Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB20520044

FS-S57

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB205

2004/4

Page 2

SPECIFICATION

Amplifier Section

CA-FSS57

Tuner FM tuning range 87.5 MHz-108.0 MHz

CD player CD Capacity 5 CDs

General Power requirement AC 120 V , 60 Hz

Speaker Section

SP-UXS57

Output Power 74 W per channel, min. RMS, driven into 6 Ω at 1 kHz with no more

than 10% total harmonic distortion.

Analog input sensitivity/Impedance (at 1 kHz) AUX/DVD:400 mV/48 kΩ

Speakers/Impedance 6 Ω - 16 Ω

AM tuning range 530 kHz-1 710 kHz

Dynamic range 87 dB

Signal-to-noise ratio 90 dB

Wow and flutter Immeasurable

Power consumption 110 W (at operation)

17 W (on standby)

1.4 W (in power save mode)

Dimensions (W/H/D) (approx.) 175 mm × 239.5 mm × 378 mm (6 15/16 in. × 9 1/2 in. × 14 15/16 in.)

Mass (approx.) 7.4 kg (16.3 lbs)

Type 2-way bass-reflex type

Speakers Woofer 12 cm cone × 1

Tweeter 4 cm cone × 1

Power handling capacity 60 W

Impedance 6 Ω

Frequency range 53 Hz to 30 kHz

Sound pressure level 84 dB/W·m

Dimensions (W/H/D) (approx.) 145 mm × 239.5 mm × 202 mm (5 3/4 in. × 9 1/2 in. × 8 in.)

Mass (approx.) 2.2 kg (4.9 lbs) each

Design and specifications are subject to change without notice.

1-2 (No.MB205)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

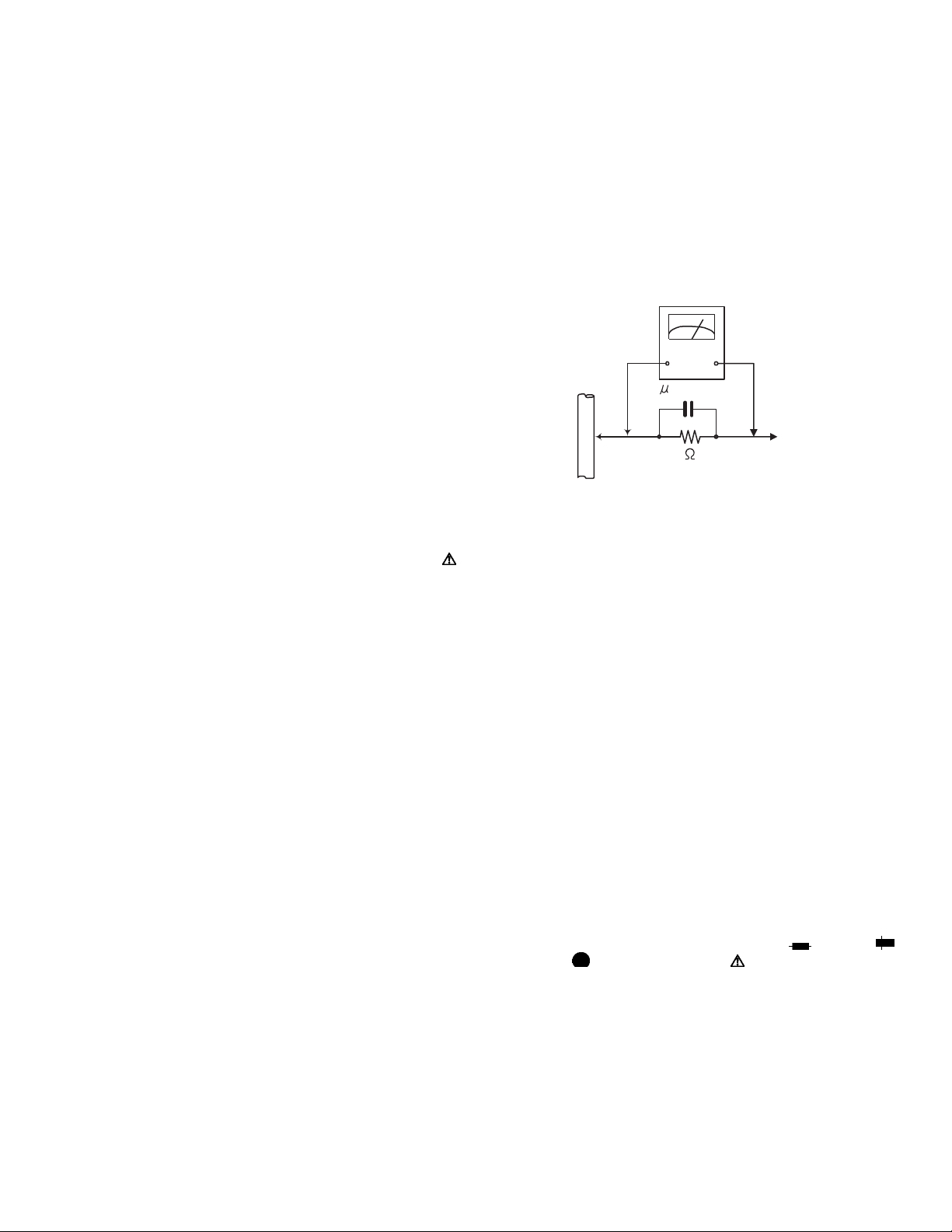

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB205)1-3

Page 4

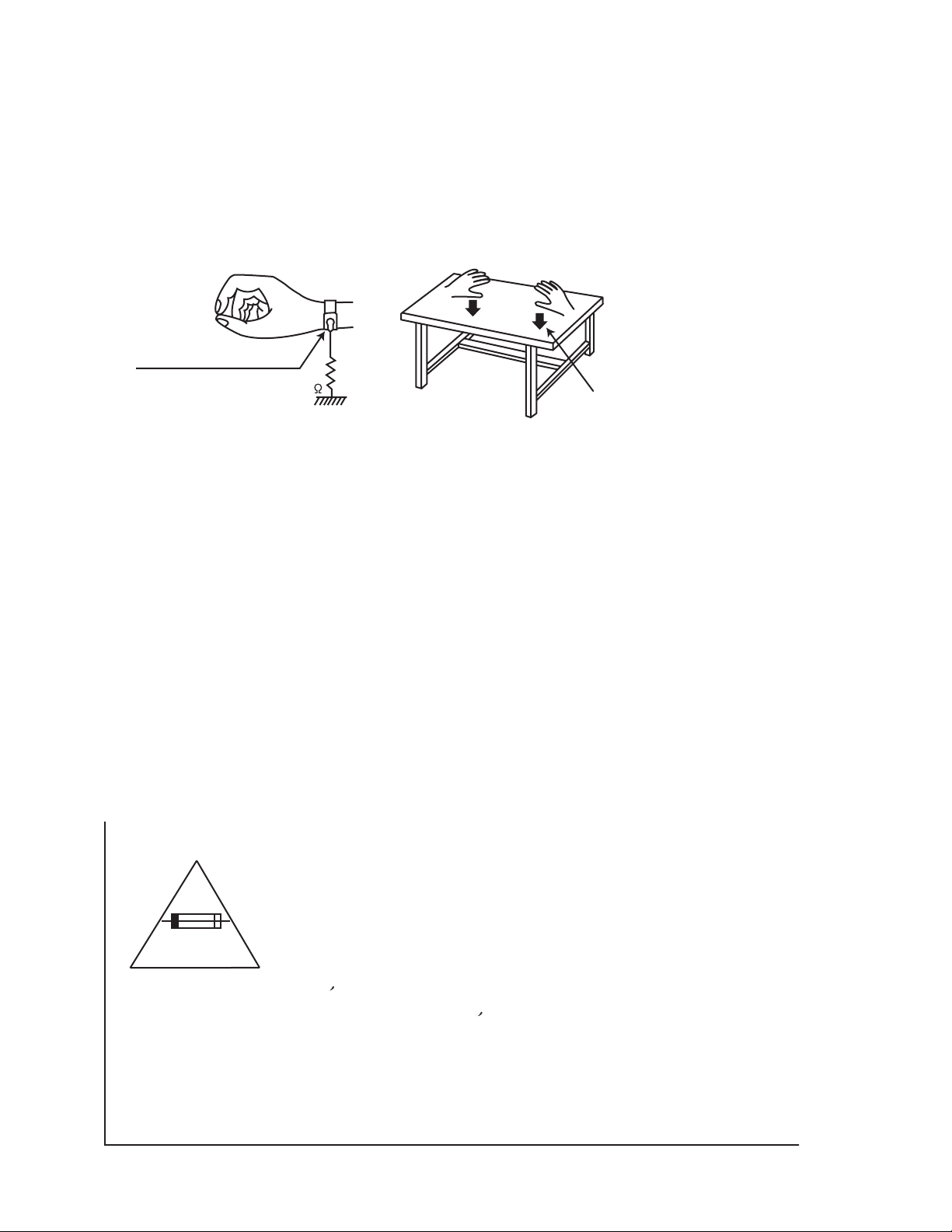

1.5 Preventing static electricity

.

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Conductive material

(conductive sheet) or iron palate

1-4 (No.MB205)

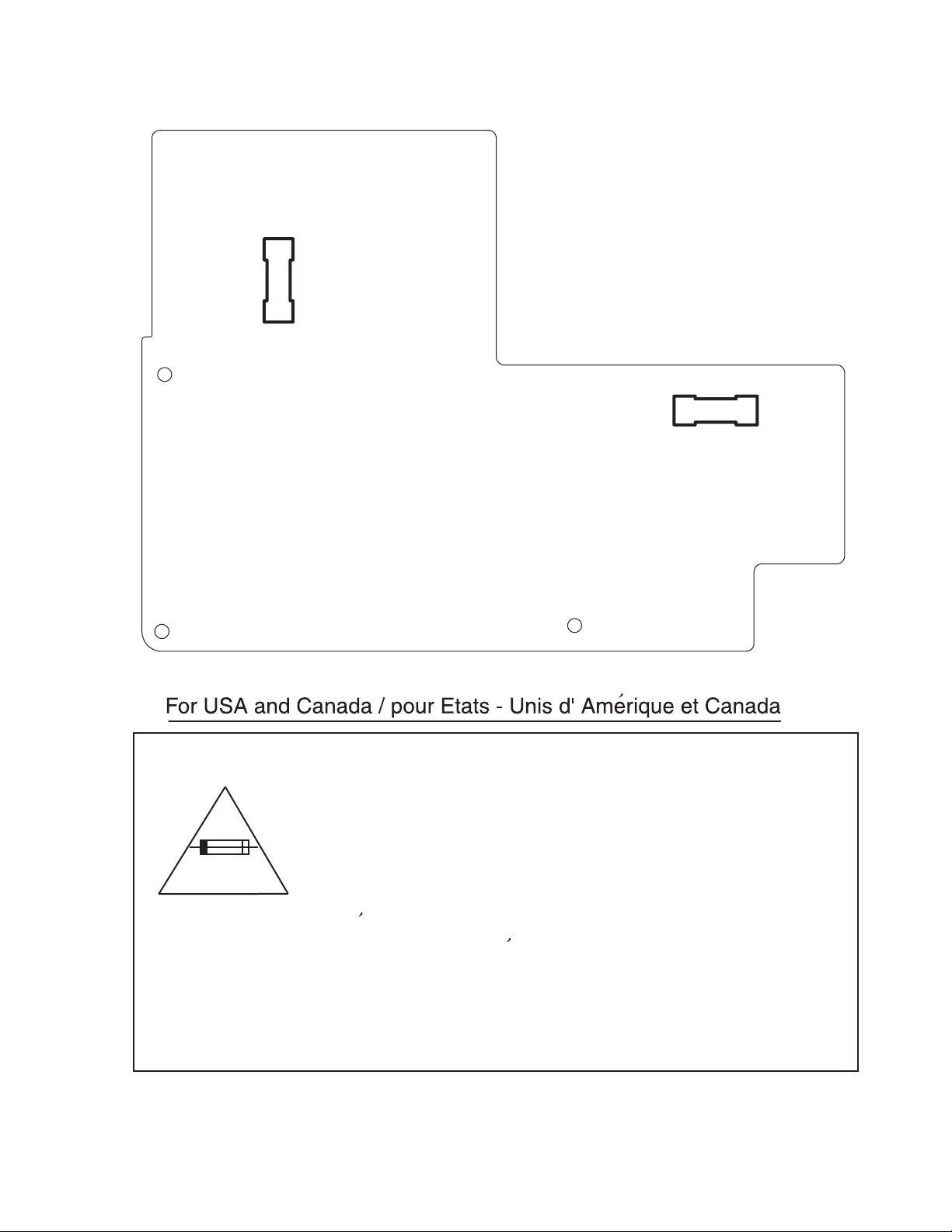

Caution: For continued protection against risk of

fire, replace only with same type 2.5 A/125 V for

F1000, 1.5 A/125 V for F1001.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F1000 comme le meme type

que 2,5 A/125 V, et 1,5 A/125 V pour F1001.

Ce sont des fusibles suretes qui functionnes rapide

^

Page 5

1.8 Importance administering point on the safety

Primary board

1.5A-125V

F1001

F1000

2.5A-125V

Caution: For continued protection against risk of

fire, replace only with same type 2.5 A/125 V for

F1000, 1.5 A/125 V for F1001.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F1000 comme le meme type

que 2,5 A/125 V, et 1,5 A/125 V pour F1001.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB205)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MB205)

