Page 1

SERVICE MANUAL

COMPACT VHS CAMCORDER

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

:

(973)317-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

JVC CANADA INC.

Head office

Montreal

Vancouver

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland, Quebec H9H 5G7

:

13040 Worster Court Richmond, B.C. V6V 2B3

(416)293-1311

(514)871-1311

(604)270-1311

S40895-04

GR-AX770U/AX970U

SPECIFICATIONS

General

Format : VHS NTSC standard

Power source : DC 11 V (Using AC Adapter)

Power consumption

Viewfinder on : 3.7 W

Signal system : NTSC-type

Video recording system

Luminance : FM recording

Color : Converted sub-carrier direct recording

Cassette : cassette

Tape speed

SP : 33.35 mm/sec. (1-5/16 ips)

EP : 11.12 mm/sec. (7/16 ips)

Recording time (max.)

SP : 40 minutes

EP : 120 minutes

Operating

temperature : 0°C to 40°C (32°F to 104°F)

Operating humidity : 35% to 80%

Storage temperature : –20°C to 50°C (–4°F to 122°F)

Weight : Approx. 850 g (1.9 lbs)

No. 86663

Dimensions : 200 mm x 112 mm x 115 mm

(W x H x D) (7-7/8" x 4-7/16" x 4-9/16")

Pickup : 1/4" format CCD

Lens : F1.6, f = 3.9 mm to 62.4 mm,

Viewfinder : Electronic viewfinder with 0.5" black/white CRT

White balance

adjustment : Auto/Manual adjustment

GR-AX770U/AX970U

(The specifications shown pertain specifically to the model GR-AX770)

Camcorder

DC 6 V (Using battery pack)

Conforms to VHS standard

(with TC-40 cassette)

16:1 power zoom lens with auto iris and macro control,

filter diameter 40.5 mm

Connectors

Video : 1 V (p-p), 75 Ø unbalanced, analog output (via

Audio : 300 mV (rms), 1 kØ analog output

Power requirement

U.S.A. and Canada : AC 120 V`, 60 Hz

Other countries : AC 110 V to 240 V`, 50 Hz/60 Hz

Output : DC 11 V , 1 A

Optional Accessories

• Battery Packs BN-V12U, BN-V20U, BN-V400U

• A/V (Audio/Video) Cable

• Compact VHS ( ) Cassettes TC-40/30/20

• Active Carrying Bag CB-V7U

Some accessories are not available in some areas. Please consult

your nearest JVC dealer for details on accessories and their

availability.

Specifications shown are for SP mode unless otherwise indicated.

E & O.E. Design and specifications subject to change without notice.

Video output connector)

(via Audio output connector)

AC Adapter

Printed in Japan

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

No. 86663

January 2002

Page 2

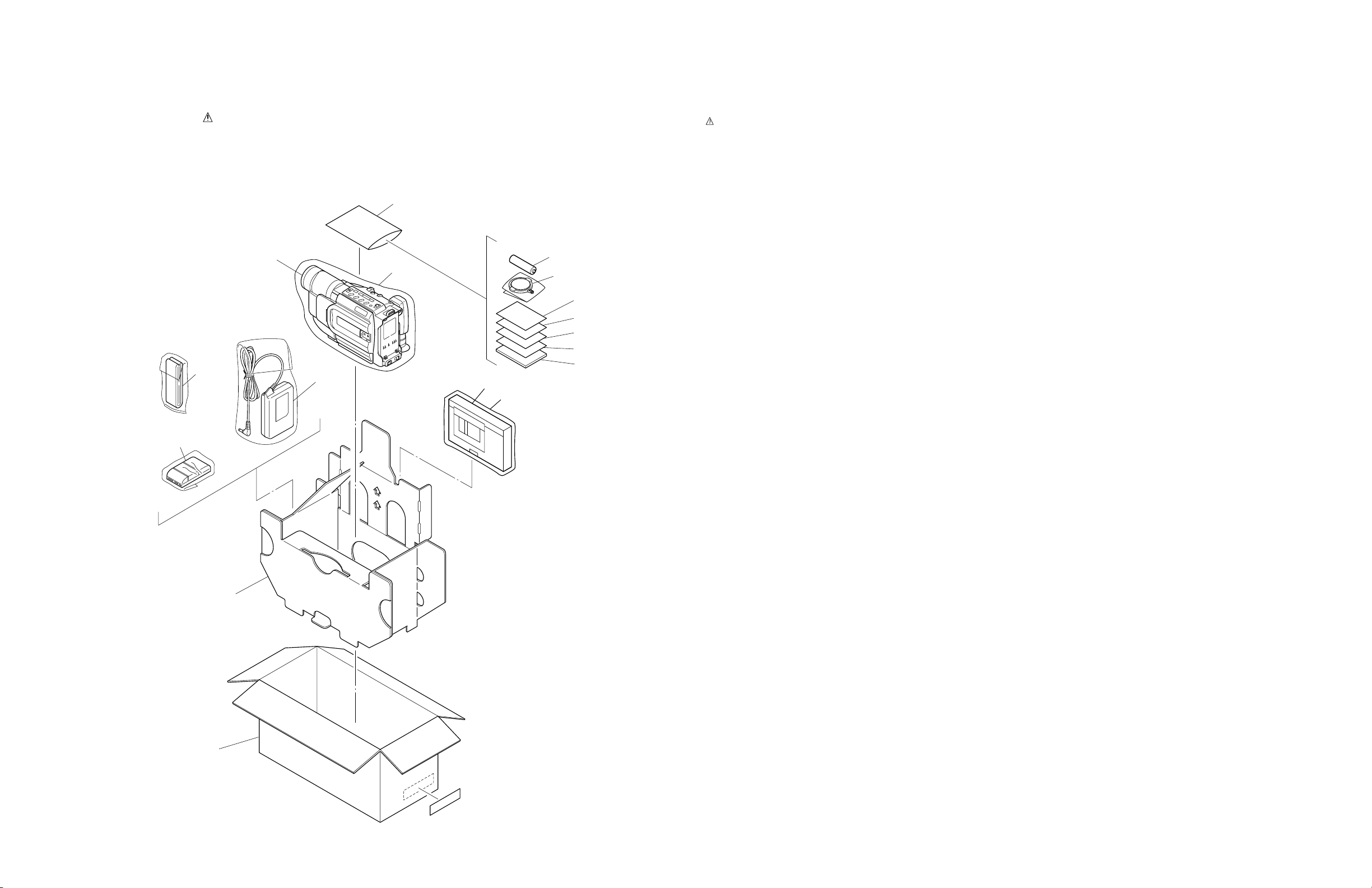

SECTION 5

PARTS LIST

SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

5.1 PACKING AND ACCESSORY ASSEMBLY <M1>

The instruction manual to be provided with this product will differ according to the destination.

4

FINAL ASSY

14

<M2>

11

3

21

22

16

15

9

8

7

6

5

# REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- -----------------------------------------------------

******************************

PACKING AND ACCESSORY ASSEMBLY <M1>

1 LY32179-001A PACKING CASE

2 LY32553-001A CUSHION

3 LY30023-002A POLY BAG

4 QPA02003506 POLY BAG

!

5 LYT0880-001C INST.BOOK(EN),AX970U

!

!

6 BT-51028-1 REGIST.CARD,AX970U

7 BT-51005-5 WARRANTY INF.,AX970U

8 BT-52004-2 WARRANTY CARD,AX770UC

9 BT-20071B SER.NET CARD,AX770UC

!

11 LY20848-001B AC ADAPTER,AP-V12U

!

13 YQ10629A BATTERY PACK,BN-V11U

14 LY20186-001A SHOULDER STRAP

15 LY43388-001A LENS CAP ASSY

16 – BATTERY,AA(R6)

21 YQ31963B-3 CASSETTE ADAPTER,C-P7U

22 YQ43446 POLY BAG

LYT0921-001A INST.BOOK(EN),AX770UC

LYT0923-001A INST.BOOK(FR),AX770UC

13

• INSTRUCTIONS

EN ....... ENGLISH

FR ....... FRENCH

2

1

LABEL

(SERIAL)

5-1 5-2

Page 3

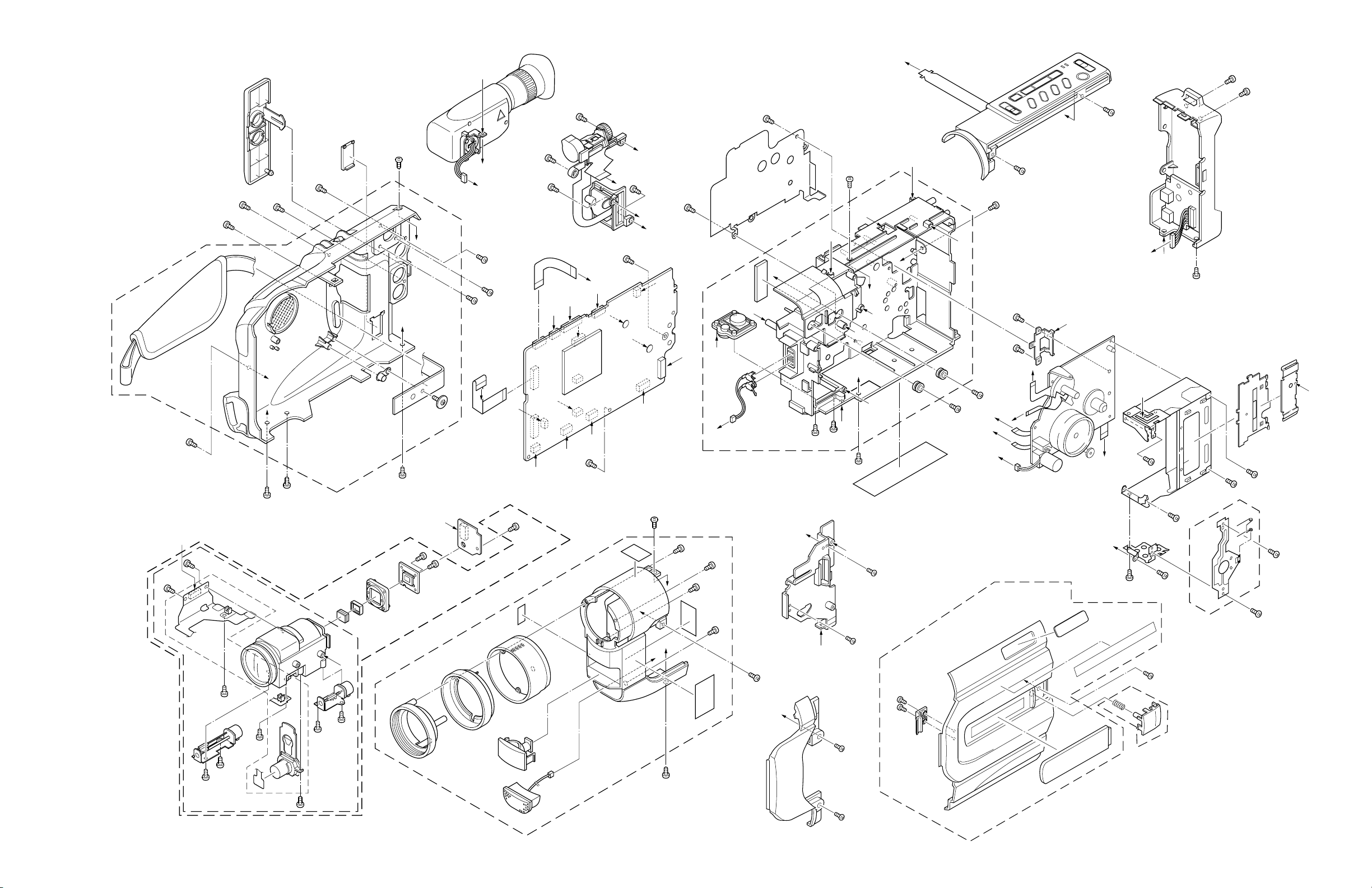

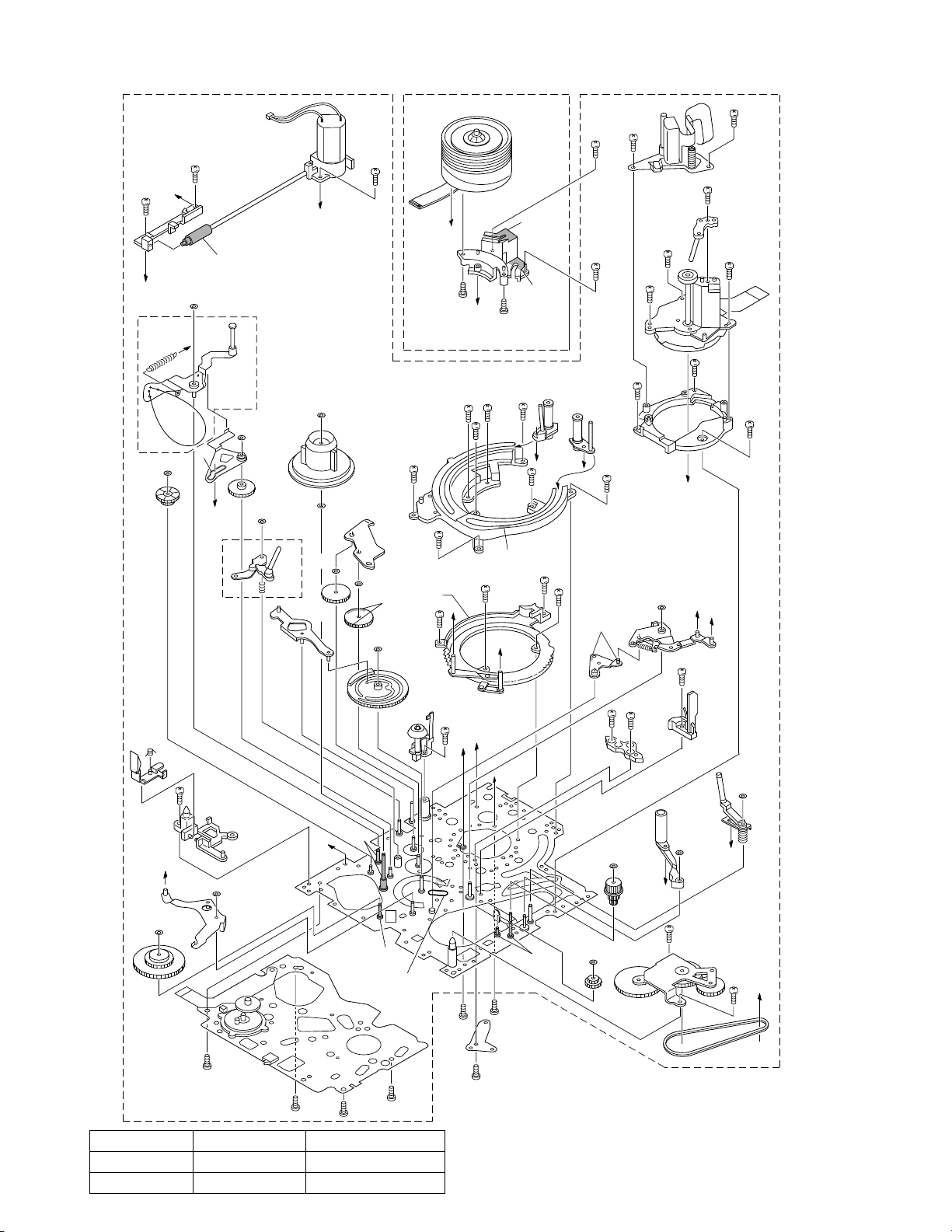

5.2 FINAL ASSEMBLY <M2>

111

117

117

110

110B

116

ss

251C

251C

251C

251B

251C

251C

251C

116

114

j

h

116

118

OPTICAL BLOCK

SECTION

251A

251C

251D

251C

252

253

251C

125

131

ELECTRONIC

gg

u

VIEWFINDER

112

115

<M4>

v

nn

148

148

148

147

ff

p

148

141

142

149

f

126

v

126

131

130

139

p

c

d

a

b

rr

140D

pp

m

140D

150

110A

s

144

n

MAIN

<01>

nn

140A

k

e

140C

j

u

146

113

113

g

113

bb

y

ff

z

s

gg

n

h

aa

140E

140E

140F

w

140B

140B

110C

145

ss

w

jj

cc

dd

ee

x

143

116

CCD

<02>

y

257

256

256

135

135H

255

254

135K

135C

251

e

135B

136

b

a

135E

k

135E

135E

135J

m

135E

jj

136

135A

mm

135F

135G

103

151

mm

105

107

105

rr

101E

104

101E

101D

RATING

LABEL

101

136

135D

104

149

f

aa

g

140

131

162

161

MECHANISM

<M3>

c

162

158

157

kk

150

dd

bb

z

155

d

ee

x

cc

pp

165

156

164

163

156

156

156

159

159A

160

160

101B

kk

101A

101C

106A

102

106

5-3 5-4

Page 4

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

147 LY20613-001B ZOOM UNIT

******************************

FINAL ASSEMBLY <M2>

101 LY20680-019A CASSETTE COVER(S)ASSY

101A LY32405-001A PLATE(WINDOW S)

101B LY42883-001A MARK

101C LY32562-003A STICKER(B)

101D LY32024-001B HINGE(CASSETTE COVER)

101E QYSLSF2060D SCREW,X2

102 QYSLSP2030D SCREW

103 LY10272-020A UPPER CASE(S),AX770UC

LY10272-026A UPPER CASE(S),AX970U

104 QYSLSF2060D SCREW,X2

105 QYSLSF2060D SCREW,X2

106 LY32041-001E BUTTON(PUSH)ASSY

106A LY30002-049B COMPRESSION SPRING

107 LY32038-001A UPPER COVER(S)ASSY

110 LY20684-001B LOWER CASE ASSY

110A LY40081-001A CAP

110B LY20682-001A GRIP BELT

110C LY30018-003A SPECIAL SCREW

111 LY31945-003A COVER(JACK)

112 LY31946-001A COVER(JIG)

113 QYSLSF2050Z SCREW,X3

114 QYSLSF2060D SCREW

115 QYSLSF2060D SCREW

116 QYSLSF2060D SCREW,X4

117 QYSLSF2060D SCREW,X2

118 QYSLSF2060D SCREW

125 LY20614-004C TOP OPE UNIT,AX770UC

LY20614-010C TOP OPE UNIT,AX970U

126 QYSLSF2060D SCREW,X2

130 LY20615-006E REAR UNIT

131 QYSLSF2060D SCREW,X3

135 LY20683-034A FRONT COVER ASSY,AX970U

LY20683-038A FRONT COVER ASSY,AX770UC

135A LY31937-001A HOOD

135B LY31938-001A COVER(HOOD)

135C LY31936-001A RING

135D LY32482-001A MICROPHONE

135E QYSLSF2060D SCREW,X4

135F LY30934-017A COVER(LIGHT),AX770UC

LY32040-001A DC LIGHT,AX970U

135G LY32058-001A STICKER(A),AX770UC

LY32058-002A STICKER(A),AX970U

135H LY32060-005A STICKER(C)

135J LY30029-0B4A SPACER(A),AX970U

!

