Page 1

A

SERVICE MANUAL

COLOUR TELEVISION

AV-29RS

V-29RS

BASIC CHASSIS

JK

CONTENTS

SPECIFICATIONS

!

★

OPERATING INSTRUCTIONS (APPENDIX)

SAFETY PRECAUTIONS

!

FEATURES

!

FUNCTIONS

!

SPECIFIC SERVICE INSTRUCTIONS

!

SERVICE ADJUSTMENTS

!

★

STANDARD CIRCUIT DIAGRAM (APPENDIX)

PARTS LIST

!

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・

・・・・・・

・・

・・・・

2

1-1

3

4

5

6

12

2-1

33

No.51730

Jul. 2000

Page 2

A

V-29RS

(

)

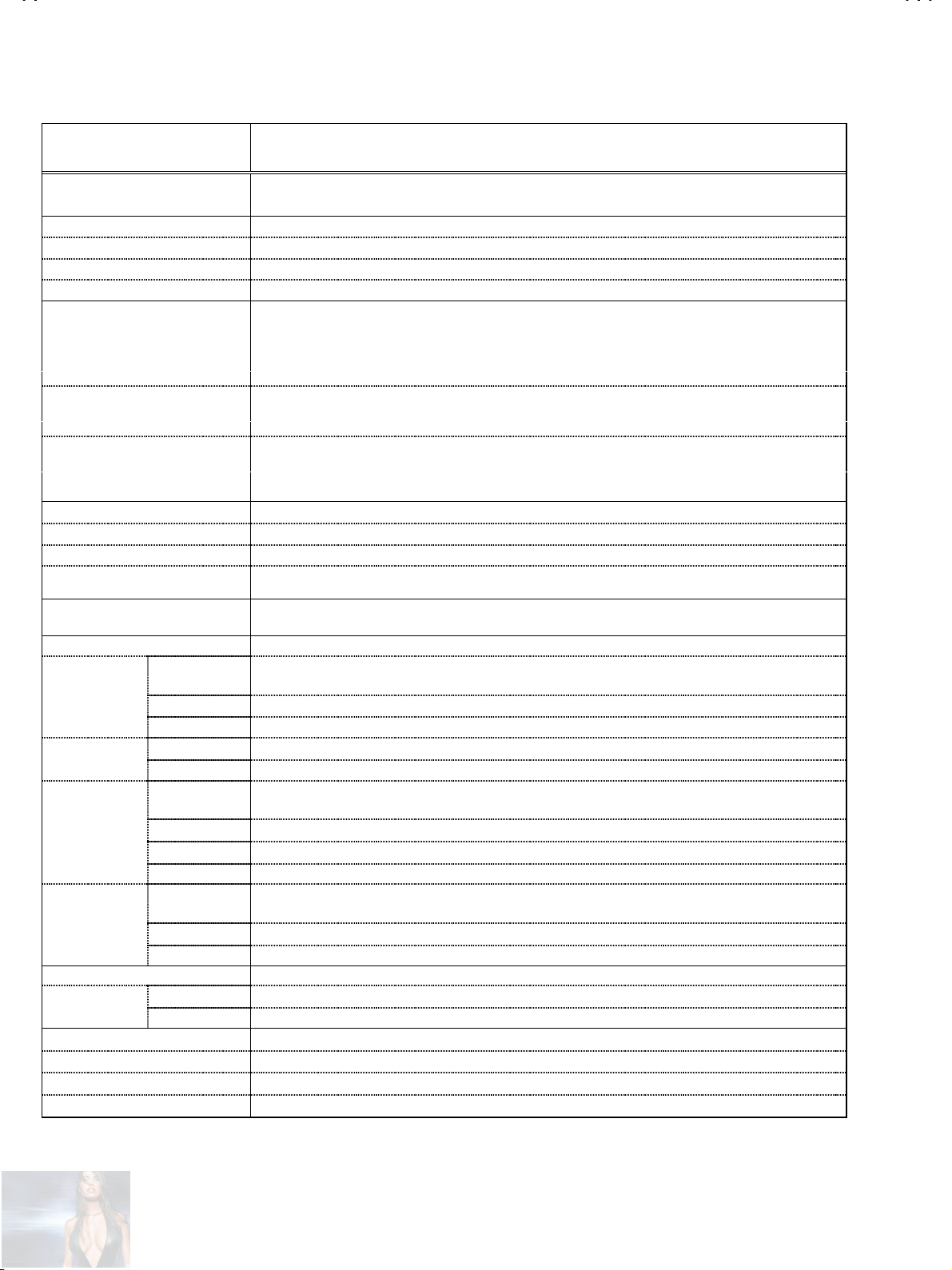

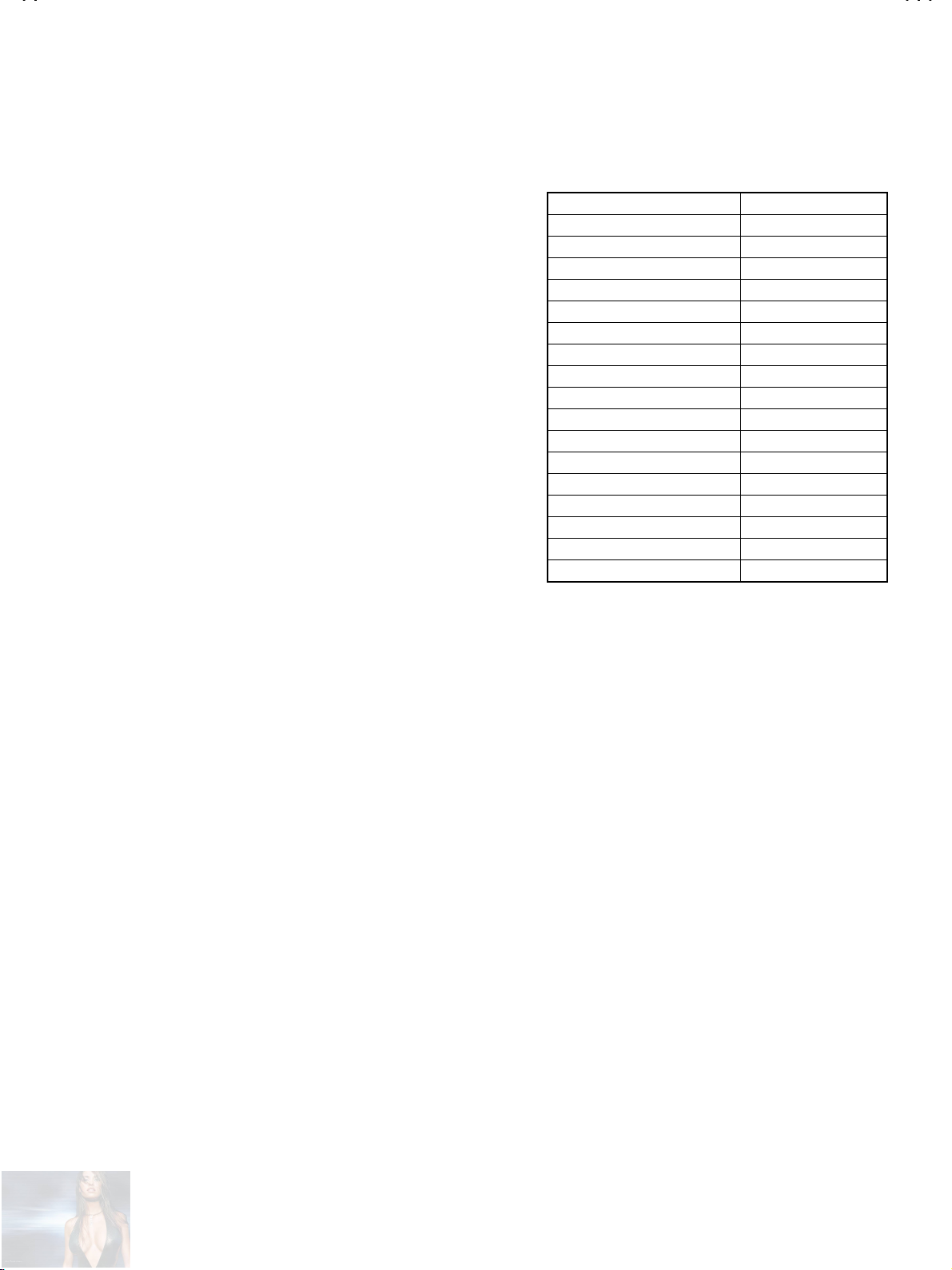

SPECIFICATIONS

Item CONTENTS

Dimensions ( W

Mass

TV RF System

Colour System

Stereo System

Teletext System

××××H××××

D )

887mm×719mm×620mm

50.0kg

B, G, I, D, K, K1, M

PAL, SECAM, NTSC3.58, NTSC4.43

A2 / NICAM (B/G, I, D/K) system

FLOF (Fastext), WST (World standard system)

Receiving Frequency

VHF(L)

VHF (H)

UHF

CATV

46.25MHz~168.25MHz

175.25MHz~463.25MHz

471.25MHz ~ 863.25MHz

Mid(X-Z, S1-S10), Super(S11-S20), Hyper(S21-S41) bands receivable

Intermediate Frequency

VIF Carrier

SIF Carrier

38.0MHz

33.5M Hz(4.5MHz), 32.5MHz(5.5MHz), 32.0MHz (6.0MHz ), 31.5M Hz(6.5M Hz)

Colour Sub Carrier Frequency

PAL

SECAM

NTSC

Power Input

Power Consumption

Picture Tube

High Voltage

Speaker & Audio Output

4.43MHz

4.40625MHz, 4.25MHz

3.58MHz / 4.43MHz

AC 110V~240V , 50/60Hz

193W ( Max) / 137W( Avg)

Visible size : 68cm measured diagonally

32.0kV±1.5kV (at zero beam current)

Open dome speaker

10W+10W, 10cm round×2

Video Audio Input ter min al s

Video1

Video2

Video3

Video4

Front terminal

S-Video

Video

Audio(L/R)

Video

Audio(L/R)

Video/Y

Cb

Cr

Audio(L/R)

S-Video

Video

Audio(L/R)

Y : 1V

C : 0.286V

1V

positive (Negative sync provided, when terminated with 75Ω)

(p-p)

(Burst signal, when terminated with 75Ω)

(p-p)

75Ω(RCA pin jack)

(p-p)

500mV(rms) (-4dBs), High impedance (RCA pin jack)

1V

75Ω(RCA pin jack)

(p-p)

500mV(rms) (-4dBs), High Impedance (RCA pin jack)

V : Composite video 1V

Y : Compon ent vid eo 1V

75Ω(RCA pin j ac k)

(p-p)

(p-p)

Compon ent video B- Y 0. 7V

Compon ent video R- Y 0.7 V

500mV(rms) (-4dBs), High Impedance (RCA pin jack)

Y : 1V

C : 0.286V

1V

positive (Negative sync provided, when terminated with 75Ω)

(p-p)

(Burst signal, when terminated with 75Ω)

(p-p)

75Ω(RCA pin jack)

(p-p)

500mV(rms) (-4dBs), High impedance (RCA pin jack)

Video Audio Output term in al

75Ω(RCA pin jack)

1V

Video

Audio(L/R)

Aerial Input Term

Headphone jack

AV Compu Link terminal

Remote Control Unit

(p-p)

500mV(rms) (-4dBs), High Impedance (RCA pin jack)

75Ωunbalanced, Coaxial

Stereo mini jack (φ3.5mm )

AV Compu LinkⅡ, mini jack (φ3.5mm )

RM-C112 (AAA/R03 dry battery×2)

Design & specifications are subject to change without notice.

75Ω(RCA pin j ac k)

75Ω(RCA pin jack)

(p-p)

75Ω(RCA pin jack)

(p-p)

2

No.51730

Page 3

A

SAFETY PRECAUTIONS

V-29RS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manuf act urer's warr an t y and wil l fur t h er reli ev e the manufacturer

of responsi bility f or person al injury or pr operty dam age res ulting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident f rom visual i nspection nor can t he protect ion

afford ed by them n ecess arily be obt ained by using rep lacem ent

compon ents rated f or higher voltag e, watt ag e, etc. R epl acem ent

parts which have these special safety characteristics are

identified in the parts list of Service manual.

compon ents hav in g su ch feat ures are id entif ied by s hadin g

on the sche matics and by (

The us e of a subst itute replacement w hich does not

manual.

have the same safety characteristics as the recommended

replac ement part shown i n the p arts list of S ervic e manu al may

cause shock, fire, or other hazards.

) on the parts list in Service

!!!!

Electrical

4.

Don't short b etween the LIV E side groun d and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

difference of the GND is show n b y th e LIVE : (") side GND, the

ISOLATED(NEUTRAL ) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuri ng apparatus (osc illoscope etc .)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above not e wi ll n ot be kept, a fus e or an y part s will be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The hig h voltage app lied t o the picture t ube must c onform wit h

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltag e conditions s hould b e kept to a mi nimum, or sh ould be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect install ation, cracked or melted high voltag e harness,

poor solderi ng, etc.). To maintain the pr oper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting

a clip l ead to th e g roun d fr am e and c on necti ng t h e oth er end of

the lead through a 10k! 2W resistor t o the an ode button.

8. W hen servic e is requir ed, obser ve the origin al lead dress . Extr a

precaut ion shou ld be gi ven to assure c orrect l ead dr ess in t he

high voltage circuit area. Where a short circuit has occurred,

those comp onents that in dicat e evidenc e of over heating should

be replaced. Always use the manufacturer's replacement

components.

9.

Isolation Check

(Saf ety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

termin als , vid eo/ au dio input an d output term in als , C on trol knobs,

metal cabinet, screw"heads, ear phone jac k, control shafts, etc.)

to be sure the product is safe to operate without danger of

electrical shock.

(1)

Dielectric Stren gth Test

The isol ation b etween th e AC pr imar y circuit and all metal parts

expos ed t o th e user, p ar tic u larly any expo sed metal part h avi ng a

return p ath to the chassis should withst and a voltage of 3000V

AC (r.m.s .) for a period of one secon d.

(. . . . W ithstand a voltag e of 1100 V AC ( r.m.s.) to an applianc e

rated up t o 120V, and 3000 V AC (r. m.s.) t o an appl iance r ated

200V or mor e, f or a peri od of on e s ec on d.)

This method of test requires a test equipment not generally found

in the service trade.

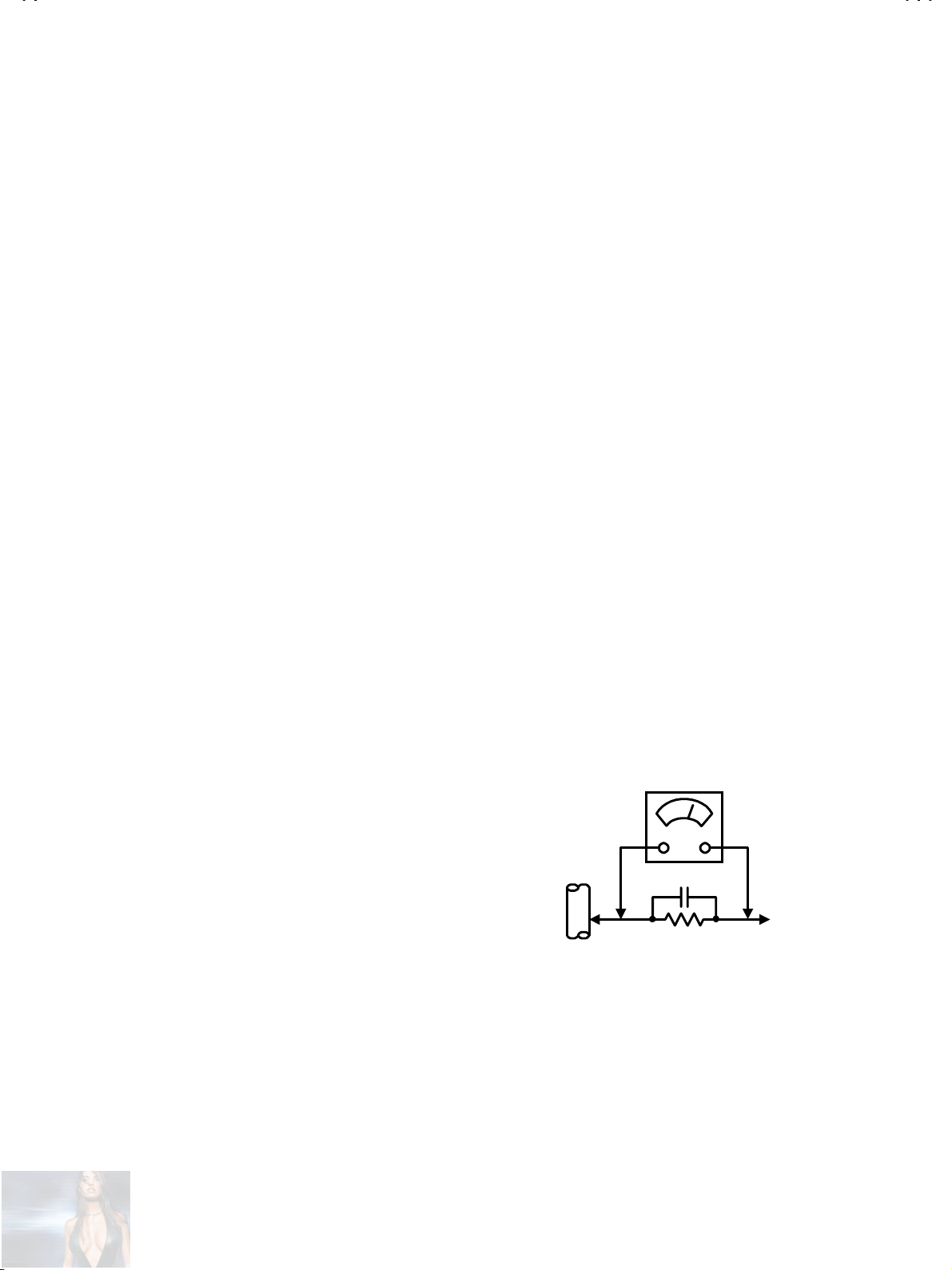

(2)

Leak age Current Check

Plug the AC lin e c or d dir ec t l y int o t he AC outlet ( d o not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground ( water pipe, etc. ). An y leak age c urr ent mus t not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

""""

Plug the AC lin e c or d dir ec t l y int o t he AC outlet ( d o not use a line

isolati on transform er during t his check. ). Use an AC voltmet er

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1 500! 10W resistor paralleled by a 0.15#F

AC-typ e capacitor betw een an expos ed metal part and a know n

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connect ion t o each exp os ed met al p art, part icul arl y any exp osed

metal part h avin g a return p ath to th e chassis , and meas ure th e

AC voltag e across the res istor. N ow, re vers e the plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However , i n t ropical area, this must n ot exceed 0.3 V AC (r.m.s. ).

