Page 1

AX-M9000

SERVICE MANUAL

MONAURAL INTEGRATED AMPLIFIER

AX-M9000

Contents

PHASE

SPEAKER

12

-180û 2

STANDBY/ON

PRESENCE

Area Suffix

E Continental Europe

GAIN CONTROL

EXT

PROCESSOR

1

SLEEP

EACH

AX M9000

MONAURAL INTEGRATED AMPLIFIER

LINE

23

45

1

MUTE

DOWN UP

6

ATT

Safety precautions --------------------------------------------------------1-2

Disassembly method -----------------------------------------------------1-3

Adjustment method -------------------------------------------------------1-10

Description of major ICs -------------------------------------------------1-11~21

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20933

Apr.2001

Page 2

AX-M9000

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to eachexposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. voltage measured Any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the JC version)

1-2

Page 3

AX-M9000

Disassembly method

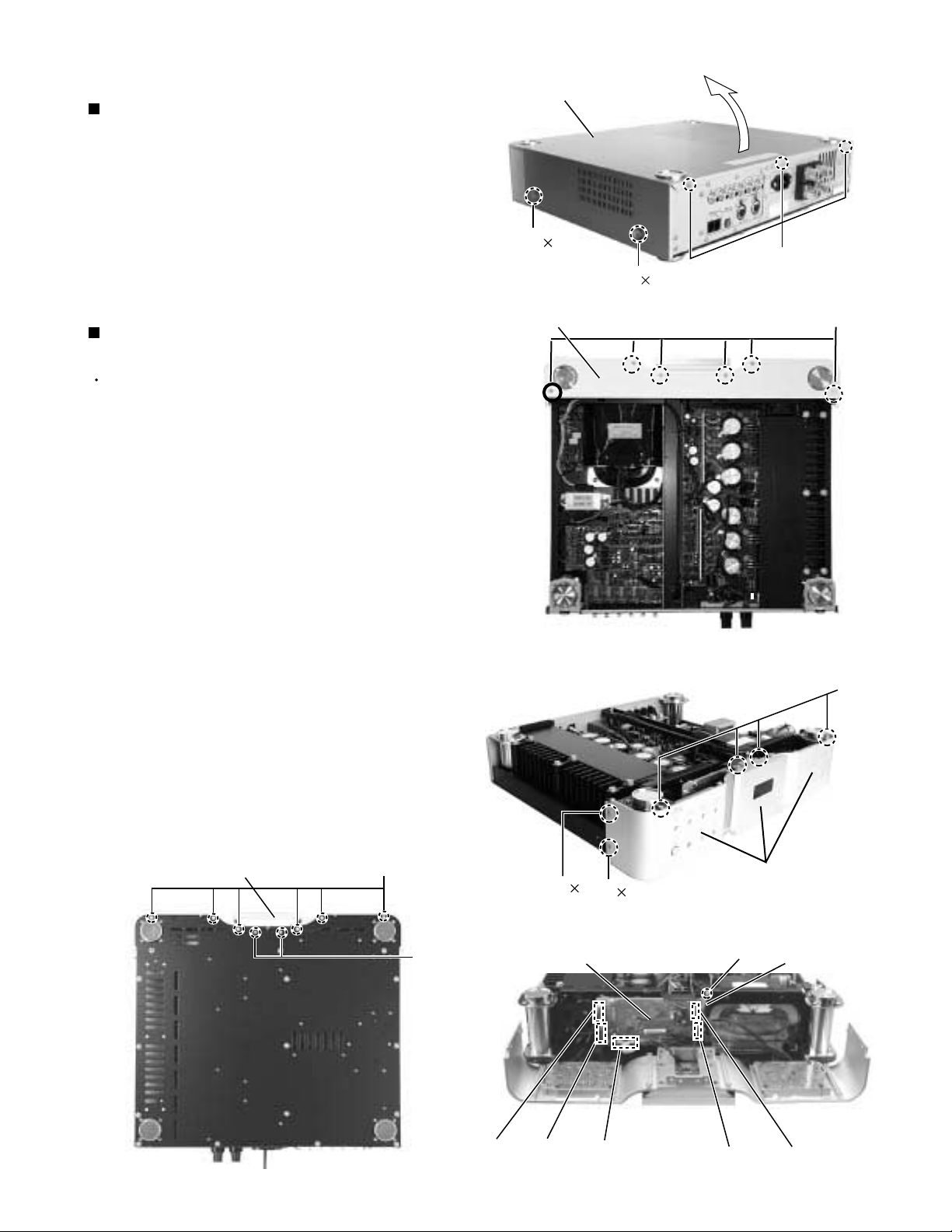

Removing the metal cover (See Fig. 1)

1.

Remove the three screws A attaching the metal

cover on the back of the body.

2.

Remove the four screws B attaching the metal cover

on both sides of the body using a hexagon wrench.

3.

Draw the metal cover upward from the behind while

pulling the both sides of the lower part of the metal

cover outward.

Removing the front panel assembly

(See Fig. 2 to 5)

Prior to performing the following procedure, remove

the metal cover.

