Page 1

ARI Standard 720-97

Refrigerant Access Valves and Hose Connectors

TM

Section 1. Purpose

Purpose.

1.1 . The purpose of this standard is to

establish, for refrigerant access valves and hose

connectors used in refrigerating and air-conditioning

systems; definitions, location requirements, dimensions

and materials, gaging procedures and conformance

requirements.

1.1.1

guidance of the industry, including manufacturers,

engineers, installers, contractors and users.

1.2

Review and Amendment

to review and amendment as technology advances.

2.1

Scope

refrigerant access valves and hose connectors as

defined in Section 3.

2.1.2

valves and hose connectors intended for use with

halogenated hydrocarbon refrigerants.

3.1

Definitions.

the standard industry definitions in the current edition

of

ASHRAE Terminology of Heating, Ventilation, Air

Conditioning and Refrigeration

defined in this section.

3.2

Refrigerant Access Valve

valve is a normally closed valve containing a refrigerant

valve core incorporating a SAE external flare

connection means and used for the purpose of

servicing refrigeration or air conditioning systems.

3.3

Refrigerant Access Valve Body

access valve body is a special fitting machined such

that is provides the external details of a SAE flare

connector and internal details to permit the insertion of

a refrigerant valve core.

3.4

Refrigerant Access Valve Hose Connector

refrigerant access valve hose connector is a modified

SAE internal threaded flare connector suitable for

sealed attachment to a refrigerant hose and containing

a flare sealing gasket and a depressor to automatically

depress the valve core pin as the connector is

threaded on the access valve external flare connection.

This standard is intended for the

Intent.

. This standard is subject

Section 2. Scope

. This standard applies to 1/4 in. SAE flare

Refrigerant

Section 3. Definitions

. This standard applies to access

. All terms in this document will follow

unless otherwise

. A refrigerant access

. A refrigerant

. A

3.5 Refrigerant Valve Core.

an assembly containing a spring and moveable core

pin and seating details, suitably threaded for insertion

into a refrigerant access valve body to provide a

normally closed valve arrangement intended for use

with a refrigeration or air conditioning system.

Depression of the core pin opens the valve.

3.6

"Shall", "Should", "Recommended", or "It Is

Recommended". "Shall", "should", "recommended", or

"it is recommended"

3.6.1

Shall

a provision specified, that provision is mandatory if

compliance with the standard is claimed.

3.6.2

Should, Recommended, or It is

Recommended

recommended" is used to indicate provisions

which are not mandatory but which are desirable

as good practice.

