Page 1

KD-SX975 / KD-SX875

SERVICE MANUAL

CD RECEIVER

KD-SX975 / KD-SX875

Contents

Safety precaution

Preventing static electricity

Location of main parts

Disassembly method

Adjustment method

1-2

1-3

1-4

1-5

1-10

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

Flow of functional

operation unit TOC read

Maintenance of laser pickup

Replacement of laser pickup

Discription of major ICs

Area Suffix

U ---- Other Areas

1-11

1-13

1-13

1-14

No.49620

Feb. 2001

Page 2

KD-SX975 / KD-SX875

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KD-SX975 / KD-SX875

Preventing static electricity

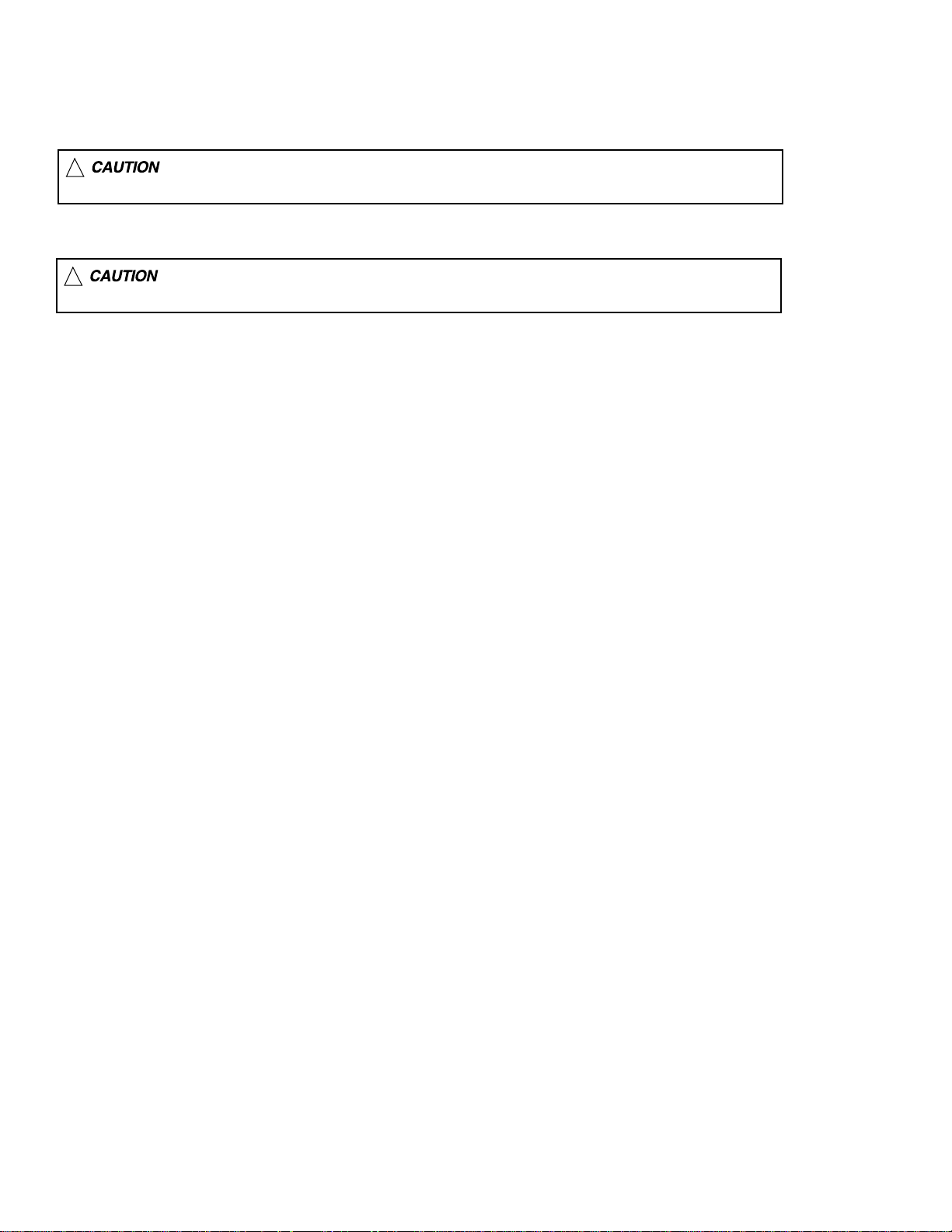

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prev ent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