This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500

GOOD EARTH GROUND

!

AC VOLTMETER

(HAVING 1000

OR MORE SENSITIVITY)

10W

!

/V,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

No.51730

3

Page 4

A

V-29RS

FEATURES

By preference, us ers can selec t the picture siz e from REG ULA R,

"

ZOOM, 16:9 modes.

The TELETEXT SYSTEM has a built-in FASTEXT and WST

"

system.

B ecause this TV uni t corresp onds t o multipl ex broadc ast, us ers

"

can enjo y music pr ograms an d spor ting ev ents wit h live real ism.

In additi on, BILINGUAL programs c an be heard in their original

language.

Users c an m ake fun to c onnect th e Dig ital V ideo D isk p layer b y

"

using the component video signal input terminal.

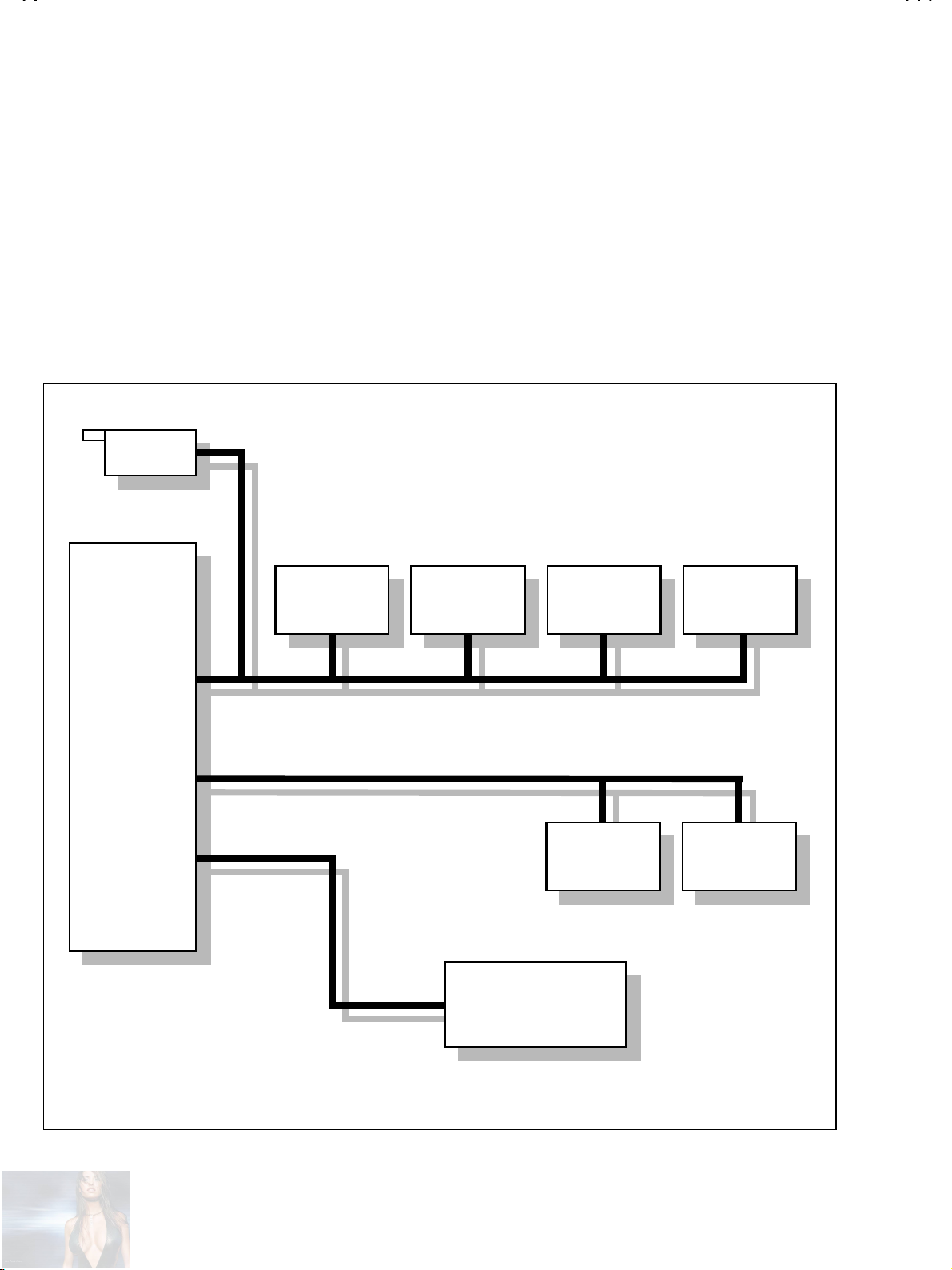

I2C BUS CONTROL SYSTEM CHART

TU1001

TU1001

TUNER

TUNER

IC1301

IC1301

VIDEO

VIDEO

CHROMA

CHROMA

Built-in ECO (ECONOMY, ECOLOGY) MODE.

"

In accordance with the brightness in a room, the brightness

and/or contrast of the picture can be adjusted automatically to

make th e opti mu m picture wh ic h is eas y on the eye.

2

C Bus controls the many ICs which have various functions each

I

"

other.

IC1501

IC1501

DEF CTRL

DEF CTRL

IC1201

IC1201

SRT

SRT

IC8801

IC8801

LED CTRL

LED CTRL

IC1701

IC1701

MICRO

MICRO

COMPUTER

COMPUTER

SCL3 / SDA3

SCL1 / SDA1

SCL2 / SDA2

MEMORY

IC1702

IC1702

MEMORY

IC301 [0S]

IC301 [0S]

DIGI COMB

DIGI COMB

IC101 [0S]

IC101 [0S]

AV SW

AV SW

4

No.51730

Page 5

A

FUNCTIONS

V-29RS

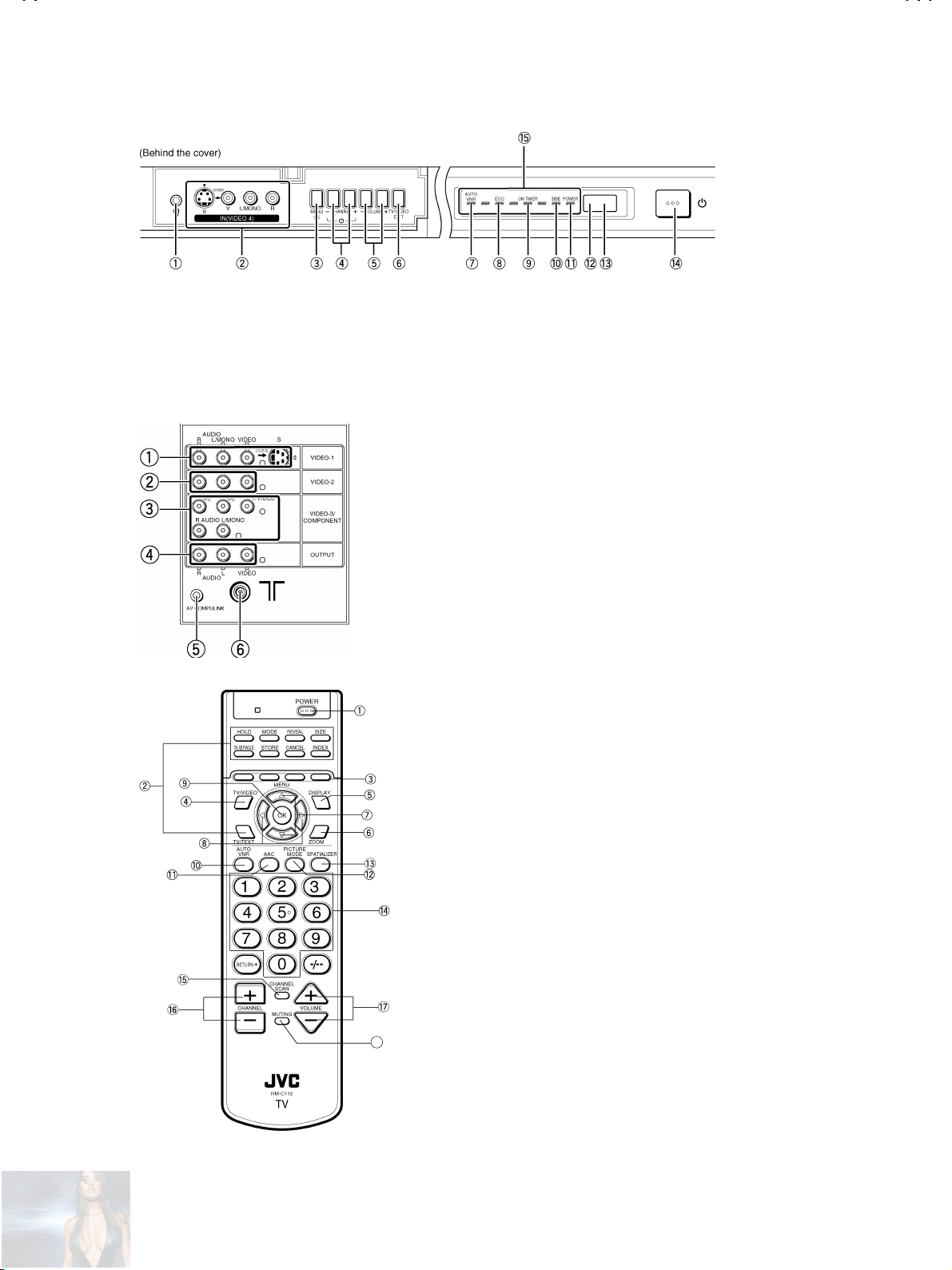

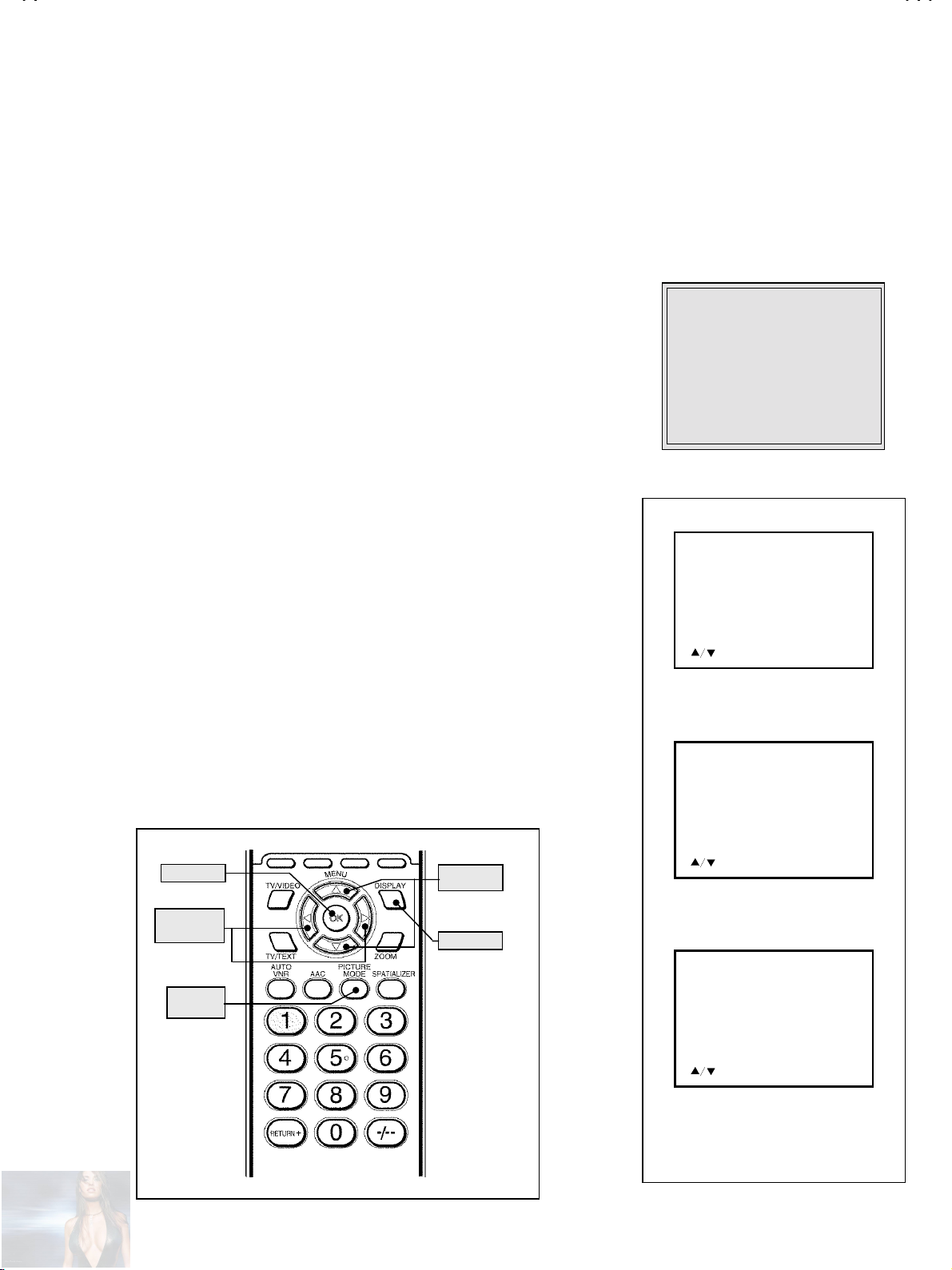

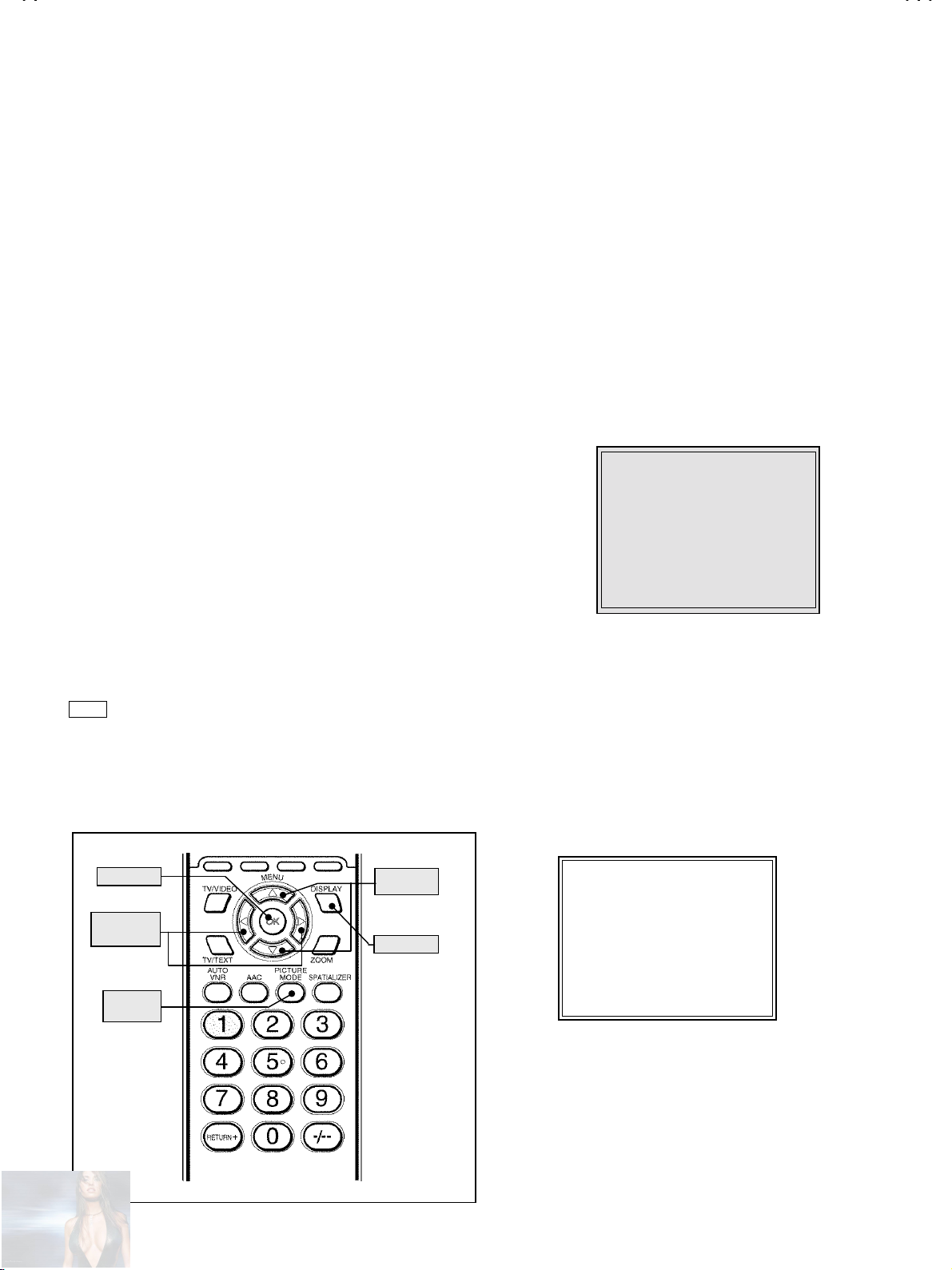

Headphone jack

①

Video-4 terminal

②

OK

③

Channel -/+ (MENUUP/DOW N)

