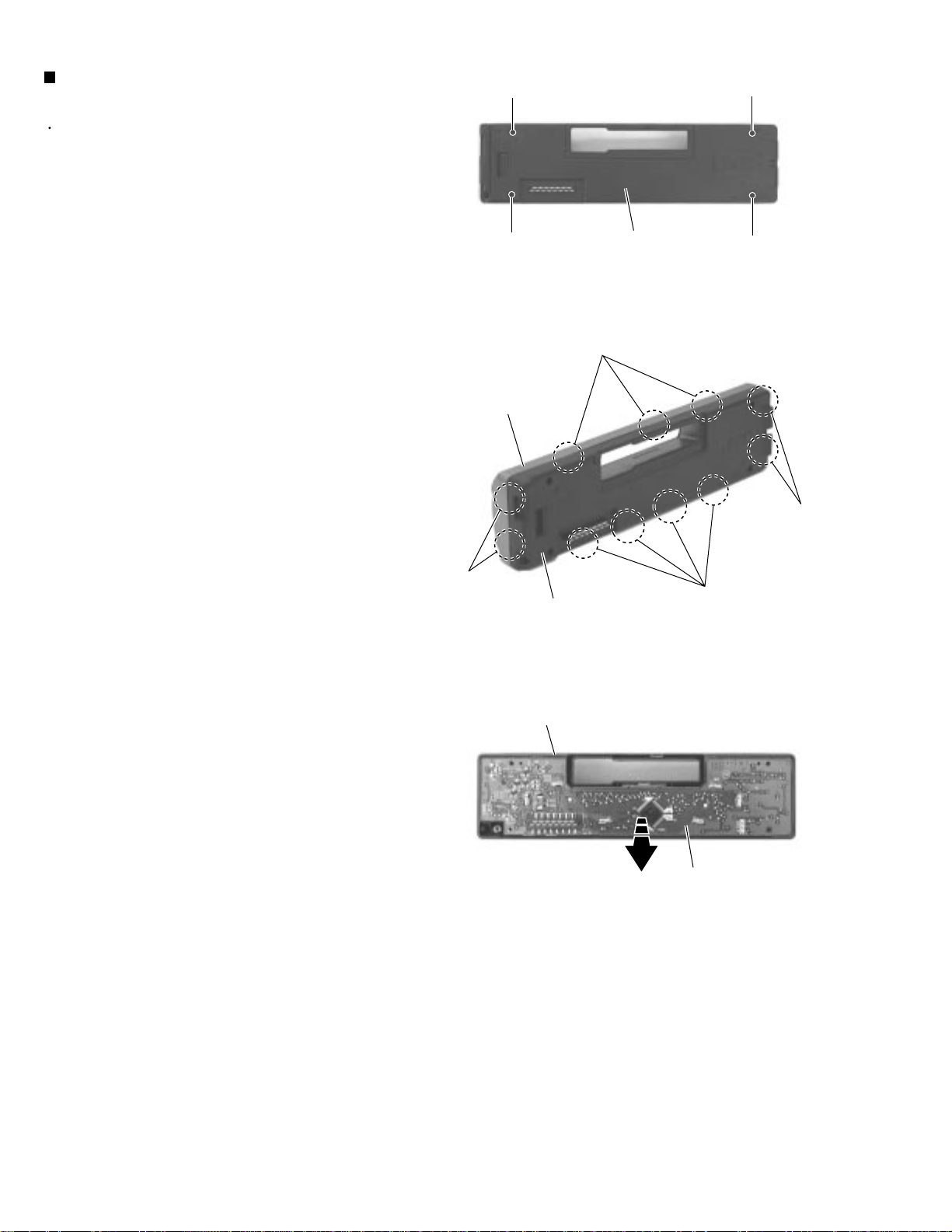

Removing the front panel assembly

(See Fig.1)

1.

Press the eject button in the lower right part of the

front panel. Remove the front panel assembly from

the body.

Removing the front chassis assembly

(See Fig.2 , 3)

KS-FX772R

Front panel assembly

Eject button

Fig.1

Joint a

Prior to performing the following procedure, remove

the front panel assembly.

1.

Release the four joints a on both sides of the front

chassis assembly and remove the front chassis

assembly toward the front.

Joint a

Front chassis assembly

Heat sink

Fig.2

Joint a

Joint a

Front chassis

assembly

Fig.3

1-3

Page 3

KS-FX772R

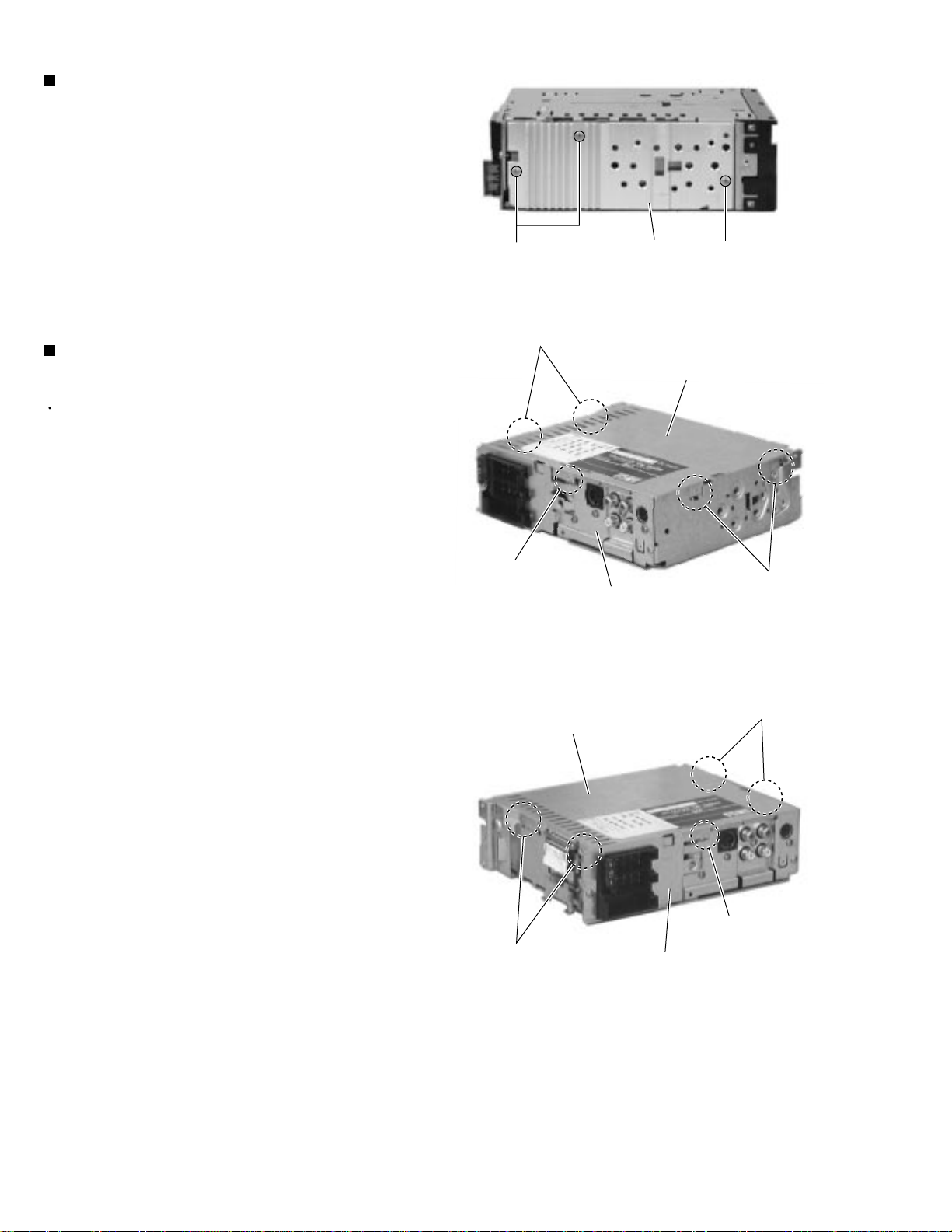

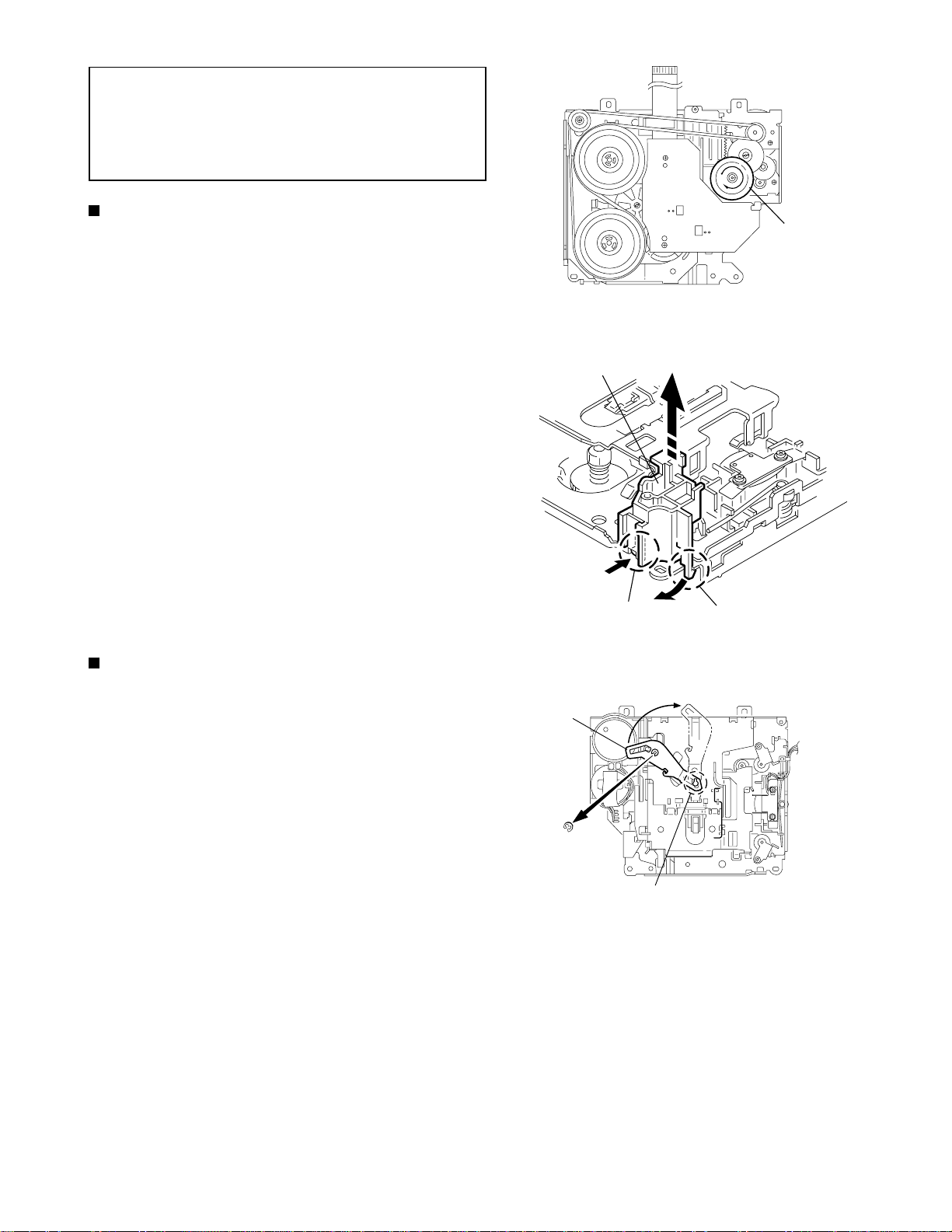

Removing the heat sink (See Fig.4)

1.