1.

Remove the six screws C attaching the top plate

using a hexagon wrench.

2.

Remove the six screws D and tow screws D'

attaching the front panel assembly from the back of

the body.

Metal cover

B 2

Top plate

A

B 2

Fig.1

C

3.

Remove the four screws E attaching the front panel

assembly from the upper part of the body.

4.

Remove the four screws F attaching the front panel

assembly on both sides of the body.

5.

Disconnect the harness from the connectors CN601,

CN602, CN603, CN604 and CN605 of the system

control board assembly.

6.

Remove the screw G attaching the earth wire.

* The front panel assembly of this machine

comprises the three sets - the front panel

(left), front panel (right) and sub-panel (center).

Front panel assembly

D

D'

Fig.2

F 2

System control board assembly

F 2

Fig.4

Front panel

assembly

G

Earth wire

E

Fig.3

CN602

CN601

CN605

Fig.5

CN603

CN604

1-3

Page 4

AX-M9000

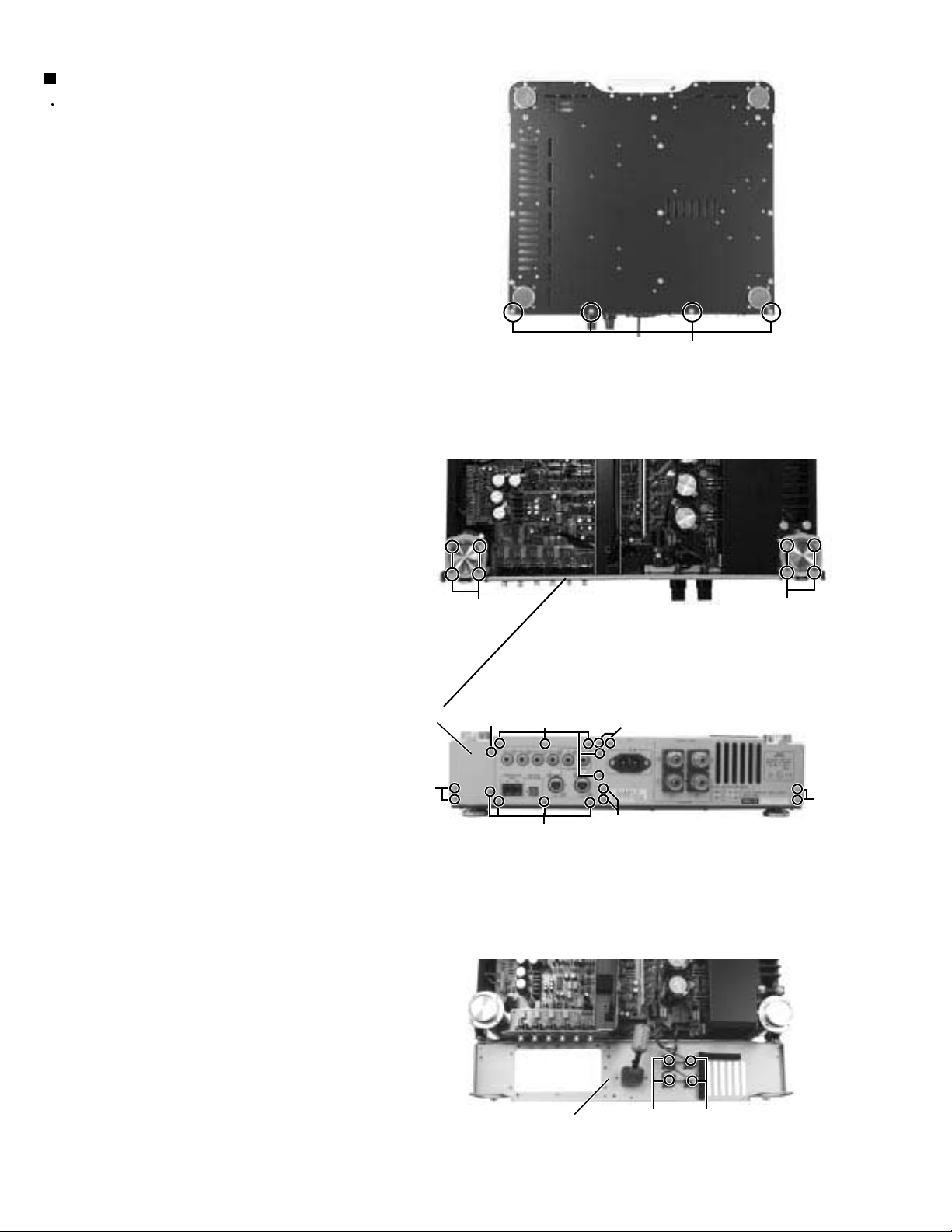

Removing the rear panel (See Fig.6 to 9)

Prior to performing the following procedure, remove

the metal cover and front panel assembly.

1.

Remove the four screws H attaching the rear panel

on the back of the set.

2.

Remove the eight screws I attaching the rear panel

on the upper part of the set.