④

Volume -/+ (MENULEFT/RIGHT)

⑤

TV/VIDEO

⑥

AUTO VNR

⑦

ECO

⑧

ON TIMER

⑨

BBE

⑩

Video-1 terminal (S,V,L,R)

①

Video-2 terminal (V,L,R)

②

Video-3 terminal (V/Y,Cb,Cr,L,R)

③

Output terminal (V,L,R)

④

AV COMPULINK terminal

⑤

Aerial socket

⑥

POWER

①

TELETEXT

②

COLOUR

③

TV/VIDEO

④

DISPLAY

⑤

ZOOM

⑥

MENU UP/DOWN

⑦

MENU LEFT/RIGHT

⑧

OK

⑨

AUTO VNR

⑩

AAC

⑪

PICTURE MODE

⑫

SPATIALIZER

⑬

CHANNEL

⑭

CHANNEL SCAN

⑮

CHANNEL +/-

⑯

VOLUME +/-

⑰

MUTING

18

⑱

POWER

⑪

ECO sensor

⑫

Remote control sensor

⑬

Main POWER SW

⑭

Dancing LED

⑮

No.51730

5

Page 6

A

V-29RS

SPECIFIC SERVICE INSTRUCTIONS

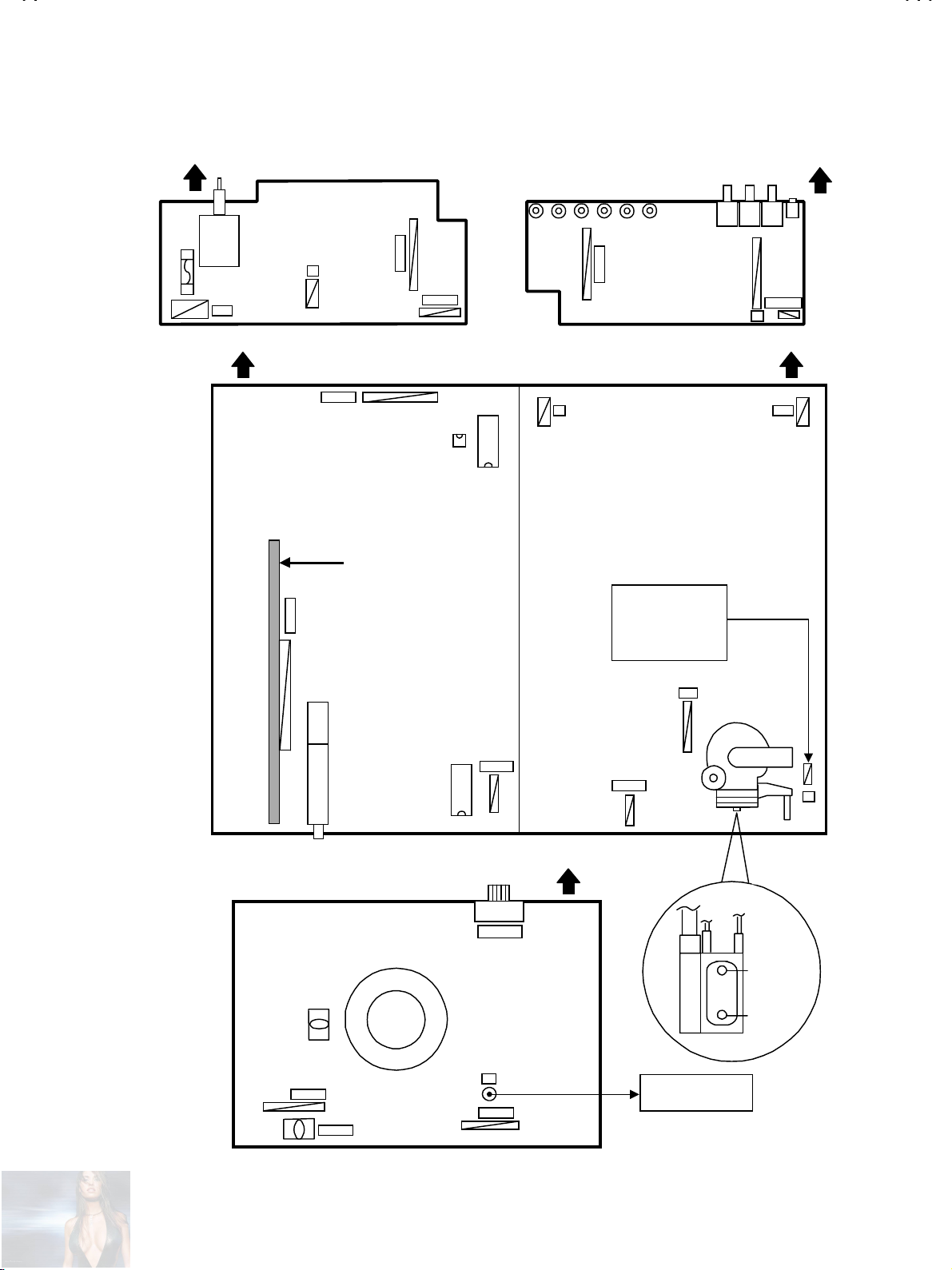

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Disconnect the power plug from wall outlet.

2. As shown in the Fig.2, remove the

3. Withdraw the rear cover toward you.

screws marke d

16

AAAA

.

CHECKING THE PW BOARD

To check the PW Board from back side.

1. Pull out the chassis (refer to REMOVING THE CHASSIS).

2. Erect the ch assis ver tic all y s o that you c an easi ly c hec k th e bac k

side of the PW Board.

REMOVING THE CHASSIS

After remo ving the rear cover.

"

1. Slightly raise the both sides of the chassis by hand and remove the

two claws under the both sides of the chassis from the front

cabinet.

2. Withdraw the chassis backward.

(If necessary, take off the wire clamp , connectors etc.)

REMOVING THE AV TERMINAL BOARD

After remo ving the rear cover.

"

1. As shown in Fig.2, remove the

2. Then remove the AV TERMINAL BOARD.

screws marke d

5

BBBB

.

REMOVING THE SPEAKER BOX

After remo ving the rear cover.

"

1. As s hown in Fig. 2, removi ng the

remove the speaker box.

2. Follow the same steps when removing the other hand speaker

box.

When removing the screws marked

NOTE :

remove the lower s ide screw f irst, and th en remove the

upper one.

screws marked

2

of the speaker box,

CCCC

CCCC

then

,

CAUTION

When erecting the chassis, be careful so that there will be no

"

co n tacting w ith oth e r PW Bo ard.

Before turning on power, make sure that the wire connector is

"

properly connected.

When conducting a check with power supplied, be sure to

"

confirm that the CRT EARTH WIRE (BRAIDED ASS

connected to the CRT SOCKET PW board.

’’’’

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it b e inadvertently remov ed, be sure t o tie the wires wit h a

new cable tie.

Y) is

REMOVING THE CONTROL BASE

After removing the cha ssis.

"

1. As shown in Fig.1, while pushing down the claws marked

remove the CONTROL BASE in the arrow direction

6

FFFF

.

,

EEEE

No.51730

FFFF

CONTROL BASE

EEEE

CLAW

CHASSIS

Fig. 1

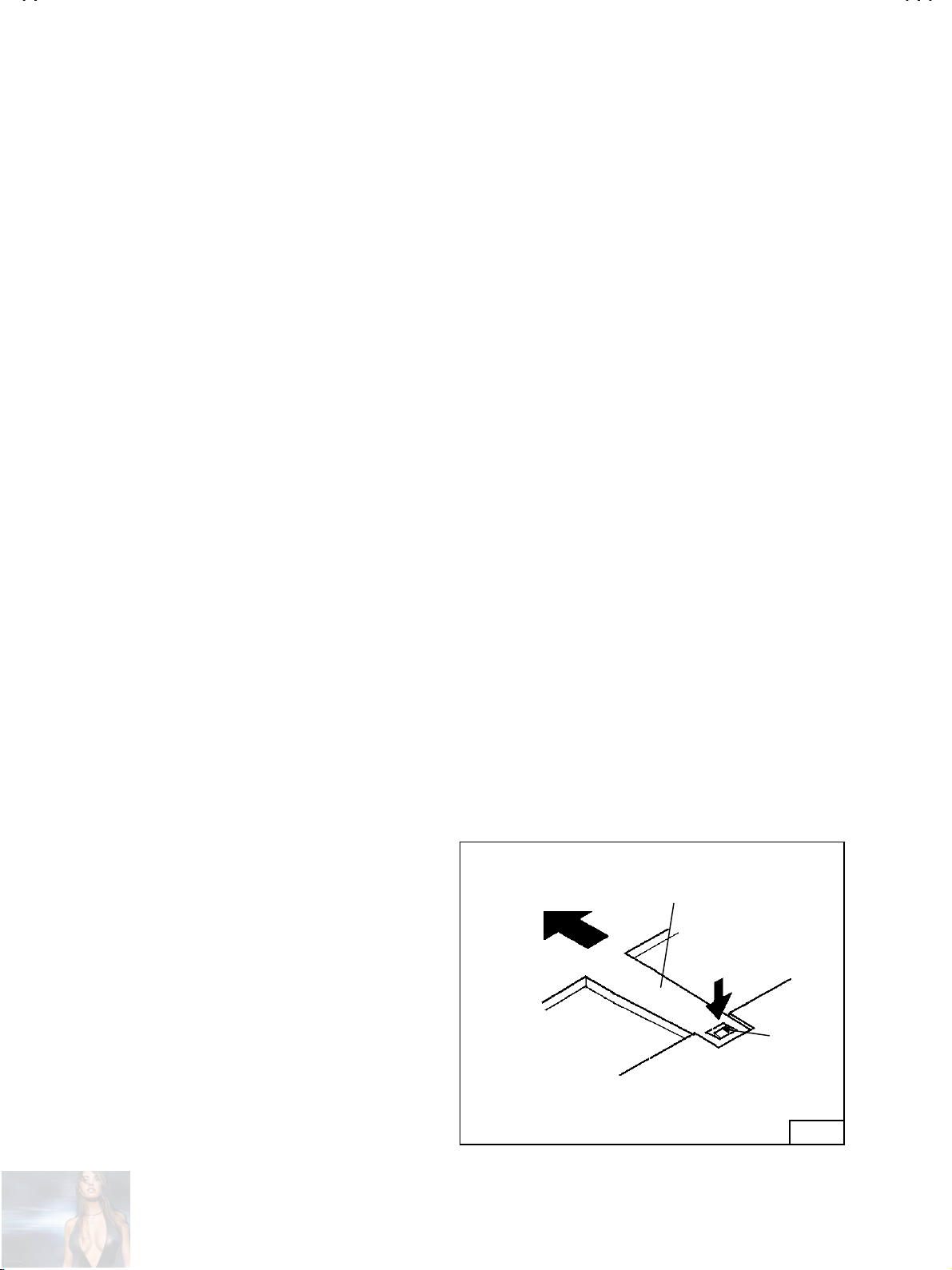

Page 7

A

FRONT CABINET

(

)

CRT

FRONT CONTROL

PWB

2/2

V-29RS

CCCC

SPEAKER BOX

POWER

DEF P WB

CRT SOCKET PWB

FRONT CONTROL

PWB(1/2)

SPEAKER BOX

CCCC

CLAW

HVT

CHASSIS

BASE

Fig.1

CLAW

MAIN PWB

AV SEL. PWB

BBBB

AV TERMINAL

BOARD

POWER CORD

REAR COVER

AAAA

Fig.2

No.51730

7

Page 8

A

V-29RS

A

A

A

A

A

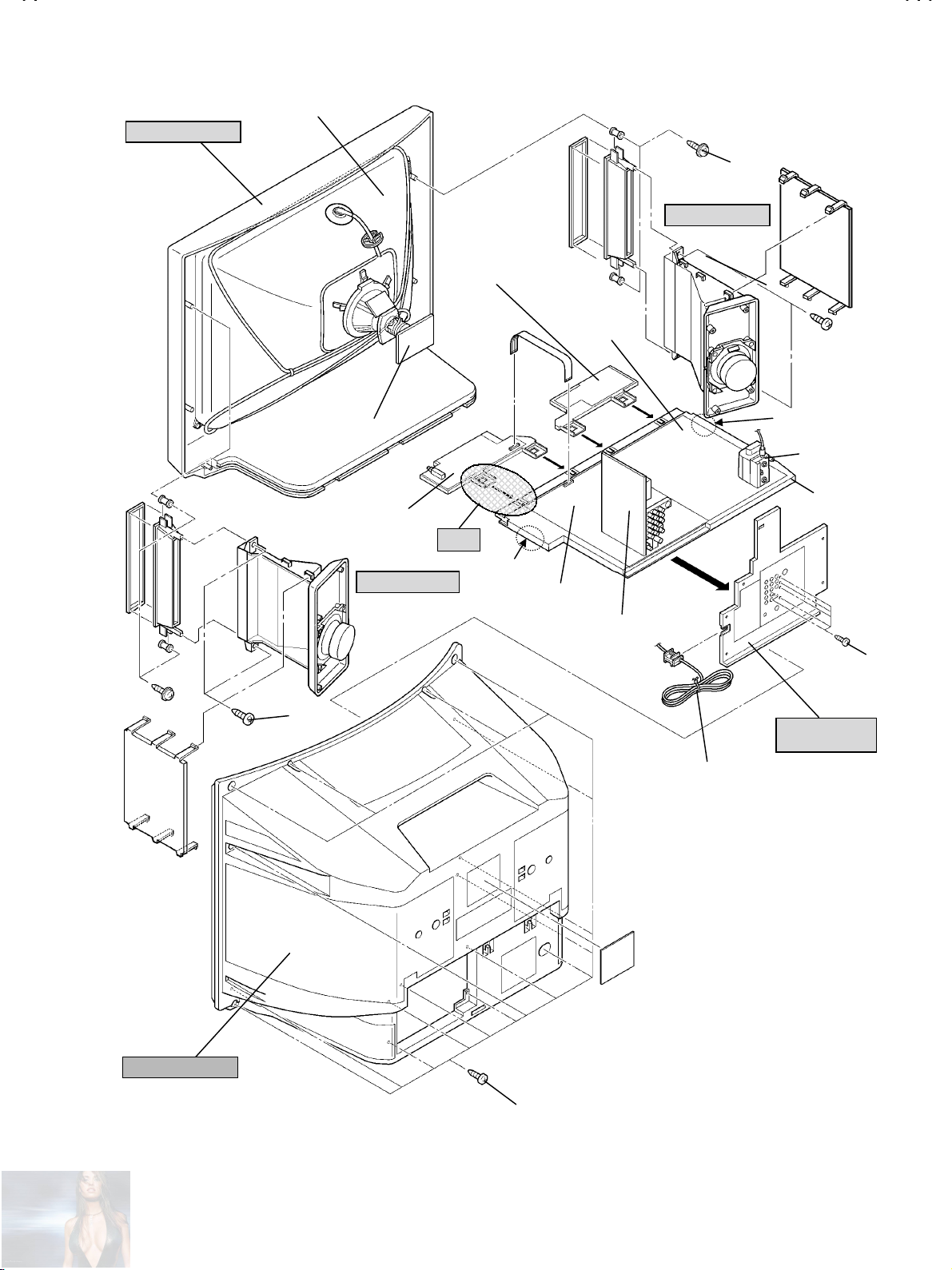

REMOVING THE CRT

Replacement of the CRT should be performed by 2 or more

"

persons.

After removing the cover, chassis etc.,

"

1. Putting the CRT change table on soft cloth, the CRT change table

should also be covered with such soft cloth (shown in Fig.3).

2. While keeping the surface of CRT down, mount the TV set on the

CRT change table balanced will as shown in Fig.3.

3. Remo ve 4 sc r ews m ark ed by arr ows w ith a box type sc rew driver

as shown in Fig.4.

Sinc e the cabin et wi ll dr op wh en sc r ews h ave b een r em oved , b e

"

sure to support the cabinet with hands.

4. After 4 sc rews have been r emoved, p ut the cabin et slowly on

cloth (At this time, be carefully so as not to damage the front

surface of the cabinet) shown in Fig.5.

The CRT should be assembled according to the opposite

"

sequence of its dism oun ting steps.

The CRT c h ang e table s h oul d prefer ab l y b e s m aller th at th e C R T

"

surfac e, and its height b e about 35cm.

CRT CHANGE TABLE

PPROX.

35cm

CLOTH

Fig. 3

CRT

CRT

CHANGE

TABLE

BOX

TYPE

SCREW

DRIVER

COATING OF SILICON GREASE FOR ELECTRICAL

INSULATION ON THE CRT ANODE CAP SECTION.

