Page 1

A

SER VICE MANUAL

COLOR TELEVISION

AV-29M201

V-29M201

BASIC CHASSIS

GA

CONTENTS

SPECIFICATIONS

!

SAFETY PRECAUTIONS

!

FEATURES

!

FUNCTIONS

!

SPECIFIC SERVICE INSTRUCTIONS

!

SERVICE ADJUSTMENTS

!

★

STANDARD CIRCUIT DIAGRAM (APPENDIX)

PARTS LIST

!

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・

・・・・・・

・・

・・・・

2

3

4

5

6

11

2-1

27

No.51731

May 2000

Page 2

A

V-29M201

SPECIFICATIONS

Items Content

Dimensions (W

Mass

TV System and Color system

TV RF System

Color System

Sound System

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

ATV Receiving Channels and Frequency

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

TV/CATV Total Cha nne l

Intermediate Frequency

Video IF Carrie r

Sound IF Carrier

Color Sub Carrier

Power Input

Power Consumption

Picture Tube

High Voltage

Speaker

Audio Power Output

Input (1, 2)

Variable Audio Output

Antenna te rminal

Accessories

××××H××××

D)

25-3/4”×23-3/8”×20-1/2” / 65.4cm×59.1cm×51.8cm

67.8Ibs / 30.8kg

CCIR(M)&(N)

NTSC / PAL-M / PAL-N

BTSC (Multi Channel Sound)

(02~06) 55.25MHz~83.25MHz

(07~13) 175.25MHz~211.25MHz

(14~69) 471.25MHz~801.25MHz

(02~06)

(07~13)

(14~22)

(23~36)

(37~64)

(65~94, 100~125)

(01, 96~99)

180 Channels

45.75MHz

41.25MHz (4.5MHz)

NTSC : 3.579545MHz

PAL-M : 3.57561149MHz

PAL-N : 3.58205625MHz

Rated Volta ge : 120V~240V AC, 50Hz/60Hz

Operating Voltage : 90V~260V AC, 50Hz/60Hz

115W(max.), 85W(avg.)

27” (68cm) measured diagonally, Full Square

29kV±1.3kV (at zero beam current)

2”×4-3/4” / 5×12cm Oval type×2

5W+5W

Video : 1Vp-p 75Ω (RCA pin jack)

Audio : 500mVrms (-4dBs), High Impedance (RCA pin jack)

More then 0~1550mVrms (+6dBs)

Low Impedance (400Hz when modula ted 100%) (RCA pin jack)

75Ω(VHF/UHF) Terminal, F-Type Connector

Remote Control Unit RM-C765-1A(AAA/R03/UM-4 dry battery×2)

(55.25MHz~799.25MHz)

Design & specifications are subject t o c hange without not ic e.

2

No.51731

Page 3

A

SAFETY PRECAUTIONS

V-29M201

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manuf act urer's warr an ty and will fur t h er reli ev e t h e manufactur er

of respons ibil it y f or pers onal injur y or prop ert y dam age r es ulti ng

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident f rom visual i nspection nor can t he protect ion

afford ed by them n ecess arily be obt ained by using rep lacem ent

compon ents rated f or higher voltag e, watt ag e, etc. R epl acem ent

parts which have these special safety characteristics are

identified in the parts list of Service manual.

compon ents hav in g suc h feat ures are id entif ied by s hadin g

on the sche matics and by (

manual.

have the same safety characteristics as the recommended

replac ement par t s how n i n th e p arts lis t of S ervic e m anu al may

cause shock, fire, or other hazards.

The us e of a subst itute replacement which does not

) on the parts list in Service

!!!!

Electrical

4.

Don't short b etween the LIV E side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

difference of th e GND is show n b y t h e LI V E : (") side GND, the

ISOLATED(NEUTRAL ) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuri ng apparatus (os cilloscope etc .)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above not e wi ll not b e kept , a f use or any parts wil l be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The hig h voltage app lied t o the picture t ube must c onform wit h

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltag e conditions s hould b e kept to a mi nimum, or sh ould be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect inst allation, cracked or melted high voltage harn ess,

poor solderi ng, etc.). To main tain the proper min imum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting

a clip lead to the gr ound fr ame and con nectin g the oth er end of

the lead through a 10k! 2W resist or t o the an ode button .

8. W hen servic e is requir ed, obser ve the origin al lead dres s. Extr a

precaut ion shou ld be gi ven to assure c orrect lead dress in th e

high voltage circuit area. W here a short circuit has occurred,

those comp onents that in dicat e evidenc e of over heating should

be replaced. Always use the manufacturer's replacement

components.

9.

Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

termin als , vid eo/ au dio inpu t an d output term in als , Control kn obs ,

metal cabinet, screw"heads, earph one jac k, cont rol s hafts, etc.)

to be sure the product is safe to operate without danger of

electrical shock.

(1)

Dielectric Stre ng th T est

The isol ation b etween th e AC pr imar y circuit and al l metal parts

exposed to the user, particularly any exposed metal part having a

return p ath to the chassis should withst and a voltage of 3 000V

AC (r.m.s .) for a peri od of on e s ec ond.

(. . . . W ithstand a voltag e of 1100 V AC ( r.m.s.) to an applianc e

rated up t o 120V, and 3000 V AC (r. m.s.) t o an appl iance r ated

200V or mor e, f or a peri od of on e s ec on d.)

This method of test requires a test equipment not generally found

in the service trade.

(2)

Leaka ge Current Check

Plug the AC lin e c or d dir ec tly into t h e AC ou tlet (do not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground ( water pipe, etc.) . A ny leakag e c urrent must not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

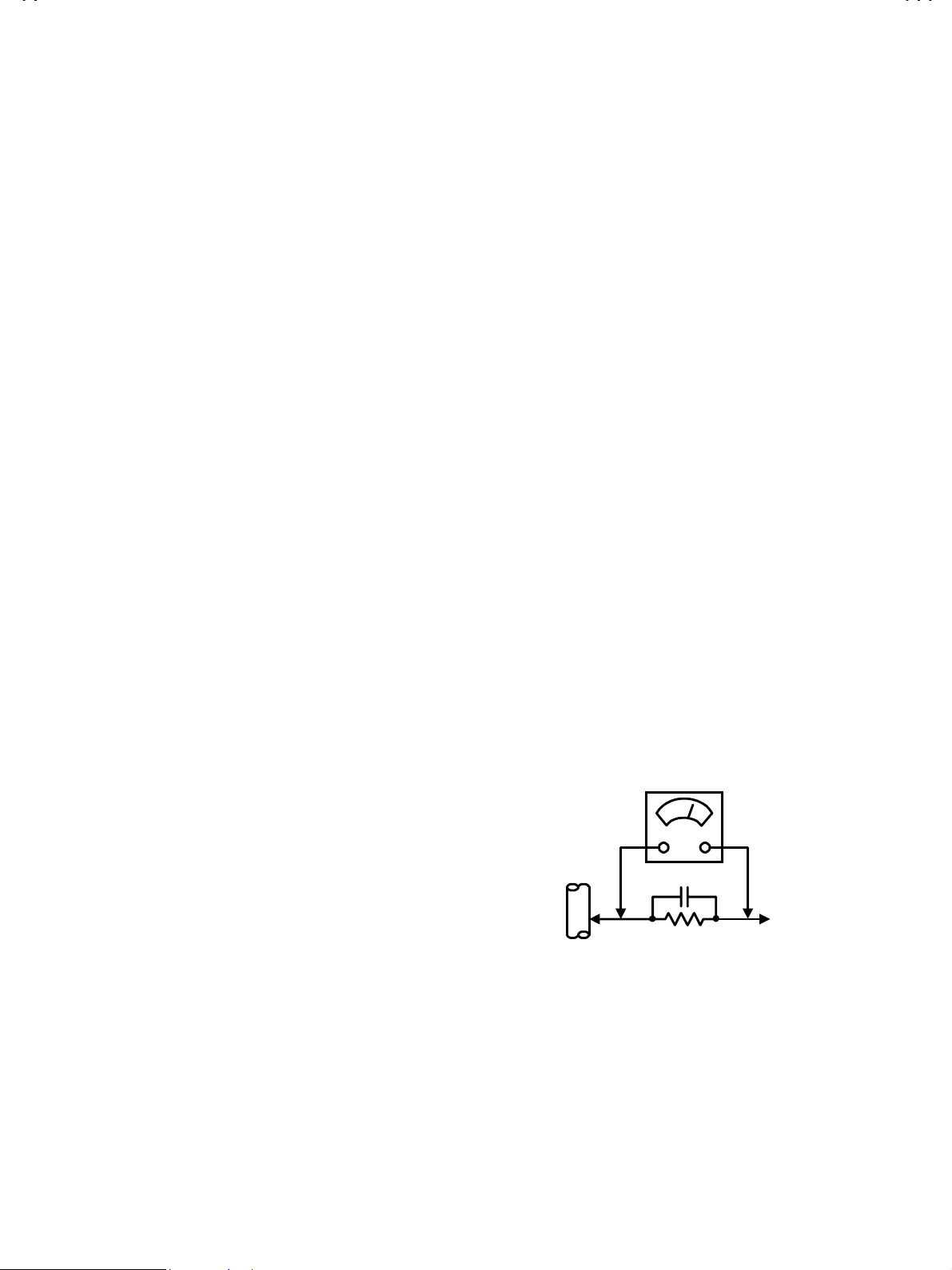

Alternate Check Method

""""

Plug the AC lin e c or d dir ec tly into t h e AC ou tlet (do not use a line

isolati on transform er during t his check.). Use an AC voltmet er

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1 500! 10W resistor paralleled by a 0.15#F

AC-typ e capacitor betw een an expos ed metal part and a known

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connect ion t o each exp os ed met al p art, p articul arl y any exp osed

metal part h avin g a return p ath to th e chassis , and meas ure th e

AC voltag e across the res istor. N ow, re vers e the plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However , i n t ropic al area, this m us t not e xc eed 0.3V AC (r . m.s . ).

This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500

GOOD EARTH GROUND

!

AC VOLTMETER

(HAVING 1000

OR MORE SENSITIVITY)

10W

!

/V,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

No.51731

3

Page 4

A

V-29M201

FEATURES

N ew ch assi s des ig n enabl es us e of a main b oard wi th s imp lif ied

"

circuitry.

Provided with miniature tuner (TV/CATV).

"

PLL synthesizer system TV/CATV totaling 180 channels.

"

Multifunctional remote control permits picture adjustment.

"

With AUDIO. VIDEO INPUT terminal.

"

Variable audio output terminal.

"

Adoption of the VIDEO STATUS function.

"

Adoption of the ON/OFF TIMER function.

"

With 75ΩV/U in common (F-Type) ANT Terminal.

"

SLEEP TIMER for setting in real time.

"

Wide range voltage (90V~260V) AC power input.