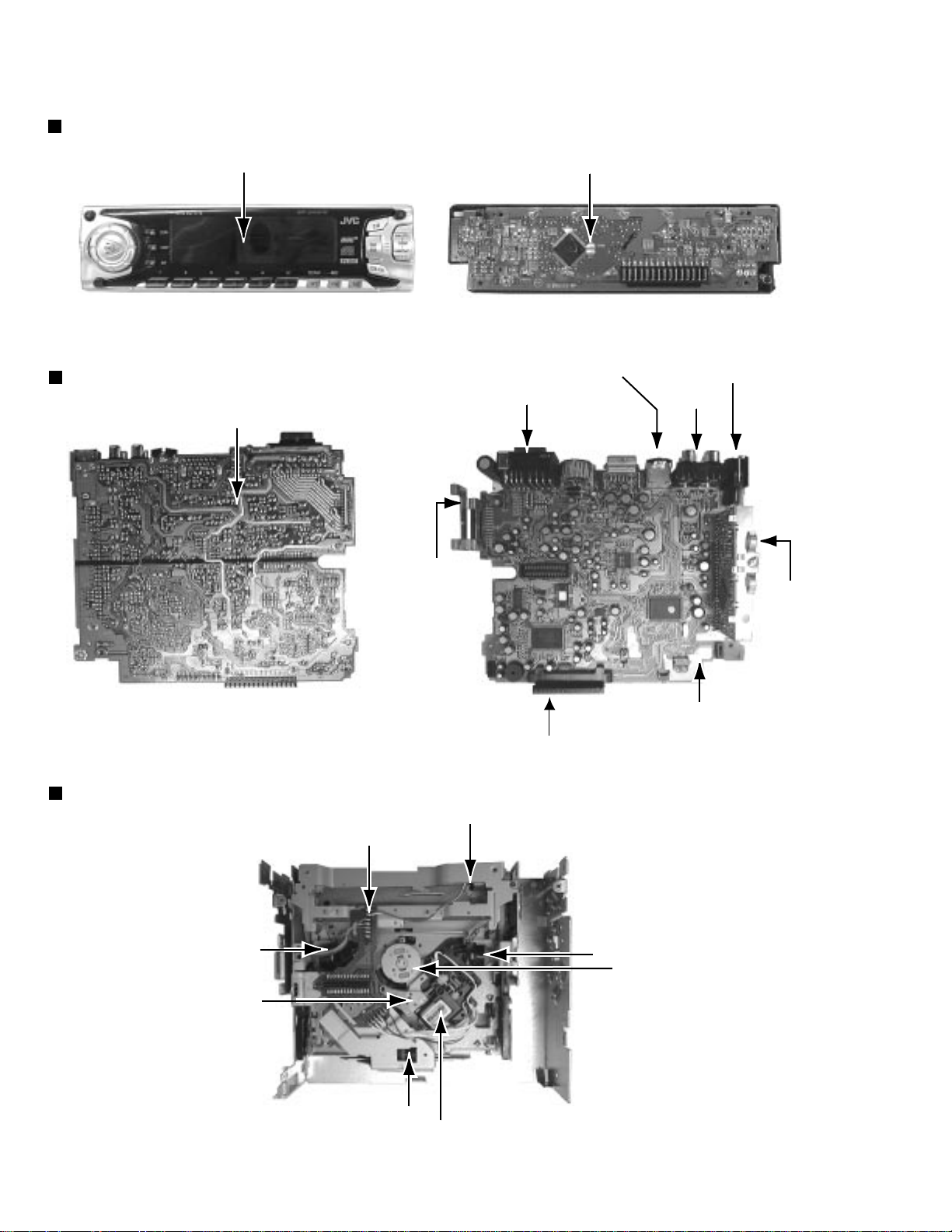

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

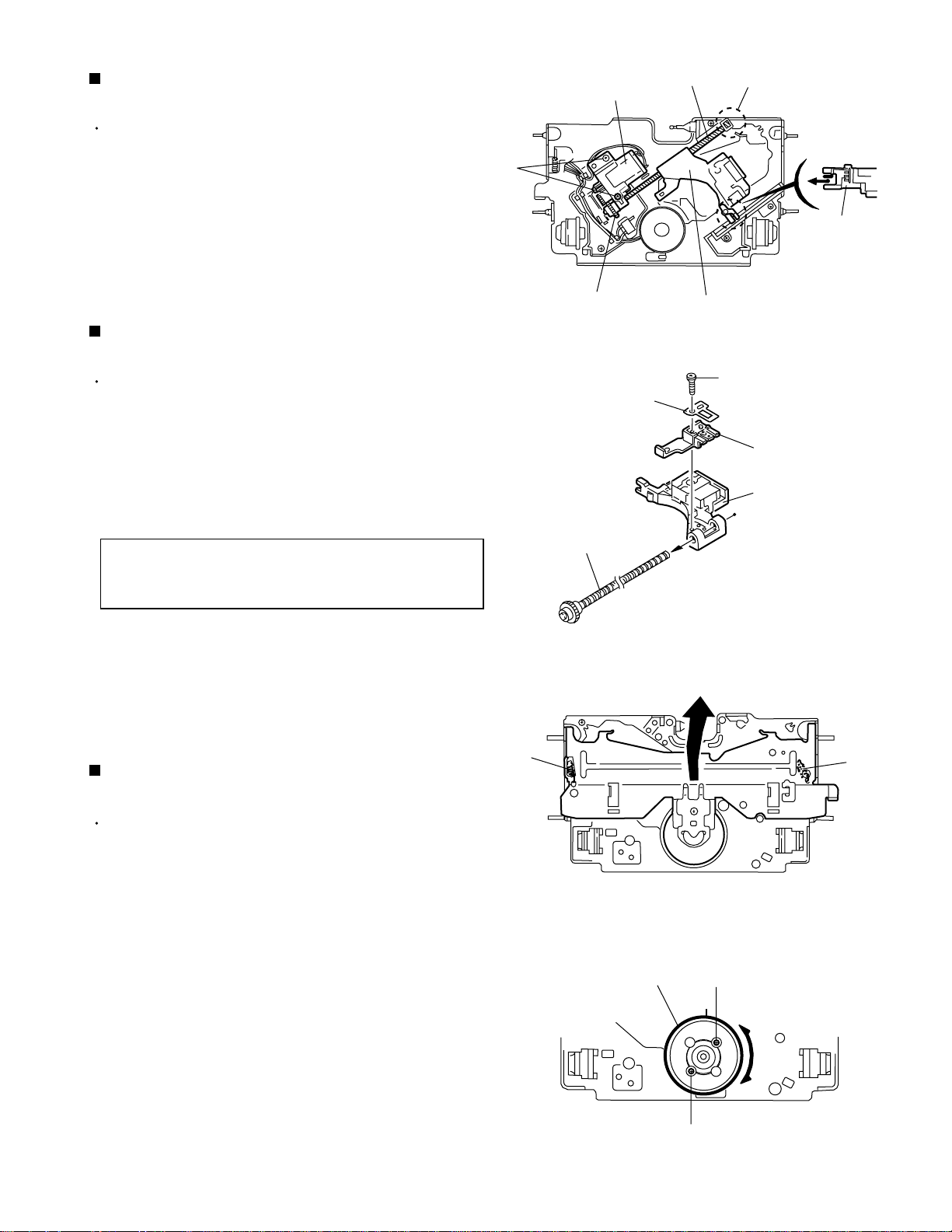

CD mechanism ass’y

Damper bracket

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

1.Solder is put up before the card wire is removed from connector on

the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

Front bracket

Feed motor ass’y

FD screw

CD mechanism

control board

Soldering

FD gear

Pickup unit

1-3

Page 4

KD-SX975 / KD-SX875

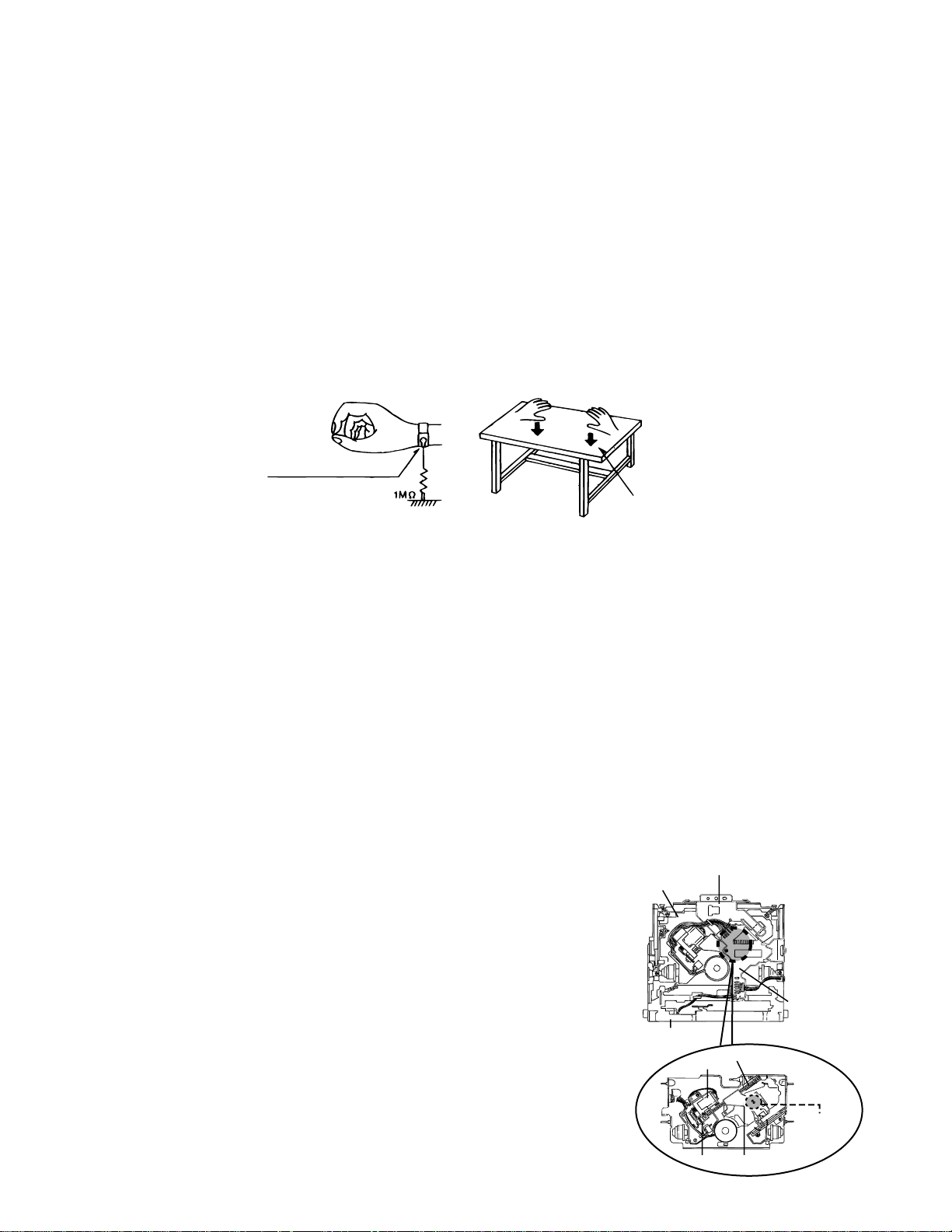

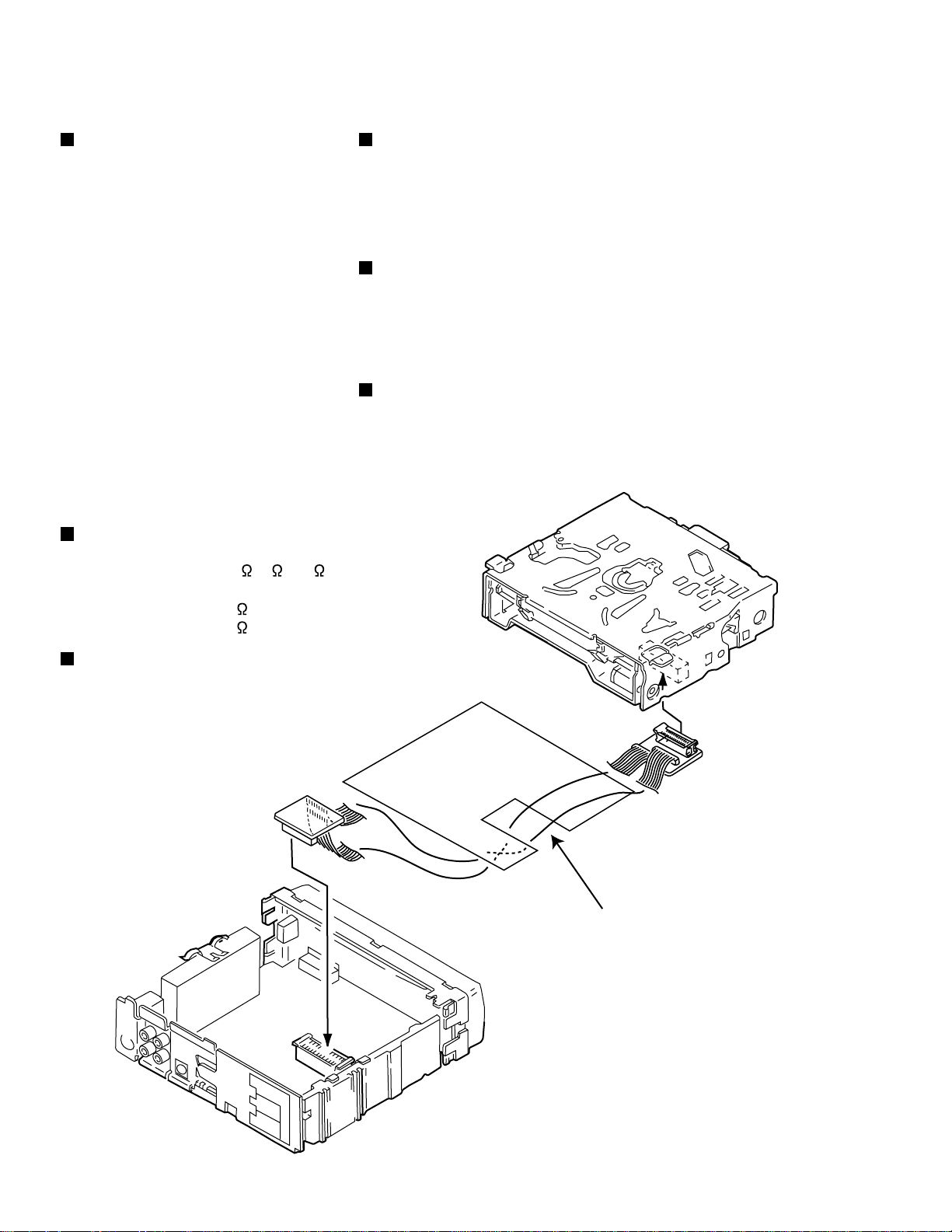

Location of main parts

Control unit

Display

Front PCB

Main unit

CD mechanism

Main board

16 pin connector

Power IC

Loading motor

Changer control

connector

Connector to front PCB

Antenna

jack

RCA jack

Main board assemb

Tuner

pack

ly

1-4

Damper

Optical

pick up unit

Mechanism relay board

Damper

Spindle motor

Damper

Feed motor

Page 5

KD-SX975 / KD-SX875

Disassembly method

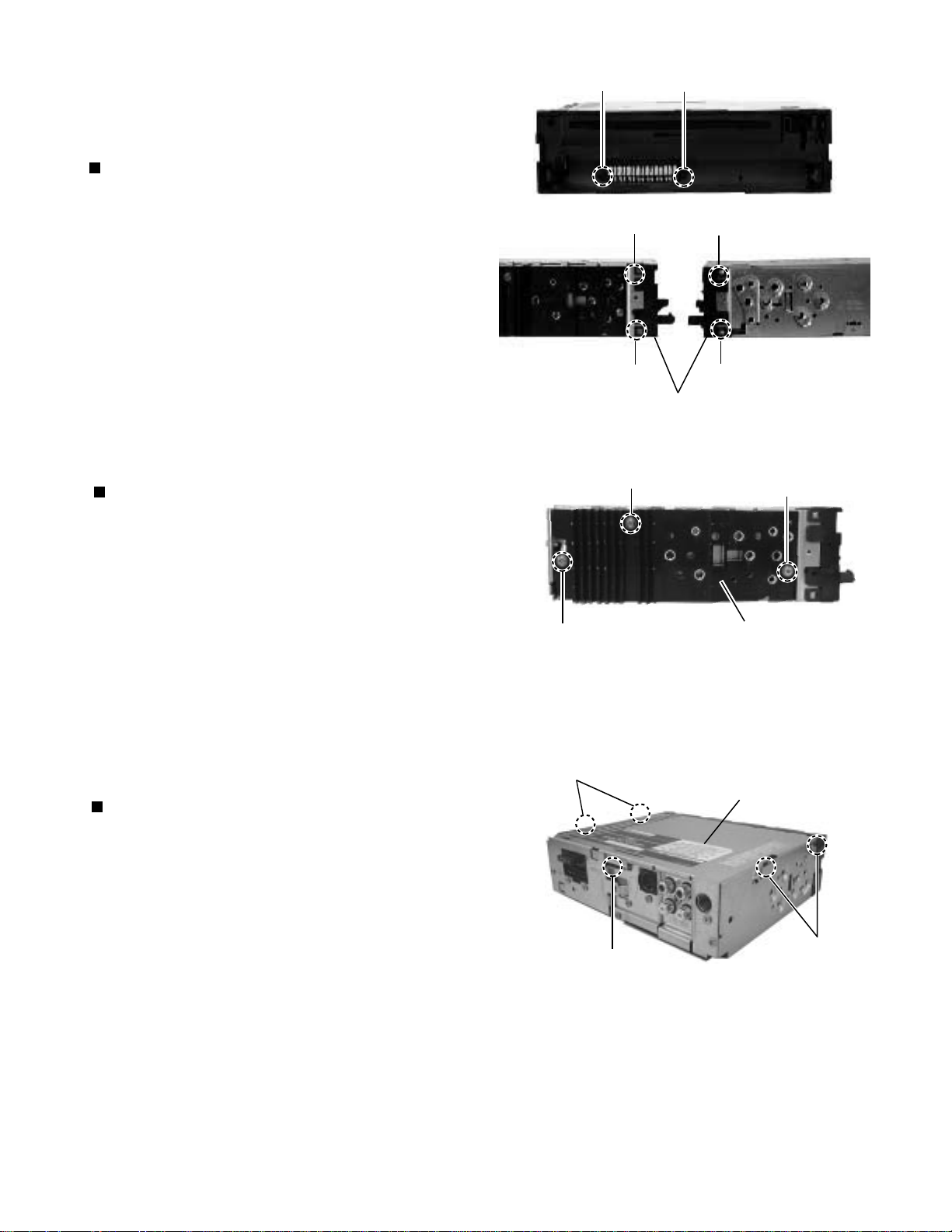

Removing the front chassis (See Fig.1)

1. Remove two screws A and insert a screwdriver to the

joints a on the side of the front chassis and two joints b

on the right side, then detach the front chassis toward the

front side.

Removing the heat sink (See

1. Remove the three screws B attaching the heat sink on

the left side of the body, and remove the heat sink.

Fig.2 )

A

a

a

Front chassis

Fig.1

B

A

b

b

B

Removing the bottom cover (See

1.2.Turn the body upside down.

Insert a screwdriver to the two joints c and two joints d on

both sides of the body and the joint e on the back of the

body, then detach the bottom cover from the body.

Fig.3 )

B

Heat sink

Fig.2

c

Regulator board

e

Fig. 3

d

1-5

Page 6

KD-SX975 / KD-SX875

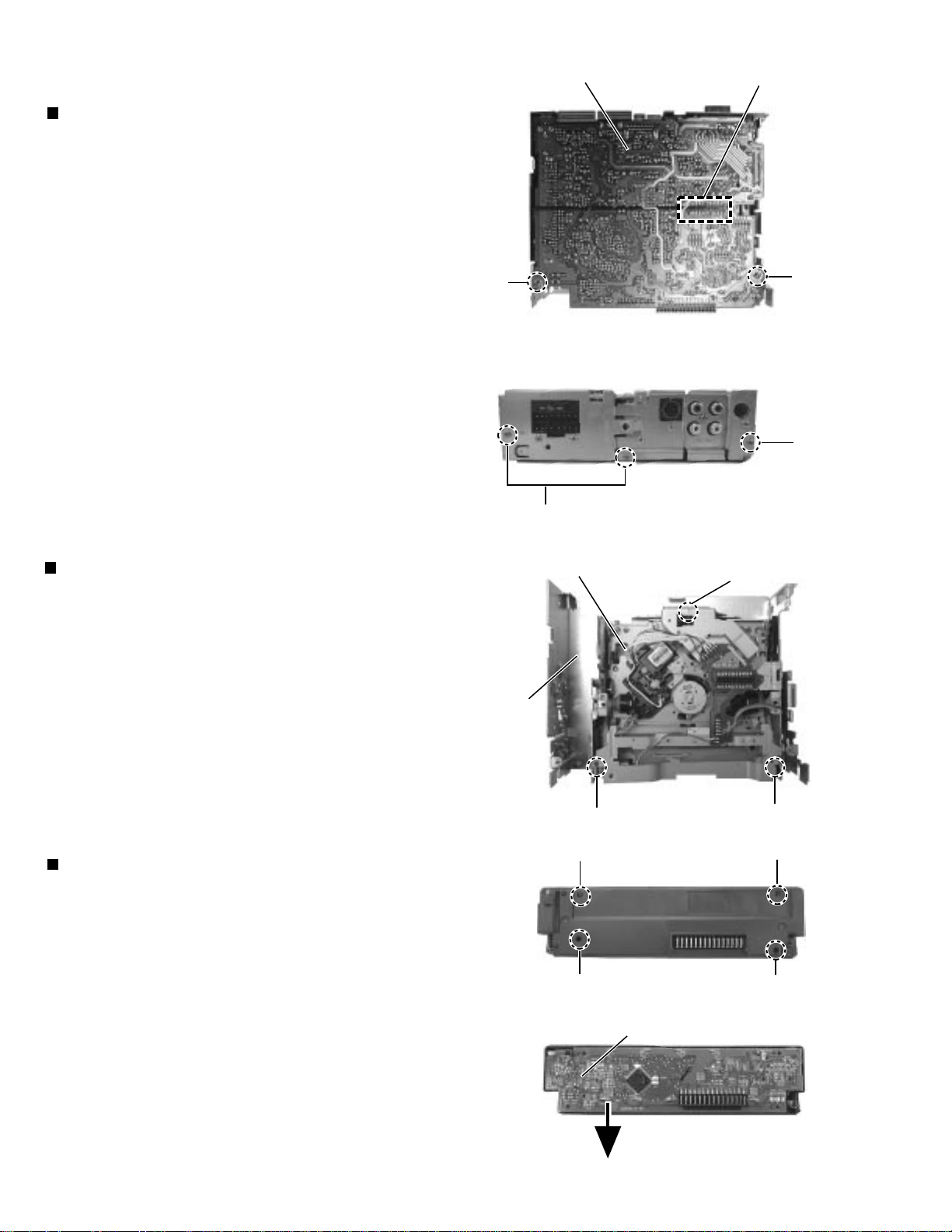

Removing the main amplifier board assembly

(See Fig.4 and 5)

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the two screws C attaching the main amplifier

board assembly on the bottom of the body.

Remove the three screws D attaching the main amplifier

4.

board assembly on the back of the body.

Disconnect connector CN501 on the main amplifier board

5.

assembly from the CD mechanism assembly.

Main amplifier board

C

D

CN501

C

Fig.4

D

Fig. 5

Removing the CD mechanism assembly

Fig.6 )

(See

Remove the front chassis.

1.

Remove the bottom cover.

2.

Remove the main amplifier board assembly.

3.

Remove the three screws E attaching the CD mechanism

4.

assembly from the top cover.

Removing the control switch board

Fig.7 and 8 )

(See

1.

Remove the front chassis.

2.

Remove the four screws F attaching the rear cover on the

back of the front panel unit.

Remove the control switch board from the front panel

3.

unit.