Page 7

SECTION 3

r

DISASSEMBLY

3.1 Main body section

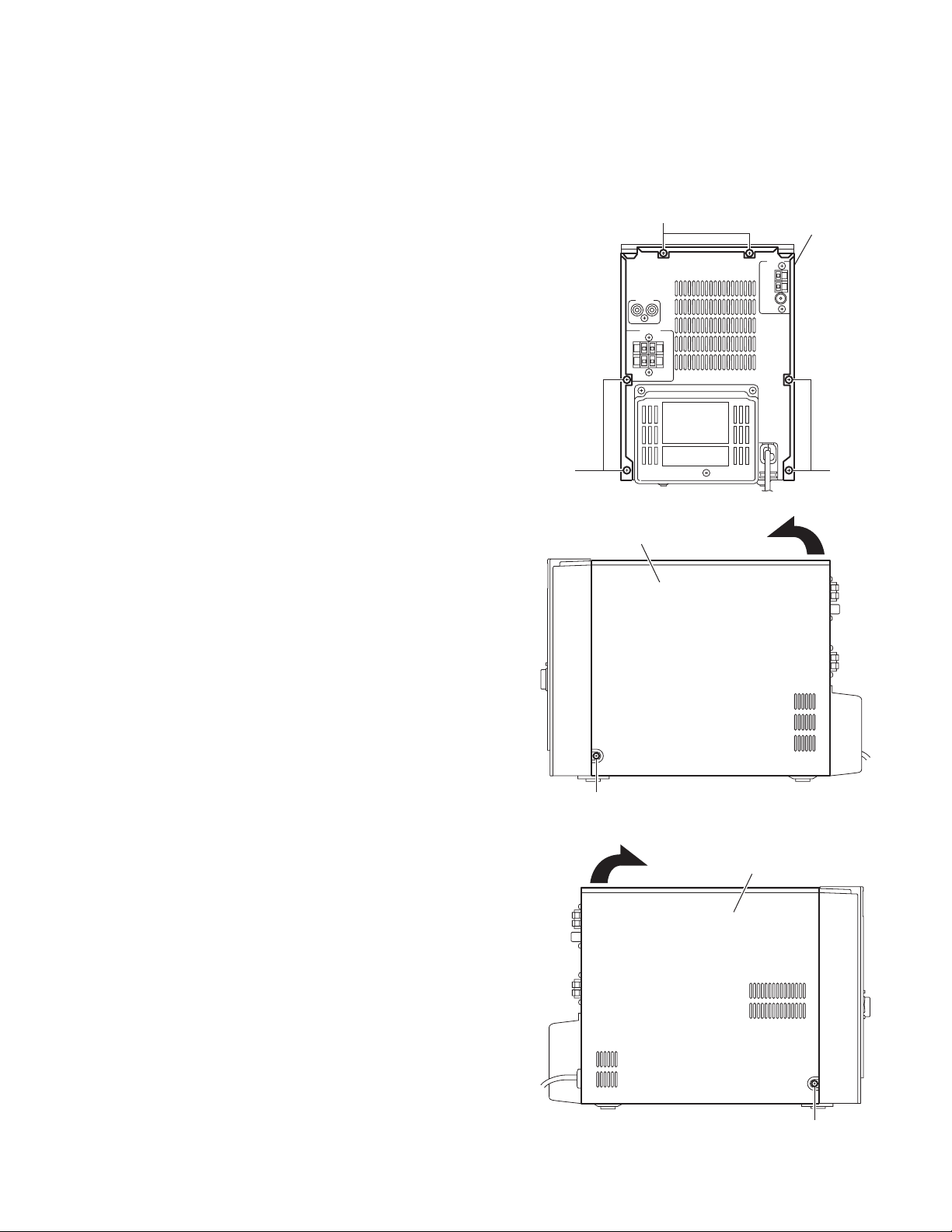

3.1.1 Removing the metal cover

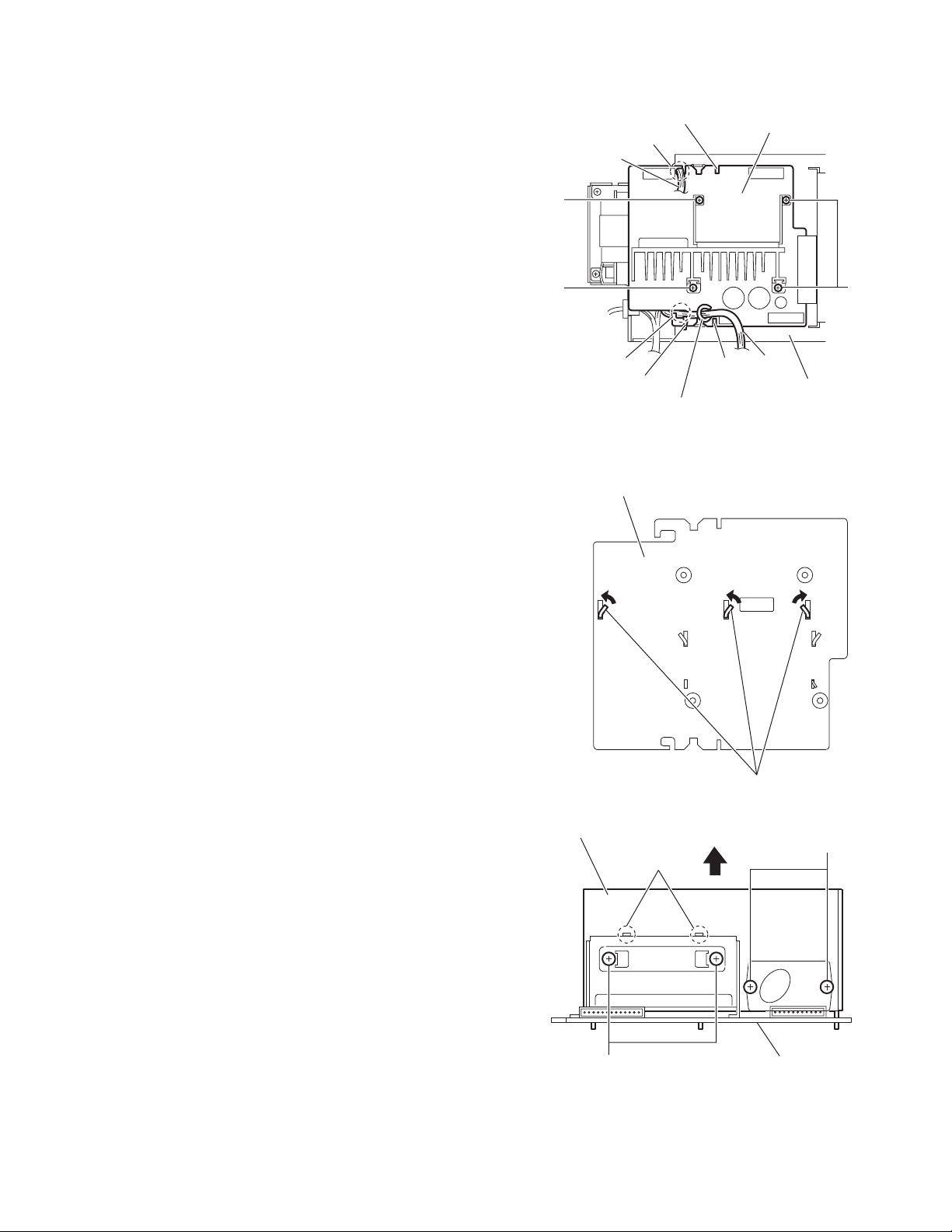

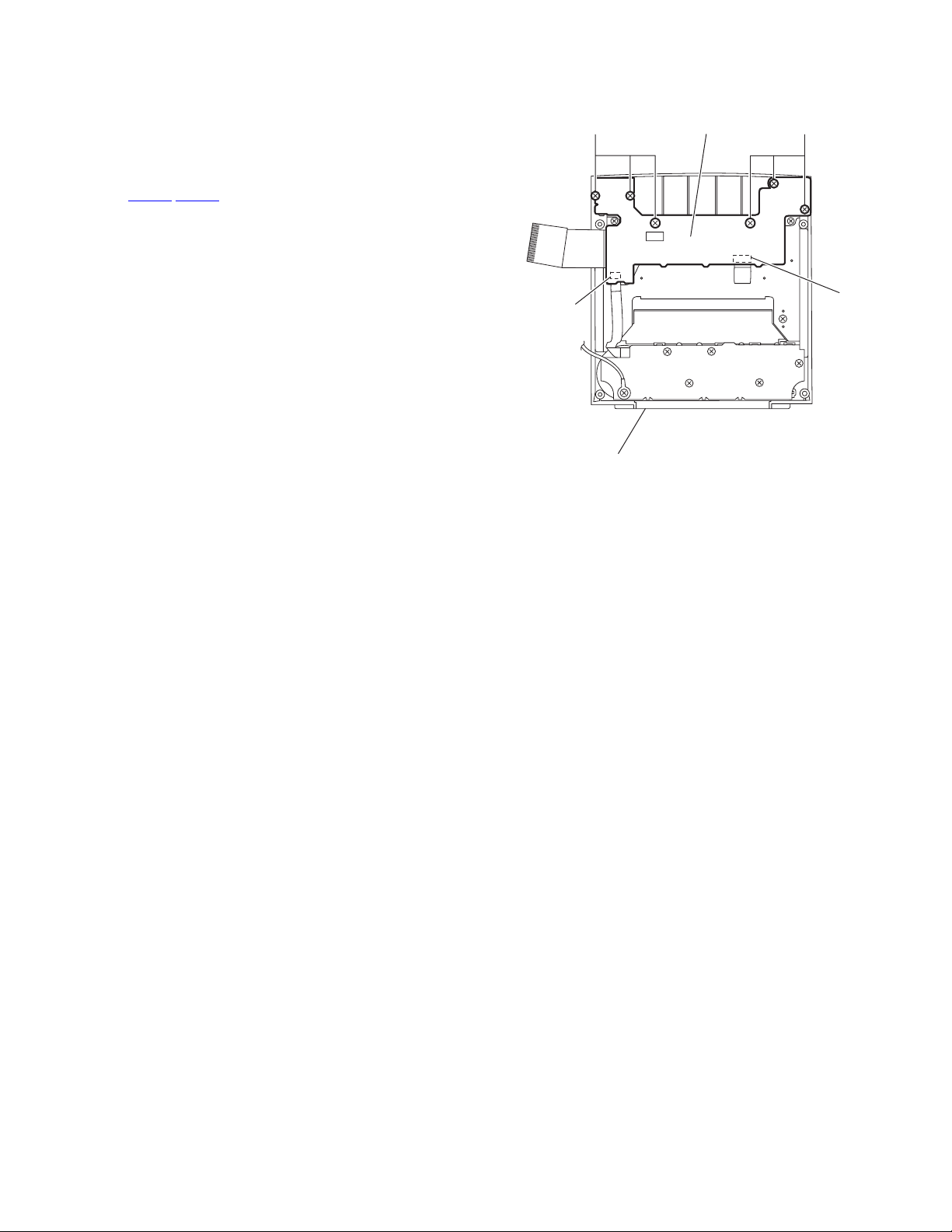

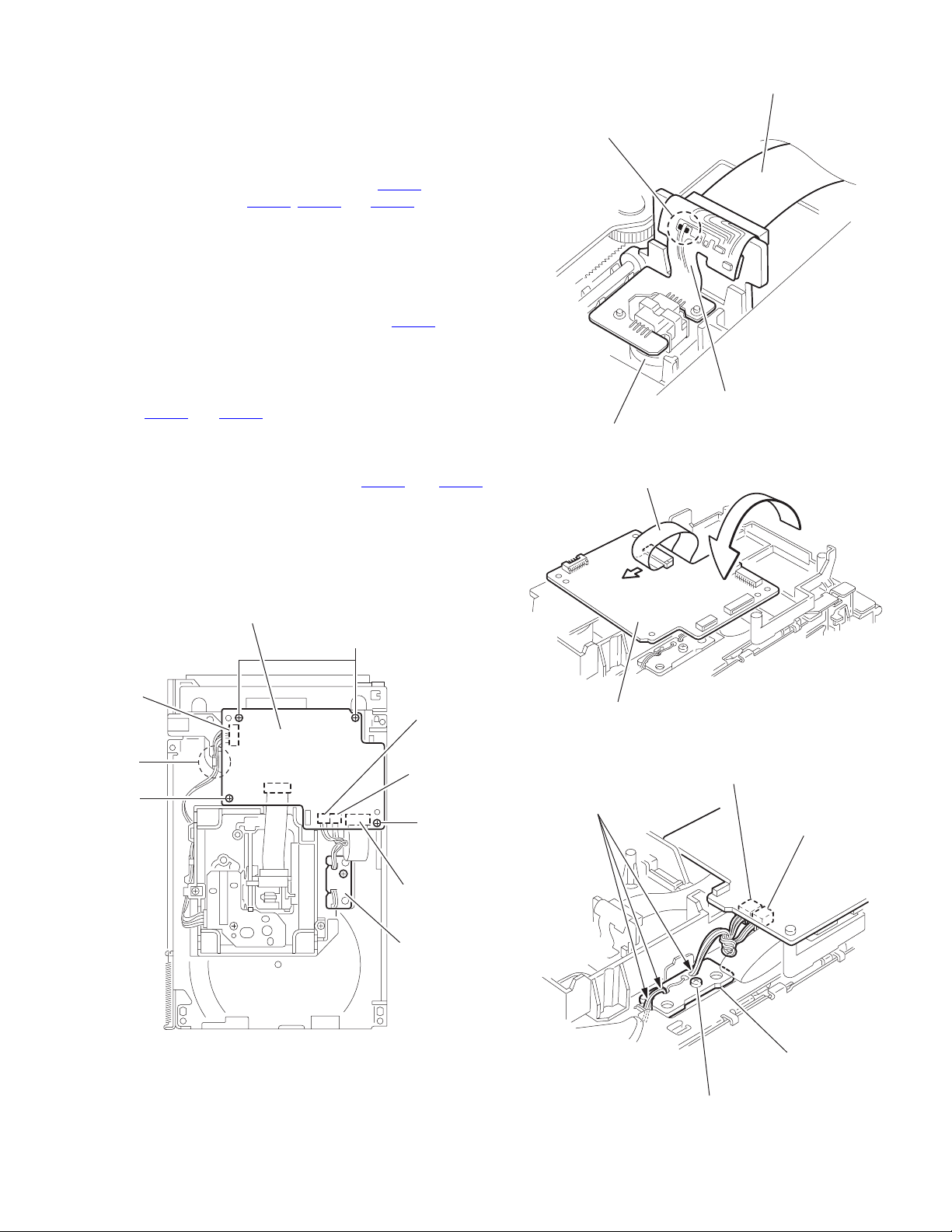

(See Figs.1 to 3)

(1) From the back side of the main body, remove the six

screws A attaching the metal cover. (See Fig.1.)

(2) From the both sides of the main body, remove the two

screws B attaching the metal cover. (See Figs.2 and 3.)

(3) Remove the metal cover in the direction of the arrow while

extending the lower sections of the metal cover. (See

Figs.2 and 3.)

