Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB38520054

MX-JE3,MX-JE31

MX-JE3

Area suffix

US ------------------------ Singapore

UW ----------- Brazil,Mexico,Peru

UX -------------------- Saudi Arabia

UY ------------------------ Argentina

UG --- Turkey,South Africa,Egypt

UE -----------------------------Turkey

UN ----------------------------- Asean

MX-JE31

(SP-MXJE3)

(CA-MXJE3) (SP-MXJE3)

Area suffix

UX -------------------- Saudi Arabia

UG --- Turkey,South Africa,Egypt

UN ----------------------------- Asean

(SP-MXJE31)

(CA-MXJE31) (SP-MXJE31)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MB385

2005/4

Page 2

SPECIFICATION

Amplifier section Output Power 80 W per channel, min. RMS, driven into 6 Ω at 1 kHz with no

more than 10% total harmonic distortion.

Digital output OPTICAL DIGITAL

OUTPUT

Audio input sensitivity/

Impedance*1

VIDEO OUT Color system NTSC/PAL selectable

Speaker Terminals 6 Ω - 16 Ω (Main speakers)

Tuner section FM tuning range 87.50 MHz - 108.00 MHz

AM (MW) tuning range 531 kHz - 1 710 kHz (at 9 kHz)

For Saudi Arabia only 531 kHz - 1 602 kHz (at 9 kHz)

Disc player section Playable disc DVD Video/CD/VCD/SVCD

Dynamic range 90 dB

Horizontal resolution 500 lines

Wow and flutter Immeasurable

Cassette deck section Frequency response Normal (type I) 50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

General Power requirement AC 110 V / AC 127 V / AC 220 V / AC 230 V - AC 240 V , (ad-

Power consumption 125 W (at operation) (MX-JE3/JE31)

Dimensions (approx.) 265 mm × 335 mm × 352 mm (W/H/D)

Mass (approx.) 8.0 kg

Speakers Type 3-Way 3-Speaker Bass Reflex Type (Magnetically Shielded

Speakers Woofer 15 cm cone × 1

Power handling capacity 80 W

Impedance 6 Ω

Frequency range 42 Hz - 29 000 Hz

Sound pressure level 83 dB/W

Dimensions (approx.) JE31: 205 mm × 335 mm × 250 mm (W/H/D)

Mass (approx.) JE31: 3.6 kg each

AUX 300 mV/47 kΩ

MIC 1/2 3.0 mV/50 kΩ

VIDEO (composite) 1 V(p-p)/75Ω

S-VIDEO Y (luminance) : 1 V(p-p)/75Ω

Midrange 5 cm cone × 1

Tweeter 2 cm dome × 1

-21 dBm to -15 dBm (660 nm ±30 nm)

C (chrominance, burst) : 0.286 V(p-p)/75Ω

530 kHz - 1 710 kHz (at 10 kHz)

530 kHz - 1 600 kHz (at 10 kHz)

CD-R/CD-RW (recorded in Audio CD/ Video CD/

Super Video CD/ MP3/ WMA/ JPEG format)

DVD-R/DVD-RW (recorded in video format)

justable with the voltage selector), 50 Hz / 60 Hz

17 W (on standby)

type)

·m

JE3: 205 mm × 335 mm × 232 mm (W/H/D)

JE3: 3.5 kg each

*1: Measured at 1 kHz, with tape recording signal 300 mV

Design and specifications are subject to change without notice.

1-2 (No.MB385)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB385)1-3

Page 4

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Connector

Short land section

Pickup

1-4 (No.MB385)

Card wire

Traverse mechanism assembly

Page 5

1.8 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

CLASS 1

LASER PRODUCT

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MB385)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB385)

Page 7

SECTION 3

DISASSEMBLY

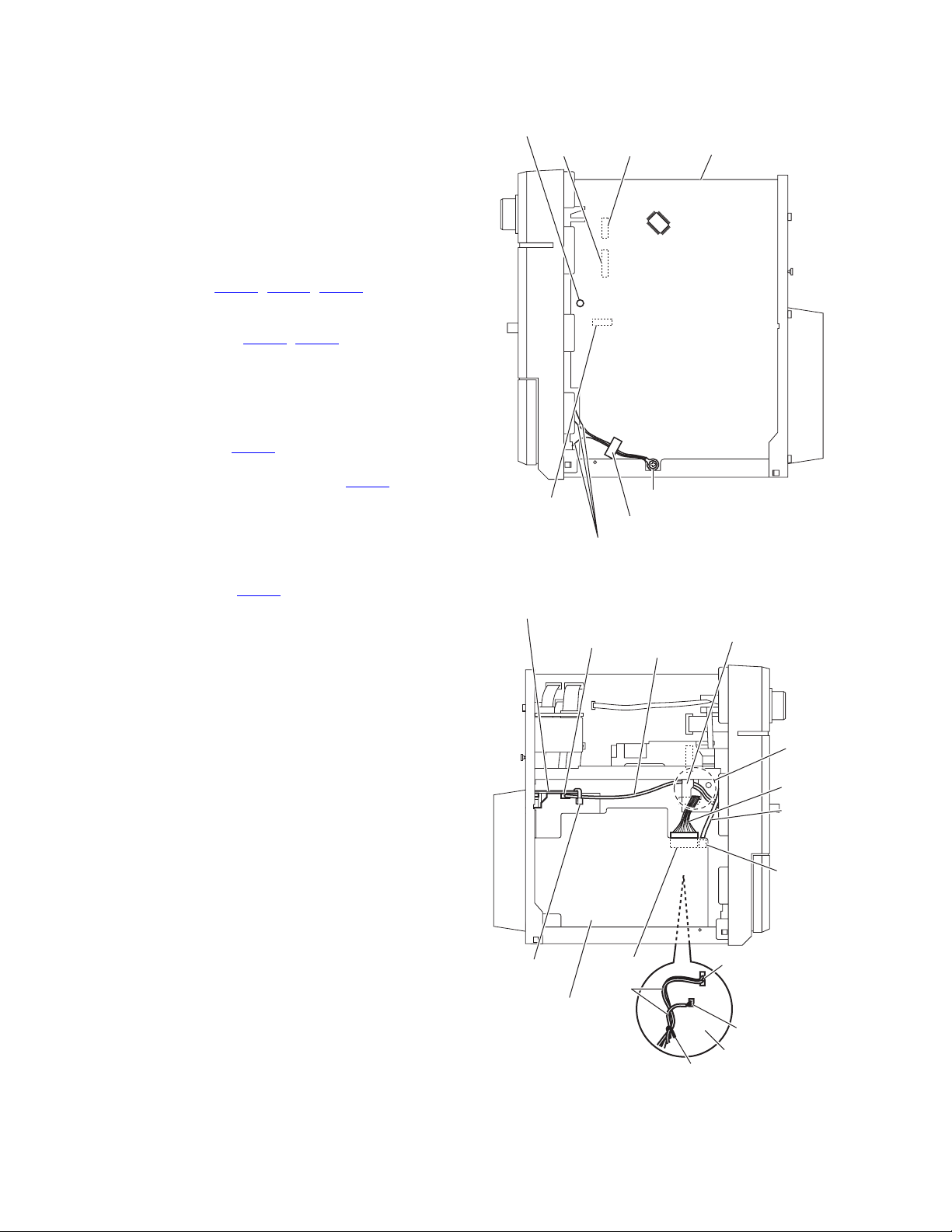

3.1 Main body section

3.1.1 Removing the metal cover

(See Figs.1 to 3)

(1) From the both sides of the main body, remove the two

screws A attaching the metal cover. (See Figs.1 and 2.)

