Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB00420037

FS-X3, FS-X1

SP-FSX1 CA-FSX1 SP-FSX1

SP-FSX3 CA-FSX3 SP-FSX3

Area Suffix

J -------------------- U.S.A.

C ----------------- Canada

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.MB004

2003/8

Page 2

SPECIFICATION

CA-FSX1/CA-FSX3 Amplifier Output Power 30 W per channel min. RMS driven into 4 Ω at 1 kHz

with no more than 10 % total harmonic distortion

Input Sensitivity/Impedance (1 kHz) LINE IN 210 mV/51 kΩ (LEVEL 1)

520 mV/51 kΩ (LEVEL 2)

Output Sensitivity/Impedance (1 kHz) LINE OUT 600 mV/5.1 kΩ

OPTICAL DIGITAL OUT -23 dBm - -15 dBm

Speaker terminals MIN. 4 Ω

Subwoofer out 220 mV/4.9 kΩ

Phones 16 Ω - 1 kΩ

CD Player Signal-To-Noise Ratio 95 dB

Wow And Flutter Unmeasurable

Tuner FM Tuner Tuning Range 87.5 MHz - 108.0 MHz

AM Tuner Tuning Range 530 kHz - 1 710 kHz

Speaker Specifications

(each unit)

Power

Specifications

Center Unit Dimensions 160 mm × 130 mm × 242 mm (W/H/D)

SP-FSX1 Type 1-Way Bass-reflex type

SP-FSX3 Type 2-Way Bass-reflex type

Power Requirements AC 120 V , 60 Hz

Power Consumption 25 W (power on mode)

1.2 W (on Standby: with display off)

4.6 W (on Standby: with display on)

(6 - 5/16" × 5? 1/8" × 9 - 17/32")

Mass Approx. 2.3 kg (5.1 lbs)

Speaker 8.0 cm (3-3/16")cone × 1

Power Handling Capcity 30 W

Impedance 4Ω

Frequency Range 55 Hz 20 000 Hz

Sound Pressure Level 81 dB/W

Dimensions 114 mm × 176 mm × 174 mm (W/H/D)

4-1/2" × 6-15/16" × 6-7/8")

Mass Approx. 1.3 kg (2.9 lbs) each

Speaker (Woofer) 10.0 cm (3-15/16") cone × 1

Speaker (Tweeter) 2.0 cm (13/16") dome × 1

Power Handling Capcity 30 W

Impedance 4 Ω

Frequency Range 55 Hz 40 000 Hz

Sound Pressure Level 85 dB/W

Dimensions 147 mm × 246 mm × 210 mm (W/H/D)

(5-13/16" × 9-11/16" × 8-5/16")

Mass Approx. 2.4 kg (5.3 lbs) each

·m

·m

Design and specifications are subject to change without notice.

1-2 (No.MB004)

Page 3

1.1 Safety Precautions

Good earth ground

d

AC VOLTMETER

SECTION 1

PRECAUTION

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

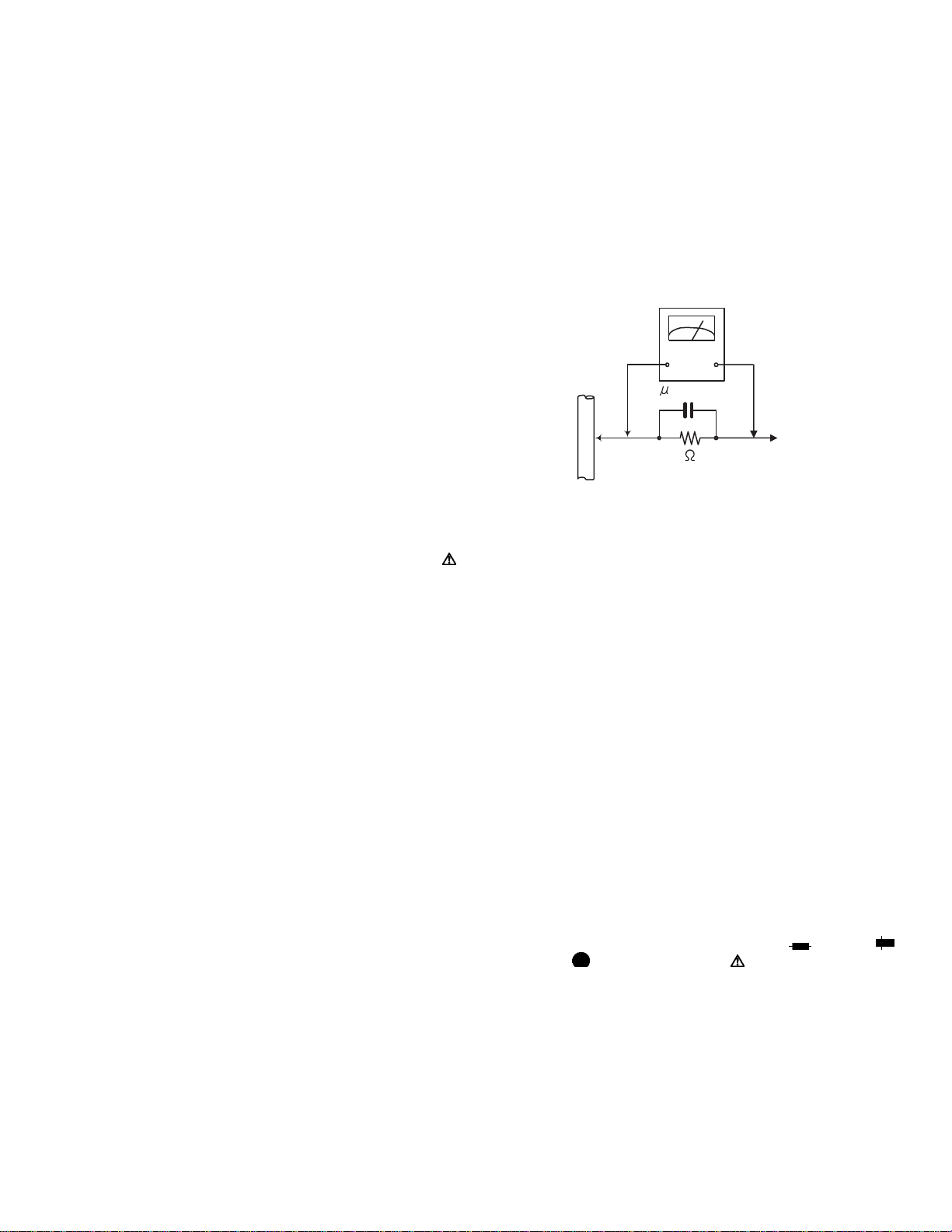

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000

in the following manner. Connect a 1,500

paralleled by a 0.15

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

Ω per volt or more sensitivity

Ω 10W resistor

µF AC-type capacitor between an

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each expose

metal part.

(No.MB004)1-3

µ

Page 4

1.5 Importance administering point on the safety

Power supply board (Forward side)

F9101

Caution: For continued protection against risk of

fire, replace only with same type 5A/125V for

F9101.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F9101 comme le meme type

que 5A/125V.

Ce sont des fusibles suretes qui functionnes rapide.

^

1-4 (No.MB004)

Page 5

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conducti ve sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before in stallation, both sides of th e laser diode on th e replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto r CN101

on the CD servo board.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Flexible wire