Subseq uent to r eplacem ent of th e CRT and HV tr ansf ormer or

repair of the anode cap, etc. by dismounting them, be sure t o

coat silicon grease for electrical insul ati on as sh ow n in Fig.6.

Wipe around the anode button with clean and dry cloth. (Fig.6)

Coat silic on greas e on the secti on around th e anode butt on. At

this tim e, t ake c are s o th at any s ilic on gr eases dos e n ot stic k t o

the anode button. (Fig.7)

Silicon grease product No. KS - 650N

CRT

node button

Silicon gr ease

coating

CABINET

pprox.

20mm (Do not

coat grease on

this section

node button

(No sticking of

silicon grease)

Fig. 4

CRT

CRT

CHANGE TABLE

Fig. 5

Silicon gr ease

should b e c oat ed

by 5mm or more

from the outside

diamet er of

anode cap.

Coating position

of silicon grease

node cap

Fig. 6 Fig. 7

8

No. 51730

Page 9

A

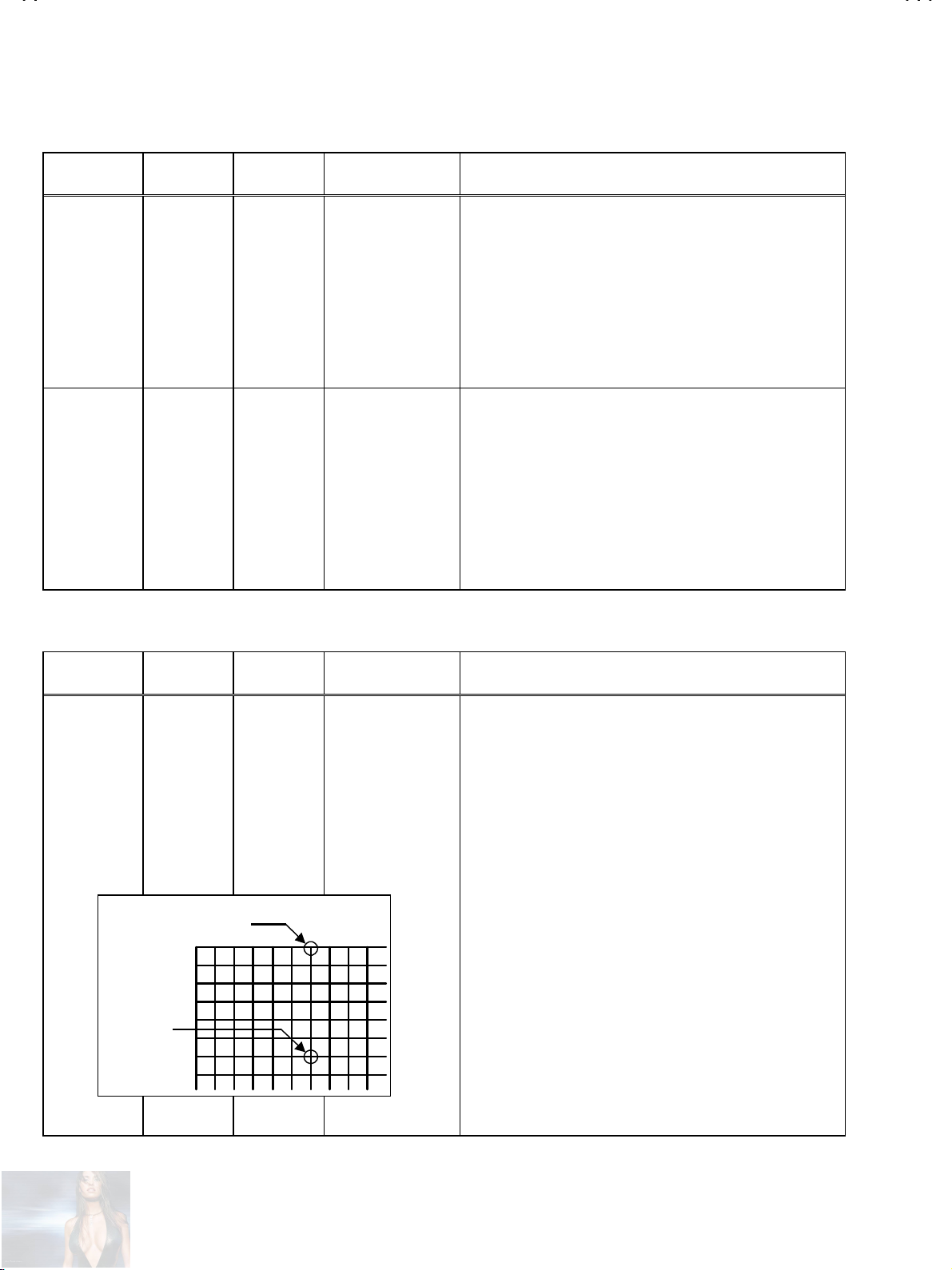

REPLACEMENT OF MEMORY ICs

UP/DO

1. Memory ICs

This model uses memory ICs. This memory IC data are for proper

operation of the video and deflection circuits. When replacing, be sure to

use ICs written with the initial values of data.

2. Procedure for replacing memory ICs

(1)

Power off

Switch off th e pow er an d dis connect the power plug from the wall out let .

V-29RS

(2)

Replace the memory IC

Be sure to u se memo ry ICs written with the i nitial data values.

(3)

Power on

Connect the power plu g int o the wall outl et an d s wi tc h power on.

(4)

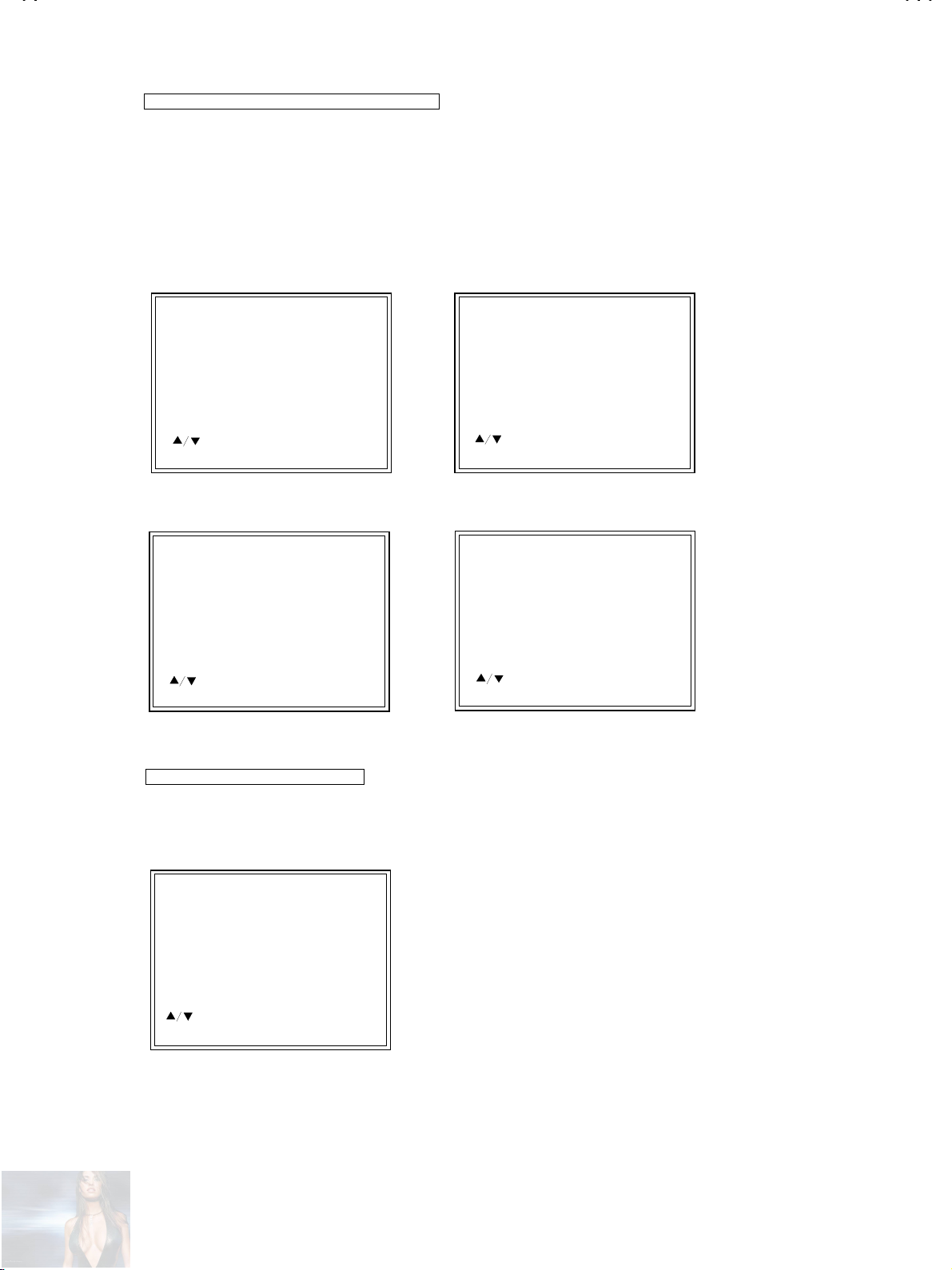

Check and set SYSTEM CONSTANT SET

It must not adjust without signal.

1) Press the

DISPLAY

key and the

PICTURE MODE

key of the REMOTE

CONTROL UNIT simultaneously.

2) T he SERVICE MENU screen of Fig . 1 will be display ed.

3) While the S ERVICE MENU is displ ayed, again press the

PICTURE MODE

key simultaneously, and the SYSTEM CONSTANT SET

DISPLAY

screen of Fi g. 2 will be displa yed .

4) Ch eck the setting val u es of th e SYSTE M CO NSTAN T SE T of Table 1 i n p age

later. If th e value is dif ferent, select the setting it em with th e

key, and set the correct value with the

MENU LEFT/RIGHT

MENU UP/DOWN

key.

5) Press the OK key to memorize the setting value.

6) Press the

(5)

Receive channel s ett in g

DISPLAY

key twice, and return to the normal screen.

Refer to the OPERATING INSTRUCTIONS, and set the receive channels as

described.

(6)

User setti n gs

Check the user setting items according to Table 2. Where these do not agree, refer

to the OPERATING INSTRUCTIONS.

(7)

SERVICE MENU setting

Verif y what to s ee in th e SERVICE MEN U, an d s et wh at e ver in nec es sary.

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

key and

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. WB PRESET

7. AUTO PROGRAM (OFF)

1-7 : SELECT DISP : EXIT

M

*******-**** V*.**P

JVC JK BASIC V

**

Fig.1

SYSTEM CONSTANT SET 1/3

COLOUR : MULTI

MSP : YES

SUPER BASS : NO

CENTER SPEAKER : NO

TEXT : YES

:SEL -/+:OPE DISP:EXIT

SYSTEM CONSTANT(1/3)

SYSTEM CONSTANT SET 2/3

BLUE BACK MUTE : NO

VOLUME LIMIT : YES

COLOUR AUTO : NO

TILT : YES

C-TRAP : 1

OK

MENU

LEFT/RIGHT

PICTURE

MODE

MENU

WN

DISPLAY

No. 51730

:SEL -/+:OPE DISP:EXIT

SYSTEM CONSTANT(2/3)

SYSTEM CONSTANT SET 3/3

E.M.C : NO

N/S WHITE BACK : NO

7 LED SPEED : 100

:SEL -/+:OPE DISP:EXIT

SYSTEM CONSTANT(3/3)

Fig.2

9

Page 10

A

V-29RS

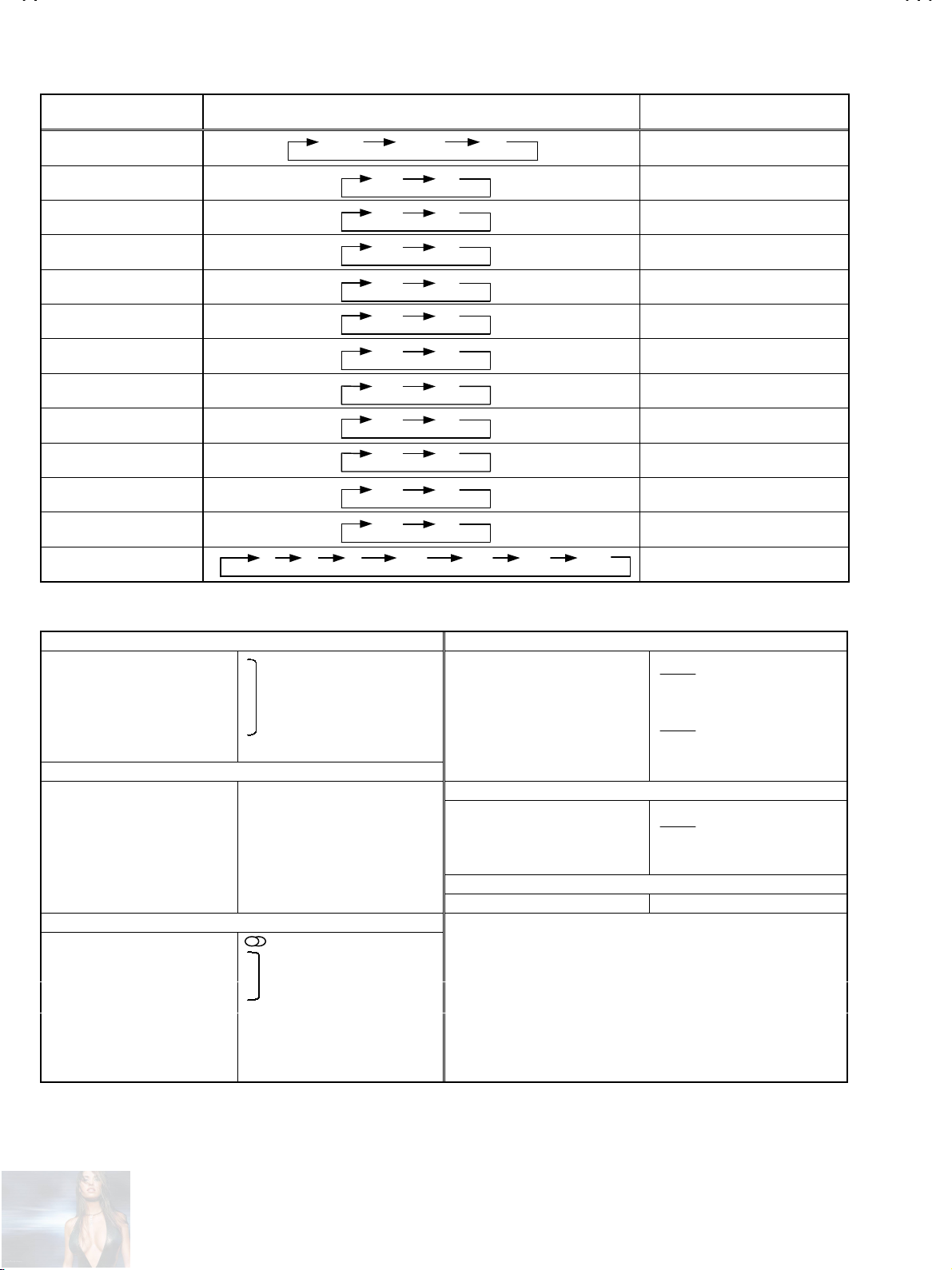

INITIAL SETTING VALUES OF SYSTEM CONSTANT SET (TABLE 1)

CONTENTS VARIABL E RANGE INI TIAL SETTING VALUE

COLOUR

MSP

SUPER BASS

CENTER SPEAKER

TEXT

BLUE BACK MUTE

VOLUME L IMIT

COLOUR AUTO

TILT

C-TRAP

E.M.C

N/S WHITE BACK

7 LED SPEED

MULTI TRIPLE PAL

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

1 0

YES NO

YES NO

00 10 20 1250 1260 1270

……

MULTI

YES

NO

NO

YES

NO

YES

NO

YES

1

NO

NO

100

USER SETTING CONDITIONS (TABLE2)