(2) From the back side of the main body, remove the six

screws B attaching the metal cover. (See Fig.3.)

(3) Remove the metal cover from the main body while lifting

the rear section of the metal cover in the direction of the arrow. (See Figs.1 and 2.)

Metal cover

Metal cover

A

Fig.1

Metal cover

B

A

Fig.2

B

B

Fig.3

(No.MB385)1-7

Page 8

3.1.2 Removing the front panel assembly

(See Figs.4 to 7)

• Remove the metal cover.

(1) From the right side of the main body, remove the screw C

attaching the earth wires on the reverse side of the main

board. (See Fig.4.)

Reference:

After attaching the earth wires, fix them with a spacer as

before. (See Fig.4.)

(2) Remove the plastic rivet attaching the main board. (See

Fig.4.)

(3) From the inside of the main body, disconnect the card wires

from the connectors (CN303

ward side of the main board. (See Fig.4.)

(4) Remove the wire clamp fixing the wires and disconnect the

wires from the connector (CN301

side of the main board. (See Fig.5.)

Reference:

After connecting the wires to the connectors, fix the wires

with the wire clamp as before. (See Fig.5.)

(5) From the left side of the main body, disconnect the parallel

wire from the connector CN103

(See Fig.5.)

(6) Disconnect the wire from the connector CN119

transformer board. (See Fig.5.)

Reference:

After connecting the wire, pass the wire through the slot

b of the holder board as before. (See Fig.5.)

(7) Remove the tie band fixing the wire and disconnect the

wire from the connector CN106

board. (See Fig.5.)

Reference:

• After connecting the wire, fix the wire with a new tie

band as before. (See Fig.5.)

• After connecting the wire, pass the wire through the

slot b of the holder board as before. (See Fig.5.)

(8) From the top side of the main body, remove the two screws

D attaching the front panel assembly to the main body.

(See Fig.6.)

(9) From the bottom side of the main body, remove the three

screws E and two screws F attaching the front panel assembly. (See Fig.7.)

(10) Release the claws a and remove the front panel assembly

from the main body in the direction of the arrow. (See

Fig.7.)

, CN860, CN880) on the for-

, CN302) on the forward

on the transformer board.

on the

on the speaker terminal

Plastic rivet

CN860

CN303

Speaker terminal board

CN880

Spacer

Earth wires

CN106

Parallel wire

Main board

C

Fig.4

Holder board

b

Wire

Parallel

wire

CN103

1-8 (No.MB385)

Tie band

wires

Transformer board

CN119

CN301

CN302

Main board

Wire clamp

Fig.5

Page 9

Front panel assembly

D

D

Fig.6

Front panel assembly

Fig.7

a

E

F

a

E

(No.MB385)1-9

Page 10

3.1.3 Removing the tuner

(See Figs.8 and 9.)

• Remove the metal cover.

(1) From the top side of the main body, disconnect the card

wire from the connector CN21 on the main board. (See

Fig.8.)

(2) From the back side of the main body, remove the two

screws G attaching the tuner to the rear panel. (See Fig.9.)

3.1.4 Removing the video board

(See Figs.8 and 9.)

• Remove the metal cover.

(1) From the top side of the main body, disconnect the card

wire from the connector CN410

Fig.8.)

(2) From the back side of the main body, remove the screw H

attaching the video board to the rear panel. (See Fig.9.)

on the main board. (See

Tuner

CN410 CN21 Main board

Video boardCard wires

Fig.8

Tuner

H

Video board

G

Rear panel

Fig.9

1-10 (No.MB385)

Page 11

3.1.5 Removing the rear panel

(See Figs.10 and 11)

• Remove the metal cover.

(1) From the back side of the main body, remove the screw J

attaching the rear cover. (See Fig.10.)

(2) Release the sections c and remove the rear cover from the

rear panel. (See Fig.10.)

(3) Remove the two screws K and fifteen screws L attaching

the rear panel. (See Fig.11.)

Reference:

Remove the tuner and video board as required. (See

Figs.8 and 9.)

(4) From the both sides of the main body, release the sections

d of the center chassis in the direction of the arrow and release the joints e attaching the rear panel to the bottom

chassis. (See Fig. 11.)

J

c

Rear panelRear cover

Fig.10

Rear panel

L

L

e e

L

Bottom chassis

d

L

K

Fig.11

(No.MB385)1-11

Page 12

3.1.6 Removing the DVD mechanism assembly

r

r

(See Figs.12 and 13)

• Remove the metal cover, tuner and video board.

(1) From the top side of the main body, remove the three

screws M attaching the DVD mechanism assembly on the

center chassis. (See Fig.12.)

(2) From the forward side of the main board, disconnect the

card wires from the connectors (CN11

(See Fig.12.)

Reference:

When reassembly, pass the card wire through the section f of the main board before connecting the card wire

to the connector CN11

(3) Remove the spacers fixing the card wires. (See Fig.12.)

Reference:

After connecting the card wires, fix them with the spacers

as before. (See Fig.12.)

(4) From the inside of the main body, take out the DVD mech-

anism assembly.

(5) Remove the tray fitting from the DVD mechanism assembly

in the direction of the arrow. (See Fig.13.)

. (See Fig.12.)

, CN511, CN513).

