Just Better Platinum Series User Manual

™

Specifications

DV-42N, DV-85N,

DV-142N, DV-200N & DV-285N

MOTOR

1/2 HP, 60HZ, 115 Volt; Capacitor start;

Automatic thermal overload protected.

INTAKE

DV-42N 1/4 Male Flare

DV-85N 1/4 x 3/8 Male Flare

DV-142N,

DV-200N & DV-285

FREE AIR DISPLACEMENT

DV-42N 1.5 42

DV-85N 385

DV-142N 5 142

DV-200N 7 200

DV-285N 10 285

-250 Series

MOTOR

1/2 HP, 50 HZ, 230 Volt;

Automatic thermal overload

INTAKE PORT

See Above

FREE AIR DISPLACEMENT

DV-42N-250

DV-85N-250 2.5 71

DV-142N-250 4.2 119

DV-200N-250

DV-285N-250 8.3 237

3/8 x 1/4 x 3/8 Male Flare

CFM Liters Per Minute

Capacitor start;

protected.

50 HZ

Liters Per

CFM Minute

1.25 35

5.8 167

Dual voltage motors

available upon

request

Platinum® Series Vacuum Pumps

OPERATING INSTRUCTIONS

& PARTS MANUAL

2-Stage, Direct Drive

Gas Ballast

Valve

Exhaust

Intake

Isolation

(Blank Off)

Valve

NOTE: Platinum® pumps are not to

be used on Ammonia or Lithium

Oil Fill Plug

Do not wrench down

or use sealant on threads

Oil Drain Valve

Close drain finger tight

In order to make the best use of your

investment, familiarize yourself with the

new features and operating instructions

before starting pump. With just routine

care your

reliable service by following proper

maintenance guidelines.

are designed for deep vacuum work in

refrigeration systems only.

IMPORTANT:Use oil specifically refined

for deep vacuum pumps. Using oil not

refined for deep vacuum pumps and/or

operating with contaminated oil will void

warranty.

Platinum

will give you years of

Platinum

pumps

PLEASE READ THE “KEEPING THE

LIFE IN YOUR PUMP” BOOKLET

Bromide (salt water) systems. Pump

maintenance is the responsibility of

the owner.

PLEASE READ THE “KEEPING THE LIFE IN YOUR PUMP” BOOKLET

Each Platinum pump has been factory tested to guarantee 15 micron or

better and listed CFM performance. The serial number has been recorded.

Complete and mail the Warranty Registration Card within 10 days of

purchase to validate your warranty. Or you can register your product

on-line at www.jbind.com. You will be notified of any technical updates.

25,400 Microns = 1"

IMPORTANT

This unit has been drained for shipment.

DO NOT ATTEMPT TO OPERATE

WITHOUT ADDING OIL.

1

OIL

TA

CUU

G

V

CAPACITY

DV-42N

30 oz. (865 cc)

DV-85N

27 oz. (785 cc)

DV-142N

23 oz. (660 cc)

Slowly add oil until oil level rises to the

top of OIL LEVEL line. Replace oil fill plug.

If oil is too low, you will hear air out of

the exhaust. If the oil level is too high,

excess oil will be blown out the exhaust.

Pump oil should be changed after each

DV-200N

23 oz. (660 cc)

DV-285N

24 oz. (705 cc)

OPERATION

IMPORTANT

DO NOT START PUMP BEFORE ADDING OIL

The following procedures will prevent oil from being drawn

START-UP

Open one intake port and isolation valve,

close gas ballast valve and start pump.

Make vacuum connections.

Crack gas ballast valve for the first part of

the evacuation procedure. After pump

quiets down from initial volume of air,

close valve and continue evacuating.

Failure to close valve will result in poor

pump performance.

into cartridge and creating hard start-up.

use. If system is heavily contaminated, oil

may have to be changed several times

during evacuation.

After initial fill up of oil, it is best to check

oil level with pump running.

SHUT-DOWN

Close isolation valve and open gas

ballast valve all the way. Continue

running pump for 2-3 seconds. With

gas ballast valve still opened, stop pump

and then close valve.

Remove hose connections and cap

intakes.

ISOLATION

(BLANK-OFF) VALVE

OPEN

POSITION

PAUSE

POSITION

CLOSED

POSITION

Quarter-turn on/off. No additional valve

needed to isolate system.

When checking pressure rise, slowly turn

handle counter-clockwise. Pause at 45 °.

Valve completely closed at 90 °.

PUMP MOTOR

Pump and oil must be above 30 °F. Line

voltage must be equal to motor

nameplate ±10%. Normal operating

temperature is approximately 160°F,

which is hot to the touch. Line voltage and

ambient conditions will affect this

somewhat. Motor has automatic resetting

thermal overload protection.

designed for continuous duty and will run

for extended periods without overheating.

