Page 1

Tech tips from the pros

Keeping

the Life in Your Pump

Copyright© 2009, JB Industries Inc.

Page 2

2 3

IMPORTANT

JB PUMPS ARE NOT TO BE USED ON AMMONIA OR LITHIUM BROMIDE

(salt water) SYSTEMS. Pump maintenance is the responsibility of the owner.

Remember to change the oil. JB recommends

changing oil after every evacuation and for larger

jobs, you may need to change the oil a few times.

Hydrofl ouric and hydrochloric acids and moisture

collect in the oil. Left sitting in a pump, they act

as an abrasive on internal surfaces, rusting and

corroding them.

Figure 1

Cleaning and Testing Your Vacuum Pump

One of the easiest ways to spot if your pump is

in need of a good cleaning is to look at the sight

glass. If the oil looks milky, rusty, or full of

debris, then the inside of the pump is in worse

shape (Figure 1).

To clean, start the vacuum pump and allow

it to run for about 15 minutes to warm up the

oil. Make sure that you have allowed enough

working room to safely drain and capture the oil.

After the oil has stopped dripping, tilt the pump

forward to remove any remaining excess oil (Figure 2). Then, stand the pump on the nose of the

cover (Figure 3) to allow any trapped oil in the

wells and stators to drain. Let sit for a few minutes and return the pump to its normal running

position. Repeat tilting forward. Close drain

valve. Dispose of contaminated oil properly.

Once the oil has been completely removed,

return the pump to the position in fi gure 3 and

remove either the 2 rubber feet from the bottom

of the pump or remove pump base (depends on

the age of the pump which option is available).

Next, turn the pump on to the motor end (Figure

4) and remove the 6 socket head cover screws

holding the cover in place (Figure 5). Remove

the cover from the pump and wipe the inside

surface with a dry, clean rag. The sight glass

is more diffi cult to clean. Try pouring in some

solvent and using a pipe cleaner.

Figure 2Figure 3Figure 4Figure 5

Next, remove the oil defl ector which is held in

place with a socket head screw (Figure 6). Wipe

with a clean, dry rag. If needed, a wire brush can

be used to clean any discoloration to metal parts

(this will not affect the pump’s performance once

the cleaning is complete). Remove the cover seal

and clean cover seal (Figure 7). Wipe the outside

of the cartridge’s surfaces with a clean, dry rag. A

wire brush can be used on all surfaces including

the exhaust valve and the intake relief valve. If

they are discolored, they will still perform fi ne.

DO NOT DISTURB THE FOUR CARTRIDGE

BOLTS OR THE TWO SMALLER HEX

HEAD SCREWS (FIGURE 8). These are the

setting screws.

If the intake relief valve set or the exhaust valve

set is damaged and needs replacing, these items

can be ordered through your local wholesaler

under JB Part Number PR-18. It is best to replace

after completing the cleaning of the cartridge. Pay

attention to the order in which they are assembled

for correct reinstallation.

Reassemble the oil defl ector (Figure 6). Clean out

the channel for the cover seal with a clean, dry rag

and smear some grease into the channel. This will

help hold the cover seal in place for reinstallation

of the cover. If the cover seal seems a little tight,

stretch the seal a little and try again. All seals

in JB pumps are designed to be reused. Reset

the cover in place and replace the cover screws.

Tighten in a crisscross pattern. Reattach feet or

base.

Next, return the pump to its normal running position and place where you drained the oil. Open

the drain valve, the 3/8” port on the intake, and the

isolation valve. Have 1/3 cup of clean oil ready.

Start the pump and pour the clean oil into the

intake port. Let the pump run for 5 to 6 seconds

and then shut the pump off. Drain the oil, tipping

the pump forward as in Figure 2 to completely

drain. Close the drain valve and dispose of spent

oil properly after the fl ushing is complete.

