JVC GZ-MC100EK, GZ-MC100EX, GZ-MC100EY, GZ-MC100EZ Service Manual

YF060200411

SERVICE MANUAL

DIGITAL MEDIA CAMERA

GZ-MC100EK, GZ-MC100EX,

GZ-MC100EY, GZ-MC100EZ

GZ-MC100EK, GZ-MC100EX,

GZ-MC100EY, GZ-MC100EZ [M4S327]

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YF060

2004/11

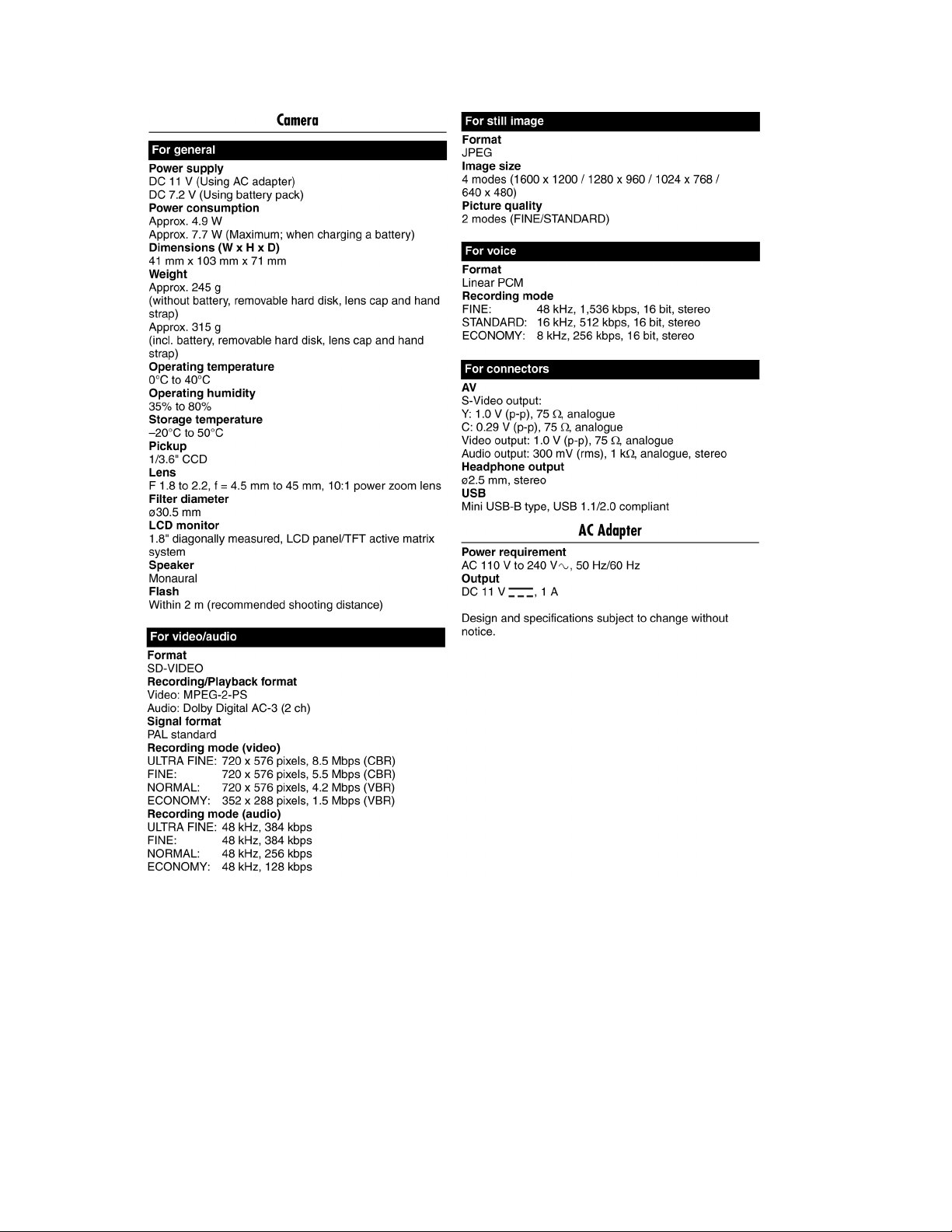

SPECIFICATION

1-2 (No.YF060)

SECTION 1

r

e

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

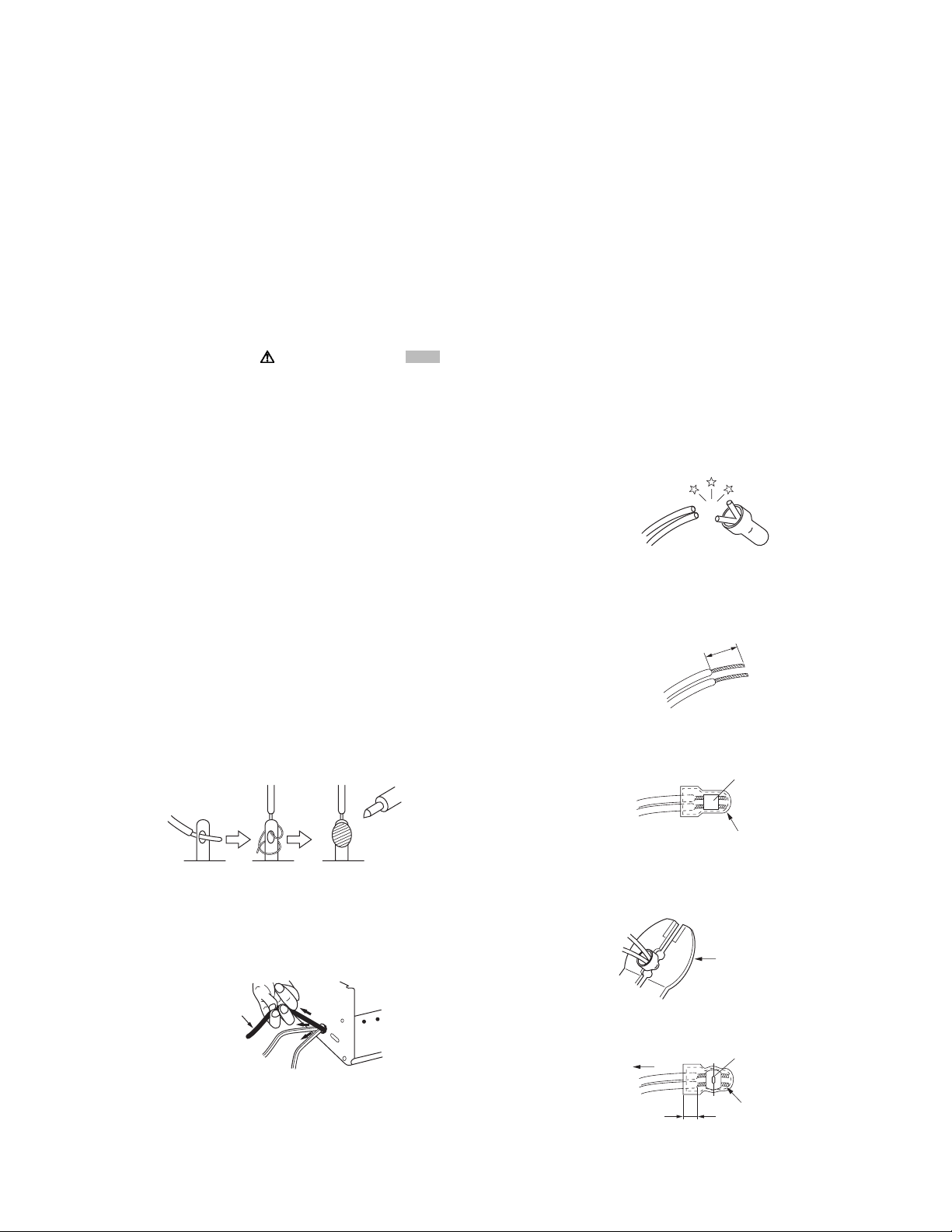

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.1-1-7

(No.YF060)1-3

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF060)

