Page 1

A

SER VICE MANUAL

REAR PROJECTION TELEVISION

V-48WP30

BASIC CHASSIS

AV-48WP30

SB2

CONTENTS

SPECIFICATIONS

!

SAFETY PRECAUTIONS

!

FEATURES

!

FUNCTIONS

!

INSTALLATION

!

TECHNICAL INFORMATION

!

1

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

2

3

4

4

7

8

MAIN PARTS LOCATION

!

SPECIFIC SERVICE INSTRUCTIONS

!

SERVICE ADJUSTMENTS

!

TROUBLESHOOTING

!

PARTS LIST

!

★

OPERATING INSTRUCTIONS

★

STANDARD CIRCUIT DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・

・・・

・・・・・・

・・・・・・・

・・・・・・・

・・・・・・・・・・・・・・

No.51914

Feb. 2002

9

10

19

51

53

2-1

Page 2

A

V-48WP30

SPECIFICATIONS

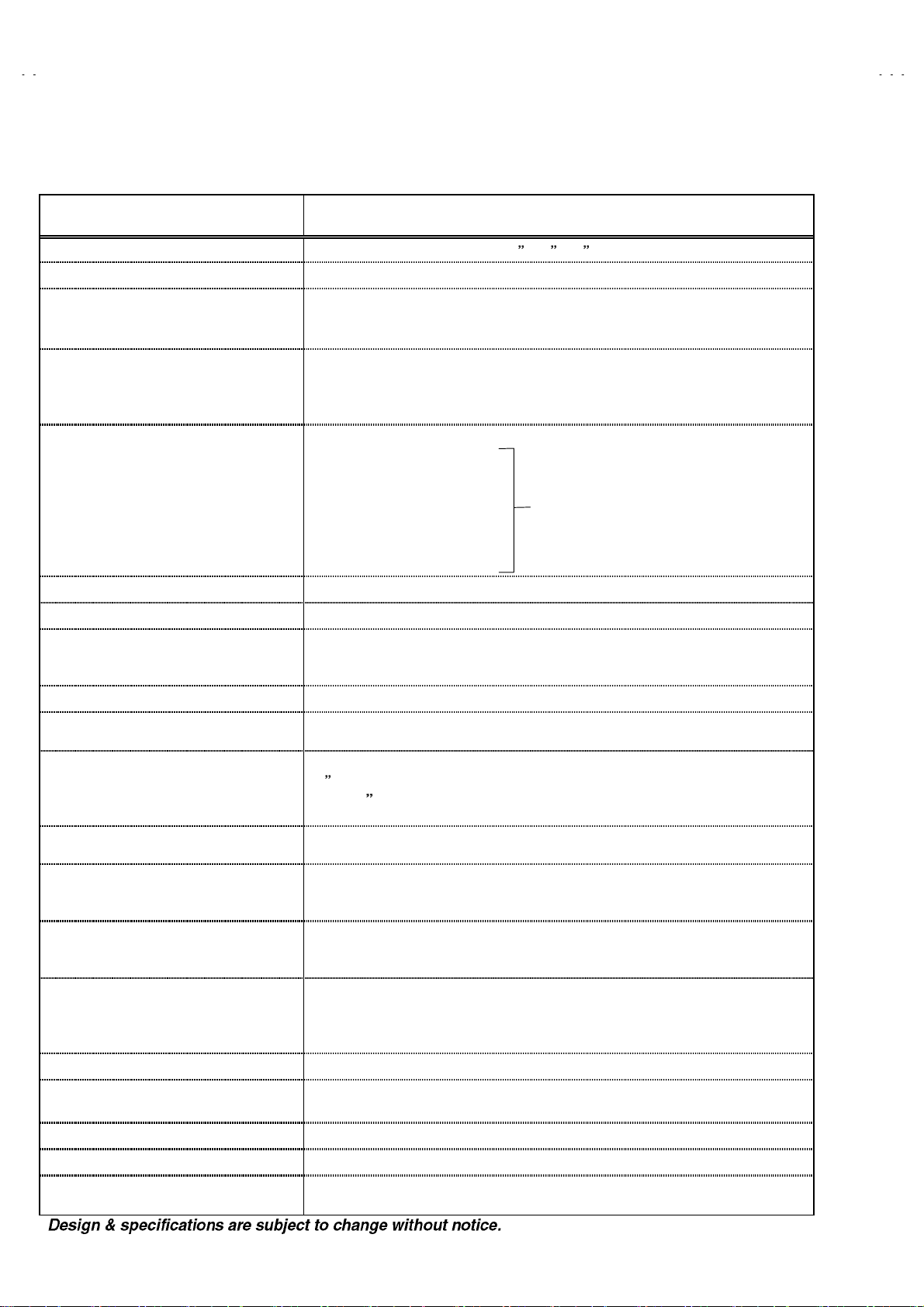

Items Contents

Dimensions (W

Mass

TV RF System

Color System

Sound System

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

CATV Receiving Channels an d Frequenc y

Low Band

High Band

Mid Band

Super Band

Hyper Ban d

Ultr a B a nd

Sub Mid Band

TV/CATV Total C hannel

Antenna Terminal

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier

Power Input

Power Consumption

Screen

Screen Size

Projection Tube

High Voltage

Speaker

Audio Power Out put

External Input

Audio Output

Digital-Input

Speaker Input

AV Compulink

Remote Control Unit

D)

××××H××××

Video Input

Audio Input

S-Video

Component Input

ⅢⅢⅢⅢ φ

120.0cm×124.4cm×60.9cm ( 47-1/4

81.0 kg (179.0 Ibs)

CCIR (M)

NTSC

BTSC System (Multi Channel Sound)

(02~06) 54MHz~88MHz

(07~13) 174MHz~216MHz

(14~69) 470MHz~806MHz

(02~06, A-8) by (02~06&01)

(07~13) by (07~13)

(A~1) by (14~22)

(J~W) by (23~36)

(W+1~W+28) by (37~64)

(W+29~W+84) by (65~125)

(A8, A4~A1) by (01, 96~99)

180 Channels

75Ω(VHF/UHF) F-type connector

45.75MHz

41.25MHz (4.5MHz)

3.58MHz

120V AC, 60Hz

248W

Transparent screen (unitized fresnel lens / double lenticular lens)

(122cm) Measured diagonally, 16:9 ratio (W:106.3cm, H:59.8cm)

48

17cm (6.7

31kV±1.0kV (at z ero b eam cur r ent )

13cm round×2, φ5.5cm r ound×2

φ

10W+10W

1Vp-p, 7 5Ω (RCA pin jack×4)

500mVrms ( -4dBs ), high impedance (RCA pin jack×8)

Y: 1Vp-p positive (negative sync provided, when terminated with 75Ω)

C: 0.286V

Mini-DIN 4pin connector×2

P

B

P

R

Y: 1Vp-p

1080i DTV (digital broadcast) ready

Fix : 500mVrms(-4dBs) low impedance (1kHz when modulated 100%)

DVI-D signal link 19pin connector

(Digital-input terminal is not compatible with computer signal.)

45W 16Ω(max imum input)

3.5mm m in i jac k

RM-C322G

(AA/R6/UM-3 b atter y×2)

) tube ×3 ( R / G / B )

(burst signal, when terminated with 75Ω)

p-p

: ±0.35Vp-p

: ±0.35Vp-p

,75

Ω

(RCA pin jack×2)

,75

Ω

(RCA pin jack×2)

,75

Ω

(RCA pin jack×2)

24

×49×

(54MHz~804MHz)

)

2

No. 51914

Page 3

A

SAFETY PRECAUTIONS

V-48WP30

1. The design of this product cont ains special hardware, m any

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the

original circuits. Service should be performed by qualified

personn el only.

2. Alter ati ons of t h e d esign or circ uitry of th e products s h oul d n o t

be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have

special safe ty-related characteristics. These characteristics are

often not evi dent from vis ual insp ecti on nor c an the pr otecti on

afforded by them necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts that have these special safety

charact erist ics are identif ied in th e parts lis t of Servic e m anual.

Electric al comp on ent s hav ing su ch f eatur es ar e id ent ifi ed

by shading on the sche m atic s an d by (

in Service manual.

does not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Servi ce m a nua l ma y cause s hock, f i re, or ot her h a zards .

4.

Use isolat i on tra nsformer wh en hot chassis.

The chass is an d any su b-chass is c ontain ed in som e prod ucts

ar e con nect ed t o on e sid e of th e AC p owe r lin e. An is olat ion

transf ormer of adequate cap acity should be ins erted between

the produc t and the AC power supp ly point while perf ormin g

any service on some products when the HOT chassis is

exposed.

5.

Don't short b etween the LIVE s ide gr ound a nd IS OLATE D

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

differenc e of the G ND is shown by t he LI VE : (") side GND,

the ISOLATED(N EUTRAL) : (#) sid e GND an d EARTH : ($)

side GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a meas uring app aratus (oscill osc ope etc.)

the LIVE side GND and ISOLATED(NEUTRAL) sid e GND or

EARTH side GND at the same time.

If above note will not be kept, a fuse or any parts will be broken.

6. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

7. The high vol t age applied t o the pictur e tube must conf orm wit h

that specif ied in Service manual. Excessi ve high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefor e operation under excessive high

voltag e conditi ons sh ould b e kept to a mini mum, or shoul d be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorr ect inst allati on, crac ked or melt ed high volt age har ness,

poor sold ering, etc.). T o maint ain the proper minimu m level of

soft X-Ra y emiss ion, comp onents i n the high voltag e circuit ry

includi ng the pic ture tu be must be the exact r eplacem ents or

alternatives approved by the manufacturer of the complete

product.

8. Do not check high voltage by drawing an arc. Use a high

voltag e meter or a high vol t age prob e wit h a VTVM. Disc harg e

the picture tube before attempting meter connection, by

connect ing a c lip lead to t he gr ound fr am e and c onnect ing t h e

other end of the lead through a 10kΩ 2W resistor to the anode

button.

9. When service is required, observe the original lead dress.

Extra pr ecauti on shou ld be gi ven to assure c orrect l ead dr ess

in the high voltage circuit area. Where a short circuit has

occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

The use of a substitute replacement which

) on th e parts li st

!!!!

10.

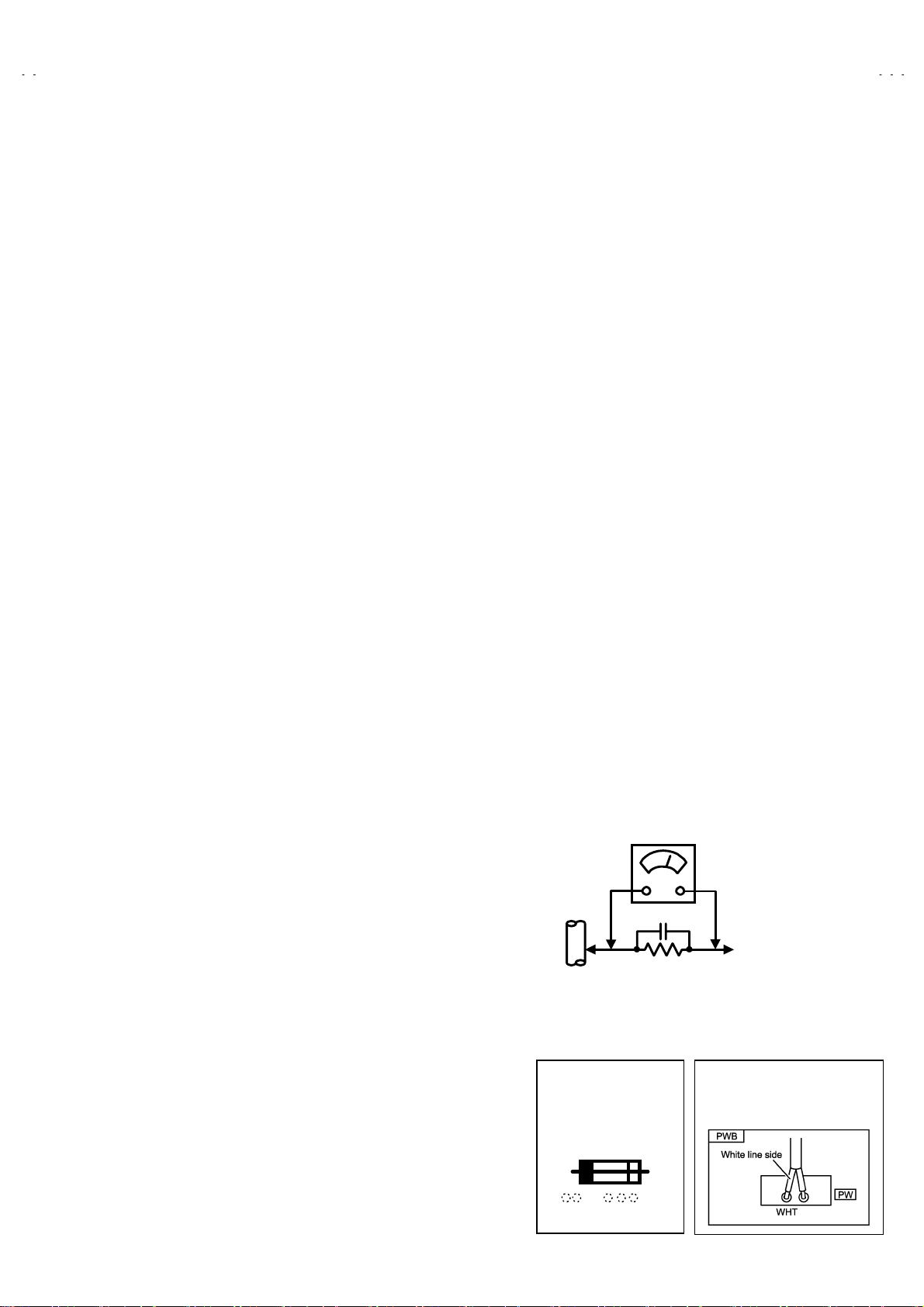

Isolation Check

(Saf ety for Electri cal Shock Hazard )

After r e- assembling t he product, always perf orm an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screwheads, earphone jack, control

shafts , etc.) to b e sure th e produc t is saf e to oper ate with out

danger of electric al sh oc k.

