Page 1

SERVICE MANUAL

COLOUR TELEVISION

AV-T2912

Supplement

/ZAR

AV-T2912

BASIC CHASSIS

GA

The following item for the AV-T2912

Therefore, this service man ual describe s only the items which differ from those of the AV-T2922

service manual.

For details other than those described in this manual, please refer to the AV-T2922

manual (No.51917 Mar. 2002) .

■ OUTLINE

Since the picture tube was c hanged, we have issued the SERVICE MANUAL for AV-T292/ZAR.

Since the picture tube was c hanged, we have issued the SERVICE MANUAL for AV-T2912/ZAR.

■ HOW TO IDENTIFY MODELS

Identify that the model name “AV-T2912Z” is printed on the margin of the rating label affi xed

to the rear cover.

model was changed partly from AV-T2922

/ZAR

(AR)

(AR)

service

model.

(AR)

1

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

Page 2

A

V-T292

2

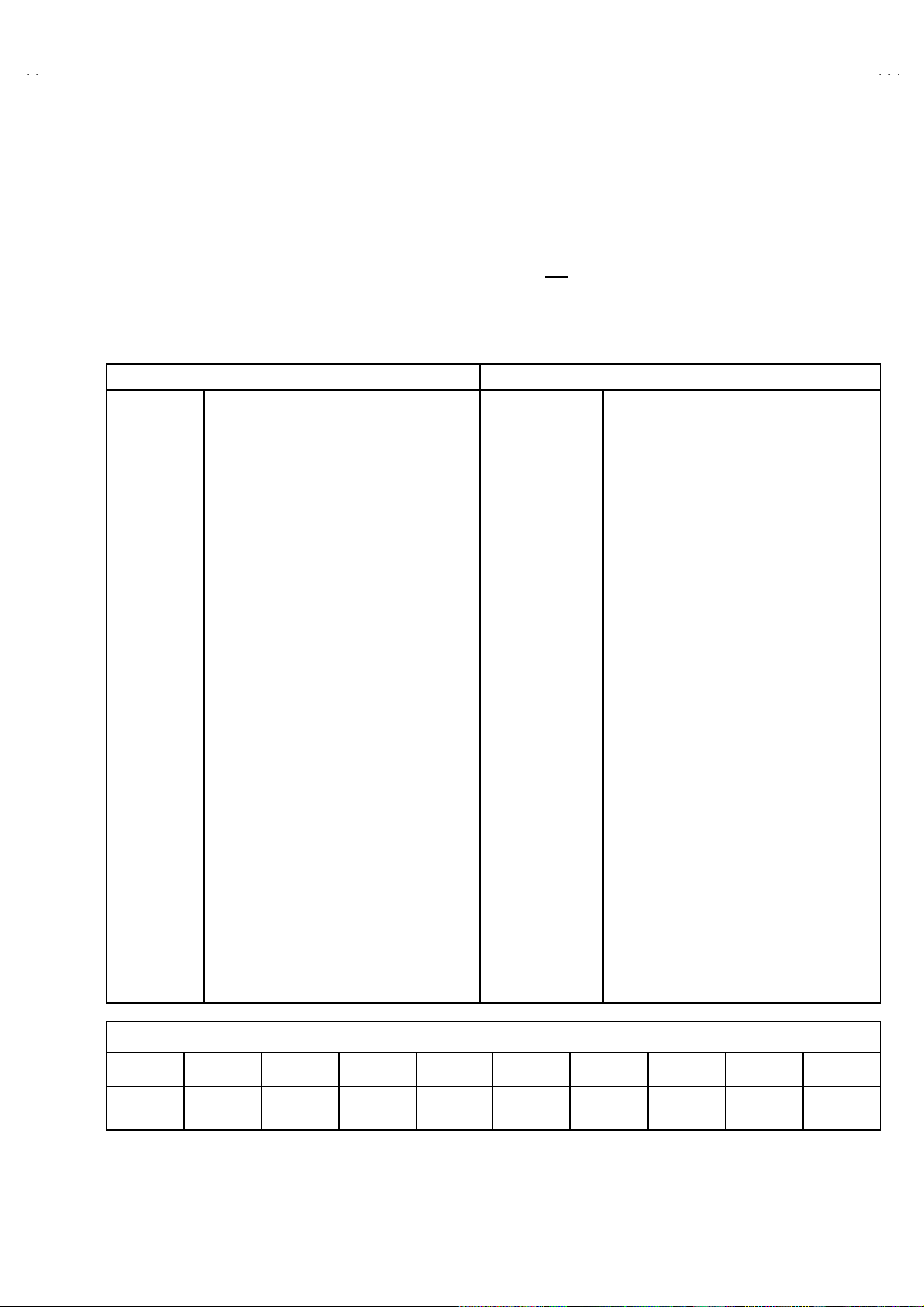

PARTS LIST

CAUTION

! The parts identified by the ! sym bol are impor tant for t he s afety. Whene ver r eplaci ng these parts, be s ure t o use s pec if ied o nes to secur e

the safet y .

!

The parts not ind ic ated in this Parts L ist and tho se whi ch are filled wi th lines in the Parts No. columns will not be supplied.

! P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be s upplied.

ABBREVIATIONS OF R ESISTOR S, CAPACITORS AND TOLERANCES

RESISTORS CAPACITORS

C R Carbon Resistor C CAP. Ceramic Capacitor

F R Fusible Resistor E CAP. Electrolyt ic Capacitor

P R Plate Res istor M CAP. Mylar Capacitor

V R Variable Resisto

HV R High Voltage Resistor MF CAP. Metalized Film Capacitor

MF R Metal Film Resistor MM CAP. Metalized Mylar Capacitor

MG R Metal Glazed Resistor MP CAP. Metalized Polystyrol Capacitor

MP R Metal Plate Resi sto r PP CAP. Po lyp ropylen e Ca pa citor

OM R M etal Oxide Film Resistor PS CAP. Polystyrol Capacitor

CMF R Coating Metal Film Resistor TF CAP. Thin Film Capacitor

UNF R Non-F lammabl e Resi stor MPP CAP. Metalize d P olypr op ylene Cap acitor

CH V R Chip Variable Resistor TAN. CAP. Tantalum Capacitor

CH MG R Chip Metal Glazed Resistor CH C CAP. Chip Ceramic Capacitor

COMP. R Composition Resist or BP E CAP . Bi-Pola r El ectrolytic C a pacit or

LP TC R

Linear P ositive T emperat ure C o efficient

Resistor

r

HV CAP. High Voltage Capacitor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CA P.

CH TAN. E CAP.

Chip A luminum B i-Po lar Cap acitor

Chip T ant alum Elec tr olytic Capacitor

CH AL BP E CAP.

Chip T ant alum Bi-Polar Electrolyt ic C a pac itor

TOLERANCES

FGJ KMNRHZ P

±1% ±2% ±5% ±10% ±20% ±30%

+30%

-10%

No.51917

+50%

-10%

+80%

-20%

+100%

-0%

31

Page 3

A

V-T2922

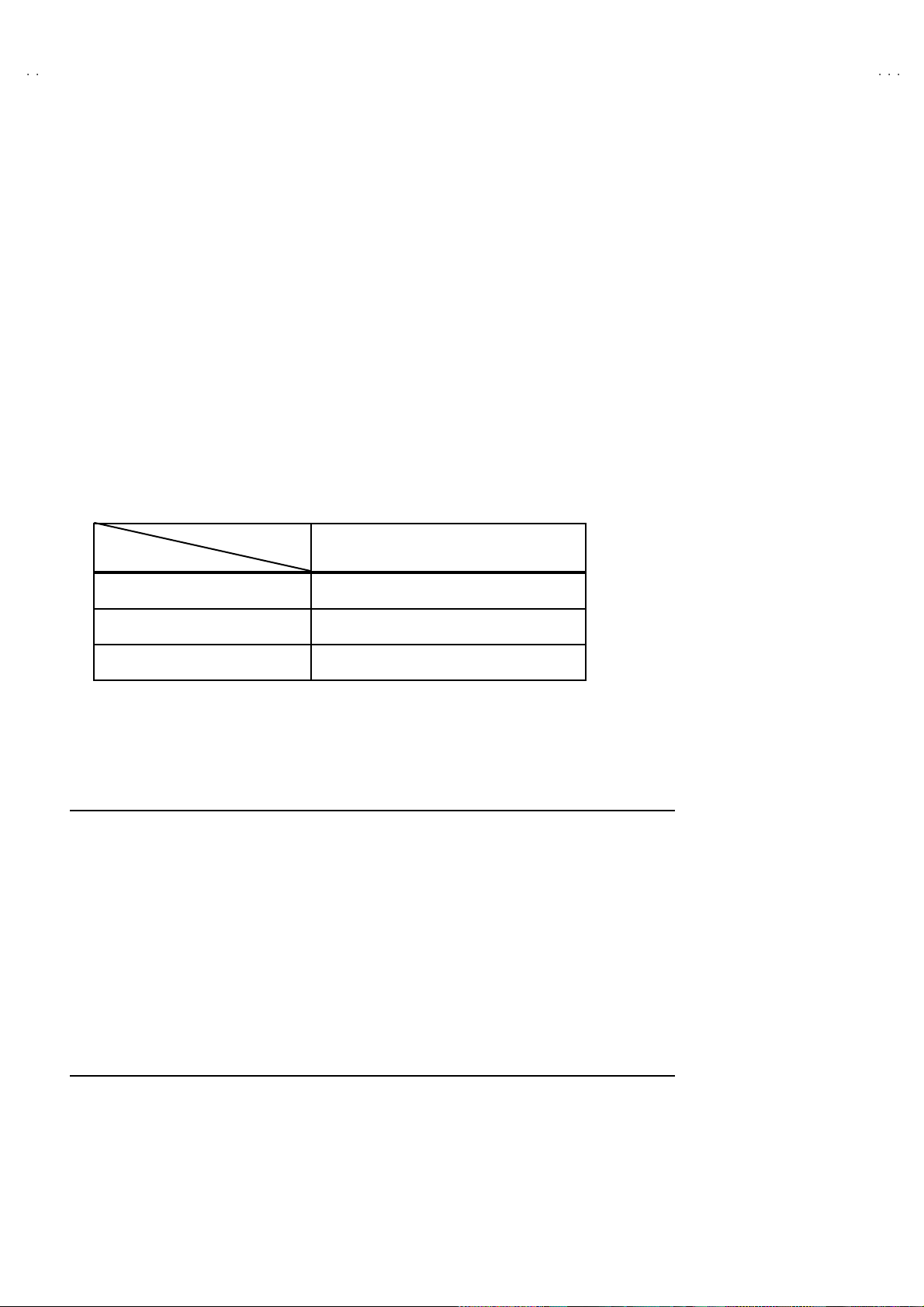

CONTENTS

!

USING PW BOARD & REMOT E CONTROL UNIT

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・・ ・・

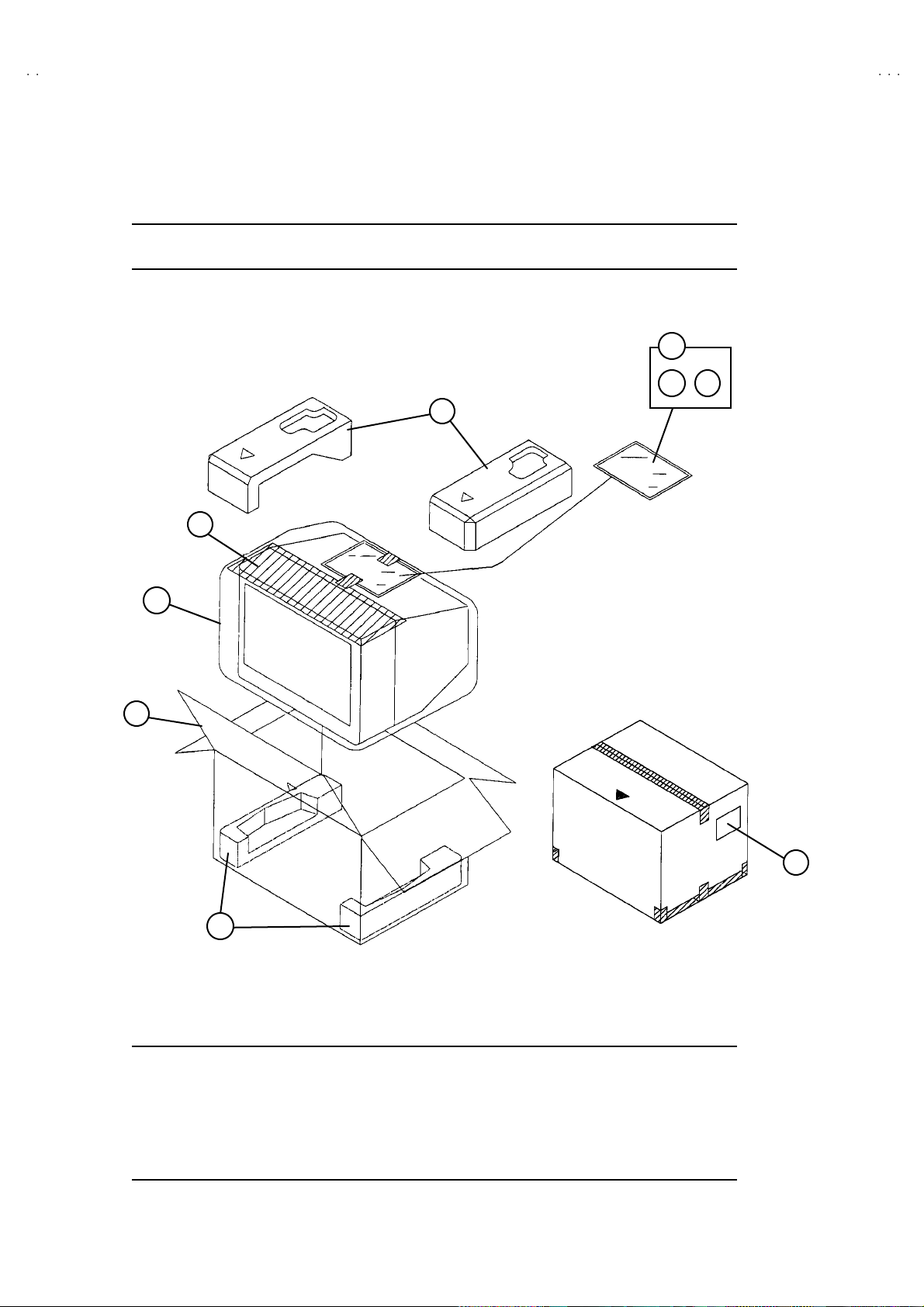

! EXPLODED VIEW PARTS LIST・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・ 32

!