Short land section

CN601

CD servo board

(No.MB004)1-5

Page 6

1.9 Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

1-6 (No.MB004)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB004)1-7

Page 8

SECTION 3

A

A

DISASSEMBLY

3.1 Main body section

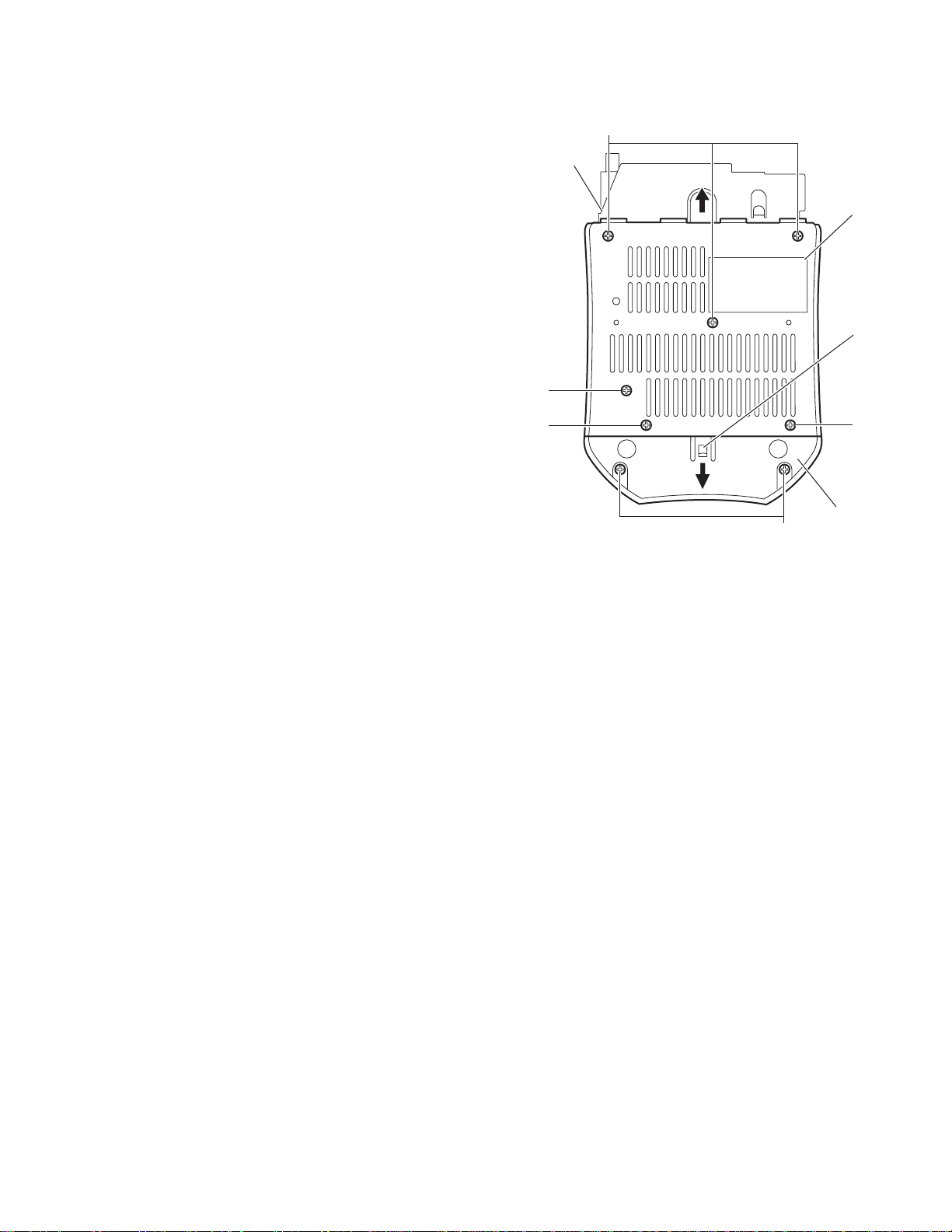

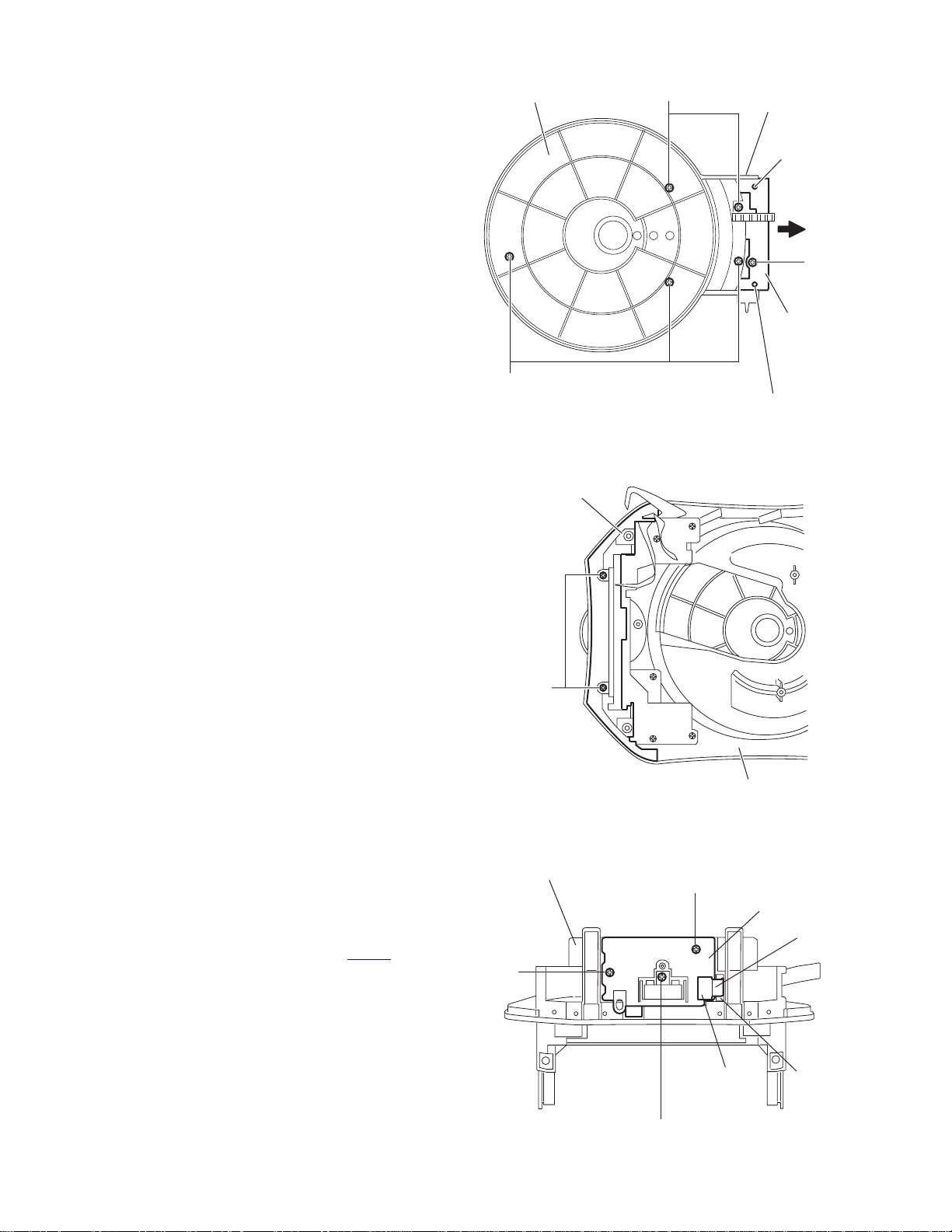

3.1.1 Removing the rear cover

(See Figs.1 and 2)

(1) From the back side of the mai n body, remove the fifteen

screws A attaching the rear cover. (See Fig.1.)

(2) Remove the two screws B attaching the fan cover. (See

Fig.1.)

(3) Remove the rear cover and disconnect the power cord

from the connector CN900

the main body. (See Fig.2.)

(4) Remove the strain relief in the di rection of the arrow. (See

Fig.2.)

Reference :

Before attaching the rear cover, pass the power cord through

the guide hole a on the rear cover. (See Fig.2.)

on the power supply board of

A A

B

Fan cover

Fuse

CN900

Fuse clip

B

Fig.1

Gurde hole a

Fig.2

A

Rear cover

Strain

relief

Power

supply

board

Power cord

Rear cover

1-8 (No.MB004)

Page 9

3.1.2 Removing the bottom case (A)

(See Fig.3)

• Prior to performing the following procedures, remove the rear

cover.

(1) From the bottom side of the main body, remove five screws

C and screw D attaching the bottom case (A).

(2) Remove the bottom case (A) in the direction of the arrow

while lifting the rear section of the bottom case (A).

3.1.3 Removing the bottom case (B)

(See Fig.3)

(1) From the bottom side of the main body, remove the two

screws E attaching the bottom case (B).

(2) Release the claw b of the bottom case (B) and remove the

bottom case in the direction of the arrow.

Note :

When turning the main body upside down to remove the bottom case (A) and the bottom case (B), place a cushion beneath the main body so as not to scratch the top case

assembly, volume control knob or other parts.

Bottom

chassis

D

C

C

Fig.3

E

Bottom

case (A)

Claw b

C

Bottom

case(B)

(No.MB004)1-9

Page 10

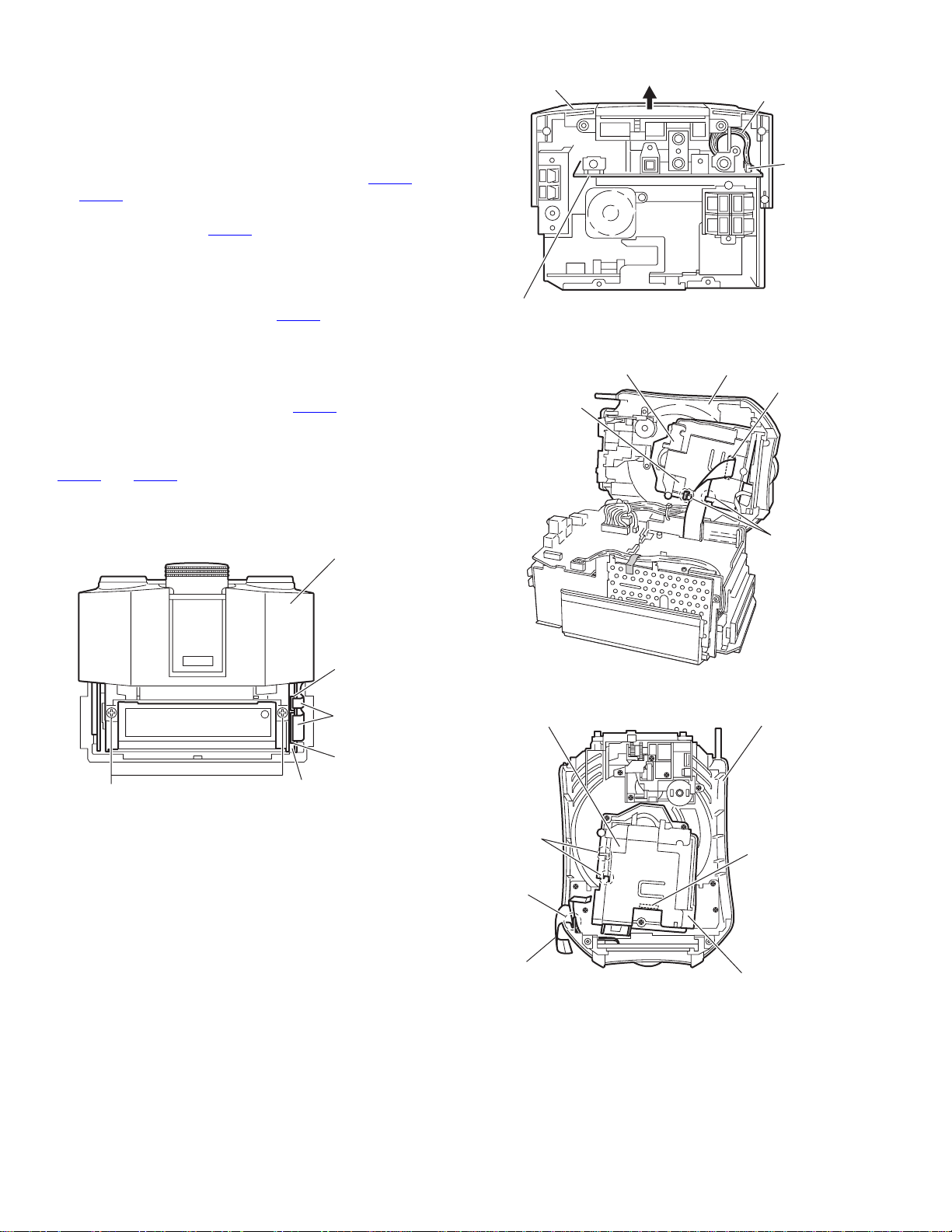

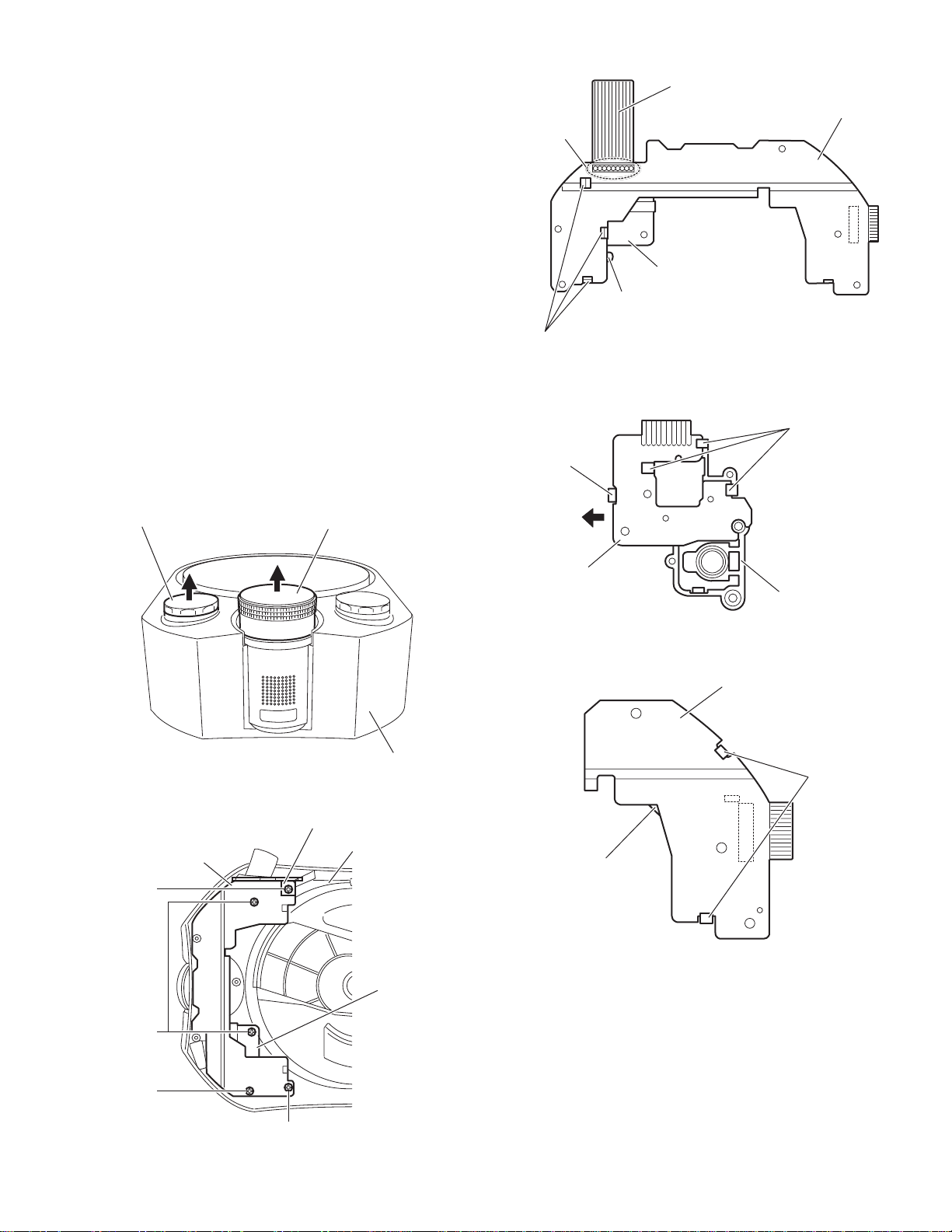

3.1.4 Removing the top case assembly

(See Figs.4 to 7)

• Prior to performing the following procedures, remove the rear

cover and bottom case (B).

(1) From the front side of the main body, remove the two

screws F attaching the top case assembly. (See Fig.4.)

(2) Disconnect the card wires from the connectors CN721

CN741 on the micon board. (See Fig.4.)

(3) From the back side of the main body, disco nnect the wire

from the connector CN451

Fig.5.)

(4) Remove the top case assembly while lifting it in the direc-

tion of the arrow. (See Fig.5.)

(5) From the inside of the to p case assembly, disconnect the

card wire from the connector CN651

board. (See Figs.6 and 7.)

Reference :

Reassembly of the top case assembly.