3.

Remove the six screws J, two screws K, nine screws

L and one screw M attaching the rear panel.

4.

Draw the rear panel upward from the behind at the

legs while pulling the rear panel outward.

5.

Remove the four screws N attaching the speaker

output cord.

* If necessary, remove the power plug, connector

clamp, etc.

Rear panel

(Bottom)

Fig.6

I

Fig.7

M

L

K

H

I

1-4

J

J

L

Rear panel

J

Fig.8

N

Fig.9

N

Page 5

<Removing the front panel section>

AX-M9000

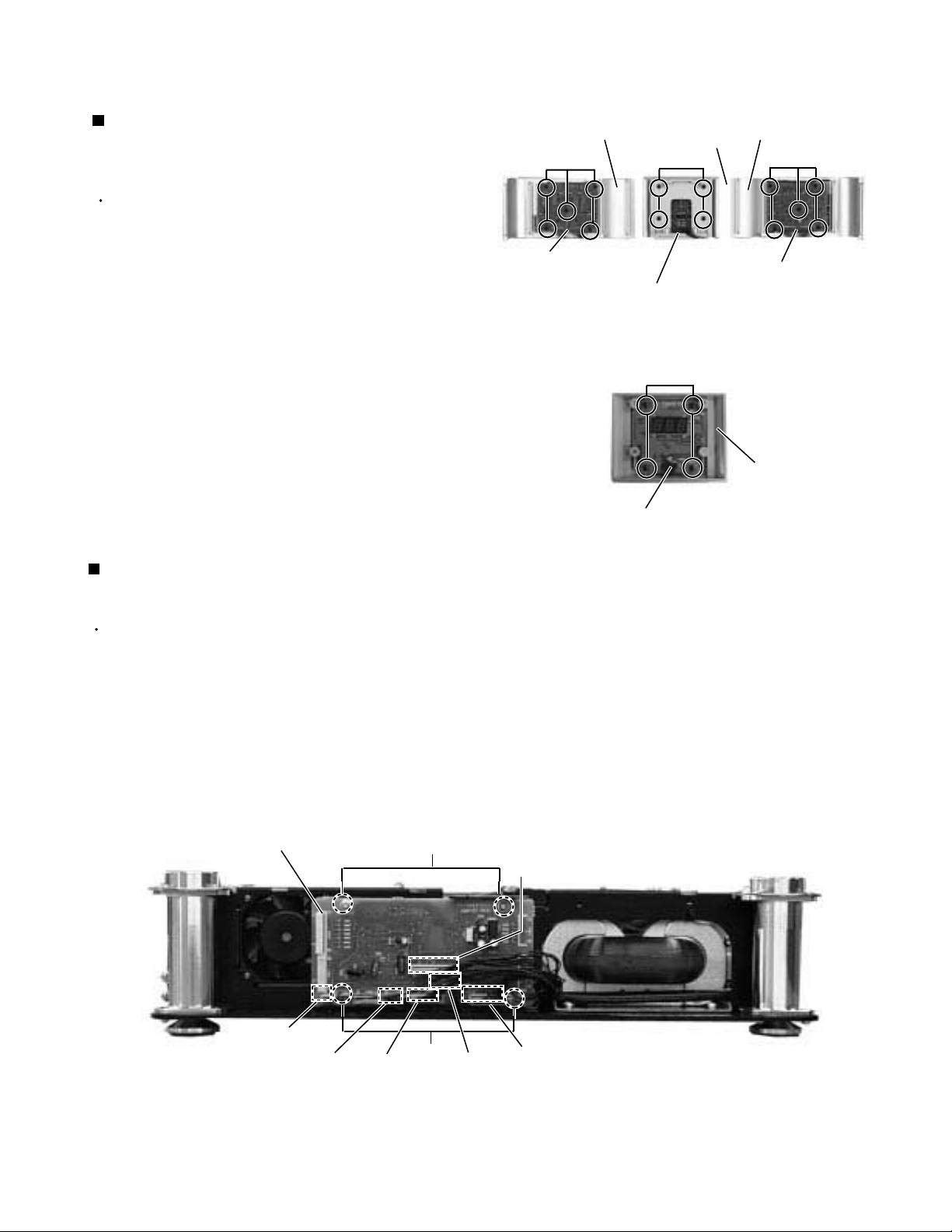

Removing the control switch board

assembly 1 & 2 and display board

assembly (See Fig.10 to 11)

Prior to performing the following procedure, remove

the metal cover and front panel assembly.

Remove the ten screws O attaching the control

1.

switch board assembly 1 & 2 on the back side of the

front panel assembly (left & right sides).

2.

Remove the four screws P attaching the metal base

on the backside of the sub-panel assembly (center).

Remove the four screws Q on the backside of the

3.

metal base. Then the display board assembly can be

removed.

Removing the system control board

assembly (See Fig. 12)

Front panel (right)

O

Control switch board (1)

Metal base

Display board

Sub-panel

P

Fig.10

Q

Fig.11

Front panel (left)

O

Control switch board (2)

Metal base

Prior to performing the following procedure, remove

the metal cover and front panel assembly.