EXPLODED VIEW

!

PRINTED WIRING BOARD PARTS LIST

"

MAIN PW BOARD ASS’Y (With CRT SOCKET PW BOARD)・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・ 34

"

FRONT CONTRO L PW BOARD ASS’Y

!

REMOTE CONTROL UNIT PARTS LIST ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・ 39

!

PACKING

!

PACKI NG PARTS LIST

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・・ ・・・・

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・・

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・・・・・ ・・・・・・・・・・・・

USING P.W. BOARD & REMOTE CONTROL UNIT

Model

P.W.B AS S’Y

MAIN P.W.B

(W ith in CRT SOCKET PW B )

FRONT CO NTROL PWB SGA-4005A-R2

AV-T2922

SGA-1020A-R2

/AR

32

33

38

39

39

REMOTE CONTROL UNIT RM-C363-1H

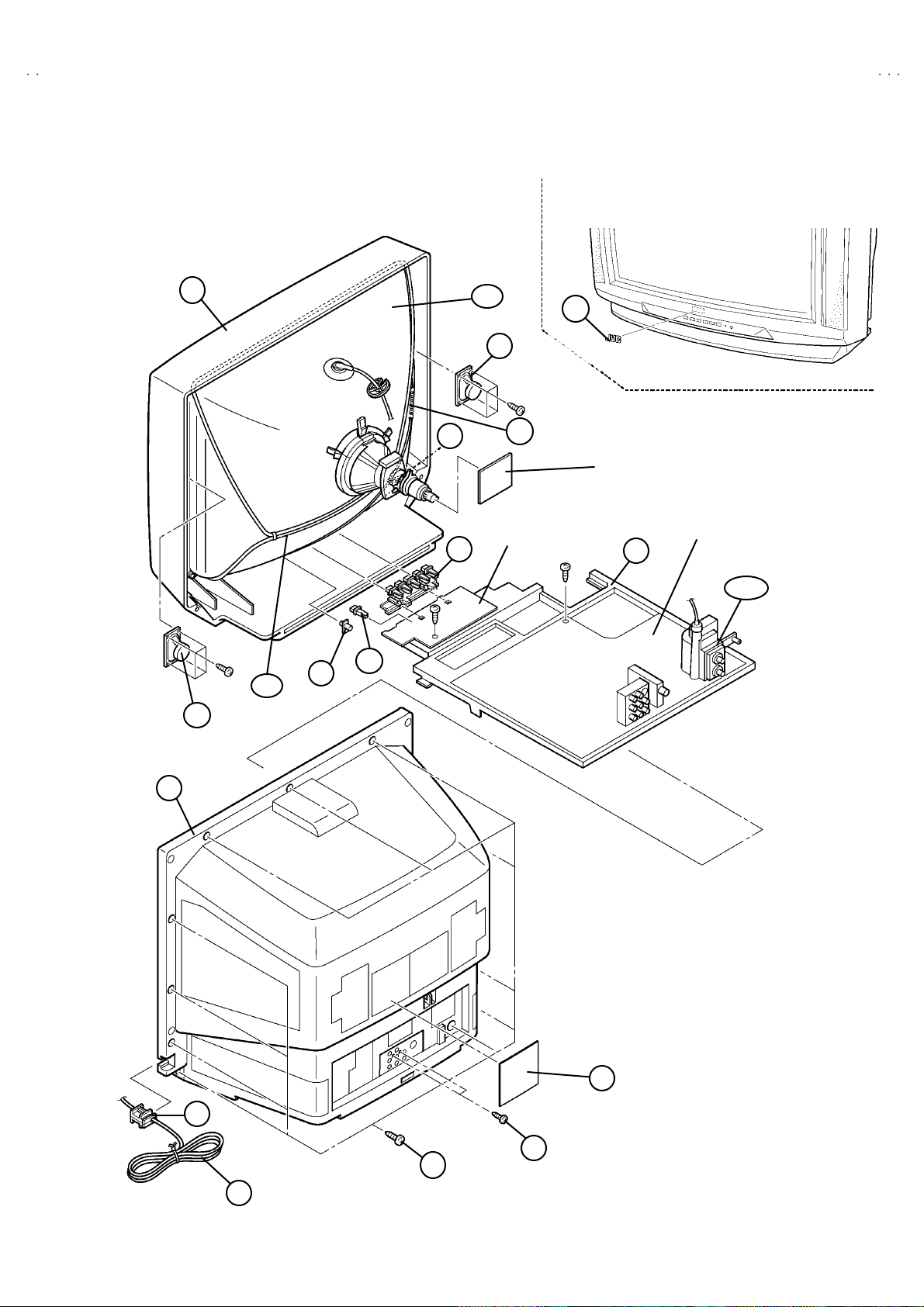

EXPLODED VIEW PARTS LIST

!

Ref.No. Part No. Part Name Description

V01 A68AJB82X02 PICTURE TUBE(C) Inc.DY,PC MAGNET, WEDGE

!

!

L01 CELD058-001J3 DEG.COIL

!

T1522 QQH0115-001 H.V.TRANSF. (Within MAIN PWB)

1 LC10571-002A-D FRONT CABINET

!

2 CHGB0015-0B BRAIDED WIRE

3 CHGB0016-0C BRAIDED WIRE(SUB)

6 CEBSS12D-04KJ2 SPEAKER (×2)SP01,SP02

7 LC20217-004B-A CONTROL KNOB

!

8 LC30856-002A-A POWER KNOB

!

!

9 CM12985-003-VA CHASSIS BASE

!

10 QMPR150-200-JC POWER CORD

!

11 CM23169-001-A POWER CORD CLAMP

12 LC10572-001B-D REAR COVER

!

13 QYSBSFG4016Z TAPPING SCREW (×11)

14 QYSBSB3010Z TAPPING SCREW (×2)

!

15 LC30462-008A-D RATING LABEL

16 LC30191-002A-A REMOCON LENS

!

17 CM48006-007-C JVC MARK

32

No.51917

Page 4

A

2

EXPLODED VIEW

(

)

V-T292

!

1

!

V01

3

FRONT

!

C ONT RO L PW B

7

17

6

2

CRT SOCKET PWB

W ith in MAIN PWB

!

MAIN PWB

9

!

T1522

!

!

!

L01

6

16

8

!

12

!

15

!

11

14

(×2)

10

!

(×11)

13

No.51917

33

Page 5

A

V-T2922

PRINTED WIRING BOARD PARTS LIST

MAIN PW BOARD ASS’Y (SGA-1020A-R2)

!

Symbol No. Part No. Part Name Description

RESISTOR

R1001 NRSA02J-563X MG R 56kΩ 1/10W J

R1003-04 NRSA02J-561X MG R 560Ω 1/10W J

R1006 NRSA02J-820X MG R 82Ω 1/10W J

R1101 NRSA02J-562X MG R 5.6kΩ 1/10W J

R1102 NRSA02J-182X MG R 1.8kΩ 1/10W J

R1103 QRE121J-101Y C R 100Ω 1/2W J

R1104 NRSA02J-180X MG R 18Ω 1/10W J

R1105 NRSA02J-270X MG R 27Ω 1/10W J

R1111 NRSA02J-394X MG R 390kΩ 1/10W J

R1112 NRSA02J-334X MG R 330kΩ 1/10W J

R1113 NRSA02J-101X MG R 100Ω 1/10W J

R1116 NRSA02J-680X MG R 68Ω 1/10W J

R1131 NRSA02J-102X MG R 1kΩ 1/10W J

R1132 NRSA02J-331X MG R 330Ω 1/10W J

R1133 NRSA02J-102X MG R 1kΩ 1/10W J

R1134 NRSA02J-271X MG R 270Ω 1/10W J

R1135 NRSA02J-471X MG R 470Ω 1/10W J

R1161 NRSA02J-332X MG R 3.3kΩ 1/10W J

R1162 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1163 NRSA02J-103X MG R 10kΩ 1/10W J

R1164 NRSA02J-102X MG R 1kΩ 1/10W J

R1165 NRSA02J-273X MG R 27kΩ 1/10W J

R1166 NRSA02J-103X MG R 10kΩ 1/10W J

R1167 NRSA02J-102X MG R 1kΩ 1/10W J

R1168 NRSA02J-101X MG R 100Ω 1/10W J

R1169 NRSA02J-561X MG R 560Ω 1/10W J

R1170 NRSA02J-683X MG R 68kΩ 1/10W J

R1201 NRSA02J-821X MG R 820Ω 1/10W J

R1202 NRSA02J-102X MG R 1kΩ 1/10W J

R1203 NRSA02J-821X MG R 820Ω 1/10W J

R1204 NRSA02J-681X MG R 680Ω 1/10W J

R1205 NRSA02J-152X MG R 1.5kΩ 1/10W J

R1213 NRSA02J-391X MG R 390Ω 1/10W J

R1215 NRSA02J-824X MG R 820kΩ 1/10W J

R1216 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1217 NRSA02J-563X MG R 56kΩ 1/10W J

R1220 NRSA02J-471X MG R 470Ω 1/10W J

R1251-52 NRSA02J-750X MG R 75Ω 1/10W J

R1301 NRSA02J-102X MG R 1kΩ 1/10W J

R1303-04 NRSA02J-562X MG R 5.6kΩ 1/10W J

R1307 NRSA02J-472X MG R 4.7kΩ 1/10W J

R1308 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1309 NRSA02J-103X MG R 10kΩ 1/10W J

R1311 NRSA02J-273X MG R 27kΩ 1/10W J

R1312 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1314 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1341 NRSA02J-121X MG R 120Ω 1/10W J

R1342-43 NRSA02J-333X MG R 33kΩ 1/10W J

R1351-53 NRSA02J-151X MG R 150Ω 1/10W J

R1354-56 NRSA02J-331X MG R 330Ω 1/10W J

R1357-59 NRSA02J-101X MG R 100Ω 1/10W J

R1360-62 QRZ0111-152 C R 1.5kΩ 1/2W K

R1363-65 QRG029J-123 OM R 12kΩ 2W J

R1366-68 NRSA02J-272X MG R 2.7kΩ 1/10W J

R1401 NRSA02J-103X MG R 10kΩ 1/10W J

R1402 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1403 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1404 NRSA02J-102X MG R 1kΩ 1/10W J

R1405 NRSA02J-221X MG R 220Ω 1/10W J

R1406-08 NRSA02J-472X MG R 4.7kΩ 1/10W J

R1410 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1412 QRE121J-3R9Y C R 3.9Ω 1/2W J

R1413 QRE121J-561Y C R 560Ω 1/2W J

R1414 QRX01GJ-R68 MF R 0.68Ω 1W J

R1415 QRE121J-102Y C R 1kΩ 1/2W J

R1416 NRSA02J-563X MG R 56kΩ 1/10W J

R1418 NRSA02J-563X MG R 56kΩ 1/10W J

R1419 NRSA02J-183X MG R 18kΩ 1/10W J

!

Symbol No. Part No. Part Name Description

RESISTOR

R1421 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1422 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1423 NRSA02J-103X MG R 10kΩ 1/10W J

R1501 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1503 NRSA02J-103X MG R 10kΩ 1/10W J

R1504 NRSA02J-104X MG R 100kΩ 1/10W J

R1505 NRSA02J-822X MG R 8.2kΩ 1/10W J

R1506 NRSA02J-102X MG R 1kΩ 1/10W J

R1510 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1512 NRSA02J-103X MG R 10kΩ 1/10W J

R1513 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1514 NRSA02J-333X MG R 33kΩ 1/10W J

R1521 QRL039J-182 OM R 1.8kΩ 3W J

R1523 NRSA02J-222X MG R 2.2kΩ 1/10W J

R1524 QRE121J-103Y C R 10kΩ 1/2W J

R1525 QRG01GJ-561 OM R 560Ω 1W J

R1526 QRL029J-152 OM R 1.5kΩ 2W J

R1529 NRSA02J-621X MG R 620Ω 1/10W J

R1532 QRL039J-182 OM R 1.8kΩ 3W J

R1533 QRE121J-220Y C R 22Ω 1/2W J

R1544 QRL029J-223 OM R 22kΩ 2W J

R1562 QRA14CF-6341Y MF R 6.34kΩ 1/4W F

!

!

R1563 QRA14CF-3241Y MF R 3.24kΩ 1/4W F

R1581 QRE121J-273Y C R 27kΩ 1/2W J

R1582 QRE121J-393Y C R 39kΩ 1/2W J

R1584 QRE121J-223Y C R 22kΩ 1/2W J

R1603 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1605 NRSA02J-821X MG R 820Ω 1/10W J

R1607 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1609 NRSA02J-821X MG R 820Ω 1/10W J

R1611 NRSA02J-223X MG R 22kΩ 1/10W J

R1613 NRSA02J-333X MG R 33kΩ 1/10W J

R1620 NRSA02J-183X MG R 18kΩ 1/10W J

R1621 QRT039J-2R2 MF R 2.2Ω 3W J

R1622 NRSA02J-183X MG R 18kΩ 1/10W J

R1626 NRSA02J-822X MG R 8.2kΩ 1/10W J

R1631 NRSA02J-473X MG R 47kΩ 1/10W J

R1651 NRSA02J-102X MG R 1kΩ 1/10W J

R1652 NRSA02J-561X MG R 560Ω 1/10W J

R1653 NRSA02J-272X MG R 2.7kΩ 1/10W J

R1654 NRSA02J-333X MG R 33kΩ 1/10W J

R1655 NRSA02J-332X MG R 3.3kΩ 1/10W J

R1656 NRVA02D-152X MF R 1.5kΩ 1/10W D

R1658 NRVA02D-153X MF R 15kΩ 1/10W D

R1660 NRSA02J-512X MG R 5.1kΩ 1/10W J

R1661 NRSA02J-473X MG R 47kΩ 1/10W J

R1662-65 NRSA02J-123X MG R 12kΩ 1/10W J

R1666-67 NRSA02J-562X MG R 5.6kΩ 1/10W J

R1668 NRSA02J-473X MG R 47kΩ 1/10W J

R1669-70 NRSA02J-471X MG R 470Ω 1/10W J

R1671 NRSA02J-102X MG R 1kΩ 1/10W J

R1672 NRSA02J-102X MG R 1kΩ 1/10W J

R1673-74 NRSA02J-823X MG R 82kΩ 1/10W J

R1675-76 NRSA02J-181X MG R 180Ω 1/10W J

R1677 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1678 NRSA02J-223X MG R 22kΩ 1/10W J

R1679 NRSA02J-223X MG R 22kΩ 1/10W J

R1680 NRSA02J-223X MG R 22kΩ 1/10W J

R1681 NRSA02J-223X MG R 22kΩ 1/10W J

R1682 NRSA02J-683X MG R 68kΩ 1/10W J

R1685 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1686 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1687 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1688 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1691 NRSA02J-102X MG R 1kΩ 1/10W J

R1692 NRSA02J-102X MG R 1kΩ 1/10W J

R1701 NRSA02J-563X MG R 56kΩ 1/10W J

R1702 NRSA02J-223X MG R 22kΩ 1/10W J

34

No. 51917

Page 6

A

V-T292

2

Symbol No. Part No. Part Name Description

!

