Page 1

KS-FX711/KS-FX511

SERVICE MANUAL

CASSETTE RECEIVER

KS-FX711/KS-FX511

KS-FX711

Contents

LOUD

SEL

D

I

SP

7

CD CHANGER CONTROL

MO

10

9

8

KS-FX511

LOUD

SEL

D

I

SP

7

CD CHANGER CONTROL

MO

10

9

8

Safety precaution

Disassembly method

Adjustment method

Description of major ICs

11 12

RPT

11 12

RPT

KS-FX711

TAP

E

FM/AM

Multi

Music

Scan

RND

MODE

KS-FX511

Multi

Music

Scan

RND

MODE

SS

M

CDCH

SCM

TAP

E

FM/AM

SS

M

CDCH

SCM

Area Suffix

U Other areas

1-2

1-3

1-18

1-22

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.49713

Mar. 2002

Page 2

KS-FX711/KS-FX511

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

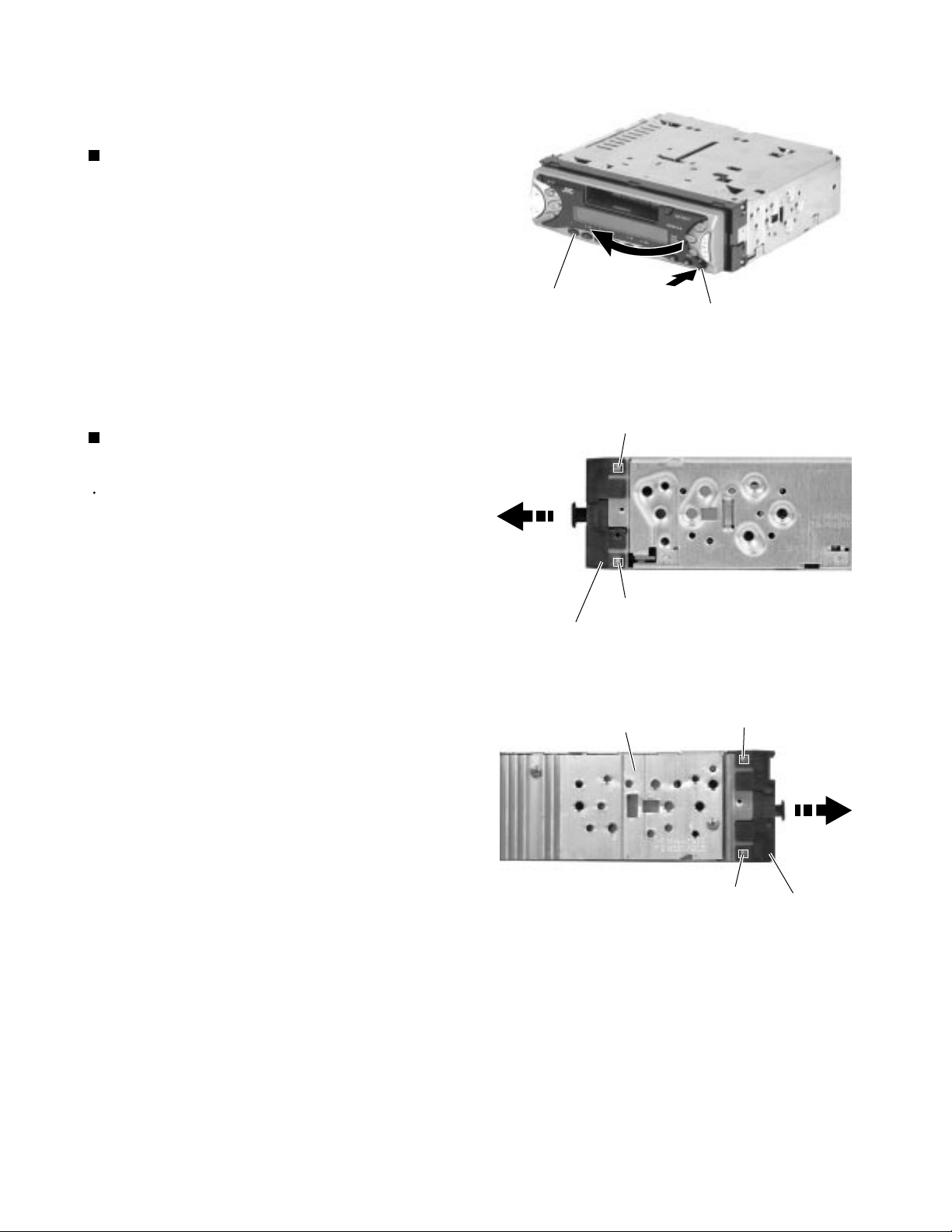

Disassembly method

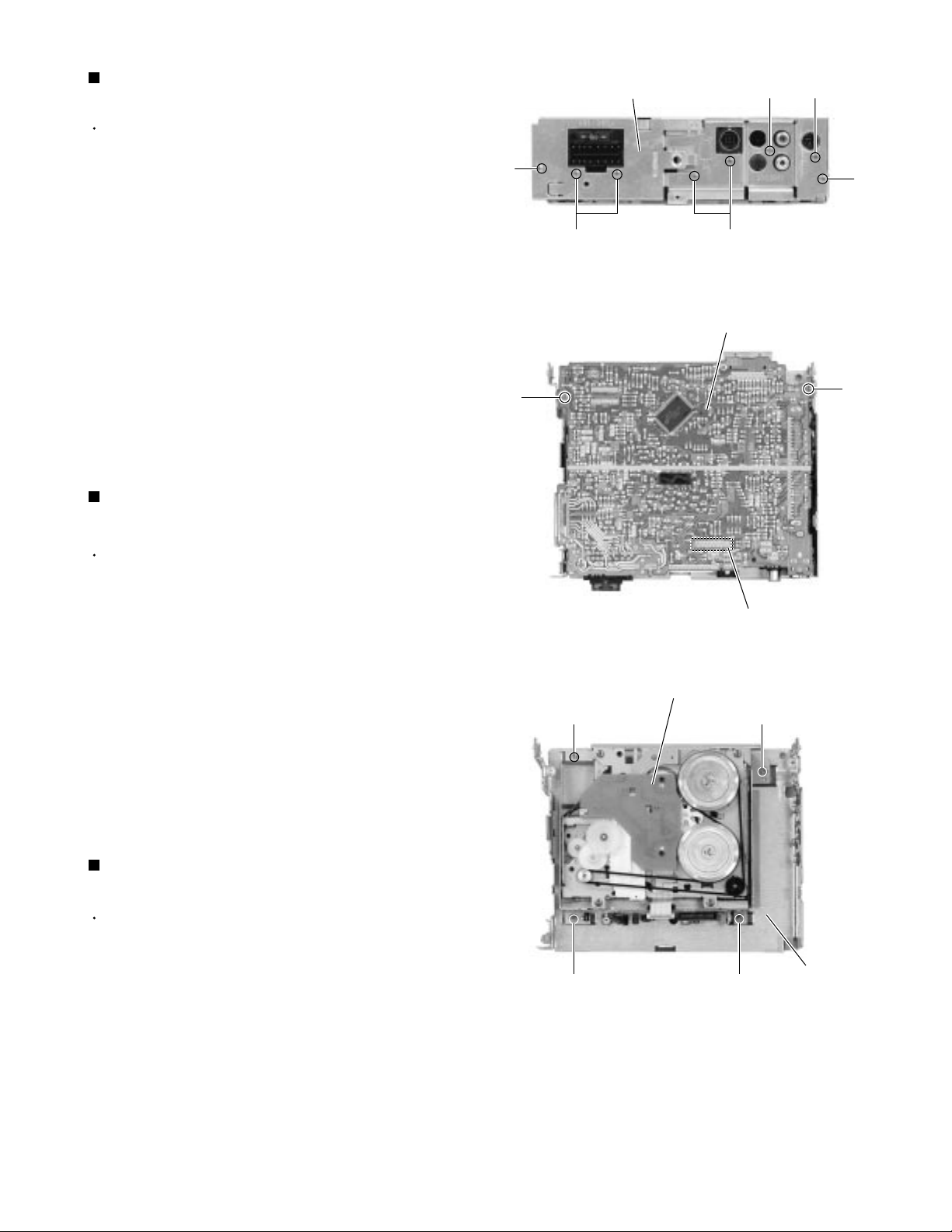

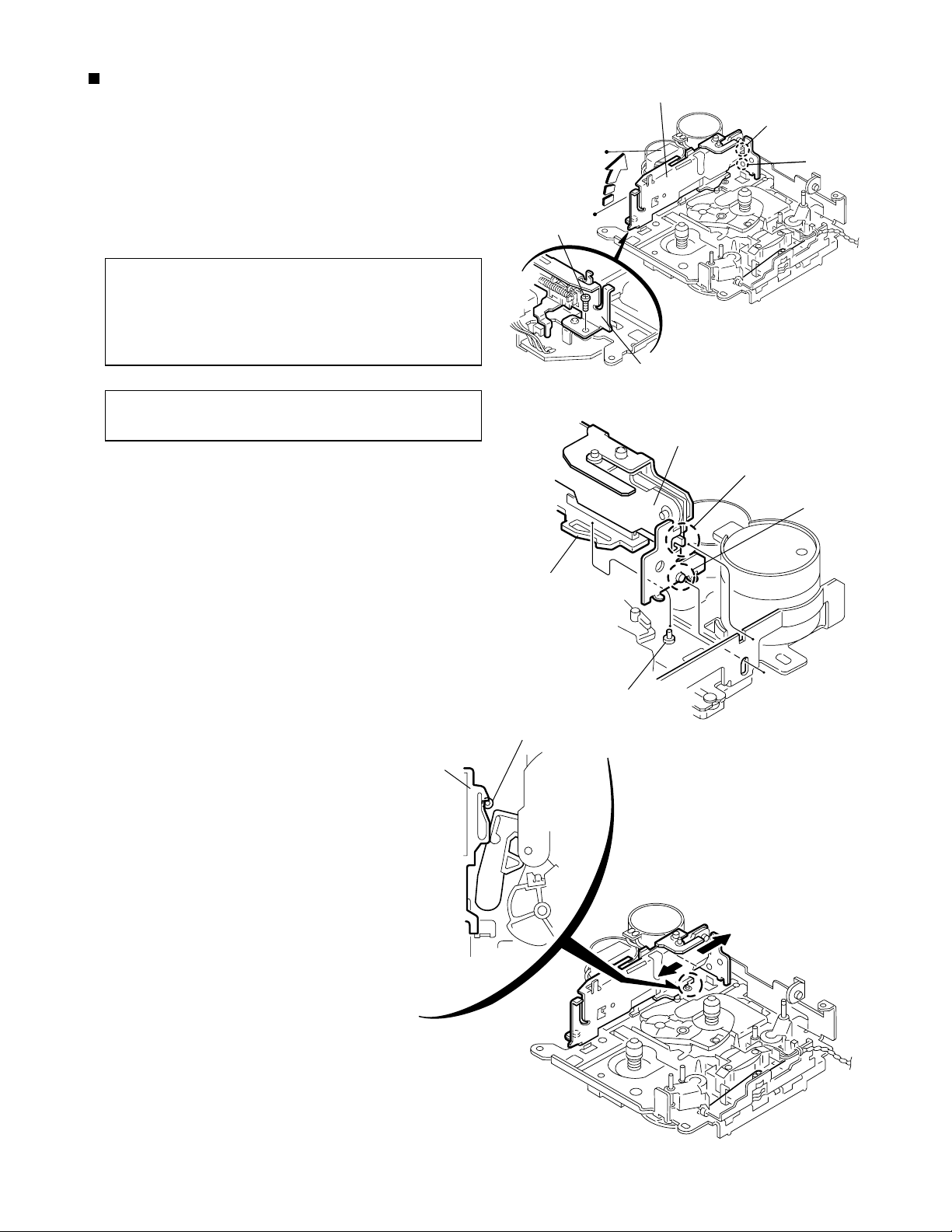

<Main body>

Removing the front panel assembly

(See Fig.1)

1.

Press the eject button in the lower right part of the

front panel. Remove the front panel assembly from

the body.

KS-FX711/KS-FX511

Front panel assembly

Eject button

Fig.1

Removing the front chassis assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Release the four joint tabs a on both sides of the

front chassis assembly and remove the front chassis

assembly toward the front.