Remove the four screws R attaching the system

1.

control board assembly.

Disconnect the connectors CN611, CN612, CN613,

2.

CN614, CN615 and CN616.

System control board assembly

CN614

CN613 CN616

R

R

CN612

CN611

CN615

Fig.12

1-5

Page 6

AX-M9000

CN402

CN401

TB403

TB404

Signal

processing

board

Power AMP board

CN301

TB402

T

11

Fig.13

TB401

Heat sink cover

CN453

S

U

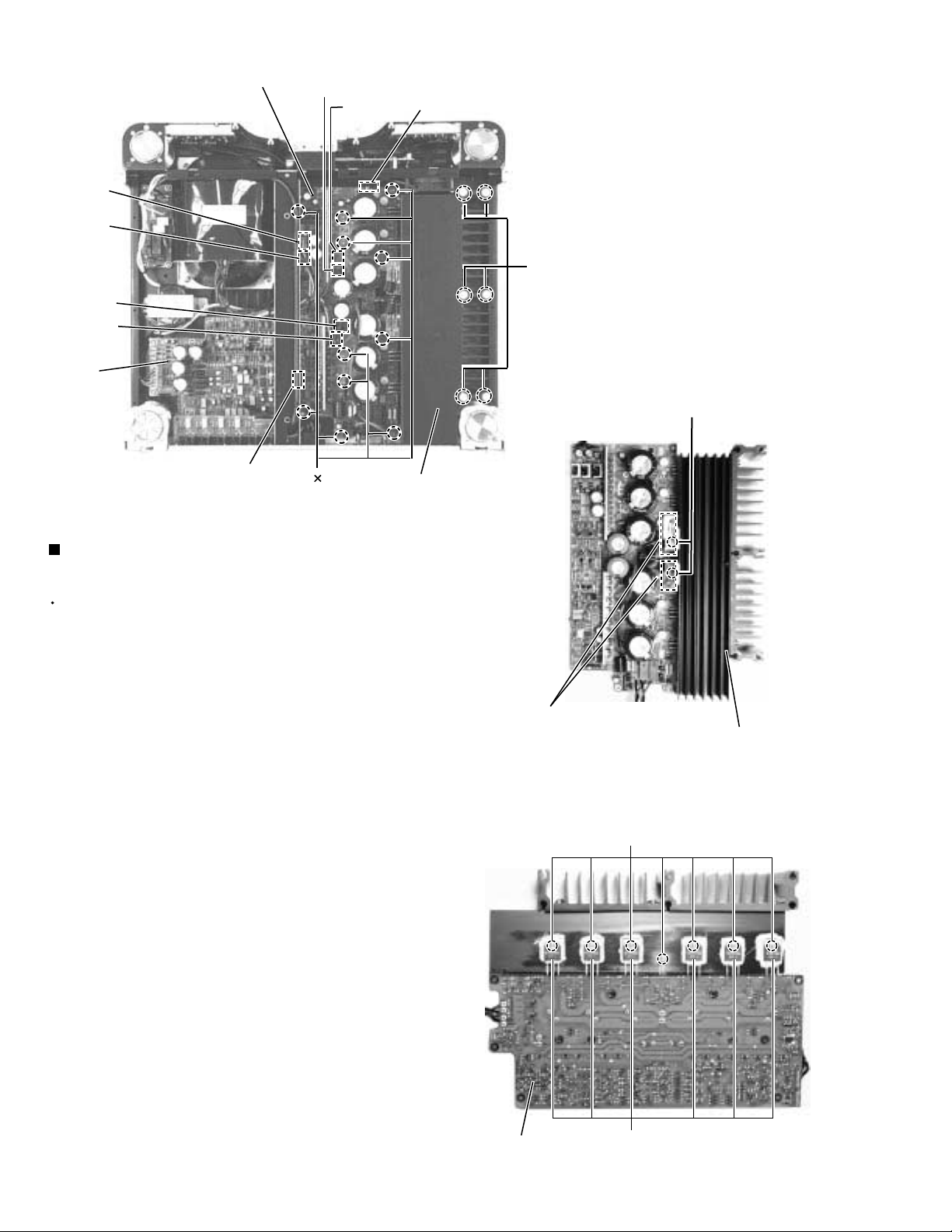

Removing the power AMP board

assembly / heat sink (See Fig. 13 to 15)

Prior to performing the following procedure, remove

the metal cover, system control assembly and rear

cover.

Remove the six through bolts S attaching the heat

1.

sink and the heat sink cover.

Remove the eleven screws T attaching the power

2.

AMP sub-board assembly.

Disconnect the harness, which is extending from

3.

power transformer, from the connectors TB401,

TB402, TB403 and TB404.

Disconnect the harness, which is extending from the

4.

power transformer for pre-AMP, from the connectors

CN401 and CN402.

Disconnect the harness, which is extending from the

5.

fan, from the connector CN453.

Disconnect the harness, which is extending from the

6.

signal processing board, from the connector CN301.

