Rev

JA77-005

Switch Plate with Removable Legends

Installation and Operating Manual

REV B

Jupiter Avionics Corporation

1959 Kirschner Road

Kelowna BC

Canada V1Y 4N7

Tel: +1 778 478 2232

Toll-Free: 1 855 478 2232

www.jupiteravionics.com

B Page i

Revision

A

B

Prepared:

Checked:

Approved:

IMPORTANT:

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

Copyright 2016 Jupiter Avionics Corp.

All rights reserved

Jupiter Avionics Corporation (JAC) permits a single copy of this manual to be printed or downloaded for the express use

of an installing agency. Any such electronic or printed copy of this manual must contain the complete text of this copyright

notice. Any unauthorized commercial distribution of this manual is strictly prohibited. Except as described above, no part

of this manual may be reproduced, copied, transmitted, disseminated, downloaded, or stored in any storage medium for

any purpose without the express prior written consent of JAC.

Information in this document is subject to change without notice.

To confirm the current revision status of this manual, visit the JAC website:

www.jupiteravionics

.com

RECORD OF REVISIONS

Rev Date Description ECR

May 2016 Initial release, Serial number 1001 and higher. 3157

Mar 2017 Minor file changes; latest Mechanical Installation 3979

MPB

Rev B Page ii

JAC

03-29-17

SRM

JAC

03-29-17

KDV

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

Table of Contents

SECTION 1 - DESCRIPTION ................................................................................................................................................. 1

1.1 System Overview .................................................................................................................................................... 1

1.2 Features Overview .................................................................................................................................................. 1

1.3 Inputs and Outputs .................................................................................................................................................. 1

1.3.1 Inputs ............................................................................................................................................................... 1

1.4 Specifications .......................................................................................................................................................... 1

1.4.1 Electrical Specifications................................................................................................................................... 1

1.4.2 Mechanical Specifications ............................................................................................................................... 1

SECTION 2 – INSTALLATION ............................................................................................................................................... 2

2.1 Introduction .............................................................................................................................................................. 2

2.2 Continued Airworthiness ......................................................................................................................................... 2

2.3 Unpacking and Inspecting Equipment..................................................................................................................... 2

2.3.1 Warranty .............................................................................................................................................................. 2

2.4 Installation Procedures ............................................................................................................................................ 2

2.4.1 Installation Limitations ......................................................................................................................................... 2

2.4.2 Cabling and Wiring .............................................................................................................................................. 2

2.4.3 Mechanical Installation ........................................................................................................................................ 3

2.4.4 Legend Replacement .......................................................................................................................................... 3

2.5 Legend Text Selection using ProCS™.................................................................................................................... 3

2.5.1 Front Panel Switches ...................................................................................................................................... 3

2.4.5 Post Installation Checks ...................................................................................................................................... 4

2.6 Installation Kit .......................................................................................................................................................... 4

2.6.1 Recommended Crimp tool .............................................................................................................................. 4

2.7 Installation Drawings ............................................................................................................................................... 4

SECTION 3 – OPERATION .................................................................................................................................................... 5

3.1 Introduction .............................................................................................................................................................. 5

3.2 Front Panel Controls ............................................................................................................................................... 5

3.3 Operation ................................................................................................................................................................. 5

Appendix A - Installation Drawings ................................................................................................................................... A1

A1 Introduction ............................................................................................................................................................ A1

A2 Installation Drawings ............................................................................................................................................. A1

Appendix B - Installation Documents ............................................................................................................................... B1

B1 Airworthiness Approval ......................................................................................................................................... B2

B2 Instructions for Continued Airworthiness .............................................................................................................. B2

Rev B Page iii

JA77-005 Switch Plate with Removable Legends

Name

Qty

Type

Power input

1

+28 Vdc lights power

SECTION 1 - DESCRIPTION

1.1 System Overview

The JA77-005 Switch Plate with Removable Legends allows the aircraft customizer to present a professionally

finished configurable switch panel for the ever-present extra switches.

The JA77 accepts standard aircraft grade toggle switches (i.e. Honeywell TL series or MS24523).

The legends are removable and available with any text or font. Blank legends and hole plugs (JAC Part No PLTPLUG-0003) are also available to cover unused switch holes.

1.2 Features Overvi e w

The JA77-005 has accommodation for up to four toggle switches.