Tab a

Tab a

Front chassis assembly

Heat sink

Fig.2

Tab a

Fig.3

Tab a

Front chassis

assembly

1-3

Page 4

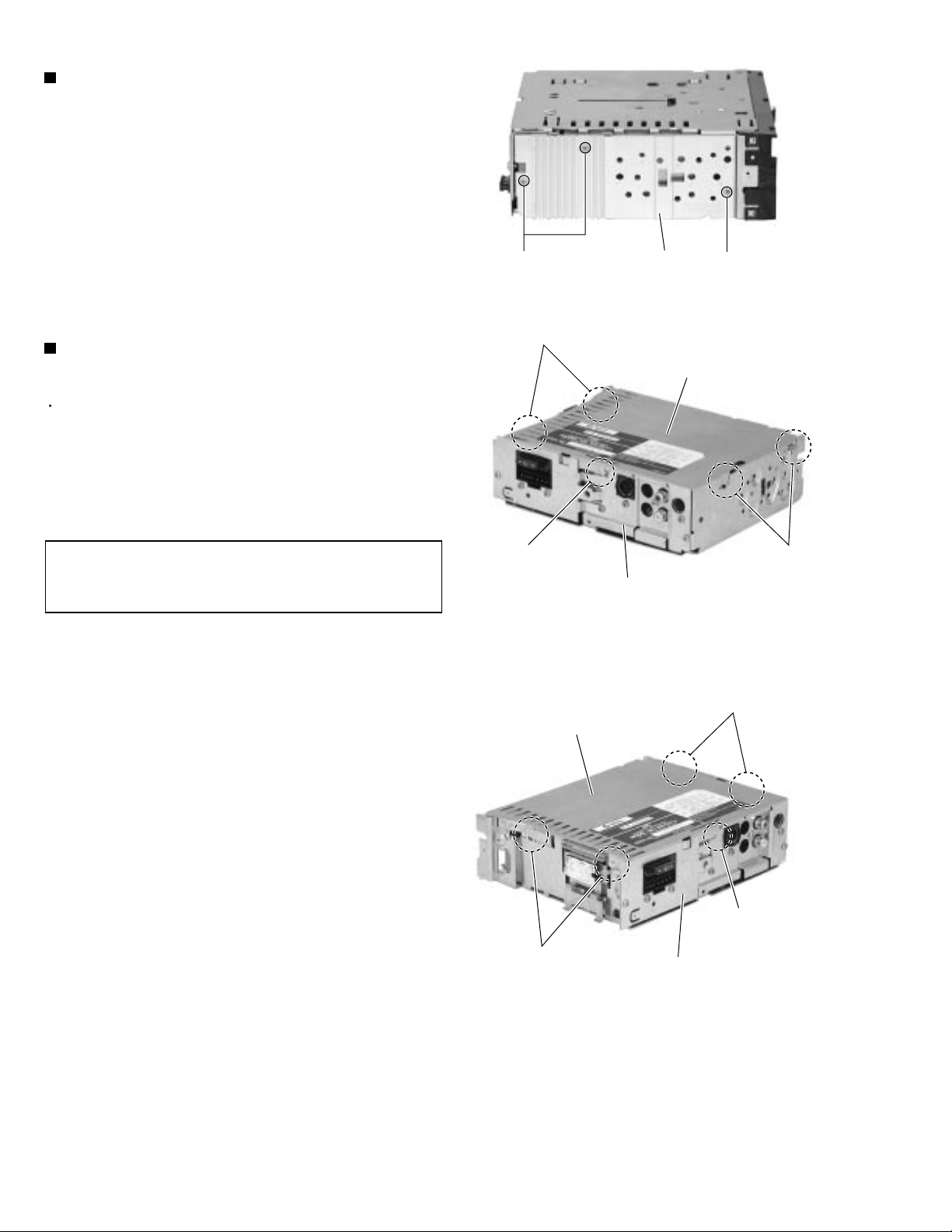

KS-FX711/KS-FX511

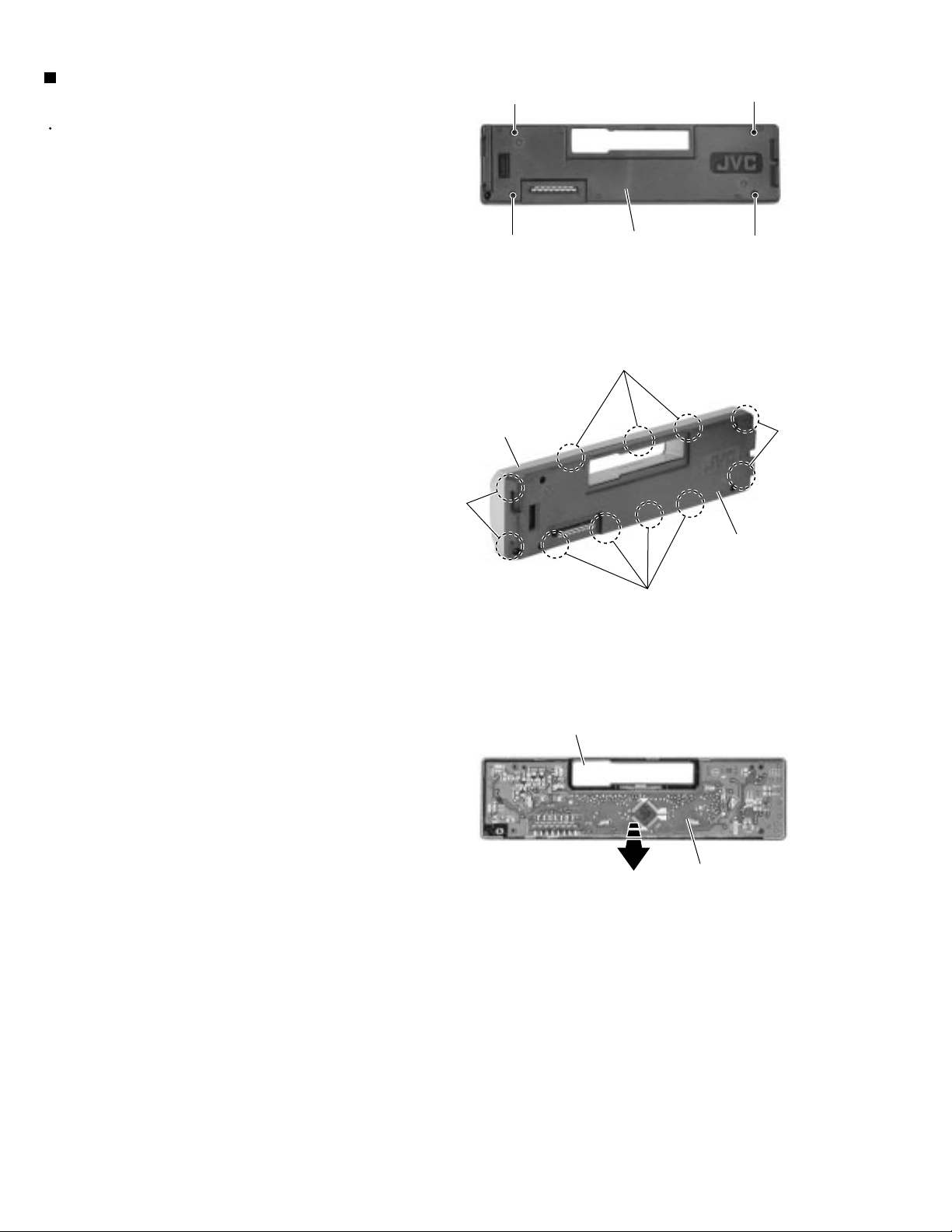

Removing the heat sink (See Fig.4)

1.

Remove the three screws A on the left side of the

body.

Removing the bottom cover

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly

and the heat sink.

1.

Turn over the body and unjoint the four joints b and

joints c with the bottom cover and the body using a

screwdriver.

CAUTION:

When disengaging the joint c using a

screwdriver, do not damage or break the

board.

AA

Joints b

Joint c

Bottom cover

Heat sink

Fig.4

Bottom cover

Joints b

Rear panel

Fig.5

Joints c

1-4

Joints b

Joint c

Rear panel

Fig.6

Page 5

KS-FX711/KS-FX511

Removing the main board

(See Fig.7)

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink and the bottom cover.

1.

Remove the screw B, the five screws C and the two

screws D attaching the rear bracket on the back of

the body. Remove the rear bracket.

D

Rear bracket

E

Removing the main amplifier board assembly

(See Fig.8)

Fig.7

CC

Main board

B

C

D

E

Prior to performing the following procedure, remove

the front chassis, the heat sink, bottom cover and the

rear panel.

1.

Remove the two screws E attaching the main

amplifier board assembly on the top cover.

2.

Disconnect connector CP701 on the main amplifier

board assembly from the cassette mechanism

assembly.

Cassette mechanism assembly

F

Removing the cassette mechanism assembly

(See Fig.9)

Prior to performing the following procedure, remove

the front chassis, the heat sink, bottom cover and the

main amplifier board assembly.

1.

Remove the four screws F attaching the cassette

mechanism assembly from the top cover.