135K YQ44341-6 CAUTION LABEL

136 QYSLSF2060D SCREW,X3

139 QYSPSTU1725M SCREW

140 LY20832-001B FRAME ASSY,AX970U

LY20832-002B FRAME ASSY,AX770UC

140A YQ31843 BASE

140B QYSLSF2060D SCREW,X2

140C LY30029-0A4A SPACER(A)

140D LY41082-001A CUSHION(OP),X2

140E YQ43810-1-1 CONTACT(LIGHT),X2,AX970U

140F WJM0259-001A E-SI C WIRE C-F,AX970U

141 LY32327-001A SHIELD CASE(MAIN)

142 QYSPSPU1720Z SCREW

143 QYSLSF2060D SCREW

144 QYSLSF2060D SCREW

145 WJT0072-001A E-CARD WIRE, OP-MAIN CN15

146 QAL0389-001 FPC, MAIN CN22-CCD CN5301

148 QYSLSF2060D SCREW,X4

149 LY41173-001A SPECIAL SCREW,X2

150 LY30018-050A SPECIAL SCREW,X2

151 QYSLSP2030D SCREW

155 LY31808-001C CASSETTE HOUSING FINAL ASSY

156 LY42722-003A SCREW,X4

157 LY31294-001B CASSETTE COVER INSIDE

158 LY32026-001B BRACKET(C.C/S)

159 LY31790-001A FRONT FRAME ASSY

159A YQ44144-1-1 TAPE GUIDE

160 SPSH1725M SCREW,X2

161 LY32326-001A BRACKET(MECHA)

162 LY42722-003A SCREW,X2

163 QYSLSF1750D SCREW

164 LY31807-001A SIDE BRACKET L

165 LY42722-003A SCREW

– OPTICAL BLOCK SECTION –

251 LY30948-003A OP BLOCK ASSY

251A PTY30948-002 FOCUS MOTOR

251B PTY30948-301 ZOOM MOTOR

251C PTY30151-016 TAPPING SCREW,X9

251D PTY30948-006 IRIS MOTOR UNIT

252 LY41757-001A OPTICAL LPF

253 LY31441-001A SPACER RUBBER

254 LY20346-001A CCD SPACER

255 LYH30374-001A CCD BASE ASSY

256 QYSPSGU2080Z SCREW,X2

257 LY30018-072A SPECIAL SCREW

5-5

Page 5

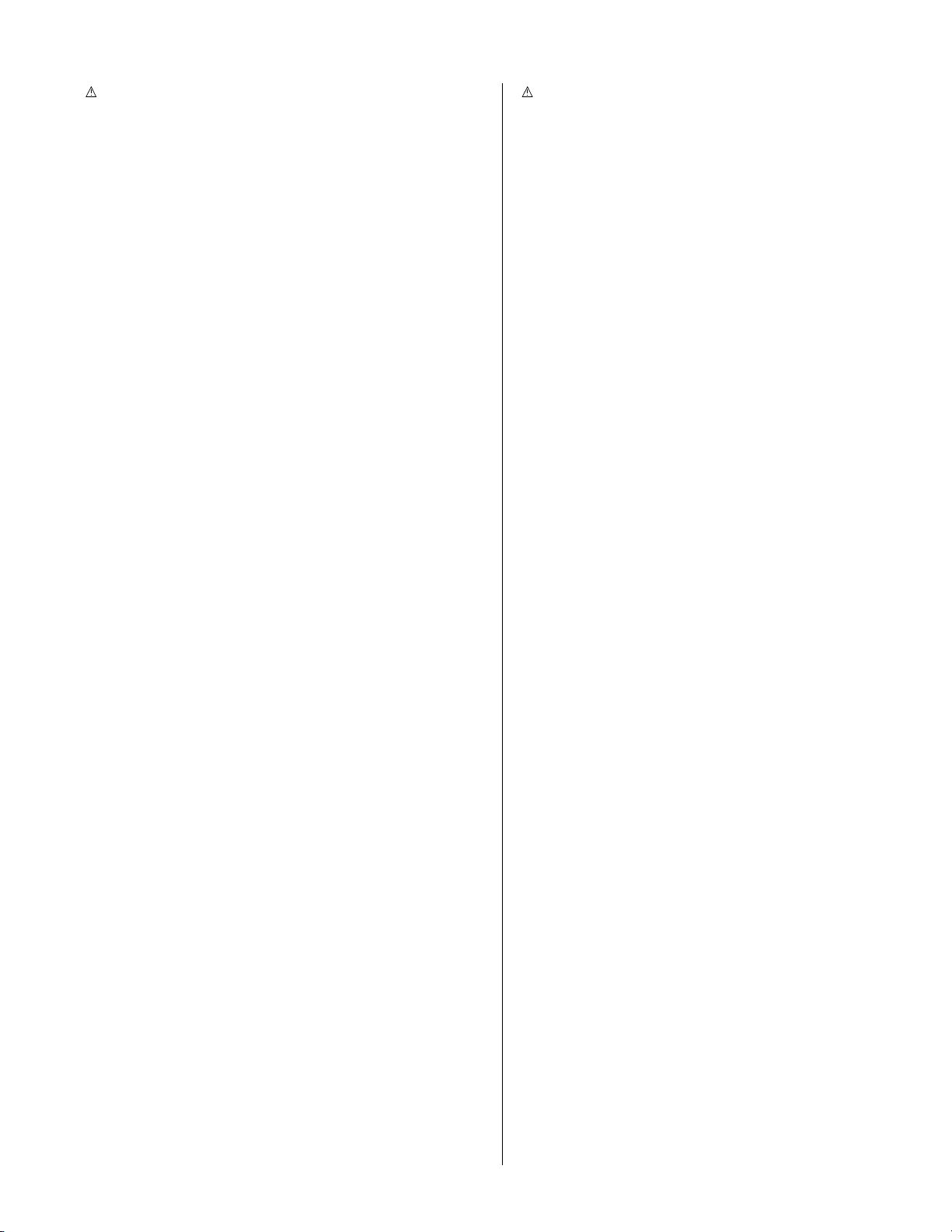

5.3 MECHANISM ASSEMBLY <M3>

400

410

410

j

409

AA

g

440

j

411

439A

404

414

405

AA

b

403

402

b

439

414

413

412

430

429A

428

461

429

BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety

and performance. We recommend that genuine JVC parts be used.

457

420

419

469

458

459

426

n

423

427

401

470

442

457

455

445

445

441

434

433

465

c

470

m

425

AA

468

465

464

408

410

h

453

454

421

418

AA

417

416

415

BB

g

425

425

423

431

469B

AA

432

AA

x

425

n

425

423

x

y

h

425

AA

469A

AA

469B

425

425

424

AA

423

m

422

y

a

463

436

435

459

447

446

445

444

442

443

c

d

462

438

437

d

5-6

467

460

467

466

467

BB

AA

467

452

451

Classification Part No. Symbol in drawing

Grease KYODO-SH-P AA

Oil YTU94027 BB

450

457

449

456

471

BB

471

472

473

NOTE:The section marked in AA and BB indicate

lubrication and greasing areas.

450

448

a

Page 6

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

******************************

MECHANISM ASSEMBLY <M3>

400 YMA0033A-E MECHA(B)ASSY

401 LY20612-001B MAIN DECK ASSY

402 LY31817-001A CASSETTE GUIDE(LEFT)

403 LY31815-001A SW LEVER(LEFT)

404 LY42581-001A TORSION SPRING

405 LY42722-001A SCREW

408 LY31826-001A MOTOR BRACKET ASSY

409 YQ20793 WORM BRACKET

410 LY42722-001A SCREW,X3

411 LY31925-001A WHEEL GEAR

412 LY42730-001A MIDDLE GEAR

413 LY42521-001A CANCEL LEVER ASSY

414 LY42754-003A SLIT WASHER,X2

415 YQ20827-2-1 CONTROL CAM

416 PQM30017-25 SLIT WASHER

417 LY42733-001A LOADING GEAR(T)ASSY

418 LY42754-003A SLIT WASHER

419 LY42732-001A LOADING GEAR(S)ASSY

420 LY42754-003A SLIT WASHER

421 LY42403-001A COVER PLATE

422 LY42452-001A LOADING RING ASSY

423 LY42728-001A SCREW,X4

424 LY10239-001A GUIDE RAIL

425 LY42728-001A SCREW,X8

426 LY30161-001B POLE BASE(S)ASSY

427 LY30162-002A POLE BASE(T)ASSY

428 LY42523-001A DRIVE LEVER ASSY

429 LY42545-001A SLANT ARM ASSY

429A LY42547-001A TORSION SPRING(S)

430 LY42754-003A SLIT WASHER

431 LY42739-003A ROLLER BASE ASSY

432 LY42722-001A SCREW

433 LY42494-001A LINK ARM ASSY

434 PQM30017-25 SLIT WASHER

435 LY40018-002A PINCH ROLLER ARM ASSY

436 PQM30017-25 SLIT WASHER

437 LY42541-001B TAKE UP GUIDE ARM ASSY

438 LY42754-003A SLIT WASHER

439 LY42571-001A TENSION ARM ASSY

439A LY42669-001A TENSION SPRING

440 LY42754-003A SLIT WASHER

441 YQ20797-1-5 MOTOR BASE

442 LY42722-001A SCREW,X2

443 YQ44460 SCREW

444 QAR0212-001 CAPSTAN MOTOR

445 YQ44304 TAPPING SCREW,X3

446 LY42731-001A SLANT POLE BASE ASSY

447 YQ44304 TAPPING SCREW

448 YQ43710-2 TIMING BELT

449 LY42678-001A CENTER PULLEY UNIT

450 LY42722-002A SCREW,X2

451 LY42670-001A SUPPLY CLUTCH ASSY

452 LY42754-003A SLIT WASHER

453 YQ31861-1-7 REEL DISC

454 LY42755-001A WASHER

455 LY31924-001A TAKE UP GEAR

456 LY42738-001A BRAKE SUB GEAR

457 LY42754-003A SLIT WASHER,X3

458 LY42544-001B A/C HEAD UNIT

459 SPSN1750Z SCREW,X2

460 LY42517-001A EJECT LEVER ASSY

461 LY42754-003A SLIT WASHER

462 YQ31833-1-1 LED GUIDE

463 LY42722-001A SCREW

464 LY42729-001A DRUM SPACER

465 LY42722-001A SCREW,X2

466 QSW0888-001 ROTARY ENCODER

467 LY42722-002A SCREW,X4

468 LY31814-001A LINK LEVER

469 YDV2098A DRUM ASSY

469A YDM1003-1-5 CATCHER

469B QYSPSPU1735M SCREW,X2

470 LY42722-001A SCREW,X2

471 SPSH1740Z SCREW,X2

472 LY43542-001A BRUSH

473 LY42722-003A SCREW

5-7

Page 7

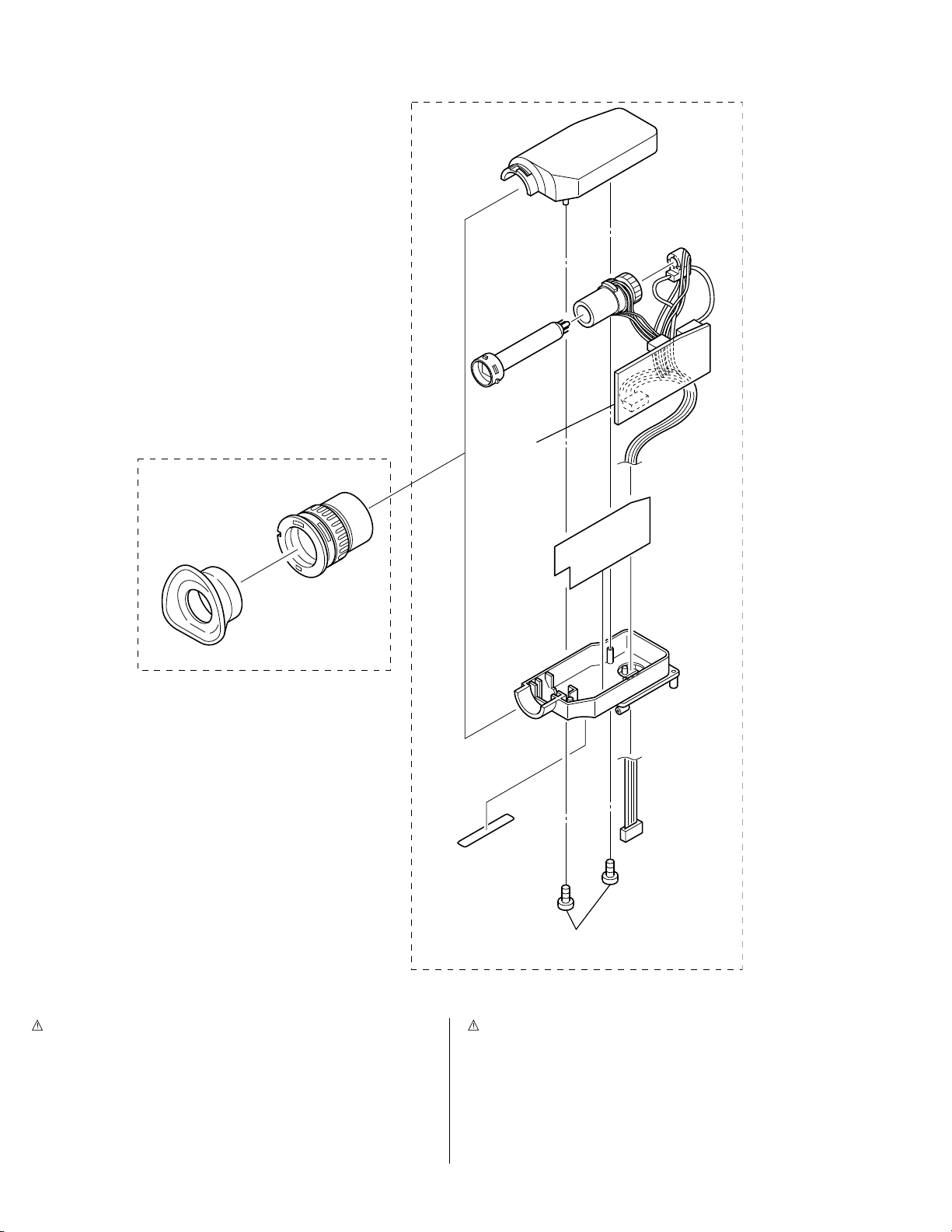

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4> [GR-AX770UC]

350

353

352

351

357A

357

ELECTRONIC

VIEWFINDER

<60>

SERIAL NO.