RESISTOR

R1703 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1704 NRSA02J-103X MG R 10kΩ 1/10W J

R1705 NRSA02J-102X MG R 1kΩ 1/10W J

R1706 NRSA02J-563X MG R 56kΩ 1/10W J

R1707 NRSA02J-103X MG R 10kΩ 1/10W J

R1708 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1709 NRSA02J-103X MG R 10kΩ 1/10W J

R1710 NRSA02J-102X MG R 1kΩ 1/10W J

R1711 NRSA02J-124X MG R 120kΩ 1/10W J

R1712 NRSA02J-184X MG R 180kΩ 1/10W J

R1713 NRSA02J-102X MG R 1kΩ 1/10W J

R1714 NRSA02J-103X MG R 10kΩ 1/10W J

R1715 NRSA02J-224X MG R 220kΩ 1/10W J

R1716 NRSA02J-102X MG R 1kΩ 1/10W J

R1717 NRSA02J-102X MG R 1kΩ 1/10W J

R1721 NRSA02J-102X MG R 1kΩ 1/10W J

R1722 NRSA02J-561X MG R 560Ω 1/10W J

R1724 NRSA02J-221X MG R 220Ω 1/10W J

R1725 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1726 NRSA02J-221X MG R 220Ω 1/10W J

R1727 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1728 NRSA02J-221X MG R 220Ω 1/10W J

R1729 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1730 NRSA02J-221X MG R 220Ω 1/10W J

R1731 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1732 NRSA02J-682X MG R 6.8kΩ 1/10W J

R1734 NRSA02J-102X MG R 1kΩ 1/10W J

R1735-36 NRSA02J-473X MG R 47kΩ 1/10W J

R1737 NRSA02J-683X MG R 68kΩ 1/10W J

R1738 NRSA02J-562X MG R 5.6kΩ 1/10W J

R1740 NRSA02J-101X MG R 100Ω 1/10W J

R1741 NRSA02J-103X MG R 10kΩ 1/10W J

R1742 NRSA02J-102X MG R 1kΩ 1/10W J

R1743 NRSA02J-392X MG R 3.9kΩ 1/10W J

R1744 NRSA02J-102X MG R 1kΩ 1/10W J

R1745 NRSA02J-392X MG R 3.9kΩ 1/10W J

R1746 NRSA02J-102X MG R 1kΩ 1/10W J

R1747 NRSA02J-392X MG R 3.9kΩ 1/10W J

R1748 NRSA02J-102X MG R 1kΩ 1/10W J

R1749 NRSA02J-102X MG R 1kΩ 1/10W J

R1754-55 NRSA02J-222X MG R 2.2kΩ 1/10W J

R1756 NRSA02J-103X MG R 10kΩ 1/10W J

R1761 NRSA02J-102X MG R 1kΩ 1/10W J

R1762 NRSA02J-153X MG R 15kΩ 1/10W J

R1764 NRSA02J-105X MG R 1MΩ 1/10W J

R1765 NRSA02J-122X MG R 1.2kΩ 1/10W J

R1766 NRSA02J-102X MG R 1kΩ 1/10W J

R1771-72 NRSA02J-221X MG R 220Ω 1/10W J

R1773 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1774 NRSA02J-102X MG R 1kΩ 1/10W J

R1775 NRSA02J-102X MG R 1kΩ 1/10W J

R1799 NRSA02J-333X MG R 33kΩ 1/10W J

R1801-03 NRSA02J-221X MG R 220Ω 1/10W J

R1811 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1812 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1813 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1815 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1901 QRF154K-4R7 UNF R 4.7Ω 15W K

!

R1902 QRL039J-393 OM R 39kΩ 3W J

!

R1905 QRF154J-680 UNF R 68 Ω 15W J

R1910 QRE121J-564Y C R 560kΩ 1/2W J

R1911 QRN141J-183Y C R 18kΩ 1/4W J

R1921 QRE121J-681Y C R 680Ω 1/2W J

R1922-23 QRT029J-R22 MF R 0.22Ω 2W J

R1924 QRE121J-103Y C R 10kΩ 1/2W J

R1925 QRE121J-102Y C R 1kΩ 1/2W J

R1926 QRE121J-152Y C R 1.5kΩ 1/2W J

R1929 QRE121J-332Y C R 3.3kΩ 1/2W J

R1932 QRE121J-4R7Y C R 4.7Ω 1/2W J

R1941 QRK129J-150 C R 15Ω 1/2W J

Symbol No. Part No. Part Name Description

!

RESISTOR

R1942 NRSA02J-223X MG R 22kΩ 1/10W J

R1943 QRE121J-152Y C R 1.5kΩ 1/2W J

R1944 NRSA02J-103X MG R 10kΩ 1/10W J

R1945 NRSA02J-332X MG R 3.3kΩ 1/10W J

R1946 NRSA02J-123X MG R 12kΩ 1/10W J

R1948 NRSA02J-152X MG R 1.5kΩ 1/10W J

R1949 NRSA02J-153X MG R 15kΩ 1/10W J

R1950 NRSA02J-103X MG R 10kΩ 1/10W J

R1951 NRSA02J-332X MG R 3.3kΩ 1/10W J

R1952 NRSA02J-472X MG R 4.7kΩ 1/10W J

R1959 NRSA02J-0R0X MG R 0.0Ω 1/10W J

R1961 QRT029J-1R2 MF R 1.2Ω 2W J

R1962 QRT029J-1R2 MF R 1.2Ω 2W J

R1964 QRE121J-272Y C R 2.7kΩ 1/2W J

R1965 QRE121J-473Y C R 47kΩ 1/2W J

R1966 QRE121J-223Y C R 22kΩ 1/2W J

R1981 QRZ0057-825 C R 8.2MΩ 1W J

!

CAPACITOR

C1001 QETN1HM-106Z E CAP. 10µF 50V M

C1007 QETN1CM-477Z E CAP. 470µF 16V M

C1008-09 QETN1EM-476Z E CAP. 47µF 25V M

C1011 NCB21HK-103X C CAP. 0.01µF 50V K

C1101-02 NCB21HK-103X C CAP. 0.01µF 50V K

C1104-05 NCB21HK-103X C CAP. 0.01µF 50V K

C1111 QETN1EM-476Z E CAP. 47µF 25V M

C1112-14 NCB21HK-103X C CAP. 0.01µF 50V K

C1116 QFV71HJ-224Z MF CAP. 0.22µF 50V J

C1117 QETN1EM-476Z E CAP. 47µF 25V M

C1118 NCB21HK-103X C CAP. 0.01µF 50V K

C1119 NDC21HJ-681X C CAP. 680pF 50V J

C1120 QETN1HM-474Z E CAP. 0.47µF 50V M

C1123-24 NCB21HK-103X C CAP. 0.01µF 50V K

C1161 QETN1HM-106Z E CAP. 10µF 50V M

C1163-64 NDC21HJ-470X C CAP. 47pF 50V J

C1165-66 NCB21HK-103X C CAP. 0.01µF 50V K

C1202 QETN1CM-107Z E CAP. 100µF 16V M

C1205 NDC21HJ-680X C CAP. 68pF 50V J

C1207 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1208 QETN1HM-475Z E CAP. 4.7µF 50V M

C1209 QETN1CM-227Z E CAP. 220µF 16V M

C1210 NCB21HK-103X C CAP. 0.01µF 50V K

C1211 NDC21HJ-681X C CAP. 680pF 50V J

C1212 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1213 QETN1HM-105Z E CAP. 1µF 50V M

C1214 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1215 QETN1HM-106Z E CAP. 10µF 50V M

C1251-52 QETN1HM-106Z E CAP. 10µF 50V M

C1255 QETN1HM-106Z E CAP. 10µF 50V M

C1256 QETN1CM-107Z E CAP. 100µF 16V M

C1291-92 QETN1CM-107Z E CAP. 100µF 16V M

C1294 QETN1CM-107Z E CAP. 100µF 16V M

C1296 QETN1CM-107Z E CAP. 100µF 16V M

C1301-02 NDC21HJ-150X C CAP. 15pF 50V J

C1303 NDC21HJ-120X C CAP. 12pF 50V J

C1304 NCB21HK-103X C CAP. 0.01µF 50V K

C1305 NDC21HJ-120X C CAP. 12pF 50V J

C1306 QETN1EM-476Z E CAP. 47µF 25V M

C1307 NCB21HK-103X C CAP. 0.01µF 50V K

C1308-09 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1311 QFV71HJ-334Z MF CAP. 0.33µF 50V J

C1312 QFLC1HJ-103Z M CAP. 0.01µF 50V J

C1313 QETN1HM-475Z E CAP. 4.7µF 50V M

C1342 QETN1HM-335Z E CAP. 3.3µF 50V M

C1354-55 NDC21HJ-271X C CAP. 270pF 50V J

C1356 NDC21HJ-331X C CAP. 330pF 50V J

C1357 QETN1CM-107Z E CAP. 100µF 16V M

C1382 QCZ0121-102 C CAP. 1000pF 3kV Z

!

C1401-02 QETN1HM-105Z E CAP. 1µF 50V M

No. 51917

35

Page 7

A

V-T2922

Symbol No. Part No. Part Name Description

!

CAPACITOR

C1403 QEM61EK-225Z E CAP. 2.2µF 25V K

C1405 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1406 QFLC1HJ-103Z M CAP. 0.01µF 50V J

C1410 QETN1VM-107Z E CAP. 100µF 35V M

C1411 QETN1VM-477Z E CAP. 470µF 35V M

C1412 QFLC2AK-393Z M CAP. 0.039µF 100V K

C1413 QETM1VM-228 E CAP. 2200µF 35V M

C1414 QETN1HM-105Z E CAP. 1µF 50V M

C1415 QFN31HJ-152Z M CAP. 1500pF 50V J

C1501 QETN1CM-107Z E CAP. 100µF 16V M

C1503 NCB21HK-103X C CAP. 0.01µF 50V K

C1505-06 NCB21HK-103X C CAP. 0.01µF 50V K

C1507 QETN1HM-105Z E CAP. 1µF 50V M

C1511 QETN1HM-106Z E CAP. 10µF 50V M

C1521 QCB32HK-151Z C CAP. 150pF 500V K

C1522 QCB32HK-331Z C CAP. 330pF 500V K

C1523 QETN2CM-105Z E CAP. 1µF 160V M

C1524 QFZ0198-133 MPP CAP. 0.013 µF1.5kVH±3%

!

C1525 QFZ0119-474 MPP CAP. 0.47µF 200V ±3%

!

!

C1526 QEZ0203-107 E CAP. 100µF 160V M

C1541 QETM2EM-336 E CAP. 33µF 250V M

C1542 QCB32HK-821Z C CAP. 820pF 500V K

C1543 QETM1VM-108 E CAP. 1000 µF 35V M

C1544 QCB32HK-821Z C CAP. 820pF 500V K

C1546 QETN1CM-227Z E CAP. 220µF 16V M

C1547 QETN1CM-108Z E CAP. 1000µF 16V M

C1548 QCZ0122-821 C CAP.

C1561 QETN1VM-107Z E CAP. 100µF 35V M

C1581 QFLC1HJ-473Z M CAP. 0.047µF 50V J

C1583 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1584 QFLC2AJ-104Z M CAP. 0.1µF 100V J

C1604 QENC1HM-474Z BP E CAP. 0.47 µF 50V M

C1607 QENC1HM-474Z BP E CAP. 0.47 µF 50V M

C1609 QETN1CM-107Z E CAP. 100µF 16V M

C1613 QETM1EM-108 E CAP. 1000 µF 25V M

C1615 QETM1EM-108 E CAP. 1000µF 25V M

C1617 QETM1EM-108 E CAP. 1000µF 25V M

C1618 QFV71HJ-224Z MF CAP. 0.22µF 50V J

C1622 QETN1HM-105Z E CAP. 1µF 50V M

C1623-24 QENC1HM-474Z BP E CAP. 0.47 µF 50V M

C1631 QETN1EM-476Z E CAP. 47µF 25V M

C1637-38 NCB21HK-392X C CAP. 3900pF 50V K

C1651 NCB21HK-103X C CAP. 0.01µF 50V K

C1652 QETN1CM-107Z E CAP. 100µF 16V M

C1653 QETN1EM-476Z E CAP. 47µF 25V M

C1654 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1655 QENC1HM-475Z BP E CAP. 4.7µF 50V M

C1656 QENC1HM-105Z E CAP. 1µF 50V M

C1657 QETN1HM-225Z E CAP. 2.2µF 50V M

C1658 NCB21HK-473X C CAP. 0.047 µF 50V K

C1659 QETN1HM-474Z E CAP. 0.47µF 50V M

C1660-61 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1662 QBTC1CK-335Z TAN.CAP. 3.3µF 16V K

C1663 QETN1HM-105Z E CAP. 1µF 50V M

C1664 QBTC1CK-106Z TAN.CAP. 10µF 16V K

C1665-66 QETN1HM-105Z E CAP. 1µF 50V M

C1667 QETN1HM-336Z E CAP. 33µF 50V M

C1668 QETN1HM-105Z E CAP. 1µF 50V M

C1669-70 QENC1HM-105Z E CAP. 1µF 50V M

C1671 QETN1HM-225Z E CAP. 2.2µF 50V M

C1672 NCB21HK-222X C CAP. 2200pF 50V K

C1673 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1674 QETN1HM-225Z E CAP. 2.2µF 50V M

C1675 NCB21HK-222X C CAP. 2200pF 50V K

C1676 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1677 NCB21HK-223X C CAP. 0.022µF 50V K

C1679 QETN1HM-105Z E CAP. 1µF 50V M

C1680 QETN1EM-476Z E CAP. 47µF 25V M

C1682-83 QETN1HM-475Z E CAP. 4.7µF 50V M

C1684-86 QETN1HM-106Z E CAP. 10µF 50V M

Symbol No. Part No. Part Name Description

!