Remove the three screws A on the left side of the

body.

Removing the bottom cover

(See Fig.5 , 6)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly

and the heat sink.

1.

Turn over the body and unjoint the five joints b with

the bottom cover and the body using a screwdriver.

A

Joint b

Joint b

Heat sink

Fig.4

Rear panel

Fig.5

A

Bottom cover

Joint b

Joint b

Bottom cover

Joint b

Joint b

Rear panel

Fig.6

1-4

Page 4

KS-FX772R

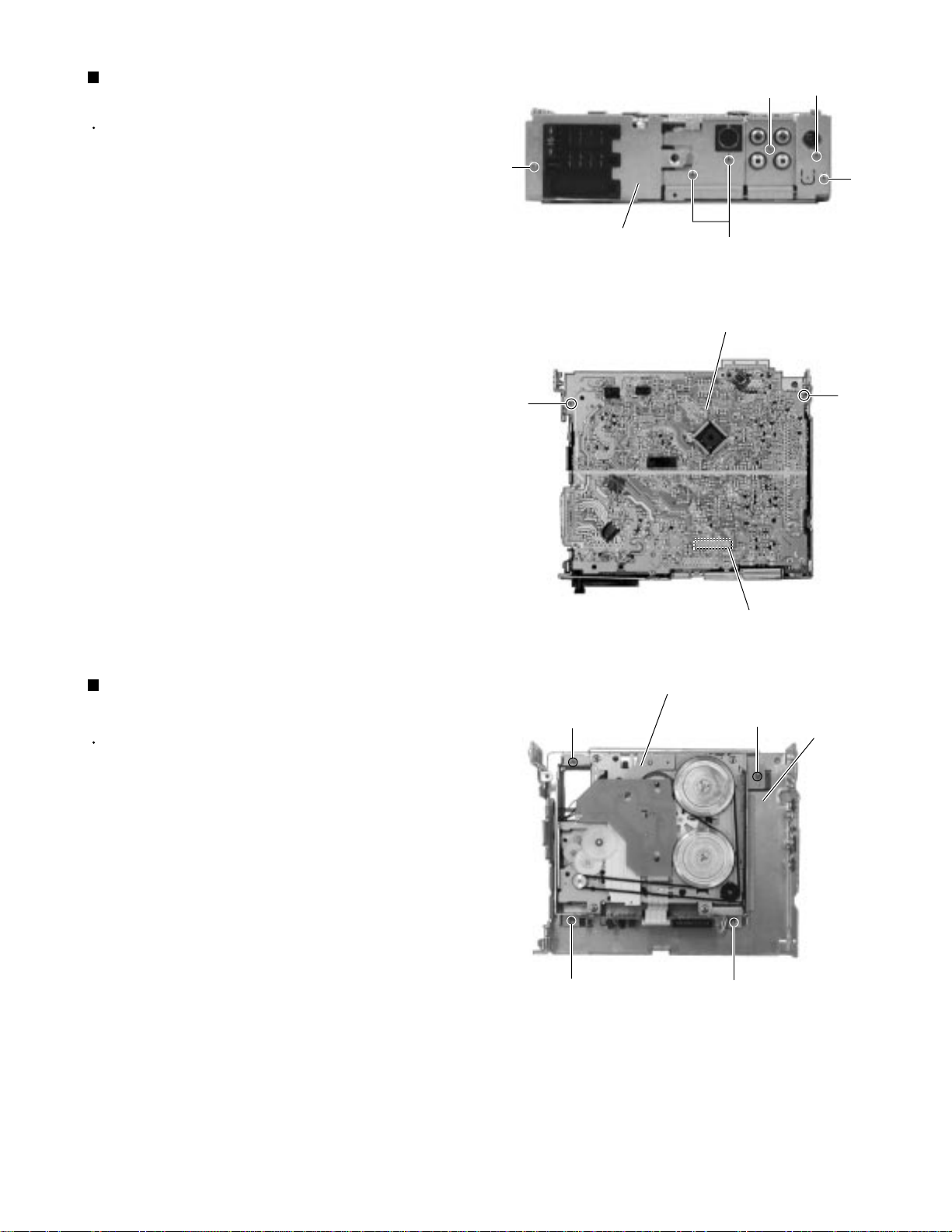

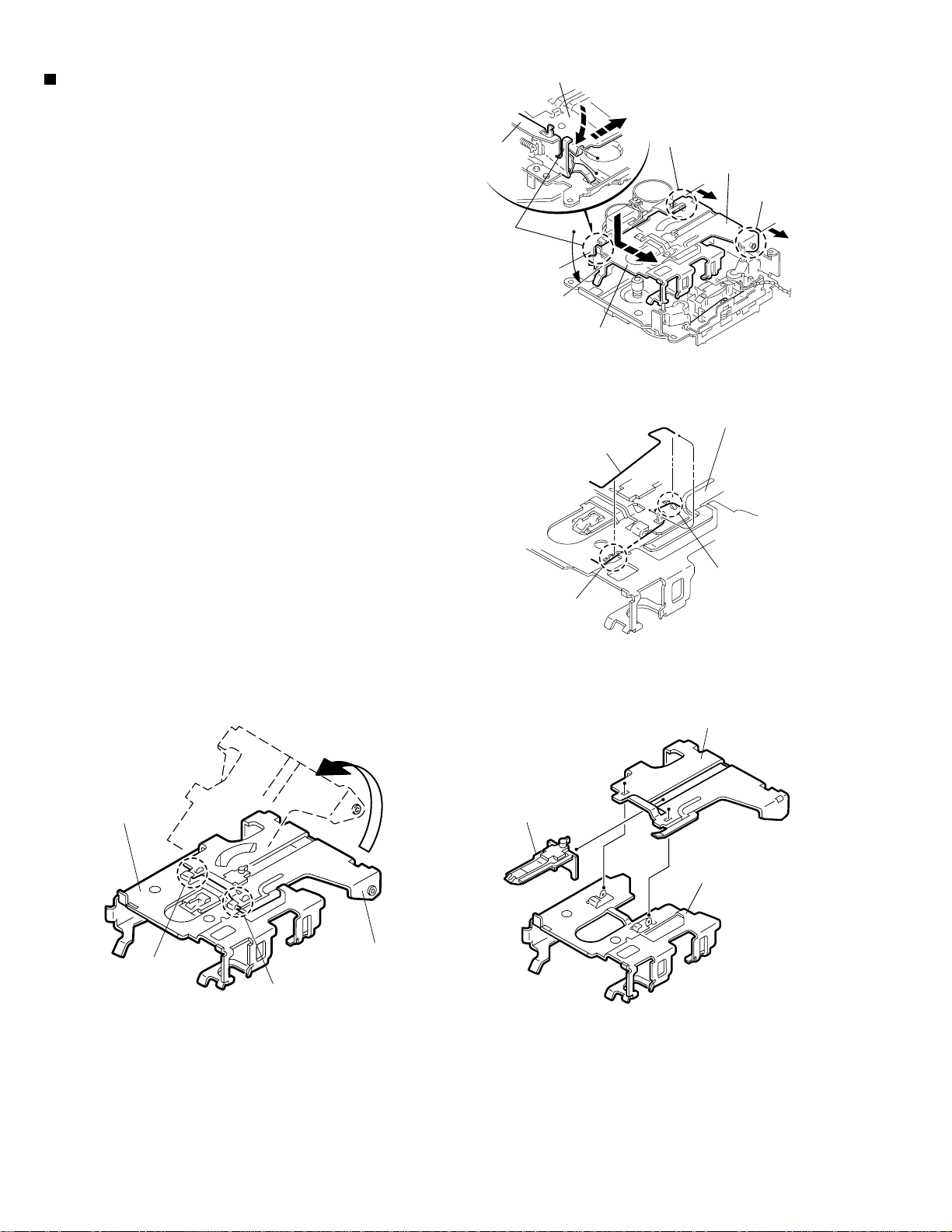

Removing the main board

(See Fig.7 , 8)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink and the bottom cover.

1.

Remove the screw B, the three screws C and the

two screws D attaching the rear bracket on the back

of the body. Remove the rear panel.

2.

Remove the two screws E attaching the main board

on the bottom of the body. Disconnect connector

CN701 on the main board in the direction of the

arrow.

D

E

Rear panel

Fig.7

C

Main board

B

C

D

E

Removing the cassette mechanism section

(See Fig.9)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink, the bottom cover and the main board.

1.

Remove the four screws F attaching the cassette

mechanism section on the back of the top chassis.

