Page 1

AV28CT1E KS / AV28C T1EK

B

B

AV28CT1EPS / AV28CT1EP

SERVICE MANUAL

COLOUR TELEVISION

AV28CT1EKS / AV28CT1EKB

AV28CT1EPS / AV28CT1EPB

AV28 CT1 EIS

BAS IC CHASSIS

ⅡⅡⅡⅡ

JK

AV28CT1EIS

CONTENTS

!

SPECIFICATIONS

!

SAFETY PRECAUTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! WAR NING ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! SPECIFIC SERVICE INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SERVICE ADJUSTMENTS

! PARTS LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 4

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 6

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 5

・・・・・・

・・・ 6

・・・・・・

・・・・・・・・・・・・・ 7

・・・・・・・・・・・・・・・・・・・・・・・・・・

13

2

★ ST ANDARD CIRCUIT DIAGRAM ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・ 2-1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

No.519 52

Mar. 2002

Page 2

A

V28CT1EPS / AV28CT 1EPB

A

A

y

V28CT1EKS / AV28CT 1EKB

V28CT1EIS

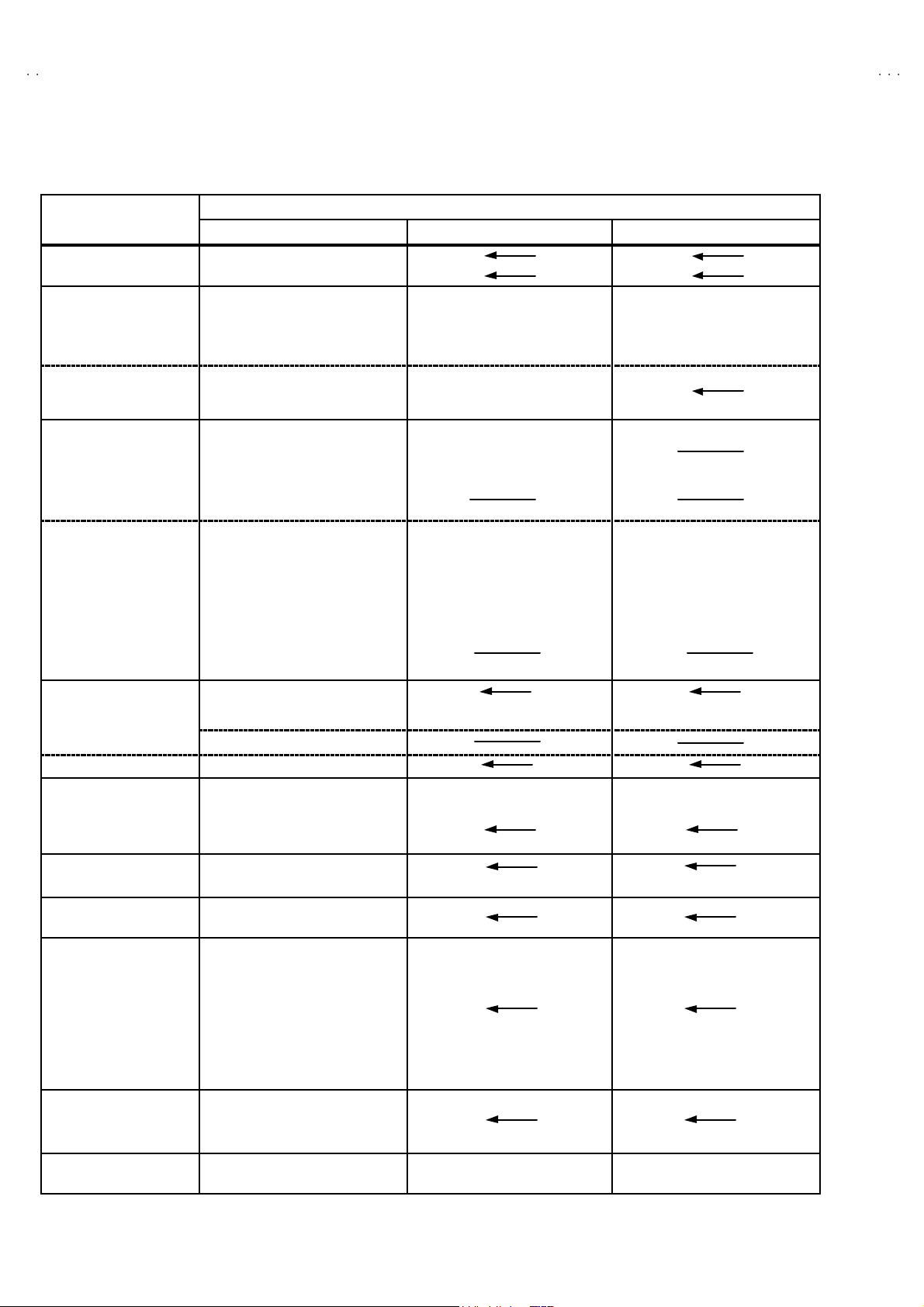

SPECIFICATIONS

Item

Di mensions ( W××××H××××D ) 72 5mm×4 80m m×4 96m m

Mass 33 .8 kg

TV RF System

Colour Sy stem PA L / SECA M /

Stere o Sy st em A2 / NICAM NICAM NICAM

Teletext System FLOF (Fastext)

Receiv ing Frequency

VHF 47 MHz ~ 47 0MHz 47 MHz ~ 47 0M H z

UHF 470MHz ~ 8 62MHz 47 0MHz ~ 862MHz 470MHz ~ 862MHz

French CATV

Interme diate Fr equenc

VIF Carrier 38.9MHz (B/G, I ,L)/ 33.95MHz ( L’) 38.9 MHz ( I ) 38.9MHz ( I )

SIF Carrier 33.4MHz (5.5MHz:B/ G) / 32.9MHz

Colour Sub Carr ier Fr eq.

PAL 4.43MHz 4.43MHz 4.43MHz

SE CAM 4.40625MHz / 4.25MHz

NT S C 3.58MHz / 4.43MHz 3.58MHz / 4.43MHz 3.58MHz / 4.43MHz

Power Input AC 220V~2 40V , 5 0Hz

Power Consumption

Aerial Input Term 75 Ωun ba l anc ed, C oaxi al

Picture Tube Visi ble si ze : 66 cm, Meas ured

Hi gh Vo lt ag e 30.0kV (at zero beam

Speake r

Au dio Output 5W + 5W

EX T-1 /EXT-2/EX T-3

(Input / Output)

EXT-4 (Input) Video

Au di o (L /R )

S / Video

AUDIO OUT (Variable)

Headphone jac k St ereo min i jac k ( φ3.5mm )

Remote Control Unit

(AAA/R03 dr y batte ry ×2)

AV28 CT 1 E PS/EP B AV28 CT 1 EIS AV28 CT 1 EKS/E KB

CCIR ( B/G , I ,L) CCIR (I ) CCIR ( I )

NTSC (Only in EXT mode)

TOP (German system)

WST(Standard system)

116MHz ~ 1 72M H z /

220MHz ~ 4 69M H z

(6.0 MHz:I ) / 32.4MHz (6. 5MHz :L) /

27.45 MHz ( 6.5MHz:L’)

15 6W ( Max) / 122W ( Av g)

St andby : 0.8 W

12 2W /h (ITA LY)

diagon ally

1kV

+

current)

10 cm×3c m Oval type×2

21 -pin E ur o c onnec to r

(SCART socket)

1V p- p 7 5 Ω(RCA pi n ja ck)

50 0mVr ms( - 4dBs ), High

Im pe da nce ( RCA pin jack )

Y : 1V

sync P rovide d, when ter m inat ed

wi t h 7 5Ω)

C : 0 .28 6V

ter m inat ed w it h 7 5Ω)

0~1 Vrms , Low Imp ed ance

(RCA pi n jack ×2)

RM-C54H (AV2 8C T1EPS)

RM-C50 ( AV2 8CT1EP B)

-1. 5kV

p-p

PO SITI VE (Neg ativ e

p-p

(Burst signal, when

PA L / NTSC (Only in EX T mod e) PA L / NTSC (Only in EX T mod e)

FLOF ( Fast ext)

WST(Standard system)

32.9MHz ( 6.0MHz:I) 32.9MHz (6.0 MHz:I)

RM-C55 H (AV28CT1EI S) RM-C55 H (AV28CT1EKS)

Content

RM-C51 ( AV2 8CT1EK B)

De sign & sp eci f icat ions are subje ct to cha nge wi thout notice .

2

No.51952

Page 3

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

V28CT1EPS / AV28CT 1EP

V28CT1EI

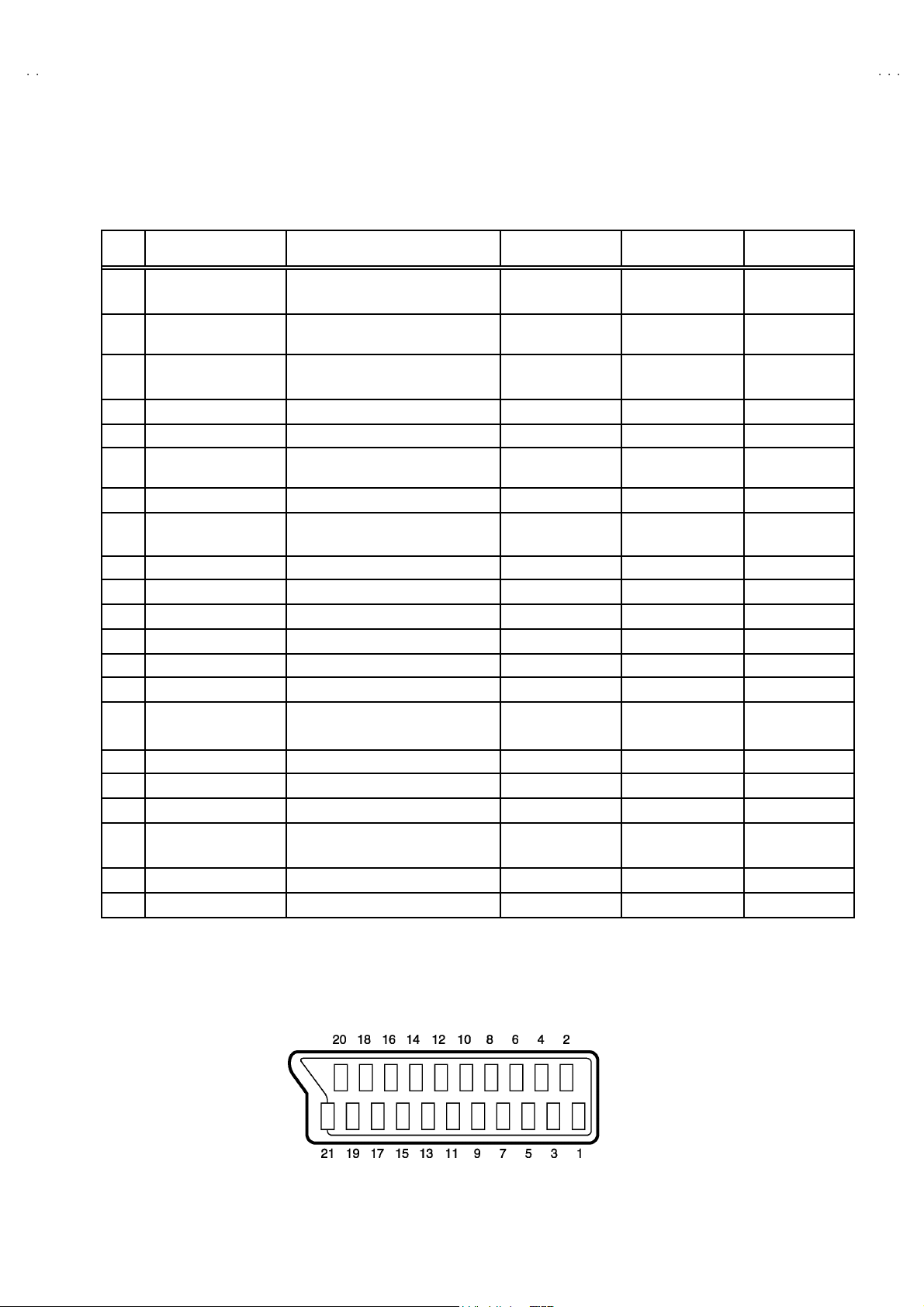

■■■■21-pin Euro connector (SCART socket) : EXT-1 / EXT-2 / EXT-3

(P-P= Peak to Peak, S-W= Sync tip to white peak, B-W= Blanking to white peak)

Pin

Signal Designation Matching Value EXT-1 EX T-2 EXT-3

No .

1 AUDIO R o ut put 50 0mVr ms( N ominal),

Low impedance

2 AUDIO R i n put 50 0m Vr ms( N ominal),

High i m pe da nce

3 AUDIO L output 50 0mVr ms( N ominal),

Low impedance

4 AUDIO GND ○○○

5 GND (B)

6 AUDIO L input 500mVrms(Nominal),

High i m pe da nce

7B input 700mV

8 FUNCTON SW

(SLOW SW)

9 GND (G)

10 SCL3 NC ○ NC

11 G in put 70 0m V

12 SDA3 NC ○ NC

13 GND (R)

14 GND (YS) ○ NC NC

15 R / C input R : 700mV

16 Ys i n put

17 GND(VIDEO outp ut) ○○○

18 GND(VIDEO input) ○○○

19 VID EO output 1V

20 VID EO / Y i np ut 1V

21 COM MON G ND ○○○

Low : 0-3V, High : 8-12V, High

impedance

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75Ω○

, 75Ω○NC NC

B- W

, 75Ω○NC NC

B- W

, 75Ω

B-W

, 75Ω

P- P

(Nega tiv e g oin g sync ), 75Ω○

P- P

(Nega tiv e g oin g sync ), 75Ω○ ○ ○

P- P

○

(TV OUT)

○○○

○

(TV OUT)

○○○

○○○

○○○

○○○

○○○

○

(only R)

(TV)

○

(LINE OUT)

○

(LINE OUT)

○

(only C)

NC NC

○

(LINE OUT)

NC

NC

○

(only C)

NC

[Pin assignment]

No.51952

3

Page 4

A

V28CT1EPS / AV28CT 1EPB

SAFETY PRECAUTIONS

1. The d es ign of th is product con ta ins sp ec ial har d ware , many

circuits and components spe cially for safety purp oses. For

con tinu ed pr ot ection , n o chan g es sh ou ld b e ma de to the orig inal

d esi gn un l ess auth oriz ed in writi n g by th e ma nu fact urer.