CAPACITOR

C1691-92 QETN1HM-106Z E CAP. 10µF 50V M

C1693-94 NCB21HK-392X C CAP. 3900pF 50V K

C1701 NDC21HJ-102X C CAP. 1000pF 50V J

C1703 NCB21HK-102X C CAP. 1000pF 50V K

C1704 NCB21HK-103X C CAP. 0.01µF 50V K

C1705 NDC21HJ-471X C CAP. 470pF 50V J

C1706 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1707 NDC21HJ-180X C CAP. 18pF 50V J

C1708 NDC21HJ-220X C CAP. 22pF 50V J

C1709 QETN1EM-476Z E CAP. 47µF 25V M

C1710 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1711 NCB21HK-103X C CAP. 0.01µF 50V K

C1712-13 QETN1CM-107Z E CAP. 100µF 16V M

C1714 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1715 NDC21HJ-150X C CAP. 15pF 50V J

C1716 NDC21HJ-390X C CAP. 39pF 50V J

C1717 NDC21HJ-151X C CAP. 150pF 50V J

C1718 NRSA02J-0R0X MG R 0.0Ω 1/10W J

C1719 QETN1HM-106Z E CAP. 10µF 50V M

C1720 NDC21HJ-151X C CAP. 150pF 50V J

C1722 NCB21HK-103X C CAP. 0.01µF 50V K

C1761 QETN1HM-105Z E CAP. 1µF 50V M

C1762 NDC21HJ-221X C CAP. 220pF 50V J

C1763 NCB21HK-102X C CAP. 1000pF 50V K

C1765 NDC21HJ-101X C CAP. 100pF 50V J

C1766 QENC1HM-474Z BP E CAP. 0.47 µF 50V M

C1771 QETN1EM-476Z E CAP. 47µF 25V M

C1772 NCB21HK-103X C CAP. 0.01µF 50V K

C1773 QETN1HM-105Z E CAP. 1µF 50V M

C1779 NDC21HJ-100X C CAP. 10pF 50V J

C1780 NRSA02J-0R0X MG R 0.0Ω 1/10W J

C1781 NRSA02J-0R0X MG R 0.0Ω 1/10W J

C1805 QETN1CM-227Z E CAP. 220µF 16V M

C1806 NCB21HK-103X C CAP. 0.01µF 50V K

C1811-13 NCB21HK-103X C CAP. 0.01µF 50V K

C1901 QFZ9072-104 MF CAP. 0.1µFAC275V K

!

C1902 QFZ9072-104 MF CAP. 0.1µFAC275V K

!

C1903 QCZ9074-472 C CAP. 4700pFAC250V M

!

C1904 QCZ9074-472 C CAP. 4700pFAC250V M

!

!

C1905 QCZ9074-472 C CAP. 4700pFAC250V M

!

C1906 QEZ0371-337 E CAP. 330μF 400V M

C1921 QCZ0325-222 C CAP. 2200pF 2kV K

C1924 QETN1VM-477Z E CAP. 470µF 35V M

C1925 QFN31HJ-102Z M CAP. 1000pF 50V J

C1926 QFN31HJ-222Z M CAP. 2200pF 50V J

C1928 QFLC1HJ-104Z M CAP. 0.1µF 50V J

C1931 QCZ0122-391 C CAP . 390pF 2kV K

C1941 QCZ0325-561 C CAP. 560pF 2kV K

!

C1942 QEZ0203-107 E CAP. 100µF 160V M

C1943 QCB32HK-561Z C CAP. 560pF 500V K

C1944 QETN1CM-477Z E CAP. 470µF 16V M

C1945 QETN1CM-108Z E CAP. 1000µF 16V M

C1946 QETN1EM-107Z E CAP. 100µF 25V M

C1947 QETN1HM-106Z E CAP. 10µF 50V M

C1952 QETN1EM-108Z E CAP. 1000µF 25V M

C1953 QCZ0122-561 C CAP. 560pF 2kV K

C1957 QCB31HK-471Z C CAP. 470pF 50V K

C1961 QETN1CM-107Z E CAP. 100µF 16V M

C1962 QETN1HM-476Z E CAP. 47µF 50V M

!

C1981 QCZ9075-471 C CAP. 470pFAC250V K

!

C1982 QCZ9075-222 C CAP. 2200pFAC250V M

C1983 QCZ9075-471 C CAP. 470pFAC250V K

!

TRANSFORMER

T1111 CELT001-209J3 C.WAVE TRANSF.

T1521 CE42034-002 H.DRIVE TRANSF.

!

T1522 QQH0115-001 H.V.TRANSF.

T1921 CETS090-001J8 SWITCH.TRANSF.

!

36

No. 51917

Page 8

A

V-T292

2

Symbol No. Part No. Part Name Description

!

COIL

L1001 QQL244J-150Z PEAKING COIL

L1003 QQL244J-4R7Z PEAKING COIL

L1101 QQLZ014-R22 PEAKING COIL

L1131 QQL244J-220Z PEAKING COIL

L1161 QQL244J-220Z PEAKING COIL

L1205 QQL244J-4R7Z PEAKING COIL

L1301 QQL244J-390Z PEAKING COIL

L1381 QQL244J-390Z PEAKING COIL

L1501 QQL244J-4R7Z PEAKING COIL

!

L1521 QQR1137-002 LINEARITY COIL

L1701-02 QQL244J-4R7Z PEAKING COIL

L1704 QQL39BK-8R2Z COIL 8.2µH K

L1771 QQL244J-4R7Z PEAKING COIL

L1941-42 QQL26AK-820Z COIL 82µH K

DIODE

D1001 MTZJ33A-T2 ZENER DIODE

D1201 1SS133-T2 SI.DIODE

D1202 MTZJ7.5B-T2 ZENER DIODE

D1253-56 MTZJ9.1C-T2 ZENER DIODE

D1341 1SS133-T2 SI.DIODE

D1401 1N4003-T2 SI.DIODE

D1402 MTZJ75-T2 ZENER DIODE

D1510 1SS133-T2 SI.DIODE

D1512 RH3G-F1 SI.DIODE

D1541 RH1S-T3 SI.DIODE

!

D1542 RU3AM-LFC4 SI.DIODE

!

D1543 RGP10J-5025-T3 SI.DIODE

D1544 RH1S-T3 SI.DIODE

D1561 1SS81-T2 SI.DIODE

!

D1562 MTZJ7.5S-T2 ZENER DIODE

!

D1581 RGP10J-5025-T3 SI.DIODE

D1582 MTZJ9.1B-T2 ZENER DIODE

D1631 1SS133-T2 SI.DIODE

D1632 1SS133-T2 SI.DIODE

D1633 1SS133-T2 SI.DIODE

D1634 1SS133-T2 SI.DIODE

D1656-57 MTZJ9.1C-T2 ZENER DIODE

D1691-92 MTZJ9.1C-T2 ZENER DIODE

D1701 1SS133-T2 SI.DIODE

D1703 1SS133-T2 SI.DIODE

D1704 1SS133-T2 SI.DIODE

D1710 MTZJ5.6A-T2 ZENER DIODE

D1712 1SS133-T2 SI.DIODE

D1713 1SS133-T2 SI.DIODE

D1771-72 MTZJ5.6A-T2 ZENER DIODE

D1801-03 MTZJ15B-T2 ZENER DIODE

D1805 MTZJ15B-T2 ZENER DIODE

!

D1901 GSIB460 DIODE

!

D1903 RGP10J-5025-T3 SI.DIODE

D1905 MTZJ6.8A-T2 ZENER DIODE

D1921 RGP10J-5025-T3 SI.DIODE

!

D1922 RGP10J-5025-T3 SI.DIODE

!

D1923 MTZJ15A-T2 ZENER DIODE

D1924 1SS133-T2 SI.DIODE

D1927 1SS133-T2 SI.DIODE

D1928 1SS133-T2 SI.DIODE

D1929 MTZJ15A-T2 ZENER DIODE

D1941 RU3AM-LFC4 SI.DIODE

!

D1942 RGP10J-5025-T3 SI.DIODE

D1943 1SS133-T2 SI.DIODE

D1945 MTZJ5.1B-T2 ZENER DIODE

D1948 RU3YX-LFC4 SI.DIODE

D1961 MTZJ7.5A-T2 ZENER DIODE

D1962 1SS133-T2 SI.DIODE

TRANSISTOR

Q1101 2SC5083/L-P/-T SI.TRANSISTOR

Q1131 2SC2412K/QR/-X SI.TRANSISTOR

Q1161 2SC2412K/QR/-X SI.TRANSISTOR

Q1201-02 2SC2412K/QR/-X SI.TRANSISTOR

Q1301-02 2SC2412K/QR/-X SI.TRANSISTOR

Q1341-42 2SC2412K/QR/-X SI.TRANSISTOR

Q1351-53 2SC4544-LB SI.TRANSISTOR

Symbol No. Part No. Part Name Description

!

TRANSISTOR

Q1401 2SC2412K/QR/-X SI.TRANSISTOR

!

Q1511 2SC2785/JH/-T SI.TRANSISTOR

Q1521 BSN304-T F.E.T.

Q1522 2SD2499-LB SI.TRANSISTOR H.OUT

!

Q1601 2SC2412K/QR/-X SI.TRANSISTOR

Q1603 DTC124EKA-X DIGI.TRANSISTOR

Q1604-05 DTC323TK-X DIGI.TRANSISTOR

Q1631 2SA1037AK/QR/-X SI.TRANSISTOR

Q1651-54 DTC323TK-X DIGI.TRANSISTOR

Q1701-02 2SC2412K/QR/-X SI.TRANSISTOR

Q1703 DTC124EKA-X DIGI.TRANSISTOR

Q1761 2SC2412K/QR/-X SI.TRANSISTOR

Q1921 2SA933AS/QR/-T SI.TRANSISTOR

Q1941 2SA966/OY/-T SI.TRANSISTOR

Q1942-44 2SC2412K/QR/-X SI.TRANSISTOR

Q1961 2SA949/Y/Z1-T SI.TRANSISTOR

IC

IC1001 AN7805F I.C(MONO-ANA)

IC1101 M52342SP I.C(MONO-ANA)

IC1201 TB1230N I.C(D IGI-OTHER)

IC1251 BA7612N I.C(MONO-ANA)

IC1291 AN78N05 I.C.(M)

IC1292 AN78L09-T I.C(MONO-ANA)

IC1293 AN78L05-T I.C(MONO-ANA)

IC1401 LA7840 I.C(MONO-ANA)

IC1541 AN7809F I.C(MONO-ANA)

!

IC1601 LA4485 I.C(MONO-ANA)

IC1651 UPC1851BCU I.C(MONO-ANA)

IC1652 BA15218N I.C(MONO-ANA)

IC1701 M37267M8-100SP I C

IC1702 AT24C02-T2922AR I.C. (SERVICE)

IC1703 L78LR05E-MA I.C(MONO-ANA)

!

IC1921 STR-F6654 I.C(HYBRID)

IC1941 SE130N I.C(H)

!

OTHERS

CF1001 QAX0349-001 CERAMIC FILTER

CF1131 QAX0339-001 CERAMIC FILTER

CF1161 SFSH4.5MCB CERAMIC FILTER

CL1002 QZW0028-002 WIRE CLAMP

!

CP1941 ICP-N75-Y I.C.PROTECT

CP1942 ICP-N50-Y I.C.PROTECT

!

EF1301 CE42142-222Z EMI FILTER

!

F1901 QMF51E2-3R15J4 FUSE 3.15A

FC1901 CEMG002-001Z FUSE CLIP

FC1902 CEMG002-001Z FUSE CLIP

!

FR1542 QRZ9024-R56 F R 0.56 Ω 2W K

!

FR1543 QRZ9023-2R2 F R 2.2 Ω 2W J

FR1561 QRZ9017-4R7 F R 4.7 Ω 1/4W J

!

!

FR1585 QRZ9021-2R2 F R 2.2 Ω 1W J

FR1586 QRE121J-682Y C R 6.8kΩ 1/2W J

J1001 QNN0086-001 PIN JACK

K1401 QQR0621-001Z BEADS CORE

K1921 QQR0582-001Z BEADS CORE

K1923 QQR0582-001Z BEADS CORE

K1941-43 QQR0582-001Z BEADS CORE

LF1901 QQR0676-001 LINE FILTER

!

!

PC1921 TLP621/GR/ I.C(PH.COUPLER)

SF1101 QAX0324-002 SAW FILTER

SK1351 CE42535-001J1 C.R.T.SOCKET

!

TH1901 QAD0101-9R0 P.THERMISTOR

!

!

TH1902 QAD0101-9R0 P.THERMISTOR

!

TU1001 QAU0229-001 TUNER

!

VA1901 ERZV10V621CS VARISTOR

X1301 QAX0305-001Z CRYSTAL

X1701 QAX0468-001Z CRYSTAL

No. 51917

37

Page 9

A

V-T2922

FRONT CONTROL PW BOARD AS S’Y

(SG A-4 005A-R2)

!

Symbol No. Part No. Part Name Description

RESISTOR

R4701 QRE121J-103Y C R 10kΩ 1/2W J

R4702 QRE121J-562Y C R 5.6kΩ 1/2W J

R4703-04 QRE121J-103Y C R 10kΩ 1/2W J

R4705 QRE121J-562Y C R 5.6kΩ 1/2W J

R4706 QRE121J-103Y C R 10kΩ 1/2W J

R4707-08 QRE121J-223Y C R 22kΩ 1/2W J

R4709 QRE121J-561Y C R 560Ω 1/2W J

R4710-11 QRE121J-223Y C R 22kΩ 1/2W J

R4712 QRE121J-561Y C R 560Ω 1/2W J

R4713 QRE121J-103Y C R 10kΩ 1/2W J

CAPACITOR

C4701 QETN1EM-476Z E CAP. 47µF 25V M

C4702 QCB32HK-561Z C CAP. 560pF 500V K

COIL

L4701 QQL03BJ-560Z COIL 56µH J

DIODE

D4702 SPR-39MVWF L.E.D.