CN701

Fig.8

F

Top chassis

FF

Fig.9

1-5

Page 6

KS-FX711/KS-FX511

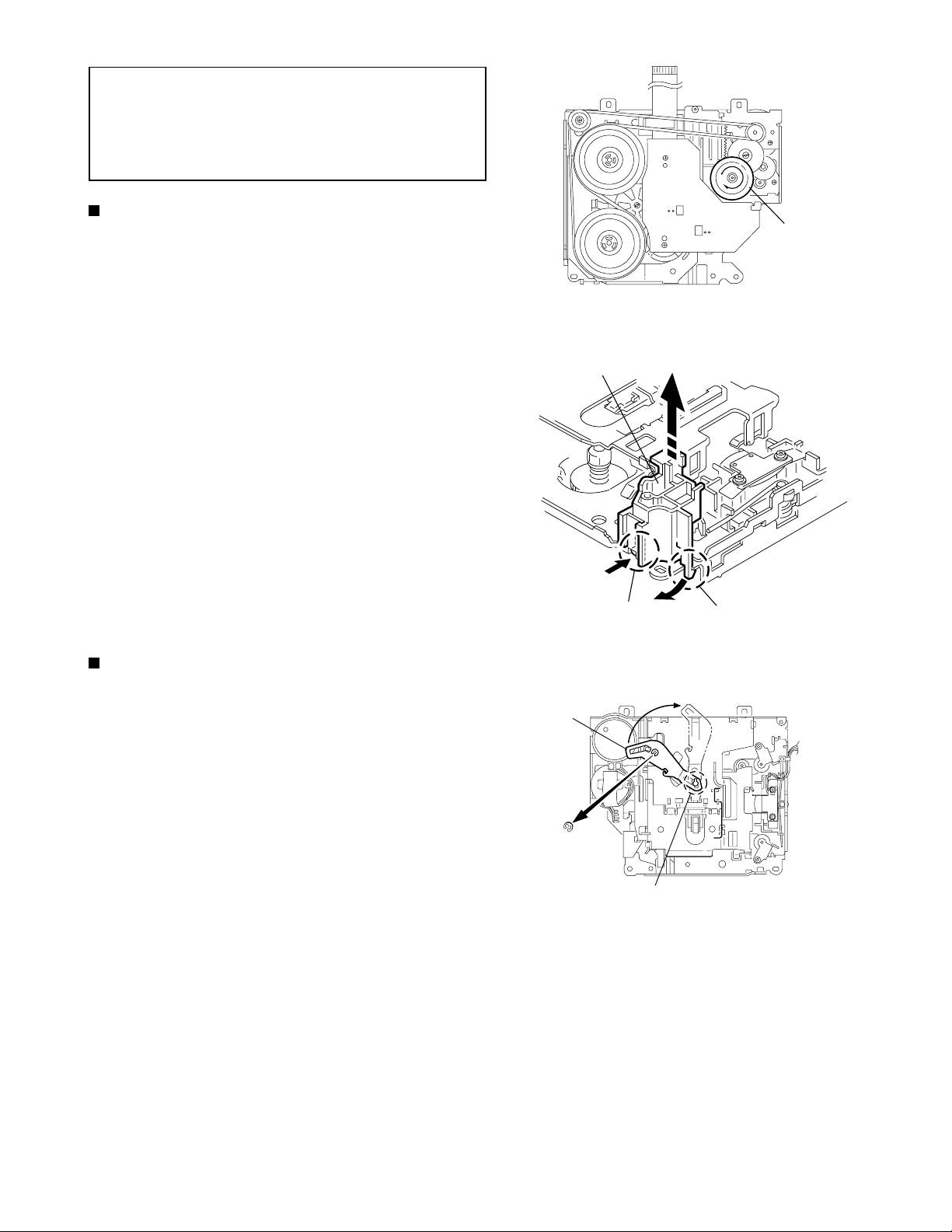

Removing the control switch board

(See Fig.10 to 12)

Prior to performing the following procedure, remove

the front panel assembly.

1.

Remove the four screws G attaching the rear cover

on the back of the front panel assembly.

2.

Unjoint the eleven joints d with the front panel and

the rear cover.

3.

Remove the control switch board on the back of the

front panel.

Joints d

G

G

Front panel

Rear cover

Fig.10

Joints d

G

G

Joints d

Front panel

Rear cover

Joints d

Fig.11

Control switch board

Fig.12

1-6

Page 7

KS-FX711/KS-FX511

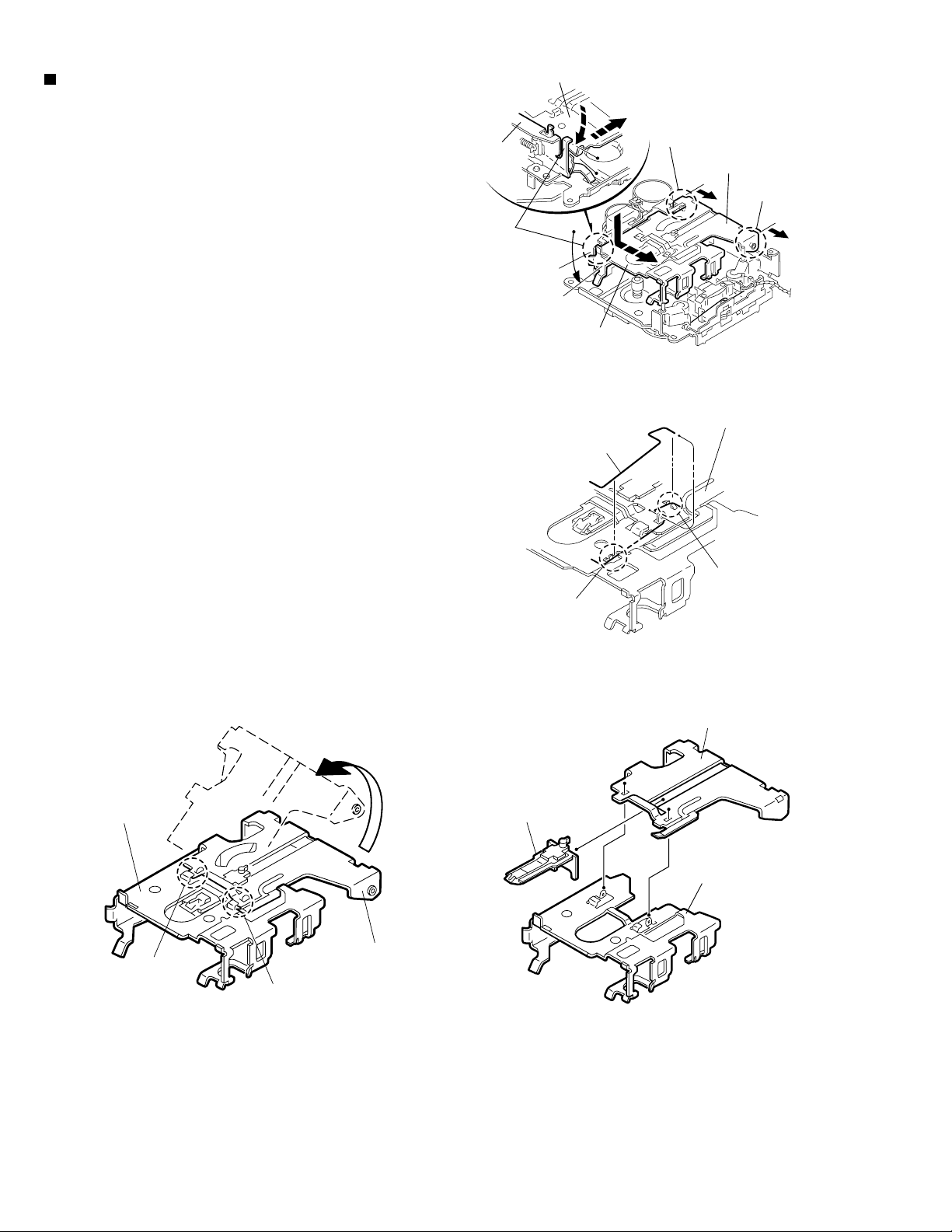

REFERENCE:

Prior to performing the following

procedures, turn the mode gear on the

bottom of the body until the respective part

comes to the EJECT position (Refer to

Fig.1).

Removing the cassette guide (See Fig.2)

1.

Turn the mode gear to set to RVS play or

subsequent mode.

2.

Remove the cassette guide from the main chassis

while releasing each two joint tabs a in the direction

of the arrow.

Mode gear

Fig.1

Cassette guide

Removing the load arm (See Fig.3)

1.

Remove the E-washer attaching the load arm.

2.

Move the load arm in the direction of the arrow and

release the joint b on the cassette catch.

Load arm

E-washer

Tab a

Joint b

Tab a

Fig.2

Fig.3

1-7

Page 8

KS-FX711/KS-FX511

Removing the cassette hanger assembly /

cassette holder (See Fig.4 to 7)

1.

Check the mode is set to EJECT. Push down the

front part of the cassette holder and move in the

direction of the arrow to release the joint c.

2.

Move the rear part of the cassette hanger assembly

in the direction of the arrow to release it from the two

joint bosses d.

3.

Release the holder stabilizer spring from the hooks e

and f, then pull out from the cassette hanger

assembly.

4.

Bring up the rear side of the cassette hanger

assembly to release the joint g and h.

5.

Pull out the cassette catch from the cassette hanger

assembly.

Cassette holder assembly

Side bracket

Joints c

Cassette holder assembly

Cassette stabilizer spring

Fig.4

Boss d

Cassette hanger assembly

Cassette hanger

assembly

Boss d

Cassette holder

assembly

Hook g

Fig.6

Hook f

Hook e

Fig.5

Cassette hanger assembly

Cassette catch

Cassette holder assembly

Cassette hanger assembly

Hook h

Fig.7

1-8

Page 9

KS-FX711/KS-FX511

Removing the side bracket assembly

(See Fig.8 to 10)

1.

Remove the screw A attaching the side bracket

assembly.

2.

Detach the front side of the side bracket assembly

upward and pull out forward to release the joint i and

j in the rear.

CAUTION:

CAUTION:

When reassembling, make sure that the

boss k of the main chassis is set in the

notch of the load rack under the side

bracket assembly. Do not reattach the

load rack on the boss k.

After reattaching the side bracket

assembly, confirm operation.