The JA77-005 has two legends per switch.

Each legend is fully dimmable from a +28 Volt light dimmer bus.

Up to five characters are available per removable legend.

The Dzus plate has a baked-on flat urethane paint finish to resist scratches and nicks.

1.3 Inputs and Outputs

Refer to the JA77-005 connector map for the mating connector designators and pin assignments for the

input and output signals.

1.3.1 Inputs

1.4 Specifications

1.4.1 Electrical Specifications

Lights Input

LIGHTS INPUT Voltage 0 - 28 Vdc

LIGHTS INPUT current 100 mA max.

1.4.2 Mechanical Specifications

Height 1.875 in [47.6 mm] max

Depth behind faceplate 0.32 in [8.1 mm] max

Faceplate width 5.75 in [146 mm] max

Weight without switches 0.28 lbs. [0.13 kg] max

Material brushed aluminum with flat black

urethane finish

Connector One 2-pin male Microfit

Mounting 4 Dzus fasteners

Installation kit part number INST-JA77

Rev B Page 1

JA77-005 Switch Plate with Removable Legends

SECTION 2 – INSTALLATION

2.1 Introduction

This section contains unpacking and inspection procedures, installation information, and post-installation checks.

2.2 Continued Airworthiness

Maintenance of the JA77-005 is on condition only. Scheduled inspection and/or periodic maintenance of this unit is

not required.

2.3 Unpacking and Inspecting Equipment

Unpack the equipment carefully. Check for shipping damage and report any problems to the relevant carrier. Confirm

that the Authorized Release Certificate or Certificate of Conformance is included. Complete the on-line warranty card

from the Jupiter Avionics Corporation (JAC) website – www.jupiteravionics.com/warranty

2.3.1 Warranty

This product manufactured by JAC is warranted to be free of defects in workmanship or performance for 2 years from

the date of installation by an approved JAC dealer or agency. This warranty covers the cost of all materials and labour

to repair or replace the unit, but does not include the cost of transporting the defective unit to and from JAC or its

designated warranty repair centre, or of removing and replacing the defective unit in the aircraft. This warranty does

not cover failures due to abuse, misuse, accident, or unauthorized alteration or repairs.

THIS WARRANTY IS VOID IF THE PRODUCT IS NOT INSTALLED BY AN AUTHORIZED JAC DEALER. If the online warranty card is not completed, the product will be warranted from the date of manufacture.

Contact JAC for return authorization, and for any questions regarding this warranty and how it applies to your unit(s).

JAC is the final arbiter concerning warranty issues.

2.4 Installation Procedures

CAUTION: The power input circuitry of the unit may be damaged if the installation does not conform to the

wiring instructions in this manual.

2.4.1 Installation Limitations

Those installing the JA77, on or in a specific type or class of aircraft, must determine that the aircraft installation

conditions are within standards. The JA77 may be installed only by following the applicable airworthiness

requirements.

2.4.2 Cabling and Wiring

All wire shall be selected in accordance with the original aircraft manufacturer’s maintenance instructions, or AC43.131B Change 1, Paragraphs 11-76 through 11-78. Unshielded wire types shall qualify to MIL-W-22759 as specified in

AC43.13-1B Change 1, Paragraphs 11-85, 11-86, and listed in Table 11-11. For shielded wire applications, use Tefzel

MIL-C-27500 shielded wire with tag ring or equivalent (for shield terminations) to make the most compact and easily

terminated interconnect. Follow the Connector Map and Interconnect in Appendix A of this manual.

Maintain wire segregation and route wiring in accordance with the original aircraft manufacturer’s maintenance

instructions.

Rev B Page 2

Among the options is ‘- - - -‘ which signifies that

Clicking on a customizable legend will open a drop-

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

Unless otherwise noted, all wiring shall be a minimum of 22 AWG. Refer to the Interconnect drawing for additional

specifications. Check that the ground connection is clean and well secured.

2.4.3 Mechanical Installation

The JA77-005 can be mounted in any attitude and location with adequate space for the front panel and sufficient

clearance for the connector and wiring harness. It requires no direct cooling.

2.4.4 Legend Replacement

The JA77-005 illuminated legends are field replaceable. For further information, refer to the ‘Legend Replacement’

document in Appendix A of this manual.