PICTUIRE SETTING FEATURES

CONTRAST

BRIGHT

SHARP

COLOUR

TINT

WHITE BALANCE

A.A.C

AUTO VNR

COLOUR SYSTEM

ZOOM

ECO SENSER

PICTURE TILT

STEREO /

BASS

TREBLE

BALANCE

AI VOLUME

BBE

SPATIALIZER

Ⅰ・Ⅱ

PICTURE FEATURES

SOUND SETTING

CENTER

COOL

ON

AUTO

TV : According to preset CH

VIDEO : AUTO

REGULAR

ACTIVE

CENTER

CENTER

ON

ON

ON

SLEEP TIMER

ON TIMER

BLUE BACK

CHILD LOCK

CHANNEL GUARD

AUTO SHUT OFF

VIDEO-3 SETTING

LANGUAGE

AUTO PROGRAM

EDIT / MANUAL

DEMO OFF

OFF

ON

OFF

OFF

VIDEO

INSTALL

ENGLISH

PRESET CH only

Others : blank

DEMO

10

No. 51730

Page 11

A

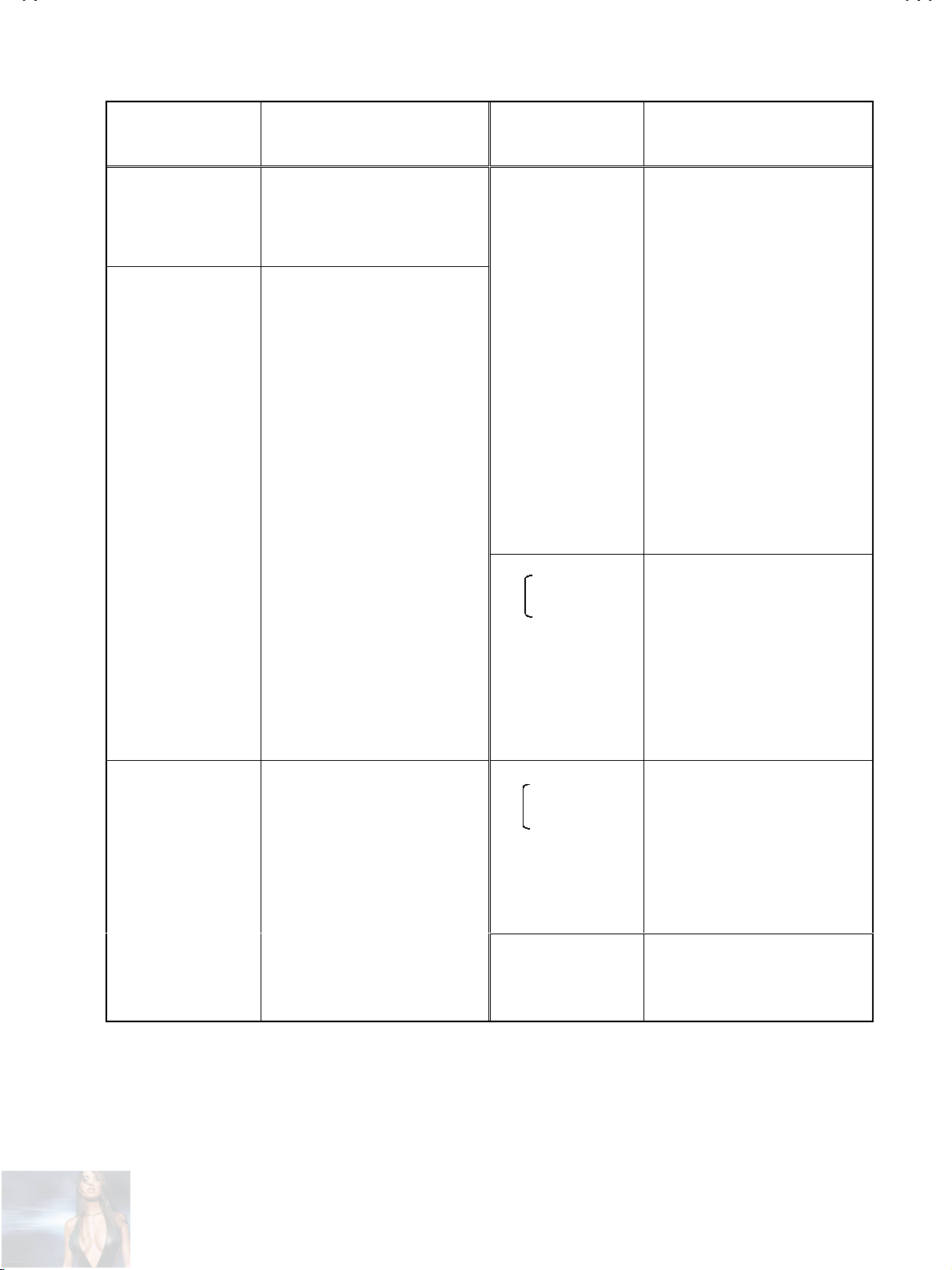

SERVICE MENU SETING I TEMS ( TABLE 3)

Setting item Setting value Setting item Setting value

V-29RS

1. IF VCO 4. DEF

2. V / C

1. CUT OFF (R, G, B)

2. DRIVE ( R, B)

3. BRIGHT

4. CONT.

5. COLOUR

6. TINT

7. BLACK OFFSET (R-Y, B-Y)

8. SHARP

5. VSM PRESET

BRIGHT

STANDARD

NORMAL

1. V-SHIFT

2. V-SIZE

3. SUBTITLE

4. H-CENT

5. H-SIZE

6. EW- PIN

7. TRAPEZ

8. EW. COR. L

9. EW. COR. H

10. V. S-COR

11. V-LIN

12. H-BLK-R

13. H-BLK-L

14. V-EHT

15. H-EHT

16. EHT-G AIN

1. BRIGHT

2. CONT

3. COLOUR

4. SHARP

5. TINT

1. AUDIO

(Do not adjust)

1. ERROR LIMIT

2. A2 ID THR

3. BASS

4. TREBLE

6. WB PRESET

COOL

MID

WARM

7. AUTO PROGRAM

(Do not adjust)

No. 51730

1. R DRIVE

2. B DRIVE

ON / OFF

11

Page 12

A

V-29RS

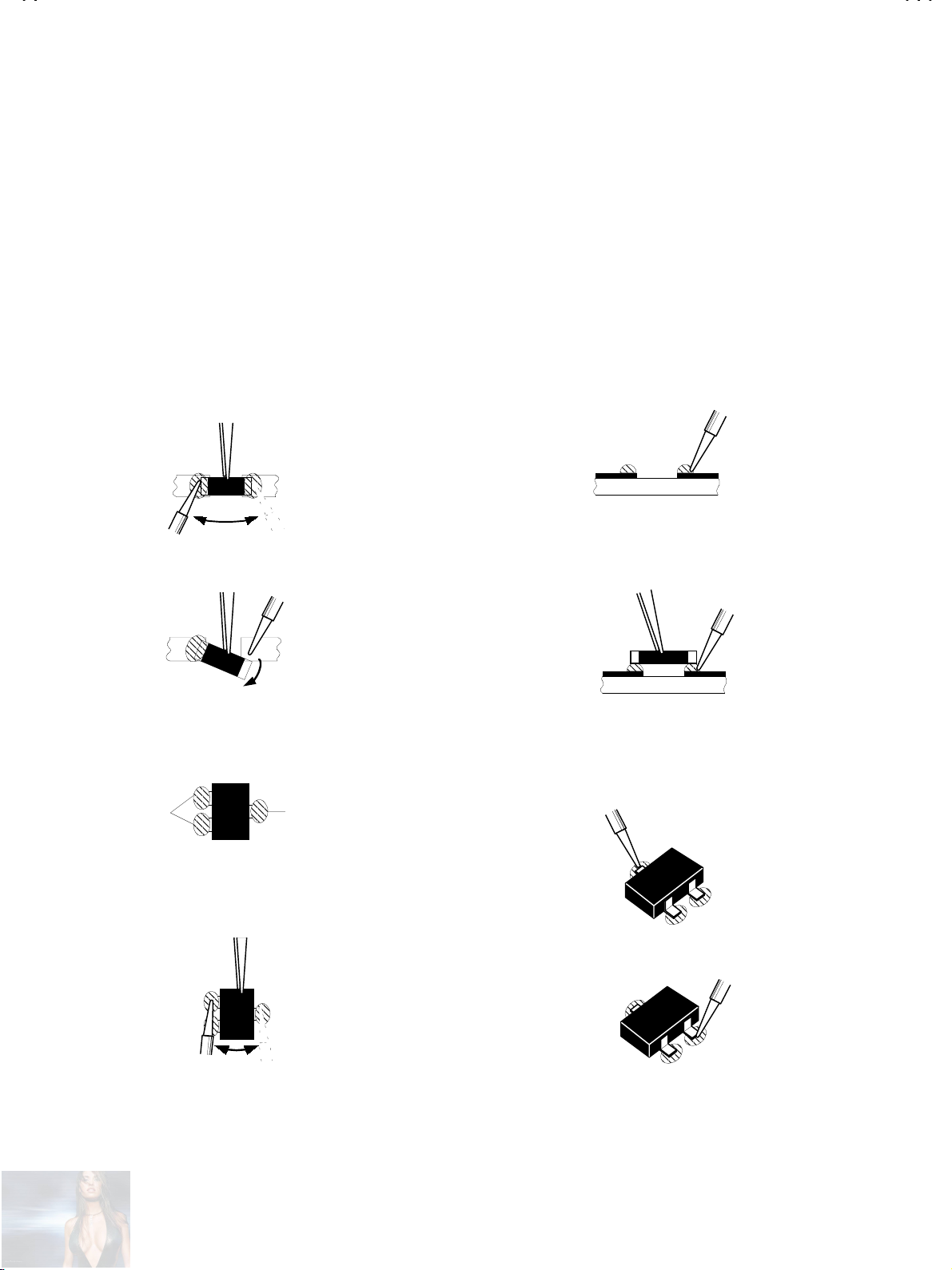

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

!

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip p art aft er rem oving it.

SOLDERING IRON

!

1. Use a high insulati on soldering iron with a thin p ointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMEN T STEPS

!

How to remove Chip parts

1.

Resistors, capacitors, etc

####

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at eac h end.

(2) S hif t wi th tweezers an d rem o ve t h e ch ip p ar t.

Transistors, diodes, variable resistors, etc

####

(1) Apply extra solder to each lead.

SOLDER

SOLDER

2. How t o i nst al l Chip p arts

Resistors, capacitors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp th e chip part with tw eezers and pl ace it on th e sold er.

Then heat an d m elt t h e s old er at b oth en ds of th e chip part .

Transistors, diodes, variable resistors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

as indicated in the figure.

A

A

(2) As shown in the figure, push the part with tweezers and

alternat el y melt t he s old er at each lead . Shif t and r emov e th e

chip part.

Note : After removing the part, remove remaining solder from the

pattern.

12

No. 51730

(4) Then solder leads

and C.

B

C

A

C

B

B

Page 13

A

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1.

There are 2 ways of adjusting this TV: One is with the

REMOTE CONTRO L UNIT and t he oth er is t he conv ention al

method using adjustment pa rts and components.

2.

The adjustment with the REMOTE CONTROL UNIT is made

on the basis of the init ial sett ing valu es . The set tin g val ue s

which adjust the screen t o it s o pt i mum cond ition may differ

from the initial setting values.

3. Make sure that connection is correctly made to AC power

source.

4. Turn on the p ower of the set and eq uipment before use, and

start the adjustment procedures after waiting at least 30 minutes.

5. Unl ess other wis e specifi ed, prep are the mos t suitab le rec eption

or input signal for adjustment.

6. Never touc h any adjus tm ent par ts, whic h are not spec ifi ed in the

list for this adjustment variable resistors, transforms, condensers,

etc.

7. Preparation for adjustment (presetting)

Unless oth erwise sp ecified in t he adjust ment items , preset t he

following functions with the REMOTE CONTROL UNIT.

User mode set ting condition

PICTURE MODE (VSM) STANDARD

WHITE BALANCE MID

ZOOM REGULAR

CONTRAST CENTER

BRIGHT CENTER

SHARP CENTER

COLOUR CENTER

A.A.C OFF

AUTO VNR OFF

PICTURE TILT CENTER

BLUE BACK O FF

AUTO SHUTOFF OFF

ECO SENSOR OFF

AI VOLUME OFF

BBE OFF

SLEEP TIMER OFF

BALANCE CENTER

SPATIALIZER OFF

V-29RS

MEASURING INSTRUMENT AND FIXTURES

1. DC voltme t er (or digital voltmeter)

2. Oscilloscope

3. Signal ge nerator (Pattern genera tor) [PAL / SECAM / NTSC]

4. Remote control unit

ADJUSTMENT CONTENTS

CHECK OF B1 POWER SURPLY

●

CHECK OF HIGH VOLTAGE

●

FOCUS ADJUSTMENT

●

CHECK OF IF CIRCUIT

●

SETTING OF VSM PRESET

●

SETTING OF WHITE BALANCE PRESET

●

VIDEO / CHROMA CIRCUIT ADJUSTMENT

●

DEFLECTION CIRCUIT ADJUSTMENT

●

AUDIO CIRCUIT ADJUSTMENT

●

PURITY, CONVERGENCE ADJUSTMENT

●

[Do not adjust]

No. 51730

13

Page 14

A

V-29RS

UP/DO

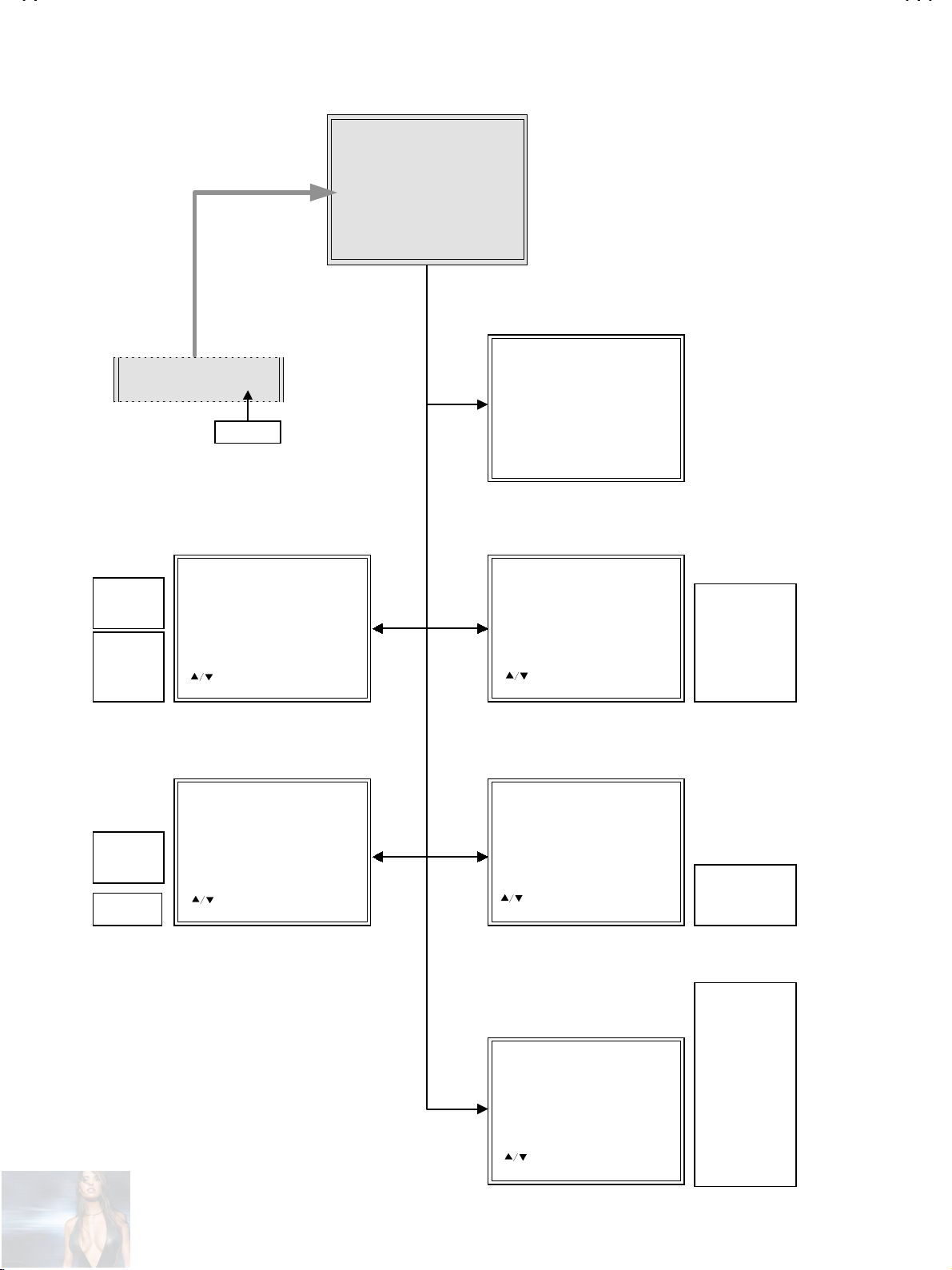

BASIC OPERATION OF SERVICE MENU

1. The adjustment using SERVICE MENU

The followi ng adjustm ent items us e the SERVICE ME NU in the seri es of the adjust ment. The adjus tments are made on the basis of the

initial setting values. The adjustment values which adjust the screen to the optimum condition can be different from the initial setting values.

With the SERVICE NEMU, various settings can be made, and they are broadly classified in the following items of settings.

IF

・・・・・・・・・・・・・・・・・・・・・・・・・

V/C

・・・・・・・・・・・・・・・・・・・・・・・

AUDIO

・・・・・・・・・・・・・・・・・・・・

DEF

・・・・・・・・・・・・・・・・・・・・・・・

VSM PRESET

WB PRESET

AUTO PROGRAM

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・

Adjustment of the IF circuits.

Adjustment of the VIDEO/CHROMA circuit.

Adjustment o f the sound circuit

[Do not ad just]

.

Adjustm en t of th e DEFLECTIO N circ u it f or eac h aspect mod e gi ven below

REGULAR (50/60Hz)

ZOOM (50/60Hz)

16:9 (50/60Hz)

Adjustm en t of th e initial setting values of VS M c on dition as BRIG H T , ST AN D AR D an d S O FT .

(VSM : Video Status Memory)

Adjustment of the initial setting value of WHITE BALANCE PRESET values as COOL, MID and WARM.

By turning the power switch on, you can get the state of AUTO PROGRAM

[Do not adjust ]

.

2. Key operation of the SERVICE MENU

[Enter to SERVICE MENU]

Press the

DISPLAY

key and th e

PICTURE M ODE

key of the REMOTE CONTROL

UNIT simultaneously. Then enter the SERVICE MENU mode as shown in Fig.1.

[Exit from SERVICE MENU]

When c omplet e the ad just ment work, pr ess th e

SERVICE MENU. And then press the

DISPLAY

DISPLAY

key to return to the main

key again, return to the normal

screen.

[Select the SUB MENU from MAIN MENU]

In main SERVICE MENU, press the 1~7 key of the remote control unit, to select any

of the adjustment items.

The colours which selected item characters are changed.

