Page 1

DEEP VACUUM

Its Principle and Application

With deep vacuum, we are sure of our results before we

leave the job. No more waiting to see if we get a call back to

determine the results of our work. Deep vacuum is the only

method we can use to tell us, for sure, that a system is

thoroughly dry and free of noncondensables and leaks.

Measuring Evacuation– Microns Or Inches?

A micron is a measurement of pressure starting

from a perfect vacuum (no pressure) expressed in linear

increments. One inch equals 25,400 microns. It should

be noted at this point that when we discuss vacuum in

terms of microns, we are referring to total absolute

pressure as opposed to gauge pressure. Besides using

a more accurate unit of measure (you can’t read frac-

tions on a bourdon tube type gauge),

we are also starting from the same

So what’s

a micron?

29" 30"

1/25,400

of an inch

Pumps And How To Select Them

Deep vacuum pumps are the first item to come to

mind when we think of vacuum tools. Unfortunately the

first mistake is usually made in the selection of these

pumps with reasoning that goes like this— “The larger

the pump I get, the faster I can do the job.” Pump

capacity has very little to do with evacuation time in

refrigeration systems, as is easily seen when we

examine the following.

The refrigeration system itself is constructed of

several feet of small diameter tubing with return bends

and metering devices to offer restriction during evacuation. Compound this with the fact that service valves,

measuring point (theoretical perfect

vacuum).

The bourdon tube type gauge, you

will also remember, uses atmospheric

pressure as its reference point, which

is constantly changing during the day.

The weather forecaster always includes this reading, barometric pressure, along with the temperature.

When an area is covered by a HIGH, it

translates into high barometric pressure and vice versa for a LOW.

Visit us at our website: www.jbind.com

when provided, have 1/4" male flare ports which only

have a 3/16" orifice.

We also know that the only way to get more flow

through a given orifice is by increasing the pressure

across that orifice. But does a pump create pressure

that increases the flow? No. We tend to forget two basic

principles. A vacuum pump creates a void toward which

the system pressure flows. The second point is that as

pressure decreases in the system during evacuation,

flow decreases. Therefore, it’s impossible for us to

increase pressure or flow through our gauge ports with

a larger pump.

Pumps in the 1-1/2 to 10 CFM class are adequate

to handle 99% of our work. As a rule of thumb, the CFM

rating squared equals the maximum system tonnage. A

7 CFM pump is rated for 49 tons; 3 CFM pump is rated

for 9 tons. They are all that should be purchased for

service and installation. In many cases, depending on

the system line sizes of large tonnage systems, it is

better to put two or more of the small, easily handled

pumps at different locations. This will overcome some of

the pressure drop problems and actually be faster than

a single large pump.

Pump Construction

Rotary vane deep vacuum pumps are readily

available and are best suited for our work. Piston type

pumps, because of the clearance necessary between

piston and head, are incapable of producing a deep

vacuum or at best are very inefficient. Many single stage

compressors, similar to a hermetic compressor will not

evacuate a system into a micron range, the last inch of

pressure on the compound gauge, nor will it condense

any moisture vapor in the system.

Two stage pumps (2 pumps in series) have the best

record in our business because they are capable of

producing consistently lower pressures and are

much more efficient when removing moisture

vapor. The pump should be equipped with a

blankoff valve which allows us to perform the

isolation test (pressure rise) which is required in

deep vacuum procedures.

The gas ballast feature should be on all

pumps for refrigeration. At the beginning of

evacuation, water vapor is quickly removed and if

a system is laden with moisture, can very quickly

contaminate the oil. Through the gas ballast, a

fine metering valve connected to the second

stage of the pump, a small amount of relatively

Page 2

dry ambient air is admitted to help prevent the moisture

vapor from condensing in the oil.

So far, we have defined our pump requirement as

follows: 2-stage, rotary vane; blankoff valve; gas ballast

valve; 1-1/2 to 10 CFM. A system is evacuated to

between 300 and 400 microns so obviously these

pumps should be able to produce vacuum in the low

micron range with a safety factor of at least 25 microns

total absolute. Thus, the pump should be able to achieve

vacuum readings of at least 25 microns total absolute.

We should also look for light weight and rugged construction because we all know the vacuum pump will be

at our side as we climb those ladders to the roof top.

Finally, when checking out pumps, look at safety.

Belt driven units should never be used without belt

guards—if you don’t give a darn about your own fingers,

etc., give children and others exposed a chance.

Hospitals and court rooms around the world are full

because of this negligence.