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

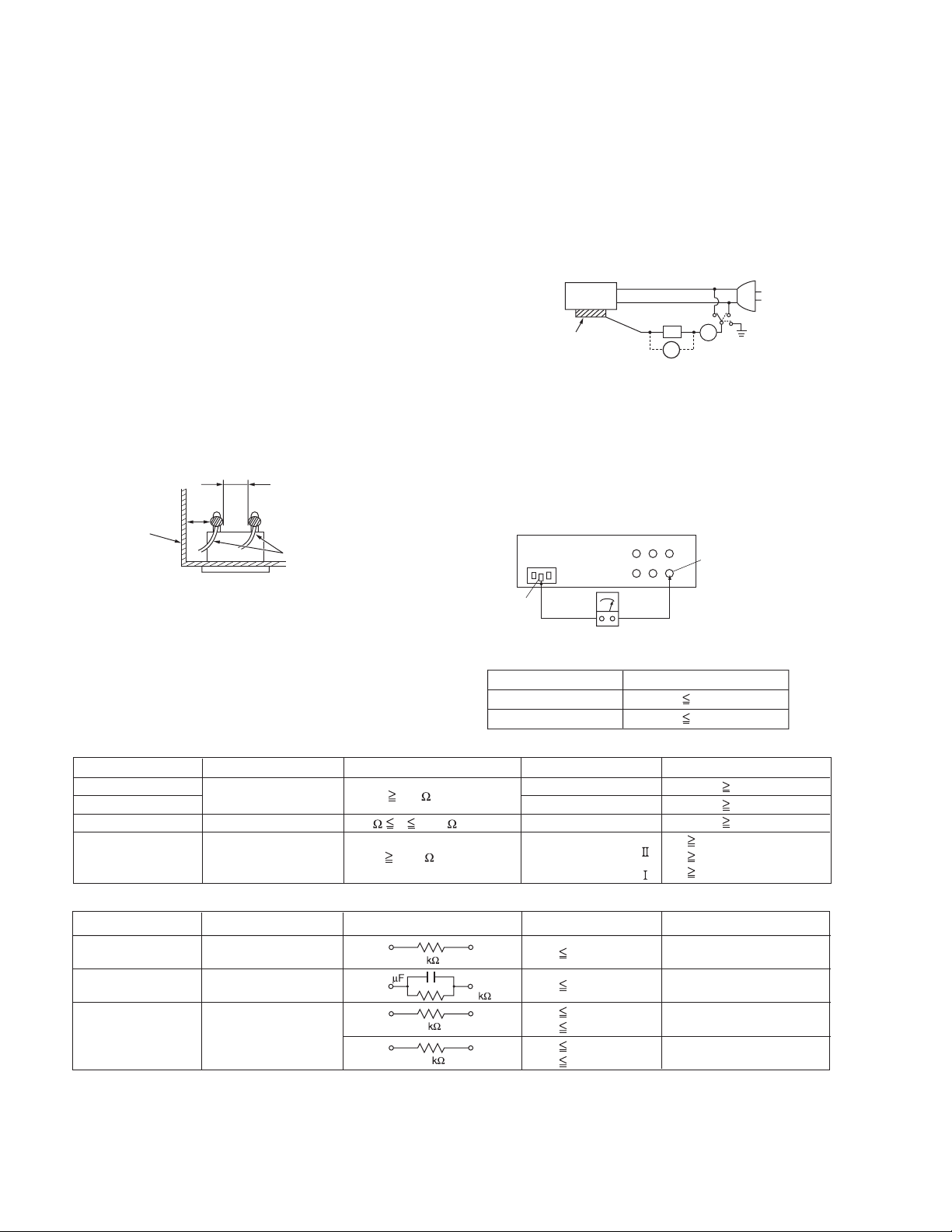

2.1 Handling Microdrives

Microdrives are used in GZ-MC100 and GZ-MC200. Although the appearance is different, a Microdrive is exactly the same as a hard

disc that is used in a PC. Therefore, unlike handling conventional tapes, caution must be paid in handling Microdrives.

The handling of Microdrives is explained in this section.

2.1.1 The structure of Microdrives

The detailed inside structure of Microdrives is not disclosed as it is treated as trade secrets. However, it is essential to have knowledge

of the structure of Microdrives in order to carry out service properly. Some information about Microdrives is given here.

A Microdrive is mainly consisted of the following parts.

• A magnetic recording disk that is coated with magnetic material. (Disk)

• A reading/ writing head. (Head)

• A motor that turns the disk.

• A circuit board that is loaded with electrical circuit which controls the motor, the head positioning, and input/ output of the

signal.

1 head type Microdrives use one side of the disk, and 2 head type

Microdrives use both sides of the disk with heads on each side

of the disk.The disk and the head do not contact and there is

certain space kept between them. The head reads the pre

recorded servo information to control the head itself. When the

head is not in access to the disk, it is kept in a shelter to avoid

damaging the disk with shocks from outside.

The difference between a 2GB Microdrive and a 4GB Microdrive

is only whether it has one head or two heads and there is no

difference in performance, as shown in the specification list. A

2.5 inch hard disk that is used in a note PC is shown as a

reference. As a 2.5 inch hard disk is bigger than a Microdrive, it

has more disks and heads resulting in more capacity. On the

contrary, it seems impossible to increase the disks for a

Microdrive because of size restriction. High capacity will be

achieved by improving the areal density and rotation speed of the

future products.

Microdrive

Model name Microdrive 3K4-2 Microdrive 3K4-4 Travelstar 4K80-80

Model number HMS360402D5CF00 HMS360404D5CF00 HTS428080F9AT00

Capacity 2 GB 4 GB 80 GB

Interface

Form factor 1inch 1inch 2.5inch

System type Consumer electronics Consumer electronics Laptop

Cache buffer 128 KB 128 KB 8 MB

Disks / Heads 1/1 1/2 2/4

Rotational speed (RPM) 3,600 (RPM) 3,600 (RPM) 4,200 (RPM)

Media transfer rate 97.9 Mb/sec max 97.9 Mb/sec max 351 Mb/sec max

Interface transfer rate

Average seek (ms) 12 (ms) 12 (ms) 13 (ms)

Average latency (ms) 8.33 (ms) 8.33 (ms) 7.1 (ms)

Areal density 56.5 Gb/sq. inch 56.5 Gb/sq. inch 68.5 Gb/sq. inch

Typical idle acoustic (Bels) 㧙㧙2.4B

Operating shock (G) 200 G (2ms) 200 G (2ms) 250 (2ms)

Non-operating shock (G) 2000 G (1ms) 2000 G (1ms) 800 (1ms)

Operating ambient temperature ()0 㨪 70 ()0 㨪 70 ()5 㨪 55 ()

Non-operating ambient temperature ()