Replac em en t p arts m ust be ident ic al to thos e u sed in th e or i ginal

ci rcu it s. Serv ice s ho uld b e perfor med by qualif ied p ers on nel

on ly.

2. Alte rati on s of t he desig n or cir cuitry of t he pr od ucts sh ould not be

made. Any design alterations or additions will void the

manufact ur er 's warrant y and will f urth er r eliev e t he ma nu factu r er

of r esp onsi b ility for per so na l injur y or p roperty dam ag e resul t in g

th erefr om.

3. Many el ectr ical an d m echanica l p ar ts in th e pr od ucts ha ve

special safety-related characteristics. T hese characteristics are

oft en no t e v ident f r om v isua l i nsp ection n or ca n t he pr o tec t io n

aff or de d by th em nece ssar i l y be ob tain ed b y u s ing replacem en t

com po ne nts ra ted f or hi g he r voltag e, w att ag e, etc. R ep l acement

p arts whic h ha ve th ese sp eci al s afet y ch ar ac t er ist ics are

ide ntified i n the parts list of Servic e m anual. El ectric al

components having such features are identified by shading

on the sch e mat ic s and by (

manual. The us e of a substitute r ep la cem en t whic h do es n ot

h ave th e same saf ety ch ar act er ist ics as t he r eco mmen de d

replac em ent part sh own i n th e p ar ts l i st of S er vi ce man ual may

cause shock, fire, or other hazards.

!!!!

) on the parts list in Service

4. Do n't short between the LIVE s ide ground and ISOLATED

(NEUTRAL) s ide ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

diff er enc e of th e GND i s s ho wn b y th e LIV E : (") side GND , the

ISO LATED(NEUT RAL) : ( #) side GND and EARTH : ($) side

GND. Don't sh ort b et ween th e LIV E sid e GN D and

ISO LATED(NEUT RAL) side GND or EARTH side GND an d

n ever m ea s ur e w it h a m ea suring a ppa r atus ( osc illos cop e etc.)

th e LI VE si d e GND an d IS OLA TED (NE UTR AL ) s ide G ND or

EARTH side GND at th e s ame tim e.

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

th at t he B1 set ti ng s hou l d b e ch eck e d or adju ste d ( Se e

ADJUST MENT OF B1 POWE R SUPPL Y) .

6. The hi gh volta ge app lie d t o the pictu r e tu be mu st con form wit h

th at s p ecified in S ervi ce manual. E xcessi ve high volt ag e c a n

cau s e an i ncr e ase i n X- R ay em i ssi on , ar c ing an d possi b le

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

preve nt ed. If s ever e arc ing occ ur s, r emove t he AC pow er

immed i ate ly an d de ter m i ne th e c a use b y visua l insp ec t io n

(inc or rect ins tal lat i on, cracke d or melte d high v o lt age har n es s,

p oor so lder i ng, et c.). To maint ai n the p roper min im u m le vel of

sof t X-Ray em ission, c omponen ts in th e high vol tag e ci r cui try

incl ud ing t he pi ct ur e tu be must be t he e xact r ep l aceme nts or

alte rn at i ves ap pr ove d b y th e ma nuf act urer of th e c om pl et e

product.

7. Do n ot c hec k high vol t age b y draw ing an ar c. Us e a high vol t age

meter or a hi g h v oltag e pr ob e wit h a V TVM. Discharge th e

picture tube before attempting meter connection, by connecting

a cl i p lead to th e gr ou nd f ra me and c onn ec ti n g th e oth er end of

the lead through a 10kΩ 2W resis to r to the anod e butt on .

8. When s e r vice is r equ ired, ob serve th e origi na l lea d dr ess . Extr a

prec aut ion sh ou ld b e g iven t o ass ur e corr ec t l ea d dr ess i n the

high vol tag e c ircui t a r ea. W her e a s hort ci r cuit h as oc cu rre d,

th ose co mp on ent s tha t i ndi ca te evide nce of ove r hea ting sho ul d

b e re plac e d. A lways us e th e ma nuf act ur er's r ep l acement

components.

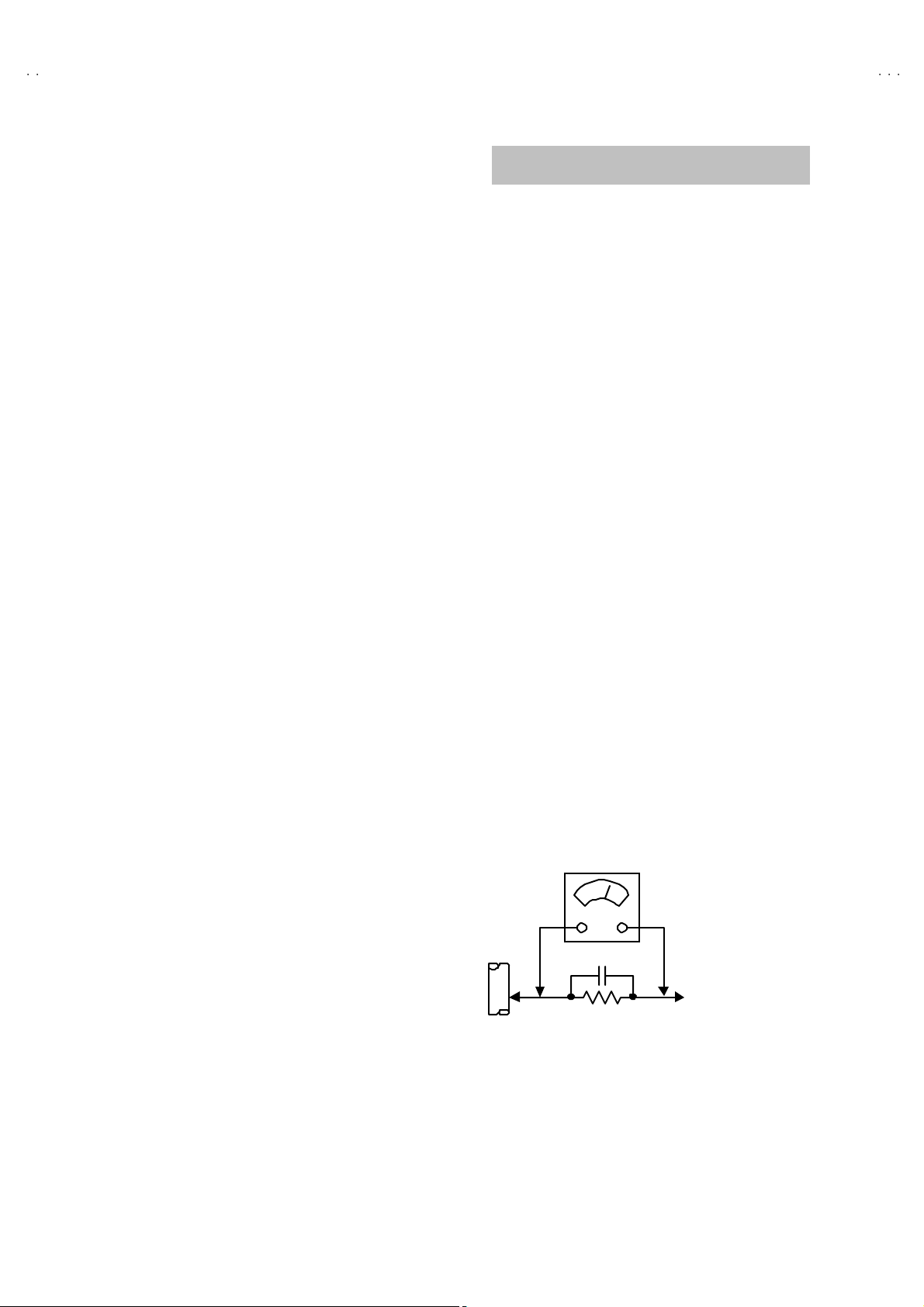

9. Isolation Check

(1) Di electric Strength Test

(2) Leakage Current Check

AV28CT1EPS / AV28CT1EPB

(Safety for Electrical Shock Hazard)

Af ter re- ass emb l in g th e pr odu c t, al w ays per f orm an i sol at ion

ch ec k on the expo sed metal parts of t he c abin et ( a ntenn a

ter m inals, video /audio inpu t and ou tput t erminals , C on trol kn obs,

metal cabi n et, scr ew he ad s, ea r ph one j ack, con trol s haf ts, etc.)

to be s u re th e p roduct is s af e t o ope r ate with ou t dan ger of

elect ri cal s hoc k.

The i solation be tw een the A C prim a ry c ircu i t an d al l me tal p ar ts

exp osed t o th e us er , p arti cular l y any e xp osed met al p art having a

retu rn p ath to t he chass is sho uld withs tan d a vol t age of 3 000 V

AC (r.m. s.) for a period of one second.

(. . . . W it hstan d a vo lt ag e of 1 10 0V A C (r .m. s.) t o an ap pl ianc e

rate d up to 12 0V , an d 3 00 0V AC ( r .m. s.) to an ap pl ian ce r at ed

200V or more, for a period of one second.)

This meth od of test requi res a t est equi pmen t n ot gen erally found

in t he servic e trad e.

Plug th e A C line c ord direc t ly in to the A C ou tl et ( d o not use a lin e

isol ati o n tr ansf or m er during this check .) . Usi n g a " Lea kag e

Curr ent T este r", me asur e th e lea kag e cu rre nt f rom each exp osed

metal p art of the cabinet, p art icu larly any expos ed me tal p ar t

h avi ng a re tur n path to the c h assis , t o a kn ow n go od ea rt h

ground (water pip e, e tc.) . An y l eaka ge curren t m ust n ot e xceed

0.5mA AC (r.m.s.).

Howev e r, i n tr op ic al area , th is must no t exce ed 0.2 mA AC

(r.m.s. ).

""""

Alternate Che ck M et hod

Plug th e A C line c ord direc t ly in to the A C ou tl et ( d o not use a lin e

isol ati o n tr an s for m er dur ing t his che ck .) . Use an AC vo lt me ter

h avi ng 1 00 0 ohms pe r volt or mor e s ens itivity i n th e fo llow i ng

manner. Con nec t a 1 50 0Ω 10W res ist or par a lle led by a 0 .1 5µF

AC-type c apa citor bet we en an ex po sed met al pa rt a nd a kno wn

g ood e ar th gro un d (water pipe , etc.). M eas ure th e A C v o lt ag e

acr oss th e r es ist or w i th th e AC vo ltm eter . M ove th e r esis tor

con nec ti on to each exp ose d metal part, part ic ularly any exp osed

metal p art havin g a retu rn pat h to t he chassis, an d m eas u r e th e

AC vol tag e ac ro ss the r es ist or. No w , rev er se th e plu g in th e AC

ou tl et and re pe at eac h mea s ur emen t. Any volt ag e me asured

must not exc eed 0.75V AC (r.m. s.). This c orre sponds to 0.5m A

AC (r.m. s.).

Howeve r, in tropical are a, this must not exceed 0.3V AC ( r .m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 Ω /V,

OR MOR E SENSITIVITY)

0.15μF AC-T YPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON E A C H EX PO SE D

ME T AL PA RT

4

No.51952

Page 5

A

V28CT1EKS / AV28CT 1EK

B

A

S

V28CT1EI

SAFETY PRECAUTIONS

1. The design of thi s pro du ct c ont ains spe ci al hard ware and many

circuits and components spe cially for safety purp oses. For

con tinu ed pr ot ection , n o chan g es sh ou ld b e ma de to the orig inal

d esi gn un l ess auth oriz ed in writi n g by th e ma nu fact urer.

Replac em en t p arts m ust be ident ic al to thos e u sed in th e or i ginal

ci rcu it s. Serv ice s ho uld b e perfor med by qualif ied p ers on nel

on ly.

2. Alte rati on s of th e des ig n or ci rc uitr y of th e pr od uct sho uld no t be

made. Any design alterations or additions will void the

manufact ur er 's warrant y and will f urth er r eliev e t he ma nu factu r er

of r esp onsi b ility for per so na l injur y or p roperty dam ag e resul t in g

th erefr om.