The Electronic Vacuum Gauge

Coupled with good procedures which we will get

into later, the electronic gauge tells

1

0

us positively that we have a

noncondensable and a leak free

ATM

Last Inch

Of Pressure

0

1

0

2

0

system. In general these gauges are

heat sensing devices, in that the

sensing element which is mechani-

3

0

cally connected to the system being

evacuated generates heat. The rate

at which this heat is carried off

The last inch of

pressure, as

indicated on the

compound

gauge is 25,400

microns.

changes as the surrounding gases

and vapors are removed. Thus, the

output of the sensing element (either

thermocouple or thermistor)

changes as the heat dissipation rate

changes. This change in output is

indicated on a meter which is

calibrated in microns of mercury.

Evacuation is complete when a system holds at 500

microns. The compound gauge only indicates that a

vacuum is being produced. The vacuum gauge on the

other hand, is the only tool for accurately reading that

low pressure.

Vacuum Gauge

Selection And Accuracy

The most important feature of all is range. If the

micron gauge only indicates from 50 to 1,000 microns,

The electronic vacuum gauge

is the least purchased deep

vacuum tool. Yet, without

this instrument you might

just as well forget about

deep vacuum

altogether.

Battery

Battery/Electeric

you will not be able to determine whether you are

pumping against a leak or against moisture. Look for an

instrument that reads from 50 microns to at least

9,000 microns.

A digital display with easily read numbers gives you

instant and continuous readout, whereas a gauge with

color-coded lights, displays the reading “within a range”

of microns. You have a “wait” period to see whether the

system is going up or down in microns.

Portable micron gauges typically operate from

battery power and should have a low battery sensor.

Some models have AC adaptor capability so you won’t

run out of power on the job.

Another feature to look for is a sturdy case to

protect the instrument. Finally, when you buy instruments of this type, remember that you are really only

buying answers, and the instrument should give you

these answers quickly and accurately. You get paid for

adjusting refrigeration systems, not your tools.

As already noted, we are talking about accuracy

when we talk about micron type gauges. Gauge accuracy is affected by two factors. Extreme temperatures

especially with exposure to the summer sun on a hot

roof top or pavement and sensor contamination.

The vacuum sensor is factory calibrated on air. If

refrigerant gas or oil is drawn into the vacuum sensor of

a remote reading unit or unit connected to the pump

during the system evacuation, the gas will cause an

erroneous reading. Any oil entering into the vacuum

sensor via hose will also affect gauge accuracy. Improper shut down of pump after evacuation and loss of

power will suck back oil and contaminate the hose and

micron gauge.

A hose used for charging or testing will contain

droplets of system oil spurted into the hose when the

schrader valve is opened. If this same hose is used on

the hookup to the gauge, oil will collect in the gauge

sensor. This can be prevented by using a dedicated

hose, preferably O-Ring type, for evacuation.

Evacuate Through The Gauge Manifold

Evacuate through the gauge manifold if, and only if,

it is O-ring sealed, piston construction. Other types leak

under vacuum. Next look at the design of the center

port. In order to handle the full capacity of both the high

and low side, the center intake should have double size

flow path throughout its length. All J/B 1/4" manifolds

have this feature. We suggest the fitting be replaced with

a 3/8mf x 1/8mp. You will now have a fulll flow

3/8" to the vacuum pump. You also have the

option of using the M4-Series manifold which is

designed to evacuate, charge or test a system

without disconnecting hoses and features

a 3/8" fitting.

Leak-Proof Hook-up

Deep vacuum has it own unique properties

which requires leak-proof design not only in the

manifold but in all components. The only connecting lines that are absolutely vacuum tight are

soft copper tubing or flexible metal hose. Charg-

Page 3

ing and testing hoses are designed for pressure. Even

with the advanced technology of today's hoses, permeation through the hose compound still exists. When

checking pressure rise, the atmosphere will permeate to

the lower pressure in the hoses and the micron reading

will slowly rise.