(1)

Dielectric Streng th T est

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having

a return path to the chassis should withstand a voltage of

1100V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up t o 120V, an d 3000 V AC (r. m.s.) to an ap pli anc e rat ed

200V or mor e, f or a peri od of on e s ec on d.)

This method of test requires test equipment not generally found

in the service trade.

(2)

Leak age Current Check

Plug th e AC lin e c ord dir ec tly into th e AC outl et ( do not us e a

line is olati on transf ormer during this ch ec k .) . Us ing a "L eakage

Current Tester", measure the leakage current from each

exposed metal part of the cabinet, particularly any exposed

metal part having a return path to the chassis, to a known good

earth gr ound ( water pi pe, etc.) . An y l eakage c urrent mus t n ot

exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

""""

Plug th e AC lin e c ord dir ec tly into th e AC outl et ( do not us e a

line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled

by a 0.15μF AC-type capacitor between an exposed metal

part and a known good earth ground (water pipe, etc.).

Measure the AC voltage across the resistor with the AC

voltm eter . Mo ve the resis t or c on n ection to eac h e xp os ed metal

part, particularly any expo se d metal part having a return path to

the chass is, and m easure the AC voltag e across the r esistor.

Now, reverse the plug in the AC outlet and repeat each

measur ement. A ny volt age m easur ed mus t not exc eed 0.75V

AC (r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000

GOOD

EARTH

GROUND

11.

High voltage hol d do wn circuit chec k.

After repair of the high voltage hold down circuit, this circuit

shall be checked to operate correctly.

See item "

circuit

This mark shows a fast

operating fuse, the

letters indicat e d be lo w

show the rating.

0.15μF AC-TYPE

1500

10W

Ω

How to check the high voltage hold down

".

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

POWER CORD

REPLACEMENT WARNING.

Connecting the white line side of power

cord to “WHT” character side.

/V,

Ω

A V

No. 51914

3

Page 4

A

V-48WP30

FEATURES

New chassis d esi gn enable use of an in t er ac ti ve on sc r een control.

"

2-3PULL DOWN : You can enjoy DVD movies at the highest picture quality.

"

MOTION COMPENSATION : With this function, the seamless reproduction of dynamic motion on the screen has been realized.

"

Bullet-in DSD (Digital Supper Detail) circuit and 3 dimension Y/C separate circuit.

"

Receive DTV broadcast (1080i / 720p / 480p / 480i)

"

Built-in HDCP / Component (Y / P

"

Built-in Hyper Sound, BBE circuit.

"

/ PR)

B

FUNCTIONS

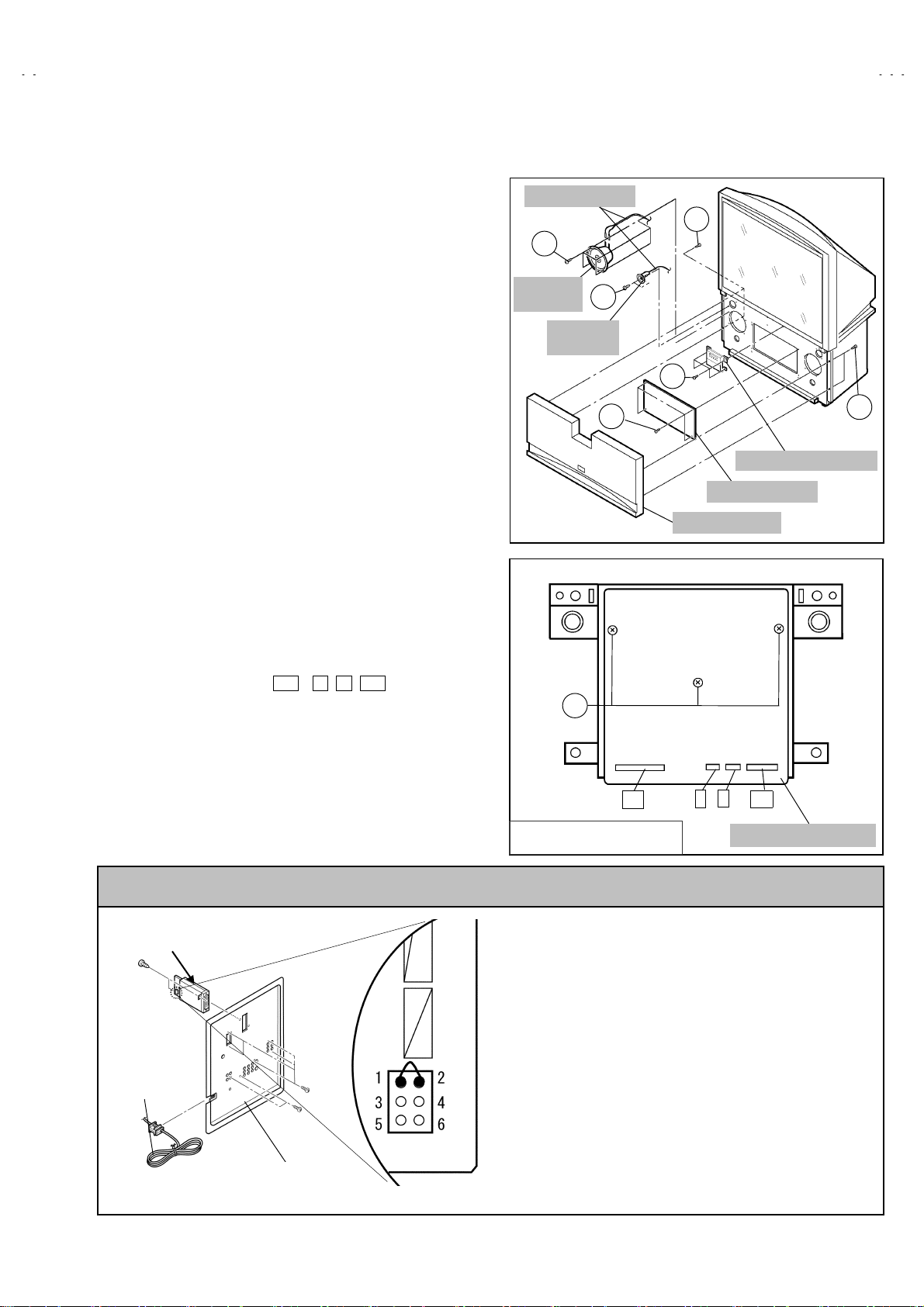

■■■■

FRONT CONTROL KEY & T ERMINAL

2

1

■

REAR TERMINAL

MENU Button ( OPERATE

5

4

3

1

Channel -/+ Button ( OPERATE / )

2

VOLUME -/+ Button

3

MAIN POWER SW Button

4

POWER LAMP (BLUE)

5

INPUT4

6

( AUDIO / VIDEO / S-VIDEO )

)

▼

6

1

7

DIGITAL IN

6

5

6

8

10

9

4

3

2

4

No. 51914

1

( DVI-D Signal Link 19pin )

INPUT 1

2

( AUDIO / VIDEO / S- VIDEO )

INPUT 2

3

( AUDIO / VIDEO )

INPUT 3

4

( AUDIO / VIDEO / S- VIDEO )

INPUT 2

5

( COMPONENT VIDEO )

INPUT 3

6

( COMPONENT VIDEO )

SPEAKER INPUT

7

AUDIO OUT

8

AV COMPULINK

9

AUDIO INPUT(For DIGITAL IN)

A

Ⅲ

Page 5

A

■■■■

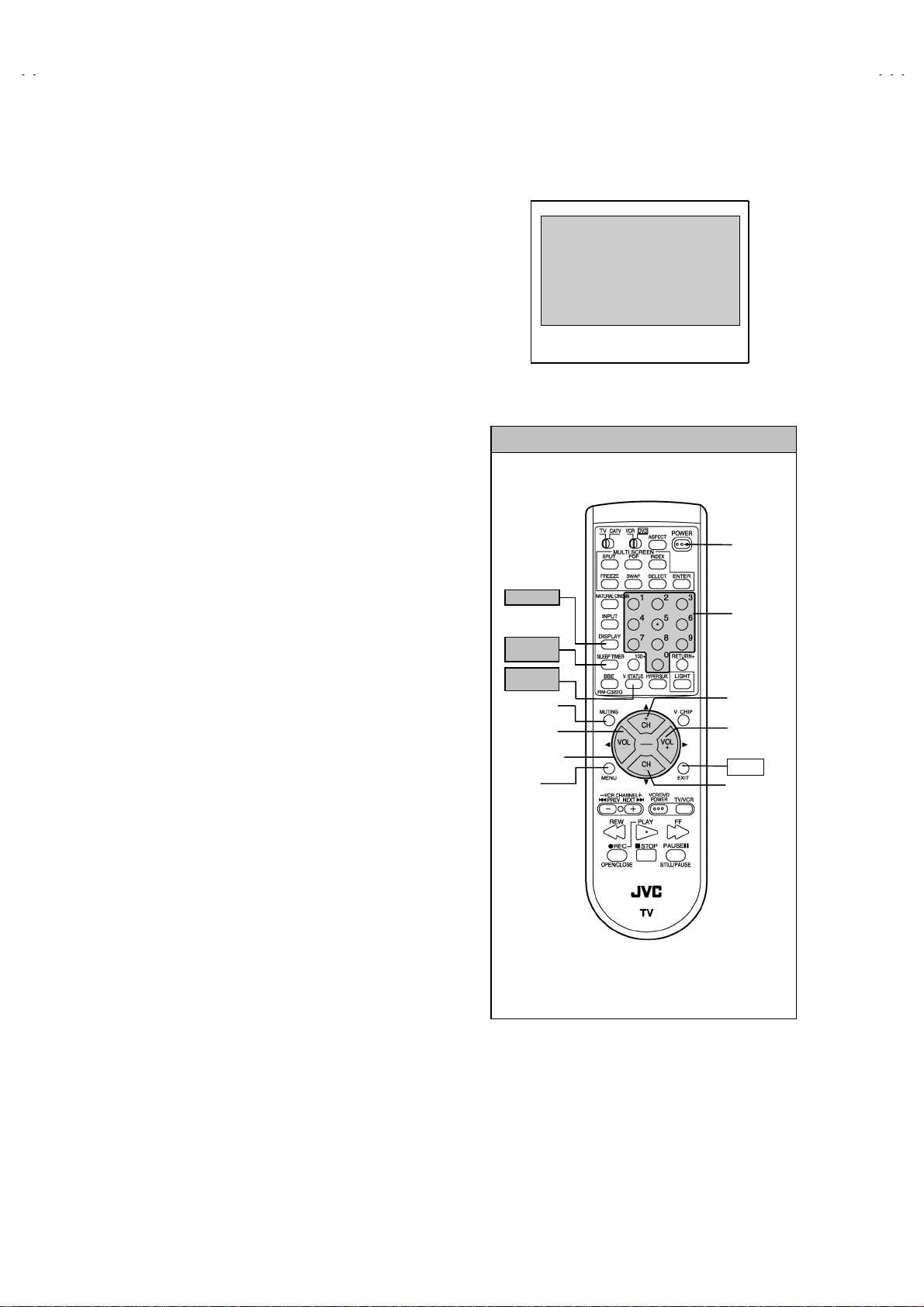

REMOTE CONTROL UNIT [ RM-C322G ]

3 2

POWER Key

1

ASPECT Key

2

V-48WP30

4

5

6

7

8

17

15

16

18

1

VCR / DVD Key

3

TV / CATV Key

4

NATURAL CINEMA Key

5

INPUT Key

6

DISPLAY Key

7

SLEEP TIMER Key

8

BBE Key

9

V.STATUS Key

A

19

9

10

12

11

20

13

14

21

HYPER SURROUND Key

B

MUTING Key ( memory Key )

C

FUNCTION Key ( ▲ / ▼ /

D

MENU Key

E

MULTI SCREEN Key

F

NUMBERS Key

G

100+ Key

H

/ )

RETURN+ Key

I

22

LIGHT Key

J

V-CHIP Key

K

EXIT Key

L

VCR / DVD Key

M

No. 51914

5

Page 6

A

V-48WP30

■■■■

DIGITAL-IN TERMINAL FUNCTIONS

PIN

No.

1 RX2- 13 RX3+

2RX2+14 5V

3 GND2/ 4 15 GND

4

5 RX4+ 17 RX0-

6 SCL 18 RX0+

7 SDA 19 GND0/5

8NC20RX5-

9 RX1- 21 RX5+

10 RX1+ 22 GNDC

11 GND1/3 23 TXC+

12 RX3- 24 TXC-

PIN NAME

RX4-

PIN

No.

16 HTPLG

PIN NAME

PIN AS SIG NMENT

17

18

19

20

21

22

23

24

9

10

1

2

11

3

12

4

13

5

6

14

7

8

15

16

6

No. 51914

Page 7

A

INSTALLATION

1. INSTALLATION SITE

1. The rear of this s et is provi ded with ventilati on openings . Inst all the set

more than 5 c m from a wall and in a loc at i on w ith good ven t i l ation.

2. Avoid the following types of locations.

(1) U ns table locat i ons (l oc ati on mus t b e abl e to wi ths tand heav y wei ght).

(2) Locatio ns subjected to direct sunlight.

(3) Near sto ves or other heating devic es.

(4) Locations subjected to humidity or oily smoke.

(5) Dusty locations.

(6) Locati ons wi th strong vibration.

2. INSTA LLATION ADJUSTMENT

When installing, moving or changing the orientation of the set, perform

static convergence adjustment according to the following procedure.

V-48WP30

(m ore than 5cm)

Wall

VENTILATION OPENING

1. Press the MENU key of the remote control unit.

2. Select the "CONVERGENCE" in the INITIAL SETUP menu with Function

key.