Figure 6

Figure 7

Figure 8

DO NOT

DISTURB THESE

Page 3

4 5

Cleaning and Testing Your Vacuum Pump Continued

Using Charging and Testing

Hoses for Evacuation

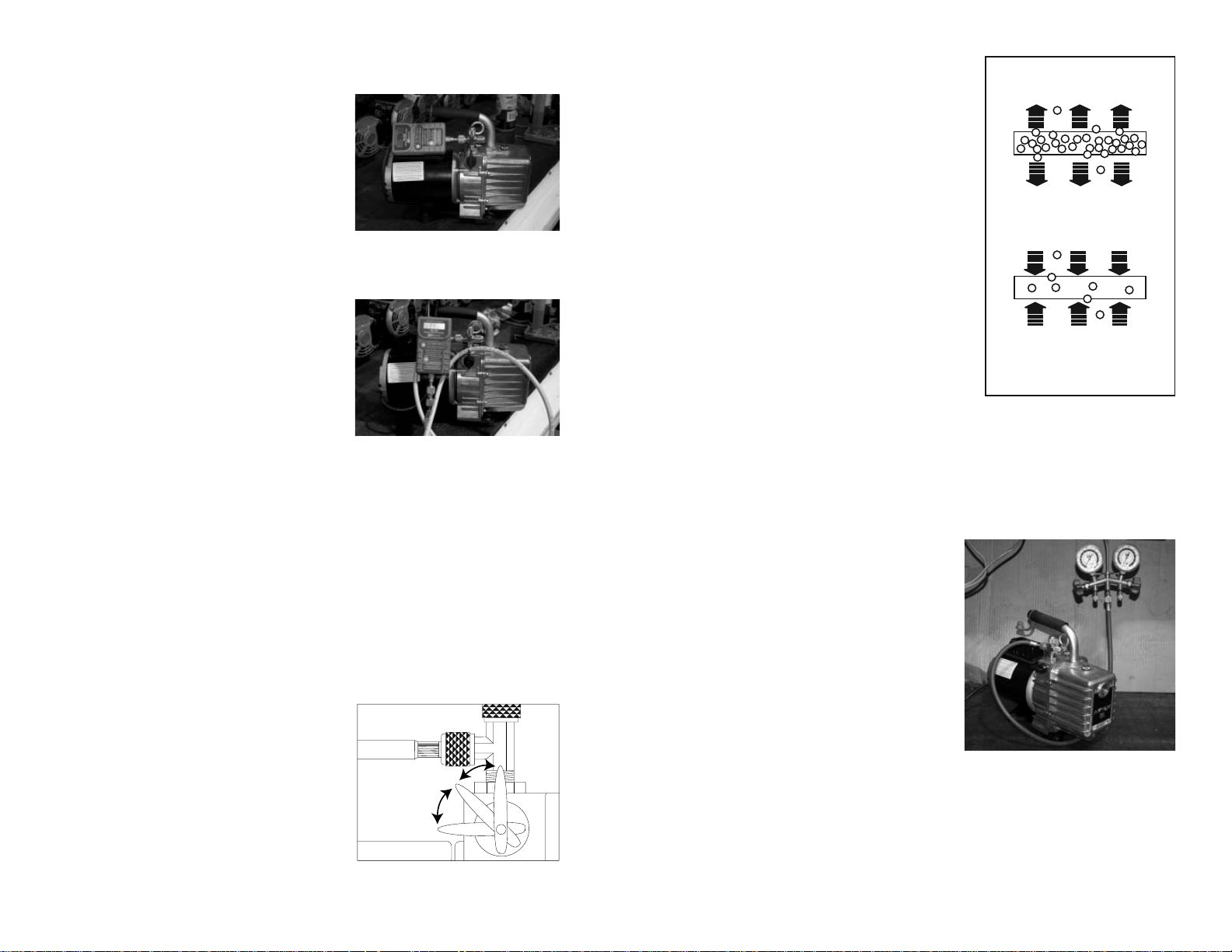

DIRECTION OF PERMEATION

THROUGH HOSE WALL

Now, fi ll the pump to the proper oil

level and allow the pump to run with

the isolation valve closed for 3 or 4

minutes to warm up the oil. Check all

o-ring caps for dirt and proper seal.

Connect a micron gauge (JB recommends the JB DV-22N pictured to the

right) directly to either the 1/4” port or

Figure 9

the 3/8” port on the intake tee (Figure

9). Do not use a charging line. Open

the isolation valve.

Using a charging line, especially a

new line, will give you a higher micron reading because you are reading

the environment inside the hose (see

Figure 10).

Figures 9 and 10 are the same, but

Figure 10

fi gure 9 is a direct connection hook-up

and fi gure 10 is a connection through a new charging line. Both hook-ups are

allowed to run the same length of time, but #9 is at 20 microns while #10 is at

297. If left on, the charging line hook-up will come down in its micron reading,

but it will take a much greater period of time. If the hose is cleaned out with alcohol and vacuumed for a long period of time, the micron reading will go lower.