3. Man y elec tr i cal a nd me chanical p ar ts in the pr od uct h ave spe ci al

saf ety- r elat ed ch ar act erist ics. Thes e characteri stics a re oft en not

evi d ent from visu al insp ec ti o n no r can th e p rotect i on af forde d by

th em n ecess ar y be o bta in ed by usi ng replac em ent c om pon en ts

rate d for hi gh er volta ge, wa tta ge , etc. R e pl acement p art s whic h

4. The leads i n the p rodu cts ar e r ou ted an d d r es sed wit h t ies,

AV28CT1EKS

/ AV28CT1E KB

AV28CT1EIS

h ave th ese spe c ial s af et y c har ac ter istic s ar e i d ent if ied in th e

Pa rts Lis t of Serv ice Ma nu al . Elec tr i cal compon en ts h avi ng suc h

fe atur es are identifi ed b y sh adin g on the sche ma tic s and by (!)

on t he Par ts List in the S ervi ce Manual. The u s e of a s ub stitut e

replac em ent w hi ch d oes no t h av e th e s am e saf ety

ch ar ac ter i stic s as the re c om mend ed r eplace ment part sho wn in

th e Par ts List of Se rvi ce Man ual may cause sh ock , fire, or ot her

hazards.

cl am ps, tu bi ng ’ s, b ar rie rs a nd t he like t o be s epa ra ted from live

p arts, high t emperature pa rts, m oving parts an d / or sh arp ed ges

for t he p reven ti on of e lectr i c sh oc k and fire h azar d. W he n

ser vic e is r e quired , the or igin al le ad r outin g and d ress sh ould b e

ob ser v ed , and it sh oul d b e co nfi r m ed t hat th ey h ave bee n

retu rn ed to no rm al , aft er re- as se mblin g.

WARNING

1. The eq uipme nt h as b ee n d esig ned a nd m anu fact ur ed to me et i nternatio nal saf ety sta nd ards.

2. It is t he leg al resp onsib ili ty o f th e re pa irer t o e nsure th at thes e safet y sta ndar ds are mai nt aine d.

3. Rep airs mu st b e m ad e i n acc ordan ce with the rele vant saf ety st an dar ds .

4. It is ess en ti al t hat saf ety cri ti cal c ompon ent s are replac ed by a pp ro ved part s.

5. If main s vol t age selec tor is p rovide d, ch eck s etti n g f or loca l vo ltag e.

No.51952

5

Page 6

A

V28CT1EPS / AV28CT 1EPB

A

A

(

)

(

)

)

(

)

)

(

)

)

(

)

)

V28CT1EKS / AV28CT 1EKB

V28CT1EIS

FEATURES

"

By pref er enc e, users can s ele ct th e pictur e size fr om REG UL AR ,

PANORAMIC, FULL, 14:9 ZOOM, 16: 9 ZOO M, 16 :9 ZOOM SUB

TITL E mod es. W he n th e TV u ni t r e ceived W SS pict ur e si gn al, th e

pictu re can be ch an ged t o 16:9 ZOOM m ode autom atically.

" The T ELE TEXT S YSTE M has a b uilt - in FAS TEXT, TOP (On l y

AV 28CT1 EPS / EPB) an d W ST s ystem.

" Be c aus e th is T V un it cor r espon ds t o m ultiplex br oa dc a st, u sers

can enjoy music programs and sporting events with live realism.

In ad di ti on , BI LIN GUAL programs can b e h ear d in th eir or i g in al

language.

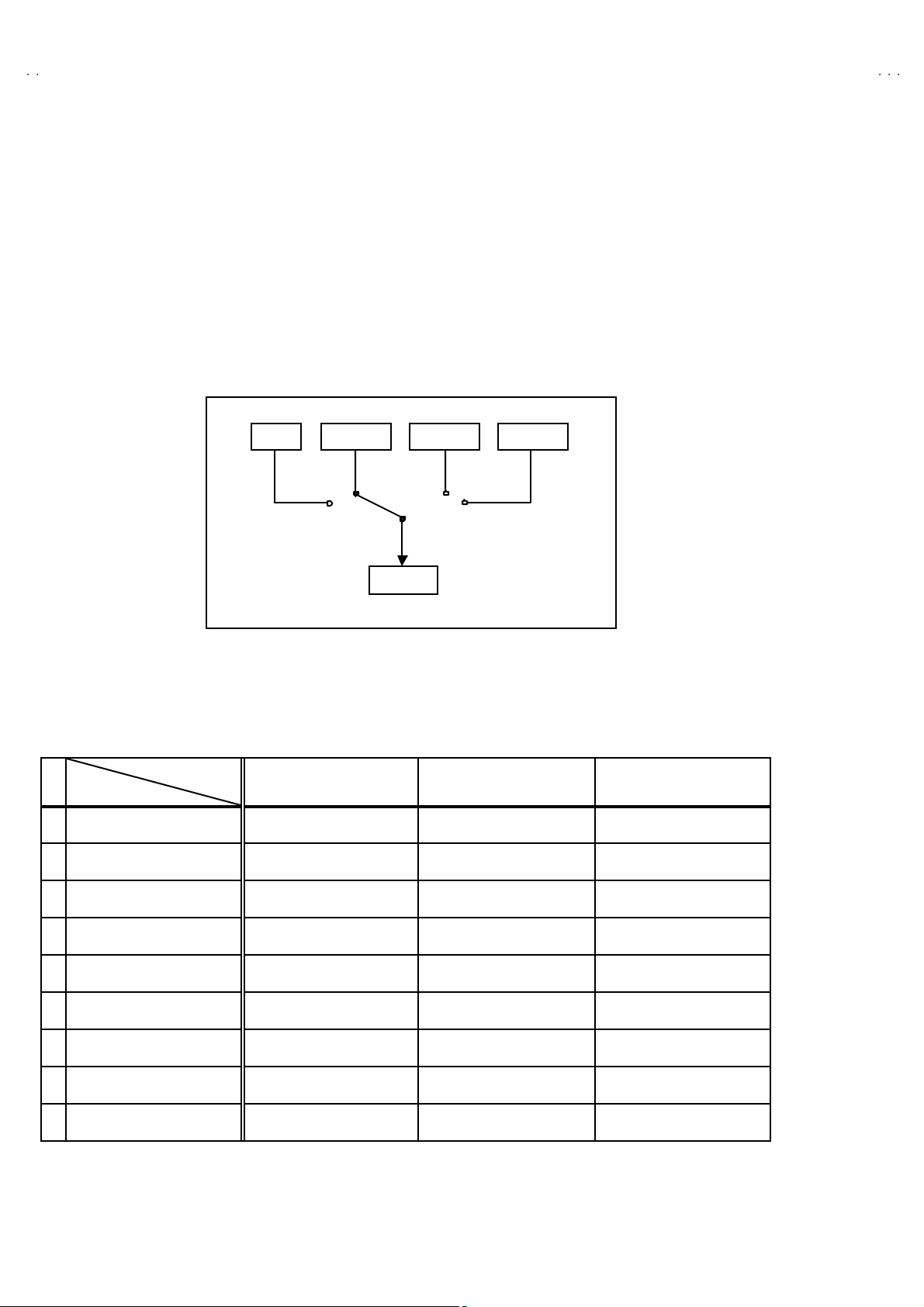

TV EXT-1 EXT-3

EXT-2

"

Users can make VCR dubbing of picture and sound by controlling

th e AV s elec tor to se lec t an optiona l so urc e at th e EXT- 2 outp ut

sh own in figu re.

EXT-4

MAIN DIFFERENCE LIST

Model Name

!!!!

Part Name

MAIN PWB SJK-1716A-U2

AV SEL. PWB SJK0S712A-H3 ← SJK0S912A-H3

FRONT CABINET ASSY

!

POWER CORD QMPK160- 185- JC QM PN130-185-JC ←

!

RATI NG LABEL

EURO LABEL

!

INST BOOK

REM OTE CO NT ROL

UNI T

S. DIAGRAM

ONLY ITALY(SERVICE)

AV28CT1EPS / EPB AV28CT1EIS AV28CT1EKS / EKB

LC10001-006C-U

LC10001-007B-U (EPB)

LC11415-001A-U

LC11415-002A-U (EPB

AEM1064-014-E (EPS)

AEM1064-015-E (EPB)

LCT1137- 001A- U

LCT1136- 001A- U (EPB

RM-C54H-1C (EPS)

RM-C50-1C (EPB)

28CT1EP-HSA-E

EPS

EPS

EPS

←

LC10001-006C-U

LC11372-003A-U

AEM1064-013-E

LCT1138- 001A- U LCT1138- 001A- U

RM-C5 5H- 1C

××

EPS

SJK-1916A-U2

LC10001-006C-U (EPS

LC10001-007B-U (EPB)

LC11364-005A-U

LC11364-006A-U (EKB

AEM1064-011-E (EKS)

AEM1064-012-E (EKB)

RM-C55H-1C (EKS)

RM-C51-1C (EKB)

EKS

6

No.51952

Page 7

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

V28CT1EPS / AV28CT 1EP

SPECIFIC SERVICE INSTRUCTIONS

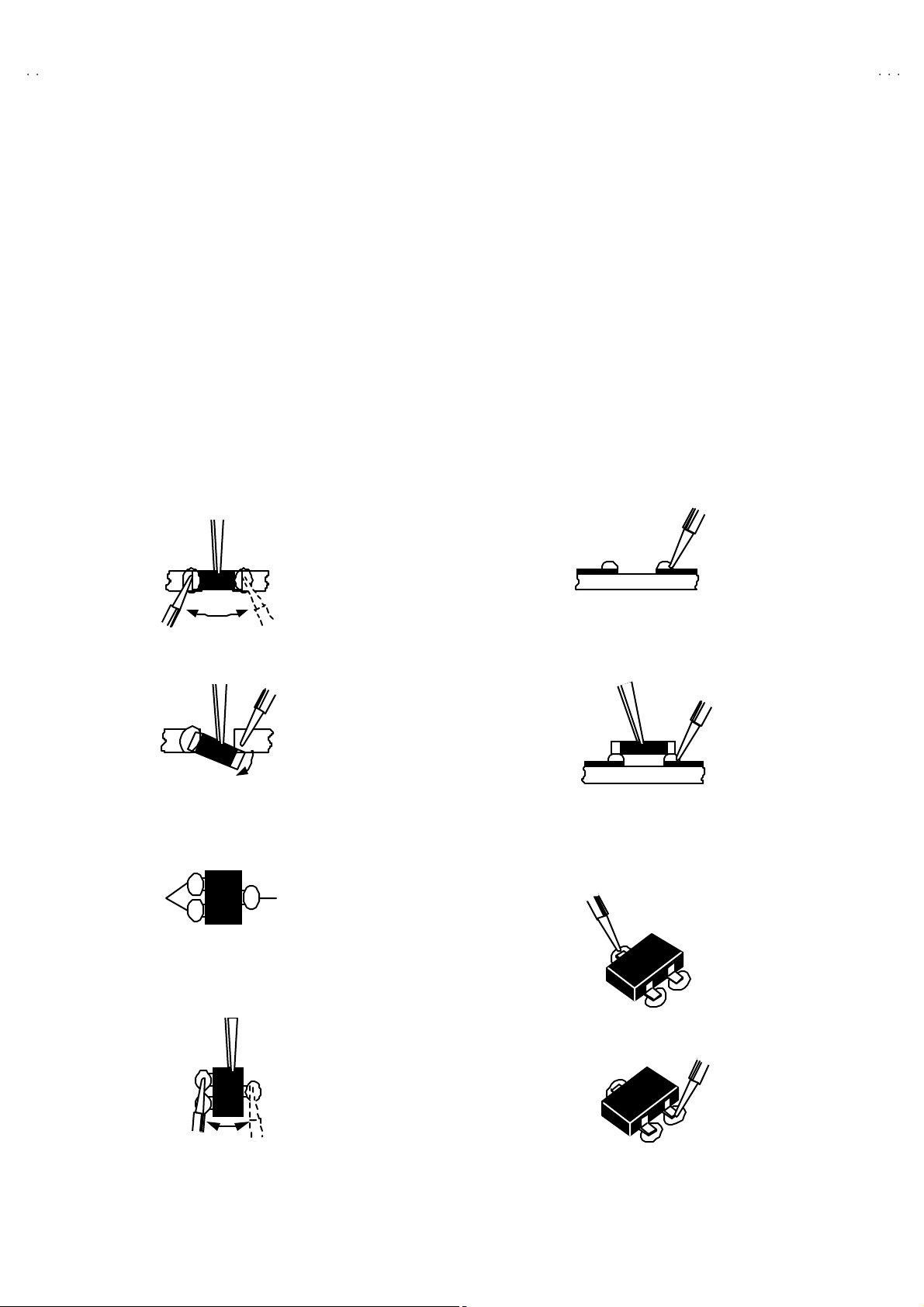

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating for more than 3 seconds.

2. Do n ot rub t he el ect rodes an d the resis t p arts of the p att ern.

3. When removi ng a c hip part, mel t the s older ad equ atel y.

4. Do n ot reuse a ch ip p art afte r removi ng it .

! SOLDERING IRON

1. Us e a hi g h ins ulati o n s older i ng i r on with a t hin po in ted end of it .

2. A 3 0 w s oldering ir on is r ec ommend ed for easi l y r emovi ng par ts .

!

REPLACEMENT STEPS

1. How to remove Chip parts

####

Resi st ors, ca pacit ors , etc

(1) As sh own in the f igure, pu sh th e pa rt with tw ee zers and

alte rn at el y m el t the sol de r at each en d.

(2) Sh if t w ith tw eeze rs and r em o ve th e ch ip p ar t.

#### Trans isto rs, dio des, va ria bl e r esistors, et c

(1) Ap ply e xt ra so lder to ea ch lead .

SOLDE R SOLDE R

2. How to install Chip parts

####

Resi st ors, ca pacitors , et c

(1) Ap ply sold er to th e pattern as ind ic ated in the fi gure.

(2) Gr asp t he ch ip p art with twee zers and pl ac e it on th e s old er.

The n hea t and melt th e so lder a t b oth en ds of t he chip part.

#### Trans isto rs, diodes , varia bl e r es ist or s, et c

(1) Ap ply sold er to th e pattern as ind ic ated in the fi gure.