CD mechanism assembly

Top cover

E

F

F

Control switch board

Fig. 6

Fig. 7

E

E

F

F

1-6

Fig. 8

Page 7

KD-SX975 / KD-SX875

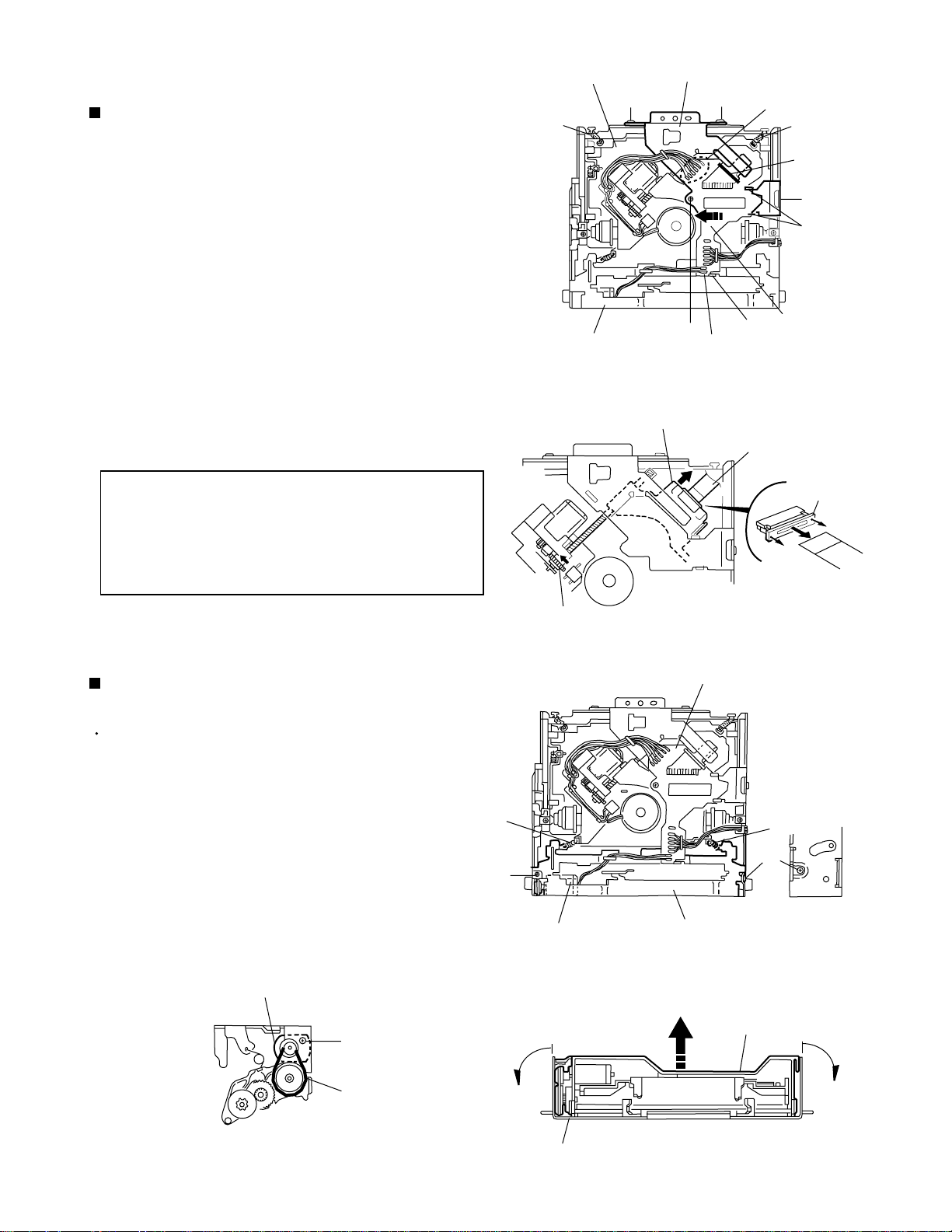

<CD mechanism section>

Removing the CD mechanism control

board (See Fig.1 and 2)

1.

Unsolder the part a and b on the CD mechanism

control board.

2.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

3.

Remove the screw A attaching the CD mechanism

control board.

4.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots d and the front bracket slot e.

5.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily.

(Refer to Fig.2)

CD mechanism assembly

D

h

Front bracket

Pickup unit

Damper bracket

D

A

Fig.1

e

b

Flexible wire

a

h

c

D

d

CD mechanism

control board

Shift the lock

Removing the loading motor

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the CD mechanism control board.

1.

Remove the two springs f attaching the CD

mechanism assembly and the front bracket.

2.

Remove the two screws B and the front bracket

while pulling the flame outward.

3.

Remove the belt and the screw C from the loading

motor.

Loading motor

C

FD gear

f

B

Loading motor

Pull outward

Fig.2

CD mechanism control board

f

B

Front bracket

Fig.3

Front bracket

Pull outward

Fig.5

Belt

Flame

Fig.4

1-7

Page 8

KD-SX975 / KD-SX875

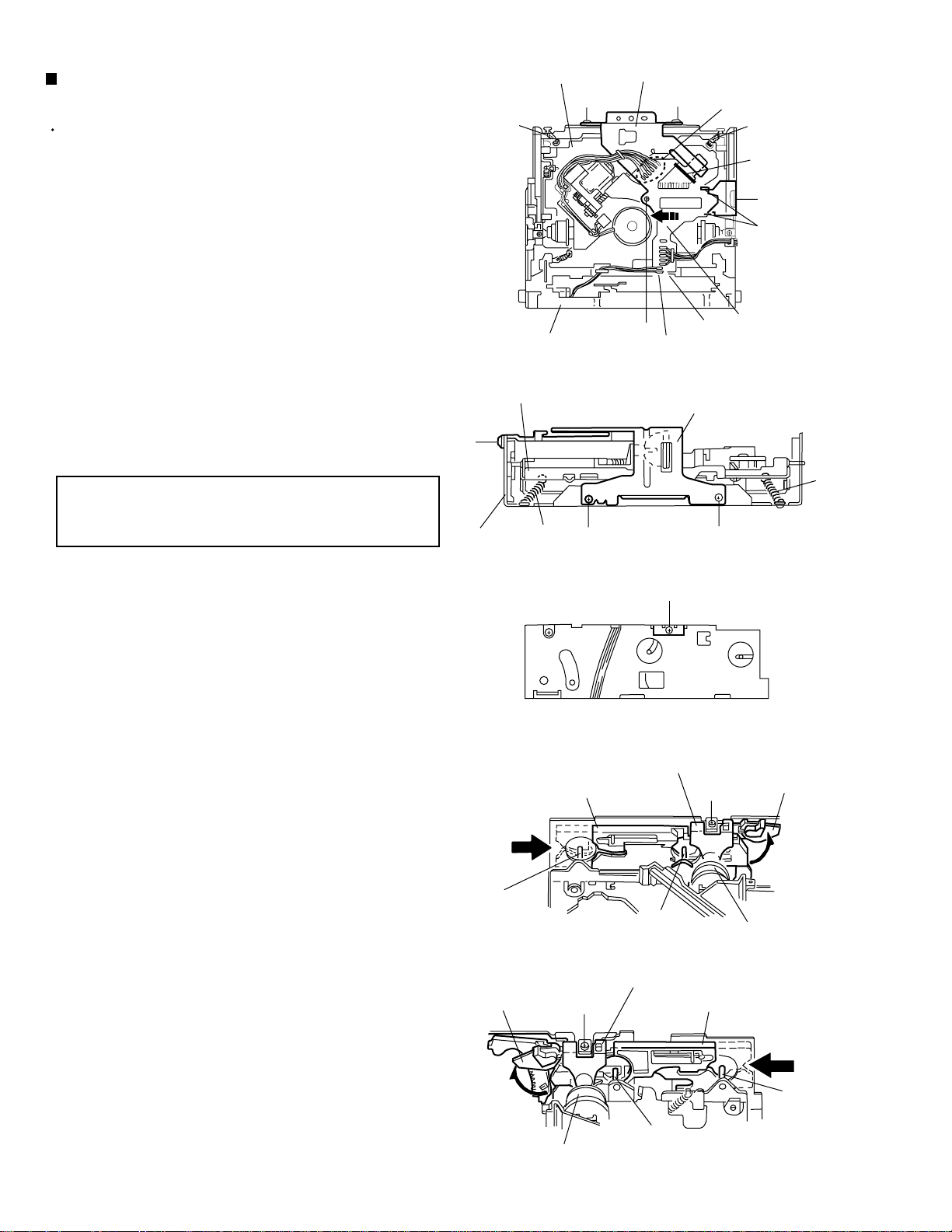

Removing the CD mechanism assembly

(See Fig.1, 6 to 9)

Prior to performing the following procedure, remove

the CD mechanism control board and the front

bracket (loading motor).

1.

Remove the three screws D and the damper

bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts g

as shown in Fig.8 and 9.

3.

Remove the CD mechanism assembly and the two

springs h attaching the flame.

4.

Remove the two screws E and both sides rear

damper brackets from the dampers. Detach the CD

mechanism assembly from the left side to the right

side.

ATTENTION:

The CD mechanism assembly can be

removed if only the rear damper

bracket on the left side is removed.

CD mechanism

h

Front bracket

CD mechanism

D

Flame

assembly

D

assembly

h

D

Damper bracket

D

A

Fig.1

e

b

Damper bracket

D

Fig.6

a

h

c

D

d

CD mechanism

control board

h

Fix plate (L)

g

Fix arm (R)

D

Fig.7

Rear damper bracket

g

Fig.8

Rear damper bracket

E

Fix plate(R)

E

Fix arm (L)

Damper

1-8

Damper

g

g

Fig.9

Page 9

KD-SX975 / KD-SX875

Removing the feed motor assembly

(See Fig.10)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism assembly.

1.

Remove the two screws F and the feed motor

assembly.

Removing the pickup unit

(See Fig.10 and 11)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part i of the FD screw.

Feed motor assembly

F

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.10

Part i

Part j

Pickup unit

G

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw G attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickup unit,

reattach the part j of the pickup unit,

then the part i of the FD screw.

Removing the spindle motor

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism assembly and

the feed motor assembly.

1.

Turn up the CD mechanism assembly and remove

the two springs k on both sides of the clamper arms.

Open the clamper arm upward.

2.

Turn the turn table, and remove the two screws H

and the spindle motor.

k

FD screw

Spindle motor

Fig.11

k

Fig.12

H

H

Fig.13

1-9

Page 10

KD-SX975 / KD-SX875

Adjustment method

Test instruments required adjustment

1.Digital oscilloscope (100MHz)

2.AM Standard signal generator

3.FM Standard signal generator

4.Stereo modulator

5.Electric voltmeter

6.Digital tester

7.Tracking offset meter

8.Test Disc JVC : CTS-1000

9.Extension cable for check

EXTGS004-26P

Standard measuring conditions

Power supply voltage DC14.4V(10.5

Load impedance 4 (4 to 8 allowance)

Line-out Level / Impedance:

KD-SX975 : 4.0 V 20 k load (full scale)

KD-SX875 : 2.0 V 20 k load (full scale)

Standard volume position

Balance and Bass & Treble volume : Indication "0"

BBE:OFF

Frequency Band

FM

MW

Dummy load

Exclusive dummy load should be used for AM,and FM.

For FM dummy load, there is a loss of 6dB between SSG output

and antenna input. The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

–

16V)