Side bracket assembly

Joint i

Joint j

A

Side bracket assembly

Fig.8

Side bracket assembly

Joint i

Joint j

Load rack

Load rack

Boss k

Boss k

Fig.9

Fig.10

1-9

Page 10

KS-FX711/KS-FX511

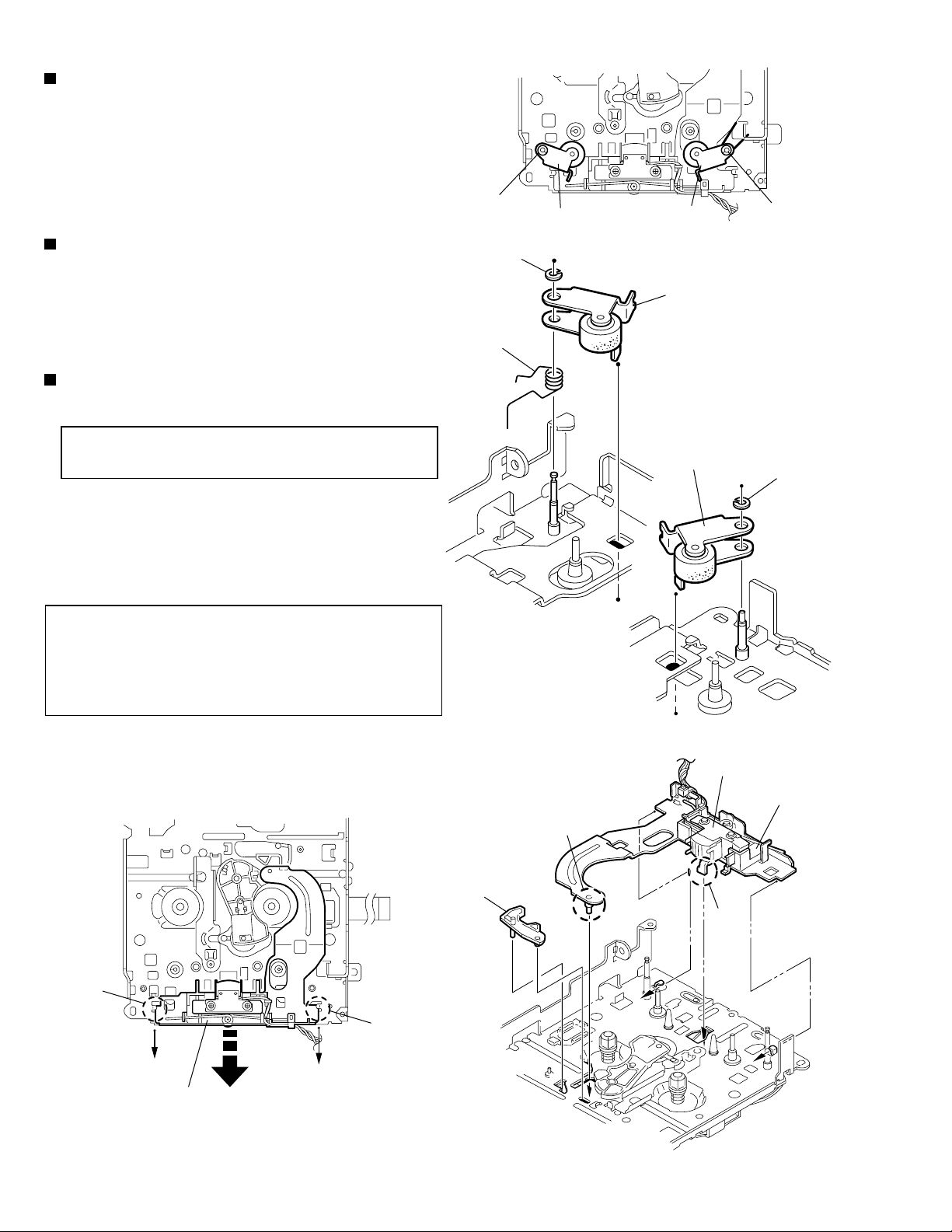

Removing the pinch arm (F) assembly

(See Fig.11 and 12)

1.

Remove the polywasher and pull out the pinch arm

(F) assembly.

2.

Remove the compulsion spring.

Removing the pinch arm (R) assembly

(See Fig.11 and 13)

1.

Remove the polywasher and pull out the pinch arm

(R) assembly.

Removing the slide chassis assembly

(See Fig.14 and 15)

Polywasher

Pinch arm

(R) assembly

Polywasher

Compulsion spring

Fig.11

Pinch arm

(F) assembly

Pinch arm (F) assembly

Polywasher

REFERENCE:

It is not necessary to remove the head

and the tape guide.

1.

Move the slide chassis assembly in the direction of

the arrow to release the two joints l and remove from

the main chassis.

2.

Remove the rack link.

CAUTION:

When reassembling, first reattach the rack

link, and next fit the boss m and hook n of

the slide chassis assembly to the hole of

the main chassis, and engage the two joints

l.

Rack link

Fig.12

Boss m

Pinch arm

(R) assembly

Fig.13

Head

Hook n

Polywasher

Tape guide

Joint l

Slide chassis assembly

1-10

Fig.14

Joint l

Fig.15

Page 11

KS-FX711/KS-FX511

Removing the head / tape guide

(See Fig.16 and 17)

REFERENCE:

1.

Remove the band attaching the wire to the head.

2.

Remove the two screws B, the head and the head

support spring.

3.

Remove the pinch arm spring from the tape guide.

4.

Remove the tape guide and the pinch spring arm.

CAUTION:

CAUTION:

It is not necessary to remove the slide

chassis assembly.

When reattaching the pinch arm spring, set

both end of it to the pinch spring arm (

remarked o).

When reattaching the head, set the wires

into the groove of the tape guide (Fig.16).

B

Slide chassis assembly

Head

Tape guide

Fig.16

B

Pinch arm spring

Head

Head support spring

Tape guide

Removing the flywheel assembly (F) & (R)

(See Fig.18 and 19)

REFERENCE:

1.

Remove the belt at the bottom.

2.

Remove the two polywashers on the upper side.

3.

Pull out each flywheel assembly downward.

Flywheel assembly (F)

It is not necessary to remove the slide

chassis assembly.

Belt

o

Pinch spring arm

o

Slid chassis assembly

Fig.17

Polywasher

Polywasher

Flywheel assembly (R)

Fig.18

Flywheel assembly (F)

Fig.19

Flywheel assembly (R)

1-11

Page 12

KS-FX711/KS-FX511

Disassembling the flywheel assembly (F)

(See Fig.20 and 21)

1.

Push and turn counterclockwise the spring holder (F)

to release the three joints p on the bottom of the

flywheel.

2.

The spring holder (F), the TU spring and the friction

gear play come off.

3.

Remove the polywasher and felt.

Flywheel assembly (F)

Joints p

Flywheel assembly (R)

Joints q

Disassembling the flywheel assembly (R)

(See Fig.20 and 22)

1.

Push and turn clockwise the spring holder (R) to

release the three joints q on the bottom of the

flywheel.

2.

The spring holder (R), the FF spring and the friction

gear FF come off.

3.

Remove the polywasher and the felt.

Removing the reel board

(See Fig.23 and 24)

1.

Remove the two screws C attaching the reel board.

2.

Move the reel board in the direction of the arrow to

release the joint r.

3.

Unsolder the wires if necessary.

CAUTION:

When reattaching, confirm operation of

the MODE switch and the ST-BY switch.

The mode position between EJECT and

ST-BY is optimum for reattaching.

Joint p

Fig.20

Polywasher

Polywasher

Spring holder (R)

Spring holder (F)

TU spring

Friction gear FF

Friction gear play

Felt

Flywheel assembly (F)

FF spring

Felt

Flywheel assembly (R)

Fig.21 Fig.22

Joint q

1-12

Connect the card wire extending from

the reel board to the FFC pad before

reattaching the reel board.

FFC pad

C

Reel board

C

Fig.23

Joint r

FFC pad

CT-1 switch

MODE switch

Soldering

ST-BY switch

Fig.24

Page 13

KS-FX711/KS-FX511

Removing the gear base arm / gear base

link assembly (See Fig.25 to 27)

1.

Move the gear base arm in the direction of the arrow.