2.5 Legend Text Selection using ProCS™

The JA77-005 has no required adjustments, but the configuration program ProCS™ can be used to customize the text

for each legend either at the time of ordering the unit, or if text changes are required after installation. The JA77-005

need not be connected to a computer to select the legend text.

For information on ordering customized legends, refer to the ProCS™ Ordering Instructions on the JAC website.

2.5.1 Front Panel Switches

The Front Panel Switches window is used to specify the text for each legend.

down menu listing the options for that label. The

currently selected option will be highlighted. To escape

from the menu, click on the desired option, or right-click

in the window. A 'Print…’ box will appear. Click outside

the box to escape, or select it to print the 'Front Panel

Switches’ window showing the current label selections.

the legend will be left blank, and ‘New…’ which

allows the user to enter a completely new

legend of up to five characters. If a ‘new’

legend has been added, the option ‘Edit …’ is

added to the menu to enable changes to the

newly created label.

In the example shown here, the option ‘New…’ has been

selected. A pop-up ‘New Label’ window will appear,

allowing the user to create a customized legend – in this

case, JAC. The new legend name will now be shown in

the appropriate position on the faceplate representation

in the software program.

Rev B Page 3

Micro-Fit Crimp Tool

Tool Type

Hand crimping tool

MOLEX

63819-0000

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

2.5.2 Post Installation Checks

2.5.2.1 Voltage/Resistance checks.

Do not attach this unit until the following conditions are met:

a) Check P9 pin 1 for +28 Vdc lights buss voltage.

b) Check P9 pin 2 for continuity to ground (less than 0.5 Ω).

c) Check all pins for shorts to ground or adjacent pins.

2.5.2.2 Configuration

Ensure that any switches inserted into the JA77-005 are configured correctly. This may be done at the factory, on the

maintenance bench or in the aircraft before the power on checks are performed.

2.5.2.3 Power on Checks.

Power up the aircraft’s systems and confirm normal operation of all functions controlled by the JA77 switches.

When all performance checks are satisfied, complete the necessary regulatory documentation before releasing the

aircraft for service. Refer to Appendix B.

2.6 Installation Kit

The kit required to install this unit is included with the unit.

The installation kit (Part # INST-JA77) consists of the following:

Quantity Description JAC Part #

1 Connector Assembly CON-8500-0001

2 Female crimp pins CON-8501-0001

2.6.1 Recommended Crimp tool

2.7 Installation Drawings

The drawings and documents required for Installation can be found in Appendix A of this manual.

Rev B Page 4

JA77-005 Switch Plate with Removable Legends

1

2

3

SECTION 3 – OPERATION

3.1 Introduction

This section contains the operating instructions for the JA77-005.

3.2 Front Panel Controls

Note: The eight legends are removable and may be replaced with custom ordered parts.

1 Switches (not included)

2 Upper legends

3 Lower legends

The JA77-005 Five Dzus Switch Plate allows the aircraft customizer to present a professional finished configurable

switch panel for extra switches. The JA77 accepts standard aircraft grade toggle switches (i.e. Honeywell TL series or

MS24523). The legends are removable and available with any text or font.

Blank legends and hole plugs are also available to cover unused switch holes.

3.3 Operation

Note: Check with your installing agency for confirmation of the operation of all switches. The legends are

interchangeable to allow customization.

Each switch position is associated with two replaceable legends; one above and one below the switch. The legends

will dim with the aircraft lighting buss.

Rev B Page 5

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

Appendix A - Installation Drawings

A1 Introduction

The drawings necessary for installation and troubleshooting of the JA77-005 Switch Plate with Removable Legends

are in this Appendix, as listed below.

A2 Installation Drawings

DOCUMENT Rev

JA77-005 Connector Map A

JA77-005 Interconnect A

JA77-005 Mechanical Installation B

Reference Documents

TOL-CUST-EXTR Legend Replacement A

Rev B Page A1

JUPITER AVIONICS TEMPLATE AUTOCAD PORTRAIT SIZEA REV B.DWT

TITLE

APPROVED

PREPARED

CHECKED

L00N3

NCAGE CODE PART NO. SHEET

DOC NO.

CONFIDENTIAL & PROPRIETARY

TO JUPITER AVIONICS CORP.