LABEL

a

355

356

a

354

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

!

******************************

ELECTRONIC VIEWFINDER ASSEMBLY <M4>

!

350 LY20701-007A B/W VF ASSY

!

351 PEDP0193 CRT

!

352 QQD0026-001 DEFLECTION YOKE

5-8

353 LY10165-001B CASE(L)

354 QYSPSGU1760M TAP SCREW,X2

!

355 LY41280-001A SHEET(SHIELD)

!

356 PTY20701-011 BOTTOM CASE ASSY

357 PTY20374-201 LENS ASSY

357A LY20411-001A EYE CAP

Page 8

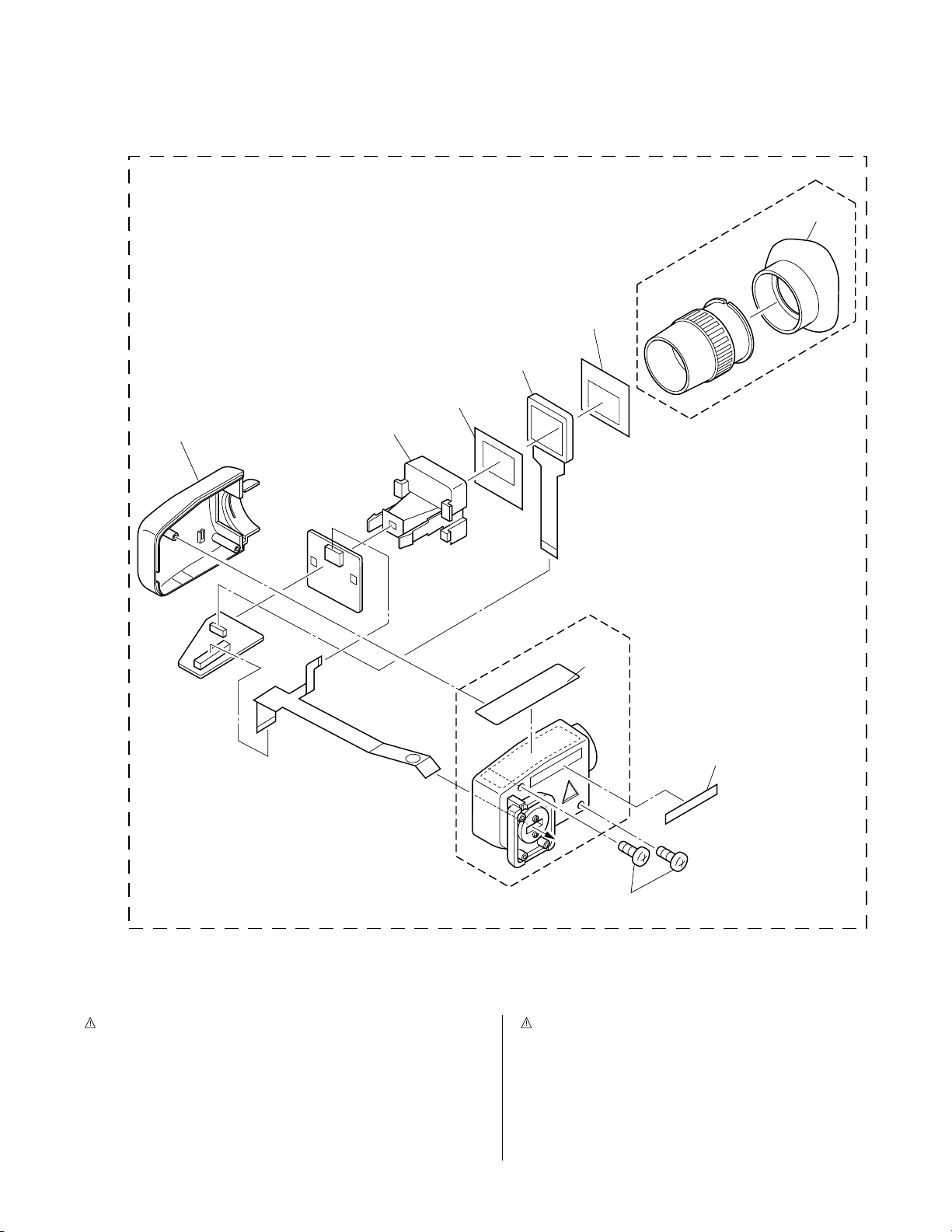

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4> [GR-AX970U]

300

307

BL

<06>

302

303

304

301

309

309A

305

301A

C-VF

<06>

310

SERIAL NO.

LABEL

308

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

******************************

ELECTRONIC VIEWFINDER ASSEMBLY <M4>

!

300 LY20846-001A CVF ASSY

!

301 LY32068-001A BOTTOM CASE ASSY

301A LY42882-001A LABEL(COL/CAUT)

302 LY32321-001A HOLDER(LED)

303 LY43510-001A SPACER(HOLDER)

304 QLD0117-001 LCD MODULE

305 LY43418-001B SPACER(LED)

!

307 LY10137-001C TOP CASE

308 QYSPSGT1760D SCREW,X2

309 LY20309-001B EYE PIECE.ASSY

309A PTY20307-201 EYE CAP

310 QAL0397-001 FPC

5-9

Page 9

5.5 ELECTRICAL PARTS LIST

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

Q2023 2SC4617/QR/-X TRANSISTOR

******************************

MAIN BOARD ASSEMBLY <01>

PW1 YB10356UD1-01 MAIN BOARD ASSY,AX770UC

YB10356US1 MAIN BOARD ASSY,AX970U

IC101 UPD703039-040 EC(MICRO C ROM)

or UPD70F3040-040 IC(MICRO C ROM)

IC102 AT25080N-10SC-X IC

or CAT25C08SI IC

or X25170S8I-2.5-X IC

or 25LC080-I/SN-X IC

IC103 RS5C314 IC

IC104 IC-PST3427U-X IC

!

IC1601 LB11951WA-MPB IC

IC1602 TA75S393F IC

IC2001 MC74AC04DT IC

or TC74AC04FT IC(DIGITAL)

IC3501 HA118224F IC

IC4001 JCY0140-3 IC

IC4003 UPD6467GR-512-X IC(MICRO C ROM)

IC4201 BA10324AF-XE IC

IC4202 BA10324AF-XE IC

IC4501 UPD16835AGS IC

IC4701 MM1512XN IC

IC5201 HD49326BF IC

IC5202 JCY0098 IC

IC6001 FA7706F IC

IC6801 S-814A33AUC-W IC

IC7005 BA4558F IC,AX970U

Q101 2SA1774/RS/-X TRANSISTOR

or 2SA1836/6-7/-X TRANSISTOR

Q102 DTC144EE DIGI TRANSISTOR

or RN1104 DIGI TRANSISTOR

or UN9213J DIGI TRANSISTOR

Q103 2SC4617/QR/-X TRANSISTOR

or 2SC4783/5-6/-X TRANSISTOR

Q104 DTC144EE DIGI TRANSISTOR

or RN1104 DIGI TRANSISTOR

or UN9213J DIGI TRANSISTOR

Q105 2SA1774/RS/-X TRANSISTOR

or 2SA1836/6-7/-X TRANSISTOR

Q108 DTC114EE DIGI TRANSISTOR

or RN1102 DIGI TRANSISTOR

or UN9211J DIGI TRANSISTOR

Q109 DTC114EE DIGI TRANSISTOR

or RN1102 DIGI TRANSISTOR

or UN9211J DIGI TRANSISTOR

Q1601 2SC4617/QR/-X TRANSISTOR

or 2SC4783/5-6/-X TRANSISTOR

Q2001 DTA114TE DIGI TRANSISTOR

Q2007 PUMX1 PAIR TRANSISTOR

or UMX1N PAIR TRANSISTOR

or HN1C01FU/G/-X PAIR TRANSISTOR

Q2008 PUMT1 PAIR TRANSISTOR

or HN1A01FU/G/-X PAIR TRANSISTOR

or UMT1N PAIR TRANSISTOR

Q2021 DTC144EE DIGI TRANSISTOR

or RN1104 DIGI TRANSISTOR

or UN9213J DIGI TRANSISTOR

Q2022 DTC144EE DIGI TRANSISTOR

or RN1104 DIGI TRANSISTOR

or UN9213J DIGI TRANSISTOR

!

or 2SC4783/5-6/-X TRANSISTOR

Q2071 2SC4617/QR/-X TRANSISTOR

or 2SC4783/5-6/-X TRANSISTOR

Q3501 HN1C01FU/G/-X PAIR TRANSISTOR

Q3502 HN1C01FU/G/-X PAIR TRANSISTOR

Q3901 HN1A01FU/G/-X PAIR TRANSISTOR

Q4201 2SC4617/QR/-X TRANSISTOR

or 2SC4783/5-6/-X TRANSISTOR

Q4202 2SC4617/QR/-X TRANSISTOR

or 2SC4783/5-6/-X TRANSISTOR

Q4251 RPM-22PB PHOTO TRANSISTOR

Q4501 DTC114EE DIGI TRANSISTOR

or RN1102 DIGI TRANSISTOR

or UN9211J DIGI TRANSISTOR

Q4701 2SA1774/QR/-X TRANSISTOR

or 2SA1836/5-6/-X TRANSISTOR

Q4702 2SA1774/QR/-X TRANSISTOR

or 2SA1836/5-6/-X TRANSISTOR

Q6101 SSM5G01TU MOS FET

Q6201 SSM5G01TU MOS FET

Q6301 FDC6506P MOS FET

Q6306 SSM3K02F MOS FET,AX970U

Q6401 SSM5G01TU MOS FET

Q6501 SSM5G01TU MOS FET

Q6608 DTC144EE DIGI TRANSISTOR

or RN1104 DIGI TRANSISTOR

or UN9213J DIGI TRANSISTOR

Q6621 HN1C01FU/G/-X PAIR TRANSISTOR,AX970U

Q6622 2SA1577/QR/-X TRANSISTOR,AX970U

or 2SA1608/3-4/-X TRANSISTOR,AX970U

Q6701 TPC6102 MOS FET

Q6702 2SC4097/QR/-X TRANSISTOR

or 2SC4173/3-4/-X TRANSISTOR

Q6802 DTA113ZU DIGI TRANSISTOR

Q6811 2SA1577/QR/-X TRANSISTOR

or 2SA1608/3-4/-X TRANSISTOR

Q7001 PUMX1 PAIR TRANSISTOR,AX970U

or HN1C01FU/G/-X PAIR TRANSISTOR,AX970U

or UMX1N PAIR TRANSISTOR,AX970U

Q7003 PUMX1 PAIR TRANSISTOR,AX970U

or HN1C01FU/G/-X PAIR TRANSISTOR,AX970U

or UMX1N PAIR TRANSISTOR,AX970U

Q7005 PUMX1 PAIR TRANSISTOR,AX970U

or HN1C01FU/G/-X PAIR TRANSISTOR,AX970U

or UMX1N PAIR TRANSISTOR,AX970U

Q7301 2SA1774/QR/-X TRANSISTOR,AX770UC

or 2SA1836/5-6/-X TRANSISTOR,AX770UC

Q7303 UMD3N DIGI TRANSISTOR,AX970U

Q7304 PUMX1 PAIR TRANSISTOR,AX970U

or HN1C01FU/G/-X PAIR TRANSISTOR,AX970U

or UMX1N PAIR TRANSISTOR,AX970U

Q7310 CPH3101 TRANSISTOR,AX770UC

Q7311 2SC4617/QR/-X TRANSISTOR,AX770UC

or 2SC4783/5-6/-X TRANSISTOR,AX770UC

D101 SB007W03Q SB DIODE

D102 UDZS7.5B ZENER DIODE

D103 1SS355 DIODE

D104 1SS355 DIODE

D5201 1SS355 DIODE

D6301 MBR130 SB DIODE

D6601 RB480Y SB DIODE

D6602 RB480Y SB DIODE

5-10

Page 10

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

D6616 UDZS8.2B ZENER DIODE

D6701 CRS09 SB DIODE

D6702 CRS09 SB DIODE

R101 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R102 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R103 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R105 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R106 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R107 NRVA63D-153X CMF RESISTOR 15kØ,1/16W

R108 NRVA63D-243X CMF RESISTOR 24kØ,1/16W

R109 NRVA63D-183X CMF RESISTOR 18kØ,1/16W

R110 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R111 NRSA63J-273X MG RESISTOR 27kØ,1/16W

R112 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R113 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

R114 NRSA63J-821X MG RESISTOR 820Ø,1/16W

R115 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R117 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R118 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R119 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R120 NRSA63J-273X MG RESISTOR 27kØ,1/16W

R121 NRSA63J-273X MG RESISTOR 27kØ,1/16W

R122 NRSA63J-393X MG RESISTOR 39kØ,1/16W

R125 NRSA63J-273X MG RESISTOR 27kØ,1/16W

R126 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R127 NRSA63J-221X MG RESISTOR 220Ø,1/16W

R128 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R129 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R130 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R136 NRSA63J-474X MG RESISTOR 470kØ,1/16W

R138 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R139 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R140 NRSA63J-753X MG RESISTOR 75kØ,1/16W

R141 NRSA63J-334X MG RESISTOR 330kØ,1/16W

R142 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R143 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R144 NRSA63J-221X MG RESISTOR 220Ø,1/16W

R145 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R146 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R147 NRSA63J-472X MG RESISTOR 4.7kØ,1/16W

R148 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R149 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R150 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R151 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R152 NRSA63J-474X MG RESISTOR 470kØ,1/16W

R153 NRSA63J-474X MG RESISTOR 470kØ,1/16W

R154 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R155 NRSA63J-104X MG RESISTOR 100kØ,1/16W

!

R156 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R157 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R158 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R159 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R160 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R162 NRSA63J-472X MG RESISTOR 4.7kØ,1/16W

R163 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R164 NRSA63J-221X MG RESISTOR 220Ø,1/16W

R165 NRSA63J-151X MG RESISTOR 150Ø,1/16W

R166 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R167 NRSA63J-183X MG RESISTOR 18kØ,1/16W

R168 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

R169 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R170 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R171 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R172 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R177 NRSA63J-183X MG RESISTOR 18kØ,1/16W

R178 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

R179 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R180 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R181 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R183 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R185 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R188 NRSA63J-472X MG RESISTOR 4.7kØ,1/16W

R189 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R190 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R1601 NRV142F-R33X CMF RESISTOR 0.33Ø,1/4W

R1602 NRV142F-R33X CMF RESISTOR 0.33Ø,1/4W

R1603 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1604 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1605 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R1606 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R1607 NRSA63J-471X MG RESISTOR 470Ø,1/16W

R1608 NRSA63J-154X MG RESISTOR 150kØ,1/16W

R1609 NRSA63J-471X MG RESISTOR 470Ø,1/16W

R1610 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R1611 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1612 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1613 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R1615 NRSA63J-152X MG RESISTOR 1.5kØ,1/16W

R1616 NRSA63J-152X MG RESISTOR 1.5kØ,1/16W

R1617 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1618 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R1619 NRSA63J-334X MG RESISTOR 330kØ,1/16W

R1620 NRSA63J-221X MG RESISTOR 220Ø,1/16W

R1621 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R1622 NRSA63J-221X MG RESISTOR 220Ø,1/16W

R1623 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R1624 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R1625 NRSA63J-123X MG RESISTOR 12kØ,1/16W

R1626 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R1627 NRSA63J-223X MG RESISTOR 22kØ,1/16W

R1628 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R2001 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R2002 NRSA63J-332X MG RESISTOR 3.3kØ,1/16W

R2003 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R2004 NRSA63J-681X MG RESISTOR 680Ø,1/16W

R2005 NRSA63J-272X MG RESISTOR 2.7kØ,1/16W

R2006 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R2011 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R2012 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R2021 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R2022 NRSA63J-334X MG RESISTOR 330kØ,1/16W

R2023 NRSA63J-151X MG RESISTOR 150Ø,1/16W

R2024 NRSA63J-133X MG RESISTOR 13kØ,1/16W

R2025 NRSA63J-823X MG RESISTOR 82kØ,1/16W

R2027 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R2028 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R2030 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R2031 NRSA63J-332X MG RESISTOR 3.3kØ,1/16W

R2051 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R2071 NRSA63J-473X MG RESISTOR 47kØ,1/16W

