Page 1

A34000

1/4 SAE TEE

W/SWIVEL

COUPLE R

MATCHING

REFRIGERAN T

KE Y

TEMPER ATUR E

SENSOR

SUCTION LINE

LIQUID LIN E

CONDENSING

UNIT

REFRIGERAN T

TANK

TO

SUCTION SER VICE

VALV E

QC RESTRICT OR

FITTING

TO

LIQUID LINE

SER VICE VALV E

TEMPER ATUR E

SENSO R

SUPERHEAT

SUBCOOL

SUCTION LINE

LIQUID LIN E

MATCHING

REFRIGERAN T

KE Y

TEMPER ATUR E

SENSOR

CONDENSING UNIT

TO

LIQUID

SE RVICE

VALVE

TEMPER ATUR E

SENSOR

SUPERHEAT

SUBCOOL

SUCTION LINE

LIQUI D

LINE

TEMPERA TURE

SENSOR

EX PA NSION

VALV E

MATCHING

REFRIGERANT KE Y

EVAPORA TOR

TEMPERA TURE

SENSOR

SUPERHEAT

SUBCOOL

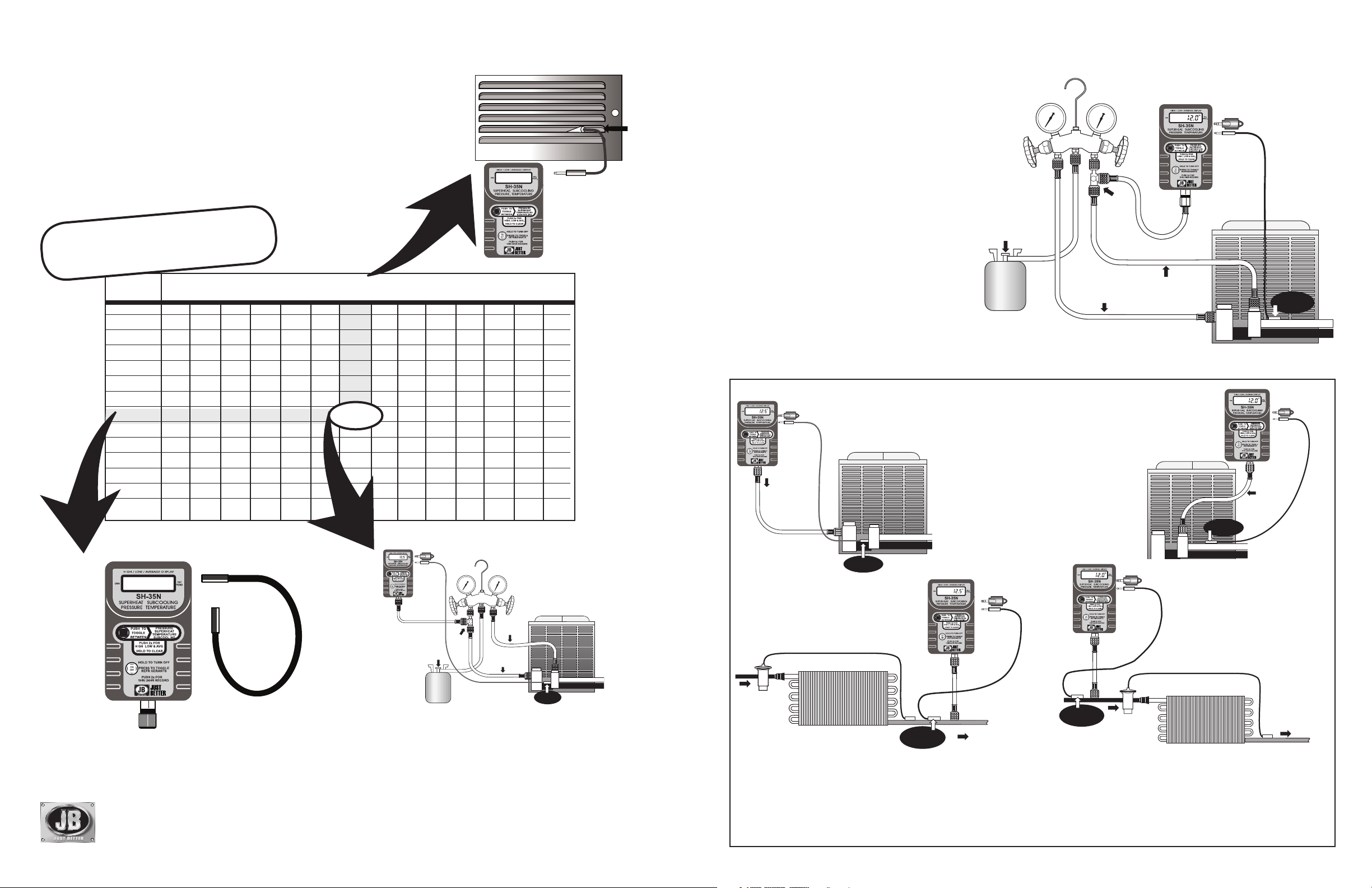

1. Connect the gauge to the A34000 tee fitting on

the high (liquid) side of the manifold as shown.

2. Install the Temperature Sensor on the liquid line

next to the liquid service valve and plug into

gauge.

3. For system refrigerants other than R-22, plug in

the matching Refrigerant Key into the gauge.

4. Toggle the gauge display to show

SUBCOOLING.

5. Very slowly add or remove refrigerant until the

gauge displays the required Subcooling value.

SUPERHEAT TEST

SUCTION LINE

LIQUID LI NE

MATCHING

REFRIGERANT

KEY

TEMPERA TURE

SENSOR

CONDENSING UNIT

TO

SUCTIO N

SER VICE

VALVE

TEMPERA TURE

SENSOR

SUPERHEAT

SUPERHEAT

SUBCOOLING TEST

1. Turn on the gauge.

2. For refrigerants other than R-22, plug in the

matching Refrigerant Key.

TESTING FOR CHARGE

