Just Better Deep Vacuum Pump Cartridge User Manual

REPLACING MOTOR

Loosen 4 Motor Bolts. Lift Motor Off.

(Do Not Remove Bolts)

Trap

Loosen Coupler

Setscrew

On Motor Shaft

1. With pump standing on oil

cover, rotate coupling so set

screws are facing trap assembly opening. Re-install motor

while aligning at side of motor

shaft with set screw.

IMPORTANT

ASSEMBLE IN THIS ORDER

a. Tighten four (4) motor screws

and then

b. Tightened coupler set screw

on motor shaft.

2. Re-install foot mounting bracket

and rubber feet.

Part # Replacement For

D10043 DV-42 obsolete

D10086 DV-3 & DV-85C obsolete

D10087 DV-85 obsolete

D10128 DV-5 & DV-127 obsolete

D10143 DV-142 (4 Digit Serial No.) obsolete

PR-202 DV-85N

PR-203 DV-142N

PR-204 DV-200N

PR-212 DV-42N

PR-214 DV-285N

PR-302 DV-85N (Manufactured after January, 2000)

PR-303 DV-142N (Manufactured after January, 2000)

PR-304 DV-200N (Manufactured after January, 2000)

PR-305 DV-42N (Manufactured after January, 2000)

PR-314 DV-285N (Manufactured after January, 2000)

Should you need further assistance call our toll

free Technical Service number 1-800-323-0811.

Visit our web site at: www.jbind.com

E-mail: sales@jbind.com

JB INDUSTRIES

Aurora, IL 60507 U.S.A.

BEFORE OPERATING

1. Be sure pump switch is in “Off”

position and plug in.

2. Open oil drain and intake cap.

While pump is running, immediately place 2 or 3 ounces

of fresh oil into intake and run

pump for 3 or 4 seconds. Repeat procedure at least 2 times.

Allow oil to drain out.

3. Close oil drain and replace

intake cap.

4. Fill with fresh FastVac Deep

Vacuum Pump oil to top edge of

oil level line. For those pumps

without line, the correct level is

1/8" below top of sight glass.

Replace oil ll plug.

5. Run Vacuum Test.

© 2008 J/B Industries, Inc.

Form #10086-308/1M

Printed in U.S.A.

Replacement Instructions

for Deep Vacuum Pump Cartridge

NOTE: Instructions pertain to

all pump series. Pump

styles may vary from illustrations.