[Method of setting]

1. IF

[VCO]

1 Key

①

②

③

・・・・・・・・・・

The VCO (CW) screen will be displayed.

DISPLAY Key

Selec t

As you press t his k ey, y ou w il l r eturn to the

・・・

1.IF

.

SERVICE MENU

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

OK

MENU

LEFT/RIGHT

MENU

WN

DISPLAY

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. WB PRESET

7. AUTO PROGRAM (OFF)

.

SUB MENU 1.IF(VCO)

VCO (CW)

TOO HIGH

ABOVE REFERENCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

SERVICE MENU

SERVICE MENU

SERVICE MENU

1-7 : SELECT DISP : EXIT

M

*******-**** V*.**P

JVC JK BASIC V

**

Fig.1

**....**

**

****

****

MHz

**

14

DISP: EXIT

PICTURE

MODE

No. 51730

Page 15

A

V-29RS

2.V/C, 4.DEF, 5.VSM PRESET

2, 4, 5, 6 Key

①

MENU UP/DOWN Key

②

MENU LEFT/RIGHT

③

OK Key

④

DISPLAY Key

⑤

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

SUB MENU 2.V/C

V/C 50Hz PAL

1. CUT OFF (R)

- + : OPERATE DISP : EXI T

(G)

(B)

:SELECT

- **

- **

- **

SUB MENU 5.VSM PRESET

VSM PRESET

STANDARD

and

6.WB PRESET

Select on e from

Select setting items.

Set (adjust) the setting values of the setting items.

Memorize the setting value.

(Before storing the setting values in memory, do not press the CH, TV, POWER ON / OFF key -

if you do, the values will not be stored in memory.)

Return to the

2. V/C, 4. DEF, 5. VSM PRESET

SERVICE MENU

screen.

SUB MENU 4.DEF

**

**

DEF

- + : OPERATE DISP : EXIT

Hz

****

1. V-SHIFT

:SELECT

***

(**)

SUB MENU 6.WB PRESET

WB PRESET

MID

and

6.WB PRESET

.

1.BRIGHT

:SELECT

- + : OPERATE DISP : EXIT

3.AUDIO

and

(Do not adjust)

3.AUDIO

7.AUTO PROGRAM

***

7.AUT O PR OGRAM

(Do not adjust)

SUB MENU 3.AUDIO

AUDIO

1. ERROR LIMIT

C_AD_BITS = 00000000

:SELECT

- + : OPERATE DISP : EXIT

・・・・・・・・・・・・・・・・・

・・・・・・・・

***

H

1.R DRIVE

:SELECT

- + : OPERATE DISP : EXI T

***

It is no requirement to adjustmen t.

AUTO PROGRAM contents displays on the screen. Need not for service.

No. 51730

15

Page 16

A

V-29RS

(

)

(

)

)

SERVICE MENU FLOW CHART

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. WB PRESET

7. AUTO PROGRAM (OFF)

1-7 : SELECT DISP : EXIT

M

*******-**** V*.**P

JVC JK BASIC V

**

7.AUTO PROGRAM (OFF

VSM PRESET STANDARD

BRIGHT

STANDARD

SOFT

1. BRIGHT

2. CONT.

3. COLOUR

4. SHARP

5. TINT

COOL

MID

WARM

1. R DRIVE

2. B DRIVE

- + : OPERATE DISP : EXIT

- + : OPERATE DISP : EXIT

SUB MENU 1. IF

ON/OFF

TOGGLE SWITCH

VCO (CW)

TOO HIGH

ABOVE RE FE RE NCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

**

** ....**

**

****

****

DISP: EXIT

SUB MENU 5. VSM PRESET SUB MENU 2. V/ C

V/C 50Hz PAL

1.BRIGHT

:SELECT

***

SUB MENU 6. WB PRESET

WB PRESET MID

1.R DRIVE

:SELECT

***

1. CUT OFF (R)

- + : OPERATE DISP : EXIT

:SELECT

(G)

(B)

SUB MENU 3. AUDIO

AUDIO

1. ERROR LIMIT

C_AD_BITS = 00000000

:SELECT

- + : OPERATE DISP : EXIT

VCO

MHz

- **

- **

- **

Do not adjust

H

***

1. CUT OFF

2. DRIVE

3. BRIGHT

4. CONT.

5. COLOUR

6. HUE

7. BLACK OFFSET

8. SHARP

9. PURITY

1. CONC LIMIT

2. A2 ID THR

4. BASS

5. TREBLE

1. V-SHIFT

2. V-SIZE

SUB MENU 4. DEF

DEF

Hz

**

**

****

1. V-SHIFT

:SELECT

- + : OPERATE DISP : EXIT

16

No. 51730

***

(**)

3. SUBTITLE

4. H-CENT

5. H-SIZE

6. EW -PIN

7. TRAPEZ

8. EW .CO R.L

9. EW .CO R.H

10. V.S-COR

11. V-LIN

12. H-BLK-R

13. H-BLK-L

14. V-EHT

15. H-EHT

16. EHT-GAIN

Page 17

A

ADJUSTMENT LOCATIONS

)

(

)

V-29RS

FRONT

POWER

F901

FRONT CO NTROL PW B (1/2)

SW

W

PW

FRONT

CN002

MAIN PWB POWER&DEF PWB

CN001

AV SEL. PWB

CN006

CN001

MEMORY

IC702

IC701

FRONT CO NTROL PW B (2/2)

CN002

F

W DEG

1PIN : B1(TP-91

2PIN : NC

3PIN : NC

4PIN : NC

5PIN : GND

FRONT

CN013

FRONT

TUNER

CRT SOCKET PWB

(SOLDER SIDE)

CN008

TP-E

IC301

CN008

FOCUS

E1

CN009

TOP

CN009

CRT EARTH

BRAIDED WIRE

HV

1

5

X

FOCUS1

SCREEN1

No. 51730

17

Page 18

A

V-29RS

ADJUSTMENTS

CHECK ITEMS BEFORE ADJUSTMENTS

Item

Check of B 1

Power Supply

Measuring

instrument

Signal

generator

DC voltmeter

Test point Adjustment part Description

TP-91(B1)

TP-E(

)

####

[X Connector

on POWER

DEF P WB]

1. Input the bl ac k an d wh it e si gn al.

2. Select 2. V/C from the SERVICE MENU.

3. Select 1. CUT OFF with MENU UP / DOWN key.

4. Show one hori z ontal line by pressing th e 1 key.

5. Turn the SCREEN VR until not to display the one horizontal line.

6. Connect the DC voltmeter to TP-91(B1) and TP-E(#).

7. Make sure that the voltage is DC134.0 ±2.0V.

8. Readjust the SCREEN VR to app ear the hori zontal lin e faintl y,

and cancel the horiz on t al line by pressi ng th e 2 k ey.

Check of Hi gh

Voltage

Signal

generator

High voltage

meter

FOCUS ADJUS TMENT

Item

Adjustment of

FOCUS

Measuring

instrument

Signal

generator

CRT anode

Test point Adjustment part Description

FOCU S 1 [In FBT]

FOCUS 2

[CRT SOCKET PWB]

1. Input t h e bl ac k an d wh it e si gnal.

2. Select 2. V/C from the SERVICE MENU.

3. Select 1. CUT OFF with MENU UP / DOWN key.

4. Show on e hor i z ont al line by press in g the 1 key.

5. Turn the SCREEN VR until not to display the one horizontal line.

6. Connect a High voltage meter to CRT ANODE.

7. Make sure that the voltage is DC 32.0kV±1.5kV.

8. Readjust the SC REEN VR to app ear th e horiz ontal line faintl y,

and cancel the horizontal line by pressing 2 key.

1. Input the cross-hatch signal.

2. By turni ng the FOCU S 1 VR, ad just the pic ture s o that th e 7th

horizontal line from the upper side of the cross-hatch picture

becomes thinnest.

3. By turni ng the FOCU S 2 VR, ad just the pic ture s o that th e 7th

vertical line from the left side may become uniform at the line

center and its p er ip h ery.

4. Carry out adjus tment by repeating the steps 2 and 3 ab ov e.

5. Make sure t h at when t h e sc r een is darkened, the lines remain i n

good focus.

FOCUS 2

FOCUS 1

18

No. 51730

Page 19

A

CHECK OF IF CIRCUIT

V-29RS

Item

Adjustment of

VCO

Measuring

instrument

Remote

control unit

VCO (CW)

TOO HIGH

ABOVE REFERENCE

JUST REFERENCE

BELOW REFERENCE

TOO LOW

**

**....**

****

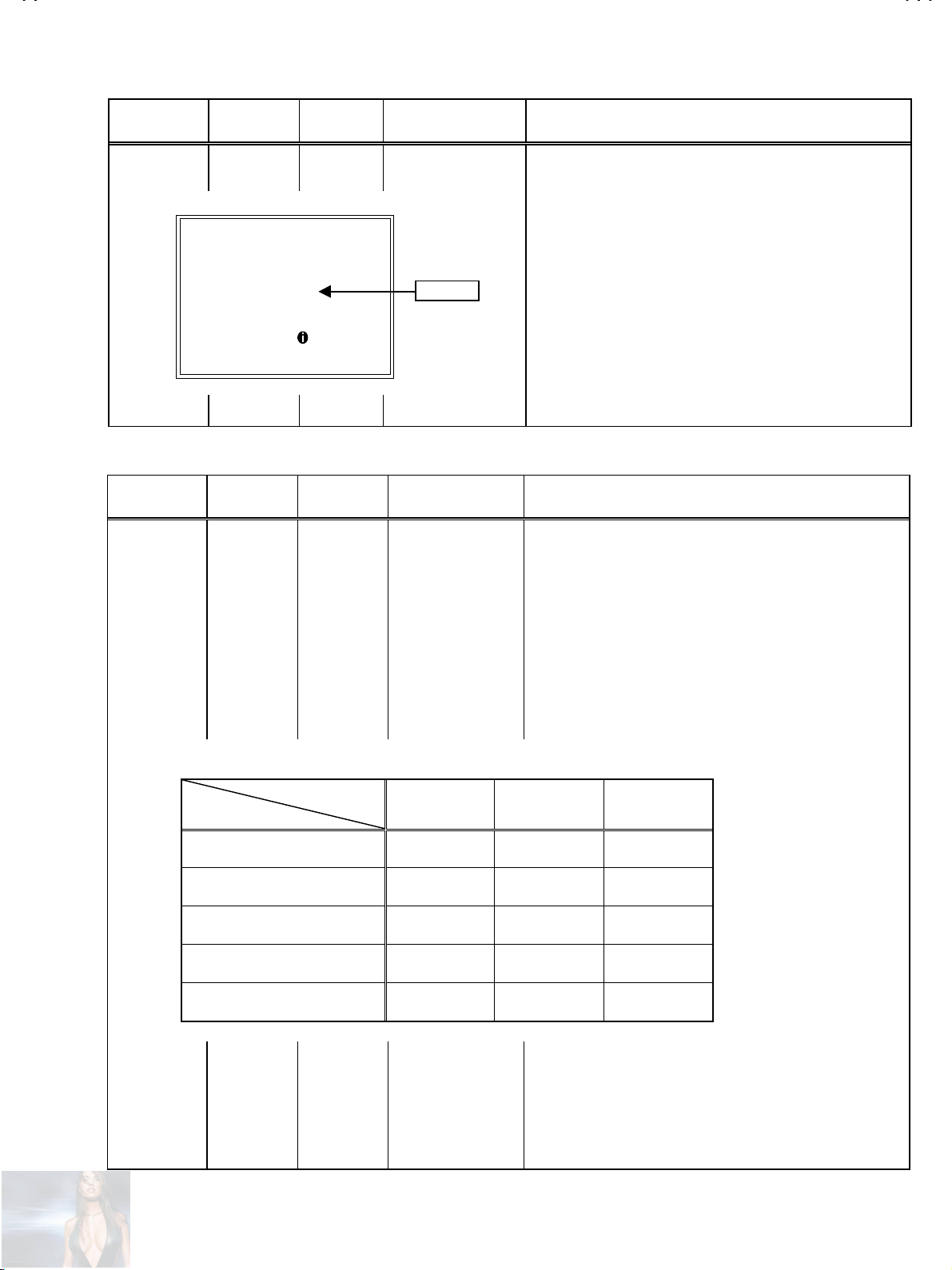

SETTING OF VSM PRESET

Item

Setting of

VSM PRESET

Measuring

instrument

Remote

control unit

Test point Adjustment part Descrip tion

Under normal conditions, it is no adjustment required.

1.IF

MHz

**

****

YELLOW

: EXIT

Test point Adjustment part Description

5.VSM PRESET

1. BRIGHT

2. CONT.

3. COLOUR

4. SHARP

5. TINT

"

It must not adjus t w ith ou t br oadcast sig n al.

"

1. Selec t 1.IF f rom the S ERVICE MENU, then dis plays t he VCO

adjustment screen.

2. Check the characters colour of the JUST REFERENCE

displayed to yellow.

1. Select 5.VSM PRESET from the SERVICE MENU.

2. Select PICTURE MODE to BRIGHT in the user setting MENU.

3. Adjust the MENU UP/DOWN and -LEFT/RIGHT key to bring the

set valu es of 1.BR IGHT~5. TINT to the values shown in the

table.

4. Press the OK key and memorize the set value.

5. Respectively select the PICTURE MODE to STANDARD and

SOFT, and m ak e si milar sett in g as in 3 abo ve.

6. Press the OK key and memorize the set value.

[INITIAL SETTING VALUES OF VSM PRESET]

PICTURE MODE

ITEM

1. BRIGHT

2. CONT

3. COLOUR

4. SHARP

5. TINT

BRIGHT STANDARD SOFT

+0 +0 +0

+17 +0 -4

+0 +0 -1

+0 +0 -3

+0 +0 +0

No. 51730

19

Page 20

A

V-29RS

SETTING OF WHITE BALANCE PRESET

Item

Setting of

WHITE

BALANCE

PRESET

[INITIAL SETTING VALUES OF WHITE BALANCE PRESET]

ITEM

Measuring

instrument

Remote

control unit

1. R DRIVE

2. B DRIVE

Test point Adjustment part Description

WHITE BALANCE

6.WB PRESET

1. R DRIVE

2. B DRIVE

COOL MID WARM

0-3+26

0-23-27

1. Select 6.WB PRESET from the SERVICE MENU.

2. Select COOL in the user setting MENU.

3. Adjust the MENU UP/DOWN and LEFT/RIGHT key to bring the

set values of 1.R DRIVE~2.B DRIVE to the values shown in the

table.

4. Press the OK key and memorize the set value.

5. Respectively select the WHITE BALAMCE MODE to MID and

WAR M, and m ak e sim il ar ad jus t m ent as in 3 above.

6. Press the OK key and memorize the set value.

VIDEO / CHROMA CIRCUIT ADJUSTMENT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

CONTENTS PAL SECAM NTSC3.58 NTSC4.43

1. CUTOFF

2. DRIVE

3. BRI GHT

4. CONT

5. COLOUR

6. TINT

7. BLACK OFFSET

8. SHARP

R

G

B

R

B

TV

VIDEO

COMPONENT

TV

VIDEO

COMPONENT

TV / VIDEO

COMPONENT

TV

VIDEO

COMPONENT

R-Y

B-Y

TV

VIDEO

COMPONENT

-60

-60

-60

+0

+0

0+3+1

-1 +2 +2

-2

-15 0 0

000

+2

+10 +18 +0 0

+8 +17

+6 +6 +7 0

+6 +6 +14 0

+6 -13

-

-

-12 -13 -12

-8 -7 -9

0

0

-10

--

--

-

-

-

-

-

-

20

No. 51730

Page 21

A

V-29RS

Item

Adjustment

of WHITE

BALANCE

(Low Light)

H LINE ON

H LINE OFF

R CUTOFF

R CUTOFF

Signal

generator

Remote

control unit

▲▲▲▲

▼▼▼▼

Measuring

instrument

Test point Adjust m ent part Description

1.CUT OFF

R, G, B

SCREEN VR

[In FBT]

G CUTOFF

B CUTOFF

B CUTOFF

G CUTOFF

Set the PICTURE MODE to STANDARD.

"

1. S et the W HIT E BALANCE to COOL.

2. Receive a bl ac k an d w hi t e sig nal (colour off ) .

3. Select 2. V/C from the SERVICE MENU.

4. Select 1.CUT OFF with the MENU UP/DOWN key.

5. Show one hor i z ont al line with th e 1 key.

6. G radually t urn the SC REEN V R from th e left en d to th e right

directi on to bring one of the r ed, green or blue c olour faint ly

visible.

7. Press 4~9 key, an d bring out th e other 2 colou rs and make

one horizontal line visible in white.

8. Turn the SCREEN VR and bring one white horizontal line

faintl y vis i bl e.

9. Press 2 key, tur n off on e hor i z ontal line.

10. Press the OK key and memorize the set value.

▲▲▲▲

▲▲▲▲

▼▼▼▼

▼▼▼▼

Adjustment

of WHITE

BALANCE

(High Light)

DRIVE

DRIVE

R

R

▲▲▲▲

▼▼▼▼

Signal

generator

Remote

control unit

2.DRIVE

DRIVE

DRIVE

R, B

The adjustment for Low Light WHITE BALANCE should be

"

finished.

Set the PICTURE MODE to STANDARD.

"

1. Set the WH IT E BALANCE to COOL.

2. Inp ut th e black and white signal (colour off ).

3. Select 2.V/C from the SERVICE MENU.

4. Select 2.DRIVE with the MENU UP/DOWN key.

5. Change the screen c olour to white with 4 key or 7 key (dri ve of

red), 6 key or 9 key ( drive of blue).