R2072 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

R3501 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R3502 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R3506 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R3507 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R3508 NRSA63J-153X MG RESISTOR 15kØ,1/16W

5-11

Page 11

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

R3901 NRSA63J-100X MG RESISTOR 10Ø,1/16W

R3902 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R3903 NRSA63J-182X MG RESISTOR 1.8kØ,1/16W

R4001 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R4002 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R4003 NRSA63J-563X MG RESISTOR 56kØ,1/16W

R4004 NRSA63D-153X MG RESISTOR 15kØ,1/16W

R4009 NRSA63D-153X MG RESISTOR 15kØ,1/16W

R4010 NRSA63D-153X MG RESISTOR,AX970U 15kØ,1/16W

R4016 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R4019 NRSA63D-822X MG RESISTOR 8.2kØ,1/16W

R4020 NRSA63D-471X MG RESISTOR 470Ø,1/16W

R4021 NRSA63D-181X MG RESISTOR 180Ø,1/16W

R4022 NRSA63D-182X MG RESISTOR 1.8kØ,1/16W

R4025 NRSA63D-222X MG RESISTOR 2.2kØ,1/16W

R4026 NRSA63J-563X MG RESISTOR 56kØ,1/16W

R4027 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4028 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4031 NRSA63J-102X MG RESISTOR,AX970U 1kØ,1/16W

R4032 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R4033 NRSA63J-392X MG RESISTOR 3.9kØ,1/16W

R4034 NRSA63J-332X MG RESISTOR 3.3kØ,1/16W

R4035 NRSA63J-332X MG RESISTOR 3.3kØ,1/16W

R4201 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4202 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R4203 NRSA63J-223X MG RESISTOR 22kØ,1/16W

R4204 NRSA63J-331X MG RESISTOR 330Ø,1/16W

R4205 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R4206 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4207 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4208 NRSA63J-472X MG RESISTOR 4.7kØ,1/16W

R4209 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4210 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R4211 NRSA63J-243X MG RESISTOR 24kØ,1/16W

R4214 NRSA63J-472X MG RESISTOR 4.7kØ,1/16W

R4215 NRSA63J-683X MG RESISTOR 68kØ,1/16W

R4216 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4217 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R4218 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R4219 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4220 NRSA63J-152X MG RESISTOR 1.5kØ,1/16W

R4221 NRSA63J-334X MG RESISTOR 330kØ,1/16W

R4222 NRSA63J-154X MG RESISTOR 150kØ,1/16W

R4223 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R4224 NRSA63J-223X MG RESISTOR 22kØ,1/16W

R4251 NRSA63J-182X MG RESISTOR 1.8kØ,1/16W

R4252 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4253 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4254 NRSA63J-684X MG RESISTOR 680kØ,1/16W

R4255 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R4256 NRSA63J-824X MG RESISTOR 820kØ,1/16W

R4257 NRSA63J-822X MG RESISTOR 8.2kØ,1/16W

R4258 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R4259 NRSA63J-683X MG RESISTOR 68kØ,1/16W

R4262 NRSA63J-302X MG RESISTOR 3kØ,1/16W

!

R4501 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

!

R4502 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

!

R4503 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

!

R4504 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

R4505 NRSA63J-271X MG RESISTOR 270Ø,1/16W

R4507 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4508 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R4512 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R4514 NRSA63J-223X MG RESISTOR 22kØ,1/16W

R4515 NRSA63J-182X MG RESISTOR 1.8kØ,1/16W

R4701 NRSA63D-112X MG RESISTOR 1.1kØ,1/16W

R4703 NRSA63J-681X MG RESISTOR 680Ø,1/16W

R4704 NRSA63J-122X MG RESISTOR 1.2kØ,1/16W

R4706 NRSA63D-680X MG RESISTOR 68Ø,1/16W

R4707 NRSA63D-751X MG RESISTOR 750Ø,1/16W

R4709 NRSA63J-681X MG RESISTOR 680Ø,1/16W

R4710 NRSA63J-122X MG RESISTOR 1.2kØ,1/16W

R5201 NRSA63J-243X MG RESISTOR 24kØ,1/16W

R5202 NRSA63J-220X MG RESISTOR 22Ø,1/16W

R5213 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R5214 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R5215 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R5216 NRSA63J-100X MG RESISTOR 10Ø,1/16W

R5217 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6001 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6002 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R6003 NRVA63D-912X CMF RESISTOR 9.1kØ,1/16W

R6004 NRVA63D-681X CMF RESISTOR 680Ø,1/16W

R6005 NRVA63D-203X CMF RESISTOR 20kØ,1/16W

R6008 NRVA63D-103X CMF RESISTOR 10kØ,1/16W

R6012 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R6015 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6021 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R6024 NRSA63J-224X MG RESISTOR 220kØ,1/16W

R6025 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6026 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6027 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6028 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6029 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6103 NRVA63D-223X CMF RESISTOR 22kØ,1/16W

R6104 NRVA63D-103X CMF RESISTOR 10kØ,1/16W

R6203 NRVA63D-103X CMF RESISTOR 10kØ,1/16W

R6204 NRVA63D-123X CMF RESISTOR 12kØ,1/16W

R6303 NRVA63D-183X CMF RESISTOR 18kØ,1/16W

R6304 NRVA63D-472X CMF RESISTOR 4.7kØ,1/16W

R6306 NRS12BK-R47W MG RESISTOR,AX970U 0.47Ø,1/2W

R6307 NRSA63J-104X MG RESISTOR,AX970U 100kØ,1/16W

R6401 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R6501 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R6502 NRSA63J-471X MG RESISTOR 470Ø,1/16W

R6603 NRVA63D-683X CMF RESISTOR 68kØ,1/16W

R6604 NRVA63D-392X CMF RESISTOR 3.9kØ,1/16W

R6605 NRSA63J-274X MG RESISTOR 270kØ,1/16W

R6606 NRSA63J-272X MG RESISTOR 2.7kØ,1/16W

R6612 NRSA63J-823X MG RESISTOR 82kØ,1/16W

R6613 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6614 NRSA63J-153X MG RESISTOR 15kØ,1/16W

R6616 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R6622 NRVA63D-104X CMF RESISTOR,AX970U 100kØ,1/16W

R6623 NRVA63D-473X CMF RESISTOR,AX970U 47kØ,1/16W

R6624 NRSA63J-273X MG RESISTOR,AX970U 27kØ,1/16W

R6625 NRSA63J-822X MG RESISTOR,AX970U 8.2kØ,1/16W

R6626 NRVA63D-273X CMF RESISTOR,AX970U 27kØ,1/16W

R6627 NRVA63D-183X CMF RESISTOR,AX970U 18kØ,1/16W

R6702 NRSA63J-330X MG RESISTOR 33Ø,1/16W

R6704 NRVA63D-123X CMF RESISTOR 12kØ,1/16W

R6706 NRZ0058-R20X MG RESISTOR 0.2Ø,1/2W

R6707 NRS016J-121X MG RESISTOR 120Ø,1W

R6708 NRS016J-121X MG RESISTOR 120Ø,1W

R6709 NRS016J-121X MG RESISTOR 120Ø,1W

R6710 NRVA63D-823X CMF RESISTOR 82kØ,1/16W

5-12

Page 12

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

R6711 NRVA63D-333X CMF RESISTOR 33kØ,1/16W

R6713 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

R6715 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R6801 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R6802 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R6811 NRSA63J-101X MG RESISTOR 100Ø,1/16W

R6812 NRSA63J-222X MG RESISTOR 2.2kØ,1/16W

R6961 NRSA63J-223X MG RESISTOR 22kØ,1/16W

R7061 NRVA63D-183X CMF RESISTOR,AX970U 18kØ,1/16W

R7062 NRVA63D-334X CMF RESISTOR,AX970U 330kØ,1/16W

R7077 NRVA63D-123X CMF RESISTOR,AX970U 12kØ,1/16W

R7083 NRSA63J-105X MG RESISTOR,AX970U 1MØ,1/16W

R7085 NRVA63D-822X CMF RESISTOR,AX970U 8.2kØ,1/16W

R7086 NRVA63D-123X CMF RESISTOR,AX970U 12kØ,1/16W

R7088 NRVA63D-223X CMF RESISTOR,AX970U 22kØ,1/16W

R7090 NRVA63D-822X CMF RESISTOR,AX970U 8.2kØ,1/16W

R7091 NRVA63D-123X CMF RESISTOR,AX970U 12kØ,1/16W

R7093 NRVA63D-223X CMF RESISTOR,AX970U 22kØ,1/16W

R7095 NRVA63D-822X CMF RESISTOR,AX970U 8.2kØ,1/16W

R7096 NRVA63D-123X CMF RESISTOR,AX970U 12kØ,1/16W

R7098 NRVA63D-223X CMF RESISTOR,AX970U 22kØ,1/16W

R7099 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7100 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7101 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7102 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7103 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7123 NRSA63J-0R0X MG RESISTOR,AX970U 0Ø,1/16W

R7124 NRVA63D-103X CMF RESISTOR,AX970U 10kØ,1/16W

R7301 NRVA63D-182X CMF RESISTOR,AX770UC 1.8kØ,1/16W

R7305 NRVA63D-821X CMF RESISTOR,AX770UC 820Ø,1/16W

R7317 NRVA63D-332X CMF RESISTOR,AX970U 3.3kØ,1/16W

R7318 NRVA63D-561X CMF RESISTOR,AX970U 560Ø,1/16W

R7319 NRSA63J-360X MG RESISTOR,AX970U 36Ø,1/16W

R7321 NRSA63J-333X MG RESISTOR,AX970U 33kØ,1/16W

R7331 NRSA63J-103X MG RESISTOR,AX770UC 10kØ,1/16W

R7332 NRSA63J-152X MG RESISTOR,AX770UC 1.5kØ,1/16W

R7333 NRSA63J-473X MG RESISTOR,AX770UC 47kØ,1/16W

R7337 NRSA63J-0R0X MG RESISTOR,AX970U 0Ø,1/16W

R7338 NRSA63J-0R0X MG RESISTOR,AX970U 0Ø,1/16W

R7339 NRSA63J-0R0X MG RESISTOR,AX970U 0Ø,1/16W

RA101 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA102 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA103 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA104 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA106 NRZ0038-101X NETWORK RESISTOR 100Ø

RA107 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA108 NRZ0038-222X NETWORK RESISTOR 2.2kØ

RA109 NRZ0038-474X NETWORK RESISTOR 470kØ

RA110 NRZ0038-474X NETWORK RESISTOR 470kØ

RA111 NRZ0038-474X NETWORK RESISTOR 470kØ

RA112 NRZ0038-104X NETWORK RESISTOR 100kØ

RA6020 NRZ0038-102X NETWORK RESISTOR 1kØ

C103 NBE20JM-106X T CAPACITOR 10µF,6.3V

C104 NCB31EK-103X CAPACITOR 0.01µF,25V

C105 NCB21CK-224X CAPACITOR 0.22µF,16V

C107 NCB31EK-103X CAPACITOR 0.01µF,25V

C108 NBE21AM-225X T CAPACITOR 2.2µF,10V

C109 NBE20JM-106X T CAPACITOR 10µF,6.3V

C110 NDC31HJ-101X CAPACITOR 100pF,50V

C112 NEA70JM-226X E CAPACITOR 22µF,6.3V

C113 NCB31EK-103X CAPACITOR 0.01µF,25V

C114 NCB31EK-103X CAPACITOR 0.01µF,25V

C115 NCF31EZ-104X CAPACITOR 0.1µF,25V

C116 NCB31EK-103X CAPACITOR 0.01µF,25V

C118 NCF31EZ-104X CAPACITOR 0.1µF,25V

C119 NCB31EK-103X CAPACITOR 0.01µF,25V

C120 NCB31EK-103X CAPACITOR 0.01µF,25V

C121 NCF31EZ-104X CAPACITOR 0.1µF,25V

C122 NCF31EZ-104X CAPACITOR 0.1µF,25V

C123 NDC31HJ-100X CAPACITOR 10pF,50V

C124 NDC31HJ-100X CAPACITOR 10pF,50V

C125 NCB31EK-103X CAPACITOR 0.01µF,25V

C126 NDC31HJ-100X CAPACITOR 10pF,50V

C127 NCB31CK-333X CAPACITOR 0.033µF,16V

C128 NCB21CK-474X CAPACITOR 0.47µF,16V

C129 NCB31CK-333X CAPACITOR 0.033µF,16V

C131 NCF31EZ-104X CAPACITOR 0.1µF,25V

C132 NCF31EZ-104X CAPACITOR 0.1µF,25V

C133 NCF31EZ-104X CAPACITOR 0.1µF,25V

C134 NCF31EZ-104X CAPACITOR 0.1µF,25V

C138 NCB31EK-103X CAPACITOR 0.01µF,25V

C140 NDC31HJ-220X CAPACITOR 22pF,50V

C142 NCB31CK-104X CAPACITOR 0.1µF,16V

C143 NDC31HJ-3R0X CAPACITOR 3pF,50V

C144 NDC31HJ-101X CAPACITOR 100pF,50V

C1201 NCB31HK-102X CAPACITOR 0.001µF,50V

C1202 NBE20JM-106X T CAPACITOR 10µF,6.3V

C1205 NCB31EK-153X CAPACITOR 0.015µF,25V

C1206 NBE20JM-106X T CAPACITOR 10µF,6.3V

C1601 NCB21EK-104X CAPACITOR 0.1µF,25V

C1602 NCB30JK-105X CAPACITOR 1µF,6.3V

C1603 NCB31HK-472X CAPACITOR 0.0047µF,50V

C1604 NCB31HK-472X CAPACITOR 0.0047µF,50V

C1605 NCB31CK-333X CAPACITOR 0.033µF,16V

C1606 NCB21EK-104X CAPACITOR 0.1µF,25V

C1607 NCB21CK-474X CAPACITOR 0.47µF,16V

C1608 NCB31HK-332X CAPACITOR 0.0033µF,50V

C1609 NBE20JM-106X T CAPACITOR 10µF,6.3V

C1610 NCB31HK-681X CAPACITOR 680pF,50V

C1611 NCB31CK-104X CAPACITOR 0.1µF,16V

C1612 NCB21CK-105X CAPACITOR 1µF,16V

C1613 NCB31CK-333X CAPACITOR 0.033µF,16V

C1614 NCB31CK-104X CAPACITOR 0.1µF,16V

C1615 NCB31CK-104X CAPACITOR 0.1µF,16V

C1616 NCB31CK-104X CAPACITOR 0.1µF,16V

C1617 NCB31CK-104X CAPACITOR 0.1µF,16V

C1618 NCB31CK-104X CAPACITOR 0.1µF,16V

C1619 NCB31CK-104X CAPACITOR 0.1µF,16V

C1620 NBE21AM-106X T CAPACITOR 10µF,10V

C1621 NBP41CM-106X T CAPACITOR 10µF,16V

C1625 NCB31CK-104X CAPACITOR 0.1µF,16V

C1628 NDC31HJ-101X CAPACITOR 100pF,50V

C1630 NBE20JM-106X T CAPACITOR 10µF,6.3V

C2001 NBE20JM-106X T CAPACITOR 10µF,6.3V

C2002 NFV41HJ-183X MPPS CAPACITOR 0.018µF,50V

C2003 NDC31HJ-331X CAPACITOR 330pF,50V

C2004 NBE20JM-226X T CAPACITOR 22µF,6.3V

C2005 NCB21CK-105X CAPACITOR 1µF,16V

C2021 NCB31HK-682X CAPACITOR 0.0068µF,50V

C2022 NBE20JM-106X T CAPACITOR 10µF,6.3V

C2023 NBP21CM-105X T CAPACITOR 1µF,16V

C2024 NCB31HK-122X CAPACITOR 0.0012µF,50V

C2025 NCB21CK-105X CAPACITOR 1µF,16V

C2026 NCB31HK-222X CAPACITOR 0.0022µF,50V

C2027 NCB21CK-474X CAPACITOR 0.47µF,16V

C2028 NCB21CK-105X CAPACITOR 1µF,16V

5-13

Page 13

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

C2029 NCB21CK-105X CAPACITOR 1µF,16V

C2031 NCB31CK-104X CAPACITOR 0.1µF,16V

C2032 NCB31HK-472X CAPACITOR 0.0047µF,50V

C2033 NBE20JM-475X T CAPACITOR 4.7µF,6.3V

C2034 NCB31CK-104X CAPACITOR 0.1µF,16V

C2035 NBE20JM-226X T CAPACITOR 22µF,6.3V

C2036 NBE20JM-106X T CAPACITOR 10µF,6.3V

C2038 NCB21CK-474X CAPACITOR 0.47µF,16V

C2051 NCB31EK-103X CAPACITOR 0.01µF,25V

C2071 NBE20JM-106X T CAPACITOR 10µF,6.3V

C2072 NCB31HK-222X CAPACITOR 0.0022µF,50V

C3506 NCB31EK-103X CAPACITOR 0.01µF,25V

C3507 NCB31EK-103X CAPACITOR 0.01µF,25V

C3508 NCB31EK-103X CAPACITOR 0.01µF,25V

C3510 NCB31CK-104X CAPACITOR 0.1µF,16V

C3512 NCB10JK-106X CAPACITOR 10µF,6.3V

C3513 NCB31CK-223X CAPACITOR 0.022µF,16V

C3514 NCB30JK-105X CAPACITOR 1µF,6.3V

C3515 NCB31EK-103X CAPACITOR 0.01µF,25V

C3902 NCB31EK-103X CAPACITOR 0.01µF,25V

C3903 NDC31HJ-3R0X CAPACITOR 3pF,50V

C4002 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4003 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4004 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4005 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4006 NDC31HJ-100X CAPACITOR 10pF,50V