DVD mechanism assembly

M

Main board

Card wire

Center chassis

M

Space

Card

wires

Space

CN513CN11

CN511

f

Card wire

Fig.12

DVD mechanism assembly

Tray fitting

Fig.13

1-12 (No.MB385)

Page 13

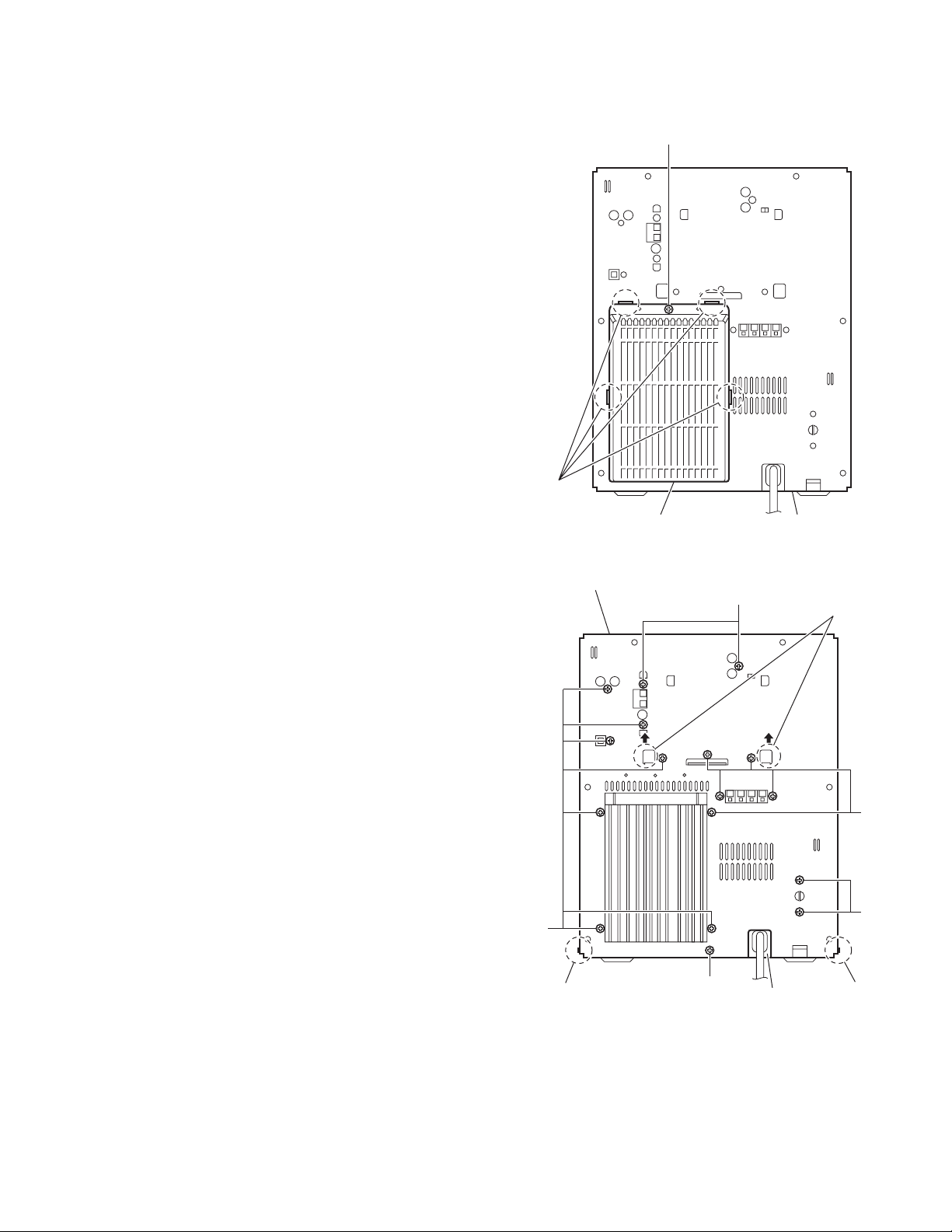

3.1.7 Removing the main board

(See Figs.14 and 15)

• Remove the metal cover, tuner, video board and rear panel.

(1) From the right side of the main body, remove the screw N

attaching the earth wires on the reverse side of the main

board. (See Fig.14.)

Reference:

After attaching the earth wires, fix them with a spacer as

before. (See Fig.14.)

(2) Remove the plastic rivet attaching the main board. (See

Fig.14.)

(3) From the inside of the main body, disconnect the card wires

from the connectors (CN11

, CN880) on the forward side of the main board.

CN860

(See Figs.14 and 15.)

Reference:

When reassembly, pass the card wire through the section f of the main board before connecting the card wire

to the connector CN11

(4) Remove the wire clamp fixing the wires and disconnect the

wires from the connector (CN301

side of the main board. (See Fig.15.)

Reference:

After connecting the wires to the connectors, fix the wires

with the wire clamp as before. (See Fig.15.)

(5) Disconnect the parallel wire from the connectors (CN220

) on the main board. (See Fig.15.)

CN221

(6) Release the lock g of the connector CN216 on the main

board in the direction of the arrow 1 and disconnect the

main board from the connector CN216

minal board toward this side. (See Fig.14.)

Note:

When releasing the lock g, take care not to break it. (See

Fig.14.)

(7) Release the lock h of the connector CN201

board in the direction of the arrow 2 and disconnect the

main board from the connector CN201

the arrow 3. (See Fig.14.)

Note:

When releasing the lock h, take care not to break it. (See

Fig.14.)

, CN303, CN511, CN513,

. (See Fig.14.)

, CN302) on the forward

on the speaker ter-

on the primary

in the direction of

CN880

f

CN860

Plastic

rivet

CN303

Spacer

Earth wires

,

Main board

CN201

CN511

CN513

Card

wires

Main board

CN201

N

3

h

2

Primary board

Fig.14

Card wire

CN11

CN880

CN513

CN11

CN216

1

Speaker terminal

board

Main board

f

CN511

CN216

CN206

g

CN860

CN221

Main boardParallel wire

CN220

wires

CN303

CN301

CN302

Main board

Wire clamp

Fig.15

(No.MB385)1-13

Page 14

3.1.8 Removing the center chassis assembly

(See Fig.16)

• Remove the metal cover, tuner, video board and rear panel.

(1) From the top side of the main body, disconnect the card

wires from the connectors (CN11, CN511, CN513) on the

main body.

Reference:

When reassembly, pass the card wire through the section f of the main board before connecting the card wire

to the connector CN11

(2) Remove the two screws P attaching the center chassis as-

sembly.

(3) Take out the center chassis assembly with the DVD mech-

anism assembly from the main body.

.

CN513

CN511

CN11

Card wire

Main board

f

3.1.9 Removing the transformer board

(See Fig.17)

• Remove the metal cover, tuner, video board, rear panel and

center chassis assembly.

(1) From the top side of the main body, disconnect the wires

from the connectors (CN119

board.

(2) Disconnect the parallel wire from the connector CN103 on

the transformer board.

(3) Remove the four screws Q attaching the transformer board

and take out the transformer board from the main board.