6. Press the OK key, and memorize the set values.

B

▲▲▲▲

B

▼▼▼▼

No. 51730

21

Page 22

A

V-29RS

Item

Adjustment

of

SUB BR I GHT

Adjustment

of

SUB

CONTRAST

Adjustment

of SUB

COLOUR

ⅠⅠⅠⅠ

Measuring

instrument

Remote

control unit

Remote

control unit

Remote

control unit

Test point Adjust m ent part Description

3.BRIGHT

4.CONT.

5.COLOUR [ Adju stm ent meth od wi tho ut meas uring instrument]

PAL COLOUR 1. Receive the PAL broadcast.

1. Receive any broadc ast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 3.BRIGHT with th e MENU UP/D OWN key.

4. Set the initial setting value with the MENU LEFT/RIGHT key.

5. If the brightness is not the best with the initial setting value,

make fin e adj us tm en t unt il y ou g et t h e bes t br ig ht n ess .

6. Press the OK key and memorize the set value.

1. Receive any broadc ast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 4.CONT with the MENU UP/DOWN key.

4. Set the initial setting value with the MENU LEFT/RIGHT key.

5. If the contras t is n ot the bes t with th e ini tial setti ng value, mak e

fine adjustment until you get the best contrast.

6. Press the OK key and memorize the set value.

2. Select 2.V/C from the SERVICE MENU.

3. Select 5.COLOUR with the MENU UP/DOWN key.

4. Set the init ial setting value for PA L COLOUR with th e MENU

LEFT/RIGHT key.

5. If the colour is not the best with the initial set value, make

fine adjustment until you get the best colour.

6. Press the OK key and memorize the set value.

SECAM COLOUR 1. Receive the SECAM broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 5.COLOUR with the MENU UP/DOWN key.

4. Set the initial setting value for SECAM COLOUR with the MENU

LEFT/RIGHT key.

5. If the colour is not the best with the initial set value, make

fine adjustment until you get the best colour.

6. Press the OK key and memorize the set value.

NTSC 3.58 COLOUR

NTSC 4.43 COLOUR

1. Recei ve th e NT SC 3. 58MHz bro adcast.

2. Make similar fine adjustment of NTSC 3.58 COLOUR in the

same manner as for ab ove.

1. When NTSC 3.58 is set, NTSC 4.43 will be aut omatic ally s et at

the respective values.

22

No. 51730

Page 23

A

V-29RS

Item

Adjustment

of SUB

COLOUR

ⅡⅡⅡⅡ

W

Measuring

instrument

Signal

generator

Oscilloscope

Remote

control unit

Y

Cy

G

Test point Adjust m ent part Description

TP-47G

TP-E(

####

[CRT

SOCKET

PWB ]

5.COLOUR [Adjustment method using m ea suri ng instrument]

)

PAL COLOUR 1. Input the PAL full field colour bar signal (with 75% white).

2. Select 2.V/C from the SERVICE MENU.

3. Select 5.COLOUR with the MENU UP/DOWN key.

4. Set the initial s etting value of PAL COLOUR with the MENU

LEFT/RIGHT key.

5. Connect the oscilloscope between TP-47G and TP-E(#).

6. Adjust PAL CO LOUR to br ing the val ue of

to

(Volt ag e differenc e betw e en w hi te (W) and green (G) ).

-3V

7. Press the OK key and memorize the setting value.

B

R

Mg

-

(

)

0V

(A)

(+)

in the illus trati on

(A)

SECAM COLOUR 1. Input the SECAM full field colour bar signal ( with 75% white).

2. S et the init i al setting valu e of SECA M CO LO UR with the MENU

LEFT/RIGHT key.

3. Adjust SECAM COLOUR to bring the value of

illustr ation to

green (G)) .

4. Press the OK key and memorize the setting value.

NTSC COLOUR 1. Input the N TSC 3 .58 MHz full f iel d colou r bar si gnal ( with 75%

white).

2. Set the initial setting value of NTSC 3.58 COLOUR with the

MENU LEFT/RIGHT key.

3. Adjust NT SC 3.5 8 COLOU R and bring t he value of

illustr ation to

green (G)) .

4. Press the OK key and memorize the setting value.

NTSC 4.43 COLOUR

1. When NTSC 3.58 is set, NTSC 4.4 3 will be automat icall y set at

the respective values.

(Voltage difference between white (W) and

-5V

(V olt age di ff eren ce b etwe en w hit e (W ) and

+3V

(A)

(A)

in the

in the

No. 51730

23

Page 24

A

V-29RS

(B)

Item

Adjustment

of

SUB TINT

Adjustment

of

SUB TINT

ⅠⅠⅠⅠ

ⅡⅡⅡⅡ

Measuring

instrument

Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

Test point Adjust m ent part Description

[Adjustment meth od wi tho ut me as urin g instr u m ent]

1. receive the NTSC 3. 58 MHz broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 6. TINT with the MENU UP/DOWN key.

4. S et the initial s etting val ue of NT SC 3.58 TINT with the ME NU

LEFT/RIGHT key.

5. If you cannot get th e b est tint with t h e initial setting val ue, m ak e

fine adjustment until you get the best tint.

6. Press the OK key and memorize the set value.

1. When NTSC 3.58 is set, NTSC 4.43 will be aut omatic ally s et at

the respective values.

[Adjustment meth od usi ng m ea suri ng instrument]

1. Input th e NTSC 3 .58MHz full fiel d colour bar sign al (with 75%

white).

2. Select 2.V/C from the SERVICE MENU.

3. Select 6. TINT with the MENU UP/DOWN key.

4. Set th e initi al sett ing value of N TSC 3. 58 T INT wit h the MENU

LEFT/RIGHT key.

5. Connect the osc i lloscop e bet w een TP -4 7G an d TP -E (#)

6. Adjust NTSC 3.58 TINT to bring the value of (B) in the

illustr ation to

cyan (Cy)).

7. Press the OK key and memorize the setting value

(volt age diff erenc e between white (W) and

+4V

TP-47G

TP-E(

####

[CRT

SOCKET

PWB]

6. TINT

NTSC 3.58 TINT

NTSC 4.43 TINT

6. TINT

)

NTSC 3.58 TINT

B

R

Mg

(

)

-

0V

W

Y

(+)

Cy

G

NTSC 4.43 TINT

24

No. 51730

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

Page 25

A

V-29RS

Item

Adjustment

Of

SECAM

BLACK

OFFSET-

Adjustment

Of

SECAM

BLACK

OFFSET-

ⅠⅠⅠⅠ

R-Y

R-Y

ⅡⅡⅡⅡ

▲▲▲▲

▼▼▼▼

Measuring

instrument

Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

Test point A djustm ent part Description

[Method of adjustment without measuring instrument]

1. Receive the SE CAM broadcast.

2. Select 2. V/C from SERVICE MENU.

3. Select 7. BLACK OFFSET with the MENU UP / DOWN key.

4. Set the init ial setting value f or 7. B LACK OFFS ET (R-Y) and

(B-Y) with

5. If the picture is not the best w ith the initial sett ing value, m ake

fine adjus t m ent un til you get the best pic t u r e.

6. Press the OK key and memorise the set value.

[Method of adjustment using measuring instrument]

1. Input the SECAM full field colour bar signal ( with 75% white).

2. Select 2. V/C from SERVICE MENU.

3. Select 7. BLACK OFFSET with the MENU UP / DOWN key.

4. Connect the oscilloscope between

5. By using

OFFSET (R-Y) s o that i t bec om es th e w avef orm c hang es f r om

to

(A)

6. Connect the oscilloscope between

7. By using

OFFSET (B-Y) so that it becomes the waveform changes from

to

(C)

8. If th e pict ure is not th e b est w it h the adjus ted picture, make f in e

adjust m ent un t il you get t h e bes t pic ture.

9. Press the OK key twice to return to the normal screen.

and 7 or 6 and 9 keys of the remote control.

4

and 7 keys of the rem ot e contr ol, ad just th e BLAC K

4

shown in the figure.

(B)

and 9 keys of the rem ot e contr ol, ad just th e BLAC K

6

shown in the figure.

(D)

35 PIN (R-Y)

36 PIN (B-Y)

IC 1301 On

MAIN PWB

[R-Y]

7. BLACK OFFSET

(R-Y)

(B-Y)

B-Y

▲▲▲▲

B-Y

▼▼▼▼

7. BLACK OFFSET

(R-Y)

(B-Y)

pin of IC 1301 and TP -E.

35

pin of IC 1301 and TP -E.

36

(A) (B)

[B-Y]

(C) (D)

No. 51730

25

Page 26

A

V-29RS

DEFLECTION CIRCUIT ADJUST MENT

There ar e 3 modes of th e adjustment ( 1 ) 50H z mode ( ①REGULAR ②ZOOM ③16:9 ), ( 2 ) 60Hz mode ( each aspect mod e )

depending upon the kind of signals ( vertical frequency 50Hz / 60Hz ).

The adjustment using the remote control unit is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

DEFLECTION ADJUSTMENTS INITIAL SETTING VALUE

Initial settin g val ue

Setting item Adjustment name

1. V-SHIFT

2. V-SIZE

3. SUBTITLE

4. H-CENT

5. H-SIZE

6. EW-PIN

7. TRAPEZ

Vertical shift -5 -1 0 +1 0 0

Vertical size +7 -1 +36 +35 -39 -39

Subtitle 0 +1 -7 +7 0 0

Horizontal center -10 +5 -1 -1 0 -1

Horizontal size -12 -1 -4 -4 0 -1

Side pin correction -3 +1 -4 -4 +2 0

Trapez oid al dis torti on c orrec t i on +4 -2 0 -1 0 +1

REGULAR

50Hz 60Hz 50Hz 60Hz 50Hz 60Hz

ZOOM 16:9

・・・・・

8. EW.COR.L

9. EW.COR.H

10.V.S-COR

11.V-LIN

12. H-BLK- R

13. H-BLK-L

14.V-EHT

15.H-EHT

16.EHT-GAIN

Corner pi n c orr ec ti on Low side -2 0 -1 -1 +1 +1

Corner pin correction High side -2 0 0 0 +1 +1

Vertical size correction +1300000

Vertical Linearity +2 -1 -1 - 1 +1 0

Horiz ont al Blanking R ig ht 0 0 0 0 +7 7 0

Horiz ont al Blanking L eft 0 0 0 0 +2 0

V size correction level caused by EHT change -4 0 0 0 0 0

H size correction level caused by EHT change -3 0 0 0 0 0

Size correction gain caused by EHT change +3 0 0 0 0 0

26

No. 51730

Page 27

A

V-29RS

Item

Adjustment

of

V-SHIFT

Adjustment

of V-SIZE

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjust m ent part Description

1. V- SHIFT

At first, select the ASPECT mode to REGULAR.

●

1. Input the cir c l e p attern signal.

2. Select 4.DEF from the SERVICE MENU.

3. Select 1.V-SHIFT with the MENU UP/DOWN key.

4. Adjust V-SHIFT to make

A = B

.

5. Press th e OK k ey an d m em orize th e s et valu e.

A

B

2.V-SIZE

6. Input the cross-hatch signal.

7. Select 2.V-SIZE and set the initial setting value.

8. Adjust V-SI ZE and make sur e that th e vertic al screen siz e is in

the bellow table.

9. Press the OK key and memorize the set value.

Screen

size

[VERTICAL SIZE]

ASPECT MODE REGULAR ZOOM 16 : 9

Screen size

Picture size 100%

V SIZE

Picture

size

100%

92% 74%

295mm

(90% position)

No. 51730

27

Page 28

A

V-29RS

Item

Adjustment of

H.CENTER

Adjustment

of

H.SIZE

Measuring

instrument

Signal

generator

Remote

control unit

C

Signal

generator

Remote

control unit

Test point Adjustment part Descrip tion

4.H-CENT.

10. Inp ut the circle p attern signal.

11. Select 4.H-CENT and set the initial setting value.

12. Adjust H-CENT to make C=D.

13. Press the OK key and memorize the set value.

D

5.H-SIZE

14. Input the circle p attern signal.

15. Select 5.H-SIZE and set the initial setting value.

16. Adjust H-S IZE an d mak e sur e th at th e horiz ontal sc reen size

of the picture is in the bellow table.

17. Press the OK key and memorize the set value.

Adjustment of

EW-PIN

[HORIZONTAL SIZE]

ASPECT MODE REGULAR ZOOM 16:9

Signal

generator

Remote

control unit

H SIZE

Straight

6.EW-PIN

92% 85% 92%

18. Select 6.EW-PIN and set the initial set ting va lue

19. Adjust EW-PIN and m ake t he 2 nd ver tic al li nes at t he l eft and

right edg es of t h e s c reen str ai ght . A lso make s ure th at th e 3r d

vertical lines are straight.

20. Press the OK key and memorize the set value.

28

No. 51730

Page 29

A

V-29RS

Item

Adjustment

of TRAPEZ

Adjustment of

EW. COR. L/H

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjust m ent part Descrip tion

7.TRAPEZ

Parallel

Signal

generator

Remote

control unit

8.EW. COR. L

9.EW. COR. H

Straight Straight

21. Input the cross-hatch signal.

22. Select 7.TRAPEZ with the MENU UP/DOWN key.

23. Set the initial setting value of TRAPEZ with the MENU

LEFT/RIGHT key.

24. Adjust T RAPEZ and bring t h e vertical li n es at the right and left

edges of the screen parallel .

25. Press the OK key and memorize the set value.

26. Select 8.EW. COR. L with the MENU UP / DOWN key.

27. Set the initial setting value of EW. COR. L with the MENU

LEFT/RIGHT key.

28. Adjus t E W. CO R . L, and bring the lin e to straig ht at the corn er

of the screen bottom.

29. Select 9.EW. COR. H with the MENU UP / DOWN key.

30. Set the initial setting value of EW . COR. H with the MENU

LEFT/RIGHT key.

31. Adjus t EW. CO R . H, and bri ng the lin e t o s tr aight at t h e c orn er

of the screen top.

32. Press the OK key and memorize the set value.

Adjustment

of V-S.CR &

V.LINEARITY

Signal

generator

Remote

control unit

10. V-S.CR

11. V-LIN

TOP

CENTER

BOTTOM

No. 51730

In case when the vertical linearity has been deteriorated

●●●●

remarkably, perform the following steps.

33. Input the cross-hatch signal.

34. Select 11.V-LIN with the MENU UP/DOWN key.

35. Set the initial setting value of 11.V-LIN with the MENU

LEFT/RIGHT key.

36. Select 10.V-S.CR with the MENU UP / DOWN key.

37. Set the initial setting value of 10.V-S.CR with the MENU

LEFT/RIGHT key.

38. Adjust 11.V-LIN and 10.V-S.CR so that the spaces of each line

on top, cent er an d bottom bec om e uniform.

29

Page 30

A

V-29RS

Item

Measuring

instrument

Test point Adjust m ent part Descri ption

At first the adjustment in 50Hz-REGULAR mode should be

done, then the data for the other aspect mode is corrected in

the respective value at the same time. And confirm the

deflect ion adj ust ment in itial s etti ng valu e in 60H z( N TSC Vid eo

mode ) REGULAR mode. If the adjustment in 50Hz each aspect

mode h as b een don e an d s tored, t h e data for th e same aspect

modes in 6 0Hz is c orrec ted in the r espectiv e value. O nly the

data for th e oth er as p ect mod e in 60Hz is corr ec t ed for itself.

AUDIO CIRCUIT ADJUSTMENT

Do not adjust 3.AUDIO(1. ERROR LIMIT, 2. A2 ID THR, 3. BASS, 4. TREBLE) of the SERVICE MENU as it requires no adjustment.

