Page 1

OPERATION

1. Push square button to turn gauge on. If unit does not

display any characters, check to be sure batteries are

correctly installed. The start-up display will show the

letters “

the overrange indicator “ 1”.

2. Push the lower square button to select the desired

display units. The gauge will save the selected unit

and use that unit every time the gauge is turned on.

3. The micron gauge power saver feature automatically

turns the gauge off after 10 minutes. To continue,

repress the start button;

followed by the current reading.

J:B ” followed by either the micron value or

J:B will be displayed

LOW BATTERY INDICATOR

If 3 blinking decimal points are displayed, the

battery is low. Replace with 9 volt battery.

CLEANING VACUUM SENSOR

Fill vacuum hose connection fitting half full with

alcohol. Replace cap. Gently shake the gauge to allow

the alcohol to rinse the inside of the sensor. Remove

cap and pour out the alcohol. Turn gauge upside down

and allow the vacuum sensor to dry for 20-30 minutes

before using gauge or replacing cap.

WARRANTY

DV-22N is warrantied for 12 months after manufacture date. The warranty covers a 6 month over-thecounter return with the balance covering repair only.

Misuse or damage from impact, etc. are not covered.

For repair, return the complete unit to your local wholesaler. In warranty items must have a copy of the invoice

included.

Operating Instructions

DV-22N

Digital Micron Gauge

• Reads Vacuum In 7 International Units: Microns,

PSIA, InHg, mBars, Pascals, Torr, mTorr

• 25 to 12,000 Microns Vacuum Range

• Uses 9V Alkaline Battery (not included)

TESTING VACUUM PUMP

It is a good idea to attach the micron gauge to the

vacuum pump before evacuation to make sure the pump

pulls down to at least 50 microns. If it doesn't, your pump

is contaminated and the oil should be changed. Do not

shut-off the blank-off valve on the pump and expect the

gauge to hold a vacuum as the gauge will fall back to

atmosphere. The reason for this is that the sensor is too

close to the pump and the gauge's sensor doesn't have

time to equalize.