C4007 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4008 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4009 NDC31HG-100X CAPACITOR 10pF,50V

C4010 NDC31HG-100X CAPACITOR 10pF,50V

C4012 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4013 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4014 NCB31CK-104X CAPACITOR 0.1µF,16V

C4015 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4016 NCB31CK-104X CAPACITOR 0.1µF,16V

C4017 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4018 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4019 NCF31EZ-104X CAPACITOR,AX970U 0.1µF,25V

C4020 NCB31CK-104X CAPACITOR,AX970U 0.1µF,16V

C4021 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4023 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4026 NCB10JK-106X CAPACITOR 10µF,6.3V

C4027 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4028 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4029 NCB31CK-104X CAPACITOR 0.1µF,16V

C4030 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4031 NCB30JK-105X CAPACITOR 1µF,6.3V

C4032 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4033 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4034 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4035 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4036 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4037 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4038 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4039 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4042 NCB30JK-105X CAPACITOR,AX970U 1µF,6.3V

C4045 NCB30JK-105X CAPACITOR 1µF,6.3V

C4046 NDC31HJ-221X CAPACITOR 220pF,50V

C4047 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4048 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4201 NEA71HM-225X E CAPACITOR 2.2µF,50V

C4202 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4203 NCB31CK-104X CAPACITOR 0.1µF,16V

C4205 NCB31EK-103X CAPACITOR 0.01µF,25V

C4206 NCB31CK-104X CAPACITOR 0.1µF,16V

C4207 NCB31EK-103X CAPACITOR 0.01µF,25V

C4208 NCB31CK-104X CAPACITOR 0.1µF,16V

C4209 NCB31CK-104X CAPACITOR 0.1µF,16V

C4210 NCF21CZ-105X CAPACITOR 1µF,16V

C4251 NEA71HM-335X E CAPACITOR 3.3µF,50V

C4252 NCB31CK-104X CAPACITOR 0.1µF,16V

C4253 NCB31EK-153X CAPACITOR 0.015µF,25V

C4254 NCB31EK-153X CAPACITOR 0.015µF,25V

C4256 NEA71CM-106X E CAPACITOR 10µF,16V

C4504 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4505 NDC31HJ-330X CAPACITOR 33pF,50V

C4506 NCB31HK-102X CAPACITOR 0.001µF,50V

C4507 NCB31HK-102X CAPACITOR 0.001µF,50V

C4508 NCB31HK-102X CAPACITOR 0.001µF,50V

C4509 NCB31HK-102X CAPACITOR 0.001µF,50V

C4510 NCB31CK-104X CAPACITOR 0.1µF,16V

C4511 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4512 NEA71CM-107X E CAPACITOR 100µF,16V

C4702 NDC31HJ-270X CAPACITOR 27pF,50V

C4703 NDC31HJ-150X CAPACITOR 15pF,50V

C4704 NCB30JK-105X CAPACITOR 1µF,6.3V

C4705 NCB31EK-103X CAPACITOR 0.01µF,25V

C4706 NEA70GM-107X E CAPACITOR 100µF,4.0V

C4707 NEA70JM-226X E CAPACITOR 22µF,6.3V

C4708 NCF31EZ-104X CAPACITOR 0.1µF,25V

C4709 NBE20JM-106X T CAPACITOR 10µF,6.3V

C4716 NDC31HJ-270X CAPACITOR 27pF,50V

C4717 NDC31HJ-150X CAPACITOR 15pF,50V

C5203 NCB10JK-106X CAPACITOR 10µF,6.3V

C5207 NCB31EK-103X CAPACITOR 0.01µF,25V

C5208 NCB31EK-103X CAPACITOR 0.01µF,25V

C5209 NCB31EK-103X CAPACITOR 0.01µF,25V

C5210 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5211 NCB21CK-105X CAPACITOR 1µF,16V

C5212 NCB21CK-105X CAPACITOR 1µF,16V

C5213 NCB31HK-332X CAPACITOR 0.0033µF,50V

C5214 NCB31EK-103X CAPACITOR 0.01µF,25V

C5218 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5219 NBP21CM-685X T CAPACITOR 6.8µF,16V

C5221 NCB11EK-105X CAPACITOR 1µF,25V

C5222 NCB31CK-104X CAPACITOR 0.1µF,16V

C5223 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5225 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5227 NCB31CK-104X CAPACITOR 0.1µF,16V

C5228 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5229 NCB11EK-105X CAPACITOR 1µF,25V

C5230 NCB21EK-104X CAPACITOR 0.1µF,25V

C5232 NDC31HJ-100X CAPACITOR 10pF,50V

C5233 NDC31HJ-100X CAPACITOR 10pF,50V

C5234 NDC31HJ-100X CAPACITOR 10pF,50V

C5235 NDC31HJ-100X CAPACITOR 10pF,50V

C5236 NDC31HJ-100X CAPACITOR 10pF,50V

C5237 NDC31HJ-100X CAPACITOR 10pF,50V

C6002 NEA71CM-106X E CAPACITOR 10µF,16V

C6004 NCF21CZ-105X CAPACITOR 1µF,16V

C6005 NCB21CK-105X CAPACITOR 1µF,16V

C6006 NCB31EK-103X CAPACITOR 0.01µF,25V

C6007 NCB21CK-105X CAPACITOR 1µF,16V

C6009 NDC31HJ-101X CAPACITOR 100pF,50V

C6010 NCB21CK-224X CAPACITOR 0.22µF,16V

C6011 NCB31EK-103X CAPACITOR 0.01µF,25V

5-14

Page 14

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

C6012 NCB21CK-224X CAPACITOR 0.22µF,16V

C6013 NCB21CK-154X CAPACITOR 0.15µF,16V

C6014 NCB31CK-104X CAPACITOR 0.1µF,16V

C6015 NCB31CK-104X CAPACITOR 0.1µF,16V

C6016 NCB31EK-473X CAPACITOR 0.047µF,25V

C6017 NCF21CZ-105X CAPACITOR 1µF,16V

C6018 NCB21CK-224X CAPACITOR 0.22µF,16V

C6020 NCB21CK-224X CAPACITOR 0.22µF,16V

C6021 NCB31EK-103X CAPACITOR 0.01µF,25V

C6101 NCB21CK-105X CAPACITOR 1µF,16V

C6102 NCB10JK-106X CAPACITOR 10µF,6.3V

C6105 NCB31HK-681X CAPACITOR 680pF,50V

C6110 NCB31HK-152X CAPACITOR 0.0015µF,50V

C6201 NCB21CK-105X CAPACITOR 1µF,16V

C6202 NCB10JK-106X CAPACITOR 10µF,6.3V

C6203 NBE40JM-476X T CAPACITOR 47µF,6.3V

C6205 NCB31HK-472X CAPACITOR 0.0047µF,50V

C6210 NCB31HK-472X CAPACITOR 0.0047µF,50V

C6301 NCB11CK-225X CAPACITOR 2.2µF,16V

C6302 NCB10JK-106X CAPACITOR 10µF,6.3V

C6303 NBE40JM-476X T CAPACITOR 47µF,6.3V

C6305 NCB31HK-561X CAPACITOR 560pF,50V

C6307 NEA71CM-106X E CAPACITOR,AX970U 10µF,16V

C6310 NCB31HK-102X CAPACITOR 0.001µF,50V

C6401 NCB21CK-105X CAPACITOR 1µF,16V

C6402 NCF21CZ-105X CAPACITOR 1µF,16V

C6501 NCB21CK-105X CAPACITOR 1µF,16V

C6502 NCF21CZ-105X CAPACITOR 1µF,16V

C6602 NCF21CZ-105X CAPACITOR 1µF,16V

C6603 NCB11EK-105X CAPACITOR 1µF,25V

C6606 NCB11EK-105X CAPACITOR 1µF,25V

C6607 NCF21CZ-105X CAPACITOR 1µF,16V

C6610 NCB31EK-103X CAPACITOR 0.01µF,25V

C6616 NCB21CK-105X CAPACITOR 1µF,16V

C6622 NCB21CK-105X CAPACITOR,AX970U 1µF,16V

C6701 NCB21CK-105X CAPACITOR 1µF,16V

C6702 NCB41CK-106X CAPACITOR 10µF,16V

C6711 NCB31HK-472X CAPACITOR 0.0047µF,50V

C6801 NCF21CZ-105X CAPACITOR 1µF,16V

C6802 NCF21CZ-105X CAPACITOR 1µF,16V

C6811 NCB21CK-105X CAPACITOR 1µF,16V

C7021 NBP41EM-475X T CAPACITOR,AX970U 4.7µF,25V

C7022 NCB31EK-103X CAPACITOR,AX970U 0.01µF,25V

C7041 NBE21AM-106X T CAPACITOR,AX970U 10µF,10V

C7053 NCB31EK-103X CAPACITOR,AX970U 0.01µF,25V

C7054 NBP41EM-475X T CAPACITOR,AX970U 4.7µF,25V

C7056 NCB21EK-104X CAPACITOR,AX970U 0.1µF,25V

C7058 NCB31CK-104X CAPACITOR,AX970U 0.1µF,16V

C7061 NCB11CK-475X CAPACITOR,AX970U 4.7µF,16V

C7062 NCB11CK-475X CAPACITOR,AX970U 4.7µF,16V

C7063 NCB11CK-475X CAPACITOR,AX970U 4.7µF,16V

C7069 NCB31EK-103X CAPACITOR,AX970U 0.01µF,25V

C7323 NCB31CK-104X CAPACITOR,AX970U 0.1µF,16V

C7325 NBE20JM-106X T CAPACITOR,AX770UC 10µF,6.3V

C7326 NBE20JM-106X T CAPACITOR,AX770UC 10µF,6.3V

C7329 NDC31HJ-100X CAPACITOR,AX770UC 10pF,50V

L101 NQL365K-220X COIL 22µH

L1601 NQL144M-1R0X COIL 1µH

L2021 NQL315K-470X COIL 47µH

L2022 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2023 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2051 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2052 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2071 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2072 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L3502 NQL365K-220X COIL 22µH

L4001 NQL365K-220X COIL 22µH

L4201 NQR0006-001X FERRITE BEAD

L4501 NQR0006-001X FERRITE BEAD

L4502 NQL034K-220X COIL 22µH

L4701 NQL365K-220X COIL 22µH

L5201 NQL315K-470X COIL 47µH

L5202 NQL365K-220X COIL 22µH

L5203 NQL365K-220X COIL 22µH

L6001 NQL62EM-100X COIL 10µH

L6002 NQL62EM-100X COIL 10µH

L6101 NQL64EM-330X COIL 33µH

L6201 NQL64EM-470X COIL 47µH

L6301 NQL52EM-220X COIL 22µH

L6302 NQR0006-001X FERRITE BEAD

L6401 NQLZ011-470X COIL 47µH

L6501 NQLZ011-470X COIL 47µH

L6601 NQL52EM-221X COIL 220µH

L6701 NQL52EM-100X COIL 10µH

L7005 NQL365K-220X COIL,AX970U 22µH

L7007 NQL365K-220X COIL,AX970U 22µH

L7304 NQL144K-100X COIL,AX770UC 10µH

X101 NAX0251-001X CRYSTAL RESONATOR

X102 NAX0325-001X CRYSTAL RESONATOR

X4001 QAX0709-001 CRYSTAL RESONATOR

WR1 WJV0039-001A

!

J101 QAB0050-001 LI BATTERY

E-PRIMARY WIRE,JP2001/2002-JP2003/2004

J504 LY31356-002A JACK UNIT

CN1 QGF0508F1-10X FPC CONNECTOR

CN2 QGF0508F1-14X FPC CONNECTOR

CN3 QGF0505F2-18X FPC CONNECTOR

CN4 QGA1201F2-02X CONNECTOR

CN5 QGF0508F1-11X FPC CONNECTOR

CN6 QGA1201C2-02X CONNECTOR,AX970U

CN7 QGF0508F1-11X FPC CONNECTOR

CN8 QGA1201C2-02X CONNECTOR

CN11 QGF0507F3-20X FFC/FPC CONNECTOR,AX970U

CN12 QGA1201F2-03X CONNECTOR,AX770UC

CN13 QGF0507F4-14X FFC/FPC CONNECTOR

CN15 QGF0507F3-22X FFC/FPC CONNECTOR

CN18 QGF0507F4-12X FFC/FPC CONNECTOR

CN22 QGF0508F1-14X FPC CONNECTOR

CN25 QGB0506L1-30X CONNECTOR

CN28 QGA1002F1-13X CONNECTOR

!

F6001 NMFZ007-2R0X-K FUSE T2.0A,50V

!

F6002 NMFZ007-1R25X-K FUSE T1.2A,50V

!

F6004 NMFZ007-R40X-K FUSE T0.4A,50V

!

F7301 NMFZ010-R50X-A FUSE,AX770UC T0.5A

OT1 LY30016-049A SPACER-A

OT2 PU59915-105 #500SPACER0.01

SD1 LY43421-001A SHIELD PLATE

L1602 NQL144K-100X COIL 10µH

L2001 NQL144K-470X COIL 47µH

L2003 NQL034K-470X COIL 47µH

L2004 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

L2005 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

5-15

Page 15

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

******************************

CCD BOARD ASSEMBLY <02>

PW2 YB10356A2-01 CCD BOARD ASSY

Q5301 2SC3931/CD/-X TRANSISTOR

or 2SC4774/RS/-X TRANSISTOR

R5301 NRSA63J-105X MG RESISTOR 1MØ,1/16W

R5302 NRSA63J-562X MG RESISTOR 5.6kØ,1/16W

C5301 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5302 NBP21EM-155X T CAPACITOR 1.5µF,25V

C5303 NCB31HK-152X CAPACITOR 0.0015µF,50V

C5304 NCF31EZ-104X CAPACITOR 0.1µF,25V

C5305 NDC31HJ-270X CAPACITOR 27pF,50V

CN5301 QGF0505F1-14X FPC CONNECTOR

******************************

C-VF BL BOARD ASSEMBLY <06>[AX970U]

PW1 YB20920A1 C-VF BOARD ASSY

IC7701 CXD3518R IC

D7701 MA365 VARI CAP DIODE

D7702 MA111 DIODE

R7702 NRSA63J-102X MG RESISTOR 1kØ,1/16W

R7703 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R7704 NRSA63J-333X MG RESISTOR 33kØ,1/16W

R7705 NRSA63J-103X MG RESISTOR 10kØ,1/16W

R7707 NRVA63D-393X CMF RESISTOR 39kØ,1/16W

R7708 NRVA63D-124X CMF RESISTOR 120kØ,1/16W

R7710 NRSA63J-104X MG RESISTOR 100kØ,1/16W

R7712 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R7714 NRVA63D-822X CMF RESISTOR 8.2kØ,1/16W

C7701 NCB31EK-103X CAPACITOR 0.01µF,25V

C7702 NBE20JM-106X T CAPACITOR 10µF,6.3V

C7703 NBE20JM-335X T CAPACITOR 3.3µF,6.3V

C7704 NCB31HK-332X CAPACITOR 0.0033µF,50V

C7705 NCB31EK-103X CAPACITOR 0.01µF,25V

C7706 NDC31HJ-470X CAPACITOR 47pF,50V

C7707 NCB31HK-102X CAPACITOR 0.001µF,50V

C7708 NCB31EK-103X CAPACITOR 0.01µF,25V

C7709 NCB31CK-104X CAPACITOR 0.1µF,16V

C7711 NBP41EM-475X T CAPACITOR 4.7µF,25V

C7712 NCB31EK-103X CAPACITOR 0.01µF,25V

C7713 NCB31CK-104X CAPACITOR 0.1µF,16V

C7714 NCB31CK-104X CAPACITOR 0.1µF,16V

C7715 NDC31HJ-220X CAPACITOR 22pF,50V

C7716 NDC31HJ-220X CAPACITOR 22pF,50V

L7701 NQL38DK-220X COIL 22µH

L7702 NQL085J-8R2X COIL 8.2µH

L7703 NQL365K-220X COIL 22µH

CN7701 QGF0512C1-18X FPC CONNECTOR

CN7702 QGF0512C1-16X FPC CONNECTOR

– SUB BOARD ASSMBLY –

PW2 YB20920A2 BL BOARD ASSY

D7801 NSCW100A0/ST/-X LE DIODE

CN7801 QGF0503F4-06X FFC/FPC CONNECTOR

******************************

E.VF BOARD ASSEMBLY <60>[AX770UC]