A

Metal cove

A

A

Fig.1

Metal cover

B

Fig.2

Metal cover

B

Fig.3

(No.MB205)1-7

Page 8

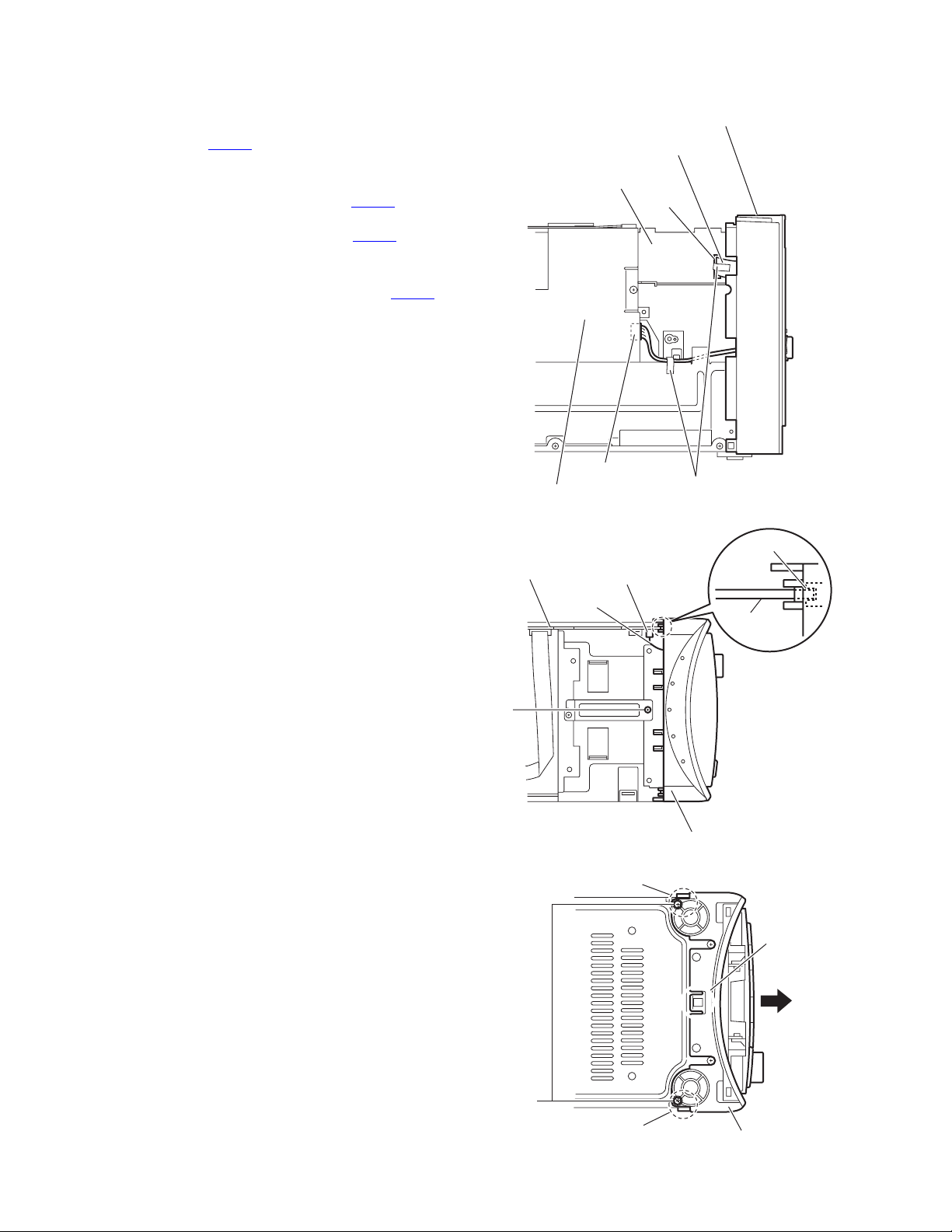

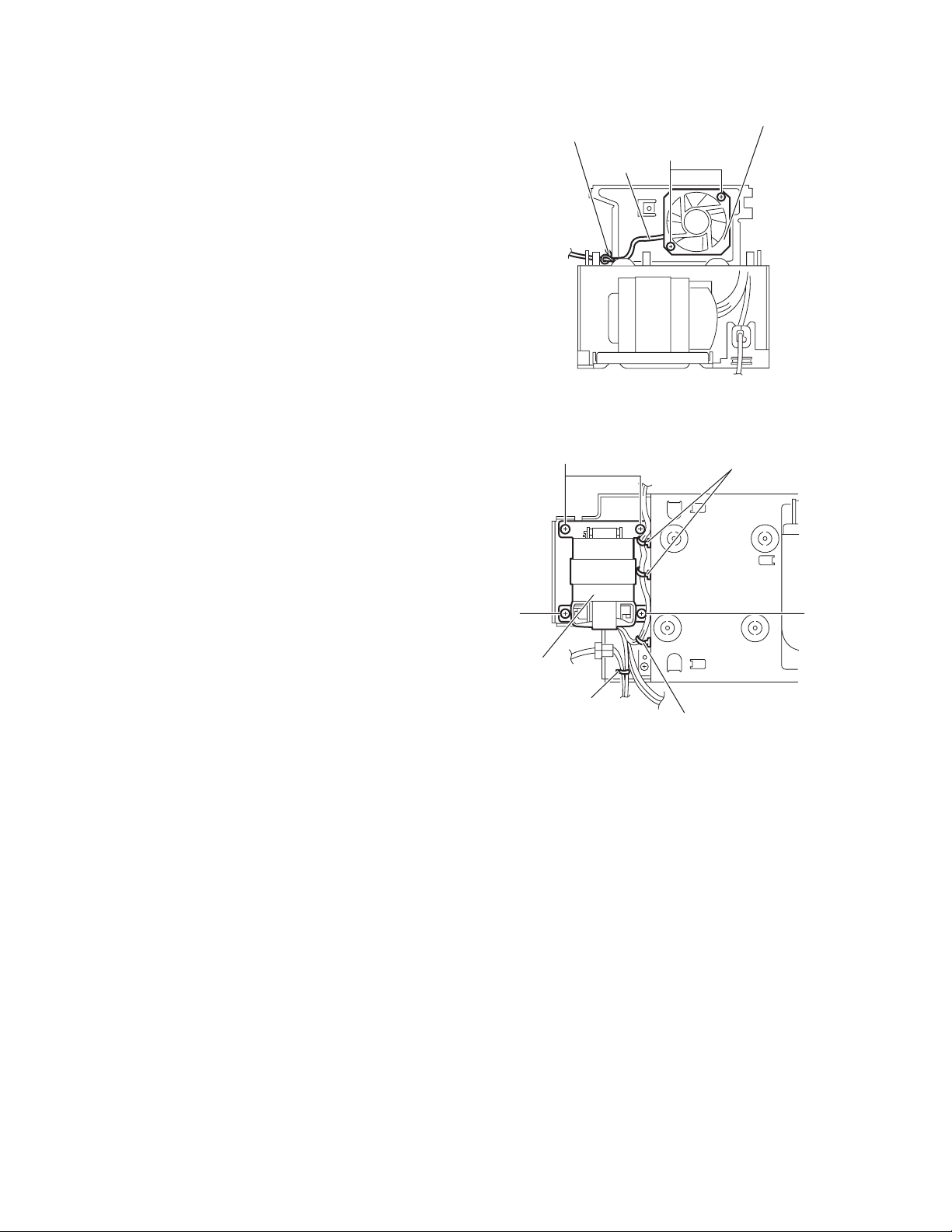

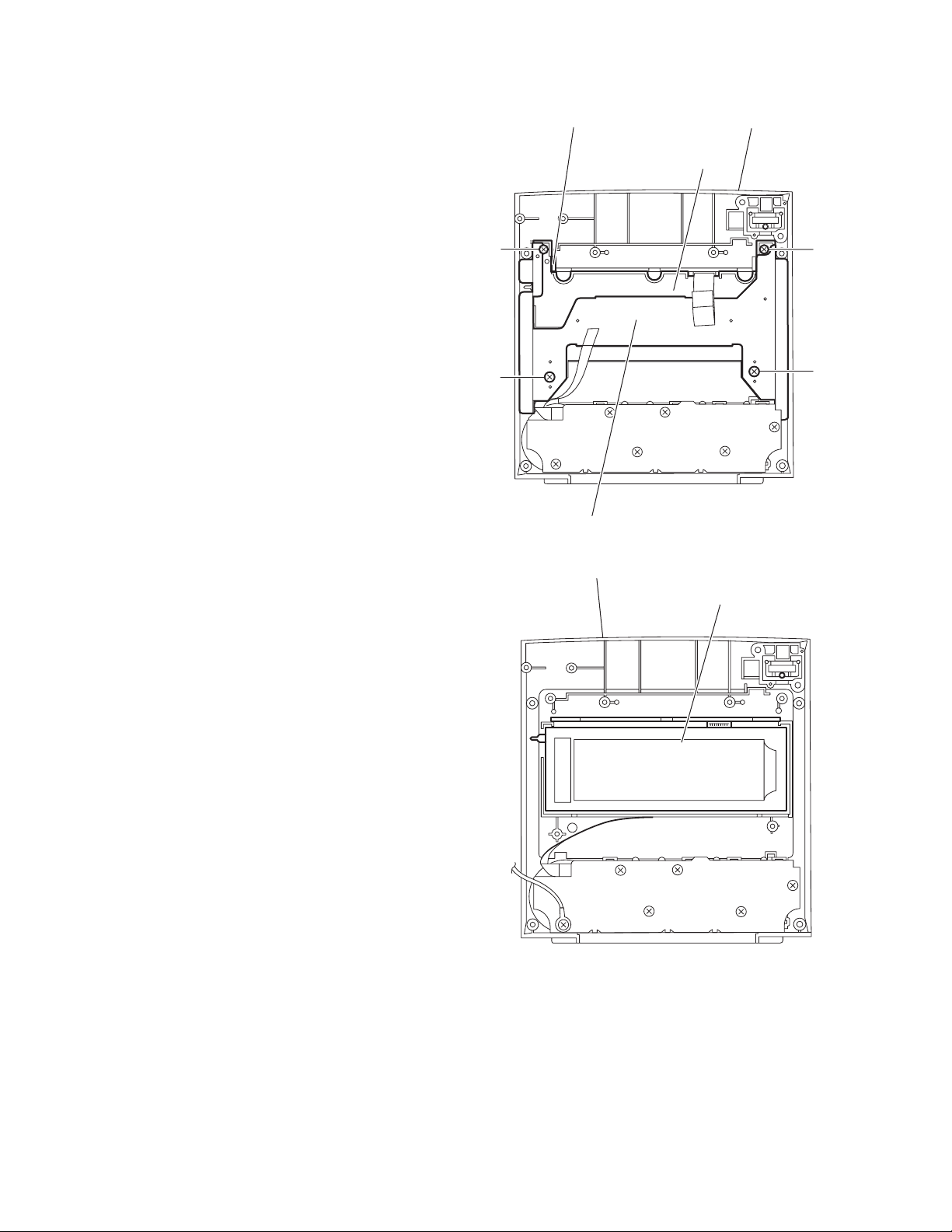

3.1.2 Removing the front panel assembly

(See Figs.4 to 6)

• Remove the metal cover.

(1) From the left side of the main body, disconnect the wire

from the connector CN104 on the power supply board.

(See Fig.4.)

Reference:

After connecting the wire to the connector CN104

wire with the spacer as before. (See Fig.4.)

(2) Disconnect the card wire from the connector CN700

micon board. (See Figs.4 and 5.)

Reference:

After connecting the card wire to the connector CN700

fix the card wire with the spacer as before. (See Fig.4.)

(3) From the top side of the main body, remove the screws C

attaching the front panel assembly. (See Fig.5.)

(4) From the bottom side of the main body, remove the two

screws D attaching the front panel assembly. (See Fig.6.)

(5) Release the two hooks a and hook b from the both and bot-

tom sides of the front panel assembly, and remove the front

panel assembly in the direction of the arrow. (See Fig.6.)

Reference:

When attaching the front panel assembly, fit the micon board

to the notch c on the back side of the front panel assembly.

(See Fig.5.)

, fix the

on the

Front panel assembly

Card wire

Micon board

CN700

,

CN104

Power supply board

Spacer

Fig.4

Micon board

C

c

CN700

Card wire

Micon board

Front panel assembly

Fig.5

a

b

1-8 (No.MB205)