• Before reattaching the top case assemb ly to the main body,

connect the card wire to the connector CN651

board and hang it to the holder section c of the CD mechanism

assembly. (See Figs. 6 and 7)

• Let the card wire to be connected across the connectors

and CN741 go through the slit d on the top case as-

CN721

sembly. (See Fig. 7.)

on the function board. (See

on the CD servo

on the CD servo

and

Top case asembly

Function board

CD mechanism assembly

CD servo board

Wire

CN451

Fig.5

Top case assembly

CN651

F

Fig.4

Top case assembly

CN741

Card wires

CN721

Micon board

CD servo board

Holder

section c

Notch d

Card wire

Fig.6

Top case assembly

CN651

CD mechanism assembly

Fig.7

Holder

section

c

1-10 (No.MB004)

Page 11

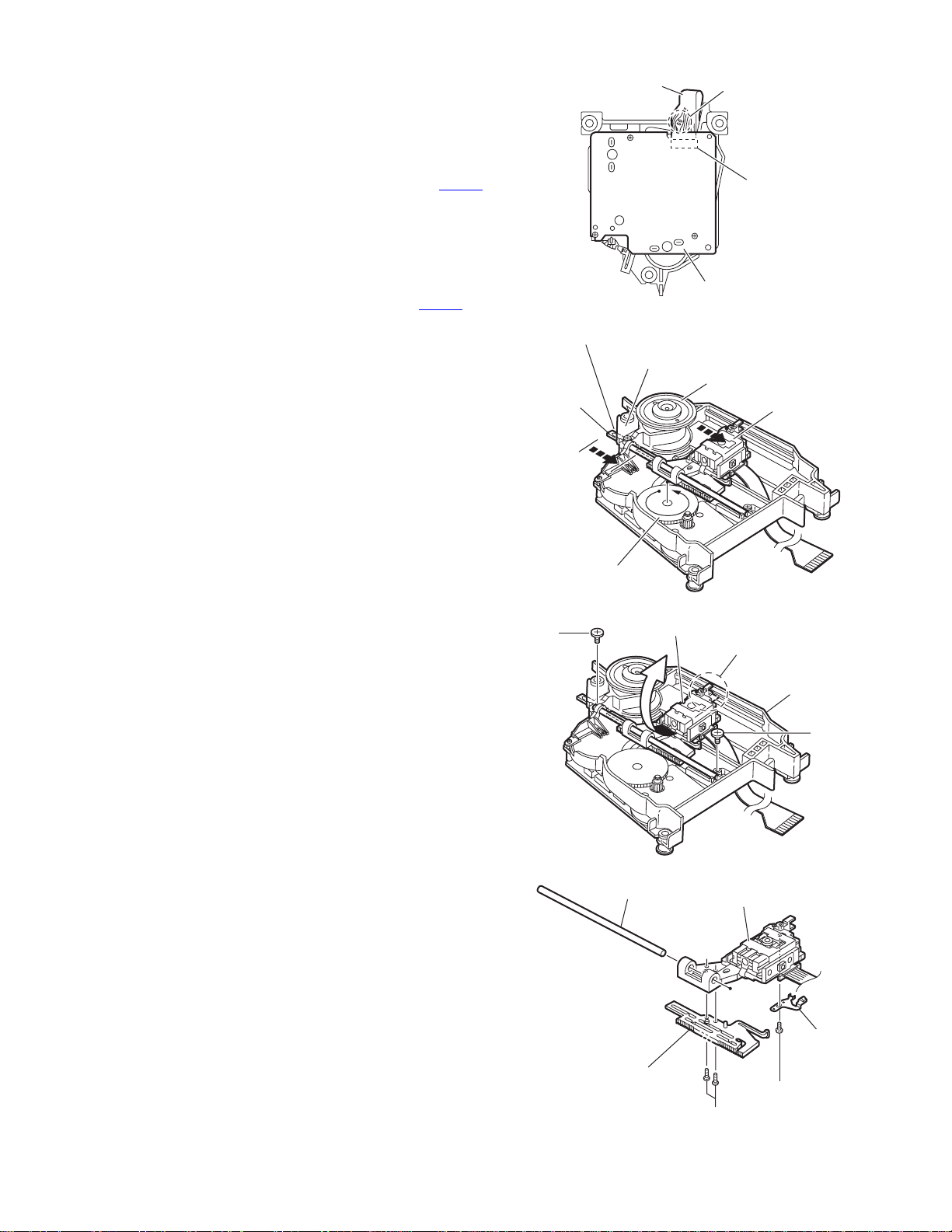

3.1.5 Removing the tuner

r

(See Fig.8)

• Prior to performing the following procedures, remove the rear

cover, bottom case (B) and top case assembly.

(1) From the right side of the main body, disconne ct the card

wire from the connector CN1

on the tuner.

CN1

3.1.6 Removing the function board

(See Fig.9)

• Prior to performing the following procedures, remove the rear

cover, bottom case (B) and top case assembly.

(1) From the top side of the main body, disconnect the fan mo-

tor wire from the connector CN942

(2) Disconnect the wires from the connectors CN893

CN895 on the function board.

(3) Remove the spacer and tie band fixing the wires.

(4) Disconnect the wire from the connector CN301

ital amplifier board.

(5) Remove the three screws G attaching the function board.

(6) Lift the function board in the direction of the arrow and dis-

connect it from the connector CN951

board.

Reference :

When connecting the fan motor wire, put it through the slit e of

the function board.

on the function board.

and

on the dig-

on the digital amplifier

Tie band

CN301

Wire

Card wire

Digital amplifier

board

Spacer

Fig.8

CN942

G

CN893

Fig.9

Tune

CN951

G

Wire

CN895

G

Slit e

Fan motor

Function board

Fan motor wire

3.1.7 Removing the micon board

(See Fig.10)

• Prior to performing the following procedures, remove the rear

cover, bottom case (A), bottom case (B) and top case assembly.

(1) From the right side of the main body, remove the tie bands

bundling the wires.

(2) Disconnect the wire from the connector CN805

con board.

(3) Disconnect the card wires from the connectors CN661

CN871 on the micon board.

(4) Disconnect the wire from the connector CN893

tion board.

(5) Remove the two screws H and two screws J attaching the

micon board.

(6) Pull the micon board toward this side, disconnect the con-

nectors CN801

Reference :

• After connecting the card wire to the connector CN661

the micon board, bend it as was done before disassembly

and insert it inside the center chassis.

• After connecting the wires to the connectors (CN805

CN893

) on the micon and function boards, bundle the wires

with the tie bands.

and CN802 on the micon board.

on the mi-

and

on the func-

on

Micon board

CN805

Wire

Tie bands

Fanction board

CN893

H

H

J

CN801

CN661

,

CN802

Card wire

Fig.10

J

CN871

Card wire

(No.MB004)1-11

Page 12

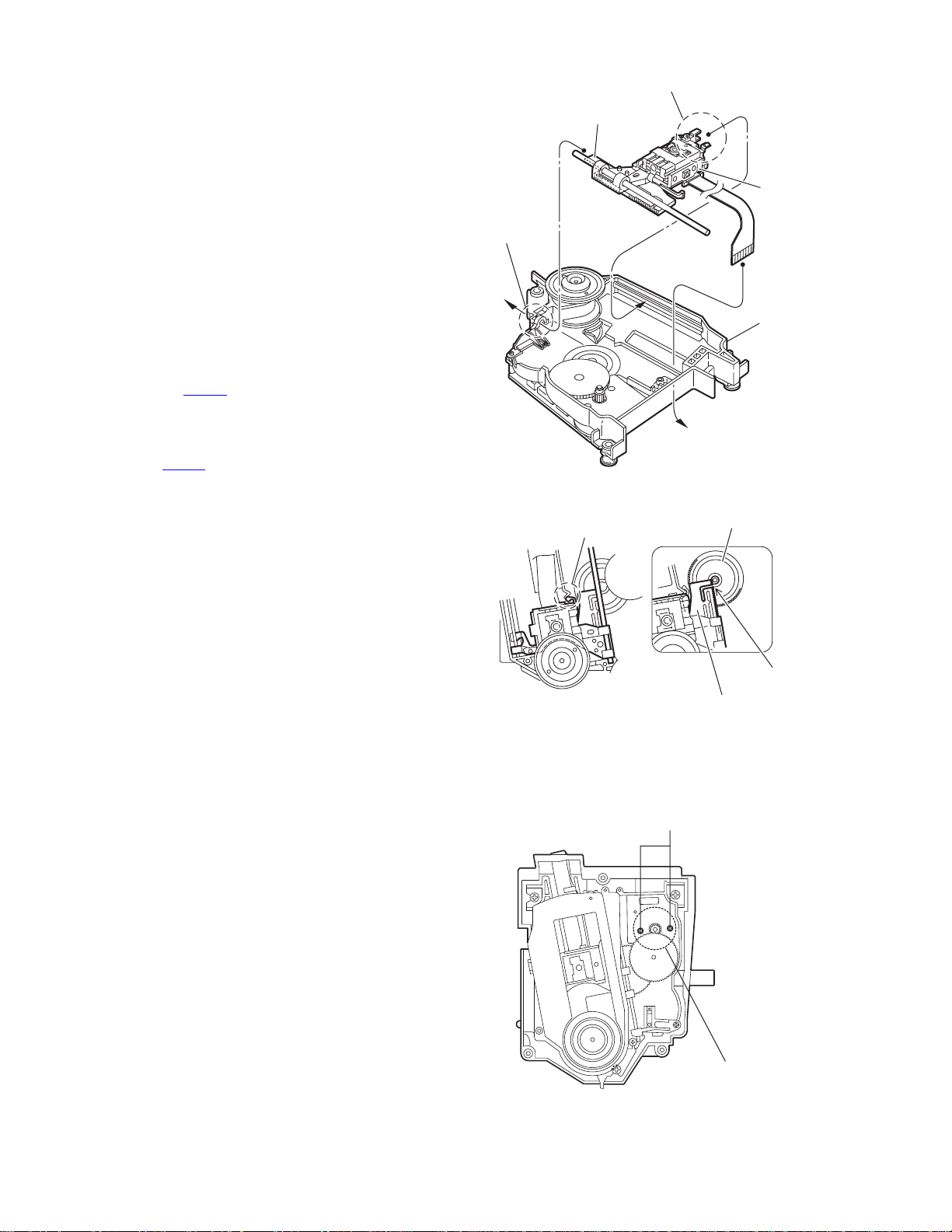

3.1.8 Removing the digital amplifier board

(See Fig.11)

• Prior to performing the following procedures, remove the rear

cover, bottom case (A), bottom case (B) and top case assembly.

(1) From the left side of the main body, disconnect the wire

from the connector CN301

(2) Remove the spacer and tie band fixing the wire.

(3) Remove the two screws K, two screws L and screw L' at-

taching the digital amplifier board.

(4) Pull the digital amplifier board toward this side, disconnect

the connectors CN961

board.

Reference :

• When attaching the screw L', attach the ea rth w ire togeth er

it.

• After connecting the wire, fix the wire with the spacer and tie

band.

3.1.9 Removing the power supply board

(See Figs.12 to 14)

• Prior to performing the following procedures, remove the rear

cover, bottom case (A), bottom case (B), top case assembly,

tuner, function board, micon board and digital amplifier board.

(1) From the top side of the main body, remove the two screws

M attaching the center chassis. (See Fig.12.)

(2) From the bottom side of the main bo dy, remove the two

screws N attaching the power supply board. (See Fig.13.)

(3) Disconnect the card wire from the connector CN903

power supply board. (See Fig.14.)

(4) Remove the three screws P attaching the power supply

board. (See Fig.14.)

(5) Remove the barrier (E) and barri er (F) under the power

supply board. (See Fig.14.)

Reference :

• Before attaching the each parts, pass the card wire through

the holes f on the center chassis.

• After attaching the center chassis, put the earth wire through

the slit g of the power supply board and sections h of the

center chassis.