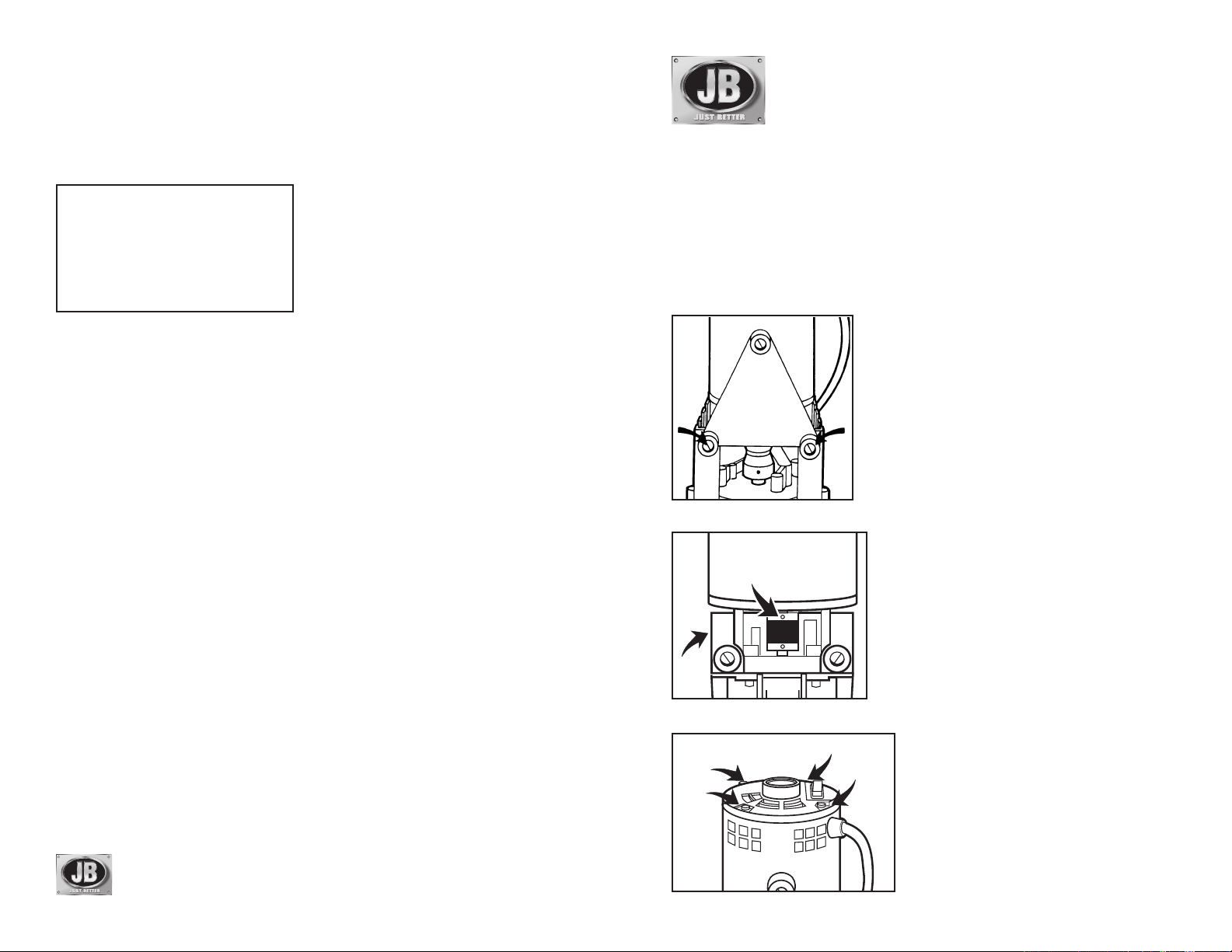

FIG. 1

(Models

with Foot

Mounting

Bracket

only)

FIG. 2

Cartridge kit also contains 2

new O-rings, 1 cover gasket

and shaft seal. Before replacing

cartridge, be thoroughly familiar

with Replacing Pump

Cartridge procedures.

You will need the following tools:

Hammer

Medium Screwdriver

5/32" and/or 1/8" and 3/16"

Allen Wrench

11/16" Socket Head

3/8" or 7/16" Wrench or socket

Thread sealant

Vaseline or grease

DRAIN OIL

REMOVING MOTOR

1. Stand pump on oil cover. If

pumps has foot mounting

bracket, remove unit by loosening foot screws.

(FIG. 1)

2. Turn coupling until setscrews

are facing you. With 5/32" or

1/8" Allen wrench (depending

on model) loosen setscrew on

motor shaft. (FIG. 2) Loosen

four (4) motor thru bolts (FIG.

3). Remove motor. DO NOT

REMOVE BOLTS FROM MOTOR AT ANY TIME.

If old cartridge is frozen, i.e.

coupler will not turn, remove

oil cover (FIG. 4) and four (4)

cartridge bolts (FIG. 5). By

turning cartridge, coupler will

rotate into position.

3. Loosen setscrews on coupler

and remove coupling.

(FIG. 2)