D

a

Front panel assembly

Fig.6

Page 9

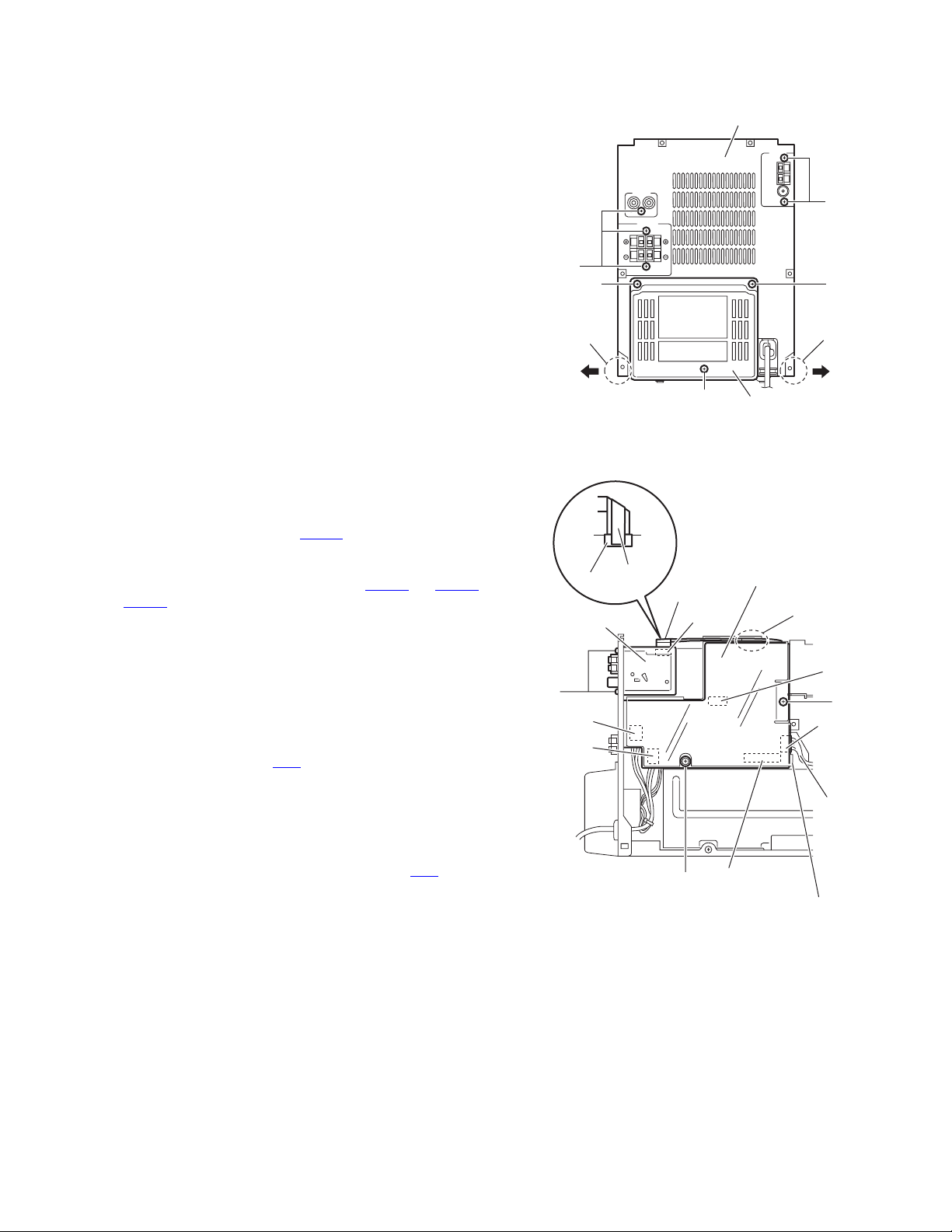

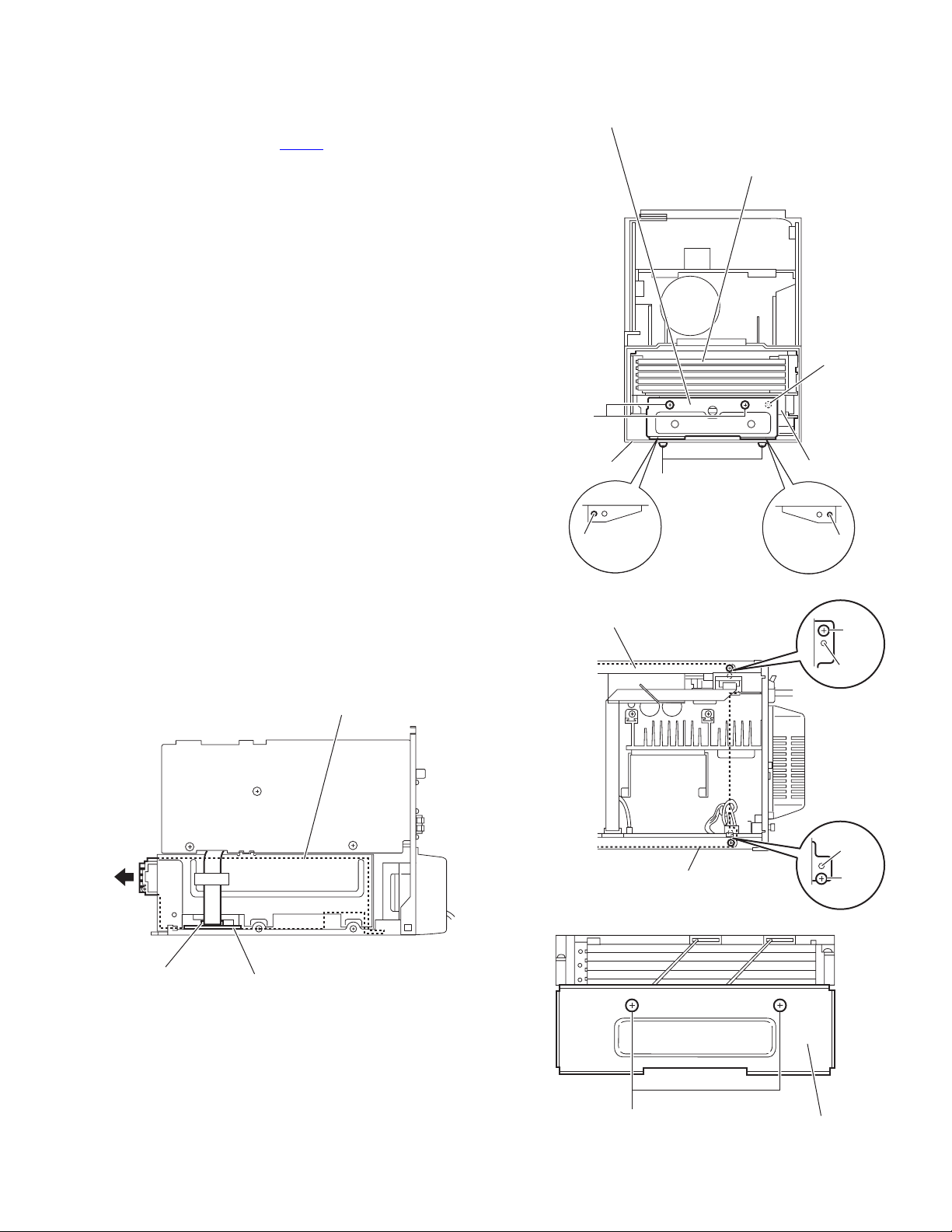

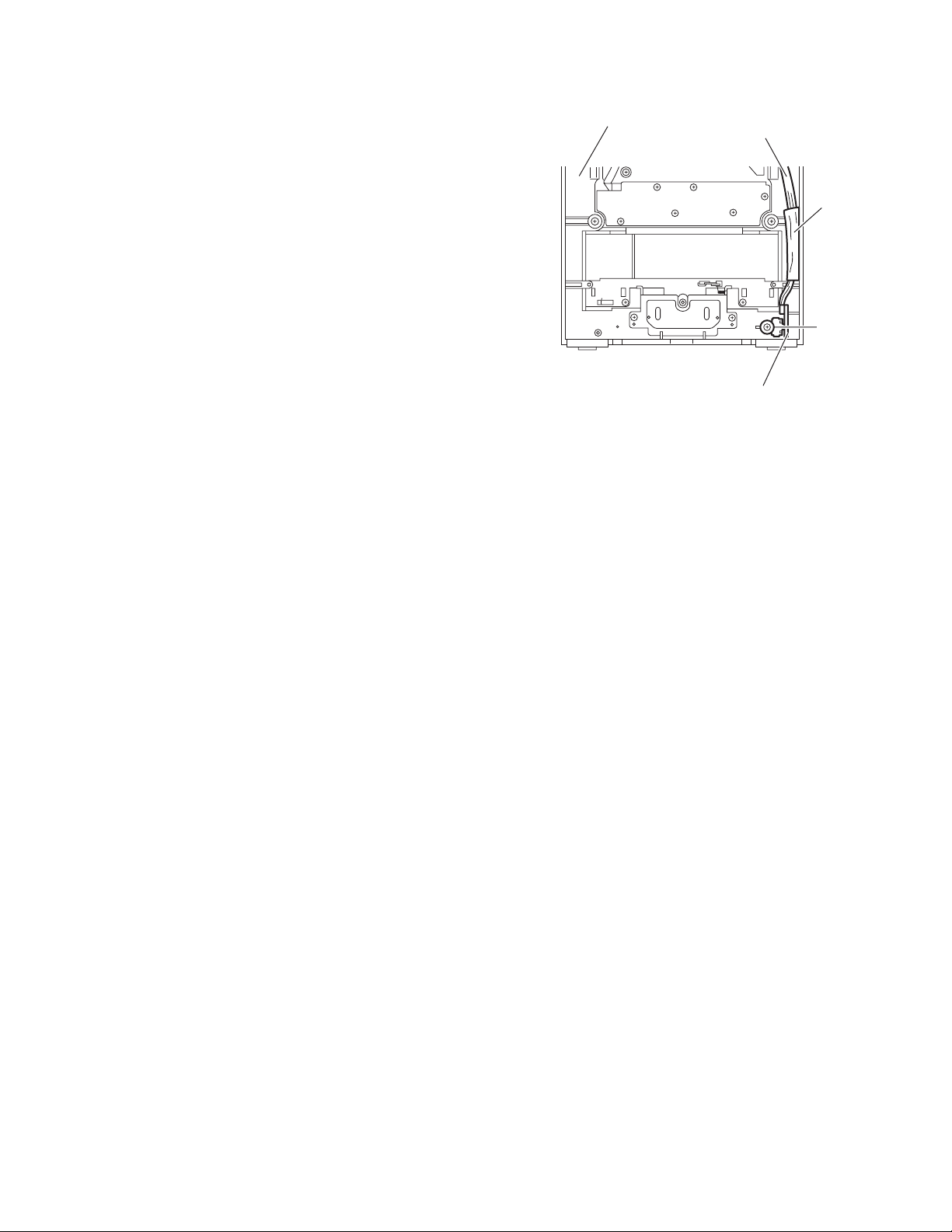

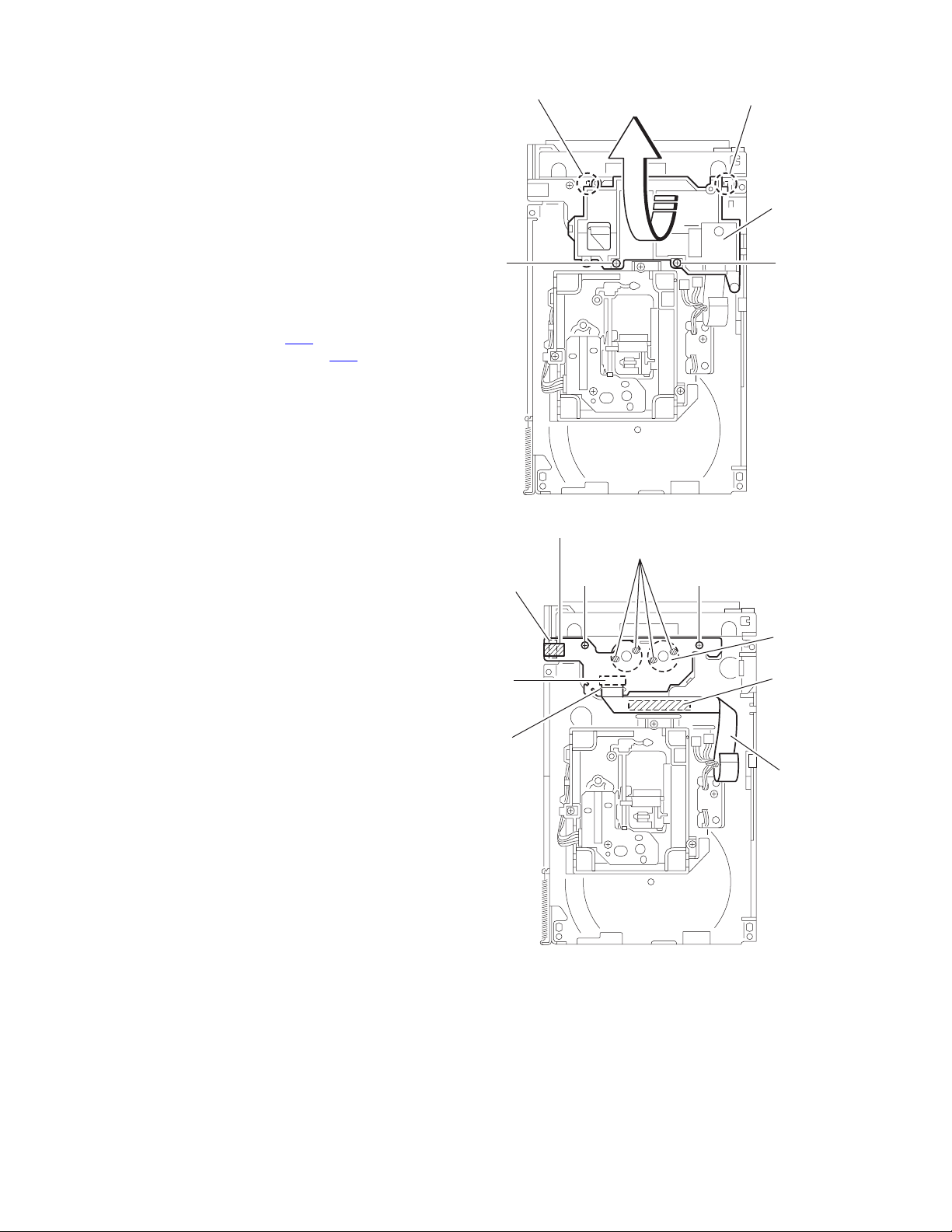

3.1.3 Removing the rear panel

(See Fig.7)

• Remove the metal cover.

(1) From the back side of the main body, remove the five

screws E attaching the rear panel.

(2) Remove the screw F attaching the rear cover.

(3) Remove the rear panel from the chassis while extending

the sections d of the rear panel in the direction of the arrow.

Reference:

When removing the rear cover, remove the screw F and two

screws F'.

E

F'

Rear panel

E

F'

3.1.4 Removing the power supply board

(See Fig.8)

• Remove the metal cover.

(1) From the left side of the main body, remove the screw G

and screw H attaching the power supply board.

(2) Disconnect the connectors CN103

board toward this side.

(3) From the forward side of the power supply board, discon-

nect the wires from the connectors (CN100

).

CN104

Reference:

When attaching the screw G, attach the primary protector with

it.

3.1.5 Removing the tuner

(See Fig.8)

• Remove the metal cover.

(1) From the left side of the main body, disconnect the card

wire from the connector CN1

(2) From the back side of the main body, remove the two

screws J attaching the tuner.

Reference:

• After attaching the tuner, put the card wire on the section e

of the primary protector.

• When connecting the card wire to the connector CN1

card wire with the spacer as before.

on the power supply

to CN102,

on the tuner.