Card wire

on the digital amplifier board.

and CN981 on the digital amplifier

on the

Hole f

Center chassis

Digital amplifier board

CN981

CN961

Earth Wire

L

N

N

K

Spacer

CN301

L'

Fig.11

Power supply board

Bottom chassis

Fig.13

Power supply board

P

Tie band

K

Wire

L

Card wire

Bottom chassis

Earth wire

1-12 (No.MB004)

Slit g

Fig.12

Section h

M

M

P

Barrier (E)

Barrier (F)

P

CN903

Fig.14

Page 13

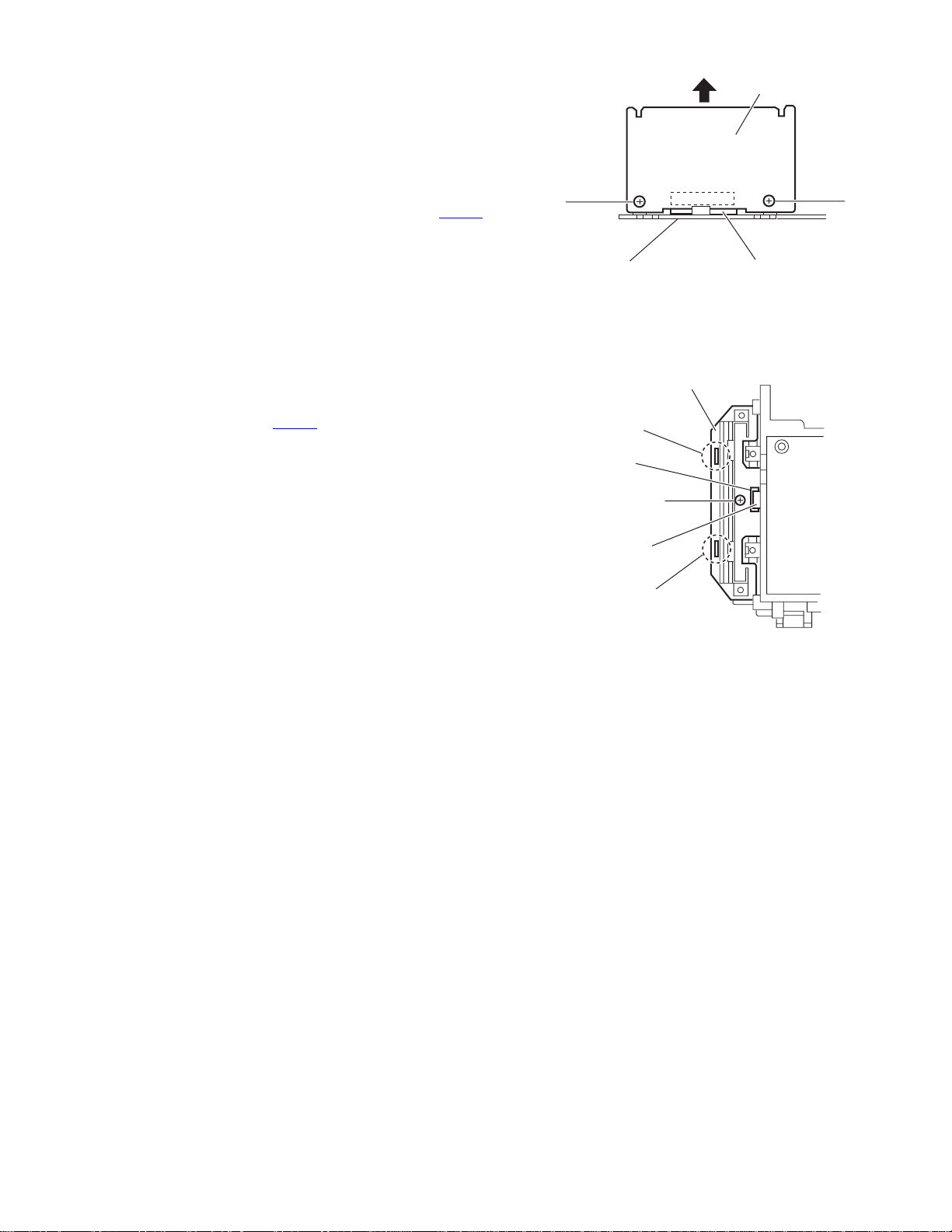

3.1.10 Removing the regulator board

(See Fig.15)

• Prior to performing the following procedures, remove the rear

cover, bottom case (A), bottom case (B), top case assembly,

tuner, function board, micon board, digital amplifier board and

power supply board.

(1) From the side of the power supply board, remove the two

screws Q attaching the regulator board.

(2) Disconnect the regulator board from the connector CN931

on the power supply board in the direction of the arrow.

Q

Regulator board

Q

3.1.11 Removing the FL board

(See Fig.16)

• Prior to performing the following procedures, remove the rear

cover, bottom case (B) and top case assembly.

(1) From the top side of the main bo dy, disconnect the card

wire from the connector CN751

(2) Remove the screw R attaching the FL board.

(3) Release the two engagement sections i of the bottom

chassis, take out the FL board.

on the FL board.

Power supply board

FL board

Engagement

section i

CN751

R

Card wire

Engagement

section i

CN931

Fig.15

Fig.16

(No.MB004)1-13

Page 14

3.2 Top case assembly section

• Prior to performing the following procedures, remove the top

case assembly.

Note :

Be careful not to scratch the top case, volume control knob or

other parts.

3.2.1 Removing the CD mechanism assembly

(See Fig.17)

(1) From the inside of the top case assembly, remove the three

screws S attaching the CD mechanism assembly.

(2) Take out the CD mechan ism assembly from the top case

assembly.

3.2.2 Removing the CD door mechanism assembly

(See Figs.17 and 18)

(1) Remove the cover in the direction of the arrow. (See

Fig.17.)

(2) From the inside of the to p case assembly, disconnect the

wire from the connector CN461

board. (See Fig.17.)

(3) Remove the three screws T attaching the gear bracket and

take out the gear bracket. (See Fig.17.)

(4) Remove the two screws U attaching the CD door mecha-

nism assembly and take out the CD door mechanism assembly. (See Fig.17.)

Reference :

Before attaching the CD door mechanism assembly, put the

wire through the two slits j of the CD door mechanism assembly and then attach the two screws U. (See Figs.17 and 18.)

on the CD door switch

Top case assembly

CD mechanism assembly

S

T

Gear bracket

U

Fig.17

CD door

mechanism assembly

CD door

mechanism

assembly

T

Cover

CD door

switch

board

CN461

Fig.18

Slits j

1-14 (No.MB004)

Page 15

3.2.3 Removing the CD door switch board

r

(See Fig.19)

• Prior to performing the following procedure s, remove the CD

door mechanism assembly.

(1) Disconnect the wire of the CD door motor from the connec-

tor CN452

(2) Remove the screw V attaching the CD door switch board.

(3) Release the CD door switch bo ard from the projection k

and then remove it from the engagement section m in the

direction of the arrow.

3.2.4 Removing the CD door motor

(See Figs.19 and 20)

• Prior to performing the following procedure s, remove the CD

door mechanism assembly.

(1) Disconnect the wire of the CD door motor from the connec-

tor CN452

(2) Turn over the CD door mech anism assembly and remove

the belt. (See Fig.20.)

(3) Remove the two screws W attaching the CD doo r motor.

(See Fig.20.)

Note :

Take care not to attach grease of the gears on the belt.

on the CD door switch board.

on the CD door switch board. (See Fig.19.)

CD door motor

Engagement section m

CD door mechanism assembly

CN452

Fig.19

CD door

mechanism assembly

CD door

switch board

Projection k

V

Belt

3.2.5 Removing the CD door assembly

(See Fig.21)

• Prior to performing the following procedure s, remove the CD

mechanism assembly and CD door mechanism assembly.

(1) From the inside of the top case assembly, remove the boss

p of the CD door assembly while extending the section n of

the top case assembly in the direction of the arrow.

(2) Remove the boss r of the CD door assembly while extend-

ing the section q of the top case assembly in the direction

of the arrow.

Section q

CD doo

motor

W

Fig.20

Top case assembly

Section n

Boss r

CD door assembly

Fig.21

Boss p

(No.MB004)1-15

Page 16

3.2.6 Removing the CD door LED board

(See Fig.22)

• Prior to performing the following procedures, remove the CD

mechanism assembly, CD door mechanism assembly and CD

door assembly.

(1) From the reverse side of the CD door assembly, remove

the five screws X attaching the CD door cover.

(2) Remove the screw X attaching the CD door LED board.

(3) After removing the CD door cover, remove the CD door

LED board from the projections (s, t) and take out it in the

direction of the arrow.

CD door cover

X

CD door

Projection s

X

CD door

LED board

3.2.7 Removing the front holder assembly

(See Fig.23)

• Prior to performing the following procedures, remove the CD

mechanism assembly.

(1) From the inside of the top case assembly, remove the two

screws Y attaching the front holder assembly.

(2) Take out the front holder assembly.

3.2.8 Removing the front board

(See Fig.24)

• Prior to performing the following procedures, remove the CD

mechanism assembly and front holder assembly.

(1) From the forward side of the front holder assembly, remove

the three screws Z attaching the front board.

Reference :

• Remove the card wire from the connector CN731

front board as required.

• Before attaching the front board, pass the card wire through

the hole u on the front holder assembly.

on the

X

Projection t

Fig.22

Front holder assembly

Y

Top case assembly

Fig.23

Front holder assembly

Z

Front board

Card wire

Z

1-16 (No.MB004)

Z

Fig.24

CN731

Hole u

Page 17

3.2.9 Removing the volume board and LED board

A

(See Figs.25 to 29)

• Prior to performing the following procedure s, remove the CD

mechanism assembly and front holder assembly.

(1) From the top side of the top case assembly, pull out the vol-

ume and function knobs. (See Fig.25.)

(2) From the inside of the top case assembly, remove the three

screws AA and screw AA' attaching the volume board.

(See Fig.26.)

Reference :

When attaching the screw AA', attach the barrier (D) together it.

(3) Remove the screw AA attaching the LED board. (See

Fig.26.)

(4) Take out the volume board together the LED board.

(5) From the reverse side of the volume board , release the

three claws v attaching the push button (A). (See Fig.27.)

(6) Remove the solders from the soldered section w on the vol-

ume board and disconnect the parallel wire. (See Fig.27.)

(7) Release the claw x of the push button (A) and remove the

LED board from the engagement section y of the push but-

ton (A) in the direction of the arrow. (See Fig.28.)

(8) Release the claw z of the button base (B) and remove the

button base (B) from the volume board. (See Fig.29.)

Soldered

section w

Claw v

Claw x

Parallel wire

Volume board

LED board

Push button (A)

Fig.27

Engagement

sections y

Function knob

Volume board

A'

Volume knob

Fig.25

Barrier (D)

Top case assembly

Top case assembly

LED board

LED board

Button base(B)

Fig.28

Volume board

Fig.29

Push button (A)

Claws

z

AA

AA

AA

Fig.26

(No.MB004)1-17

Page 18

3.3 CD mechanism assembly section

• Prior to performing the following procedures, remove the CD

mechanism assembly.