Section 4. Location Requirements

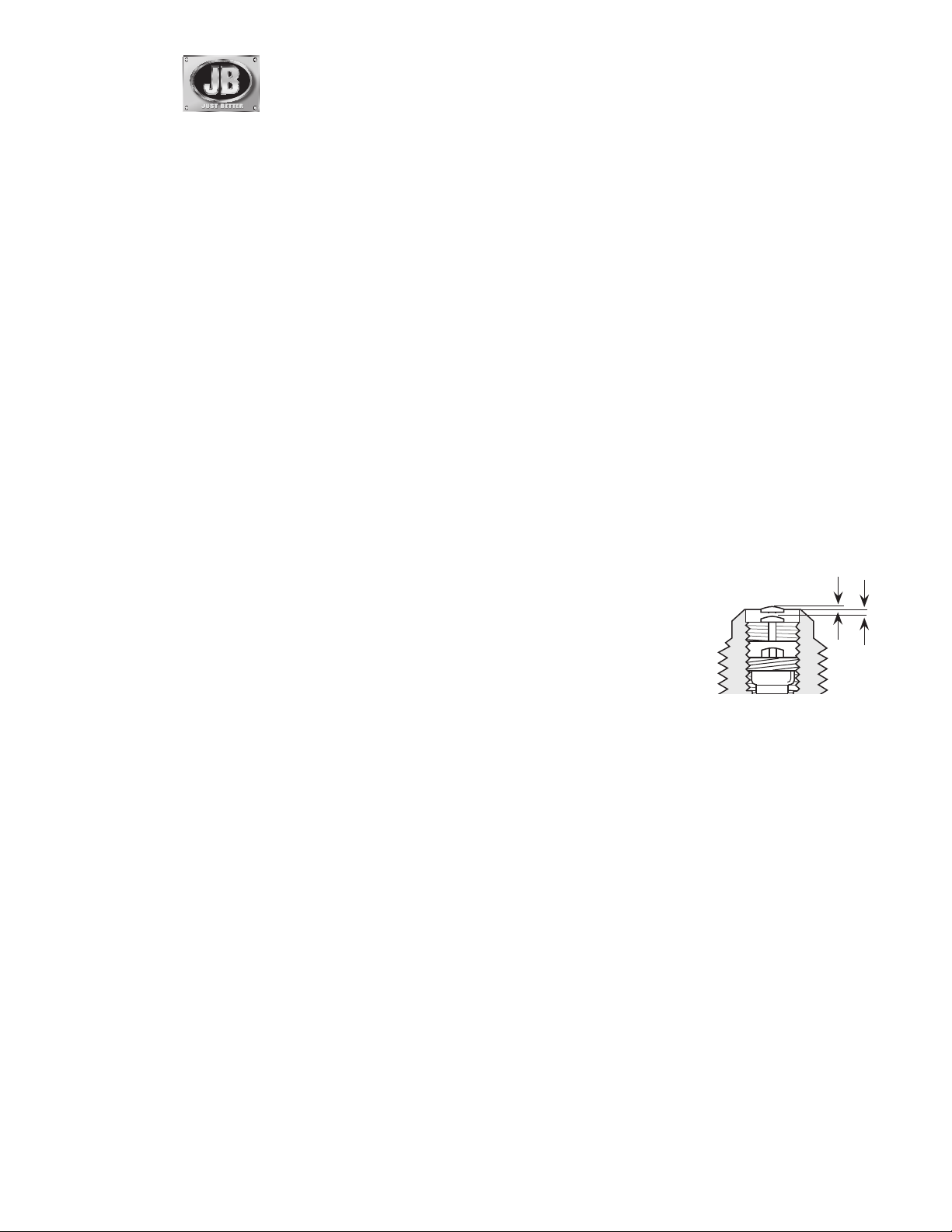

Figure 1

REQUIRED PIN LCATION

With A Recommended

Initial Assembly Torque of

1-1/2 To 3 In. Lbs.

4.1

Location of Valve Core Pin in Access Valve Body

The internal machining of the access valve body shall

be such that the insertion of the valve core into the

valve body with a recommended initial assembly

torque between 1-1/2 to 3 inch pounds [1.7 to 3.4 cm

kg or 0.17 to 0.34N • m], shall provide a refrigerant

seal and position the top of the core pin at a location

between 0.010 in. [0.25 mm] above to 0.035 in. [0.89

mm] below the end face of the valve body flare, see

Figure 1 above.

4.2

Location of Hose Connector Gasket and Core Pin

Depressor

specified by this standard, the core pin depressor in

the hose connector shall be positioned to permit

threaded engagement with the access body flare

threads and connector gasket contact with the body

flare face before the depressor engages the core pin.

It is recommended that for full flow the hose connector

and pin depressor should be capable of depressing the

core pin a minimum of 0.020 in. [0.51 mm].

. With the core pin located within the limits

shall be interpreted as follows:

. Where "shall" or "shall not" is used for

. "Should", "recommended", or "it is

A refrigerant valve core is

.010

MAX.

.035

MAX.

.