This test can be performed on a pump with dirty, used oil and then with the

pump cleaned and fl ushed, as described earlier, to see the difference that just

maintaining the cleanliness inside your pump affects the performance for deep

vacuum.

Isolation Valve

It is a quarter turn between on and off.

There is no additional valve needed

to isolate the system. When checking for pressure rise, slowly turn the

handle counter-clockwise. The pause

position is at 45 degrees and the valve

is completely closed at 90 degrees

(Figure 11).

PAUSE

POSITION

CLOSED

POSITION

Figure 11

OPEN

POSITION

You probably think there is a leak. However, an evacuation/ dehydration hook-up

requires a leak-proof design in all of the

components. Only soft copper tubing,

pure rubber hoses, or fl exible metal hoses

are absolutely vacuum tight. Charging

hoses are designed for positive pressure.

CHARGING SYSTEM

Gas under pressure in the hose

will permeate to the lower

pressure of the atmosphere.

Even with the advanced technology of today’s hoses, permeation through the hose

compound still exists (Figure 12).

If you have blanked-off your pump

to check pressure rise and your hoses

and connections are not leak-free, the

atmosphere will permeate to the lower

pressure in the hoses. Your reading will

slowly rise and you will spend time look-

EVACUATION (Hose under Vacuum)

The atmosphere which has a higher

pressure permeates to the lower

pressure in the hose.

Figure 12

ing for system leaks.

Information on Testing the Vacuum Pump’s Isolation Valve

The easiest way to test the isolation valve

for leakage is to turn the pump on with

the isolation valve in the closed position.

Connect a charging line to the center port

of the manifold (Figure 13), and have the

high side capped off and CLOSED and

the low side capped off and OPENED.

Then, connect the charging line to the

intake of the pump and wait. If, within

5 to 10 minutes, you do not see the low

(compound) gauge going into inches of

vacuum, there is no leak in the isolation

valve.

What does happen when a micron gauge

is connected directly to the intake of a vacuum pump with an isolation valve/ It

is all related to the connections to, and including, the intake, the volume of what

is being vacuumed, the depth of vacuum, and the length of time that the volume

is in the deep vacuum.

Figure 13

Page 4

6 7

Information on Testing Vacuum Continued

Brass isolation ball

Stem w/ o-ring

Retainer ring

Figure 14

First, let’s look at the construction of JB’s isolation valve (Figure 14). This fi g-

ure shows the isolation valve in the closed position. The brass ball is sandwiched

between two Tefl on seals, making a positive seal, with a solid brass surface

blocking access to the intake chamber. The adapter nut on the top, outside of the

pump, is where the intake fi tting is connected. It is sealed with Loctite and an o-

ring. If this nut has not been disturbed, the chances of a leak are very minimal.

The stem has a dual o-ring seal and, even if this leaked, with the isolation valve

in the closed position there would be no effect on holding a vacuum. A leak at

the stem would effect the depth of vacuum the pump could achieve.

With a micron gauge connected directly to the intake of the pump and vacuumed

to 50 microns, closing the isolation valve will result in a rapid rise in pressure,

almost to atmosphere. Look closely at the area around the isolation valve. Even

though small, air is trapped in this area. When we begin to close the isolation

valve, there is a position of the ball that allows this trapped air to enter the vacuum being created. On a large system, this small amount of air would not create

a conspicuous change in microns. However, with almost no volume, the sudden

introduction of air to this direct hook-up is obvious and would be displayed on

a micron gauge. Refer to the previous page for the isolation valve positions.

When the isolation valve is put in the pause position, this gives the cartridge

(the pumping mechanism) access to the air trapped in this area and within a few

seconds, that trapped air is removed.

Moving to the connections on the pump, the factory intake is loctited into place

and each pump is tested for leaks. If this is not disturbed, the chances of a leak

Adapter nut w/ o-ring

Teflon seals (2 each)

Retainer Plug w/ o-ring

Poly Ball 7/16”

(oil check system)

are virtually non-existent. Any leak would

come from the connection at the port being

used and to the connection to the system.