Power AMP sub-board

assembly (1) (2)

Heat sink

Fig.14

V

After removing each screw U attaching the power

7.

AMP sub-board assembly (1) & (2), take off the

power AMP sub-board assembly from the heat sink.

Remove the seven screws V attaching transistor

8.

Q335~Q340.

1-6

Power AMP board

Transisitor Q335~Q340.

Fig.15

Page 7

AX-M9000

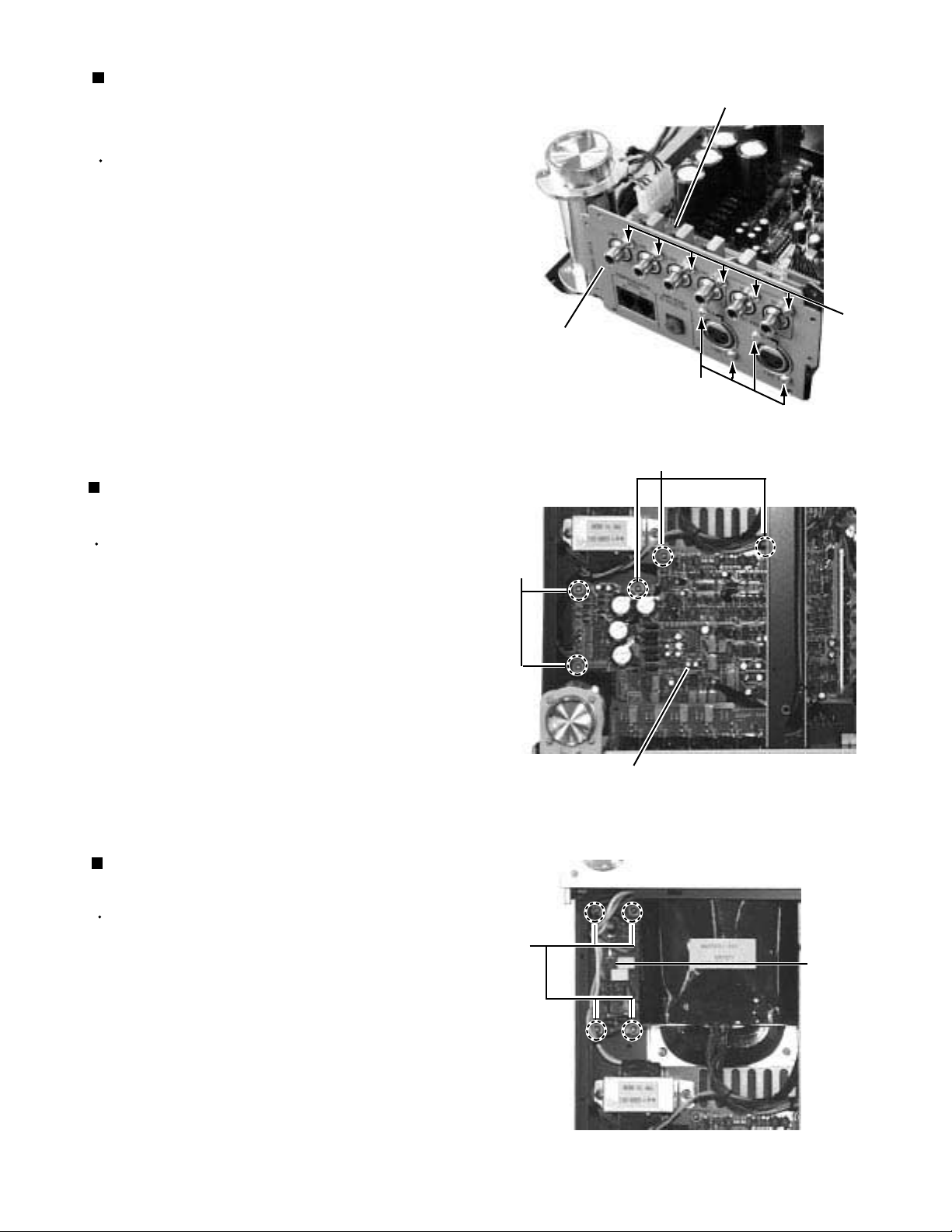

Removing the current mode source

selector board assembly and rear

terminal panel (See Fig. 16)

Prior to performing the following procedure, remove

the metal cover and the rear panel.

1.

Remove the six screws W attaching the RCA pins on

the current mode source selector board assembly.

Then, the current mode source selector board can

be removed.

2.

Remove the four screws X attaching the cannon

connector on the signal processing board.

3.

Then, the rear terminal panel can be removed.

Removing the signal processing board

assembly (See Fig. 17)

Current mode source selector board assembly

W

Rear terminal panel

X

Fig.16

Y

Prior to performing the following procedure, remove

the metal cover and the rear panel.

1.

Remove the current mode source selector board

assembly and the rear terminal panel.

2.

Remove the five screws Y attaching the signal

processing board assembly.

3.

Remove the connectors CN251 and CN252.