"

4

No.51731

Page 5

A

FUNCTIONS

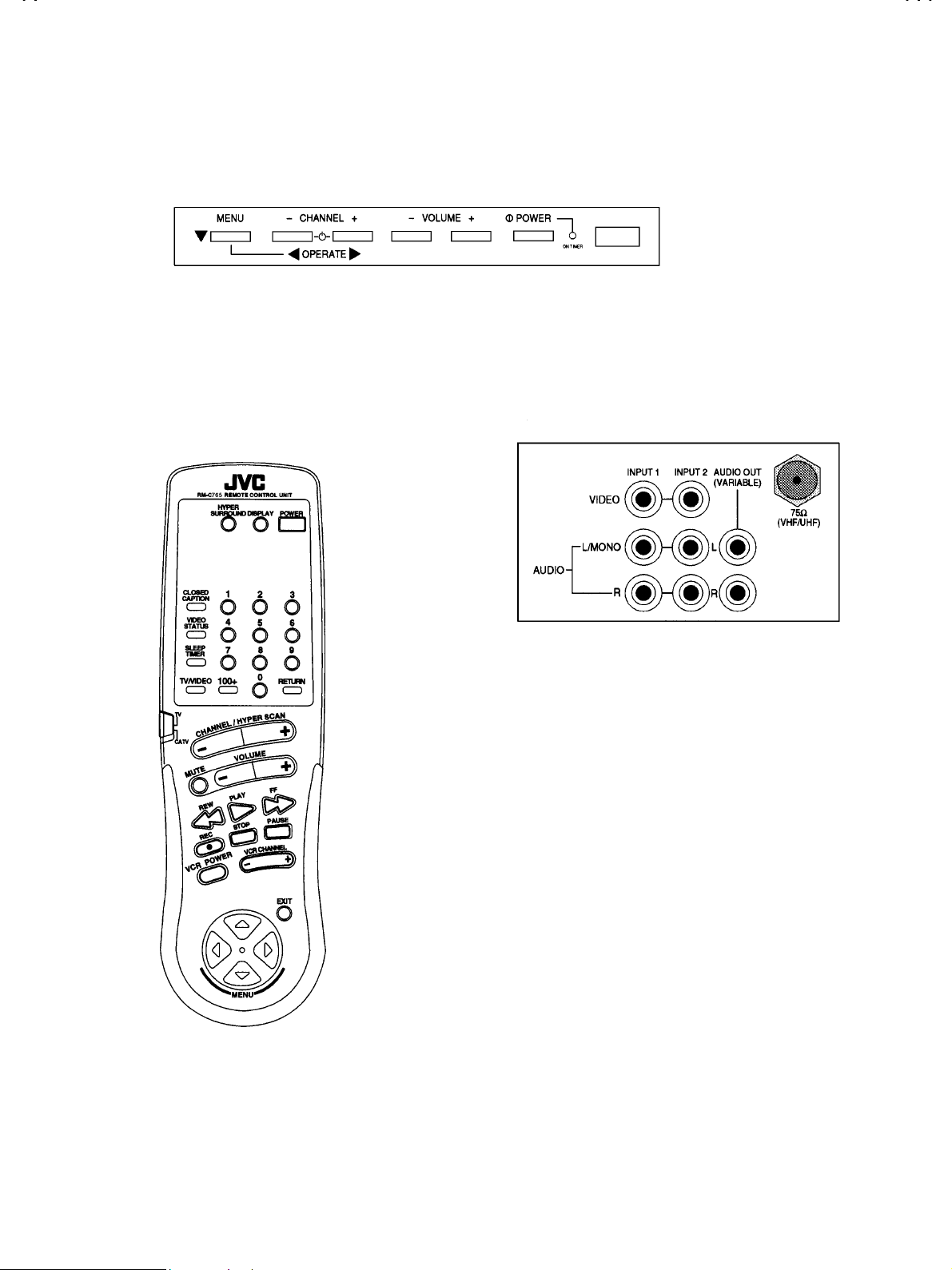

■

FRONT CONTROL

V-29M201

■

REMOTE CONTROL UNIT

(RM-C765-1A)

■■■■

REAR VIEW

No.51731

5

Page 6

A

V-29M201

SPECIFIC SERVICE INSTRUCTIONS

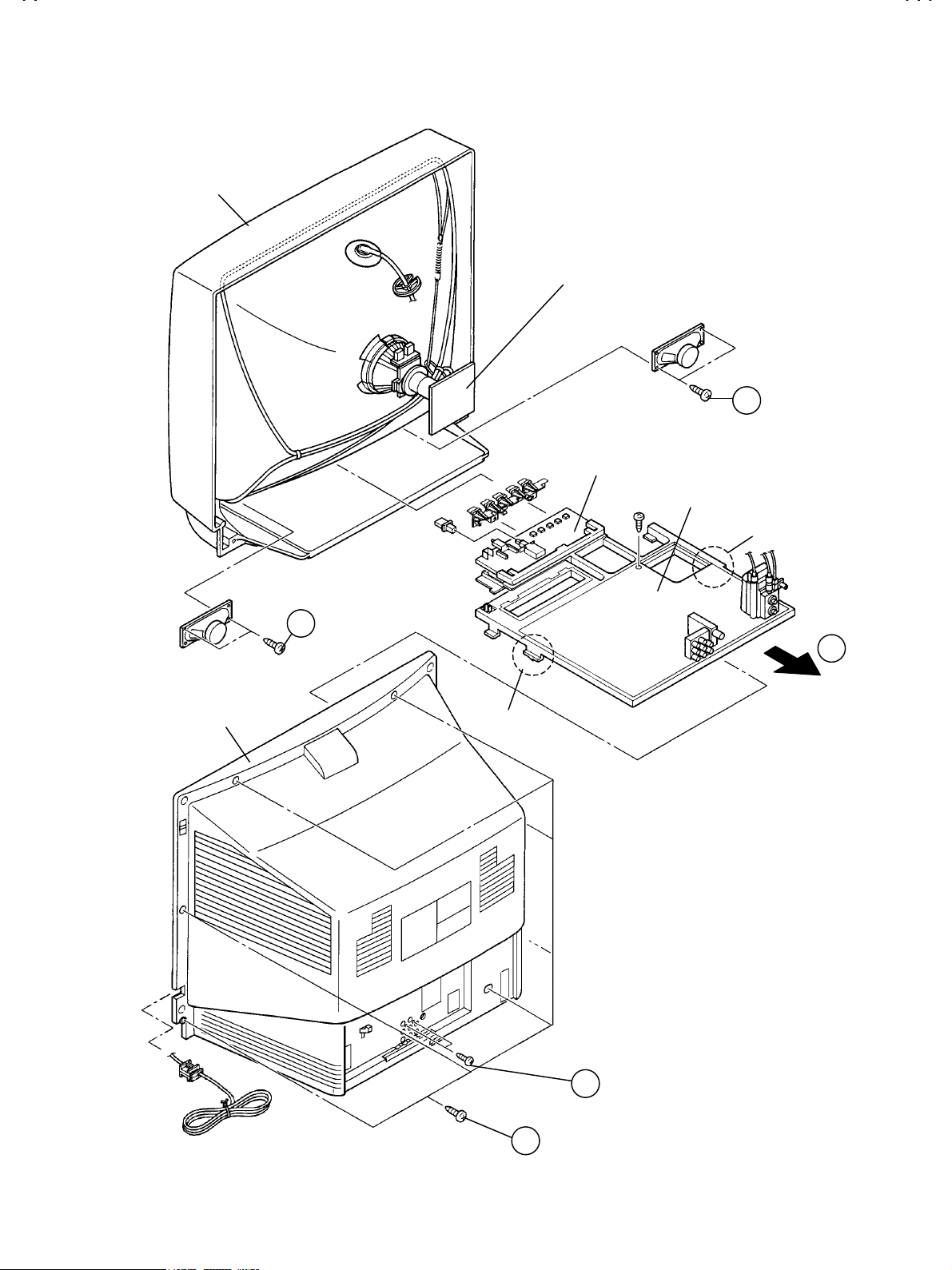

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply co rd.

2. R emove th e 7 s cr ews m ark ed

shown in Fig.1.

When rei nstalling t he rear cover , carefully push it inward after

*

*

**

inserting the chassis into the rear cover groove.

and 2 scr ews m ark ed

AAAA

REMOVING THE CHASSIS

After removing the rear co ver.

%%%%

1. Sli ghtly r aise th e both s ides of the ch assis b y han d and r emov e

the 2 claws under the both sides of the chassis from the front

cabinet.

2. Dr aw the chassis backwar d along the rail i n the arr ow direc tion

marked

(If necessary, take off the wire clamp , connectors etc.)

as shown in the Fig.1.

CCCC

BBBB

as

When conducting a check with power supplied, be sure to

*

*

**

confirm that the CRT earth wire is connected to the CRT

SOCKET PWB and the MAIN PWB.

REMOVING THE SPEAKER

After removing the rear cover and chassis.

%%%%

1. Remove the 2 screws marked

2. Follow the same steps when removing the other hand speaker.

as shown in Fig.1.

DDDD

CHECKING THE MAIN PW BOARD

1. To check the back sid e of th e MA IN PW Board.

1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

2) Erect th e chass is ver tic ally s o that you c an eas il y check t he

back side of the MAIN PW Board.

[CAUTION]

When erect ing the chassis, be c areful so th at there will b e no

%%%%

contacting with other PWB.

Befor e turning on pow er, m ake sur e th at th e CRT ear th wir e and

%%%%

other connectors are properly connected.

WIRE CLAMPING AND CABLE TYING

1. Be sure clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with a

new cable tie.

6

No. 51731

Page 7

A

FRONT CABI.

V-29M201

CRT SOCKET PWB

(Wit hin MAIN PW B)

D

FRONT

CONTROL PWB

REAR

COVER

MAIN PWB

CLAW

D

C

CLAW

(×2)

B

(×7)

A

No. 51731

7

Page 8

A

V-29M201

(CW)

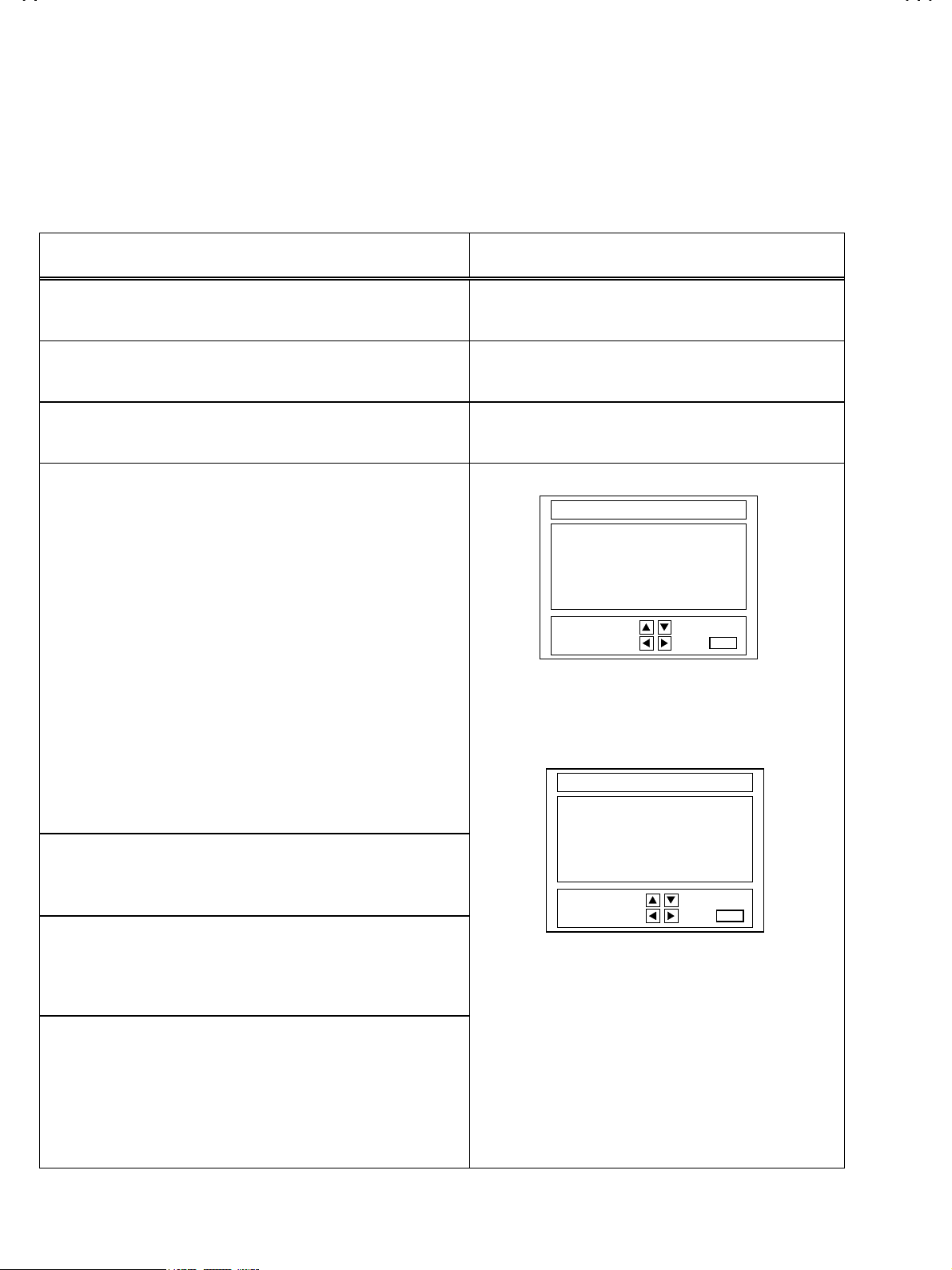

MEMORY I C REPLAC EMENT

1. Memory IC

This model use a memory IC.

The memor y IC st or es dat a for proper op eration of vi d eo an d deflection c ir c ui ts .

When replacing, be sure to use an IC containing this (initial value) data.

2. Memory IC repl acement procedure

PROCEDURE SCREEN DISPLAY

(1) Power off

Switch off the power and dis connec t th e pow er c or d from the out l et.

(2) Replace the me mor y IC

.

Be sure to u se memo ry ICs written with the i nitial data values.

(3) Power on

Connect the power cord to the outlet and switch on the power.

(4) System const ant chec k and set ting

It must not adjust with ou t sign al.