▲/▼

3. Press the Function / key, the convergence adjustment screen appears

with crosses ( +) displayed in 9 locations.

Locati ons where the cross es appear in 3 colours

Convergence adjustment is required. Perform steps 4 to 5.

Locations where the crosses are white:

The convergence is adjusted correctly.

lf all the crosses are white, no convergence adjustment is needed.

"

4. The locations of the crosses correspond to the positions of the number keys on

the remote control. A box appears around the selected cross.

5. Press the S ELECT but ton to chan ge the col or of th e box to the c olor of the

cross you want to adjust (r ed or blue).

You cannot adjust the green cross.

"

6. Use the / and / buttons to adjust the position of the cross.

To cancel the ad jus tments before complet i ng the pr oc edu re, press t he EXIT

"

button.

7. Press the ENTER button to end the convergence adjustment procedure.

lf you do not us e the TV c ontrols f or roughl y one minut e, the con vergence

"

adjust m ent sc reen autom atically dis app e ar s .

:

Fig.1

Fig.2

No. 51914

7

Page 8

A

V-48WP30

TECHNICAL INFORMATION

■

MAIN MICRO COMPUTER (CPU) FUNCTION

(MIN102H57K)

PIN

№№№№

PIN NAME

1 CONV. SW

2 /VSYNC

3 LB PRO

4 NC

5 /RST

6 CONV. BUSY

7 /TEST

8 YS

9 NC

10 NC

11 A_MUTE

12 /HSYNC

13 M_MUTE

14 OSDXI

15 OSDXO

16 SDA2

17 AC_IN

18 SCL2

19 TU_POW

20 VCOI

21 PDO

22 /IP_RESET

23 YM

24 B

25 LED_POWER

26 G

27 R

28 VREF

29 IP_ERR

30 IREF

31 COMP

32 AVDD

33 CLL

34 VREFLS

35 SUB_CCD

36 NC

37 VSS

38 MAIN_CCD

39 VREFHS

40 CLH

41 VDD

42 LED_DATA

I/O

I/O

I/OI/O

CONVERGENCE SW

OOOO

V.SYNC IN for OSD

IIII

LOW B Protection

IIII

NC

-

Micon Reset input

IIII

CONV.

OOOO

+3.3V

IIII

OSD YS OUT

OOOO

Micon test pin

OOOO

NC

OOOO

TV Sound Muting

OOOO

H.sync input for OSD

IIII

Monitor Out Muting

OOOO

-

-

I2C BUS (SDA) for MTS

OOOO

AC 50/60Hz in

IIII

I2C BUS (SCL) for MTS

OOOO

Tuner Power Control

OOOO

LPF input

IIII

LPF output

OOOO

OOOO

OSD YM out

OOOO

OSD Blue out

OOOO

LED for Power

OOOO

OSD Green Out

OOOO

OSD Red Out

OOOO

IIII

AMDP program load det.

IIII

IIII

IIII

+3.3V

IIII

For Sub CCD

IIII

STD VOL in for Sub CCD

IIII

For Sub CCD

IIII

NC

-

GND

IIII

For main CCD

IIII

STD VOL in for CCD

IIII

For main CCD

IIII

+3.3V

OOOO

Front control Data

OOOO

FUNCTION

PIN

№№№№

PIN NAME

43 LED_CLOCK

44 LED_ON_TIMER

45 SBO0

46 SBD0

47 AP DATA

48 INC

49 ECO RST

50 ROT COIL L

51 ROT COIL R

52 H BLK

53 SN COIL_R

54 SN COIL_L

55 BS POW

56 I2C STOP

57 NC

58 /LOB_POW

59 COMPULINK

60 /POWERGOOD

61 /MECA_ON

62 /MAIN_POW

63 NC

64 /B1 POW

65 C / N

66 X-RAY

67 EE CDS

68 KEY2

69 KEY1

70 SCL1

71 SDA1

72 REMO

73 AP REQ

74 VSS

75 OSC2

76 OSC1

77 VDD

78 SCL0

79 AP CLK

80 SDA0

81 NC

82 NC

83 NC

84 P MUTE

I/O

I/O

I/OI/O

OOOO

OOOO

-

-

-

-

OOOO

OOOO

OOOO

OOOO

OOOO

Ter restr ial Mag net i sm Sensor

OOOO ↑

OOOO

OOOO

-

OOOO

IIII

IIII

IIII

OOOO

-

OOOO

-

IIII

-

IIII

IIII

OOOO

I/O

I/O

I/OI/O

IIII

-

IIII

OOOO

IIII

IIII

OOOO

-

I/O

I/O

I/OI/O

-

-

-

OOOO

FUNCTION

F. LED CLK

LED on tim er

Eco Reset

Picture rotation

Picture rotation

H.BLK

BS pow er control

I2C BUS STOP

LOB power control

AV CompulinkⅢInput

Power Condition Check

Machine SW Interrupt

MAIN POWER CONTROL

NC

B1 POWER CONTROL

X-ray detection

Front Key i nput 2

Front Key i nput 1

I2C BUS (CLK) for E2PROM

I2C BUS (SDA) for E2PROM

Remocon IN

GND

4MHz OSC

4MHz OSC

+3.3V

I2C BUS (CLK) for General

I2C BUS (SDA) for General

NC

Pictur e mu ting

8

No. 51914

Page 9

A

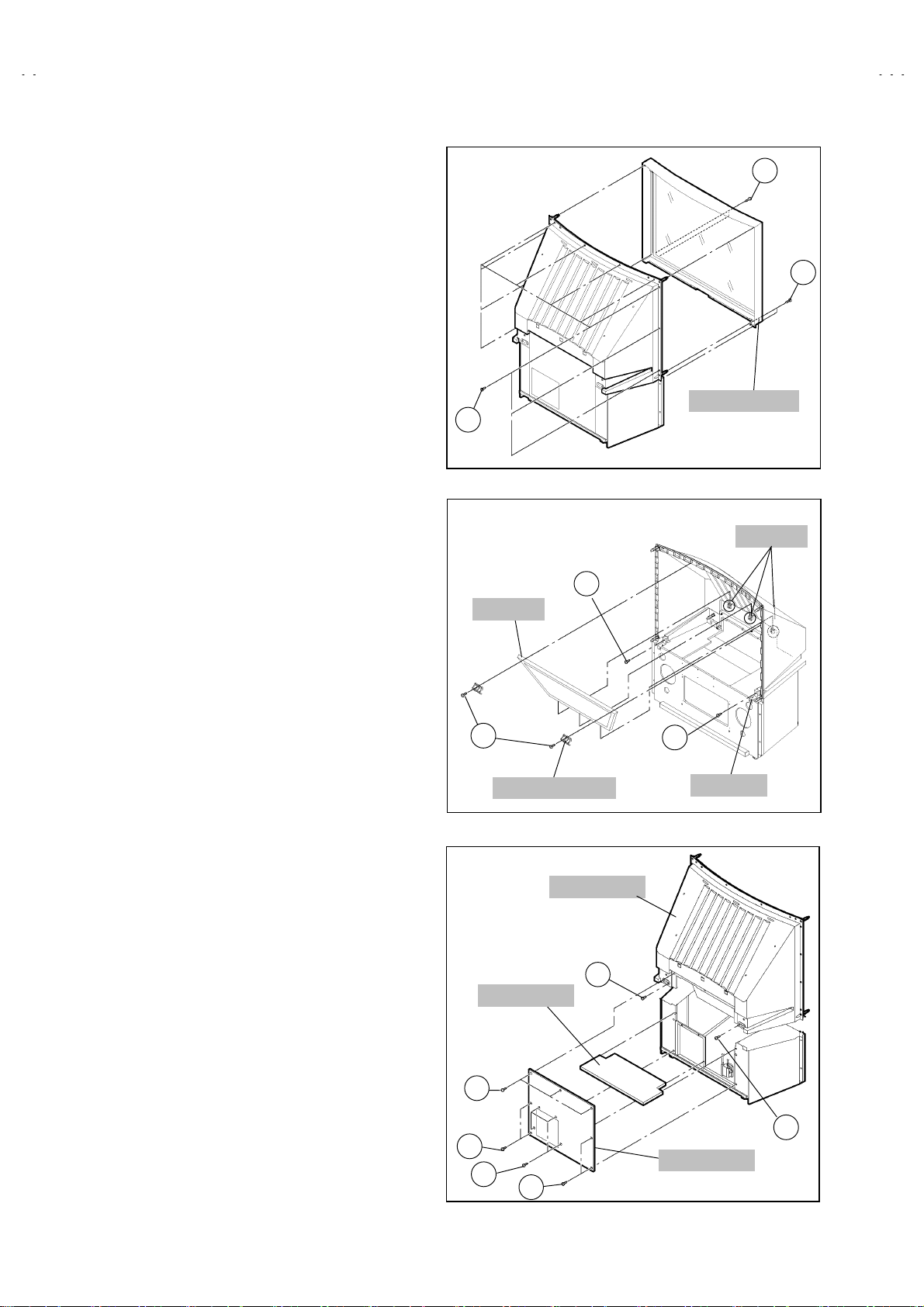

MAIN PARTS LOCATION

■

PWB ASS’Y ARRANGEMENT

The PWB ASS’Y is indicated below.

V-48WP30

MAIN PWB ASS’Y (SSB-1051A-M2)

"

POWER & DEF PWB ASS’Y (SSB-2051A-M2)

"

R CRT SOCKET PWB ASS’Y (SSB-3151A-M2)

"

G CRT SOCKET PWB ASS’Y (SSB-3251A-M2)

"

B CRT SOCKET PWB ASS’Y (SSB-3351A-M2)

"

R VM PWB ASS’Y (SSB-7151A-M2)

"

G VM PWB ASS’Y (SSB-7251A-M2)

"

B VM PWB ASS’Y (SSB-7351A-M2)

"

FRONT CONTROL PWB ASS’Y (SSB0L051A-M2)

"

REMOCON SENSOR PWB ASS’Y (SSB-8051A-M2)

"

FRONT CONTROL ASS’Y

CONVERGENCE PWB ASS’Y (SSB-5051A-M2)

"

CONVERGENCE OSD PWB ASS’Y (SSB0T051A-M2)

"

CENTER SPEAKER PWB ASS’Y (SSB0A051A-M2)

"

DIGITAL CONVERGENCE MODULE PWB ASS’Y

"

LINE FILTER PWB ASS’Y (SSB-9051A-M2)

"

DEF OSC PWB ASS’Y (SSB0H051A-M2)

"

I-P CONVERT MODULE PWB ASS’Y (SSB0D051A-M2)

"

FRONT I/F PWB ASS’Y (SSB0L251A-M2)

"

AV JACK PWB ASS’Y (SSB0J051A-M2)

"

RECEIVER PWB ASS’Y (SSB0R251A-M2)

"

DIGITAL INPUT MODULE PWB ASS’Y (SSB-7851A-M2)

"

REMOCON SENSOR

PWB

(Included in CONVERGENCE PWB)

PROJECTION UNIT

FRONT CONTROL

PWB

DIGITAL

CONVERGENCE

MOULE PWB

CONVERGENCE OSD

PWB

CONVERGENCE

PWB

FRONT I/F

PWB

I-P COVERT MODULE

PWB

LINE FILTER

PWB

AV JACK PWB

RECEIVER PWB

POWER & DEF

PWB

MAIN PWB

CRT SOCKET

PWB (R/G/B)

CENTER SPEAKER

PWB

DEF OSC

PWB

AV TERMANEL BOARD

(This figure is only MAIN UNIT)

VM

PWB (R/G/B)

