Page 1

B

SERVICE MANUAL

COLOUR TELEVISION

AV28CH1 EUS

AV28 CH1 EU

BASIC CHASSIS

AV28CH1EUS

AV28CH1EUB

MF

CONTENTS

! SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUTIONS

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST

★

STAND ARD CIRCUIT DIAGRAM

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 5

・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 12

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

31

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2- 1

4

6

No.519 44

Mar. 2002

Page 2

A

V28CH1EUS

A

y

V28CH1EUB

SPECIFICATIONS

Item

Dimensions ( W××××H××××D ) 72 5mm×4 80m m×496mm

Mass 34 .7 kg

TV RF System

Colour Sy stem PA L / SECA M / NT SC (Only i n EXT mode)

Stere o Sy st em A2 (B /G,D/K)/ NICAM(B/G,I ,D/K,L)

Teletext System FLOF (Fastext)

Receiving Frequency

Interme diate Fr equenc

VIF Carrier 38 .9 MHz ( B/G , I ,L)/ 3 3.9 5 MHz (L’)

SIF Carrier 33 .4 MHz ( 5.5MHz :B/ G) / 32.9MHz (6.0 MHz:I ) / 32.4MHz (6.5MHz:L , D/K) / 40 .45MHz (6.5MHz:L’ )

Colour Sub Carrier Fr eq.

SE CAM 4.40625MHz/4.25MHz

Power Input AC 2 30V , 50Hz

Power Consumpti on

CCIR (B/G,D/K, I ,L, L ’)

TOP (German syst em)

WST(W orld Standard system)

VHF 47 MHz ~ 47 0MHz

UHF

470MHz ~ 8 62MHz

PAL 4.43MHz

NT S C 3.58MHz / 4.43MHz

16 5W ( Max) / 112W(Avg) , sta ndby : 2.8W

AV28CH1EUS / AV28CH1EUB

Content

Aerial Input Term

Pictur e Tube

Hi gh Vo lt ag e

Speake r

Au dio Output 5W + 5W

EX T-1 /EXT-2/EXT- 3

(Input / Output)

S / Video

EXT-4 (Input) Video

Au di o (L /R )

S / Video

AUDIO OUT (Vari able)

Headphone jack St ereo mi n i jac k (φ3.5mm )

Remote Control Unit RM-C 54 H (AAA/R 0 3 dr y batte ry×2) : (A V2 8CH1EUS) / R M-C50( AAA/R03 d r y bat tery×2 ) : (A V2 8CH1EUB)

75 Ωun ba l anc ed, C oaxi al

Visi ble si ze : 66 cm, Meas ured di a gon al l y

1kV

+

30.0kV (at zero beam current)

-1. 5kV

(10c m×3cm) ov al typ e ×2

21 -pin E ur o c onnec to r

(SCART socket)

p-p

Y : 1V

C : 0.3V

1V p- p 7 5Ω(RCA pi n jack)

50 0mVr ms( -4dB s ), H igh Impe dan ce ( RCA pin jack )

Y : 1V

C : 0.3V

0~1 Vrms, Low Imp ed ance

(RCA pi n jack ×2)

POSITIVE (Negative sync Provided, when terminated with 75Ω)

p-p

(Burst signal, when terminated with 75Ω)

p-p

POSITIVE (Negative sync Provided, when terminated with 75Ω)

p-p

(Burst signal, when terminated with 75Ω)

De sign & sp eci ficatio ns ar e su bje ct to change wi thou t no t ice .

2

No.51944

Page 3

A

V28CH1EUS

A

V28CH1EUB

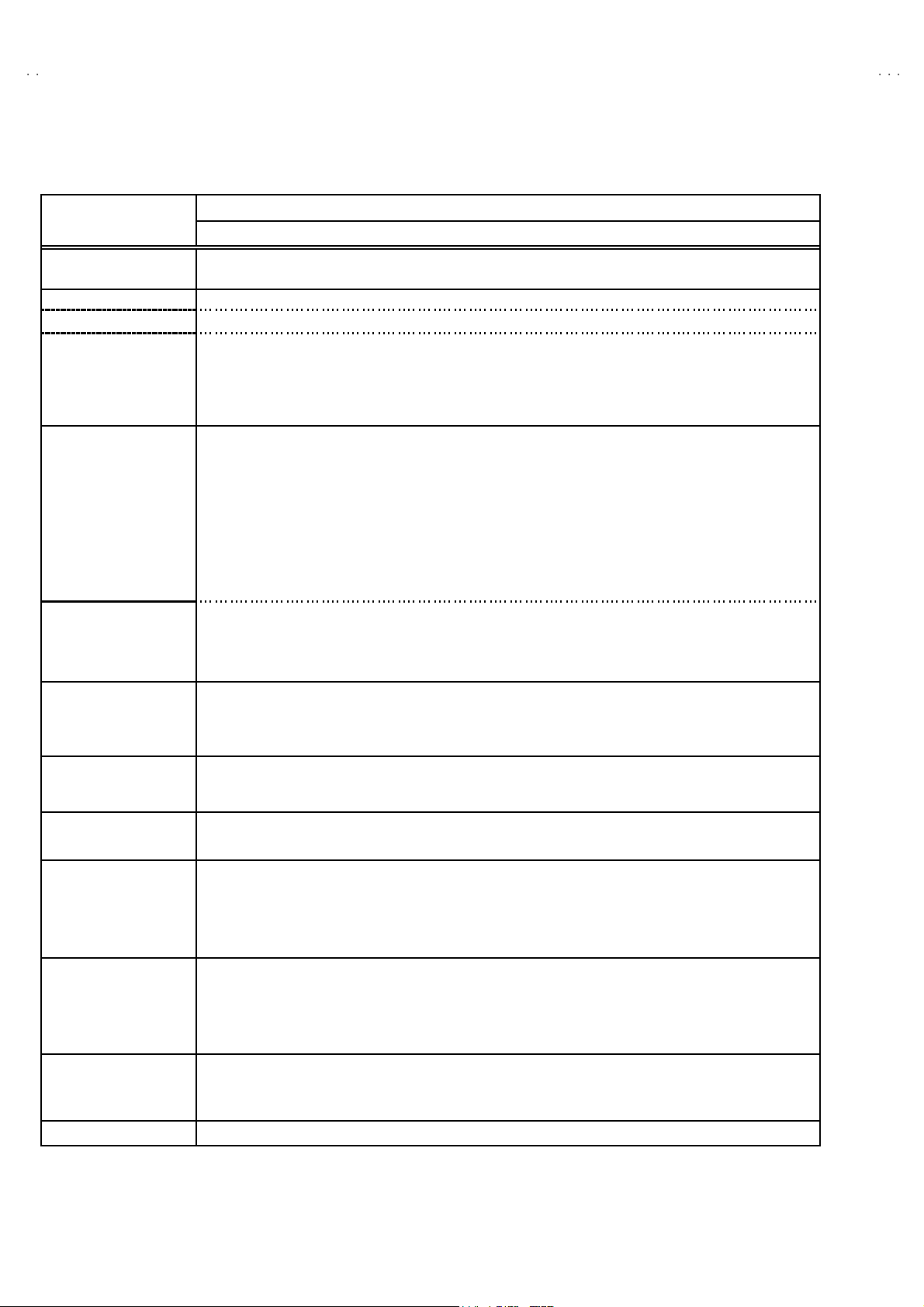

■■■■21-pin Euro connector (SCART socket) : EXT-1 / EXT-2 / EXT-3

(P-P= Peak to Peak, B-W= Blanking to white peak)

Pin

Signal Designation Matching Value EXT-1 EXT-2 EXT-3

No .

1 AUDIO R o ut put 50 0mVr ms( N ominal),

Low impedance

2 AUDIO R input 50 0mVr ms( N ominal),

High i m pe da nce

3 AUDIO L o utput 50 0mVr ms( N ominal),

Low impedance

4 AUDIO GN D ○○○

5 GND (B)

6 AUDIO L input 500mVrms(Nominal),

High i m pe da nce

7B input 700mV

8 FUNCTION SW

(SLOW SW)

9 GND (G)

10 SCL3 NC ○ NC

11 G in put 70 0m V

12 SDA3 NC ○ NC

13 GND (R)

14 GND (YS) ○ NC NC

15 R / C input R : 700mV

16 Ys i n put

17 GND(VIDEO output) ○○○

18 GND(VIDEO input) ○○○

19 VID EO output 1V

20 VIDEO / Y inp ut 1V

21 COMMON GN D ○○○

Low : 0-3V, High : 8-12V, High

impedance

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75Ω○

, 75Ω○○NC

B- W

, 75Ω○○NC

B- W

, 75Ω

B- W

, 75Ω

P- P

(Nega tiv e g oin g sync ), 75Ω○

P- P

(Nega tiv e g oin g sync ), 75Ω○ ○ ○

P- P

○

(TV OUT)

○○○

○

(TV OUT)

○○○

○○○

○○○

○○○

○○○

○

(only R)

(TV)

○

(LINE OUT)

○

(LINE OUT)

○

NC NC

○

(LINE OUT)

NC

NC

○

(only C)

NC

[Pin assignment]

No.51944

3

Page 4

A

V28CH1EUS

A

V28CH1EUB

SAFETY PRECAUTIONS

1. T he design of th is pr od uc t con ta in s sp eci al hard ware, many

circuit s and components specially for safety purposes. For

con tinu ed pr ot ection , n o chan g es sh ou ld b e ma de to the o ri g inal

d esi gn un l ess auth oriz ed in writi n g by th e ma nu fact urer.

Replac em en t p arts m ust be ident ic al to thos e u sed in th e or i ginal

ci rcu it s. Serv ice s ho uld b e p er for m ed by qu al if i ed p ers on nel

on ly.

2. Alte r ati on s of the design or ci r cui try of t he prod ucts sh ould not be

made. Any design alterations or additions will void the

manufact ur er 's warrant y and will f urth er r eliev e t he ma nu factu r er

of r esp onsi b ility for per so na l injur y or p r op er ty d am ag e r esult ing

th erefr om.

3. M an y e lectric al and mech ani ca l parts i n th e prod ucts ha ve

special safety-related characteristics. These characteristics are

oft en no t e v ident f r om v isua l i nsp ection n or ca n t he pr o tec t io n

aff or de d by th em nece ssar i l y be ob tain ed b y u sin g r ep l acement

com po ne nts ra ted f or hig he r vol tage, watt ag e, etc. R ep l acem en t

p arts whic h ha ve th ese sp eci al s afet y ch ar ac t er ist ics are

ide ntified i n the parts list of Servic e manua l. El ec tric al

components having such features are identi fied by shading

on t he sche mat ic s an d by (

manual. The us e of a sub s ti tu te rep lacem en t whi ch does n ot

h ave th e same saf ety ch ar act er ist ics as t he r eco mmen de d

replac em ent part sh own i n th e p ar ts lis t of S er vic e man ual may

cause shock, fire, or other hazards .

!!!!

) on the parts list in Service

4. Don't shor t between the LIVE side ground and ISOLATED

(NE UTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

diff er enc e of th e GND i s s ho wn b y th e LIV E : (") side GND , the

ISO LATED(NEUT RAL) : (#) si de GND and EAR T H : ($) side

GND. Don't sh ort b et ween th e LIV E sid e GN D and

ISO LATED(NEUT RAL) side GND or EARTH side GND an d

n ever m ea s ur e w it h a m ea suring a ppa r atus ( osc illos cop e etc.)

th e LI VE si d e GND an d IS OLA TED (NE UTR AL ) s ide G ND or

EARTH side GND at th e s ame time.

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

th at t he B1 set ti ng s hou l d b e ch eck e d or adju ste d ( Se e

ADJUST MENT OF B1 POWE R SUPPL Y) .

6. The hi gh v olta ge app li e d t o th e pictu re tu be mu st confor m with

th at s p ecified in S ervi ce manual. E xcessi ve high volt ag e c a n

cau s e an i ncr e ase i n X- R ay em i ssi on , ar c ing an d possi b le

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

preve nt ed. If s ever e arc ing occ ur s, r emove t he AC pow er

immed i ate ly an d de ter m i ne th e c a use b y visua l insp ec t io n

(inc or rect ins tal lat i on, cracke d or melte d high vo ltage har n ess,

p oor so lder i ng, et c.). To maint ai n the p roper min im u m le vel of

sof t X- R ay emi ssi on, c omp on en ts i n th e hi gh v oltag e cir c uitr y

incl ud ing t he pi ct ur e tu be must be t he e xact r ep l aceme nts or

alte rn at i ves ap pr ove d b y th e ma nuf act urer of th e c om pl et e

product.

7. Do not c hec k high volt age b y dr awing an ar c. Us e a high vol t age

meter or a hi g h v oltag e pr ob e wit h a V TVM. Discharge th e

picture tube before attempting meter connection, by connecting

a cl i p lead to th e gr ou nd f ra me and c onn ectin g th e other end of

the lead through a 10kΩ 2W resi sto r to the anod e b utt on .

8. When se rvice i s require d, ob ser ve th e or i gina l lea d dress. E x tr a

prec aut ion sh ou ld b e g iven t o ass ur e corr ec t l ea d dr ess i n the

high vol tag e c ircui t a r ea. W her e a s hort ci r cuit h as oc cu rre d,

th ose co mp on ent s tha t i ndi ca te evide nce of ove r hea ting sho ul d

b e r e pl ace d. A l wa ys u se th e ma nuf act urer's r ep l acem en t

components.