%%%%

1) Si mult aneousl y press the D ISPLA Y key and VI DEO S TAT US k ey

of the remote control unit.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) While the SERVICE MENU is displayed, again simultaneously

press t h e D IS PLAY an d VIDEO STATU S keys to dis pl a y the Fi g.2

SYSTEM CONSTANT screen.

4) Refer to the SYSTEM CONSTANT table and check the setting

items. W here th ese diff er, sel ect the s etting item wit h the M ENU

UP / DOW N key an d adjust the setting with the ME NU LEFT /

RIGHT keys. (The letters of the selected item are displayed in

yellow.)

5) Af ter adjus ting, release t he MEN U LEFT / RIG HT k ey to store t he

setting value.

6) Press the EXIT key twice to return the normal screen.

(5)

Receive chann el settin g

Refer to the OPERATING INSTRUCTIONS (USER’S GUID E) and

set the receive channel s (Channels Prese t) as described.

(6)

User setti n gs

Check the user setting items according to Table 2.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER’S GUIDE) and set the items as described.

SERVICE MENU

PICTURE SOUND

VIDEO STAT US OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK VCO

I2C BUS CTRL

SELECT BY

OPERATE BY

Fig.1

SYSTEM CO NST ANT

GAME : YES

HYPER SCAN : YES

SURROUND : YES

CCD : YES

VIDEO : 2

SELECT BY

OPERATE BY

Fig.2

EXIT BY

EXIT

EXIT BY

EXIT

IT

IT

(7)

SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is

necessary. (Fig.1) refer to the SERVICE ADJUSTMENT for setting.

8

No. 51731

Page 9

A

V-29M201

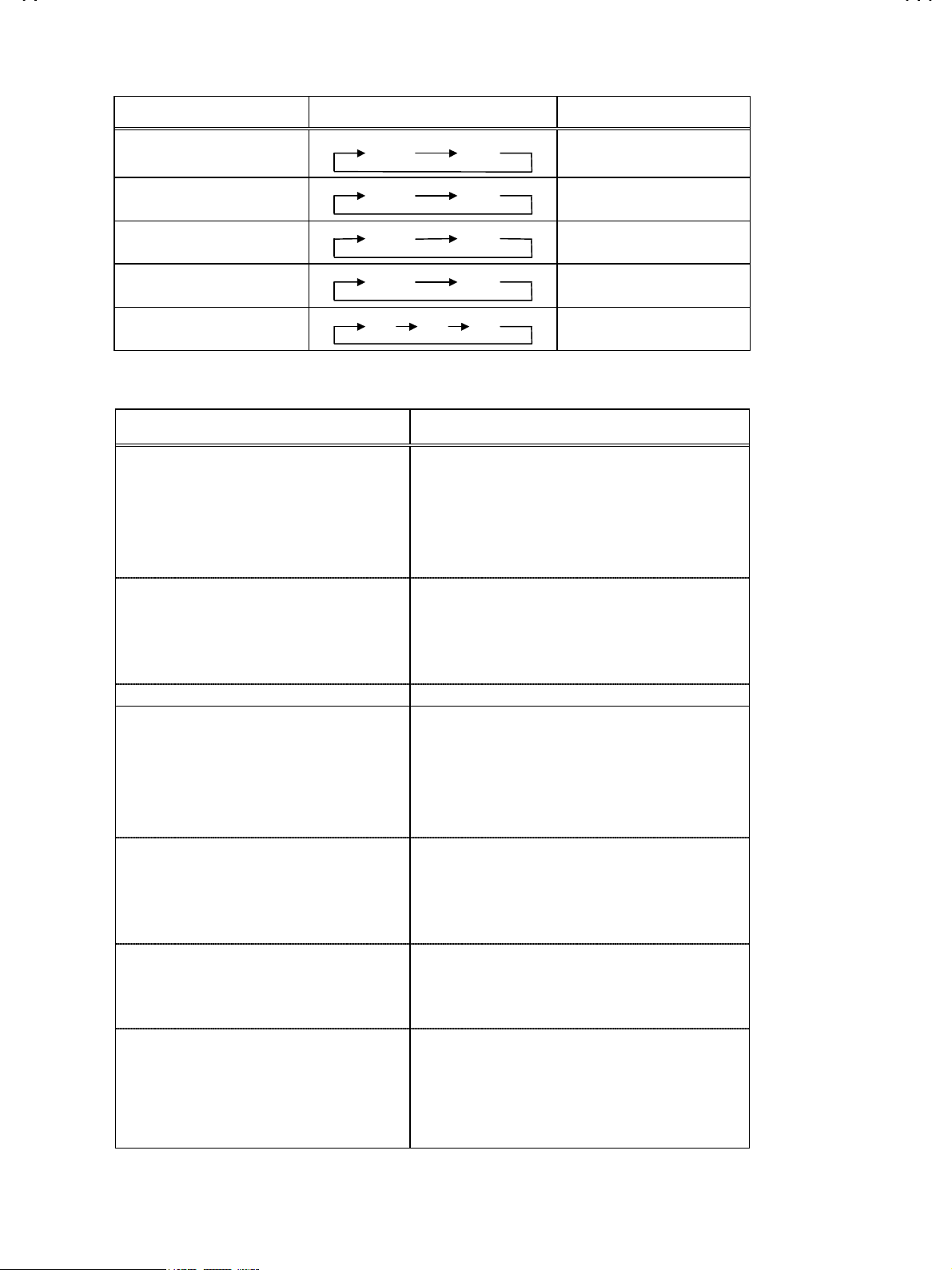

TABLE 1

TABLE 2

1. Setting of FUNCTION

2. Settin g of ME NU

( System Constant Setting )

Setting item Setting content Setting value

GAME YES

HYPER SCAN YES

SURROUND YES

CCD YES

VIDEO 2

(User settin g val ue)

Setting item Setting value

MAIN POWER OFF

SUB POWER ON

CHANNEL CH 02

CHANNEL PRESET Refer to OPERATING INSTRUCTIONS

VOLUME 10

TV/VIDEO TV

DISPLAY OFF

SLEEP TIMER 0

VIDEO STATUS STANDARD

CLOSED CAPTION OFF (CC1/T1)

HYPER SURROUND OFF

TINT CENTER

COLOR CENTER

PICTURE CENTER

BRIGHT CENTER

DETAIL CENTER

BASS CENTER

TREBLE CENTER

BALANCE CENTER

MTS STEREO

TV SPEAKER ON

SET CLOCK Unnecessary to set

ON/OFF TIMER NO

CHANNEL SUMMARY Unnecessary to set

SET LOCK CODE Unnecessary to set

AUTO TUNER SETUP Unnecessary to set

TUNER MODE AIR

NOISE MUTING OFF

CLOSED CAPTION OFF (CAPTION : CC1 TEXT : T1)

LANGUAGE ENG.

YES NO

YES NO

YES NO

YES NO

210

No. 51731

9

Page 10

A

V-29M201

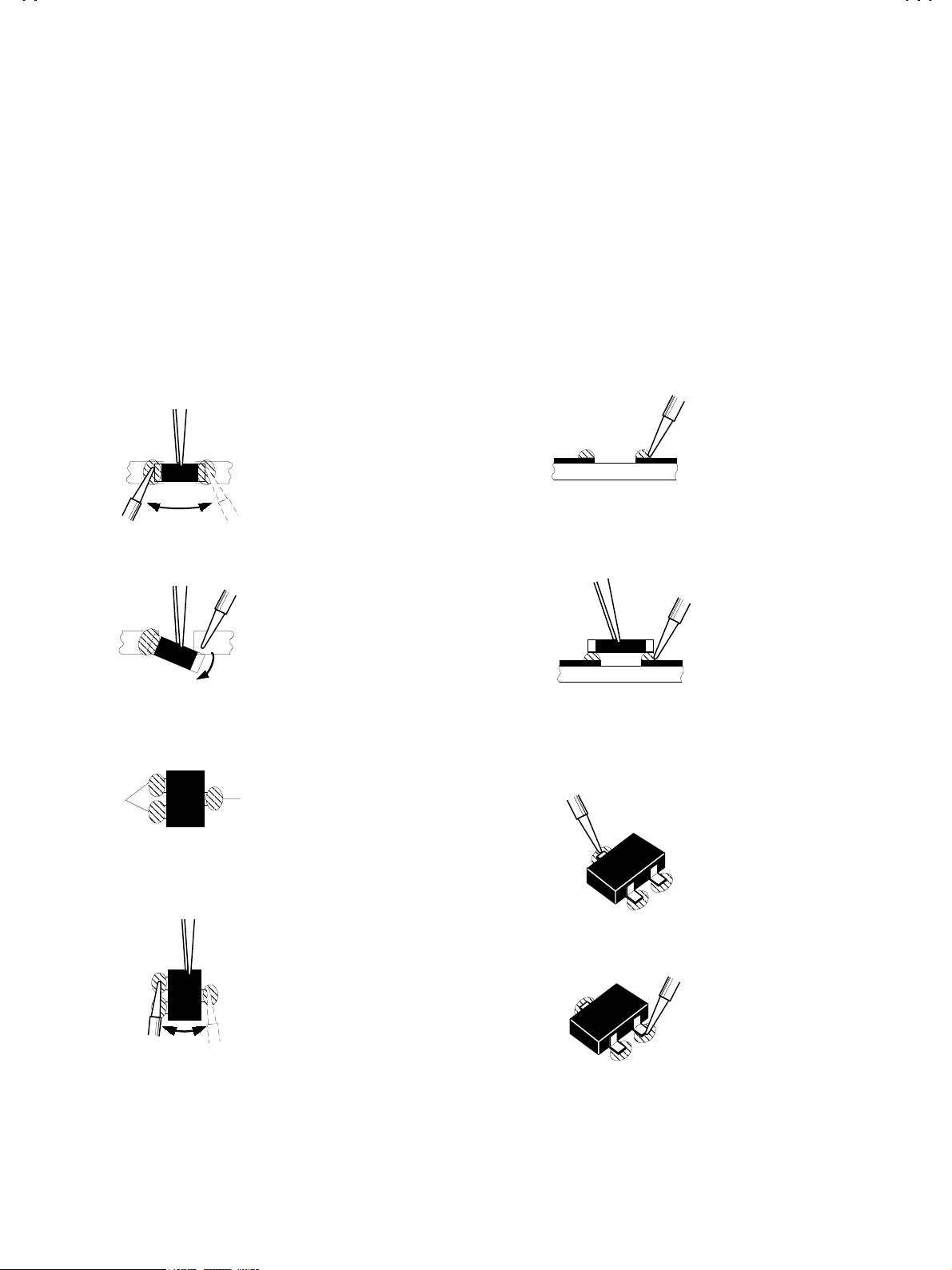

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

!

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reus e a chip p ar t after removi ng it.

SOLDERING IRON

!

1. Use a high insul ati on solder in g iron with a thi n p oint ed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMEN T STEPS

!

How to remove Chip parts

1.

Resistors, capacitors, etc

####

(1) As shown in the figure, push the part with tweezers and

alternately m elt th e s older at each en d.

(2) S hif t wi th tweezers an d r em o ve the chip par t.

Transistors, diodes, variable resistors, etc

####

(1) Apply extra solder to each lead.

SOLDER

SOLDER

2. How to install Chip par ts

Resistors, capacitors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp th e chip part with tw eezers and pl ace it on th e sold er.

Then heat an d m elt t h e s old er at b oth en ds of th e chip part .

Transistors, diodes, variable resistors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

as indicated in the figure.

A

A

(2) As shown in the figure, push the part with tweezers and

alternat el y melt t he s old er at each lead . Shif t and r emov e th e

chip part.

Note : After removing the part, remove remaining solder from the

pattern.

10

No.51731

(4) Then solder leads

A

and C.

B

C

C

B

B

Page 11

A

V-29M201

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION:

1. You can ma ke the n eces sary adjust me nts f or t his unit with eith er th e r emot e cont ro l unit or with the adj ustme nt equ ipmen t a nd

part s as given below.

2. Adjustm en t with th e remote con trol un it i s m ade on t h e ba sis of t h e initial settin g v al u es , howev er, the new set ti n g values which

set the screen to its optimum condition may differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for the set and test equipment before use, and start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception or input signal for adjustment.

6. Never touch any adjustment parts which are not specified in the list for this adjustment-variable resistors, transformers, cond ensers, etc .

7. Presett i ng b ef or e ad jus tment.

Unless otherwise specified in the adjustment instructions, preset the following functions with the remote control unit.