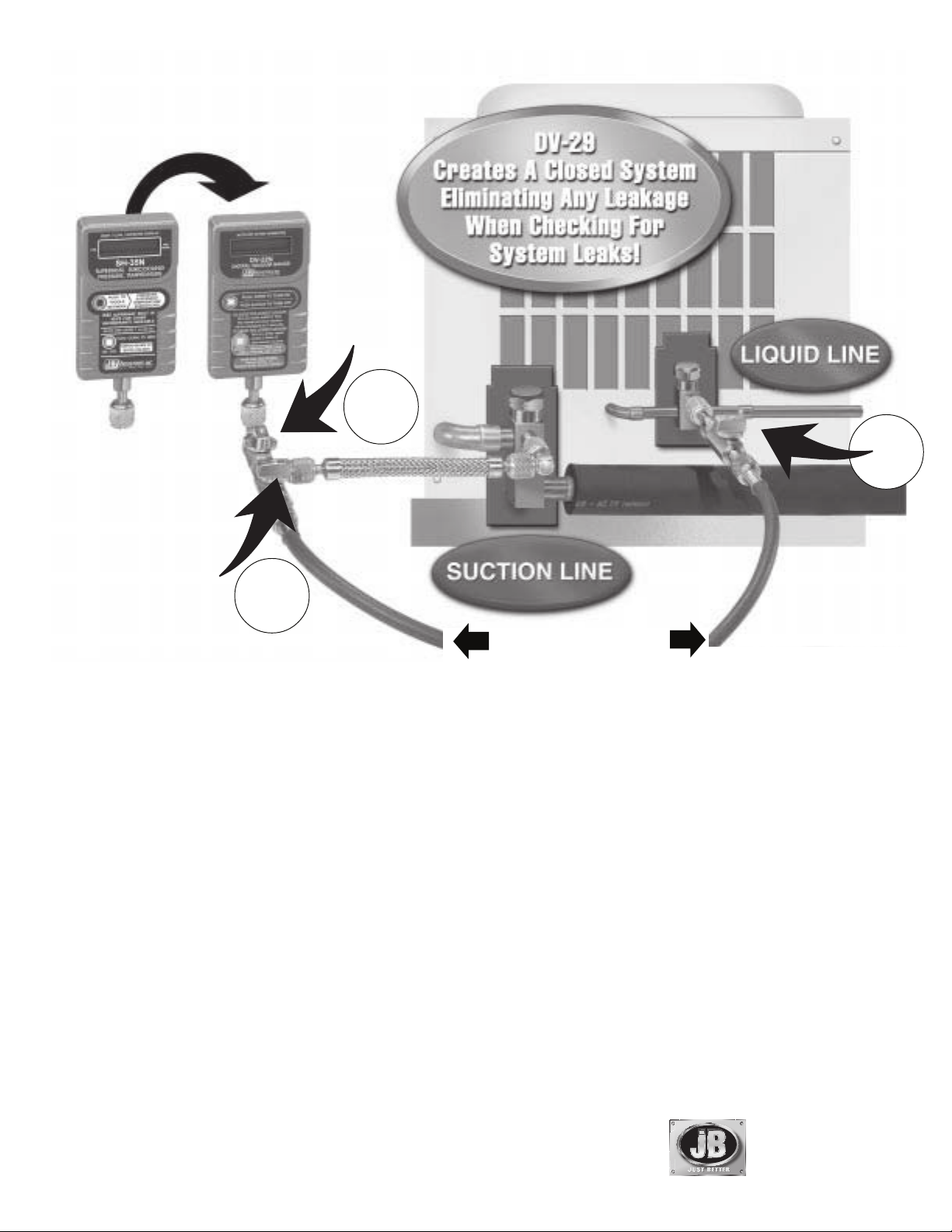

DV-29 HOOK-UP

The most leak-proof setup is by using the DV-29 (see

page 2) which works with all micron gauges. This unit

creates a closed system eliminating any leakage under

deep vacuum.

The DV-29 test unit eliminates other problems when

attaching the micron gauge into the system. If the micron

gauge is attached directly to the vacuum pump or with 3'

dedicated hose, we will get a lower reading as the gauge

is sensing what the pump is doing and not what the

pump is doing to the system.

GENERAL MICRON GAUGE HOOK-UP

When designing your hook-up system, choose from

the following hoses, valve and coupler designed for leakproof service in a deep vacuum environment.

1. D10436 or D10427 1/4" Metal Hose and D10636 or

D10660 3/8" Metal Hose with o-ring couplers. Your

hook-up through manifold, pump and if desired, to the

micron gauge.

2. A34000 Quick Coupler Tee w/o-ring seal. Since the

most accurate reading is obtained at the compressor's

high or low side, use to tee-off the gauge.

3. D10162 ball valve with O-ring quick coupler to valve

off gauge before charging. Depending on the gauge, it

should be remembered that the electronic gauge's

sensors will not take pressure beyond 1 to 100

pounds. Depending on hook-up, use with metal hose

or A34000 coupler.

Page 2

Valve position pictured for Pressure Rise Test.

Valve "A" to micron gauge is open and valves

from manifold to "B" and "C" are "closed".

When charging,

close this valve.

Most micron

gauges will not

withstand high

pressure.

A

Suggested Application

When Charging Using

Superheat Method:

With Valve "A" closed,

remove Micron Gauge

and attach Superheat

Gauge. Bleed at

Quick Coupler before

charging.

B

Before making connection as pictured, close all Ball

Valves before hookup.

male flare, use D10244 O-ring Swivel Coupler included.

Leak-Proof Test Unit

Deep vacuum has it own unique properties which

requires leak-proof design in all the components including couplers and hoses. DV-29 unit with flexible metal

hose and O-ring seal couplers is absolutely vacuum tight.

Pulling a Vacuum

Open all valves and pull a vacuum. When the sensor

reads between 300 and 400 microns and only if compressor is in the vacuum, close valves to the high and

low side of the system, leaving the valve closest to the

micron gauge open. You now have the micron gauge

within the system to check for pressure rise.

NOTE: If micron gauge has 1/4"

C

Hoses to Manifold

Pressure Rise Test

When the sensor reads between 300 and 400 mi-

crons,

DV-29 Method. Blank-off the high and low side ball

valves attached to the system.

General Hookup Method. This includes using copper

tubing or metal hose to the high and low side. Close

blank-off valve on the pump. This will isolate the gauge

from the pump.

Wait for at least 5 to a maximum of 20 minutes to

allow system pressure to equalize. The reading you see at

the end of this test will be very close to what you actually

have in the system. A rapid rise during this test to atmospheric pressure indicates a leak, while a slower rise to

around 1500 microns indicates moisture is present.

JB INDUSTRIES

630.851.9444

Printed in USA

© 2007 J/B Industries Inc.

Loading...

Loading...