Page 1

JVC AV-29TS2

Recommended Safety Parts

Item Part No. Description

(AV-29TS2EN)

V01 A68ESF002X011 PICTURE TUBE(ITC)

L01 CELD020-00437 DEGAUSSING COIL

T1551 CETH019-00AJ1 H.V.TRANSF. (SERVICE)

1 CM12798-002-E REAR COVER

10 AEEMP001-185 POWER CORD

11 CM47016-001-H CORD CLAMP

12 CM23156-A01-E RATING LABEL For GBR/GER/ITA

13 CM23157-001-E RATING LABEL For GBR/ESP

R1466 QRD14CJ-2R2SX C R 2.2 Ω 1/4W J

R1585 QRV141F-2941AY MF R 2.94k Ω 1/4W F

R1586 QRV141F-1582AY MF R 15.8k Ω 1/4W F

R1991 QRZ0057-825 CR 8.2M Ω 1W J

C1521 QFZ0117-4001L MPP CAP. 400p F 1.5kVH±2.5%

C1522 QFZ0117-9501L MPP CAP. 9500p F 1.5kVH±2.5%

C1523 QFP32GJ-223M PP CAP. 0.022pF 400V J

C1525 QFZ0119-684S MPP CAP. 0.68pF 200V ±3%

C1531 QFZ0119-154S MPP CAP. 0.15 µF 200V ±3%

C1902 QCZ9034-472A C CAP. 4700 p F AC400V P

C1903 QCZ9034-472A C CAP. 1/00 p F AC400V P

C1904 QCZ9034-472A C CAP. 4700 p F AC400V P

C1992 QCZ9041-471A C CAP. 470 p F AC400V K

C1993 QCZ9041-332A C CAP. 3300 p F AC400V M

T1901 CETS083-00137 SW TRANSF.

D1901 D3SBA60 DIODE BRIDGE

Q1521 BU2508AX POWER TRANSISTOR H.OUT

IC1902 TLP721F(D4-GR) I.C.(PH.COUPLER)

CP1952 ICP-N50-Y I.C.PROTECT

CP1953 ICP-N50-Y I.C.PROTECT

FR1551 QRZ0054-4R7M F R 4.7 Ω 1/4W J

FR1552 QRH017J-1R0M F R 1 Ω 1W J

FR1553 QRH0173-1R0M F R 1 Ω 1W J

FR1954 QRH017K-R8ZM F R 0.82 Ω 1W K

SK3001 CE42535-001J1 C.R.T. SOCKET

C8901 QFZ9040-474N MF CAP. 0.47p F AC275V M

C8904 QFZ9040-473N MM CAP. 0.047p F AC275V M

F8901 QMF51D2-3R15J1 FUSE 3.15A

LF8901 CE42144-00132 LINE FILTER

S8901 QSP4K21-C01 PUSH SWITCH MAIN POWER

TH8901 CEKP010-00102 W.P.THERMISTOR

R0403 QRZ0054-470M F R 47 Ω 1/4W J

5 CQ40317-001-E INST BOOK For GBR/GER/FRA/NED/ITA/ESP

6 CQ40318-001-E INST BOOK For FIN/NOR/DEN/SWE/POR

(AV-29TS2EK)

V01 A68ESF002X011 PICTURE TUBE (ITC)

L01 CELD020-00437 DEGAUSSING COIL

T1551 CETH019-00AJ1 H.V.TRANSF. (SERVICE)

1 CM12798-002-E REAR COVER

10 AEENP003-185A POWER CORD

11 CM47016-001-H CORD CLAMP

12 CM22875-012-E RATING LABEL

R1466 QRD14CJ-2R2SX C R 2.2 Ω 1/4W J

R1585 QRV141F-2941AY MF R 2.94k Ω 1/4W F

R1586 QRV141F-1582AY MF R 15.8k Ω 1/4W F

R1991 QRZ0057-825 C R 8.2M Ω 1W J

C1521 QFZ0117-4001L MPP CAP. 4000 p F 1.5kVH±2.5%

C1522 QFZ0117-9501L MPP CAP. 9500 p F 1.5kVH±2.5%

C1523 QFP32GJ-223M PP CAP. 0.022 µ F 400V J

C1525 QFZ0119-684S MPP CAP. 0.68 µ F 200V ±3%

C1531 QFZ0110-154S MPP CAP. 0.15 µ F 200V ±3%

C1902 QCZ9034-472A C CAP. 4700 p F AC400V P

C1903 QCZ9034-472A C CAP. 4700 p F AC400V P

C1904 QCZ9034-472A C CAP. 4700 p F AC400V P

C1992 QCZ9041-471A C CAP. 470p F AC400V K

C1993 QCZ9041-332A C CAP. 3300p F AC400V N

T1901 CETS083-001J7 SW TRANSF.

D1901 D3SBA60 DIODE BRIDGE

Q1521 BU2508AX POWER TRANSISTOR H.OUT

IC1902 TLP721F(D4-GR) I.C.(PH.COUPLER)

CP1952 ICP-N50-Y I.C.PROTECT

CP1953 ICP-N50-Y I.C.PROTECT

FR1551 QRZ0054-4R7M F R 4.7 Ω 1/4W J

FR1552 QRH017J-1R0M F R 1 Ω 1W J

FR1553 QRH017J-1R0M F R 1 Ω 1W J

FR1954 QRH017K-R82M F R 0.82 Ω 1W K

SK3001 CE42535-001J1 C.R.T. SOCKET

C8901 QFZ0040-474N MF CAP. 0.47 µ F AC275V M

Recommended Safety Parts

Item Part No. Description

C8904 QFZ9040-473N MM CAP. 0.047 µ F AC275V M

F8901 QMF51D2-3R15J1 FUSE 3.15A

LF8901 CE42144-00132 LINE FILTER

S8901 QSP4K21-C01 PUSH SWITCH MAIN POWER

TH8901 CEKP010-001J2 W.P. THERMISTOR

R0403 QRZ0054-470M F R 47 Ω 1/4W J

5 CQ40319-001-E INST.BOOK

(AV-29TS2PF)

V01 A68ESF002X011 ITC TUBE(C)

L01 CELD020-004J7 DEGAUSSING COIL

T1551 CETH019-00A31 H.V. TRANSF.(SERVICE)

1 CM12798-002-E REAR COVER

10 AEEMP001-185 POWER CORD

11 CM47016-001-H CORD CLAMP

12 CM23159-001-E RATING LABEL

R1466 QRD14CJ-2R2SX C R 2.2 Ω 1/4W J

R1585 QRV141F-2941AY MF R 2.94k Ω 1/4W F

R1586 QRV141F-1582AY MF R 15.8k Ω 1/4W F

R1991 QRZ0057-825 C R 8.2M Ω 1W J

C1521 QFZ0117-4001L MPP CAP. 4000 p F 1.5kVH±2.5%

C1522 QFZ0117-9501L MPP CAP. 9500 p F 1.5kVH±2.5%

C1523 QFP32G3-223M PP CAP. 0.022µF 400V J

C1525 QFZ0119-684S MPP CAP. 0.68 µF 200V ±3%

C1531 QFZ0119-154S MPP CAP. 0.15 p F 200V ±3%

C1902 QCZ9034-472A C CAP. 4700 p F AC400V P

C1903 QCZ9034-472A C CAP. 4700 p F AC400V P

C1904 QCZ9034-472A C CAP. 4700 p F AC400V P

C1992 QCZ9041-471A C CAP. 470 p F AC400V K

C1993 QCZ9041-332A C CAP. 3300 p F AC400V N

T1901 CETS083-001J7 SW TRANSF.

D1901 D3SBA60 DIODE BRIDGE

Q1521 BU2508AX POWER TRANSISTOR H.OUT

IC1902 TLP721F(D4-GR) I.C.(PH.COUPLER)

CP1952 ICP-N50-Y I.C.PROTECT

CP1953 ICP-N50-Y I.C.PROTECT

FR1551 QRZ0054-4R7M F R 4.7 Ω 1/4W J

FR1552 QRH017J-1R0M F R 1 Ω 1W J

FR1553 QRH017J-1R0M F R 1 Ω 1W J

FR1954 QRH017K-R82M F R 0.82 Ω 1W K

SK3001 CE42535-001J1 C.R.T. SOCKET

C8901 QFZ9040-474N MF CAP. 0.47 µ F AC275V M

C8904 QFZ9040-473N MM CAP. 0.047 p F AC275V M

F8901 QMF51D2-3R15J1 FUSE 3.15A

LF8901 CE42144-001J2 LINE FILTER

S8901 QSP4K21-C01 PUSH SWITCH MAIN POWER

TH8901 CEKP010-00132 W.P. THERMISTOR

R0609 QRZ0054-470M F R 47 Ω 1/4W J

R0403 QRZ0054-470M F R 47 Ω 1/4W J

5 CQ40321-001-E INST.BOOK

(AV-21TS2EN)

V01 A51EAL155X01 PICTURE TUBE(ITC)

L01 CELD018-005J7 DEGAUSSING COIL

T1551 QQH0018-001 FLYBACK TRNSF.