Switch Plate with Removable Legends - Five Dzus

JA77-005 1/1

JA77-005 Connector Map Rev A.dwg

TAT

2 PIN FEMALE MICRO-FIT

MATING CONNECTOR

1 2

VIEW IS FROM REAR OF MATING CONNECTOR

LIGHTS GROUND

+28 VDC LIGHTS

P1

JAC

05-19-16

DS

JAC

05-19-16

KDV

JUPITER AVIONICS TEMPLATE AUTOCAD PORTRAIT SIZEA REV B.DWT

TITLE

APPROVED

PREPARED

CHECKED

L00N3

NCAGE CODE PART NO. SHEET

DOC NO.

CONFIDENTIAL & PROPRIETARY

TO JUPITER AVIONICS CORP.

Switch Plate with Removable Legends - Five Dzus

JA77-005 1/1

JA77-005 Interconnect Rev A.dwg

TAT

JA77-005 INTERCONNECT WIRING NOTES

NOTES

ALL WIRE SIZE SHOULD BE 24 AWG MIN UNLESS OTHERWISE SPECIFIED. UNSHIELDED WIRE

SHOULD BE SELECTED PER FAA AC43.13-1B CHANGE 1 PARA 11-76 TO 11-78. WIRE TYPES

SHOULD BE IN ACCORDANCE WITH MIL-W-22759 AS DESCRIBED IN FAA AC43.13-1B CHANGE 1

PARA 11-85 AND 11-86 AND LISTED IN TABLE 11-11 OR 11-12.

CONNECTION TO AIRFRAME GROUND SHOULD BE MADE WITH 22 AWG WIRE. LENGTH NOT TO

EXCEED 3 FT (0.91 M).

2

1.

JA77-005

P1

2 PIN FEMALE MICRO-FIT

MATING CONNECTOR

J1

+28 VDC LIGHTS 1

LIGHTS GROUND 2

+28 VDC LIGHTS

22 AWG

2

22 AWG

JAC

05-10-16

DS

JAC

05-10-16

KDV

CENTER OF GRAVITY

WEIGHT: 0.28 lbs [0.13 kg] MAX.

0.03in [0.8mm]

0.94in

23.9mm

2.87in

72.9mm

0.14in

3.6mm

1.875in MAX

47.6mm MAX

146.1mm MAX

5.75in MAX

0.49in MAX Dia.

12.4mm MAX

A

A

B

B

TITLE

CONFIDENTIAL & PROPRIETAR Y

JUPITER AVIONICS TEMPLATE SOLIDWORKS LANDSCAPE SIZEA REV B.DRW DO T

5 Dzus - Switch Plate

JA77-005 Mechanical Installation Rev B.SLDDRW

DOC. NO.

1/1

SHEET

JA77-005

PART NO.

L00N3

DRAWING NOT TO SCALE

TO JUPITER AVIONICS CORP.

APPROVED

CHECKED

TATPREPARED

N/A

N/A

MATERIAL:

FINISH:

NCAGE CODE

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

ANGLES ARE IN DEGREES

TOLERANCES:

1 DEC PLACE:

0.1

2 DEC PLACE: 0.01

3 DEC PLACE: 0.005

ANGLES: 0.5 DEG

0.32in MAX

8.1mm MAX

0.32in MAX

8.1mm MAX

SECTION A-A

SECTION B-B

JAC

SRM

03-28-17

JAC

KDV

03-28-17

Jupiter Avionics Corporation Audio Controllers

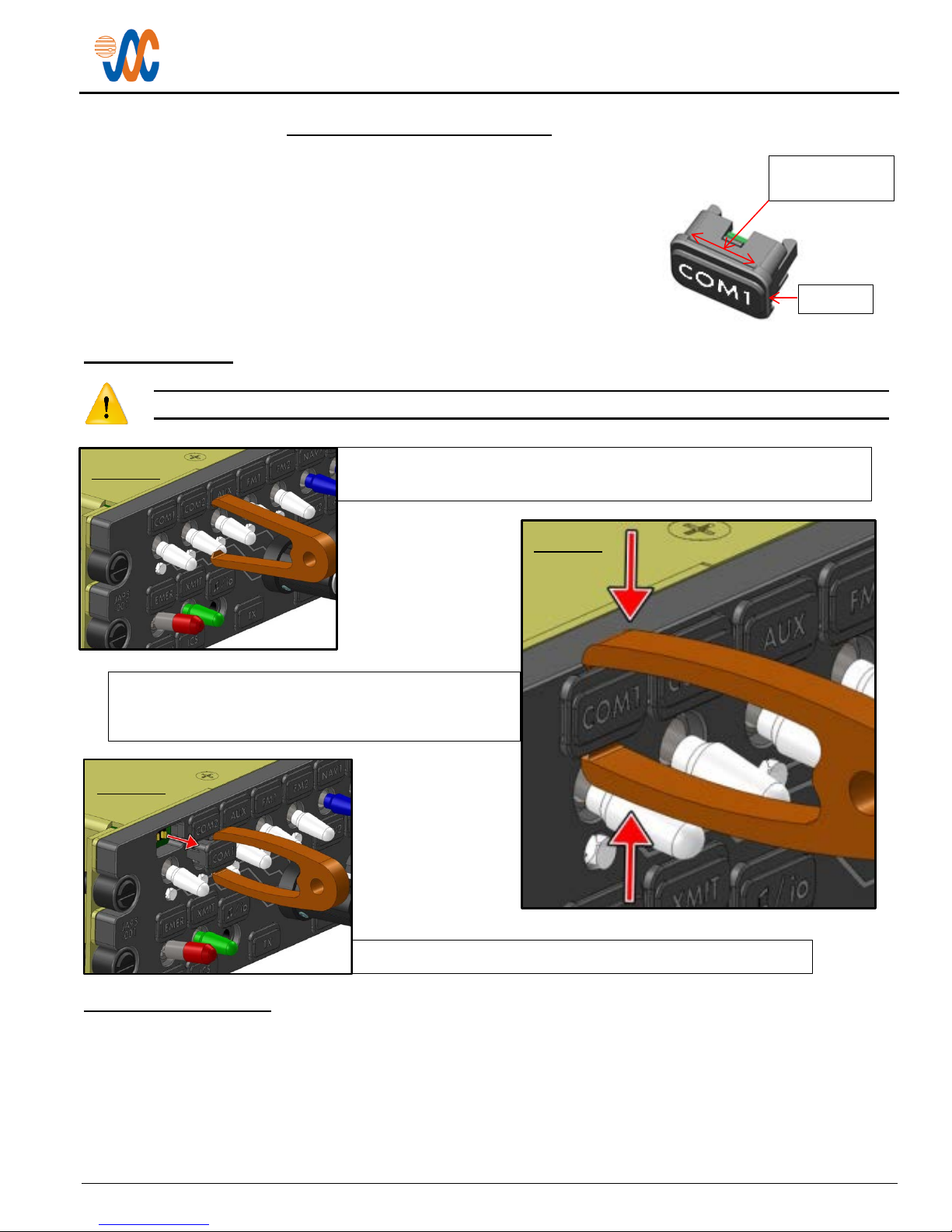

Jupiter Avionics Corporation (JAC) products have field-replaceable illuminated

To facilitate legend removal, JAC provides a legend extractor tool - part #

To remove a legend, hold the extractor firmly between

Pull the legend away from the faceplate as shown in figure 3.

Figure 1

Figure 2

Legend

Extractor tool

recess

Legend Replacement

Field-Replaceable Legends

legends. This permits easy customization, and allows the same units to be used

in multiple different configurations with only minimal changes.

The internal circuitry ensures that, although the legends are individually

illuminated, the illumination is consistent and uniform throughout all legends, and

never needs to be balanced. This means that if it is a requirement to change the

labelling due to damage or for a different project, there is no need for costly and

time-consuming illumination checks.

Legend Removal

Caution: Take care not to scratch or otherwise damage the faceplate or the legend.

TOL-CUST-EXTR (figure 1) that fits into the recesses on the legend.

the forefinger and thumb, and use a tweezer-like action

to grip the legend (figure 2).

Figure 3

Legend Replacement

To replace a legend, align the text correctly, and then apply gentle pressure until the body of the legend support seats

firmly into the faceplate.

Once the new legend is in place, ensure that it has seated correctly by checking that it illuminates. The unit is now

ready for use.