TRANSISTOR

Q4701 2SA933S(QR)-T SI.TRANSISTOR

Q4702 2SC1740S/QR/-T SI.TRANSISTOR

IC

IC4701 PIC-37243SR IR DETECT UNIT

OTHERS

S4701 QSW0619-003Z PUSH SWITCH VOL+

S4702 QSW0619-003Z PUSH SWITCH VOL-

S4703 QSW0619-003Z PUSH SWITCH CH+

S4704 QSW0619-003Z PUSH SWITCH CHS4705 QSW0619-003Z PUSH SWITCH MENU

S4901 QSP4K21-C01 PUSH SWITCH POWER

!

LC30190-001B-A L.E.D.HOLDER

38

No. 51917

Page 10

A

2

REMOTE CONTROL UNIT PARTS LIST (RM-C363-1H)

Ref.No. Part No. Part Name Description

!

25-1168 B BATTARY COVER (RM-C363-1H)

V-T292

PACKING

4

1

5

!

6 7

2

3

8

2

PACKING PARTS LIST

Ref.No. Part No. Part Name Description

!

1 LC10058-017A PACKING CASE

2 LC10774-002A-D CUSHION ASSY 4pcs in 1set

3 CP30899-001-R TOP COVER

4 CP30897-004-R POLY BAG

5 CP30897-001-R POLY BAG

6 RM-C363-1H REMOCON UNIT

!

7 LCT1100-001A-D INST BOOK

8 CM36242-012-R POS LABEL

No. 51917

39

Page 11

VICTOR COMPANY OF J APAN, LIMITED

HOME AV NETWORK BUSINESS UNIT 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama, Kanagawa-prefecture, 221-8528, Japan

4

T2922AR-CK #3

Printed in Japan

VP 0203

DP3051

Page 12

AV-T2922

STANDARD CIRCUIT DIAGRAM

NOTE ON USING CIRCUIT DIAGRAMS

1.SAFETY

The components identified by the symbol and shading are

critical for safety. For continued safety replace safety critical

components only with manufactures recommended parts.

2.SPECIFIED VOLTAGE AND WAVEFORM VALUES

The voltage and waveform values have been measured under the

following condition s.

(1)Input signal : Colour bar signal

(2)Setting positions of

each knob/button and

variable resistor

(3)Internal resistance of tester

:DC 20k

/V

(4)Oscilloscope sweeping time

:H

20µS/div

:V

5mS/div

:Others

Sweeping time is

specified

(5)Voltage values

:All DC voltage values

Since the voltage values of signal circuit vary to some extent

according to adjustments, use them as reference values.

3.INDICATION OF PARTS SYMBOL [EXAMPLE]

In the PW board

:R1209

R209

4.INDICATIONS ON THE CIRCUIT DIAGRAM

(1)Resistors

Resistance value

No unit :[

]

K

:[K

]

M

Rated allowable power

No indication :1/ 16 [W]

Others :As specified

Type

No indication

:Carbon resistor

OMR

:Oxide metal film resistor

MFR

:Metal film r esistor

MPR

:Metal plate resistor

UNFR

:Uninflammable resistor

FR

:Fusible resistor

Composition resistor 1/2 [W] is specified as 1/2S or Comp.

(2)Capacitors

: Original setting position

when shipped

5.NOT E FOR REPAIR ING SERVI CE

This mod el's power cir cuit is pa rtly diffe rent in th e GND. The

difference of the GND is shown by the LIVE : ( ) side GND and the

ISOLATED(NEUTRAL) : ( ) side GND.Therefore, care must be

taken for the following points.

(1)Do not touch the LIVE side GND or the LIVE side GND and the

ISOLATED(NEUTRAL) side GND simultaneously. If the above

caution is not respected, an electric shock may be caused.

Therefore, make sure that the power cord is surely removed from

the receptacle when, for example, the chassis is pulled out.

(2)Do not short between the LIVE side GND and ISOLATED(NEUTRAL)

side GND or never measure with a measuring apparatus measure

with a measuring apparatus ( oscilloscope, etc.) the LIVE side GND

and ISOLATED(NEUTRAL) side GND at the same time.

If the above precaution is not respected , a fuse or any parts will be broken.

Since the circuit diagram is a standard one, the ci rcuit and

circuit constants may be subject to change for improvement

without any not ice.

NOTE

Due improvement in performance, some part numbers show

in th e ci rcui t diag ram may not agre e wi th th ose i ndica ted i n

the part list.

When ordering parts, pl ease use t he numbers t hat appear

in the Par ts List.

Type

MM

:Metalized mylar capacitor

PP

:Polypropylene capacitor

MPP

:Metalized polypropylene capacitor

MF

:Metalized film capacitor

TF

:Thin film capacitor

BP

:Bipolar electrolytic capacitor

TAN

:Tantalum capacitor

(3)Coils

No unit

:[

µ

H]

Others

:As specified

(4)Power Supply

:B1

:9V

:5V

Respective voltage values are indicated

(5)Test point

:T est point

:Only test point display

(6)Conne cting method

:Connector

:Wrapping or solder ing

:Receptacle

(7)Ground symbol

:LIVE side ground

:ISOLATED(NEUTRAL) side ground

:EARTH ground

:DIGITAL ground

:[M ]

Capacitance value

1 or higher :[pF]

less than 1

:[µF]

Withstand voltage

No indication :DC50[V]

Others :DC withstand voltage [V]

AC indicated

:AC withstand voltage [V]

Electrolytic Capacitors

47/50[Example]:Capacitance value [µF]/withstand voltage[V]

No indication

:Ceramic capacitor

:B2 (12V)

AV-T2922

/AR

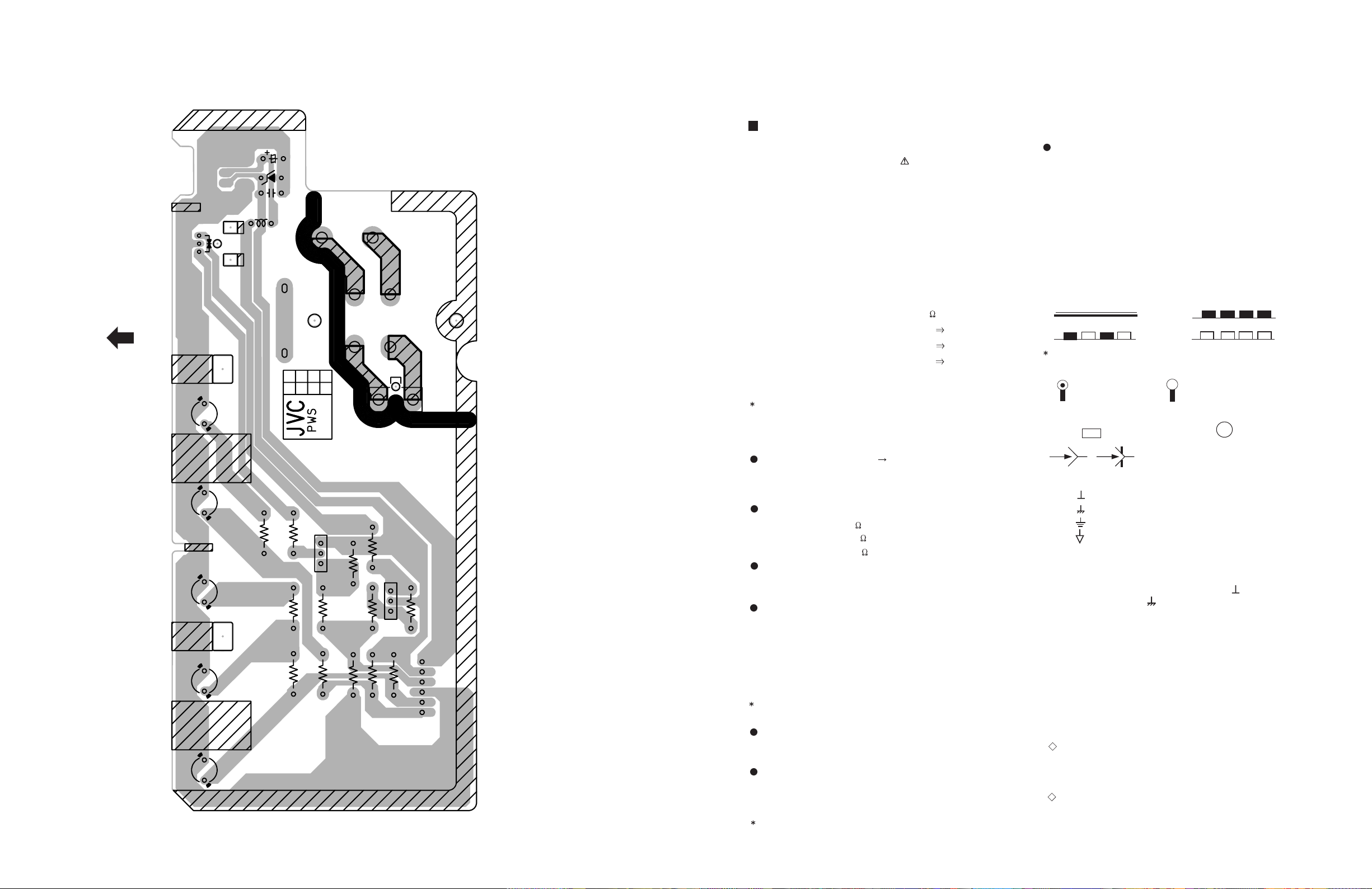

FRONT CONTROL PWB PATTERN

AV-T2922

FRONT

31

IC701

D702

S701S702S703S704S705

C701

D701

C702

L701

-1

Group No.

