Page 1

LD 5000 REFERIGERANT LEAK DETECTOR

JB INDUSTRIES INC.

Page 2

PRODUCT OVERVIEW

JB Industries is proud to unveil the new, revolutionary LD 5000 PROWLER

refrigerant gas leak detector. Using our new proprietary JBI Electrochemical sensor technology for unparalleled accuracy coupled with the unique

user features, there simply is no better hand held probe type service leak

detector system on the market. The LD 5000 uses a long life sensor that

is designed to detect the more current and more diffi cult HFC refriger-

ants such as R-134a, R-410A, R-404A, R-407C, and R-507 in addition

to all HCFC (R-22) and refrigerants including SNAP approved hydrocarbon blends. The sensitivity is extremely accurate for all HFC, HCFC and

blended refrigerants as well as the new HFO refrigerants. The sensor is

durable and will not be damaged by overexposure to refrigerant gas or

contaminated by condensate water. Its slim-line design makes it easy to

probe diffi cult to search areas. The technology provides for low battery

consumption, excellent circuit stability, extremely long sensor life, and the

electrochemical function of the sensor does not diminish over time with

use. The sensor life has been tested to be greater than ten years, which

is unique in the industry and it is safe to use in a combustible atmosphere.

The PROWLER features a large LCD screen that fl ips upward so the user

can adjust the screen position for better visibility. The bar graph shows

the intensity of a leak to help pinpoint the source of the leak. The sensitivity can be programmed from high to medium to low. If a leak is detected,

there is an audible alarm that will sound, vibration in handle, and bar graph

on the screen. The LCD display also indicates the amount of remaining battery life. The LD 5000’s unique digital leak size indicator takes the

guesswork out of whether or not to repair a small leak. The adjustable

LCD display is independent from the audio and/or vibrating handle alarms

and sensitivity level, allowing for the precise pinpointing of the leak source.