(2) Gr asp th e chip p art w it h twe eze rs and p lace it on th e so lder.

(3) First solder lead A as indicated i n t he figure.

V28CT1EI

A

(2) As sh own in the f igure, pu sh th e pa rt with tw ee zers and

alte rn at el y m el t the sol d er at eac h le ad . Shi ft and remove the

chip part.

(4) Then so lder le ads B and C.

Note : A fte r re moving the part, r emove remain ing so lder fro m the

pattern.

No.51952

C

A

C

B

B

7

Page 8

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

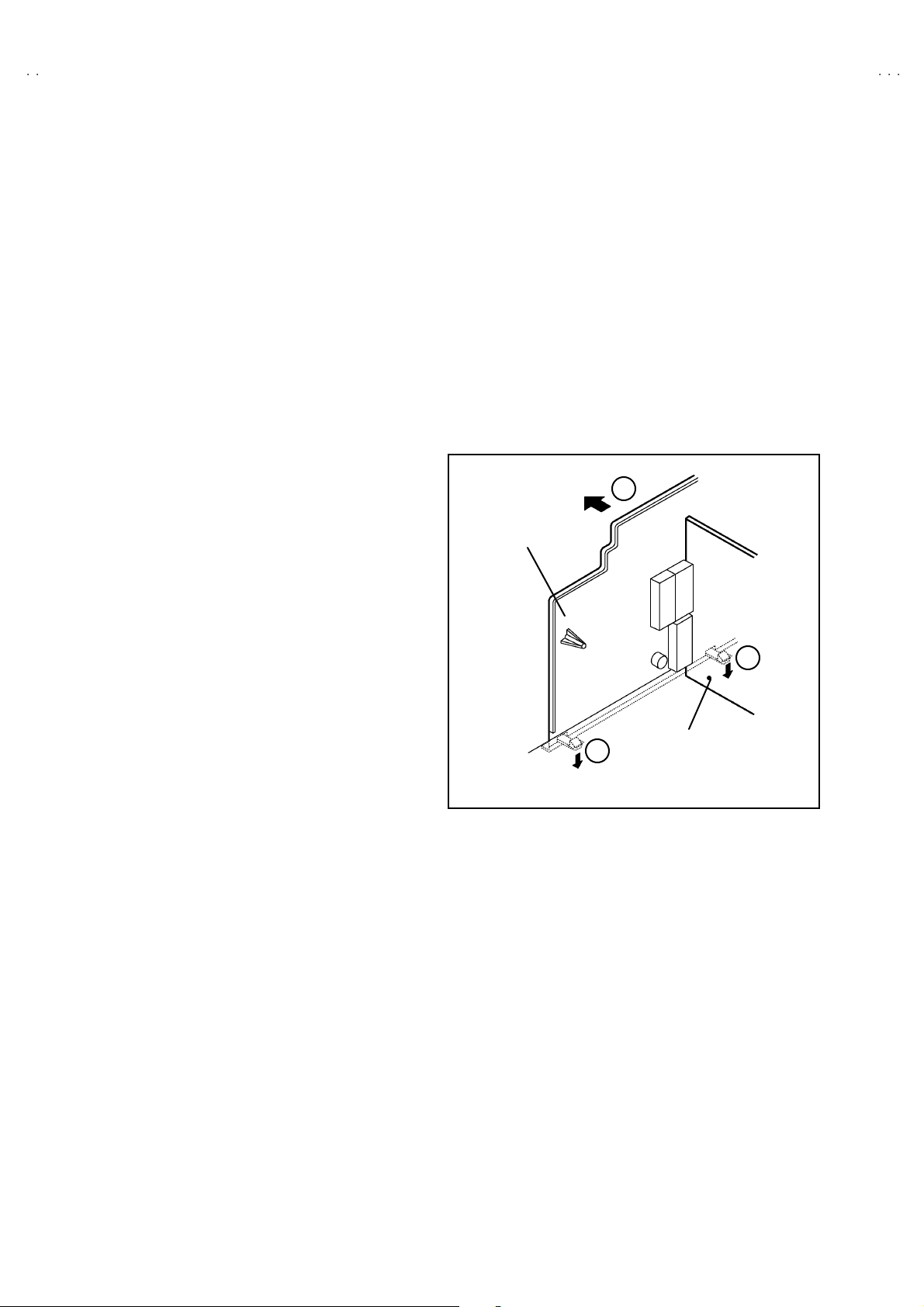

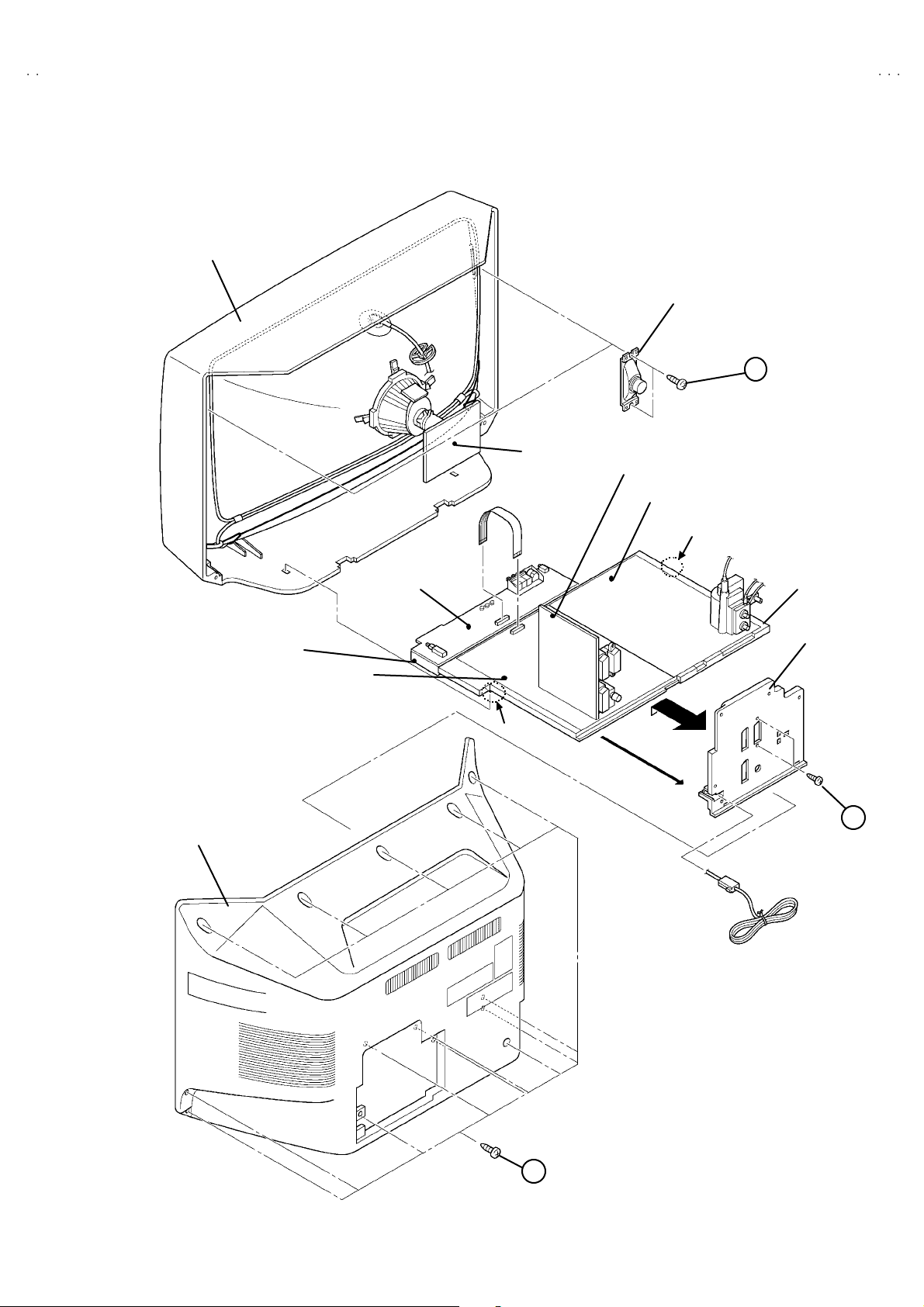

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unp lug t he powe r c ord.

2. Remove the 14 screws marked“

3. Withdr a w t he rear co ver to wa rd you .

REMOVING THE CHASSIS

"

After removing the rear cover.

1. Sli ght ly rai se th e bo th si de s of th e c hass is by h and and re mo ve

th e tw o claws u nd er th e b oth s id es of the chassis fr om t he front

cab inet .

2. Withdr a w t he chass is backward.

(If n ecessary, take off the wire clamp, conne ctors etc.)

REMOVING THE AV TE RMINAL BOARD

" After removing the rear cover.

1. Remove the 2 scr ew s mar ked“

2. Remove the claws marked “

shown in Fig. 2.

3. Remove th e to p of t he A V TE RMINAL BOA RD slight ly in th e

direc ti o n of arr ow “

” as sh own in Fi g. 2 .

$$$$

”as sh own i n t he F ig. 1.

!!!!

”as sh own in th e Fig. 1.

""""

” u nde r the C H ASS IS as

####

D

AV TERMINAL

BOARD

REMOVING THE SPEAKER

"

After removing the rear cover.

1. Remove the 2 scr ew s mar ked“

2. Fol low th e s ame st eps when removi ng th e other ha nd speake r.

”as shown in Fig. 1.

%%%%

CHECKING THE PW BOARD

To c h eck the b ack side of th e PW B oard.

1) Pull out the ch assis . ( Refe r to RE MOVING TH E CH ASSIS).

2) Erect the c hassis vertically so that you can easily check the

b ack si de of th e PW B oard.

[CAUTION]

" When e recting the chassis, be careful s o that there will be no

contacting with other PW Board.

" Be for e turning on po wer , make sure t ha t the w i re c o nn ec to r i s

properly connec ted.

"

W hen co ndu cting a ch eck w ith p ow er su ppli ed , b e sure to c onfir m

th at t he CRT E ART H WI RE (B RA ID ED AS S’Y) is co nne cted t o

th e C RT SOCKE T PW b oar d.

WIRE CLAMPING AND CABLE TYING

1. Be sure t o cla mp the wir e.

2. Never r em o ve th e c able tie used f or ty ing th e w i res toge the r.

Sh ould it be in adve rt ent l y rem oved, b e sure to ti e th e wi res w it h

a n ew c able ti e.

C

AV SE L PWB

C

Fig . 2

8

No.51952

Page 9

A

B

A

B

A

S

FRONT CABINET

CRT

SOCKET

PWB

V28CT1EKS / AV28CT 1EK

V28CT1EPS / AV28CT 1EP

V28CT1EI

SP EAKER

E

AV SE L . P WB

POWER & DEF. PWB

CLAW

C ONT RO L BASE

REAR COVER

FRONT CO NTROL

PWB

MAIN PWB

CHAS SIS

AV TERMINAL

BOARD

CLAW

B

A

Fig . 1

No.51952

9

Page 10

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

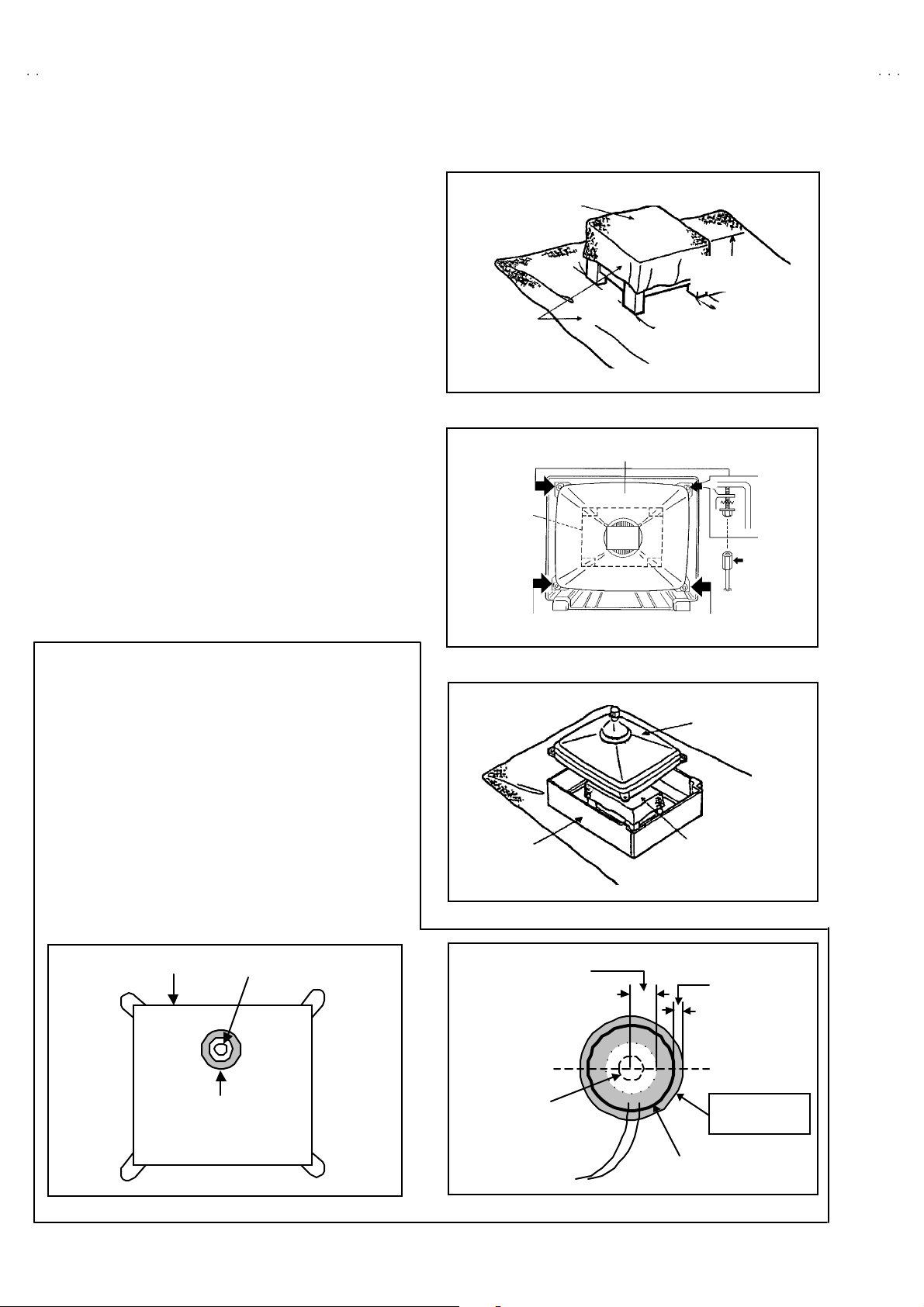

REMOVING THE CRT

∗

Replac em en t of the CRT sho ul d be per formed b y 2 or mor e

p ers ons.