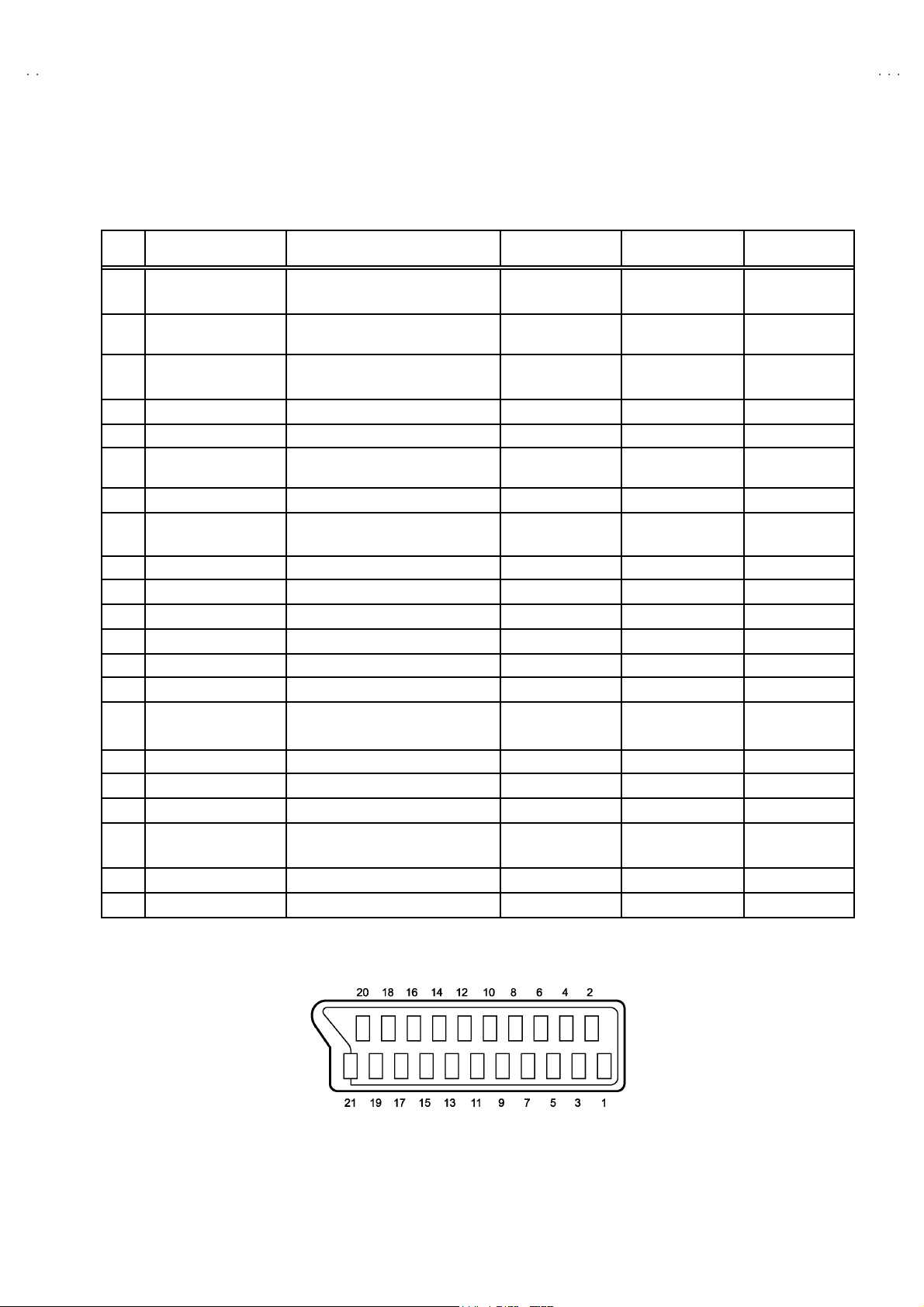

9. Isolation Check

(1) Dielectric Strength Test

(2) Leakage Current Check

(Safety for Electrical Shock Hazard)

Af ter re- ass emb l in g th e pr odu c t, al w ays per f orm an i sol at ion

ch ec k on the expo sed metal parts of t he c abin et ( a ntenn a

ter m inals, video /audio inpu t and ou tput t erminals , C on trol kn obs,

metal cabi n et, scr ew he ad s, ea r ph one j ack, con trol s haf ts, etc.)

to be s u re th e p roduct is s af e t o ope r ate with ou t dan ger of

elect ri cal s hoc k.

The iso l ati on be tween the AC pr imary ci rcuit an d all metal parts

exp osed t o th e us er , p arti cular l y any e xp os ed met al p art having a

retu rn p ath to t he chass is sho uld withs tan d a vol t age of 3 000 V

AC (r.m. s.) for a period of one second.

(. . . . W it hs tan d a v o lt ag e of 1 10 0V A C (r.m. s.) t o an applianc e

rate d up to 12 0V , an d 3 00 0V AC ( r .m. s.) to an ap pl ian ce r at ed

200V or more, for a period of one second.)

This meth od of test requi res a t est equ ipment n ot g enerally found

in t he servic e trad e.

Plug th e A C line c ord d irect ly into th e AC ou tlet ( d o not use a line

isol ati o n tr ansf or m er du r in g thi s ch eck.). Usi n g a " Lea kage

Curr ent T este r", me asur e th e lea kag e cu rre nt f rom each exp osed

metal p art of the cabinet, p art icu larly any expos ed me tal p ar t

h avi ng a re tur n path to the c h assis , t o a kn own go od ea rt h

ground (water pip e, e tc.) . An y l eaka ge curren t m ust n ot e xceed

0.5mA AC (r.m.s.).

Howev e r, i n tr op ic al area , th is must no t exce ed 0.2 mA AC

(r.m.s.).

""""

Alternate Che ck M et hod

Plug th e A C line c ord d irect ly into th e AC ou tlet ( d o not use a line

isol ati o n tr an s for m er dur ing t hi s che c k.). U se an AC vo lt me ter

h avi ng 1 00 0 ohms pe r volt or mor e s ens itivi ty in th e fo ll owing

manner. Con nec t a 1 50 0Ω 10W res ist or par a lle led by a 0 .1 5µF

AC-type c apa cit or bet ween an expo sed met al pa rt a nd a known

g ood e ar th gro un d (water pipe , etc.). M eas ure th e A C volt ag e

acr oss th e res ist or w ith th e AC vo ltm eter . Move th e r esis tor

con nec ti on to each exp ose d metal part, part ic ularly a ny exp os ed

metal p art havin g a retu rn pat h to t he ch as sis , an d m easu re th e

AC vol tag e ac ro ss the res ist or . No w, re vers e th e pl u g i n th e AC

ou tl et and re pe at eac h mea s ur emen t. Any volt ag e me asured

must no t e xceed 0 .75V AC (r.m. s.). This c orre spo nds to 0.5mA

AC (r.m. s.).

Howeve r, in tropica l are a, this must n ot exceed 0.3V AC ( r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLT MET ER

(HAVING 1000 Ω /V,

OR MOR E SENSIT IVITY)

0.15μF AC-T YPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON E A C H EX PO SE D

ME T AL PA RT

4

No.51944

Page 5

A

A

FEATURES

V28CH1EUS

V28CH1EUB

"

New c hass is d es ign ena bl e us e of an i nte rac ti ve on screen

control.

"

The TELETEXT SYSTEM has a built-in FASTEXT (UK syst em),

TOP (Germ an syst em) and W ST (world standard system)

system.

"

Be c aus e th is T V un i t cor r esp on ds t o m ultiple x br oa dc a st, u s ers

can enjoy music programs and sporting events with live realism.

In ad di ti on , BI LIN GUAL programs can b e h ear d in th eir or i g in al

language.

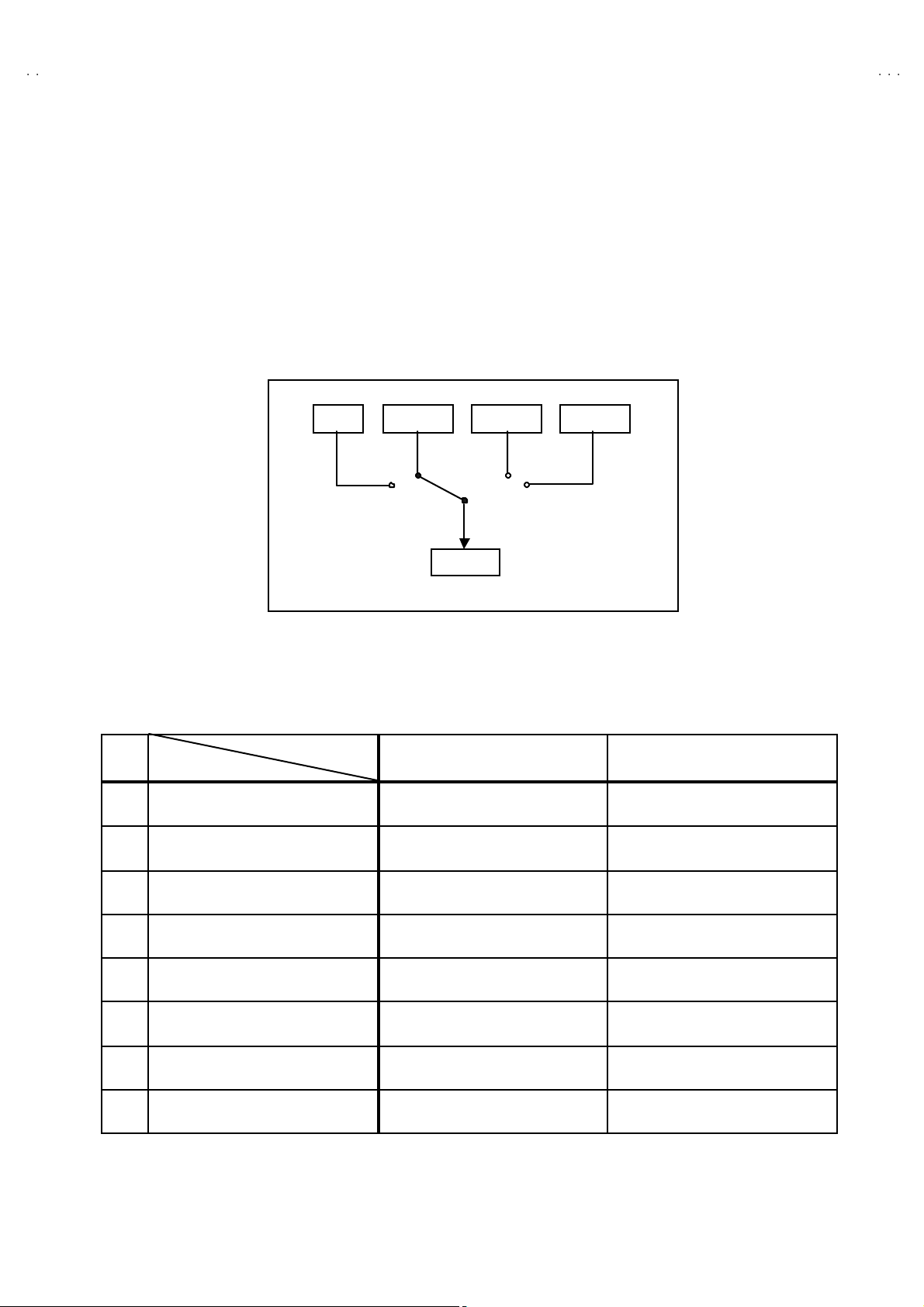

TV EXT-1 EXT-3

EXT-2

"

Users can make VCR dubbing of picture and sound by controlling

th e AV s elec tor to se lec t an optiona l so urc e at th e EXT- 2 outp ut

sh own i n fi gu re.

EXT-4

MAIN DIFFERENCE LIST

Model Name

!

Par t Name

!

FRONT CABINE T ASSY LC 10001- 008C- U LC 1000 1-00 9B-U

!

DOOR LC 20 00 1-01 0A-U LC 20 00 1-01 2A-U

!

POWER KNOB LC 30 10 4- 01 0A -U LC 30 10 4- 01 2A -U

RE A R COVER LC 10 03 -0 09 B- U LC 10 00 3- 01 0B -U

!

JV C MA RK LC 40 35 4- 00 3A -U LC 40 35 4- 00 1C-U

!

RATING L ABEL

LC 114 14 -001A -U

EURO LABEL AEM1064-009-E AEM1064-010-E

REMOTE CONTROL UNIT RM-C54H-1C RM-C50-1C

AV28CH1EUS AV28CH1EUB

LC 114 14 -002A -U

No.51944

5

Page 6

A

V28CH1EUS

A

V28CH1EUB

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug t he po wer c or d.

2. Remove the 14 screws marked

3. Withdra w t he r ear cover to wa rd you .

REMOVING THE CHASSIS

"

After removing the rear cover.

1. Sl i ght ly r aise the bo th side s of th e c hass is by h and and re mo ve

th e tw o claws u nd er th e both sid es of the ch assis fr om t he fro nt

cab inet .

2. Withdra w t he chass is back wa rd .

(If necessary, take off the wire clamp, co nnectors etc.)

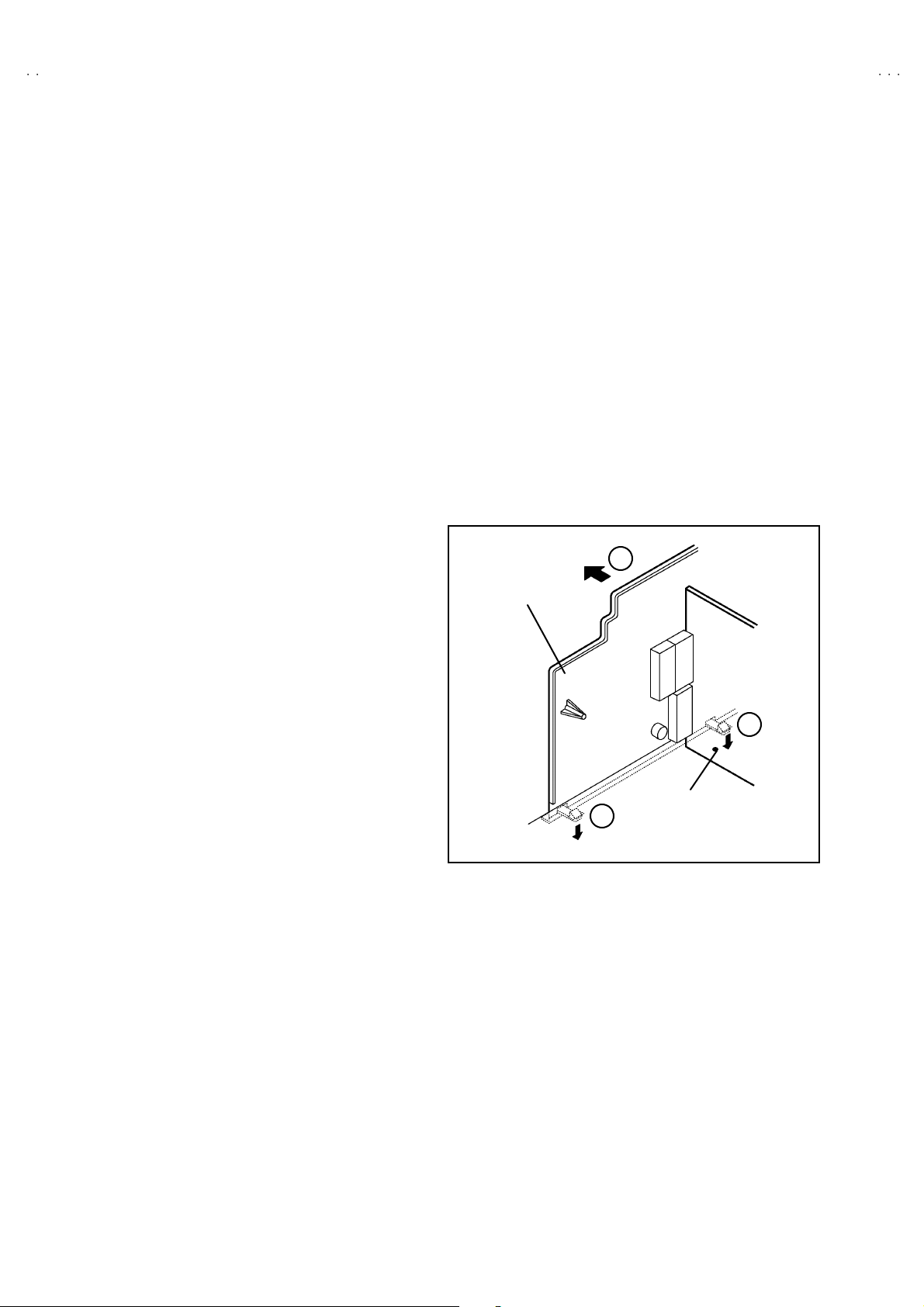

REMOVING THE AV TERMINAL BOARD

" After removing the rear cover.