3. AUDIO [Do not adjust]

Sett ing item Variable range fixed value

1. ERROR LIMIT

000H ~ FF0H

100H

2. A2 ID THR 00H ~ FFH 14H

3. BASS -17 ~ +17 +0

4. TREBLE -17 ~ +17 +0

30

No. 51730

Page 31

A

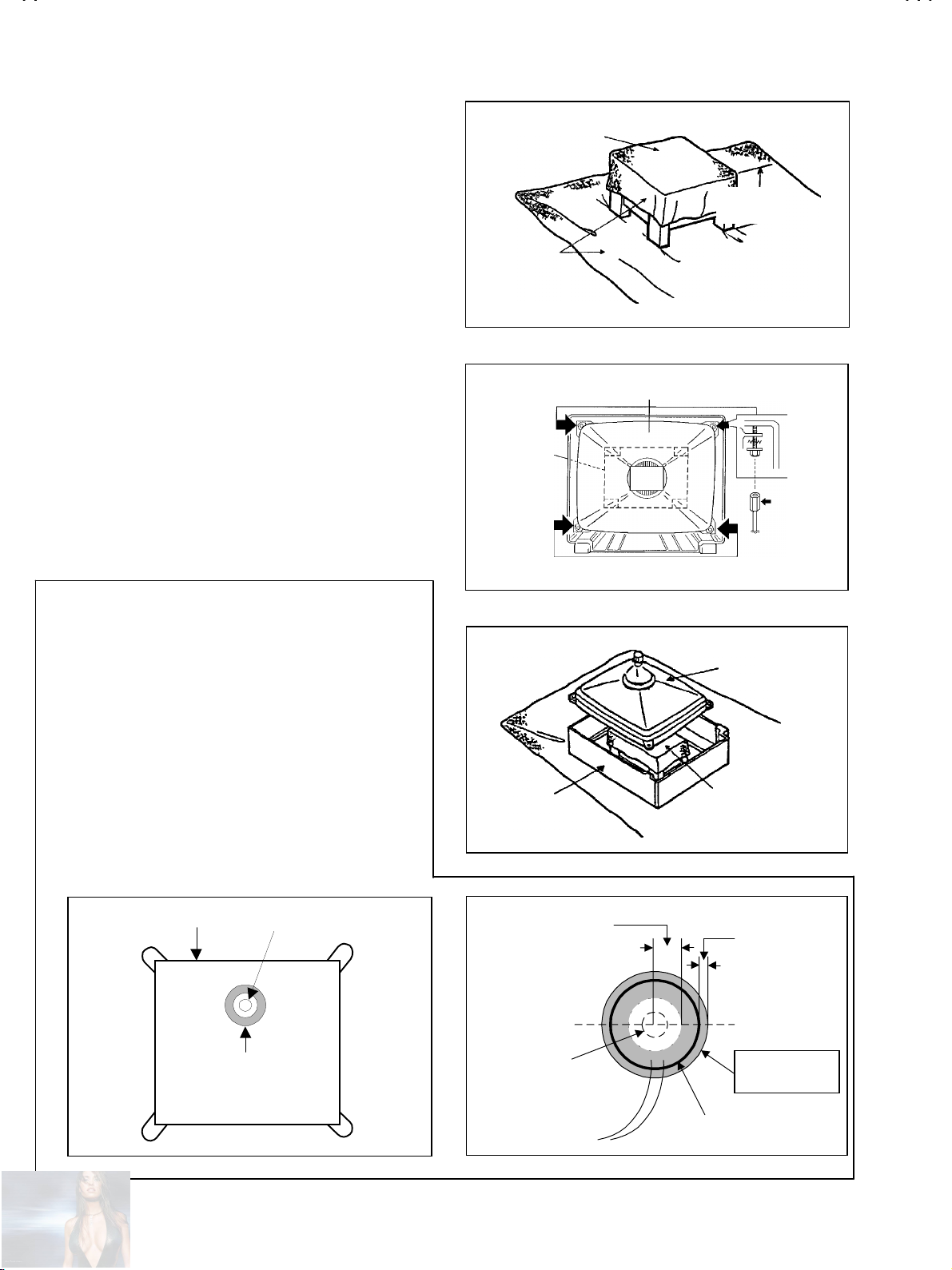

PURITY, CONVERGENCE ADJUSTMENT

g

g

g

PURITY ADJU STMENT

V-29RS

1. Demagnet ize CRT with the demagnetize r.

2. Loosen the retainer screw of the deflection yoke.

3. R emove the wed g es.

4. Input a green r aster signal fr om the sign al gener ator, an d turn

the screen to green raster.

5. M ove t h e def l ec tion yoke bac k ward.

6. Brin g the long l ug of the pur ity magnets on the sh ort lug an d

position them horizontally. (Fig.2)

7. Adj us t t h e g ap b etween t w o l ugs s o th at th e G R EEN RAST ER

will come into the center of the screen. (Fig.3)

8. Move the defl ection yoke forward, and fix the pos ition of the

deflection yoke so that the whole screen will become green.

9. Insert the wedge to the top side of the deflection yoke so that it

will not move.

WEDGE

CRT

DEF. YOKE

P/C MAGNETS

P : PURITY MAGNET

4 : 4 POLES

6 : 6 POLES

(con ver g ence magnets )

(con ver g ence magnets )

Fig.1

DYNAMIC CONVERGENCE ADJUSTMENT

PURITY MAGNET(P)

46

P / C MAGNETS

PURITY MAGNETS

CRT SOCKET PWB

10. Input a crosshatch signal.

11. Verify that the scr een is horizont al.

12. Inp ut red and blu e raster si gnals, and make su re that pur ity is

properly adjust ed.

Short lu

Bring the long lug over the short lu

and position them horizontally.

Fig.2

(FRONT VIEW)

CENTER

Fig.3

Long lu

GREEN RASTER

No.51730

31

Page 32

A

V-29RS

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4- pole conver gence magn ets, overlap th e red and bl ue

lines in the center of the screen (Fig.1) and turn them to

magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the magenta

(red/bl ue) and gr een li nes in th e cent er of th e screen and tur n

them to white.

4. R epeat 2 and 3 above, an d m ak e best conver g ence.

After ad jus t m ent , fi x the w ed g e at th e ori gi nal positi on.

●

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets w ith glu e.

DYNAMIC (periphery) CONVERGENCE

ADJUSTMENT

After adjusting purity & static convergence.

(FRONT VIEW)

Fig.1

(FRONT VIEW)

TOP

1. Move the deflection yoke up and down to adjust the pin cushion

distortion in the screen top and bottom. (See Fig. 2)

2. Move t he d eflec ti on yok e left t o righ t to overl ap the lin es i n t he

periph er y, an d m atc h the Yv.(See Fi g. 3)

3. R epeat the steps 1 an d 3 and obtain an optim um converg ence.

4. Diffe rential coil ADJUSTMENT.

In case wher e the horiz ontal lines of red and blue arou nd the

center of both sides of the picture as shown in Fig. 4, adjust the

X

difference by using the differential coil on the top of the

V

deflection yoke (Fig.5) so as to minimize the X

V coil

X

difference.

V

(FRONT VIEW)

GREEN

RED

YV

(FRONT VIEW)

v

X

BLUE

BLUE(RED)

RED(BLUE)

BOTTOM

Fig.2

Fig.3

BLUE

GREEN

RED

RED

GREEN

BLUE

YV

BLUE

GREEN

RED

GREEN

Fig.5

Fig.4

32

No.51730

Page 33

A

PARTS LIST

CAUTION

V-29RS

The parts identified by the

!

the safety .

The par ts n ot indicated in th is Par ts Lis t and those whic h ar e fil led with lin es

!

P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

!

symbol are important for the safety. Whenever replacing these parts, be sure to use specified ones to secure

!

in the Parts No. columns will not be supplied.

ABBREVIATIONS OF RESISTO RS, CAPACITO RS AND TOLE RANCES

RESISTORS CAPACITORS

C R Carbon Resistor C CAP. Ceram ic Capacitor

F R Fusible Resistor E CAP. Electrolytic Capacitor

P R Plate Resistor M CAP. Mylar Capacitor

V R

HV R High Voltage Resistor MF CAP. Metalized Film Capacitor

MF R Metal Film Resisto r MM CAP. Metalized Mylar Capac itor

MG R Metal Glazed Resistor MP CAP. Metalized Polystyrol Capacitor

MP R Metal Plate Resistor PP CAP. Polypropylene Capacitor

Variable Resisto

r

HV CAP. High Voltage Capacitor

OM R Metal Oxide Film Resistor

CMF R Coating Metal Film Resistor TF CAP. Thin Film Capacitor

UNF R Non-Flammable Resistor MPP CAP. Metalized Polypropylene Capacitor

CH V R Chip Variable Resistor TAN. CAP. Tantalum Capacitor

CH MG R Chip Metal Glazed Resistor CH C CAP. Chip Ceramic Capacitor

COMP. R Composition Resistor BP E CAP. Bi-Polar Electrolytic Capacitor

LPTC R

Linear Positive Temperature Coefficient

Resistor

PS CAP

.

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP.

CH TAN. E CAP.

CH AL BP E CAP.

Polystyrol Capacitor

Chip Aluminum Bi-Polar Capacitor

Chip Tantalum Electrolytic Capacitor

Chip Tantalum Bi-Polar Electrolytic Capacitor

TOLERANCES

FGJKMNRHZP

1%

±

2%

±

5%

±

10%

±

20%

±

±

30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

No.51730

33

Page 34

A

V-29RS

CONTENTS

USING PW BOARD & REMOTE CONTROL UNIT

!!!!

REMOTE CONTROL UNIT PARTS LIST

!!!!

EXPLODED VIEW PARTS LIST(

!!!!

EXPLODED VIEW (

!!!!

EXPLODED VIEW PARTS LIST (

!!!!

EXPLODED VIEW (

!!!!

PRINTED WIRING BOARD PARTS LIST

!!!!

"

MAIN PW BOARD ASS'Y

"

POWER & DEF PW BOARD ASS' Y

"

CRT SOCKET PW BOARD ASS’Y

"

FRONT CONTROL PW BOARD ASS'Y

"

AV SEL. PW BOARD ASS'Y

PACKING

!

PACKING PARTS LIST

!

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

)

ⅠⅠⅠⅠ

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

)

ⅡⅡⅡⅡ

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ⅠⅠⅠⅠ

ⅡⅡⅡⅡ

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

)

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

)

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

34

35

35

35

36

37

38

41

44

45

46

48

48

USING PW BOARD & REMOTE CONTROL UNIT

Model

PWB ASS'Y

MAIN PWB

POWER & DEF PWB

CRT SOCKET PWB

FRONT CONTROL PWB

AV SEL. PWB

REMOTE CONTROL UNIT

AV-29RS

SJK-1003A-H2

SJK-2003A-H2

SJK-3001A-H2

SJK-8011A-H2

SJK0S003A-H2

RM-C112-1H

34

No.51730

Page 35

A

REMOTE CONTROL UNIT PARTS LIST [ RM-C112-1H ]

V-29RS

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

EXPLODED VIEW PA RTS LI ST (

Ref.No. Part No. Part Name Description

!

12 LC31220-001B INDICATE WINDOW

25 CM48125-009 JVC MARK

26 LC31169-001B-H L.E.D.LENS

27 LC31070-003A-H OPERATION SHEET

37 LC10762-001 B-H FRONT CABINET

!

38 LC20532-003B-H DOOR

39 CM48229-00A-C DOOR LATCH

40 LC31162-001B-H CENTER PLATE

41 LC20585-001 B-H RIGHT PLATE

42 LC31067-001 A-H POWER KNOB

43 CM35235-003-H SPRING

44 LC31165-001B-H LEFT PLATE

ⅠⅠⅠⅠ

)

!"#$%&$ '()*+%&$ '()*+%(," -"./)01*0&2

++3 4!56783695- :;88<!=+>?@<!

++6 4!56<>369A; BCD-<+>?@<!

EXPLODED VIEW (

ⅠⅠⅠⅠ

)

FRONT CABINET

25

27

26

40

!

39

37

12

44

38

41

No.51730

43

42

35

Page 36

A

V-29RS

ⅡⅡⅡⅡ

EXPLODED VIEW PARTS LIST(

Ref.No. Part No. Part Name Description

!

V01 A68LTF356X PICTURE TUBE

!

DY01 QQD0042-001 DEF YOKE

!

L01 QQW0073-001 DEG COIL

!

T2551 QQH0077-002-I2 HVT (SERVICE)

!

1 CHGB0020-0B-FH BRAIDED WIRE

2LC10765-002B-H CONTROL BASE R

!

3 CE41488-00A WEDGE ASSY (×4)

4 CE42388-00A P.C.MAGNET

5 CHFD125-08BD-N FFC WIRE

6LC10764-001 A-H CHASSIS BASE

!

7LC10765-001 B-H CONTROL BASE L

!

8LC10766-001 B-H TERMINAL BOARD

!

9 QYSBSF3012M TAPPING SCREW (×5)For AV BOARD

10 A48457-3-H SPRING

11 QNZ0369-001 ANODE WIRE

!

13 QMP40D0-200J5 POWER CORD

!

15LC10763-002B-H REAR COVER

!

16 LC20377-001B-H RATING LABEL

!

17 QYSBSFG4016Z TAPPING SCREW (×16)

18 CM23167-A01-H CORD CLAMP

!

20 CEBSF10P-03KJ6 SPEAKER (×2)SP01,SP02

22 LC10051 -001A-H DOME COVER (×2)

24 LC10767-001 A-H DOME ADAPTOR (×2)

30 LC40226-001A SPACER (×4)

34 CM34837-A39-H STICK SHEET (×2)

35 CHGB0017-0C BRAIDED SUB ASSY

36 LC10050-001 A-H HORN (×2)

37 LC10762-001 B-H FRONT CABINET

!

)

36

No.51730

Page 37

A

V-29RS

A

EXPLODED VIEW (

!

37

!

!

L01

V01

30

ⅡⅡⅡⅡ

DY01

!

)

11

3

1

!

4

CRT SOCKET

PWB

FRONT

CONTROL PWB

35

10

!

30

24

22

34

36

30

!

5

2

20

7

POWER & DEF

PWB

!

T2551

!

8

34

22

24

30

!

15

36

20

MAIN PWB

V SEL. PWB

!

!

6

9

18

!

13

!

16

17

No.51730

37

Page 38

A

V-29RS

PRINTED WIRING BOARD PA RTS LIST

MAIN PW BOARD ASS’Y (SJK-1003A-H2)

BE,F&G+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!<BDB8?!

!3HH6IHJ %!B;H6KIH!HL MN+! H$H!+3O3HP+++K

!3HH5IH9 %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3HHR %!B;H6KI3HAL MN+! 3HHQ!+3O3HP+++K

!3H3H %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!3H33 %!B;H6KI366L MN+! 3$6Q!+3O3HP+++K

!3H36 %!B;H6KIJJ3L MN+! JJH!+3O3HP+++K

!3H3J %!B;H6KI6RHL MN+! 6R!+3O3HP+++K

!3H3A %!B;H6KI6R3L MN+! 6RH!+3O3HP+++K

!3H35 %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!36H3 %!B;H6KI3HAL MN+! 3HHQ!+3O3HP+++K

!36H6 %!B;H6KIARJL MN+! ARQ!+3O3HP+++K

!36HJ %!B;H6KI3SAL MN+! 3SHQ!+3O3HP+++K

!36HA %!B;H6KI66AL MN+! 66HQ!+3O3HP+++K

!36H5 %!B;H6KI59JL MN+! 59Q!+3O3HP+++K

!36H9 %!B;H6KI9S6L MN+! 9$SQ!+3O3HP+++K

!36HR %!B;H6KIJJJL MN+! JJQ!+3O3HP+++K

!36HTI3H %!B;H6KI663L MN+! 66H!+3O3HP+++K

!3653 %!B;H6KIARJL MN+! ARQ!+3O3HP+++K

!3656 %!B;H6KIJT6L MN+! J$TQ!+3O3HP+++K

!365J %!B;H6KIARJL MN+! ARQ!+3O3HP+++K

!365A %!B;H6KI3HJL MN+! 3HQ!+3O3HP+++K

!3655 %!B;H6KIS6JL MN+! S6Q!+3O3HP+++K

!3659 %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!365R %!B;H6KIJJJL MN+! JJQ!+3O3HP+++K

!365S %!B;H6KI6R6L MN+! 6$RQ!+3O3HP+++K

!365T %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!369H %!B;H6KIS6JL MN+! S6Q!+3O3HP+++K

!3693 %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3696 %!B;H6KI35JL MN+! 35Q!+3O3HP+++K

!369J %!B;H6KI6RJL MN+! 6RQ!+3O3HP+++K

!369A %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3695 %!B;H6KIS63L MN+! S6H!+3O3HP+++K

!3699 %!B;H6KI66JL MN+! 66Q!+3O3HP+++K

!369RI9S %!B;H6KI3H3L MN+! 3HH!+3O3HP+++K

!369T %!B;H6KI3HJL MN+! 3HQ!+3O3HP+++K

!36RH %!B;H6KI9S6L MN+! 9$SQ!+3O3HP+++K

!36R3 %!B;H6KI3HJL MN+! 3HQ!+3O3HP+++K

!3JH3 %!B;H6KIH!HL MN+! H$H!+3O3HP+++K

!3JH6 %!B;H6KI36JL MN+! 36Q!+3O3HP+++K

!3JHA U!NH3NKI363 ?M+! 36H!++++3P+++K

!3JH5 %!B;H6KI596L MN+! 5$9Q!+3O3HP+++K

!3JH9 %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!3JHR %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3JHS %!B;H6KIAR3L MN+! ARH!+3O3HP+++K

!3JHT %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!3J3HI33 %!B;H6KIJT3L MN+! JTH!+3O3HP+++K

!3J3AI35 %!B;H6KI596L MN+! 5$9Q!+3O3HP+++K

!3J39 %!B;H6KI66AL MN+! 66HQ!+3O3HP+++K

!3J3SI6H %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3J63 %!B;H6KI6R6L MN+! 6$RQ!+3O3HP+++K

!3J69 %!B;H6KI596L MN+! 5$9Q!+3O3HP+++K

!3J6R %!B;H6KI3H3L MN+! 3HH!+3O3HP+++K

!3J6SI6T %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3JJH %!B;H6KIAR6L MN+! A$RQ!+3O3HP+++K

!3JJ3 %!B;H6KI3H3L MN+! 3HH!+3O3HP+++K

!3JJA %!B;H6KI596L MN+! 5$9Q!+3O3HP+++K

!3JJ5 %!B;H6KI6RJL MN+! 6RQ!+3O3HP+++K

!3JJ9 %!B;H6KI3HJL MN+! 3HQ!+3O3HP+++K

!3JJR %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3JJS %!B;H6KI596L MN+! 5$9Q!+3O3HP+++K

!3JJT %!B;H6KIH!HL MN+! H$H!+3O3HP+++K

!3JAHIA3 %!B;H6KI9S3L MN+! 9SH!+3O3HP+++K

!3JA6 %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!3JA9 U!<3A3KI3H6= >+! 3Q!++3OAP+++K

!3J53I5J %!B;H6KI6R6L MN+! 6$RQ!+3O3HP+++K

!3J5A %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3J55 %!B;H6KI35JL MN+! 35Q!+3O3HP+++K

!3J59 %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

!3J5R %!B;H6KI666L MN+! 6$6Q!+3O3HP+++K

!3J5S %!B;H6KI3H6L MN+! 3Q!+3O3HP+++K

BE,F&G+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!<BDB8?!