Removing the power switch board

assembly (See Fig. 18)

Prior to performing the following procedure, remove

the metal cover.

1.

Remove the four screws Z attaching the power

switch board assembly.

Y

Signal processing board

Fig.17

Z

Power

switch

board

2.

Remove the cable connecting to the transformer.

Fig.18

1-7

Page 8

AX-M9000

Removing the core transformer

for pre-AMP (See Fig. 19)

Prior to performing the following procedure, remove

the metal cover.

1.

Remove the two screws A attaching the power

transformer for pre-AMP.

Removing the transformer

for power AMP (See Fig. 20)

Prior to performing the following procedure, remove

the metal cover and the front panel assembly.

Remove the four screws B attaching the power

1.

transformer for power AMP.

A

Power transformer

for pre-AMP

Fig.19

Power transformer for power AMP

B

1-8

Fig.20

Page 9

AX-M9000

Arrangement drawings for the clamp binding

In order to secure the performance of the machine, refer to the following arrangement drawings

when the lines are clamped.

CLAMP

Orange, Blue wire

Gray wire

Black wire

Purple wire

Red wire

Yellow, Brown wire

CN insertion

CN insertion

Red, Black wire

CN insertion

S CLAMP

White wire

Red wire

S CLAMP

White wire 2

Red wire 2

Fig 1.

CLAMP

CLAMP

WR104WR103

WR102

S CLAMP

Red wire 2

Black wire

CLAMP

S CLAMP

White RED wire

Brown wire

13P

8P

12P

Fig 2.

1-9

Page 10

AX-M9000

Adjustment method

1. List of measuring devices

Measuring devices : Electronic voltmeter

Oscilloscope

Low-frequency transmitter (50Hz-20 kHz of transmitting frequency and output of 0

dBs at the 600 terminal)

Distortion factor tester (with a built-in band path filter)

2. Adjustments and confirmation

Description

Adjusting method

Standard value

Remarks

Standard

output

Total distortion

factor

Output level

Hum noise

Frequency

characteristics

AC voltage of

speaker terminal

Adjustments of

idling currency

1) INPUT LINE1 - Output at the time of THD0.5% at f=1kHz

1) INPUT LINE1 - Distortion factor at the time of

200W (40.0V) at 8 load

1) Output level at the time when inputting 1kHz 200mV

to LINE 1

1) Line 1

2) Base hum

1) Line 1

1) No signal, no load, Vol. 0.0

1) Prior to turning the power on, turn the R398

counterclockwise fully

2) After connecting the 3 pin and 4 pin of the CN303 to the

electronic voltmeter, adjust the voltage to 2-3mV.

3) After elapsing five minutes, adjust the voltage to

3.5+/-0.5mV. Since there is backlash, thoroughly adjust it.

4) After elapsing two minutes, make sure that the voltage

falls within 3.5-7mV. In case where the voltage does not

fall within the specified value, readjust it to the values

specified in 3) above.

Input short

Volume min.

100Hz

1kHz

10kHz

Vol. 99. 5

Vol. 99. 5

Vol. 69. 5

Vol. 44. 0

Vol. 99. 5

More than

210W/8 (41.0V)

20Hz Less than 0.04%

1kHz Less than 0.04%

20kHz Less than 0.06%

192mV +/- 10mV

Less than 10mV

Less than 0.4mV

45.6dB 1dB

45.6dB 1dB

33.4dB 1dB ATT ON

31.0dB 1dB

5.8dB 1dB

45.6dB 1dB

Less than +/- 1mV

Confirmation of

idling currency

Crosstalk

1-10

1) No signal, no load, rated power

Confirm under the room temperature of 20-25

1) INPUT LINE 1 - The output at the

input terminal side shall be +20dBm

as a standard.

The CH to be measured shall be terminated at 10k

Line1

to

Line2

Line1

to

Line5

Five minutes later

after turning the

power on

100Hz More than 70dB

1kHz More than 70dB

10kHz More than 70dB

100Hz More than 70dB

1kHz More than 70dB

10kHz More than 70dB

Page 11

Description of major ICs

BU2114F-X (IC542,543,544) : LED controller

1. Pin layout

AX-M9000

2. Pin function

Pin No.

1

2

3

Symbol

SIN

CK

LATCH

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

SOUT

EN

RST

GND

GND

GND

08

07

06

05

04

03

02

01

VDD

SIN

CK

LATCH

SOUT

EN

RST

GND

GND

GND

I/O

O

O

O

O

O

O

O

O

O

1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

VDD

01

02

03

04

05

06

07

08

Function

I

I

I

Serial data input terminal

Shift lock of the shift register

When this terminal is set at "L", the latch output will be secured,

In addition, when the output of the shift register is changed during

"H", the latch output will be changed simultaneously.

Output of the shift register at the final stage

I

I

-

-

-

Enable terminals of 01 to 08

Reset of the shift register and latch

Ground

Ground

Ground

Output of the shift register at the 8th stage

Output of the shift register at the 7th stage

Output of the shift register at the 6th stage

Output of the shift register at the 5th stage

Output of the shift register at the 4th stage

Output of the shift register at the 3rd stage

Output of the shift register at the 2nd stage

Output of the shift register at the 1st stage

-

Power supply

1-11

Page 12

AX-M9000

MN101CP10A(IC521) : System controller

1.Pin layout

2. Pin function

Pin No.