2GB 4GB 80GB

CompactFlash TypeΤCompactFlash Type

33 MB/sec max 33 MB/sec max 100 MB/sec max

-40 㨪 70 () -40 㨪 70 () -40 㨪 70 ()

hard disk

Τ ATA ATA- 6

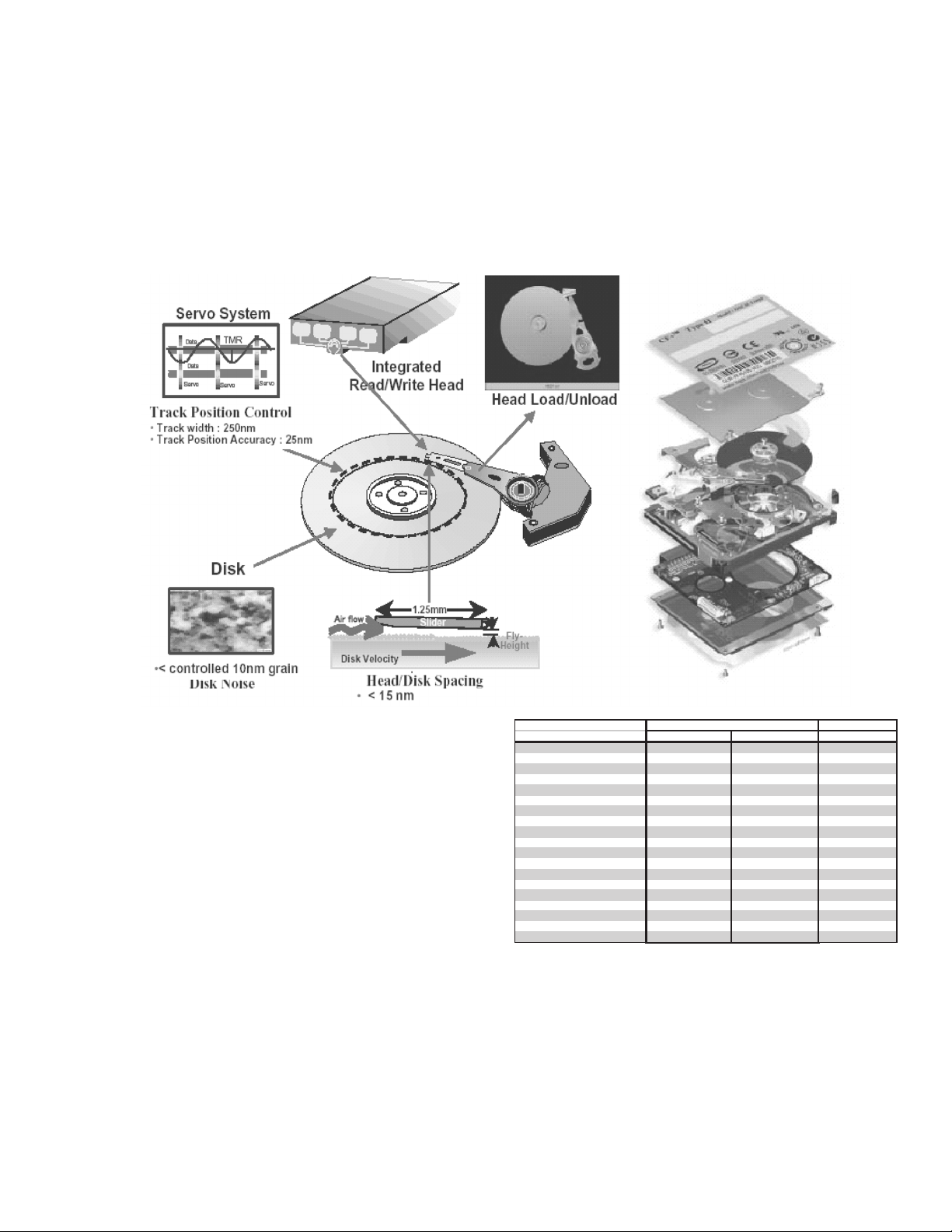

Shock tolerance during non-operation is remarkably high. Microdrives are designed to tolerate shock during non-operation as

they are removed or carried out more often than other hard disks.

However, Microdrives are vulnerable to falls and shocks just like

other precision instruments.

Microdrives are made in conformity with the standard of CompactFlash Type II. The thickness of the drive is less than 5.5mm,

thus failures can occur by folding or twisting the disks. The standard for torsional stress is 6kg approx. and for flexing stress is

4kg approx. Be sure to carry Microdrives in protection cases on

the service sites, and strongly recommend the customers to do

so, too.

(No.YF060)1-5

2.1.2 Precautions on handling Microdrives

Shock

Main causes of failures in hard disks including Microdrives are

listed as follows.

(1) Failures caused by shocks

(2) Failures caused by static electricity

(3) Failures caused by power cut during the operation

NOTE:

The shock of 200G(G:Gravity), a maximum impact value in

operation, is equivalent of the impact of dropping from 2030cm above the hard floor. The shock of 2000G, a maximum

impact value in non-operation, is equivalent of the impact of

dropping from 75 - 100cm above the hard floor.

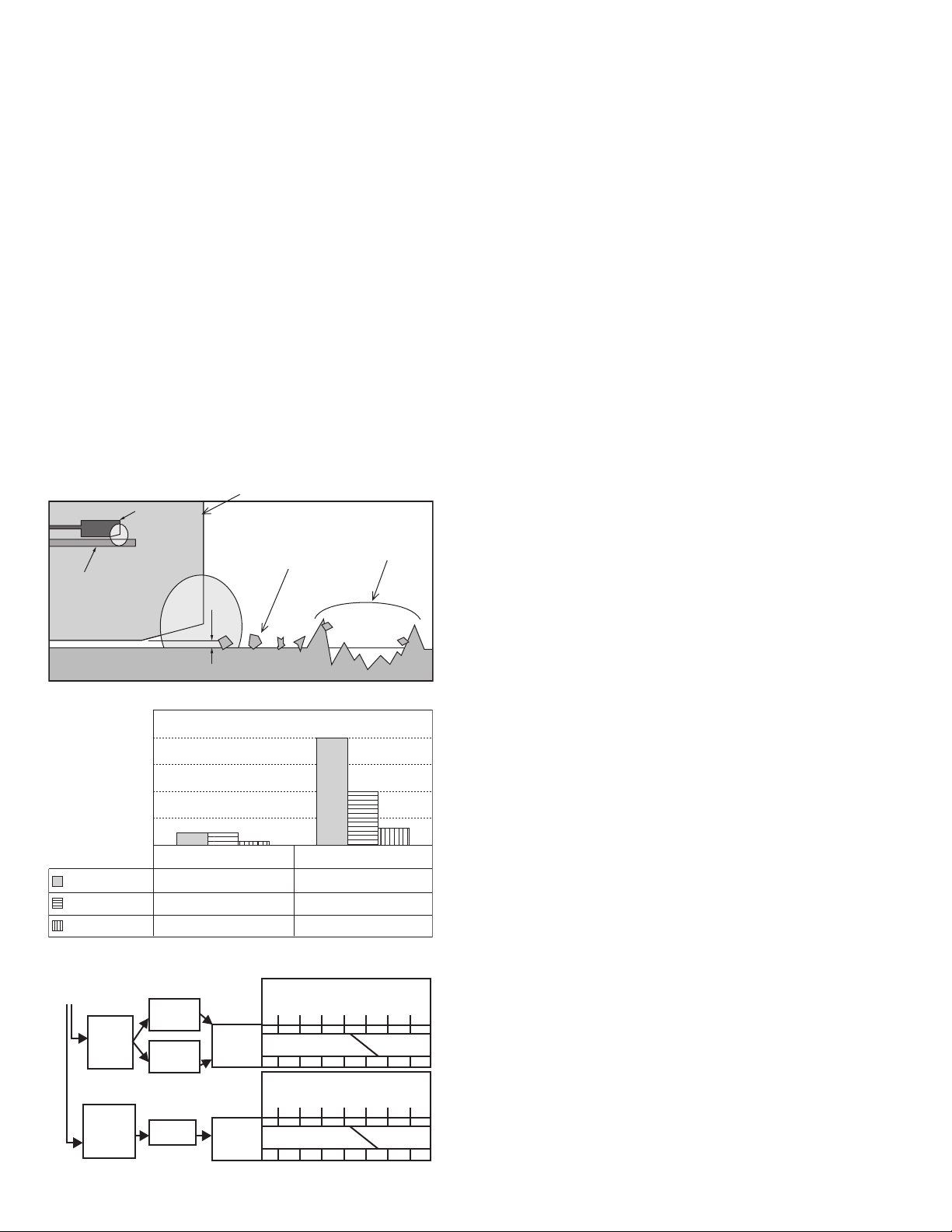

2.1.2.1 Failures caused by shock

One of the causes of the Microdrive failures is a crash between

the disk and the head caused by falls or shocks. The results of

the crash are listed as follows.