EVAPORA TOR

SUCTION LINE

LIQUI D

LINE

EXP ANSION

VALV E

MATCHING

REFRIGERANT

KE Y

TEMPERA TUR E

SENSO R

TEMPERA TUR E

SENSO R

SUPERHEAT

SUPERHEAT

2. Plug in the Temperature Sensor and mount the

sensor as shown.

3. Toggle the display to show Superheat or

Subcooling.

CHARGING

BY THE SUBCOOLING METHOD

APPLICATIONS

?

Refrigeration Systems

?

High Efficiency Residential

?

Large Commercial A/C Rooftop

Packages Up To And Over 100 Tons

Average Subcooling Value is 10°–12°.

Contact manufacturer or wholesaler for specific temperatures.

Systems With TXV And No Receiver

OUTDOOR

TEMP°F

EVAPORATOR ENTERING AIR-°F.Wet-Bulb Temperature

50 52 54 56 58 60 62 64 66 68 70 72 74 76

55 9 12 14 17 20 23 26.9 29 32 35 37 40 42 45

60 7 10 12 15 18 21 24.3 27 30 33 35 38 40 43

65 6 10 13 16 19 21.9 24 27 30 33 36 38 41

70 7 10 13 16 19.6 21 24 27 30 33 36 39

75 6 9 12 16.2 18 21 24 28 31 34 37

80 5 8 13.3 15 18 21 25 28 31 35

85 12.5 11 15 19 22 26 30 33

90 10.2 9 13 16 20 24 27 31

95 6 10 14 18 22 25 29

100 8 12 15 20 23 27

105 5 9 13 17 22 26

110 6 11 15 20 25

115 8 14 18 23

A

WET BULB TEMPERATURE OF EVAPORATOR ENTERING AIR

1. Turn on with zero pressure. Gauge will automatically calibrate to

“Zero” for altitude and atmospheric pressure changes.

2. Wet the sock with water and slip on to sensor. Mount on the

building return air grill or air return line of blower to measure the

Indoor Wet Bulb temperature.