Fig.8

Cassette mechanism section

F

F

Fig.9

CN701

F

F

Top chassis

1-5

Page 5

KS-FX772R

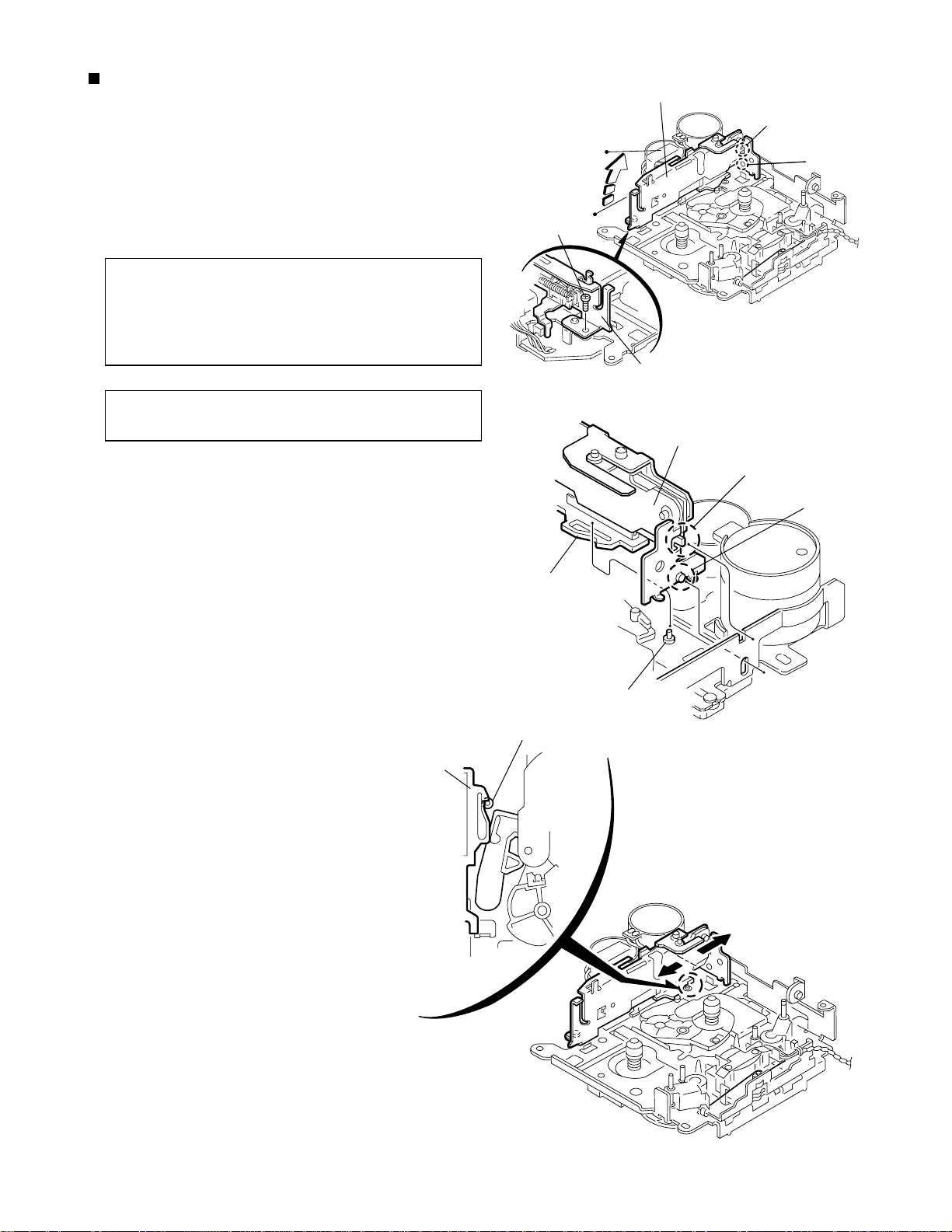

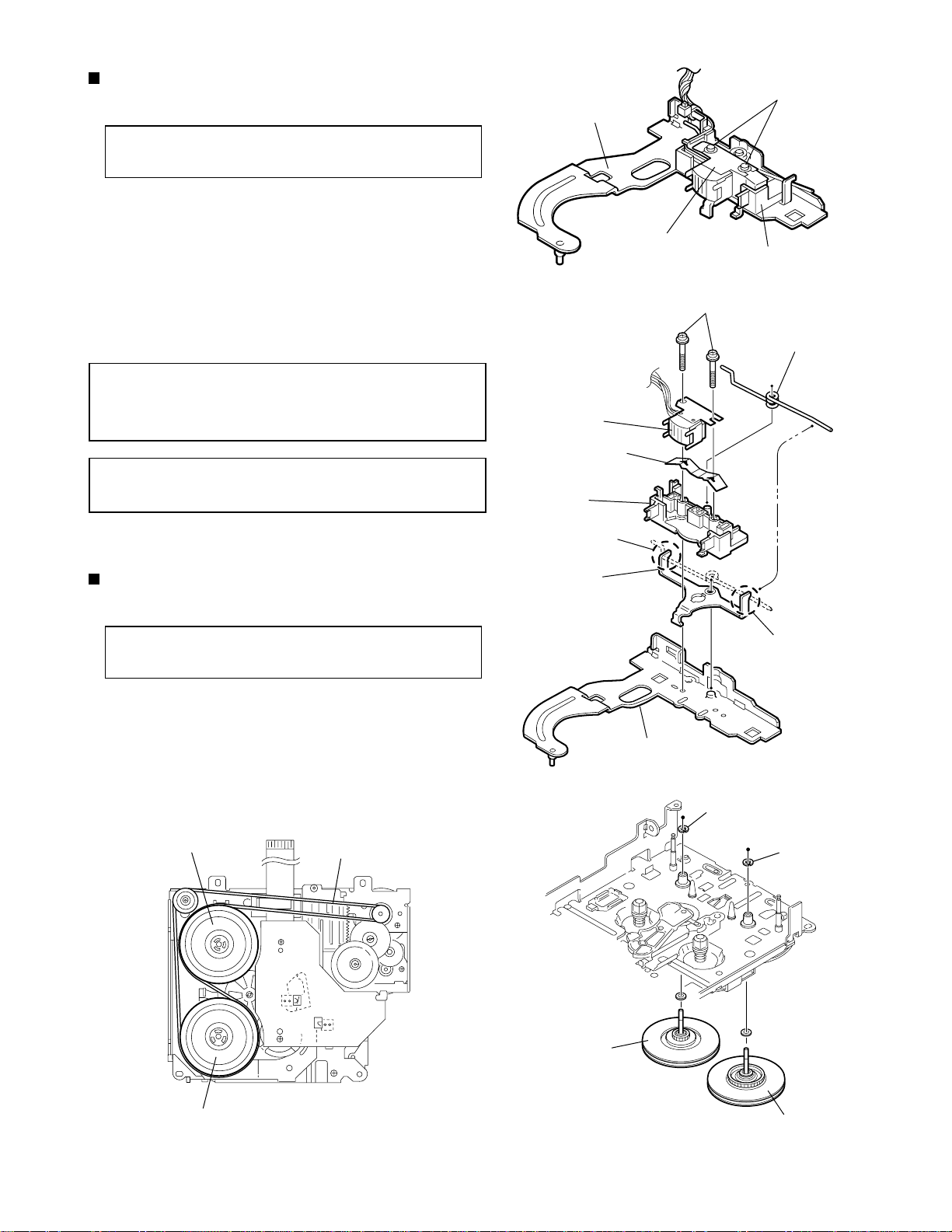

Removing the control switch board

(See Fig.10 ~ 12)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Remove the four screws G attaching the rear cover

on the back of the front panel assembly.

2.

Unjoint the eleven joints c with the front panel and

the rear cover.

3.

Remove the control switch board on the back of the

front panel.

G

G

Front panel

Rear cover

Joint c

G

G

Fig.10

Joint c

Joint c

Rear cover

Front panel

Joint c

Fig.11

Control switch board

Fig.12

1-6

Page 6

KS-FX772R

REFERENCE:

Prior to performing the following

procedures, turn the mode gear on the

bottom of the body until the respective part

comes to the EJECT position (Refer to

Fig.1).

Removing the cassette guide (See Fig.2)

1.

Turn the mode gear to set to RVS play or

subsequent mode.

2.

Remove the cassette guide from the main chassis

while releasing each two joint tabs a in the direction

of the arrow.

Mode gear

Fig.1

Cassette guide

Removing the load arm (See Fig.3)

1.

Remove the E-washer attaching the load arm.

2.

Move the load arm in the direction of the arrow and

release the joint b on the cassette catch.

Load arm

E-washer

Tab a

Joint b

Tab a

Fig.2

Fig.3

1-7

Page 7

KS-FX772R

Removing the cassette hanger assembly /

cassette holder (See Fig.4 to 7)

1.

Check the mode is set to EJECT. Push down the

front part of the cassette holder and move in the

direction of the arrow to release the joint c.

2.

Move the rear part of the cassette hanger assembly

in the direction of the arrow to release it from the two

joint bosses d.

3.

Release the holder stabilizer spring from the hooks e

and f, then pull out from the cassette hanger

assembly.

4.

Bring up the rear side of the cassette hanger

assembly to release the joint g and h.

5.

Pull out the cassette catch from the cassette hanger

assembly.