UL MARK

CKF1269-

PW

12

S901

1

NOZAKI

00.01.28

LIVE

2

P

2-12

MENU CH - CH + VOL - VOL +

R712

R706

R703

R702

Q701

BE

R710

R713

R705

R709

R711

R707

EB

R704

Q702

R701

R708

61

No.51917

ISOLATED

N

VP0203

DP6060

Mar. 2002 No. 51917

Page 13

AV-T2922

CONTENTS

AV-T2922

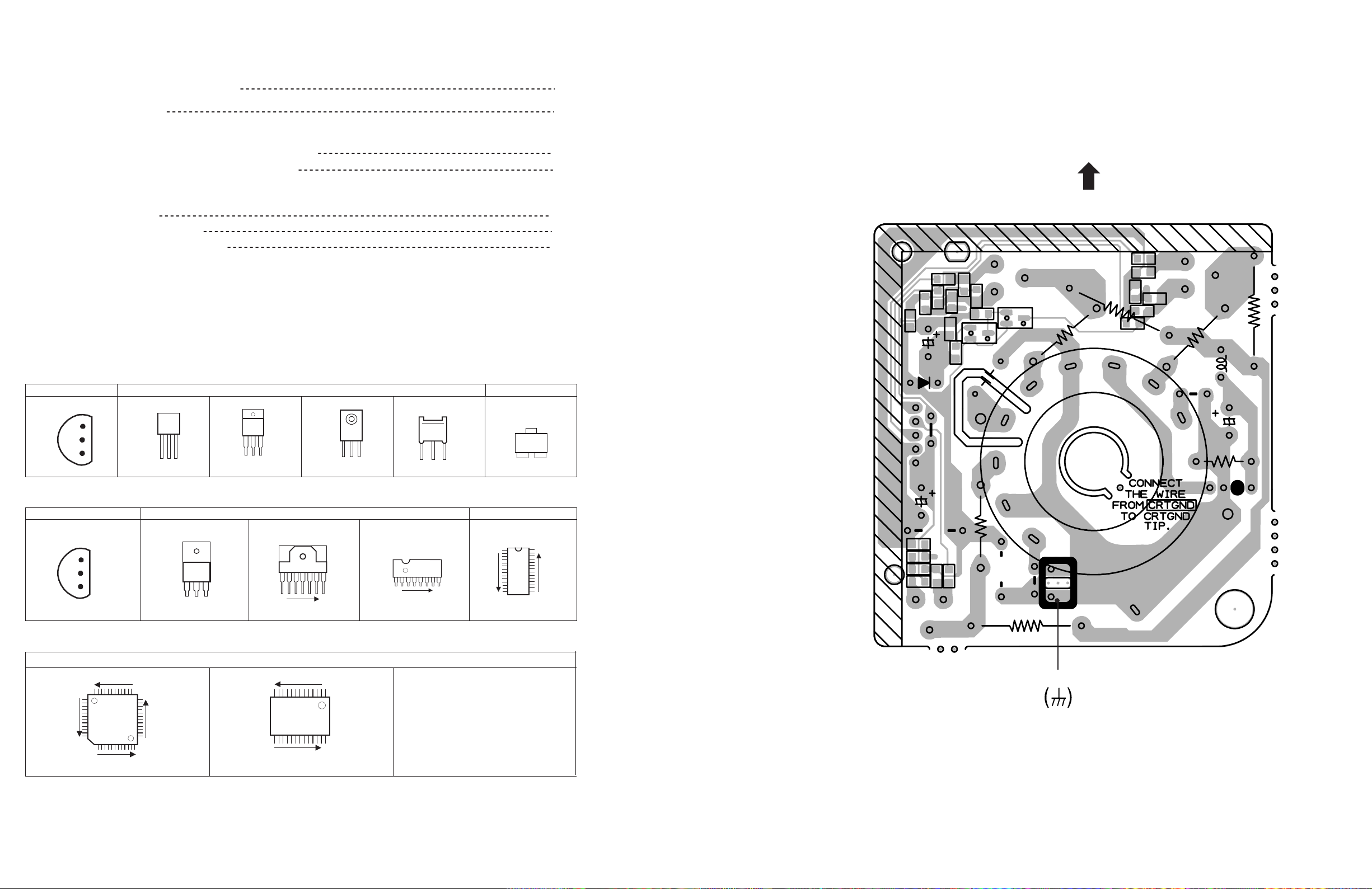

CRT SOCKET PWB PATTERN

SEMICONDUCTOR SHAPES

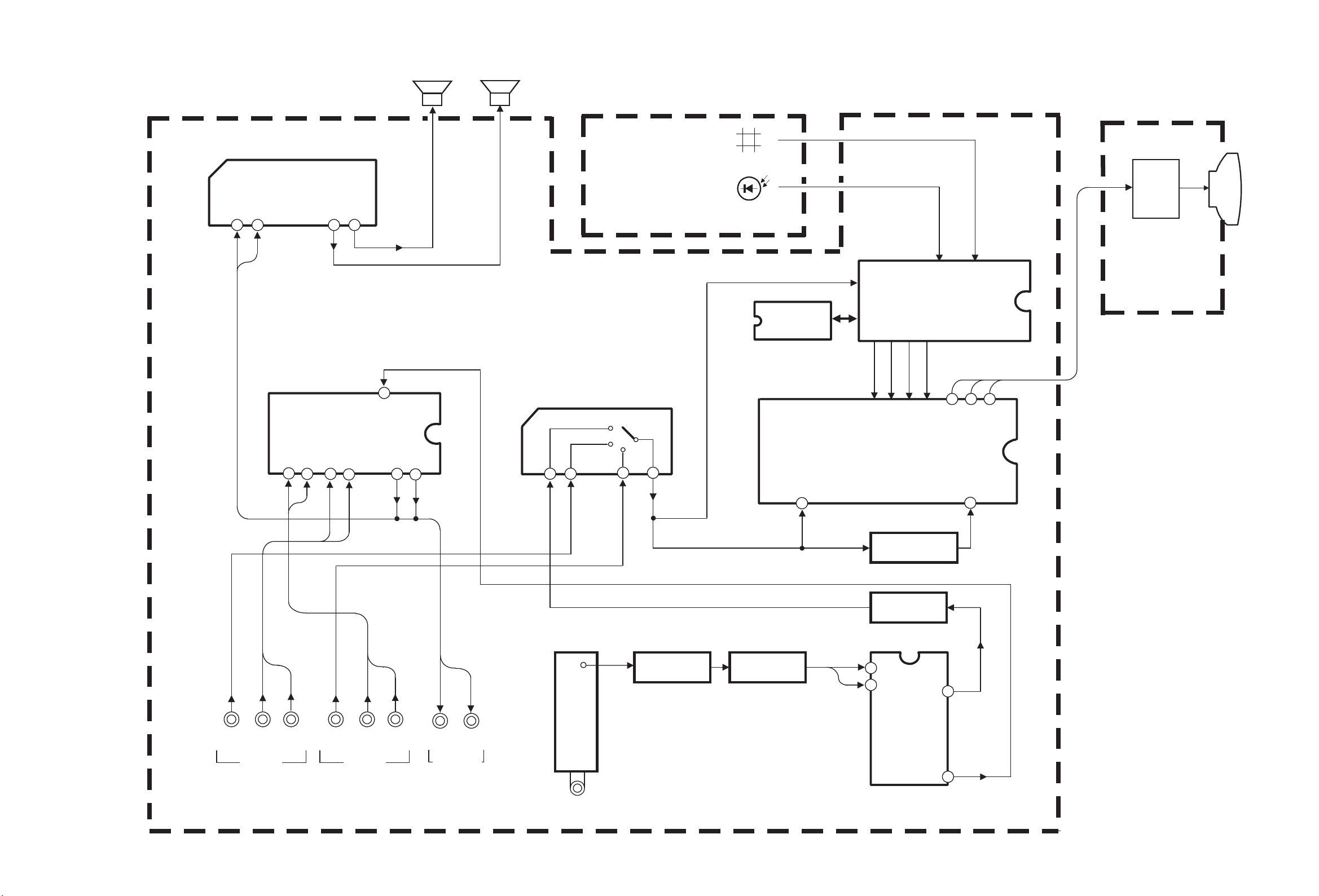

BLOCK DIAGRA M

CIRCUIT DIAGRAMS

MAIN & FRONT CONTROL PWB CIRCUIT DIAGRAM

MAIN & CRT SOCKET PWB CIRCUIT DIAGRAM

P ATTERN DIAGRAMS

MAIN PWB PATTERN

CRT SOCKET PWB PATTERN

FRONT CONTROL PWB PATTERN

SEMICONDUCTOR SHAPES

TRANSISTOR

BOTTOM VIEW

E

C

B

ECB

(G)(D)(S)

IC

B O TT OM VI EW F R O NT V IEW TO P VI EW

BCE

FRONT VIEW

ECB

ECB

TO P VI EW

CHIP TR

C

BE

2-2

2-3

2-5

2-7

2-9

2-11

2-12

R367

R358

W412

C342

D341

5

C357

R352

C355

1

C3

R342

MARK

W049

SCREEN

T

R357

C354

R354

R366

52

R355

R341

E

Q341

R343

TP-R

C382

GK

B

G2

G1

C

Q352

Q342

RK

TOP

R361

HE

R364

R353

C353

H

R359

R368

BK

C356

R356

B

C

E

Q353

R362

R365

L381

Y003

E

4

C381

R381

U

MARK

1

E1

CHIP IC

OUT

E

IN

IN OUTE

1 N

1 N

W050

1

N

E

C

C351

Q351

R351

B

R360

Y001

Y002

R363

SK351

TP-E

UL MARK

CKF0866-

Group No.

/2!

-1

TOP VIEW

N

N

N

1

N

1

N

TP-E

2-2

No.51917No.51917

2-11

Page 14

R.G.B.

OUT

V01

CRT

SP(L)

CONTROL PWB

IC702

MEMORY

IC701

MICRO COMPUTER

IC201

V/C & DEF

15 1614

CRT SOCKET

PWB

42

45

C

VIDEO

REMOCON

Q201, Q202

BUFFER

Q131

BUFFER

IC101

18

10

4

5

SF101

SAW F.

Q101

AMP

IF

IC701

KEY

R

G

B

OUT

C V IN

V. OUT

FM. OUT

SP(R)

IC601

AUDIO AMP

1 2 11 13

RL

LR

IN OUT

IC251

VIDEO SW

1 4

6 8

R2

V2

L2R1

V1

L1

RL

INPUT 1

INPUT 2

OUT PUT

(VARIABLE)

IC651

MTS & TONE/VOL CONT.

36

37 38

39

25

26

7

R

L

OUT

R1 L1

IN

R2 L2

IN

V1

V TV V2

YS.

R. G. B.

ANT INPUT

TU001

TUNER

MAIN PWB

BLOCK DIAGRAM

AV-T2922

AV-T2922

No.51917

2-3 2-4

No.51917

Page 15

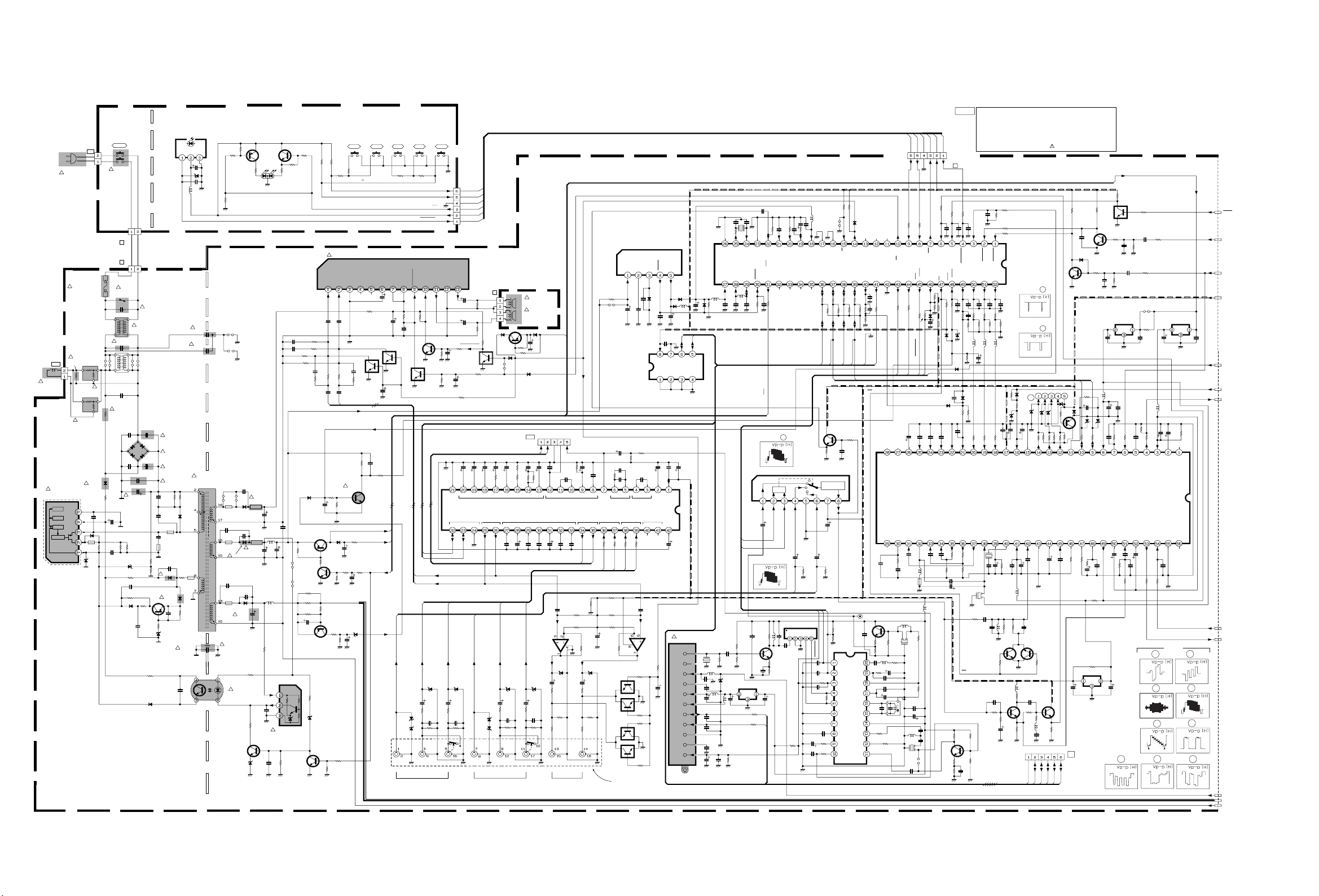

CIRCUIT DIAGRAMS MAIN & FRONT CONTROL PWB CIRCUIT DIAGRAM

FRONT CONTROL PWB

Q701

2SA933AS/QR/-T

4.2V

R712

560

1/2W

C953

QCZ0122-561

Y910

D948

RU3YX-LFC4

QCB32HK-561Z

C943

560p

ICP-N50-Y

D942

QCZ0325-561

C941

560p 2KV

D941

!

C942

100/160

PC921

R959

0

11.2V

D945

560p

! CP942

470/16

R948

1.5k

4.9V

4.8V

(RED) (GREEN)

:POWER :TIMER

SPR-39MVWFD702

!

CP941

ICP-N75-Y

C952

1000/25

QETN1EM

-108Z

C957

470p

QQL26AK-820Z

L942

C944

1000/16

L941

QQL26AK-820Z

R941

15

1/2W

129.4V

11.2V

C949

OPT

Q944

*2

0V

C954

OPT

Q702

2SC1740S/QR/-T

0V

R709

560

1/2W

A-Vcc

C945

82

!

IC941

SE130N

ERROR AMP

R952

4.7k

C606

A-GND

R707

22k

1/2W

0V

R708

22k

1/2W

OPT

C603

OPT

R605

820

2SA966/OY/-T

R942

22k

Y945

BW

Y943

BW

1.2 2WMFR

100/16

2SA949/Y/Z1-T

.47/50

820R609

C621

OPT

R615

C624

.47/50

D962

*5

C511

10/50

Q941

LOW-B SW

12.8V

12V

Q942

*2

R961

1.2 2WMFR

R962

R963

OPT

(1/2W)

C961

129.4V

Q961

B1-GND

R951

3.3k

D944

BW

Q943

0V

SGA-4005A-R2

IN

CH2

1.2V

C604

BP

R603

6.8k

C623

.47/50

STB12V

!

Q511

0.1V

R512

10k

C946

100/25

R945

3.3k

R944

10k

C947

10/50

MTZJ7.5A-T2

R706

10k

1/2W

S701

S705 : QSW0619-003Z

BTL IN

GND

NC

NC

QRT039J-2R2

.47/50

C620

OPT

R614OPT

OPT

BP

R514

33k

4.4V

0V

R947

BW

R946

12k

B1

D961

C962

47/50

R621

2.2

Q605

3W

*10

VOL-VOL+

OUT

BTL

NC

0V

P_ON/OFF

C512

OPT

C609

100/16

C613

1000/25

Q604

0V

R513

0

HD_VCC

H_VCC

R704

R701

10k

10k

1/2W

1/2W

R705

5.6k

1/2W

!

IC601

CH1 IN

1.2V

C607

BP

OPTR608

OPTR604

R607

6.8k

BP

RL

2SC2785/JH/-T

R510

0

12.7V

D943

*5

R943

1.5k

1/2W

0.1V

0.5V

R964

2.7k

1/2W

129V

R965

47k

1/2W

0V

R966

22k

1/2W

*2

R949

15k

0.5V

R950

10k

CH-CH+

MENU

S705

S704S703S702S701

R702

R703

5.6k 1/2W

10k 1/2W

KEY1

KEY2

T-ON/OFF

STB5V

REMOCON

CN00N

AUDIO AMPLA4485

OUT

CH2

GND

MUTE

STAND-BY

Vcc

Vcc

FILTER

10.7V

21.5V

C618

0.22

TF

*10

-0.1V

C622

1/50

OCP

V1

D255

*6

D256

*6

V1 V2L1 L2 L RR2

VIDEO

10V

2.1V

0V

C615

R620

18k

(L/MONO)

INPUT 1 INPUT 2

1000/25

R611

22k

C617

1000/25

Q601

0V

*2

0V

R613

33k

R612

C610

OPT

OPT

Q602

OPT

R624

OPT

R626

8.2K

C668

1/50

A-GND

SDA

2.4V 2.5V

SDA1

SCL1

L

R

R1

L1

D692

D691

*6

*6

C692

C691

10/50

10/50

R691

R692

1k

1k

C693

C694

3900p

3900p

R693

R694

OPT

OPT

R1

CN0PW

PW

POWER CORD

!

QMPR150-200-JC

FUSE

F901

QMF51E2-3R15J4!

Y905

!

R905

68 15W UNFR

QRF154J-680

QAD0101-9R0

!

RGP10J-5025-T3

GND

Vcc

D929

TH902

QAD0101-9R0

! D903

0V

18.5V

158.4V

0V

K923

QQR0582

-001Z

2.3V

R921

1/2W

*9

BW

Y906

BW

!TH901

D928

*5

680

!