2.

Insert a slotted screwdriver to the gear base spring

under the gear base arm, and release the gear base

arm upward from the boss on the gear base

assembly.

3.

Remove the gear base arm from the main chassis

while releasing the two joints s.

4.

Move the gear base link assemby in the direction of

the arrow to release the two joints t.

REFERENCE:

When reattaching the gear base arm,

make sure that the boss on the gear

base assembly is inside the gear base

spring.

Removing the FFC pad

(See Fig.27 and 29)

Gear base

link assembly

Gear base spring

Joint t

Gear base arm

Joints s

Hook u

FFC pad

Hook u

Joint t

Fig.25

Gear base arm

Screwdriver

1.

Push each joint hook u of the FFC pad and remove

toward the bottom.

Gear base link assembly

Fig.26

Gear base arm

Fig.27

FFC pad

1-13

Page 14

KS-FX711/KS-FX511

Removing the mode gear

(See Fig.28 and 31)

1.

Remove the polywasher on the bottom and pull out

the mode gear.

Removing the mode switch actuator

(See Fig.28, 29 and 31)

1.

Pull out the mode switch actuator at the bottom.

REFERENCE:

When reattaching the mode switch

actuator to the main chassis, make sure to

set on the shaft and insert v into the slot w.

Removing the direction link / direction

plate (See Fig.29 to 31)

1.

Remove the polywasher attaching the direction link.

2.

Bring up the direction link to release the three joints

x, y and z at a time.

3.

Move the direction plate in the direction of the arrow

to release the two joints a’.

REFERENCE:

When reattaching the direction plate,

engage the two joints a’ and move in the

direction of the arrow (Refer to Fig.30).

Mode switch actuator

Direction plate

Direction link

Fig.28

Direction plate

Joints a'

Joint z

Direction link

Slot w

Joint y

Polywasher

Fig.29

Direction plate Mode rack assembly

Joint b'

Mode gear

Polywasher

Mode rack assembly

Joint x

Joint b'

Joint c'

REFERENCE:

When reattaching the direction link,

move the direction plate in the direction

of the arrow and engage the three joint

x, y and z at a time (Refer to Fig.31).

Removing the mode rack assembly

(See Fig.29 and 30)

1.

Move the mode rack assembly in the direction of the

arrow to release the two joints b’ and the joint c’.

REFERENCE:

When reattaching, set the two b’ on the

bottom of the mode rack assembly into the

slots of the main chassis and move in the

direction of the arrow (See Fig.30).

Joints a'

Fig.30

Direction link

Mode switch actuator

Polywasher

v

Mode gear

Direction plate

Mode rack assembly

Fig.31

1-14

Page 15

KS-FX711/KS-FX511

Removing the gear base assembly / take

up gear / reflector gear (See Fig.32 to 34)

1.

Push in the pin d’ of the gear base assembly on the

upper side of the body and move the reflector gear

toward the bottom, then pull out.

2.

Remove the polywasher on the bottom and pull out

the take up gear.

3.

Move the gear base assembly in the direction of the

arrow to release it from the two slots e’ of the main

chassis.

REFERENCE:

The parts are damaged when removed.

Please replace with new ones.

Gear base assembly

Pin d'

Polywasher

Slot e'

Slot e'

Fig.32

Take up gear

Removing the reel driver / reel spindle

(See Fig.34)

1.

Draw out the reel driver from the shaft on the main

chassis and remove the reel driver spring and the

reel spindle respectively.

CAUTION:

The reel driver is damaged when

removed. Please replace with a new

one.

Reflector gear

Reel driver

Reel driver spring

Reel spindle

Main chassis

Fig.33

Reel driver

Reel driver spring

Reel spindle

Gear base assembly

Slots e’

Take up gear

Reflector gear

Polywasher

Fig.34

1-15

Page 16

KS-FX711/KS-FX511

Removing the side bracket assembly

(See Fig.35 to 39)

1.

Remove the eject cam plate spring.

2.

Push the joint f‘ through the slot to remove the load

rack downward.

3.

Move the eject cam limiter in the direction of the

arrow to release it from the boss g’ of the side

bracket assembly and from the two joints h’.

4.

Move the eject cam plate in the direction of the arrow

to release the joint i’.

Joint f'

CAUTION:

Joint h'

When reassembling, confirm operation of

each part before reattaching the eject cam

plate spring.

Side bracket assembly

Boss g'

Eject cam limiter

Side bracket assembly

Joint h'

Joint f'

Eject cam plate spring

Joint h'

Load rack

Fig.35

Boss g'

Eject cam limiter

Eject cam plate

Fig.37

Joint h'

1-16

Fig.36

Side bracket assembly

Boss g'

Eject cam plate

Fig.38

Load rack

Joint i'

Side bracket assembly

Eject cam plate

Joint i'

Fig.39

Page 17

KS-FX711/KS-FX511

Removing the main motor assembly /

sub motor assembly (See Fig.40 to 42)

1.

Remove the belt at the bottom.

2.

Remove the polywasher and pull out the mode gear.

3.

Pull out the reduction gear (B).

4.

Remove the polywasher and pull out the reduction

gear (A).

5.

Remove the two screws D attaching the main motor

assembly.

6.

Remove the two screws E attaching the sub motor

assembly.

7.

Unsolder the wires on the reel board if necessary.

CAUTION:

When reassembling, adjust the length of the

wires extending from the sub motor

asswmbly by attaching them to the side of

the sub motor assembly with the wires

extending from the main motor assembly

using a spacer.

Belt

Reduction gear (B)

Reduction gear (B)

E

Polywasher

Fig.40

D

E

Mode gear

Polywasher

Reduction gear (A)

D

Main motor

assembly

Reduction

gear (A)

Polywasher

Sub motor

assembly

Spacer

Main motor assembly

Sub motor assembly

Main motor assembly

Sub motor assembly

Fig.41

Spacer

Fig.42

1-17

Page 18

KS-FX711/KS-FX511

Adjustment method

Test instruments reqired for adjustment

1. Digital osclloscope(100MHz)

2. Frequency Counter meter

3. Electric voltmeter

4. Wow & flutter meter

5. T est T apes

MC-109C

VT724.......................

VT739............For playback frequency measurement

VT712....For wow flutter & tape speed measurement

VT703..................... For head azimuth measurement

6. T orque gauge .................... Cassette type for CTG-N

...................

for TAPA CURL confirmation

(without Padd type)

for DOLBY level measurement

(mechanism adjustment)

Standard volume position

Balance and Bass,Treble volume .Fader

:Center(Indication"0")

Loudness,Dolby NR,Sound,Cruise:Off

Volume position is about 2V at speaker output with

following conditions.Playback the test tape VT721.

AM mode 531kHz to 1602kHz

FM mode 87.5 MHz to 108.0 MHz

Measuring conditions(Amplifier section)

Power supply voltage.............. DC14.4V (11V to 16V allowance)

Load impedance ........... 4 (4 to 8 allownce)

Line out level/impedance ...............................

2.0V/20k load (250 nWb/m)

1-18

Page 19

Arrangement of adjusting & test points

Cassette mechanism

(Surface)

Motor assembly

KS-FX711/KS-FX511

Tape speed adjust

Head section view

Azimuth screw A

(Forward)

Playback head

Azimuth screw B

(Reverse)

Azimuth screw B

(Reverse)

Azimuth screw A

(Forward)

Playback Head

1-19

Page 20

KS-FX711/KS-FX511

Arrangment of adjusting

Head amplifier board section (Reverse side)

R411

VR402

FSMW1093A

B409

R426

C423

R425

D401

1

T11

R424

IC402

VR402:Rch

(Dolby NR level

B407

C425

C424

Q401

R410

B406

D402

R401

R416

C419

C422

C413

C414

B408

C421

adj)

C418

R420

Q403

R412

11

R414

R415

R418

B411

B410

21

R413

R417

C417

B404

CJ403

2

C415

1

B413

C416

B403

(Dolby NR F

C412

1

IC401

31

C411

B405

B412

VR401

B402

R423

requency response adj)

B401

R408

C410

C409

R405

R406

C405

C406

R407

C407

C403

C408

R403

R402

C402

2

CJ401

1

C404

R404

C401

1

R422

Q402

VR401:Rch

Information for using a car audio service jig

1. We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

2. As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

3. Extension cord : EXTKSRT002-18P ( 18 pin extension cord ) For connection between mechanism assembly

and main board assembly .