Platinum

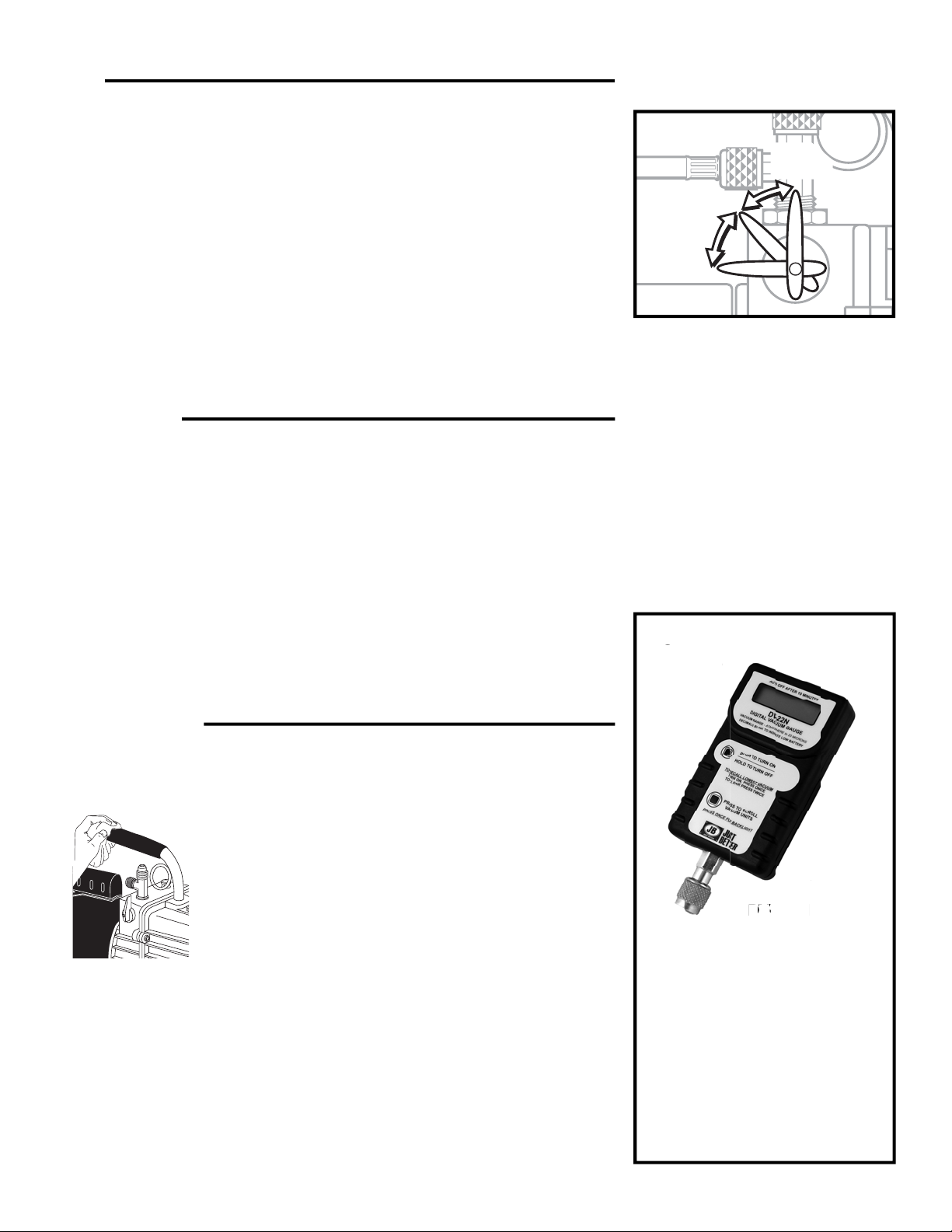

DIGITAL

VACUUM

VA

GAUGES

AU

is

CHANGING OIL

To reach deep vacuum, Platinum pumps need

clean, moisture-free oil throughout evacuation.

Care should be taken to avoid contact on skin and clothing when changing oil.

Used oil should be disposed of in a leakproof corrosive-resistant container.

1. After every evacuation while pump is warm and oil is thin, place

pump on level surface and open oil drain. Oil can be forced from

the pump by opening one intake and partially blocking the

exhaust with a cloth while the pump is running. Do not operate

the pump for more than 20 seconds using this method.

2. Close drain. Remove oil fill cap and fill to top of OIL LEVEL line

with

Black Gold

FLUSHING

If the oil is badly contaminated, flushing may be

Black Gold

Repeat as required until contamination is removed from oil resevoir, pump

rotors, vanes and housing.

Dispose of all oil used in flushing of pump.

oil into the intake connection while pump is running.

Pump Oil. Replace oil fill cap.

necessary. Slowly

pour 1/3-1/2 cup

After Evacuation, Oil Contains Rust

Forming Water and Corrosive Acids.

Drain Immediately While Pump Is Warm.

DV-22N

Reads Vacuum In 7

International Units:

Microns, PSIA, InHg,

MBars, Pascals, Torr, MTorr

Digital Display With Solid State Circuitry

+32°F to +120° F (0

Ambient Temperature

NIST Traceable

Solid State Design – No Adjustment

Necessary For Temperature

Automatic Power Off Battery Saver

Saves Last Vacuum

Readout After Shutdown

Low Battery Indicator

°

C to 48.9°C)

2