PW LY41289-005A E.VF BOARD ASSY

IC7001 BA7149F-XE IC

Q7001 2SD968A(RS) PH TRANSISTOR

Q7002 2SA1748(QR) PH TRANSISTOR

Q7003 2SA1748(QR) PH TRANSISTOR

D7001 MA142WA SI DIODE

R7002 NRSA02J-3R9X MG RESISTOR 3.9Ø,1/10W

R7003 NRVA02D-153X CMF RESISTOR 15kØ,1/10W

R7005 NRSA02J-102X MG RESISTOR 1kØ,1/10W

R7006 NRSA02J-113X MG RESISTOR 11kØ,1/10W

R7007 NRSA02J-330X MG RESISTOR 33Ø,1/10W

R7008 NRSA02J-394X MG RESISTOR 390kØ,1/10W

R7009 NRSA02J-103X MG RESISTOR 10kØ,1/10W

R7010 NRVA02D-104X CMF RESISTOR 100kØ,1/10W

R7011 NRSA02J-223X MG RESISTOR 22kØ,1/10W

R7012 NRSA02J-221X MG RESISTOR 220Ø,1/10W

R7013 NRSA02J-102X MG RESISTOR 1kØ,1/10W

R7014 NRSA02J-472X MG RESISTOR 4.7kØ,1/10W

R7015 NRSA02J-223X MG RESISTOR 22kØ,1/10W

R7016 NRSA02J-122X MG RESISTOR 1.2kØ,1/10W

R7017 NRSA02J-472X MG RESISTOR 4.7kØ,1/10W

R7018 NRSA02J-223X MG RESISTOR 22kØ,1/10W

R7019 NRSA02J-120X MG RESISTOR 12Ø,1/10W

R7020 NRSA02J-685X MG RESISTOR 6.8MØ,1/10W

R7021 NRSA02J-475X MG RESISTOR 4.7MØ,1/10W

R7022 NRSA02J-475X MG RESISTOR 4.7MØ,1/10W

R7023 NRSA02J-564X MG RESISTOR 560kØ,1/10W

R7024 NRSA02J-105X MG RESISTOR 1MØ,1/10W

R7025 NRSA02J-275X MG RESISTOR 2.7MØ,1/10W

R7026 NRSA02J-275X MG RESISTOR 2.7MØ,1/10W

VR7001 NVP0001-221X TRIM RESISTOR,V.SIZE

VR7002 NVP0001-225X TRIM RESISTOR,BRIGHT

VR7003 PERE0595-565 V RESISTOR,FOCUS

C7001 QFV11HJ-104A F CAPACITOR 0.1µF,50V

C7002 QEDP1AM-227 E CAPACITOR 220µF,10V

C7003 QEDP1AM-227 E CAPACITOR 220µF,10V

C7004 QEDP1AM-227 E CAPACITOR 220µF,10V

C7005 NCF21CZ-105X CAPACITOR 1µF,16V

C7006 NCB21HK-152X CAPACITOR 0.0015µF,50V

C7007 NCB11CK-105X CAPACITOR 1µF,16V

C7008 NCF21CZ-105X CAPACITOR 1µF,16V

C7009 PECA1131-A107 E CAPACITOR 100µF,10V

C7010 CM316UJ472J100A CAPACITOR

C7011 NDC21HJ-180X CAPACITOR 18pF,50V

C7012 QEKC1HM-105Z E CAPACITOR 1µF,50V

C7013 NCF21HZ-104X CAPACITOR 0.1µF,50V

C7014 NCF21HZ-104X CAPACITOR 0.1µF,50V

C7015 QCZ0212-151 CAPACITOR 150pF,1kV

C7016 PECA1006 CAPACITOR 330pF,500V

L7001 QQR0970-001 LINEARITY COIL

L7002 PU49994-220 COIL 22µH

L7003 PELN1101-680JY COIL 68µH

!

T7001 QQH0011-002 FB TRANSF

CN7001 B4B-ZR CAP HOUSING

CN7002 WJK0095-002A WIRE ASSY

OT1 PU59915-105 SPACER#500, for L7001

5-16

(Sanwa)-M2A6B2/6C3

GR-AX770UC/AX970U

Page 16

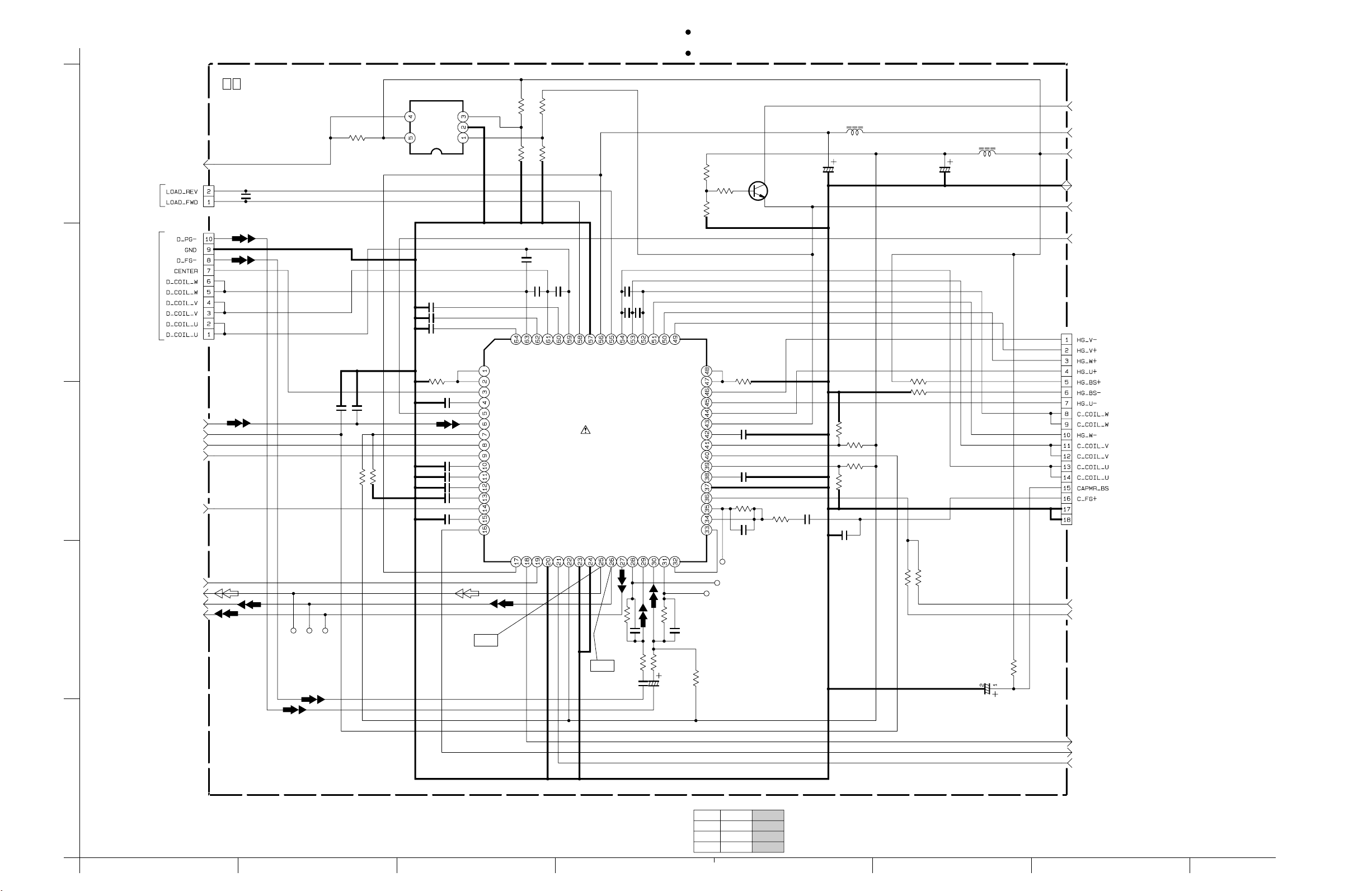

SECTION 4

24

C331

11/10

22201816

WF25

C329

0.1/50

C330

0.1/50

R344

47K

R343

18K

R345

10K

R346

15K

Measurement point

Waveform number

CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM

Safety precautions

The Components identified by the symbol are

critical for safety. For continued safety, replace safety

critical components only with manufacturer's recommended parts.

1. Units of components on the schematic diagram

Unless otherwise specified.

1) All resistance values are in ohm, 1/6 W, 1/8 W (refer to

parts list).

Chip resistors are 1/16 W.

K: KØ (1000Ø), M: MØ (1000KØ)

2) All capacitance values are in µF, (P: PF).

3) All inductance values are in µH, (m: mH).

4) All diodes are 1SS133, MA165 or 1N4148M (refer to parts

list).

2. Indications of control voltage

AUX : Active at high

AUX or AUX(L) : Active at low

3. Interpreting Connector indications

1

2

Removable connector

3

1

2

Wire soldered directly on board

3

4) Indication on schematic diagram

Voltage Indications for REC and PB mode on the schematic diagram are as shown below.

REC mode

12 3

2.5

(5.0)

PB mode

1.8

PB and REC modes

(Voltage of PB and REC modes

are the same)

Note: If the voltages are not indicated on the schematic

diagram, refer to the voltage charts.

5. Waveform measurement

1) Video circuits

REC : Colour bar signal in SP mode, normal VHS mode

PB : Alignment tape, colour bar SP mode, normal VHS

mode

2) Audio circuits

REC : 1KHz, –8 dBs sine wave signal in SP mode, normal

VHS mode

PB : REC then playback it

3) Movie Camera circuits

Measured using a correctly illuminated gray scale or colour

bar test chatrs in the E-E mode

4) Indication on schematic diagram

Waveform indications on the schematic diagram are as

shown below.

1

Non-removable Board connector

2

3

1

2

4

Board to Board

3

Connected pattern on board

The arrows indicate signal path

4. Voltage measurement

1) Video circuits

REC : Colour bar signal in SP mode, normal VHS mode

PB : Alignment tape, colour bar SP mode, normal VHS

mode

— : Unmeasurable or unnecessary to measure

2) Audio circuits

REC : 1KHz, –8 dBs sine wave signal in SP mode, Nor-

mal VHS mode

PB : REC then playback it

3) Movie Camera circuits

Measured using a correctly illuminated gray scale or colour

bar test charts in the E-E mode

S40884-03

5) Waveform indications

Waveform number

WF25

REC/PB 1.2 Vp-p

50 mV/2 msec/DIV

Oscilloscope Volts and Time/Division, Probe 10 : 1

Mode : REC or PB modes

Waveform name or

measurement point

ALC OUT

Level : 1.2 Vp-p

4-1

Page 17

6. Signal path Symbols

The arrows indicate the signal path as follows.

Playback signal path

Playback and recording signal path

Recording signal path

(including E-E signal path)

Capstan servo path

CIRCUIT BOARD NOTES

1. Foil and Component sides

1) Foil side (B side) :

Parts on the foil side seen from foil face (pattern face)

are indicated.

2) Component side (A side) :

Parts on the component side seen from component face

(parts face) indicated.

Drum servo path

(Example)

R-Y

Playback R-Y signal path

Y

Recording Y signal path

7. Indication of the parts for adjustments

The parts for the adjustments are surrounded with the circle as

shown below.

8. Indication of the parts not mounted on the circuit board

“OPEN” is indicated by the parts not mounted on the circuit

board.

R216

2. Parts location guides

Parts location are indicated by guide scale on the circuit board.

REF No. LOCATION

Category: IC

Horizontal “A” zone

Vertical “6” zone

(A : Component side)

(D : Discrete component)

B : Foil side

C : Chip component

IC

IC101 B C 6 A

Note:

For general information in service manual, please refer

to the Service Manual of GENERAL INFORMATION Edition 4 No. 82054D (January 1994).

OPEN

4-2

S40884-03

Page 18

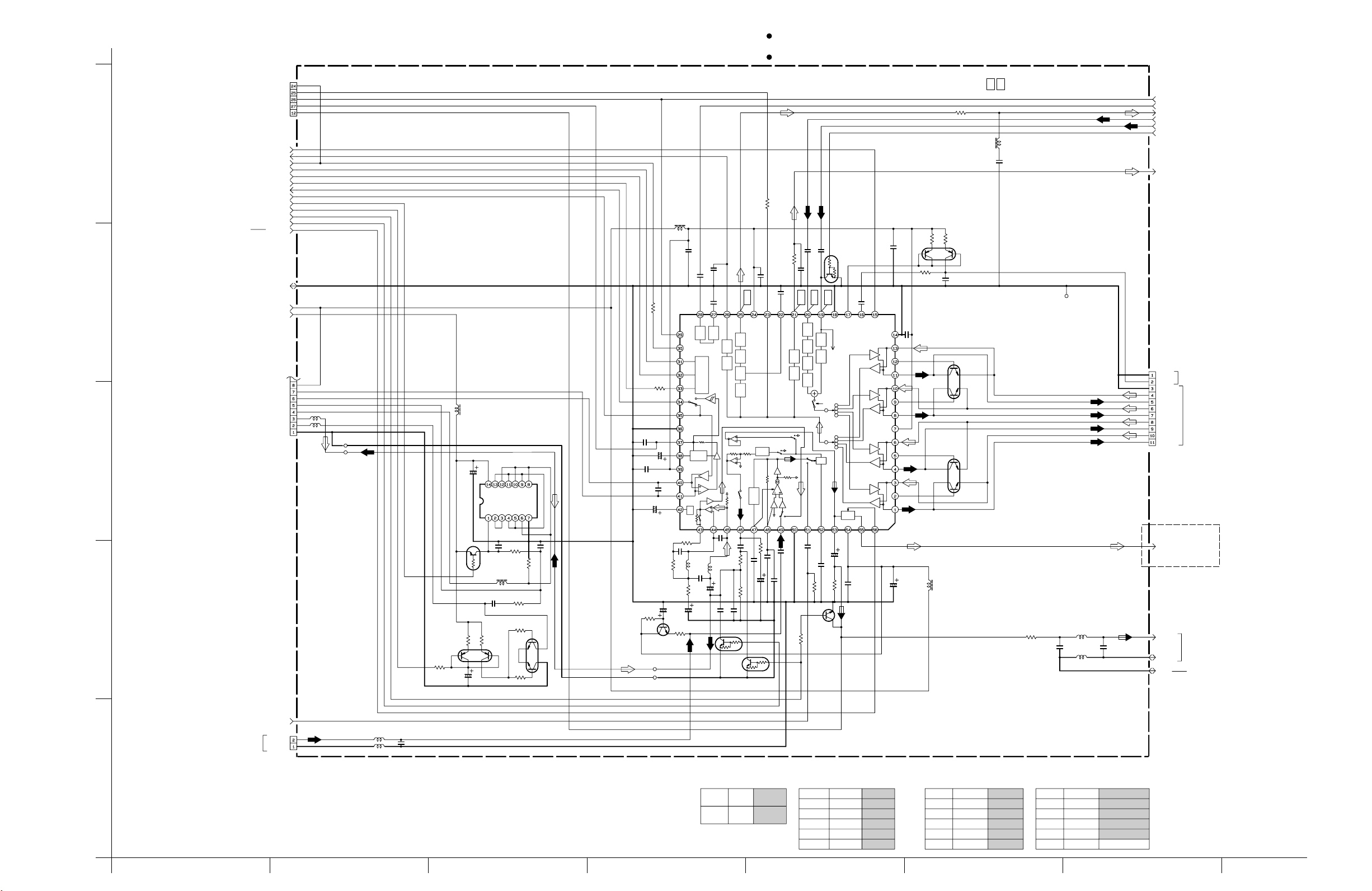

)

: The number of patch cords

∗

are indicated by interconnected.