1 CM12774-A01-E REAR COVER

10 AEEMP001-185 POWER CORD

11 CM46618-A01-E POWER CORD CLAMP

12 CM23156-A04-E RATING LABEL For GBR/GER/ITA

13 CM23158-002-E RATING LABEL For GBR/ESP

R1585 QRV141F-2941AY MF R 2.94k Ω 1/4W F

R1586 QRV141F-1582AY MF R 15.8k Ω 1/4W F

R1991 QRZ0057-825 C R 8.2M Ω 1W J

C1521 QFZ0125-952N MPP CAP. 9500 p F 2000V±2.5%

C1524 QFZ0119-254S MPP CAP. 0.25 µ F 200V ±3%

C1531 QFZ0119-154S MPP CAP. 0.15 µ F 200V ±3%

C1902 QCZ9034-472A C CAP. 4700 p F AC400V P

C1903 QCZ9034-472A C CAP. 4700 p F AC400V P

C1904 QCZ9034-472A C CAP. 4700 p F AC400V P

C1992 QCZ9041-471A C CAP. 470 p F AC400V K

C1993 QCZ9041-332A C CAP. 3300 p F AC400V M

T1551 QQH0018-001 FLYBACK TRANSF.

T1901 CETS085-001J4 SWITCH.TRANSF.

D1901 D3SBA60 DIODE BRIDGE

Q1521 BU2506DX POWER TRANSISTOR H.OUT

IC1902 TLP721F(D4-GR) I.C.(PH.COUPLER)

CP1952 ICP-N50-Y I.C.PROTECT

CP1953 ICP-N50-Y I.C.PROTECT

FR1551 QRZ0054-4R7M F R 4.7 Ω 1/4W J

FR1552 QRH017J-1R0M F R 1 Ω 1W J

Recommended Safety Parts

Item Part No. Description

FR1553 QRH017J-1R0M F R 1 Ω 1W J

FR1954 QRH017J-1R2M F R 1.2 Ω 1W J

FR1968 QRZ0054-331M F R 330 Ω 1/4W J

SK3001 CE42535-001J1 C.R.T. SOCKET

C8901 QFZ9040-474N MF CAP. 0.47 µ F AC275V M

C8904 QFZ0040-473N MM CAP. 0.047 µ F AC275V M

F8901 QMF51D2-3R15J1 FUSE 3.15A

LF8901 AEELF002-001 LINE FILTER

S8901 QSP4K21-C01 PUSH SWITCH MAIN POWER

TH8901 CEKP010-001J2 W.P.THERMISTOR

R0403 QRZ0054-470M F R 47 Ω 1/4W J

5 CQ40317-001-E INST BOOK For GBR/GER/FRA/NED/ITA/ESP

6 CQ40318-001-E INST BOOK For FIN/NOR/DEN/SWE/POR

(AV-21TS2EK)

L01 CELD018-00537 DEGAUSSING COIL

T1551 QQH0018-001 FLYBACK TRANSF.

V01 A51EAL155X01 PICTURE TUBE(ITC)

1 CM12774-A01-E REAR COVER

10 AEEMP003-185A POWER CORD

11 CM46618-A01-E POWER CORD CLAMP

12 CM22875-014-E RATING LABEL

R1585 QRV141F-2941AY MF R 2.94 k Ω 1/4W F

R1586 QRV141F-1582AY MF R 15.8 k Ω 1/4W F

R1991 QRZ0057-825 C R 8.2M Ω 1W J

C1521 QFZ0125-952N MPP CAP. 9500p F 2000V±2.5%

C1524 QFZ0119-254S MPP CAP. 0.25 µ F 250V J

C1531 QFZ0119-154S MPP CAP. 0.15 µ F 200V ±3%

C1902 QCZ9034-472A C CAP. 4700 p F AC400V P

C1903 QCZ9034-472A C CAP. 4700 p F AC400V P

C1904 QCZ9034-472A C CAP. 4700 p F AC400V P

C1992 QCZ9041-471A C CAP. 470 p F AC400V K

C1993 QCZ9041-332A C CAP. 3300 p F AC400V N

T1551 QQH0018-001 FLYBACK TRANSF.

T1901 CETS085-001J4 SWITCH.TRANSF.

D1901 D3SBA60 DIODE BRIDGE

Q1521 BU2506DX POWER TRANSISTOR H.OUT

IC1902 TLP721F(D4-GR) I.C. (PH.COUPLER)

CP1952 ICP-N50-Y I.C.PROTECT

CP1953 ICP-N50-Y I.C.PROTECT

FR1551 QRZ0054-4R7M F R 4.7 Ω 1/4W J

FR1552 QRH017J-1R0M F R 1 Ω 1W J

FR1553 QRH0173-1R0M F R 1 Ω 1W J

FR1954 QRH017J-1R2M F R 1.2 Ω 1W J

FR1968 QRZ0054-331M F R 330 Ω 1/4W J

SK3001 CE42535-001J1 C.R.T. SOCKET

C8901 QFZ9040-474N MF CAP. 0.47 µ F AC275V M

C8904 QFZ9040-473N MM CAP. 0.047 µ F AC275V M

F8901 QMF5102-3R15J1 FUSE 3.15A

LF8901 AEELF002-001 LINE FILTER

S8901 QSP4K21-C01 PUSH SWITCH MAIN POWER

TH8901 CEKP010-001J2 W.P. THERMISTOR

R0403 QRZ0054-470M F R47 Ω 1/4W J

5 CQ40319-001-E INST. BOOK

Page 2

JVC AV-29TS2

Safety Precautions

1. The design of this product contains special

hardware, many circuits and components

specially for safety purposes. For continued

protection, no changes should be made to the

original design unless authorized in writing by

the manufacturer. Replacement parts must be

identical to those used in the original circuits.

Service should be performed by qualified

personnel only.

2. Alterations of the design or circuitry of the

products should not be made. Any design

alterations or additions will void the manufacturers warranty and will further relieve the

manufacturer of responsibility for personal

injury or property damage resulting therefrom.

3.Many electrical and mechanical parts in the

products have special safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the

protection afforded by them necessarily be

obtained by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special

safety characteristics are identified in the

parts lists. Electrical components having such

features are identified by shading on the

schematics and by ( ) on the parts list. The

use of a substitute replacement which does

not have the same safety characteristics as

the recommended replacement part shown in

the parts list may cause shock, fire, or other

hazards.

4. Don’t short between the LIVE side ground

and ISOLATED (NEUTRAL) side ground or

EARTH side ground when repairing. Some

models power circuit is partly different in the

GND. The difference of the GND is shown by

the LIVE ( ) side GND, the ISOLATED

(NEUTRAL): ( ) side GND and EARTH ( )

side GND. Don’t short between the LIVE side

GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND and never measure with a

measuring apparatus (oscilloscope etc.) the

LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same

time. If above note will not be kept, a fuse or

any parts will be broken.

5. If any repair has been made to the chassis, it

is recommended that the B1 setting should be

checked or adjusted (See ADJUSTMENT OF

B1 POWER SUPPLY).

6. The high voltage applied to the picture tube

must conform with that specified in Service

manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and

possible component damage, therefore

operation under excessive high voltage

conditions should be kept to a minimum, or

should be prevented. If severe arcing occurs,

remove the AC power immediately and

determine the cause by visual inspection

(incorrect installation, cracked or melted high

voltage harness, poor soldering, etc.). To

maintain the proper minimum level of soft XRay emission, components in the high voltage

circuitry including the picture tube must be the

exact replacements or alternatives approved

by the manufacturer of the complete product.

7. Do not check high voltage by drawing an arc.

Use a high voltage meter or a high voltage

probe with a VTVM. Discharge the picture

tube before attempting meter connection, by

connecting a clip lead to the ground frame

and connecting the other end of the lead

through a 1 0k Ω 2 2W resistor to the anode

button.

