Page 1

INSTALLATION INSTRUCTIONS

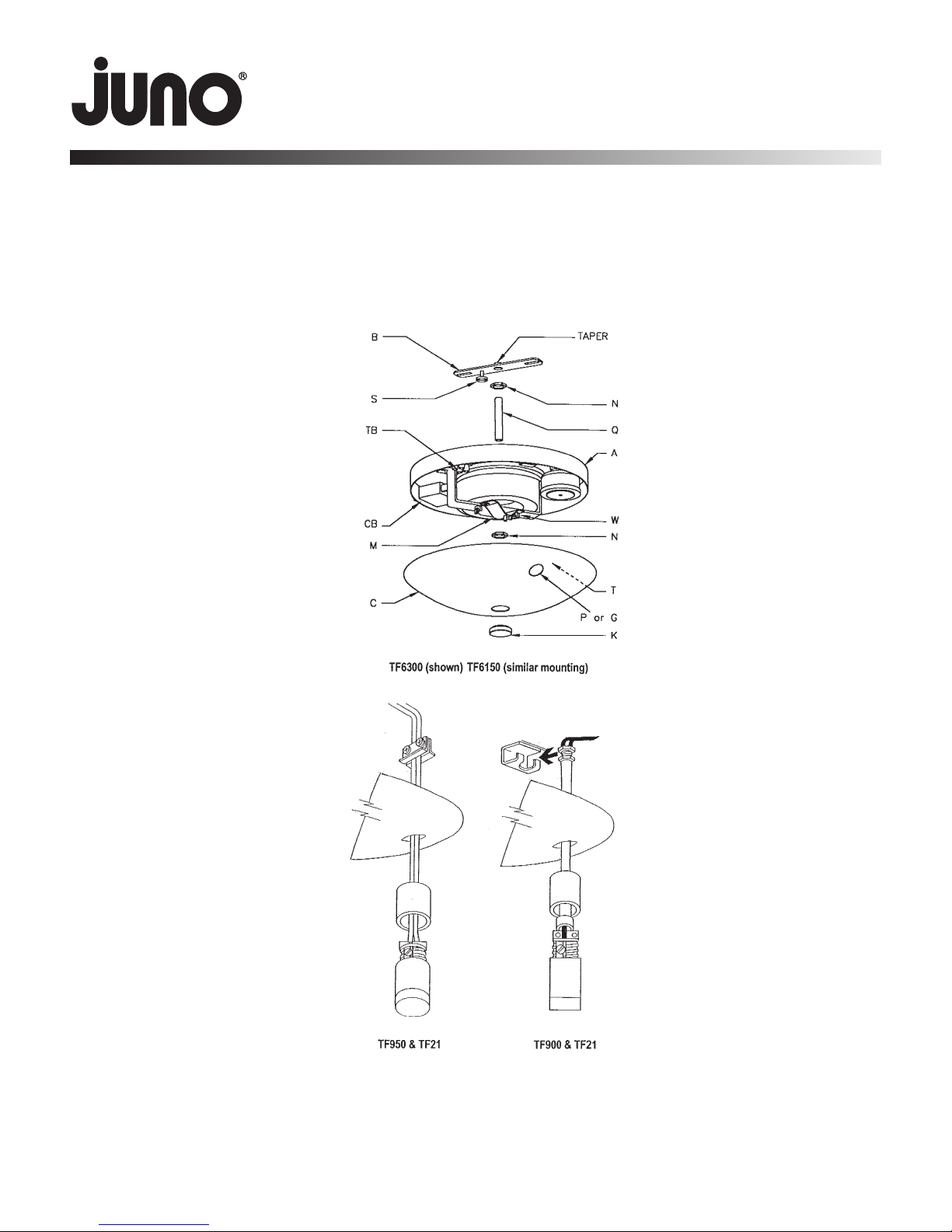

Surface Mount Power Units

TF6150E 12 volt, 150 watt, single output

TF6300 12 volt, 300 watt, single output

SAVE THESE INSTRUCTIONS

IMPORTANT SAFEGUARDS:

When using electrical equipment, always adhere to basic safety precautions including the following:

IMPORTANT SAFETY/ OPERATING INSTRUCTIONS

1. Read all instructions.

2. Do not conceal or extend bus bar con-

ductors (Flex 12 Trac) through a building

wall.

3. Do not install this system in damp or wet

locations.

4. To reduce the risk of fire and burns, do

not install this lighting system where the

uninsulated open bus bar conductors

can be shorted or contact any conductive materials.

5. Do not install any luminaire closer than

6 inches (15.25 cm) from any curtain, or

similar combustible material.