, fix the

J

CN101

CN100

d

CN1

Tuner

Spacer

F

Fig.7

Card wire

CN1

CN103

H

Fig.8

d

Rear cover

Power supply board

e

CN102

G

CN104

Wire

Primary protector

(No.MB205)1-9

Page 10

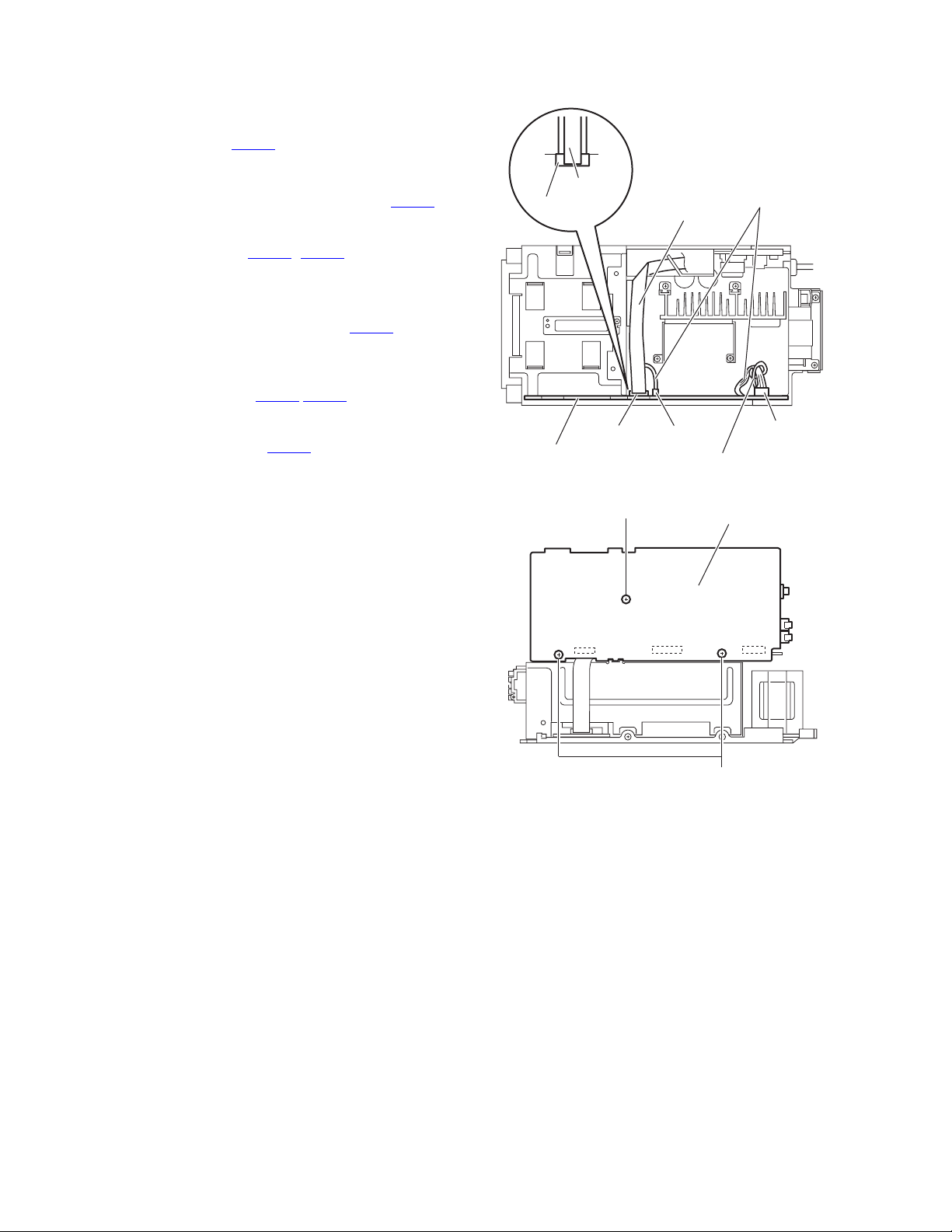

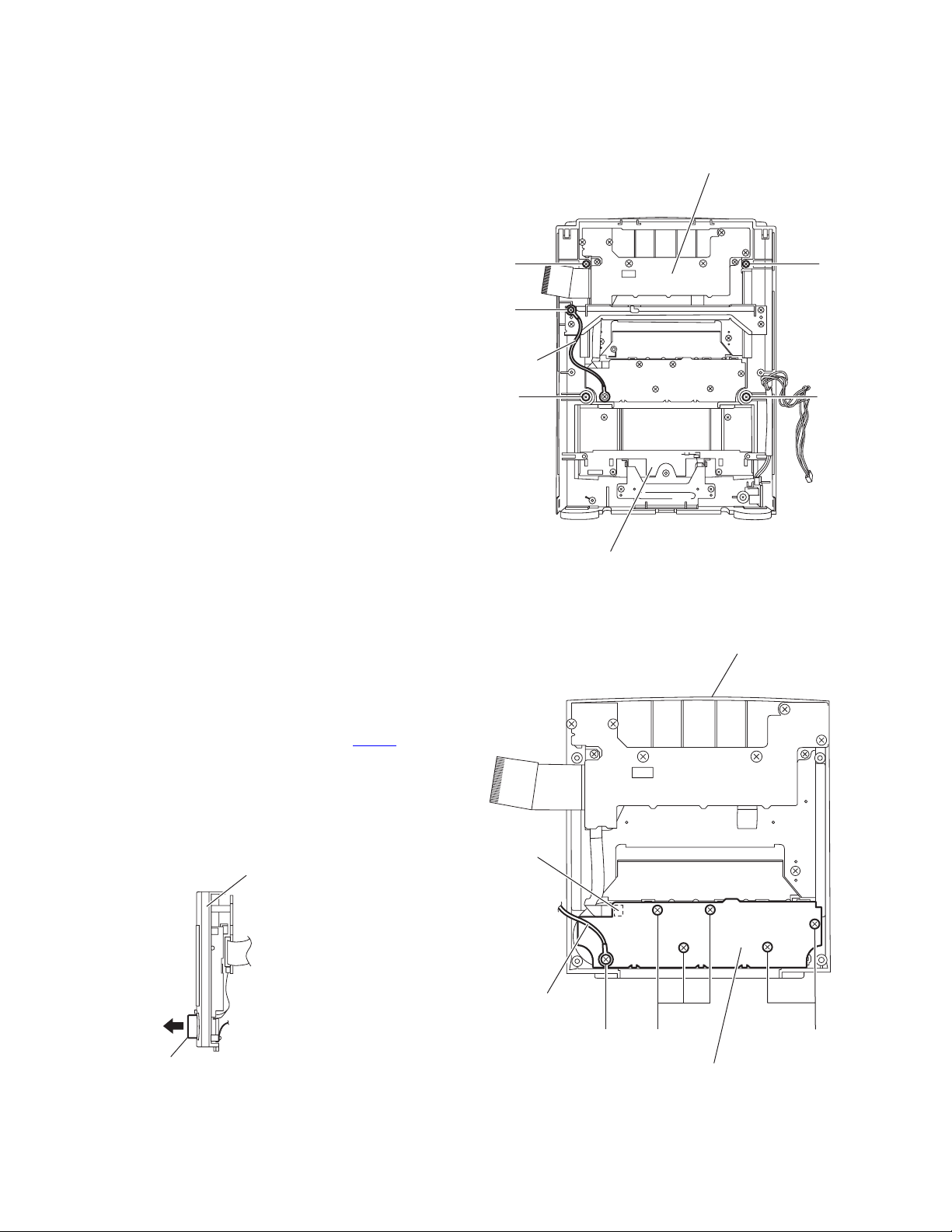

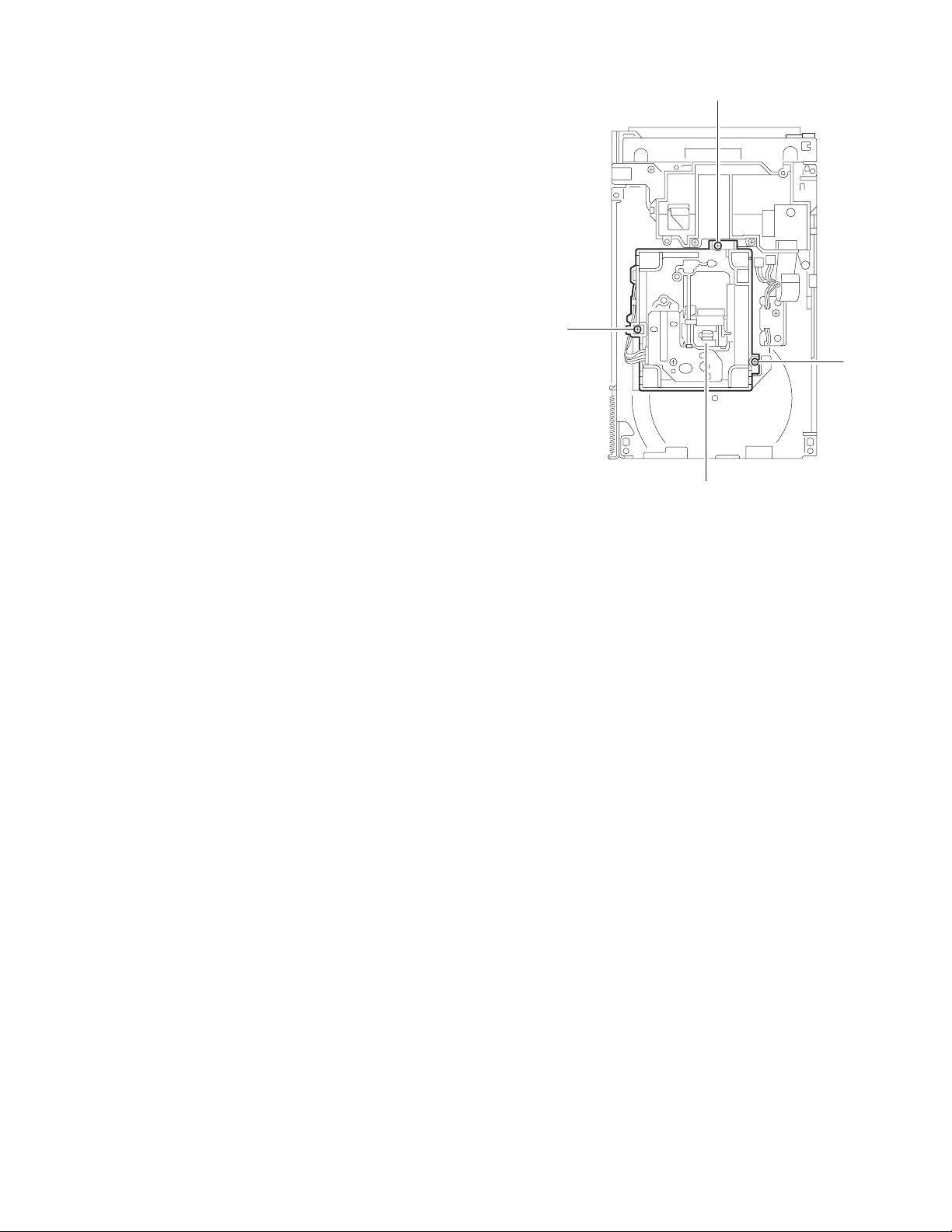

3.1.6 Removing the micon board

(See Figs.9 and 10)

• Remove the metal cover, front panel assembly and rear panel.

(1) From the top side of the main body, disconnect the card

wire from the connector CN766 on the micon board. (See

Fig.9.)

Reference:

When connecting the card wire to the connector CN766

fix the card wire with the spacer as before.

(2) From the forward side of the micon board, disconnect the

wire from the connectors (CN750

board. (See Fig.9.)

Reference:

When reassembling, fix the wire with the wire holder after connecting the wire to the connector CN760

micon board as before. (See Fig.9.)

(3) From the right side of the main body, remove the three

screws K attaching the micon board. (See Fig.10.)

(4) Disconnect the connectors (CN761

board toward this side. (See Fig.10.)

(5) From the forward side of the micon board, disconnect the

card wire from the connectors CN765

, CN760) on the micon

on the

,CN762) on the micon

. (See Fig.10.)

,

Micon board

CN766

Spacer

CN766

Card wire

CN750

Wire holder

Fig.9

Wires

CN760

CN765

K

CN762

Fig.10

Micon board

CN761

K

1-10 (No.MB205)

Page 11

3.1.7 Removing the power amplifier board

(See Fig.11)

• Remove the metal cover, front panel assembly, rear panel,

power supply board and micon board.

(1) From the top side of the main body, remove the wire holder

and tie band fixing the wire 1.

(2) Remove the four screws L attaching the power amplifier

board.

Reference:

• When attaching the power amplifier board, align the sections

f of the main chassis in the slots of the main amplifier board.

• After attaching the power amplifier board, pass the wire 1

through the section g of the power amplifier board.

• When reassembling, fix the wire 1 with the wire holder and

new tie band as before.

• When reassembling, pass the wire 2 through the section h

of the power amplifier board.

3.1.8 Removing the heat sink

(See Figs.12 and 13)

• Remove the metal cover, front panel assembly, rear panel,

power supply board, micon board and power amplifier board.

(1) From the reverse side of the power amplifier board, bend

the claws i of the heat sink in the direction of the arrow.

(See Fig.12.)

(2) From the forward side of the power amplifier board, remove

the four screws M attaching the heat sink. (See Fig.13.)

(3) Disengage the joints j and remove the heat sink in the di-

rection of the arrow. (See Fig.13.)

h

Wire 2

L

L

g

Tie band

Wire holder

Power amplifier board

f

Power amplifier board

Wire 1

f

Fig.11

L

Main chassis

Heat sink

M

i

Fig.12

M

j

Power amplifier board

Fig.13

(No.MB205)1-11

Page 12

3.1.9 Removing the fan

(See Fig.14)

• Remove the metal cover, front panel assembly, rear panel,

power supply board, micon board and power amplifier board.

(1) From the back side of the main body, remove the wire hold-

er fixing the wire.

Reference:

After attaching the fan, fix the wire with the wire holder as

before.

(2) Remove the two screws N attaching the fan.

3.1.10 Removing the power transformer

(See Fig.15)

• Remove the metal cover, front panel assembly, rear panel,

power supply board, micon board and power amplifier board.

(1) From the top side of the main body, remove the wire hold-

ers fixing the wire.

(2) Remove the tie band.

(3) Remove the four screws P attaching the power transformer

and take out the power transformer from the main body.

Reference:

After attaching the power transformer, fix the wires with the

wire holders and new tie band as before.

P

Wire holder

P

Wire

Fan

N

Fig.14

Wire holders

P

Power

transformer

Tie band

Wire holder

Fig.15

1-12 (No.MB205)

Page 13

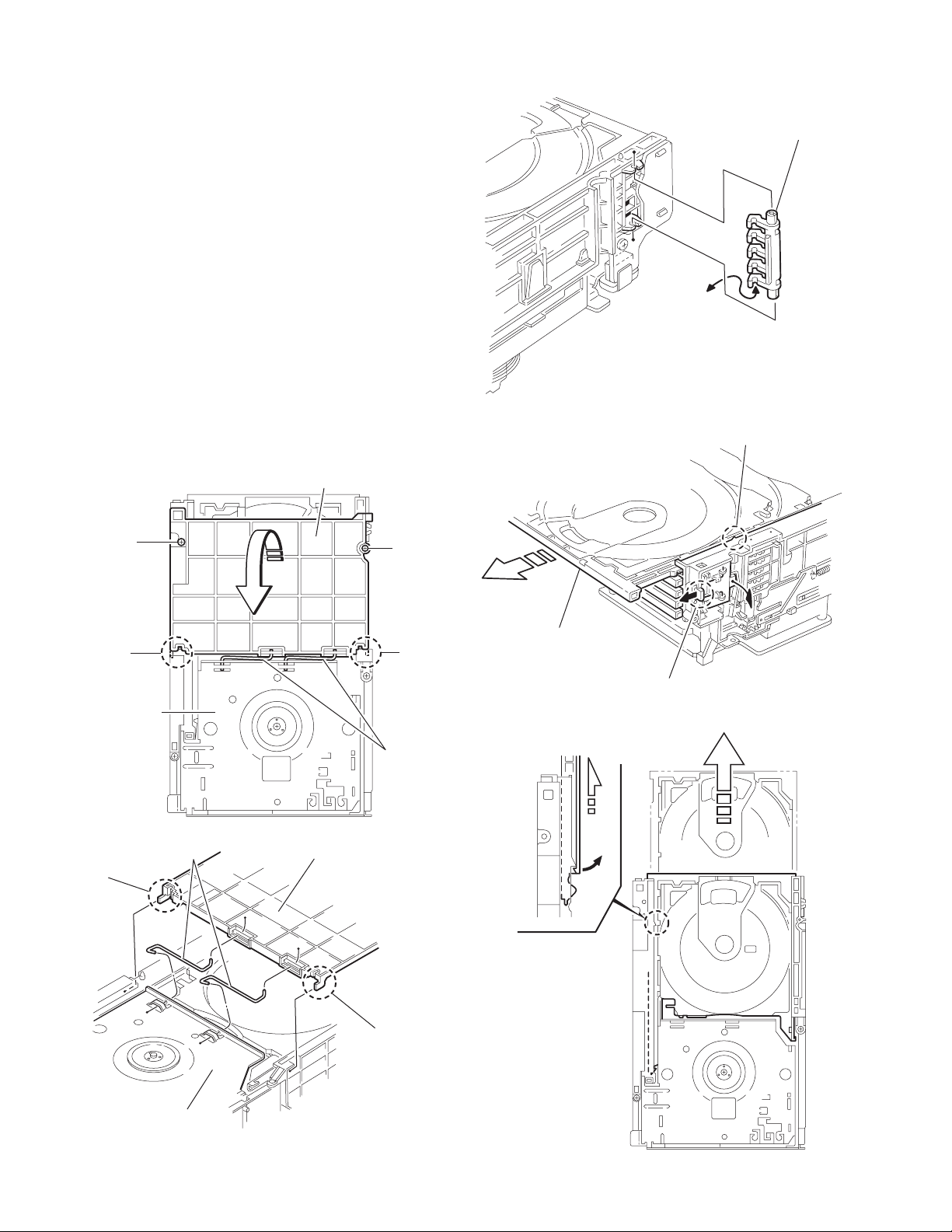

3.1.11 Removing the CD changer mechanism assembly

(See Figs.16 to 19.)

• Remove the metal cover and front panel assembly.

(1) From the right side of the main body, disconnect the card

wire from the connector CN651

board. (See Fig.16.)

(2) From the bottom side of the main body, remove the two

screws Q attaching the CD bracket (F) to the bottom chassis. (See Fig.17.)

Reference:

When attaching the CD bracket (F), align the projections

k of the bottom chassis in the holes of the CD bracket

(F). (See Fig.17.)

(3) From the front side of the main body, remove the two

screws R attaching the CD bracket (F) to the main chassis.

Reference:

When attaching the CD bracket (F), align the projection

m of the main chassis in the holes of the CD bracket (F).

(See Fig.17.)

(4) From the top side of the main body, remove the two screws

S attaching the CD changer mechanism assembly. (See

Fig.18.)

Reference:

Align the projections n on the bottom chassis in the holes

of the CD changer mechanism assembly before attaching the screws S. (See Fig.18.)

(5) Take out the CD changer mechanism assembly in the di-

rection of the arrow. (See Fig.16.)

Note:

When take out the CD changer mechanism assembly,

be careful not to damage the several parts on the CD

servo control board. (See Fig.16.)

(6) From the back side of the CD changer mechanism assem-

bly, remove the two screws T attaching the CD bracket (R).

(See Fig.19.)

CD changer mechanism assembly

on the CD servo control

CD bracket (F)

CD changer mechanism assembly

R

Bottom chassis

Q

k

Fig.17

CD changer mechanism assembly

m

Main chassis

k

S

n

CN651

CD servo control board

Fig.16

Bottom chassis

Fig.18

T

Fig.19

n

S

CD bracket (R)

(No.MB205)1-13

Page 14

3.2 Front panel assembly

• Remove the metal cover and front panel assembly.

3.2.1 Removing the front assembly section

(See Fig.20)

(1) From the inside of the front panel assembly, remove the

screw U attaching the earth wire.

Reference:

When attaching the screw U, attach the earth wire with it.

(2) Remove the four screws V attaching the front assembly

section.

(3) Take out the front assembly section from the main body.

V

U

Earth wire

Front assembly section

V

3.2.2 Removing the switch board

(See Figs.21 and 22)

• Remove the front assembly section.

(1) From the front side the front assembly section, pull out the

volume knob in the direction of the arrow. (See Fig.21.)

(2) From the inside of the front assembly section, remove the

five screws W and screw W' attaching the switch board.

(See Fig.22.)

(3) Disconnect the card wire from the connector CN510

switch board. (See Fig.22.)

Reference:

When attaching the screw W', attach the earth wire with

it. (See Fig.22.)

(4) Take out the switch board from the front assembly section.

(See Fig.22.)

Front assembly section

on the

V

Front panel assembly

CN510

V

Fig.20

Front assembly section

Volume knob

1-14 (No.MB205)

Fig.21

Earth wire

W' W

W

Switch board

Fig.22

Page 15

3.2.3 Removing the back light board

(See Figs.23)

• Remove the front assembly section.

(1) From the inside of the front assembly section, remove the

six screws X attaching the back light board.

(2) Take out the back light board from the front assembly sec-

tion and disconnect the card wires from the connectors

(CN551

,CN552) on the back light board.

Back light board

XX

CN551

Front assembly section

CN552

Fig.23

(No.MB205)1-15

Page 16

3.2.4 Removing the FL board

Y

Y

(See Figs.24 and 25)

• Remove the front assembly section and back light board.

(1) From the inside of the front assembly section, remove the

four screws Y attaching the lens holder. (See Fig.24.)

(2) Take out the lens holder with the LED lens and cover sheet.

(See Fig.24.)

(3) Take out the FL board from the front assembly section.

(See Fig.25.)

LED lens

Lens holder

Cover sheet

Fig.24

Front assembly section

Front assembly section

Y

Y

FL board

1-16 (No.MB205)

Fig.25

Page 17

3.2.5 Removing the headphone jack board

r

(See Fig.26)

(1) From the inside of the front panel assembly, remove the

screw Z attaching the headphone jack board.

(2) Take out the headphone jack board from the front panel as-

sembly.

Reference:

After attaching the headphone jack board, fix the wire with the

spacer as before.

Front panel assembly

Wire

Space

Z

Headphone jack board

Fig.26

(No.MB205)1-17

Page 18

3.3 CD changer mechanism

r

3.3.1 Removing the tray assembly

(See Fig.1 ~ 5)

(1) Remove the two screws A from the top cover and release

the two joints a on both sides of the body.

(2) Remove the top cover with the two rods attached to the top

cover and lifter assembly respectively.

(3) Remove the open det lever on the left side of the body.

(4) Push part b of the slide (R) assembly on the right side of

the body to unlock the tray assembly. Draw out the trays to-

ward the front.

Attention:

The tray can be locked if all tray assemblies are attached.

(5) From top of the body, move the stopper tab c in the direc-

tion of the arrow and release. Pull out the tray assemblies

from the body.

Caution:

Remove the tray assembly from top tray 5 in order.

Attention:

When reattaching the sub tray of the tray assembly, or when

removing the CD remaining inside, refer to another section.