1

Page 2

ARI Standard 720-97

Refrigerant Access Valves and Hose Connectors

TM

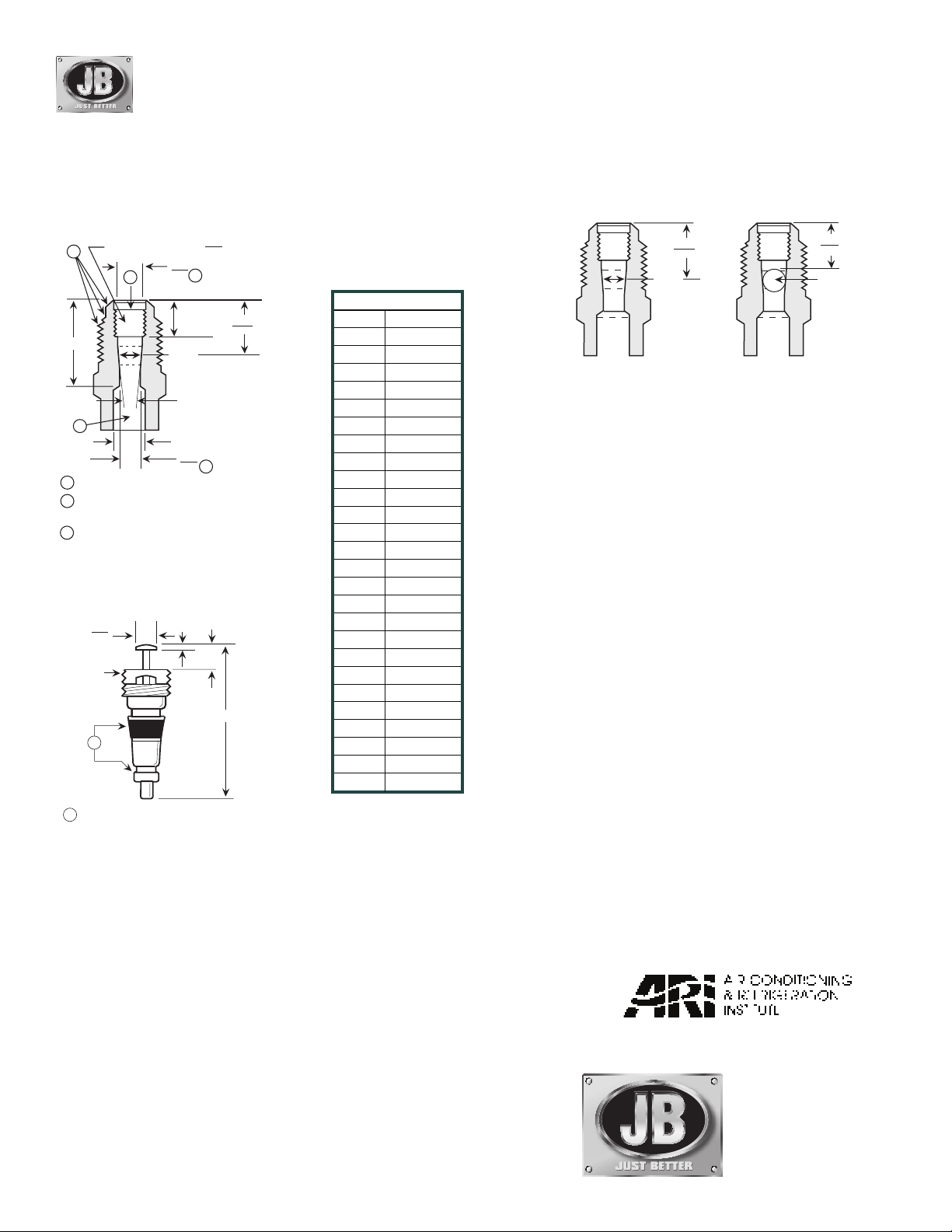

Section 5. Dimensions and Materials

REFRIGERANT ACCESS VALVE DIMENSIONS

1/4" SAE FLARE SIZE

Dimensions In Inches

.210-36UNS-1MOD.P.D. TH'D.

3

1

REF.

.551

1

Counterbore and/or Chamfer Optional.