1. Remov e th e 2 s cr ews m ar ked

2. Remove the claws marked

Fig. 2.

3. Slight ly in t he di re ction of ar r ow

####

as sh own in th e Fig. 1.

!!!!

as sh own in th e Fig. 1.

""""

un der t he CHAS SIS as sho wn in

as sh own in Fi g. 2.

$$$$

D

AV TERMINAL

BOARD

REMOVING THE SPEAKER

" After removing the rear cover.

1. Remov e t he 2 s cr ews m ar ked

2. F ollow th e s ame st eps when removi ng th e other ha nd speake r.

as sh own in Fi g. 1.

%%%%

CHECKING THE PW BOARD

To c h eck the b ack side of th e PW B oard.

1) Pu ll out the chassis. (R efer to RE MOV ING THE CHAS SIS ).

2) Erect the chassis vertically so that you c an easily check the

b ack si de of th e PW B oard.

[CAUTION]

"

When erecting the chassis, be careful s o that there will be no

contacting with other PW Board.

"

Be for e turning on po wer, ma ke s ur e t ha t the wi re co nn ector is

properly connec ted.

"

W hen condu cting a ch eck w ith p ow er su pplied , b e sure to c onfi r m

th at t he CRT E ART H WI RE (B RA ID ED AS S’Y) is co nne cted t o

th e C RT SOCKE T PW b oar d.

WIRE CLAMPING AND CABLE TYING

1. Be sure to cla mp th e wire.

2. Never r emo ve th e c able tie use d f or ty ing th e wires to gether.

Sh ould i t be i n adve rt ent l y remov e d, b e su re to ti e th e wires w it h

a n ew c able ti e.

C

AV SE L PWB

C

Fig . 2

6

No.51944

Page 7

A

A

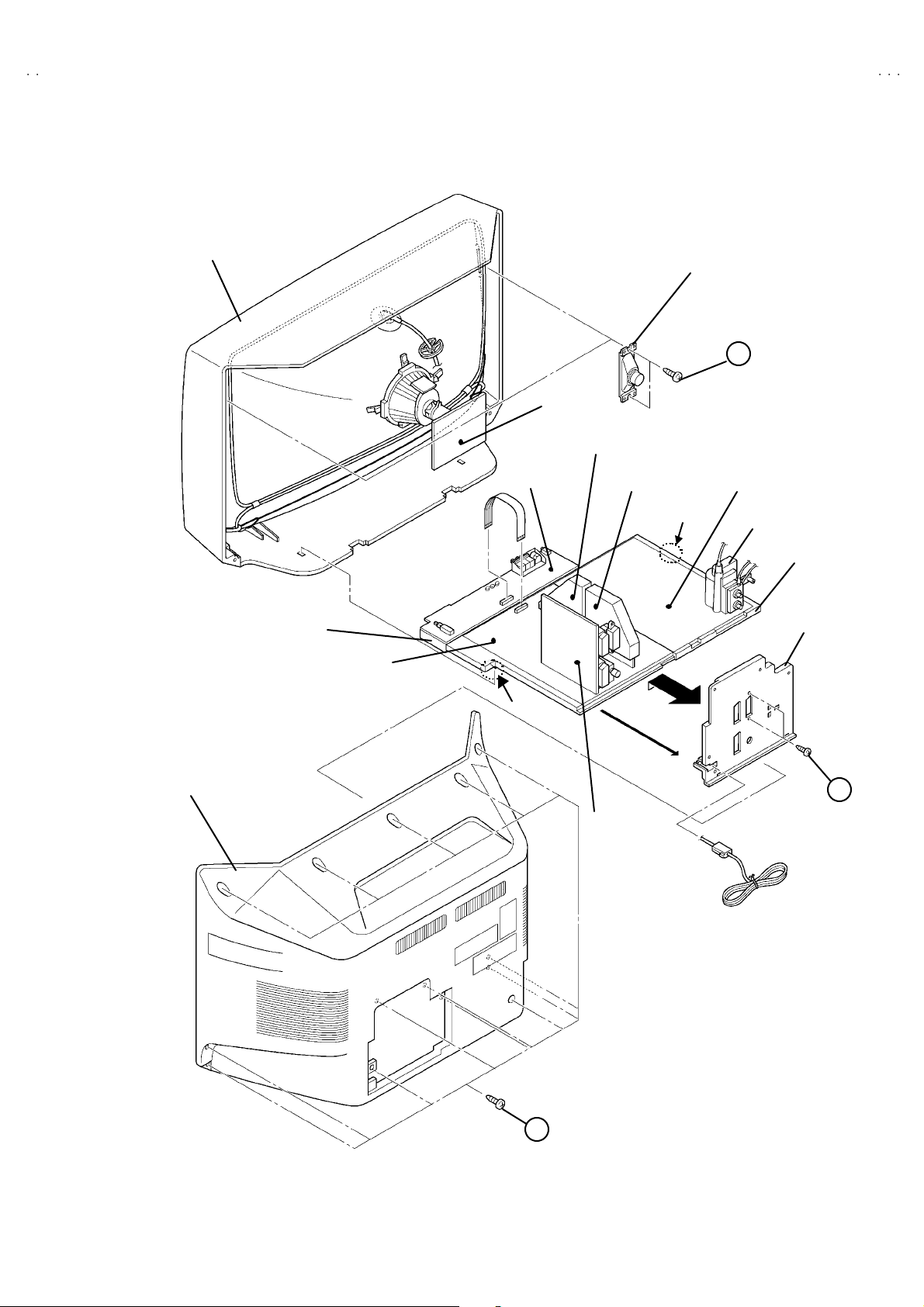

FRONT CABINET

S

CRT

SOCKET

PWB

FRONT

C ONT RO L

PWB

MICON PWB

10 0Hz PW B

V28CH1EUS

V28CH1EUB

PEAKER

E

POWER & DEF. PWB

C ONT RO L BASE

REAR COVER

MAIN PWB

CLAW

AV SW PWB

CLAW

FBT

CHASSIS

AV TERMINAL

BOARD

B

A

Fig . 1

No.51944

7

Page 8

A

V28CH1EUS

A

V28CH1EUB

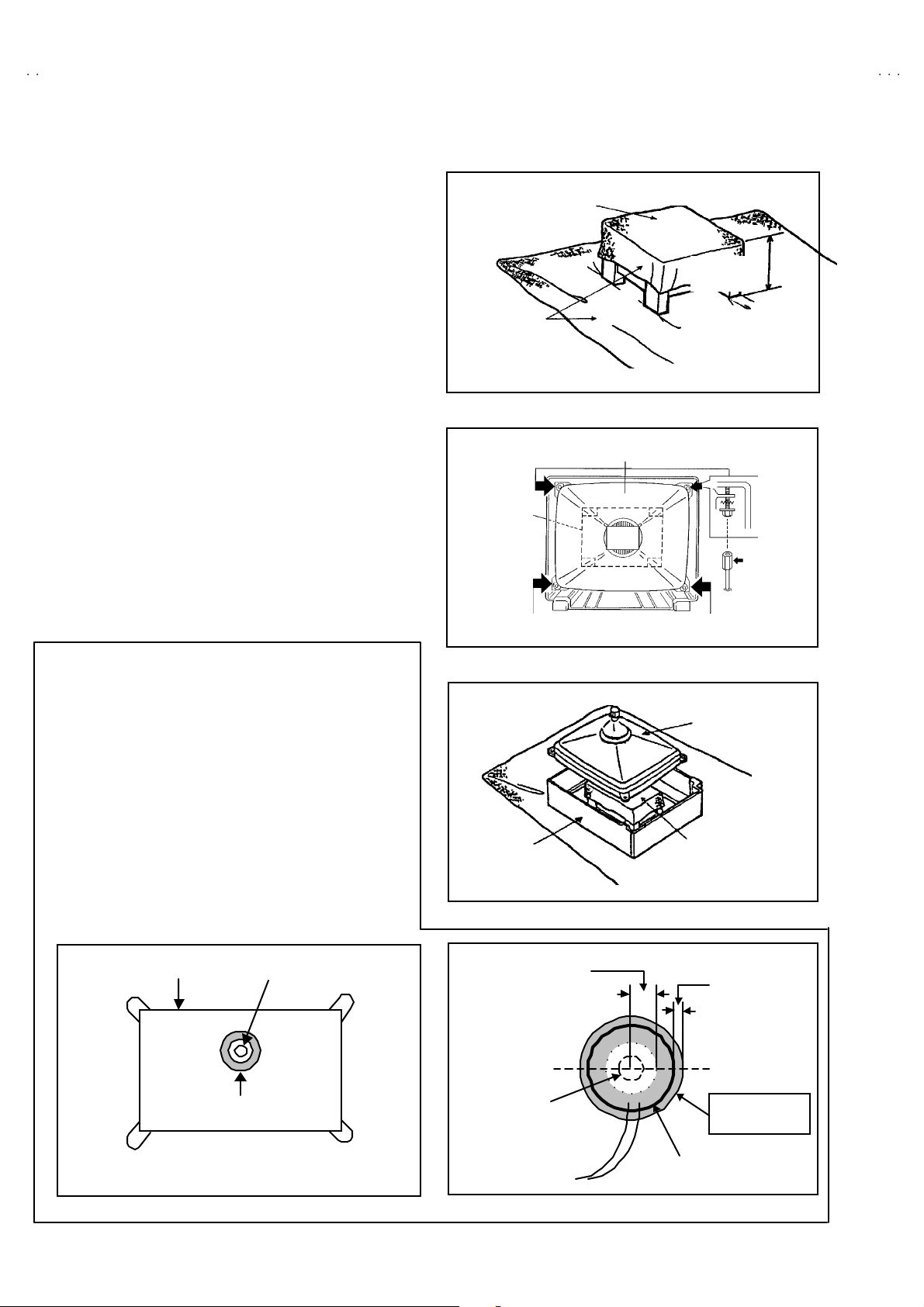

REMOVING THE CRT

∗

Replac em en t of th e CRT sho uld be p er for m ed by 2 or more

p ers ons.

• After removing the cover, chassis etc.,

1. Putti ng th e CR T c hange tabl e o n sof t cloth , the CRT chang e ta ble

sh ould al so b e c over ed w ith s uch soft clot h (sho wn in Fi g. 3).

2. W hile kee pin g th e surf ac e of CRT down , m ou nt the TV s et on t he

CRT change table balanced will as shown in Fig.4.

3. R em ove 4 sc re ws mar ke d by arro ws with a b ox typ e scr e w driver

as s hown in Fig. 4.

• Si nc e the cab inet will dr op wh en scr ew s h ave b een remo ved, be

sure t o su pport t he cab inet with hands.

4. After 4 screws have been removed, put the cabinet slowly on

cloth (At this time, be ca refully so as not to damage the front

sur fac e of th e c abin et) sh own in Fig.5 .

• The CRT s h oul d b e ass em bl ed accor di n g to the o pp osite

sequence of its dismounting steps.

∗

The CRT cha ng e t able sh ould pref er ab l y be sm al ler t hat the CRT

sur fac e, and its height b e about 35c m.

CRT CHANGE TABL E

AP PROX.

35 cm

CLOTH

Fig. 3

CRT

CRT

CHANGE

TABLE

BOX

TYPE

SCREW

DRI VER

COATING OF SILICON GREASE FOR ELECTRICAL

INSULATION ON THE CRT ANODE CAP SECTION.

•

Su bs e qu ent to re pl ac ement of t he C RT an d HV tr an sfor m er o r

repair of t he an od e ca p, etc. by dis mount i ng the m, be sure to c oa t

si lic o n g re ase fo r el ectric al insu latio n as sh ow n in Fig .6.

W ipe a roun d t he an ode b utton with cl ea n and dr y cl ot h. (F ig. 6)

Coat si l ic on greas e on t he sect ion arou nd th e a no de bu tt on. At

this time, take care so t hat any silicon greases dose not stick to

the ano de button . (F ig.7 )

★★★★

Sil icon grease product No. KS - 650N

CRT

An od e b utton

Silic on greas e

coating

CABINET

Ap prox.

20mm (Do not

coat grease on

this section

An od e b utton

(No s ti cki ng of

silicon grease)

Fig. 4

CRT

CRT

CHANGE TA BLE

Fig. 5

Silic on greas e

sh oul d be coa ted

b y 5mm or m ore

fr om th e outs id e

diameter of

an od e c ap.