• After removing the cover, chassis etc.,

1. Pu tting the CR T c han ge ta ble o n sof t c loth , th e CRT cha ng e ta ble

sh ould al so b e c over ed w ith s uch soft clot h (sho wn in Fi g. 5).

2. While k ee pi n g th e surf ac e of CRT dow n , m ou nt the TV s et on t he

CRT change table balanced will as shown in Fig.6.

3. R em ove 4 s c rews mark e d by arro ws with a box typ e scr e w dr iver

as s hown in Fig. 6.

• Si nc e th e cab inet w ill dr op wh en scr ew s h ave b een remo ved, be

sure t o su pport t he cabinet with h ands.

4. After 4 screws have been removed, put the cabinet slowly on

cloth (At th is time, be carefully so as not to damag e the front

sur fac e of th e c abin et) sh own in Fig.7 .

• The CR T sh ould b e ass em bled acc or ding to th e opp osi te

sequence of its dismounting steps.

∗

T he C RT chang e t able sh ould pr ef erab ly b e small er t hat th e CRT

sur fac e, and its height b e about 35c m.

CRT CHANGE TABLE

AP PROX.

35 cm

CLOTH

Fig. 5

CRT

CRT

CHA NGE

TABLE

BOX

TYPE

SCREW

DRI VER

COATING OF SILICON GREASE FOR EL ECT RICAL

INSULATION ON THE CRT ANODE CAP SECTION.

•

Subs e qu ent to re pl ac ement of t he C RT an d HV tr an sfor m er o r

repair of t he an od e cap, etc. by d is mount i ng the m, be sure to coa t

si lic o n g rease for electric al ins u l ati o n as sh ow n in Fig.8 .

W ipe a r oun d t he an ode b utt on with cl ea n and dry c lot h. (F i g. 8)

Coat si l ic on greas e on t he sect ion arou nd th e a no de bu tt on. At

this time, take c are so that any silicon greases dose n ot stic k to

the ano de button . (F ig.9 )

★★★★

Silicon grease product No. KS - 650N

CRT

An od e b utton

Silic on greas e

coating

CABINET

Ap prox.

20mm (Do not

coat grease on

this s ection

An od e b utton

(No s ti cki ng of

silicon grease)

Fig. 6

CRT

CRT

CHANGE TA BLE

Fig. 7

Silic on greas e

sh oul d be coa ted

b y 5mm or m or e

fr om th e outs id e

diameter of

an od e c ap.

Coat ing posi t io n

of silico n gr eas e

An od e ca p

Fig. 8 Fig. 9

10

No. 51952

Page 11

A

B

A

B

A

S

REPLACEMENT OF MEMORY ICs

1. Memory ICs

This TV use memory ICs. In the memory ICs, there are memorized data

for cor r ectl y op erating th e video an d def l ection cir cu its . W h en r ep lac ing

memory IC s, b e s ure t o us e IC s wri tte n with th e initial values of da ta.

2. Procedure for replacing memory ICs

PROCE DURE

(1) Powe r off

Switch the p ower of f and un plug th e pow er cor d fro m t he ou tlet.

V28CT1EKS / AV28CT 1EK

V28CT1EPS / AV28CT 1EP

V28CT1EI

(2) Rep la ce ICs.

Be sure to use memory ICs writt en with the in it ial data values.

(3) Powe r o n

Plug th e p ower c ord i nt o the outlet a nd swit ch t he po we r on .

(4) Check an d s et SY STEM CONSTAN T SET :

It must not adjust wit hout sig nal.

****

1) Pr ess th e INFORMAT I ON ke y and th e MUT IN G k ey of th e

REMOTE CONTROL UNIT simultane ous ly.

2) The SERVICE MENU screen of Fig. 1 will be displayed.

3) Whi le th e S ERVICE ME NU is displ a yed, p r ess t he

INFORMATION key and MUTING key simultane ously, and the

SYSTEM CONSTANT SET screen of Fig. 2 will be display ed.

4) Check the se tting va lues of the S YSTEM C ONST A NT SET of

Table 1. If the value is d ifferent, select th e s ettin g item with th e

FUNCTION U P/ DOWN key, and s et the correct va lue with the

FUNCTION - /+ ke y.

5) Press the MENU key to memorize the setting va lue.

6) Pres s t he IN FOR MATION ke y t wice, a nd r etu rn t o th e no rmal

screen.

SE RV ICE MEN U

1. IF 2. V/C

3. AUDIO 4. DEF

5. VS M PRES ET 6 . VP S

7. AUTO PROGRAM (OFF)

1- 7 : SE LECT : EXI T

Fig.1

SY STE M CON ST AN T S ET

MO DE L= JK _EU R O (V

COUNTRY :

INCH :

MO DE L : W T

- + : STORE : EXIT

OK

JVC JK- II EU RO V00

******** - *****

Fig.2

*.****

**

**

)

(5) Setting of re cei ve ch anne ls

Se t the rec eive c h an ne l.

NAME OF REMOTE CONTROL KEY

Names of key

ke y

For setting , ref er to the OPERATIN G INSTRUCTIONS.

INFORMATION

iiii

(6) User se tting s

Check th e us er sett in g values of T ab le 2, an d if sett in g value is

MU T I N G

diff er ent , set the c orr ec t val u e.

For setting , ref er to the OPERATIN G INSTRUCTIONS.

OK

▼

▼

(7) Setting of SERV ICE MENU

Ve rif y the s et ting it ems of th e SER VIC E MENU of Tab le 3, an d r ese t

where necessary.

ME NU

FUNCTION UP/DOWN

For setting , ref er to the SERVICE ADJUSTMENTS.

▼

FUNCTION -/+

▼

No. 51952

11

Page 12

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

SETT I NG VALU ES OF SYST EM CONS TANT SE T (TABLE 1)

Setting item Setting content

AV28 CT1 EPS / EPB AV28 CT1 EIS AV28CT1EKS / EKB

Setting value

COUNT RY EP IR EK

INCH 28 28 28

MO DE L W T

EK EPIR

WT

3224 28

WR

USER SETTING VALUES (TABLE 2)

PICTURE SE TTING EX T SET TI NG

TINT

CONTRAST

BRIGHT

SHAR P

COLO UR

ECO MOD E

PICTURE F EAT URES FEATUR ES

AUT O VNR

COLOUR S YSTEM

4:3 AUT O ASPE CT

SOUND SETTING INSTALL

STEREO / Ⅰ・Ⅱ

BA SS

TR EBL E

BALANCE

HYPE R S OUND

COOL

REFER to VSM PRESET

NOTHING

AUT O

TV : Acco rding t o preset CH

EXT : AUTO

PA NO RA MI C

+8

CENTER

OFF

ID

S-IN

DUB BING

SLEEP TIMER

BLUE BA CK

CHI LD LO CK

DECODER (EXT-2)

LA NG UA G E

EDIT/MANUAL

DEMO OFF

BLANK

BLANK

EXT- 1→EX T-2

OFF

ON

ID : No.****

ALL CH OFF

OFF

ENGL ISH

PRES ET CH on ly

The others : BLANK

SERVICE MENU SETTING ITEMS (TABLE 3)

Setting item Setting value Setting item Setting value

1. IF VCO 4. DEF. 1. V-SHIFT

2. V / C 1. CUT OFF

1. AUDIO

(Do not adju st)

2. DRI VE

3. BRIGHT

4. CONT.

5. COLO UR

6. HUE

7. BLAC K O FFS ET ( Onl y SEC AM)

8. SHAR P

9. PURITY

1. CONC LIMIT

2. A2 ID THR

3. AL C

4. BA SS

5. TR EBL E

5. VS M PRESE T

COOL

NORMAL

WARM

6. VP S

(Do not adju st)

7. AUT O PROG RAM

(Do not adju st)

2. V-SIZE

3. SUBT IT LE

4. H-CENT

5. H-S IZE

6. EW - PIN

7. TR APE Z

8. EW. COR. L

9. EW. COR. H

10. V. S- COR

11 . V- LIN

12. H- BL K-R

13. H- BL K- L

14. V-EHT

15 . H - EHT

16. EHT-GAIN

1. BRIGHT

2. CONT.

3. COLO UR

4. SHAR P

5. HUE

6. R DRIVE

7. B DRIVE

VP S

PDC

ON / O FF

12

No. 51952

Page 13

A

B

A

B

A

S

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1. There ar e 2 w ays of ad ju st ing this TV: One is wi th the

REMOTE CONTROL UNIT and the other is the conventional

method using adjustment pa rts and components.

2. The s etting (adjustment) using the REMOTE CONTROL

UNIT is made on the basis of th e init ial setting values. The

se tting va lues which adj u st the scree n to t h e opt imum

condition can be different from the initial setting values.

3. Make s ur e th at conn ec t i on i s c orr ect ly ma de t o AC p ower

source.

4. Tur n on the power of th e TV and measu r in g i nstrument for

warmi n g u p for at l east 30 minut es b ef ore sta rt ing adju stment .

5. If th e r ec eive or i np ut si g nal is not speci fi ed , use t he m ost

ap prop riate s igna l f or a dj ust ment.

6. Never tou c h p ar ts ( suc h as var i ab le resist or s, tran sformers an d

condensers) not shown in the adjustment items of this service

adjustment.

7. Preparatio n f or ad j ustment ( pr es etting):

Unles s oth er wis e speci fi ed i n the a djust ment it em s, p r eset th e

follo wing funct io ns with the REMOTE CONTROL U NIT :

" Setting position

PICTURE MODE (VSM) NORMAL

SLEEP TIMER OFF

BALANCE CE NTER

ZOOM PANORAMIC

V28CT1EKS / AV28CT 1EK

V28CT1EPS / AV28CT 1EP

V28CT1EI

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmeter (or digit al voltmeter)

2. Oscilloscop e

3. Si gn al g enerat or (Patt ern g en erator) [ PAL / SE CA M / NTSC ]

4. Remote control unit

ADJUSTMENT ITEMS

●

B1 power supply check.

●

Adjustment of FOCUS.

●

IF ci rcuit a djust me nt.

●

VS M p r eset ad ju st s ettin g.

●

VIDEO / CHROMA circ uit adjustment.

●

DEFLECTION circuit adjustment.

●

H. BLANKIN G ADJUSTME NT.

●

AUDIO circuit adjustment. (Do not adjust)

No. 51952

13

Page 14

A

V28CT1EKS / AV28CT 1EKB

A

A

5

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

ADJUSTMENT LOCATIONS

FRON T

FRONT CONTROL PWB

F90 1

PW

POWER SW

FRON T

MAIN PWB POWER&DEF PW B

CN001

AV SEL PWB

CN006

CN001

MEMORY

IC702

IC701

F

SP R

SP L

FRON T

W DEG

TUNER

CRT SOCKET PWB

T P-47R

T P-47G

CN008

TP-E

IC301

CN008

(SOLDER SIDE)

T P-47B

E1

CN009

TOP

CN009

HV

X

1

1pin:B1( TP-91)

2pin:NC

3pin:NC

4pin:NC

5pin:GN D

FOCUS

SCREEN

14

No. 51952

Page 15

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

y

y

V28CT1EPS / AV28CT 1EP

V28CT1EI

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNI T.

2. SE RVICE MENU ITEMS

With the SERVI CE MENU , v ar iou s s ett ings ( ad ju stments) c an b e m ade , and th ey a re b roadly clas sif ied i n th e f ol lowing i te ms of s et tings

(adjus tm ents ):

(1) 1. IF ・・・・・・・・・・・・・・・・・・・・ ・・・ This mode adjust s the se tting values of the IF circuit.

(2) 2.V /C ・・・・・・・ ・・・・・・・・・・・・・ ・・ This mode adjust s the se tting values of the VID EO / CH ROMA circui t.

(3) 3.AUDIO ・・・・・・・・・・・・・・・・・・・ This mode adjusts the setting values of the multiplicit y SOUND circuit.

(4) 4. DEF ・・・・・・・ ・・・・・・・・・・・・・ ・ T hi s m ode adjust s th e setti ng values o f the DE FLECT ION c ircui t f or eac h as pect m od e g i ven be low.

REGULA R (50/ 60 Hz)

PA NO RA MI C ( 50 / 60 Hz)

14 :9 Z O OM (50/ 60 Hz)

16 :9 Z O OM (50/ 60 Hz)

SUB TI TLE (50/ 60Hz)

FU LL (50/ 60Hz)

(5) 5.V SM PRESET ・・・・・・・・・・・・・ This mode adjusts the initial setting values of COO L,NOMAL and WARM.