1

2

This Diameter Must Be Concentric With Pitch

Diameter Of Internal Th'd. Within .003 T.I.R.

3

1/4" SAE Flare External Dimensions To

Conform To ANSI/SAE J513f "Refrigeration

Tube Fittings"

.076

.064

CORE

SEAL

4

VALVE

SEAL

Figure 2

DIA.

Figure 3

TYPICAL BODY DIMENSIONS

.206-36 UNS-1

MOD. TH'D.

4

Sealing Materials to Be Compatible

with Halogenated Hydrocarbon

Refrigerants and Refrigerant Oil For

The Intended Application.

TYPICAL CORE DIMENSIONS

5.1

Dimensions

.192

.197

DIA.

.189

.181

2

MIN.FULL

TH'D DEPTH

.293

EXACT

DATUM DIA.

.1693

17°±30'

INCL. ANGLE

MIN. DIA.

.168

DIA.

.155

2

.150

REF.

.109

REF.

.025

.875

.4091

.3941

MAX.

CONVERSION TABLES

INCHES MILIMETERS

.875 22.2

.551 14.0

.4091 10.39

.3941 10.01

.308 7.82

.293 7.44

.189 4.80

.181 4.60

.1719 4.366

.1693 4.300

.168 4.27

.155 3.94

.150 3.81

.109 2.77

.076 1.93

.064 1.63

.035 0.89

.025 0.64

.010 0.25

.003 0.08

DEGREES RADIANS

17°30' 0.3054

16°30' 0.2880

IN.LBS. CM.KG.

1-1/2 1.7

3 3.5

. See Figures 2 and 3 (above).

5.1.1 While conformance to Figures 2 and 3 is

recommended, where components do not meet the

constructional and dimensional requirements

shown, all access valves shall still interchange with

components that meet these requirements and

shall comply with all mandatory requirements to be

in conformance with this standard.

5.2

Materials.

Materials used for the seals on the valve

core shall be compatible for service with halogenated

hydrocarbon refrigerants and refrigerant oil for the

intended application.

Section 6. Gaging Procedures

6.1

ACCESS VALVE BODY GAGING PROCEDURES

Figure 4

PLUG GAGE

Gaging.

Dimensions In Inches

.4091

.3941

EXACT

DATUM DIA.

.1693

Figure 5

BALL GAGE

.308

.293

.1719 DIA.

BALL

Figures 4 and 5 (above) show two

accepted methods of gaging the access valve body.

Section 7. Voluntary Conformance

7.1

Conformance.

While conformance with this

standard is voluntary, conformance shall not be

claimed or implied for products or equipment within its

Purpose

(Section 1) or

(Section 2) unless such

Scope

claims meet all of the requirements of the standard.

APPENDIX A. References-Normative

A1 Listed here are all standards, handbooks, and other

publications essential to the formation and

implementation of the standard. All references in this

appendix are considered as part of the standard.

A1.1 ANSI/SAE Standard J513f-MAY94,

Refrigeration Tube Fittings

, 1994, American

National Standards Institute/Society of Automotive

Engineers, 11 West 42nd Street, New York, NY

10036, U.S.A./400 Commonwealth Drive,

Warrendale, PA 15096, U.S.A.

A1.2

ASHRAE Terminology of Heating, Ventilation,

Air Conditioning and Refrigeration,

American

Society of Heating, Refrigerating and AirConditioning Engineers, Inc., 1791 Tullie Circle

N.E., Atlanta, GA 30329, U.S.A.

APPENDIX B. References-Informative

A1 None.

ANSI/ARI Standard 720-97 used by permission

4301 N. Fairfax Drive, Suite 425, Arlington, VA 22203

Phone: 703-524-8800 Web: www.ari.org

JB INDUSTRIES

630.851.9444

Printed in USA

© 2007 J/B Industries Inc.

www.jbind.com

sales@jbind.com

2

Loading...

Loading...