Coat ing posi t io n

of silico n gr eas e

An od e ca p

Fig. 6 Fig. 7

8

No. 51944

Page 9

A

A

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating for more than 3 seconds.

2. Do n ot rub t he elect rodes an d t he r esis t p ar ts of the patt ern.

3. When r emovi ng a c hip part, mel t th e s older ad equate ly.

4. Do n ot reuse a chip part after removi ng it .

! SOLDERING IRON

1. Us e a hi g h i ns ulati o n solder ing iron with a t hi n po in ted end of it.

2. A 3 0 w s older ing iron is rec omm end ed for easil y remov ing p ar ts .

!

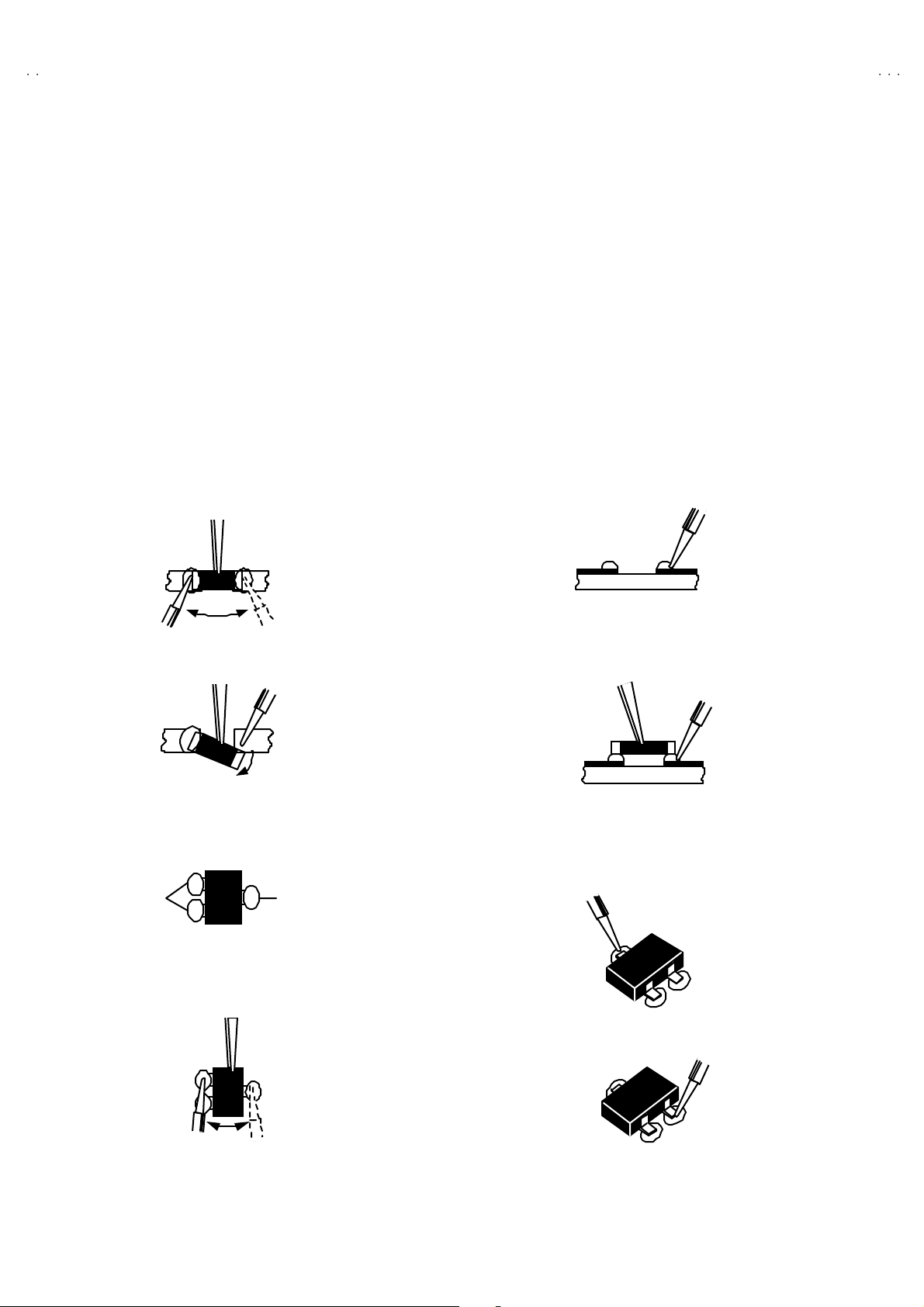

REPLACEMENT STEPS

1. How to remove Chip parts

####

Resi st ors, ca pacit ors , etc

(1) As s h own in t he f ig ur e, pu s h th e pa rt with tw ee zers and

alte rn at el y melt th e s older at each en d.

(2) Sh if t w ith tw eeze rs and r em o ve th e ch ip p ar t.

#### T ran s ist ors, diodes , varia bl e resist or s, etc

(1) Ap ply e xt ra solder to ea ch le ad.

SOLDE R SOLDE R

V28CH1EUS

V28CH1EUB

2. How to install Chip parts

####

Resi st ors, ca pa cit ors , etc

(1) Apply solder to th e patter n as ind icated in the figure.

(2) Gr asp t he ch ip p art with tw ee zers and pl ac e it on th e s old er.

The n hea t and melt th e so lder a t b oth en ds of t he chip part.

#### T ran s istors, dio des, va ria bl e r esistors, et c

(1) Apply solder to th e patter n as ind icated in the figure.

(2) Gr asp th e chip part with t we ezers an d pl ace it on th e solder.

(3) First solder lead A as indicated in the figure.

A

(2) As s h own in t he f ig ur e, pu s h th e pa rt with tw ee zers and

alte rn at el y melt th e sold er a t each l e ad . Shift an d r em ove t he

chip part.

(4) The n so lder le ads B and C.

Note : A fte r re movin g t he part , remove remain ing so lder from the

pattern.

C

A

C

No.51944

B

B

9

Page 10

A

V28CH1EUS

A

V28CH1EUB

REPLACEMENT OF MEMORY ICs

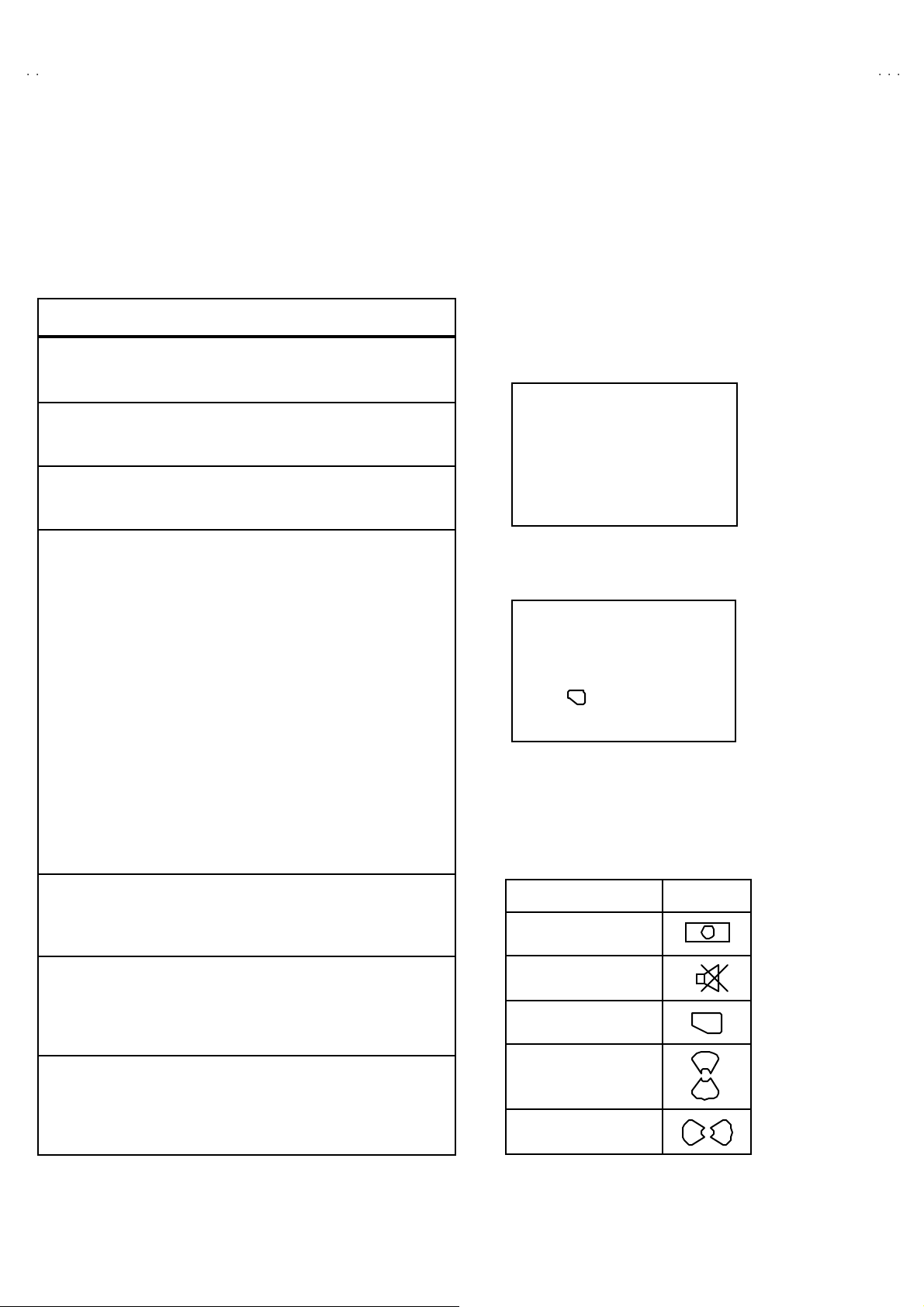

1. Memory ICs

This TV use memory ICs. In the memory ICs, there are memorized data

for cor r ectl y op erating th e video an d def l ection cir cu its . Wh en r ep l aci ng

memory IC s, b e s ure t o us e IC s wri tte n with th e initial values of da ta.

2. Procedure for replacing memory ICs

PROCEDURE

(1) Power of f

Switch the p ower of f and un plug th e pow er cor d fro m t he ou tlet.

(2) R epla ce IC s.

Be sure to use memory ICs written with the initial data values.

(3) Powe r on

Plug th e p ower c ord i nt o the outlet a nd swit ch t he po we r on .

(4) Check and s et SY STEM CO NSTANT SET :

****

It must not adjust without sig na l.

1) Pr ess th e INFORMAT I ON ke y an d th e MU TING key of th e

REMO TE CONTROL UNIT simultaneous ly.

2) The SERVICE MENU screen of Fig. 1 will be displayed.

3) W hi le th e S ERVIC E ME NU is d is played, pr es s th e

INFORMATION key and MUTING key s imultaneously, and the

SYSTEM CONSTANT SET screen of Fig. 2 will be displayed.

4) Check th e se tting va lues of the S YSTEM C ON ST A NT SET of

Table 1. If the value is d if fere nt, se lect the s ettin g item with th e

FUNCTION U P/ DOWN key, and s et the correct va lue with the

FUNCTION - /+ ke y.

5) Press the MENU key to memorize the setting value.

6) Pr ess t he IN FORMATION ke y t wice, a nd r etu rn t o th e normal

screen.

SE RV ICE MEN U

1. IF 2. V/C

3. A UDI O 4. D EF

5. VSM P RESET 6. S TATUS

7. P IP 8. ---

9. SHIPPING (OFF) 0. BUS FREE

1 -9 : SE LE CT

SY STE M CON ST ANT S ET

1. DESTINATION EU

- /+ : STORE i : EXIT

OK

Fig.1

Fig.2

i

: EXI T

NAME OF REMOTE CONTROL KEY

(5) Se tt in g of re cei ve chann e ls

Names of key

ke y

Se t the rec eive c h an ne l.

For setting , ref er to the OPE RATING IN S TRUC TIONS.

(6) U ser se tting s

INFORMATI ON

MU T I N G

iiii

Check th e us er sett in g values of Tab le 2, and i f sett in g value is

diff er ent , set the c orr ec t val u e.

For setting , ref er to the OPE RATING IN S TRUC TIONS.

(7) Setting of SERVICE MENU

Ve rif y the set ti ng it ems of th e SER VIC E ME NU of Tab le 3, an d rese t

ME NU

FUNCTION UP/ DO WN

OK

▼

▼

where n ecessary.

For setting , ref er to the SE RVICE ADJUSTM ENT S.