Check for mechanism driving section such as motor ,etc..

Cassette mechanism

Disassembly method

1. Remove the bottom cover.

2. Remove the front panel assembly.

3. Remove the top cover .

4. Install the front panel.

5. Confirm that current is being carried by connecting

an extension cord jig.

Note

Available to connect to the CP701 connector when installing the front panel.

Extension cord

EXTKSRT002-18P

to Cassette mechanism

1-20

EXTKSRT002-18P

Main board

to Main board

Front panel assembly

Page 21

KS-FX711/KS-FX511

Mechanism adjustment section

Item Adjusting & Confirmation Methods Adjust Std. Value

1. Tape running

adjustment

2. Azimuth

adjustment

confirmation

a) At Forward playmode, using mirror tape, make adjustment

with Azimuth screw A and Azimuth screw B, without curl of 4

parts of head tape guide.

b) At Reverse play mode, using mirror tape, make adjustment

with Azimuth screw A and Azimuth screw B, without tape

curl of 4 parts of head guide.

c) At Forward / Reverse play mode, make confirmation of no

tape curl of 4 parts of head tape guide.

a) At forward play mode, make adjustment of peak of Lch / Rch

output with Azimuth screw A.

* For Oscilloscope litharge corrugation, set 45 as standard.

b) At Reverse play mode, make adjustment of peak of Lch / Rch

output with Azimuth screw B.

* For Oscilloscope litharge corrugation, set 45 as standard.

c) With AC volt meter confirm the difference of output for 4ch

between Lch / Rch at forward play mode and Lch / Rch

Reverse play mode being within 3.0dB.

d) After operation, make confirmation of Lch / Rch azimuth

output being within 1.0dB from adjustment value.

Azimuth

screw A

Azimuth

screw B

2.T ape Speed and

Wow & Flutter

HEAD

Tape guide

OK

HEAD TAPE

1.Check to see if the reading of the frequency counter & W ow

flutter meter is within 2940-3090 Hz( FWD/REV ), and less

than 0.35% ( JIS RMS ).

2.In case of out of specification, adjust the motor with a builtin volume resistor .

Tape curl NG

0

Phase

Built-in

volume resistor

45

T ape Speed

2940-3090Hz

Wow&Flutter

Less than

0.35%

(JIS RMS)

3.Playback

Frequency

response

1.Play the test tape ( VT724 : 1kHz ) back and set the volume

position at 2V .

2.Play the test tape ( VT739 )back and confirm 0 3dB at1kHz/

10kHz and -4+2dB at 1kHz/63Hz.

3.When 10kHz is out of specification, it will be necessary to

read adjust the azimuth.

Speaker out

1kHz/10kHz

: 0dB 3dB,

63Hz/1kHz

: -4dB+2dB,

1-21

Page 22

KS-FX711/KS-FX511

Description of major ICs

AN80T05 (IC901) : Power regulator

1.Terminal layout & Block diagram

Reference V oltage

ASO & Peak

Thermal

Protection

Current Protection

Pre

Drive

1 2 3 4 5 6 7 8 9 10 11 12

ILL

10V

2.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

Pre

Drive

MODE2 MODE1 STB VDD

5.6V

AMP

Out

AMP VCC ANT COM

Symbol Function

ILL10V

TUNER

FM/AM

PWR-CNT

5.6V

REMOTOE

MEMORY

10V power supply for illumination.

When 5V is input,becomes AM. and the antenna output is turned on.

When 5V is input,becomes AM. and the output of FM is switched.

When 5V is input, outputs to ILL,COM,and AMP. It is 0V usually.

5.6V power supply.

Power supply supply to remote amplifier

Back up. connects with ACC with it.

NC

9V

AMVCC

FMVCC

GND

8.7V power supply.

The power supply of 8.7V to AM.

The power supply of 8.7V to FM.

Ground

AMP

Out

Pre

Drive

Pre

Drive

8.7VAM8.7VFM8.7V

Pre

Drive

GND

1-22

Page 23

KS-FX711/KS-FX511

CXA2560Q (IC401) : Dolb y B type noise reduction system with play back equalizer amp.

1.Pin layout & block diagram

PBFB2

31

PBRIN2

32

PBGND

33

PBFIN2

34

VCT

35

45k

PBREF

36

PBFIN1

37

PBGND

38

PBRIN1

39

PBFB1

40

2. Pin function

Pin No. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PBTC1

PBOUT1

OUTREF1

TAPEIN1

Vcc

NC

LINEOUT1

TCH1

NC

MSLPF

G2FB

G1FB

MSTC

MSOUT

NC

NRSW

MUTESW

TAPESW

DRSW

MSMODE

MSSW

NC

TCH2

LINEOUT2

PBTC2

30 29 28

7k/12k

12345

PBTC1

300k

30k

30k

300k

7k/12k

F2

F1

PBOUT2

+

+

-

PBOUT1

OUTREF2

27

70 /120

1

1

70 /120

OUTREF1

TAPEIN2

100k

100k

TAPEIN1

GND

26

T2

T1

Vcc

I/O Function

Playback equalizer amplifier

capacitance

Playback equalizer amplifier

O

output

Output reference

O

TAPE input

I

Power supply

-

Line output

O

Time constant for the HLS

-

Cut-off frequency adjustment

of the music sensor LPF

Music signal interval detection

Music signal interval detection

Time constant for detecting

music signal interval

Music sensor out

O

No use

Dolby NR control

I

Mute function control

I

Playback equalizer amplifier

I

control

Head select control

I

Music sensor mode control

I

Music sensor control

I

Time constant for the HLS

Line output

O

LPF

DIREF

25

BIAS

MUTE

TAPE EQ

FWD/RVS

Vcc

+

-

6

NC

LINEOUT2

23 22 21

24

OFF/B

+

-

F3

OFF/B

-

+

8910

7

LINEOUT1

TCH2

NR

NR

TCH1

NC

MS MODE

NR MODE

MS ON/

DET

NC

OFF

MSSW

MSLPF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

MUTESW

NRSW

NC

MSOUT

MSTC

G1FB

G2FB

Pin No. Symbol

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

DIREF

GND

TAPEIN2

OUTREF2

PBOUT2

PBTC2

PBFB2

PBRIN2

PBGND

PBFIN2

VCT

PBREF

PBFIN1

PBGND

PBRIN1

PBFB1

I/O Function

-

Resistance for setting the

reference

-

Ground

I

TAPE input

O

Output reference

O

Playback equalizer amplifier

output

-

Playback equalizer amplifier

capacitance

I

Playback equalizer amplifier

feedback

I

Playback equalizer amplifier

input

-

Playback equalizer amplifier

ground

I

Playback equalizer amplifier

input

O

Center

O

Playback equalizer amplifier

reference

I

Playback equalizer amplifier

input

-

Playback equalizer amplifier

ground

I

Playback equalizer amplifier

input

I

Playback equalizer amplifier

feedback

1-23

Page 24

KS-FX711/KS-FX511

LA4743K(IC301):Power AMP

1.Block diagram

IN 1

TAB

IN 2

+

0.22 F

+

0.22 F

11

1

12

Vcc 1/2 Vcc 3/4

6 20

-

+

Protective

circuit

-

+

2200 F 0.022 F

+

9

-

7

+

OUT 1+

OUT 1-

PWR GND1

8

+

OUT 2+

5

-

OUT 2-

3

PWR GND2

2

ST BY

R.F

47 F

IN 3

PRE GND

IN 4

+5V

ST ON

+

0.22 F

N.C

+

0.22 F

4

Stand by

Switch

Mute

10

+

Ripple

Filter

Mute

22

circuit

3.3 F

+

15

-

+

-

17

19

10K

+

OUT 3+

OUT 3-

Low Level

Mute ON

25

18

21

23

PWR GND3

OUT 4+

OUT 4-

13

14

Protective

circuit

-

+

+

-

1-24

ON TIME C

22 F

Muting &

16

+

ON Time Control

Circuit

PWR GND4

24

Page 25

2.Terminal layout

KS-FX711/KS-FX511

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

TAB

GND

RFOSTBY

RFO+

VCC1/2

RROGND

RRO+

Vref

RRIN

RFIN

SGND

LFIN

LRIN

ONTIME

LRO+

GND

LROVCC

LFO+

MUTE

LFOGND

NC

Header of IC

Power GND

Outpur(-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

No connection

LA4743K

1-25

Page 26

KS-FX711/KS-FX511

LC72366-9A74 (IC701) : Micro controller

1. Pin layout

25

~

40

2. Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

J-BUS SCK

DIMMER IN

TUNER ILLUM

TAPE ILLUM

DIMMER OUT

FF/REW MODE

SEEK/STOP

RADIO/TAPE

BEEP LEVEL

24 ~ 1

41 ~ 64

Symbol FunctionPin No.