• The scratch on the surface of the disk (crash scar) disables

reading/ writing of the damaged part.

• The magnetic material that came off by the crash (disk fragment) causes head reading failure.

• The head distortion deteriorates the read/ write attribute.

• The change in the space between the head and the disk disables the normal read/ write.

Stronger shocks result in the motor axis distortion, causing axial

runout and deterioration in performance such as disabling the

trace of normally recorded signal.

Pay extra caution not to drop or give shocks to the Microdrive

while servicing, and make sure to store the Microdrive in a provided plastic case.

Head

Head

Crash scar

2000

2000

300

Disk

Disk

Impact value (G)

(G):Gravity

Microdrive

2.5 inch HDD

3.5 inch HDD

2500

2000

1500

1000

500

Disk fragment

㧔0.03um㧕

Head floating height

0

Operation Non-operation

200

200

55

2.1.2.2 Failures caused by static electricity

Microdrives are designed to tolerate static electricity up to 15kV

approx. However, head destruction or boot failure will occur as a

result of high static electricity given to the magnetic head of a Microdrive that is very vulnerable to static electricity.

As same as handling other electronic parts, make sure not to

take charge of static electricity before touching a Microdrive for

checking or repairing.

In addition, make sure to store the Microdrive in a provided plastic case when it is not in use.

The voltage of 15kV has enough power to break Microdrives destroying heads etc. Errors in Microdrives may occur with lower

voltage. Asking the customers about the recording condition:

whether it was inside the car in winter, right after getting off the

car or in the carpeted area of a hotel etc., is recommended to investigate failures with poor reproducibility.

2.1.2.3 Failures caused by power cut during the operation

When the power is cut off while writing the data on the Microdrive, writing failure occurs in the writing sector (512 byte). As a

result, an error will occur while reading the data.

The effects on the system, given by the bad writing sector, depend on the types of the written files on the sector.

If it is user data, the recorded movie may not be replayed.

To prevent failure in writing, do not insert/ remove the Microdrive

or cut off the power unless otherwise indicated or needed.

"Read Sequential Error" may be detected if Full Check of the Microdrive is performed with the DDD.

NOTE:

"Read Sequential error" may be detected as a result of defective Microdrive disables the reading. Abnormal reading may

also occur when the user removes the power plug or the battery while the Microdrive is in operation; the writing is not completed and the reading cannot be performed normally.

In the latter case, the failure will be corrected by running the

Full Check after the DDD Clean Disk has been performed.

Running the Clean Disk is recommended when the recorded

movies cannot be read or the Read Sequential Error occurs.

If an error is detected even after running the Full Check, other

causes of the failures are considered.

Shock

Crash

between

the head

and the

disk

Operation

Excessive

power is

generated

in the

mechanism

Operation/ Non-operation

1-6 (No.YF060)

Disk

fragment

Crash scar

on the disk

Disk

shift

50 100 150 200 250 300 350

Read

error

1400 1600 1800 2000 2200 2400 2600

Performance

deterioration

(G):Gravity

Shocks(G)

Shocks(G)

Read error

Performance

deterioration

Normal

Normal

Model:HMS360404D5CF00SERIES

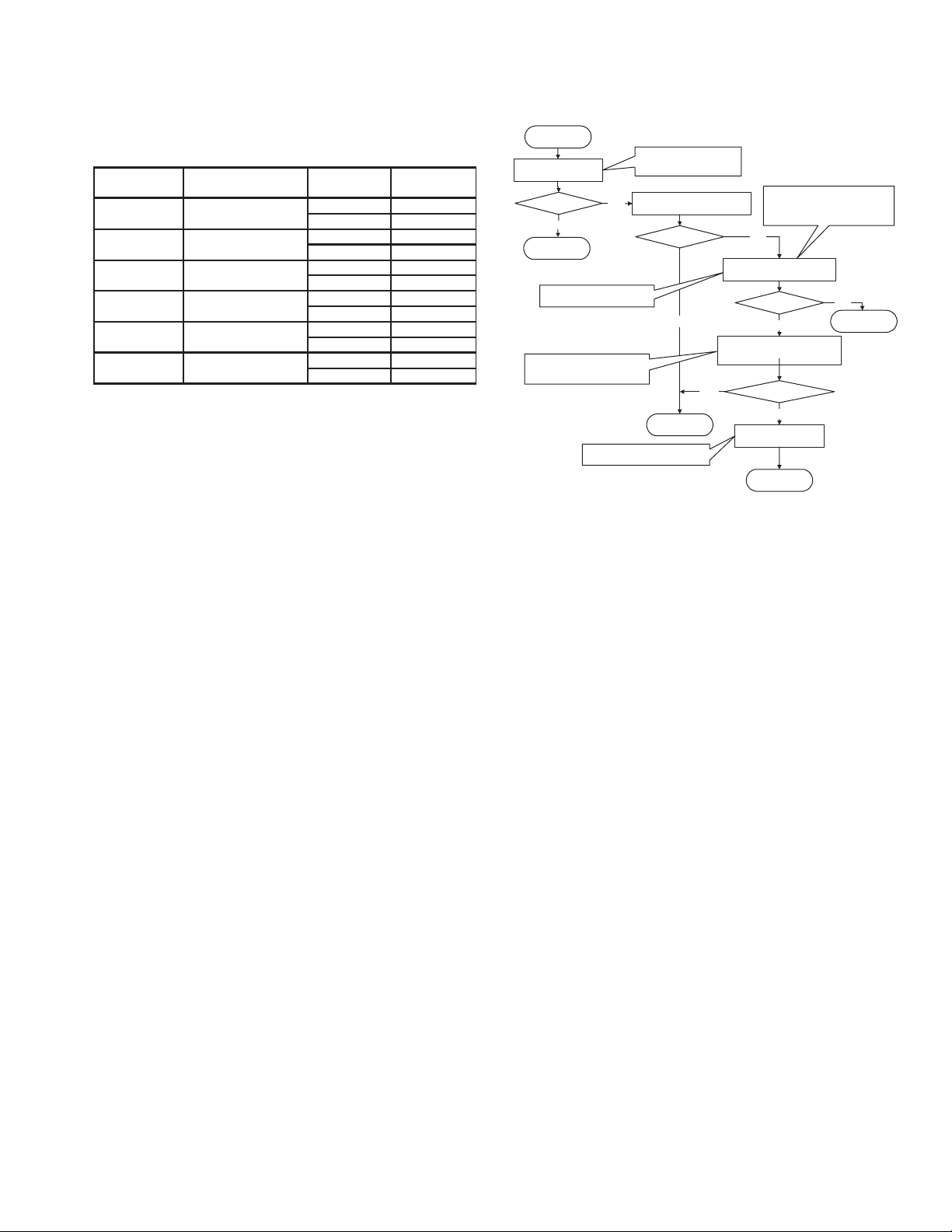

2.1.3 Microdrive backup

Unlike the information on tapes, customers' information on

Microdrives can become unreadable in an instant. Backing up

users' record is strongly recommended to avoid any accident.