VIDEO STATUS NORMAL

TINT, COLOR, PICTURE, BRIGHT,

DETAIL

BASS, TREBLE, BALANCE CENTER

HYPER SURROUND OFF

CENTER

ADJUSTMENT EQUIPMENT

1. DC voltm et er (or digit al voltmet er )

2. Oscilloscope

3. Signal generator ( Pattern genera tor ) [NTSC] [PAL -M] [PAL-N]

4. Remote control unit

5. TV audio multiplex signal generator

6. Frequency counter

ADJUSTMENT ITEMS

Check of B1 POWER SUPPLY

%

IF VCO adjustment

%

RF AGC adjustment

%

FOCUS adj us tment

%

DEFLECT IO N ad jus t m ent

%

V. HEIGHT, V. POSITION, V. LIN., V S CR adjustment

H. POSITION adjustment

VIDEO / CHROMA adjustment

%

WHITE BALANCE ( Low light ) adjustment

WHITE BALANCE ( High light ) adjustment

SUB BRIGHT adjustment

SUB CONTRAST adjustment

SUB COLOR adjustment

SUB TINT adjustment

MTS circuit adjustment

%

INPUT LEVEL check

STEREO VCO adjustment

SAP VCO adjustment

FILTER check

SEPARATION adjust ment

No. 51731

11

Page 12

A

V-29M201

(

)

(

)

(

)

(

)

(

)

(

)

)

(

)

(

)

(

)

ADJUSTMENT LOCATI ONS

F901

IC702

MEMORY

IC701

CPU

FRONT

MAIN PWB ASS'Y(1/2)

SOLDER SIDE

TOP

MPX

5

IC201

1

IC651

AV JAC K

TUNER

T111

IC101

C

CW

TP-E

U

13

B1

TP-91

Q522

HV

T522

HVT

B1

UPPER : FOCUS

LOWER : SCREEN

FRONT

D702

TP-R

T

U

P-E(

T

CRT SOCKET

PWB ASS'Y(2/2)

E1

CRT EARTH

BRAID ED ASS' Y

With in MAIN PWB ASS'Y

12

IC701

POWER/

ON TIME R

LED

S901

POWER SW

FRONT CONTROL PWB ASS'Y

No. 51731

VOL

VOL

+

+

+

+

CH

―

―

―

―

CH

+

+

+

+

OPERATE

SUB POWER

MENU

―

―

―

―

Page 13

A

BASIC OPERATION OF SERVICE MENU

1. TOOL OF SERVICE MENU OPERATIO N

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

In general, basic setting( adjust m ents ) items or verific ati ons are perfor m ed in the SERVIC E ME NU .

(1) PICTURE

(2) SOUND

(3) VIDEO STATUS

(4) OTHERS

(5) LOW LIGHT

(6) HIGH LIGHT

(7) RF A F C CHK

(8) VCO (CW)

2

(9) I

C BUS CTRL

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

3. Basic Oper a t io ns o f t he SE RV ICE MEN U

(1) How to enter the SERVICE MENU.

Press t h e DISPL A Y k ey an d VIDEO STATU S k e y of th e remot e control un it at t he same tim e t o en ter the SERVI C E MEN U s c reen

shown in figure page la ter.

This sets the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECTION circuits.

This sets the setting values (adjustment values) of the AUDIO circuit.

This is used when the THEATER and GAME MODE is adjusted.

This is used when the OTHERS MODE is adjusted.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This is used when the IF VCO is adjusted.

[Do not adjust]

This is used when the IF VCO is adjusted.

This is used when ON/OFF of the I2C BUS CTRL is set.

[Fixed ON]

V-29M201

①

(2) SERVICE MENU screen selection

Press the UP / DOWN key of the MENU to select any of the following items.

(The lett ers of t h e sel ec t ed it ems are disp l ayed in yellow .)

PICTURE

●

VIDEO STATUS

●

LOW LIGHT

●

RF AFC CHK

●

I2C BUS CTRL

●

SOUND

●

OTHERS

●

HIGH LIGHT

●

VCO (CW)

●

(3) Ente r the any setting ( adjustment ) mode

PICTURE, SOUND and OTHERS mode

"

1) If select any of PICTURE, SOUND or OTHERS items, and the LEFT / RIGHT key is pressed from SERVICE MENU ( MAIN

MENU ), the screen ② will be dis p layed as sh ow n in fi gure pag e later.

2) T hen the U P / DOWN key is press ed, th e PIC TU RE mod e scr een ③ or th e SOUND m ode s cr een ④ or the OTHERS mode

screen ⑤ is displayed, and the PICTURE, SOUND or OTHERS setting can be performed.

VIDEO STATUS, LOW LIGHT, HIGH LIGHT, RF AFC CHK, VCO (CW) and I

"

1) If select any of VIDEO STATUS / LOW LIGHT / HIGH LIGHT / RF AFC CHK / VCO (CW) / I

2

C BUS CTRL mode

2

C BUS CTRL items, and the LEFT

/ RIGHT k ey is pr essed f r om SER V I CE MEN U ( MAIN MEN U ), the scr eens ⑥ ⑦ ⑧ ⑨ ⑩ ⑪ will be disp lay ed as shown in

figure page later.

2) Then the settin gs or verific ati ons c an b e performed.

No. 51731

13

Page 14

A

V-29M201

①①①①

SERVICE MENU (MAIN MENU)

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK VCO (CW)

I2C BUS CTRL

SELECT BY

OPERATE BY

⑧⑧⑧⑧

HIGH LIGHT MODE

HIGH LIGHT

***

***

******

⑨⑨⑨⑨

RF AFC CHK MODE [DO NOT ADJUST]

EXIT BY

***

***

******

EXIT BY

EXIT

EXIT

②②②②

SCREEN

IT

IT

SELECT BY

1. NOISE

STATUS

SELECT BY

OPERATE BY

④④④④

SOUND MODE

EXIT BY

EXIT

********

********

****************

EXIT BY

EXIT

***

***

******

IT

IT

③③③③

1. PICTURE

**** ****

**** ****

**** ******** ****

SELECT BY

OPERATE BY

⑤⑤⑤⑤

1.OSD POS.

**** ****

**** ****

**** ******** ****

SELECT BY

OPERATE BY

PICTURE MODE

OTHERS MODE

***

***

******

****

****

********

EXIT BY

EXIT

***

***

******

****

****

********

EXIT BY

EXIT

IT

IT

RF AFC

FINE

STATUS

SELECT BY

OPERATE BY

⑩⑩⑩⑩

VOC (CW) MODE

VCO (CW)

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

SYNC : YES

⑪⑪⑪⑪

I2C BUS CTRL MODE

[FIXED ON]

I2C BUS ON

OPERATE BY

***

***

******

********

********

****************

********

********

****************

EXIT BY

EXIT

EXIT BY

EXIT

EXIT BY

EXIT

ON

IT

⑥⑥⑥⑥

VIDEO STATUS MODE

THEATER

TINT G DRI V E

COLOR B DRI V E

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

IT

IT

SELECT BY

OPERATE BY

BRIGHT

BRIGHT

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

⑦⑦⑦⑦

LOW LIGHT MODE

***

***

******

*** *** ***

*** *** ***

*** *** ****** *** ***

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

EXIT BY

EXIT

EXIT BY

EXIT

Press

VIDEO

STATUS

IT

IT

Key

TINT G DRI V E

COLOR B DRI V E

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

GAME

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

EXIT BY

EXIT

IT

14

No. 51731

Page 15

A

(4) Setting method

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / RIGHT key of the MENU

Setting(adjust) the SETTING VALUE of the SETTING ITEM.

When the key is released the SETTING VALUE will be stored

(memorized).

3) EXIT key

Returns to the previous screen.

[NOTE] (PICTURE MODE ONLY)

When the INT IAL SET TING VA LUE is tur ned to yel low, y ou can ad just

the values but you cannot adjust the values when it is turned to red

(because the sign al c on ditions, etc . ar e n ot m et.)

(5) Releasing SERVICE MENU

1) After returni ng to the SERVICE MENU upon c ompletion of t he setting

(adjust m ent ) w or k, pr ess the EXIT k ey ag ai n.

The s ettings f or LOW LIGHT and H IGH LIGHT are descr ibed in t he W HITE

★

BALANCE page of ADJUSTMENT.

1. PICTURE

**** ****

**** ****

**** ******** ****

SELECT BY

OPERATE BY

PICTURE MODE

SETTING

ITEM

1. NOISE

STATUS

SELECT BY

OPERATE BY

SOUND MODE

***

***

******

****

****

********

EXIT BY

IT

EXIT

INITIAL

SETTING VALUE

↓ (Adjust)

SETTING VALUE

***

***

******

****

****

********

EXIT BY

IT

EXIT

V-29M201

The setting for VCO(CW) are described in the IF VCO page of ADJUSTMENT.

★

THEATER

The letter of the selected

Items are displayed in yellow.

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

EXIT BY

EXIT

1. OSD POS.

**** ****

**** ****

**** ******** ****

SELECT BY

OPERATE BY

OTHERS MODE

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

IT

Press

VIDEO

STATUS

Key

VIDEO STATUS MODE

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

GAME

***

***

******

****

****

********

EXIT BY

EXIT

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

EXIT BY

EXIT

IT

IT

No. 51731

15

Page 16

A

V-29M201

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values ; however, the new setting values which set

the screen in its optimum condition may differ from the initial setting.

2. Do not change the initial Setting Values of the Setting (Adjustment) items not listed In “ADJUSTMENT”.

PICTURE MODE

"

The four setting items in the video mode No.8 EXT PIC., No.9 EXT BRI., No.10 EXT COL., and No.11 EXIT TINT are linked to the items in

$

the TV MODE N o.1 PICT URE, N o.2 BRIG HT, N o. 5 COL.N TSC and N o.6 TINT , res pectiv ely. When the s etting items in th e TV mode are

adjust ed, th e val u es in th e s etting i t ems i n t h e vid eo m ode ar e revised au t om at ically t o the sa m e v alu es i n the T V m ode.(Th e initial setting

values given in ( ) are off-set values.)

When the f our items (No.8, 9, 10 and 11) are adjus t ed in t h e vid eo mode, th e s etti ng v alues in each it em ar e re vised ind ep endently.

$

No. Setting (Adjustment) item Variable range Initial setting value

1. PICTURE

2. BRIGHT 0~127 64

3. COL. PALM 0~127 80

4. COL. PALN 0~127 80

5. COL. NTSC 0~127 95

6. TINT

7. TV DTL 0~63 33

8. EXT PIC.

9. EXT BRI.

10. EXT COL.

11. EXT TINT

12. EXT DTL 0~63 30

13. P/N KILL 0 / 1 0

14. Y S CONT 0~31 31

15. TV Y-DL 0~41

16. EXT Y-DL

17. WPL SW 0 / 1 0

18. Y GAMMA 0 / 1 0

19. P/N G P. 0 / 1 0

20. COL. L SW 0 / 1 1

21. COL. LMT.

22. PN C. ATT 0~31

23. OFST. SW 0 / 1 0

24. OFST. B-Y 0~15 8

25. OFST. R-Y 0~15 8

26. C-TOF SW 0 / 1 1

27. TV T FO 0~31

28. TV T Q 0~30

29. EXT T FO 0~30

30. EXT T Q 0~30

31. C-TRAP 0 / 1 0

32. C-TR. FO 0~32

33. C-TRAP Q 0~31

34. FIX B/W 0 / 1 0

35. APA P. FO 0~32

36. DC TRAN.

37. B. ST. SW 0 / 1 0

38. B. ST. PO. 0~70

39. ABL GAIN 0~74

40. ABL PO. 0~70

41. HALF T.

42. DRV G SW 0 / 1 0

43. NT. COMB 0 / 1 1

44. COIN DE T

45. NOISE L.

46. VCD MODE 0 / 1 0

47. V AGC SP 0 / 1 0

48. H POS. 50

49. H BLK. 50

50. V POS. 50

0~127

0~127

25 (0)

±

25 (0)

±

25 (+4)

±

25

±

0~4

0~3

0~7

0~2

0~3

0~3

0~31

0~7

0~7

60

65

(+3)

1

1

4

1

3

3

6

0

2

16

No. 51731

Page 17

A

PICTURE MODE

"

No. Setting (Adjustment) item Variable range Initial setting value

51. V SIZE50 0~127 71

52. V S CR50 0~127 83

53. V LIN. 50 0~31 4

54. H POS. 60 0~31 10

55. H BLK. 60 0~70

56. V POS. 60 0~70

57. V SIZE60 0~127 72

58. V S CR60 0~127 99

59. V LIN. 60 0~31 3

60. RF AGC 0~255 160

SOUND MODE

"

No. Setting (Adjustment) item Variable range Initial setting value

1. NOISE 0 / 1 1

2. IN LEVEL 0~63 50

3. FH MON. 0 / 1 0

4. ST VCO 0~63 25

5. PILOT 0 / 1 0

6. FILTER 0~63 30

7. LOW SEP. 0~63 22

8. HI SEP. 0~63 23

9. 5FH MON. 0 / 1 0

10. SAP VCO 0~63 26

11. IN GAIN 0 / 1 0

12. FIL. OFF. 0~10 0

V-29M201

VIDEO STATUS MODE

"

Setting (Adjustment) item Variable range

TINT

COLOR

PICTURE -30~+20 -10 -10

BRIGHT

DETAIL

G DRIVE -99~+50 -22 0

B DRIVE -99~+50 -54 0

R CUT.