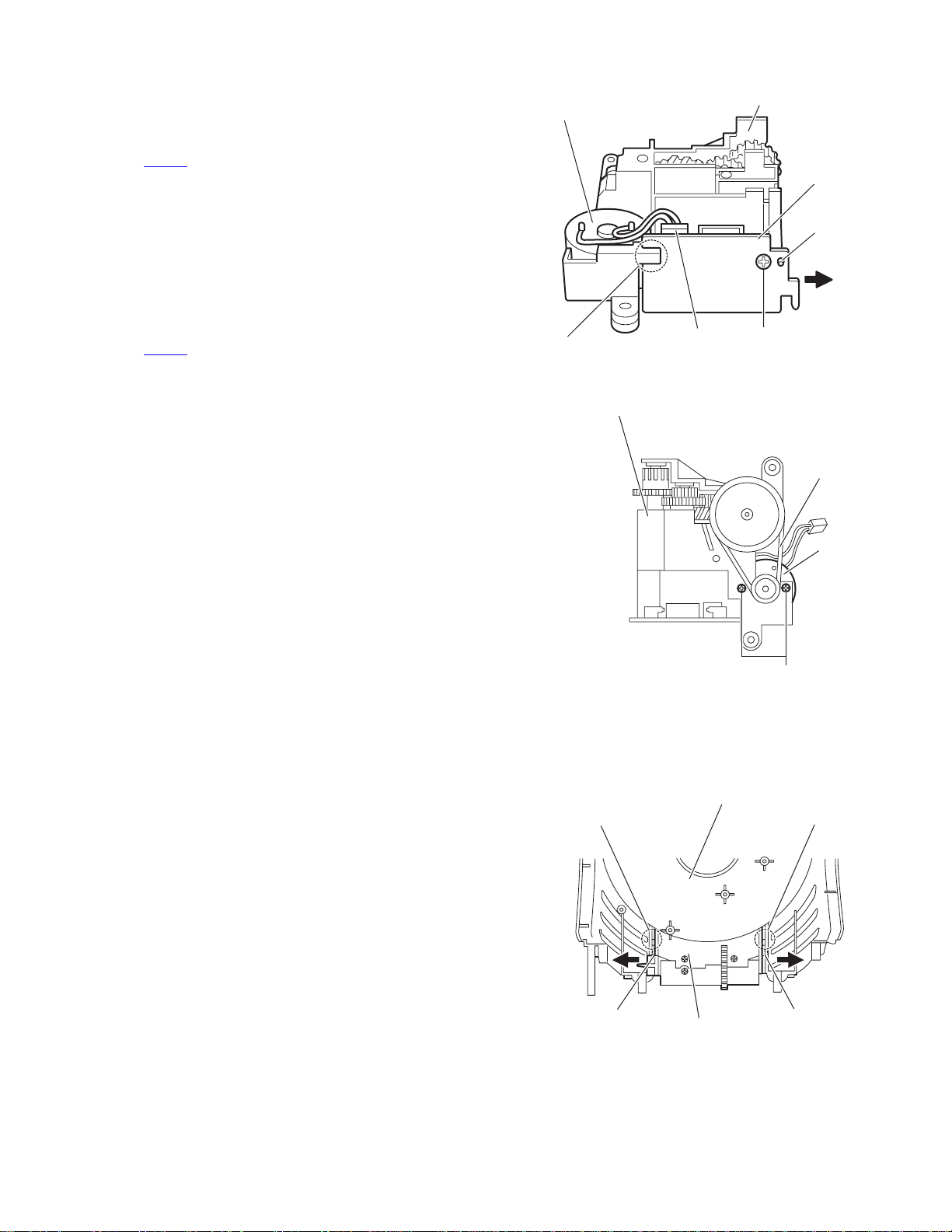

3.3.1 Removing the CD traverse mechanism assembly

(See Figs.1 and 2)

(1) From the forward side of the CD traverse mechanism as-

sembly, release the two join ts a attaching the pickup cover

to the CD traverse mechanism assembly. (See Fig.1.)

(2) Remove the three screws A attaching the CD traverse

mechanism assembly to the CD mechanism holder and

take out the CD traverse mechanism assembly. (See

Fig.1.)

Reference :

After attaching the assist spring to the CD mechanism holder,

attach the CD traverse mechanism assembly to the CD mechanism holder. (See Fig.2.)

A

CD traverse

mechanism

assembly

Joints a

3.3.2 Removing the CD servo board

(See Fig.3)

• Prior to performing the following procedures, remove the CD

traverse mechanism assembly.

Caution :

Be sure to solder the short land section b on the flexib le wire

before disconnecting the flexible wire fro m connector CN601

on the CD servo board.

If the flexible wire is disconnected without attaching solder, the

pickup may be destroyed by static electricity.

(1) From the reverse side of the CD traverse mechanism as-

sembly, solder the short land section b on the flexible wire.

(2) Disconnect the flexible wire from the connector CN601

the CD servo board.

(3) Remove the three screws B attaching the CD servo board.

(4) Remove the solders from the two soldered section c and d,

remove the CD servo board in an upward direction.

Caution :

When attaching the CD servo board, be sure to remove the

solder from the short land section b after connecting the flexible wire.

on

CD pickup cover

A

Fig.1

CD traverse mechanism assembly

CD mechanism holder

Fig.2

Flexible wire

B

soldered

section c

B B

soldered section d

CD traverse mechanism assembly

Fig.3

CD mechanism holder

Assist spring

Short land section b

CN601

CD servo board

1-18 (No.MB004)

Page 19

3.3.3 Removing the pickup assembly

(See Figs.4 to 7)

• Prior to performing the following procedure s, remove the CD

traverse mechanism assembly.

Caution :

Be sure to solder the short land section b on the flexible wire

before disconnecting the flexible wire from connector CN601

on the CD servo board.

If the flexible wire is disconnected without attaching solder, the

pickup may be destroyed by static electricity.

(1) From the reverse side of the CD traverse mechanism as-

sembly, solder the short land section b on the flexible wire.

(See fig.4.)

(2) Disconnect the flexible wire from the connector CN601

the CD servo board. (See fig.4.)

(3) From the top side of the CD traverse mechanism assem-

bly, turn the middle gear in the direction of the arrow so that

the pickup assembly is shifted to the reverse side of the

turn table assembly.

Move the pickup assembly until the section e of the rack

plate in the lower section of the pickup assembly comes out

of the chassis base assembly. (See fig.5.)

(4) Remove the two screws C attaching the shaft of the pickup

assembly. Next, disengage the hook f from the chassis

base assembly and then remove the pickup assembly with

the shaft. (See fig.6.)

(5) Pull the shaft out of the pickup assembly. (See fig.7.)

(6) Remove the two screws D attaching the rack plate to the

pickup. (See fig.7.)

(7) Remove the screw E attaching the P.S.spring to the pick-

up. (See fig.7.)

on

Rack plate

Section e

Middle gear

C

Flexible wire

CD servo board

Chassis base assembly

Pickup assembly

Short land section b

CN601

Fig.4

Turn table assembly

Pickup assembly

Fig.5

Section f

Shaft

Rack plate

Chassis assembly

C

Fig.6

Pickup

P.S.spring

E

D

Fig.7

(No.MB004)1-19

Page 20

3.3.4 Reinstalling the pickup assembly

(See Figs.8 and 9)

Reference :

Refer to the explanation of "Removing the pickup assembl y"

on the preceding page.

(1) Attach the P.S.spring and rack plate to the pickup.

(2) Insert the shaft into the pickup.

(3) Engage the hook f of the pickup assembly to the chassis

base assembly first, and set the section e of the rack plate

in the opening section g.

Then reinstall the pickup assembly while shifting it to the

turn table assembly side (inward) so that the section h of

the rack plate is positioned as shown in Fig.9.

(4) Move the pickup assembly to the center position and fasten

the shaft with the two screws C. (Make sure that the section

i of the rack plate is correctly engaged with the rack gear.)

(5) After passing the flexible wire of the pickup through the

opening section of the chassis base assembly, connect it

to the connector CN601

Note :

When reinstalling the pickup assembly, remove the solder

from the short land section b after connecting the flexible wire

to the connector CN601

on the CD servo assembly.

on the CD servo board.

Section f

Section e

Pickup

assembly

Section g

Chassis base

assembly

Fig.8

3.3.5 Removing the feed motor assembly

(See Fig.10)

• Prior to performing the following procedures, remove the CD

traverse mechanism assembly and CD servo board.

From the forward side of the CD traverse mechanism assembly, remove the two screws F attaching the feed motor assembly.

Section h

Rack gear

Section i

Rack plate

Fig.9

F

1-20 (No.MB004)

Feed motor assembly

Fig.10

Page 21

4.1 Test instruments require d for ad justment

(1) Digital oscilloscope

(2) Electric voltmeter

(3) Test disk : CTS-1000

4.2 Adjusting and confirming contents

4.2.1 Adjustment of the CD section

(1) Indication of the C1 error (CD test mode 1)

(2) Indication of the auto adjusting value (CD test mode 2)

(3) Cancellation of the test mode

4.2.2 System test mode (FL all lighting-up check)

4.3 Adjusting and confirming methods

4.3.1 Adjusting and confirming of the CD sectio n

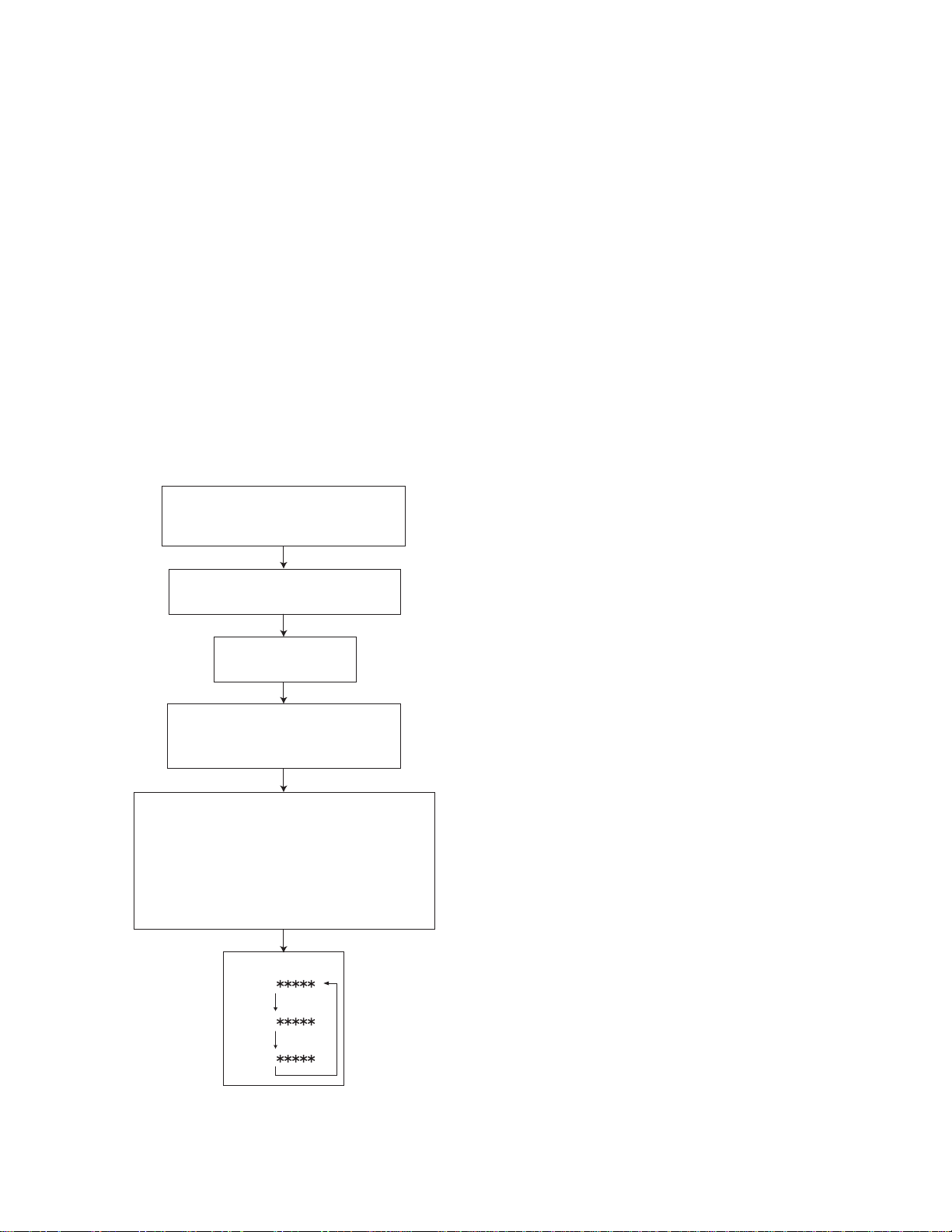

(1) Indication of the C1 error (CD test mode 1)

While pressing both the STOP and

AHB plus buttons on the main

unit, turn on the primary power supply.

SECTION 4

ADJUSTMENT

Press the STANDBY/ON button

on the main unit.

FL indication

CD TEST MODE 1

Press the OPEN/CLOSE button

on the main unit and insert the

test disc.

Press key 1, 2 or 4 of the remote control

unit to start measurement. The number of

error corrections will be displayed every 10

seconds.

Key 1: Normal-speed playback

Key 2: 2x-speed playback

Key 4: 4x-speed playback

FL indication

x1 Err

x2 Err

x4 Err

(No.MB004)1-21

Page 22

(2) Indication of the auto adjusting value (CD test mode 2)

While pressing both the STOP and

AHB plus buttons on the main

unit, turn on the primary power supply.

Press the STANDBY/ON button

on the main unit.

FL indication

CD TEST MODE 1

Wait a moment while keeping to

press the SET key on the remote

controller.