8. When service is required, observe the original

lead dress. Extra precaution should be given

to assure correct lead dress in the high

voltage circuit area. Where a short circuit has

occurred, those components that indicate

evidence of overheating should be replaced.

Always use the manufacturers replacement

components.

9. Isolation Check

Safety for Electrical Shock Hazard

After re-assembling the product, always

perform an isolation check on the exposed

metal parts of the cabinet (antenna terminals,

video/audio input and output terminals,

Control knobs, metal cabinet, screwheads,

earphone jack, control shafts, etc.) to be sure

the product is safe to operate without danger

of electrical shock.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and

all metal parts exposed to the user, particularly

any exposed metal part having a return path to

the chassis should withstand a voltage of 3000V

AC (r.m.s.) for a period of one second. (. . . .

Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC

(r.m.s.) to an appliance rated 200V or more, for

a period of one second.)

This method of test requires a test equipment

not generally found in the service trade.

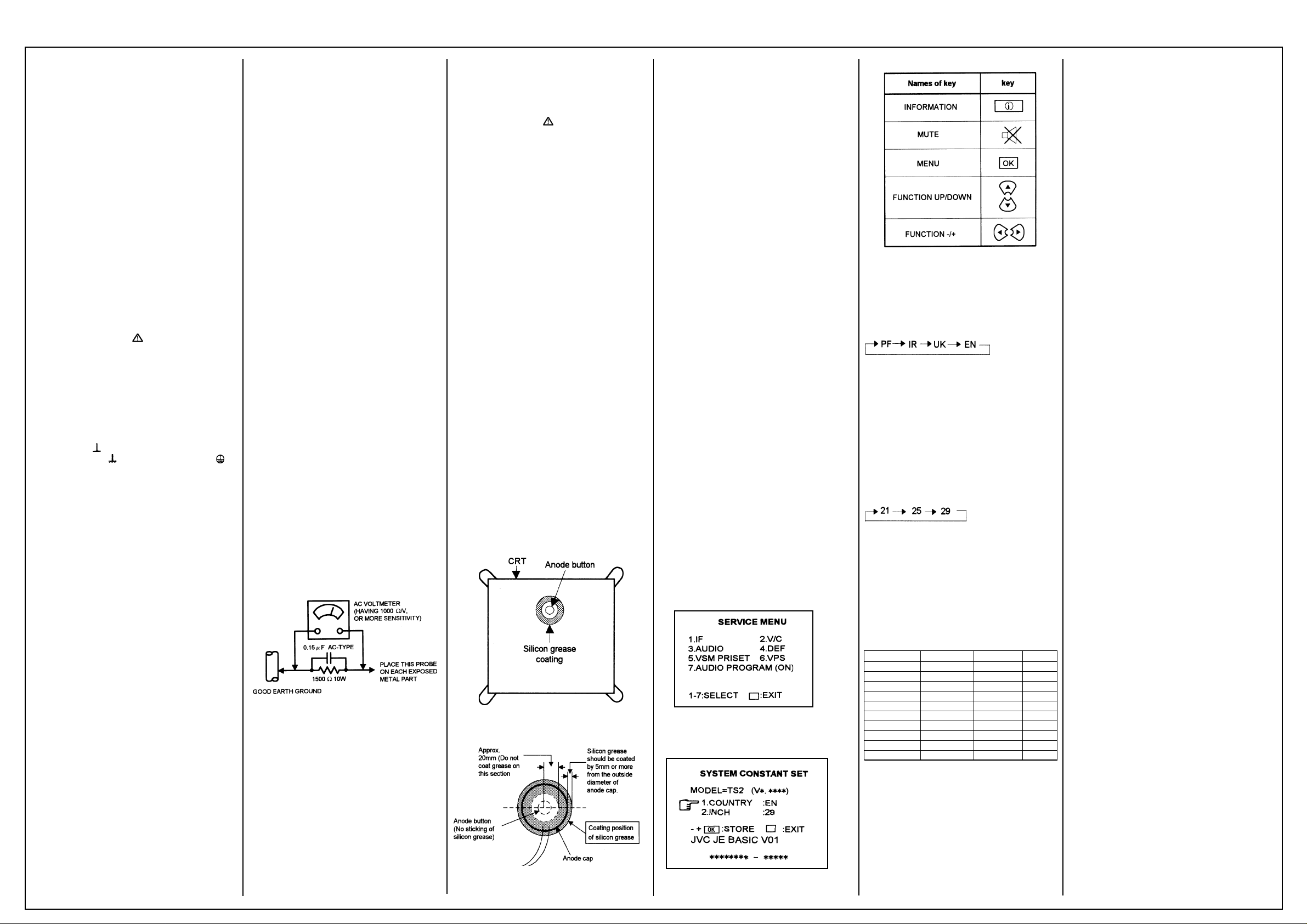

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet

(do not use a line isolation transformer during

this check.). Using a “Leakage Current Tester’,

measure the leakage current from each exposed

metal part of the cabinet, particularly any

exposed metal part having a return path to the

chassis, to a known good earth ground (water

pipe, etc.). Any leakage current must not exceed

0.5mA AC (r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet

(do not use a line isolation transformer during

this check.). Use an AC voltmeter having 1000

ohms per volt or more sensitivity in the following

manner. Connect a 1500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known

good earth ground (water pipe, etc.). Measure

the AC voltage across the resistor with the AC

voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed

metal part having a return path to the chassis,

and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage

measured must not exceed 0.35V AC (r.m.s.).

This corresponds to 0.5mA AC (r.m.s.).

1. The design of this product contains special

hardware and many circuits and components

specially for safety purposes. For continued

protection, no changes should be made to the

original design unless authorized in writing by

the manufacturer. Replacement parts must be

identical to those used in the original circuits.

Service should be performed by qualified

personnel only.

2. Alterations of the design or circuitry of the

product should not be made. Any design

alterations or additions will void the manufacturer’s warranty and will further relieve the

manufacturer of responsibility for personal

injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the

product have special safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the

protection afforded by them necessary be

obtained by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special

safety characteristics are identified in the

Parts List. Electrical components having such

features are identified by shading on the

schematics and by ( ) on the Parts List. The

use of a substitute replacement which does

not have the same safety characteristics as

the recommended replacement part shown in

the Parts Lists may cause shock, fire, or other

hazards.

4. The leads in the products are routed and

dressed with ties, clamps, tubing’s, barriers

and the like to be separated from live parts,

high temperature parts, moving parts and / or

sharp edges for the prevention of electric

shock and fire hazard. When service is

required, the original lead routing and dress

should be observed, and it should be

confirmed that they have been returned to

normal, after re-assembling.

Warning

The equipment has been designed and manufactured to meet international safety standards.

It is the legal responsibility of the repairer to

ensure that these safety standards are maintained. Repairs must be made in accordance

with the relevant safety standards. It is essential

that safety critical components are replaced by

approved parts. If mains voltage selector is

provided, check setting for local voltage.

COATING OF SILICON GREASE FOR ELECTRICAL

INSULATION ON THE CRT ANODE CAP

SECTION.

Subsequent to replacement of the CRT and HV

transformer or repair of the anode cap, etc. by

dismounting them, be sure to coat silicon grease

for electrical insulation as shown in Fig.4. Wipe

around the anode button with clean and dry

cloth. (Fig.4) Coat silicon grease on the section

around the anode button. At this time, take care

so that any silicon greases dose not stick to the

anode button. (Fig. 5)

* Silicon grease product No. KS - 650N

Fig. 4

Fig. 5

REPLACEMENT OF MEMORY ICs

1. Memory ICs

This TV use memory ICs (EEP-ROM IC). In the

memory ICs, there are memorized data for

correctly operating the video and deflection

circuits. When replacing memory ICs, be sure to

use ICs written with the initial values of data.

2. Procedure for replacing memory ICs

PROCEDURE

(1) Power off

Switch the power off and unplug the power code

from the outlet.

(2) Replace ICs.

Be sure to use memory Cs written with the initial

data values.

(3) Power on

Plug the power code into the outlet and switch

the power on.

(4) Check and set SYSTEM CONSTANT SET:

1) Press the INFORMATION key and the MUTE

key of the REMOTE CONTROL UNIT

simultaneously.

2) The SERVICE MENU screen of Fig. 1 will be

displayed.