3. Turn on the furnace fan to create a flow of air across the wet sock

for 5 minutes. The final number will be your Wet Bulb Temperature.

OUTDOOR TEMPERATURE

1. Remove sock and measure the

Outdoor Air Temperature.

B C

1. Find the outdoor temperature and evaporator entering air wetbulb temperature on chart. The target superheat value is at the

intersection of the two.

If you have to do repairs, recheck your temperatures.

2. Make your connections and toggle the gauge to show SUPERHEAT.

For system refrigerants other than R22, plug in matching Refrigerant

Key.

3. Very slowly add or refrigerant to lower superheat or remove

refrigerant to raise superheat until the gauge displays the target

value.

OBTAINING TARGET SUPERHEAT VALUE

JB INDUSTRIES

AURORA, IL 60507 USA

Technical service: 800-323-0811

E-Mail:sales@jbind.com

Web Site:www.jbind.com

12.5

Sample Superheat Chart

(Located on condensing unit.

For older models contact manufactu

r

er)

WET

SOCK

IN AIR

FLOW

TEMPER AT URE

SENSO R

TEMPERA TURE

SENSOR

SUCTION LINE

LIQUID LIN E

REFRIGERAN T

TANK

TO

SUCTION SE RVIC E

VALVE

QC RESTRICT OR

FITTING

TO

LIQUID LINE

SER VICE VALV E

TEMPER ATURE

SENSOR

A34000

1/4 SAE TEE

W/SWIVEL

COUPLE R

MATCHING

REFRIGERAN T

KE Y

TEMPER ATURE

SENSOR

SUPERHEAT

SUPERHEAT

SUPERHEAT

TARGET

SUPERHEAT VALVE

SUPERHEAT

Page 2

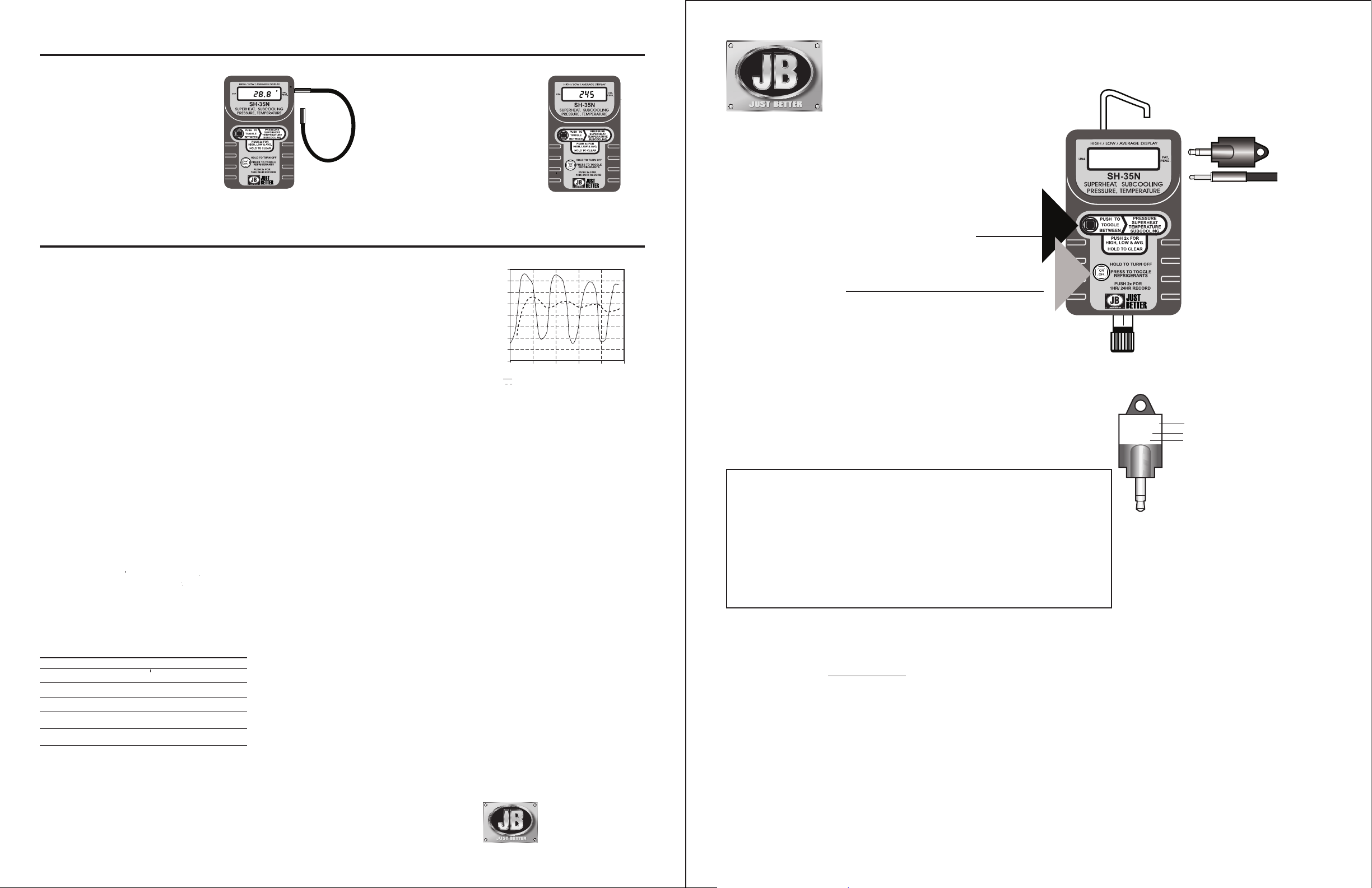

Not intended for use on hazardous or corrosive fluids

GAUGE SPECIFICATIONS:

Pressure display range: 29 InHg to 600 psig (-98kPa to 4134 kPa)

(+/- 1 PSI to 200 psi, 0.5% to 600 psi)

Temperature display range: -40°F to 200°F (-40°C to 93°C)

Operating temperature: -10°F to 120°F (-12°C to 49°C)

(+/- 1°F * 32°F/120°F, +/- 1.5°F * -10°F/32°F)