YTU94074-20

∗

YTU94077-20

YUJ40095A-3

∗

SO3

SCK3

V_OVL

DSP (Page 4-11)

V_OVL_B

SDET_CTL

CLKCPU

ASTB

V_DSP_CS

AD0

AD2

AD3

AD4

AD1

AD5

AD6

AD7

AD8

AD9

AD10

AD11

V_OVL_A

V_PULSE

AD12

With BW-VF MODEL

CN12

GND

VF_BL4.8

BW_VF_Y

GND

ROUT

REG_2V

REG_3.2V

R/W_L

OMT

FI

CFM

WAIT_L

AD13

DSTB_L

AD14

AD15

HD_H

BOUT

GOUT

OSD_CLK

OSD_DATA

OSD_CS

NCNCNC

DSP_REST

CAM_Y

EJECT_SW

TXD

VDVHS

TG_CLK

CDS_CLK

CAM_ADCK

CAM_C

H_GAIN

PB_CTL

AL_3.2V

AD_0

AD_1

AD_2

AD_3

AD_4

AD_5

AD_6

AD_7

AD_8

AD_9

ID

HDTG

VDTG

PBLK

LHFO

V_FF

H_OFFSET

V_OVL

AO_SIG_J

V_OUT

V_TP_FM

RXD

V_FF

60

E. VF

(Page 4-33)

JIG_CONN.

JIGCN_SW

VPP_7.8V

GND

DISCHG_L

MCU_RST

TCCS_TXD

AD_0

AD_1

AD_2

AD_3

AD_4

AD_5

AD_6

AD_7

AD_8

AD_9

TG_CLK

CDS_CLK

CAM_ADCK

ID

HDTG

VDTG

PBLK

LHFO

CDS_CS

DSGAT

CCD_SCS

GND

YTU93106A

YTU94145B-30

NC

GND

PLI_AD

GND

V_PB_C

CVF_R

CVF_G

CVF_B

BWVFADJ

VF_RPD

REG_15V

REG-8-5V

TG/CDS

(Page 4-17)

∗

DIAL_MN

CN25

REG_3.2V

02

(Page 4-29)

CN5301

V4V3V2V1GND

H1

H2

V1

SUB

CCD_LV

CCD_HV

CCD_OUT

CCD

V4V3V2V1NC

GND

VOUTVDD

1234567

OP BLOCK

89

1011121314

VL

H1

H2

RG

SUB

GND

YTU94074-14

YTU94077-14

∗

CN22

SUB

CCD_OUT

CCD_HV

GND

GND

V4V3V2

CCD_LV

H1RGH2

GND

SCK3

SO3

CN15

RG

ZOOM2

ZOOM4

ZOOM3

ZOOM1

FOCUS1

FOCUS4

FOCUS2

FOCUS3

ZOOM1

ZOOM3

ZOOM4

ZOOM2

FOCUS3

FOCUS2

FOCUS4

FOCUS1

OP_VCC

F/Z/I/MDA

(Page 4-13)

WB_SENS

H_OFFSET

H_GAIN

VDVHS

DSP_REST

Z_REG_4.8V

IR_DC

ZF_REG_4.8V

OP_VCC

DUMP-

DUMP+

DRIVE+

IRIS_O/C

LENS_CLK

LENS_CS

F_SENS

HE_OUT+

HALL_A/D

F_LED

DUMP+

HE_IN-

HE_IN+

HE_OUT-

REG_4.8V

REG_3.2V

IR_FLICK

IRIS_PWM

LENS_LED

DRIVE+

ZOOM_LED

GND

SCK3

SO3

DUMP-

UNREG

GND

∗

HE_OUT+

HE_IN-

YTU94074-22

YTU94077-22

HE_IN+

HE_OUT-

Z_SENS

ZOOM_LED

Z_L_VCC

BWYGAIN

CN11

HRP2

HRP1

BWYGAIN

HDCVF

VDCVF

V_PLS_ON

BWBLEBEL

BWYOUT

DAC_3.2V

V_PB_F

V_REC_C

V_REC_F

2FSC

S_DET+

SPK_VOL

SH_SIG

NOTE

VD_H

S_DET_L

4.1

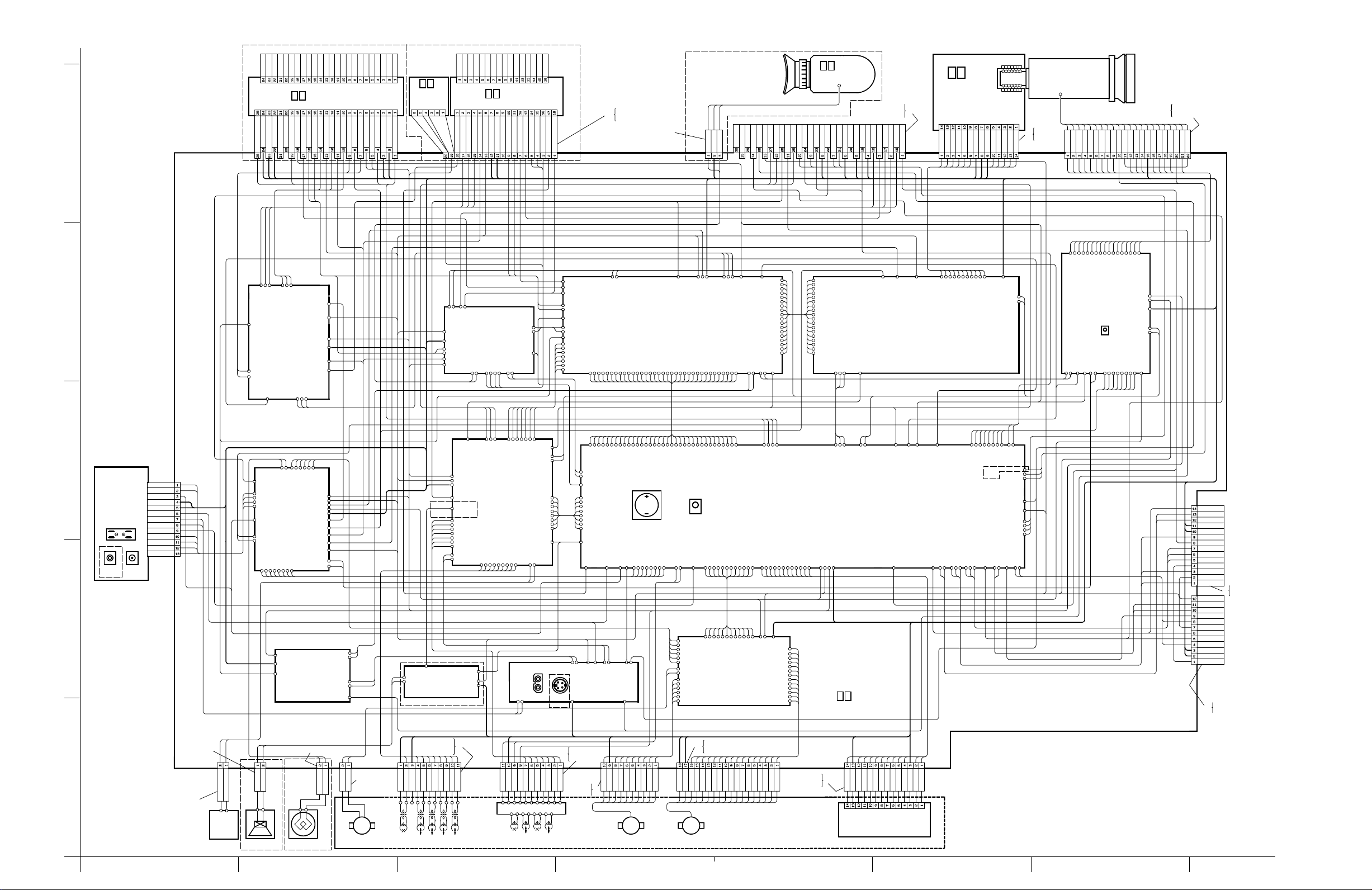

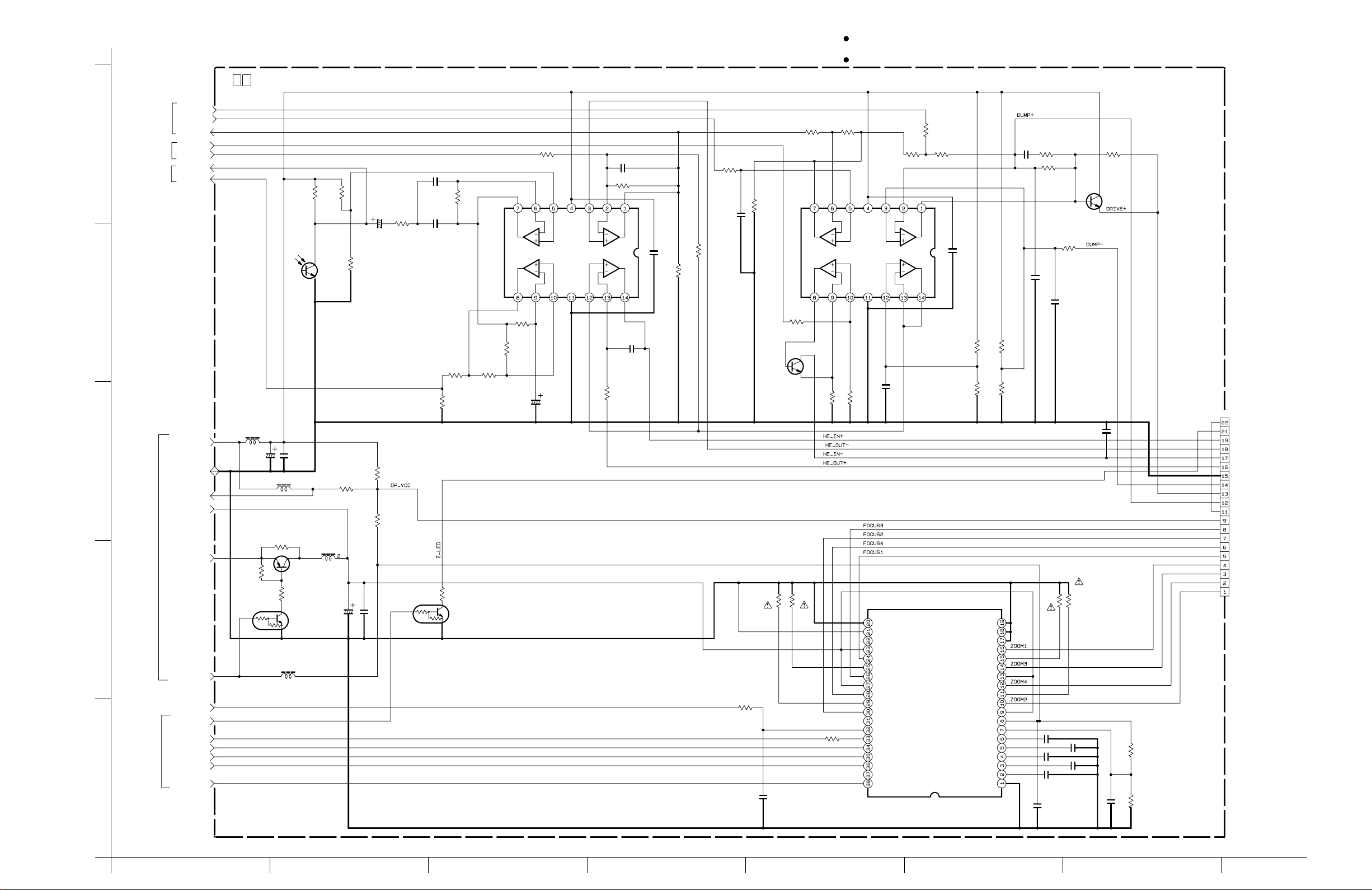

BOARD INTERCONNECTIONS

OPEN

Q2H

OEH

STH1

GND

GND

5

4

REV_SW/RVS_SW

DAC_3.2V

GND

CVF_R

CVF_G

CVF_B

LCD/CVF

(Page 4-21)

MREG_4.8

VSS

VF_LCD

LCD(MONITOR) MODULE

CLK2

CLK1

SIG_GND

07

MONITOR

HDCVF

VDCVF

HRP1

DSP_REST

PMIRROR

NC/VD_YD

NC/MV_PL_ON

MONI_B

MONI_R

MONI_G

REG_-15V

REG_3.2V

REG_4.8V

GND

REG+12V

VF_COM

GOUT

BOUT

ROUT

MONI_B

STH2RLVBRGBCLK3

MONI_G

REG_3.2V

VCOM

VEE

MONI_R

REG+12V

VDD

VGH

MREG_4.8

REG_15V

STV2

VSS

CPV

OEV

REG_4.8V

REG_4.8V

STV1

UD

CN7602

CN7601

LCD_CTL

GND/BL_GND

With C-VF MODEL

VGL

VSS

C-VF BL

(Page 4-30)

CN7801

GND/BL_GND

OPEN_SW

CN16

C_VF_PANEL

VDD

VSS

VST

VCK

STBENDWN

RGT

HST

HCK2

HCK1

BLK

BLUE

RED

GREEN

COM

0

6

0

6

C-VF

CN7701

N.C

V

8

.

4

_

G

E

VF_BLK

R

SO3

REG_3.2V

GND

HDCVF

VDCVF

REG+12V

REG_4.8V

(Page 4-31)

REG+12V

CVF_B

CVF_R

CVF_G

VF_COM

REG_3.2V

SCK3

BW/CVF

BWVFADJ

BWYGAIN

(Page 4-23)

(Page 4-25)

BW_VF_Y

VF_BL4.8

VF_BLK

GND

GND

CVF_SO3

CVF_SCK3

NC

CVF_CS

VDCVF

HDCVF

BWBLEBEL

BWYOUT

V_PLS_ON

VF_CS

VF_CTL

HRP2

VF_RPD

CN7702

CVF_SCK3

CVF_CS

SI3

CVF_SO3

3

2

1

REAR UNIT

(Page 4-36)

BATT_TERM

PC OUT DC_IN

OPEN

CN28

ADP_DC

ADP_DC

ADP_H

GND

GND

EDIT

J_GND

BATT_L

TT_BATT

BATT_+

BATT_+

BATT_CHK

YUJ40095A-2

∗

RX

∗

YUJ40095A-2

CN8

MIC

MIC_HOT

MIC_GND

OPEN

CN27

SPEAKER

DISCHG_L

BATT_CHK

BATT_+

ADP_DC

TT_BATT

ADP_H

(Page 4-19)

MCU_RST

PLI_AD

LAMP_ON

REG_CS

AREG_SO

AD_REF

SPK-

SPK+

REG

AREG_CLK

REG_4.8V

GND

DAC_3.2V

CAP_CTL

DRM_CTL

MTR_OSC

CAP_PWR

M_UNREG

DRM_PWR

LAMP_RTN

LAMP_4.5V

REG_4.8V

REG_3.2V

REG_2V

UNREG

GND

REG_-15V

REG_15V

REG+12V

REG-8-5V

AL_3.2V

Z_REG_4.8V

PLI_PWM

V_BATT

ZF_REG_4.8V

T_BATT

V OUT

(Page 4-15)

YUJ40095A-2

∗

With

CN6

DC LIGHT

MODEL

LAMP_RTN

DC LIGHT

CAM_Y

CAM_C

SC_OUT

SY_OUT

V_OUT

LAMP_4.5V

CN4

LOAD_REV

LOAD_FWD

LOADING

MOTOR

∗

YUJ40095A-2

M

CN5

F LY. E

HEAD

SPK+

SPK-

GND

GND

FE_S

OPEN

PA_SIG

SPEAKER

YTU94074-11

YTU94077-11

V_CH2_F

V_CH4_F

V_CH1_F

V_CH2_S

V_CH4_S

V_CH1_S

VIDEO HEAD

REG_4.8V

REG_3.2V

GND

V_OVL

PA_SIG

AH_GND

AH_REC

AH_PB

AE+

AECTL_HED+

CTL_HED-

AO_SIG

AO_GND

REG_3.2V

∗

V_CH3_F

V_CH3_S

V_PB_C

A_MUTE

GND

OPEN

V_PB_F

PB_CTL

V_TP_FM

V_REC_F

V_REC_C

AO_SIG_J

VTR ASP

PRE/REC

CTL_AMP

AUDIO

(Page 4-9)

FE_S

V_CH3_F

V_CH3_S

V_CH1_F

V_CH1_S

V_CH4_F

V_CH4_S

V_CH2_F

V_CH2_S

JACK (Page 4-27)