FUNCTION -/+

▼

▼

10

No. 51944

Page 11

A

A

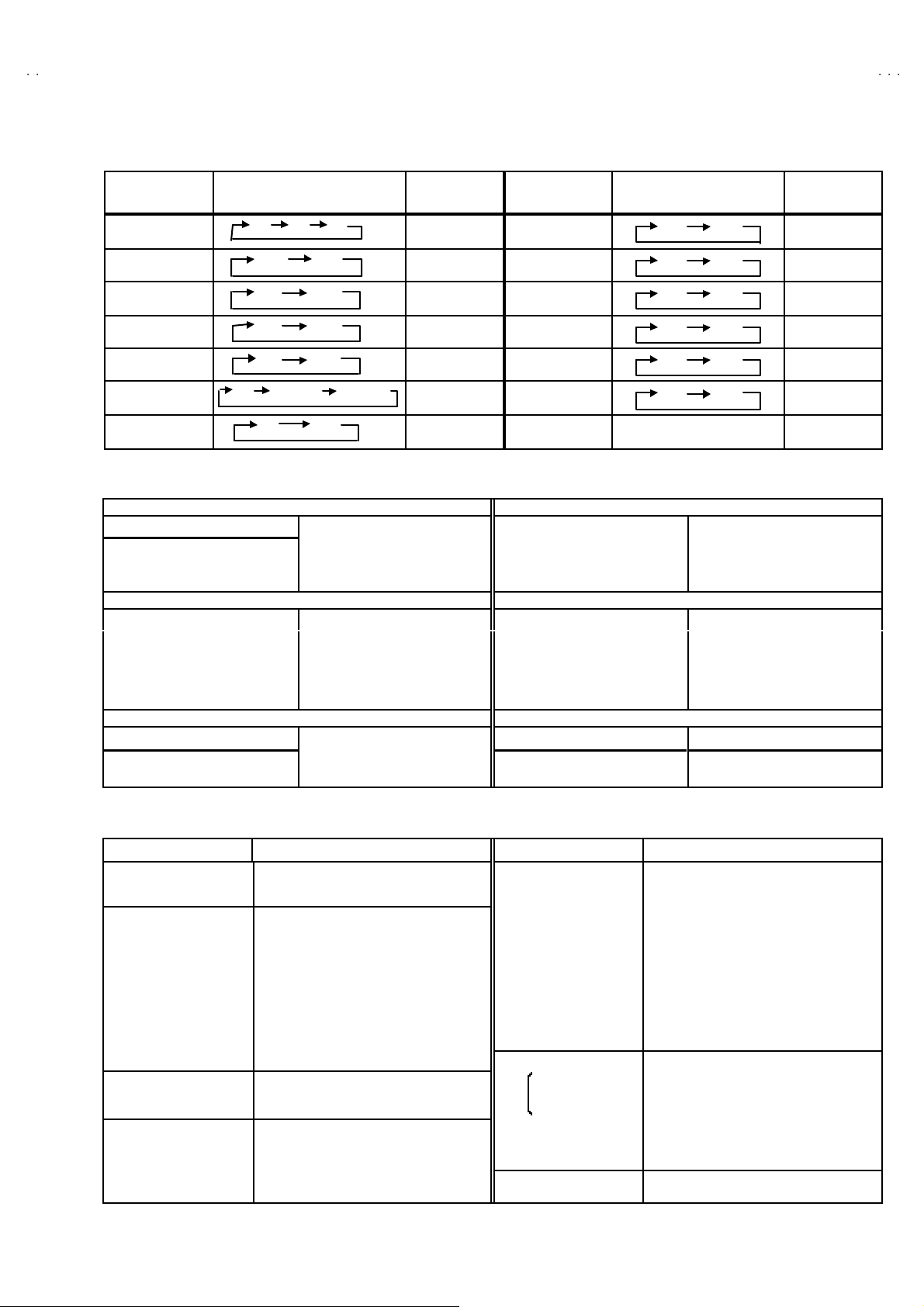

SETT I NG VALU ES OF SYST EM CONS TANT SE T (TABLE 1)

V28CH1EUS

V28CH1EUB

Setting item Setting content Setting value

16 :9

NO

NO

EKEU EI

4:3

YE SNO

YE SNO

YE S

2TUNER1TUNER

YE S

DESTIN A TION EU DOLBY NO

CRT TYPE 16:9 BB E NO

PURITY NO PROGRESSIVE NO

PICTURE TILT NO TDA9178 NO

DIGIP URE PRO NO TONE IC NO

PIP NO F LAT NO

PIC&TE XT NO

NO

Setting item

Setting content Setting value

YE SNO

YE SNO

YE SNO

NO

NO

YE S

YE SNO

YE S

USER SETTING VALUES (TABLE 2)

PICTURE SE TTING EX T SET TI NG

TINT COOL

CONTRAST / BRIGH T

SHAR P / COLO UR

PICTURE FEATURES FEATURES

DIGITAL VNR AUTO

Digipure PRO AUTO

COLO UR S YST E M TV : Acco rd in g t o pr eset C H

4:3 AUT O ASPE CT PA NO RAMIC

SOUND SET TING INSTALL

BA SS / TREBL E / BA LANCE LANGUAGE ENGLISH

HYPER SOUND OFF EDIT/MANUAL PRESET CH only

REFER to VSM PRESET

EXT : AUTO

CENTER

ID

S-IN

DUBBING

SLEEP TIMER

BLUE BA CK

BLANK

BLANK

EXT- 1→EX T-2

OFF

ON

The others : BLANK

SERVICE MENU SETING IT EMS (TAB LE 3)

Setting item Setting value Setting item Setting value

1. IF 1. VCO

2. ATT ON /OFF

2. V / C 1. RGB BLK

3.A UD IO

(Do not adjust)

9.S HIPPI NG

(Do not adjust)

2. W D R R

3. W D R G

4. W D R B

5. BRIGHT

6. CONTRAST

7. COLO UR

8. HUE

9. SHAR P

10. VC O A DJ .

1. ER R LI MIT

2. A2 ID THR

ON/OFF

4. DE F. 1. V- SH IF T

5. VSM PRESET

COOL

NORMA L

WARM

6.S TATUS

(Do not a dju st)

No. 51944

2. V-SIZE

3. H-CENT

4. H-S IZE

5. TR APE Z

6. EW - PIN

7. COR-P IN

8. COR-UP

9. COR-LO

10. ANGLE

11 . BOW

12. V-S.CR

13 . V- LIN

1. CONT.

2. BRIGHT

3. SHAR P

4. COLO UR

5. HUE

6. W D R R

7. W D R G

8. W D R B

VP S

PDC

11

Page 12

A

V28CH1EUS

A

V28CH1EUB

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1. There ar e 2 w ays o f adjusting this T V: On e is wi th t he

REMOTE CONTROL UNI T and the other is the conventional

method using adjustment parts and components.

2. The setting (adjustment) us ing the REMOTE CONTROL

UNIT is made on the basis of th e init ial setting values. The

se tting va lues which adj u st the scree n to t h e opt imum

condition can be different from the initial setting values.

3. M ak e s ure th at c onn ect i on is c orrect ly ma de t o AC p ow er

source.

4. T ur n on th e pow e r of th e TV a nd m easu ring ins tr um en t for

warmi n g u p for at l east 30 minut es b ef ore sta rt ing adju stment .

5. If th e r ec eive or i np ut si g nal is not speci fi ed , use t he m ost

ap prop riate s igna l f or a dj ust ment.

6. N ever tou ch parts ( s uch as variab le res ist ors, transform er s an d

condensers) not shown in the adjustment items of this service

adjustment.

7. Prep ar ati o n f or ad j ustmen t ( pr es ettin g) :

Unles s oth er wis e speci fi ed i n the a djust ment it em s, p r eset th e

follo win g funct ions with th e REMOTE CONTROL UNI T.

"

Setti ng posit ion

PICTURE MODE (VSM) NORMAL

SLEEP TIMER OFF

TONE BALAN CE CENTER

ZOOM PANORAMIC

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Si gn al gener at or (Patt ern gener at or) [ PAL / SE CA M / NT SC]

4. Remote control unit

ADJUSTMENT ITEMS

●

Check ing i t ems.

●

Adjustment of FOC US & SCREEN

●

VS M p r eset ad ju st s ettin g.

●

VIDEO / CHROMA circ uit adjustment.

●

DEFLECTION c ircuit adjustment.

●

AUDIO circuit adjustment. (Do not adjust)

12

No. 51944

Page 13

A

A

ADJUSTMENT LOCATIONS

(

)

5

V28CH1EUS

V28CH1EUB

FRON T

FRONT CONTROL PWB

F90 1

PW

POWER SW

CN001

FRON T

MAIN PWB POWER&DEF PWB

CN002

AV SEL PWB

CN006

IC702

MEMORY

100Hz PWB

IC701

F

SP R

SP L

FRON T

W DEG

TUNER

CRT SOCKET PWB

T P- 47R

T P- 47G

CN013

TP-E

MIC OM PWB

CN008

SOLDER SIDE

T P- 47B

CN009

TOP

E1

CN014

HV

HVT

FOCUS1

FOCUS2

SCREEN

X

1

1pin:B1( TP-91)

2pin:NC

3pin:NC

4pin:NC

5pin:GN D

No. 51944

13

Page 14

A

V28CH1EUS

A

y

y

V28CH1EUB

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SE RVICE MENU ITEMS

With the SERVI CE M EN U, var i ou s sett in gs ( ad jus tm en ts) c an b e m ade , a nd th ey a re b r oad l y c lass if ied in th e f ol l owing items of s et tings

(adjus tm ents ):

(1) 1. IF ・・・・・・・ ・・・・・・・・・・・・・ ・・・ This m ode adjust s the se tting values of the IF circui t.

(2) 2.V /C ・・・・・・・ ・・・・・・・・・・・・・ ・・ T his m ode adjusts th e setting valu es o f th e VIDEO / CHROMA ci rcuit.

(3) 3.AUDIO・・・・・・・ ・・・・・・・・・・・・ This mode adjusts the setting values of the multiplic ity SOUND circuit.

(4) 4. DEF ・・・・・・・ ・・・・・・・・・・・・・ ・ This m od e adjust s th e setti ng values o f the DE FLECT ION c ircui t f or eac h as pect m od e g i ven be low.

FULL (100/120Hzi)

PA NO RA MIC ( 1 00 /12 0 H z i )

SUBTITLE (100/120Hzi)

COMP RESS (Fix ed val u e) (100/1 20H zi)

(5) 5.V SM PRESE T

(VSM : Video Status Memory)

3. BASIC OPERATION OF SERVICE MENU

(1) Ho w to enter SERVICE MENU

Press the INFORMATION key a nd the MUTING key of t he

REMO TE CONT RO L U NI T si mu lt an eou s ly, an d th e

SERVICE MENU screen of Fig. 1 will be displa yed.

(2) Selection of SUB MENU SCREEN

Press one of keys 1~5 of the REMOTE CO NTROL UNIT

an d sel e c t th e S UB M ENU SCR EEN ( See Fi g. 3 ), fo rm th e

SERVICE MENU.

SERVICE MENU → SUB MENU

・・・・・・・ ・・・・・・

1. IF

2. V / C

3. AUDIO

4. DE F.

5. VS M PRESE T

6. STATUS

7. PI P

8. ---

9. SHIPPING(OFF)

0. BUS FREE

Thi s mode adjust s th e in itial s ett ing va lues of COOL, N ORM AL an d WAR M .

SE RVICE M ENU

SE RV ICE MEN U

1. IF 2. V/ C

3. AU DIO 4. DE F

5. VS M PRESET 6. ST ATUS

7. PI P 8. -- -

9. SH IPPING ( OFF) 0. BU S FREE

1 -9 : SE LE CTi : EXI T

Fig.1

NEME OF REMOTE CONTOROL KEY

Names of ke

INFORMATI ON

MU T I N G

ME NU

Do no t W o rk

FUNCTION UP/ DO WN

FUNCTION -/+

Fig.2

ke

iiii

OK

▼

▼

▼

▼

14

No. 51944

Page 15

A

A

SERVICE MENU

SERVICE ME NU

1. I F 2. V /C

3. AUDIO 4. DEF

5. VSM PR ESET 6. STAT US

7. PIP (OFF) 8. - - -

9. SHIPPING (O FF) 0. BUS FREE

1-9 : SELE CT : EX ITi

V28CH1EUS

V28CH1EUB

1. V- SH I F T

2. V- SI Z E

3. H-CENT

4. H-SIZE

5. TRAPEZ

6. EW -PIN

7. COR PIN

8. COR-UP

9. COR-LO

10. A NGLE

11. B OW

12.V- S.CR

13.V-LIN

DE F *** Hz FUL L

1. V- SHI F T

: STORE i : EXIT

OK

- / +

4. DEF

***

1.IF(VCO)

IF SER VICE M E NU

1. VCO

2. ATT O N/O FF

1-2 : SELECT i : EXIT

2. V/C

V/C

PAL

1. RGB_BLK

- / +

: STORE i : EXIT

OK

****

Do no t move

1. RGB BL K

2. WDR R

3. WDR G

4. WDR B

5. BRIGHT

6. CONT RAST

7. COL OUR

8. HUE

9. SHA RP

10. VCO ADJ

COOL

NORMAL

WARM

1. CONT .

2. BRIGHT

3. SHA RP

4. COL OUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

5. VSM PRESET

VSM PRESET NORMA L

1.CONT

: STORE i : EXIT

OK

- / +

***

- / +

Fig.3 SUB MENU SCREEN

No. 51944

3. AUDIO

AUDIO

1. ERR LIMIT 10H

C_AD_BIT S =

: STORE i : EXIT

OK

* ** *** **

Do no t adjust

1. ERR L IMIT

2. A2 ID T HR

15

Page 16

A

V28CH1EUS

A

V28CH1EUB

(3) Meth od of Set ti ng

1) Meth od of Setti ng 1. IF

[VCO] ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・ It mus t not adjust wit hout si g nal.

① 1 K ey・・・・・・・・・・・・・・・・・・・・ ・・・・・ Se lect 1.IF.

② 1 K ey・・・・・・・・・・・・・・・・・・・・ ・・・・・ Se le ct 1 .VCO(CW )

Make sure that the arrow position between the ABOVE REF and BELOW REF.

③ INFORMATION K ey ・・・・・・・ ・・・・・ Return t o th e SERVICE ME NU scr e en.

2) Meth od of s ett in g 2.V/C, 3.AUDIO, 4.DEF and 5.VSM PRESET.

① 2~5 K ey・・・・・・・・・・・・・・・・・・・・ ・・ Select one from 2.V/C, 3.AUDI O, 4.DEF and 5 .VSM PRESET.

②

FUNCTION U P / DOWN Key

③

FUNCTION - /+

④

ME NU Key

⑤

INFOMATION K ey

・・・・・・・ ・・・・・・・・・・

・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・ ・・・・・・

・・・・

Select s etting items.

Set ( adjust) th e setting valu es o f th e setting it ems.

Memorize the setting value.

(Bef or e st or ing t he s ett in g valu es in memory, do not pres s t he CH, TV , POW ER ON / OF F key if you d o, the valu es will not be stored in memory.)

Retu rn t o th e SE RVICE M E NU s cr een.

3) Can not setting 6.S TATUS, 7. PIP, 8. --- , 9 .SH IP PING(OFF ) & 0.B US FR EE .

(4) R ele ase of SERV IC E M E NU

1) Af ter c o mp l eti ng th e se tti ng , ret urn t o the SER VIC E ME NU , then ag ai n p r ess th e INFOR MATIO N ke y.

16

No. 51944

Page 17

A

A

ADJUSTMENTS

CHECK ITEM

Item

Check of B1

Power Supply

Measuring

instrume nt

Signal

generator

DC v o l tm et er

Remote

control unit

Test point Ad justment part Description

TP-91(B1)

TP-E(####)

[X connector

on POWER

DE F PW B ]

1.R G B BL K 1. Recei ve a an y broa dca s t.