Cassette holder assembly

Side bracket

Joints c

Cassette holder assembly

Cassette stabilizer spring

Fig.4

Boss d

Cassette hanger assembly

Cassette hanger

assembly

Boss d

Cassette holder

assembly

Hook g

Fig.6

Hook f

Hook e

Fig.5

Cassette hanger assembly

Cassette catch

Cassette holder assembly

Cassette hanger assembly

Hook h

Fig.7

1-8

Page 8

KS-FX772R

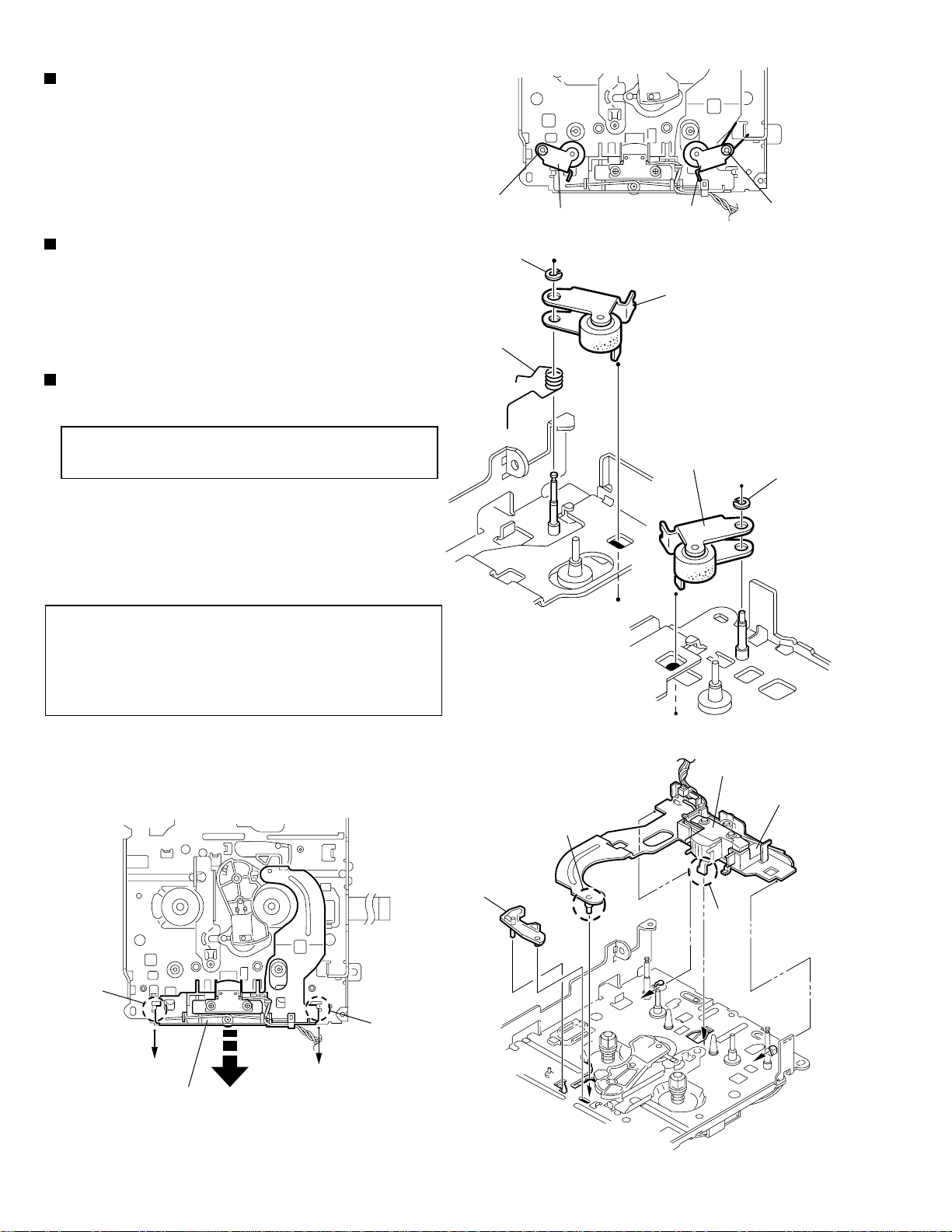

Removing the side bracket assembly

(See Fig.8 to 10)

1.

Remove the screw A attaching the side bracket

assembly.

2.

Detach the front side of the side bracket assembly

upward and pull out forward to release the joint i and

j in the rear.

CAUTION:

CAUTION:

When reassembling, make sure that the

boss k of the main chassis is set in the

notch of the load rack under the side

bracket assembly. Do not reattach the

load rack on the boss k.

After reattaching the side bracket

assembly, confirm operation.

Side bracket assembly

Joint i

Joint j

A

Side bracket assembly

Fig.8

Side bracket assembly

Joint i

Joint j

Load rack

Load rack

Boss k

Boss k

Fig.9

Fig.10

1-9

Page 9

KS-FX772R

Removing the pinch arm (F) assembly

(See Fig.11 and 12)

1.

Remove the polywasher and pull out the pinch arm

(F) assembly.

2.

Remove the compulsion spring.

Removing the pinch arm (R) assembly

(See Fig.11 and 13)

1.

Remove the polywasher and pull out the pinch arm

(R) assembly.

Removing the slide chassis assembly

(See Fig.14 and 15)

Polywasher

Pinch arm

(R) assembly

Polywasher

Compulsion spring

Fig.11

Pinch arm

(F) assembly

Pinch arm (F) assembly

Polywasher

REFERENCE:

It is not necessary to remove the head

and the tape guide.

1.

Move the slide chassis assembly in the direction of

the arrow to release the two joints l and remove from

the main chassis.

2.

Remove the rack link.

CAUTION:

When reassembling, first reattach the rack

link, and next fit the boss m and hook n of

the slide chassis assembly to the hole of

the main chassis, and engage the two joints

l.

Rack link

Fig.12

Boss m

Pinch arm

(R) assembly

Fig.13

Head

Hook n

Polywasher

Tape guide

Joint l

Slide chassis assembly

1-10

Fig.14

Joint l

Fig.15

Page 10

KS-FX772R

Removing the head / tape guide

(See Fig.16 and 17)

REFERENCE:

1.

Remove the band attaching the wire to the head.

2.

Remove the two screws B, the head and the head

support spring.

3.

Remove the pinch arm spring from the tape guide.

4.

Remove the tape guide and the pinch spring arm.

CAUTION:

CAUTION:

It is not necessary to remove the slide

chassis assembly.

When reattaching the pinch arm spring, set

both end of it to the pinch spring arm (

remarked o).

When reattaching the head, set the wires

into the groove of the tape guide (Fig.16).

B

Slide chassis assembly

Head

Tape guide

Fig.16

B

Pinch arm spring

Head

Head support spring

Tape guide

Removing the flywheel assembly (F) & (R)

(See Fig.18 and 19)

REFERENCE:

1.

Remove the belt at the bottom.

2.

Remove the two polywashers on the upper side.

3.

Pull out each flywheel assembly downward.

Flywheel assembly (F)

It is not necessary to remove the slide

chassis assembly.

Belt

o

Pinch spring arm

o

Slid chassis assembly

Fig.17

Polywasher

Polywasher

Flywheel assembly (R)

Fig.18

Flywheel assembly (F)

Fig.19

Flywheel assembly (R)

1-11

Page 11

KS-FX772R

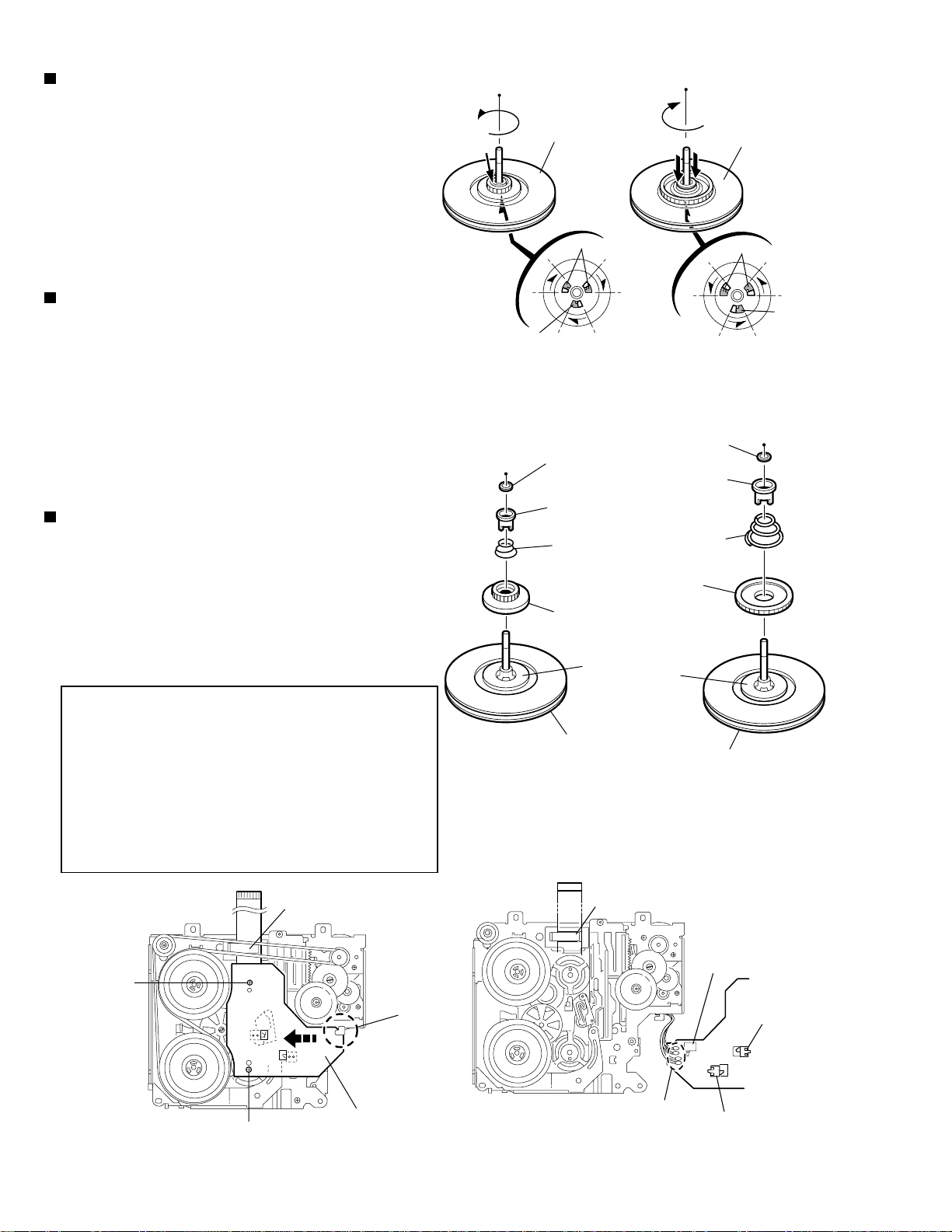

Disassembling the flywheel assembly (F)

(See Fig.20 and 21)

1.

Push and turn counterclockwise the spring holder (F)

to release the three joints p on the bottom of the

flywheel.

2.

The spring holder (F), the TU spring and the friction

gear play come off.

3.

Remove the polywasher and felt.

Flywheel assembly (F)

Joints p

Flywheel assembly (R)

Joints q

Disassembling the flywheel assembly (R)

(See Fig.20 and 22)

1.

Push and turn clockwise the spring holder (R) to

release the three joints q on the bottom of the

flywheel.

2.

The spring holder (R), the FF spring and the friction

gear FF come off.

3.

Remove the polywasher and the felt.

Removing the reel board

(See Fig.23 and 24)

1.

Remove the two screws C attaching the reel board.

2.

Move the reel board in the direction of the arrow to

release the joint r.

3.

Unsolder the wires if necessary.

CAUTION:

When reattaching, confirm operation of

the MODE switch and the ST-BY switch.

The mode position between EJECT and

ST-BY is optimum for reattaching.

Joint p

Fig.20

Polywasher

Polywasher

Spring holder (R)

Spring holder (F)

TU spring

Friction gear FF

Friction gear play

Felt

Flywheel assembly (F)

FF spring

Felt

Flywheel assembly (R)

Fig.21 Fig.22

Joint q

1-12

Connect the card wire extending from

the reel board to the FFC pad before

reattaching the reel board.

FFC pad

C

Reel board

C

Fig.23

Joint r

FFC pad

CT-1 switch

MODE switch

Soldering

ST-BY switch

Fig.24

Page 12

KS-FX772R

Removing the gear base arm / gear base

link assembly (See Fig.25 to 27)

1.

Move the gear base arm in the direction of the arrow.

2.

Insert a slotted screwdriver to the gear base spring

under the gear base arm, and release the gear base

arm upward from the boss on the gear base

assembly.

3.

Remove the gear base arm from the main chassis

while releasing the two joints s.

4.

Move the gear base link assemby in the direction of

the arrow to release the two joints t.