File Transfer Time Measurement

Recording detail

(Recording Capacity)

FAT32

Normal format

FAT32

Quick format

15m(1GB)

30m(2GB)

45m(3GB)

60m(4GB)

Detection detail

via PCMCIA card

via USB2.0 reade

via PCMCIA card

via USB2.0 reade

transmitted by PCMCIA card

transmitted by USB2.0 reader

transmitted by PCMCIA card

transmitted by USB2.0 reader

transmitted by PCMCIA card

transmitted by USB2.0 reader

transmitted by PCMCIA card

transmitted by USB2.0 reader

Microdrive 1 Microdrive 㧞

N2B12JRA N2HNY1VA

12m31s 12m36s

00m37s 00m40s

00m18s 00m19s

00m10s 00m09s

16m16s 15m46s

07m25s 07m57s

29m30s 29m47s

14m08s 14m49s

41m23s 42m48s

22m47s 23m23s

56m15s 56m34s

30m02s 29m53s

The above data shows: the elapsed time of copying the recorded

information on a Microdrive to a PC and the elapsed time of

formatting the Microdrive with the PC.

From the results of the measurement, it is clear that the data

transfer with a commercial USB2.0 Reader/ Writer is about twice

as quick as transfer with a PCMCIA card.

Using USB2.0 Reader/ Writer is recommended when frequent

data backup or data re-writing on the Microdrive is required.

Backup should be performed all the recorded files on the Microdrive.

Formatting must be done with the main unit that operates normally.

If a Microdrive that is more than 2 GB is formatted with the main

unit, it is formatted as FAT (FAT16), and a drive that is more than

2GB is formatted FAT32.

2.1.4 Checking the main unit/ Microdrive good or bad

In order to repair or check MC100 - 200, judging the cause of the

failures, whether it is the main unit or the Microdrive, is essential.

The product failures that are brought into repair/ check fall into

the following categories.

(1) Microdrive failures caused by the users handling such as

fall, shocks, and submergence.

(2) Main unit operation failures caused by the Microdrive fail-

ures.

(3) Microdrive operation failures caused by the main unit fail-

ures.

NOTE:

Unlike DVC tapes, the Microdrives of MC100 - 200 are recognized as parts of the main unit. It is essential that the main unit

and the Microdrive are brought in as a pair for service. Basically, do not accept the main unit alone for repair or check.

2.1.4.1 Separations of the parts failures

The procedure to identify the causes of the failures whether it is

in the main unit or in the Microdrive is explained in this section.

Start

Check the Water Exposure Seal

Check the appearance

Troubles?

YES

Go to

2.1.4.2

Perform a general operation check

such as record/ replay.

Check whether there is an emergency

record in the main unit, and check the

details of the record.

The failure caused by the user's PC or

by the supplied software is considered.

Check the Water Exposure Seal,

significant scratches on the

exterior, bends, and dents.

Perform a general operation check

NO

using a MD other than the user drive.

Troubles?

YES

YES

Go to

2.1.4.4

Check whether it is a Microdrive failure

or a main unit failure by using the user's

Microdrive. Be sure to make a backup in

case of an accident.

NO

Operate a general operation check

using the user Microdrive.

Troubles?

NO

Check whether there is an emergency

record in the main unit, and check the

details of the record.

With an emergency record?

NO

Recheck the details of

the failure with the user.

YES

Go to 2.1.4.3

End

2.1.4.2 Microdrive failures caused by user handling

As previously explained, Microdrive failures may possibly be

caused by falls or shocks. Further more, dropping Microdrives in

the water causes crucial failures to Microdrives.

Supplied Microdrives (not all the commercial Microdrives) have

the same type of Water Exposure Seal that are used in cellular

phones.

Before checking the failures, check whether there is a Water Exposure Seal display appeared.

In addition, check whether there are any significant scratches,

bends, or dents that shows the sign of falls or shocks.

Other check items are as follows.

(1) Check whether there are any letters written with a pencil or

a pen on the label of the Microdrive. The pen pressure

gives distortion on the Microdrive, resulting in an operation

failure. It is noted in the Instruction Book.

(2) Check whether there are any stickers affixed on the Micro-

drive. The space between the Microdrive and the housing

is very little. Affixing unnecessary stickers may lead loading the Microdrive in a wrong position, resulting in contact

failure or remove disk failure. There is a hole on the reverse

side of the Microdrive for ventilation through special filter.

Sealing the holes gives effect on the operation.

(3) Check whether the Microdrive label is peeled or turned. If

there are peel or turn in the label, the loading failure may

occur. Peels or turns will not occur under normal conditions, thus storage or usage under hot and humid condition, near organic solvent, or exposure to the direct sunlight

are considered.

(No.YF060)1-7

When it is submerged, the white

Water Exposure Seal turns to red.

As the center part of the seal turns

to pink, the color seen from the

hole is pink. The 1mm hole

diameter prevents the seal from

getting affected by wet hands

under normal conditions. It is not

affected by the humidity of normal

storage or operational conditions.

Normal condition

Water Exposure Seal

display is appeared

(changes from white to red)

Displays of Water Exposure Seal

6mm

1mm

2mm

1.5mm 1.5mm

4mm

Air is taken into inside

the Microdrive from this

hole through special

filter for ventilation. DO

NOT SEAL THIS HOLE

is displayed.

Location of a Water

Exposure Seal (inside)

2.1.4.3

Main unit operation failures caused by the main unit/

Reverse side of the Microdrive

Microdrive failures.

2.1.4.2 There is a possibility of a Microdrive being damaged even

though there is no notable failure in appearance.

Main unit failures also result in abnormal operation in a Microdrive.

Identifying the causes of the failures in the main unit is explained

in this section.

In the diagram, MD stands for a Microdrive, CG for a compact

flash card, and SD for a SD card.

2.1.4.3

MD Diagnosis

Backup the record

of the user MD

Can it be

back upped?

YES

Perform the DDD Full Check

Troubles?

YES

Format the MD

with the main unit

Perform the DDD Clean Disk

Perform the DDD Full Check

Return the user backup data.

Troubles?

YES

MD failure

2.1.4.4 Operation failures caused by main unit failures

2.1.4.3 Judging from the separation of the main unit and MD, the

operation failure is more likely to be caused by the main unit failure. However, the main unit failure has not been determined yet,

as there is a possibility of the user MD failure causing the main

unit damage. The following procedure shows how to determine

the main unit failure.

Backup by connecting to the PC via USB or PCMCIA adapter

Read/ write by other

NO

devices is impossible

Go to 2.1.4.5

Check the emergency

NO

record of the main unit

Any record?

Format the MD with the main unit

Perform the DDD Clean Disk

Return the user backup data

Perform a detailed operation

NO

check by using the user MD

Troubles?

Main unit failure

NO

YES

YES

Either the bad data file or the

damaged MD causes the disabled

read/ write is not yet determined

at this point.

Go to 2.1.4.4

Although main unit failure is generally

speculated, the cause of the failure is

not determined whether the main unit/

MD at this point

Perform an operation check on

all items including MD and SD

The failure is resolved by

performing the formatting

NO

and the Clean Disk.

End

2.1.4.4

Main unit

diagnosis

An operation check

with other MD

Troubles?

NO

YES

An operation check

with CF and SD

Troubles in both

SD and CF?

YES

NO

Troubles

only in CF?

YES

NO

Main unit failure

The user MD/ FC may bend the

main unit socket pin(s). Using

defective MD/ FC results in

repeated failures, as they bend the

main unit connector every time

they are used. User MD/ CF should

be checked when abnormal main

unit socket is found.

Ask how many MDs/ CFs the user

has, then check all user MDs/ CFs.

