Just Better M2 User Manual

Directions For Use

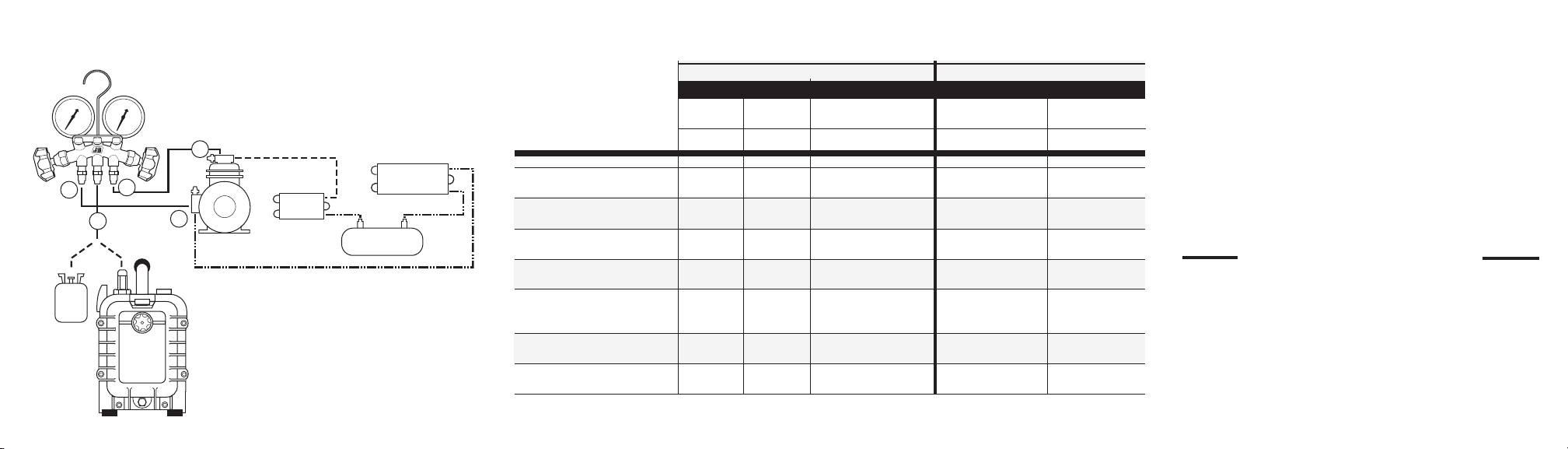

C

A

B

D

E

CONDENSER

COMPRESSOR

RECEIVER

EVAPORATOR

Caution: Always consult

MANIFOLD COMPRESSOR

equipment manufacturer's

A B C D E

service manual or instruc-

Charging and Discharge Suction

tion sheet for recommended

Low Side High Side Evacuation Port Service Valve Service Valve

procedures.

Blue Red Yellow Red Blue

To Observe Closed Closed Back Seated Back Seated &

Operating Pressures & Cracked Open Cracked Open

To Charge Refrigerant Open Closed Connect Line Back Seated Front Seated

Through Suction Valve to Refrigerant Supply & Cracked Open

To Charge Oil Open Closed Connect Line Back Seated Front Seated

Through Suction Valve To Oil Supply

To Charge Liquid Refrigerant Closed Open Connect Line Midway Open

Through Discharge Valve To Refrigerant

To Build Low Pressure; Open Open Refrigerant Back Seated Midway Open

For Control Setting Line Closed & Cracked Open

Or Leak Detecting

To Purge Refrigerant Closed Open Refrigerant Back Seated

From Discharge Valve Line Open & Cracked Open

To Evacuate With Open Open Connect To Midway Open Midway Open

Auxiliary Vacuum Pump Vacuum Pump

LIMITED WARRANTY

Manifold bar has a lifetime warranty, while the components, i.e.

gauges, hoses, handles, hose holders, etc. are covered under

the limited warranty policy. Products are warranted for a period

of one year from date of shipment by JB and limited to repair,

replacement or credit, if in our opinion are defective due to

workmanship and/or materials. Defective components should be

returned to the wholesaler from which the product was purchased for evaluation.

Manifolds are designed for use with all refrigerants except

ammonia (R-717). Working pressures are limited to gauge dial

range. Use of this manifold under any other conditions voids the

warranty.

FOR PROFESSIONAL USE ONLY

JB manifolds are designed for use by technically trained

AC/R service engineers only. Due to the high pressures encountered in all systems that this manifold will be used on, plus the

dangers due to the physical and chemical nature of refrigerants

and oils present in all systems, misapplication could result in

injury or death.