(VSM : Video Status Memory)

(6) 6.V PS ・・・・・・・ ・・・・・・・・・・・・・ ・ Thi s m ode sh ows the monitor of t he VPS a nd PD C .(Do not adjust).

(VP S : Vide o Pro gr am Syst em, PDC : Progra m Delive ry Code)

(7) 7. AUTO P ROGRAM ・・・・・・・ ・・ By t urni ng the p ower switch o n, you c an ge t the st ate of AU T O PR OG RAM. (Do not adjust)

3. BASIC OPERATION OF SERVICE MENU

(1) How to enter SERVICE MENU

Press the INFORM ATION key and the MUTING key of t he

REMO TE CONT RO L U NI T si mu lt an eou s ly, an d th e

SERVICE MENU screen of Fig. 1 will be displayed.

(2) Selection of S UB MENU SCREEN

Press one of keys 1~7 of the REMOTE CONTROL UNIT

an d sel e c t th e S UB M ENU SCR EEN ( See Fi g. 3 ), fo rm th e

SERVICE MENU.

SERV ICE MENU → SUB ME NU

1. IF

2. V / C

3. AUDIO

4. DE F.

5. VSM PRESET

6. VP S

7. AUTO PROGRAM

SE RVICE M ENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VS M PR ES ET 6 . VP S

7. AUTO PROGRAM (OFF)

1-7 : SELECT : EXIT

Fig.1

NEME OF REMOTE CONTOROL KEY

Names of ke

INFORMATION

MUTI NG

MENU

FUNCTIO N UP/DOWN

FUNCTIO N -/ +

Fig.2

ke

iiii

OK

▼

▼

▼

▼

No. 51952

15

Page 16

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. VPS

7. AUTO PROGRAM (OF F)

1-7 : SELECT : EXI T

7. AU TO PRO G RAM

7. AUTO PROGRAM (OF F)

7. AUTO PROGRAM (ON )

Do not adjust

COOL

NOR MAL

WARM

1. BR IGHT

2. CONT .

3. COL OU R

4. SHA RP

5. HU E

6. R DR IV E

7. B DR IV E

Do not adjust

5. VSM PRESET

VSM PRESET

NOR MAL

1. BR IGHT

- + : STORE : EXIT

OK

VPS = 0000H(- - -)

PD C 8 / 30 / 1 = 0 404 H

***

6. VPS

VPS

: EXI T

1.IF (VCO)

VCO (CW)

**

** ....**

**

****

****

TOO HIGH

ABOVE REFER ENCE

JUST REFERENCE

BEL OW R EFE RE NC E

TOO LOW

2. V /C

V/C

PAL

1. CUT OFF ( R)

OK

- +

****

(G)

****

(B)

****

: ST ORE : EXI T

MHz

: EXI T

1. CUT OFF

2. DR IVE

3. BR IGHT

4. CONT .

5. COL OU R

6. HU E

7. BLAC K OFFS ET

8. SHARP (Do not adjust)

9. PUR ITY (Do not adjust)

3. AU DIO

AU DIO

1. CONC L IMI T 0AH

C AD B I TS = 00 00000 0

: ST ORE : EXI T

OK

- +

SU B M ENU 4. D EF

DEF PANORAMIC

1. V- SHIFT

: ST ORE : EXI T

- +

OK

Fig. 3 SUB MENU SCREEN

***

(**)

Do not adjust

1. CONC LIM IT

2. A2 ID THR

3. ALC

4. BA SS

5. TREBLE

1. V-SHIFT

2. V-SIZE

3. SUB TITLE

4. H-C ENT

5. H-SI Z E

Hz

**

**

****

6. EW -PIN

7. TRAPEZ

8. EW.COR.L

9. EW.COR.H

10. V.S-COR

11 . V-L I N

12 . H -BL K-R

13 . H -BL K-L

14. V-EHT(Do not adjust)

15 . H -EHT ( Do no t ad jus t)

16 . EH T-G A IN (D o n o t ad jus t)

16

No. 51952

Page 17

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

V28CT1EPS / AV28CT 1EP

(3) Method of Setting

1) Meth od of Set ting 1. IF

[VCO]

① 1 Key ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・ Select 1.IF.

② The VCO (CW) screen will be displayed in yellow when the AFC voltage is at a certain level and in blue when it is at other levels .

③ INFORMATION K ey ・・・・・・・ ・・・・・ Return t o the SE RVICE MENU scre en.

2) Meth od of s ett in g 2.V/C, 3.AUDIO, 4.DEF an d 5.VSM PRESET.

① 2~5 K ey・・・・・・・・・・・・・・・・・・・・ ・・ Select one from 2.V/C, 3.AUDIO, 4.DEF and 5 .VSM PRESET.

② FUNCTION UP / DOW N Key・・・・・ Se lect s etting i tems.

③ FUNCTION -/+ ・・・・・・・ ・・・・・・・・・・ Set ( adjust) the se tting values of th e settin g it ems.

(U se the num ber keys of the REMOTE CONTROL UNI T for s etting of WHITE BALANC E.

For the s etti n g, ref er to ea ch it em c on cerned.)

④ MENU Key ・・・・・・・・・・・・・・・・・・・・ Memorize t he setting value.

(Bef or e st or ing t he s ett in g values i n me mo r y, do no t pr ess t he C H, TV, POWE R O N / OF F key -

if you d o, the valu es will not be stored in memory.)

⑤ INFORMATION K ey ・・・・・・・ ・・・・・ Ret urn t o the SERVICE ME NU sc r ee n.

3) Meth od of s ett in g 6.VPS and 7 . AU T O PR O GR AM .

6.V PS ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・ This mode displayed monitor of VPS systems. (Do not adjust)

7.AUT O PROGRAM・・・・・・・ ・・・・・・・・ W hen the MAI N POW ER is tur ne d on w it h the sta te of AU TO P RO GR AM ON, you ge t a m od e

that initializes every existing set value including language s elect ion. Because this mode is set

at th e factor y upo n co mpl eti on of the a djust ment , you need not t o use i t for servi ce.

(Do not adju st in this mode.)

V28CT1EI

(4) R ele ase o f SER V ICE M ENU

1) Af ter co mp leting th e setti ng , r etur n to t he SERVIC E ME NU , then ag ai n p r ess th e INFOR MATIO N ke y.

No. 51952

17

Page 18

A

V28CT1EKS / AV28CT 1EKB

A

A

SC

OCUS

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

ADJUSTMENTS

CHECK ITEM

Item

Check of B1

Power Supply

Measuring

instrume nt

Signal

generator

DC vo ltmeter

Remote

control unit

Test point Ad justment part Description

TP-91(B1)

TP-E(#### )

[X connector

on POWER

DE F PW B]

1. Recei ve a an y broa dcast.

2. Pu sh t he “ZOOM” k e y an d s elect the FULL mode .

3. Sele ct 2 .V/C f rom the SE RVICE M EN U.

4. Se lect 1. CUT OFF wit h Fu nctio n UP/ DOW N k ey.

5. Sh ow one ho riz on tal line w i th the 1 k ey.

6. Tur n the SCREEN VR, the whol e blac k scr een disp lay.

7. Con nect a D C vol tm eter t o TP- 9 1(B 1) a nd T P- E(#).

8. Mak e sure t hat the vol t age i s D C 14 4.5 ±2.0V.

9. Readjust the S CRE EN VR to ap pear th e hor izon tal li n e fai n tly,

an d cancel t he hor i zonta l lin e to p ress th e 2 key.

Check of High

Volt age

Signal

generator

DC volunteer

Remote

control unit

ADJUS TMENT OF FOCUS

Item

Ad justment of

FOCUS

Measuring

instrume nt

Signal

gener ator

CRT anode

Chassis GND

Test point Ad justment part Description

FOCUS VR

[In FBT]

1. Recei ve a an y broa dcast.

2. Pu sh t he “ZOOM” k e y an d s elect the FULL mode .

3. Sele ct 2 .V/C f rom the SE RVICE M EN U.

4. Se lect 1.CUT OFF wit h Fu nctio n UP/DOW N key.

5. Sh ow one h orizo ntal l in e with t he 1 key.

6. Tur n the SCREEN VR, the whol e blac k scr een disp lay.

7. Connect a DC voltmeter t o CRT ANODE and chassis GND.

8. Mak e sure t hat the vol t age i s D C 3 0.0kV .

9. Readjust t he SCREEN VR to appea r th e hor i zon tal lin e fain tly,

an d c onnec t the h orizo ntal l in e to press 2 key.

1. Receive a cross-hatch signal. S elect FULL m ode.

2. W hile watc hi ng th e s cr een , a djus t the FOCUS VR to m ake th e

ver ti cal and ho rizo ntal l ines as f in e a nd sha rp as possi b l e.

3. Make sure th at w hen the s c reen is darke ned , the lines r e ma i n

in good focus.

+1kV

-1.5kV

F

VR

REEN VR

18

No. 51952

Page 19

A

B

A

B

A

S

IF CIRCUIT ADJUSTMENT

Item

Ad justment of

VCO

Measuring

instrume nt

Remote

control unit

VCO( CW)

***.**

T OO HI GH

ABOVE REFERE NCE

JUS T REF ERENCE

BEL OW REFERE NCE

T OO LO W

: EXIT

Test point Ad justment part Description

MHz

VSM PR ES ET AD JUS T SET TIN G

Item

Setting of

VS M PRESET

Measuring

instrume nt

Remote

control unit

Test point Ad justment part Description

fv

YELLOW

1. BR I G HT

2. CONT.

3. COLOUR

4. SHARP

5. HUE

6. R DRIVE

7. B DRIVE

V28CT1EKS / AV28CT 1EK

V28CT1EPS / AV28CT 1EP

V28CT1EI

"

U nd er n orma l c ondi ti ons, no ad just ment is r e quired .

1. Recei ve an y br oadc ast.

2. Select 1 .IF from t he SERVICE MENU.

3. Check th e charact ers co l our of the JU ST REFE REN CE

displayed to yellow.

1. Sele ct 5 .VSM P RESET from th e S ERVICE MENU.

2. Se lect C OOL with t he MEN U key of t he re mote con tr ol un it.

3. Ad ju st th e FUNC TION UP /D OW N and -/ + key t o bring t he s et

val u es of 1.B RIG HT ~ 7.B DR IVE to the val ues s h ow n in the

tabl e.

4. Press the ME NU key a nd mem or iz e th e s et va lue.

5. Respectively select the VSM PRESET mode for NORMAL and

WARM, an d m ake si milar a djust ment as i n 3 abo ve.

6. Press the ME NU key a nd mem or iz e th e s et va lue.

∗

Refe r to O PERATIN G INSTRUCTIONS for the PICTURE

MO DE .

VSM preset mode

Setting item

1. BRIGH T

SE TT ING VAL UE

2. CONT.

SE TT ING VAL UE

3. COLO UR

SE TT ING VAL UE

4. SH ARP

SE TT ING VAL UE

5. HUE

SE TT ING VAL UE

6. R DRIVE

SE TT ING VAL UE

7. B D RIVE

SE TT ING VAL UE

COOL NORM AL WAR M

+0 +0 +0

+12 +10 +2

+6 +0 -2

+0 +0 -2

+0 +0 +0

-20 +0 +16

+23+0-13

SE TT ING VALUES OF VSM PRESE T

No. 51952

19

Page 20

A

V28CT1EKS / AV28CT 1EKB

A

A

ote Control Unit

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

VIDEO / CHR OMA CIRCUIT ADJUSTMENT

The setting (adjustment) using the REMOTE CONTROL UNI T is made on the basis of the initial setting values.

The setting values which adj ust the screen to the optimum condition can be different from the initial setti ng val ues.

Colour sy stem

Setting Item

(Adjustment Item )

R -100 5. COLOUR +14 +0 +8

1. CUTOFF

2. DRIVE

3. BR IG HT +0

4. CONT. -10 9. PURITY (Do not adjust)

Item

Ad j ust men t

of WHITE

BALANCE

(Low Light)

Rem

H. LIN E O N

G -100

B - 100 R-Y +0

R

B+0

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Initial set ting v al ue

+0

Test point Ad justment part Description

1.CUT OFF

SCREEN VR

[In FBT]

H. LIN E O F F

Setting item

6. HUE

7. BLACK OFFSET

(SECAM)

8. SH ARP

(Do not adjust)

(R)***

(G)

***

(B)***

B- Y +0

"

Se t th e PICTURE MODE to NORMAL.

1. Rec eive a bl ack a nd white sign al ( col o ur of f).

2. Sele ct 2 .V/C f rom the SE RVICE M EN U.

3. Select 1.CUT OFF with the FUNCTION UP/DOWN key.

4. Pu sh t he “ZOOM” k e y an d s elect the “PA NOR AM IC” mod e.

5. Sh ow one ho riz on tal line w i th the 1 k ey.

6. Gr ad ua lly turn the SC REEN VR fr om th e left en d to th e r i ght

direc ti o n to bring o ne of th e r ed , g r een or blue co l our f aint ly

visible.

7. Press 4 ~9 key, and br ing ou t the o the r 2 colours a nd make

on e h or izont al l ine vi sible i n white.

8. Turn th e SC R EEN VR a nd br i ng on e white horiz on tal lin e

faintly visible.

9. Press 2 ke y, tu rn of f 1. CUT OF F sc reen .

10 . Press the MENU key a nd mem oriz e th e s et va lue.