FL indication

CD TEST MODE 2

Press the SET key on

the remote controller.

FL indication

:

Description of the indication

:

Adjusting value

Each time the SET key

on the remote controller

is pressed, the indication

changes from FG to AOC1.

FG

Mantissa part of the focus gain

FEXP

Characteristic part of the focus gain

E2 status

E3 status

E1 status

FBAL

Adjusting value of the focus balance

FOFS

Adjusting value of the focus offset

FES

Disturbance amplitude during the focus gain adjustment

TG

Mantissa part of the tracking gain

TEXP

Characteristic part of the tracking gain

TBAL

Tracking balance adjusting value

TOFS

Tracking offset adjusting value

TES

Disturbance amplitude during the tracking gain adjustment

FAGC

Focus precise gain

ABC2

Tracking balance

ABC1

Focus balance

AGC2

Tracking coarse gain

AGC1

Focus coarse gain

AOC1

Focus offset

Press the CANCEL key

on the remote controller.

FL indication

CD TEST MODE 1

(3) Cancellation of the test mode

To cancel the test mode, press the STANDBY/ON button on the main unit.

1-22 (No.MB004)

Page 23

4.3.2 System test mode (FL all lighting-up check)

Go to the Adjustment Mode.

Press the "2", "STOP" and "STANDBY/ON"

keys on the remote controller simultaneously.

FL indication

All lighting-up

By pressing any of the keys on the

remote controller, the initial display

screen is resumed.

By pulling out the power supply cord of the

main unit the test mode will be canceled.

In the adjustment mode a 1-second real-time

increment sets the clock to gain 1 minute.

(No.MB004)1-23

Page 24

TROUBLE SHOOTING

5.1 Flow of functional operation until TOC read

Power ON

Disc play Key

Automatic tuning of FO offset and TE offset

SECTION 5

Slider turns REST

SW ON.

Laser ON

Detection of disc

Check Point

Confirm that the voltage at

the pin32 of IC251 is 0V.

(ON: 0V)

Tracking error waveform at TOC reading

IC601

20pin(TEOUT)

Approx.

1.4V

VREF

Disc status

to rotate

Approx. 3sec

Tracking

servo

off status

Automatic measurement

of TE amplitude and

automatic tuning of TE

balance

Tracking

servo

on status

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Confirm that the Focus error

S-curve signal at the pin32 of

IC651 is approx. 1.4Vp-p.

Confirm that the signal from

pin24 of IC651(one side of

R808) is 0V as a accelerated

pulse during approx. 640ms.

Confirm the waveform of the

Tracking error signal at the

pin20 of IC601(one side of

R604) (See Fig.1.)

1-24 (No.MB004)

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eye-pattern

at the pin5 of IC601

Page 25

5.2 Maintenance of laser pickup

(1) Cleaning the pickup lens

Before you replace the pickup, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

Is RF output

0.9 0.22Vp-p?

NO

Replace it.

5.3 Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Pickup Removal" on the previous page)

YES

O.K

(3) The level of RF output (EFM ou tput, amplitude of eye pat-

tern: pin5 of IC601) will be low.

(4) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to

match the characteristics of the whole optical block, do not

touch the semi-fixed resistor. If the laser power is lower

than the specified value, the laser diode is almost worn out,

and the laser pickup should be replaced. If the semi-fixed

resistor is adjusted while the pickup is functioning normally,

the laser pickup may be damaged due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3 seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at 5pin of IC601.

Finish.

(No.MB004)1-25

Page 26

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB004)

Printed in Japan

WPC

Page 27

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

FS-X3,FS-X1

CD-ROM No.SML200308

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

SP-FSX3 SP-FSX3CA-FSX3

SP-FSX1 SP-FSX1CA-FSX1

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

2-1

2-3

2-13 to 21

No.MB004SCH

2003/8

Page 28

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 29

< MEMO >

2-11

Page 30

Block diagram

F

F

/

R

Q

U

TUNER

MODULE

Front board

IC731

REMOCON

RECEIVER

STANDBY/ON

SWITCH

STANDBY

/POWER ON

LED

Volume board

VOL/FUNCTION

SWITCH

OPERATION

SWITCH

, , ,

CD OP/CL

AHB PRO

FW701

CN731

CN711

Micon board

L/R

CN871

TUDAIN

TUCLK

TUDAOUT

TUCE

CN741

KEY3

V.JOGA

V.JOGB

F.JOGA

F.JOGB

CN721

CDIND

FMIND

AMIND

LINEIND

KEY1 to KEY3

S-IND

P-IND

RMIN

VJOGA

VJOGB

FJOGA

FJOGB

CDIND

FMIND

AMIND

LINEIND

KEY1

KEY2

L8101,L8201

DOLBY

FILTER

IC801

SYSTEM

MICON

TUL

TUR

SMUTE

LMUTE

MT0

MT1

MTS

VOLCE

VOLCLK

VOLDATA

AHB1

CLSW

OPSW

BUZZER

TOPIND

OLOAD

MODON

F-SHIFT

PRT

THERM

CDDOUT

CDCMND

CDSTAT

CDREQ

CDCLK

CDRST

BUZZER

ALARM2

ALARM3

POWERFL

FLDATA

FLCLK

FLSTB

FLBK

POWER

INH

BSTCTL

BEAT1

BEAT2

FTU

MI+6.0V,A+10V

CD+7.5V

CDL

CDR

THERM

LINE OUT L/R

DIGITAL OUT

CN805

MOTOR

CN661

W803

CN802

CN801

J4311

LINE IN L/R

J4341

FAN

M

Function board

LINE OUT L

LINE OUT R

CDDOUT

CN895

CN942

Q9431

Q9432

FAN SW.

CN893

CD+7.5V

A+10V

MI+5V

CD servo board

OUTL

CN651

OUTR

TX

KCMND

M STAT

MRDY

KCLK

MCS

UNIT MICON

CN902

CN901

CN931

Q4111,Q4211

Q4311

L.O.MUTE

LMUTE

THERM

IC651

DIGITAL SERVO

PROCESSOR

MCLK,MDATA

MLD,/DMUTE

STAT,/RESET

FLAG,BLKCK

SUBQ,SQCK

IREFx4

IC251

BEAT1,BEAT2,INH

Q9011,TH910

THERM DET.

POWER

FTU

LSELO

LSERO

LINEINL

LINEINR

TUL/TUR

CDL/CDR

VOLCE

VOLCLK

VOLDATA

AHB1

SMUTE

MT0,MT1,MTS

OLOAD,MODON

F-SHIFT,PRT

&

TVD,ECM

ECS,TRD

FOD

Q9601 to

IC48

FUNCT

E.VO

TBAL,

GCTL,

BDO,A

BEAT-C

FLDATA

FLCLK

FLSTB

FLBK

&

2-1

FW701

INDICATOR

LED board

LINE,AM

FM,CD

CN941

M+6V

CD+7.5V

A+10V

Regulator board

Q9421 to Q9423

M6V

Q9701 to Q9707

CD7.5V

IC991

A10V REG.

Page 31

MT0

D

MT1

MTS

IC451

CD DOOR

MOTOR

DRIVER

OUT1

OUT2

CN451

CD door switch board

CN461

CD DOOR

SW

CN452

M

CD DOOR

MOTOR

Q1103

Q1203

Q3007

SMUTE

CN001

CD

WR471

CD door LED board

IC111 toIC113

IC121 to IC123

IC131

AMP.

IC301

IC302

FREQ.

CONT.

SMUTE

F-SHIFT

MODON

CD DOOR

BLUE

INDICATOR

IC132

HALF

BRIDGE

IC303

REG.

Q3002

Q3003

16V

CN981

2ch-SPEAKER

L/R

CN302

5V

CLSW,OPSW,TOPIND

IC481

FUNCTION

&

E.VOL

HPL

HPR

Q4101,Q4201,Q4301

H.P.MUTE

SMUTE

IC431

H.P.AMP.

Q4324

AMP MUTE

LOUT/ROUT

LOUT

ROUT

Q4321,Q4322

S.W.MUTE

IC492

AMP.

S

ON

T

AHB1

AHB

CONTROL

AHBCTL

AMPMUTE

HPL

HPR

SWOUT

LOUT

ROUT

J4301

HEADPHONE

JACK

J4321

SUB WOOFER OUT

JACK

Digital amplifier board

CN310

WR311

AHBCTL

OLOAD

CN951

PRT

CN961

CN605

TBAL,FBAL,FE,TE

GCTL,/RFDET,OFT

BDO,ARF,RFENV

IC601

RF&SERVO AMP.

DQSY,SBCK,SUBC

A+C,B+D

E,F,MD,LD

For CD TEXT

CN601

PICK UP

CM

RD

FOCUS & SPINDLE & FEED

IC801

& TRACKING BTL DRIVER

SM+,SMRM+,RM-

F+,FT+,T-

M

SPINDLE/FEED

MOTOR

601 to Q9604

BEAT-CUT

FLDATA

FLCLK

FLSTB

FLBK

CN903

CN751

DI751

FL TUBE

BSTCTL

/REST,/OPEN

Q9401,Q9403 to Q9407

BURST CONT.

Q9301,Q9302,Q9305

VDISP

POWER

IC931

FL3.5V REG.

POWERFL

REST/OPEN

SWITCH

T9200

POWER

TRANS.