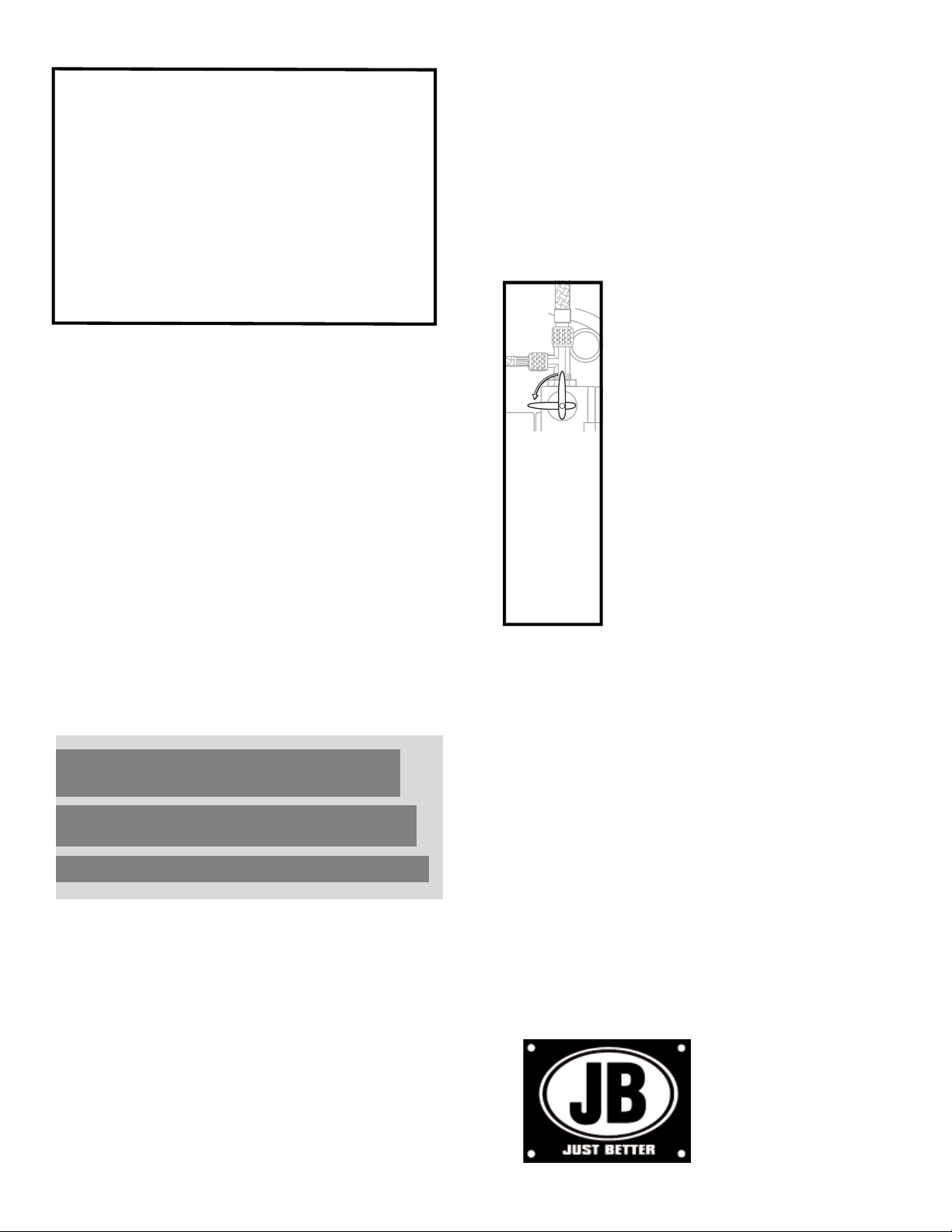

Another source of leakage is the gasket seal in

valve and hose

couplers. This seal is

designed for charging

and will not give a

Deep Vacuum

O-Ring Coupler Cut-Away

perfect seal required

in deep vacuum

service. An O-ring

seal coupler, such as

that made by J/B,

forms around irregularities in the flare

fitting. When the

coupler is screwed

down, we get a metal

Flare

Fitting

Specially

Designed

Groove

Locks

O-Ring In

Place

45°

Positive

Stop

to metal seat and the

o-ring lays around

the lip of the flare to give a positive seal.

blank-off valve on the pump and expect the gauge to

hold a vacuum as the gauge will fall back to atmosphere. The reason for this is that the sensor is too

close to the pump and the gauge's sensor doesn't have

time to equalize.

Most Leak-Proof Micron Gauge Hook-up

The most leak-proof setup is by using the DV-29.

This unit creates a closed system eliminating any

leakage under deep vacuum.

DV-29 Micron Gauge Hook-Up

Connecting Lines

We have now covered the simplest hookup to this

point; gauge

J/B Piston Type Manifolds

manifold with

two 1/4" I.D.

connecting

lines to the

1

2

3

1. Stem seats retract completely

from flow path.

2. Double size flow path throughout length of center port.

3. Convert to 3/8" port with 3/8mf x

1/8mp

system and a

3/8" connection

to the pump via

line or fittings.

Much has been

said and

written regarding line size,

which would

lead us to

believe the

bigger line we connect, the faster job we’ll do. This

would be true except for the compressor’s service

valves 3/16" orifice. Therefore, we only need to keep the

connecting lines’ I.D. larger than 3/16" This is one of the

limiting time factors in evacuation.