DIGITAL INPUT

MODULE PWB

No. 51914

9

Page 10

A

V-48WP30

A

A

A

A

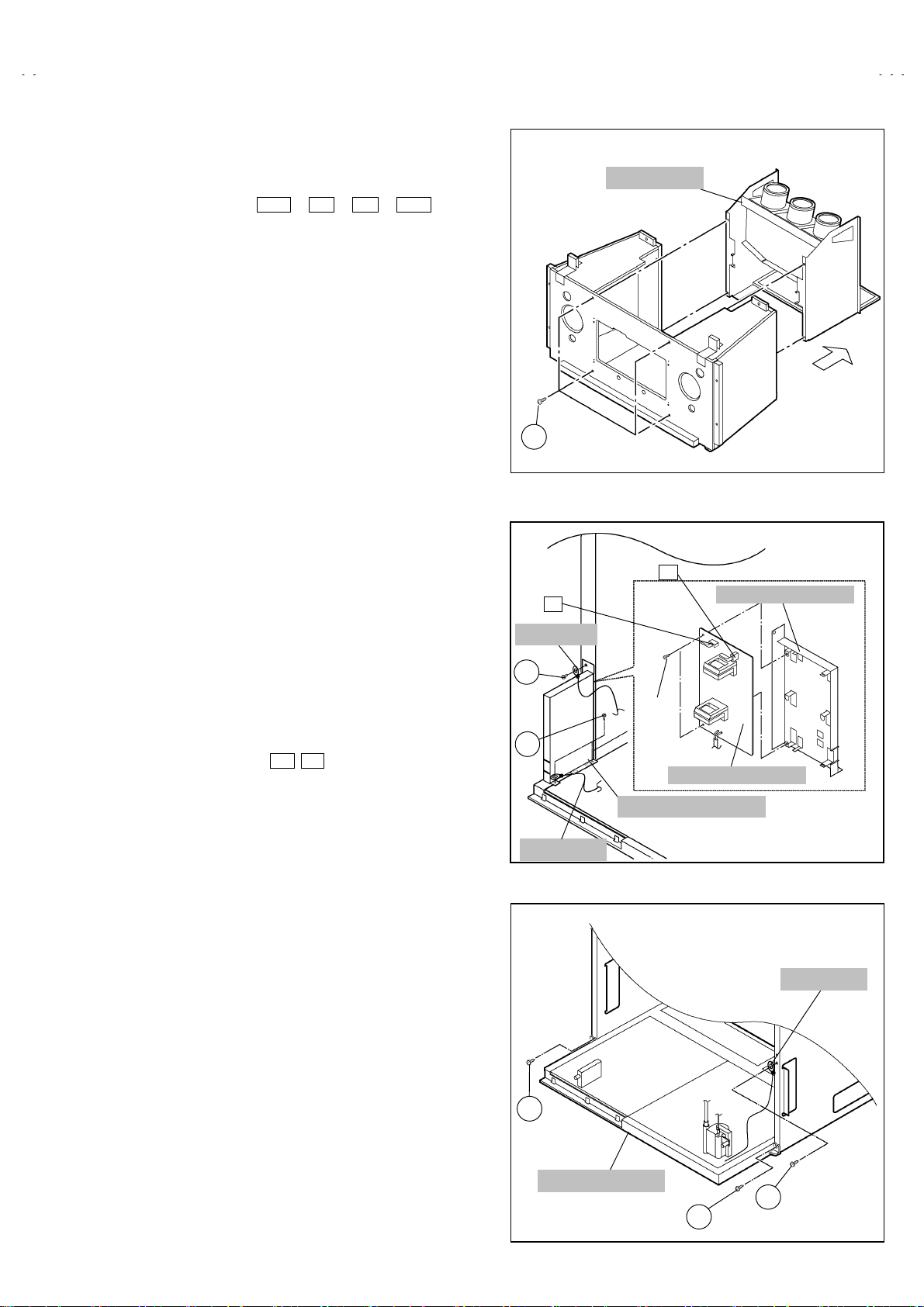

SPECIFIC SERVICE INSTRUCTIONS

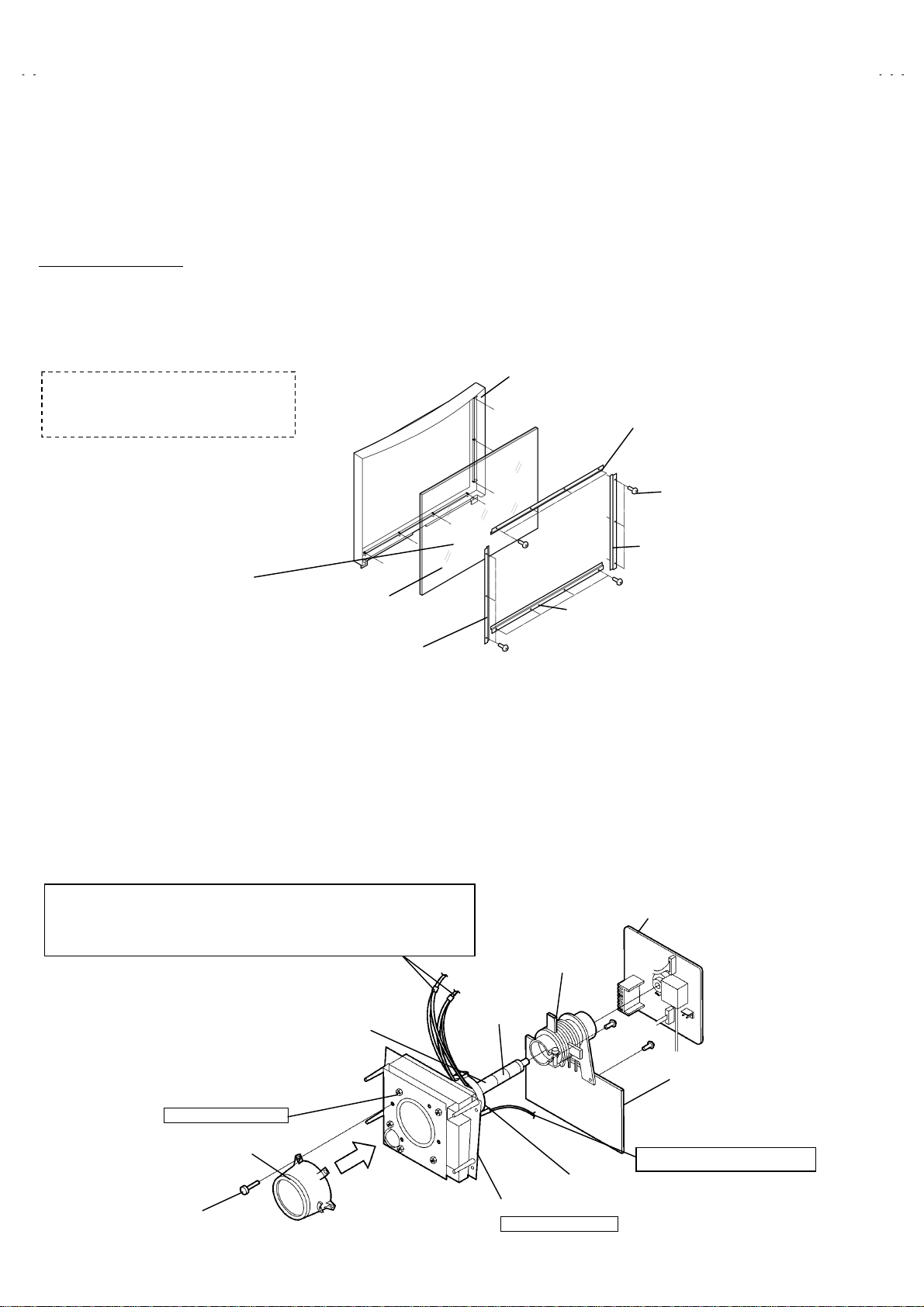

SCREEN HANDLING CAUTIONS

■■■■

SCREEN STORAGE

Store the SCREEN ASS’Y in a standing position in order to avoid deformation. If the screen is stored horizontally, there is risk of def orming the

screen face.

When necessary to place the SCREEN ASS’Y horizontally, position the screen side upwards and sure to place spacers between the screen and

resting site (floor or stand etc.) to prevent the screen from sagging.

■

SCREEN SURFACE

Since the screen surface is easily scratched or soiled, use ample care when handling.

DISASSEMBLY PROCE D URE

%

If the screen or screen panel need to

be replaced, remove the A screws

FRONT CABINET

SCREEN BRACKET (TOP)

(X3)

Leave the screen with flesnel lens and

double lenticular lens attached. If cannot be

disassembled further.

SCREEN

SCREEN BRACKET

(LEFT)

(X4)

SCREEN BRACKET

(BOTTOM)

(X3)

SCREEN BRACKET (RIGHT)

(X4)

PROJECTION UNIT REPLACEMENT

■

ADJUSTMENT DURING REPLACEMENT

When replcing the three R, G and B projection units, first replace the R and B units and perform focus / screen / raster centerin g adjustments

with ref er ence to the G unit. T hen replac e the G unit and perform G foc us / screen / converg ence adjustm ent. Finall y perform R & B .

Convergence adjustments.

■

DISASSEMBLY CAUTION

The projection units include locations that are not to be disassembled during service. When replacing projection unit parts, disassemble to the

state indicated in the figure below.

The figure indicates screws and wires that are not to be removed. Use care not to remove these.

Deflection yoke wires : to connector on POWER & DEF. PWB ASS’Y.

&

[R=”RHV”, G=”GHV”, B=”BHV”]

Convergence yoke wires : to connector on CONVERGENCE PWB ASS’Y

&

[R=”R”, G=”G”, B=”B”]

Use care to simultaneously removes all three-projection units.

R CRT SOCKET PWB ASS’Y

G CRT SOCKET PWB ASS’Y

B CRT SOCKET PWB ASS’Y

PC MAGNET

Check tha t tape is applied to the CRT neck.

If absent, the deflection yoke can dislodge.

Do not remove screws

LENS ASS’Y

LENS ASS’Y SCREW (X 4)

10

No. 51914

PC MAGNET

TAPE

DEF / CONVER. YOKE

CRT ASS’Y(COUPLER ASS’Y)

Do not disassembly

VM PWB PWB (R/G/B)

ANODE wires : to DIVIDER

●

Page 11

A

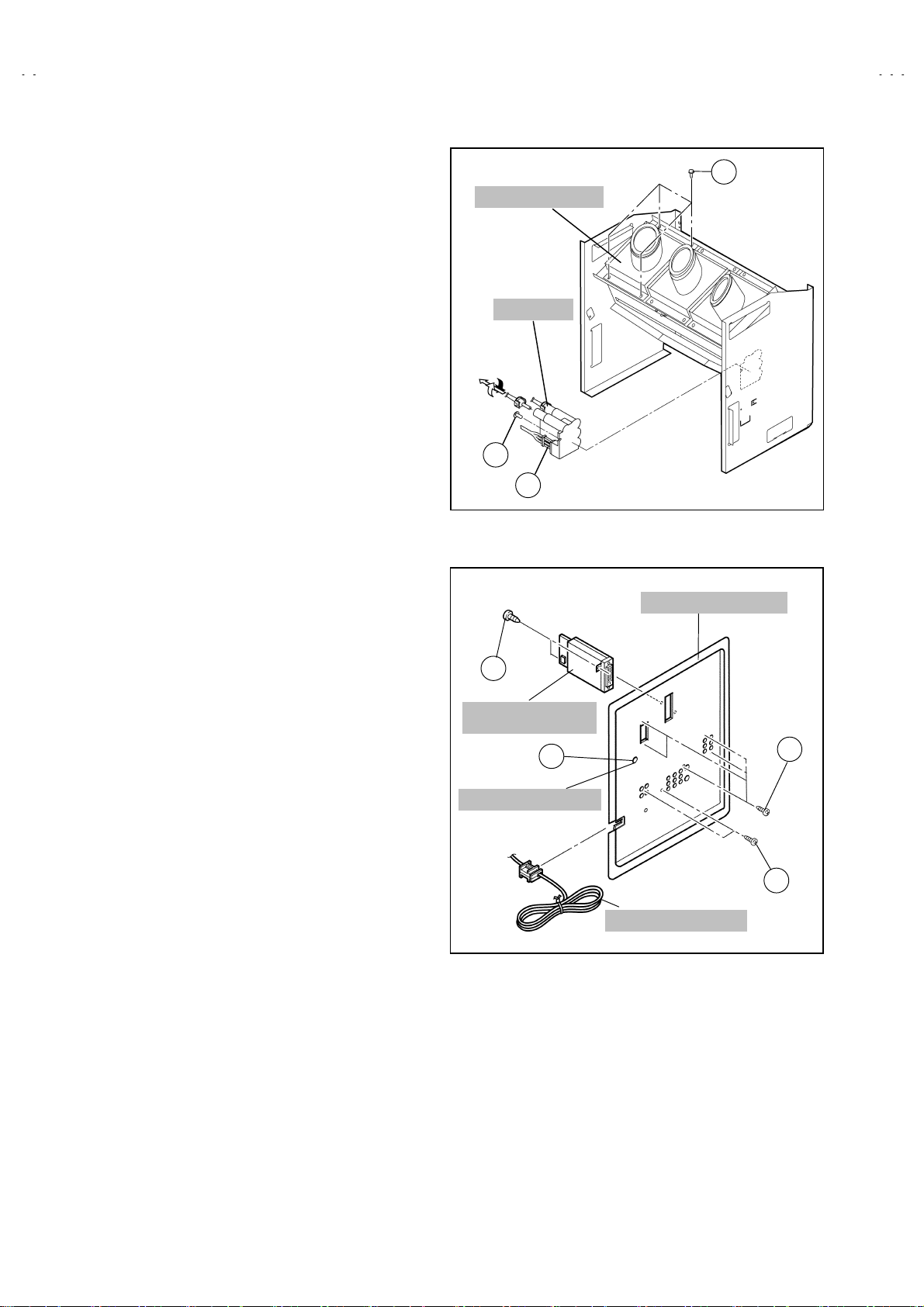

DISASSEMBLY PROCEDURE

V-48WP30

SPEAKER GRILLE

!

1. Remove 4 screws A from rear side.

2. Remove the SPEAKER GRILLE.

SPEAKER (WOOFER)

!

Remove the SPEAKER GRILLE

"

1. Remove 4 screws B.

2. Take out the WOOFER.

3. Disconnect the speaker wire from speaker terminal.

SPEAKER (TWEETER)

!

Remove the SPEAKER GRILLE

"

1. Remove 2 screws C.

2. Take out the TWEETER.

3. Disconnect the speaker wire from speaker terminal.

FRONT BOARD

!

Remove the SPEAKER GRILLE.

"

1. Remove 4 screws D.

2. Remove the FRONT BOARD.

FRONT CONTROL BOX

!

Remove the SPEAKER GRILLE.

"

1. Remove 4 screws E attaching the F RONT CONTROL BOX.

BH

2. Disc onnect the c on nector

CONTROL PWB.

3. Remove the FRONT CONTROL BOX.

, X ,

,

R

on the FRONT

BG

SPEAKER WIRE

B

SPEAKER

(WOOFER)

SPEAKER

(TWEETER)

F

A

C

E

D

FRONT CONTROL BOX

FRONT BOARD

SPEAKER GRILL

A

FRONT CONTROL PWB

!

Remove the SPEAKER GRILLE.

"

Remove the FRONT CONTROL BOX.

"

1. Remove 3 screws F from rear side of FRONT CONTROL BOX.

2. Remove the FRONT CONTROL PWB.

CAUTION AT DISASSEMBLY

48WP30CP-S

: DIGITAL INPUT MODULE

POWER CORD

SB

AV JACK BOARD

connector

BH

FRONT CONTROL BOX

REAR SIDE

X

BG

FRONT CONTROL PWB

R

Prior to disassembly, unplug the power code from the AC outlet

"

without fail. (Turn the power “off”.)

Short the SB connector (1) pin and (2) pin of the DIGITAL

"

INPUT MODULE. (At the time of assembling)

Bef ore the rear panel is i nserted int o the cabi net, releas e the

"

short-cir cuit betw een the SB conn ec tor (1) pin an d (2) pin of the

DIGITAL INPUT MODULE.