2.1.4.5 Disabled read/ write with other devices

When read/ write cannot be done with the main unit, the main

unit failure is considered in most cases. Recognition failure

caused by the main unit writing bad data can be considered.

The causes of read/ write failures are as listed below.

(1) Damaged mechanism parts or electric parts inside the MD.

(Hardware failure)

(2) Damaged information in the MD. (Software failure)

In the case (1), it seems very difficult to recover, but there is a

possibility of recovery in the case (2) by using commercial software.

The following procedure shows how to figure out whether the

damage is in the hardware or in the software, and whether it is

recoverable or not.

2.1.4.5

Recoverability

diagnosis

An operation check

with other MD

Troubles?

NO

Main unit failure

2.1.4.5.1 Microdrive hardware failure

Although no failure was found in the MD appearance at the time

of the separation of 2.1.4.1, actually there is considerable damage disabling the operation. In this case, "Shipping Damage"

(damage caused by the transportation) is displayed as a result of

DDD diagnosis. Surely, a possibility of the products damaged on

route from the production plants to the shops and then to the consumers cannot be denied.

However, MDs are stored in protection cases or in main units and

the transportation shock that damages only the MDs is unrealistic. A failure cause by the user handling is more likely considered.

YES

Perform an operation check with CF and SD.

Use SD with theoretical value of 10MB/s or more.

Use CF with 40x high speed or more.

For details, refer to 5.

The Combinations of media and the main unit

Main unit failure

Check bend or break

in the socket pin(s).

Check the MD socket

of the main unit.

Troubles?

NO

YES

Check the connector part of

the main unit housing and

user MD/ CF

Carry out the servic

End

A failure caused by the user handling

is considered, and no more recovery

Perform the DDD

Full Check

Troubles?

YES

MD Hardware failure

is expected.

Please explain the user that it is a

MD failure.

NO

The main unit operation failure may be

caused by an unrecognizable MD after

user's editing works such as formatting

and adding/ deleting files or

maintenance works such as

defragmentation and check disk done

with a device other than the main unit.

Main unit failure

MD software failure

1-8 (No.YF060)

Recovery method

Asking a data recovery company (a data salvage company)

seems the only way.

Even if the MD is not recognized a drive, a transmission may be

possible with the MD (light hardware failure). In this case, system

recovery software such as Norton Utilities in Norton SystemWorks 2004 (NOTE1: ) may help drive recognition.

Once the drive recognition is recovered, the record may be recovered by the method mentioned in 4.5.2 MD software failure.

However, if it is a hardware failure, banning the use of the MD is

strongly recommended.

2.1.4.5.2 Microdrive software failure

Most of the software failures are caused by the unrecognizable

MD after user's editing works such as formatting and adding/ deleting files or maintenance works such as defragmentation and

check disk done with a device other than the main unit.

Many cases under this condition, recovery can be done by using

recovery software, which can recover MPEG2 data, such as Final

Data 2.0 Premium. It enables the drive recognition and the data

reading. Once the data is recovered, follow the below procedure.

2.1.4.5.2

Countermeasure for

the software failure

Start the data

recovery software

Is the data

recognized

NO

Recommend a data

recovery company

Perform an operation check on

all items including MD and SD.

YES

Backup the user MD record

Format the MD with the main unit

Perform the DDD Clean Disk

Perform the DDD Full Check again

Troubles?

NO

Return the user backup data

Perform a detailed operation

check by using the user MD

Troubles?

YES

Main unit failure

If backup is impossible,

do not proceed to the further works.

Further recovery is not expected.

Please explain the user that it is

a MD failure.

MD failure

YES

Explain the user that the possible cause

of the failure may be the users PC works.

Check again whether the user did a

prohibited or not guaranteed operation

by the Instruction Book.

Performing formatting

NO

and Clean Disk resolve

the failure

End

NOTE1:

Norton SystemWorks 2004 (Latest version on 2004/ 9/ 29)

It is Symantec's data recovery software.

For system requirements and other details, please check their

web site.http://www.symantec.com/region/jp/products/

NOTE2:

Final Data 2.0 Premium Office (Latest version on 2004/9/29)

It is AOS Technologies' data recovery software.

Although there are some kinds of recovery software as FINALDATA series from this company, this is the cheapest one that

can recover MPEG2.

For system requirements and other details, please check their

web site.http://www.finaldata.ne.jp/

2.1.4.5.3 Reusing Microdrives

If a Microdrive of a user is reused for another user, normal data

deletion may not completely erase the previous user's information (images) and the previous user's information may come

back. Unlike hard disks of PCs, most of the recorded contents of

Microdrives are images and audio data, thus there is a little possibility of recorded personal information in Microdrives. However,

proper handling in reusing Microdrives is required as a business

organization.

There are levels in erasing data in disks.

• Level 1: Zero Write method (once)

• Level 2: Random Write method (once)

• Level 3: Random/ Zero Write method (twice)

• Level 4: US Department of Defense (DoD5220.22-M)

• Level 5: US Department of Defense (DoD5220.22-Expanded)

• Level 6: Guttmann method

At least level 3 data erasure is recommended.

Data erasure software is commercially available from software

companies. It seems convenient to use Final Data 2.0 Premium

as there is a data erasing function in it.