G CUT.

B CUT.

Initial settin g val ue

THEATER GAME

20 0 0

±

20 -3 -3

±

20 0 0

±

15 0 -5

±

10 0 0

±

10 0 0

±

10 0 0

±

No. 51731

17

Page 18

A

V-29M201

A

OTHERS MODE

"

No. Setting (Adjustment) item Variable range Initial setting value

1. OSD POS. 0~31 7

2. LOCK DET 0 / 1 0

3. SD SEL. 0~20

4. H-CK SW 0 / 1 0

LOW LIGHT MODE

"

Setting (Adjustment) item Variable range Initial setting value

R CUTOFF 0~255 20

G CUTOFF 0~255 20

B CUTOFF 0~255 20

HIGH LIGHT MODE

"

Setting (Adjustment) item Variable range Initial setting value

G DRIVE 0~255 128

B DRIVE 0~255 128

RF AFC CHK MODE

"

Setting (Adjustment) item Variable range Initial setting value

RF AFC ON / OFF ON

FINE -77~+77

2

I

C BUS CTRL MODE

"

Setting (Adjustment) item Variable range Initial setting value

I2C BUS ON / OFF

±××

[Fixed ON]

DO NOT

DJUST

18

No. 51731

Page 19

A

■■■■

)

ADJUSTMENTS

B1 POWER SUPPLY

Item

Check of

B1 POWER

SUPPLY

Measuring

instrument

DC Vol tme t e r

ADJU STMENT O F IF VCO

Item

IF VCO

adjustment

Measuring

instrument

Signal

generator

VCO (CW

TOO HIGH

ABOVE REFERENCE

BELOW REFERE NCE

TOO LOW

SYNC : YES

Test point Adjustment ite m Description

B1 ( B1

1

(TP-91)

TP-E(#)

( B1

3

Test point Adjustment ite m Description

Connector

pin)

Connector

pin)

CW TRANSF. (T111)

[VCO (CW)] mode

YELLOW

1. Receive a blac k an d w hi te sign al (c olor off ) . (NT S C)

2. Connect the DC voltmeter to B1

91) and TP-E(#) (B1 connector 3

3. Confirm that the voltage is DC129.5V V.

Under normal conditions, no adjustment is required. and it

%

must not ad jus t w it hout sign al.

1. Receive a NTSC broadcast. (use channels without offset

frequency).

2. Select the VCO(CW) mode from the SERVICE MENU.

3. Confirm the color change (yellow) from “TOO HIGH” to

TOO LOW”by CW TRAN SF. and “SYNC : YES” being

“

shown on the screen. Then, adjust CW TRANSF. until

BELOW REFERENCE” mark turns yellow and confirm

“

again “ SYNC : YES” being shown on the screen.

V-29M201

connector 1 pin (TP-

pin).

+2

-2.5

ADJU STMENT O F RF AGC

RF AGC

adjustment

ADJU STMENT O F FOCUS

FOCUS

adjustment

Signal

generator

EXIT BY

EXIT

IT

No.60 RF AGC

FOCUS VR

[In HVT]

1. Receive a broadcast.

2. Select “No.60 RF AGC” of the PICTURE mode in SERVICE

MENU.

3. Press the MUTING key and turn off color.

4. W ith the M ENU L EFT k ey, g et nois e in t he scr een pic ture. ( 0

side of sett in g value)

5. Press the MENU R IGHT k ey and s top wh en n ois e dis app ears

from the screen.

6. Change to other channels and make sure that there is no

irregularity.

7. Press the MUTING key and get color out.

1. Receive a crosshatch signal.

2. While looking at the screen, adjust FOCUS VR so that the

vertic al and hor i z ont al lines will be cl ear and in fin e det ail.

3. Make sure t hat the pictur e is in focus even when the sc reen

gets dark en ed.

No. 51731

19

Page 20

A

V-29M201

(

)

(

)

(

)

ADJUSTMENT OF DEFLECTION CIRCUIT

Item

V. HEI GHT ,

V. POSITION,

V. LIN.

V. S CR

adjustment

Screen

size

92%

Measuring

instrument

Signal

generator

Test point Adjustment ite m Description

No.56 V POS. 60

No.57 V SIZE 60

No.58 V S CR60

No.59 V. LIN. 60

No.50 V POS.50

No.51 V SIZE 50

No.52 V S CR50

No.53 V LIN.50

Scree s ize

Picture

size

100%

[60Hz]

1. Receive a crosshatch signal.(NTSC or PAL-M)

2. Confirm that the value of PICTURE MODE “No.56 V PO S.

60” is 0.

3. C onfirm th e initial setting value of t he “No.57 V SIZE 60”,

No.58 V S CR60” and “No.59 V LIN. 60”.

4. Adjust the vertical screen size to 92% with the PICTURE

MODE “No. 57 V SIZE 60”.

5. Adjust the PICTURE M ODE “No.59 L LIN. 60” and “No.58

V S CR60” to get the best vertical linearity.

NOTE :

1. The PICTURE MODE “No.56 V POS. 60” is fixed on value 0.

2. Bottom of screen is to be located within the 85%~95% range.

[50Hz]

1. Receive a crosshatch signal. (PAL-N)

2. Confirm the initial setting value of the “No.50 V POS.50”,

“No.51 V SIZE 50” , “No.52 V S CR 50” and “No.53 V LIN.50”.

3. Adjust the vertical screen size to 92% with the PICTURE

MODE “No.51 V SIZE50”.

4. Adjust the P ICT URE MO DE “ No. 53 V LIN. 50” and “N o.52 V S

CR50” to get the best vertical linearity.

5. Adjust the PICTURE MODE “No.50 V POS.50” so that the

vertic al cent er lin e com es clos e to th e CRT vertic al cent er as

much as possible.

Readjust V SIZE, V LIN., V S CR if necessary.

"

H. POSITION

adjustment

Signal

generator

Picture size

100%

No.54 H PO S .60

No.48 H PO S .50

NOTE :

1. Bottom of screen is to be located within the 85%~95% range.

[60Hz]

1. Receive a crosshatc h sig n al. ( NTSC or PAL- M)

2. Select the “No.54 H POS. 60” of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial setting value of the "No.54 H POS. 60".

4. Adjust the “No.54 H POS. 60” until the screen will be

horizontally centered.

[50Hz]

1. Receive a crosshatch signal. (PAL-N)

2. Select the “No.48 H POS. 50” of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial setting value of the "No.48 H POS. 50".

4. Adjust the “No.48 H POS. 50” until the screen will be

horizontally centered.

20

No. 51731

Page 21

A

ADJUSTMENT OF VIDEO / CHROMA CIRCUIT

Item

WHITE

BALANCE

(Low Light)

adjustment

Measuring

instrument

Signal

Generator

Remote

control unit

[LOW LIGHT] MOD E

R CUTOFF

BRIGHT

*** *** ***

*** *** ***

*** *** ****** *** ***

BRIGHT

REMOTE CONTROL UNIT

Test point Adjustment ite m Description

BRIGHT

R CUTOFF

G CUTOFF

B CUTOFF

SCREEN VR

G CUTOFF

***

***

******

B CUTOFF

EXIT BY

IT

EXIT

BRIGHT

V-29M201

1. Receive a bl ac k-and- w hit e si gnal.(Color off )

2. Select the【LOW LIGHT】MODE from the SERVICE MENU.

3. Set the initial s etting value of BRIGHT with th e LEFT / RIGH T

key of the remote control unit.

4. S et the initial s etting val ue of R CUT OFF, G CUT OFF and B

CUTOFF with the

5. Dis play a singl e horiz ontal line by p ressing t he

remote control unit.

6. Turn the screen VR all the way to the left.

7. Turn th e screen VR gradually t o the right f rom the left u ntil

either one of the red, blue or green colors appears faintly.

8. Adjust the two colors which did not appear until the single

horizontal line tha t is displayed becomes white using the

keys of the remote control unit.

⑨⑨⑨⑨

9. Turn the scr een VR to where the singl e horizontal lin e glows

faintly.

10. Press the

The

*

②②②②

EXIT key is the cancel key for the WHITE BALANCE.

③③③③

to

④④④④

key of the remote control unit.

⑨⑨⑨⑨

key to return to the regular screen.

key of the

①①①①

to

④④④④

WHITE

BALANCE

(High Light)

adjustment

H.LINE O N

1 2

R CUTOFF

4 5

R CUTOFF

7 8

H.LINE O FF

G CUTOFF

G CUTOFF

Signal

Generator

Remote

control unit

[HIGH LIGHT] MODE

G DRIVE

HIGH LIGHT

***

***

******

B DRIVE

EXIT

3

B CUTOFF

6

B CUTOFF

9

G DRIVE

B DRIV E

***

***

******

EXIT BY

IT

EXIT

1. Receive a blac k an d w hi te sign al (c olor off ) . (NT S C)

2. Select the HIGH LIGHT mode in the SERVICE MENU.

3. Confirm the initial setting value of “G DRIVE” and “B DRIVE”.

4. Adjust the screen color to white with the

⑤⑤⑤⑤, ⑥⑥⑥⑥, ⑧⑧⑧⑧

and

keys of the remote control unit.

Remote Control Unit

key : H.LINE ON

①

key : H.LINE OFF

②

key : EXIT

③

key : G DRIVE

⑤

key : B DRIVE

⑥

key : G DRIVE

⑧

key : B DRIVE

⑨

▲

▲

▼

▼

⑨⑨⑨⑨

No. 51731

21

Page 22

A

V-29M201

Item

SUB BR I GHT

adjustment

SUB

CONTRAST

adjustment

SUB COLOR

adjustment

Measuring

instrument

Remote

control unit

Remote

control unit

Remote

control unit No.3 COL. PA LM

Test point Adjustment ite m Description

No.2 BRIGHT

No.1 PICTURE

1. Receive a NT SC broadcast.

2. Select “No.2 BRIGHT” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.2 BRIGHT” .

4. If the brightness is not the best with the in itial settin g value,

make fin e adjustm ent of th e “No.2 BRIG HT” until you get th e

optimu m bri ghtness.

1. Receive a NT SC broadcast.

2. Select “No.1 PICTURE” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.1 PICTURE”.

4. If the contrast is not the best with the initial setting value, make

fine adjustment of the “No.1 PICTURE” until you get the

optimum contrast.

[PAL-M]

1. Receive a PAL -M br oadcast.

2. S elect “No.3 COL. PALM” of t he PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.3 COL. PALM”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

SUB TINT

adjustment

Remote

control unit

No.4 C O L . P A LN

No.5 C O L . NTSC

No. 6 TINT

[PAL-N]

1. Receive a PAL -N bro adcast.

2. Select “No.4 C OL. PA LN” of the P ICT URE mod e in S ER VICE

MENU.

3. Confirm the initial setting value of the “No.4 COL. PALN”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

[NTSC]

1. Receive a NT SC broadcast.

2. Select “No.5 COL. NTSC” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.5 COL. NTSC”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

1. Receive a NTSC color bar signal.

2. Select “No. 6 TINT” of the PICTURE mode in SERVECE

MENU.

3. Confirm the initial setting value of the “No. 6 TINT”.

4. If the tint is not the best with the ini tial setti ng valu e, mak e fine

adjust m ent un t il you get t h e bes t tint.

22

No. 51731

Page 23

A

ADJUSTMENT OF MTS CIRCUIT

[

]

Item

MTS INPUT

LEVEL

check

MTS

STEREO VCO

adjustment

Measuring

instrument

Signal

generator

Frequency

counter

Test point Adjustment part Description

R OUT

[AUDIO OUT]

No.2 IN LEVEL

No.3 FH MON

No.4 ST VCO

V-29M201

1. Select the “No.2 I N LEVE L” of the SOUND mode in SE RVICE

MENU.

2. Verify that the “No.2 IN LEVEL” is set at its initial sett ing

value.

1. Receive a NTSC RF signal (non modulated sound signal) from

the anten n a t ermi n al.