, CN250) on the transformer

Card

wires

DVD mechanism assembly

Q

P

Center chassis assembly

Fig.16

1-14 (No.MB385)

Power

cord

CN250

Q

CN119

Transformer board

Fig.17

Q

CN103

Parallel wire

Page 15

3.1.10 Removing the speaker terminal board

(See Fig.18.)

• Remove the metal cover, tuner, video board, rear panel, main

board and center chassis assembly.

(1) From the top side of the main body, remove the tie band fix-

ing the parallel wire.

Reference:

After connecting the parallel wire, fix it with the new tie

band.

(2) Disconnect the parallel wire from the connector CN106

the speaker terminal board.

(3) Release the locks (i, j) of the connectors (CN205

and disconnect the speaker terminal board in an upward direction.

Note:

When releasing the locks (i, j), take care not to break them.

on

, CN214)

Speaker terminal board

CN205

CN214

i

j

Primary board

CN106 Tie band

Speaker terminal board

Fig.18

Parallel wire

(No.MB385)1-15

Page 16

3.1.11 Removing the regulator board and main amplifier board

(See Figs.19 and 20)

• Remove the metal cover, tuner, video board, rear panel, main

board, center chassis assembly and speaker terminal board.

(1) From the top side of the main body, disconnect the regula-

tor and main amplifier boards in an upward direction while

releasing the locks (k, m) of the connectors (CN202

CN203) on the primary board. (See Fig.19.)

Note:

When releasing the locks (k, m), take care not to break

them. (See Fig.19.)

(2) Take out the regulator and main amplifier boards at the

same time from the main body.

(3) Remove the two screws R attaching the leaf spring to the

heat sink and remove the regulator board from the heat

sink. (See Fig.20.)

(4) Remove the two screws R attaching the main amplifier

board to the heat sink. (See Fig.20.)

,

Main amplifier board

k

CN202

Primary board

m

Primary board

Regulator board

Regulator board

CN203

Fig.19

Main amplifier board

1-16 (No.MB385)

R

Leaf spring

R

Heat sink

Fig.20

Page 17

3.1.12 Removing the primary board

r

(See Fig.21)

• Remove the metal cover, tuner, video board, rear panel, main

board, center chassis assembly, speaker terminal board, regulator board and main amplifier board.

(1) From the top side of the main body, disconnect the wire

from the connector CN119

Reference:

Pass the wire through the slot n of the holder board before connecting the wire to the connector.

(2) Remove the screw S attaching the primary board on the

bottom chassis.

(3) Remove the section p of the primary board and take out the

primary board from the bottom chassis.

on the transformer board.

Primary board Bottom chassis

p

S

Holde

board

n

Transformer board

Fig.21

CN119

Wire

(No.MB385)1-17

Page 18

3.1.13 Removing the FL board

V

(See Figs.22 and 23)

• Remove the metal cover and front panel assembly.

(1) From the front side of the front panel assembly, pull the vol-

ume knob out of the front panel assembly. (See Fig.22.)

(2) From the inside of the front panel assembly, remove the six

screws T attaching the FL board. (See Fig.23.)

(3) Release the claws q in the direction of the arrow and take

out the FL board from the front panel assembly. (See

Fig.23.)

3.1.14 Removing the switch board

(See Figs.22 to 24)

• Remove the metal cover and front panel assembly.

(1) From the front side of the front panel assembly, pull the mi-

crophone knob out of the front panel assembly. (See

Fig.22.)

(2) From the inside of the front panel assembly, remove the

three screws U and screw U' attaching the stay bracket.

(See Fig.23.)

Reference:

When attaching the screw U', attach the earth wire with

it. (See Fig.23.)

(3) From the inside of the front panel assembly, remove the

eleven screws V attaching the switch board. (See Fig.24.)

(4) Take out the switch board from the front panel assembly.

q

T

U

U'

Earth wire

TT

FL board

T

U

Stay bracketFront panel assembly

3.1.15 Removing the cassette mechanism assembly

(See Fig.24)

• Remove the metal cover and front panel assembly.

(1) From the inside of the front panel assembly, remove the

three screws W, screw W' and two screws X attaching the

cassette mechanism assembly.

(2) Take out the cassette mechanism assembly from the front

panel assembly.

Reference:

• When attaching the screw W', attach the earth wire with it.

• When attaching the screws X, attach the swing cam (L)/(R)

with them.

Front panel assembly

Volume knob

V

X

Earth

wire

Swing cam (R)

Switch board

Cassette mechanism

W'

assembly

Fig.23

Front panel assembly

X

W

Swing cam (L)

Microphone knob

1-18 (No.MB385)

Fig.24

Fig.22

Page 19

3.2 DVD mechanism section

• Remove the DVD mechanism assembly from the main body.

(See "3.1.6 Removing the DVD mechanism assembly".)

3.2.1 Removing the clamper base

(See Fig.1)

(1) From the top side of the DVD mechanism assembly, re-

move the two screws A attaching the clamper base.

(2) Lift the clamper base in an upward direction to remove it

from the projections a of the DVD mechanism assembly.

(3) Slide the clamper base in the direction of the arrow and re-

move it from the joints b.

Clamper base

A

a

b

3.2.2 Removing the tray assembly

(See Fig.2)

(1) From the top side of the DVD mechanism assembly, re-

move the two screws B attaching the shaft guide of the tray

assembly.

(2) Remove the tray assembly from the projections c of the

DVD mechanism assembly and take out the tray assembly.

a

A

DVD mechanism assembly

Tray assembly

b

Fig.1

DVD mechanism assembly

Shaft guide

cc

B

Fig.2

(No.MB385)1-19

Page 20

3.2.3 Removing the traverse mechanism assembly

(See Figs.3)

(1) From the bottom side of the DVD mechanism assembly, re-

move the four screws C attaching the traverse mechanism

assembly.

(2) Take out the traverse mechanism assembly with the DVD

module board.

DVD mechanism assembly

DVD module board

3.2.4 Removing the DVD module board

(See Figs.4 and 5)

• Remove the traverse mechanism assembly.

(1) From the side of the traverse mechanism assembly, solder

the short land sections d on the pickup. (See Fig.4.)

(2) From the bottom side of the traverse mechanism assem-

bly, release the lock of the connector CN101

module board in the direction of the arrow 1 and disconnect

the card wire. (See Fig.5.)

Caution:

• Solder the short land sections d on the pickup before

disconnecting the card wire from the connector CN101

on the DVD module board. If the card wire is disconnected without attaching solder, the pickup may be destroyed by static electricity. (See Figs.4 and 5.)

• When attaching the DVD module board, be sure to remove solders from the short land sections d after connecting the card wire to the connector CN101

DVD module board. (See Figs.4 and 5.)

(3) Disconnect the card wire from the connector CN201

DVD module board. (See Fig.5.)