D9101

IC901

SW.REG

CN971

L9101

F9101

Power supply board

CN900

AC IN

FL board

2-2

Page 32

Standard schematic diagrams

C

2

P

R

V

System control / Front / Key / Volume / LED section

0V

0V

0V

0V

0V

0V

0V

0V

TO TUNER MODULE

0V

0V

0V

LS712

QSW0993-001

S701-S706

1N4148WS

CN871

QGF1205F1-11

MPX

R

+9V

L

TUDAIN

TUCLK

TUDAOUT

TUCE

4.322MHz

RDSSTB

RDSDATA

RDSCLK

R7114 R7113

1k 1k

VJOGA

QSW0651-001ZQSW0651-001Z

QSW0651-001ZQSW0651-001ZQSW0651-001ZQSW0651-001Z

2SA1037AK/R/

0V

D8703

FTU

0V

L8101

QQR1372-001

MPX

C8704

0.1/16

R8701

470K

C8705

82P/50

R8702

X8701

C8706

47P/50

QAX0263-001Z

0.047/16

C8707

10K

R8704

C8708

10/16

INH

R7117

R7118

VJOGB

D+5V

5.4V

Q8701

9.9V

1N4148WS

9.2V

R8709

2.2K

9.1V

Q8702

UN2211

0V

DOLBY FILTER

L8201

QQR1372-001

RDS

B/E/EN/EV

0V

0V

0V

2.5V

1K

2.3V

0V

5.4V

5.4V

0.5V

0V 0V

R8703

10K

R7112 R7111

1k 1k

47K

47K

FJOGA

FJOGB

R7101R7102R7103

3.3K1.8K2K

DGND

0V

5.4V0V5.4V

5.4V

VJOGA

VJOGB

FJOGA

FJOGB

D8702

FS-X5

FS-X3

FS-X1

C8201

0.0056/50

C8101

0.0056/50

IC871

SAA6588T

MRD

NC

CIN

NC

SCOUNT

GND

VREF

OSCO

MPX

OSCI

AVSS

DVSS

AVDD

DVDD

DAVN

NC

GND

SDA

NC

SCL

FUNCTION SWVOL

LS711

QSW0992-001

R7115

R7116

S7101S7102S7103S7104

5.0V

5.0V

KEY1

KEY2

0.015/50

R8202

1k

R8201

5.1K

R8101

5.1K

R8102

1k

C8701

2.7V

560P/50

2.7V

0V

2.7V

2.7V

0V

0V

2.7V

0V

0.8V

CDIND

C8102

C8202

0V0V0V

FMIND

NI

C8202

C8102

330P/50

47K

47K

AMIND

R8204

R8104

C8703

LINEIND

*

*

*

*

R8104

R8204

2.2k

C8702

NI

QGF1016F3-13

CN711

CN721

QGF1016F2-13W

5.0V

KEY3

TUR

TUL

2.2/50

LVA10441-A4

KEY3KEY1

R7104

KEY2

3.3K

S7105S7106

CD OP/CL

AHB PRO

C8012

0.1/16

C8013

0.1/16

C8014

0.1/16

C8015

0.1/16

Q8404

2SC2812N/6/

R8010

VERSION

E

10K

47K

J/C

20K

US/UF/UB/UJ

15K 10K

UP/UT

UW

30K 10K

A

R8801

10K

INH&RESET

Q8801

UN2213

12.7V

R8804

33k

5.3V

0V

0.8V

CDIND

0V

FMIND

0V

AMIND

0V

LINEIND

C8011

0.01/50

MODON

F-SHIFT

INH

CDIND

FMIND

AMIND

S-IND

P-IND

LINEIND

FJOGA

FJOGB

VJOGA

VJOGB

5V

0V 0V

R8012

NONE

10K

10K

13K10K

R8802

10K

Q8802

5.4V

UN2214

0V

0V

0V

R8803

100K

LVA10441-A5 L

AM IND

D7204

SML-310VT/JK/-X

Q7204

0V

LINEIND

R8097 R8098

10K 10K

SMUTE

LMUTE

BSTCTL

2.2K

2.2K

2.2K

R8054

R8055

R8057

0V

5.3V

0V

DSP RESET

BURST MODE

AMP SOURCE MUTE

AMP LINE OUT MUTE

SUB SYSTEM CLOCK

GND

32.768kHz

32.768kHz

MNOD

0V

0V

2.6V

2.6V

22P/50

C8002

C8004

0.1/16

QAX0416-001Z

0V

8.2K

R8303

0V

FM IND CD IND

D7203

SML-310VT/JK/-X

2SC2812N/6/

AMIND

MTS

CLSW

OPSW

1K1K22K

2.2K

R8053

R8052

R8051

R8050

5.1V

CD DOOR

CD DOOR OPEN SW

CD DOOR CLOSE SW

CD DOOR MOTOR SPEED

FL SERIAL DATA OUT

NET MD CHIP SELECT

NET MD STATUS

NET MD COMMAND

NET MD SERIAL CLOCK IN

CD COMMAND

0V0V0V

3.7V

R8016

1K1K1K

X8001

QAX0401-001

C8003

CDCMND

22P/50

C8005

100/16

R8304

10K

C8307

0.001/50

D7202

SML-310VT/JK/-X

Q7203

2SC2812N/6/

0V 0.8V

FMIND

TUCE

MT1

MT0

TUCLK

TUDAIN

2.2K

1K1K1K

R8046

R8047

R8048

R8049

0V0V0V0V0V0V0V

CLOCK

DATA IN

C.ENABLE

TUNER

TUNER

TUNER

OPEN MOTOR

CLOSE MOTOR

TUNER DATA OUT

CD DOOR

FL LOGIC 5V ON/OFF

FL BLANKING

FL CLOCK

FL LATCH

NET MD&

MD RESET

MD STATUS

( RX)

MD COMMAND

( TX)

FUNCTION CD

FAN MOTOR ON/OFF

BEAT CUT

NET MD REQUEST

RDS CLOCK OUT

RDS DATA I/O

PC CONTROK KEY ON

HARD RESET

RDS STROBE

CD READY

PC CONTROL

KEY DISABLE

CONECTION

CD STATUS

CD SERIAL CLOCK

BUZZER/ALARM CONTROL1

CD RESET

0V

0.2V

4.8V

5.4V 0V

R8017

R8018

R8020

CDSTAT

CDCLK

CDRST

C8006

1000/10

R8094

47

CLOCK

USB

1K

100P/50

FW701

PRT

FTU

R8405 R8407

12K 22K

0.6V

0V

R8406

1K

C8802

4.7/25

0V

D8802

1N4148WS

CDIND

FMIND

AMIND

LINEIND

FW701

QUM036-10Z3Z3

R8071

R8072

R8073

R8075

R8076

R8077

R8078

R8079

R8080

R8081

R8082

1K

R8085

1K

R8086

1K

R8087

1K

R8088

BEAT1

R8091

TOPIND

BEAT2

MTS

LOCK

Q8405

2SA1037AK/RS/

0V

R8408

3.9K

Q8406

UN2212-X

INH

RESET

5.4V

Q8803

0V

UN2213

LINE IND

R7202

220

D7205

SML-310VT/JK/-X

5V 5V 5V 0V

Q7205

2SC2812N/6/

ALARM2

ALARM3

POWER2

POWERFL

C8018

2.2k

2.2K

2.2K

C8017

1500P/50

1500P/50

R8958

R8064

R8065

R8068

R8069

470K

820K

0V0V0V

0V

2.2K

MODULA-

5.3V

TION ON

FREQ

2.2K

0V

SHIFT

OVERLOAD

1K

4V

DETECT

0V

MD IND

2.2K

5.4V

AMP INH

2.2K

4.6V

CD IND

2.2K

0V

FM IND

2.2K

0V

AM IND

2.2K

0V

STANDBY IND( RED)

2.2K

POWER IND( GREEN)

5.4V

100

0V

FUNCTION TUNER

2.2K

0V

LINE IND

0V

0V

USB IND

0V

DSP RESET CONTROL

5.4V

FJOG INPUT A

5.4V

FJOG INPUT B

5.4V

VJOG INPUT A

0V

VJOG INPUT B

0V

DAVss

0V

BEAT CUT 1

3.3K

5V

CD DOOR IND

0V

BEAT CUT 2

0V

LINE INPUT

LEVEL ADJUST

5.4V

DAVdd

0V

ON/OFF

DAC EMPHA

ALARM CONTROL3

ALARM CONTROL2

A/D GND

KEY1

KEY2

5V

4.9V

2.2K

2.2K1K1K

R8001

R8002

2.7V

1K

R8003

5.3V

5.3V

0V

DSP DATA IN

FL POWER ON

DSP DIR/USB LOCK ERROR

MODEL DETECT

VERSION DETECT

LOCK DETECT

5V

1.0V

R8005

R8006

R8004

0V

0V 0V 0V 0V

R8957

10k

AHB1

OLOAD

VOLCE

VOLCLK

POWER

VOLDATA

1K

51K

2.2K

2.2K1K2.2K

R8061

R8062

R8063

R8059

R8058

0V

0V

5.4V

0V0V5.4V

POWER ON

VOL/DSP CLOCK

VOL/DSP DATA OUT

AHB PLUS CONTROL2

AHB PLUS CONTROL1

VOL/DSP CHIP ENABLE

SYSTEM MICON

IC801

OVER LOAD

MN101C49KKX1

MAIN SYSTEM CLOCK

A10V SAFETY

CD7.4V SAFETY

SAFETY3

Vdd

AD POWER

8.00[MHz]out

8.00[MHz]in

2.9V

2.7V

2.4V

5.4V

2.9V

2.8V

5.4V

1K

R8007

1/16

R8009

10K

0V

R8010

*

0V

R8092

10K

R8093

10K

C8301

0.001/50

0.001/50

*

10K

R8011

R8012

KEY1

KEY2

R8301

10K

Q8301 Q8302

0V 0V

C8302

Q8301,Q8302

C8001

SAFETY1

SAFETY2

D8001

MA152WK

X8301

C8303 C8306

8.00MHz

47P/50 47P/50

0V

C8304

C8305

27P/50

33P/50

R8302

8.2K

0V

2SC2814/4-5/2SC2814/4-5/

Q7202

2SC2812N/6/

HCMS

RM IN

C8008

C8007

100/16

CDIND

0V

5.4V

0.5V

4.5V

0V

3.9V

0V

0V

5.4V

0V

0V

0V

0V

0V

0V

0V

0V

5.4V

0V

0V

0V

1.5V

0V

0V

5.2V

R8095

10K

R8025

R8027

R8023

R8021

0.01/50

C8009

100P/50

1k

2.2K

ƒ

ƒ

10K

100

ƒ

R8960

ƒ

R8024

C8010

R8045

R8043

R8042

R8041

R8040

R8959

R8036

R8034

R8032

R8031

R8028

G

5.3V

RMIN

1K

100

100

100

100

47K

5.6K

2.2K

1K

2

2-3

LVA10441-A3

ƒ

MARKS

FS-X1,X3,X5

B/E/EN/EV

A/C/J/UT

US/UP/UF/UW

R8960 R8024 R8031 R8032

NI

/UJ

47k

1k 1k 1k

NI NI NI

Page 33

2

2

C

/

2

1

LVA10441-A6

red green

REMOCON

GP1UM271XK

IC731

5.3V

5.4V

RMIN

0V

C7301

100/16

820

R7305

D7302

EL-19-21SDRC/-X

2SC2812N/6/

5V

0V

0V

Q7302

POWER ON LEDSTANDBY LED

R7304

D7301

LNJ308G8J-X

5V

0V

S-IND

220

Q7301

0.8V

2SC2812N/6/

P-IND

RMIN

S-IND

P-IND

R7301

1.8K

KEY3

S7301

KEY3

QGF1036F1-07

CN731

POWER

QSW0651-001Z

R1

47K 47K

10K 10K

22K 22K

10K

R2

47K

}

¶

INHRESET

UN2213R1

R2

UN2211

UN2212

UN2214

NOTES

1.VOLTAGE ARE CD-MEASURED WITH A DIGITAL

VOLT METER WITHOUT INPUT SIGNAL.

CONDITION - CD STOP MODE

2.UNLESS OTHERWISE SPECIFIED.

RESISTORS ARE 1/16W 5% METAL GLAZE RESISTOR.

ALL RESISTANCE VALUES ARE IN OHM( ) .

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN F( P=pF) .

ALL INDUCTANCE VALUES ARE IN H( m=mH) .

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE

( F) /RATED VOLTAGE ( V) .

