DV-29

MICRON GAUGE BLANKOFF TEST UNIT INSTRUCTIONS

TM

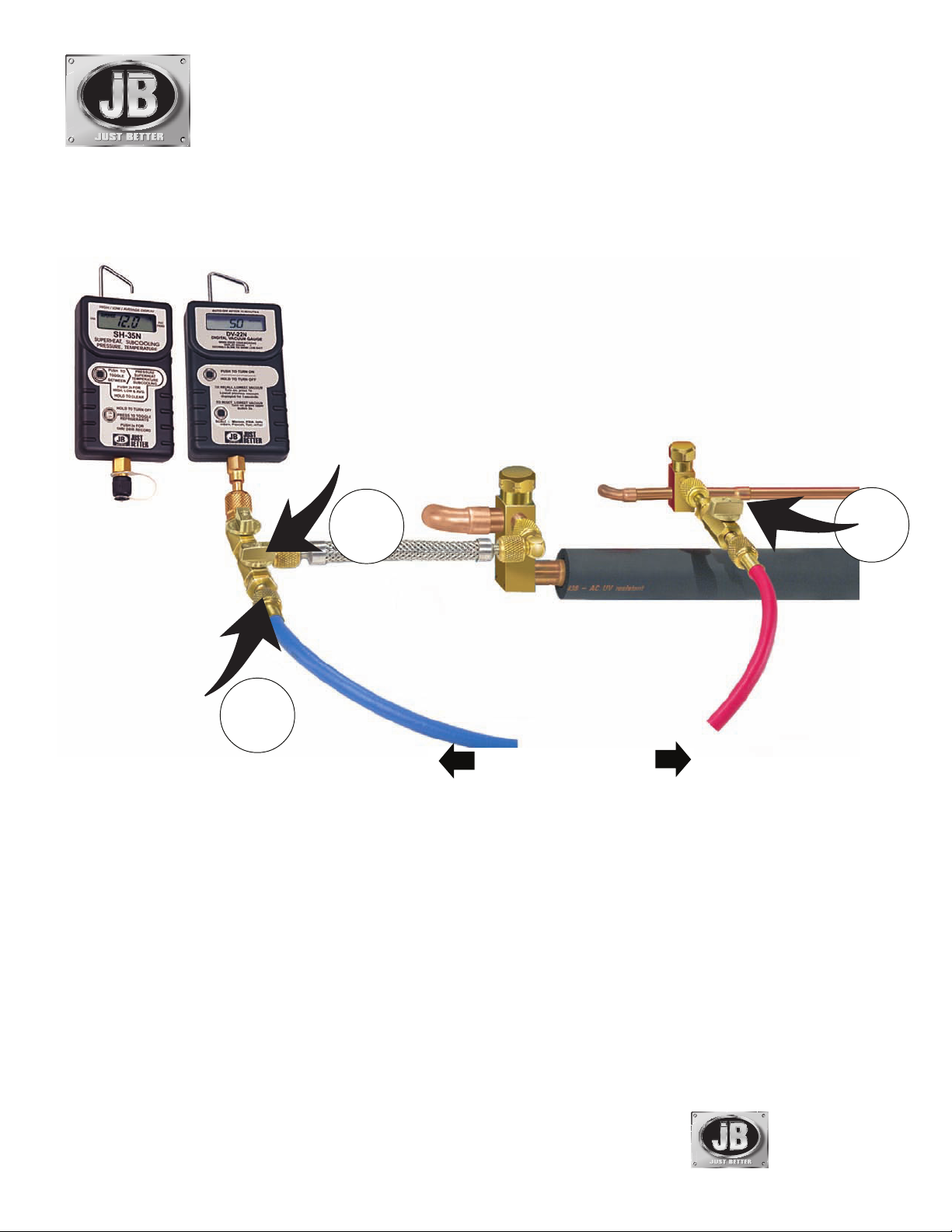

Valve position pictured for Pressure Rise Test.

Valve "A" to micron gauge is open and valves

from manifold to "B" and "C" are "closed".

When charging,

close this valve.

Most micron

gauges will not

withstand high

pressure.

A

Suggested Application

When Charging Using

Superheat Method:

With Valve "A" closed,

remove Micron Gauge

and attach Superheat

Gauge. Bleed at

Quick Coupler before

charging.

B

Before making connection as pictured, close all Ball

Valves before hookup. NOTE: If micron gauge has 1/4"

male flare, use D10244 O-ring Swivel Coupler included.

Leak-Proof Test Unit

Deep vacuum has it own unique properties which requires

leak-proof design in all the components including couplers

and hoses. DV-29 unit with flexible metal hose and O-ring

seal couplers is absolutely vacuum tight.

Pulling a Vacuum

Open all valves and pull a vacuum. When the sensor

reads between 300 and 400 microns and only if

compressor is in the vacuum, close valves to the high and

C

Hoses to Manifold

low side of the system, leaving the valve closest to the

micron gauge open. You now have the micron gauge

within the system to check for pressure rise.

Pressure Rise Test

Wait for at least 5 to a maximum of 20 minutes to allow

system pressure to equalize. The reading you see at the

end of this test will be very close to what you actually

have in the system. A rapid rise during this test to

atmospheric pressure indicates a leak, while a slower rise

to around 1500 microns indicates moisture is present.

Form No. 10729-308

JB INDUSTRIES

630.851.9444

Printed in USA

© 2007 J/B Industries Inc.

Loading...

Loading...