(4) Remove the two screws D attaching the DVD module

board. (See Fig.5.)

(5) Remove the DVD module board from the projection e in an

upward direction and remove the engagement section g in

the direction 3 while removing the engagement section f in

the direction of the arrow 2. (See Fig.5.)

on the DVD

on the

on the

C

Traverse mechanism assembly

Fig.3

d

Traverse mechanism assembly

Fig.4

e

D

Card wire

11

2

Card wire

CN101

C

Pickup

CN201

D

g

3

1-20 (No.MB385)

f

DVD module board

Traverse mechanism assembly

Fig.5

Page 21

3.2.5 Removing the pickup

(See Figs.4,6 to 8)

• Remove the traverse mechanism assembly.

(1) From the side of the traverse mechanism assembly, solder

the short land sections d on the pickup. (See Fig.4.)

(2) Release the lock of the connector on the pickup in the di-

rection of the arrow and disconnect the card wire. (See

Fig.6.)

Caution:

• Solder the short land sections d on the pickup before

disconnecting the card wire from the connector on the

pickup. If the card wire is disconnected without attaching solder, the pickup may be destroyed by static electricity. (See Figs.4 and 6.)

• When attaching the pickup, be sure to remove solders

from the short land sections d after connecting the

card wire to the connector on the pickup. (See Figs.4

and 6.)

(3) Remove the screw E attaching the plate and thrust spring.

(See Fig.6.)

(4) Remove the engagement section h attaching the plate to

the feed holder and remove the plate. (See Fig.6.)

(5) Remove the engagement sections (i, j), remove the thrust

spring. (See Fig.6.)

(6) Remove the shaft of the pickup from the section k on the

traverse mechanism assembly and remove the shaft from

the section m while moving it in the direction of the arrow.

(See Fig.7.)

(7) Remove the pickup from the section n of the traverse

mechanism assembly and take out the pickup with the

shaft. (See fig.7.)

(8) From the bottom side of the pickup, remove the two screws

F attaching the SW actuator and lead spring. (See Fig.8.)

(9) Pull the shaft out of the pickup. (See Fig.8.)

i

Thrust spring

Plate

E

j

Thrust spring

h

Card wire

Traverse mechanism assembly

Feed holder

Connector

Fig.6

Traverse mechanism assembly

Pickup

k

Shaft

Pickup

Fig.7

Torsion spring

m

n

(No.MB385)1-21

Page 22

3.2.6 Attaching the pickup

(See Figs.4,6 to 9)

• See "3.2.5 Removing the pickup".

(1) Attach the shaft, SW actuator and lead spring to the pickup.

(See Fig.8.)

(2) Align the pickup to the section n of the traverse mechanism

assembly first and set the both ends of the shaft of the pickup in the sections (k, m) of the traverse mechanism assembly. (See Fig.7.)

Note:

When attaching the shaft to the section m, attach it under

the torsion spring. (See Fig.7.)

(3) Attach the plate and thrust spring. (See Fig.6.)

(4) Remove solders from the short land sections d after con-

necting the card wire to the connector on the pickup. (See

Figs.4 and 6.)

(5) Turn the feed gear M in the direction of the arrow 1 to move

the pickup in the direction of the arrow 2. (See Fig.9.)

Shaft

Feed gear M

Fig.8

Pickup

SW actuator

Lead spring

F

1

2

Pickup

Fig.9

1-22 (No.MB385)

Page 23

3.2.7 Removing the feed motor

(See Figs.10 to 12)

• Remove the traverse mechanism assembly.

(1) From the top side of the traverse mechanism assembly, re-

move the screw G attaching the plate and thrust spring.

(See Fig.10.)

(2) Remove the engagement section p attaching the plate to

the feed holder and remove the plate. (See Fig.10.)

(3) Remove the engagement sections (q, r), remove the thrust

spring. (See Fig.10.)

(4) Remove the wires from the soldered section s on the spin-

dle motor board. (See Fig.11.)

Reference:

When attaching the feed motor, pass the wire through

the section t on the spindle base. (See Fig.11.)

(5) Remove the feed holder, feed motor, lead screw, feed gear

E and feed gear M at the same time after removing the

three screws H attaching the feed holder. (See Fig.11.)

(6) From the side of the feed holder, remove the two screws J

attaching the feed motor. (See Fig.12.)

3.2.8 Removing the spindle motor board

(See Figs.11 and 13)

• Remove the traverse mechanism assembly and DVD module

board.

(1) From the top side of the traverse mechanism assembly, re-

move the wires from the soldered section s on the spindle

motor board. (See Fig.11.)

(2) From the bottom side of the traverse mechanism assem-

bly, remove the three screws K attaching the spindle motor

board. (See Fig.13.)

Feed gear M

Feed gear E

H

Feed holder

J

H

Feed motor

Spindle base

Fig.11

Lead screw

Wires

Spindle motor board

Feed holder

t

s

q

Thrust spring

Plate

G

r

Thrust spring

p

Fig.12

Traverse mechanism assembly

Feed holder

Traverse mechanism assembly

K

Fig.13

Fig.10

(No.MB385)1-23

Page 24

3.2.9 Removing the switch board

(See Fig.14.)

(1) From the bottom side of the DVD mechanism assembly, re-

move the screw L attaching the switch board.

(2) Disconnect the card wire from the connector CN1 on the

switch board.

(3) Remove the wires from the soldered section u on the

switch board.

(4) Lift the switch board while pressing the claw v of the DVD

mechanism assembly in the direction of the arrow and remove it from the section w.

Reference:

Put the wires on the section x after attaching the switch board

to the DVD mechanism assembly.

3.2.10 Removing the motor

(See Figs.14 and 15)

• Remove the clamper base and tray assembly.

(1) From the bottom side of the DVD mechanism assembly, re-

move the wires from the soldered section u on the switch

board. (See Fig.14.)

(2) From the top side of the DVD mechanism assembly, re-

move the belt from the motor pulley. (See Fig.15.)

Note:

Take care not to attach grease on the belt.

(3) Remove the two screws M attaching the motor to the DVD

mechanism assembly and take out the motor from the bottom side of the DVD mechanism assembly. (See Fig.15.)

Reference:

Put the wires on the section x after attaching the motor to the

DVD mechanism assembly. (See Fig.14.)

Card wire

L

M

Switch board

CN1

w

x

u

v

Wires

DVD mechanism assembly

Fig.14

Motor pulley

Belt

DVD mechanism assembly

Fig.15

1-24 (No.MB385)

Page 25

3.3 Cassette mechanism assembly section

• Prior to performing the following procedures, remove the cassette mechanism assembly.

(See "3.1.16 Removing the cassette mechanism assembly".)