One of the most common errors with both

the o-ring and the gasket couplers is the

wrenching down of these couplers with

a pair of pliers or channel locks (Figure

15). Please refer to our “Principles of Deep

Vacuum” article. This article can be found

on JB’s website www.jbind.com under technical information/ troubleshooting. Or type

http://www.jbind.com/tools/userfi les/fi le/

Deep_Vacuum.pdf into your web browser to

take you directly to the page.

As this article shows, there is a need for

sealing with a vacuum tight o-ring (Figure

16). Gaskets, like those used in charging

lines, are made for pressure. What wrenching of the coupler does is to smash the brass

cup that holds the gasket or o-ring against

the male fl are fi tting. This causes the brass

cup to expand outward against the threads of

the coupler and makes it tight to turn. This

causes the o-ring to fall out of the cup that is

holding the o-ring or gasket in place.

Another error that we see is that technicians

have a brass adapter fi tting on the intake of the

pump with no copper gasket. The fi rst time you

wrench the adapter into place, it might seal.

But, as soon as you break the seal and retighten,

there is a chance for a leak. The best hook-up

that guarantees there are no leaks in the system

is by using JB’s DV-29. This hook-up is

depicted in Figure 17. The DV-29 consists of a

fl exible metal hose, ball valve with depressor, a

90° male fl are with coupler, and valve assembly

with male connections. The hook-up and parts

are depicted in JB’s catalog, version 42 on page

13.

Charging lines have been used for many years

for the vacuum end of air conditioning and

refrigeration servicing. Charging line use

Figure 15

DO NOT WRENCH

DOWN COUPLER

Deep Vacuum

O-Ring Coupler Cut-Away

Flare

Fitting

Specially

Designed

Groove

Locks

O-Ring in

Place

Figure 16

Figure 17

45°

Postive

Stop

Page 5

8 9

Information on Testing Vacuum Continued

stretches back as far as when Inches of Mercury (inHg) was the way measuring

of a vacuum on a system was taught. A charging line hose can be vacuumed to

50 microns if it is clean. New environmental hoses, fresh off of the shelf, will

only reach about 300 microns until they are cleaned out with alcohol and vacuumed out for a while. Why is this? First, the charging lines are mostly gaskets

made for positive pressure. Second, they are permeated. See page 5 for how

charging lines and permeation occur. The only vacuum tight hose is a fl exible

metal hose. Third, the compound of the hose inside will outgas when under a

vacuum until it is cleaned out, as discussed earlier.

Another source of leakage is the gasket seal in the valve and hose couplers. This

seal is designed for charging and will not give a perfect seal required in deep

vacuum service. An o-ring seal coupler, like the ones JB makes, forms around

any irregularities in the fl are fi tting. When the coupler is screwed down, we get

a metal to metal seat and the o-ring lies around the lip of the fl are giving it a

positive seal.

If you are used to using a compound gauge when testing for a leak or holding

a vacuum, using a digital gauge will be a little tricky the fi rst time you use it.

Digital vacuum gauges, like JB’s DV-22N, will display microns jumping up and

down in measure. You might think that the gauge is erratic or that there is a leak

in the system. The reason for the changing microns is due to a whole other area

of understanding the environment inside a system being vacuumed. We will

discuss this event in the next section “Information on Digital Micron Gauges”.

To help show the difference of a digital and analog displays in microns, and a

compound gauge display in inches of mercury (inHg) as it relates to their displays of vacuum, we need to hook them up. Take a compound gauge, an analog

gauge, a digital micron gauge, and an empty refrigerant tank. This hook-up is

illustrated on the next page in Figure 18. This allows you to demonstrate the

four components in holding a vacuum: the connections, the volume, the depth

of vacuum, and the length of time that volume is in deep vacuum.

Link all three gauges together by solid brass adapters and o-ring couplers and

couple to the tank. The tank is connected by an o-ring coupler to one of the

intake ports of the pump by way of braided metal hose with o-ring connections.

Then, with the isolation valve in the open position, we can begin to vacuum this

hook-up and watch the readings on the various gauges move into deep vacuum.

Within seconds, the compound gauge’s needle should be nearing 27-29” while

the digital and analog gauge readings are still heading into deeper microns.

After the digital and analog gauges are at 500-600 microns, close the isolation

valve. You will see the digital and analog readings start a pretty rapid rise in

micron readings. Notice that the compound gauge’s needle has not moved.