2. Select the “No.3 FH MON” of SOUND mode in SERVICE

MENU, change the setting value from 0 to 1.

3. Connect the frequency connector to R OUT RCA pin of the

AUDIO OUT.

4. Select the “No.4 ST VCO”.

5. Confirm the initial setting value of the “No.4 ST VCO”.

6. Adj ust the “No.4 ST VCO” so th at the frequ ency count er wil l

displ ay 15. 73kHz±0.1kHz.

7. Select the “No.3 FH MON” of the SOUND mode, and reset the

setting v al u e fr om 1 to 0.

MTS SAP

VCO

adjustment

MTS FILTER

check

MTS

SEPARATION

adjustment

L-Channel

signal waveform

1 cycle

Signal

generator

Frequency

counter

TV audio

multiplex

signal

generator

Oscilloscope

MPX

Connector

4

pin SDA

pin GND

3

[M AI N PWB]

R OUT

AUDIO OUT

L OUT

R OUT

[AUDIO OUT]

R-Channel

crosstalk portion

Minimum

No.9 5FH MON.

No.10 SAP VCO.

No.6 FILTER

No.7 LOW SEP.

No.8 HI SEP.

1. Receive a NT SC RF si gn al (n on modulated s ou nd si gn al) fr om

the anten n a t ermi n al.

2. Connect between pin 4

(pin 3

3. Select the “No.9 5FH MON.” of the SOUND mode in SERVICE

MENU, and reset the setting value from 0 to 1.

4. Connect the frequency connector to R OUT RCA pin of the

AUDIO OUT.

5. Select the “No.10 SAP VCO”.

6. Confirm the initial setting value of “No.10 SAP VCO”.

7. Adjust th e “N o.10 SA P VCO ” s o th at th e f r equenc y c onnec tor

will display 78.67kHz±0.5kHz.

8. Select the “No.9 5FH MON.” of the SOUND mode, and reset

the setting value from 1 to 0.

1. Select the “No.6 FLTER” of the SOUND mode in SERVICE

MENU.

2. Verify that the “No.6 FLTER” is set at its initial setting value.

1. Input a s tereo L sig nal (30 0Hz) fr om the TV Au dio multi plex

signal g en er at or to the anten n a ter m in al. (NTSC)

2. Connect an oscilloscope to L OUT RCA pin of the AUDIO

OUT, and display one cycle portion of the 300Hz signal.

3. Change the c onn ect ion of t he osc ill osc ope t o R OUT RCA pin

of the AUDIO OUT, and enlarge the voltage axis.

4. Select the “No.7 LOW SEP.” of the SOUND mode in SERVICE

MENU.

5. Confirm the initial setting value of the “No.7 LOW SEP.”.

6. Adjus t the “No.7 LOW SEP.” so that the stroke element of the

300Hz sig n al wi ll b ec om e minim um .

7. Ch ange th e signal t o 3kHz, and si milarly adjust the “N o.8 HI

SEP.”.

of MPX connector) through 1MΩ resistor.

of MPX connector and GND

No. 51731

23

Page 24

A

V-29M201

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After rep air i ng the hi gh voltag e h old d ow n circuit sh ow n in Fi g. 1.

This circuit shall be checked to operate correctly.

2. CHECKI NG OF THE HIGH VOLTAGE HOLD DOWN CIRCUIT

(1) Turn the POWER SW ON.

(2) As shown in Fig.2, set the resistor (between X connector 1 & 3 ).

(3) Make sure that the screen picture disappears.

(4) Tempor ar il y un pl ug t h e p ow er c or d.

(5) Remove the resistor (between X connector 1 & 3 ).

(6) Again plug the power cord, make sure that the normal picture is displayed on the screen.

B1

Q941

Q942

IC701

31 48

Q511

H-Vcc

D510

IC201

3

H-OUT

D562

R563

RESISTOR

RESISTOR

RESISTORRESISTOR

15.3k

15.3kΩ±

Ω±1% 1/4W

15.3k15.3k

Ω±Ω±

4

3 2 1

Fig. 1

1% 1/4W

1% 1/4W1% 1/4W

R562

Q521

C561

Q522

T521

X

FR561

D561

T522

10

5

HEATER

24

D562

3 2 1 X

R562

R563

Fig. 2

No. 51731

CONNECTOR

FR561

C561

D561

Page 25

A

V-29M201

SELF CHECK FUNCTIONS

1. Outline

This mod el has self check f unctions given b elow. W hen a malf unction has been det dcted, the SUB- POWE R is turned off and th e LED

flashes to inform of the failure. The malfunction is detected by the signal input state of the control line connected to the microcomputer.

2. Self check items

Check ite m Detecte d co nt en t s D etection method Abnormality st ate

Over-c urrent protector Operati on of over - c urrent

protection circuit

X-ray protector Operation of X-ray protection

circuit

CRT NECK protector When the vertical circuit S-

correction capacitor C413 is

shorted, detect the potential

drop of the C413, and prevent

the burn damage to the CRT

NECK.

The microc omputer det ects at 1

second intervals.

If NG is detected for more than 1

ms, a malfu nc tion is int erpreted.

The microc omputer det ects at 1

second intervals.

If NG is detected for more than 1

ms, a malfu nc tion is int erpreted

The microc omputer det ects at 1

second intervals.

If NG is detected for more than 1

ms, a malfu nc tion is int erpreted

During an abn ormalit y th e su bpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is main tained until the power

cord is unpl ug g ed an d

reinserted.

During an abnormality the subpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

During an abnormality the subpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

3. Self check indicating function

The self check function begins detection about 5

seconds after pow er is sup pl i ed.

In the event a malfunction is detected, the sub-power is

cutoff immediately.

At this time, the POWER/ON TIMER LED flashes to

inform of t he m a lf unction .

Item LED flashing intervals Priority of detection

OCP/X-ray At 0.5 – second intervals 1

NECK At 0.5 – second intervals 2

Because OCP and X-ray protectors are inputted to the same pin in the microcomputer, the judgement will be logical sum (OR).

"

POWER

supplied

About 5 seconds

after

Detection

start

Malfuction is

detected

SUB-POWER OFF

Flashing

POWER /

ON TIMER LED

No. 51731

25

Page 26

A

V-29M201

26

No. 51731

Page 27

A

PARTS LIST

CAUTION

V-29M201

The parts identified by the

!

the safety .

T he parts not indic at ed in th is P arts Li s t and those whic h are fil led with lin es

!

P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

!

symbol are important for the safety. Whenever replacing these parts, be sure to use specified ones to secure

!

in the Parts No. columns will not be supplied.

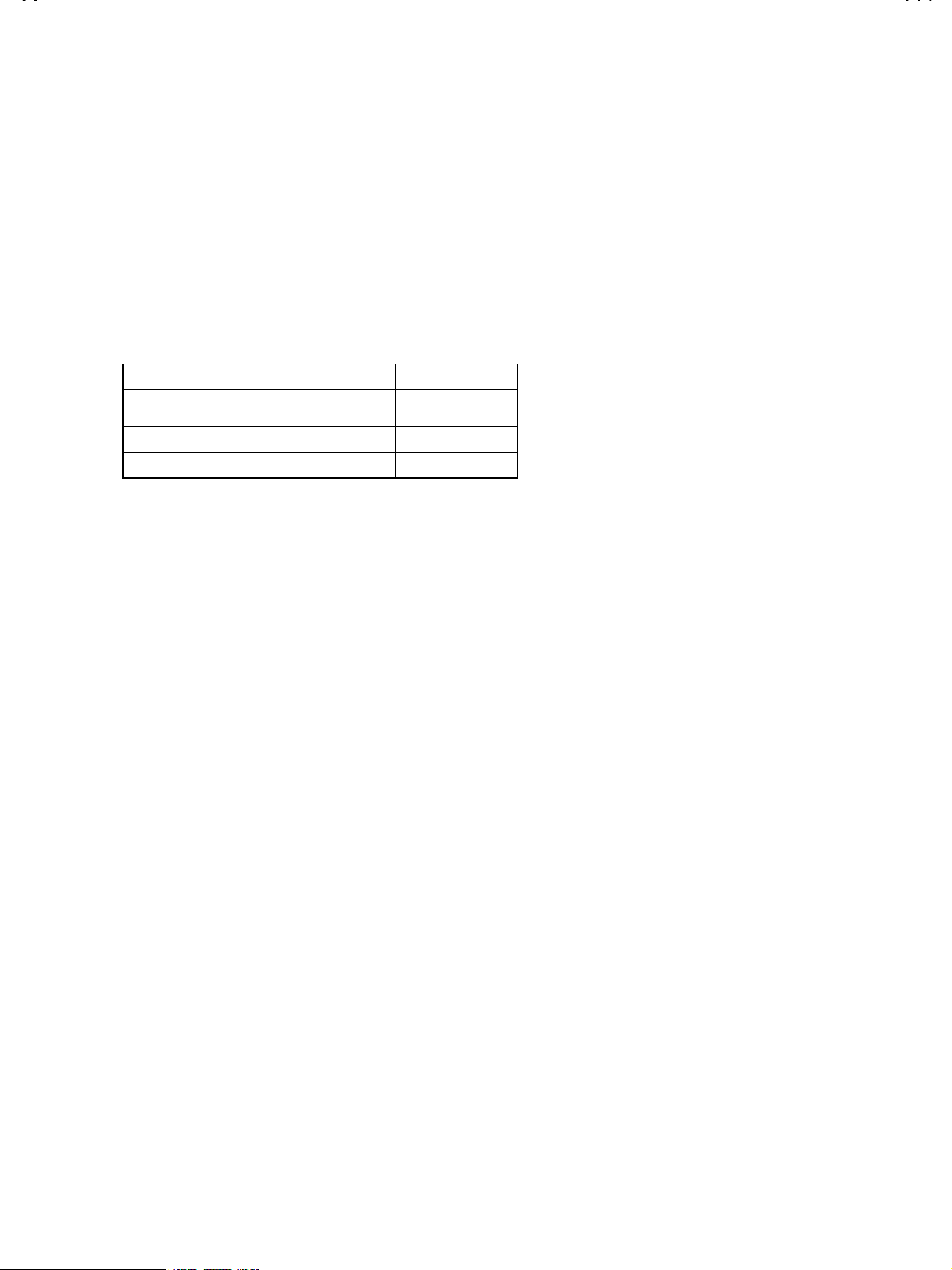

ABBREVIATIONS OF RESISTO RS, CAPACITO RS AND TOLE RANCES

RESISTORS CAPACITORS

C R Carbo n Resistor C CAP. Ceram ic Capacitor

F R Fusible Resistor E CAP. Electrolytic Capacitor

P R Plate Resistor M CAP. Mylar Capacitor

V R

HV R High Voltage Resistor MF CAP. Metalized Film Capacitor

MF R Metal Film Resistor MM CAP. Metalized Mylar Capacitor

MG R Metal Glazed Resistor MP CAP. Metalized Polystyrol Capacitor

MP R Metal Plate Resistor PP CAP. Polypropylene Capacitor

OM R Metal Oxide Film Resistor

Variable Resisto

r

HV CAP. High Voltage Capacitor

PS CAP

.

Polystyrol Capacitor

CMF R Co ating Metal Film Resistor TF CAP. Thin Film Capacitor

UNF R Non-Flammable Resistor MPP CAP. Metalized Polypropylene Capacitor

CH V R Chip Variable Resistor TAN. CAP. Tantalum Capacitor

CH MG R Chip Metal Glazed Resistor CH C CAP. Chip Ceramic Capacitor

COMP. R Composition Resistor BP E CAP. Bi-Polar Electrolytic Capacitor

LPTC R

Linear Positive Temperature Coefficient

Resistor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP.

CH TAN. E CAP.

CH AL BP E CAP.

Chip Aluminum Bi-Polar Capacitor

Chip Tantalum Electrolytic Capacitor

Chip Tantalum Bi-Polar Electrolytic Capacitor

TOLERANCES

FGJKMNRHZP

1%

±

2%

±

5%

±

10%

±

20%

±

30%

±

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

No.51731

27

Page 28

A

V-29M201

CONTENTS

USING PW BOARD & REMOTE CONTROL UNIT

!

EXPLODED VIEW PARTS LIST

!

EXPLODED VIEW

!

PRINTED W IRING B OARD PARTS LIST

!

MAIN PW BOARD ASS'Y (SGA-1017A-M2)

"

FRONT CONTROL PW BOARD ASS'Y (SGA-4006A-M2)

"

REMOTE CONTROL UNIT PARTS LIST

!

PACKING

!

PACKING PARTS LIST

!