Symbol

1

KY10 (DOWN)

2

KY11 (LINE)

3

KY12 (MUTE)

4

TMP IN1

5

TMP IN2

6

VREF+

7

VDD

8

OSC2

9

OSC1

10

VSS

11

XI

12

XO

13

MMOD

14

SADATO

15

SADATI

16

SACLK

17

SBDATO

18

SBDATI

19

SBCLK

20

SREQO

21

RST

22

VOLCS

23

VOLCLK

24

VOLDATO

25

AT T

26

MUTE LED

27

M.WAKE

28

SREQI

29

INH

30

ROT3

31

ROT2

1

~

16

~

4964

48

~

~

33

17

I/O

O

O

O

O

O

O

O

O

O

O

O

32

Pin function

I

Key input 10

I

Key input 11

I

Key input 12

I

Temperature detect 1

I

Temperature detect 2

AD reference voltage

terminal 5.0V

2.0 5.0V supply

Clock out

I

Clock in

0.0V supply

I

GND

Open

I

Memory extended mode

SA data out

I

SA data in

SA clock

SB data out

I

SB data in

I

SB clock

Request for the communication

output between the sets

I

Reset terminal

VOL. CS

VOL. clock

VOL. out

Input ATT

Mute LED

I

Return form the stop mode

I

Request for the communication

output between the sets

I

INM

I

Rotary input 3

I

Rotary input 2

Pin No.

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Symbol

ROT1

C

B

A

POWER

ABS

MONPRO

ALLEACH

PRESEN1

PRESEN2

SPKB

SPKA

FANH

GM1

GM2

HPS

LRST

FANL

LDATO

LCLK

LACH

B.CON

RM

KY1 (HPS)

KY2 (EACH)

KY3 (PRO)

KY4 (PRE)

KY5 (SP)

KY6 (PHASE)

VSS

KY7 (POWER)

KY8 (ATT)

KY9 (UP)

I/O

Pin function

I

Rotary input 1

O

Line decoder C

O

Line decoder B

O

Line decoder A

O

Power SW

O

Absolute phase SW

O

MON/ PRO SW

O

All each (LED)

O

Presence SW1

O

Presence SW2

O

Speaker B

O

Speaker A

O

Fan control High

O

GM volume output 1

O

GM volume output 2

O

HPS filter SW

O

Serial/ Parallel IC reset

O

Fan control LOW

O

Serial/ Parallel IC out data

O

Serial/ Parallel IC clock

O

Latch

O

Brightness control

O

Remote control input

I

Key input 1

I

Key input 2

I

Key input 3

I

Key input 4

I

Key input 5

I

Key input 6

(GND)

I

Key input 7

I

Key input 8

I

Key input 9

1-12

Page 13

NJM2903M-XE(IC454) : Temperature detector

1. Pin layout

A OUTPUT

1

8

V

AX-M9000

+

A -INPUT

A +INPUT

GND

2. Block diagram

+

V

D101

2

3

4

Q110

(TOP VIEW)

Q109

D103

Q111

D104

D102

7

6

5

Q112

B OUTPUT

B -INPUT

B +INPUT

Q8

Q7

Q1

+INPUT

-INPUT

GND

Q101

Q103

Q105

Q104

Q106

Q102

Q107

Q108

Q5

Q6

OUTPUT

Q4

Q3

R1

Q2

1-13

Page 14

AX-M9000

NJM5532M-D-W(IC152,153) : Presence circuit amp

1. Pin layout

2. Block diagram

+INPUT

INPUT

A OUT

A - IN

A + IN

V -

1

2

3

4

8

7

6

5

V +

B OUT

B - IN

B + IN

V+

OUTPUT

V

1-14

Page 15

OPA134PA(IC108, 201, 301) : OP Amp.

Pin layout

Offset Trim

1

8

AX-M9000

Offset Trim

2

- In

+ In

V -

3

4

-

+

8-Pin DIP, SO-8

TC74HC04AF(IC264) : Data line buffer

Pin layout

14

13

12

11

10

Vcc

6A

6Y

5A

5Y

4A

9

1A

1Y

2A

2Y

3A

3Y

1

2

3

4

5

6

V +

7

6

Output

5

NC

A

L

H

Y

H

L

GND

4Y

7

(TOP VIEW)

8

1-15

Page 16

AX-M9000

TC74HC238AF-X(IC525) : Line recorder

1. Pin layout

2. Truth table

ENABLE

G1 G2A

L

X

X

H

H

H

H

H

H

H

H

A

B

C

G2A

G2B

G1

Y7

GND

INPUTS

SELECT

CB

G2B

X

X

X

XXXX

H

X

H

X

LL

L

L

L

LL

LL

L

LL

LL

H

LL

LL

H

HH

LL

1

2

3

4

5

6

7

8

(TOP VIEW)