Figure 18

(NOTE: If the compound gauge’s needle does move toward zero on the scale,

you have an air leak in your connections). Open the isolation valve again and

this time let the hook-up vacuum for 5 minutes. Then close the isolation valve

again and watch. Open the isolation valve for about a minute, then move the

valve to the pause position for about 5 seconds, then close the valve completely.

This removes that trapped air around the isolation valve. You will still see a rise

in pressure, but not as rapid. The readings will start to stabilize the longer this

hook-up is allowed to vacuum down and use the pause position of the isolation

valve the slower and lower the rise in pressure.

If you increase the volume of the cylinder and follow the same procedure, you

will notice a slower and lower rise. If you watch your compound gauge, you

will notice there is no movement.

Page 6

10 11

Information on Digital Micron Gauges

There are three main complaints that are stated on the returns that JB receives

from the DV-22N and DV-24N. First, “inaccurate readings”. Second, “erratic

readings”. Third, “will not hold a vacuum”. Each of these complaints involves

both the understanding of the gauge functions and the principles of vacuum.

Inaccurate Readings: Please note, for the DV-22N and DV-24N we have

a stated accuracy that references AVERAGE accuracy. Thus, between 250 and

6000 microns the unit is +/-10% AVERAGE accuracy and between 50 to 250

microns it is +/-15% AVERAGE accuracy. This does not mean our gauge has a

large accuracy discrepancy.

The term AVERAGE is an important part of this accuracy description. The

number of increments displayed on the JB digital micron gauge between 50 and

250 microns are 97. Between 250 microns and 6000 microns, there are 232 increments. If you take a comparison reading between the DV-22N and the MKS

Baratron master gauge at each of the increments displayed on the Digital micron

gauge the average accuracy would be +/-10% in one range and +/-15% the average in the other range. Also, the number of increments decrease from the lower

micron readings to the higher micron readings.

For example, from 250 to 300 microns there are 16 increments, from 650-700

microns there are only 7 increments, between 1000 and 1050 there are 4 increments, and between 4000 and 4500 there are 4 increments. So at 650 to 700

microns the gauge has the ability to show 650-658-667-675-680-685-690-695.

But at the micron range of 4000 to 4500, the gauge only displays 4125-4250-

4375. This is important because when the system has an actual micron level of

4260, the digital micron gauge will show a reading of 4375 because the threshold for the lower value that the gauge displays, 4250, has not been reached.

Once that threshold has been reached, the gauge will display that lower value

of 4250. Because the readings in these higher micron ranges only need to show

the movement through them , the difference between 4375 and 4250 is of no

concern in reaching the ultimate vacuum desired. This is why the JB DV-22N is

designed with the most increments in range that are going to be the most critical

in determining if the system is ready for charging.

If you understand the size of a micron, then small differences in ranges is nothing to be concerned about. For instance:

Micron Range

60-100

200-350

500-700

900-1500

2500-4000

Micron Difference

10-20

30-40

50-60

80-100

200-300

Information on Digital Micron Gauges Continued

When a DV-22N comes in for repair, it is compared to a secured system set up

with a N.I.S.T. Certifi ed analog gauge (DV-6 Hastings). Usually starting around

(1)60-100 microns, then (2)200-350 microns, then (3)500-700 microns, then

(4)900-1000 microns. These ranges of vacuum are the most common that people work with to determine deep vacuum. We have been comparing the DV-22N

to the N.I.S.T certifi ed gauge on a secured system for a number years and has

proven to be highly accurate in all four ranges of vacuum. The average accuracy

as stated earlier in this section has proven to be consistent against this measure.

Erratic Readings: There are three issues involved in the dis-

cussion of erratic readings. One is the understanding of the gauge’s displayed

micron increments that was just discussed. The second involves the re-sampling

period. The third is the environment inside the system being evacuated. When

the DV-22N is turned on, the display will show “JB” and the sensor will start to

calculate the ambient temperature.

Once the gauge has fi nished calculating the ambient temperature, it will display

the number “1” if it is not introduced to a vacuum level of 9000 microns or less.