L01

CNDEG

DEG

DEG-COIL

CELD058

-001J3

!

IC921

STR-F6654

OVP

TSD

OSC

DRIVE

MAIN PWB

SGA-1020A-R2

POWER

!

S901

QSP4K21-C01

CN00P

P

P

CN00P

!

VA901

ERZV10V621CS

! C902

0.1 275VAC QFZ9072-104

C907

OPT

!

4.7 15W

R901

QRF154K-4R7

C908

OPT

C909

OPT

!

R902

39k

C906

3WOMR

QEZ0371-337

QCZ0122-391C931

C924

470/35

R922

0.15 2WMFR

C922

470p

QCS31HJ-471Z

D905

MTZJ6.8A-T2

D924

C926

0.0022

LIVE

! LF901

QQR0676-001

330/400

R923

0.15 2WMFR

BWR928

OPTC927

OPTR927

*5

MY

! C901

.1 AC275V

QFZ9072-104

Y907

BW

Y908

BW

R911

18k

1/4W

R926

1.5k

1/2W

ISOLATED

LF902

OPT

R910

560k

1/2W

RGP10J-5025-T3

RGP10J-5025-T3

8.7V

8.4V

R925

1k

1/2W

R929

3.3k 1/2W

D927

*5

C702

QCB32HK

-561Z

! C903

.0047 AC250V

QCZ9074-472

! D901

GSIB460

! C904

.0047 AC250V

QCZ9074-472

!

C905

.0047 AC250V

QCZ9074-472

C929

OPT

R933

OPT

C930

OPT

K921

QQR0582-001Z

C921

2200p 2KV

QCZ0325-222

K922

BW

C923

OPT

! D921

! D922

8.9V

C925

MY

0.001

Q921

2SA933AS/QR/-T

D923

*9

.0022 AC250V

QCZ9075-222

C928

0.1

MY

OUT Vcc GND

4.9V

C981

470p AC250V

QCZ9075-471

C983

470p AC250V

QCZ9075-471

R932

4.7 1/2W

!

C982

IC701

PIC-37243SR

REMOCON

RECEIVER

C701

4.9V

47/16

D701

OPT

L701

QQL03BJ

-560Z

R713

LIVE ISOLATED

!

!

R930

OPT

D926

OPT

K924

BW

R924

10k

1/2W

17.4V

2.1V

! T921

SW TRANSF

CETS090-001J8

Y912

Y913

OPT

Y911

BW

K943

QQR0582

-001Z

C955

OPT

K942

QQR0582

-001Z

RGP10J-5025-T3

C956

OPT

K941

QQR0582

-001Z

RU3AM-LFC4

QEZ0203-107

R981

!

8.2M 1W

QRZ0057-825

12.2V

TLP621/GR/

MTZJ5.1B-T2

R711

22k

1/2W

R710

22k

1/2W

10k

BW

!

!

AV-T2922

OUT

CH1

CN00S

9.8V

MUTE-MIX1

C619

OPT

SCL

S

R617

(1K)

OPT

R619

(1K)

OPT

R622

18k

14.1V 4.9V

Q603

*4

R623

OPT

!

SP01

R

CEBSS12D-04KJ2

!

SP02

L

CEBSS12D-04KJ2

-3.1V

12.5V

HD_VCC

D632

*5

Q631

*1

0V

Y601

D634

BW

*5

D631

*5

R632

C631

47/25

OPT

R631

47k

D633

*5

FR720

Y704

OPT

BW

MUTE-MIX1

MPX

TVL

TVR

GND

SOA

NRVA02D-152X

NRVA02D-153X

C664

10/16

TAN

R658

15k

5.2V

CNMPX

R656

C663

1.5k

1/50

TAN

R655

3.3k

1.1V

4.6V

R656

R658

C665

C667

1/50

33/50

C666

R660

1/50

5.1k

4.5V

2.8V

4.6V 4.6V

IC651

VARIABLE

LINEIIC BUS

4.6V

4.6V

4.6V 4.6V 4.6V

4.6V

C677

0.022

V2

L2

D253

*6

D254

*6

(L/MONO)

VIDEOAUDIO AUDIO AUDIO

C671

2.2/50

D657*6D656

*6

C686

10/50

R672

1k

C638

3900p

R684

OPT

C672

0.0022

R2

C673

IC652

BA15218N

AMP

C685

10/50

R671

1k

C637

3900p

R683

OPT

COM

TVL

TVR

C661

0.1

MY

4.5V

SAP DEMODULATIONdbx NR

UPC1851BCU

4.6V

0.0022

C674

4.5V

C683

4.7/50

R670

R674

R676

180

4.5V

SI1SOASTISRBITIWTIWRBdo2VO F

4.6V

C675

C669

1/50

BP

4.5V

D655

OPT

470

82k

OUTPUT

(VARIABLE)

.47/50

R682

68k

C660

0.1 MY

3.1V

4.6V 4.6V 4.6V

C676

0.1 MY

R662

12k

R663

12k

4.5V

C659

TVR

R666

5.6k

R661

47k

D653

C682

4.7/50

R669

470

R673

R675

C662

3.3/16

R654

33k

5.2V

MTS & TONE/VOL CONTROL

0.1 MY

2.2/50

(1/2)

C658

0.047

R651

1k

4.6V

TVL

R688

0

R2

R667

5.6k

R664

12k

R665

12k

C680

47/25

R668

47k

OPT

Q651

*10

Q652

*10

82k

Q653

180

C709

47/25

C657

2.2/50

PILOT

4.6V

R687

0

L2

0V

*10

0V

Q654

*10

J001

QNN0086-001

REAR AV JACK

IC703

L78LR05E-MA

5V REG & RESET

CD

INPUT

5.9V

12.7V

C730

C710

OPT

0.1

MY

R652

560

R653

2.7k

C655

47/25

4.7/50

BP

C656

1/50

DET

PHASE

ER1EL2ER2TVLTVRLBCLTCTLORBCRTCTROSURLOTROTD-GND

4.6V 4.6V

R6860R685

0

R1

L1

C670

1/50

BP

4.5V

4.5V

IC652

AMP

(2/2)

4.5V

R678

0V

22k

R679

22k

0V

0V

R680

22k

0V

R681

22k

AV-T2922

GND

RESET5VOUTPUT

0V

D709

BW

D702

BW

C711

0.01

C722

0.01

DD

V

A0A1A2

IC702

AT24C02-T2922AR

MEMORY

C651

0.01

C653

C654

0.1 MY

VRE

PD1PD2d01 PHD1PHD2COMSDTNDTSOT

Vcc

9V

1/2

DET

Vcc

FIXED

LINE OUTEXT1 ININEXT2TV OUTOUT TONE/SURROUND

MOAFOLFOREL1

4.4V

NCNC

TU001

R677

6.8k

C684

10/50

IF2

TU

4.9V4.9V

D706

BW

L703

BW

C712

100/16

SCL2

4.9V

NP

SCL

C652

100/16

C679

1/50

!

TUNER QAU0229-001

IF1

NC

33V

BT

NC

BP

BM

SDA

SCL

SAS

NC

AGC

ANT INPUT

100/16

C713

SDA2

4.9V

SDA

Vss

0V

32.2V

10/50

STB5V

SP-ON/OFF

A-MUTE

AVCC

CV-IN

X701

QAX0468-001Z

CRYSTRL

L702

D708

4.7

OPT

R758

L704 ;

CELP055-8R2Z

CF001

QAX0349-001

47.25MHz

0.01

C011

C010

OPT

L001

15

C007

470/16

C006

OPT

C005

OPT

C003

OPT

C001

:

NOTE

*1

:

2SA1037AK/QR/-X

*2

:

2SC2412K/QR/-X

*3

:

DTA124EKA-X

*4

:

DTC124EKA-X

*5

:

1SS133-T2

*6

:

MTZJ9.1C-T2

*7 :

MTZJ5.6A-T2

MTZJ7.5B-T2

*8 :

CN00N

N

R718

R776

OPT

C766

.47/50

C761

C707

18p

CH

C708

22p

CH

R773

0

2.1V

2.2V

Vss

X IN

X OUT

DD

OSC1

OSC2

V

4.9V

4.9V

4.9V

L704

8.2

C714

OPT

R721

0.1

MY

C715

C716

15p

47p

CH

CH

C762

BP

1/50

220p CH

L701

4.7

C763

C706

0.1

0.001

R764

1M

2.2V

CV IN

CNVss

RESET

PW_ON/OFF

4.9V

4.8V

R722

1k

560

C717

150p

CH

MY

R761

R762

1k

15k

2.2V

2.2V

0.7V

4.9V

HLF

AVcc

RVCO

VHOLDNC

NC

NC

NC

R724

220

SDA2

3.3k

Y701

0

D703

*5

NC

NC

NC

0V

0V

H/S

IIC

A-MUTE

SDA2

SDA1

SCL2

SCL1

2.4V

2.4V

4.9V

4.9V

R726

R728

R730

R731

220

220

220

6.8k

R729

R727

R725

6.8k

6.8k

6.8k

SDA1

SCL2

SCL1

CTL_GND

Ym

0V

TV/EXT

BUS

FREE

0V

C728

OPT

R732

6.8k

OPTC729

2.2kR754

2.2kR755

BUS_FREE

0V

SP-ON/OFF

SEL1

0V

R774

1k

SEL1

SEL2

P_ON/OFF

9.1V

R765

3.4V

VIDEO SW

3.8V

V2

AGC_MUTE

C113

C114

R113

C124

R114

OPT

C116

0.22

R161

3.3k

6dB AMP &

75Ω DRIVE

IN3

100/16

C251

10/50

AGC_ADJ.

0.01

0.01

100

0.01

R162

0

C256

4.2V

9.1V

R251

RF_AFC

2.8V

1.5V

R766

1k

Vcc

75

OUT

4V

R111

390k

R112

330k

IC101

M52342SP

2.1V

RF AGC

DELAY

4.7V

AFT

OUT

1.6V

RFAGC

OUT

VIF

1.4V

IN

VIF

1.4V

IN

INTER

SW

IF AGC

FILTER

FM F/B

FM OUT

1.2k

C765

100p

CH

TP-12B

C123

0.01

EQ

APC

V.OUT

VCC.F

VCO

VCOGND

VCC

SIF

OUT

SIF

SW

SIF

IN

IC251 8

2.3

IN1AB

3.6V

C255

10/50

SEL2

SEL1

TP126

1.2

VTV

L101

0.22

R103

100

C105

1/2W

0.01

R101

C101

0.01

R006

82

4.7L003

D001

MTZJ33A-T2

L002

OPT

C002

OPT

9.1V

5.6k

1.7V

Q101

R102

1.8k

4.9V

C008

47/25

SDA1

SCL1

R001

56k

2SC5083/L-P/-T

1V

R104

C102

R105

0.01

AN7805FIC001

9.1V

INOUT

C009

47/25

560R004

R003

560

CTRL

0V

18

27

C103

OPT

BA7612NIC251

IN2

0V 3.8V

V1

SF101

QAX0324-002

C104

0.01

R170

68k

Q761

*2

MUTE

GND

C252

10/50

R252

75

C161

10/50

C162

OPT

9.1V

0.9V

1.5V

3.4V

4.9V

C312

0.01

2.1V

4V

OPT

4V

9.1V

2.2V

0V

2.1V

MY

Q131

*2

R1341kR133

R135

C121

OPT

R116

68

C122

R164

1k

T111

4.7/50

NC

DACVM OUT

IC201

TB1230N

V/C&DEF IC

NC

R311

27k

C311

0.33

TF

L131

22

1.5V

270

470

L112

OPT

C120

.47/50

680p CHC119

0.01C118

C117

47/25

CELT001-209J3

10kR163

CF161

SFSH4.5MCB

C313

NC

Color

FSC OUT

Filter

APC

2..9V 2..1V0V2..3V

C214

0.1

MY

L302

K301

CF131

QAX0339-001

CF131

R117

OPT

R131

C163

47p

L161

22

C164

47p

Y161

C166

0.01

R7161kR717

1k

4.9V 4.9V 0V

KEY-1

KEY-2

MUTE

SEL2

AGC

0V

R736

47k

R775

R737

1k

68k

R734

1k

R735

47k

D704

C719

10/50

AGC_MUTE

AGC_ADJ.

C813

0.01

2.5V

4.5V

B-IN

Limiter

Analog

GND

Y-I N

Fsc

C308

0.1

MY

BW

BW

L113

BW

R132

330

1k

C112

0.01

C111

47/25

CH

CH

OPT

R733

OPT

R749

1k

C718

0

0V 0V

SD

T-ON/OFF

ADJ.