REFERENCE:

When reattaching the gear base arm,

make sure that the boss on the gear

base assembly is inside the gear base

spring.

Removing the FFC pad

(See Fig.27 and 29)

Gear base

link assembly

Gear base spring

Joint t

Gear base arm

Joints s

Hook u

FFC pad

Hook u

Joint t

Fig.25

Gear base arm

Screwdriver

1.

Push each joint hook u of the FFC pad and remove

toward the bottom.

Gear base link assembly

Fig.26

Gear base arm

Fig.27

FFC pad

1-13

Page 13

KS-FX772R

Removing the mode gear

(See Fig.28 and 31)

1.

Remove the polywasher on the bottom and pull out

the mode gear.

Removing the mode switch actuator

(See Fig.28, 29 and 31)

1.

Pull out the mode switch actuator at the bottom.

REFERENCE:

When reattaching the mode switch

actuator to the main chassis, make sure to

set on the shaft and insert v into the slot w.

Removing the direction link / direction

plate (See Fig.29 to 31)

1.

Remove the polywasher attaching the direction link.

2.

Bring up the direction link to release the three joints

x, y and z at a time.

3.

Move the direction plate in the direction of the arrow

to release the two joints a’.

REFERENCE:

When reattaching the direction plate,

engage the two joints a’ and move in the

direction of the arrow (Refer to Fig.30).

Mode switch actuator

Direction plate

Direction link

Fig.28

Direction plate

Joints a'

Joint z

Direction link

Slot w

Joint y

Polywasher

Fig.29

Direction plate Mode rack assembly

Joint b'

Mode gear

Polywasher

Mode rack assembly

Joint x

Joint b'

Joint c'

REFERENCE:

When reattaching the direction link,

move the direction plate in the direction

of the arrow and engage the three joint

x, y and z at a time (Refer to Fig.31).

Removing the mode rack assembly

(See Fig.29 and 30)

1.

Move the mode rack assembly in the direction of the

arrow to release the two joints b’ and the joint c’.

REFERENCE:

When reattaching, set the two b’ on the

bottom of the mode rack assembly into the

slots of the main chassis and move in the

direction of the arrow (See Fig.30).

Joints a'

Fig.30

Direction link

Mode switch actuator

Polywasher

v

Mode gear

Direction plate

Mode rack assembly

Fig.31

1-14

Page 14

KS-FX772R

Removing the gear base assembly / take

up gear / reflector gear (See Fig.32 to 34)

1.

Push in the pin d’ of the gear base assembly on the

upper side of the body and move the reflector gear

toward the bottom, then pull out.

2.

Remove the polywasher on the bottom and pull out

the take up gear.

3.

Move the gear base assembly in the direction of the

arrow to release it from the two slots e’ of the main

chassis.

REFERENCE:

The parts are damaged when removed.

Please replace with new ones.

Gear base assembly

Pin d'

Polywasher

Slot e'

Slot e'

Fig.32

Take up gear

Removing the reel driver / reel spindle

(See Fig.34)

1.

Draw out the reel driver from the shaft on the main

chassis and remove the reel driver spring and the

reel spindle respectively.

CAUTION:

The reel driver is damaged when

removed. Please replace with a new

one.

Reflector gear

Reel driver

Reel driver spring

Reel spindle

Main chassis

Fig.33

Reel driver

Reel driver spring

Reel spindle

Gear base assembly

Slots e’

Take up gear

Reflector gear

Polywasher

Fig.34

1-15

Page 15

KS-FX772R

Removing the side bracket assembly

(See Fig.35 to 39)

1.

Remove the eject cam plate spring.

2.

Push the joint f‘ through the slot to remove the load

rack downward.

3.

Move the eject cam limiter in the direction of the

arrow to release it from the boss g’ of the side

bracket assembly and from the two joints h’.

4.

Move the eject cam plate in the direction of the arrow

to release the joint i’.

Joint f'

CAUTION:

Joint h'

When reassembling, confirm operation of

each part before reattaching the eject cam

plate spring.

Side bracket assembly

Boss g'

Eject cam limiter

Side bracket assembly

Joint h'

Joint f'

Eject cam plate spring

Joint h'

Load rack

Fig.35

Boss g'

Eject cam limiter

Eject cam plate

Fig.37

Joint h'

1-16

Fig.36

Side bracket assembly

Boss g'

Eject cam plate

Fig.38

Load rack

Joint i'

Side bracket assembly

Eject cam plate

Joint i'

Fig.39

Page 16

KS-FX772R

Removing the main motor assembly /

sub motor assembly (See Fig.40 to 42)

1.

Remove the belt at the bottom.

2.

Remove the polywasher and pull out the mode gear.

3.

Pull out the reduction gear (B).

4.

Remove the polywasher and pull out the reduction

gear (A).

5.

Remove the two screws D attaching the main motor

assembly.

6.

Remove the two screws E attaching the sub motor

assembly.

7.

Unsolder the wires on the reel board if necessary.

CAUTION:

When reassembling, adjust the length of the

wires extending from the sub motor

asswmbly by attaching them to the side of

the sub motor assembly with the wires

extending from the main motor assembly

using a spacer.

Belt

Reduction gear (B)

Reduction gear (B)

E

Polywasher

Fig.40

D

E

Mode gear

Polywasher

Reduction gear (A)

D

Main motor

assembly

Reduction

gear (A)

Polywasher

Sub motor

assembly

Spacer

Main motor assembly

Sub motor assembly

Main motor assembly

Sub motor assembly

Fig.41

Spacer

Fig.42

1-17

Page 17

KS-FX772R

Adjustment method

Test Instruments reqired for adjustment

1.Digital osclloscope(100MHz)

2.Frequency Counter meter

3.Electric voltmeter

4.Wow & flutter meter

5.Test Tapes

VT724

VT739

VT712

VT703

6.Torque gauge

Measuring conditions(Amplifier section)

Power supply voltage

Load impedance

Line out level / Impedance

For playback frequency measurement

For wow flutter & tape speed measurement

for DOLBY level measurement

For head azimuth measurement

Cassette type for CTG-N

(mechanism adjustment)

DC14.4V(11V to 16V allowance)

4 (4 to 8 allowance)

Tuner area

Band range

FM : 87.5MHz to 108.0MHz

AM : (MW) 522kHz to 1620 kHz

(LW) 144kHz to 279 kHz

DUMMY LOAD

Exclusive dummy load should be used for AM

and FM dummy load,there is a loss of 6dB

between SSG output and antenna input. The

loss of 6dB need not be considered since

direct reading of figures are applied in this

working standard.

2.0V / 20k

1-18

Page 18

Arrangement of adjusting & test points

Cassette mechanism

(Surface)

Motor assembly

KS-FX772R

Tape speed adjust

Head section view

Azimuth screw A

(Forward)

Playback head

Azimuth screw B

(Reverse)

Azimuth screw B

(Reverse)

Azimuth screw A

(Forward)

Playback Head

1-19

Page 19

KS-FX772R

Arrangment of adjusting

Head amplifier board section (Reverse side)

R411

VR402

FSMW1093A

B409

R426

C423

R425

D401

1

T11

R424

IC402

VR402:Rch

(Dolby NR level

B407

C425

C424

Q401

R410

B406

D402

R401

R416

C419

C422

C413

C414

B408

C421

adj)

C418

R420

Q403

R412

11

R414

R415

R418

B411

B410

21

R413

R417

C417

B404

CJ403

2

C415

1

B413

C416

B403

(Dolby NR F

C412

1

IC401

31

C411

B405

B412

VR401

B402

R423

requency response adj)

B401

R408

C410

C409

R405

R406

C405

C406

R407

C407

C403

C408

R403

R402

C402

2

CJ401

1

C404

R404

C401

1

R422

Q402

VR401:Rch

Information for using a car audio service jig

1. We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

2. As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

3. Extension cord : EXTKSRT002-18P ( 18 pin extension cord ) For connection between mechanism assembly

and main board assembly .

Check for mechanism driving section such as motor ,etc..

Cassette mechanism

Disassembly method

1. Remove the bottom cover.

2. Remove the front panel assembly.

3. Remove the top cover .

4. Install the front panel.

5. Confirm that current is being carried by connecting

an extension cord jig.

Note

Available to connect to the CP701 connector when installing the front panel.

Extension cord

EXTKSRT002-18P

to Cassette mechanism

1-20

EXTKSRT002-18P

Main board

to Main board

Front panel assembly

Page 20

KS-FX772R

Item

Head

1.

azimuth

adjustment

Conditions

Test tape:

SCC-1659

VT703(10kHz)

Adjustment and Confirmation methods

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis. After installing the

cassette housing, perform the azimuth

adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VT724 (1kHz) and play it back in

1.

the reverse play mode.

Set the Rch output level to max.

Load VT703 (10kHz) and play it back in

2.

the forward play mode. Adjust the Rch

and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

S.Values Adjust

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

Tape speed

2.

and wow

flutter

confirmation

Play back

3.

frequency

response

confiramation

When VT721 (315Hz) is played back,

5.

the level difference between channels

should be within 1.5dB.

Test tape: VT712

(3kHz)

Test tape: VT724

(1kHz)

VT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015 3045(FWD

/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VT724, and set the volume

1.

position at 2V.

Play test tape VT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015

3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3db

1kHz / 10kHz

: -1 3db

Built-in volume

resistor

1-21

Page 21

KS-FX772R

Description of major ICs

HA13164A(IC901):Regulator

1.Terminal layout

2.Block diagram

3.Pin function

11

12

10

8

2

1

7

Surge Protector

BIAS TSD

15

3

TAB

note1) TAB (header of IC)

connected to GND

13

9

6

4

5

14

UNIT R:

C:F

1-22

Pin No. Symbol Function

1

2

EXT

ANTOUT

Output voltage is VCC-1 V when M or H level applied to CTRL pin.

Output voltage is VCC-1 V when M or H level to CTRL pin and H level

to ANT-CTRL.

3

4

5

6

7

8

9

10

11

12

13

14

15

ACC-IN

5.6V

SW5V

ACC-HOL

ANTCTP

MEMORY

MEMDET

9V

PWR-CNI

8V

ILL 10V

IILL-ADJ

GND

Connected to ACC.

Regular 5.6V.

Output voltage is 5V when M or H level applied to CTRL pin.

Output for ACC detector.

L:ANT output OFF , H:ANT output ON

Connected to VCC.

Low battery detect.

Output voltage is 9V when M or H level applied to CTRL pin.

L:BIAS OFF, M:BIAS ON, H:CD ON

Output voltage is 8V when H level applied to CTRL pin.

Adjustment pin for ILM output voltage.