3) While the SERVICE MENU is displayed press

the INFORMATION key and MUTE key

simultaneously, and the SYSTEM CONSTANT

SET screen of Fig. 2 will be displayed.

4) Check the setting values of the SYSTEM

CONSTANT SET of Table 1. If the value is

different, select the setting item with the

FUNCTION UP/DOWN key, and set the

correct value with the FUNCTION -/+ key.

5) Press the MENU key and memorize the

setting value.

6) Press the INFORMATION key twice, and

return to the normal screen.

(5) Setting of receive channels

Set the receive channel. For setting, refer to the

OPERATING INSTRUCTIONS.

(6) User settings

Check the user setting values of Table 2, and if

setting value is different, set the correct value.

For setting, refer to the OPERATING INSTRUCTIONS.

7) Setting of SERVICE MENU

Verify the setting items of the SERVICE MENU

of Table 3, and reset where necessary.

For setting, refer to the SERVICE ADJUSTMENTS.

SERVICE MENU

Fig.1

SYSTEM CONSTANT SET

Fig.2

NAME OF REMOTE CONTROL KEY

SETTING VALUES OF SYSTEM CONSTANT

SET

Setting item

1. COUNTRY

Setting content

Setting value

AV-29TS2EN

EN

AV-29TS2EK

UK

AV-29TS2PF

PF

Setting item

2. INCH

Setting content

Setting value

AV-29TS2EN

29

AV-29TS2EK

29

AV-29TS2PF

29

USER SETTING VALUES

Setting Item Value Item Value

SUB POWER ON COOL/NORMAL COOL

CHANNEL 1 POSITION SLEEP TIMER OFF

CHANNEL PRESET See; OPERATING SPATIAL EFFECT OFF

INSTRUCTIONS BLUE BACK ON

VOLUME Appropriate ZOOM REGULAR

sound volume

TV/EXT TV ECO OFF

DISPLAY CHANNEL DISPLAY BALANCE CENTER

P/S/N TV/PAL LANGUAGE ENGLISH

HYPER SOUND OFF CHILD LOCK ID No.*****

Table 2

SERVICE MENU SETTING ITEMS

Setting item

1. IF

Setting value

1. VCO

2. DELAY POINT

3. LV LEVEL (Only AV-29TS2PF)

Setting item

2. V/C

Setting value

1. CUTOFF

2. DRIVE

3. BRIGHT

4. CONT.

5. COLOUR (PAL/SECAM/NTSC)

6. TINT (NTSC)

7. BLACK OFFSET (SECAM)

8. SHARP (Do not adjust)

9. TEXT CONT (Do not adjust)

10. DC TRAN RATE (Do not adjust)

11. BLACK OFFSET (Do not adjust)

12. B.S.OFF (Do not adjust)

Setting item

3. AUDIO

Setting value

(Do not adjust)

1. CONC LIMIT

2. A2 ID THR

Setting item

4. DEF.

Setting value

1. TRAREZ

2. V-SHIFT

3. V-SIZE

4. H-CENT

5. H-SIZE

6. EW-PIN

7. V-S. CR (Fixed)

8. V-EDGE (Fixed)

9. EW-COR (Fixed)

10. ABL POINT (Do not adjust)

11. ABL GAIN (Do not adjust)

Setting item

5.VSM PRESET

Setting value

1. BRIGHT

(COOL/NORMAL/WARM)

2. CONT.

3. COLOUR

4. SHARP

5. TINT

6. R DRIVE

7. B DRIVE

8. BASS

9. TREBLE

Setting item

6. VPS (Do not adjust)

Setting value

VPS

Setting item

7. AUTO PROGRAM (Do not adjust)

Setting value

ON/OFF

BEFORE STARTING SERVICE ADJUSTMENT

1. There are 2 ways of adjusting this TV: One is

with the REMOTE CONTROL UNIT and the

other is the conventional method using

adjustment parts and components.

2. The setting (adjustment) using the REMOTE

CONTROL UNIT is made on the basis of the

initial setting values. The setting values which

adjust the screen to the optimum condition

can be different from the initial setting values.

3. Turn on the power of the TV and measuring

instrument for warming up for at least 30

minutes before starting adjustment.

4. Make sure that connection is correctly made

to AC power source.

5. If the receive or input signal is not specified,

use the most appropriate signal for adjustment.

Page 3

JVC AV-29TS2

Adjustments Cont’d

6. Never touch parts (such as variable resistors,

transformers and condensers) not shown in

the adjustment items of this service adjustment.

7. Preparation for adjustment (presetting):

Unless otherwise specified in the adjustment

items, preset the following functions with the

REMOTE CONTROL UNIT:

1) PICTURE MODE (VSM) COOL

2) SLEEP TIMER OFF

3) HYPER SOUND OFF

4) BALANCE CENTER

5) ECO OFF

6) ZOOM REGULAR

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator) [PAL

SECAM/NTSC]

4. Remote control unit

ADJUSTMENT ITEMS

Adjustment item Adjustment item

B1 POWER SUPPLY VIDEO/CHROMA CIRCUIT

CHECK ADJUSTMENT

FOCUS ADJUSTMENT DEFLECTION CIRCUIT

ADJUSTMENT

IF CIRCUIT AUDIO CIRCUIT

ADJUSTMENT (Do not adjust.)

VSM PRESET

ADJUST SETTING

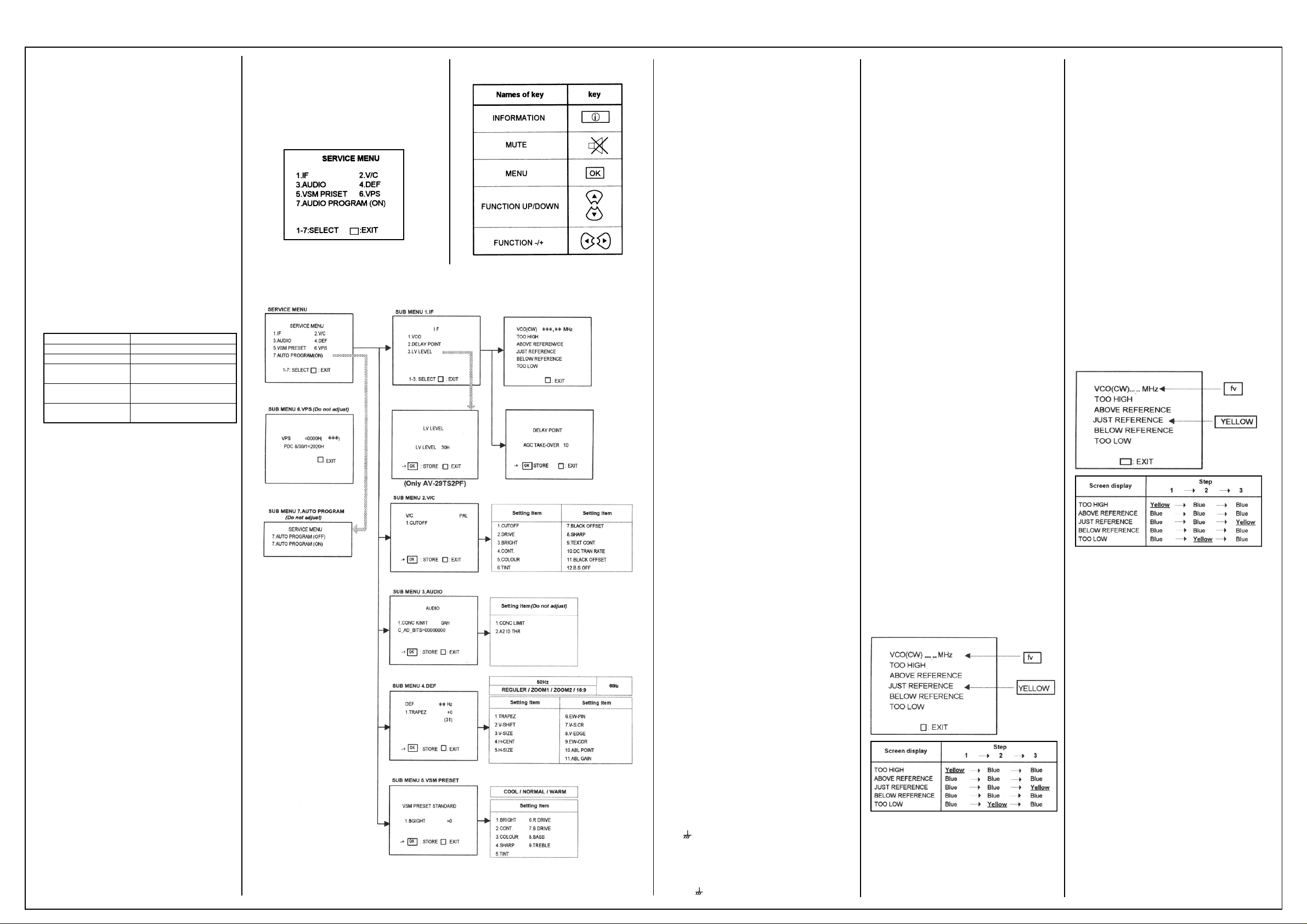

BASIC OPERATION OF SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE

CONTROL UNIT.