After rel easing th e shor t-circ uit bet ween the SB conn ectors, do

"

not turn the power on until the rear p anel is inserted into th e

cabinet.

Negligence in carrying out the above steps may cause the

*

inactivation of the TV.

No. 51914

11

Page 12

A

V-48WP30

SCREEN ASS’Y

!

Remove the SPEAKER GRILLE.

"

Remove the FRONT CONTROL BOX.

"

1. Remove 4 screws G under the SCREEN ASS’Y from fron t side.

2. Remove 10 screws H from rear side.

3. Remove the SCREEN ASS’Y.

:

NOTE

Place the screen with face upwards on a flat stand.

"

Because of the large size, at least two parsons are

"

recomm en ded for rem ov al an d reas sembl e.

Use core not to scratch the screen during work.

"

Duri ng assembl y, be sur e to eng age the l eft and ri ght tabs

"

with the cabinet mounting positions.

When than s port ing the SC REEN ASS’ Y, avoid gr aspi ng th e

"

top of the screen panel, instead grasp the left and right areas.

MIRROR

!

Remove the SPEAKER GRILLE.

"

Remove the FRONT CONTROL BOX.

"

Remove the SCREEN ASS’Y.

"

1. Remove 2 screws I attaching the mirror stopper.

2. Raise slightly to disengage of the mirror from the hooks.

3. Remove the MIRROR.

:

NOTE

T he M IRROR is front-coated . Do not touch t he front of the

"

MIRROR.

At least 2 persons are recommended for removable and

"

reassemble.

GGGG

GGGG

SCREEN ASS’Y

H

HOOKS

M

MIRROR

REAR PANEL

!

1. Loosen 7 screws

2. Remove 4 screws K.

3. Raise slightly REAR PANEL upward.

4. Remove the REAR PANEL.

:

NOTE

B efor e the rear p anel is ins ert ed in to the c abi n et, rel eas e th e

"

short-cir cuit b etween the S B conn ector ( 1) pin an d (2) pin of

the digital input unit

Af ter releasing t he short-circ uit bet ween the SB c onnectors,

"

do not turn the power on until the rear panel is ins erted into

the cabinet

PA RTITION

!

Remove the REAR PANEL.

"

1. Pull out the PA R T I T IO N back war d.

REAR COVER

!

Remove the SPEAKER GRILLE.

"

Remove the FRONT CONTROL BOX.

"

Remove the SCREEN ASS’Y.

"

1. Remove 2 screws L.

2. Remove 2 screws M from front side

3. Sligh tly pull for back side to di se nga ge of the REAR C OVER from

hooks.

4. Remove the REAR COVER.

J.

I

MIRROR STOPPER

PARTITION

J

J

K

J

M

BRACKET

REAR COVER

L

L

REAR PANEL

12

No. 51914

Page 13

A

MAIN UNIT

!

Remove the SPEAKER GRILLE.

"

Remove the connector BH

"

FRONT CONTROL PWB.

Remove the REAR PANEL.

"

1. Remove 4 screws

2. Pull out th e MAIN UNIT rear side.

NOTE :

Except for confirmation of projection of images on the screen

"

and audio output thr ough the speakers , the removed main

unit is still workable in the same state as if it is still built in the

TV set. Therefore, the main unit can be removed, if

necessary, for board diagnosis, electric testing, etc. apart

from conf ir m ati on of screen im ag es and audio output.

When wire clamps are removed during work, use care to

"

restore them precisely to their original positions.

Perf ormanc e can be aff ect ed if these ar e not ret urn ed to t he

original positions.

Because of the large size, at least two persons are

"

recomm en ded for rem ov al an d reas sembl e.

W hen carr yin g th e m ain un it, us e c ar e n ot to dr op, s h ock or

"

shake it.

D o not stain or damag e the l ens of the projection unit.

"

Do not look through the projection unit.

"

CHECKING THE P.W. BOARD

#

When checkin g th e M AIN PWB, POWER & DEF PW B, etc., raise

the MAIN UNIT with the DIVIDER side down for the sake of

convenience. You can checking the MAIN P.W.B.

from front side.

O

!

, X , R , BG on the

O

F

EARTH WIRE

P

MAIN UNIT

B

V-48WP30

LINE FILTER BRACKET

LINE FILTER P.W. BOARD

!

Remove the REAR PANEL.

"

Remove the AV JACK BOARD.

"

1. Disconnect the connector

BOARD.

2. Remove 3 sc rews P attach ing th e LI NE F ILTE R BR ACK ET and

earth wir e.

3. Remove 2 screws Q attaching LINE FILTER P.W. BOARD.

4. Remove the LINE FILTER P.W . BOARD.

MAIN CHASSIS

!

Remove the REAR PANEL.

"

Remove the AV JACK BOARD.

"

R emove the LINE FILTER BR ACKET .

"

1. Remove 2 screws R both side of the MAIN CHASSIS.

2. Remove 1 screws

3. Pull out the MAIN CHASSIS for back sid e.

:

NOTE

If necessary, remove the anode wires, connectors,

"

respectively.

R’

B F on the LI NE FILTE R P.W .

attaching the earth wire.

Q

P

LINE FILTER P.W.BOARD

LINE FILTER BRACK ET

EARTH WIRE

EARTH WIRE

R

MAIN CHASSIS

R’

R

No. 51914

13

Page 14

A

V-48WP30

PROJECTION UNIT

!

Remove the SPEAKER GRILLE

"

Remove the FRONT CONTROL BOX

"

Remove the REAR PANEL

"

R emo ve the MAIN UNIT .

"

1. Remove the CRT SOCKET PWB.

2. Remove 4 screws S attaching the PROJECTION UNIT.

3. Pull out the PRO J EC T IO N UNIT, upwar d.

:

NOTE

Refer to “PROJECTION UNIT REPLACEMENT” on

"

page 8 when tak ing out and repl ac ing the PROJE CTION

UNIT.

When wire clamps are removed during work, use care to

"

restore them precisely to their original positions.

Perf orm ance can be affected if th es e are not r etur ned to

the origin al positions .

HV DIVIDER

!

Remove the REAR PANEL

"

1. Remove 1 screws

2. Remove the HV DIVIDER.

Wires of the transformer (FBT) and CRT of each PROJECTION

*

UNIT can be removed by turning the connector portions.

:

NOTE

If nec essary, remove the anod e w ir es, an d replacing the

"

HV DIVIDER, take care to correctly engage the

connector.

U

!!!!

AV JACK BOARD

!

Remove the REAR PANEL

"

1. Remove 7 screws V.

2. Pull out the POWER CORD C LAMP f r om AV J ACK BOARD l eft

side.

3. Remove nut

4. Remove the AV JACK BOARD.

attaching the DIVIDER.

T

!!!!

attaching the antenna terminal.

W

!!!!

PRO J E CTION UN I T

HV DIV IDER

TurnPull

T

U

X

DIGITAL INPUT

MODULE

W

ANTENNA TERMINAL

S

AV JACK BOARD

V

DIGITAL INPUT MODULE

!

Remove the REAR PANEL

"

1. Remove 2 screws X from rear side of the AV JACK BOARD.

2. Remove the DIGITAL INPUT MODULE.

14

V

POWER CORD CLAMP

No. 51914

Page 15

A

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

!

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part aft er rem oving it.

SOLDERING IRON

!

1. Use a high ins ul ation sold erin g iron with a thin p oint ed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

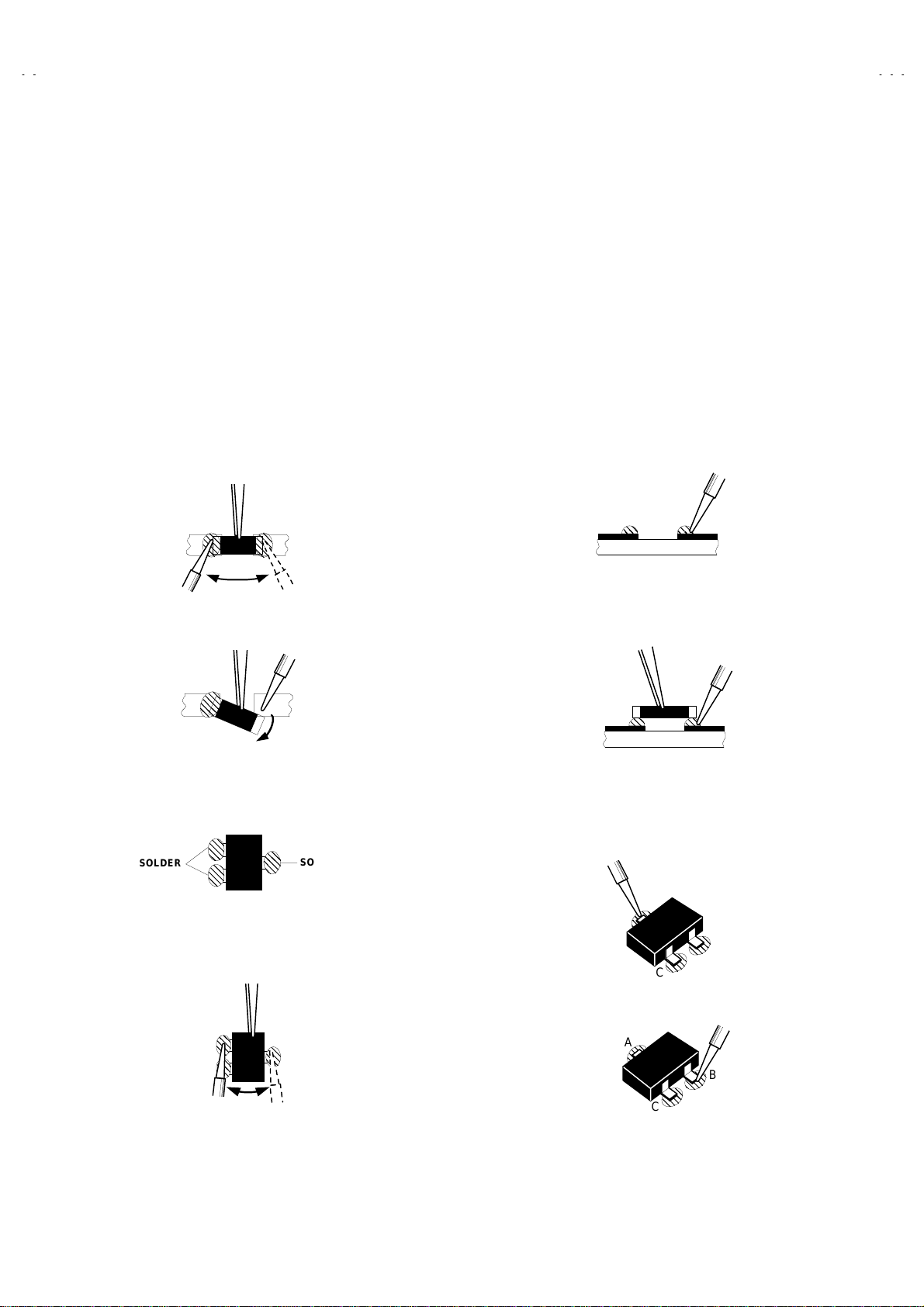

REPLACEMEN T STEPS

!

How to remove Chip parts

1.

Resistors, capacitors, etc

####

(1) As shown in the figure, push the part with tweezers and

alternately melt th e s older at each end.

(2) Shif t wi th tweezers an d r em o ve the chip part.

Transistors, diodes, variable resistors, etc

####

(1) Apply extra solder to each lead.

V-48WP30

2. How to i n stal l Ch ip p arts

Resistors, capacitors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp th e chip part wit h twe ezers and plac e it on t he s older.

Then heat an d m elt t h e s old er at b oth en ds of th e chip part .

Transistors, diodes, variable resistors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

as indicated in the figure.

A

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternat el y melt t he s old er at each lead . Shif t and r emov e th e

chip part.

Note : After removing the part, remove remaining solder from the

pattern.

SOLDER

No. 51914

A

(4) Then solder leads

A

C

and C.

B

C

B

B

15

Page 16

A

V-48WP30

MEMORY IC REPLACEMENT

1. Memory IC

This model use a memory IC.

This mem ory IC s tores dat a for prop er oper ation of th e vid eo

and deflection circuits.

When rep lacing, be sure to use an IC c ontaining this (i nitial

value) data.

2. Memory IC replacemen t pro cedu re

(1) Power off

Switch off the power and disconn ect the power c ord from

the wall out l et.

(2) Replac e the me mo ry I C

Initial val ue must be ent ered into the new IC .

(3) Power on

Connect the power cord to the wall outlet and switch on the

power.

SERVICE MENU

SERVICE MENU

1.PICTURE/SOUND 7.I2C BUS

2.YC SEP 8.PP

3.LOW LIGHT 9.IP

4.HIGH LIGHT 0.SELF-CHK

5.RF AFC

6.

Fig.1

SERVICE MENU SELECT KEY

(4) SERVICE MENU setting

1) Press

SLEEP TIMER

SLEEP TIMER 0 MIN

DISPLAY

key and

key and, while the indication of

is being displayed, press

VIDE O S TAT US

key on the r emote

control unit (Fig.2) simultaneously.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) Verify what to set in the SERVICE MENU, and set

whatever is necessary (Fig.1).

Refer to the SERVICE ADJUSTMENT for setting.

4) Press the EXIT key twice to return normal screen.

(5) Rec eive channel setting

Refer to the OPERATING INSTRUCTIONS (USER’S

GUIDE) and set the receive channels (Channels Preset) as

described.

(6) User settings

Check th e us er s ett ing items according to after page.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER’S GUIDE) and set the items as

described.