1 – 3 87.5MHz – 108.0MHz

531kHz – 1602kHz

How to connect the extension cable for adjusting

EXTGS004-26P

1-10

Page 11

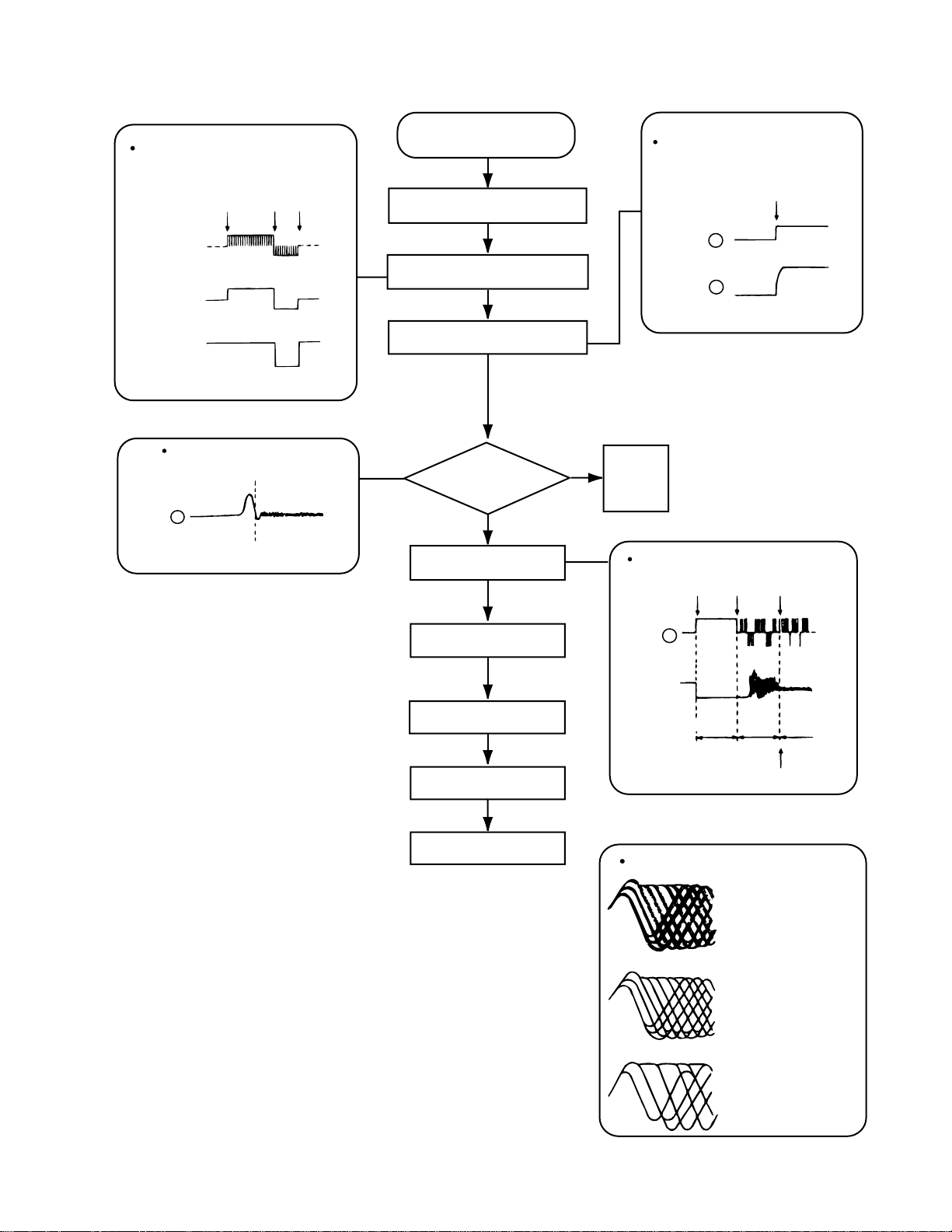

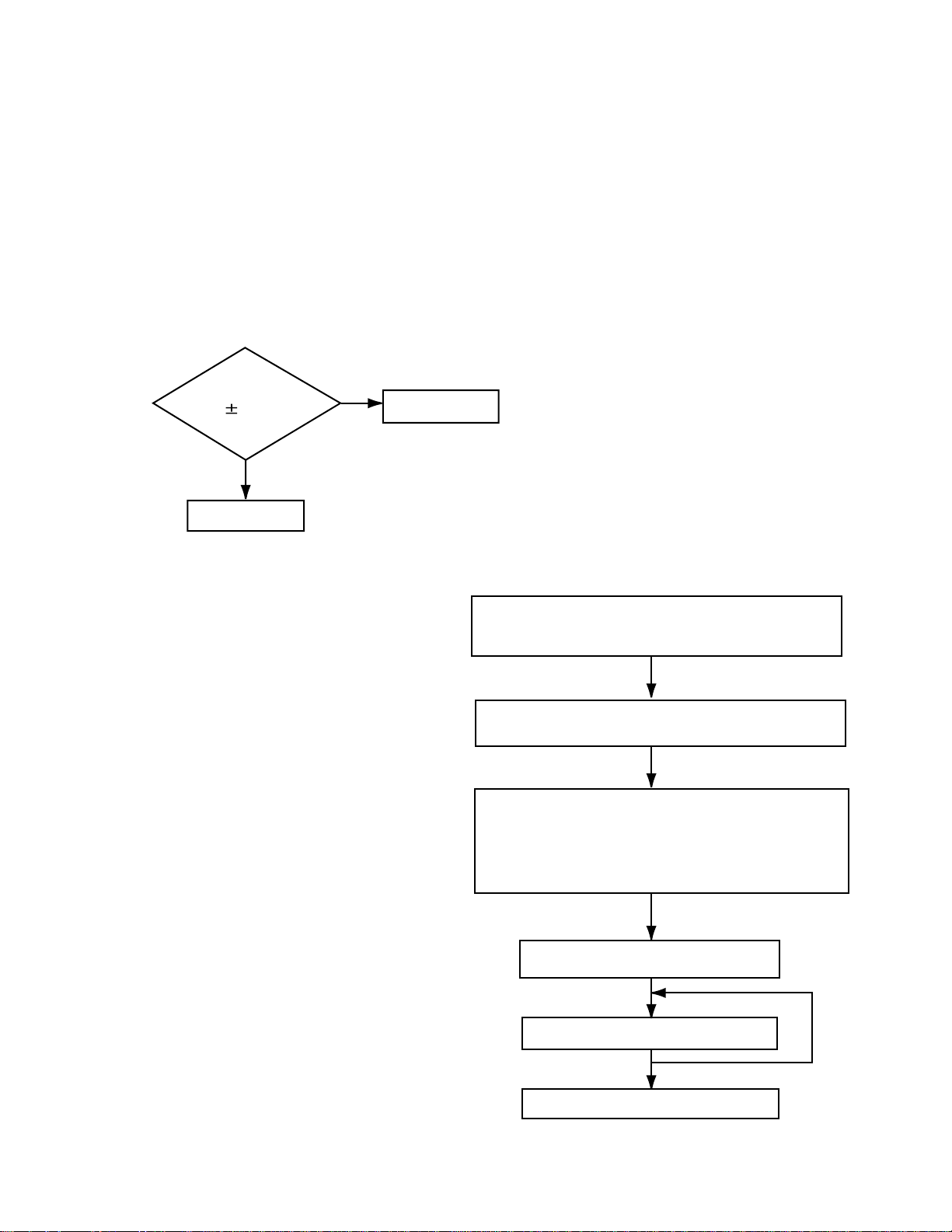

Flow of functional operation unit TOC read

Power ON

When the pickup correctly moves

to the inner area of the disc

Set Function CD

KD-SX975 / KD-SX875

When the laser diode correctly

emits

Microprocessor

commands

FMO

TC9462"53"

FEED MOTOR

+TERMINAL

IC581" 6 "

REST SW

When correctly focused

FEO

TA2109

14

Focus Servo Loop ON

$83

$82

$81

5V

Hi-Z

0V

6V

4V

2V

OFF

ON

Pickup feed to the inner area

2.2V

RF signal eye-pattern

remains closed

RF signal eye-pattern

opens

Disc inserted

YES

Laser emitted

Focus search

Disc rotates

Tracking loop closed

TOC readout

YES

Microprocessor

commands

SEL

TC9462

LD

CN501

57

1

"No disc"

display

When the disc correctly rotates

Microprocessor

commands

DMO

TC9462

Spindle

motor(-)

IC581" 5 "

$84 $86 $ A200

55

Acceleration Servo CLV

Rough

Servo

0.5 Sec 0.5 Sec

$84

5V

0V

4V

0V

5V

2.2V

0V

6V

3.2

2V

Jump to the first track

Play

Tracking Servo Loop ON

RF signal

Rough Servo Mode

CLV Servo Mode

(Program Area)

CLV Servo Mode

(Lead-In Area;

Digital: 0)

1-11

Page 12

KD-SX975 / KD-SX875

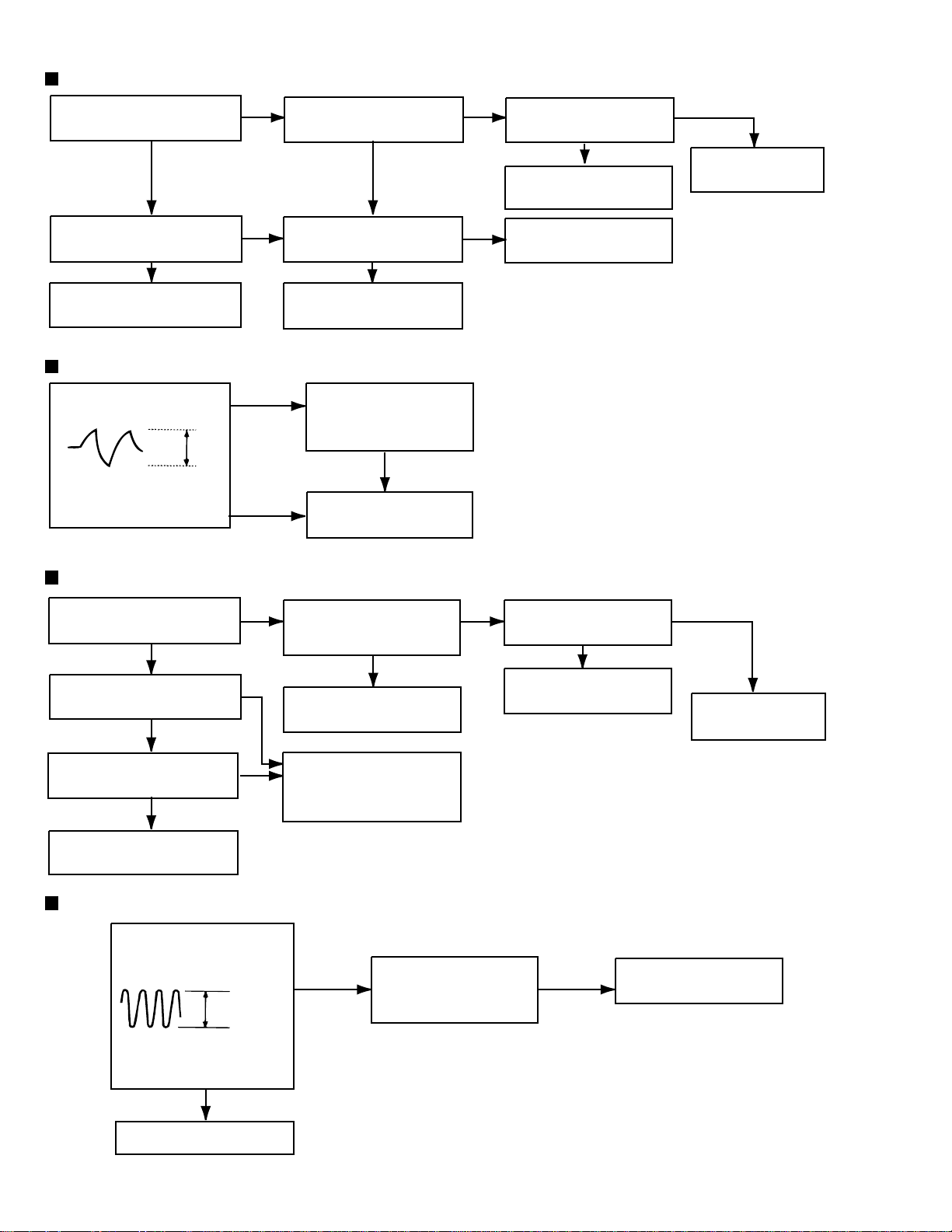

Feed section

Is the voltage output at

IC521 pin "53" 5V or 0V?

YES

Is 4V present at both

sides of the feed motor?

YES

NO YES NO

NO

Is the wiring for IC521

(90)~(100) correct?

NO

Is 6V or 2V present at

IC581 " 6 " and " 7 "?

NO

Is 5V present at IC581

pin "20"?

Check the vicinity of

IC521.

YES

Check the feed motor

connection wiring.

YES

Check CD 9V

and 5V.

Check the feed motor.

Focus section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC581 pins "8" and "9"?

Spindle section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Is the RF waveform at TP1

distorted?

YES

Proceed to the Tracking

section

Check IC581.

NO

YES

NO

NO

NO

Check the circuits in

the vicinity of IC501

pins "8","9"and"15".

Check the pickup and

its connections.

Is 4V present at IC581

pins "4" and "5"?

Check the spindle motor

and its wiring

Check the circuits in the

vicinity of IC501 "19"~

"24" or the pickup

YES

YES

NO

Is 4V present at IC521

pins "55" ?

Check the vicinity of

IC581.

NO

YES

Check IC501 and

IC521.

Tracking section

1-12

When the disc is rotated

at first:

Approx. 1.2V

Is the tracking error signal

output at IC501 "12"?

YES

Check IC521.

YES YES

Check the circuit in the

vicinity of IC501 pins

"2"~"12".

Check the pickup and

its connections.

Page 13

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up,please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

(1) The level of RF output (EFM output:ampli tude of eye pattern) will be low.

KD-SX975 / KD-SX875

Is RF output

1.3 0.4Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power. Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value, the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally, the laser

pickup may be damaged due to excessive current.

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

1-13

Page 14

KD-SX975 / KD-SX875

Description of major ICs

UPD178078GF-543 (IC701): SYSTEM CPU

1.Terminal layout

2.Block diagram

TO0/VTR-CONT

TI00/POWER

TI01/CD-ON

TI50/MUTE

TO50/NC

TI51/STAGE

TO51/NC

SI0/SB0/SDA0/NC

SO0/SB1/SDA1/VOL-DA

SCK0/SCL/VOL-CLK

SI1/JBUS-SI

SO1/JBUS-SO

SCK1/JBUS-SCK

STB/NC

BUSY/NC

SI3/NC

SO3/LCD-DA

SCK3/SCL/LCD-CLK

TXD0/LM1

RXD0/LM0

INTP0/NC

INTP7/NC

BEEP0/BUZZER

BUZ/NC

RESET

X1

X2

V

DDPORT

GNDPORT

VDD

VM45/VTR-LOGIC

REGOSC

REGCPU

GND0

GND1

16-bit TIMER/

EVENT COUNTER

8-bit TIMER/

EVENT COUNTER 0

8-bit TIMER/

EVENT COUNTER 1

WATCHDOG TIMER

BASIC TIMER

SERIAL

INTERFACE 0

SERIAL

INTERFACE 1

SERIAL

INTERFACE 3

8

INTERRUPT

CONTROL

BUZER OUTPUT

SYSTEM

CONTROL

VOLT AGE

REGULATOR

1

~

30

UART0

100 ~ 81

31 ~ 50

80

~

51

78k/0

CPU

CPRE

RAM

PD178078

:3Kbyte

PD178076

:2Kbyte

RESET

CPU

PERIPHERAL

V

OSC

VCPU

ROM

PD178078

:60Kbyte

PD178076

:48Kbyte

PORT 0

PORT 1

PORT 2

PORT 3

PORT 4

PORT 5

PORT 6

PORT 7

PORT10

PORT 12

PORT 13

A/D

CONVERTER

FREQUENCY

COUNTER

PLL

PLL

VOLT AGE

REGULATOR

NC,JBUS-INT,SW1,

8

REMOCON,PS1,PS2,

DETACH,NC

KEY0,KEY1,KEY2,LEVEL,

8

SM,OPEN.NC,

JBUS-SI,JBUS-SO,

8

JBUS-SCK,NC,VOL-DA,

VOL-CLK

VTR-LOGIC,VTR-CONT,

8

POWER,CD-ON,MUTE,

NC.BUZZER.NC

8

NC

NC,LCD-CE,SW2,SW3,

8

SW4,RST-SW,ENC1,ENC2

8

TEL MUTING.STAGE1.STAGE2

8

3

5

8

8

MONO,SEEK/STOP,

FM/AM.DIM IN.ANTENNA.