Output voltage is 10V when M or H level applied to CTRL pin.

Connected to GND.

Page 22

CXA2559Q(IC401):Playback equalizer amplifier with music sensor

30

29

28

27

26

LPF

5

25

BIAS

MUTE

TAPE EQ

FWD/RVS

6

1.Pin layout

3.Pin function

1

10

30

21

2.Blockdiagram

31

32

33

34

35

36

37

38

39

40

45k

7k/12k

300k

300k

7k/12k

1

30k

30k

100k

+

F2

F1

+

-

2

T2

X1

X1

T1

100k

3

4

Vcc

F3

KS-FX772R

24

23

22

21

24dB

-

+

MS MODE

+

-

+

DET

-

24dB

7

8

9

MS ON/

OFF

10

20

19

18

17

16

15

14

13

12

11

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Symbol

PBTC1

PBOUT1

OUTREF1

TAPEIN1

Vcc

NC

LINEOUT1

TCH1

NC

MSLPF

G2FB

G1FB

MSTC

MSOUT

NC

NRSW

MUTE

METAL

DIRECTION

FF/REW

MSSW

NC

TCH2

OUT2

DIREF

GND

TAPEIN2

OUTREF2

PBOUT2

PBTC2

PBFB2

PBRIN2

PBGND

PBFIN2

VCT

PBREF

PBFIN1

PBGND

PBRIN1

PBFB1

I/O

Function

-

Terminal of capacity of reproduction equalizer reproduction

O

Equalizer output terminal

O

Output standard terminal

I

Tape input terminal

-

Power supply terminal

-

Non connection

O

Line-out output terminal

-

Time constant for the HLS

-

Non connected

-

Detection LPF terminal between tunes

-

Detection level set terminal between tunes

-

Detection level set terminal between tunes

-

Time constant connection terminal for the detection between tunes

O

Detection output terminal between tunes

-

Non connected

I

Dolby NR control

I

Mute function control terminal

I

Reproduction equalizer control terminal

I

Head change control terminal

I

Detection mode control terminal between tunes

I

Detection function control terminal between tunes

-

Non connected

-

Time constant for the HLS

O

Line-out output terminal

-

Resistance connection terminal for standard current setting

-

Earth terminal

I

Tape input terminal

O

Output standard terminal

O

Reproduction equalizer output terminal

-

Terminal of capacity of reproduction equalizer

I

Reproduction equalizer return terminal

I

Reproduction equalizer input terminal

-

Reproduction equalizer system earth terminal

I

Reproduction equalizer input terminal

O

Middle point terminal

O

Reproduction equalizer standard terminal

I

Reproduction equalizer input terminal

-

Reproduction equalizer system earth terminal

I

Reproduction equalizer input terminal

I

Reproduction equalizer return terminal

1-23

Page 23

KS-FX772R

UPD178018AGC625(IC701) : Main system control CPU

1. Pin layout

2. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

80 ~ 61

1

~

20

21 ~ 40

60

~

41

Port Name I/O Descriptions

KEY 0

KEY 1

KEY 2

LEVEL

SM

SQ

LCDCE

LCDDA

LCDSCK

BUSI/O

OPEN

BUSSI

BUSSO

BUSSCK

NC

NC

NC

NC

INLOCK

NC

GNDPORT

VDDPORT

NC

AFCK

MONO

FM/AM

SEEK/STOP

NC

IFC

VDDPLL

FMOSC

NC

GNDPLL

AMEO

FMEO

IC

SD/ST

STAGE0

NC

MOTOR

I

I

I

I

I

I

O

O

O

I

I

I

O

I/O

-

-

-

-

-

-

-

O

O

O

O

O

I

I

-

I

-

O

O

-

I

I

O

Key input 0

Key input 1

Key input 2

Level meter input

S.meter level input

S.Quality level input

CE output to LCD driver

Data output to LCD driver

Clock output to LCD driver

I/O selector output for J-BUS, H : OUT, L: INPUT

Door open detect input

J-BUS Data input

J-BUS Data output

J-BUS Clock in/output

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Port GND

Port Vdd

Non connect

AF check output, L: AF check

Monaural on /off selecting output, H:mono on

FM/AM switching output L : FM H : AM

Auto seek /stop selecting output, H: Seek, L:Stop

Pulse signal input port for Cruise control

FM/AM midle frequency counter input

PLL Vdd

FM/AM limited generator frequency input

None connect

PLL GND

AM error out output

FM error out output

GND

Station detector, Stereo signal input, H:Find Station, L:Stereo

Pull up

Non connect

Main motor output

1-24

Page 24

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Port Name I/O Descriptions

FF/REW

F/R

DOLBY

MSIN

I2CSCK

I2CDAO

I2CDAI

REEL

SUBMO1

SUBMO2

MODE

TAPEIN

STANDBY

NC

NC

NC

NC

NC

NC

MUTE

PCNT

TELMUTE

NC

NC

LEDB

LEDR

ACCDET

POWER

RDSSCK

RDSDA

REMOCON

DETACH

J-BUSINT

REGCPU

GND

X2

X1

REGOSC

VDD

RESET

I

O

O

I

O

O

I

O

I

O

O

O

I

-

-

-

-

-

O

O

I

O

O

O

I

O

I

I

I

I

I

-

-

-

I

-

-

-

Output for input signal lev el s witching f or MS L : FF,REW H : PLAY

FWD,REV running direction s witch signal input

Dolby on "H" output

MS input

I2C information clock output

I2C information data output

I2C information clock input

Switch for detecting tape end position

Sub motor clock direction input

Sub motor clock opposite detection drive output

Mechanism mode position detection input

Cassette in detection input H : cassette in L : cassette out

Standby position detection input H : eject side L : operation side

Non connect

Non connect

Non connect

Non connect

Non connect

Non connect

Mute output , L : mute on

Power ON /OFF switching output , H : power on

Telephone mute signal detection input

Non connect

Non connect

LED color control

LED color control

Power sa v e 1 Working togethe ACC Power save : L

Power sa v e 2, Working together Back up by H input, stop mode

Clock input for RDS

RDS data input

Remocom input

Detach signal input H : Power save

Cut-in input for J-BUS signal

Regulator for CPU power supply, Connect the GND with0.1 F.

Ground

Connecting the crystal oscillator for system clock

Connecting the crystal oscillator for system clock

Regulator for oscillator circuit.Connect the GND with 0.1 F.

Vdd

Pull up

KS-FX772R

UPD178018AGC625(2/2)

1-25

Page 25

KS-FX772R

LA4743K(IC301):Power AMP

1.Block diagram

IN 1

TAB

IN 2

+

0.22 F

+

0.22 F

11

1

12

Vcc 1/2 Vcc 3/4

6 20

-

+

Protective

circuit

-

+

2200 F 0.022 F

+

9

-

7

+

OUT 1+

OUT 1-

PWR GND1

8

+

OUT 2+

5

-

OUT 2-

3

PWR GND2

2

ST BY

R.F

47 F

IN 3

PRE GND

IN 4

+5V

ST ON

+

0.22 F

N.C

+

0.22 F

4

Stand by

Switch

Mute

3.3 F

OUT 3+

OUT 3-

10K

+

Low Level

Mute ON

10

+

Ripple

Filter

Mute

22

circuit

+

15

-

+

-

17

19

25

18

21

23

PWR GND3

OUT 4+

OUT 4-

13

14

Protective

circuit

-

+

+

-

1-26

ON TIME C

22 F

Muting &

16

+

ON Time Control

Circuit

PWR GND4

24

Page 26

2.Terminal layout

KS-FX772R

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

GND

GND

RROUTSTANDBY

RROUT+

VCC

FROUTGND

FROUT+

RIPPLE

FRIN

RRIN

SGND

RLIN

FLIN

ONTIME

FLOUT+

GND

FLOUTVCC

RLOUT+

MUTE

RLOUTGND

NC

Header of IC

Power GND

Outpur(-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

Rear Lch input

Front Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front Lch

Muting control input

Output (-) for front Lch

Power GND

No connection

LA4743K

1-27

Page 27

KS-FX772R

LC75823W (IC651) : LCD driver

1. Pin Layout & Symbol

S50

S51

COM1

COM2

COM3

INH

OSC

CE

CLOCK

DATA

S49

S52

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

S6

S7

S5

S3

S4

S11

S12

S13

S10

S9

S8

2. Pin Function

Pin No. Symbol I/O Function

1 to 2

3 to 52

NC

S1 to S52

--

Non connected

O

Segment output pins used to display data transferred

by serial data input.

53 to 55

COM1 to COM3

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

56

VDD

--

Power supply connection. Provide a voltage of between

4.5 and 6.0V.

57

INH

I

Display turning off input pin.

INT="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

58~60

61

NC

OSC

--

Non connected

I/O

Oscillator connection.

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

62

CE

Serial data CE : Chip enable

interface connection

63

CLOCK

I

to the controller. CLOCK : Sync clock

S14

S15

S16

1-28

64

DATA

DATA : Transfer data

Page 28

SAA6579T-X(IC71):RDS

1.Pin layout

1

DATA

2

Vref

3

MUX

4

dd

V

5

GND

6

CIN

7

SCOUT

8

2.Block diagram

KS-FX772R

CLK

16

15

OSCO

14

OSCI

13

Vdd

12

GND

11

TEST

10

MODE

9

121413

3.Pin function

4

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLT AGE

Pin No.

1

2

3

4

ANTIALIASING

FILTER

6 11

Symbol

VP1

57 kHz

BANDPASS

(8th ORDER)

COSTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGERATION

AND SYNC

RECONSTRUCTION

FILTER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

Description

OSCILATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

910

Non connected

DATA

Vref

MUX

RDS data output

Reference voltage output (0.5VDDA)

Multiolex signal input

QUALITY BIT

GENERATOR

DIFFERENTIAL

DECODER

1

2

15

15

10

11

12

13

14

15

16

5

6

7

8

9

Vdd

GND

CIN

SCOUT

MODE

TEST

GND

Vdd

OSCI

OSCO

+5V supply voltage for analog part

Ground for analog part (0V)

Subcarrier input to comparator

Subcarrier output of reconstruction filter

Oscllator mode / test control input

Test enable input

Ground for digital part (0V)

+5V supply voltage for digital part

Oscillator input

Oscillator output

Non connected

CLK

RDS clock output

1-29

Page 29

KS-FX772R

TEA6320T-X (IC161) : E.volume

1.Pin layout

2.Block diagram

10 8 9 7 6

5

12

SDA

1

GND

2

OUTRL

OUTFL

MUTE

TL

B2L

B1L

IVL

ILL

QSL

IDL

ICL

IMD

IBL

IAL

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3.Pin functions

Pin

Symbol

No.