Evacuation should always be done from both the

low and high sides of the system. This could save as

much as 3/4 of the time when evacuating from only one

side. Short connecting lines will save some time;

however, not nearly what some maintain. In relation to

the lengths of tubing in the system, we add very little

restriction via connecting lines.

Before You Start

It is a good idea to attach the micron gauge to the

vacuum pump to make sure the pump pulls down to at

least 50 microns. If it doesn't, your pump is contaminated and the oil should be changed. Do not shut-off the

Hoses to Manifold

1. Works with all micron gauges

2. No additional equipment needed

3. Leak-proof components

The DV-29 test unit (see illustration) eliminates

other problems when attaching the micron gauge into

the system. If the micron gauge is attached directly to

the vacuum pump or with 3' dedicated hose, we will get

a lower reading as the gauge is sensing what the pump

is doing and not what the pump is doing to the system.

General Micron Gauge Hook-up

When designing your hook-up system, choose from

the following hoses, valve and coupler designed for

leak-proof service in a deep vacuum environment.

1. D10436 or D10427 1/4" Metal Hose and D10636 or

D10660 3/8" Metal Hose with o-ring couplers. Your

hook-up through manifold, pump and if desired, to the

micron gauge.

2. A34000 Quick Coupler Tee w/o-ring seal. Since the

most accurate reading is obtained at the

compressor's high or low side, use to tee-off the

gauge.

3. D10162 ball valve with O-ring quick coupler to valve

off gauge before charging. Depending on the gauge,

it should be remembered that the electronic gauge's

sensors will not take pressure beyond 1 to 100

pounds. Depending on hook-up, use with metal hose

or A34000 coupler.

Page 4

Dispelling The Argument Of

“No Deep Vac On Heat Pumps, Etc.”

The word “sublimation,” the ability of moisture

to go directly from solid ice to vapor without

passing through a liquid state, is commonly used in

vacuum. This phenomenon is observed when the

wash is hung out in the winter and freezes solid.

Still, in time it dries due to sublimation (drying). If

lines are in a cold ambient, it is possible to have

ice in the system. It will be removed during

evacuation. Of course, the addition of heat (heat

gun only) at these cold spots speeds up the job.

Pressure Rise Test

We previously mentioned that the only difference

between deep vacuum and the methods of the past is

that we can measure what we have done. This is called

the Pressure Rise Test.

When the sensor reads between 300 and 400

microns,

DV-29 Method. Blank-off the high and low side ball

valves attached to the system.

General Hookup Method. This includes using

copper tubing or metal hose to the high and low side.

Close blank-off valve on the pump. This will isolate the

gauge from the pump.

Wait for at least 5 to a maximum of 20 minutes to

allow system pressure to equalize. The reading you see

at the end of this test will be very close to what you

actually have in the system. A rapid rise during this test

to atmospheric pressure indicates a leak, while a slower

rise to around 1500 microns indicates moisture is

present.

READINGS AFTER 5-20 MINUTES

Evacuation Brings Out The Worst In A System!

Remember, hydrofluoric and hydrochloric acids, and their

pal, moisture, do collect in the oil. Having nothing but time

on their hands, they effectively destroy pull down and act

as an abrasive on internal surfaces. If left sitting in an idle

pump, these culprits keep busy by rusting and corroding

internal surfaces. Deep vacuum pumps need a fill or two

for every job.

In order for your pump to pull a near perfect

vacuum, oil must be clean and moisture free throughout evacuation. Just

take a few minutes during and after

each job to drain, flush and refill. Keep

your pump running at peak performance and maintenance free for years

to come.

Always store your vacuum equip-

ment plugged or capped to prevent

Preventing

“Hard

Start-Up”

After closing

the isolation

valve, open

the gas

ballast valve

and shut the

pump off.

contamination due to condensation

and dirt. Because a slight cut or dirt on

the o-ring seals can cause leaks, the

mating flare fitting faces should be

wiped and checked for damage before

hookup. Vacuum pump oil makes a

fine lubricant at these connections.

Under

500 Microns

Slow Rise To

1500 Microns

Evacuation Complete

Moisture

Rapid Rise To ATM Leak

There are many evacuation level recommendations

including the statement “evacuate the system to below

200 microns.” This should not be considered. Note we

say “system” because it is possible to evacuate piping or

some component other than the compressor to below

this level. Refrigeration oil has a vapor pressure and by

going below 200 microns, you will degas particles of the

refrigeration oil. By changing the makeup of the oil, it will

no longer be a true lubricating oil.

Printed in U.S.A.

2007 JB Industries Inc.

JB Industries

PO Box 1180

Aurora, IL 60507-1180

www.jbind.com

e-mail: Sales@jbind.com

Technical Assistance

800.323.0811

Loading...

Loading...