DISPLAY

SLEEP

TIMER

VIDEO

STATUS

MEMORY

(MUTING)

VALUE

SELECT(-)

FUNCTION

MENU

POWER

NUMBER

ITEM

SELECT(▲)

VALUE

SELECT(+)

EXIT

ITEM

SELECT(▼)

Fig.2

16

No. 51914

Page 17

A

SHIPPING FACTORY SETTING

VIDEO STATUS MEMORY (NTSC / 480p)

Item

TINT COLOR PICTURE BRIGHT DETAIL

STANDARD 00 00 00 00 00

THATER 00 00 00 00 00

DYNAMIC 00 00 +10 00 +1

(HD)

Item

TINT COLOR PICTURE BRIGHT DETAIL

STANDARD 00 00 00 00 00

THATER 00 00 00 00 00

DYNAMIC 00 00 +2 00 00

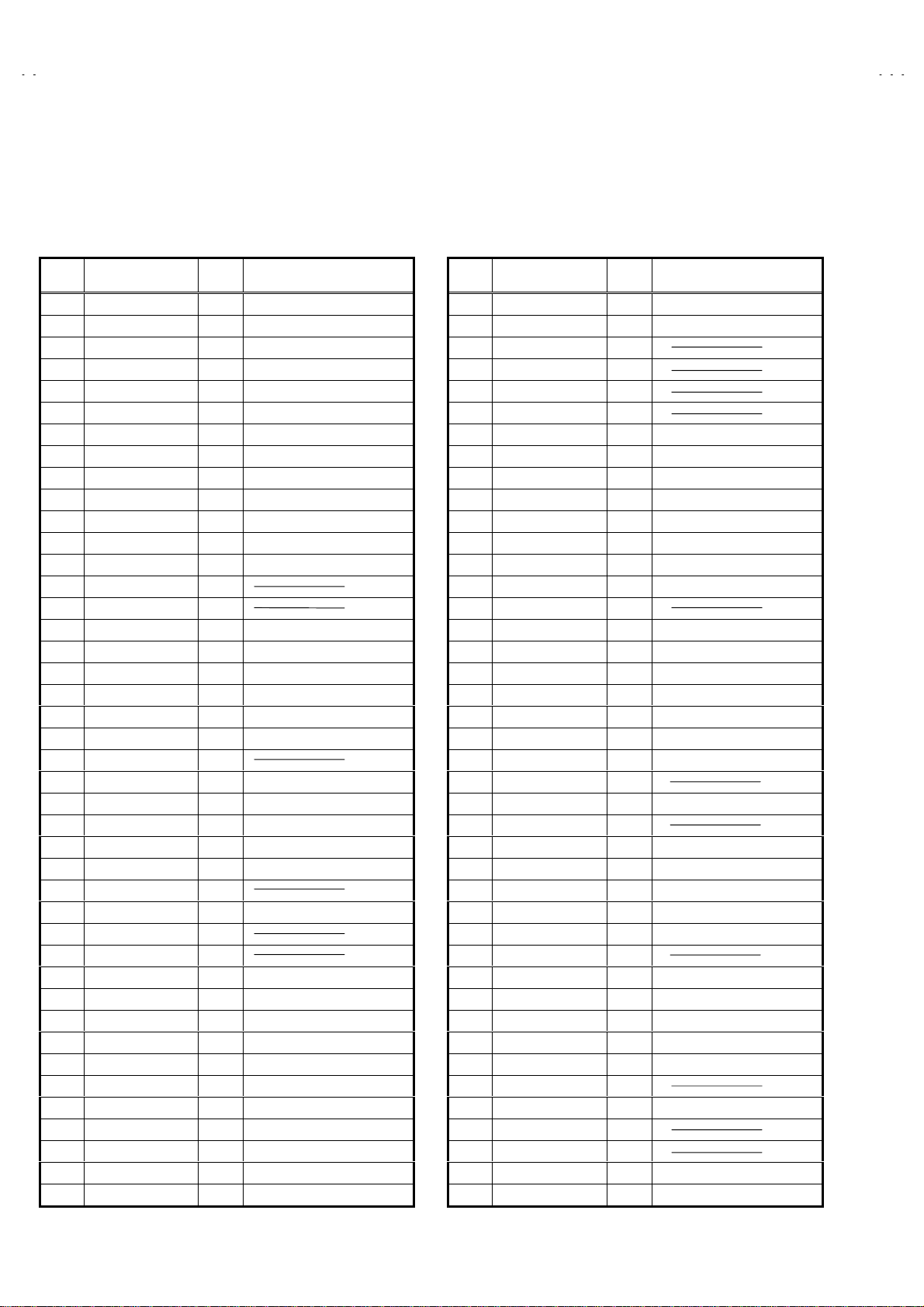

CHANNEL SETTING (CHANNEL SUMMARY)

BAND CH Display Setting BAND CH Display Setting

02

○

03 O 28

VHF

L

04

05

06

07

○

○

○

○

08 T 33

VHF

09

H

10 V 35

11

○

○

12 A-7 93

UHF

MID

13

14

36

41 A-3 97

46 A-2 98

63

69

A14

B15

C16

D17

E18

○

○

○

○

○

○

○

○

○

○

F19

G20 W+29

H21

○

I22 W+51

J23

SUPER

K24

L25

○

M26

SETTI NG VALUE

SETTI NG VALUE

SUPER

SUBMID

HYPER

ULTRA

N27

P29

Q30

R31

S32

U34

W36

A-6 394

A-5 95

A-4 96

A-1 99

A-8 01

W+11 47

W+12 48

W+17 53

W+23 59

W+78

W+84

V-48WP30

○

○

○

○

○

○

○

○

○

○

○

No. 51914

17

Page 18

A

V-48WP30

SHIPPING FACTORY SETTING

(USER SETTING)

Setting item Setting value Setting item Setting value

POWER

CHANNEL

BBE

VOLUME

INPUT

OFF

CABLE-02

ON

10

TV

TINT / COLOR / PICTURE

/BRIGHT / DETAIL

COLOR TEMPERATURE

DIG. NOISE CLEAR

Refer to setti n g o f Video

status m em or y at shi pping

factory setting

HIGH

CENTER

DISPLAY

NATURAL CINEMA

SLEEP TIMER

ASPECT

VIDEO STATUS

HYPER SURROUND OFF MTS STEREO

SPLIT SOURCE

POP SOURCE

VERTICAL POSITION

CENTER CH INPUT

XDS ID

CONVERGENCE

POWER INDICATOR

OFF

AUTO

0

REGULAR

DYNAMIC

LEFT SIDE : CH 02

RIGHT SIDE : CH 04

LEFT SIDE : CH 02

RIGHT UPPER : CH 04

RIGHT CENTER : CH 05

RIGH T BOTTOM : CH 07

CENTER

OFF

ON

OPTIMUM CONDITION

HIGH

NOISE MUTING

BASS / TREBLE / BALANCE

SET CLOCK

ON / OFF TIMER

LANGUAGE

CLOSED CAPTION

FRONT PANEL LOCK

AUTO SHUT OFF

AUTO TUNER SET UP

DIGITAL-IN ( at 480p signal

input )

CHANNEL SUMMARY

V-CHIP

SET LOCK CODE

AUTO DEMO

ON

CENTER

Unnece ssary to set

NO

ENG

OFF ( CC1 / T1 )

OFF

OFF

Unnece ssary to set

SIZE 1

Refer to Last memory (CH.

summary)

OFF

Unnece ssary to set

OFF

18

No. 51914

Page 19

A

SERVICE ADJUSTMENTS

V-48WP30

ADJUSTMENT PREPARATION

1. You can make the necessary adjustments for this unit with

either the Remote Control Unit or With the adjustment

tools and parts as give n belo w.

2.

Adjustment with the Remote Control Unit is made on t he

basis of the initial setting values, h owever, the new setting

values wh ich s et t he scree n t o it s op timu m condi tion may

differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on t he power for set and test eq uipm ent bef ore us e, and

start the adjustment procedures after waiting at least 30

minutes.

5. Unless otherwise specified, prepare the most suitable reception

or input signal for adjustment.

6. Never touch any adjustment setting value which are not

specified in the list for this adjustment.

7. Preset ti ng b efore adjust m ent

Unless otherwise specified in the adjustment instructions,

preset the following functions with the remote control unit:

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator)

NTSC / 480i / 480p / 720p / 1080i / HDCP

[

4. Remote control unit

5. TV audio multiplex signal generator

6. Frequency counter

ADJUSTMENT ITEMS

Adjustment items

1Check (×4)

2 FOCUS & B EAM SP OT adjustment

3 CONVERG ENCE & DEFL EC TION a dj u stment

4 VIDEO adj us tment

5 MTS adjus t m en t

SETTING POSITION

"

SETTING ITEM SETTING POSITION SETTING ITEM SETTING POSITION

VIDEO STATUS STANDARD ASPECT FULL

BASS, TREBLE, BALANCE CENTER VERTICAL POSITION CENTER

HYPER SURROUND OFF BBE ON

TINT, COLOR, PICTURE,

BRIGHT, DETAIL

COLOR TEMPERATURE HIGH AUTO SHUTOFF OFF

DIGITAL NOISE CLEAR CENTER

CENTER ON/OFF TIMER NO

]

ADJUSTMENT FLOWCHART

WHEN REPLACING SCREEN AND PROJECTION UNIT

Contains only the main adj us tm en t s . Als o c onfirm other adj us tm ents as required.

●

No. 51914

19

Page 20

A

V-48WP30

A

ADJUSTMENT LOCATION (1/2)

CONVERGENCE PWB

IC 805 IC 804

B G R

R/G/B CRT SOCKET PWB

MAIN PWB

FRONT

B

F

LINE FILTER

PWB

S 801

SERVICE

SWITCH

CONVERGENCE OSD PWB

DIGITAL CONVERGENCE

MODULE PWB

F

M

CN00M

CN010

TUNER

(TU101)

CN00Y

CN00P CN00X

FRONT I/F PWB

BG BH

G H

G

RECEIVER

PWB

AJ

DIG I TAL IN PUT PW B

FRONT

CONVERGENCE

OSD PWB

TOP

IC701

CPU

AF

FRONT CONTROL PWB

POWER POWER SW

BG R X BH

H

CN001

MEMORY IC

IC703

CN002

E

CN003

LED

CH - CH + VOL - VOL +MENU

INPUT 3

REMOCON SENSOR PWB

B

POWER/DEF

PWB

P

J

G VM PWB

G CRT SOCKET PWB

CN010

20

1Pin : L

2Pin : R

3Pin : GND

4Pin : SOA

5Pin : NC

POWER CORD

S2

1

5

TUNER

I-P CONVERT.

MODULE

PWB

S2

DIGITAL INPUT

PWB

V

JACK

PWB

DC SY Q2 AJ

CN007

No. 51914

CN006

DEF OSC PWB

S1

Page 21

A

ADJUSTMENT LOCATION (2/2)

REAR

TOP

TOP

MAIN PWB

AV JACK PWB

V-48WP30

DIGITAL INPUT MODULE PWB

DVI-D

terminal

IC

FOCUS PACK

MAIN PWB

DC

Q

SY

SB

CONNECTOR

LINE

FILTER

PWB

H

CRT SOCKET PWB

RGK

TP-E TP-R

KR

R CRT SKT PWB G CRT SKT PWB B CRT SKT PWB

B

CN001

SG001

GBK RGK

TP-E TP-G

E

SG001

KG

POWER / DEF PWB

GBK

SG001

TP-E TP-B

KB

IC701

CPU

5Pin : TP-91(B1)

4Pin : NC

3Pin : X-ray1

2Pin : X-ray2

1Pin : TP-E ( )

MEMORY IC

IC703

S1

5

1

CN002

J

G VM PWB

DEF OSC PWB

E

CN003

CN010

RHV

GHV

AB

S1

5

BHV

FBT

No. 51914

A

1

21

Page 22

A

V-48WP30

(

)

)

BASIC OPERATION OF SERVICE MENU

1.

TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2.

SERVICE MENU ITEMS

In general, basic setting (adjustments) items or verifications are performed in the SERVICE MENU.

1. PICTURE / SOUND

2. YC SEP

・・・・・・・・・・・・・・・・・・・・

3. LOW LIGHT

4. HIGH LIGHT

5. RF AFC

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

6. (BLANK)

7. I2C BUS

8. PP

9. IP

0. SELF-CHK

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

3. BASIC OPERATIO NS OF THE SERVICE MENU

(1) How to enter the SERVICE MENU.

Press

SLEEP TIMER

TIMER 0 MIN.

VIDEO STATUS

to enter th e

SERVICE MENU

(2) SERVICE MENU screen selection

Press th e nu mb er k ey t o sel ec t an y of t h e foll ow i ng items.

1.PICTURE/SOUND 7.I2C BUS

2.YC SEP 8.PP

3.LOW LIGHT 9.IP

4.HIGH LIG HT 0. SELF-CHK

5.RF AFC

key and, whil e the indic ation of “

” is being displayed, press

key on the remote control unit simultaneously

This sets the setting values of the VIDEO/CHROMA /AUDIO and DEFLECTION circuits.

This is used when the YC mode is adjusted.

[Do not adjust]

This sets the setting values of the WHITE BALANCE circuit.

This sets the setting values of the WHITE BALANCE circuit.

This is used when the IF VCO is adjusted.

This is used when ON/OFF if the I

2

[Do not adjust]

C BUS control is stop.

This sets the setting value of the output of P&P data.

This sets the setting value of the IP circuit.

[Do not adjust]

This sets the self checking of the TV circuit.

SLEEP

DISPLAY

key and

screen as sh own in t h e fig. 1.

KEY FUNCTION of SERVICEMENU

[Do not adjust]

SERVICE MENU

1. PICTURE/SOUND

2. YC SEP

3. LOW LIGHT

4. HIGH LIGHT

5. RF AFC

6.

Fig. 1

7. I2C BUS

8. PP

9. IP

0. SELF-CHK

(3) Enter the any setting mode

1. PICTURE / SOUND mode

"

1) S el ec t the 1. PICTURE / SOUND items with the number

key, and the FUNCTION (▲/▼) key is pressed the 1.