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

(With CRT SOCKET PW BOARD)

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

USING P.W. BOA RD & REMOTE CONTROL UNIT

Model

P.W.B ASS’Y

MAIN P.W.B (With CRT SOCKET PWB) SGA-1017A-M2

AV-29M201

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

28

28

29

30

34

34

35

35

FRONT CONTROL P.W.B SGA-4006A-M2

REMOTE CONTROL UNIT RM-C765-1A

EXPLODED VIEW PARTS LIST

Ref.No. Part No. Part Name Description

!

L01 CELD058-002J3 DEGAUSING COIL

!

V01 A68ADT25X01 ITC TUBE(C) (Inc.DY)

!

T1522 CE42674-001 J1 H.V.TRANSF. (Within MAIN PWB)

!

1 CM12919-008-MA FRONT CABINET

!

2 CHGB0015-0B BRAIDED WIRE

3 CHGB0016-0C BRAIDED WIRE(SUB)

4 CEBSS12D-04KJ2 SPEAKER (×2)SP01,SP02

!

5 CM36568-A02-A PUSH KNOB

6 CM36652-001-A POWER KNOB

7CM12985-002-VA CHASSIS BASE

!

8 QMPD290-200-JC POWER CORD

!

9 LC20106-001D-A CORD CLAMP

!

10CM12920-B02-VA REAR COVER

!

11 QYSBSFG4016Z TAPPING SCREW (×7)

12 QYSBSB3010Z TAPPING SCREW (×2)

13 GQ30018-001A-A RATING LABEL

!

14 CM35983-001-H REMOCON WINDOW

15 CM48006-006-C JVC MARK

28

No.51731

Page 29

A

EXPLODED VIEW

V-29M201

!

1

!

L01

V01

15

14

2

3

!

4

CRT SOCKET PWB

(Wit hin MAIN PW B)

5

FRONT CONTROL

PWB

!

MAIN PWB

6

!

4

!

T1522

!

7

!

!

10

!

13

9

12

(×2)

!

8

11

(×7)

No.51731

29

Page 30

A

V-29M201

PRINTED WIRING BOARD PA RTS LIST

MAIN PW BOARD ASS’Y (SGA-1017A-M2)

!"#$%&'(%) *+,-'(%) *+,-'(+#. /.01,23-2%4

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

56!7!895

5:;;: (5!<;=>?@ABC DE'5 @AF!':G:;H'''>

5:;;=?;I (5!<;=>?@A:C DE'5 @A;!':G:;H'''>

5:;;@ J5KL;:M?I5M N'5 I)M!'':GIH'''>

!

5:;;A (5!<;=>?O=;C DE'5 O=!':G:;H'''>

5::;: (5!<;=>?@A=C DE'5 @)AF!':G:;H'''>

5::;= (5!<;=>?:O=C DE'5 :)OF!':G:;H'''>

5::;B J56:=:>?:;:P Q'5 :;;!'':G=H'''>

5::;I (5!<;=>?:O;C DE'5 :O!':G:;H'''>

5::;@ (5!<;=>?=M;C DE'5 =M!':G:;H'''>

5:::: (5!<;=>?BLIC DE'5 BL;F!':G:;H'''>

5:::= (5!<;=>?BBIC DE'5 BB;F!':G:;H'''>

5:::B (5!<;=>?:;:C DE'5 :;; !':G:;H'''>

5:::A (5!<;=>?AO;C DE'5 AO!':G:;H'''>

5::B: (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5::B= (5!<;=>?BB:C DE'5 BB; !':G:;H'''>

5::BB (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5::BI (5!<;=>?=M:C DE'5 =M; !':G:;H'''>

5::B@ (5!<;=>?IM:C DE'5 IM; !':G:;H'''>

5::A: (5!<;=>?BB=C DE'5 B)BF!':G:;H'''>

5::A= (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5::AB (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5::AI (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5::A@ (5!<;=>?=MBC DE'5 =MF !':G:;H'''>

5::AA (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5::AM (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5::AO (5!<;=>?:;:C DE'5 :;; !':G:;H'''>

5::AL (5!<;=>?@A:C DE'5 @A; !':G:;H'''>

5::M; (5!<;=>?:=BC DE'5 :=F !':G:;H'''>

5:=;: (5!<;=>?O=:C DE'5 O=; !':G:;H'''>

5:=;= (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:=;B (5!<;=>?O=:C DE'5 O=; !':G:;H'''>

5:=;I (5!<;=>?AO:C DE'5 AO; !':G:;H'''>

5:=;@ (5!<;=>?:@=C DE'5 :)@F!':G:;H'''>

5:=:B (5!<;=>?BL:C DE'5 BL; !':G:;H'''>

5:=:@ (5!<;=>?O=IC DE'5 O=;F!':G:;H'''>

5:=:A (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:=:M (5!<;=>?@ABC DE'5 @AF !':G:;H'''>

5:==; (5!<;=>?IM:C DE'5 IM; !':G:;H'''>

5:=@:?@= (5!<;=>?M@;C DE'5 M@ !':G:;H'''>

5:B;: (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:B;B?;I (5!<;=>?@A=C DE'5 @)AF!':G:;H'''>

5:B;M (5!<;=>?IM=C DE'5 I)MF!':G:;H'''>

5:B;O (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:B;L (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:B:: (5!<;=>?=MBC DE'5 =MF !':G:;H'''>

5:B:= (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:B:I (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:BI: (5!<;=>?:=:C DE'5 :=; !':G:;H'''>

5:BI=?IB (5!<;=>?BBBC DE'5 BBF!':G:;H'''>

5:B@:?@B (5!<;=>?:@:C DE'5 :@;!':G:;H'''>

5:B@I?@A (5!<;=>?BB:C DE'5 BB;!':G:;H'''>

5:B@M?@L (5!<;=>?:;:C DE'5 :;;!':G:;H'''>

5:BA;?A= J5K;:::?:@= Q'5 :)@F!'':G=H'''R

5:BAB?A@ J5E;=L>?:=B 9D'5 ''': = F !''''= H '''>

5:BAA?AO (5!<;=>?=M=C DE'5 =)MF!':G:;H'''>

5:I;: (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:I;= (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:I;B (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:I;I (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:I;@ (5!<;=>?==:C DE'5 ==; !':G:;H'''>

5:I;A?;O (5!<;=>?IM=C DE'5 I)MF!':G:;H'''>

5:I:; (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:I:B J56:=:>?BL:P Q'5 BL;!'':G=H'''>

5:I:I J5C;:E>?5AO DN'5 ;)AO!'''': H '''>

5:I:A (5!<;=>?@ABC DE'5 @AF !':G:;H'''>

5:I:O (5!<;=>?@ABC DE'5 @AF !':G:;H'''>

5:I:L (5!<;=>?:OBC DE'5 :OF !':G:;H'''>

5:I=:?== (5!<;=>?;5;C DE'5 ;);!':G:;H'''>

!"#$%&'(%) *+,-'(%) *+,-'(+#. /.01,23-2%4

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

56!7!895

5:I=B (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:@;: (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:@;B (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:@;I (5!<;=>?:;IC DE'5 :;;F!':G:;H'''>

5:@;@ (5!<;=>?O==C DE'5 O)=F!':G:;H'''>

5:@;A (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:@:; (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:@:= (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:@:B (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:@:I (5!<;=>?BBBC DE'5 BBF !':G:;H'''>

5:@=: J5S;BL>?:O= 9D'5 :)OF!''''B H '''>

5:@=B (5!<;=>?===C DE'5 =)=F!':G:;H'''>

5:@=I J56:=:>?:;BP Q'5 :;F!'':G=H'''>

5:@=@ J5E;:E>?@A: 9D'5 @A;!'''':H '''>

5:@=A J5S;=L>?:@= 9D'5 :)@F!''''= H '''>

5:@=L (5!<;=>?A=:C DE'5 A=; !':G:;H'''>

5:@B= J5S;BL>?:O= 9D'5 :)OF!''''B H '''>

5:@BB J56:=:>?==;P Q'5 ==!'':G=H'''>

5:@II J5S;=L>?==B 9D'5 ==F!''''=H '''>

5:@A= J5<:IQN?A=;:P DN'5 A)=F!'':GIH'''N

!

5:@AB J5<:IQN?BMI:P DN'5 B)MIF!'':GIH'''N

!

5:@O: J56:=:>?=MBP Q'5 =MF!'':G=H'''>

5:@O= J56:=:>?BLBP Q'5 BLF!'':G=H'''>

5:@OI J56:=:>?==BP Q'5 ==F!'':G=H'''>

5:A;B (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:A;@ (5!<;=>?O=:C DE'5 O=; !':G:;H'''>

5:A;M (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:A;L (5!<;=>?O=:C DE'5 O=; !':G:;H'''>

5:A:: (5!<;=>?==BC DE'5 ==F !':G:;H'''>

5:A:B (5!<;=>?BBBC DE'5 BBF !':G:;H'''>

5:A=; (5!<;=>?:OBC DE'5 :OF !':G:;H'''>

5:A=: J58;BL>?=5= DN'5 =)=!''''BH '''>

5:A== (5!<;=>?:OBC DE'5 :OF !':G:;H'''>

5:A=A (5!<;=>?O==C DE'5 O)=F!':G:;H'''>

5:AB: (5!<;=>?IMBC DE'5 IMF !':G:;H'''>

5:A@: (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:A@= (5!<;=>?@A:C DE'5 @A; !':G:;H'''>

5:A@B (5!<;=>?=M=C DE'5 =)MF!':G:;H'''>

5:A@I (5!<;=>?BBBC DE'5 BBF !':G:;H'''>

5:A@@ (5!<;=>?BB=C DE'5 B)BF!':G:;H'''>

5:A@A (5T<;=/?:@=C DN'5 :)@F!':G:;H'''/

5:A@O (5T<;=/?:@BC DN'5 :@F !':G:;H'''/

5:AA; (5!<;=>?@:=C DE'5 @):F!':G:;H'''>

5:AA: (5!<;=>?IMBC DE'5 IMF !':G:;H'''>

5:AA=?A@ (5!<;=>?:=BC DE'5 :=F!':G:;H'''>

5:AAA?AM (5!<;=>?@A=C DE'5 @)AF!':G:;H'''>

5:AAO (5!<;=>?IMBC DE'5 IMF !':G:;H'''>

5:AAL?M; (5!<;=>?IM:C DE'5 IM;!':G:;H'''>

5:AM:?M= (5!<;=>?:;=C DE'5 :F !':G:;H'''>

5:AMB?MI (5!<;=>?O=BC DE'5 O=F!':G:;H'''>

5:AM@?MA (5!<;=>?:O:C DE'5 :O;!':G:;H'''>

5:AMM (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:AMO?O: (5!<;=>?==BC DE'5 ==F!':G:;H'''>

5:AO= (5!<;=>?AOBC DE'5 AOF !':G:;H'''>

5:AO@?OO (5!<;=>?;5;C DE'5 ;);!':G:;H'''>

5:AL:?L= (5!<;=>?:;=C DE'5 :F !':G:;H'''>

5:M;: (5!<;=>?@ABC DE'5 @AF !':G:;H'''>

5:M;= (5!<;=>?==BC DE'5 ==F !':G:;H'''>

5:M;B (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:M;I (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:M;@ (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:M;A (5!<;=>?@ABC DE'5 @AF !':G:;H'''>

5:M;M (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:M;O (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:M;L (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:M:; (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:M:: (5!<;=>?:=IC DE'5 :=;F!':G:;H'''>

5:M:= (5!<;=>?:OIC DE'5 :O;F!':G:;H'''>

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

30

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

No. 51731

Page 31

A

V-29M201

!"#$%&'(%) *+,-'(%) *+,-'(+#. /.01,23-2%4

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

56!7!895

5:M:B (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:M:I (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:M:@ (5!<;=>?:OBC DE'5 :OF !':G:;H'''>

5:M:A?:M (5!<;=>?:;=C DE'5 :F !':G:;H'''>

5:M=: (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:M== (5!<;=>?@A:C DE'5 @A; !':G:;H'''>

5:M=I (5!<;=>?==:C DE'5 ==; !':G:;H'''>

5:M=@ (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:M=A (5!<;=>?==:C DE'5 ==; !':G:;H'''>

5:M=M (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:M=O (5!<;=>?==:C DE'5 ==; !':G:;H'''>

5:M=L (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:MB; (5!<;=>?==:C DE'5 ==; !':G:;H'''>

5:MB:?B= (5!<;=>?AO=C DE'5 A)OF!':G:;H'''>

5:MBI (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MB@?BA (5!<;=>?IMBC DE'5 IMF!':G:;H'''>

5:MBM (5!<;=>?AOBC DE'5 AOF !':G:;H'''>

5:MBO (5!<;=>?@A=C DE'5 @)AF!':G:;H'''>

5:MI; (5!<;=>?:;:C DE'5 :;; !':G:;H'''>

5:MI: (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:MI= (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MIB (5!<;=>?BL=C DE'5 B)LF!':G:;H'''>

5:MII (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MI@ (5!<;=>?BL=C DE'5 B)LF!':G:;H'''>

5:MIA (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MIM (5!<;=>?BL=C DE'5 B)LF!':G:;H'''>

5:MIO?IL (5!<;=>?:;=C DE'5 :F !':G:;H'''>

5:M@;?@= (5!<;=>?;5;C DE'5 ;);!':G:;H'''>

5:M@I?@@ (5!<;=>?===C DE'5 =)=F!':G:;H'''>

5:M@A (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:MA: (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MA= (5!<;=>?:@BC DE'5 :@F !':G:;H'''>

5:MAI (5!<;=>?:;@C DE'5 :D!':G:;H'''>

5:MA@ (5!<;=>?:==C DE'5 :)=F!':G:;H'''>

5:MAA (5!<;=>?:;=C DE'5 :F!':G:;H'''>

5:MM:?M= (5!<;=>?==:C DE'5 ==;!':G:;H'''>

5:MMB (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:MMI?M@ (5!<;=>?:;=C DE'5 :F !':G:;H'''>

5:MLL (5!<;=>?BBBC DE'5 BBF !':G:;H'''>

5:O;:?;B (5!<;=>?==:C DE'5 ==;!':G:;H'''>

5:O::?:B (5!<;=>?;5;C DE'5 ;);!':G:;H'''>

5:O:@ (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:L;: J5N:@IR?I5M U(N'5 I)M!''':@ H '''R

!