2. SERVICE MENU ITEMS

With the SERVICE MENU, various settings

(adjustments) can be made, and they are

broadly classified in the following items of

settings (adjustments):

1) 1. IF

This mode adjusts the setting values of the IF

circuit.

2) 2.VIC

This mode adjusts the setting values of the

VIDEO / CHROMA circuit.

3) 3.AUDIO

This mode adjusts the setting values of the

multiplicity SOUND circuit.

4) 4.DEF

This mode adjusts the setting values of the

DEFLECTION circuit.

5) 5.VSM PRSET

This mode adjusts the initial setting values of

COOL, NORMAL and WARM. (VSM: video

status memory)

6) 6.VPS

This mode shows the monitor of the VPS and

PDC.(Do not adjust).

(VPS: Video Program System, PDC: Program

Delivery Code)

7) 7.AUTO PROGRAMBy turning the power

switch on, you can get the state of AUTO

PROGRAM. (Do not adjust)

3. BASIC OPERATION OF SERVICE MENU

1) How to enter SERVICE MENU

Press the INFORMATION key and the MUTE

key of the REMOTE CONTROL UNIT simultaneously, and the SERVICE MENU screen of Fig. 1

will be displayed.

2) Selection of SUB MENU SCREEN

Press one of keys 1~7 of the REMOTE CONTROL UNIT and select the SUB MENU

SCREEN (See Fig. 3), form the SERVICE

MENU.

SERVICE MENU > SUB MENU

1. IF

2.V/C

3. AUDIO

4. DEF.

5. VSM PRESET

6. VPS

7. AUTO PROGRAM

Fig. 1

NAME OF REMOTE CONTROL KEY

Fig. 3 SUB MENU SCREEN.

3) Method of Setting

1) Method of Setting 1.IF

[1. VCO]

1) 1 Key. Select 1.IF.

2) 1 Key. Select 1 .VCO

3) The VCO (CW) screen will be displayed in

yellow when the AFC voltage is at a certain

level and in blue when it is at other levels.

4) INFORMATION Key. As you press this twice,

you will return to the SERVICE MENU.

[2. DELAY POINT]

1) 1 Key. Select 1.IF.

2) 2 Key. Select 2.DELAY POINT.

3) FUNCTION -/+. Set (adjust) the setting values

of the setting items.

4) MENU Key Memorize the set value. (Before

storing the setting values in memory, do not

press the CH, TV / VIDEO, DISPLAY, POWER

ON / OFF keys - if you do, the values will not

be stored in memory.)

5) INFORMATION Key When this is pressed

twice, you will return to the SERVICE MENU.

[3. LV LEVEL] (Only AV-29TS2PF)

1) 1 Key. Select 1.IF.

2) 3 Key. Select 3.LV LEVEL

3) FUNCTION -/+. Set (adjust) the setting values

of the setting items.

4) MENU Key. Memorize the set value. (Before

storing the setting values in memory, do not

press the CH, TV / VIDEO, DISPLAY, POWER

ON / OFF keys - if you do, the values will not

be stored in memory.)

5) INFORMATION Key. When this is pressed

twice, you will return to the SERVICE MENU.

2) Method of setting 2.V/C, 3.AUDIO, 4.DEF,

5.VSM PRESET and 6.VPS.

1) 2~6 Key. Select one from 2. V/C, 3. AUDIO,

4. DEF, 5. VSM PRESET and 6. VPS.

2) FUNCTION UP/DOWN Key. Select setting

items.

3) FUNCTION -/+. Set (adjust) the setting values

of the setting items. (When 1. CUTOFF of 2.V/

C is selected, press its “-“ or “+” key, and the

whole will change to a faint horizontal line

appearing in its center. Press the same “-“ or

“+” key again, and the screen will return to the

original 1.CUTOFF screen.)

4) MENU Key. Memorize the setting value.

(Before storing the setting values in memory,

do not press the CH, TV / VIDEO, DISPLAY,

POWER ON / OFF key - if you do, the values

will not be stored in memory.)

5) DISPLAY Key. Return to the SERVICE MENU

screen.

3) Method of setting 7.AUTO PROGRAM.

1) This mode initializes every existing set value

collectively to the preset value at the time of

shipment from the factory.

4) Release of Service Menu

1) After completing the setting, return to the

SERVICE MENU, then press the display key.

POWER SUPPLY CHECK

Item

Check of B1 voltage

Measuring instrument

Signal generator DC voltmeter

Test point

TP-91(B1)

TP-E( ) [X connector in

MAIN PWB]

Description

1. Receive a whole black signal.

2. Connect a DC voltmeter to TP-91 (B1) and

TP-E ( )

3. Make sure that the voltage is DC142.5±2V.

(29”) DC116.5±2V. (21”)

FOCUS ADJUSTMENT

Item

Adjustment of FOCUS

Measuring instrument

Signal generator

Adjustment part

FOCUS VR [In HVT]

Description

1. Receive a cross-hatch signal.

2. While watching the screen, adjust the

FOCUS VR to make the vertical and horizontal lines as fine and sharp as possible.

3. Make sure that when the screen is darkened,

the lines remain in good focus.

IF CIRCUIT ADJUSTMENT (for AV-29TS2EN/

AV-29TS2EK)

Item

Adjustment of VCO

Measuring instrument

Remote control unit

Adjustment part

P. CW TRANSF. [In IF PWB]

Description

Do not make any adjustment unless the

adjustment is out of way and you cannot get

correct PICTURE.

1. Select 1 IF from the SERVICE MENU.

2. Press 1 key and select 1.VCO.

3. Select a receivable broadcast channel with

the CHANNEL key.

4. Turn the core of P. CW TRANSF. until the

colour of the characters TOO HIGH displayed

on the screen changes from blue to Yellow.

(Step 1)

5. Turn the core of P. CW TRANSF. until the

colour of the characters TOO LOW changes

from blue to Yellow. (Step 2)

6. Then slowly turn back the core of P. CW

TRANSF. until the colour of the characters

JUST REFFERENCE changes from blue to

Yellow. (Step 3)

7. Press the INFORMATION key three times to

return to normal screen.

8. Perform CHANNEL PRESET again, and

make sure that each broadcast is being

received properly.

Item

Adjustment of DELAY POINT

Measuring instrument

Remote control unit

DELAY POINT (AGC TAKE-OVER)

1. Receive a black and white signal (colour off).

2. Select 1.IF from the SERVICE MENU.

3. Select 2.DELAY POINT by pressing the 2 key

on the remote control.

4. Adjust the FUNCTION - or + key until video

noise disappears.

5. Press the MENU key and memorize the set

value.

6. Turn to other channels and make sure that

there are no irregularities.

Setting item (Adjustment item)

DELAY POINT

(AGC TAKE-OVER)

Variable range

0~63

Initial setting value

30

IF CIRCUIT ADJUSTMENT [FOR AV-29TS2PF]

Item

Adjustment of VCO

Measuring instrument

Remote control unit

Adjustment part

P.CW TRANSF

P.L-VL CW TRIM.C

Description

Do not make any adjustment unless the

adjustment is out of way and you cannot get

correct PICTURE.

1. Select 1 IF from the SERVICE MENU.

2. Press 1 key and select 1 .VCO.

3. Select a SECAM L or PAL broadcast channel

with the CHANNEL key.

4. Turn the core of P.CW TRANSF. until the

colour of the characters TOO HIGH displayea

on the screen changes from blue to Yellow.

(Step 1)

5. Turn the core of P.CW TRANSF. until the

colour of the characters TOO LOW changes

from blue to Yellow. (Step 2)

6. Then slowly turn back the core of P.CW

TRANSF. until the colour of the characters

JUST REFERENCE changes from blue to

Yellow. (Step 3)

7. In the district SECAM L’ broadcast, can be

received select a SECAM L broadcast

channel with the CHANNEL key and adjust

the P.L-VL CW TRIM.C in same manner as for

above step. And as necessary, readjust P.CW

TRANSF.