NC,LCD-DA,LCD-CLK,

JBUS-/O,LM0,LM1,BUCK,

CCE

SD/ST,NC,IFC

BUS0,BUS1,BUS2,BUS3,

RST

NC

AN10/KEY0

AN17/NC

DD

AV

AVSS

AMIFC/NC

FMIFC/IFC

EO0

EO1

VCOL

VCOH

DDPLL

V

GNDPLL

1-14

IC

GND2

Page 15

KD-SX975 / KD-SX875

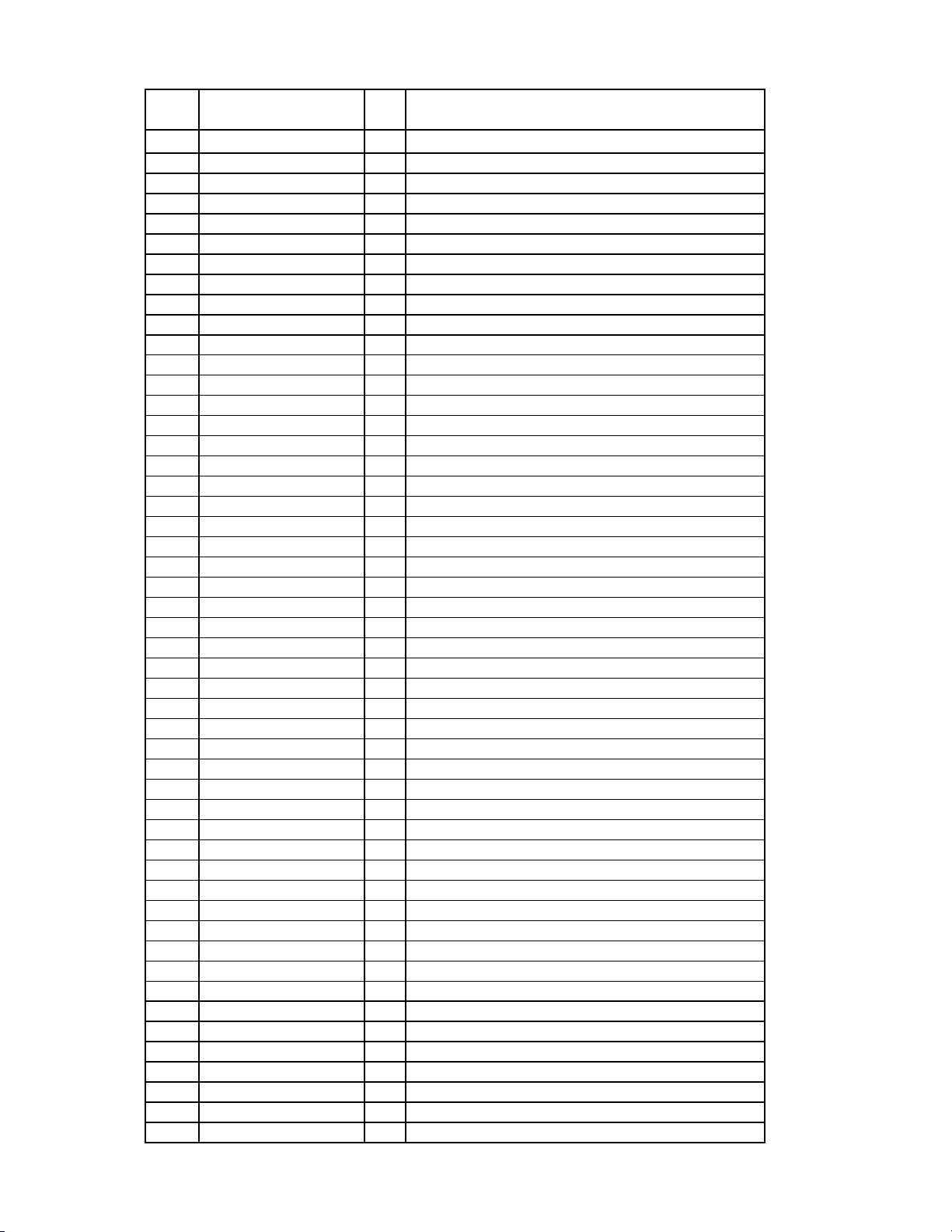

3.Pin function

Pin

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

NC

JBUS-INT

JBUS-SI

JBUS-SO

JBUS-SCK

NC

NC

NC

VOL-DA

VOL-CLK

NC

LCD-DA

LCD-CLK

JBUS-I/O

NC

LCD-CE

SW2

SW3

SW4

RST-SW

ENC1

ENC2

KEY0

KEY1

KEY2

LEVEL

AVDD

SM

OPEN

NC

NC

AVSS

REGCPU

VDD

REGOSC

X2

X1

GND

SD/ST

GND2

NC

IFC

VDDPLL

OSC-INPUT

NC

GNDPLL

AME0

FME0

ICVPP

RESET

UPD178078GF(1/2)

I/OSymbol

-

Non connection

I

JVC BUS COMMUNICATION LINE

I

JVC BUS COMMUNICATION LINE

O

JVC BUS COMMUNICATION LINE

O

JVC BUS COMMUNICATION LINE

-

Non connection

-

Non connection

-

Non connection

O

VOL IC COMMUNICATION LINE

O

VOL IC COMMUNICATION LINE

-

Non connection

O

CD DRIVER COMMUNICATION LINE

O

LCD DRIVER COMMUNICATION LINE

O

JVC BUS OUTPUT SELECT

-

Non connection

O

LCD DRIVER COMMUNICATION LINE

I

CD MECHA SW

I

CD MECHA SW

I

CD MECHA SW

I

TRAVERSE MECHA REST SW

I

ENCODER INPUT

I

ENCORDER INPUT

I

KEY INPUT

I

KEY INPUT

I

KEY INPUT

I

AUDIO LEVEL INPUT

-

-

I

SIGNAL LEVEL METER INPUT

I

DOOR OPEN DATECTION

-

Non connection

-

-

-

-

-

-

-

-

-

SYSTEM CLOCK

I

SYSTEM CLOCK

-

-

-

-

I

STATION DETECTOR & STERO IND

-

Non connection

-

IF COUNT INPUT

I

-

-

FM,AM OSC INPUT

I

Non connection

-

-

-

PLL ERROR OUTPUT FOR AM

O

PLL ERROR OUTPUT FOR FM

O

SETTING TO WRITE FOR FLASH

-

SYSTEM RESET

I

SYSTEM RESET

FUNCTION

1-15

Page 16

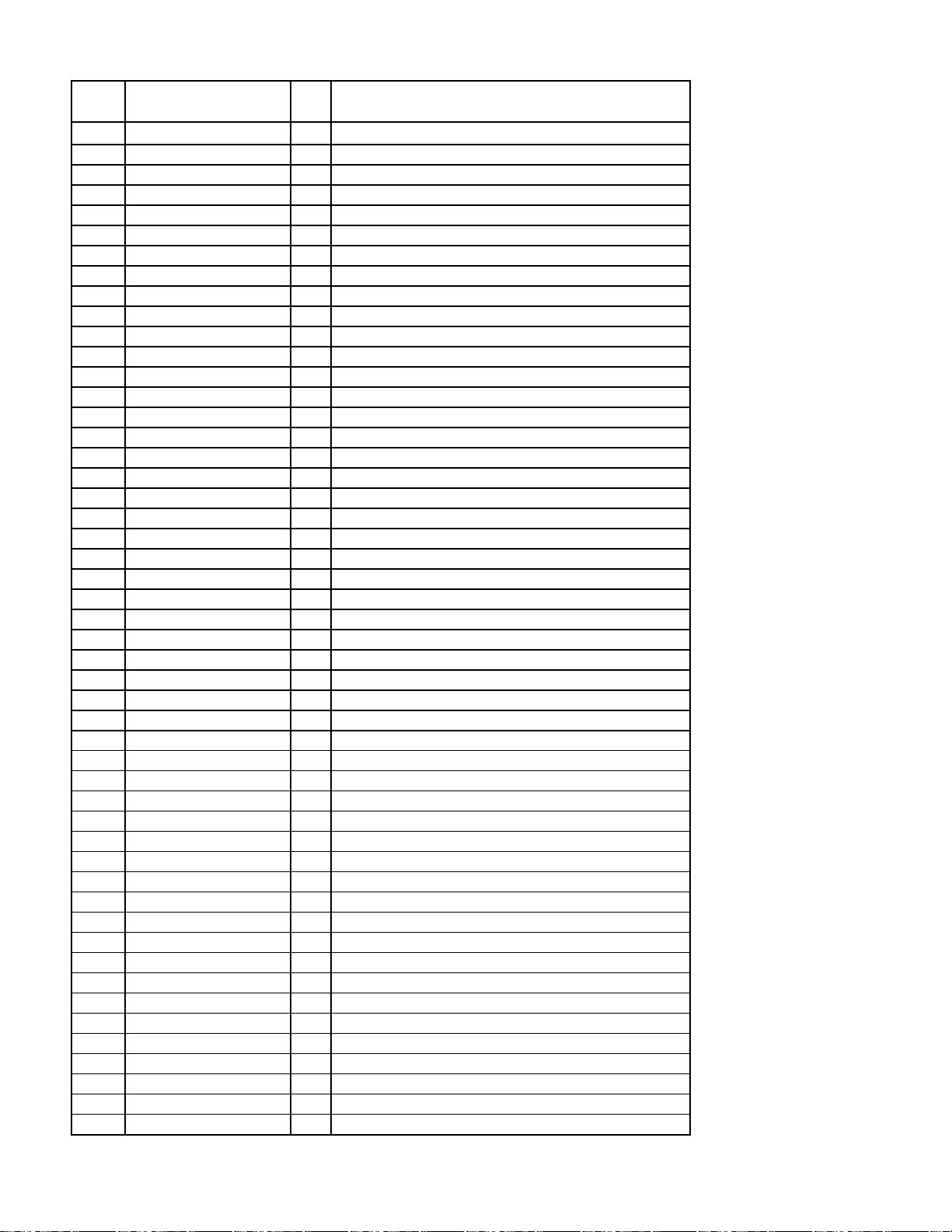

KD-SX975 / KD-SX875

Pin

NO.

51

SW1

52

REMOCON

53

VTR-LOGIC

54

VTR-CONT

55

POWER

56

CD-ON

57

MUTE

58

NC

59

BUZZER

60

NC

61

NC

62

NC

63

NC

64

NC

65

NC

66

NC

67

NC

68

NC

69

LM0

70

LM1

71

BUCK

72

CCE

73

BUS0

74

BUS1

75

BUS2

76

BUS3

77

RST

78

PS1

79

PS2

80

DETACH

81

NC

82

GND1

83

MONO

84

SEEK/STOP

85

FM/AM

86

DIMIN

87

ANT

88

TEL MUTE

89

STAGE1

90

STAGE2

91

NC

92

NC

93

NC

94

NC

95

NC

96

NC

97

NC

98

DIMMER

99

VDDPORT

100

GNDPORT

I/OSymbol

I

I

-

O

O

O

-

I

-

-

-

-

-

-

-

-

O

O

O

O

I/O

I/O

I/O

I/O

O

I

I

I

-

O

O

O

I

O

I

-

-

-

-

-

-

-

-

O

-

UPD178078GF(2/2)

FUNCTION

CD MECHA SW

REMOCON INPUT

Non connection

Non connection

POWER CONT.

CD POWER CONT.

MUTE CONT

Non connection

BEEP FOR SW OPERATION

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

CD MECHA DRIVER CONT.

CD MECHA DRIVER CONT.

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

CD LSI COMMUNICATION LINE

ACC DETECTION INPUT

MEMORY DETECTION

DETACH DETECTION

Non connection

MONO BY FORCE

SWITCHING SEEK & STOP

BAND SW

OUTPUT L

ILM CONTROL

ANT COTROL

TEL MUTE IN

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

Non connection

DIMMER CONTROL

-

-

1-16

Page 17

+

+

-

-

+

+

-

-

-

+

+

BA3220FV-X(IC341/IC441) : Line Out Amp

KD-SX975 / KD-SX875

1.Terminal layout

2.Block diagram

14

3220

17

8

CL-

14

1

LGND

13

REFL

2

Vcc

OUTL OUTR RGND

3

INL

1112

4

NFLCL+

10

REFR

FILTER

56

FIL

CR-

9

NFR

CR+

8

7

INR

1-17

Page 18

KD-SX975 / KD-SX875

BD3860K (IC301):E.Volume

1.Terminal layout

33 23

2.Bockdiagram

GND FIL VCC SEL1

6 5 9 40 36 35 343328323130 2919 15 14

POWER

SUPPLY

A1

41

B1

42

C1

43

D1

44

INPUT

1

2

3

4

SELECTOR

A2

B2

C2

D2

34

44

1 11

INPUT

GAIN

0 18 dB

INPUT

GAIN

0 18 dB

22

12

VIN1 LOUD1 HF1 LF1 DET1 TIN1 TNF1 BNF1

MAIN

VOLUME

0 -40 dB

LOUDNESS

MAIN

VOLUME

0 -40 dB

LOUDNESS

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

LOGIC

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

TREBLE

-14 +14dB

TREBLE

-14 +14dB

-14 +14dB

-14 +14dB

BASS

BASS

BOUT1VCA1 MIX1 BBOUT1

FADER

CH1 FRONT

0 -5 dB

FADER

CH1 REAR

0 -5 dB

FADER

CH2 REAR

0 -5 dB

FADER

CH2 FRONT

0 -5 dB

OUTF1

13

OUTR1

12

SI

7

SC

8

OUTR2

10

OUTF2

11

3.Pin function

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

A2

B2

C2

D2

FIL

GND

SI

SC

VCC

OUTR2

OUTF2

OUTR1

OUTF1

BOUT1

BNF1

BOUT2

BNF2

TNF2

TNF1

TIN2

BBOUT2

MIX2

CH2 Input Pin A

CH2 Input Pin B

CH2 Input Pin C

CH2 Input Pin D

1/2 VCC Pin

Ground Pin

Serial Data Receiving Pin

Serial Clock Receiving Pin

Power Supply Pin

CH2 Rear Output Pin

CH2 Front Output Pin

CH1 Rear Output Pin

CH1 Front Output Pin

CH1 Bass Filter Setting Pin

CH1 Bass Filter Setting Pin

CH2 Bass Filter Setting Pin

CH2 Bass Filter Setting Pin

CH2 treble Filter Setting Pin

CH1 treble Filter Setting Pin

CH2 treble Input Pin

CH2 BBE II Signal Output Pin

CH2 Output MIX Amplifier

Inverse Input Pin

39 38 37 25 24 26 23 22 21 20 18 17 16

Pin

Symbol Function

No.