TOL-CUST-EXTR – Legend Replacement Page 1 of 1

JA77-005 Switch Plate with Removable Legends

Installation and Operating Manual

Appendix B - Installation Documents

Rev B Page B1

JA77-005 Switch Plate with Removable Legends

Installation and Oper at i ng Manual

B1 Airworthiness Approval

Airworthiness approval of the JA77-005 may require completion of a TCCA Major Modification Report per CAR STD

(AWM) 571 Appendix L, or a FAA Form 337. The sample wording for a description of the work is provided to assist

the Installing Agency in preparing Instructions for Continued Airworthiness (ICA) when installing a Jupiter Avionics

JA77-005 Switch Plate with Removable Legends. It is the installer’s responsibility to determine the applicability of the

method used. Installations performed outside Canada must follow the applicable aviation authority’s regulations.

Sample Wording:

Installed a Jupiter Avionics JA77-005 Switch Plate with Removable Legends in [aircraft location].

Installed in accordance with the JA77-005 Installation Manual, Revision [ ], and AC 43.13-2, Chapters 2, and 3.

The JA77-005 Installation Manual provides detailed installation instructions and wiring diagrams (Section 2, and

Appendices A and B).

Aircraft equipment list, weights and balance amended. Compass compensation checked and found to conform to

applicable regulations.

B2 Instructions for Continued Airworthiness

Maintenance of the JA77-005 Five Dzus - Switch Plate is “on condition” only. Periodic maintenance of the JA77-005 is

not required.

The following sample Instructions for Continued Airworthiness (ICA) provides assistance in preparing ICA for the

Jupiter Avionics JA77-005 unit installation as part of a Type Certificate (TC) or Supplemental Type Certificate (STC)

project to comply with CAR STD (AWM) 523/527/525/529.1529 or FAR 23/25/27/29.1529 “Instructions for Continued

Airworthiness”.

Items that may vary by aircraft make and model are shown in brackets (“[ ]”) and should be filled in as appropriate.

Some of the checklist items do not apply, in which case they should be marked “N/A” (Not Applicable).

Instructions for Continued Airw orthi nes s, Jupiter Avionics JA77-005 Switch

Plate with Removable Legends i n an [Aircraft Make and Model]

1. Introduction

[Aircraft that has been altered: Registration number, Make, Model and Serial Number]

Content, Scope, Purpose and Arrangement: This document identifies the Instructions for Continued

Airworthiness for a Jupiter Avionics JA77-005 installed in an [aircraft make and model].

Applicability: Applies to a Jupiter Avionics JA77-005 installed in an [aircraft make and model].

Definitions/Abbreviations: None, N/A.

Precautions: None, N/A.

Units of Measurement: None, N/A.

Referenced Publication s: JA77-005 Installation and Operating Manual

STC/TC # [applicable STC/TC number for the specific aircraft installation]

Distribution: This document should be a permanent aircraft record.

Rev B Page B2

JA77-005 Switch Plate with Removable Legends

Installation and Oper at i ng Manual

2. Description of the System/Alteration

Jupiter Avionics JA77-005 Switch Plate with Removable Legends. Refer to Appendix A of this manual for

interconnect information. Refer to aircraft manufacturer approved interconnect for actual installation.

3. Control, Operation Information

Refer to section 3 of this manual.

4. Servicing Information

N/A

5. Maintenance Instructions

Maintenance of the JA77-005 is ‘on condition’ only. Periodic maintenance is not required.

6. Troubleshooting Information

N/A

7. Removal and Replacement Information

Refer to Section 2 of this manual - the JA77-005 Installation and Operating Manual. If the unit is removed and

reinstalled, a functional check of the equipment should be conducted.

8. Diagrams

Refer to Appendix A of this manual - the JA77-005 Installation and Operating Manual - for installation drawings

and interconnect examples.

9. Special Inspection Requirements

N/A

10. Application of Protective Treatments

N/A

11. Data: Relative to Structural Fasteners

JA77-005 and appropriate mounting hardware installation, removal and replacement should be in accordance

with applicable provisions of AC 43.13-1B and AC 43.13-2A.

12. Special Tools

N/A

13. This Section is for Commuter Category Aircraft Only

A. Electrical loads: Refer to Section 1 of the JA77-005 Installation and Operating Manual.

B. Methods of balancing flight controls: N/A.

C. Identification of primary and secon d ary structures: N/A.

D. Special repair methods applicable to th e airplane: N/A.

14. Overhaul Period

No additional overhaul time limitations.

15. Airworthiness Limitation Section

N/A

Rev B Page B3

Loading...

Loading...