Top cover

Open det leve

Fig.3

c

A

a

Lifter assembly

a

Rod

Fig.1

Top cover

A

a

Tray assembly

(Tray 5)

b

Fig.4

Rod

Lifter assembly

1-18 (No.MB205)

a

Fig.2

Fig.5

Page 19

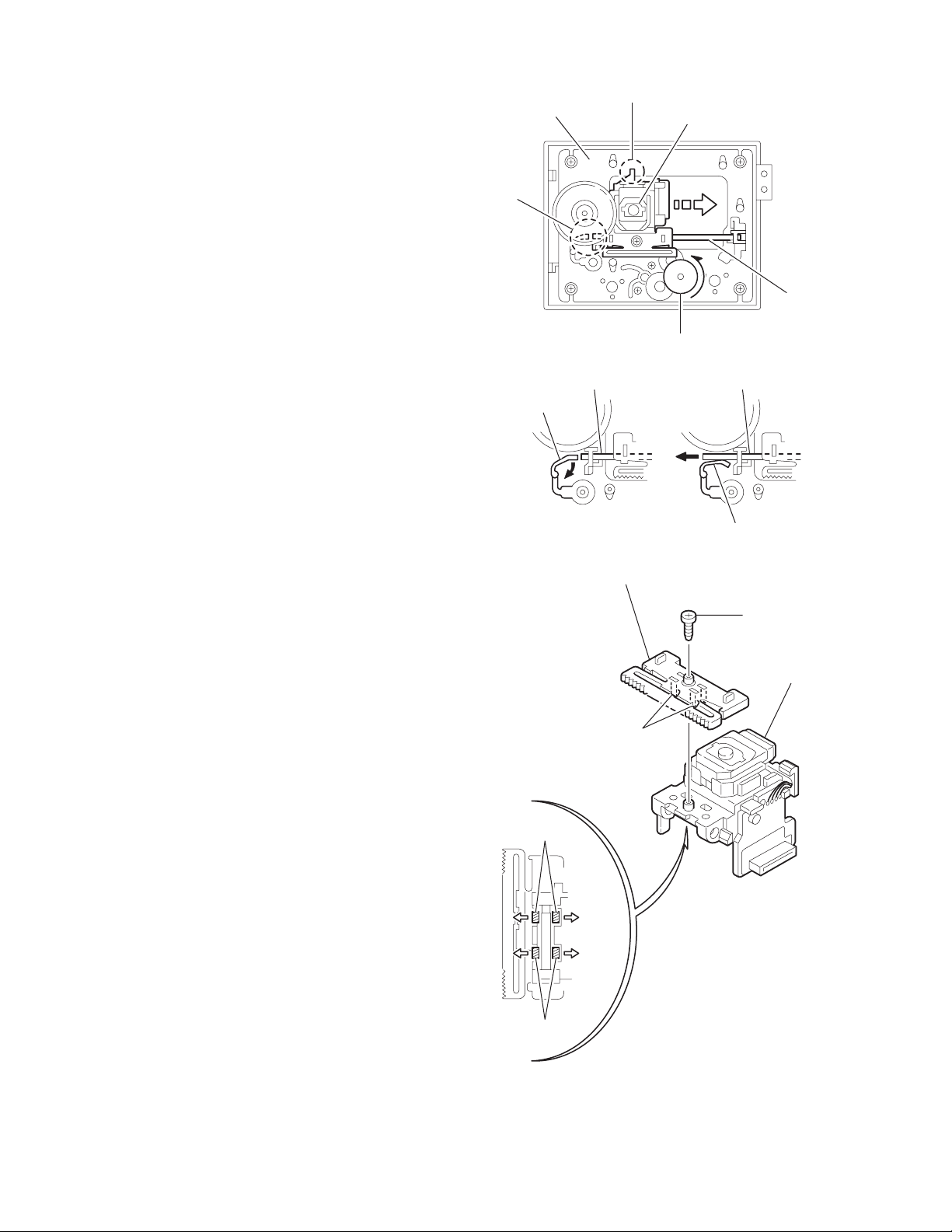

3.3.2 Removing the servo control board

(See Fig.6 ~ 9)

Caution:

Solder the short-circuit point on the pickup before disconnecting the card wire extending from the pickup. If you do not follow

this instruction, the pickup may be damaged.

(1) Disconnect the card wire from connector CN251

wire from connector CN252

vo control board on the bottom of the body. Disconnect the

wire from joint d.

(2) Solder the short round point on the flexible board of the pick

up.

(3) Remove the four screws B and turn the servo control board

as shown in the figure.

(4) Disconnect the card wire from connector CN601

servo control board.Caution: Unsolder the short-circuit

point after reassembling.

Caution:

When reassembling, twist the wires to be connected to connector CN252

3.3.3 Removing the switch board

(See Fig.9)

(1) Disconnect the wires from connector CN252

on the servo control board.

(2) Remove the screw C attaching the switch board.

(3) Release the wires from the slot e of the switch board.

Caution:

When reassembling, let the wires through the slot e of the

switch board and twist them twice.

and CN253 twice.

Servo control board

, CN253 and CN602 on the ser-

and each

on the

and CN253

B

Card wire

Short round

Flexible board

Pickup

Fig.7

Card wire

CN601

CN602

d

B

Fig.6

CN253

CN252

B

CN251

Switch board

Servo control board

Fig.8

Servo control board

CN253

e

CN252

Switch board

C

Fig.9

(No.MB205)1-19

Page 20

3.3.4 Removing the motor board

(See Fig.10 , 11)

• Prior to performing the following procedure, remove the servo

control board.

(1) Turn over the body and remove the two screws D. Move

the CD module bkt. in the direction of the arrow to release

two joints f.

(2) Unsolder the four soldered parts on the motor of the motor

board.

Caution:

If removing the motor board with the motor, you should

remove the screws attaching the motor from top of the

body(Refer to another section).

(3) Remove the two screws E attaching the motor board.

(4) Remove the spacer fixing the motor board and tray switch

board, and disconnect connector CN2

(5) Disconnect the card wire from connector CN1

board.

Caution:

When reconnecting the card wire, let the card wire through the

slot g of the motor board and attach it to the bottom of the body

using a double tape.

on the motor board.

on the motor

f

f

CD Module

braket

DD

Fig.10

Spacer

Soldering point

CN2

CN1

g

E

E

Motor

Double

face tape

Card wire

Fig.11

1-20 (No.MB205)

Page 21

3.3.5 Removing the CD tramecha assembly

(See Fig.12)

• Prior to performing the following procedure, remove the servo

control board.

(1) Turn over the body and remove the three screws F attach-

ing the tramecha.

F

F

F

CD Tramecha assembly

Fig.12

(No.MB205)1-21

Page 22

3.3.6 Removing the pickup

(See Fig.13 , 14)

• Prior to performing the following procedure, remove the servo

control board and CD tramecha assembly.

(1) From top of the CD tramecha assembly, turn the cam gear

in the direction of the arrow to move the pickup assembly

outward.

(2) Push down the stopper h in the direction of the arrow and

pull out the shaft.

(3) Release the joint i of the pickup assembly and mecha

base.

(4) Remove the screw G attaching the CD rack. Release the

four tabs j at the bottom of the CD rack.

Mecha base

h

Stopper

i

Pickup assembly

Shaft

Cam gear

ShaftShaft

Stopper

Fig.13

CD lack

G

Pickup

j

j

1-22 (No.MB205)

j

Fig.14

Page 23

3.3.7 Removing the side (L)/ tray switch board

(See Fig.15 ~ 17)

• Prior to performing the following procedure, remove the tray

assembly.

(1) Remove the two screws H attaching the side (L) on top of

the body.

(2) From the side of the body, remove the spacer fixing the tray

switch board and motor board. Disconnect connector CN3

on the tray switch board and detach the side (L) upward.

(3) Remove the screw J attaching the tray switch board.

(4) Push the joint tab k of the side (L) in the direction of the ar-

row and remove the tray switch board outward, then re-

lease joint l.

H

Side (L)

H

Fig.15

H

H

Side (L)

CN3

Spacer

Side (L)

Fig.16

k

Tray switch board

Fig.17

l

J

(No.MB205)1-23

Page 24

3.3.8 Removing the side (R) assembly

(See Fig.18 ~ 22)

• Prior to performing the following procedure, remove the tray

assembly.

(1) Push and release the two tabs m of the gear cover through

the two notches inside the side (R) assembly. Remove the

gear cover outward.

(2) Remove the spring attached to part n of the hook on the

right side of the body.

(3) From top of the body, turn the 1 gear clockwise to move the

elevator cam rearward.Move the two slots o and joint p of

the elevator cam as shown in Fig.21 and remove the elevator cam outward.

(4) Remove the three screws K and detach the side (R) up-

ward.

Caution:

When reattaching the side (R) assembly, make sure to fit the

shaft (part q) into the slot of the select lever.

Side (R) assembly

m

Fig.20

K

Side (R)

assembly

K

Side (R) assembly

K

Fig.18

q

Spring

n

Elevator cam

o

o

p

Fig.21

K

Side (R) assembly

1 gear

Gear cover

1-24 (No.MB205)

Sprihg

K

n

Fig.22

Elevator com

Fig.19

Page 25

3.3.9 Removing the lifter assembly

(See Fig.23 ~ 27)

• Prior to performing the following procedure, remove the tray

assembly and side (L)/ side (R) assembly.

(1) From top of the body, turn the 1 gear clockwise to move the

lifter assembly upward as shown in Fig.24.

(2) From top of the body, turn the 2 gear clockwise to move the

hook toward the front until it stops.

(3) Move the hook stopper in the direction of the arrow while

pushing the tab r of the hook stopper to unlock it. Release

four joints s to detach from the rack holder.

Release the rod from part t.

(4) Turn the 1 gear clockwise again to move the lifter assembly

upward.

(5) Remove the lifter assembly from the body upward at posi-

tion u where the four pins on the right and left sides of the

lifter assembly fit to the notches of the v.

Move the lifter assembly toward the front and release from

the hook.

2 gear

1 gear

Hook

t

s

Rod

s

s

r

s

Hook stopper

Fig.25

Lifter assembly

1 gear

u u

Hook stopper

Hook

2 gear

Fig.23

1 gear

Lifter

assembly

Lifter assembly

v

Lifter assembly

Fig.26

u

u

Hook stopper

Hook

Fig.24

v

Fig.27

(No.MB205)1-25

Page 26

3.3.10 Removing the rack holder assembly/ sensor assembly

(See Fig.28 ~ 33)

• Prior to performing the following procedure, remove the tray

assembly, side (L)/ side (R) assembly, lifter assembly.

Attention:

If the slide gear of the body places at joint w of the rack holder

assembly, turn the 1 gear counterclockwise to move the slide

gear toward the front. Remove the rack holder assembly.

(1) Remove the three screws J attaching the rack holder as-

sembly. Release joint w from the notch.

Caution:

When reattaching the rack holder assembly, do not nip

the wire x extending from the sensor assembly.

(2) Remove the two screws M attaching the sensor assembly.

(3) Move the sensor assembly in the direction of the arrow to

release from the slot at joint y.

(4) Remove the spring attached to the bottom of the sensor as-

sembly from the boss z on the sensor slider.

(5) Remove the screw N and O attaching the sensor board and

SV resister respectively.If necessary, unsolder the sensor

board.

Caution:

When reattaching the SV resister, attach the sensor slider to

the sensor bracket and fit the lever on the bottom of the SV resister into slot a’ of the sensor slider.

Caution:

When reattaching the rack holder assembly, turn the 1 gear

clockwise to move the slide gear and slide lever inside the

body rearward.

• Let the wire extending from the sensor assembly through notch

x to the bottom of the body.

• Fit pin c’of the slide lever into hole b’ of the sensor slider on

the bottom of the sensor assembly while attaching the spring

to the boss z of the sensor slider.

• Engage joint y of the sensor assembly to the notch of the body.

Rack holder

assembly

Rack holder

assembly

L

w

L

1 gear

x

L

Fig.28

Rack holder

assembly

1-26 (No.MB205)

w

w

Fig.29

Page 27

x

O

Soldering

SV resister

N

Sensor board

point

M

z

M

Sensor slider

y

a'

Fig.30

b'

Sensor assembly

Spring

Spring

a'

Slide gear

Sensor braket

Sensor slider

Fig.32

M

Sensor assembly

M

y

b'

z

z

Fig.31

c'

Spring

Fig.33

Slide lever

(No.MB205)1-27

Page 28

3.3.11 Removing the motor

r

(See Fig.34 ,35)

• Prior to performing the following procedure, remove the servo

control board and top cover.

Attention:

You need not to remove the tray assembly, and in such case,

move it.

(1) Remove the two belts on top of the body.

(2) Remove the four screws N attaching the motor.

(3) Remove the motor board from the bottom of the body.

(Refer to the section “Removing the motor board”.)

Attention:

When removing the motor board with the motor, you need not

to unsolder four soldered parts.

Caution:

When reattaching the motor, turn the side where the label

should be put to the front side.

Motor

Moto

NN

Belt

Fig.34

Label

Belt

Fig.35

1-28 (No.MB205)

Page 29

3.3.12 Taking out the CD in play mode

r

(See Fig.36 ~ 39)

Attention:

Refer to “Removing the tray assembly”.

(1) Remove the top cover upward.

(2) Unlock the tray assembly and draw out the tray assembly

toward the front.

(3) From top of the body, turn the 1 gear clockwise to move the

lifter assembly upward.

(4) From top of the body, turn the 2 gear clockwise to move the

sub tray remaining inside the lifter assembly toward the

front, then pull out.

(5) Take out the CD on the sub tray.

(6) After clearing away the CD, insert the sub tray into the main

tray.

Caution:

When reattaching the sub tray, move the tray stopper on

the bottom of the main tray in the direction of the arrow

to lock the sub tray certainly.

(7) Push the tray assembly toward the body and reattach.

Tray assembly

Tray assembly

Tray stopper

Sub tray

Fig.37

Main tray

2 gear

1 gear

Sub tray

Sub tray

Fig.38

Fig.36

Tray stoppe

Fig.39

(No.MB205)1-29

Page 30

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

1-30 (No.MB205)

Page 31

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB205)1-31

Page 32

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB205)

Printed in Japan

WPC

Page 33

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

FS-S57

CD-ROM No.SML200404

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2004 VICTOR COMPANY OF JAPAN, LTD.

2-1

2-3

2-15 to 20

No.MB205SCH

2004/4

Page 34

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 35

< MEMO >

Page 36

0

R

H

U

m

Block diagram

CD servo and CD system control section

A,B

C,D

E,F

CN601 CN602

LD,MD

CD

PICK UP

T+/F+/-

REST SW

FEED

MOTOR

SPINDLE

MOTOR

SM+/FM+/-

/REST_SW

IC601

RF

&

SERVO

AMP.

FOCUS

TRACKING

SPINDLE

BTL AMP.

/DR_MUTE

PC1,PC2

FM ANT

AM ANT

IC801

FEED

CN3 CN2

TBAL,FBAL

TE,FE,GCTL

/RFDET

OFT,BDO

ARF,RFENV

TRV,TRD

FOD,SPINDLE

AD0 to AD10

D0 to D3

IC671

DRAM

IC682

/CAS

/RAS

IC681

/WE

FM/AM tuner unit section Signal processing and syste

IC1

FM/AM

TUNER

TUL

TUR

9V

TUDIN

TUDOUT

CE,CLK

CN1

CN766

Q760

Q7601

TUNE

SWITC

FT

IC651

DIGITAL

SERVO

&

OUTL

OUTR

SDATAIN

SDATAOUT

TUCLK

TUCE

PROCESSOR

IC900

SYSTEM

MICON

/DCAS

/DRAS

/DWE

CASCNT

RASCNT

WECNT

TXTD

TXTCK

/RST_DSP

MON

FLAG

DQSY

BLKCK

MLD

MDATA

STAT

MCLK

TXD0

RXD0

RESET

CN765

CN651

CDL,CDR

CDCMD

CDRST

CDSTAT

Q7700,Q7701

TWIN

INVERTER

BUFFER

2-1

CD tray control section

IC1

TRAY MOTOR DRV.

IC2

POSITION MOTOR DRV.

CD tray switch

section

CN3

SW1 to SW6

SWITCH

SW8

SWITCH

IC1

POSITION

SENSOR

TR_OP

TR_CL

POS_UP

POS_DOWN

S.TR_ST

SW7

SWITCH

CN2

TR1_CL to TR5_CL

M.TR_OP

CN1

S.TR_END

L.SENSOR

CN251CN252 CN253

IC251

UNIT

MICON

IC201

EEPROM

E2PSDA

E2PSCL

AUX.