SDA

1

SCL

32

VCC

31

OUTRR

30

OUTFR

29

TR

28

B2R

27

B1R

26

IVR

25

ILR

24

QSR

23

IDR

22

Vref

21

ICR

CD-CH

TAPE

TUNER

20

19

18

17

CAP

IBR

IAR

I/O

Serial data input/output.

I/O

MUTE

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

17

Symbol

IAR

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

I

Input A right source.

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

GND

OUTRL

OUTFL

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

IBL

IAL

Ground.

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

-

output to an external equalizer.

Bass control capacitor left channel.

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

Not used

Input C left source.

I

Not used

Input B left source.

I

Input A left source.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTFR

OUTRR

Vcc

SCL

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

I

Serial clock input.

1-30

Page 30

HD74HC126FP-X (IC801) : Buffer

KS-FX772R

1.Terminal layout

1C

1

1A

2

1Y

3

2C

4

2A

5

2Y

6

GND

7

2.Block diagram

Input

VU

14

4C

13

4A

12

4Y

11

3C

10

3A

9

3Y

8

Vcc Vcc

1A

2A

3A

4A

1C

2C

3C

See Function Table

4C

3.Pin function

Output

1Y

2Y

Output

2Y

Output

3Y

Output

4Y

Input

C

L

H

H

A

X

L

H

Output

Y

Z

H

L

Note) H:High level

L:Low level

X:Irrelevant

Z:Off(High-impedance)

State a 3-state input

1k

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

LB1641 (IC402) : DC motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

VCC1

VCC2 P2

Note) CL includes probe and jig capacitance

2. Pin function

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

10

OUT2

1 0 1 0

0 1 0 1

1 1 0 0

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-31

Page 31

1

2

3

4

5

KS-FX772R

Block diagram

SUB

MOTOR

ABC

TO CD CHANGER

J801 CP901

SCK

SI/SO

IC801

CHANGER CONTROL

JBUS SI

JBUS SO

JBUS I/O

J1

AM

FM

AM/FM TUNER P ACK

Tuner.Power AMP.Changer/System Controller

JBUS SCK

TU1

CD RCH

CD LCH

SEEK/STOP

SD/ST

SMETER

TO SPEAKER

CONNECTOR TO REAR LINE OUT

L/R F

L/R R

IC301

POWER AMP

.