0V0V0V

CN741

0V

5V

QGF1016F2-07W

0.8V

5.4V

CDDOUT

P-IND

KEY3

S-IND

RMIN

R8045

1K

R8043

100

R8042

100

R8041

100

R8040

100

R8959

47K

R8036

5.6K

R8034

2.2K

R8032

ƒ

R8031

ƒ

0K

R8028

100

R8960

R8024

3

1

K

8010

1/50

9

50

TUDAOUT

FLBK

FLCLK

FLSTB

FLDATA

FS-X5

FS-X3

FS-X1

C8612

10/50

10/16

Q8612

2SC2812N/6/

FCD

D8012

1N4148WS

RDSCLK

RDSDATA

1K

RESET

RDSSTB

CDREQ

RMIN

R8096

10K

CPH3121-X

7.4V

6.6V

R8613

680

0V

Q8611

5.2V

C8612

CD+5V

*

D8611

MA3033/H/

3.1V

R8611

R8612

15K

C8611

47/16

10K

D8612

1N4148WS

CDCMND

CDSTAT

CDREQ

CDCLK

CDRST

FCD

CDL

CDR

C8601

0.1/16

QGF1036F1-19

R8601

100

R8602

100

R8603

100

R8604

100

R8605

100

R8606

100

R8111

220

R8211

220

MI+6V

A+10V

CD+7.5V

CN661

3.9V

0.3V

2.1V

4.9V

0V

1.7V

0.3V

5.2V

5.2V

0V

0V

TO CD MECHA

1.6V

0V

0V

1.6V

0V

0V

7.4V

7.4V

CN801

QGB2024K1-06S

0V

6.1V

10.0V

0V

7.5V

0V

OF

TO CN901

LVA10440-A1

C8901

2200P/50

ALARM25VALARM3

BUZZER

R8954

100K

SAFETY

SAFETY1

SAFETY2

68K

R8904R8903

39K

27K 68K

R8901 R8902

D8004

MA152WA

MI+6V SW

Q8901

2SA1362/G/

6.1V 6.1V

R8911

12K

4.4V

POWER2

D8006

MA152WK

5.4V

0V

Q8902

UN2211

0V

POWERFL

FLDATA

FLCLK

FLSTB

FLBK

POWER

INH

BSTCTL

BEAT1

BEAT2

THERM

FTU

QJK005-061601

CN805

QGA2008F1-26

MODON

F-SHIFT

PRT

THERM

MT0

CDL

0V0V0V

1.6V

TUR

TUL

SMUTE

0V

1.0V

TO CN895 OF LVA10440-A2

MT1

0V

0V

MTS

VOLCE

LOCK

0V0V0V

0V

0V

VOLCLK

VOLDATA

0V

LMUTE

0.3V

AHB1

CDR

1.6V

CLSW

5.4V

OPSW

0V

BUZZER

TOPIND

5.4V

CDDOUT

1.7V

5.4V

OLOAD

4.0V

0V

0V

0V

4.0V

A+10V

WR803

QGB1214J1-12S

CN802

4.9V

3.8V

4.5V

0V

0.5V

4.6V

12.7V

5.0V

0V

0V

0V

0V

10.1V

0V

7.6V

0V

TO CN893

5.5V

0V

OF

OF

TO CN902

LVA10440-A2

LVA10440-A1

2-4

Page 34

Function / CD door switch / CD door LED / AHB control section

HEADPHONE

LINE OUT

LINE IN

SUB WOOFER OUT

DIGITAL OUT

J4301

QNS0170-001

J4311J4311

QNS0077-002QNS0077-002

C4211

150P/50

C4212

150P/50

C4311

0.01/50

EB431

E409182-001SM

QNN0284-001

J4321

C4321

C4323

0.01/50

J4321

J4341

GP1FA550TZ

C4342

10/10

0V

5.2V

1.7V

R4341

100

C4111

C4112

R4323

0.01/50

C4341

NI

1k

R4215

R4115

150P/50

150P/50

D4311

MA153

R4322

*2

*2

*2

*2

*2

*2

R4214

R4114

6.8k

1K

1K

Q4211

2SC3661

22K

22K

0V

0V

Q4321

2SC3661

L4201

B1026

B1025

L4101

B1027

L4301

R4216

R4221

0V

68K

R4121

0.8V

UN2211

*

LINE OUT MUTE

0.8V 0.8V

R4211

0V

68K

R4116

22k

R4321

2.2k

1.3V

Q4323

0V

D4341

1SS388

2.2K

Q4102

2SC3661 2SC3661

0V

0.8V 0.8V

0V

*

C4205

C4105

R4212

0V

R4111

0V

Q4111

2SC3661

Q4322

UN211E

22k

4.8V

1.3V

Q4324

UN2111

1.3V

0V

0V

2.2K

LINEINL

LINEINR

1.0V

R4324

4.7k

4.9V

R4107

3.9K

R4112

D4321

1SS355

0.01/50

3.9K

5.4V

C4312

Q4202

0V

2.2K

0V

Q4311

UN2113

R4106

R4208R4108

2.7K2.7K

HPSW

5.5V

0.3V

LMUTE

SMUTE

AMPMUTE

HPSW

CDDOUT

22

VOLCLK

VOLDATA

VOLCE

R4207

R4217

H.P.AMP

R4203

C4203

150P/50

5.0V

5.0V

R4205

*

OUT2

-IN1

C4102

150P/50

C4802

47/16

2.2k

C4202

R4204

*

3.3k

5.0V

5.0V

10K 9.1K

0V

C4801

VEE +IN2

47/16

R4104

R4103

2.2k

22/16

3.3k

C4231

0.1/25

C4232

R4231

R4302 R4301

7.5K

0.0012/50

0.1/25

C4234

-IN2

+IN1

5.0V

*

C4204

220/10

2.2K

R4206

22

C4104

220/10

C4106

C4206

*

*

HA17558AF

IC431

9.6V

VCC

OUT1

5.0V

R4105

*

C4103

47K

47K

R4117

R4804

10

D4801

GS1J-X

C4303

4.7/25

C4236

47/16

TUR

10/16

C4237

4.7/25

C4302

100/16

CDR

10/16

C4238

R4303

150

C4201

BUZZER

0.1/16

C4239

C4101

4.7/25

LINEINR

C4240

10/16

( 1/4W)

R4202

2.2K

R4102

2.2K

9.9V

D4301

UDZS6.8B

Q4201

2SC3661

0.8V

0.8V

Q4101

2SC3661

Q4301

UN211L

7.7V

0V

0V

0V

0V

10.1V

H.P.MUTE

4.7/25

C4301

R4201

R4109 R4209

R4101

*

*

*

*

R4250

0

C4233

0V0V0V

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

4.9V

RTRE

LTRE

4.9V

C4133

RIN

LIN

4.9V

0.1/25

0.0012/50

4.9V

4.7/25

C4136

LSERO

LSELO

4.9V

10/16

C4137

4.9V

CDR

TUR

LINER

BUZZER

TUL

CDL

BUZZER

LINEL

NC NC

0V

4.9V

4.9V

4.9V

10/16

10/16

0.1/16

C4140

C4138

C4139

LINEINL

TUL

CDL

BUZZER

FS-X1

FS-X3

R4150

R4157

R4257

3.3k

2.2k

0

R4801

LC75342M-X

IC481

2.2K

R4802

9.8V

CL

DICEVSS

0V0V0V

2.2K

R4803

VDD

ROUTNCVref

RBASS1

RBASS2

TEST

LOUT

LBASS2

LBASS1

0V

4.9V

4.9V

4.9V

C4132

0.1/25

2.2K

22/16

7.5K

C4131

C4134

R4131

2-5

D4704

UDZS6.8BUDZS6.8B

D4702,D4704

CD DOOR

SELU1E54CM-SSELU1E54CM-S

D4701,D4703

BLUE IND

D4703

D4702

4.3V 4.3V

4.0V 4.0V

Q4702

2SC2812N/6/

390

390

R4705

R4704

4.7V 4.7V

LVA10440-A5

CD DOOR SW

D4701

390

390

R4702

R4701

GS1J-X

Q4701

2SC2812N/6/

CD DOOR MOTOR

Q4703

2SC2812N/6/

4.7V

5.3V

CN452

QGA2501C1-02

D4503D4506

CRS01-W

S4501

QSW0518-001

S4502

QSW0518-001

6.7V

R4707

10K

WJK0154-001A

R4709

2.2K

LVA10440-A7

WR471

CN461

QGA2001F2-05X

1.6V

1.6V

0V

0V

5.4V

CN451

QGA2001C1-08

5.4V

0V

7.6V

CLSW

OPSW

TOPIND

4.4V

0V

3.3

R4509

3.3

R4507

1.1V

3.3

R4508

CD DOOR MOTOR DRIVER

IC451

!

TA8409F-W

0V

IN2

6.7V

VCC

OUT2

0V

NC

0V

GND NC

R4502

15k

47/10

C4502

0V

IN1

4.4V

VREF

1.1V

OUT1

6.7V

VS

0V

R4501R4503

11k20K

MT0

MT1

Q4501

2SC2812N/6/

MTS

0V

LOCK

3.3

R4510

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

FUNCTION & E.VOL

D4502D4501

GS1J-X GS1J-X

R1

R2

R1 R2

UN2111

10K 10K

UN2113 47K 47K

UN211L

4.7K

47K 22K

UN211E

R1

4.7K

R2

Page 35

C4301

.7/25

UTE

R4201

R4109 R4209

R4101

CN895

QGA2008C1-26

CDR

1.6V

0V

CDL

1.6V

TUR

0V

TUL

0V

SMUTE

*

*

*

*

* MARKS

B/E/EN/EV

A/C/J/UT

US/UP/UF/UW

*2 MARKS

FS-X3,X1

FS-X3,X1

C4102

C4202

0.0033/25

/UJ

150P/50

QQL231K-470YJ/C

OTHER NI

L4101

L4201

L4301

C4106

C4206

0.0047/25

C4105

R4105

C4205

R4205

0.001/50

NI

B1025

B1026

B1027

NI

0

10k

NI

1k

R4101

R4201

3.3k

R4109

R4209

4.7k

22k

NI

MT0

MT1

MTS

LOCK

VOLCE

VOLCLK

VOLDATA

LMUTE

AHB1

CLSW

OPSW

BUZZER

TOPIND

CDDOUT

OLOAD

MODON

F-SHIFT

THERM

1.0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

5.4V

0V

5.4V

1.7V

TO CN805 OF LVA10441-A3

5.4V

4.0V

0V

4.0V

PRT

0V

0V

R4261

R4161

300k

R4265

220K

300k

R4913

150

( 1/4W)

R4165

220K

C4912

47/10

4.7V

C4166

10/16

R4164

1k

R4163

15k

0V

Q4161

2SC2812N/6/

D4911

MA152WK

2SC2812N/6/

0V

9.6V

VCC

OUT1

0V

0V

R4166

R4264

4.7V

4.7V

820

0V

0V

OUT2

-IN1

Q4261

R4263

15k

1k

C4266

10/16

R4266

4.7V

4.7V

C4263

0.1/16

MY

R4277

C4262

0.1/16

MY

C4265

22/16

IC492

HA17558AF

C4165

22/16

R4177

47K

47K

ROUTLOUT

AMPMUTE

OLOAD

MODON

F-SHIFT

PRT

820

+IN2

-IN2

VEE

+IN1

0V 4.7V

C4162

0.1/16

MY

C4163

0.1/16

MY

THERM

R4919

AHB CONTROL

R4918

5.1K

100K

FAN SW

Q9431

!

2SA1037AK/R/

7.2V

7.2V

0V

Q9432

UN2212

R9431

2.2K

0V7.6V

0V

QGA2501C1-06

QJK034-042204

QGB1214K1-06S

QGA2001C1-02

C9431

10/16

A+10V

AGND

CD+7.5V

MGND

MI+5V

DGND

CN893

ROUT

AGND

LOUT

AHBCTL

WR311

CN942

CN951

10.1V

0V

7.6V

0V

5.5V

TO W803 OF

LVA10441-A3

0V

0V

0V

0V

0V

TO CN310 OF

LVA10441-A1

1.3V

5.4V

4.0V

0V

4.0V

TO CN961 OF

LVA10441-A1

0V

FAN MOTOR

QAR0272-001

R4250

0

R4157

R4257

S-X1

3.3k

S-X3

2.2k

R4150

0

C4155

C4255

0.039/16NINI

R4155

1k

R4255

C4255

MY

MY

C4256

C4156

C4256

0.01/16

MY

1k

*

R4257

*

*

AHB

C4156

C4155

R4157

*

*

1k

R4901

C4901

47/16

D4901

UDZS4.7B

*

C4913 C4915

10/16 1/50

AHB1

NOTES

1.VOLTAGE ARE CD-MEASURED WITH A DIGITAL VOLT METER WITHOUT INPUT SIGNAL.

CONDITION - CD STOP MODE

UN2211

UN2212

R1R2R2

10K 10K

22K 22K

R1

RESISTORS ARE 1/16W 5% METAL GLAZE RESISTOR.

ALL RESISTANCE VALUES ARE IN OHM( ) .

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN F( P=pF) .

ALL INDUCTANCE VALUES ARE IN H( m=mH) .

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE

( F) /RATEDMYVOLTAGE ( V) .

2.UNLESS OTHERWISE

SPECIFIED.

}

¶

INHRESET

LVA10440-A2

2-6

Page 36

Digital amplifier section

0

2

N

1K1K

E

T

m

S.MUTE

2SD1328/ST/-X

Q1203

R1234

8.2K

R1233

15K

Q1103

Q1203

1

To W311 of

LVA10440-A2

LINE

2ch

QGA2001F2-04X

CN310

R

GND

L

AHBCTL

CN310

1

2

3

4

1.4

2

4.4

3

4.9

0

0

0

0

R1133

( A.GND)

S.MUTE

2SD1328/ST/-X

Q1103

R1134

8.2K

15K

( A.GND)

R1235

2.2K

R1135

IC131

2.5

3.1

2.4

1.8

5.0

0

180P/50

R1210

820

5V

( A.GND)

IC121

NJM4580M-X

5V

R1309

R1310

2.7K 1.8K 2.7K

180P/50 3.3K

R1110

820

5V

( A.GND)

IC111

NJM4580M-X

1

2

3

4

5

6

7

8

C1232

R1236

3.3K

R1211

8.2K

R1212

5.6K

R1213

5.6K

C1132 R1136

R1111

8.2K

1200P/50

R1112

5.6K

R1113

2.5

2.5

0

2.5

2.5

2.5

4.9

R1311

C1107

5.6K

R1117,R1217

R1215

R1216

R1115

R1116

C1203

2200P/50

A16V

IC121

NJM4580M-X

C1204

470P/50

C1103

2200P/50

A16V

IC111

NJM4580M-X

R1107

C1104

470P/50

R1207

10K

10K

4.7/35

R1208

330

4.7/35

R1108

330

Q1104

Q1204

1

2

3

4

5

C1205

Q1204

UMY1N-W

C1105

Q1104

UMY1N-W

IC111

IC121

1

7.9

2