INPUT

TO

FAN

CN750

Q7500,Q7501

J2100

AUXL,AUXR

CDSTAT

FANON

FAN

DRIVER

Page 37

system control section

Q7600

Q7601

TUNER

WITCH

FTUNER

H/PSW

INHB

SPKRLY

Q7801

Q7802

SPEAKER

CIRCUIT

TUL

TUR

RY200

OUTL

OUTR

J2000

SPEAKER

OUTPUT

CN760

Power transformaer

T1101

TRANS

CN102

DIODE

BRIDGE

Primary section

CN101

T1100

TRANS

Q1100

Q1200 to Q1202

US6V REG.

CN100

AC

INPUT

00

EM

ON

VOLDA

VOLC K

VOLC E

/PRT,/SMUTE

POUTRLY

SPKRLY

VOLUME

CDL

CDR

AUXL

AUXR

/SMUTE

POUTRLY

H/PSW,INHB

IC901

& HPF

F1,F2

FLVH

/PRT

SIGL

SIGR

US6V

US10V

US8V

US3.3V

CN352

CN762CN761

CN351

POUTRLY

CN103

CN350

H/PL

H/PR

OUTL,OUTR

SIGL,SIGR

/PRT

Headphone

W5600

CN104

H/PL,H/PR

H/PSW

Q3200 to Q3202

H/P MUTING

Q3100 to Q3102

SYSTEM MUTE

/SMUTE

US3.3V

INHB,H/PSW

POUTRLY,US6V

IC343

US3.3V

REG.

J5600

HEADPHONE

JACK

Power amplifier section

+VH

-VH

IC340

POWER

AMP.

Q3105 to Q3107

PROTECTOR

US10V

IC341

US10V

S2

REG.

US8V

IC342

US8V

S2

REG.

POWERKEY

KEY1,KEY2

REM,VOLM,VOLP

FLDATA,FLSTB

FLBK,FLCLK

L-LED

C-LED

R-LED

Q7400 to Q7402

LED DRIVER

LEDCTL

LED CTL

Q7550

L-LED

C-LED

R-LED

LEDRED

LEDGREEN

CN700

CN550

POWERKEY

LEDRED

LEDGREEN

REM

REMSENSOR

S5200

TOP SWITCH

POWER

LED

IC520

LLED

CLED

RLED

DISPLAY

BACK

LIGHT

User key control sectionSource selector switch section

CN551

CN510

FL display section

CN552

FLDATA,FLSTB

CN570

FLVH,FLBK

FLCLK,F1,F2

VOLM

VOLP

KEY1

S5100 to S5116

KEY2

KEY MATRIX

J5100

VOLUME

DI570

FL DISPLAY

2-2

Page 38

Standard schematic diagrams

2

Primary and power amplifier section

IC340

STK432-070

R3100

4.7K

R3101

4.7K

C3100C3101

R3102

20K

Q3101

2SC3576-JVC-T

100P100P

R3104

10K

10/35

C3103

10/35

4.7/50

C3102

C3104

R3106R3107

47K47K

R3103

Q3100

R3105

10K

220

KRA102M-T

Q3102

2SC3576-JVC-T

C3105

100P

C3109

R3109

R3108

C3107

10P

47/50

820UNF( 1/4)

C3106

R3110

R3111

C3110C3111

R3112

33K

MTZJ9.1B-T2

10/50

L3100

0.39

10UNF( 1/4W)

10UNF( 1/4W)

0.10.1

C3112

0.22

R3113

0.22

R3114

220

R3116

R3115

100

C3114

D3100

C3113 C3116

0.022 0.022

Q3103

KTA1268/GL/-T

D3101

10K

R3117

2.2K

R3118

0.022

10/50

R3119

C3115

10/50

MTZJ9.1B-T2

D3102

R3120

R3121

2202.2K

100

0.22

R3123

D3104

R3122

R3124

0.22

C3117

Q3104

KTA1268/GL/-T

10K

10/50

L3101

R3125

0.39

R3138

C3119C3120

R3126

C3118

100P

10UNF( 1/4W)

R3127

C3121

10P

10UNF( 1/4W)

10UNF( 1/4W)

0.10.1

C3000

2200/502200/50

C3002

C3001

4.7K

R3150

B3010

Q3105

C3122

R3133

R3129

82K

R3128

47/50

120K

C3123

22/50

820UNF( 1/4)

R3130

10K

KTC3199/GL/-T

C3124

0.022

R3132

4.7FR( 1/4W)

R3134

100K

47K47K

R3131

100K

R3137

10K

Q3106

KTC3199/GL/-T

C3126

R3135

47/35

100K

C3125

Q3107

KTA1267/YG/-T

22/50

D3103

R3136

1.2K

2200/25

2-3

(SHEET 2)

NI

L3200

B3007

CN352

QGB2510K2-09

R3200

R3201

NI

2.7k

R3300

0.47

IC343

PQO33RDO1SZ

C3306

TH332

C3304

100/16

R3311

R3310

QAD0015-103Z

D3304

100/16

MTZJ3.6B-T2

C3300

10/50

C3301

10/50

D3300

IC341

KIA7810API

MTZJ11C-T2

10K

R3301R3302

10K

D3301

QGB2510K2-12

CN351

IC342

KIA7808API

R3303

0.33

NI

B3006

10K

10/50

D3302

R3304R3305

MTZJ11C-T2

18K

D3303

10/50

C3302

C3303

C3200

R3204

220

4.7/50

R3206

47K

Q3200

R3207 R3208

10K 10K

KRA102M-T

820

Q3201

820

2SC3576-JVC-T

Q3202

2SC3576-JVC-T

R3202

R3203

820

NI

B3008

L3201

820

(SHEET

Page 39

C3002

2200/25

CN350

S2

EP300

QNZ0136-001Z

QGB2510K2-14

CN103

QGB2510J1-14

+VH

AMPG

-VH

S2G

S2

DG

US10V

US6V

POUTRLY

INHB

H/PR

H/PGND

H/PL

H/PSW

C1303

0.1/50

0.1/50

1N5402M-20

D1303

1N5402M-20

D1302

1N5402M-20

C1302

0.1/50

C1300

D1300

D1301

1N5402M-20

C1301

0.1/50

C1403

0.1/50

1N4003S-T5

D1403

1N4003S-T5

1N4003S-T5

0.1/50

D1402

C1402

0.1/50

C1400

D1400

D1401

1N4003S-T5

C1401

0.1/50

B1601B1602

R1501

1K

Q1500

KTC3199/GL/-T

D1500

R1502

S1AC1

S1AC2

S2AC1

S2AC2

CN102

QGA3901C1-05

10K

R1500

47K

10/50

D1501

C1500

MTZJ5.1B-T2

T1101

(SHEET 3)

CN104

QGA2501F1-04

C1600

1000p

R1101

3.3K

Q1100

KTC3199/GL/-T

C1200

100/16

D1201

R1203

D1200

MTZJ5.6B-T2

R1202

1K

1K

Q1200

KTA1023/OY/-T

R1200

10K

Q1202

KTC3199/GL/-T

R1201

Q1201

KTC3199/GL/-T

1K

C1100

1N4003S-T5

1000/25

D1100

D1101

RY110

QSK0124-001

T1100

C1101

QCZ9105-472

LF110

QQR1321-001

R1102

CN101

QGA7901F2-02

CN100

QGA7901F2-02

3.3M

(SHEET 2)

(SHEET 2)

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 1

2-4

Page 40

Signal processing and system control section

3

7

R7056

2

12K

CD

TAT

R2116

6.2K

7.5K

7.5K

1.8K

R2141

CDR

AUXR

10K

TUR

1.5K

0.27

C2119

100/16

C2221

470

R2218

2SC2001/K/-T

0.1

100/16

0.1

C2220

C2223

C2222

100

R2221

Q2211

VOLCK

VOLDA

VOLCE

R2222

2.2K

R2224

US9V

R2112

2.2k

R2113

0.18

C2118

0.12

0.15

1.8K

R2117

22/16

C2116

C2115

C2117

2.2K

0.15

22/16

R2017

1.8K

0.27

C2019

6.2K

R2016

C2016

C2017

C2018

0.12

2.2k

1.5K

R2013

R2012

470

R2111

R2110

0.1

0.18

10/35

0.1

10/35

0.0027

C2114

C2112

C2113

C2111

C2109

C2110

0.18

0.1

0.18

10/35

0.0027

0.1

C2015

C2014

C2013

C2012

C2010

C2011

7.5K

7.5K

1.8K

R2041

R2010

R2011

R2140

4.7/50

C2108

IC901

LC75345M-X

10/35

C2009

R2040

R2501

10/35

4.7/50

C2126

0.018

100K

C2105

C2107

R2147

C2215

100/16

100K

R2047

C2026

10/35

0.018

4.7/50

4.7/50

C2005

C2007

C2008

470

CDL

AUXL

SIGL

10K

R2500

TUL

QNN0420-001

J2100

C2102

0.001

D2100

30K

R2100

SIGR

220P

220P

C2101

C2100

30K

30K

R2103

R2102

AUXR

D2101

30K

R2101

AUXL

(SHEET 1)

(SHEET 1)

*

J2000

(SHEET 1)

51K

C2213

10/50

QZW0038-001

PP700

CN762CN761

QGB2510J1-12QGB2510J1-09

NI

C2701

B7070

*

0.047

0.001

0.001

C2500

R2000

4.7

C2507

CN760

QGA2501C1-05

MTZJ5.1C-T2

D2600

C2504

C2508

C2502

B7071

0.047

B7072

0.047

C2501

4.7

R2001

C2505

0.0022 0.0022

C2503

0.047

B7073

*

NI

*

C2610

NI

*

NI

C2611

NI

NI

QUY150-050Y

R2600

1N4003S-T5

4.7 22

D2601

C2602

100/50

D2603

C2600

4.7/50

B2620

R2620

R2621

R2622

R2623

B2623

D2602

1N4003S-T5

L2001L2000

*

*

*

*

1N4003S-T5

C2601

Q2209

47/63

R2601

47K

R2115 R2015

R2602

NI

30K

D2205

R2114

R2207

/AHB

D7520

QSK0109-001

MTZJ24C-T2

D7521

NI

R2603

Q2600

D2206

NI

RY200

D2000

NI

100K

R2604

KTC3200/GL/-T

47K

Q2210

2SD601A/QR/-X2SD601A/QR/-X

R7520

NI

R7521

NI

KTA1268/GL/-T

12K

R2609

NI

MTZJ22C-T2

KTD863/Y/-T

Q2601

D2605

30K

R2014

R2208

120K

180 180

R2020

D2604

Q2602

MTZJ18C-T2

R2605

C2231

D2230

0.15

1/50

330K

R2228

C2239

3K

R2232

1/50

R2230

56K

56K

R2231

R2021

C2605

NI

NI

R2606

C2230

Q7802

UN2211-X

Q7801

KTC3199/GL/-T

1.5K

R7803

180

R2030

R2610

47/63

15K

15K

0.47/50 0.01

C2604

R2607

C2607

NI

C2606

C2700

R2608

NI

R7804

C7800

0.001

10K

QGF1036C1-17

C2703

NI

DGND

/PRT

NI

C7501

SPKRLY

FANFB

FLVHCTL

F1

F2

FLVH

NI

B2703

K2703

B2700

NI

K2700

NI

B2702

K2702

NI

K2701

CN765

R7701

B2701

/TEMP

/SAFETY0

VOLCK

2.2K

R7075

VOLDA

VOLCE

TUCE

SDATAIN

TUCLK

SDATAOUT

FTUNER

/AHB

/SMUTE

FLVHCTL

POUTRLY

SPKRLY

FANON

/PRT

Q7700

CDRST

CDCMD

R7700

2.2K

2.2K

R7704

KRC104M-T

2.2K

R7076

2.2K

R7077

2.2K

R7083

2.2K

R7084

2.2K

R7085

R7086

2.2K

R7087

5.6K

2.2K

R7089

1K

R7090

10K

R7091

4.7K

R7093

R7094

2.2K

2.2K

R7095

2.2K

R7096

10K

R7705

10K

Q7701

KRC102M-T

100K

R7706

CDSTAT

D7300

US6V

10K

R7296

CDL

CDR

C7300

100/16

2SD601A/QR/-X

D7302

MTZJ5.1C-T2

33K

R7300

IC900

MN101C57DEB

X7000

QAX0718-001Z

33P

C7012

C7304

C7305

R7302

100K

Q7300

R7301

47K

R7303

10K

R7254

S

CDRST

L-LED

R-LED

C-LED

5.6K

5.6K

5.6K

1.2K

R7060

R7062

R7061

R7057

R7018

C7018

0.01

1K

33P

C7013

NRST

0.01

L

QQL

100/16

K7

D7301

VDD

10K

R7304

C7302

4.7/50

C7301

D7303

2.2/50

10K

Q7301

UN2215-X

2-5

(SHEET 4)

Page 41

(

)

(SHEET 6)

4

7/50

QGF1201F3-11

CN766

C2702

Q7600

0.001

B2712

NI

2SB709A/R/-X

NI

NI

C7610

B2610

4.7/50

C7600

Q7601

UN2211-X

R7601

1K

10K

R7600

10K

R7602

R7604

R7605

R7603

1K

1K

LC72723

C7601

22P

C7603

0.1

IC760

QAX0263-001Z

X7600

10/501K560P

0.1

330P

C7616

C7606

C7607

NI

NI

TUR

TUL

10K

R7254

VDD

QQL231K-4R7Y

/SAFETY0

RDSDATA

/TEMP

RDSCLK

LEDCTL

DGND

MMOD

NRST

KEY2

KEY1

REM

VOLM

VOLP

FLBK

CDCMD

CDRST

FLSTB

CDSTAT

R-LED

5.6K

R7061

B

POWERKEY

C-LED

5.6K

2.2K

100

1.2K

1.2K

1.2K

100

R7052

R7053

R7054

R7060

R7056

R7055

R7057

CN777

R7048

2.2K

R7047

2.2K

R7046

2.2K

R7045

2.2K

2.2K

R7041

2.2K

R7037

2.2K

R7036

2.2K

R7034

2.2K

R7033

R7031

2.2K

2.2K

R7030

2.2K

R7029

R7248

*VERSION

R7246

10K

10K

R7245

NI

K7049

R7777

*VERSION

C7240

0.01

L7040

R7241

100K

10K

R7235

C7605

L7600

B2662

SDATAIN

TUCLK

SDATAOUT

TUCE

FTUNER

LEDCTL

C7402

L-LED

C7401

R-LED

C7400

C-LED

C7602

22P

C7604

R7233

R7234

*VERSION

*VERSION

R7660

*VERSION

RDSCLK

RDSDATA

160

R7551

1SS355-X

D7551

Q7550

UN2215-X

D7550

1SS355-X

390

R7408

390

R7407

Q7402

KTC3199/GL/-T

R7406

NI

390

R7405

390

R7404

Q7401

KTC3199/GL/-T

R7403

NI

390

R7402

390

R7401

Q7400

KTC3199/GL/-T

R7400

NI

47/35 47/35 47/35

R7661

*VERSION

LEDRED

LEDGREEN

2SC2001/K/-T

470

Q7602

R7606

220/10

C7608

POWERKEY

REM

LEDGREEN

LEDRED

KEY0

FL5V

VOLM

KEY1

KEY2

VOLP

FLDATA

FLBK

FLCLK

FLSTB

QGF1036C1-23

CN700

C7551

100/16

SHEET 3

10/50

C7550

10K

R7214

R7230

10K

R7229

R7018

K7023

K7025

0.01

C7018

1K

33P

C7013

NRST

0.01

L7300

QQL231K-100Y

100/16

K7300

301

VDD

10K

R7304

D7304

C7302

.