OUT LR

OUT RR

OUT LF

OUT RF

IC161

E.VOLUME

TUNER L/R

TAPE L/R

IC701

SYSTEM CONTROL MICON

LRO

RRO

SWITCH

TAPE END.STANDBY

J321

F/R

MODE

STANDBY

FF/REW

MOTOR

SUB02,01

TAPE IN

DOLBY

MS

REEL

KEY 0 – 2

CP401

CJ601

CJ403

CJ401

CP701

MAIN

MOTOR

MOTOR

TAPE IN

MODE

STANDBY

PHOTO

REEL

DOLBY

F/R

MS OUT

LCH

RCH

FF/REW

CE

CLOCK

DATA

HEAD

CJ402

LCH

RCH

IC401

PB EQ

IC402

DC MOTOR DRIVER

SUBMO+

SUBMO-

MECHANISM CONTROL

LCD1

QLD0158-001

S3 – S52

COM0 – COM3

IC651

LCD DRIVER

KEY

– S620

S601

LCD DRIVER/KEY SWITCH CIRCUT

2-1

Page 32

Standard schematic diagrams

Receiver & System control section

TU1

QAU0259-001

5

J1

QNB0100-002

L1

4.7u

D5

D6

1SS133-T2

1SS133-T2

C43

C33

150P

1k

R34

R44

R33

1k

R32

3.9k

C31

0.012

2SC3661-X

R748

2SC3661-X

Q31

68k

Q32

Q701

2SC2412K/R/-X

4

R43

10k

C32

R42

1k

0.058

C41

0.001

2SC2412K/R/-X

Q42

1k

Q41

R31

2SC2412K/R/-X

SW5V

10V

STANDBY

TAPEIN

MODE

SUB02

SUB01

3

REEL

MS

DOLBY

FR

FFREW

D705

UDZS5.6-X

D706

UDZS5.6-X

R706

R701

R702

R703

D707

UDZS5.6-X

R704

R705

D708

UDZS5.6-X

MOTOR

270

270

270

R751

R752

D709

UDZS5.6-X

10k

DETACH

KEY0

KEY1

KEY2

LCDCE

LCDCK

LCDDA

150k

LEDB

150k

LEDR

10k

10k

C717

0.047

CP401

QGB1214J1-18S

2

CJ601

VMC0334-001

D701

UDZS5.6-X

D702

UDZS5.6-X

D703

UDZS5.6-X

D704

UDZS5.6-X

1

J801

QNZ0095-001

0.47/50

1k

C42

2.2/50

FMEO

9V

CH.R

CH.L

C803

C802

120p

2SA1037AK/RS/-X

R2

1.5k

Q1

R41

DTC114EKA-X

C1

100/16

D1

MTZJ9.1C-T2

R1

33

10V

AMEO

FM/AM

C77

47/16

C76

0.01

C75

47p

R73

X71

2.2k

QAX0263-001Z

C74

82p

R59

470

47u

C55

0.47/50

L2

R750

47K

R807

100k

R808

100k

R809

100

330k

R810

47p

4.7k 47k

R72

2.2k

R58

2SC2412K/R/-X

C2

SAA6579T-X

RDSCK

15k

Q52 C54

R806

IC801

HD74HC126FP-X

KS-FX772R

LA4743K

J321

QNN0175-001

C321

150p

2.2/50

390p

C303

390p

C313

Q781

DTA114EKA-X

220/10

C982

10/16

390p

C304

390p

C314

Q782

DTA114EKA-X

C782

CRS03-W

D982

C322

150p

100

100

1k

R341

R321

Q321

CRS03-W

D981

Q341

2SD1048/6-7/-X

10k

R902

C981

4.7/25

C301

R305

0.1

R301

27k

RR

C5

1/50

1/50

SEEK/STOP

LEDB

KEY0

KEY1

KEY2

LCDCE

LCDDA

LCDCK

C6

0.1/50

Q8

47p

0.015

0.015

C8

2SC2412K/R/-X

C81

C82

Q4

DTA114EKA-X

D4

1SS355-X

Q5

DTA114EKA-X

9V

AFCK

FMOSC

SM

RDSCK

RDSDA

C708

C707

27P

C706

27P

C705

C704

R12

0

Q9

R11

22k

Q3

C73

2.2k

R53

Q51

2SC2412K/R/-X

47k

R54

0.047

R5

1SS355-X

1SS355-X

0.022

C71

100k

R805

JBUSSCK

47k

DTC114EKA-X

JBUSSI

JBUSSO

JBUSIO

22k

R804R802

330k

DTC114EKA-X

47k

SK/ST

SM

SD/ST

MONO

C78

0.01

RDSDA

TAPE.L

TAPE.R

C52

0.01

R60

47k

330P

C51

Q53

DETACH

100k

R801

C9

220/10

0.047

2SA1037AK/RS/-X

C3

47p

Q2

R3

IC71

R57

D3

D2

D7

1SS355-X

R4

3.3k

C72

560P

2.2/50

R71

R55

10k

0.1

C53

10k

0.0047

R56

2.2k

10k

R803

100

C801

R81

10k

10k

R82

C7

Q7

4.7k

R8

4.7k

R9

Q10

0.1

DTA114EKA-X

C4

C164

R162

1/50

0

TAPE.L

0

R164

0

R163

R161

C163

0

TAPE.R

TU.R

CH.R

C709

0.1

R731

10k

0.1

X701

0.1

100/6.3

ACCDET

47k

R732

QAX0406-002Z

C718

1/50

C162

1/50

2.2/50

C161

MS

MODE

SUB01

SUB02

MOTOR

47k

47k

47k

47k

47k

R735

R737

R734

R736

R733

R709

0

R730

330p

4.7k

R728

4.7k

R727

4.7k

R726

2SC2412K/R/-X

4.7k

R10

STANDBY

47k

R738

390

POWER

15k

Q6

R83

2SC2412K/R/-X

PCNT

TELMUTE

R729

47k

R718

R719

R720

R721

R722

R723

R725

R724

TU.R

TU.L

15k

1200p

1200p

C83

C84

R84

R168

TU.L

C165

1/50

C167

47/16

10k

10k

10k

10k

10k

4.7k

4.7k

4.7k

2.2k

CH.L

22k

R167

2.2/50

C166

C168

MUTE

TEA6320T-X

100/16

47k

R747

C172

0.0082

IC161

C169

0.0082

R165

47k

R746

IC701

22k

47k

R740

TAPEIN

UPD178018AGC625

4.7k

R717

JBUSIO

FFREW

C173

0.15

C178

0.0056

C176

0.033

C174

0.22

C171

0.22

C175

0.033

C170

0.15

R166

2.2k

47k

R741

4.7k

R716

JBUSSI

C177

0.0056

R169

330k

1SS355-X

330k

R170

R742

STAGE0JBUSSO

REEL

4.7k

4.7k

R715

R714

JBUSSCK

1SS355-X

56k

R743

FR

SCL

SDA

DOLBY

C181

C183

270

R173

R172

C184

C182

10

C179

D161

D162

47k

R171

0.082

C180

100/16

47k

R745

9V

4.7k

4.7k

R712

47k

C701

0.001

R713

SEEK/STOP

10k

RL

R342

R351

R331

R352

100

100

1k

FR

FL

R891

Q902

2SA1855/RST/-T

R892

47k

D891

1SS355-X

C891

D353

1SS355-X

R353

2.2k

1SS355-X

R333

2.2k

D333

2SD1048/6-7/-X

R782

47k

D902

1SS355-X

47k

R907

1k

R906

R905

10k

Q901

DTC114EKA-X

C909

2200/6.3

1k

1SS355-X

D892

0.1

FL

2.2/50

RL

2.2/50

SDA

PCNT

9V

SCL

270

RR

2.2/50

FR

2.2/50

MUTE

LMETER

Q976

UN2211-X

POWER

R976

ACCDET

9V

10V

PCNT

R707

SW5V

R708

STAGE0

SD/ST

47k

R711

FMEO

AMEOLEDR

C702

FMOSC

0.1

TELMUTE

FM/AM

MONO

AFCK

SK/ST

0.1

C244

1SS355-X

51k

R247

0.001

C713

LMETER

C243

D242

0.1

D241

1SS355-X

47/10

100k

Q241

2SC2412K/R/-X

C242

L903

330P

C714

R243

12k

15k

R246

Q977

2SA1037AK/RS/-X

47u

L902

C703

220/10

R307R6R308

47k1247k

27k

R977

R978

47u

R306

R309

47k

47k

12k

Q891

UN2211-X

1k

1k

R322

R332

Q351

2SD1048/6-7/-X

Q331

R781

4.7k

Q784

DTC114EKA-X

D782

1SS355-X

D783

1SS355-X

0.1/50

18k

4.7k

1/50

220/10

C907

C905

R904

C908

R903

C308

C309

R302

2.2/50

27k

C318

2.2/50

27k

R311

R312

27k

2.2/50

4.7k

1SS355-X

1SS355-X

D343

D323

D781

MTZJ11C-T1

R910

C319

R343

2.2k

R323

2.2k

2SD1048/6-7/-X

C781

100/16

IC901

HA13164

100/16

C906

1k

47/16

22/16

C302

C327

4.7/25

0.1

C305

C307

2.2

C910

0.047

C904

2200/16

C903

1N5401-TU-15

D901

L901

0.1

C306

QQR0703-001

0.047

C902

QMFZ047-100-T

10/16

C901

F1

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Tuner signal

Cassette signal

Front signal

Rear signa

CD signal

IC301

0.1

C323

0.1

C324

C325

0.1

C326

0.1

150P

C911

47

R901

CP901

QNZ0112-001

ABCD E F G

2-3

Page 33

KS-FX772RKS-FX772R

Mecha control circuit section

Q403

5

680

CJ403

QGF1219F1-10

4

R401

0.015

C411

24k

R410

12k

R411

33k

VR402

18k

0.1

0.10.1

C413C412

R413

C417

2SB1322/RS/-T

3.3k

DSK10C-T1

D402

47k

R422

Q402

DTC114EKA-X

R423

100P

C408

R417

10k

R418

15k

R415

C421

22k

0.01

R416

1.5M

0.1

C422

C415

0.01

IC402

LB1641

D401

MA3051/M/-X

3.3k

R424

10/16

C423

C425

0.01

0.1

C424

33

R425

C407

100P

22/16

C409

180 180

100P

C406

100P

C405

R406 R407

0.015

C410

R408

R409

12k

24k

3

CJ402

100P

C401

100k

R402

100P

C402

100k

R403

100P

C403

100k

R404

100P

C404

100k

R405

2

33k

VR401

CXA2559Q

22/16

C414

IC401

100

R412

0.1

C416

220P

C418

3.9k

R414

0.47/50

C419

CJ401

QGB1214K1-18S

Cassette signal

1

2-4

HABC DEFG

Page 34

KS-FX772R

LCD driver & Operation switch section

5

CP701

VMC0335-001

LCD1

QLD0224-002

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S20

S21

S22

S19

S23

S28

S24

S25

S26

S27

S29

S30

S31

S33

S34

S32

S35

S40

S41

S43

S39

S42

S44

S45

S37

S38

S36

S48

S50

S51

S46

S47

S49

COM3

S52

COM2

COM1

4

10V

LEDR

GND

R663

1k

Q661

2SD601A/R/-X

3

2.2/6.3

C662

100P

R662 R661 R665

680 680 560

C663

D662 D663

UDZS6.2B-X UDZS6.2B-X

C661

2SD601A/R/-X

2SD601A/R/-X

Q662

2.2/6.3

SMLU12E16W

D661

Q663

100P

C664

R664

1k

2SD601A/R/-X

Q664

R666

560

LEDB

REMOCON

5V

10K

R655

LCDCK

10K

R656

10K

R654

KEY2

ACC5V

KEY1

KEY0

MA152WK-TX

D655

LCDDA

D654

MA152WK-TX

MA152WA-TX

D653

D652

MA152WA-TX

R653

180K

R652

C653

C651

C652

R651

1.5k

0.01

4.7/6.3

47k

680p

S49

S50

S51

S52

COM1

COM2

COM3

INH

OSC

CE

CLOCK

DATA

S37

S39

S36

S35

S34

S46

S43

S42

S41

S40

IC651

S38

S10S9S8S7S6

S11

S45

S44

S48

S47

LC75823W

S3

S5

S4

S33

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

S13

S12

S16

S15

S14

2

R649

D613

D619

D620

1k

R648

D616

D617

D618

1k

680

R646

R647

D614

D615

D610

390

390

680

R645

R644

R643

D611

IC652

D601

D657

10K

R657

MA3062

RPM6938-SV4

D604D605

D607

D609 D612

390

R642

D608

D606

390

R641

1k

1.2k

1.2k

R640

R639

R638

D602

D603

820

1k

R637

2.2k

R636

R635

2.2k

C654

47

R658

4.7/6.3

R601

820

S601 S603S602

R607

820 820

S608

R613 R614 R615

820 820

S615 S616

S609

R602

R608

S610

S617

R603

R609

1.2k

1.2k

1.2k

820

R604 R605

1.8k 2.7k

S604

R610

1.8k 3.9k2.7k

S611

R616 R617

1.8k 2.7k

S618

S619

S605

S612

R611

S620

S613

S606

R612

S614

R618

3.9k

S621

1

ABCD E F G

2-5

Page 35

Printed circuit boards

5

Main board

T1B

J1

4

L1

D5

D6

B906

B907

B908

3

B911

R11

C81

C51

R54

C52

C53

R56

Q51

R57

Q52

2

J321

C321

RL

R341

Q341

R342

R352

R322

R343

R353

TU1

1

C32

R32

R34

C3

B901

C33

C82

B910

C54

Q53

R59

C55

Q32

Q3

R5

10

C2

D3

C9

C8

B825

R12

R53

B913

R722

R8

C43

B959

C6

B824

B820

C5

R84

B803

R721

Q9

B916

R60

B821

B920

B822

B823

Q8

B814

D702

D701

L2

15

20

R55

R58

FL

R321

R351

Q321

Q351

Q331

R323

D353

D343

C31

D1

R43

R33

C41

R31

C42

Q1

R42

Q42

B801

R41

Q31

B826

B902

Q41

R4

D2

D7

B904

Q7

R9

C244

C83

R83

R701

C714

C162

R81

Q6

R10

C4

B914

Q10

Q5

D4

C718

B827

B819

R810

C7

C71

R719

B811

R720

1

D709

B918

B828

R82

C84

Q4

D703

R706

C1

D708

KS-FX772RKS-FX772R

Front board(Forward side)

R618

R652

C653

R664

Q663

C664

R614

T1A

R666

D661

R665

Q664

C661

S617

IC652

C662

R663

Q661

00

R615

CA_IN

R616

Main

S614

Main

R639

R638

R612

Sub

D606

Sub

S621

D603

S618

D602

MODE

Cr_O2

Pho_Tr

Anode

D.GND

Q662

R661

R662

S620

D605

D604

R617

S619

D608

ST BY

D601

S601

S604

D619

R635

S603

R648

R649

R602

S602

R411

VR402

R425

R637

R604

R603

R647

R605

R651

C651

R636

R640

C413

1

T11

R424

IC402

D620

Q901

R905

IC161

D241

C172

R247

D162

D161

C904

R906

R168

R170

L901

R902

D901

R901

C982

C901

Q902

D891

Q891

C902

C908

C178

C174

C176

C183

C171

C170

R169

C241

R165

C169

Q241

R245

C243

B807

B956

B941

B942

C801

R809

R801

B943

R717

R715

R891

B806

C181

B930

1

C182

C184

R171

C177

C175

C180

R166

R244

B933

R747

R733

R737

R738

R806

IC801

14

1

R807

R808

B934

C179

D982

C319

R805

R892

R242

R243

CP901

1

5

C891

13

9

C327

D892

C314

R314

C303

C309

R312

R307

R302

R303

R311

B954

B946

R736

Q781

B935

B944

R782

R71

R72

C78

R803

C72

R804

B808

IC71

3

2

7

C910

C981

14

15

11

10

R304

R301

R306

B960

R313

R308

B958

R309

C318

D902

C907

Q977

R977

Q976

C781

R976

B945

D781

D783

C782

Q782

D782

R781

C75

18

17

4

8

D981

12

C302

C911

C313

C308

16

R731

C709

19

C305

25

C323

C304

C324

C325

R305

B948

R978

B947

L903

L902

C301

C307

C326

IC301

2

1

C306

Front board(Reverse side)

Head amp board(Reverse side)

C909

Q784

C903

B809

B810

C73

C76

C74

R73

X71

C77

FSMW1093A

C423

D401

R426

B409

B957

R903

B927

R907

C166

R167

B815

C173

D242

R246

R241

R802

IC901

R162

C163

B929

61

C704

R172

B816

R707

B919

R748

R164

R730

C707

R708

R904

R163

C168

1

C905

C164

C165

B931

C242

B938

B939

1

3

J801

C322

Q701

B924

D706

C161

R740

R729

D707

R724

R752

R705

R910

R-CH

TP02

R161

C167

C713

41

B932

R173

IC701

C708

C705

C706

X701

B940

B818

8

7

4

6

R331R332

C802

C906

B802

R333

D333

D323

R1

R6

R3

Q2

B903

R2

B905

R44

C803

R741

B928

B923

R711

C701

R713

B912

B917

R714

R716

R732

B804

R723

B936

R751

R704

B937

1

C717

R728

R718

B817

R725

C703

21

CP401

2

L-CH

TP01

B953

B813

R742

R735

R745

R743

R734

R746

C702

B926

B925

C712

B805

R712

B921

1

B915

B909

R726

R727

R750

R702

R703

D704

D705

R709

R653

S605

D652

R654

R641

D654

B407

C425

R601

R646

C424

S608

R410

Q401

D616

D655

CP701

R658

C654

R607

D618

GEB10035A

S1A

R644

R645

LCD1

D617

R608

R657

D657

R610

R609

D610

S612

D611

D612

S615

32

33

48

49

64

1

IC651

R613

17

16

D613

S606

IC652

R642

R611

C652

R643

R656

R655

D653

D662

D661

2

1

D663

D614

S609

D615

S610 S611

14

15

D609

C663

S613

D607

S616

Cam switch board (Reverse side)

C418

C419

C416

C414

C421

R416

C422

R401

B406

D402

R420

B408

Q403

B403

R412

11

R414

R415

R418

B411

B410

R413

R417

C417

B404

2

C415

1

B413

C412

1

21

CJ403

IC401

31

B405

B412

C411

R423

B401

R408

VR401

C410

R406

C407

R403

1

R405

C404

R404

C403

R422

C401

R402

2

Q402

1

B402

CJ401

C409

C405

R407

C406

C408

C402

7001 02

MainMain+

Sub-

1

Sub+

0802

1

ST BY

MODE

PHOT

O

Cr02

2-6

HABC DEFG

Loading...

Loading...