23

24

25

26

27

28

29

30

BBOUT1

31

32

33

34

35

LOUD1

36

37

LOUD2

38

39

40

41

42

43

44

VCA2

LF2

HF2

DET2

NC

DET1

TIN1

MIX1

VCA1

LF1

HF1

VIN1

VIN2

SEL2

SEL1

A1

B1

C1

D1

CH2 High Pass VCA Output Pin

CH2 Low Pass Filter Setting Pin

CH2 High Pass Filter Setting Pin

CH2 High Pass Attack/Release Time Setting Pin

Non connect

CH1 High Pass Attack/Release Time Setting Pin

CH1 treble Input Pin

CH1 BBE II Signal Output Pin

CH1 Output MIX Amplifier Inverse Input Pin

CH1 High Pass VCA Output Pin

CH1 Low Pass Filter Setting Pin

CH1 High Pass Filter Setting Pin

CH1 Loudness Filter Setting Pin

CH1 Main Volume Input Pin

VCH2 Loudness Filter setting Pin

CH2 Main Volume Input Pin

CH2 Input Gain Output Pin

CH1 Input Gain output Pin

CH1 Input Pin A

CH1 Input Pin B

CH1 Input Pin C

CH1 Input Pin D

BOUT2BNF2TNF2TIN2BBOUT2MIX2VCA2DET2LF2HF2LOUD2VIN2SEL2

1-18

Page 19

HA13164(IC961):REGULATOR

1.Terminal layout

123456789101112131415

KD-SX975 / KD-SX875

2.Block diagram

ANT OUT

C3

0.1u

EXT OUT

C4

0.1u

ANT CTRL

CTRL

CD OUT

C5

0.1u

AUDIO OUT

C6

10u

11

12

10

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

14

UNIT R:

+B

ACC

ILMOUT

R1

C7

0.1u

C8

0.1u

C1

100u

VCC ACC

8

2

1

7

Surge Protector

BIAS TSD

15

3

note1) TAB (header of IC)

connected to GND

ILM AJGND

13

C2

0.1u

C:F

3.Pin function

Pin No. Symbol Function

1

2

EXTOUT

ANTOUT

Output voltage is VCC-1 V when M or H level applied to CTRL pin.

Output voltage is VCC-1 V when M or H level to CTRL pin and H level

to ANT-CTRL.

3

4

5

6

7

8

9

10

11

12

13

14

15

ACCIN

VDDOUT

SW5VOUT

COMPOUT

ANT CTRL

VCC

BATT DET

AUDIO OUT

CTRL

CD OUT

ILM AJ

ILM OUT

GND

Connected to ACC.

Regular 5.7V.

Output voltage is 5V when M or H level applies to CTRL pin.

Output for ACC detector.

L:ANT output OFF , H:ANT output ON

Connected to VCC.

Low battery detect.

Output voltage is 9V when M or H level applied to CTRL pin.

L:BIAS OFF, M:BIAS ON, H:CD ON

Output voltage is 8V when H level applied to CTRL pin.

Adjustment pin for ILM output voltage.

Output voltage is 10V when M or H level applies to CTRL pin.

Connected to GND.

1-19

Page 20

KD-SX975 / KD-SX875

HD74HC126FP-X (IC771) : Buffer

1.Terminal layout

1C

1

1A

2

3

1Y

4

2C

5

2A

6

2Y

GND

2.Block diagram

7

Input

3Y

14

3A

13

12

3C

11

4Y

10

4A

9

4C

8

Vcc

Vcc Vcc

1A

2A

3A

4A

1C

2C

3C

See Function Table

4C

3.Pin function

Output

1Y

Output

2Y

Output

3Y

Output

4Y

Input Output

C

A

L

X

H

L

H

H

Note:

1k

CL

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

Y

Z

H

L

H : High

L : Low

X : H and L

Z : H.L.X

S1

1k

1-20

Page 21

LC75873NW(IC601):LCD Driver

KD-SX975 / KD-SX875

1.Pin layout

60 41

61

80

1 20

3.Pin function

Pin No.

79,80

1,2,3

to 66

67

78

69

40

21

Pin name

S1/P1 TO S4/P4

S5 to S68

COM1

COM2

COM3

2.Block diagram

VDD1

VDD2

INH

OSC

VDD

VSS

I/O

O

O

S5

S4/P4

S3/P3

S2/P2

COM2

COM3

COMON

DRIVER

CLOCK

GENERATOR

COM1

S68

S67

DI

CL

SEGMENT DRIVER

SHIFT REGISTOR

ADDRESS

DETECTOR

CE

S1/P1

Description

Segment outouts for displaying the display data

transferred by serial data input.

The S1/P1 to S4/P4 pins can be used as generalpurpose output ports under serial data control.

Common driver outputs.

The frame frequency f0 is given by :

f0 = (FOSC/384)Hz.

74

76

77

78

75

71

72

70

OSC

CE

CL

DI

INH

VDD1

VDD2

VDD

I/O

I

I

I

I

I

I

-

Oscillator connection

An oscillator circuit is formed by connecting an

external resistor and capacitor to this pin.

Serial data transfer inputs.

Connected to the controller.

CE:Chip enable

CL:Synchronization clock

DI:Transfer data

Display off control input

INH= "L"(VSS) Display forced off

S1/P1 to S4/P4 = "L"

(These pins are forcibly set to the

segment output port function and held

at the low level.)

S5 to S68 = "L"

COM1 to COM3"L"

INH = "H"(HDD) Display on

However, serial data transfer is possible when

the display is forced off by this pin.

Used for applying the LCD drive 2/3 bias voltage

externally. Must be connected to VDD2 when a

1/2 bias drive scheme is used.

Used for applying the LCD drive 1/3 bias voltage

externally. Must be connected to VDD1 when a

1/2 bias drive scheme is used.

Power supply connection.

Provide a voltage of between 3.0 and 6.0V.

73

VSS

-

Power supply connection. Connect to ground.

1-21

Page 22

KD-SX975 / KD-SX875

LA4743K(IC351):Power AMP

1.Block diagram

IN 1

TAB

IN 2

+

0.22 F

+

0.22 F

11

1

12

Vcc 1/2 Vcc 3/4

6 20

-

+

Protective

circuit

-

+

2200 F 0.022 F

+

9

-

7

+

OUT 1+

OUT 1-

PWR GND1

8

+

OUT 2+

5

-

OUT 2-

3

PWR GND2

2

ST BY

R.F

47 F

IN 3

PRE GND

IN 4

+5V

ST ON

+

0.22 F

N.C

+

0.22 F

4

Stand by

Switch

Mute

10

+

Ripple

Filter

Mute

22

circuit

3.3 F

+

15

-

+

-

17

19

10K

+

OUT 3+

OUT 3-

Low Level

Mute ON

25

18

21

23

PWR GND3

OUT 4+

OUT 4-

13

14

Protective

circuit

-

+

+

-

1-22

ON TIME C

22 F

Muting &

16

+

ON Time Control

Circuit

PWR GND4

24

Page 23

2.Terminal layout

KD-SX975 / KD-SX875

F

F

VREF

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

TAB

GND

OUTFRSTBY

OUTFR+

VCC1/2

OUTRRGND

OUTRR+

VREF

INRR

INFR

SGND

INFL

INRL

ONTIME

OUTRL+

GND3

OUTRLVCC3/4

OUTFL+

MUTE

OUTFLGND4

NC

Header of IC

Power GND

Outpur(-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

Non connection

LA4743K

1-23

Page 24

KD-SX975 / KD-SX875

LA6567H-X(IC581):CD DRIVER

1.Pin layout & blockdiagram

VCC2

V05-

V05+

V04+

V04-

V03+

V03-

FR

1

2

3

4

5

6

7

FR

CH 3,4,5

Power supply

CH5

CH4

CH3

Thermal shutdown

Output control

Level shiftLevel shiftLevel shiftLevel shift

Input

22K 11K

Signal system power supply

28

27

26

25

24

23

22

FR

REV

FWD

S-GND

VCONT

VIN4

VIN4G

VCC-S

FR

V02+

V02-

V01+

V01-

VCC1

VIN1

VIN1G

8

9

10

11

12

13

14

CH2

CH1

CH1,2

Power supply

11K

22K

5VREG(PNPTr

The outside putting)

22K

11K

22K

11K

21

20

19

18

17

16

15

VREF-IN

REG-OUT

REG-IN

VIN3G

VIN3

VIN2G

VIN2

1-24

Page 25

KD-SX975 / KD-SX875

2. Pin function

Pin no. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

VCC2

V05V05+

V04+

V04V03+

V03V02+

V02V01+

V01-

VCC1

VIN1

VIN1G

VIN2

VIN2G

VIN3

VIN3G

REG-IN

REG-OUT

VREF-IN

VCC-S

VIN4G

VIN4

VCONT

S-GND

FWD

LA6567H-X(2/2)

Function

CH3,4,5 Power supply( It is short with VCC1,VCC-S)

Loading output(-)

Loading terminal (+)

CH4 Output terminal(+)

CH4 Output terminal(-)

CH3 Output terminal(+)

CH3 Output terminal(-)

CH2 Output terminal(+)

CH2 Output terminal(-)

CH1 Output terminal(+)

CH1 Output terminal(-)

CH1,2(BTL) Power supply(It is short with VCC-S,VCC2)

CH1 Input terminal

CH1 Input terminal(For gain adjustment)

CH2 Input terminal

CH2 Input terminal(For gain adjustment)

CH3 Input terminal

CH3 Input terminal(For gain adjustment)

Regulator terminal(Outside putting PNP base)

Regulator terminal(Outside putting PNP collector)

Standard voltage input terminal

Signal system power supply(It is short with VCC1,VCC2)

CH4 Input terminal(For gain adjustment)

CH4 Input terminal

5CH(VLO) Output voltage set terminal

Signal system GND

5CH(VLO)Signal output switch terminal(FWD),Input of logic of loading part

28

REV

5CH(VLO)Signal output switch terminal(REV),

Input of logic of loading part

Frame(FR)at the center becomes system GND.

Please be short-circuited on the outside and use the terminal of the power supply system

and three teminals of VCC-S, VCC1,VCC2.

1-25

Page 26

KD-SX975 / KD-SX875

TA2109F-X (IC501) : RF amp.

1. Pin layout

24 13

112

2. Block diagram

SBAD

13

FEO

14

10pF

FEN

15

VRO

16

RFRP

17

RFIS

18

RFGO

19

10k ohm

21k ohm

20k ohm

20k ohm

50k ohm

36pF

7.96k ohm

50uA

20k ohm

15k ohm 30k ohm

15k ohm

20uA

10k ohm

21k ohm

12k ohm

12k ohm

PEAK

BOTTOM

10k ohm

10k ohm

30k ohm

21k ohm 29k ohm

24k ohm 24k ohm

180k ohm

1.74k ohm

20pF

65uA

47k ohm

SW3

13k ohm

7.67k ohm

10k ohm

3 STATE

DET.

SW2

680 ohm

2.12k ohm

SW1

LOC

1k ohm

20pF

TEO

TEN

2VRO

TEB

SEL

LDO

MDI

12

11

10

9

8

7

6

3. Pin function

Pin

SymbolI/O

No.

Vcc

FNI

FPI

TPI

TNI

MDI

SEL

I

I

I

I

I

O

I

I

O

I

O

10

11

12

1

2

3

4

5

6

7

8

9

LDO

TEB

2VRO

TEN

TEO

RFGC

20

AGCI

21

re=130 ohm

RFO

22

GND

23

RFN

24

23.5k ohm

3.3k ohm

12k ohm

1.53k ohm

3.3k ohm

Pin function

Power supply input terminal

Main beam I-V amp input terminal

Main beam I-V amp input terminal

Sub beam I-v input terminal

Sub beam I-V input terminal

Monitor photo diode amp input terminal

Laser diode amp output terminal

Laser diode control signal input terminal

T. error balance adj. signal input terminal

Reference voltage output terminal

TE amp negative input terminal

TE error signal output terminal

180k ohm

40pF

180k ohm

Pin

No.

13

14

15

16

17

18

19

20

21

22

23

24

180k ohm

20pF

60k ohm

60k ohm

40pF

SymbolI/O

SBAD

RFRP

RFGO

RFGC

FEO

FEN

VRO

RFIS

AGCI

RFO

GND

RFN

O

O

I

O

O

I

O

I

I

O

-

I

TNI

TPI

FPI

FNI

Vcc

5

4

3

2

1

I-I

I-I

20k ohm

20k ohm

20k ohm

20k ohm

Pin function

Sub beam adder signal output terminal

Focus error signal output terminal

FE amp negative input terminal

Reference voltage (VREF) output terminal

Track count signal output terminal

RFRP detect circuit input terminal

RF gain signal output terminal

RF amplitude adj. control signal input terminal

RF signal amplitude adj. amp input terminal

RF signal output terminal

Ground terminal

RF amp negative input terminal

1-26

Page 27

TC9462F(IC521):

1.Pin layout & Block Diagram

KD-SX975 / KD-SX875

RST

DD

XV

80

79

81DV

SR

82RO

83DV

DD

84DVR

85LO

86DV

SL

87TEST1

88TEST2

89TEST3

90BUS0

91BUS1

92BUS2

93BUS3

94V

DD

95V

SS

96BUCK

97CCE

98TEST4

99TSMOD

100

1 2 3

TEST0

XO78XI

LPF

HSO

Micon

interface

UHSO

SS

XV

77

4 5

EMPH

DD

V

75

76

1bit

DAC

PXO

SS

PXI

V

74

73

Clock

generator

Correction

circuit

Audio out

circuit

6

7 8 9 10 11 12 13

SS

V

BCK

LRCK

AOUT

TESIO1

72

DOUT

71

TESIN

MBOV

DACT

69

70

Address circuit

16KRAM

Digital out

IPF

CKSE

SBOK

DMOUT

68

CLCK

IO3

IO265IO164IO063V

67

66

ROM

RAM

Synchronous

guarantee

EFM decode

Sub code

decoder

14 15

16 17 18 19 20 21 22

SS

DD

V

V

DATA

SFSY

SS

DD

V

FLGD60FLGC59FLGB58FLGA57SEL562V

61

62

Servo

control

Digital equalizer

Automatic adjustment

circuit

CLV servo

Status

SBSY

SPDA

SPCK

COFS

PWM D/A

23 24 25

DD

V

MONIT

REF

DMO54FVO53FMO52TEBC51RFGC

55

A/D

Data

slicer

VCO

PLL

TMAX

26

REF

HSSW

P2V

TESIO0

27 28

ZDET

-

+

+

PDO

50 V

REF

49 TRO

48 FOO

TEZI

+

TMAXS

30

TMAX

47

46 TEI

45 TSIN

44 SBAD

43 FEI

42 RFRP

41 RFZI

40 RFCT

39 AV

DD

38 RFI

37 SLCO

36 AV

SS

35 VCOF

34 VCOREF

33 PV

REF

32 LPFO

31 LPFN

+

-

-

-

29

2.Pin function

PIN No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 P2V

SYMBOL

TEST0

HSO

UHSO

EMPH

LRCK

V

SS

BCK

AOUT

DOUT

MBOV

IPF

SBOK

CLCK

V

DD

V

SS

DATA

SFSY

SBSY

SPCK

SADA

COFS

MONIT

V

DD

TESIO0

REF

FUNCTIONAL DESCRIPTION

I/O

Test mode terminal.Normally, Keep at open.