PICTUR E / SO U ND mode, the scr een w il l b e dis p layed as

shown in figure page later.

2) Then the sett in gs or verificati ons c an be performed.

2.YC SEP, 3.LOW LIGHT, 4.HIGH LIGHT, 5.RF AFC,

"

2

7.I

C BUS, 8.PP, 9.IP and 0.SELF-CH K mode

1) If you select any of 2.YC SEP 3.LOW LIGHT 4.HIGHLIGHT 5.R F A FC 7 .I

2

C BUS, 8.PP , 9.I P an d 0.SE LF-C HK

mode items, and the numbers key is pressed from

SERVICE MENU, the each screens will be displayed as

shown in figure page later.

2) Then the settings or verifications can be performed.

22

No. 51914

DISPLAY

key

SLEEP TIMER

key

MUT I N G key

MENU key

FUNCTION key

& (

▲/▼

/

NUMBERS

key

VIDEO STATUS

key

EXT key

(PIP OFF)

Select the setting value

Select the setting Item

Page 23

A

V-48WP30

A

Function

/

(

Function

(

▲/▼

) key

) key

SERVICE MENU

SERVICE MENU

1. PICTURE/SOUND

2. YC SEP

3. LOW LIGHT

4. HIGH LIGHT

5. RF AFC

6.

7. I2C BUS

8. PP

9. IP

0. SELF-CHK

1.PICTURE/SOUND

NTSC

***** *****

***** *****

***** ***** ***** *****

A01 001

*** *** ******* ******

*** *** ******* ****** *** *** ******* ******

A01

*** *** *** *****

*** *** *** *****

*** *** *** ***** *** *** *** *****

S01

*********

*********

********* *********

*** *** ******* ******

A16

~~~~

A01

*** **********

*** **********

*** ********** *** **********

S57

~~~~

LOW

4.HIGH LIGHT

HW-BAL

*** ***

*** ***

*** *** *** ***

5.RF AFC

TUNER

AFC

FINE

**

**

** **

**

**

** **

***

***

*** ***

7.I2C BUS

Press th e

0 key → ON/OFF

DO NOT ADJUST

DO NOT ADJUST

YC001

~

~~

~

YC007

S01

*** **********

*** **********

*** ********** *** **********

*** *** **********

*** *** **********

*** *** ********** *** *** **********

D01

D20

~~~~

D01

*** *********

*** *********

*** ********* *** *********

*** *** **** **** *

*** *** **** **** *

*** *** **** **** * *** *** **** **** *

F01

F64

~~~~

F01

*** *********

*** *********

*** ********* *** *********

*** *** ******* **** *

*** *** ******* **** *

*** *** ******* **** * *** *** ******* **** *

2.YC SEP

YC001

********** *

********** *

********** * ********** *

*** *** ******* *** ***

*** *** ******* *** ***

*** *** ******* *** *** *** *** ******* *** ***

3.LOW LIGHT

LW-BAL

*** *** ***

*** *** ***

*** *** *** *** *** ***

I2C

***

***

*** ***

8.PP

PPA001

***

***

*** ***

9.IP

NTSC PIP

IP001 NTSC OFF FRAME 0

*****

*****

***** *****

LOW

0.SELF-CHK

IO

NG2

LOB

OK

SYNC

M:OK

MEM

OK

VCD

NG2

AIO

OK

TUN

OK

PP

NG4

OCP

TIM

S:OK

AVSW

BS

YC

OK

OK

NG2

OK

HD:NG

OK

OK

OK

OK

OK

PPA001

008

~~~~

PPB001

036

~~~~

PPC001

007

~~~~

ADM001

ADS001

VCM001

VCS001

034

~~~~

034

~~~~

038

~~~~

041

~~~~

DO NOT ADJUST

IPA001

120

~~~~

IPB001

088

~~~~

IPC001

044

~~~~

IPD001

058

~~~~

IPE001

015

~~~~

Press the 0 key → ON/OFF

No. 51914

23

Page 24

A

V-48WP30

A

(

y

(▼)

(▼)

(4) Setting method

1) UP / DOWN (▲/▼) FUNCTION key

Select the SETTING ITEM.

2) LEFT / RIGHT ( / ) FUNCTION key

Setting ( ad jus t) th e s ett i ng v al u e of th e SET T IN G ITE M .

When the MU T I NG key is pressed th e setting valu e

will be stored (memorized).

3) EXIT key

Returns to the previous screen.

(5) Releasing SERVICE MENU

1) After returning to the SERVICE MENU upon completion

of the setting work, press the EXIT key again.

SIGNAL

SYSTEM

SPECT

SIZE

**** ***********

**** ***********

**** *********** **** ***********

SETTING A01

ITEM D01

*** *** *** *** ***

*** *** *** *** ***

*** *** *** *** *** *** *** *** *** ***

1.PICTURE/SOUND

NTSC

FULL

DYNAMIC

A001

001

A16 / S01

~~~~

D20 / F01

~~~~

OFF

S57

~~~~

F64

~~~~

2.YC SEP

YC001

***

***

*** ***

FRAME

LOW

WHITE BALANCE

VIDEO STATUS

SETTING VALUE

DO NOT ADJUST

SETTING ITEM

YC001

YC107

~~~~

SETTING VALUE

WHITE BALANCE setting

"

The setting for 3.LOW LIGHT and 4.HIGH LIGHT are described in

the WHITE BALANCE pag e of ADJUSTMENT .

WHITE BALANCE key function

R.CUT OFF

R.DRIVE

R.CUT OFF

R.DRIVE

(▲)

MEMORY

MUTING

MENU ke

FUNCTION key

(▲/▼) & ( / )

Select the setting value

Select the setting Item

G.CUT OFF

G.CUT OFF

B.CUT OFF

B.DRIVE

B.CUT OFF

B.DRIVE

W.BALANCE

SETTING VALUE

(ON or OFF)

EXIT key

(▲)

(▼)

(▲)

WHITE BALANCE

3.LOW LIGHT

LW-BAL

*** *** ***

*** *** ***

*** *** *** *** *** ***

4.HIGH LIGHT

HW-BAL

*** ***

*** ***

*** *** *** ***

5.RF AFC

SETTING ITEM

Setting Value

・・・・

B.CUT OFF VALUE

G.CUT OFF VALUE

R.CUT OFF VALUE

SETTING ITEM

Setting Value

・・・・

B.DRIVE VALUE

Setting Value

・・・・

R.DRIVE VALUE

DO NOT ADJUST

24

NOTE)

TUNER 2

AFC ON

FINE

***

***

******

(

TUNER 1(MAIN)/2(SUB)

AFC Select ON/OFF

FINE Fine Tuning(-77

AFC ON :Aut o Setting

+77)

~~~~

No. 51914

Page 25

A

V-48WP30

X

8.PP

SETTING ITEM

PPA001

PPA008

~~~~

PPB001

PPB036

~~~~

PPC001

PPC007

~~~~

PPA001

***

***

*** ***

ADM001

SETTING VALUE

ADM034

~~~~

8.PP / 9.IP setting

1) FUNCTION(▲/▼) key

2) FUNCTION ( / ) key

3) SLEEP TIMER key

4) MUTING Key

5) EXIT key

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

Select the setting Item

Select the setting value.

Skip the each setting Item.

Setting value will be stored.

Ret urns to the service menu.

* Press the EXIT key again, then releasing the service menu.

0.SELF-CHK DISPLAY

Press 0 key of remote control that checks the circuit

operating status and in event of malfunction displays

stores the data in memory. (shown in figure)