AGC

TV/EXT

X-RAY

0.8V1.7V

1kR748

5.6kR738

*5

D705

OPT

C779

10p

CH

D712

*5

C812

C811

0.01

0.01

4.5V 4.6V 0V0V

R-IN

G-IN

Analog

Analog

B-Y IN

R-Y IN

2..3V

C309

0.1 MY

R315

OPT

R167

1k

6.4V

R168

100

R169

560

R713

1k

C705

C723

470p

OPT

CH

2.3V 4.5V

4.9V

NECK

RF AFC

REMOCON

/OCP

BGR

Ys

0V

0V0V

4.4V

C724

C725

C720

OPT

OPT

150p

CH

R7421kR7441kR746

R740

1k

100

C721

OPT

R743

R741

3.9k

10k

D710

*7

L706BWL707

R799

BW

33K

D510

*5

D713

*5

R756

10k

R815

0

R8130R812

0

C815

OPT

0V 0V 0V

Ys

B-IN

Ys/Ym

Digital

Analog

Digital

R-Y OUT

B-Y OUT

Y-O UT

2.2V

1.7V

1.7V

R312

X301

0

R314

*

0

C305

12p

R313

CH

OPT

0.01C307

47/25C306

R301

1K

TV/EXT

R165

27k

Q161

*2

2.3V

1.7V

R166

10K

C165

0.01

C301

CH

C303

12p

CH

C704

0.01

V-SYNC

0V

C726

OPT

R745

3.9k

C773

1/50

R811

0

G-IN

Digital

Vdd

Fsc

5V 2.7V

C213

1/50

X301;

QAX0305-001Z

EF301

CE42142-222Z

L301

39

Q302

*2

R303

5.6k

C201

OPT

R201

820

R202

1k

C202

100/16

R711

120k

R712

180k

R710

1k

R705

4.5V

1k

H-SYNC

IC701

M37267M8-100SP

MICRO COMPUTER

0V

C727

OPT

R747

3.9k

L708

BW

RF_AFC

R217

56k

R216

0

C806

0.01

C805

9.1V 6.5V

Digital R-IN

RGB-Vcc(9V)

(TEXT)

Stretch

Black

16.2MHz CRYSTAL

4V

R215

C210

820k

0.01

L205

4.7

R307

4.7k

R308

6.8k

0V

L201

0

R220

470

Q201

*2

4V

3.4V

R203

820

D201

*5

D202

*8

220/16

ABCL

Y/C-Vcc(5V)

4.8V

C304

0.01

0V

7.1V

IC701 1

5

IC701 2

5

CN00T

D801

*11

C215

C209

220/16

C205

68p CH

R204

R221

L202

C206

10/50

680

OPT

OPT

OPT

CTL_GND

CRT SOCKET PWB

T

R801

220

(TEXT)

GND

Chroma IN

2.3V

C30215p

15p

CH

Q301

SCL1

*9

*10 :

*11

BW

0 : QRSA08J-0R0YL

OPT::

G

RB

GND

*11D802

*11D803

R816

R817

OPT

OPT

220

R802

2.5V

2.3V

R-OUT

G-OUT

(Y/C)

APL

GND

2.2V

C207

0.1

MY

C208

4.7/50

*2

0V

R304

5.6k

Q202

*2

9.1V

3.4V

2.8V

R205

1.5k

CONTROLEXT

SDA1

SCL2

SDA2

MTZJ15A-T2

DTC323TK-X

: MTZJ15B-T2

:

BUS WIRE

NON-MOUNT(OPEN)

SAFETY PARTS

R704

10k

C703

1000p

D701

*5

4.5V

Q701

*2

9V

D805

OPTD804

*11

R819

OPT

OPT

R818

OPT

Q801

220

R803

0V

2.2V

B-OUT

(Digital)

GND

Video-IN

Composite

S-Inhibit

2.1V

1.5V

R309

R401

10k

10k

9.1V

C291

100/16

C CN00C

BUS_FREE

R709

10k

Q702

4.5V

R703

0

0.1V

C701

0.001

CH

SCL1

SDA1

R820

OPT

C814

OPT

D772

*7

D771

*7

R772

R771

220

220

2.4V

2.5V5V4.4V 1.3V

SCL

SDA

V Center

AFC1-filter

5.1V

2.6V

R505

C506

8.2k

0.01

C507

1/50

R218

OPT

R291

OPT

(2W)

IN OUT

C292

100/16

IC291

AN78N05

5V REG.

H_VCC

R714

10k

Q703

0V

*4

R715

220K

1.9V

*2

47/25

0.1V

L771

4.7

C771

C505

(Digital)

Vdd(5V)

Sync-OUT

0.7V

C402

1/50

R708

0

C702

OPT

R702

22k

IC293

AN78L05-T

5V REG.

5V

C296

100/16

R504

0.01

100k

Coinsident Det

V-Sepa

5.3V

C212

0.1

R214

OPT

R213

390

C780

0

INOUT

C772

0.01

R503

FBP-IN

Sync-IN

2.3V

C211

680p

C781

0

R707

10k

R701

56k

Y201

NRSA02J-0R0X

11.9V

R940

OPT

C295

OPT

R502

OPT

10k

R501

0

C503

0.01

1.9V

4.5V

Curve

H-OUT

Correction

V-ram p

V-OUT

0.5V

4.5V

C404

C403

OPT

2.2/50 HF

QEM61EK-225Z

CH

R403

R402

6.8k

0.6

4.9V

0.8 1.5

1

12 13 14

3.2

3.4 4

R706

0

34

42

31

56k

100/16

8.9V 2.5V

H Vcc

V-NF

4.4V

8.9V

L501

4.7

C501

IC292

AN78L09-T

9V REG.

OUT IN

C294

100/16

C401

VAGC-filter

(DEF)

GND

IC201

1/50

NC

SCP OUT

V-BLK OUT

NC

0.7

NECK

VP

HP

9V

11.9V

C293

OPT

X_RAY

ABL

HD

R506

1K

NFB

VD

33

45

4

5

BT

B1

B1_GND

No.51917 No.51917

2-5 2-6

Page 16

MAIN & CRT SOCKET PWB CIRCUIT DIAGRAM

Q521 D

200

3.8

IC401

2 3 7

50 25 1

R410

0

C405

R411

0.1

OPT

MY

0.4V

R404

1K

NECK

VP

R529

620

R521

2.2K

3WOMR

BSN304-T

H-DRIVE

1.5V

R523

2.2K

4 5

R406

4.7K

R408

4.7K

R407

R405

3.9K

220

4.3V

Q401

*2

VD

NFB

R532

2.2K 3WOMR

T521

CE42034-002

H-DRIVE TRANSF

C523

1/160

Q521

QCB32HK-151Z

72.2V

R423

10K

-0.1V

R533

22

1/2W

C521

150P

500V

10K

THERMAL

PROTECTION

OUT PUT

GND OUT IN

C406

0.01

MY

C407

OPT

D402

MTZJ75-T2

R419

18K

!

Q522

2SD2499-LB

H.OUT

K521

BW

D512

RH3G-F1

C522

330P

500V

QCB32HK-331Z

R524

1/2W

LA7840IC401

DRIVE PUMP UP

16.1V 27.2V

2.1V 2.1V

K401

QQR0621-001Z

OPTR420

R418

56K

R422

0

C414

1/50

HP

ABL

X_RAY

C524

1.5k MPP

QFZ0198-133

QFLC2AK-333Z

R421

0

R417

OPT

!

.013

!

C525

0.47

QFZ0119-474

2

OSC STOP

Vcc

26.2V

C415

0.0015

MY

100V MY

56kR416

V-LIN

2200/35

QETM1VM-228

200VMPP

Q522 B

2.7V

C410

100/35

D401

1N4003-T2

C411

470/35

C412

0.33

C413

R414

0.68

1W

R525

560 1W OMR

!

L521

QQR1137-002

R526

1.5k 2W

QRL029J-152

R415

R412

2.7

1/2W

R545

OPT

VH

H-LIN

OMR

R413

560

1/2W

Y401

1K 1/2W

BW

Y402

OPT

S401

OPT

V.CENTER

DOWN

UP

SW

CENT

NCNC

!

DY001

(ITC)

DEF YOKE

HV

CN0HV

1200

1000/35

QETM1VM-108

MTZJ9.1B-T2

D583

OPT

C545

1000/35

QETM1VM-108

C543

R581

1/2w

R584

1/2W

27k

22k

! FR542

.56 2W

QRZ9024-R56

D582

FR543

!

2.2 2W

QRZ9023-2R2

! D562

MTZJ7.5S-T2

AV-T2922

QCB32HK-821Z

QRE121J-682Y

C584

0.1 MY100V

QFLC2AJ-104Z

QCB32HK-821Z

RGP10J-5025-T3

R582

39k

1/2w

R583

OPT

C583

0.1

MY

C561

100/35

!D542

RU3AM-LFC4

FR586

6.8K

C544

820p

!D543

T522

QQH0115-001

C542

820p

500V

135 23

80

D561

1SS81-T2

!

FR561

4.7

QRZ9017-4R7

!

R562

MFR 1/4W

6.34K

QRA14CF-6341Y

!

R563

3.24K

MFR 1/4W

QRA14CF-3241Y

!

4

6

FR585 2.2 1W

!

L581

OPT

1/4W

X-RAY

HVT

AV-T2922

!

C526

100/160

QEZ0203-107

T522

250

QRZ9021-2R2

CN00X

X

ANODE

FOCUS

SCREEN

C581

0.047

MY

!D581

RGP10J-5025-T3

C548

820p

QCZ0122-821

D544

D541

RH1S-T3

33/250

QETM2EM-336

5

8

2WOMR

RH1S-T3

C541

R544

22K

BT

R546

OPT

TP-91(B1)

TP-E

B1

NC

GND

B1

CN0B1

R343

R342

33K

R341

120

33K

R353

150

C352

*1

:

*2

:

*3

:

*4

:

*5

:

*6

:

C342

3.3/50

D341

*5

CN10T

T

GND

CN00U

U

HB

NC

GND

HEATER

C357

100/16

9V

B

G

R

NOTE

Q341

*2

2.2V

C353

OPT

R368

2.7k

2WOMR

R352

150

2.4V

OPT

R366

2WOMR

2.7k

R351

150

2.3V

C351

OPT

Y001

OPT

Q353 C

80

2SA1037AK/QR/-X

2SC2412K/QR/-X

DTA124EKA-X

DTC124EKA-X

1SS133-T2

MTZJ9.1C-T2

Q342

*2

R364

R367

2.7k

R363

1.8V

12k

2V

12k

1.9V

R365

12k

2W OMR

146.5V

Q353

2SC4544-LB

C356

330p CH

R356

330

139.6V

Q352

2SC4544-LB

C355

270p CH

R355

330

143V

Q351

2SC4544-LB

C354

270p CH

R354

330

(10/250)

Q352 C

110

CRT SOCKET

! SK351

CE42535-001J1

R362

1.5k

1/2W

B.OUT

R359

TP-R

100

R361

1.5k

1/2W

R.OUT

R358

100

R360

1.5k

1/2W

L381

G.OUT

39

R381

OPT

R357

100

OPTC381

NC

80

BW

::BUS WIRE

0 : NRSA02J-0R0X

NON-MOUNT(OPEN)

OPT

: SAFETY PARTS

!

V01

Y002

TP-E

OPT

A68AJB82X02

R

G

B

G1 G2 G3

Y003

OPT

!

C382

.001

QCZ0121-102

BK

RK

GK

H

H

CRT SOCKET

PWB

(Within MAIN PWB)

SGA-1020A-R2

CN10U

U

Q351 C

E1

FOCUS

SCREEN

3KV

(2/2)

9.1V

C547

1000/16

VP

NECK

HP

ABL

NFB

X_RAY

HD

9V

VD

No.51917

12.4V

INOUT

IC541

AN7809F

9V REGULATOR

C546

220/16

MAIN PWB

SAG-1020A-R2

2-7 2-8

(1/2)

B1

BT

B1_GND

MAIN PWB

No.51917

Page 17

AV-T2922

AV-T2922

PATTERN DIAGRAMS MAIN PWB PATTERN

R929

W313

K922

43

C905

C908

R910

W312

C921

C931

W307

L

PC921

W306

2

R933

R948

R951

R928

1

K921

C929

C930

C923

D921

R932

K924

R949

C903

W331

R981

R950

D926

D901

R930

Q943

W330

T921

W320

8

7

5

4

3

2

C904

R952

M

9

D923

C926

8

D924

C924

4

7

R921

2

K923

C922

D929

W308 W310

6

5

4

C927

D928

R926

R925

D927

R927

R924

R922

R923

C906

W314

C928

BCE

Q921

C925

D922

IC921

531

D905

R911

POWER

SHOCK HAZARD

W309

H005

FRONT

C909

TH902

3

LIVE

W305

Y905

Y906

R905

F901

2

TH901

1

DEG

P

21

T3.15AL 250V

M

2

1

0

R901

C907

LF902

W376

C902

LF901

VA901

LK

C901

C954

D944

R902

D903

C942

C983

Q944

Y907

R959

Y908

C981

C982

Y912

D945

Y913

C949

TP-E

R684

C638

R675

R673

R672

14

W0

64

9

R678

Q651

R679 R680 R681

Q652

R6

77

R668

C684

W060

R664

W391

C676

4025

W070

W071

R685

R686

R687

R688

C658

C654

R651

C653

R652

W033

W352

W369

R220

1

W074

TVL

Q201

R203

R304

W024

R201

C201

R204

R202

C202

W343

L205

R218

C209

C207

C208

W086

R401

45

R309

W202

R504

C505

C772

10

R771

R772

R820

W028

5

W409

D713

C779

W378

D708

L702

R721

R758

D706

C713

W333

W030

GH

W055

R669

R674

W054

R670

R676

13

W061

R003

Q654

R004

Q653

C682

C683

D655

8

R6

67

R665

50 55

C506

C814

D712

D653

C679

W390

42

W389

W069

W052

C651

W066

C205

C507

R505

C212

W399

W347

W051

L201

520

C715

W706

C652

W119

R502

L704

W396

R221

C716

R214

D772

C708

IC201

C503

W375

27

C717

L771

26

C707

Q202

W201

R501

C771

W702

C211

CF131

VCO

R135

R205

C206

C402

56

1

C113

W388

L131

W058

W382

W114

W400

R764

C761

W329

1

W075

R503

D771

D804

C714

R773

X701

GF

IJK

12

615

C670

22

21 20

C667

W205

C813

R813

C766

5

C691

25

W365

R756

1

C665

W403

W342

R301

W413

Y704

R694

R660

C668

R315

R314

D201

FR720

D253

W067

C664

8

W715

C812

C709

J001

8

11

C694

R692

4

C637

3

W065

C685

W712

D254

D691

C680

R666

W056

R6

63

IC652

C671

C673

C672

C677

W348

15 10 5

R658

R655

R656

C663

C661

C662

R682

W009

5

MPX

SOA

COM

C301

L301

R308

Q302

C303

W417

R765

W076

W120

Q761

EF301

C306

X301

C210

35

40

C307

C811

C815

C806

R216

C805

D202

R801

R802

C215

1

MARK

D805

W703

1

IC702

8

C722

C711

W707

C710

IC703

2

4

1

3

C730

MICOM

W379

10

R683

7

R671

86

C6

D656

W344

D657

R661

15

R662

35

C674

C675

IC651

R654

C656

C660

C655

C657

R653

C659

TVR

GND

C302

R307

Q301

R303

W116

R215

C213

C304

C305

W204

W203

15

R816

R817

R803

R818

R819

Q801

T

D801

D802

D803

4

5

W708

L703

D702

5

C712

D709

E

IC941

C621

W359

D941

K942

C955

Y910

W355

R961

C624

H004

W300

C511

R615

J

R512

R607

R619

C952

W303

D942

D948

W370

R608

W304

EB

W716

C606

R611

K941

R945

R614

C620

IC601

W324

R510

W323

C957

W353

W363

1

51013

C

IN

R962

R941

L941

10

11

12

13

14

15

16

17

18

K943

Y911

C953

CP941

R621

R513

ISOLATED

R609

C613

C617

W301

D943

W360

Q605

C941

R943