The PROWLER does not require rechargeable batteries and operates on

4 AA batteries (included).

Certifi ed to meet the standards

of CE, EN14624, SAE J2791

24 Month Warranty

Detects R-1234yf a replacement for all HFC (R-134a) and

HCFC (R-22) refrigerants currently being phased out

Page 3

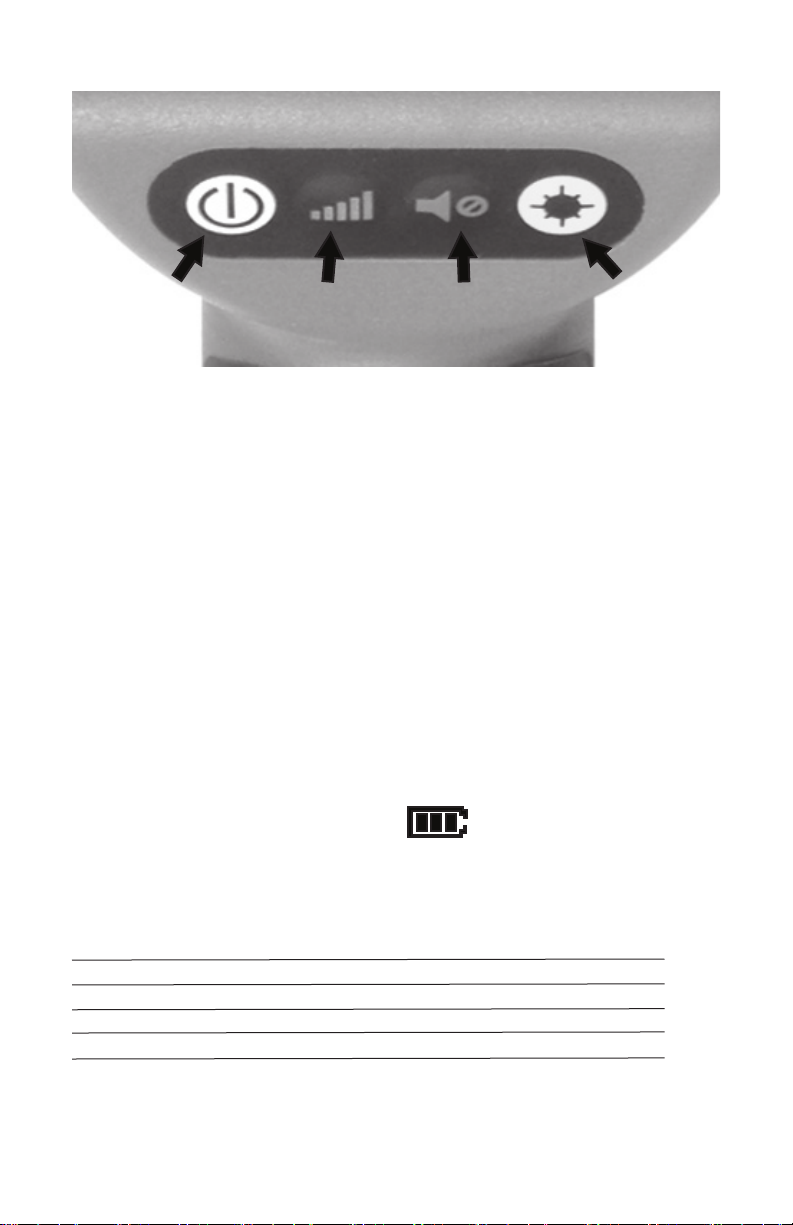

NEED A PICTURE of Control Panel

POWER ON/OFF BACKLIGHT BUTTONMUTE BUTTONSENSITIVITY

LEVEL

HOW TO OPERATE

1) TURN ON: Press the ON/OFF button once to turn on and again to turn

off. NOTE: Hold button down for approximately 1 second to turn unit off.

2) WARM UP: The detector automatically energizes the sensor condi-

tioning it for use. During the sensor conditioning cycle, the digital graph

leak size indicator wil gradually increase and the detector will sound a

slow “beep”. Warm up mode is usually less than 20 seconds and is complete when the digital graph displays all 10 bars. NOTE: When the detector has not been used for long periods, conditioning may take slightly

longer than usual.

3) READY: The detector is ready to begin searching for leaks when the

sensitivity setting (Hi, Med, or Low) and the battery indicator are displayed

on the LCD. The audio “beep” increases in frequency.

LOW BATTERY INDICATOR

The battery indicator consists of the battery outline with 3 bars within the

outline and located in the upper center portion of the LCD display. Battery level indication is the following:

Three Bars: Full Voltage

Two Bars: 1/2 Life

One Bar: 1/4 Life

No Bars: Low Voltage (Change Batteries)

No Bars/ Blinking: Unit will be disabled and not function properly

in this state

Replace the 4 AA Alkaline batteries when the battery indicator shows no

bars. Follow battery installation instructions under MAINTENANCE.

Page 4

MED

LEAK SIZE INDICATOR

The digital leak size indicating LCD graph display remains off normally but

once a leak is detected, a number of indicating bars (up to 10 bars with

increasing height) will be displayed for all HFC and HCFC refrigerants

regardless of the sensitivity setting. NOTE: The LCD display angle can

be adjusted for ease of viewing when referring to the display for leak size.

The display may be adjusted from normal viewing (closed position) to a

30 degree angle if required. The backlight may be turned on for low light

conditions.

The graph will continue to increase or decrease depending on the amount

of refrigerant sensed. The maximum value will be displayed once the leak

source has been located. This table can be used to approximate the size

of leak:

# OF BARS SIZE OF LEAK

(OZ/ YR)

1-3 bars

4-6 bars

7-10 bars

< 0.1

0.1 to 0.5

> 0.5

AUTO MUTE FUNCTION AND VIBRATING HANDLE

To silence or mute the audio beep and alarm signal, press the MUTE button. To restore the audio sound, press the MUTE button again. (NOTE:

A few seconds is required to restore sound if the mute button is pressed

in rapid succession.)

Vibrating handle mode is always on. In noisy environments or if the audio

alarm is muted the vibrating alarm provides leak detection without having

to view the display.

ADJUSTING SENSITIVITY LEVELS

The Leak Detector will default to the MED sensitivity level automatically

once the unit comes out of the warm up mode and the battery indicator

and sensitivity level are displayed.

To change sensitivity levels, press the Sensitivity button once for HI sensitivity and again for LO sensitivity.

Page 5

BACKLIGHT

To turn on the LCD display backlight, press the Backlight button once.

Press again to turn off.

LEAK TEST VIAL

The PROWLER comes with a Leak Test Vial that allows the user to make

sure the detector is performing properly. To test:

1) Remove the plastic seal label on top of the Leak Test Vial by pulling it

off (see fi g. below).

2) Turn on the detector and allow the unit to complete the warm up mode

(Sensitivity level set at MED).

3) Place the sensor close to the small hole in the top of the Leak Test Vial.

The beep rate should increase and the Digital Leak Size Indicator Graph

should display a minimum of 3 bars indicating that the sensor and electronics are working properly.

Leak Test

Vial

NOTE: Always remember to replace

the leak test vial back into the plastic

bag after test is complete. Seal the

bag to prevent the media from drying out. Replace Test Vial when the

green color is no longer visible.