2. Pu sh t he “ZOOM ” ke y an d s elect the FULL mode .

3. Select 2 . V/ C from the SER VICE MENU.

4. Select 1 . RGB BLK w ith f un ction UP / DOW N key.

5. Press the functi on +( ) key to fin d th e cut off screen (Black

screen).

6. Con nect a D C voltmet er t o T P- 9 1(B 1) a nd TP-E(#).

7. Make sure t hat th e volt age is DC139.9 ±2.0V.

8. Press the functi on – ( ) key t o return t o s ervice m enu..

V28CH1EUS

V28CH1EUB

Check of High

Volt age

Check of VCO

Signal

generator

DC volunteer

Remote

control unit

Remote

control unit

IF S ERVIC E MENU

1. VCO

2. ATT ON/OFF

1-2 : SELECT

TO O HI GH

ABOVE REF

JUST REF

BELOW REF

TO O LO W

VCO(CW)

MAI N

CRT anode

Chass is

GND

i : EXIT

****

MHz

i : EXIT

1.R G B BL K 1. Recei ve a an y broa dca s t.

2. Pu sh t he “ZOOM ” ke y an d s elect the FULL mode .

3. Select 2 . V/ C from the SER VICE MENU.

4. Select 1 . RGB BLK w ith f un ction UP / DOW N key.

5. Press the functi on +( ) key to fin d th e cut off screen (Black

screen).

6. Connect a DC voltmeter t o CRT ANODE and chassis GND.

7. Make sure t hat th e volt age is DC 31.0 kV .

+1kV

-1.5kV

8. Press the functi on – ( ) key t o return t o s ervice m enu.

1. VC O " U nd er n orm a l c ondi ti ons, no ad just ment is r e quired .

" Conf irmat ion adjus t me nt.

1. Select 1 .IF from the SERVICE MENU.

2. The n se lect 1 .VCO from th e IF S ERVICE MEN U.

3. Rec eive any bro adc ast.

4. C heck t he ar r ow () posi ti on be tween th e A BOVE REF. and

(Do not move)

BE LOW REF .

No. 51944

17

Page 18

A

V28CH1EUS

A

S

V28CH1EUB

ADJUS TMENT OF FOCUS & SCREEN

Item

DAd j ust men t

of

FOCUS

Measuring

instrume nt

Signal

generator

HVT

Test point Ad justment part Description

FOCUS VR

SCREEN VR

FOCUS VR

[In HVT]

1. Rec eive a cross -hatc h sign al. S elect FULL mode .

2. Whi l e w atc hing th e scr een , a djust th e F OC US VR to m ake th e

ver ti cal and ho rizo ntal l ines as f in e a nd sha rp as possi b l e.

3. Make sur e that when the sc re en i s d ar ke ned , the lines re ma in

in good focus.

Ad justment of

SCREEN

Signal

generator

SCREEN VR

[In HVT]

1 Press a w h ole b lack si gn al

2 Press the ZOOM key and select the FULL mode.

3 Se lect 2. V/ C from the SERVICE MENU.

4 T ur n t he SCR EEN V R c lockwis e f r om th e f ul l co unt er

V/C

PAL

cl ockw is e p osition and s t op it a t th e po i nt w h er e “ CLOW ” stat us

(mark e d in Fi g.) c h ang es f ro m 1 t o 0 to 1 ( wh ich i s

1. RGB BLK

00

ind icated at th e 3rd colu mn from the right.)

5 The n tur n th e SCREEN V R cou nt ercl o ckw is e, and st op wh ere

- / +

: STORE i : EXIT

OK

0 0 0 0 0 1 0 0

CLOW

status

th e “ C LOW ” stat us ch an ges 1 t o 0

* “C LOW ” : c ontr o l loopou t of win do w.

ERVICE MODE SCREEN

VSM PR ES ET AD JUS T SET TIN G

Item

Setting of

VS M PRESET

Setting item

VSM preset mod e

COOL +130 -11+1 0-17-9 0

Measuring

instrume nt

Remote

control unit

Test point Ad justment part Description

1. C ONT .

2. BR IG HT

3. SHARP

4. COLOUR

5. HUE

6. W DR R

7. W DR G

8. W DR B

1. Select 5.VS M P RESET fr om th e S ERVICE ME NU.

2. Select CO OL with the MENU key of t he remote con trol unit.

3. Adjust the FUNCTION UP/DOWN and -/+ key to bring the set

val u es of 1.C ON T ~ 8. WDR B to the values shown in the

tabl e.

4. Pr ess the MENU key a nd memoriz e th e s et value.

5. Respectively s elect the VSM PRESET mode for NORMAL and

WARM, an d m ake si milar a djust ment as i n 3 abo ve.

6. Pr ess the MENU key a nd memoriz e th e s et value.

∗ Refer to OPERATING INSTRUCTIONS for the PICTURE

MO DE.

1.CONT. 2.BRIGHT 3.SHARP 4.COLOUR 5.HUE 6.WDR R 7.WDR G 8.WDR B

NORMAL 00-1100000

WARM -13 0 -11 -1 0 +4 0 0

SE TT ING VAL UES OF VSM PRESET

18

No. 51944

Page 19

A

A

VIDEO / CHR OMA CIRCUIT ADJUSTMENT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

V28CH1EUS

V28CH1EUB

Setting item

(Adjustment item)

2. V/C PAL SE CAM NT SC

1.R G B BL K

2.WDR R 0

3.WDR G 0

4.WDR B (Do not adjust) -12

5. BR IG HT 0

6.CONTRAST 0

7.COLO UR 000

8. HUE +20

9.SHARP (Do not adjust) +7

Initial set ting v al ue

11.VID AG C (Do not adjust) 0

12.SY C SLI +7

13.A MOVIE +1

No. 51944

19

Page 20

A

V28CH1EUS

A

V28CH1EUB

Item

Ad j ust men t

of

WHITE

BALANCE

(High Light)

Measuring

instrume nt

Signal

generator

Remote

control unit

Test point Ad justment part Description

2. W DR R

3. W DR G

4. W DR B

(Do not adjust)

" Se t th e P ICT URE MODE to NORMAL.

1. Recei ve a bl ack a nd white sign al (col o ur of f).

2. Select 2 .V/C f r om the SERVICE M ENU.

3. Modif y 2. W DR R and 3.W DR G da ta t o ad just t he w hite

balance ( high light ).

4. Pr ess the MENU key a nd mem oriz e th e s et va lue.

5. Cha nge th e c ontrast an d brig htn ess with the remot e c ontr o l

up & dow n from lo w– light t o h igh–light a nd c heck t hat the

tr ack ing of the w h it e bal an ce is g oo d.

Ad j ust men t

of

SUB BRIGHT

Ad j ust men t

of

SUB CONT.

Remote

control unit

Remote

control unit

5. BR I G HT 1. Rec eive any broadc ast.

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 5 .BRIGHT with th e FU NCTI ON UP /DOWN key.

4. Set the initial setting value with the FUNCTION -/+ key.

5. If the brigh tn ess is n ot th e b est wi th the i n itia l se tting value ,

make fine adjustment until you get the best brightness.

6. Press the ME NU key a nd mem oriz e th e s et va lue.

6.CO NT. 1. Rec eive any bro adc ast.

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 6.CONT with t he FUNCTION UP/DOWN key.

4. Set the initial setting value with the FUNCTION - / + key.

5. If the con tr ast is n ot the be st with t he initial s e tting va lue, ma ke

fine adjustment until you get the best contrast.

6. Press the ME NU key a nd mem oriz e th e s et va lue.

20

No. 51944

Page 21

A

V28CH1EUS

A

ey

V28CH1EUB

Item

Ad j ust men t

of

SUB CO LOUR

Measuring

instrume nt

Remote

control unit

ⅠⅠⅠⅠ

Test point Ad justment part Description

7.COLO UR

(PAL~~~~NT S C)

PAL COLOUR (PAL COLOUR)

CH. key

SECAM COLOUR

MENU

( OK ) k ey

NTSC COLO UR

[Method of adjustm ent without measuring instrument]

1. Rec eive PAL broad cas t.

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 7 .COLOUR with th e FU NCTIO N UP/DOWN key.

4. Set the initial setting value for PAL COLOUR with the

FUNCTION - or + k ey.

5. If t he co lour is no t the bes t with th e in iti al set va lue, ma ke

fine adjustment until you get the best colour.

6. Press the ME NU key a nd mem oriz e th e s et va lue.

(SECAM COLO UR)

1. Rec eive a SECAM b roadc ast.

2. M ake fi n e a dj ustm e nt of SE CA M COLOUR in the s am e

manner as for abo ve.

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.58MHz C OMPOSITE VIDEO si g nal f r om th e

EXT t erminal.

2. Make s imil ar f ine ad jus tm en t of NT SC 3.58 COLO UR in th e

sam e mann er as f or a bo ve.

FUNCTION k

( INFORM ATI ON ) keyi

REMOTE CONTROL KEY

(NTSC 4.43COLOUR)

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

No. 51944

21

Page 22

A

V28CH1EUS

A

(+)

(-)

(A)

V28CH1EUB

Item

Ad j ust men t

of

SUB CO LOUR

Measuring

instrume nt

Signal

generator

Ⅱ

Ⅱ

ⅡⅡ

Oscilloscope

Remote

control unit

Test point Ad justment part Description

TP-47B

####

TP-E(

[CRT

SOCKET

PWB ]

7.COLO UR

(PAL~~~~NT S C)

)

PAL COLOUR (PAL COLOUR)

SECAM COLOUR

[Method of adjustm ent using measur ing instrument]

1. Rec eive a PAL fu ll f i eld co lour b ar si gn al (75% w hite ).

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 7 .COLOUR with th e FU NCTI ON UP/DOW N key.

4. Set the initial setting value of PAL COLOUR with the

FUNCTION - or + k ey.

5. Con nect the osc illosc ope be tw ee n T P -4 7B and T P- E( #).

6. Ad just PAL COLO UR an d b r ing th e valu e of (A) in the

illustration to the values as shown given billow (Voltage

diff er enc e betwee n wh ite ( W ) and b lu e ( B) ) .

7. Press the ME NU key a nd mem oriz e th e s etti n g value.

VOLTAGE (W-B) +8V

(SECAM COLO UR)

1. Rec eive a SECAM fu ll field co lour bar si gn al ( 75% white) .

2. Set the initial setting value of SECAM COLOUR with the

FUNCTION - /+ ke y.

3. Adju st SE C AM CO LOU R an d b ri n g t he va lu e of (A) in the

illu strati on t o th e values as s hown g iven b ill ow (Volt ag e

diff er enc e betwee n wh ite ( W ) and b lu e ( B) ) .

4. Press the ME NU key a nd mem oriz e th e s etti n g value.

WCyMgB

NTSC COLO UR

0

VOLTAGE (W-B) +7V

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.58 MHz C OMPOSITE VIDEO si gnal (full fi eld

colo ur bar with 75% w hit e) from the EXT t ermina l.

2. Set th e i nitial s etting val ue of N T SC 3 .58 COLO UR wit h th e

FUNCTION - /+ ke y.

3. Adjus t NTS C 3 .5 8 C OLO UR a nd bring th e val u e of ( A) in the

illustration to the values as shown given billow (Voltage

diff er enc e betwee n wh ite ( W ) and b lu e ( B) ) ..

4. Press the ME NU key a nd mem oriz e th e s etti n g value.

VOLTAGE (W-B) 0V

(NTSC 4.43COLOUR)

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

22

No. 51944

Page 23

A

V28CH1EUS

A

(B)

(-)

(+)

V28CH1EUB

Item

Ad j ust men t

of

SUB HUE ⅠⅠⅠⅠ

Measuring

instrume nt

Remote

control unit

Test point Ad justment part Description

8.HUE [Method of adjustment without measuring instrument]

NTSC 3.58 HUE [NTSC 3. 58 HUE]

1. Input a N TSC 3.5 8 MHz C OM POSI T E V IDEO si gn al (f ul l fi e ld

colo ur bar with 75% w hit e) from the EXT t ermina l.

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 8. HUE with t he FUNCTION UP/DOW N key.

4. Se t the initia l sett ing va lue of N TSC 3. 58 HUE wi th th e

FUNCTION - /+ ke y.

5. If you cannot get the best hue with the initial setting value,

make fine adjustment until you get the best hue.

6. Press the ME NU key a nd mem oriz e th e s et va lue.

NTSC 4.43 HUE (NTSC 4.43 HUE)

1. W hen NTS C 3.58 i s s et , NTSC 4.4 3 will be automat ic ally s et at

the respective values

Ad j ust men t

of

SUB HUE

ⅡⅡⅡⅡ

Signal

generator

Oscilloscope

Remote

control unit

W

CyMgB

TP-47B

####

TP-E(

[CRT

SOCKET

PWB]

8. HUE [Method of adjustment using measuring instrument]

)

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Input a N TSC 3.5 8 MHz C OM POSI T E V IDEO si gn al (f ul l fi e ld

colo ur bar with 75% w hit e) from the EXT t ermina l.

2. Se lect 2 .V/C f r om the SE RVICE M ENU.

3. Select 8. HUE with t he FUNCTION UP/DOW N key.

4. Se t the initia l sett ing va lue of N TSC 3. 58 HUE wi th th e

FUNCTION - or + k ey.

5. Con nect the osc illosc ope be tw ee n T P -4 7B and T P- E( #)

6. Adjus t N TSC 3. 58 H UE t o br i ng the val u e of (B) in the

illustration t o -1V (voltage difference between white (W) and

magenta (Mg)).

7. Press the MENU key and memorize the s ettin g value

0

NTSC 4.43 HUE (NTSC 4.43 HUE)

1. When NTSC 3.58 COLOUR s et, NTSC 4.43 COLOUR will

automatically set.

No. 51944

23

Page 24

A

V28CH1EUS

A

(Do not adjust)

V28CH1EUB

DEFLECTION CIRCUIT ADJUSTMENT

There are 4 aspect modes ( ①①①①FULL, ②②②②PANORAMIC, ③③③③ SUBTIT LE , ④④④④COMPRES) of the a djustme nt ( 1 ) 100 H z i mod e, ( 2 ) 1 20 Hz i

mode ・・・・・・

・・・・ ・・ depending upon the kind of signals ( vertical frequency 100Hzi / 120Hzi ).

・・・・ ・・・・・・ ・・

"

When the 100 Hz FULL mode has be en establ ished, the se ttin g of other mode s will be done automatically.