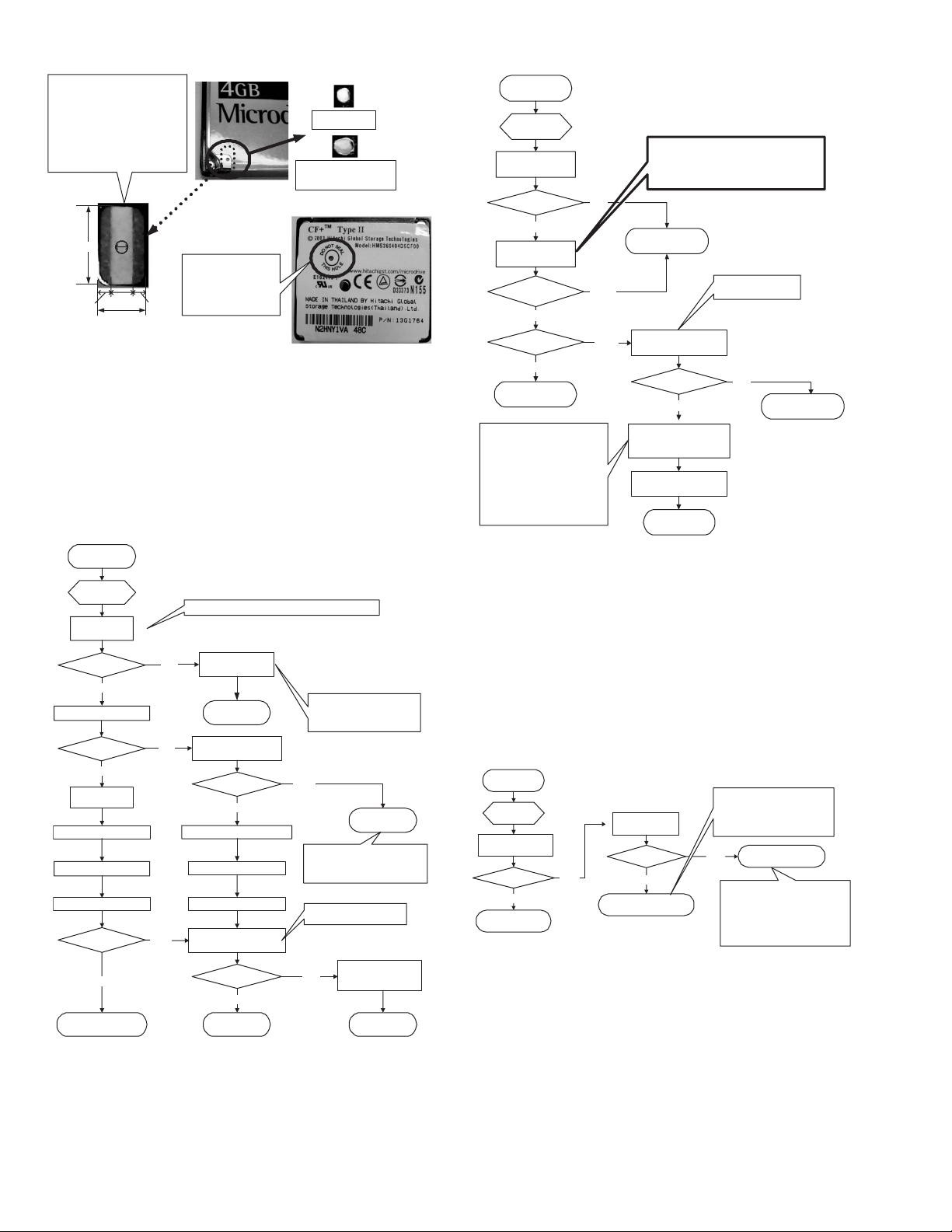

2.1.5 Combinations of media and a main unit

MC100 - 200 can record movies, pictures, and audio on compact

flash cards, SD cards in addition to Microdrives. Recording movies is partially limited. Characteristics of each medium, available

or limited operation items, and available operation time are explained in this section.

2.1.5.1 Types of media

Microdrive

Type

Capacity

Price

Unit price per 1MB

Commercially available

maximum capacity

15yen/㧬MB 52yen/㧬MB58yen/㧬MB

Available media for MC100-200

Compact Flash card

2GB 1GB1GB1GB

33000yen 52000yen58000yen

4GB 1GB1GB1GB

38000yen

38yen/㧬MB

SD card

Data for comparison

Memory stick

Commercially available maximum capacity

MC100 - 200 are basically designed to record movies by using

Microdrives.

MC100 - 200 have 2 types of slots, one for a Microdrive or a

Compact Flash card, and the other for a SD card.

From the menu, movies/ pictures/ audio can be selected for a

medium in either one of the slots.

Recording mode

Movies

Pictures

Audio

Factory setting

MD/CF

SD

SD

As movies, pictures, and audio can separately select the slots,

using one slot for all recording mode is possible. However, as

movies require large capacity and high transmission speed, the

available recording mode (image quality) is limited.

(Refer to 5.2.3 Image quality and support media.)

Recording movies in Microdrive setting is recommended.

2.1.5.2 Movies

Movies are recorded SD-VIDEO1.1 standard, (images) MPEG2-PS (with RDI),(audio) Dolby Digital AC-3, PAL 50 frame aspect

4:3

Movie recording is explained as follows.

2.1.5.2.1 Recording rate

Image Audio

Image quality mode

㧔Image size㧕

Ultra fine

㧔720480㧕

Fine

㧔720480㧕

Normal

㧔720480㧕

Economy

㧔325240㧕

Image quality

(Sensitivity comparison)

Equivalent

to DVC

Equivalent

to DVD cam

Equivalent

to VHS

Equivalent

to video CD

Bit

rate

8.5Mbps

5.5Mbps

4.2Mbps

1.5Mbps

CBR/

VBR

CBR

CBR

VBR

VBR

Sampling

frequency

48 kHz

48 kHz

48 kHz

48 kHz

Bit

rate

384kbps

384kbps

256kbps

128kbps

CBR/

VBR

CBR

CBR

VBR

VBR

RDI

32.768kbps

32.768kbps

32.768kbps

32.768kbps

Total bit rate

8.92 Mbps

5.92 Mbps

4.49 Mbps

1.66 Mbps

(No.YF060)1-9

2.1.5.2.2 Recording time (approximately minutes)

Ultra fine

㧔720480㧕

SD㧛CFޓ128MB

SD㧛CFޓ256MB

SD㧛CFޓ512MB

SD㧛CFޓ1GB

MDޓ2GB

MDޓ4GB 60 minutes 90 minutes 120 minutes 300 minutes

2 minutes

4 minutes 6 minutes

8 minutes 12 minutes

16 minutes 24 minutes

30 minutes 45 minutes

Fine

㧔720480㧕

3 minutes

Normal

㧔720480㧕

4 minutes

7 minutes

15 minutes

31 minutes

60 minutes

Economy

㧔352240㧕

10 minutes

21 minutes

43 minutes

86 minutes

150 minutes

2.1.5.2.3 Image quality and support media

Image quality mode

Ultra fine

Fine

Normal

Economy

Microdrive

1GB or less 1GB or more

٤

Not for high speed

transmission

٤

٤

٤

٤

Compact Flash card

For high speed

transmission

٤

٤

٤

٤

٤

SD card

٤

For high speed

transmission

Not for high speed

transmission

٤

٤

٤

٤

As shown above, Microdrives of 1GB or less, Compact Flash

cards, and SD cards that are not for high transmission speed

cannot record movies except in the economy mode.

If a recording mode other than economy mode is selected and

the recording is started, " Recording cannot be done with this

Medium speed" is displayed.

Microdrives can be judged by the capacity whether they are for/

or not for the movie recording. However, Compact Flash cards

and SD cards are difficult to judge from the appearances.