3.3.1 Removing the main motor and replacing the main belts

(See Figs.1 and 2)

(1) From the front side of the cassette mechanism assembly,

remove the two screws A attaching the main motor. (See

Fig.1.)

(2) From the back side of the cassette mechanism assembly,

remove the wires from the soldered sections a on the

switch board. (See Fig.2.)

Caution:

After reassembling, check the direction of the main motor and polarity of the wires. (See Fig.2.)

(3) Remove the main motor and main belts. (See Fig.2.)

Note:

When attaching the main belts, take care not to attach

grease on the main belts.

Cassette mechanism assembly

A

Fig.1

3.3.2 Replacing the F/R belts

(See Fig.3)

• Prior to performing the following procedures, remove the main

motor and main belts.

• Remove the wires of the main motor as required.

From the back side of the cassette mechanism assembly, remove the F/R belts from the flywheel 1 and flywheel 2.

Wire (Black)

Switch board

Main belt

Switch board

Cassette mechanism assembly

a

Wire (Red)

Cassette mechanism assembly

Main motor

Fig.2

Main belt

Flywheel 1

F/R belts

Fig.3

Flywheel 2

(No.MB385)1-25

Page 26

3.3.3 Removing the clutch assemblies

r

(See Figs.4 to 7)

• Prior to performing the following procedures, remove the main

motor, main belts and F/R belts.

• Remove the wires of the main motor as required.

(1) From the front side of the cassette mechanism assembly,

remove the three slit washers attaching the flywheel 1, flywheel 2 and flywheel 3. (See Fig.4.)

(2) From the back side of the cassette mechanism assembly,

pull out the flywheel 1, flywheel 2 and flywheel 3. (See

Fig.5.)

(3) Remove the stoppers in an upward direction. (See Fig.5.)

(4) Remove the springs from the sections b. (See Fig.6.)

(5) Release the claws c in the direction of the arrow, remove

the plates and pulleys. (See Fig.6.)

(6) Release the claws d in the direction of the arrow, remove

the guide arms. (See Fig.7.)

Note:

When attaching the guide arms, attach the springs with

them as before. (See Fig.7.)

(7) Remove the cam gears in an upward direction. (See Fig.7.)

(8) Take out the clutch assemblies from the cassette mecha-

nism assembly. (See Fig.7.)

Cassette mechanism assembly

Slit washer

Slit washer

Fig.4

Cassette mechanism assembly

Slit washer

Flywheel 1

Spring

b

d

Stopper

Flywheel 3

Fig.5

Cassette mechanism assembly

Pulley

c

Plates

Fig.6

Cassette mechanism assembly

d

Clutch assemblyClutch assembly

Flywheel 2

Spring

b

Stoppe

Pulley

c

1-26 (No.MB385)

Spring

Guide arm

Spring

Guide arm

Fig.7

Cam gearCam gear

Page 27

3.3.4 Removing the leaf switches

(See Fig.8)

(1) From the back side of the cassette mechanism assembly,

remove the solders from the soldered sections e attaching

the leaf switches on the switch board.

(2) From the front side of the cassette mechanism assembly,

pull out the leaf switches.

3.3.5 Removing the switch board

(See Fig.8)

(1) From the back side of the cassette mechanism assembly,

remove the solders from the soldered sections (f, g) connecting the wires.

Note:

After reassembling, check the polarity of the wires.

(2) Release the claws h in the direction of the arrow and re-

move the switch board from the cassette mechanism assembly.

Wire (Black)

e

h

h

Switch board

h

f

Wire (Red)

Switch board

e

e

h

h

3.3.6 Removing the PB head block

(See Fig.9)

(1) From the bottom side of the cassette mechanism assem-

bly, remove the tie band fixing the wire.

Reference:

After reassembling, fix the wire with a new tie band as

before.

(2) From the front side of the cassette mechanism assembly,

release the claw i in the direction of the arrow 1 and pull out

the pinch roller in an upward direction.

(3) Remove the screw B attaching the PB head.

(4) Remove the spring from the section j.

(5) Move the PB head block in the direction of the arrow 2 and

remove the hooks k from the PB head block.

(6) Take out the PB head block from the cassette mechanism

assembly.

g

Spring

j

k

Cassette mechanism assembly

Fig.8

Cassette mechanism assembly

k

2

g

PB head

k

i

1

PB head block

B

Fig.9

Pinch roller

Wire

Tie band

(No.MB385)1-27

Page 28

3.3.7 Removing the R/P head block

(See Fig.10)

(1) From the front side of the cassette mechanism assembly,

release the claw m in the direction of the arrow 1 and pull

out the pinch roller L in an upward direction.

(2) Release the claw n in the direction of the arrow 2 and pull

out the pinch roller R in an upward direction.

(3) From the bottom side of the cassette mechanism assem-

bly, remove the screw C attaching the R/P head board.

(4) From the front side of the cassette mechanism assembly,

remove the two screws D attaching the R/P head.

(5) Take out the R/P head block (R/P head and R/P head

board) from the cassette mechanism assembly.

Cassette mechanism assembly

m

R/P head

n

21

Pinch roller L

R/P head

board

C

D

Pinch roller R

D

Fig.10

1-28 (No.MB385)

Page 29

3.4 Speaker section (For MX-JE3)

3.4.1 Removing the front panel assembly

(See Figs.1 to 3)

(1) Insert the tip of a flat-bladed screwdriver or similar tool into

the space between the speaker main body and front panel

assembly, and lift the front panel assembly little by little to

remove the joint sections a. (See Figs.1 and 2.)

Note:

To prevent damaging the front panel assembly and

speaker main body, insert cushioning plates etc. into the

space between the speaker main body and front panel

assembly. (See Fig.2.)

(2) From the inside of the front panel assembly, disconnect the

gray and black wires from the terminals of the tweeter. (See

Fig.3.)

Net assembly

a

a

a

a

a

Front panel assembly

Tweeter

Fig.1

b

Fig.2

Wire(gray)

a

Cushioning

plate, etc.

Flat-bladed

screwdriver,etc.

Wire(black)

Terminals

Front panel assembly

Fig.3

(No.MB385)1-29

Page 30

3.4.2 Removing the speaker

(See Figs.4 and 5)

• Remove the front panel assembly.

(1) From the front side of the speaker main body, remove the

four screws A attaching the speaker. (See Fig.4.)

(2) Take out the speaker from the speaker main body and dis-

connect the wires (red/black, gray/black) from the terminal

of the speaker. (See Fig.5.)

Speaker

A A

Fig.4

Speaker

Terminal

Wires (gray/black) Wires (red/black)

Fig.5

1-30 (No.MB385)

Page 31

3.5 Speaker section (For MX-JE31)

3.5.1 Removing the net assembly

(See Fig.1)

From the front side of the speaker main body, remove the sections a of the net assembly toward this side.