I

Playback speed mode flag output terminal.

UHSO

HSO

O

H

H

L

O

Subcode Q data emphasis flag output terminal.Emphasis ON at "H" level and OFF at "L"

O

level.The output polarity can invert by command.

Channel clock output terminal.(44.1khz)L-ch at "L" level and R-ch at "H" level. the output

O

polarity can invert by command.

Digital GND terminal.

-O

Bit clock output terminal.(1.4112MHz)

Audio data output terminal.

O

Digital data output terminal.

O

Buffer memory over signal output terminal. Over at "H" level.

O

Correction flag output terminal. At "H" level,AOUT output is made to correction

O

impossibility by C

Subcode Q data CRCC check adjusting result output terminal.

O

The adjusting result is OK at "H" level.

Subcode P W data readout clock input/output terminal.

I/O

This terminal can select by command bit.

--

Digital power supply voltage terminal.

--

Digital GND terminal.

O

Subcode P W data output terminal.

O

Play-back frame sync signal output terminal.

O

Subcode block sync signal output terminal.

O

Processor status signal readout clock output terminal.

O

Processor status signal output terminal.

O

Correction frame clock output terminal. (7.35kHz)

Internal signal (DSP internal flag and PLL clock) output terminal.Selected by command.

O

This terminal output the text data with serial by command.

--

Digital power supply voltage terminal.

Test input/output terminal.Normally,keep at "L" level.

I

The terminal that inputted the clock for read of text data by command.

--

PLL double reference voltage supply terminal.

L

PLAYBACK SPEED

H

L

H

Nomal

2 times

4 times

L

2

correction processing.

--

REMARKS

With pull-up resistor.

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

1-27

Page 28

KD-SX975 / KD-SX875

Pin No.

26

27

28

29

30

Symbol

HSSW

ZDET

PDO

TMAXS

TMAX

I/O

2/4 times speed at "VREF" voltage.

O

1 bit DA converter zero detect flag output terminal.

O

Phase difference signal output terminal of EFM

O

Function Remarks

signal and PLCK signal.

TMAX detection result output terminal. Selected by

O

command bit (TMPS)

TMAX detection result output terminal. Selected by

O

command bit (TMPS)

DIFFERENCE RESULT TMAX OUTPUT

Longer than fixed freq. "P2VREF"

Shorter than fixed freq. "VSS"

Within the fixed freq. "Hiz"

TC9462F(2/3)

2-state output(PVREF,HiZ)

-

3-state output.

(P2VREF,PVREF,VSS)

3-state output.

(P2VREF,PVREF,VSS)

3-state output.

(P2VREF,HiZ,VSS)

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58~61

62

63

64~67

68

69

70

LPFN

LPFO

PVREF

VCOREF

VCOF

AVSS

SLCO

RFI

AVDD

RFCT

RFZI

RFRP

FEI

SBAD

TSIN

TEI

TEZI

FOO

TRO

VREF

RFGC

TEBC

FMO

FVO

DMO

2VREF

SEL

FLGA~D

VDD

VSS

IO0~3

DMOUT

CKSE

DACT

LPF amplifier inverting terminal for PLL.

I

LPF amplifier output terminal for PLL.

O

PLL reference voltage supply terminal.

VCO center frequency reference level terminal. Normally,

I

keep at "PVREF" level.

VCO filter terminal.

O

Analog GND terminal.

Data slice level output terminal.

O

RF signal input terminal.

I

Analog power supply voltage terminal.

RFRP signal center level input terminal

I

RFRP zero cross input terminal

I

RF ripple signal input terminal

I

Focus error signal input terminal

I

Sub-beam adder signal input terminal

I

Test input terminal Normally, keep at "vref" level

I

Tracking error signal input terminal. Take in at tracking

I

servo ON.

Tracking error zero cross input terminal

I

Focus servo equalizer output terminal

O

Tracking servo equalizer output terminal

O

Analog reference voltage supply terminal

RF amplitude adjustment control signal output terminal

O

Tracking balance control signal output terminal

O

Feed equalizer output terminal

O

Speed error signal or feed search equalizer output

O

terminal

Disk equalizer output terminal

O

DSP, Synchronize to PXO)

Analog double reference voltage supply terminal

APC circuit ON/OFF indication signal output terminal

O

External flag output terminal for internal signal

O

Digital power supply voltage terminal

Digital GND terminal

General I/O terminal

I/O

This terminal control IO0~IO3 terminal

I

Normally, keep at open

I

DAC test mode terminal. Normally, keep at open

I

(PWM carrier=88.2kHz for

Analog input.

Analog output.

-

-

Analog output.

Analog output.

Analog input.

(Zin:selected by command)

Analog input(Zin : 50k )

Analog input.

Analog input.

Analog input.

Analog input.

Analog input.

Analog input.

Analog input(Zin :10k )

Analog output.(2VREF AVSS)

3-state PWM signal

output.

(2VREF,VREF,VSS)

(PWM carrier

=88.2kHz)

3-state output.

(2VREF,VREF,VSS)

-

-

-

-

-

With pull-up resistor.

With pull-up resistor.

With pull-up resistor.

1-28

Page 29

Pin No.

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87~89

90~93

94

95

96

97

98

99

100

Symbol

TESIN

TESIO1

VSS

PXI

PXO

VDD

XVSS

XI

XO

XVDD

DVSR

RO

DVDD

DVR

LO

DVSL

TEST1~3

BUS0~3

VDD

VSS

BUCK

CCE

TEST4

TSMOD

RST

I/O

Test input terminal, Normally, keep at "L" level

I

Test input/output terminal. Normally, keep at "L" level

I

Digital GND terminal

Crystal oscillator connecting input terminal for DSP

I

Crystal oscillator connecting output terminal for DSP

O

Digital power supply voltage terminal

Oscillator GND terminal for system clock

Crystal oscillator connecting input terminal for system

I

clock

Crystal oscillator connecting output terminal for system

O

clock

Oscillator power supply voltage terminal for system clock

Analog GND terminal for DA converter (Rch)

R channel data forward output terminal

O

Analog supply voltage terminal for DA converter

Reference voltage terminal for DA converter

L channel data forward output terminal

O

Analog GND terminal for DA converter (Lch)

Test mode terminal . Normal keep at open

I

Micon interface data input/output terminal

I/O

Digital power supply voltage terminal

Digital GND terminal

Micon interface clock input terminal

I

Command and data sending/receiving chip enable signal

I

input terminal

Test mode terminal. Normal, keep at open

I

Local test mode selection terminal

I

Reset signal input terminal. Reset at "L" level

I

Function Remarks

KD-SX975 / KD-SX875

TC9462F(3/3)

Analog input.

Analog input.

-

-

-

-

-

-

-

-

-

-

-

-

-

With piull-up resistor.

Schmit input.

With pull-up resistor.

-

Schmit input.

Schmit input.

With pull-up resistor.

With pull-up resistor.

With pull-up resistor.

1-29

Page 30

KD-SX975 / KD-SX875

NJM4565M-WE (IC111) : Ope. amp

A OUTPUT

1

+

8

V

-

A INPUT

+

A INPUT

2

3

-

4

V

RPM6938-SV4(IC602) : Remote Censor

1.Block diagram

B OUTPUT

7

B INPUT

-

6

5

+

B INPUT

I/V

conversion

AMP

PD

magnetic shield

BPF

fo

trimming

circuit

AGC

Detector

Vcc

Comp

Vcc

22k

Rout

GND

1-30

Page 31

KD-SX975 / KD-SX875

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,Japan

(No.49620)

Printed in Japan

200102(V)

Page 32

1

CD Mechanism

ABC

CD PICKUP UNIT MECHA. SWITCH

SW1~4

TRACKING

FOCUS

CN501

RF AMP

IC501

TA2109F-X

RF

TE

FE

FMO

DMO

TRO

FOO

DSP & DAC

IC521

TC9462F

SPINDLE/FEED

MOTOR

SPINDLE

FEED

LOADING MOTOR

LOADING

CD DRIVER

IC581

LA6567-X

BUS0~3

BUCK,CCE,RST

SW1~4

LM 0/1

2

3

4

KD-SX975/KD-SX875

5

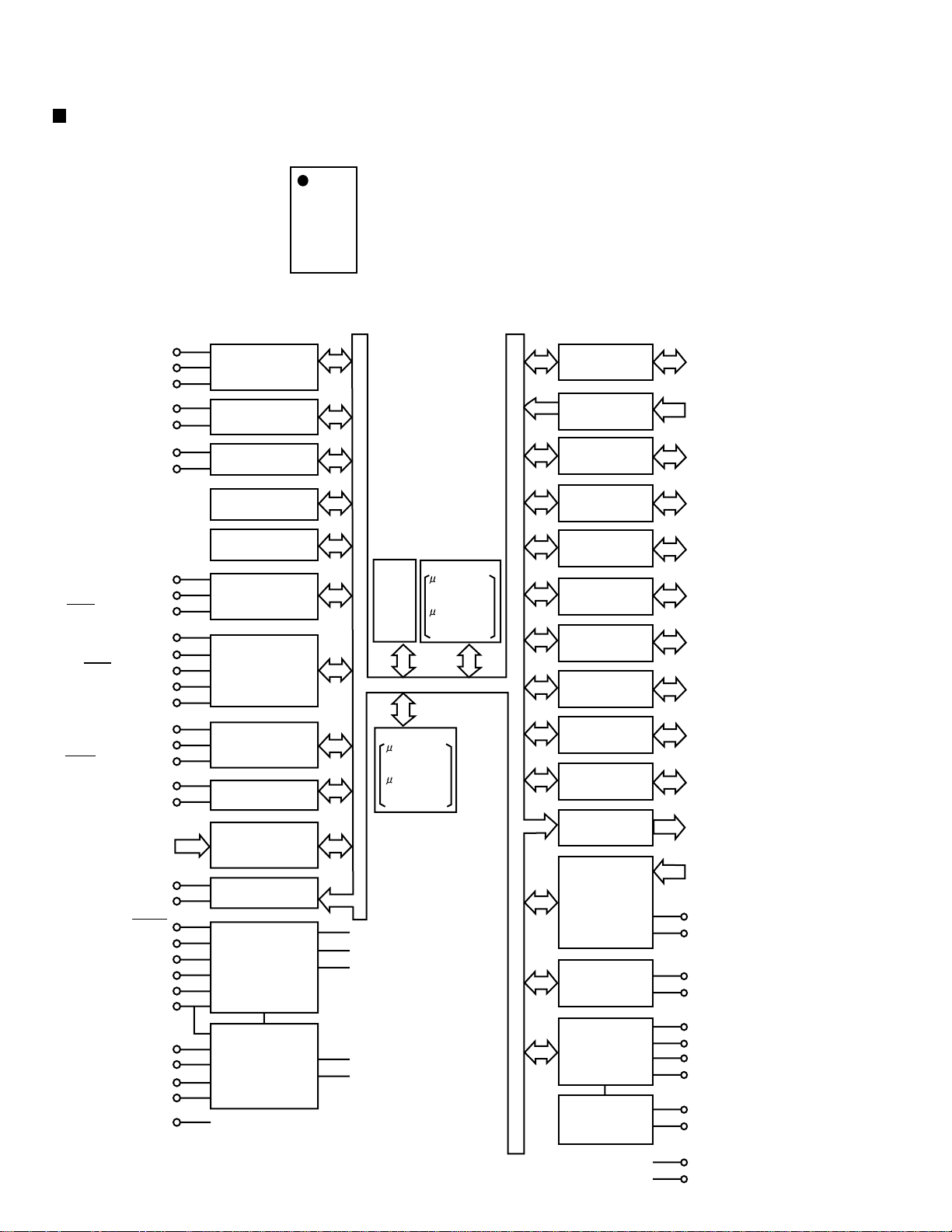

Block diagram

SYSTEM

CONTROLLER

IC701

uPD178078GF-543

CD LPF

IC111

NJM4565M

CHANGER

CONTROL

IC771

HD74HC126FP

CH L/R

TUL/R

FM/AM

TUNER

TU1

CD L/R

VOL CL

VOL DA

E.VOL

IC301

BA3860K

AM/FM

IC341,441

L/R -CH

LINE AMP

BA3220FV

POWER

AMP.

IC351

LA4743K

TEL

MUTE

FR ONT L/R

REAR L/R

(ONLY for

KD-SX975)

FRONT L

FRONT R

REAR L

REAR R

REG

CN701

J1

ENC 1,2

CN601

VOLUME JOG

EN601

REMOCON

REMOTO CONTROL

RECEIVER

IC680

RPM6938-SV4

KEY0~2

OPERATION SW.