D7303

2.2/50

Q7301

UN2215-X

330

1000/6.3

D7305

R7305

C7303

MMOD

D7306

MA700A-T2

C7237

FANFB

FANON

QGA2501C1-02

D7500

D7501

UN2213-X

Q7501

R7500

10K

0.01

10K

10/50

C7500

QQL231K-4R7Y

Q7500

2SA1037AK/R/-X

CN750

FLCLK

FLDATA

L7500

FL5V

FLVH

F1

F2

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 2

2-6

Page 42

FL display / Users key control / Source selector switch section

5116

5100

IC520

GP1UM281XK

0.01

REM

US5V

POWERKEY

LEDGREEN

LEDRED

D5400 D5401 D5402

SELU1E10WXM-P SELU1E10WXM-P SELU1E10WXM-P

D5420

NI

D5421

NI

D5422

NI

C5200

D5200

SPR-39MVWF

C5201

22/16

S5200

QSW0651-001Z

C5202

0.01

US5V

POWERKEY

REM

LEDGREEN

DGND

LEDRED

FL5V

VOLM

FLVH

KEY2

F1

KEY1

F2

VOLP

FLDATA

FLBK

FLCLK

FLSTB

US10V

RLED

CLED

LLED

QGF1016F3-23

CN550

KEY2

VOLP

KEY1

J5100

QSW0993-001

VOLP

VOLM

0.01

C5104

C5105

CN551

QGF1016F3-05

CN510

QGF1016F3-05

KEY2

0.01

KEY1

C5100C5101

0.010.01

R5100

1K

S

S

R5116

1K

CN552

QGF1016F3-09

CN570

QGF1016F3-09

FL5V

FLBK

FLDATA

FLSTB

R5700

100

C5701

100P

C5702

100P

C5704

100P

C5703

100P

FL5V

FLVH

C5700

0.01

GND

F2

FLSTB

FLDATA

FLCLK

FLBK

DI570

QLF0117-001

F1

FLCLK

VOLM

B5101

NI

2-7

Page 43

CN550

QGF1016F3-23

Y

(SHEET 1)

QJK036-042104

W5600

H/PSW

H/PL

H/PGND

H/PR

L5600

QQL231K-470Y

K5600

QQR0621-001Z

L5601

QQL231K-470Y

C5600C5601

0.010.01

J5600

QNS0170-001

(SHEET 2)

R5100 R5101 R5102 R5103 R5104 R5105 R5106

1K 1K 1.2K 1.5K 2.2K 2.7K 3.9K

0.010.01

S5100

S5116

R5116 R5115 R5114 R5113 R5112 R5111 R5110

1K 1K 1.2K 1.5K 2.2K 2.7K 3.9K

S5101

QSW0651-001Z

S5115

QSW0651-001Z

QSW0651-001Z

QSW0651-001Z

S5102

S5114

QSW0651-001Z

QSW0651-001Z

S5103

QSW0651-001Z

S5113

QSW0651-001Z

S5104

QSW0651-001Z

S5112

QSW0651-001Z

S5105

QSW0651-001Z

S5111

QSW0651-001Z

R5107

5.6K

S5106

QSW0651-001Z

S5110

QSW0651-001Z

R5109

5.6K

R5108

10K

S5107

QSW0651-001Z

S5109

QSW0651-001Z

S5108

QSW0651-001Z

SHEET 3

2-8

Page 44

CD servo and CD system control section

R654

82k

CN251

QGF1036F1-15

TR3_CL

TR2_CL

TR4_CL

TR1_CL

TR5_CL

S.TR_ST

POS_DOWN

QGA2001F1-02

CN252

S.TR_END

QGA2001F1-03

CN253

L.SENSOR

QGF1006F2-16W

CN601

M.TR_OP

POS_UP

TR_OP

TR_CL

F

E

R625

D

C626

R624

B

R622

C

C625

A

R621

0.022

C633

E

R635

R607

22k

22k

10

D

A

B

C

F

R608

F+

T+

T-

F-

R632

3.9

C632

0.1/16

R634

3.9

(SHEET 5)

(SHEET 5)

(SHEET 5)

C003

0.1

VR001

HDU-110

C002

1

C004

0.1

C001

1

1K

Q631

0

NI

0

0

0

2SA1037AK/RS/-X

C201

0.1/16

IC201

CASCNT

BR24C08FV-X

WECNT

/DWE

R601

5.6k

C603

0.1/16

R602

3.9k

33k

C604

0.1/16

C602C601

NINI

R626

NI

R623

NINI

AN22002A-W

IC601

D601

NI

R631

0

C631

10/16

0.1/16

C612

0.1/16

0.1/16

100/10

C611

C623

C624

C608

NI

R611

3.9k

3.9k

R613

R617

0.039/16

C614

330p

C605

100k

R603

R604

C607

150p

0

NI

R605

C606

TP601

0.1/16

100/10

C622

C621

R606

0

0.0027

C615

C610

0.056/16

1.2k

C617

NI

0.0018

NI

NI

R619

R618

C616

TP1

C641

100p

Q653

NI

C644

C642

NI

C643

NI

NI

Q651

NI

Q652

NI

TBAL

FBAL

FE

TP622

TE

TP623

GCTL

/RFDET

OFT

BDO

ARF

RFENV

EQX5

EQX2

TP2

EQX4

RASCNT

/DCAS

QGA2001F1-06

CN602

TBAL

FBAL

FE

TE

RFENV

OFT

/RFDET

BDO

GCTL

ARF

NI

D654

TC7SH32FU-X

IC681

0

R679

C656

0.1/16

R652

0

470p 22k

C657

0.1/16

C658

TP653

R651

47k

R653

NI

R683

NI

Q654

TC74VHC08FT-X

IC682

C812

SPINDLE

TRV

FOD

NI

NI

NI

C813

C814

1000p

1500p

C806

TRD

NI

0.01/16

0.47

NI

NI

C805

R813

R817

NI

C804

R804

C803

R808

R805

4.7k

R801

4.7k

R809

22k

R814

18k

FM+

SM-

SM+

FM-

FM+

FM-

SM+

SM-

T-

T+

F-

F+

NI

NI

C807

C808

IC801

NI

NI

C809

C811

AN4801SB

PC1

PC2

22k

R818

C802

0.1/16

/DR_MUTE

R802

2.2k

TRV

R806

3.3k

SPINDLE

R811

15k

TRD

R815

15k

FOD

C801

220/10

/DRAS

5.6k

5.6k

5.6k

5.6k

R807

R803

R816

R812

2-9

Page 45

C201

0.1/16

TXD0

RXD0

INDEX

1k

1k

100p

R284

R278

C259

CN653

NI

656

52

70p

C657

BR24C08FV-X

TC7SH32FU-X

IC681

0

R679

0.1/16

0

R283

PC1

PC2

/DR_MUTE

EQX5

EQX2

EQX4

1k

R285

S.TR_END

1k

R286

M.TR_OP

1k

R287

TR5_CL

1k

R288

TR4_CL

1k

R289

TR3_CL

1k

R290

TR2_CL

1k

R291

TR1_CL

1k

R292

S.TR_ST

RASCNT

CASCNT

WECNT

L.SENSOR

NI

NI

C261

C258

C256

WECNT

D3

D2

AD9

AD8

AD7

AD6

AD5

/DWE

A42L2604V-45L

0.1/16

C655

D1

D0

C654

AD3

0.1/16

TP653

R651

47k

R653

22k

NI

0.1/16

82k

C658

R683

R654

NI

Q654

AD2

R656

0.022

1000p

C661

C659

NI

D655

R659

15k

15k

R661

AD4AD3

IC671

AD2

AD1

AD0

AD10

AD1

AD0

AD9

AD4

AD5

AD6

IC651

MN6627911AC1

100k

560

R657

0.12

C662

C663

0.1/16

0

C664

100/10

R658

0.1/16

C653

AD7

AD8

D3

D2

AD10

D1

/DWE

/DCAS

/DRAS

0

27k

R663

NININI

R664

K653

K652

K651

C667

0.1/16

BCLK

LRCK

NI

D656

SRDATA

0.1/16

C665

R662

100

C666

100/10

47k

47k

R293

R294

0.01/16

D0

K654

R665 R666

680 560

C668

C671

R667

680

IC251

MN101C61GMB1

1k

1k

R255

10k

C251

0.1/16

TXTCK

/RST_DSP

BLKCK

MDATA

R256

C252

MCLK

MDATA

STAT

D653

R677

MON

NAX0476-001X

X651

R655

4.7k

R682

100

TXTD

DQSY

STAT

MLD

MCLK

TX

FLAG

OUTR

OUTL

47k

10k

R254

R295

QAX0684-001Z

X251

R253

D652

NI

R678

0

C651

100/10

C652

0.1/16

100/10

0.1/16

C677

C678

0

R676

R675

1k

R674

1k

C674

0.1/16

R673

1k

R672

1k

33k

R671

R669

1k

NQR0007-002X

C673

0.1/16

2700p

C669

NI

C672

NI

2700p

R668

560

1k

1k

R282

R267

1k

TXTCK

TXTD

R281

1k

/RST_DSP

TP272

MON

FLAG

DQSY

BLKCK

R264

1k

1k

R263

R262

1k

R261

1k

R258

1k

TP273

0

10k

10k

10k

NI

R296

R257

C254

R259

R265

47/6.3

NI

0

C675

10p

C676

10p

TNO

COPY

EMP

POS_DOWN

POS_UP

TR_OP

TR_CL

MLD

R297

R298

10k

R681

1/16

C679

1.2k

IC691

10k

C291

C681

1/16

XC6206P182M-X

C253

0.1/16

Q291

2SB1424/QR/-W

47/6.3

INDEX

TNO

COPY

EMP

LRCK

SRDATA

BCLK

TXD0

RXD0

TX

OUTL

OUTR

NI

C257

CN651

QGF1036F1-17

1k

R271

R274

1k

C255

0.1/16

CN652

NI

(SHEET 2)

SHEET 4

2-10

Page 46

CD tray control section

1

IC2

SW5

QSW0844-001

TR5_CL

SW6

QSW0931-001

SW4

QSW0844-001

TR4_CL

SW3

QSW0844-001

TR3_CL

SW2

QSW0844-001

TR2_CL

SW1

QSW0844-001

TR1_CL

CN3

QGB1214J1-08S

TR5_CL

TR4_CL

TR3_CL

TR2_CL

TR1_CL TR1_CL

CN2

QGB1214K1-08S

M.TR_OP

TR5_CL

TR4_CL

TR3_CL

TR2_CL

POS_DOWN

POS_UP

C7

0.1/50

M2

QRA0164-00

2-11

Page 47

IC1

POS

DOWN

QVY0002-B14

SW8

QSW0886-002

LB1641 LB1641

C5

0.01/50

IC1

C3

0.01/50

WJM0331-001A

WJM0330-001A

TR3_CL

TR2_CL

TR4_CL

TR1_CL

TR5_CL

M.TR_OP

(SHEET 4)(SHEET 4)(SHEET 4)

CN1

QGF1036F1-16

_

M2

0164-001

D1

MTZJ6.2A-T2

TR_OP

TR_CL

C6C7

0.1/501/50

M1

QRA0164-001

C2

0.1/50

C1

100/10

POS_UP

TR_OP

POS_DOWN

TR_CL

SW7

QSW0886-002

SHEET 5

2-12

Page 48

FM / AM tuner unit section

R7

C2

100k

47p

C36

R16

R6

330

C11

0.01u

L8

L5

4.7u

R4

150

C3

56p

C6

6p

L1

L4

C4

NI

C8

15p

C9

12p

TR1

2SK3601GE,F

C20

C19

3p

R9

100k

C28

12p

D5

0.7p

HVU202

C26

470p

R13

1k

C17

0.01u

C18

NI

D4

HVU202

470

R14

C30C31

L7

C15

C32

12p

270k

TR4

KTC4081

33p

C35

15p

22p

R17

2.2k

R15

5.6k

C22

0.47u

R11

51

0.01u

0.01u

C39

2200p

R8

T1

C12

1.5p

22k

D6

C16

0.022u

C43

0.01u

C63

R12

0

NI

C75

430

8p

C23

R10

47k

L13

120u

D8

C34

5V

0.01u

2-13

Page 49

TR3

DTA114EUA

R33

C51

47/50

2.2k

R48

R37

3.6K

C42

51

R29

0.022u

C63

C48

330p

4.7/35

1k

R31

C58

C52

0.01u

0.012u

1k

R34

C54

22/50

1u

C61

R36

22k

C67 C68

10p

R50

NI

10p

X1

75KHz

D7

C70

C69

47/16

3V

0.01u

68k

NI

R54

39

200p

IC1

ALP038

R44

C73

F2

C41

47/50

SC107M3-A020

LT1

PCFAZ-105

C44

0.01u

100p

R57

2.2K

C46

C45

0.47u

47/16

C27

0.01u

C53

R32

C47

1u

C49

1u

T4

R30

100

C60

3.3K

11p

100P

C50

0.47u

C59

R26

R28

0.027u

7.5k

C55

0.027u

7.5k

3.3K

1K

R47

R49

3.3K

3.3K

R43

R53

47K

1.3k

TR7

R40 R39

240

KTC4075

C65

2.2/50

R45

18K

R41

C66

2.2/50

TR6

KTC4075

R46

R42

18K

240 1.3K

R52

560

CN1

(SHEET 2)

SHEET 6

2-14

Page 50

Printed circuit boards

1

Micon board

(Micon board)

R7250

Q7400

R7402

R7401

R7400

Q7401

R7405

R7404

R7403

Q7402

R7242

R7042 R7044

R7048

R7050

R7060

R7061

R7062

R7408

R7407

R7406

R7248

C7240

R7244

R7245

R7045

R7052

R7053

R7777

R7246

CN700

R7046

C7400 C7401

R7700 R7701

C7402

R7047

R7706

R7254

C7551

R7241

R7041

R7054

CN777

Q7700

C7550

C7250

K7049

R7704

D7550

R7036

R7235

L7040

D7551

R7031 R7033

R7034

R7055

R7056

R7057

R7551

R7230

R7030

R7705

Q7701

R7229

R7028

R7029

R7027

R7075

VR290

Q7550

C7227

C7228

R7214

CN791

R7077

R7076

X7000

9

IC

R7084 R7085

R7083

CN765

R7500

C2702

C7606

D7501

CN750

IC760

R7661

C7610

C7616

R7233

R7234

R7604

R7605

R2222

R2901

R2903

R2224

W792

R2900

R2221

C2223

C2900

C2222

C2902

C2117

CN762

IC902

D2900

R2113

R2012

C2901

C2016

C2220

R2112

C2116

IC901

C2

R2117

C

R2017

C2018

R2501

Q2211

D7305

D7302

C7300

R7601

D7300

K2900

R7600

C7302

D7303

D7306

Q7600

D7301

R2930

R2931

C7600

Q7602

X7600

R7606

C7602

D7500

CN766

C7608

C7601

R7037

R7301

R7300

C7500

C7605

C7604

Q7300

L7500

C7237

L7600

Q7501

R7302

Q7500

R7602 R7603

C7603

C7607

R2908

R2910

R2907

R2909

C7018

R7018

C7012

C7013

C7304

R7221

R7022

R7021

C7305

L7300

K7300

R7209

R7089

R7087

R7007

K2701

R7090 R7091

R7095

R7094

K2702

R7208

K2700

K2703

R7009

R7008

0

0

R7086

K7025

R7220

R7020

R7305

R7096

R7093

R7006

R7296

D7304

R7304

K7023

C7303

CN790

Q7601

Q7301

R7303

C7301

2-15

C5105

J5100

C5104

CN510

C5101

R5116

S5116

C5100

CN570

R5115

S5115

R5100

S5100

R5101

R5102

S5101 S5102

R5700

(Switch board)

R5114

S5114

R5103

S5103

(FL board)

R5104

S5104

C5702

C5704

R5113

S5113

C5703

R5105

S5105

R5112

S5112

R5106

S5106

C5701

C5700

R5111

S5111

DI570

R5108

S5108

R5107

S5107

R5110

S5110

C5102

R5109

S5109

C5103

S5501

S5500

CN550

CN551

R5500

C5500

R5501

D

C5501

D5422

5402

Page 51

C2901

2012

C2016

R2112

C2116

IC901

C2018 C2019

R2111

C2114

C2115

R2117

C2118 C2119

R2016 R2017

C2017

R2501

R2218

R2011

R2116

C2015

C2014

C2221

R2943

R2111

C2113

R2047

R2147

R2010

C2013

R2013

R2942

C2111

R2110

C2009

C2026

C2012

R2500

R2141

R2040

R2041