A

X

X

XX

L

H

L

H

H

H

LLLL

L

H

L

H

HH

16

Vcc

15

Y0

14

Y1

13

Y2

12

Y3

11

Y4

10

Y5

Y6

9

OUTPUTS

Y0 Y1 Y2

Y3

Y4

Y5

Y6 Y7

LLLLLLLL

LLLLLLLL

LLL

H

LLLLLLL

L

L

L

L

H

H

L

L

L

LLLL

LLLLL

LLLLLL

L

L

L

L

L

L

L

H

H

L

L

L

L

L

L

L

L

L

L

H

L

H

LLLLLLL

X : Don't Care

SELECTED OUTPUT

NONE

NONE

L

NONE

L

L

L

L

L

L

H

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

3. Block diagram

SELECT

INOUT

1-16

A

B

C

ENABLE

INPUTS

15

Y0

14

Y1

1

2

3

4

G2A

5

G2B

6

G1

13

Y2

12

Y3

DATA

Y4

Y5

Y6

Y7

OUTPUTS

11

10

9

7

Page 17

TC74HC27AF-W(IC531) : Noa gate

1. Pin layout

AX-M9000

2. Truth table

1A

1B

2A

2B

2C

2Y

GND

1

2

3

4

5

6

7

(TOP VIEW)

14

13

12

11

10

Vcc

1C

1Y

3C

3B

3A

9

3Y

8

TC74VHC08F-X(IC281) : Dataline buffer

1. Terminal layout

14

1A

1

Vcc

AB

XL

H

X

H

X

X

L

L

X : Don't Care

2. Truth table

A

L

B

C

Y

X

L

X

L

H

L

H

Y

L

L

1B

1Y

2A

2B

2Y

GND

13

12

11

10

9

8

4B

4A

4Y

3B

3A

3Y

2

3

4

5

6

7

(TOP VIEW)

L

H

H

H

L

HH

X : Don't Care

L

L

1-17

Page 18

AX-M9000

TC74HC373HF-X(IC522, IC523, IC524) : Shift register for relay control

1. Pin layout

1

OE

Q0

2

3

D0

4

D1

5

Q1

6

Q2

D2

7

D3

8

9

Q3

GND

10

(TOP VIEW)

20

19

18

17

16

15

14

13

12

11

Vcc

Q7

D7

D6

Q6

Q5

D5

D4

Q4

LE

2. Truth table

INPUTS

OE

H

L

L

L

X : Don't Care

Z : High impedance

Qn: The Q output level immediately

before the LE becomes to "L".

LE

X

L

H

H

D

X

X

L

H

OUTPUTS

Q

Z

Qn

L

H

3. Block diagram

LE

OE

D0

34

D1

D

L

D

Q

L

Q0

D2 D3 D4

7

Q

52

Q1

813

D

L

D

Q

L

6

Q2

D5

14

D

Q

9

Q3

Q

L

12

Q4 Q5

D6

17

D

Q

L

15

D7

18

D

L

D

Q

16

Q6

Q

L

19

Q7

1-18

Page 19

TC74VHC123AF-X(IC532) : Monostable multivibrator

1. Pin layout

16

15

14

13

12

11

10

9

Vcc

1Rx/Cx

1Cx

1Q

2Q

2CLR

2B

2A

1A

1B

1CLR

1Q

2Q

1Cx

2Rx/Cx

GND

1

2

3

4

5

6

7

8

(TOP VIEW)

AX-M9000

2. Block diagram

X/CX

R

C

X

A

B

CLR

3. Timing diagram

A

B

CLR

RX/CX

Q

Q

t

w OUT

V

CC

Vref Vref

L

-

Q

Q

N

+

P

V

CC

R

D

Q

F/F

CK

Q

t

w OUT

C2

+

-

t

rr

H

t

w OUT+

Q

Q

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

CC

VrefH

VrefL

GND

V

OH

V

OL

V

OH

V

OL

t

rr

1-19

Page 20

AX-M9000

UPC1237HA (IC453) : Protection IC

1. Pin layout

12

2. Block diagram

R4

D1

R5

2

Q1

R3

1

Q2

34

R6

Q4

D4

D2

D3

5678

3

R9

Q6

R10

Q5

R11

Q20

R13

Q8

R14

Q7

8

D7

Q15

D6

Q16

R22

R24

R25

75

R16

R15

Q9

R17

R19

Q10

Q11

R18

R20

Q12

R21

Q13

Q14

4

R26

6

Q17

Q18

R27

Q19

R28

1-20

Page 21

VC5022-2(IC302) : Advanced super A

Block diagram

AX-M9000

1

2

3

4

R1

1.6k

Q1

9

Q10

8

R7

1.6k

Q9

7

Q2

R3

1.6k

R8

220

6

Q3

Q4

Q5

Q6

R4

R2

220

51

Q7

R5

51

Q8

R6

51

5

1-21

Page 22

AX-M9000

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20933)

Printed in Japan

200104(V)

Loading...

Loading...