Net assembly

a

a

aa

a

Fig.1

a

(No.MB385)1-31

Page 32

3.5.2 Removing the front panel assembly

(See Figs.2 to 4)

• Remove the net assembly as required.

(1) Insert the tip of a flat-bladed screwdriver or similar tool into

the space between the speaker main body and front panel

assembly, and lift the front panel assembly little by little to

remove the sections b. (See Figs.2 and 3.)

Note:

To prevent damaging the front panel assembly and

speaker main body, insert cushioning plates etc. into the

space between the speaker main body and front panel

assembly. (See Fig.3.)

(2) From the inside of the front panel assembly, disconnect the

gray and black wires from the terminals of the tweeter. (See

Fig.4.)

Front panel assembly

b

b

b

b

b

Front panel assembly

Tweeter

Fig.2

b

Fig.3

Wire(gray)

b

Cushioning

plate, etc.

Flat-bladed

screwdriver,etc.

Wire(black)

1-32 (No.MB385)

Terminals

Front panel assembly

Fig.4

Page 33

3.5.3 Removing the speaker

(See Figs.5 and 6)

• Remove the front panel assembly.

(1) From the front side of the speaker main body, remove the

four screws A attaching the speaker. (See Fig.5.)

(2) Take out the speaker from the speaker main body and dis-

connect the wires (red/black, gray/black) from the terminal

of the speaker. (See Fig.6.)

Speaker

A A

Fig.5

Speaker

Terminal

Wires (gray/black) Wires (red/black)

Fig.6

(No.MB385)1-33

Page 34

SECTION 4

ADJUSTMENT

4.1 Measurement Instruments Required for Adjustment

(1) Low frequency oscillator

This oscillator should have a capacity to output 0dBs to

600Ω at an oscillation frequency of 50Hz-20kHz.

(2) Attenuator impedance : 600Ω

(3) Electronic voltmeter

(4) Distortion meter

(5) Frequency counter

(6) Wow & flutter meter

(7) Test tape

VT703 : Head azimuth

(8) Blank tape

TYPE l : AC-514

(9) Test disc: VT-501, CTS-1000

4.2.2 Tuner section

FM Band cover: 87.5 - 108.0MHz

AM Band cover: 531 - 1,710kHz (at 9kHz)

530 - 1,710kHz (at 10kHz)

531 - 1,602kHz (at 9kHz) : UX version only

530 - 1,600kHz (at 10kHz) : UX version only

Voltage applied to tuner: +B : DC5.7V

VT : DC 12V

Reference measurement

output:

Input positions: AM : Standard loop antenna

26.1mV(0.28V)/3Ω

FM : TP1 (hot) and TP2 (GND)

4.2 Measurement conditons

Power supply voltage:

AC110V / AC127V / AC220V / AC230V to AC240V

50Hz / 60Hz (Adjustable with the voltage selector)

Reference output: Speaker : 0.775V/4Ω

Headphone : 0.077V/32Ω

Reference frequency and

input level:

Measurement output terminal: at Speaker J200

Load resistance: 4Ω

4.2.1 Radio Input signal

AM frequency: 400Hz

AM modulation: 30%

FM frequency: 400Hz

FM frequency deviation: 22.5kHz

1kHz, AUX : -8dBs

4.2.3 Standard measurement position of volume

Function switch to Tape

Beat cut switch to Cut

Super Bass/Active hyper Bass to OFF

Bass Treble to Center

Adjustment of main volume to reference output VOL : 28

Precautions for measurement

(1) Apply 30pF and 33kΩ to the IF sweeper output side and

0.082µ F and 100kΩ in series to the sweeper input side.

(2) The IF sweeper output level should be made as low as

possible within the adjustable range.

(3) Since the IF sweeper is a fixed device, there is no need

to adjust this sweeper.

(4) Since a ceramic oscillator is used, there is no need to

perform any MIX adjustment.

(5) Since a fixed coil is used, there is no need to adjust the

FM tracking.

(6) The input and output earth systems are separated. In

case of simultaneously measuring the voltage in both of

the input and output systems with an electronic voltmeter

for two channels, therefore, the earth should be connected particularly carefully.

(7) In the case of BTL connection amp., the minus terminal

of speaker is not for earthing. Therefore, be sure not to

connect any other earth terminal to this terminal. This

system is of an BTL system.

(8) For connecting a dummy resistor when measuring the

output, use the wire with a greater code size.

(9) Whenever any mixed tape is used, use the band pass fil-

ter (DV-12).

1-34 (No.MB385)

Page 35

4.3 Arrangement of adjusting positions

4.4 Tape recorder section

Items

Cassette Head

Azimuth Alignments

Measurement

Test tape

:VT703 (10kHz)

Measurement output

terminal

:Left and Right

speaker output

(6-ohm loaded)

or

Headphone Output

(32-ohm loaded)

PB Head

(Deck-A)

Head azimuth screw

(Forward side)

conditions

Cassette mechanism assembly

(Front side)

Head azimuth screw

(Forward side)

Head azimuth screw

(Reverse side)

REC/PB Head

(Deck-B)

Head azimuth screw

(Reverse side)

Measurement method

1. Playback the test tapeVT703 (10KHz) or equivalent.

Maximum output

2. Adjust the head azimuth screw to obtain maximum

output and both output of L / R is in 3dB.

3. Put on the screw lock paint after alignments.

Standard

values

Adjusting

positions

Adjust the head

azimuth screw

only when the

head has been

changed.

Recording Bias

Frequency Alignment

Test tape

:TYPE I AC-514

Measurement output

terminal

:Erase head terminal

(CN308 8-Pin)

1. Insert the recording tape in deck-B.

80kHz+/-3kHz

2. Starting the recording.

3. Adjust the oscillation frequency to 80kHz+/-3kHz by

core of Oscillation coil of L301.

Use the HighImpedance Probe

or Frequency

counter input.

(No.MB385)1-35

Page 36

4.5 Service mode

4.5.1 Confirming contents

(1) Cold start

(2) FL display and LED display check

(3) System ROM number, firmware version and region check

(4) Change AM frequency step 9kHz/10kHz (Toggle)

(5) Tray LOCK/UNLOCK (Toggle)

(6) System micon cold start

(7) System micon soft reset

(8) Setting of DVD NTSC mode

(9) DVD test mode

4.5.2 Confirming methods

1. Cold start

2. FL display and LED display check

Press the VOLME +(UP) button twice while

pressing the ENTER, STANDBY/ON

buttons on the remote controller at standby.

FL indication

COLD SET

Cold start is completed.