FORM NO. 28012-308

PRINTED IN U.S.A.

1

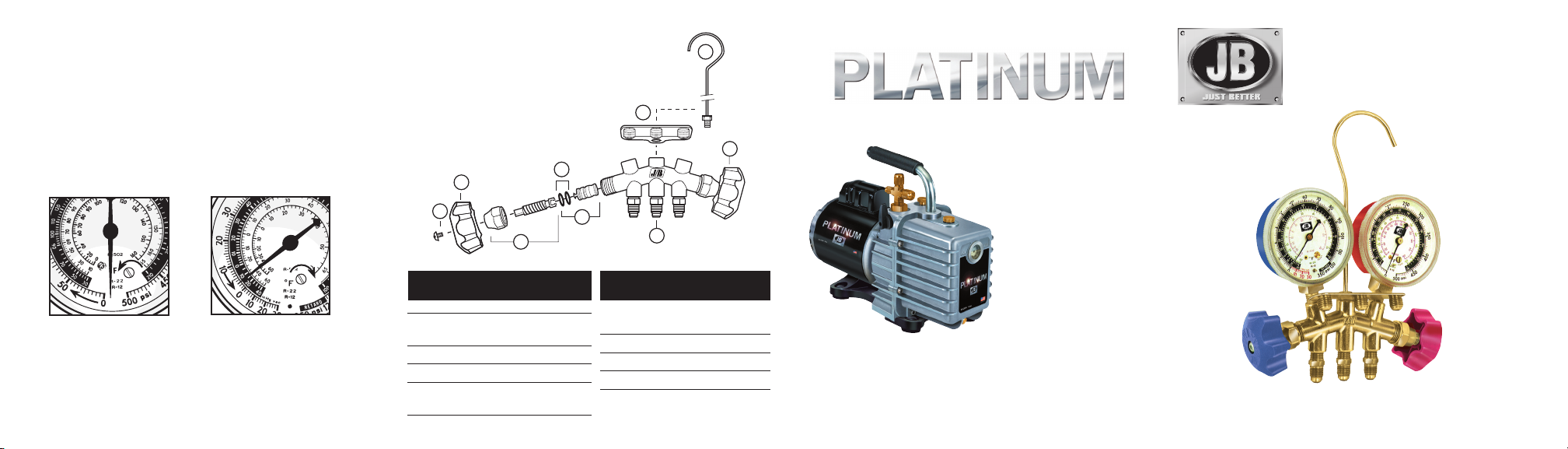

2

4

6

7

8

9

3

5

Each gauge is individually tested and calibrated prior

to shipment. Due to its sensitivity, the gauge may

need to be "zeroed in" prior to usage.

Adjusting Gauge Recal to Zero

1. Remove lens.

2. Turn recal screw slightly in the opposite direc-

tion that pointer is to be moved. Maximum recal

screw adjustment is 1/2 turn. Over adjustment will

permanently destroy calibration.

3. Replace lens.

Turn recal screw counterclockwise. Pointer

turns clockwise.

Over adjustment and/or being subjected to pressures

over dial range are not covered under warranty terms.

Gauges are sensitive instruments.

Turn recal screw

clockwise. Pointer turns

counter-clockwise.

REPAIR PARTS

See your wholesaler

for a complete line of

gauges

NO.

REF. PART NO. DESCRIPTION

1 MR-503 Handwheel Screws (2)

2 MR-501B Blue Handwheel

& Screw

3 MR-516 Stem& Nut

4 MR-509 O-Ring (P90011) (2)

5 MR-505 Piston w/Seat &

O-Rings

NO.

REF. PART NO. DESCRIPTION

6 MR-501R Red Handwheel

& Screw

7 M2-300 Hose Holder

8 M2-102N Hanging Hook

9 U1-4A 1/4" Intake

DEEP VACUUM PUMPS

Featuring

Heavy Duty,

High Performance

1/2 HP, 60 Cyc Motor

DV-42N 1.5 CFM

DV-85N 3 CFM

DV-142N 5 CFM

DV-200N 7 CFM

DV-285N 10 CFM

Also Available With

Dual Voltage Motors

Technical service: 800-323-0811

E-Mail: sales@jbind.com

Web Site: www.jbind.com

TM

©2006 JB Industries Inc.

CHARGING AND TESTING

M2 Series 2-Valve

Brass Manifold

With Free

Floating,

Double O-Ring,

Piston Seal,

LIMITED WARRANTY

INSTRUCTIONS PARTS LIST

Loading...

Loading...