MAINTENANCE

Batteries:

Install Batteries: Remove screw located at the center area of the bottom

housing and remove battery door as shown. Always insert all four batteries into the battery compartment in the same direction. Note polarity mark

on the inside of the battery compartment for proper battery orientation.

Page 6

Sensor:

Replace Filter: Unscrew sensor tip as shown to replace fi lter. Replace

fi lter whenever it becomes visibly dirty or every 2 to 3 months depending

on use.

Replace Sensor: Remove sensor by pulling out of socket. Install the new

sensor by aligning the notch in sensor cover with the raised keyway on the

sensor socket holder.(see fi gure below)

Note: Do not force sensor into socket. Misalignment can damage the

sensor pins.

Unscrew tip to

replace fi lter

IMPORTANT: Make sure sensor is fully inserted for proper operation.

The detector will stay in warm-up mode if the sensor becomes loose

or is not fully inserted.

Push straight on (do not twist)

to INSTALL sensor

Filter

Pull straight out (do not twist)

to REMOVE sensor

Keyway

CROSS SENSITIVITY TO AUTOMOTIVE CHEMICALS

Some automotive solvents and chemicals have similar hydrocarbon

properties as R-134a and may elicit a positive response (<30 seconds)

from the PROWLER. Before leak checking, clean up any of the following

chemicals that elicit a positive response:

* Rain-X windshield Wash Fluid

* Ford Spot Remover (wet)

* Ford Rust Inhibitor

* Ford Gasket Adhesive (wet)

* Loctite Natural Blue degreaser

(diluted)

* Ford Brake Parts Cleaner

* Ford Silicone Rubber (uncured)

* Motorcraft Antifreeze heated

to 160 degrees F (PARTIAL RESPONSE)

* Gunk liquid wrench

* Ford Pumice lotion (with solvent)

* Ford Motorcraft brake fl uid

* Ford Carburetor Cleaner

Page 7

PROWLER SPECIFICATIONS

Model #: LD 5000

Name: PROWLER Leak Detector, Refrigerant Gas

Sensitivity: 0.025 oz/yr R-22, 0.05 oz/yr R-134a,

0.0125 oz/yr R-1234yf, 0.05 oz/yr R-410A,

0.05 oz/yr R-404A, 0.05 oz/yr R-407A,

0.05 oz/yr R-427A

Sensor Life: > 10 years (normal use)

Response Time: Instantaneous

Power Supply: 4 AA Alkaline batteries

Battery Life: 4.5 hours continuous

Warm Up Time: < 20 seconds

Probe Length: 17”

LCD Display: Sensitivity, Battery Light, Leak Level Indication

Weight, lbs.: 1lb. 3.4 oz.

Warranty: 2 years includes sensor

EN 14624 TEST SPECIFICATIONS

Min/Max Sensitivity 1 gm/yr minimum, > 50 gr/yr maximum

Threshold (fi xed):

Min/Max Sensitivity 3 gm/yr minimum, > 50 gm/yr maximum

Threshold (moving):

Min Detection Time: Approximately 1 second

Clearing Time: Approx. 9 seconds after exposure to > 50 gm/yr

Min. Threshold after

Maximum Exposure: 1 gr/yr

Sensitivity Threshold in

Polluted Atmosphere: 1 gm/yr

Calibration Frequency: 1/yr check with calibrated leak Standard

Page 8

REPLACEMENT PARTS

Description Part Number

Replacement Sensor with fi lter LD-S101

Replacement Filters (5 pack) LD-RF5

Leak Test Vial LD-TV

Parts Kit (sensor, fi lter kit, test vial) LD-PK

Carrying case LD-CS

WARRANTY

The PROWLER LD 5000 Refrigerant Gas Leak Detector is warranted to

be free of defects in materials and workmanship for a period of two years

from the date of purchase. This warranty applies to all repairable instruments that have not been tampered with or damaged through improper

use including unauthorized opening of the unit.

RETURN PRODUCT FOR REPAIR POLICY

Every effort has been made to provide reliable, superior quality products.

However, in the event that the instrument needs repair, for units still under

warranty return to the wholesaler from whom the device was purchased.

The wholesaler should contact customer service 800-323-0811 to request

an RGA # and include all necessary documentation. For units out of warranty, the user is asked to call customer service directly at 800-323-0811

to determine estimates for repair.

JB INDUSTRIES

PO Box 1180

Aurora, IL 60507

800-323-0811

email: sales@jbind.com

www.jbind.com

© COPYRIGHT 2011 JB INDUSTRIES INC.

Loading...

Loading...