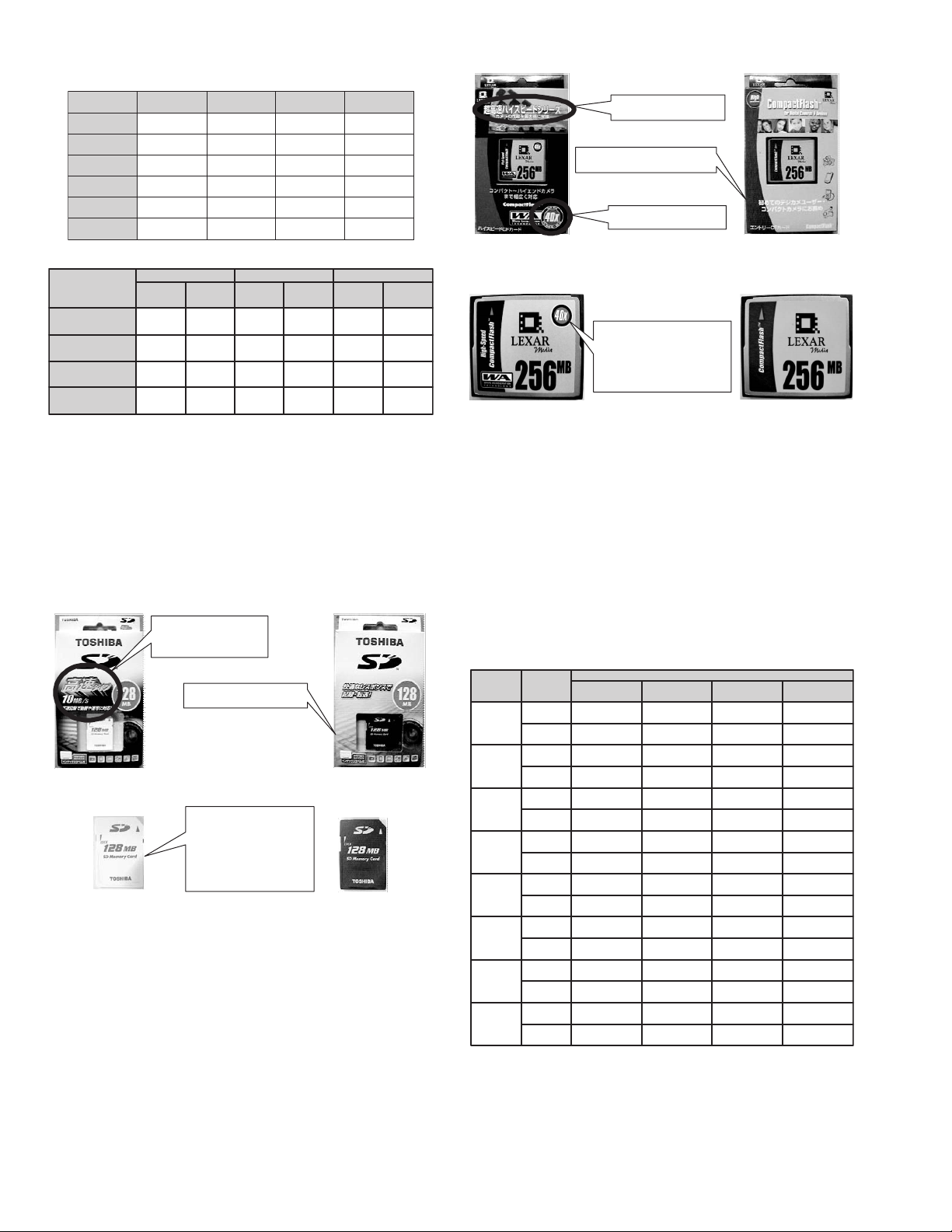

A Toshiba SD card and a LEXAR Compact Flash card are compared below.

On the package of the product,

it is noted as high-speed type.

The transmission speed of this

product is 10MB/S is written.

There is no description on

this product as a high-speed type

Package of the product for high data

transmission speed

It can be judged whether it is a

high-speed type or not by the

appearance as the color is

different.

As there is no description on the

product, a consumer does not

recognize the product of high

speed or normal speed, if he/ she

has no product to compare.

Appearance of the product for

high data transmission speed

Package of the product not for

high data transmission speed

Appearance of the product not for

high data transmission speed

SD card that is operation checked as a high-speed type has

transmission speed of 10MB/s or more. High-speed products

with less capacity (9MB/s etc.) may operate, but operation cannot be guaranteed.

On the package of the product,

it is noted as high-speed type.

There is no prescription of high-speed

type on this product package

Description of the transmission

speed as 40x

Package of the product not for

high data transmission speed

It can be judged whether it is a highspeed type or not by the appearance

as the color and the design are

different. The consumers can see

whether it is a high-speed type or not

as a description of 40x speed is

written on the product.

Appearance of the product for

high data transmission speed

Package of the product not for

high data transmission speed

Package of the product not for

high data transmission speed

Compact flash card that is operation checked as a high-speed

type has transmission speed of 40x or more. High-speed

products with less capacity may operate, but operation cannot be

guaranteed.

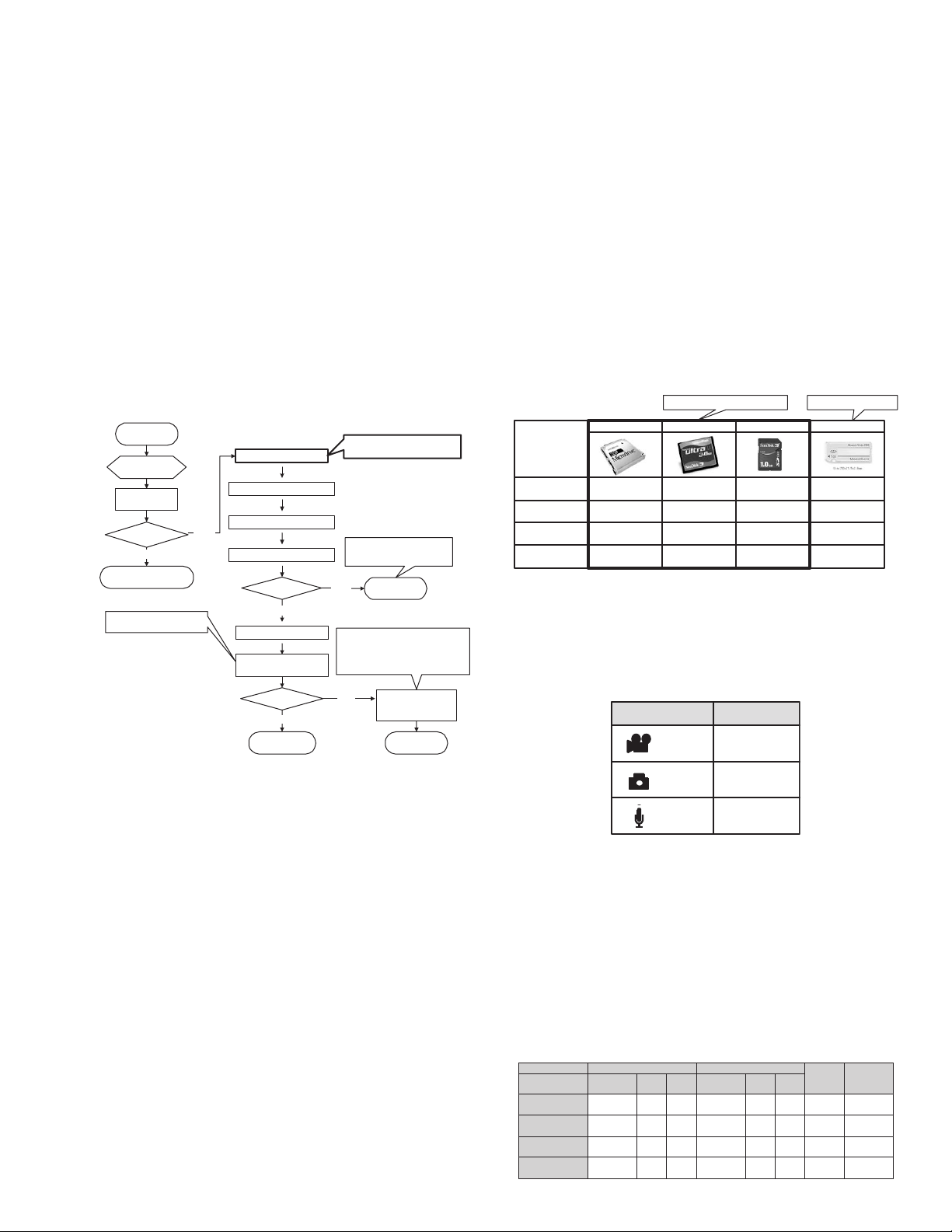

2.1.5.3 Pictures

Pictures are recorded as JPEG compression picture Exif2..2,

DCF2.0, PictBridge, DPOF standard conformity. There is no restriction of picture recording media or spec, but equivalent transmission speed as for movies is required for rapid shooting.

Picture recording is explained as follows.

2.1.5.3.1 Image size and recording numbers

%CRCEKV[

32MB

64MB

128MB

256MB

512MB

1GB

2GB

4GB

2KEVWTG

OQFG

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

(KPG

5VCPFCTF

UXGA

(16001200㧕

34

50

65

110

145

245

290

490

699

2285

1398

2797

9142

5595

9999

+OCIGUK\G

SXGA

(1280960㧕

60

120

125

250

280

560

145

245

1094

3555

2188

71104570

4376

9999

8752

9999

(1024768㧕

XGA

95

185

200

375

430

865

865

1735

1706

5565

3412

9999

9999

9999

9999

(Approx. numbers)

VGA

(640480㧕

205

375

425

755

2210

5200

7756

9999

3878

9999

7756

9999

99996826

9999

9999

9999

The value varies slightly according on each medium, Microdrive,

Compact flash card, and SD card. In addition, these values are

theoretical values, and it does not guarantee the recording numbers.

1-10 (No.YF060)

Loading...

Loading...