8. Press the INFORMATION key three times to

return to normal screen.

9. Perform CHANNEL PRESET again, and

make sure that each broadcast is being

received properly.

Continues next page.

Page 4

JVC AV-29TS2

Adjustments Cont’d

Item

Adjustment of DELAY POINT (AGC)

Measuring instrument

Signal generator

Remote control unit

DELAY POINT (AGC TAKE-OVER)

1. Receive a black and white signal (colour off).

2. Select 1. IF from the SERVICE MENU.

3. Select 2. DELAY POINT by pressing the 2 key

on the remote control.

4. Adjust the FUNCTION - or + key until video

noise disappears.

5. Press the MENU key and memorize the set

value.

6. Turn to other channels and make sure that

there are no irregularities.

Setting item (Adjustment item)

DELAY POINT (AGC TAKE-OVER)

Variable range:0~63

Initial setting value: 30

Item

Adjustment of L-DET. LEVEL

Measuring instrument

Signal generator

Oscilloscope [H-rate]

Remote control unit

Test point

EXT-1 (19) pin (TV OUT)

Description

1. Receive a SECAM-L full field colour bar

signal (100% white).

2. Connect an oscilloscope terminated 75 Ω to

EXT-1 terminal of (19) pin (TV out).

3. Select 1. IF from the SERVICE MENU.

4. Press 3 key and select 3. LV LEVEL.

5. Adjust the LV LEVEL by FUNCTION -/+ key

and make the wave detector output 1 .0Vp-p.

6. Press the MENU key and memorize the set

value.

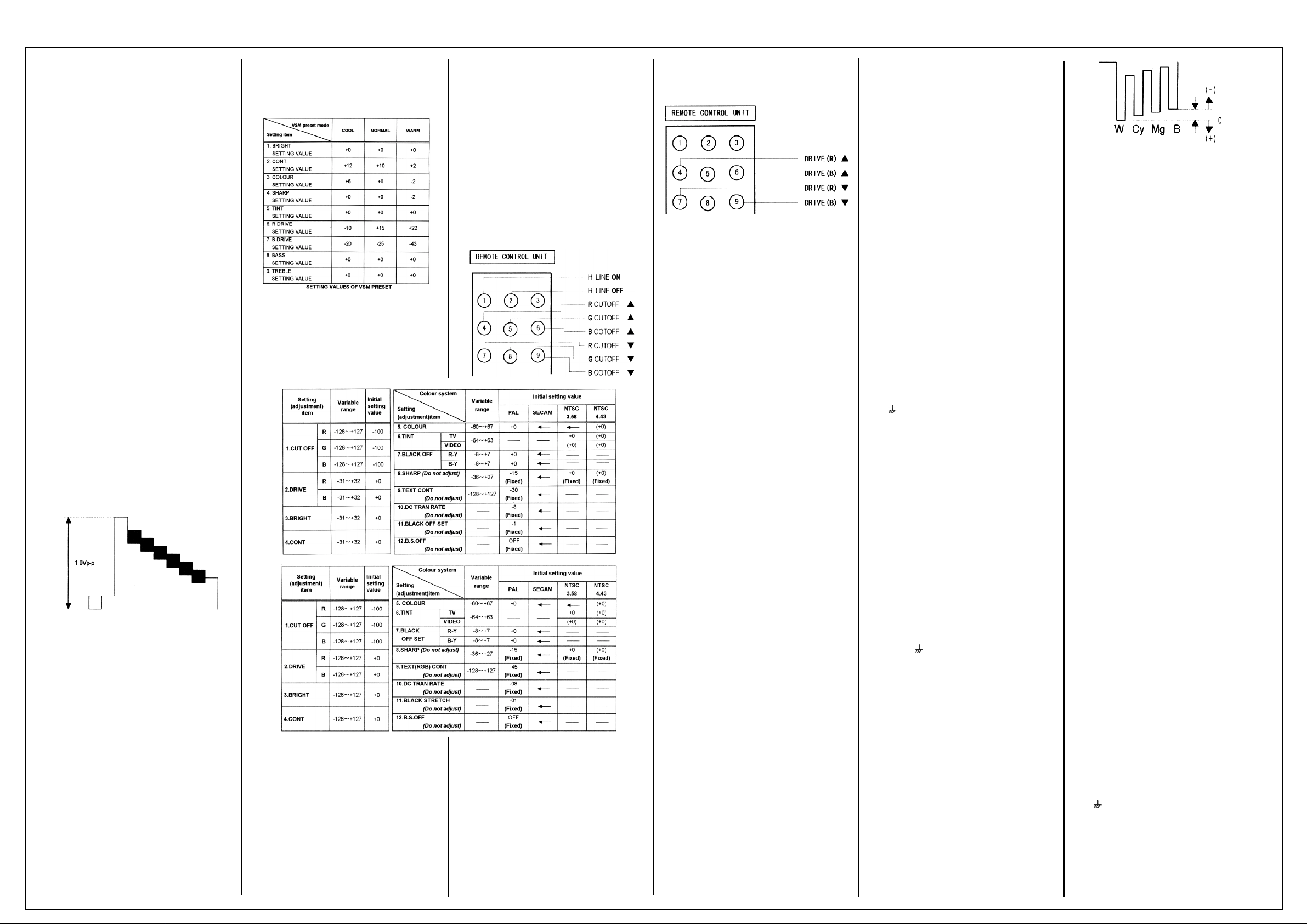

VSM PRESET ADJUST SETTING

Item

Setting of VSM PRESET ADJUST

Measuring instrument

Remote control unit

Adjustment part

1. BRIGHT

2. CONT.

3. COLOUR

4. SHARP

5. TINT

6. R DRIVE

7. B DRIVE

8. BASS

9. TREBLE

Description

1. Select 5.VSM PRESET from the SERVICE

MENU.

2. Select COOL with the PICTURE SETTING.

3. Adjust the FUNCTION UP/DOWN and -/+ key

to bring the set values of 1.BRIGHT 9.TREBLE to the values shown in the table.

4. Press the MENU key and memorize the set

value.

5. Respectively select the VSM PRESET mode

for NORMAL and WARM, and make similar

adjustment as in 3 above.

6. Press the MENU key and memorize the set

value.

* Refer to OPERATING INSTRUCTIONS for the

PICTURE SETTING.

VIDEO/CHROMA CIRCUIT ADJUSTMENT

The setting (adjustment) using the REMOTE

CONTROL UNIT is made on the basis of the

initial setting values.

The setting values which adjust the screen to

the optimum condition can be different from the

initial setting values.

Items in ( ) are automatically set to table

Item

Adjustment of WHITE BALANCE (Low Light)

Measuring instrument

Signal generator

Remote control unit

Test point

----

Adjustment part

1.CUT OFF

(R) ***

(G) ***

(B) ***

SCREEN VR [In HVT]

Description

1. Receive a black and white signal(colour off).

2. Select 2. V/C from the SERVICE MENU.

3. Select 1 .CUT OFF with the FUNCTION UP/

DOWN key.

4.Show one horizontal line with the I key. With

the SCREEN VR, adjust so that the horizontal

line will not be too bright.

5. Gradually turn the SCREEN VR from the left

end to the right direction to bring one of the

red, green and blue colour faintly visible.

6. Press 4~9 key, and bring out the other 2

colours and make one horizontal line visible in

white.

7. Turn the SCREEN VR and bring one white

horizontal line faintly visible.

8. Press 2 key, turn off 1 CUT OFF screen.

9. Press the MENU key and memorize the set

value

Item

Adjustment of WHITE BALANCE(High Light)

Measuring instrument

Signal generator

Remote control unit

Adjustment part

2.DRIVE

(R) **

(B) **

Description

1. Receive a black and white signal (colour off).

2. Select 2.V/C from the SERVICE MENU.

3. Select 2.DRIVE with the FUNCTION UP/

DOWN key.

4. Change the screen colour to white with 4/7(R)

key or 6/9(B) key.

5. Press the MENU key, and memorize the

respective set value.

Item

Adjustment of SUB BRIGHT

Measuring instrument

Remote control unit

Adjustment Part

3.BRIGHT

Description

1. Receive any broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 3.BRIGHT with the FUNCTION UP/

DOWN key.