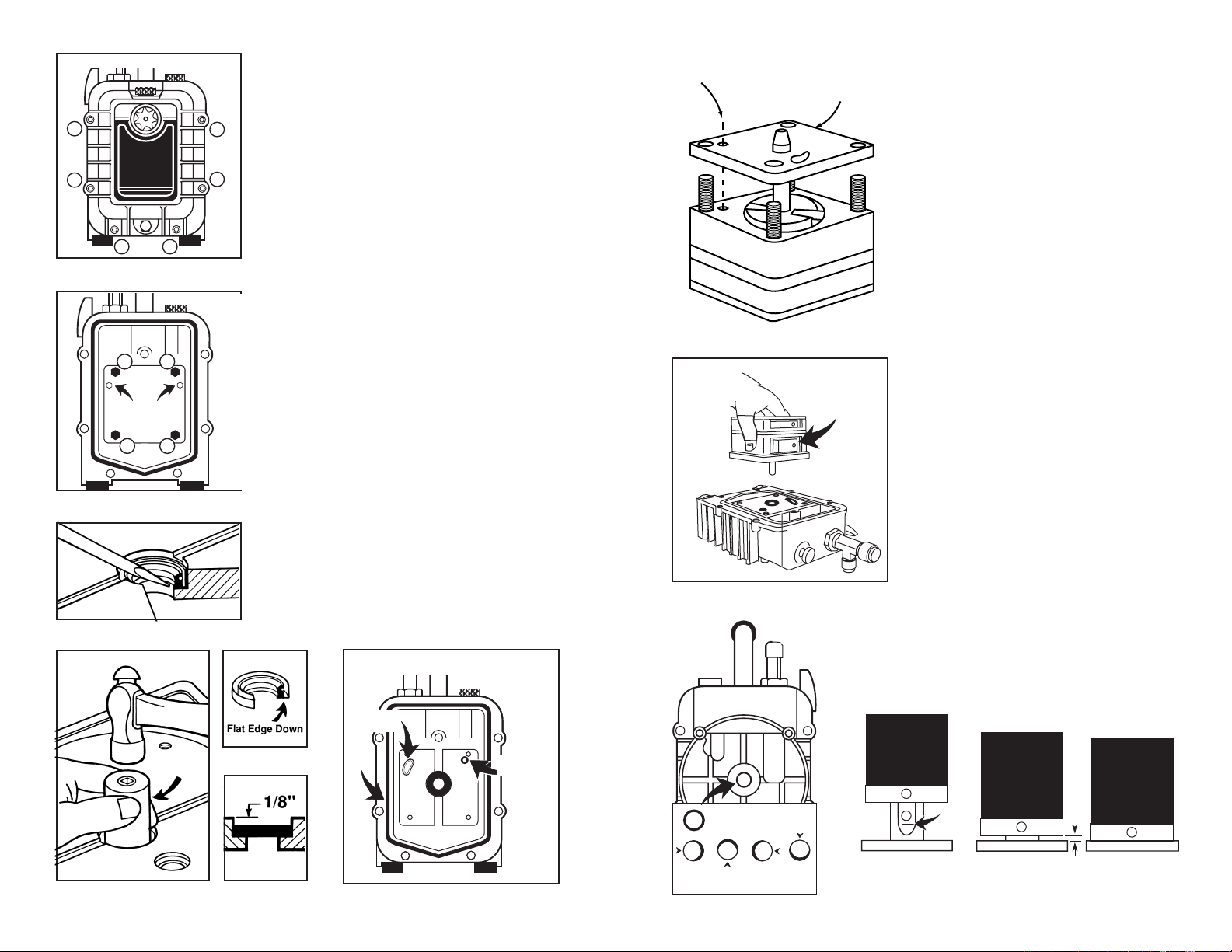

FIG. 3

FIG. 4

1/8"

Bottom

Of Flat

OIL LEVEL

1

2

3 4

5

6

Cover

Seal

Intake

O-Ring

Gas Ballast

O-Ring

Do not disturb

hex setting

screws

1 2

4 3

FIG. 5

FIG. 6

REMOVING OIL COVER

1. Using 3/16" Allen wrench remove

6 socket head cap screws from

oil cover. (FIG. 4)

REMOVING CARTRIDGE

1. Remove 4 cartridge screws (7/16"

or 3/8" wrench) (FIG. 5). Discard

old gasket seal and 2 O-rings

along with cartridge and bolts.

REPLACING SHAFT SEAL

AND O-RINGS

1. Insert screwdriver blade under

shaft seal and pry the seal from

the housing being careful not to

damage the walls or face of the

trap. (FIG. 6)

2. With clean rag remove all oil and

residue from inside hole and front

and back of trap.

3. Lay trap on at surface with

handle toward you. Press new

shaft seal with at side down into

opening by hand. To seat, tap

seal with 11/16" socket. Seal is

properly seated 1/8" down from

top edge (FIG. 7). Apply vaseline

or grease to inside edges of seal.

4. Insert intake and gas ballast

O-rings in trap (FIG. 8). Gasket

replaced after cartridge is

installed.

Align

Gas Ballast

Holes

FIG. 9

FIG. 10

If new intake plate on

cartridge differs from the

old intake plate use the old

intake plate.

Intake

Valve

REPLACING

PUMP CARTRIDGE

Read section carefully before attempting replacement.

1. Keep trap at on bench. Remove

holding nuts from cartridge,

keeping all parts in alignment.

(Four nuts can be discarded.)

Cartridge is held with shaft down

and utter valves facing intake tting. Center shaft with seal opening. (FIG. 9) Align with threaded

holes and place in position. Hand

tighten four bolts. Cross tighten

with 7/16" wrench.

2. Check alignment by rotating shaft

with coupler. If shaft moves freely

continue assembly. If shaft binds,

loosen bolts and turn shaft until

shaft rotates freely. Retighten

bolts. Shaft should be concentric

with shaft hole when viewed from

backside. (FIG. 10)

3. Replace gasket (FIG. 8) and reinstall oil cover to trap. (FIG. 4)

4. Remove setscrews on coupler.

Coat setscrew threads with

thread sealant. Re-install cou-

pling to pump cartridge with set

screw facing at side of shaft .

Tighten screw so coupler slides

on shaft but stops at bottom of

at. Tighten until screw head is

ush with coupler. Coupler should

be approximately 1/8" off trap

surface. (FIG. 11)

FIG. 7

11/16"

socket

FIG. 8

Shaft Aligned

Correctly

Shaft Touching Edge

Of Trap Hole

Bottom of Flat Correct Incorrect

FIG. 11 (Coupler styles may vary from illustration.)

Loading...

Loading...