3. System ROM number, firmware version and region check

Press the FADE MUTING button while

the ENTER, STANDBY/ON

remote controller

in a power on state.

buttons on the

FL indication

SYS X.XX #

pressing

3 CHARACTERS + ROM CORRECTION #

(Example) SYS 1.03 0

Press the FADE MUTING button again while

pressing the ENTER, STANDBY/ON

buttons

on the remote controller.

Press the VOLME - (DOWN) button while

pressing the ENTER, STANDBY/ON

buttons on the remote controller at standby.

All of the FL and LED display light up.

Indication returns to normal indication by doing

the same operation again.

This confirmation is possible in a power on state.

1-36 (No.MB385)

FL indication

DVD YYYY

YYYY : Firmware version

(Example) DVD 0471

Press the FADE MUTING button again while

pressing the ENTER, STANDBY/ON

buttons

on the remote controller.

FL indication

MX-JE3 ZZ

ZZ : Region

(Example) MX-JE3 US

Press the FADE MUTING button again while

pressing the ENTER, STANDBY/ON

buttons

on the remote controller.

If there is not the button input, each indication returns to normal indication automatically.

Page 37

4. Change AM frequency step 9kHz/10kHz (Toggle)

Press the

pressing the STOP

STANDBY/ON

button on the main

button while

unit at standby.

FL indication

## : 9K or 10K

AM ##

Setting of AM frequency is completed.

AM frequency changes by the same operation again.

5. Tray LOCK/UNLOCK (Toggle)

Press the

pressing the STOP

OPEN/CLOSE

button on the main

button while

unit at standby.

FL indication

XXXXX : LOCKED or UNLOCKED

XXXXX

Setting of tray LOCK/UNLOCK is completed.

Setting of LOCK/UNLOCK changes by the same operation again.

6. System micon cold start

Insert the power cord in an outlet while

pressing the CANCEL and

on the main unit.

This unit returns to initial setting.

7. System micon soft reset

Press the STANDBY/ON button while

pressing the CANCEL and PAUSE

buttons on the main unit at standby.

System micon is initialized.

8. Setting of DVD NTSC mode

Insert the power cord in an outlet while

pressing the SET and

the main unit.

Press the STANDBY/ON button

on the main unit at standby.

buttons

buttons on

Setting of DVD NTSC mode is completed.

This setting is maintained after having been cut off.

(No.MB385)1-37

Page 38

9. DVD test mode

Insert the power cord in an outlet while

pressing the

SET

and buttons on the

main unit.

FL indication

TEST #@

TEST #@

Press the "PAUSE" button on the main unit.

Press the button on the main unit for two seconds.

Press the "MENU" button on the remote controller.

FE Learning Condition

Region

VERSION

VERSION LIST:

JC / 1U / D / E / 2U / 3U / UB / UT / 4U / UY / EE / UF

FL indication

TEST #@0

FL indication

TEST #33

A. EEPROM INITIALIZE

(NORMAL)

B. EEPROM INITIALIZE

(FULL)

FL indication

(For Example) " 1234 "

Press the "MENU" button on the remote controller.

FL indication

" aaaa cccc "

Press the "MENU" button on the remote controller.

FL indication

ALL FL light UP

Press the "MENU" button on the remote controller.

Enter to "CHECK MODE"

1

2

DISPLAY SHOWS DEVICE KEY CHECKSUM

VERSION DISPLAY

aaaa : Syscon micon version

cccc : Backend micon version

FL ALL ON check

1-38 (No.MB385)

Page 39

1

2

Press the "1" button on the remote controller.

START PLAY

Press the "2" button on the remote controller.

WOBBLE

Press the "4" button on the remote controller.

CD LASER Current

Press the "5" button on the remote controller.

DVD LASER Current

Press the "6" button on the remote controller.

DVD-SL Jitter

Press the "7" button on the remote controller.

EEPROM (BWD)

Press the "8" button on the remote controller.

EEPROM (FWD)

FL indication

CHECK

FL indication

FL indication

FL indication

FL indication

FL indication

FL indication

WOBBLE display

CD Laser Current

DVD Laser Current

DVD-SL Jitter

Memory BWD

Memory FWD

Press the "9" button on the remote controller.

Temperature

Press the "10" button on the remote controller.

DVD-DL/SL Jitter

Press the "+10" button on the remote controller.

EEPROM Initialize

Press the "0" button on the remote controller.

Monitor Change

Press the "STOP" button on the main unit or

remote controller.

STOP

Press the "OPEN/CLOSE" button

on the main unit.

OPEN/CLOSE

Press the "PLAY" button on the main unit or

remote controller.

PLAY

FL indication

FL indication

FL indication

FL indication

FL indication

CHECK

FL indication

FL indication

Temperature

DVD-DL/SL Jitter

Monitor Display

Laser & Jitter

POWER OFF

or SOURCE CHANGE

Cancellation of the

"DVD TEST MODE"

(No.MB385)1-39

Page 40

4.5.3 Indicating check for FL display

DVD TEST MODE

TEST START

(Version info)

A. EEPROM INITIALIZE

(NORMAL)

B. EEPROM INITIALIZE

(FULL)

DEVICE KEY DISPLAY

VERSION DISPLAY

FL ALL ON

CHECK MODE

START PLAY

WOBBLE

CD LASER current

DVD LASER current

DVD-SL jitter

EEPROM (BWD)

EEPROM (FWD)

Temperature

DVD-DL/SL jitter

EEPROM initialize

Monitor change

FL displayFunction

T

E

S

T

#

@

By AC cord on with holding SET and

Note

: VERSION

@: FE learning condition

#: REGION

T

E

S

T

T

E

S

T

T

E

S

T

T

E

S

T

1

2

a

a

a

a

#

@

By pressing PAUSE (Front)

#

@

0

#

#

3

4

c

c

By pressing and holding (Front) for 2-sec

@

3

3

By pressing MENU (Remote)

By pressing MENU (Remote)

c

c

aaaa: Syscon, cccc: Backend

By pressing MENU (Remote)

C

H

E

C

K

C

H

E

C

K

By pressing MENU (Remote)

By pressing 1 (Remote)

By pressing 2 (Remote)

By pressing 4 (Remote)

By pressing 5 (Remote)

By pressing 6 (Remote)

By pressing 7 (Remote)

By pressing 8 (Remote)

By pressing 9 (Remote)

By pressing 10 (Remote)

By pressing +10 (Remote)

By pressing 0 (Remote)

STOP

OPEN/CLOSE

PLAY

C

H

E

C

K

By pressing STOP (Front or Remote)

By pressing OPEN/CLOSE (Front)

By pressing PLAY (Front or Remote)

Laser & Jitter

1-40 (No.MB385)

Page 41

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB385)1-41

Page 42

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB385)

Printed in Japan

VPT

Loading...

Loading...