S601~S620

LCDDI

LCDCLK

LCDCE

LCD DRIVER

IC602

LC75873NW

S1~S68 COM1~3

LCD1

QLD0163-001

Front P.C.B

Main P.C.B

J771

Changer

CN901

LINE OUT

J931

2-1

Page 33

KD-SX975 / KD-SX875

< MEMO >

2-2

Page 34

KD-SX975/KD-SX875

Standard schematic diagrams

Receiver & system control section

TU1

QAU0223-001

L1

R42

3.9K

Q42

R32

1K

Q32

2SD601

QAN0009-001Z

Q871

UN2211

C872

LCDCE

LCDDA

LCDCL

KEY2

KEY1

KEY0

DIMMER

0.1

C699

D708

D709

C772

0.01

ENC1

ENC2

33uH

1SS133

1SS133

0.1/50

22/16

D1

D2

C44

C43

R45

1K

R35

1K

R43

1K

R34

470

R33

10K

0.1/50

REM

10V

D711

R737

D710

47K

R779

R776

100k

R777

22K

R778

C17

120p

510

100

D31

C33

220/10

SLR-56MC3F

12p

C15

UDZS10B-X

PL701

QLD0033-001

R775

IC771

HD74HC126FP

FMOSC

150p

2SB1197K/QR/

FM/AM

SD/ST

10k

0.047

C1

C7

C34

0.22/50

Q6

R8

1K

Q8

UN2211

0.047

C771

5

4

9V

CD.R

GND

CD.L

REST

SW1

SW2

SW3

SW4

LM0

LM1

BUS0

BUS1

BUS2

BUS3

BUCK

3

CCE

RST

CD8V

CN701

QNZ0007-002

2

1

Note:/tr/s/jes/sx875/3181.001

FSDH3181-006BW 1/3

KD-SX870J/770J/777UR/875U/975U SERIES

QNZ0095-001

J1

QNZ0009-001

C41

0.056

C42

0.012

R41

Q41

1K

FMEO

2SC3661-X

2SC3661-X

C31

2.2/50

C32

0.001

1.5K

AMEO

C16

7p

J771

D701

D702

C873

Q31

2SD601

R31

1K

R871

BZ871

4.7/25

C871

0.1/50

D707

D706

D705

D704

D703

CH.R

GND

CH.L

ABCD E F G

R774

R952D951

C952

0.047

2.2/50

2.2/50

10K

R332R431

10K

C431

2.2/50

C432

2.2/50

C709

Q964

UN2211

Q951

22/16

C953

R331

10K

R432

0

B962

12k

2SD601A( R)

100

R955

1k

R956

C342

C345

C344

10K

C442

C445

C444

FMEO

AMEO

FMOSC

IFC

SD/ST

SM

PS2

Q963

2SB709A

R345

47K

R445

R965

R967

180k

R953

C951

1/50

47k

22k

R954

R951

R351

C962

UN2111

47K

R347

47K

R446

CRS03

D964

47/16

47K

R346

47K

R447

CRS03

R914

10K

D965

R962

R963

R352

R451

R452

R371

R372

D372

1SS355-X

D371

1SS355-X

D471

1SS355-X

D472

1SS355-X

R471

R472

4.7K 9.1K

33K

IC341

BA3220FV

33K

33K

BA3220FV

33K

C914

D976

1SS133

4.7K

R971

10/16

R891

C964

47K

UN2211

IC961

HA13164

4.7/25

C976

47/6.3

Q891

C963

Q976

10/16

0.047

C341

100/10

100/10

C441

100/10

C891

R892

D892

C975

C346

C347

C343

C446

C447

C443

100/10

1K

1SS355-X

UN2111

D977

0.01

2.2/50

2.2/50

2.2/50

2.2/50

D891

1SS355-X

UDZ11B-X

C977

100/16

Q977

C965

22/16

R341

R342

4.7/25

47/16

24K

R344

4.7/25

24K

150K

100/10

C348

4.7/25

47/16

4.7/25

TELMUTE

ILL

10K

R966

27K

150K

R442

R444

24K

24K

C969

1SS355-X

220/10

D961

CTRL

C968

220/10

R972

C967

47k

IC441

220/10

Q971

UN2211

C971

R343

R441

R443

C966

0.01

22/16

R354

R453

820

820

R373

2.2K( 1/10)

R473

2.2k

820

820

C961

LA4743K

R353R454

R374

2.2k

R474

2.2k

R961

1K( 1/4W)

2.2/50

D962

CRS03

0.047

C371

2.2/50

2.2/50

2.2/50

2.2/50

C351

C352

C451

C452

IC351

270P

C372

390P

C354

390P

C453

Q371

2SD1048/6-7

Q471

2SD1048/6-7

100

R475

390P

C353

390P

C454

Q372

2SD1048/6-7

Q472

2SD1048/6-7

100100

R375R476

100

R376

C357

CRS03

D963

QNN0176-001

J931

0.022

R356

R355

1SS133

D351

L961

QQR0703-001

R968

2.2K( 1/8W)

47/16

C358

10K

47K

47K

R358

R357

Q351

UN2211

D960

1N5401TU

C960

2200/16

R969

2.2K( 1/8W)

QNZ0002-001

CN901

QMFZ047-150-T

C359

22/16

4.7/25

C361

D991

D992

D993

D994

D995

D996

D997

D998

C991

C992

C993

C994

C995

C996

C997

C998

4.7/25

C362

CRS03

CRS03

CRS03

CRS03

CRS03

CRS03

CRS03

CRS03

100P

100P

100P

100P

100P

100P

100P

100P

C984 C983 C982 C981

C356

0.022

0.1 0.1 0.1 0.1

100/16

C355

0

0

0

R359

R360

0.1

C970

1SS133

270k

1SS133

0.22/50

C954

R957

D952

100

C705

22p

C707

C706

22p

220/6.3

B704

R753

R324

0

R323

0

C331

C332

R424

0

R423

0

L701

4.7uH

0.01

C714

S703

QSW0451-001

C708

220/6.3

C702

0.1

4.7uH

L702

0

0.047

47K

S701

QSW0451-001

10V

0.01

C712

51K

B961

C203

R201

R101

C2

2SB709A( R)

22K

0.47

R2

C11

BUZZER

R9

47K

15

R16

SM

QSW0451-001

MONO

SEEK/STP

FM/AM

ILL

ANT

TELMUTE

R765

R767

VDD

0.1/50

R102

Q2

UN2211

15

0.01

R6

C12

MONO

IFC

SEEK/STP

S702

R747

4.7K

C710

0.1

R760

10K

R762

10K

R763

10K

R749

0

R750

1.2K

47K

47K

R766

R768

47K

R761

10K

VSS

R710

47K

R711

47K

R712

47K

R713

47K

0.01

C5

0

R1

R11

C6

10

10K

R7

R781

330

R773

100

47K

R772

R782

C205

220/10

C4

C105

10/16

R4

10K

Q5

D4

D3

1SS355-X

1SS355-X

R5

2.2K

SI

INT

SI

SO

SO

I/O

SCK

I/O

100K

INT

SCK

22k

1/50

C103

1/50

C102

C202

R202

IC301

BUS0

C403

C302

10/16

R301

R401

CCE

VOLDA

R302

220K

BUCK

VOLCL

470P

LM1

2.2K

R745

BA3860K

C304

0.1

C303

470P

C402

R402

220K

470K

470K

LM0

2.2K

LM1

R744

UPD178078GF-543

2.2K

2.2K

R707

R706

R708

LCDCL

LCDDA

10/16

LM0

IC701

0

2.2K

R709

LCDCE

R303

6.8K

C305

0.01

R403 C411

C404

6.8K

0.1

CD.L

CH.L

CD.R

CH.R

R759

47K

10K

R758

47K

R704

R701

R702

R703

4.7K

C301

4.7/25

D301

1SS355-X

D302

1SS355-X

C401

4.7/25

RST

PS2

BUS2

BUS1

BUS3

47K

10K

R764

R746

47K

4.7K

4.7K

R404

SW2

C308

1M

0

B310

SW3

470P

1M

0.047

0.1

R304

C307

C306

BUZZER

1K

R757

10K

10K

R715

R714

SW4

REST

ENC1

ENC2

1M

1M

C321

MUTE

R756

47/16

1.2K1K4.7K

R755

CTRL

10/16

C309

R754

10K

R716

4.7/25

C310

R686

R685

R321

0.1/50

C323

2.2K

VOLDA

4.7/25

C410

2.2K

VOLCL

REM

10K

R735

0.01

C405

R322

0.1

C406

C407

0.047

C408

470P

10/16

C409

C311

0.0047

0.22

0.22

0.22

0.22

RESET

VPP

R731

47K

R729

47K

0

X1

0

QAX0406-001Z

10K

10K

10K

0.047

4.7K

R718

X701

C703

4.7K

R720

R405

3.3K

R305

3.3K

R733

R732

R725

4.7K

R722

C713

0.0047

0.01

0.1

R752

R769

10K

47K

10K

47K

KEY2

KEY1

KEY0

C412

C413

C312

C313

D324

C322

100/10

UDZS10B-X

SW1

R734

100K

R727

R726

R724

47K

R721

R719

R717

R751

10K

C711

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

CD/Main signal

Tuner signal

2-3

Page 35

KD-SX975/KD-SX875KD-SX975/KD-SX875

Mecha control circuit section

R583

LM0

LM1

LA6567H-X

LOADING-

LOADING+

C509

R586

20K( 1/10W)

SPINDLE+

SPINDLE-

0.1

FEED+

RFGC

FEED-

20K

R581

FOCUS-

FOCUS+

TRACKING-

TRACKING+

RF

RFRP

TP1

RF

C507

C506

100/6.3

C508

R510

0.1

C582

FE

SBAD

TP2

VREF

0.01

47K

R584

C510

5.6K

8.2K( 1/10W)

R585

IC581

R513

56P

6.8K

R512 R511

R514

15K 2.2K

47K

5

CN501

SW4

SW3

SW1

SW2

LOADING-

LOADING+

REST

VREF

SPINDLE+

FOCUS-

SPINDLE-

FOCUS+

FEED+

TRACKING+

FEED-

TRACKING-

LD

VCC

VF

VB

VA

VE

VC

MD

VREF

C505

0.01

LD

VCC

SW4

VF

SW3

VB

SW1

VA

SW2

VE

4

3

VCC

C504

0.01

R501

R502

VC

R504

VA

R503

VB

R505

VF

R506

VE

2

47K

47K

47K

47K

100K

100K

0.01

C513

IC501

TA2109F-X

C512

100/6.3

C502

33K

100P

C503

100/6.3

C514

MD

LD

0.01

Q501

2SB1322

C501

100/6.3

R508

R507

R509

SEL

TEB

TE

22( 1/10W)

22( 1/10W)

2.4K

R582

8.2K

C583

47/6.3

Q581

2SB1322

B582

0( 1/8W)

D581D582

DSK10CDSK10C

C581

0.01

100/10

X521

QAX0662-001Z

10P

4.7uH

L521

4.7K

R521

C521

C522

100

R571

4.7K

R522

4.7uH

L551

4.7K

R523

R524

100/6.3

0.01

C573

C574

1000P

100/6.3

4.7K

C571

R525

10K

C559

100/6.3

0.01

BUS0

BUS1

BUS2

BUS3

C560

10P

100P

0.01

27P

C556

C558

C555

C554

100/6.3

GND

R-CH

L-CH

BUCK

CCE

RST

1/50

IC521

C523

TC9462F

R556

330

C557

0.01

C553

R211

24K

R-CH

R111 R113

24K 12K

L-CH

C552

C551

100/6.3

C525

C524

0.01

0.01

100/6.3

820P820P

C212C112

C211

C111

SEL

100/6.3

4.7/25

4.7/25

C526

1.5K

R547

47/6.3

C215

22K22K

R216R217

6.8K

R545

3.3K

R544

47/6.3

C115

C549

C547

TEB

C546

22K22K

R116R117

R534

R533

R531 R532

10K 47K

0.047

0.047

0.047

C533

R543

3.3K

470K

68K

R212

R213

R112

33K

C545

0.047

R542

15K

1.5K

R541

C540

C539

R537

0.01

C538

2700P

C537

0.01

C536

R536

33K

47P

0.015

C113

120P

0.01

C534

0.033

R215

33K

12K

C213

120P

560P

C543

C542

3300P

10K

C116

100/10

100/6.3

C532

0.01

C531

100/6.3

100/6.3

R115

C544

C535

IC111

0.47

NJM4565M

0.47

RFGC

SBAD

RFRP

TE

FE

RF

CD.R

GND

CD.L

REST

SW1

SW2

SW3

SW4

LM0

LM1

BUS0

BUS1

BUS2

BUS3

BUCK

CCE

RST

CD8V

GNDGND

9V

CD/Main signal

1

Note:/tr/s/jes/sx875/3181.002

FSDH3181-006CW 2/3

KD-SX870J/770J/777UR/SX875U/975U SERIES

2-4

HABC DEFG

Page 36

KD-SX975/KD-SX875

LCD driver & operation switch section

5

4

QNZ0449-001

S28

S27

S26

S32

S31

S30

S29

S38

S37

S36

S35

S34

S33

S44

S43

S42

S41

S40

S39

S50

S49

S48

S47

S46

S45

S56

S55

S54

S53

S52

S51

S62

S61

S60

S59

S58

S57

S68

S67

S66

S65

S64

S63

COM1

COM3S3COM2

IC602

EN601

QSW0793-001

S48

S49

S50

S51

S52

S53

S54

S55

S56

S57

S58

S59

S60

S61

S62

IC601

LC75873NW

S2

S1

S4S5S6S7S8S9S10

S11

S12

S13

S14

S15

S16

S17

100

R644

470( 1/8W)

2SB815/7/-X

R646

1K( 1/8W)

Q642

UN2211

R652

R651

ENC2

ENC1

47K

47K

KEY1

KEY2

KEY0

10V

ACC5V

47K

R645

LCDCE

LCDCL

LCDDA

1SS355-X

D654

1SS355-X

D653

1K( 1/8W)

D656

1SS355-X

D659

1SS355-X

D655

D658

R653

1SS355-X

D651

1SS355-X

R655

R654

220

UDZS5.1B-X

330K

R656

R669

390K

4.7/6.3

C601

10K

C604

1SS355-X

D652

R670

S64

S65

S66

S67

S68

COM1

COM2

COM3

0.01

C602

C603

220P

R671

10K

10K

C605

0.22

0.22

3

R650

R626

D628

D614

D615

S2S1S3S4S5S6S7S8S9

270( 1/8W)

D618 D617 D616

R627

390( 1/8W)

LCD1

D619

D620

R628

560( 1/8W)

D622 D629

D623

R629

( 1/8W)

D621

R630

( 1/8W)

D624

D613

B604

R642

R641

470( 1/8W)

D641

NSPW310BS/BRS/

R643

470( 1/8W)

470( 1/8W)

D642

D643

NSPW310BS/BRS/

NSPW310BS/BRS/

Q641

S25

R603

R602

R613

820 8201.8K

820

S616

R601R604

S601

S602S603S604S605

R606

820

S607

S608S609S610

R612

820

S615

D601

B601

SML-310LT/MN/-X

B602

R620

B603

470( 1/8W)

S606

S613

R611

R605

2.7K

S611

R609

1.8K

1.2K

R608 R607

1.2K 8202.7K

2

R616

R615

R617

2.7K

S619

S620 S614

1.8K 1.2K3.9K

S618 S617

R614

R621

( 1/8W)

R622

D602

D603

D604

QLD0163-001

270( 1/8W)

D605

D607 D606

R623

270( 1/8W)

D608

D609

D610

R624

( 1/8W)

R625

D611

D612

430( 1/8W)

S14

S10

S11

S12

S13

S15

S16

S17

S18

S19

S20

S21