Ho wever, if the picture quality has not been optimized, adjust each mod e again, respectively.

" The adjustment usi ng the remote control unit is made on the basis of the initial setting values.

"

The setting values which adj ust the screen to the optimum condition can be different from the initial setti ng values.

Ini tial setti ng v alue ( 1/2) *

Setting item Ad justment name

1. V- SH IF T Ve rt ic al cent er -006 -006 00 00 0000

2. V- SIZ E Ve rt ic al he ight -006 -001 + 003 00 00

3. H-CEN T H or izont al ce nte r -014 + 002

4. H-S IZE Hor i zont al width +007 - 003

5. TRAPEZ Trap ezoi da l disto rt ion c orr ec ti on -016 - 010 00 00 0000

6. EW -PIN Si de pin cor rection -045 00 00 0000 00 00

7. CO R-P IN Cor ne r Pi n -005 00 00 +002 00 00

8. CO R-UP Corne r P in c orr ect i on Up si de - 003 - 004 + 005 0000

9. CO R-L O Cor ne r P in c orrect ion Low s id e -007 - 003 - 002 00 00

10 .AN GL E An gl e c orre ction 00 00 0000 0000 0000

11 .BOW Bo w-sh ape d dis tortio n corr ec t io n 0000 00 00 0000 0000

12.V- S.CR

13 .V- LIN

(Do not a dju st)

Ve rt ic al heig ht c or r ection -007 00 00 +013 00 00

Ve rt ic al Lin ear i ty -003 -002 00 00 0000

Ini tial setti ng v alue ( 2/2)

Setting item Ad justment name

1. V- SH IF T Ve rt ic al cent er +012 - 002 00 00 00 00

2. V- SIZ E Ve rt ic al height +009 0000 - 011 0000

3. H-CEN T Horiz ont al cente r 0000 00 00 00 00 00 00

4. H-S IZE Hor i zont al width 00 00 0000 00 00 00 00

5. TRAPEZ Tr ap ez oida l disto rt i on correc ti on -001 00 00 0000 00 00

6. EW -PIN Side pin correc ti o n -001 00 00 0000 00 00

7. CO R-P IN Cor ne r P i n -005 00 00 00 00 00 00

8. CO R-UP C or ne r P i n c orrect ion U p side + 009 0000 0000 00 00

9. CO R-L O Cor ne r P i n c orrect i on Lo w s id e +005 00 00 00 00 00 00

10 . AN GL E An gl e c orre ction 0000 00 00 00 00 0000

11 . BOW Bo w- sh ape d dis tortio n correct io n 00 00 0000 0000 00 00

12. V-S. CR

(Do not a dju st)

13 . V- L IN

(Do not a dju st)

*

* *

Initial set ting v al ue

FULL PANORAMIC

10 0Hzi 12 0Hzi 100Hzi 12 0Hzi

-003 00 00

-004 00 00

*

*

* *

Initial set ting v al ue

SUBTITLE COMPRESS

10 0Hzi 12 0Hzi 100Hzi 60 P

Ve rt ic al heig ht c or r ection +003 0000 0000 00 00

Ve rt ic al Lin ear i ty -027 00 00 00 00 0000

: Fixed value

: Fixed value

24

No. 51944

Page 25

A

A

Item

Ad j ust men t

of V-SHIFT

Measuring

instrume nt

Signal

generator

Remote

control unit

Test point Ad justment part Description

1. V- S HI FT [FULL mode]

1. Receiv e a cir cle p att ern si g nal of ve rt ic al fr eq ue ncy 5 0H z.

2. Selec t 4 .DEF f rom t he SERVI CE M ENU.

3. Select 1 .V-SHIFT wi th t he FUNCTION UP/DOW N key.

4. Ad just V-S HIFT to make A = B .

5. Check the ad justmen t value ab o ve in o ther zo om mo de . If it is a

wrong adjustment, re-adjust in PANORAMIC mode and adjust

A

B

by 1.V-SHIFT.

6. Pres s the MENU key a nd mem or iz e th e s et va lue.

V28CH1EUS

V28CH1EUB

Ad j ust men t

of V-SIZE

Screen size

Scr e en

size

Picture size 100%

ASPECT MODE FULL PANORAMIC SUBTITLE

ASPECT MODE FULL PANORAMIC SUBTITLE

SCREEN

SCREEN

TOP

TOP

SCREEN

SCREEN

BOTTOM

BOTTOM

[ SCREEN SIZE ]

92 % 87 % 70 %

92 % 87 % 70%

92 % 87 % 83 %

92 % 87 % 83%

[ SCREEN SIZE ]

2.V-SI ZE 7. R eceiv e a cross -hatc h sign al.

8. Select 2.V-SIZE and set the initial setting value.

9. Ad just V-S IZ E a nd make s ure t hat the ve rt ic al scr een siz e of

10 . Pr ess the MENU key a nd m em or iz e the s et value.

12. Press the MENU key and memorize the s et value

Picture

size

10 0%

th e p ict ure s ize is i n t he bel l ow t abl e.

11 . Input a NT SC V IDEO si gn al (6 0H z) fr om the E XT ter m i nal,

an d make s u r e t hat the v er ti cal s cr een s iz e is i n t he t ab le

below.

No. 51944

25

Page 26

A

V28CH1EUS

A

V28CH1EUB

Item

Ad justment of

H.CENTER

Ad j ust men t

of

H.S IZ E

Measuring

instrume nt

CD

90 %

Test point Ad justment part Description

3. H-CENT. 13 . Recei ve a c ir cle p atter n s ig nal.

14. Select 3.H-CENT and set the initial setting value.

15 . Ad ju s t H- CE NT to ma ke C=D.

16 . Pr ess the MENU key a nd m em or iz e the s et value.

90 %

4. H- SIZ E 17. Receive a circle pattern signal.

18. Select 4.H-SIZE and set the initial setting value.

19 . Ad ju st H-S IZE an d m ake sur e th at t he horiz on tal scr ee n size

20 . Press the MENU key a nd mem oriz e th e s et va lue.

21 . Inp ut a NTSC VIDEO signal ( 60 Hz) fr om t he E XT ter m inal,

22 . Press the MENU key a nd mem oriz e th e s et va lue.

of th e pict ur e si ze is i n th e bel l ow t abl e .

an d make sur e th at t he h ori zo nt al sc r een siz e of the eac h

ASPECT mode is in the below table.

AS PE CT

MODE

H SI Z E

Ad justment of

EW-PIN

FULL PANORAMIC SUBTITLE

92 % 95 %

[ SCREEN S IZE ]

6.E W-PI N 23 . Selec t 6 .EW-PIN an d s et t he i nitial s etti ng valu e

Straight

92 %

24 . Adju st E W - PIN and m ak e th e 2 nd.vert ic al lines at the left a nd

right ed ges of the sc r ee n st ra i ght . Als o m ake s ur e th at the 3r d

vertical lines are straight.

25 . Pr ess the MENU key a nd m em or iz e the s et value.

26

No. 51944

Page 27

A

V28CH1EUS

A

V28CH1EUB

Item

Ad j ust men t

of TRAPEZ

Ad justment of

COR. UP/LO

Straight Straight

Measuring

instrume nt

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Ad justment part Description

5. TR APEZ 26 . Recei ve a cr oss -h atc h signal.

27. Select 5.TRAPEZ with the FUNCTION UP/DOWN key.

28. Set the initial sett ing value of T RAPEZ with th e FUNCT ION

- or + key.

Parallel

7.COR-PIN

8.COR-UP

9.COR-LO

29 . Adju st TRAP EZ an d bring th e VER TICAL l in es at the righ t

an d lef t edges o f the sc re en pa ra llel .

30 . Press the ME NU key a nd mem oriz e th e s et va lue.

31. Select 8.COR-UP with the FUNCTION UP / DOW N k ey.

32. Set the init ial setting value of COR.-UP with the FUNCTION

- or + key.

33 . Adjus t CO R- UP, a nd b ri n g th e str ai gh t lin e at th e up per

corner.

34. Select 9.COR-LO with the FUNCTION UP / DOWN key.

35. Set the initial setting value of COR-LO with the FUNCTION

- or + key.

36 . Ad just COR- LO, an d b ring t he straight line at the low co rner .

37 . Press the ME NU key a nd mem oriz e th e s et va lue.

38 . If th e e xtream upper & lower corners ar e a l ittl e p in or barrel

ch ose 7.C OR -P IN an d adju st.

39. Press the MENU key and memorize the s et value

Ad j ust men t

of ANGLE

Fig. A

10. ANGLE •

No. 51944

In case where th ere is a para l lelogrammi cal d ist or ti on of

images on th e scr e en.( FigA )

40. Select 10.ANGLE with the FUNCTION UP / DOWN key.

41 . Ad just ANGE L, and b ri n g t he VERTIC AL lines str aight..

42 . Press the ME NU key a nd mem oriz e th e s et va lue.

27

Page 28

A

V28CH1EUS

A

V28CH1EUB

Item

Ad justment of

BOW

Ad justment of

V-S.CR &

V. LI NE AR IT Y

Measuring

instrume nt

Test point Ad justment part Description

11.B OW

Fig. B

12.V- S.CR

13.V- LIN

TOP

In case w here there is a b ow- shaped distortion of images on the

•

screen. (Fig.B)

43. Select 1 1.B OWwith th e FU NCTIO N UP/DOWN key.

44 . Ad just BO W , an d bri n g t he VERTIC AL lines str aight.

45 . Press the ME NU key a nd mem oriz e th e s et va lue.

Wh en the vertical linearity has been deteriorated rem arkably,

•

perform the following steps.

46 . Receiv e a cross -hatc h sign al.

47. Se lect 13.V-LIN with t he FUNCTION UP/ DOW N k ey.

48. Set the initial setting value of 13.V-LIN with t he FUNCTION

- / + key.

49. Select 12.V-S.COR with t he FUNCT ION U P / DOW N key.

50. Set the initial setting value of 12.V-S.COR with the FUNCTION

- / + key.

51 . Adju st 13 .V- LI N and 12 .V- S.COR so that th e s pac es of ea ch

line on TO P, CENTE R and BO TT OM bec ome u ni fo rm .

NO T E :D o not ad just PA NO RAM IC & SUBTITLE mode.

CENTER

BOT TOM

At first the adjustment in 100Hz FULL mode should be done,

th en th e d at a for th e ot he r asp ect mo de is corr ec t ed in the

resp ec ti ve val ue a t t he s am e ti m e. A nd co nfirm th e d eflec ti o n

ad justm en t i n itia l se tting va lue i n 12 0H z (NT SC EXT mod e)

FU LL m od e. If the adju stmen t in 10 0Hz eac h aspect mode h as

b een don e and sto red, th e data f or th e s ame as pect m od es in

12 0Hz i s cor re cte d i n th e res pect ive v a lue. Only t he da ta fo r th e

oth er as pect mod e i n 12 0Hz i s co rr ect ed f or its elf.

28

No. 51944

Page 29

A

A

AUDIO CIRCU IT ADJUSTMENT

"

Do not tou ch 3. AUDIO a dj ust me nt of the SER V ICE M ENU as it re quire s no adj ustm en t.

If values ha d ch an ge d for the s o me r eas on, set th e i nitial val ues in th e f ollowi ng table.

3. AUDIO(D o not adjust)

Setting item Variable range fixed value

1. ER R LI M IT 00 H~FFH 0AH

2. A2 ID THR 00 H~FFH 19H

V28CH1EUS

V28CH1EUB

No. 51944

29

Page 30

BLOCK DIAGRAM

AV28CH1EUS

AV28CH1EUB

AV28CH1EUS

AV28CH1EUB

EXT-1

EXT-2

EXT-3

TU001

TUNER

VTV1

L TV RTV

TV OUT

V1, L1, R1

YS, SLOW1

V2, C2, R2

L2 OUT

R2 OUT

V2 OUT

V3 / Y3, C3

L3, R3

AV SW PWB

SIF

63

IC101

AV SW

IC101

MULTI SOUND

PROCESSOR

M_CV/Y

M_C

100Hz PWB

IC662

R-OUT

L-OUT

IC101

VIDEO

PROCESSOR

& CODEC

LPF

IC663

BBE

SDA1

SCL1

R

L

IC201

SAMPLE RATE

CONVERTER

V

IC301

ENHANCE

POWER

IC665

BASS

V100, U100, Y100

IC601

POWER AMP

MAIN PWB

R

L

IC551

ROTATION

IC301

DEF & RGB

PROCESSOR

IC402

EW/V DRIVE

FRONT CTRL PWB

(2/2)

ROTATION

COIL

B

R

G

H.OUT

HEADPHONE

SP R

SP L

IC203

B-OUT

IC202

R-OUT

IC201

G-OUT

CRT SOCKET PWB

CRT

VM COIL

EXT-4

AC IN

S

KEY

FRONT CTRL PWB

(1/2)

IC001

REMOCON

RECEIVER

POWER SW

REMOCON

FUSE

LF901

SDA2 SCL2

D931

IC001

MICRO PROCESSOR

MICON PWB

T901

IC003

SO RAM

IC012

MASK

POM

IC004

MEMORY

Q521

H.OUT

H.DY

V.DY

T551

HVT

SCREEN

EHV

B1

FOCUS2

FOCUS1

IC401

V.OUT

POWER & DEF PWB

No.51944

2-3 2-4

No.51944

Page 31

CIRCUIT DIAGRAMS MAIN PWB CIRCUIT DIAGRAMS

TO AV SW PWB ASSY

SDA1

SCL1

SDA2

SCL2

TU1_SW0

TU1_SW1

TU1_AFC

VTV1

RTV1

POW_ON/OFF

BBE_ON/OFF

BBE_BOOST

CLOCK

DATA

STATUS

READY

MSP_RESET

AUDIO_MUTE

A.MUTE

AMP_MUTE

L/R_CENT

L_SUB

A_SUB_GND

R_SUB

H/P_L

H/P_GND

H/P_R

A_M+VCC

A_M-VCC

A_C_VCC

A_GND

AGC

LTV1

32V

R

L

9V

5V

8V

QGB1505J1-50

SDA1

SCL1

SDA2

SCL2

TU1_SW0

TU1_SW1

TU1_AFC

VTV1

LTV1

RTV1

POW_ON/OFF

BBE_ON/OFF

BBE_BOOST

CLOCK

STATUS

READY

MSP_RESET

AUDIO_MUTE

A.MUTE

AMP_MUTE

L/R_CENT

L_SUB

A_SUB_GND

R_SUB

H/P_L

H/P_GND

H/P_R

A_GND

NOTE

OPTION(NON MOUNT)