J_GND

GND

CN7

CTL_ERS-

DEW_SENS

A/C HEAD

2FSC

S_DET+

RX

REG_4.8V

CTL_HED-

SH_SIG

SCK3

SPK_VOL

FEH_ON

V_ENV

CTL_OUT

REC_CTL

A_BIAS

A_PB

APB_EP_H

A_MUTE

MIC_HOT

MIC_GND

AE-

CTL_HED+

V_FF

SO3

AE+

S OUTA/V OUT

OPEN

AH_PB

∗

AH_REC

VF_CS

VF_CTL

V_PLS_ON

V_ASP_CSV_ASP_CS

APB_EP_H

A_MUTE

SY_OUT

SC_OUT

GND

YTU94074-11

YTU94077-11

AH_GND

YTU94074-10

YTU94077-10

VD_H

FEH_ON

V_ENV

CTL_OUT

REC_CTL

A_BIAS

A_PB

SI3

REG_3.2V

S_DET_L

EDIT

∗

CLKCPU

V_OVL_B

V_OVL_A

V_PULSE

SDET_CTL

V_DSP_CS

ADP_H

EDIT

AO_SIG

AO_GND

GND

D_FG-

D_PG-

CN1

CENTER

DRUM_MOTOR

AD0

AD1

ASTB

RXD_DRV

TXD

RXD_DRV

V_OUT

D_COIL_W

AD2

AD3

LITHIUM

LAMP_ON

T_BATT

D_COIL_V

D_COIL_W

AD4

AD5

PLI_PWM

AREG_CLK

V_BATT

D_COIL_V

D_COIL_U

AD6

AD7

REG_CS

AREG_SO

D_COIL_U

AD8

AD_REF

AD9

AD10

AD11

AD12

AD13

AD14

AD15

IR_UNIT

CTL_ERS-

DEW_SENS

M_UNREG

DRM_PWR

DRM_CTL

CAP_PWR

CAP_CTL

MTR_OSC

LOAD_FWD

LOAD_REV

D_PGD_FGCENTER

D_COIL_W

D_COIL_V

D_COIL_U

GND

GND

C_FG+

CN3

MM

CAPSTAN

MOTOR

FI

CFM

OMT

R/W_L

DRUM_REF

CAP_REF

BATT_L

CAP_REF

CAP_STOP

DRUM_REF

M.MDA

(Page 4-7)

YTU94074-18

∗

YTU94077-18

C_COIL_U

C_COIL_U

CAPMR_BS

HD_H

WAIT_L

DSTB_L

OSD_CS

OSD_CLK

OSD_DATA

DRUM_FG

CAP_FG

DRUM_PG

CAP_STOP

DRUM_ON

DRUM_CLK

CAP_FR

CAP_FG

DRUM_FG

DRUM_PG

DRUM_ON

DRUM_CLK

HG_W-

C_COIL_V

C_COIL_V

C_COIL_W

C_COIL_W

MECHA

LOAD_F

CAP_FR

LOAD_F

HG_U-

LOAD_R

LOAD_R

HG_BS-

CVM_DET

UNREG

CVM_DET

HG_U+

HG_BS+

PMIRROR

OPEN_SW

R_SAF_SW

CAM_SW_C

CAM_SW_A

CAPMR_BS

REG_3.2V

C_COIL_U

C_COIL_V

C_COIL_W

HG_BS+

HG_V+

HG_W+

REV_SW

LCD_CTL

CPU (Page 4-5)

EN_SENS

STR_SENS

SUP_SENS

REEL_LED

TAPE_LED

S_VHS_SW

CAM_SW_B

TU_SENS

CAS_SW

GND

C_FG+

HG_W-

HG_U-

HG_BS-

HG_U+

HG_W+

HG_V+

HG_V-

YTU94074-14

HG_V-

YTU94077-14

UNREG

∗

REG4.8V

REG_3.2V

DSGAT

CCD_SCS

GND

01

CN2

CDS_CS

R_SAF_SW

SO3

SCK3

MAIN

GND

CAM_SW_A

CAM_SW_C

SENSOR

(Page 4-36)

CAS_SW

SUP_SENS

CAM_SW_B

V_FF

DIAL_MN

TU_SENS

REEL_LED

VDVHS

TAPE_LED

S_VHS_SW

GND

DSP_REST

EN_SENS

STR_SENS

KEY_C

VF_LCD

B_PHASE

A_PHASE

ZOOM_SW

PHOTO_SW

TRIG_SW

DIAL_AT

LENS_CS

LENS_CLK

DIAL_PB

DIAL_OF

IRIS_O/C

HALL_A/D

OPEN

EJECT_SW

IRIS_PWM

LENS_LED

LED_G

IR_DC

IR_FLICK

P0LUX_SW

TCCS_TXD

JIGCN_SW

VPP_7.8V

LED_R

PLI_AD

Z_SENS

F_SENS

AL_3.2V

KEY_A

MCU_RST

TXD

RXD

LIGHT_SW

RFRSH_SW

y10241001a_rev0

TO ZOOM UNIT (Page 4-35)

CN13

KEY_C

A_PHASE

B_PHASE

GND

GND

TRIG_SW

DIAL_MN

DIAL_AT

DIAL_OF

DIAL_PB

EIS_SW

PHOTO_SW

REG_3.2V

ZOOM_SW

YTU94074-14

YTU94077-14

∗

AL_3.2V

LED_G

LED_R

KEY_A

LIGHT_SW

REG_3.2V

KEY_C

EJECT_SW

RFRSH_SW

GND

GND

EIS_SW

CN18

TO

TOP OPE UNIT

(Page 4-35)

YTU94074-12

YTU94077-12

∗

4-44-3

HGFEDCBA

Page 19

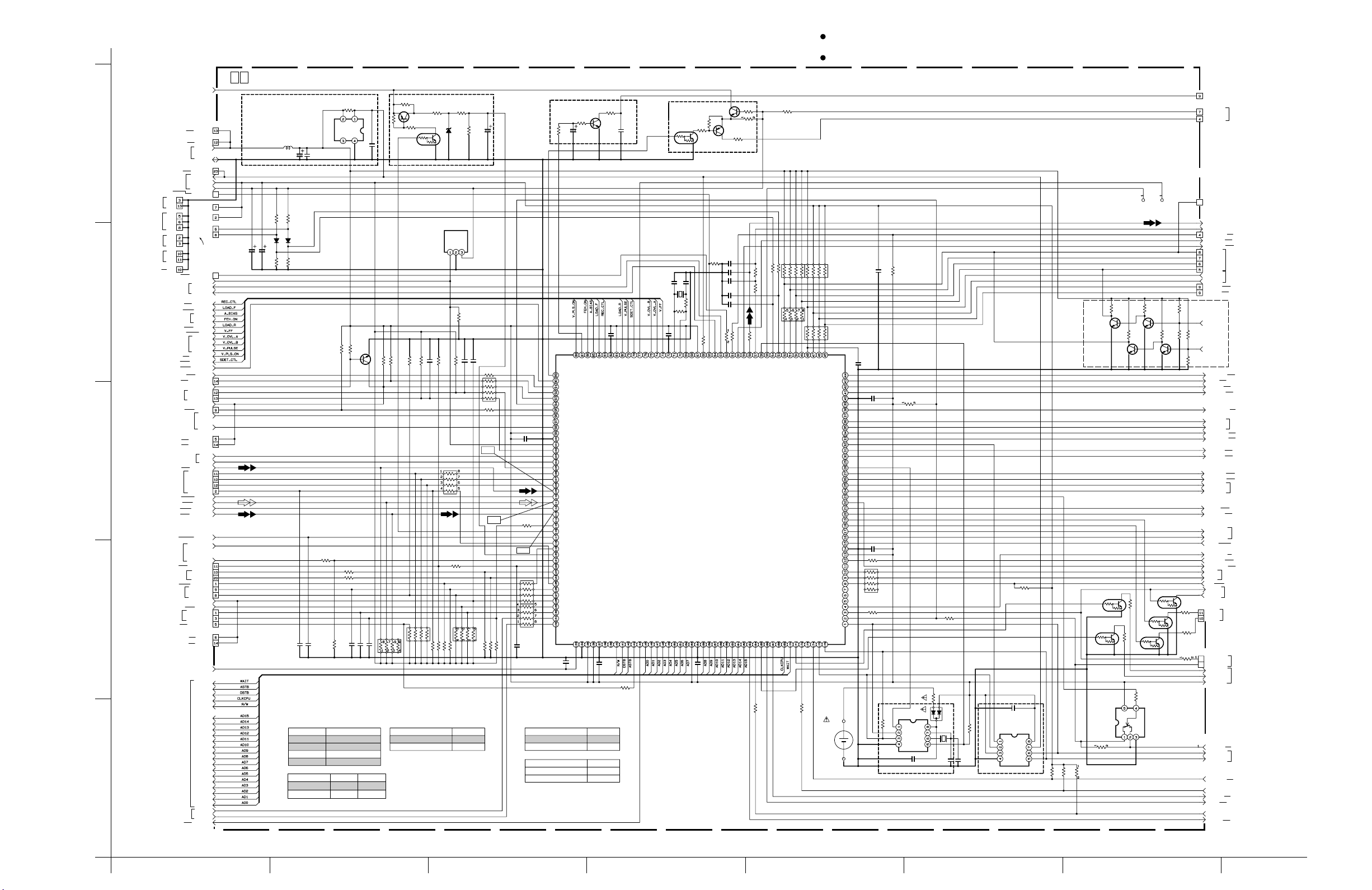

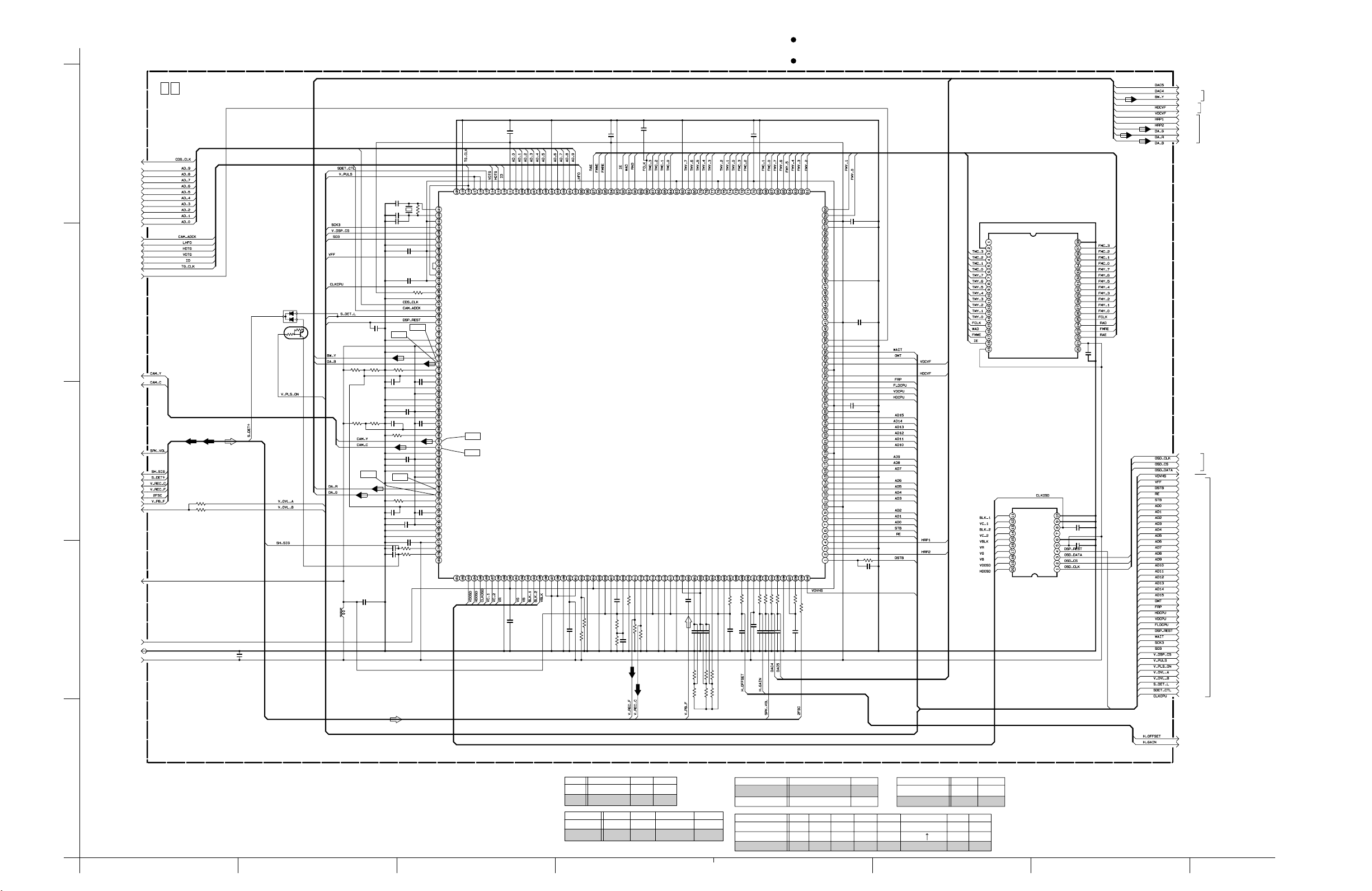

CPU SCHEMATIC DIAGRAM4.2

NOTES :

For the destination of each signal and further line connections that are cut off from

this diagram,refer to "4.1 BOARD INTERCONNECTIONS".

When ordering parts,be sure to order according to the Part Number indicated in the Parts List.

TO REG

TO REG

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

TO DSP

TO DSP

TO REG

TO REG

CN2CN2

CN25

CN18

CN13

CN7

(N.C)

(N.C)

(N.C)

AL_3.2V

AL_3.2V

AL_3.2V

MCU_RST

MCU_RST

REG_3.2V

REG_4.8V

VPP_7.8V

REG_3.2V

REG_3.2V

TU_SENS

SUP_SENS

TO SENSOR

JIGCN_SW

REMCON

PMIRROR

VF_LCD

REC_CTL

LOAD_F

A_BIAS

FEH_ON

LOAD_R

V_OVL_A

V_OVL_B

V_PULSE

V_PLS_ON

SDET_CTL

CVM_DET

ADP_H

R_SAF_SW

PEJEC_SW

B_PHASE

A_PHASE

EJECT_SW

BATT_L

JIG_CONN.

5

TO TOP OPE UNIT

JIG_CONN.

JIG_CONN.

TO SENSOR

JIG_CONN.

TO

TOP OPE UNIT

TO

ZOOM UNIT

TO A/C HEAD

JIG_CONN.

TO LCD/CVF

4

TO VTR ASP

TO M.MDA

TO VTR ASP

TO M.MDA

TO VTR ASP, DSP

TO DSP, BW/CVF

TO M.MDA

TO SENSOR

TO ZOOM UNIT

TO REAR UNIT

TO DSP

JIG_CONN.

TO M.MDA

TO DSP

TO M.MDA

TO M.MDA

TO REG

TO DSP

EJECT_SW

EJECT_SW

DRUM_FG

CAM_SW_A

CAM_SW_B

CAM_SW_C

STR_SENS

CAP_FG

CTL_OUT

DRUM_PG

HALL_A/D

DEW_SENS

F_SENS

Z_SENS

EN_SENS

LIGHT_SW

(N.C)

PLI_AD

ZOOM_SW

PHOTO_SW

S_VHS_SW

TO REG

AD_REF

WAIT_L

DSTB_L

CLKCPU

VDVHS

V_ENV

KEY_A

KEY_C

KEY_C

KEY_C

TO TOP OPE UNIT

3

TO SENSOR

TO VTR ASP

TO VTR ASP

TO F/Z/I/MDA

TO A/C HEAD

TO OP BLOCK

TO SENSOR

TO TOP OPE UNIT

2

TO ZOOM UNIT

TO SENSOR

TO TOP OPE UNIT

TO ZOOM UNIT

TO DSP

1

T_BATT

TO REG

V_BATT

TO LCD/CVF

LCD_CTL

0 1 MAIN (CPU)

UNREG

2.7V_RESET

R101

100K

CN25

CN18

AL3.2V

GND

CN25

CN25

21

CN18

CN13

CN2

C111

C112

6V

22µ/

CN25

7

C103

C104

L101

33µ

∗

T

10µ/

10V

0.01µ

10K

10K

R119

R118

D103

1SS355-X

D104

1SS355-X

6V

R120

R121

27K

27K

22µ/

V_FF

CN2

CN13

CN13

CN28

VD_H

OMT

CN18

CN25

FI

CFM

CN2

CN2

CN2

CN2

IR_DC

CN7

CN15

CN15

CN2

CN18

CN18

CN13

CN13

CN2

CN18

CN13

R126

15K

∗

∗

C135

C136

ASTB

R/W_L

AD15

AD14

AD13

AD12

AD11

AD10

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1