4. Set the initial setting value with the FUNCTION -/+ key.

5. If the brightness is not the best with the initial

set value, make fine adjustment until you get

the best brightness.

6. Press the MENU key and memorize the set

value.

Item

Adjustment of SUB CONT.

Measuring instrument

Remote control unit

Adjustment Part

4.CONT.

Description

1. Receive any broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 4.CONT with the FUNCTION UP

DOWN key.

4. Set the initial setting value with the FUNCTION - or + key.

5. If the contrast is not the best with the initial

set value, make fine adjustment until you get

the best contrast.

6. Press the MENU key and memorize the set

value.

Item

Adjustment of SUB COLOUR I

Measuring instrument

Remote control unit

Adjustment part

5.COLOUR

(PAL~NTSC)

Description

[Method of adjustment without using measuring

instrument]

Adjustment part

PAL COLOUR

(PAL COLOUR)

1. Receive any broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select SCOLOUR with the FUNCTION UP/

DOWN key.

4. Set the initial setting value for PAL COLOUR

with the FUNCTION - or + key.

5. If the contrast is not the best with the initial

set value, make fine adjustment until you get

the best contrast.

6. Press the MENU key and memorize the set

value.

Adjustment part

SECAM COLOUR

(AV-29TS2EN/AV-29TS2PF)

(SECAM COLOUR)

Description

1. Receive a SECAM broadcast. Make fine

adjustment of SECAM COLOUR in the same

manner as for above.

Adjustment part

NTSC COLOUR

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.58MHz COMPOSITE VIDEO

signal from the EXT terminal.

2. Make similar fine adjustment of NTSC 3.58

COLOUR in the same manner as for above.

Adjustment part

(NTSC 4.43 COLOUR)

1. When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

Measuring instrument

Signal generator

Oscilloscope

Remote control unit

Test point

TP-47B

TP-E( )

[CRT SOCKET PWB]

Adjustment part

5.COLOUR (PAL~NTSC)

Description

[Method of adjustment using measuring

instrument]

Item

Adjustment of SUB COLOUR II

Adjustment part

PAL COLOUR

(PAL COLOUR)

1. Receive a PAL full field colour bar signal

(75% white).

2. Select 2.V/C from the SERVICE MENU.

3. Select 7.COLOUR with the FUNCTION UP/

DOWN key.

4. Set the initial setting value for PAL COLOUR

with the FUNCTION - or + key.

5. Connect the oscilloscope between TP-47B

and TP-E( )

6. Adjust PAL COLOUR and bring the value of

(A) in the illustration to 0V (voltage difference

between white and blue).

7. Press the MENU key and memorize the

setting value.

Adjustment part

SECAM COLOUR

(AV-29T52EN/AV-29T52PF)

(SECAM COLOUR)

1. Receive a SECAM full field colour bar signal

75% white).

2. Set the initial setting value of SECAM

COLOUR with the FUNCTION -/+ key.

3. Adjust SECAM COLOUR and bring the value

of (A) of the illustration to +5V (W~B).

4. Press the MENU key and memorize the

setting value.

Adjustment part

NTSC 3.58 COLOUR

Description

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.58MHz COMPOSITE VIDEO

signal (full field colour bar with 75% white)

from the EXT terminal.

2. Set the initial setting value of NTSC 3.58

COLOUR with the FUNCTION -/+ key.

3. Adjust NTSC 3.58 COLOUR and bring the

value of (A) of the illustration to (0V (W~B

29”). (+5V (W~B 21”).

4. Press the MENU key and memorize the

setting value.

(NTSC 4.43 COLOUR)

1. When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

Item

Adjustment of SUB TINT I

Measuring Instrument

Remote control unit

Ajustment Part

6.TINT

Description

[Method of adjustment without using measuring

instrument]

Adjustment Part

NTSC 3.58 TINT

Description

[NTSC 3.58 TINT]

1. Input a NTSC 3.58MHz composite video

signal (full field colour bar with 75% white)

from the EXT terminal.

2. Select 2.V/C from the SERVICE MENU.

3. Select 6. TINT with the FUNCTION UP/

DOWN key.

4. Set the initial setting value of NTSC 3.85

TINT with the FUNCTION -/+ key.

5. If you cannot get the best tint with the initial

setting value, make fine adjustment until you

get the best tint.

6. Press the MENU key and memorize the set

value.

Description

[NTSC 4.43 TINT]

1. When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

Item

Adjustment of SUB TINT II

Measuring Instrument

Signal generator

Oscilloscope

Remote control unit

Test Point

TP-47B

TP-E( )

[CRT SOCKET PWB]

Adjustment part

6. TINT

Page 5

JVC AV-29TS2

Adjustments Cont’d

Description

[Method of adjustment using measuring

instrument]

Adjustment part

NTSC 3.58 TINT

Description

[NTSC 3.58 TINT]

1. Input a NTSC 3.58MHz composite video

signal (full field colour bar with 75% white)

from the EXT terminal.

2. Select 2.V/C from the SERVICE MENU.

3. Select 6.TINT with the FUNCTION UP/DOWN

key.

4. Set the initial setting value of NTSC 3.85

TINT with the FUNCTION - or + key.

5. Connect the oscilloscope between TP-47B

and TP-E( )

6. Adjust NTSC 3.58 TINT to bring the value of

(A) in the illustration to (+5V 29”) (+2V 21”)

(voltage difference between white and

magenta).

7. Press the MENU key and memorize the

setting value

[NTSC 4.43 TINT]

1. When NTSC 3.58 is set, NTSC 4.43 will be

automatically set at the respective values.

Item

Adjustment of BLACK OFFSET (SECAM) I

Item

Adjustment of BLACK OFFSET (SECAM) II

Measuring Instrument

Signal generator

Oscilloscope

Remote control unit

Test Point

35 PIN (R-Y)

36 PIN (B-Y)

IC-101 OF MAIN PWB

Adjustment part

7. BLACK OFFSET

(R-Y) ***

(B-Y) ***

Description

[Method of adjustment using measuring

instrument]

1. Receive a SECAM COLOUR bar signal (full

field colour bar 75% white).

2. Select 2. V/C from SERVICE MENU.

3. Select 7. BLACK OFFSET with the FUNCTION UP/DOWN key.

4. Connect the oscilloscope between 35 pin of

IC-101 and TP-E.

5. By using 4 and 7 keys of the remote control,

adjust the BLACK OFFSET (R-Y) so that it

becomes the waveform changes from (a) to

(b) shown in the figure.

6. Connect the oscilloscope between 36 pin of

IC-101 and TP-E.

7. By using 6 and 9 keys of the remote control,

adjust the BLACK OFFSET (B-Y) so that it

becomes the waveform changes from (c) to

(d) shown in the figure.

8. If the picture is not the best with the adjusted

picture, make fine adjustment until you get the

best picture.

9. Press the MENU key and memorize the

setting value.