Initial set ting v al ue

PAL

-7

OFF

SE CAM

NT SC 3.5 8

NT SC 4.4 3

+2

20

1 2

R CU TOFF

4 5

R CU TOFF

7 8

G CUTOFF

G CUTOFF

3

B CUTOFF

6

B CUTOFF

9

No. 51952

Page 21

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

)

)

V28CT1EPS / AV28CT 1EP

V28CT1EI

Item

Ad j ust men t

of WHITE

BALANCE

(High Light)

Measuring

instrume nt

Signal

gener ator

Remote

control unit

REMOTE CONTROL UNIT

1 2 3

4 5

7 8

Test point Ad justment part Description

6

9

2. DRIV E

DRIVE

(R)

DRIVE

(B)

DRIVE(R

DRIVE(B

(R)***

(B)***

▲

▲

▼

▼

"

The a dj ust me nt f or Lo w Light W H ITE BA LANC E sh ou l d b e

finish ed.

"

Se t th e PICTURE MODE to NORMAL.

1. Rec eive a bl ack a nd white sign al ( col o ur of f).

2. Sele ct 2 .V/C f rom the SE RVICE M EN U.

3. Se lect 2.DRIVE with th e FU NCTI ON UP/DOW N key.

4. Cha nge the sc reen col o ur to whi te wit h 4 key o r 7 key (D rive of

Red), 6 ke y or 9 key (Drive of Blu e) .

5. Press the MENU key, and memorize the set values.

Ad j ust men t

of

SUB BRIGHT

Ad j ust men t

of

SUB

CONTRAS T

Remote

control unit

Remote

control unit

3. BR IG HT 1. Recei ve an y br oadc ast.

2. Se le ct 2.V/C f rom the SE RVICE MEN U.

3. Select 3 .BRIGHT with th e FUN CTI ON UP/DOW N key.

4. Set the initial setting value with the FUNCTION -/+ key.

5. If th e brigh tn ess is no t th e be st wi th th e in i ti al se tting val ue ,

make fine adjustment until you get the bes t brightness.

6. Press the MENU key a nd mem oriz e th e s et va lue.

4.CO NT. 1. R ecei ve an y broadc ast.

2. Se le ct 2.V/C f rom the SE RVICE MEN U.

3. Select 4.CONT with the FUNCTION UP/DOWN key.

4. Set the initial setting value with the FUNCTION -/+ key.

5. If the contr ast is n ot the be st with the i niti al se tting va lue, ma ke

fine adjustment until you get the best contrast.

6. Press the MENU key a nd mem oriz e th e s et va lue.

No. 51952

21

Page 22

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

Item

Ad j ust men t

of SUB

COLOURⅠⅠⅠⅠ

Measuring

instrume nt

Remote

control unit

Test point Ad justment part Description

5.COLO UR

(PAL~~~~NT S C)

PAL COLOUR (PAL COLOUR)

SE CA M C OLO UR

Only

AV28CT1E PS

AV28CT1E PB

[Method of adjustment without measuring instrument]

1. Rec eive PAL b road cast.

2. Sele ct 2 .V/C f rom the SE RVICE M EN U.

3. Se lect 5.COLOUR with the FUNCTIO N UP/DOW N key.

4. Se t th e in it ial sett ing value for PAL C OLO UR with the

FUNCTION - or + k ey.

5. If t he co lour i s no t the bes t with th e initial s et value, m ake

fine adjustment until you get the best colour.

6. Press the ME NU key a nd mem or iz e th e s et va lue.

(SECAM COLOUR)

1. Recei ve a SE CAM broa dcas t.

2. M ake fi n e adjustm e nt of SE C AM COLO UR i n the s ame

manner as for abo ve.

NTSC COLO UR

(NTSC 3.58 COL OUR)

1. Input a NTSC 3.58MHz COM POSITE V IDEO sig nal fr om the

EXT t erminal.

2. Make s imil ar f in e ad justment of N TSC 3 .58 COLO UR i n th e

sam e mann er as f or a bo ve.

(NTSC 4.43 COL OUR)

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

22

No. 51952

Page 23

A

V28CT1EKS / AV28CT 1EK

B

A

B

A

S

(+)

(-)

0

(A)

V28CT1EPS / AV28CT 1EP

V28CT1EI

Item

Ad j ust men t

of SUB

COLOUR ⅡⅡⅡⅡ

Measuring

instrume nt

Signal

gener ator

Oscilloscope

Remote

control unit

Test point Ad justment part Description

TP-47B

TP-E(#### )

[CRT

SOCKET

PWB ]

5.COLO UR

(PAL~~~~NT S C)

PAL COLOUR (PAL COLOUR)

SE CA M C OLO UR

Only

AV28CT1E PS

AV28CT1E PB

[Method of adjustment using measuring instrument]

1. Rec eive a PAL full f ield co lour b ar si gn al (75% white ).

2. Sele ct 2 .V/C f rom the SE RVICE M EN U.

3. Se lect 5.COLO UR with the FUN CTI ON U P/DOW N key.

4. Se t th e i n it i al setti ng value of P AL COLO UR with t he

FUNCTION - or + k ey.

5. Con nect th e osc ill osc ope be twee n T P -4 7B and T P- E( #).

6. Ad just P AL C OL OUR an d b ring th e value of ( A) i n th e

illustration to +6V.

7. Press the ME NU key a nd mem or iz e th e s etti n g value.

VOLTAGE (W -B)

+6V

(SECAM COLOUR)

1. Rec eive a SE CA M f ul l fie ld co lour b ar si gn al(75 % w hi te) .

2. Set the initial setting value of SECAM COLOUR with the

FUNCTION - /+ ke y.

3. Adju st SE C AM C OLO UR an d br in g t he val ue of (A ) in t he

illustration to –5V.

4. Press the ME NU key a nd mem or iz e th e s etti n g value.

WCyMgB

NTSC COLO UR

VOLTAGE (W -B)

-5V

(NTSC 3.58 COLOUR)

1. Inp ut a NT SC 3.5 8MHz COMPOSI TE V IDE O s ign al (full field

colo ur bar with 75% w hit e) from th e EX T terminal.

2. Set th e initial setti ng value of NTSC 3.58 COLO UR with the

FUNCTION - /+ ke y.

3. Ad ju st NT SC 3.5 8 COL OU R and b ring th e val u e of (A) in the

illu strati on to 0V (Vo lt ag e d if fer en ce bet w een wh ite( W ) an d

blue(B).

4. Press the ME NU key a nd mem or iz e th e s etti n g value.

(NTSC 4.43 COLOUR)

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

No. 51952

23

Page 24

A

V28CT1EKS / AV28CT 1EKB

A

A

CyMg

(B)

(-)

(+)

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

Item

Ad j ust men t

of

SUB HUEⅠⅠⅠⅠ

Measuring

instrume nt

Remote

control unit

Test point Ad justment part Description

6. HUE [Method of adjustment without measuring instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Inp ut a NT SC 3.5 8MHz COMPOSI TE V IDE O s ign al (f ull field

colo ur bar with 75% w hit e) from th e EX T terminal.

2. Sele ct 2 .V / C fr om t he SERVI CE MENU.

3. Select 6. HUE with the FUNCTION UP/DOWN key.

4. Se t the ini ti a l sett in g value of NT SC 3. 58 H UE w i th th e

FUNCTION - /+ ke y.

5. If you cannot get the best hue with the initial setting value,

make fine adjustment until you get the bes t hue.

6. Press the ME NU key a nd mem or iz e th e s et va lue.

NTSC 4.43 HUE [NTSC 4.43 HUE]

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

Ad j ust men t

of

SUB HUE

ⅡⅡⅡⅡ

Signal

gener ator

Oscilloscope

Remote

control unit

W

TP-47B

TP-E(#### )

[CRT

SOCKET

PWB]

B

6. HUE [Method of adjustment using measuring instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Inp ut a NT SC 3.5 8MHz COMPOSI TE V IDE O s ign al (f ull field

colo ur bar with 75% w hit e) from th e EX T terminal.

2. Sele ct 2 .V/C f rom the SE RVICE M EN U.

3. Select 6. HUE with the FUNCTION UP/DOWN key.

4. Se t the ini ti a l sett in g value of NT SC 3. 58 H UE w i th th e

FUNCTION - or + k ey.

5. Con nect th e osc ill osc ope be twee n T P -4 7B and T P- E(#)

6. Ad just N T SC 3. 58 H UE t o bring th e valu e of (B) in the

illu strati on t o - 4 V ( vol tag e diff er enc e b et ween white (W) an d

magent a ( Mg ) ).

7. Press the MENU key and memoriz e the setting value

0

NTSC 4.43 HUE [NTSC 4.43 HUE]

1. W hen N TSC 3 .58 is set, N TSC 4.43 w ill b e aut omati ca lly se t at

the respective values.

24

No. 51952

Page 25

A

B

A

B

A

S

[Only AV28CT1EPS / AV28CT1EPB]

(c)

(d)

Item

of BLACK

OFF SET

(SECAM)ⅠⅠⅠⅠ

REMOTE CONTROL UNIT

Measuring

instrume nt

Remote

control unit

1 2 3

4

5

7

8

Test point Ad justment part Description

6

9

7. BL AC K

OFF SET

(R-Y) ***

(B-Y) ***

BLACK OFFSET ON

BLACK OFFSET

OFF

R-Y

▲

B- Y

▲

R-Y

▼

B- Y

▼

V28CT1EKS / AV28CT 1EK

V28CT1EPS / AV28CT 1EP

V28CT1EI

[Method of adjustment without measuring instrument]Ad j ust men t

1. Rec eive a SEC AM br oadc ast.

2. Sele ct 2 .V/C f rom SER VIC E MENU.

3. Se lect 7. B LACK OFFS ET with th e FUN CTIO N UP/DOWN

key.

4. Se t the i n it i al se tting val u e for BLA CK OF FSET ( R- Y) an d ( B-

Y) wit h 4 and 7 or 6 and 9 k e ys of the remot e c ontrol.

5. If the pictur e i s not th e b est wit h the in it ial set ting value, m ak e

fin e ad j ustment un til yo u get t he be st p ict ure.

6. Pr ess the MENU key a nd memor i ze t he sett in g va l ue.

of BLACK

OFF SET

(SECAM)ⅡⅡⅡⅡ

[R-Y]

[B-Y]

Signal

gener ator

Oscilloscope

Remote

control unit

35 PI N (R -Y )

36 PI N (B -Y )

IC- 301 ON

MAIN PWB

(a) (b)

7. BL ACK

OFF SET

(R-Y) ***

(B-Y) ***

[Method of adjustment using measuring instrument]Ad j ust men t

1. R eceiv e a SECAM C OL OUR bar si gn al (f ul l field co l our b ar

75% white).

2. Select 2.V /C fr om S ERVICE MENU.

3. Select 7.BL ACK OFFSET with the FUNCTION UP/DOW N

key.

4. C on nect th e os cillosc op e bet ween 35 pi n of IC-3 01 an d TP- E

(#).

5. By usi ng 4 and 7 keys of t he remote control, adjust the

BLACK OFFSET (R-Y) so that it becomes the waveform

ch anges f ro m (a ) t o ( b) shown in th e f igure.

6. C on nect th e osc il l osc ope be tween 36 pi n of IC-3 01 an d TP-E.

7. By usi ng 6 and 9 keys of the remote control, adjust the

BLACK OFFSET (B-Y) so that it becomes the waveform

ch anges f ro m (c) to (d) sh ow n i n th e figu re.

8. If the pi ctu re i s n ot th e best wit h th e adj u sted pi ctu re , m ake

fine adjustment until you get the best picture.

9. Pr ess the MENU key a nd m em or iz e the s etti n g va lue.

No. 51952

25

Page 26

A

V28CT1EKS / AV28CT 1EKB

A

A

V28CT1EPS / AV28CT 1EPB

V28CT1EIS

DEFLECTION CIRCUIT ADJUSTMENT

Th ere are 7 mo des of t h e adjus tme nt.

( 1 ) 50Hz mode ( ①①①① PANORAMIC ②②②②FULL ③③③③REGULAR ④④④④14:9 ZOOM ⑤⑤⑤⑤16:9 ZOOM ⑥⑥⑥⑥ 16:9 ZOOM SUB TITLE )

・・・・ ・

・・・・ ・

( 2 ) 60Hz mo de ( ea ch as pect mode )

"

The adjustment using the remote control unit is made on the basis of the initial setting val ues.

"

When the 50Hz PANORAMI C mode has been established, the setting of oth er modes will be done automatically.

However, if the picture quality has not been optimized, adjust each mode again, respectively.

" The setting v alues which adj ust the screen to the opti mum condition can be different from the initial setting values.

Ini tial setti ng v alue ( 1/2)

Setting item Ad justment name

1. V-SHIFTVertical center -10-1+0+0+1+0+0+0

2. V- SIZ E Vert ic al he ig ht +8 - 2 +18 +15 +38 +37 +42 +40

3. SU BT ITL E SU BTIT LE B OTTOM Vertical Li ne ar i ty -8 + 0 +0 + 0 + 0 +0 +15 +15

4. H-CENT Horizontal center -9 +5 +1 +1 +0 +0 +0 +0

5. H-S IZE H or i zont al w i dth +10 + 0 -12 -14 - 6 -6 -6 -6

6. EW-PIN Side pin correction -23 +0 -1 -1 -1 -1 -2 -1

7. TRAPEZ Tr ap ezoida l disto rt i on c orr ec tion +2 + 0 -1 + 0 - 1 + 0 + 0 +0

8. EW.COR.L CORNER PIN correction Low s ide +0 +0 +0 +0 +0 +0 +0 +0

9. EW.COR.H CORNER PIN correction High side +0 +0 +0 +0 +0 +0 +0 +0

10.V.S-CORVertical height correction +4+0+0+0+0+0+4+0

11.V-LIN Vertical Linearity -1+0+0+0+1+0+0+0

12.H-BLK-R BLANKING POSITION of Right side +0 +0 +123 +124 +0 +0 +0 +0

13.H-BLK-L BLANKING P OSITION of Left side +0 +0 +36 +27 +0 +0 +0 +0

14 .V- EHT

(Do no t adjus t )

15 .H -E HT

(Do no t adjus t )

16 .EH T-GAIN

(Do no t adjus t )

V size correction level caused by EHT cha nge-4+0+0+0+0+0+0+0

H size correction level caus ed by EHT change -3 +0 +0 +0 +0 +0 +0 +0

Size c orrection gain caused by EHT change +0 +0 +0 +0 +0 +0 +0 +0

・・・・ ・・・・・ ・

De pending upon the kind of signals ( vertical freque ncy 50Hz / 60Hz ).