5:L;= J5S;BL>?BLB 9D'5 BLF!''''BH '''>

5:L;@ J5N:@I>?AO; U(N'5 '''AO' !''': @ H '''>

5:L:; J56:=:>?@AIP Q'5 @A;F!'':G=H'''>

5:L:: J5(:I:>?:OBP Q'5 :OF!'':GIH'''>

5:L=: J56:=:>?AO:P Q'5 AO;!'':G=H'''>

5:L==?=B J58;=L>?5== DN'5 ;)==!''''=H '''>

5:L=I J56:=:>?:;BP Q'5 :;F!'':G=H'''>

5:L=@ J56:=:>?:;=P Q'5 :F!'':G=H'''>

5:L=A J56:=:>?:@=P Q'5 :)@F!'':G=H'''>

5:L=L J56:=:>?BB=P Q'5 B)BF!'':G=H'''>

5:LB= J56:=:>?I5MP Q'5 I)M!'':G=H'''>

5:LI: J5R:=L>?:@; Q'5 :@!'':G=H'''>

5:LI= (5!<;=>?==BC DE'5 ==F !':G:;H'''>

5:LIB J56:=:>?:@=P Q'5 :)@F!'':G=H'''>

5:LII (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:LI@ (5!<;=>?BB=C DE'5 B)BF!':G:;H'''>

5:LIA (5!<;=>?:=BC DE'5 :=F !':G:;H'''>

5:LIO (5!<;=>?:@=C DE'5 :)@F!':G:;H'''>

5:LIL (5!<;=>?:@BC DE'5 :@F !':G:;H'''>

5:L@; (5!<;=>?:;BC DE'5 :;F !':G:;H'''>

5:L@: (5!<;=>?BB=C DE'5 B)BF!':G:;H'''>

5:L@= (5!<;=>?IM=C DE'5 I)MF!':G:;H'''>

5:L@L (5!<;=>?;5;C DE'5 ;); !':G:;H'''>

5:LA:?A= J58;=L>?:5= DN'5 :)=!''''=H '''>

5:LAI J56:=:>?=M=P Q'5 =)MF!'':G=H'''>

5:LA@ J56:=:>?IMBP Q'5 IMF!'':G=H'''>

5:LAA J56:=:>?==BP Q'5 ==F!'':G=H'''>

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

!"#$%&'(%) *+,-'(%) *+,-'(+#. /.01,23-2%4

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

56!7!895

5:LO: J5K;;@M?O=@ Q'5 O)=D!''':H'''>

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

Q<*<Q7895

Q:;;: J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q:;;M J68(:QD?IMMK 6'Q<*) IM;#N ''':AT'''D

Q:;;O?;L J68(:6D?IMAK 6'Q<*) '''IM#N '''=@T '''D

Q:;:: (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q::;:?;= (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q::;I?;@ (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:::: J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D

Q:::=?:I (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:::A JNTM:V>?==IK DN'Q<*) ;)==#N '''@;T '''>

Q:::M J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D

Q:::O (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:::L (/Q=:V>?AO:C Q'Q<*) AO;3N'''@ ; T '''>

Q::=; J68(:VD?IMIK 6'Q<*) ;)IM#N'''@; T '''D

Q::=B?=I (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q::A: J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q::AB?AI (/Q=:V>?IM;C Q'Q<*) IM3N'''@;T '''>

Q::A@?AA (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:=;= J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:=;@ (/Q=:V>?AO;C Q'Q<*) AO3N'''@ ;T'''>

Q:=;M JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:=;O J68(:VD?IM@K 6'Q<*) ''I)M#N'''@; T'''D

Q:=;L J68(:QD?==MK 6'Q<*) ''==;#N''':A T'''D

Q:=:; (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:=:: (/Q=:V>?AO:C Q'Q<*) AO;3N'''@ ; T '''>

Q:=:= JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:=:B J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:=:I JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:=:@ J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q:=@:?@= J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q:=@@ J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q:=@A J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:=L:?L= J68(:QD?:;MK 6'Q<*) '':;;#N ''': A T '''D

Q:=LI J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:=LA J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:B;:?;= (/Q=:V>?:@;C Q'Q<*) :@3N'''@;T '''>

Q:B;B (/Q=:V>?:=;C Q'Q<*) :=3N'''@ ;T'''>

Q:B;I (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:B;@ (/Q=:V>?:=;C Q'Q<*) :=3N'''@ ;T'''>

Q:B;A J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D

Q:B;M (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:B;O?;L JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T '''>

Q:B:: J68(:VD?==@K 6'Q<*) ''=)=#N'''@; T'''D

Q:B:= JNSQ:V>?:;BK D'Q<*) ;);:#N'''@; T '''>

Q:B:B J68(:VD?IM@K 6'Q<*) ''I)M#N'''@; T'''D

Q:BI= J68(:VD?BB@K 6'Q<*) ''B)B#N'''@; T'''D

Q:B@I?@@ (/Q=:V>?=M:C Q'Q<*) =M;3N'''@; T '''>

Q:B@A (/Q=:V>?BB:C Q'Q<*) BB;3N'''@ ; T '''>

Q:B@M J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:BO= JQK;:=:?:;= Q'Q<*) :;;;3N'''BF T '''K

!

Q:I;:?;= J68(:VD?:;@K 6'Q<*) :#N '''@; T'''D

Q:I;B J6DA:6R?==@K 6'Q<*) =)=#N '''=@T'''R

Q:I;@ JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:I;A JNSQ:V>?:;BK D'Q<*) ;);:#N'''@; T '''>

Q:I:; J68(:TD?:;MK 6'Q<*) '':;;#N'''B@ T'''D

Q:I:: J68(:TD?IMMK 6'Q<*) ''IM;#N'''B@ T'''D

Q:I:= JNSQ=<R?@ABK D'Q<*) ;);@A#N'':;;T '''R

Q:I:B J68D:TD?==O 6'Q<*) '==;;#N '''B@ T '''D

Q:I:I J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:I:@ JN(B:V>?:@=K D'Q<*) :@;;3N'''@; T '''>

Q:@;: J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:@;B (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:@;@?;A (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:@;M J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:@:: J68(:VD?:;AK 6'Q<*) :;#N '''@ ; T '''D

Q:@=: JQWB=VR?:@:K Q'Q<*) :@;3N''@;;T'''R

Q:@== JQWB=VR?BB:K Q'Q<*) BB;3N''@;;T'''R

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

No. 51731

31

Page 32

A

V-29M201

!"#$%&'(%) *+,-'(%) *+,-'(+#. /.01,23-2%4

!

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

Q<*<Q7895

Q:@=B J68(=QD?:;@K 6'Q<*) '''': #N'':A;T'''D

Q:@=I JNK;::M?:;I= D**'Q<*) :;I;;3N:)IFTV'

!

Q:@=@ JNK;::L?IBI D**'Q<*) ;)IB#N''=;;T'±BX

!

Q:@=A J6K;=;B?:;M 6'Q<*) :;;#N'':A;T'''D

!

Q:@I: J68D=6D?BBA 6'Q<*) '''BB #N''=@;T'''D

Q:@I= JQWB=VR?O=:K Q'Q<*) O=;3N''@;;T'''R

Q:@IB J68D:TD?:;O 6'Q<*) ':;;;#N '''B@ T '''D

Q:@II JQWB=VR?O=:K Q'Q<*) O=;3N''@;;T'''R

Q:@IA J68(:QD?==MK 6'Q<*) ''==;#N''':A T'''D

Q:@IM J68(:QD?:;OK 6'Q<*) ':;;;#N ''':AT '''D

Q:@IO JQK;:==?O=: Q'Q<*) O=;3N'''= F T '''R

Q:@A: J68(:TD?:;MK 6'Q<*) '':;;#N'''B@ T'''D

Q:@O: JNSQ:V>?IMBK D'Q<*) ;);IM#N '''@;T '''>

Q:@OB JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:@OI JNSQ=<>?:;IK D'Q<*) ;):#N'':;;T'''>

Q:A;I J6(Q:VD?IMIK W*'6'Q<*) ';)IM#N'''@; T '''D

Q:A;M J6(Q:VD?IMIK W*'6'Q<*) ';)IM#N'''@; T '''D

Q:A;L J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:A:B J68(:6D?:;OK 6'Q<*) ':;;;#N '''=@T '''D

Q:A:@ J68(:6D?:;OK 6'Q<*) ':;;;#N '''=@T '''D

Q:A:M J68(:6D?:;OK 6'Q<*) ':;;;#N '''=@T '''D

Q:A:O JNTM:V>?==IK DN'Q<*) ;)==#N '''@;T '''>

Q:A== J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:A=B?=I J6(Q:VD?IMIK W*'6'Q<*) ';)IM#N'''@; T '''D

Q:AB: J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D

Q:ABM?BO (QW=:VR?BL=C Q'Q<*) BL;;3N'''@ ; T '''R

Q:A@: (QW=:VR?:;BC Q'Q<*) ;);:#N'''@; T '''R

Q:A@= J68(:QD?:;MK 6'Q<*) '':;;#N''':A T'''D

Q:A@B J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D

Q:A@I JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:A@@ J6(Q:VD?IM@K W*'6'Q<*) ''I)M#N'''@; T'''D

Q:A@A J6(Q:VD?:;@K W*'6'Q<*) :#N'''@; T '''D

Q:A@M J68(:VD?==@K 6'Q<*) ''=)=#N'''@; T'''D

Q:A@O (QW=:VR?IMBC Q'Q<*) ;);IM#N '''@;T '''R

Q:A@L J68(:VD?IMIK 6'Q<*) ;)IM#N'''@; T '''D

Q:AA;?A: JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T '''>

Q:AA= JW8Q:QR?BB@K 8<()Q<*) B)B#N ''':AT '''R

Q:AAB J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:AAI JW8Q:QR?:;AK 8<()Q<*) :;#N''':A T '''R

Q:AA@?AA J68(:VD?:;@K 6'Q<*) :#N '''@; T'''D

Q:AAM J68(:VD?BBAK 6'Q<*) '''B B #N '''@; T'''D

Q:AAO J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:AAL?M; J6(Q:VD?:;@K W*'6'Q<*) :#N'''@; T '''D

Q:AM: J68(:VD?==@K 6'Q<*) ''=)=#N'''@; T'''D

Q:AM= (QW=:VR?===C Q'Q<*) ==;;3N'''@; T '''R

Q:AMB JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:AMI J68(:VD?==@K 6'Q<*) ''=)=#N'''@; T'''D

Q:AM@ (QW=:VR?===C Q'Q<*) ==;;3N'''@; T '''R

Q:AMA JNSQ:V>?:;IK D'Q<*) ;):#N '''@;T'''>

Q:AMM (QW=:VR?==BC Q'Q<*) ;);==#N '''@;T '''R

Q:AML J68(:VD?:;@K 6'Q<*) :#N'''@; T'''D

Q:AO; J68(:6D?IMAK 6'Q<*) '''I M #N '''=@ T'''D