:

X

IM-BW

:

BW

NRSA63J-0R0X

:

0

2SC2412K/QR/-X

:

*1

:

2SA1037AK/QR/-X

*2

MA111-X

:

*3

MA3120/M/-X

:

*4

DTC124EKA-X

:

*5

DTA124EKA-X

:

*6

2SC1740S/QR/-T

:

*7

2SA933AS/QR/-T

:

*8

AGC

DATA

CN001

GND

GND

GND

SC_YS1

SC_R1

SC_G1

SC_B1

VTV1

1.6V

0V0V0V

0V

Y50

SC_B

SC_G

SC_R

SC_YS

VTV1

DEFFERENCE LIST

*

SMF-

1008A-U2

IC551

X

X

R551

R552

X

R553

X

X

R554

R555

X

R556

X

X

R557

R558

X

R559

X

R560

X

R561 X

R562 X

X

R563

X

R564

X

R565

X

C551

X

C552

X

C553

C554

X

C555

X

C560 X

C561

X

C562

X

X

Q561

Q562

X

CN0R1

CN0R3 X

R704

R716

R71700

X

1kR703

1k

R

L

GND

CB

Y

0V

0V

B-Y50

1008A-U2

C458 X

R464

R462 12k

R463

R473 27k

R487X27k

SMF-

GND

GND

GND

GND

A_MUTE

GND

SC_YS2

GND

0V

R-Y50

M_C

M_CV/Y

AV_LINK

CR

0V

4.8V

0V

3.8V

4.2V

M_CV/Y

M_C

AV_LINK

A.MUTE

YS2

Y701

0

X

PIP_V

8.9V

0V

S_CV

QGB1506L1-16

SDA2

SCL29V9V

3.6V

3.6V

3.1V

STATUS

SCL2

SDA2

YS2/AFC2

CN004

SPA

CV_A/D

0V

CV_A/D

C564

.1/16

TXT_CV

3.6V

TXT_CV

GND

GND

GND

LTV1

3.7V

LTV1

GND

ALC

RTV1

0V

3.7V

RTV1

ALC

SUBTITLE

Y702

X

PROTECT

SUBTITLE

L_SUB

GND

4.4V

0V

L_SUB

A_SUB_GND

POW_ON/OFF

GND

STBY_5V

GND

TU2_SW0

R_SUB

4.4V

0V

TU2_SW0

R_SUB

A_C_VCC

A_C_VCC

P_ON/OFF

TU2_AFC

TU2_SW1

0V

0V

4.9V

TU2_SW1

TU2_AFC

A_GND

A_GND

A_M-VCC

A_M-VCC

A_M+VCC

GND

32V5V5V

32V

A_M+VCC

GND

A_GND

GND

GND

H_DRIVE

GND

4.9V

C563

X

EW_DRIVE

VD-

VD+

GND

GND

EW_DRIVE

AV28CH1EUS

AV28CH1EUB

SC_B1

SC_G1

M_CV/Y

3.8V

M_CV/Y

R511

1.5k

H_PROT

H_PULSE

GND

R512

3.3k

S_CV

M_C

GND

GND

4.2V

0V

M_C

S_CV

C458

*

IC402

BA10324AF-XE

EW/V DRIVE

CN006

QGB1506L1-16

BSO

GND

C402

100/16

SC_R1

0V

SC_R

Y303

C457

.033/25

0V

SC_G

0

0V

0V

SC_B

SC_YS

R323XR324

525P/OTH

GND

0V

525P

CH

V_PROT

SC_YS1

RGBGND

X

R-Y50

SC_R2/

RGBGND

0V

0V

R-Y50

B-Y50

R458

12k

C454

.033/25

B-Y50

Y50

SC_G2/

SC_B2/

0V

Y50

C453

0.01

CN00C

CH41171-006

D774

MA3056/M/-X

C701

10/50

CH

QAX0549-001Z

24.576MHz

C302

R322

0

NQL092K-1R5X

R321

0

C301

R456

12k

R457

0V

2.9V

GND

VCC

5V 12V

C401

C404

.1/16

R461

12k

R462

*

C702

.056/16

R503

X

2V

X501

0R304

3.1V

100R301

3.5V

100R302

3.6V

LC301

3.1V

0V

.1/16

2.3V

NC

NC

1.7V

0V

L301

1.5

NQL092K-1R5X

R405

1k

3.9k

R403

.1/16

C403

1.5V

1.5V

1.5V

1.5V

.1/16

VD-

CFREE

2

I

SDA0

220R776

220R775

220R774

IICFREE

SDA0

SCL0

R712

4.9V

VDD

A0A1A2

1kR714

1kR715

CLKI

X1

X2

CLEXT

TEST

SUBST

RESN

SCL1

SDA1

VDD(D)

VSS(D)

HD

H35K

H38K

PWM

VSYNC

L302

1.5

330

2V

2V

R404

330

1k

R406

SCL0

SDA2

100

SDA1

220R773

SDA1

SCL1

R711

3.6V

SDA2

R701

HPROT

E/W

VD+

RGBGND

RGBGND

X

Y306

3.6V

SCL1

SDA1

R455

12k

6.2V

5.6V

R459

4.7k

R463

*

SCL1

SDA1

CN003

QGB1505J1-50

Y305

X

D773

MA3056/M/-X

3.6V

SDA1

SCL1

CV_A/D

R454

4.7k

C455

2.9V

6V

C456

L/R_CENT

C501

15p CH

C502

15p

NQR0431-001X

C320

2200/6.3

100/16

.1/16

.1/16

MAIN PWB

SCL1

220

R772

D772

MA3056/M/-X

SCL2

100

3.6V

NS

SCL2

10k

R501

0

X

R502

0V

3.1V

SWITCH

FH1_2

3.1V

0.2V

D771

MA3056/M/-X

BBE_BOOST

R722

1k

10k

10k

R708

R707

3.9V

0V0V0V

BBE

BOOST

ON/OFF

LR_CEN

CV_A/D

0V

0V

10k

R702*R703

LC303

NQR0431-001X

C308

.1/16

0V

3.1V

SSD

VSS(D)

HSYNC

VDD(A1)

3.1V

0V

LC302

NQR0431-001X

C303

.1/16

XCN0C2

ALC

SUBTITLE

XR723

1kR721

1kR720

BBE_ON/OFF

10k

10k

R705

R706

0V

ALC

BBE

ON/OFF

SUBTITLE

VSS

M.SW0

M.SW1

R717

0.1V

4.3V

R704

*

R716

IC701

JLC1562BF-X

18kR319

5.6kR318

NC

SCP

SVM

VDD(D)

VSS(MC)

DEF & RGB PROCESSOR

IC301

SDA9380

VSS(A1)

FBP

VDD(A2)

VSS(A2)

5.6k

R522

R521

22k

D521

*3

R474

R476

56k

12k

R475

C473

15k

.1/16

IC471

UPC358G2-XE

EHT CORRECT

C475

.1/16

(1/2)

*

*

C310

Oct-2200

100R317

3.2V1V0V

BOUT

E/W

1.2V0.3V

C452

C471

.1/16

R489

33k

12V

0V

TU1_SW1

100R316

3.1V

GOUT

D/A

820

R451

C581

X

TU2_SW1

GND

0V

0.8V

TU2_SW1

AGC

TU1_SW0

100R315

C307

3.4V

ROUT

VD+

1kR401

X

VCC

R487

AGC

TU2_SW0

0V

TU2_SW0

.1/16

7.9V

VDD(MC)

VD-

1.5V1.5V2.9V

1kR402

R473

*

GND

0.022C323

*

C.V

3.5V

TXT_CV

0.6V

BIN

VDD(A3)

C305

R493

MSP_RESET

TU1_AFC

TV_LINK/COMPULINK

TAKEOFF

1.9V

3.7V

4.8V

TU1_AFC

AV_LINK

MSP_RESET

0.022C321

0.022C322

0.6V0.8V

0.6V

RIN

GIN

VSS(A3)

VPROT

1.1V

0V3.1V0V0.2V

C491

.1/16

.047/25

X

3.3k

R491

R471

27k

6.8k

R472

R470

22k

GND

TO MICON PWB ASSY

OSD_EW

YS2/AFC2

0V

0V

YS2/AFC2

R464

*

R314

220

FBL2

HPROT

5.6kR492

C591

470p

D591

*3

R591

560

R468

220k

R469

68k

R

0.2V

OSD_R

D317

*3

VSS(A4)

VDD(A4)

PROTON

HSAFE

*3D474

R485

12k

R486

4.7k

CLOCK

G

3.7V

0.2V

3.7V

STATUS

CLOCK

OSD_G

*3D318

FBL1

B/V1

G/U1

R/Y1

VIN

UIN

YIN

DCI

(Ik)

VREFC

VREFN

VBLO

VREFH

IBEAM

(ABL)

BSOIN

CH

R592

3.3k

D592

MA3051/M/-X

R467

56k

STATUS

CH

R593

C324

R466

220k

B

0.2V

OSD_B

82P

0.5V

0.5V

0.5V

1V

0.8V

3.1V

1.5V

2.9V

R504

X

DATA

3.7V

DATA

1V

3V

2.5V

NC

0V

2.5V

R465

220k

C472

0.01

2.3V

D311

D314

PROTECT

R303

1k

READY

C309

.1/16

READY

3.7V

0V

OSD_YS

X

X

C318

C317

C316

C315

C312

27k

0.01

C521

YS

H_PULSE

1.3V

C311

.068/16

AMP_MUTE

V_PULSE

-1.1V

0V

AMP_MUTE

D315

X

0.01

0.01

0.01

0.022

0.022C314

0.022C313

C306

.1/16

220p

CH

R312

27k

R484

47k

AUDIO_MUTE

GND

0V

3.6V

SDA2

AUDIO_MUTE

X

D312

R313

18k

R595

X

ABL

SDA2

SCL2

3.6V

3.6V

SDA1

SCL2

D313

X

D316

X

R596

330R311

Q472

EHT

CORRECT

4.7k

R483

*1

SMF-1008A-U2

GND

KEY1

KEY2

TIMER_LED

STBY_5V

GND

GND

STBY_5V

IIC_FREE

3.6V

IICFREE

0V

C595

.033/25

POWER

3.3V

0V

3.3V

0V

-0.1V

Q591

FBP

KEY1

X

Q471

*1

EHT

CORRECT

R478

12k

KEY2

TIMER_LED

POW_ON/OFF

R477

12k

VS

3.4V

KEY3

4.9V

X

R480

82k

R479

150k

C474

SCL1

SDA1

SDA0

SCL0

3.5V

3.2V

3.1V

SCL1

SDA0

SCL0

X

R481

4.7k

2.7k

R482

ECO_LED

KEY3

6V

3.3V

REMOCON

ECO_LED

OSD_YS

N

C351

10/25

3D_LED

REMOCON

H/P_DET

3V

2.3V

3.1V

3D_LED

H/P_DET

ECO

OSD_B

OSD_G

OSD_R

SCP

V100

U100

Y100

ECO

GND

CN007

QGB1505J1-50

H/P_L

H/P_GND

H/P_R

C699

0.01

POW_ON/OFF

TIMER_LED

ECO_LED

3D_LED

ECO

H/P_DET

REMOCON

KEY3

KEY2

KEY1

*3D471

*3D472

*3D473

H/P_L

H/P_L

H/P_GND

H/P_GND

H/P_R

H/P_R

STBY_5V

STBY_5V

GND

GND

P.ON/OFF

TIMER_ON/OFF

ECO_ON/OFF

3D_ON/OFF

ECO

H/P DET

REMOCON

KEY3

KEY2

KEY1

GND

GND

GND

GND

12V

CN002

QGF1220C2-25

CN013

QGA2501C1-10

GND

12V

GND

Ik

B

G

R

PROTECT

SVM_Y

SVM_YS

TO FRONT PWB ASSY

TO CRTSKT PWB ASSY

AV28CH1EUS

AV28CH1EUB

[1/2]

X

C571

C572

X

CN015

V.SENCE1

80%

X

80%

X

*

ROTAT IO NIC551

V.1

GND

V.2

R559

*

R555

R556

*

R557

*

D951

TO SYNC SEP PB

YIN

9V

HDOUT

VDOUT

GND

HDIN

VDIN

525/OTH

X

0

Y302

0

Y301

Y50

525P

HD

VD

X PURITYIC571

OUT1

-V.1

V.1

GND

V.2

R572

X

R579XR578

R573

X

X

R574

X

R558

*

*

TO POW & DEF PWB ASSY

R575

R576

X

R577

X

-V.2

OUT2

V.SENCE2

VCC

5.6V12V

R561

R560

C553

*

*

80%

C554

*

80%

C555

*

R951

22

R1/2

5V

5V

32V

3.3V

3.3V

GND

GND

GND

-(B-Y)100

-(R-Y)100

GND

SDA2

SCL2

2V

V100

SDA2

SCL2

-V.2

OUT2

V.SENCE2

R580

X

X

80%

C575

X

80%

C576

X

*

C560

*

Q562

N/S_COR

HS952

10V

C951

470/16

12V

12V

10V

10V

GND

GND

GND

Y100

GND

1.9V

2.3V

U100

Y100

VCC

R581

X

C574

X

C573

X

Q572

X

SWITCH

R565

*

4.8V

*

11V

C952

.1/16

X

11.4V

IN OUT

C953

.1/16

CN005

QGB1506L1-16

10V

SCP

VOUT

H0UT

GND

GND

0.2V

0V

0.8V

SCP

HD

VD

X

Q571

SWITCH

R582

X

R583

X1/2W

R585

X

R564

4.2V

*

C562

*

*3

D982

*3

D981

IC951

BA09T

8.9V

IN OUT

IC952

BA08T

CLKOUT

GND

0V

R584

X

R563

*

Q561

*

L951

5.6

C954

470/10

L951

QQL26AM-5R6Z

C955

220/10

CN0NS

CN0R1

*

CN0R2

CN0R3

L_OUT

R_OUT

GND