Page 7

12 13

Information on Digital Micron Gauges Continued

As the system is being evacuated and the micron level is dropping down through

the increments of the gauge’s display, the gauge will re-sample ambient temperature about every 60 seconds. When this function is taking place, the gauge’s

display will show “auto-cal” (older gauges may see that the display freeze prior

to the re-sampling). The re-sampling lasts for about 15 seconds after which

the micron level that the system is at will then be displayed. For instance, the

system is at a micron level of 5500, the re-sampling begins, the “auto-cal” will

be displayed until the re-sampling is done, then the micron level at which the

system is at will be displayed.

There is also instability inside the system being evacuated. Liquids (moisture)

are being turned into gasses and molecules are moving at different rates of collision with other molecules at different areas of the system at different times

between the high and low sides. The deeper the vacuum, the further apart these

molecules get and the less rubbing together. This decrease in friction changes

the temperature around those molecules and the DV-22N is registering those

changes by way of temperature changes at the sensor’s fi lament. The environ-

ment inside a system being evacuated has more instability at higher micron

levels (9000 to 1000) than at lower micron levels (700 to 50). This is evidenced

when testing the DV-22N at the different ranges on a secured system. When

in the range of 4000 microns, the DV-22N’s display will show 4000 microns,

then jump to 4350, then regress to 3875, then jump back to 4000. After being

blanked-off at this level for a period of time, the changing back and forth will

level out to changing from the incremental display of 4000 microns and the next

incremental display up or down of either 4125 or 3875. But, when in a deeper

vacuum like 350 microns, the changes in display on increments may be from

350 to 357 and back down to 350 or even 329 as the environment inside the

system becomes more stable and the time period of these changes will be less as

most of the out gassing has been done.

Won’t Hold a Vacuum: The sensors on JB’s DV-22 digital gauges are brass

with the sensor components sealed like a light bulb. The area where the hook

shaped wire and the fi lament attach to the sensor’s body is sealed with a glass

like epoxy. The chances of this leaking are next to impossible. The rise in

pressure experienced in the use of vacuum gauges on systems is discussed on

the previous pages under “Information on Testing a Vacuum Pump’s Isolation

Valve”.

Breaking Vacuum

Breaking vacuum prior to shut down is important on larger cfm pumps. This

procedure relieves the stress on the fl exible coupler on the next start up. When a

pump is shut down without breaking vacuum, the oil in the cover is pulled back

into the cartridge and intake chamber of the pump trying to fi ll the vacuum there.

Upon the next start up the pump has to clear the oil outof these areas and all the

stress is on the fl exible part of the coupler, especially if the oil is cold. You can

see this occuring by shutting down the pump and watching the sight glass. The

oil will start to drop down and appears as if you are low on oil. Then when you

restart the pump the oil level returns to normal.

To break vaccum on the Platinum pumps, simply close the isolation valve with

the pump still running and open the gas ballast valve all the way and allow the

pump to run 2-3 seconds with the gas ballast valve opened and then shut pump

off and close the valve.

To break vacuum on the Eliminator pumps. After blanking off at the manifold

or an external isolation valve, if used, crack open the un-used intake port on the

pump and allow to run 2-3 seconds and shut pump off.

Flexible Coupler

On an analog gauge, at a micron

level of vacuum of 4000, the distance

between 4000 and 4350 is between

2T and 5T. This is a distance of about

1/16th of an inch. This distance on

other gauges may vary. Fluctuations

of the needle as the out-gassing is

happening are barely noticeable. The

downside of the analog gauge is that

magnifi cation of the needle is needed

in order to see it move between

the two increments at this range or

vacuum level (4000-4350 or 2T-5T).

Flexible couplers are a three part assembly: 2 metal hubs that look like gears

and a fl exible middle section. The one hub is attached to the shaft of the motor

and the other is attached to the shaft of the cartridge. NOTE: The color of the

fl exible middle section can be either black or yellow.

1 1/2”

7/8”

PR-208

PR-6

Middle section of PR-208 only can

be ordered seperatley PR-308

1 5/8” 2 1/4”

PR-53

2 1/8”

2 3/4”

Page 8

14 15

Replacing Coupler (Motor Removed)

Coat setscrew threads with removable thread sealant. Align coupler setscrew

with fl at surface of cartridge shaft. Tighten screw so coupler slides on to shaft

but stops at the bottom of the fl at. Tighten until screw head is fl ush with coupler

surface (approx. 40 in. lbs.).

Troubleshooting: Pump Hard to Start

Possible cause: Pump has not been shut down properly.

Step 1: Remove 1/4” cap.