NTSC PIP

IPA001

RAY

LOB

SYNC

MEM

VCD

AIO

TUN

PP

9.IP

******

******

****** ******

OFF FRAM

***

***

*** ***

0.SELF-CHK

NG

OCP

OK

TIM

M:OK

S:OK

OK

AVSW

NG2

BS

OK

TC

OK

GCR

NG4

IP

NG2

OK

HD:NG

OK

OK

OK

OK

OK

***

***

*** ***

DO NOT ADJUST

SETTING ITEM

IPA001

IPA120

~~~~

IPB001

IPA088

~~~~

IPC001

IPC044

~~~~

IPD001

IPD058

~~~~

IPE001

IPE015

~~~~

SETTING VALUE

No. 51914

25

Page 26

A

V-48WP30

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of th e in itial setting values; however, the new setting values which set the

screen in its opt imum condition may dif f er fr om t h e init ial setting.

2. Do not change the initial setting values of the setting items NOT LISTED IN ADJUSTMENT.

3. The (*1 or *2)mark ed it ems i n follow in g tab le, it is NO R EQU IRE MENT for adj ustm ent. If valu es h ad ch ange by th e mis si ng, s et the

initial values in the following table.

CAUTION

Never change

the initial setting value any adjustments

except

for those that are designated in the

adjustment proc edur es.

In case where you have made undesignated adjustments by mistake, never press the MUTING key on the

remote contr ol unit.

Whenever you had not pressed the MUTING key , you would be able to recover the initial value by switching

the POWER SW (on/off) key.

1. PICTURE / SOUND

■■■■

SOUND SYSTEM

Item

No.

A01 NOISE DET. 0 / 1 000 A09 5TH MON 0 / 1 000

A02 INPUT LEVEL

A03 FH MONITOR 0 / 1 000 A11 INPUT GAIN 0 / 1 000

A04 STEREO VCO

A05 PILOT CAN 0 / 1 000 A13 BBE BASS

A06 FILTER

A07 LOW SEP

A08 HI SEP

■■■■

DEFLECTION SYSTEM

Item

No.

D01 V.HEIGHT

D02 EW PARABORA

D03 H.WIDTH 0~63 051 D13 ADJUSTMENT 0~15 000

D04 V.S-CORR

D05 V.LINEARITY

D06 V.CENTER

D07 TRAPEZIUM

D08

D09

D10 V.EHT

Item name

Item name

EW CORNER

LOWER

EW CORNER

UPPER

Variable

range

0 ~ 63

0 ~ 63

0 ~ 63

0 ~ 63

0 ~ 63

Variable

range

127

0

~

63

0

~

63

0

~

63

0

~

63

0

~

63

0

~

0

15 008 D18

~

0

15 008 D19

~

7

0

~

Initial settin g

value

027 A10 SAP VCO

035 A12 FIL OFFSET

032 A14 BBE TREBLE

027 A15 BASS

028 A16 TREBLE

Initial settin g

value

027 D11 H EHT

022 D12 EHT GAIN

040 D14 H CENTER

039 D15

023 D16 H. BLK

029 D17 OSD OFFSET

003 D20

Item

No.

Item

No.

HORI FREQ

ADJUSTMENT

COMPULSION

TWIN SCREEN

COMPULSION

DEF RST

OUTPUT

COMPULSION

1080i

Item name

Item name

Variable

range

0 ~ 63

-128 ~ +127

-128 ~ +127

-128 ~ +127

-128 ~ +127

-128 ~ +127

Variable

range

0~7

0~7

0~255

0

255

~

0~255

0~127

0

7000

~

0

1000

/

0

1000

/

Initial settin g

Initial settin g

value

035

000

+007

000

-012

-008

value

001

002

172

141

080

044

26

No. 51914

Page 27

A

■■■■

PICTURE SYSTEM

( NTSC / 480i / 480p )

Item

No.

S01 SUB COLOR 0~127 078 058 078 058 080 062

S02 SUB TINT

(1/2)

Item name

Variable

range

0

127

~

Standard Theater Standard Theater Standard Theater

NTSC 480i 480p

078 069 078 069 070 060

V-48WP30

( 720p / 1080i / HDCP )

Item

No.

S01 SUB COLOR 0~127 065 060 070 069 059 058

S02 SUB TINT

( NTSC / 480i )

Item

No.

S03

S04

S05

S06

( 480p / 720p / 1080i / HDCP )

Item

No.

S03

S04

S05

S06

Item name

Item name

SUB BRIGHT 0~255

SUB CONTRAST 0~127

SUB BRIGHT

OFFSET

SUB CONTRAST

OFFSET

Item name

SUB BRIGHT 0~255

SUB CONTRAST 0~127

SUB BRIGHT

OFFSET

CUB CONTRAST

OFFSET

Variable

range

127

0

~

Variable

range

-128~127

-128~127

Variable

range

-128~127

-128~127

720p / 1080i HDCP

Standard Theater

078 063 070 074 070 066

NTSC 480i

Standard Theater Standard Theater

134 133 134 133

079 045 079 045

----

----

480p / 720p / 1080i HDCP SPLIT / FREEZE

Standard Theater Standard Theater Standard Theater

132 134

082 047

--

--

Standard Theater Standard Theater

480p 1080i / 720p

----

----

000 000 000 000

000 000 -010 000

(2/2)

(1/2)

(2/2)

( NTSC / 480i / 480p / 720p / 1080i / HDCP )

Item

No.

S07

S08

S09

Item name

B-Y

DEMODURATION

R-Y

DEMODULATION

G-Y MATRIX SW

Variable

range

0~63 005 002 005 002 020 048 011 020

0~7 007 000 007 000 007 000 003 000

0~3 001 003 001 003 003 003 002 003

NTSC 480i 480p 720p / 1080i / HDCP

Standard Theater Standard Theater Standard Theater Standard Theater

No. 51914

27

Page 28

A

V-48WP30

( NTSC / 480i)

Item

No.

S10

S11

S12

S13

( 480p / 720p / 1080i )

Item

No.

S10

S11

S12

S13

( HDCP )

Item

No.

S10

S11

S12

S13

(1/3)

Item name

R DRIVE 0~255

R DRIVE OFFSET -128~+127

B DRIVE

B DRIVE OFFSET -128~+127

Item name

R DRIVE 0~255

R DRIVE OFFSET

B DRIVE 0~255

B DRIVE OFFSET -128~+127

(3/3)

Item name

R DRIVE

R DRIVE OFFSET -128~+127

B DRIVE 0~255

B DRIVE OFFSET

Variable

range

Standard Theater Standard Theater

High Low High Low High Low High Low

NTSC 480i

-

080

---

080

--

+003 000 000 +008 +003 000 000 +008

0~255

-

074

---

074

-

000

+006 000 000 -025 +060 000 000 -025

(2/3)

Variable

range

-128~+127

Variable

range

0~255

-128~+127

Standard Theater Standard Theater

High Low High Low High Low High Low

--- --

000 000 000 000 +004 000 000 +007

-- ---

000 000 000 000 +006 000 000 -008

Standard Theater

High Low High Low

----

+004 000 000 +005

-- --

+005 000 -010 -023

480p 720p / 1080i

145

150

HDCP

--

--

( NTSC / 480i / 480p / 720p / 1080i )

Item

No.

S14

S15

S16

S17

S18

S19

S20

S21

Item name

R CUT OFF 0~255

R CUT OFF

OFFSET

G CUT OFF 0~255

G CUT OFF

OFFSET

B CUT OFF 0~255

B CUT OFF

OFFSET

R CUT OFF SW 0~3

B CUT OFF SW 0~3

Variable

range

-128~+127

-128~127

-128~+127

NTSC 480i 480p / 720p / 1080i HDCP

Standard Theater Standard Theater Standard Theater Standard Theater

211

-

211

-

215

---

000 +003 000 +003 000 -001 000 +007

050

-

050

-

050

---

000 000 000 000 000 000 000 000

052

-

052

-

059

---

000 +004 000 +004 000 -003 000 +005

000

001

-

-

000

001

-

-

000

001

---

---

28

No. 51914

Page 29

A

( NTSC / 480i / OTHERS SIGNAL)

Item

No.

S22

S23

S24

S25

S26

S27

Item name

BLACK GRAD CORR

START LEVEL

BLACK GRAD CORR

GAIN

WHITE GRAD CORR

START LEVEL

WHITE GRAD CORR

GAIN

WHITE CHARA CORR

START LEVEL

WHITE CHARA CORR

GAIN

Variable

range

0~15

0~15

0~15

0~15

0~15

0~15

NTSC 480i

OTHERS

SIGNAL

015 015 015

008 008 008

000 000 000

015 015 015

002 002 000

000 000 000

V-48WP30

Item

No.

S28

S29

S30

S31

S32

S33

S34

( NTSC / 480i / 480p / 720p / 1080i / HDCP )

Item

No.

S35

Item

No.

S36

Item name

ABL GAIN

ABC START

ACL GAIN

ACL START

CONTRAST LINK 0 / 1

BLACK GRADIATION

CORRECTION OFF

WHITE GRADIATION

CORRECTION OFF

Item name

TINT HD / NTSC 0 / 1

Item name

ABL OFF 0 / 1

Variable

range

0~15

0~15

0~15

0~15

Variable

range

Variable

range

0 / 1

0 / 1

Standard Theater

015 015

015 008

015 000

000 015

000 000

000 001

000 001

NTSC / 480i 480p 720p / 1080i

480p 720p / 1080i

HDCP

001 001 001 001 001

Standard Theater

000 000

ACL OFF 0 / 1

S37

DC TRANSMIT

S38

POLARITY

DC TRANSMIT CORR 0 / 1

S39

BLAKING ON / OFF 0 / 1

S40

( NTSC / 480i / OTHERS )

Item

No.

S41

Item

No.

S42

Item name

DC REPRODUCE

RATE

Item name

ACL CONTROL 0~255

0 / 1

Variable

range

0~255

Variable

range

Standard Theater Standard Theater Standard Theater

000 000

001 000

000 000

000 000

NTSC 480i OTHERS SIGNAL

160 140 160 140 160 72

SPLIT Regular Theater

OTHERS

SIGNAL

160 072 072 072

No. 51914

29

Page 30

A

V-48WP30

Item

No.

S43

S44

S45

( NTSC / 480i / OTHERS )

Item

No.

S46

S47

( ALL SIGNAL )

Item name

CONTRAST

LOWER LIMIT

CONTRAST

UPPER LIMIT

BRIGHT LOWER

LIMIT

Item name

EE THEATER

BRIGHT

EE THEATER

CONTRAST

Item

No.

S48

S49

S50

S51

S52

BRIGHT EE CONT. CORRECTION

REFRAIN EE

CONT. CORRECTION

REFRAIN EE BRIGH OFFSET

CORR (MAX)

BRIGHT EE ACL CORR. COEFF. 0~255

REFRAIN EE ACL CORR. COEFF. 0~255

Item name

Variable

range

-128~+127

-128~+127

-128~+127

Variable

range

-128~+127

-128~+127

Setting Value

Standard Theater

-070 -127

+017 +127

-020 -127

NTSC 480i

000 000 000

000 000 000

Variable

range

0~31

0~31

0~127

Setting

value

008

027

004

085

140

OTHERS

SIGNAL

S53

S54

S55

S56

S57

No use 0 / 1

No use 0 / 1

No use 0 / 1

No use 0 / 1

No use 0 / 1

000

000

000

000

000

30

No. 51914

Page 31

A

V-48WP30

(

p)

(

)

■■■■

OTHERS

Item

No.

F01 EEPROM Ver 1 0~255 051 F32 DIRECT SELECT 2 PIC. 0 / 1 000

F02 EEPROM Ver 2 0~255 001 F33

F03 H.LINE ON (BRIGHT) 0~255 133 F34

F04 H.LINE OFF (BRIGHT) 0~255 140 F35

F05 H.LINE CONTRAST 0~127 000 F36

F06 C38 / C41 SW 0 / 1 001 F37

F07 MODEL SELECT 0~255 000 F38

F08 F39 VSM SHIPPING MODE 0 / 1 000

F09 AUTO SCROLL ADJUST 1 0~15 002 F40 DVD 0~3000

F10 AUTO SCROLL ADJUST 2 0~15 004 F41

F11 AUTO SCROLL ADJUST 3 0~15 004 F42

F12 AUTO SCROLL ADJUST 4 0~15 005 F43 POWER OFF WHITE 0 / 1 000

Item name

Variable

Range

Setting

Value

Item

No.

Item name

CAPTION OSD

OSCSELECT

4 PIC.

HIGH SPEED SEARCH

4 PIC.

AGC REFLESH

4 PIC. HIGH SPEED

WAIT 1

4 PIC. HIGH SPEED

WAIT 2

4 PIC. HIGH SPEED

WAIT 3

2 PICTURE

16:9 MODE

V/C DECODE

H.MASK SETTING

Variable

Range

0~7002

0~255 040

0~255 000

0~255 040

0~255 020

0~255 040

0 / 1 000

0 / 3 000

Setting

Value

F13 AUTO SCROLL ADJUST 5 0~15 006 F44 WHITE BACK ON/OFF 0 / 1 000

F14 AUTO SCROLL ADJUST 6 0~15 007 F45

F15 AUTO SCROLL ADJUST 7 0~15 007 F46

F16 Not use 0 / 1 000 F47

F17 Not use 0 / 1 000 F48

F18 Not use 0 / 1 000 F49

F19 Not use 0 / 1 000 F53 S / N (RF) CORR.WIDTH 0~255 000

F20 Not use 0 / 1 000 F54 S / N (RF) CORR.START 0~255 000

F21 Not use 0 / 1 000 F55 S / N (BS) CORR.WIDTH 0~255 000

F22 Not use 0 / 1 000 F56 S / N (BS) CORR.START 0~255 000

F23 Not use 0 / 1 000 F57

V-CHIP ON/OFF (CANADA)

F24

EARTH MAGNETIC

F25

CORR. PICTURE

OSD OFFSET

F26

F27

F28

F29

F30 PIP 2 PICTURE 0 / 1 000 F64

F31 V.CHIP ON OFF 0 / 1 001

480p / 720p) (HDCP / 480

OSD OFFSET

1080i / HDCP1080i

CH.PROGRAM

SEARCH CYCLE

PIP FUNCTION

ON / OFF

0 / 1 000 F58

0~127 127 F59 S / N (S) CORR.WIDTH 0~255 000

0~63 033 F60 S / N (S) START 0~255 000

0~63 018 F61 OCD OFFSET (HORI.) 0~127 048

0~255 011 F62 ATT GAIN 0 / 1 000

0 / 1 000 F63 V.HEIGHT OFFSET -128~+127 000

S / N (COMP.)

CORR.WIDTH

S / N (COMP.)

CORR.START

TEXT MODE

CONT.CORR.

0~255 000

0~255 000

-128~+127 000

No. 51914

31

Page 32

A

V-48WP30

SIZE 2

Setting Value

Setting Value

HDCP720p HDCP1080i

Item

No.

F50 SEP.LEVEL 0~3 000 002 002 002 002

F51 CLAMP PLUS 0 / 1 000 000 000 000 000

F52 HD PHASE

Item

No.

F50 SEP.LEVEL

F51 CLAMP PLUS 0 / 1 000 000 000 000

F52 HD PHASE

Item name

Item name

Variable

Range

0~63

Variable

Range

0~3

0~63

NTSC 480i 480p 1080i 720p

038 035 026 039 024

HDCP 480p

SIZE 1

002 002 002 002

042 017 047 044

HDCP 480p

(1/2)

(2/2)

32

No. 51914

Page 33

A

ADJUSTMENT

CHECK ITEMS

Item

B1

POWER SUPPLY

check

Signal generator

DC Vol tmet e r

Measuring

Instrument

Test point Adjustment Item Description

S1 connector

5 pin:TP-91

1 pin:TP-E

(

#

)

1. Rec eive a bl ac k and whit e sig n al (c ol or off).

2. C onnect the DC volt meter to S1 conn ector 5 pi n (TP-

91) and TP-E(

3. Confirm that the voltage is DC140V±2V.

) (S1 connector 1 pin).

####

V-48WP30

HIGH VOLTAGE

check

X-RAY

PROTECTOR

check

H.FREQUENCY

check

Signal generator

High Voltage

meter

Resistor

6.8k

1/6W

ΩΩΩΩ

5%

±±±±

Signal

generator

Remote

control unit

CRT Anode

S1 connector

2 pin:X-Ray2

3 pin:X-Ray1

D15 : H.FREQ.

D19 : DEF.RST

1. Rec eive a w hi t e blac k sig nal.

2. Connect the high voltage meter between CRT anode

and GND.

3. Check that the High Voltage DC 31.0kV ±1.0kV.

1. Connect resistor 6.8kΩ(1/6W, ±5%) betw een

2. 2 pin & 3 pin of the connector S1.

3. Confirm that the X-RAY protector functions operated.

1. Receive th e black & whit e sig n al.

2. Preset from 0 to 1 for D19<DEF RST>, to adjust D15:

H.FREQ. and memori z e data with MUT ING key.

3. After adj ustment, to preset fr om 1 to 0 for D1 9: DEF

RST an d Press the MUTING key to memorize data.

No. 51914

33

Page 34

A

V-48WP30

FOCUS & BEAM SPOT ADJUSTMENT

Item

FOCUS &

BEAM SPOT

adjustment

LENS FOCUS

SCREW

PROJECTION UNIT & LENS ASS’Y

( CRT adjustment location )

Measuring

instrument

Signal

generator

Similar

adhesive

(Securing

adhesive)

DEFLECTION

YOKE

CENTERING

4 POLE

MAGNET

CRT FOCUS adjustment point

Test point Adjustment part Description

1. Receive a cross-hatch signal.

2. Press the ASPECT and select the FULL mode.

3. If the pictur e ti lted, adjus t th e R, G an d B D Y posit ion t o m ark

straight horizontal line.

LENS FOCUS

!

4. Makes a red single color.

: When mak ing a sing le col or, It squ eezes SC REEN VR in

NOTE

each one, or it does a lid to the lens in of the adjustm ent

color and it makes it single color.

5. By turning the LENS FOCUS screw (in LENS ass’y), for

optimum focus at the screen center. Check for absence of

difference in the peripheral focus. If the peripheral focus is

poor, slig htly shif t the cent er focus t o obtain overall b alanced

focus.

6. In the sam e mann er, p roduc e gr een and b lue si ngl e c olor and

adjust their respective focus.

7. After adj us tm en t , it fixes a scr ew.

: There is not a differenc e in th e focus i n the top and th e

NOTE

bottom, on either side, in the diagonal.

When the dif ference of the f ocus is bi g, it r em oves a main

lens, and it puts a was her b etwe en the m ain lens and t h e

coupl er and it ad jus t s it.

BEAM SPOT

!

8. Receive a d ot p at t ern signal.

9. Makes a red single color.

: When mak ing a sing le col or, It squ eezes SC REEN VR in

NOTE

each on e, or it does a lid to the lens in of the adjust ment

color and it makes it single c olor.

10. Turn the R FOCUS VR to set the dot diameter to about

30mm.

11. T urn th e 4 pole mag net of t he proj ecti on unit CRT n eck and t o

where the dots at the screen center are nearly circular.

12. Return the R FOCUS VR to its original position (just focus).

13. Turn the 2 pole magnet of the CRT neck to minimize expansion

of the dots.

14. Receive a crosshatch signal.

15. Adjust the overall screen focus.

16. In the same mann er , adj us t f or th e gre en and blue single color.

focus.

17. Secure the 4 and 2 pol e m agnets with similar adh esi v e.

CRT FOCUS

!

18. Receive a crosshatch signal.

19. Makes a red single color.

: When mak ing a sing le col or, It squ eezes SC REEN VR in

NOTE

each one, or it does a lid to the lens in of the adjustm ent

color and it makes it single color.

20. Adjust the R FOCUS VR for optimum focus at the position

indicated in the figure.

21. In the same m anner, adj us t for the gre en and bl u e si n gl e color

focus.

22. After adjustment, return the SCREEN VRs to their original

positions.

:

NOTE

When moving screen VR, always return to original.

MAGNET

2 POLE

MAGNET

G Def. Yoke (DY)

R Def. Yoke (DY)

B Def. Yoke (DY)