Maximum overpressure: 800 psig (5512 kPa)

Battery life and type: 100 hours/ 9vAlkaline battery

Auto-shutoff time: 60 minutes (extended 60 minutes by upper button action)

Refrigerant data source: NIST REFRPRO software and manufacturers data

Uses one 9v Alkaline battery

(not included)

EXTENDING

AUTO-SHUTOFF TIME

Extend time by 60 minutes by

pressing upper button.

Push lower button 2 times to

select 1 hour or 24 hours.

SUPERHEAT

REFRIGERANT KE Y

(R410A Included)

TEMPERA TURE

SENSO R

2

1

R404A

HP62

PSI/F

MANUFACTURER’S DESIGNATION

“R” NUMBER

UNITS (F or C)

Only a properly charged unit will provide the owner

with the design SEER for maximum energy efficiency.

SUPERHEAT, TEMPERATURE,

SUBCOOLING AND PRESSURE

PUSH once to toggle between displays

PUSH 2 times to recall High, Low & Average

Hold down to clear memory.

ON/OFF

PUSH once to “Turn On”

Display shows LAST refrigerant used.

HOLD down to "Turn Off"

PUSH 2 times to select 1 hour or 24 hour auto-off mode

REFRIGERANT SELECTION

PRESS once at any time to display current refrigerant.

Continue pressing to scroll the refrigerant list.

(See list of refrigerants on page 4.)

Wait 1.5 seconds, then continue pressing to reverse

scroll direction.

APPLICATION TIPS:

Allow the manifold to Zero at Turn-On:

The manifold displays will zero (CAL) each time the

manifold is turned on without pressure . Zeroing the gauge

compensates the Pressure display for changes in (1) Altitude

and (2) Barometric pressure.

Pressure Calibration

Don’t be alarmed if your manifold gauge does not agree

with your mechanical gauges. The digital manifold is

calibrated with a very accurate pressure and is not affected

by vibration, motion or position.