Step 2: Move blank-off valve to OPEN position

Step 3: Turn pump on

Step 4: Run 2 to 3 seconds and close blank-off valve.

1/8"

Bottom

Of Flat

Incorrect

Correct

Sight Glass Repair

Step 1: With cover off of the pump,

lay on two blocks of wood. Pop out

the sight glass using a broom handle or

other objects as a punch. For DV-85

series, DV-142 series, or DV-200 series

use a 1” diameter punch.

Step 2: Clean the surface with acetone

or nail polish remover. Put loctite on the

inside surface of the hole.

Step 3: Install the new sight glass from

OIL

LEVEL

NEW STYLE

SIGHT GLA S S

the outside. The hole position does not

matter with the new style sight glass.

Step 4: With the wood block covering

the sight glass, tap the sight glass into

place. Replace the cover on the pump.

Troubleshooting: Poor Pull Down

Possible cause: Check oil level

Possible cause: Missing or damages seals or o-rings

In order for your pump to pull to a near perfect vacuum, oil must be clean and

moisture-free throughout evacuation.

Step 1: With isolation valve closed, start pump. Oil level should be to the top of

the oil level line embossed on the front of the pump’s cover. Just a teaspoon low

can affect the ultimate vacuum.

Step 2: Flush pump and refi ll with fresh oil. See Cleaning and Testing Pump

Section for review.

Step 3: Check all connections to pump and system for damaged or missing orings. If brass adapters are being used, make sure copper gaskets are in place.

READ THE INSTRUCTION MANUAL FOR PROPER

START UP AND SHUT DOWN PROCEDURES.

OPEN

Step 1: Close blank-off valve.

Step 2: Open gas ballast valve.

Step 3: Run 2 to 3 seconds.

Step 4: Shut pump off.

PAUSE

POSITION

CLOSED

POSITION

POSITION

Step 5: Close gas ballast valve.

NOTE: See previously discussed topic “Breaking Vacuum”

Troubleshooting: Motor Just Hums

Possible Cause: If pump has been dropped, the armature in motor may be out of

alignment with the motor’s bell housing.

Step 1: Set pump on bench with motor standing up (Figure 3 of this booklet)

Step 2: Loosen the four motor bolts

Step 3: Shake motor and re-tighten motor bolts

Step 4: Start pump.

If this doesn’t work, the pump most likely will need to be sent in for repair.

Troubleshooting: Motor Runs but No Suction

Possible Cause: Flexible coupler is either broken or loose.

Step 1: Set pump on bench with motor standing up (Figure 3 of this booklet)

Step 2: Look between motor and pump housing from the bottom to see if the

fl exible part of the coupler is split or broken. If it is broken, see “Flexible Coupler” section of this booklet. If the coupler is not broken, the coupler may be

spinning on either the shaft to motor or cartridge.

Step 3: Go to www.jbind.com and on the tool bar go to Technical. Select

instruction sheets from the drop down menu and go to cartridge replacement instructions. These instructions are good for replacing: fl exible couplers, motors,

shaft seals, and cartridges.

Page 9

Cross reference of Vacuum Measurements

Boiling Temperatures of Water at Converted Pressures

Temp. F°

212

205

194

176

158

140

122

104

86

80

76

72

69

64

59

53

45

32

21

6

-24

-35

-60

-70

-90

Microns

759,968

535,000

525,526

355,092

233,680

149,352

92,456

55,118

31,750

25,400

22,860

20,320

17,780

15,240

12,700

10,160

7,620

4,572

2,540

1,270

254

127

25.4

12.7

2.5

0.00

Inches of Hg

Vacuum

0.00

4.92

9.23

15.94

20.72

24.04

26.28

27.75

28.67

28.92

29.02

29.12

29.22

29.32

29.42

29.52

29.62

29.74

29.82

29.87

29.91

29.915

29.919

29.9195

29.9199

29.92

Pressure

Pounds Sq. In.

14.696

12.279

10.162

6.866

4.519

2.888

1.788

1.066

0.614

0.491

0.442

0.393

0.344

0.295

0.246

0.196

0.147

0.088

0.049

0.0245

0.0049

0.00245

0.00049

0.00024

0.00005

0.00000

JB Industries

Technical Support

800-323-0811

www.jbind.com

Form 10710-308

© 2009 JB Industries

MADE IN THE USA

Loading...

Loading...