Initial set ting v al ue

PANORAMIC 14:9 ZOOM 16:9 ZOOM

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

16:9 ZOOM

SUB TITLE

Ini tial setti ng v alue ( 2/2)

Initial set ting v al ue

Setting item Adjustment name

1. V-SHIFT Vertic al center +0 +0 +0 +0

2. V- SIZ E Ve rt ic al height -6 -6 -3 -3

3. SU BT ITL E SUBTIT LE BOTTOM Verti cal Line ar i ty +0 + 0 + 0 +0

4. H-CEN T H or izont al ce nte r + 0 +0 + 1 + 1

5. H-S IZE H or i zont al w i dth -6 -6 - 21 -21

6. EW-PINSide pin correction +0+0+0+0

7. TRAPEZ Tr ap ezoidal disto rt i on c orr ec ti on + 0 +0 - 1 + 0

8. EW .COR .L C OR NE R PIN co rrect ion Low s id e + 0 + 0 +0 + 0

9. EW .COR .H CORNER PIN co rrec t ion Hig h side + 0 +0 +0 + 0

10 .V.S -COR Vert ic al he ig ht correc ti on +0 + 0 +0 + 0

11 .V- LI N Ve rt ic al Lin eari ty +0 + 0 + 0 +0

12 .H -B LK -R BL AN KIN G P OSITI ON of Right s ide +0 + 0 + 123 + 124

13 .H -B LK -L BLANKIN G P OSITI ON of Lef t sid e +0 + 0 + 36 + 27

14 .V- EHT

(Do no t adjus t )

15 .H -E HT

(Do no t adjus t )

16 .EH T-GAIN

(Do no t adjus t )

Vsize correction level caused by EHT change +0 +0 +0 +0

Hsiz e corr ect ion leve l c aused by EHT cha nge+0+0+0+0

Size c orre ction ga in ca used b y EHT chan ge + 0 +0 +0 + 0

FULL REGULAR

50 Hz 60 Hz 50 Hz 60 Hz

26

No. 51952

Page 27

A

B

A

B

A

S

Item

Ad j ust men t

of

V-SHIF T

Measuring

instrume nt

Signal

gener ator

Remote

control unit

V28CT1EPS / AV28CT 1EP

V28CT1EKS / AV28CT 1EK

Test point Ad justment part Description

1. V- S HI FT [50Hz PANORA MIC mode]

1. Rec eive a cir cle p att ern si g na l of vert ic al freq ue ncy 5 0Hz.

2. Se lect 4 .DEF f rom t he SER VI CE M EN U .

3. Se lect 1.V-SHIFT w ith t he FUNCTION UP/DOW N key.

4. Adjust V-S HIFT to make A = B.

5. Press the ME NU key a nd mem or iz e th e s et va lue.

****

For JK c hass is

A

B

Set all d ata exc ept for "PANORAM IC" to " 0".

Ad just V.CE NTE R of other asp ects w ith "P ANOR AM IC " mode

whil e al so ta king the ir p osi t io ns i n to c onsi d erat ion. If y o u wa nt

to obt ain h oriz ont al l ines wi th l ess no is e o n th e s cr ee n, ad ju st

V.LIN instead of "PANORA MIC" mod e.

V28CT1EI

Ad j ust men t

of V-SIZE &

SUBTITLE

Scr e en

size

AS PE CT

MODE

SCREEN

TOP

SCREEN

BOTTOM

2.V-SI ZE

3.S UBTITLE

Screen size

Picture

size

10 0%

Picture size 100%

PANORAMIC 14 : 9 Z OOM 16 : 9 Z OOM

87 % 80 % 70 % 70% 92 % 92%

87 % 80 % 70 % 83% 92 % 92%

[ SCREEN S IZE ]

6. Rec eive a cros s -hatc h signal.

7. Select 2.V-SIZE and set the initial setting value.

8. Adjust V-SIZE and make sure that the vertical screen size of t he

pictu re si ze is in th e bel low t abl e.

9. Press the ME NU key a nd mem or iz e th e s et va lue.

10 . W hen ad jus t th e [S UB T IT LE ], se l ect “ 3 .SU BT IT L E” an d ad jus t

to un der p ar t o f pict ur e s ize.

11 . Inp ut a NTSC VIDEO si g na l (60Hz) f r om th e EXT t er minal, and

make sure t hat th e vert ic al scr een size i s in th e t able be low.

12 . Pr ess the MENU key and mem or ize the s et value.

16 : 9 Z OOM

SUB TITLE

FULL REGULAR

No. 51952

27

Page 28

A

V28CT1EPS / AV28CT 1EPB

A

A

V28CT1EKS / AV28CT 1EKB

V28CT1EIS

Item

Ad justment of

HORIZONTAL

CENTER

Ad j ust men t

of

HORIZONTAL

SIZ E

Measuring

instrume nt

CD

90 %

Test point Ad justment part Description

4.H-CENT. 13. R eceive a c ircle p atter n s igna l.

14. Select 4.H-CENT and set the initial setting value.

15 . Ad ju st H- CE NT t o ma k e C =D .

16 . Press the ME NU key a nd mem or iz e th e s et va lue.

90 %

L

5. H-SIZ E 17. Receive a circle pattern signal.

18. Select 5.H-SIZE and set the initial sett ing value.

19 . Ad just H - SIZE and m ake sur e that t he ho riz o nta l sc reen size

20 . Press the ME NU key a nd mem or iz e th e s et va lue.

of th e pict ur e si ze is i n th e bel l ow t abl e .

AS PE CT

MODE

H SI Z E

Ad justment of

EW-PIN

* The nu meric of t he REGULA R an d 1 4:9 ZOO M mo des are

21. Input a NTSC VIDEO si gnal (6 0Hz) f rom the EXT term ina l,

22 . Press the ME NU key a nd mem or iz e th e s et va lue.

PANORAMIC 14:9 ZOOM 16 :9 ZOOM

PA L=95 %

NTSC=9 4%

Straight

L=495mm 92 % 92% 92% L= 44 0mm

[ SCREEN S IZE ]

6.E W-PI N 23. Select 6.EW- PIN an d s et t he initial s etting value

24 . Ad just EW- PIN a nd ma ke t he 2nd .ve rt ic al lin es at th e lef t and

25 . Press the ME NU key a nd mem or iz e th e s et va lue.

sh own the length o f th e 90 % ho rizo nta l size posi ti on ( L ) as

sh own in the figu r e a bov e.

an d make s ure tha t the h orizo nt al s cr e en s ize of th e eac h

ASPECT mode is in the b elow table.

16:9 ZOOM

SUB TITLE

right ed ges of th e scr ee n str aig ht. Also mak e sure t hat the 3rd

vertical lines are straight.

FULL REGULAR

28

No. 51952

Page 29

A

V28CT1EPS / AV28CT 1EP

B

A

B

A

S

V28CT1EKS / AV28CT 1EK

V28CT1EI

Item

Ad j ust men t

of TRAPEZ

Ad justment of

EW. CORNER

L/H

Straight Straight

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Signal

gener ator

Remote

control unit

Test point Ad justment part Description

7. TR APEZ 26. Rec eive a cross-h atch si gna l.

27. Select 7.TRAPEZ with the FUNCTION UP/ DOWN key.

28. Set the init ial setting value of TRAPEZ with the FUNCTION

- or + key.

Parallel

8.EW. COR. L

9.EW. COR. H

29 . Ad just TRAPE Z and b r ing t he VERT IC AL lines at the right

an d lef t edges o f the sc re en pa ralle l .

30 . Press the ME NU key a nd mem or iz e th e s et va lue.

31. Select 8.EW. COR. L with the FUNCTION UP / DOW N key.

32. Set the initial sett ing value of EW. COR. L with th e

FUNCTION – or + key.

33 . Ad just EW. C OR . L, and brin g the strai gh t li ne at the low

corner.

34. Select 9.EW. COR. H with the FUNCTION UP / DOWN key.

35. Set the init ial setting value of EW. COR. H with the

FUNCTION – or + key.

36 . Ad just EW. C OR . H , an d br i ng the str aigh t l i n e a t th e u pp er

corner.

37 . Press the ME NU key a nd mem or iz e th e s et va lue.

Ad j ust men t

Of

VERTICAL-S

CORRECTION

&

VERTICAL

LINEARITY

10. V- S.CR

11 . V- LIN

TOP

CENTER

BOT TOM

No. 51952

When the vertical linearity has been deteriorated remarkably,

•

perform the following steps.

38 . R ecei ve a cr oss- h atc h signa l.

39. Select 11.V-LIN with the FUNCTIO N UP / DOWN ke y.

40. Set the in itial setting value of 11.V-LIN wit h the FUNCTION

- / + key.

41. Select 10.V-S. COR with the FUNCTION UP / DOW N key.

42 . Set th e initial sett ing val ue o f 10.V-S. COR with the

FUNCTION

- / + key.

43. Adjust 11.V-LIN and 10.V-S.COR s o that t he s p aces of e ach

line on TOP, CENTER and BOTTOM be come unif orm.

NOTE : Do n ot adjust “PANORAMI C” & “16 : 9 Z OOM SU BTIT LE”

mode.

****

For JK chassis

On account of CRT (ITC), set V-S.COR excep t for

"PANOR AMIC " m ode to the minim um.

When ad ju sting "PA NO RAMIC" mode, sli gh tly exp an d th e

sp ac e at th e CENT ER wh ile taki ng the c ircul ar ity at th e

CENTER into consideration.

29

Page 30

A

V28CT1EPS / AV28CT 1EPB

A

A

V28CT1EKS / AV28CT 1EKB

V28CT1EIS

Item

Measuring

instrume nt

Test point Ad justment part Description

H. BLAN KING ADJUSTM ENT

Item

Ad justment of

HORIZONTAL

BL ANKING

Measuring

instrume nt

Test point Ad justment part Description

H H'

H. B LK

Capacitor

[On MAIN PWB]

At fi rst th e adj ustmen t in 50Hz -PANOR A MIC mo de sho uld be

d one, then the d at a for the o ther zoo m mode is correc t ed i n t he

resp ec ti ve val ue at t he same ti me. A nd c onf irm th e defl ec tion

adjustment initial s ett ing value in 60Hz ( TSC EXT mode )

PA NO RA MIC mo de . If th e ad ju stm en t i n 50 H z each zoo m

mode h as be en d on e a nd st ored, t he d ata f or th e same asp ect

modes in 60 Hz is corrected in the respective value. O nly t he

data for the oth er asp ect mode in 60Hz is c orrec ted for its elf .

1. Recei ve the P AL c ircl e p attern sig na l.

2. Se lect 4.D EF f rom t he SERVI CE M EN U.

3. Se lect t he asp ect [ 14 :9 ZOO M] m ode.

4. Select 12.H-BLK-R with th e FUNCTION UP/ DOWN key a nd

ad just H - BLA NKIN G s o th at 92% of the pictu re on the r ig ht s ide

is di sp layed.

5. Select 13.H-BLK-L wit h the FUNCTION UP/DOWN key and

ad just H- BL AN KING so that 9 2% of th e pi ctu r e on th e l eft si de

is di sp layed.

6. Pres s the MENU key a nd memoriz e t he set val ue.

7. Se lect t he aspect [REG U LAR ] mode.

8. Select 12.H-BLK-R with th e FUNCTION UP/ DOWN key a nd

ad just H’.B LAN KI NG s o th at 92% o f t he pic tur e o n the r igh t side

is di sp layed.

9. Select 13.H-BLK-L wit h the FUNCTION UP/DOWN key and

ad just H- BL AN KING so that 9 2% of th e pi ctu r e on th e l eft si de

is di sp layed.

10 . Press the ME NU key a nd m em or iz e th e s et va lue.

30

No. 51952

Page 31

A

V28CT1EPS / AV28CT 1EP

B

A

B

A

S

V28CT1EKS / AV28CT 1EK

V28CT1EI

AUDIO CIRCU IT ADJUSTMENT

"

Do not touch 3.AUDIO (1.CONC L IMIT, 2. A2 ID THR, 3.ALC, 4.BASS, 5.TREB LE) of th e SERVICE M ENU as it req uires no adjustment .

3. AUDIO

Setting item Variabl e range fixed value

1. CONC LI MIT(Do not adjust) 00 H ~ FFH 0AH

2. A2 ID THR(Do not adjust) 00H ~ FFH 19H

3. AL C (Do not adjust)

4. BAS S (Do not adjust) -17 ~ +17 +0

5. TREBL E (Do not adjust) - 17 ~ +17 +0

20 MS EC 2S EC 4S EC 8SEC

No. 51952

31

Page 32

A

V28CT1EPS / AV28CT 1EPB

A

A

V28CT1EKS / AV28CT 1EKB

V28CT1EIS

32

No. 51952

Loading...

Loading...