XIN

GND

J-BUS SI

J-BUS SO

J-BUS I/O

NC

LCD SO

LCD SCK

LCD CE

EVOL SO

EVOL SCK

NC

CD ILLUM

NC

OPEN

NC

NC

NC

NC

KS1

KS0

K3

K2

K1

K0

Vdd

TEST

MONO

PWR-CNT

ACC

KICK

80

65

~

I/O

I

Crystal oscillator input port

-

Connect to GND

I

Data input for J-BUS information

O

Data output for J-BUS information

O

Clock output for J-BUS information

O

Switching signal output for J-BUS information I/O, H:Out L:In

-

None connection

O

Data output for LCD driver

O

Information clock output for LCD driver data

O

Chip enable output for LCD driver

-

None connection

O

Data output for electrical volume

O

Clock output for electrical volume information

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

O

Diode matrix output port for initial establishing

I

Diode matrix output port for initial establishing

I

Diode matrix output port for initial establishing

-

Non connection

I

Diode matrix output port for initial establishing

-

5V power supply port (+B)

I

Turn on all light indicator of LCD, L: All light a LED indicator

O

FF/REW mode select signal output

O

H:Auto seek, L: Stop Use both as IF count REQ and Seek/Stop

O

Forced monaural output port, H:Turn on Forced monaural

-

Non connection

-

Non connection

O

"H" : Turn on power

-

Non connection

-

Non connection

1-26

Page 27

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

LEVELMETER

63

64

65

66

67

68

69

AM IF COUNT

70

FM IF COUNT

71

72

73

74

75

76

77

78

79

80

MOTOR

SUBMO+

SUBMO-

BEEP

TAPE IN

STANDBY

REEL

MODE

F/R

MS

SD/ST

DETACH

NC

NC

J-BUS INT

REMOCON

FM/AM

DOLBY

NC

MUTE

MEM DET

S.METER

KEY2

KEY1

KEY0

ACCDET

SENSE

NC

NC

Vdd

AM OSC

FM OSC

VSS

NC

E0

TEST1

XOUT

I/OPort Name FunctionPin No.

Main motor output, H:Transport L: Stop

O

Sub-motor output(+), Loading direction to transport output

O

Sub-motor output(-), Eject direction to transport output

O

Non connection

Switch for detecting to input cassette, L: Cassette in

I

Switch for detecting standby position

I

Switch for detecting tape end position

I

Detecting mode position input

I

Switch for detecting forward/reverse , H:FWD L:REV

I

MS input port,

I

Station detector, Stereo signal input, H:SD

I

Front panel detect

O

Non connection

Non connection

Cut in signal detecting port from J-Bus information

I

Remocon input

I

FM/AM mode switching signal port, H:FM L:AM

O

Dolby NR control

O

Non connection

Mute output port, L:Mute

O

Back-up power supply detecting port, H:input L:no input

I

Pressure voice level voltage input for level meter.

I

S meter voltage input

I

Key 2 input port

I

Key 1 input port

I

Key 0 input port

I

Hold port for Acc detecting, L: Hold mode

I

Voltage sensor port

I

Non connection

FM frequency detecting

I

Non connection

Non connection

5V power supply (+B)

Non connection

I

FM limited signal input

I

Ground port for power supply

Non connection

Error signal output port for PLL

O

Test port for LSI, To connect ground

-

4.5MHz crystal oscillator output

O

KS-FX711/KS-FX511

LC72366-9A74(2/2)

1-27

Page 28

KS-FX711/KS-FX511

HD74HC126P (IC801) : Changer control

1.Pin arrangement 2. Pin function

11C

21A

31Y

42C

52A

62Y

7GND

3. Block diagram

1A

( TOP VIEW )

14

13

12

11

10

9

8

Vcc

4C

4A

4Y

3C

3A

3Y

Input Output

CA

X

LLH

HH H

Y

ZL

1Y

1C

2A

2C

3A

3C

4A

2Y

3Y

4Y

1-28

4C

Page 29

LC75823W (IC601) : LCD driver

1. Pin Layout & Symbol

CL

OSC

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

S3

4

S4

5

S5

6

S6

7

S7

8

S8

9

S9

S10

S11

S12

S13

S14

S15

S16

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

INH

VDD

COM3

COM2

COM1

S52

S51

S50

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

KS-FX711/KS-FX511

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

2. Pin Function

Pin No.

3 to 52

53 to 55

S3 to S52

COM1 to COM3

56

57

60

61

62

63

Symbol

VDD

INH

Vss

OSC

CE

CL

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

I/O

O

Segment output pins used to display data transferred

Function

by serial data input.

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

--

Power supply connection. Provide a voltage of between

4.5 and 6.0V.

I

Display turning off input pin.

INT="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

--

Power supply connection. Connect to GND.

I/O

Oscillator connection.

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

Serial data CE : Chip enable

interface connection

I

to the controller. CL : Sync clock

64

DI

DI : Transfer data

1-29

Page 30

KS-FX711/KS-FX511

TEA6320T-X (IC161) : E.volume

1.Pin layout

2.Block diagram

10 8 9 7 6

5

12

SDA

1

GND

2

OUTLR

OUTLF

MUTE

TL

B2L

B1L

IVL

ILL

QSL

IDL

ICL

IMD

IBL

IAL

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3.Pin functions

Pin

Symbol

No.

SDA

1

SCL

32

VCC

31

OUTRR

30

OUTRF

29

TR

28

B2R

27

B1R

26

IVR

25

ILR

24

QSR

23

IDR

22

Vref

21

ICR

CD-CH

TAPE

TUNER

20

19

18

17

CAP

IBR

IAR

I/O

Serial data input/output.

I/O

MUTE

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

17

Symbol

IAR

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

I

Input A right source.

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

IBL

IAL

Ground.

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

-

output to an external equalizer.

Bass control capacitor left channel.

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

Not used

Input C left source.

I

Not used

Input B left source.

I

Input A left source.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

Vcc

SCL

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

I

Serial clock input.

1-30

Page 31

RPM6938-SV4(IC652) : LCD driver

1.Block diagram

KS-FX711/KS-FX511

AMP

I/V

conversion

PD

magnetic shield

KIA7810PI (IC902) : Regulator

1.Pin layout 2.Block diagram

R4 R18

1 2 3

Q12

R5

Z1

R6

R7

BPF

fo

trimming

circuit

R1

Q1

Q13

AGC

Q8

Q10

Q5

Q7

Detector

R8

Q6

R15

R2

Q2

Q14

C1

Q4

R9

Q9

Q15

R16

Vcc

Comp

Q3

Q11

R13

R21

R17

22k

Q16

R12

Vcc

Rout

GND

1 INPUT

Q17

R11

3 OUTPUT

R20

R19

LB1641 (IC402) : DC motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

VCC1

VCC2 P2

R10 R3

2. Pin function

10

OUT2

R14

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

2 GND

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-31

Page 32

KS-FX711/KS-FX511

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49713)

200203

Loading...

Loading...