Extending On-Time

The digital manifold will turn off automatically after 60

minutes to save battery life.

If any button is touched the digital manifold will stay on for

another 60 minutes.

Over/Under-Range Indicator

Pressures or temperatures below or above the rated

ranges will cause a “1” to be displayed.

Low Battery Indicator

Low batteries will be indicated by a blinking display.

Batteries For Low Temperature Applications

Using the gauge in a low temperature conditions will

shorten battery life. Change to

the 9 volt Lithium battery (Radio Shack 23-665) to solve

this problem.

REFRIGERANT KEY PLUG-IN

See page 4 for other

refrigerant keys available.

Metric and English keys are

not interchangeable.

SH-35N

(°F)

and SH-36N

(°C)

SUPERHEAT and SUBCOOLING GAUGE

OPERATING INSTRUCTIONS

REFRIGERATION APPLICATIONS

SETTING FOR THERMOSTAT

CONTROLLED CASES AND

COOLERS

Without plug-ins, turn on the gauge

and zero the display by holding

the lower button. Plug in the

Temperature Sensor only and toggle

to “Temperature.”

SETTING FOR THERMOSTAT

CONTROLLED CASES AND

COOLERS

Without plug-ins, turn on the gauge

and zero the display by holding the

lower button. Attempts to zero the

gauge with pressure applied will

result in (Err) display.

A/C & REFRIGERATION APPLICATIONS

Contact your TXV manufacturer for the exact superheat adjust rate.

0 5 10 15 20 25

20

18

16

14

12

10

8

6

4

Superheat ϒ

F

Time in Minutes

Expansion Valve Superheat

SH-35N Average Superheat

Hussmann RHF A 4 Door FF Case

1Ton Lo w Temp. TXV

-2 F Case T emperature

40% Heater Load

SET SUPERHEAT FOR

“HUNTING” TXV VALUES

In refrigeration and air

conditioning systems, the

expansion valve often

operates to produce an

evaporator superheat

which constantly swings up

and down in value, called

“hunting.” The SH-35N

provides the “Average”

superheat value for TXV

valve adjustment.

CHECKING TXV SETTING

The objectives of the TXV superheat setting is to prevent

liquid refrigerant floodback to the compresor and to

optimize system operation by the use of a selected setting.

The two temperature method of measuring superheat

is not recommended because it can produce a wrong

superheat measurement, due to the effect of temperature

glide of the blended refrigerants and variations in

evaporator pressure drop.

NEW RESIDENTIAL A/C SYSTEMS

For new installations of residential A/C systems, the precharge will not provide an accurate amount of refrigerant

charge because of the variation in the length of liquid and

suction line connecting to the “A” coil.

RETROFITTING SYSTEMS

Retrofitting systems to a new refrigerant can change the

TXV superheat setting. The superheat setting should

be checked before and after retrofitting to be sure the

superheat is right for the equipment.

REPLACEMENT ITEMS

PART NO. DESCRIPTION

A34000 1/4" QC x 1/4" Access Branch Tee

SH-54 6' Temperature Sensor

SH-55 Plastic Carrying Case

SH-56 Socks (5)

ACCESSORIES

SH-51 28' Temperature Sensor Extension

KEY REFRIGERANT LIST “A”

R11

R12

R13

R22

R23

R134A

R290

R401A

R401B

R402A

R402B

R403B

R404A

R406A

R407A

R408A

R409A

R410A

R411C

R413A

R414B

R416A

R417A

R422A

R500

R502

R507

R508B

RB276

SUPERHEAT

JB INDUSTRIES

630.851.9444

Printed in USA

Part No. 10737-308

© 2006 J/B Industries Inc.

Technical service: 800-323-0811

E-Mail:sales@jbind.com

Web Site:www.jbind.com

Fahrenheit and Celsius Keys are not interchangeable

SUPERHEAT

TEMPERA TURE

SENSOR

TEMP

PSI

R407B

R407C

R422B

Loading...

Loading...