Item

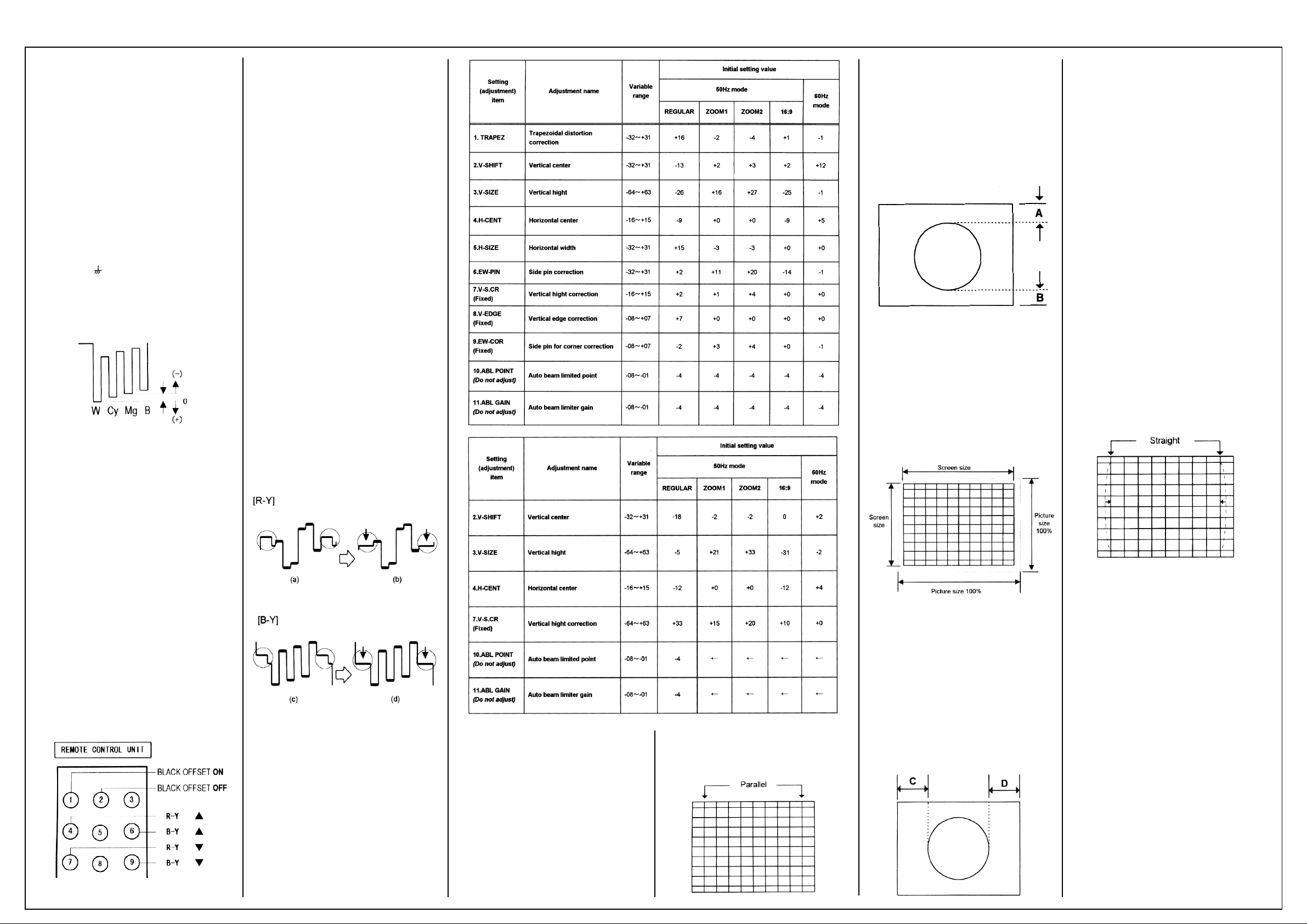

2. Adjustment of V-SHIFT

Adjustment Part

2.V-SHIFT

Description

6. Receive a circle pattern signal

7. Select 2.V-SHIFT and set the initial setting

value.

8. Adjust V-SHIFT to make A = B.

9. Press the MENU key and memorize the set

value.

Item

3. Adjustment of V-SIZE

Adjustment Part

3.V. SIZE

Description

10. Receive a cross-hatch signal.

11. Select 3.V-SIZE and set the initial setting

value.

12. Adjust V-SIZE and make sure that the

vertical screen size of the picture size is in the

bellow table.

13. Press the MENU key and memorize the set

value.

Item

5. Adjustment of H.SIZE

Adjustment Part

5.H-SIZE

Description

18. Receive a cross-hatch signal.

19. Select 5.H-SIZE and set the initial setting

value.

20. Adjust H-SIZE and make sure that the

horizontal screen size of the picture size is in

the bellow table.

21. Press the MENU key and memorize the set

value.

MODE

REGULAR ZOOM1 ZOOM2

MODEL

AV-29TS2EN 92% 85% 85%

AV-29TS2EK 92% 85% 85%

AV-29TS2PF 91% 85% 85%

Item

6. Adjustment of EW-PIN

Adjustment Part

6.EW-PIN

Description

22. Select 6.EW-PIN and set the initial setting

value

23. Adjust EW-PIN and make the I st.vertical

lines at the left and right edges of the screen

straight. Also make sure that the 2nd vertical

lines are also straight.

24. Press the MENU key and memorize the set

value.

Measuring Instrument

Remote control unit

Adjustment Part

7.BLACK OFFSET

(R-Y) ***

(B-Y) ***

Description

[Method of adjustment without measuring

instrument]

1. Receive a SECAM broadcast.

2. Select 2. V/C from SERVICE MENU.

3. Select 7. BLACK OFFSET with the FUNCTION UP/DOWN key.

4. Set the initial setting value for BLACK

OFFSET (R-Y) and (B-Y) with 4 and 7 or 6

and 9 keys of the remote control.

5. If the picture is not the best with the initial

setting value, make fine adjustment until you

get the best picture.

6. Press the MENU key and memorize the

setting value.

DEFLECTION CIRCUIT ADJUSTMENT

There are 5 modes of adjustment (1) 50Hz

mode ((1) REGULAR, (2) ZOOM1, (3) ZOOM2,

(4) 16:9) and (2) 60Hz mode (REGULAR) —

depending upon the kind of signals (VERTICAL

FREQUENCY 50Hz / 60Hz).

When the 50Hz REGULAR mode has been

established, the setting of other modes will be

done automatically. However, if the picture

quality has not been optimized, adjust each

mode again, respectively.

The setting (adjustment) using the REMOTE

CONTROL UNIT is made on the basis of the

initial setting values.

The setting values which adjust the screen to

the optimum condition can be different from the

initial set values.

Item

1. Adjustment of TRAPEZ

Measuring Instrument

Signal generator

Remote control unit

Adjustment Part

1.TRAPEZ

Description

[50Hz REGULAR mode]

1 Receive a cross-hatch signal of vertical

frequency 50Hz.

2. Select 4.DEF from the SERVICE MENU.

3. Select 1 .TRAPEZ with the FUNCTION UP/

DOWN key.

4. Set the initial setting value of TRAPEZ with

the FUNCTION - or + key.

5. Adjust TRAPEZ and bring the VERTICAL

lines at the right and left edges of the screen

parallel.

REGULAR ZOOM1 ZOOM2

92% 80% 74%

Item

4. Adjustment of H.CENTER

Adjustment Part

4.H-CENT.

Description

14. Receive a circle pattern signal.

15. Select 4. H-CENT and set the initial setting

value.

16. Adjust H-CENT to make C=D.

17. Press the MENU key and memorize the set

value.

Item

7. Adjustment of V-SCR

Adjustment Part

7.V-S.CR

Description

25. Select 7.V-S.CR and set the initial setting

value.

26. Adjust V-S.CR and make the gaps between

the horizontal lines uniform.

27. Press the MENU key and memorize the set

value.

* No alignment, but adjust this mode if result of

no alignment is too bad.

Item

8. Adjustment of V-EDGE

Adjustment Part

8. Y-EDGE

Description

28. Select 8.V-EDGE and set the initial setting

value.

29. Adjust V-EDGE and make the gaps between

the horizontal lines uniform.

30. Press the MENU key and memorize the set

value.

* No alignment, but adjust this mode if result of

no alignment is too bad.

Item

9. Adjustment of EW-COR

Page 6

JVC AV-29TS2

Adjustments Cont’d

Adjustment Part

9. EW-COR

Description

31. Select 9.EW-COR and set the initial setting

value.

32. Adjust EW-COR and make the vertical lines

at the four corners of the screen straight.

33. Press the MENU key and memorize the set

value.

* No alignment, but adjust this mode if result of

no alignment is too bad.

34. Make sure that the adjustment is properly

done on the screen of other mode.

AUDIO CIRCUIT

Do not touch 3.AUDIO(1. CONC LIMIT, 2. A2 ID

THR) of the SERVICE MENU as it requires no

adjustment.

3. AUDIO

Setting item Variable range fixed value

1. CONC LIMIT 00H~FFH 0AH

(Do not adjust)

2. A2 ID THR 00H~FFH 19H

(Do not adjust)

Remote Control

Diagram

This area is intentionally left blank.

Page 7

JVC AV-29TS2

CRT Diagram

Page 8

JVC AV-29TS2

Front Control Diagram (21”)

Page 9

JVC AV-29TS2

Front Control Diagram (29”)

Page 10

JVC AV-29TS2

IF Diagram (EN & EK) Diagram

Page 11

JVC AV-29TS2

IF Diagram (PF) Diagram

Page 12

JVC AV-29TS2

AV Selector & Multi Sound Processor Diagram

Page 13

JVC AV-29TS2

Microprocessor / Text Diagram

Page 14

JVC AV-29TS2

Power Deflection Diagram (21”)

Page 15

JVC AV-29TS2

Power Deflection Diagram (29”)

Loading...

Loading...