6. To reduce the risk of fire and overheating, make sure all connections are tight.

7. Turn off electrical power before installing

or modifying the system in any way.

8. Use 10 or 12 gauge wire to connect the

output to the Trac.

9. These transformers are intended for use

with Juno Flex 12 Series or Trac 12/25

Series low voltage lighting systems only.

PARTS LIST

Open the carton and identify all of the following parts:

(1) Chassis / transformer assembly (A)

(1) Cover (C)

(1) Knob (K)

(1) Parts bag including:

(1) Mounting strap (B)

(1) Grommet (G)

(2) Nuts, 1/8 inch (N)

(1) Nipple, 1/8 x 2 3/4 inch (Q)

(1) Ground screw (S)

(2) Wire nuts

PRODUCT FEATURES

Juno’s surface mounted power units are

used to convert 120 volts AC to 12 volts

nominal to provide power to the Flex 12

trac. The Trac length should not exceed 24

feet in either direction from the feed. The

power units are designed to be mounted

to a standard ceiling mounted junction box

that is adequately supported. They can

be used with one or two Pendants, or with

the Flexible Feed (Pendants and Flexible

Feed sold separately). The power units are

capable of supporting up to 20 lbs. They

should not be mounted in any location that

may entrap heat.

The TF6150E is capable of operating from

50 to 150 watts of lamp load and is dimmable with most higher quality incandescent

dimmers. In some cases, dimmers designed

for electronic transformers may be necessary for optimal dimming results. The unit

has short circuit and overload protection that

will automatically reset itself when the short

or overload is removed.

The TF6300 is capable of operating from

150 to 300 watts of lamp load and is dimmable only with dimmers specifically

designed for magnetic transformers. To

protect against an overload or short circuit,

the unit contains a circuit breaker that must

be manually reset after the short or overload

has been removed.

INSTALLATION

WARNING: Make sure power is off

before assembly

1. Make sure that the supply wires protrude

from the junction box at least 7 inches.

2. Thread the nipple (Q) through the nut

(N) and strap (B) with the tapered side

away from the nut as shown. Attach the

ground screw (S) to the strap.

3. Pass the supply wires from the junction

box through the nipple as shown. Secure

the strap to the junction box with two

screws. Connect the ground wire from

the junction box to the ground screw on

the strap.

4. Adjust the nipple to protrude 2 inches

from the mounting surface and lock in

place with the nut.

5. (TF6300 only) Loosen the two wing nuts

(W) on the center mounting bracket (M)

of the transformer assembly and rotate

the bracket out of the way.

6. Pass the supply wires and the nipple

through the center of the assembly (A).

Raise the assembly to the mounting

surface. Place the remaining nut over

the supply wires and thread it onto the

nipple to hold the assembly in place.

7. Rotate the assembly if necessary to orient the pendant(s) as desired, and finish

tightening the nut to secure the assembly in place.

8. Connect the white and black supply

wires to the stranded input wires from

the assembly with the wire nuts provided.

9. (TF6300 only) Carefully bend the supply

wires to the side, rotate the top bracket

back in place, and tighten the wing nuts.

10. Install the Pendant Feed or Flexible

Feed per the appropriate instructions on

the following page.

----- See steps 11-15 on back. -----

16. Connect the feed wires to the terminal

block (TB). CAUTION: For all connections, make sure that the stripped wire

is fully inserted into the connector, all

strands of copper are inserted in the terminal and all 4 screws are tight.

17. Connect the green ground wire from the

assembly to the tab (T) on the inside of

the cover (C).

18. (TF6300 only) Make sure that the circuit

breaker switch (CB) located on the side

of the assembly, is on.

19. Put the cover in place and secure it to

the assembly with the knob (K). Install

the Trac and fixtures per the instructions

included with them.

20. Apply AC power. Confirm that all fixtures

function acceptably. Adjust fixtures as

desired.

pg 1 of 3

Page 2

INSTALLATION INSTRUCTIONS

Surface Mount Power Units

TF6150E 12 volt, 150 watt, single output

TF6300 12 volt, 300 watt, single output

SAVE THESE INSTRUCTIONS

Flexible Feed, Using:

TF950 Flexible Feed Kit &

TF21 Electrical Feed Cylinder

Note: The Flexible Feed is not intended to

support the Trac or any weight, only to provide power to the Trac.

11. Insert tinned end of wires through holes

in top of feed cylinder and firmly tighten

terminal screws.

12. Pass wires through top cap and screw

cap onto feed cylinder.

13. Pass wires through grommet (G) in

cover. Determine cord length, leaving

some slack and tighten clamp in place.

14. Hook wire onto bracket.

15. Return to step 16 on the previous page.

Pendant Feed, Using:

TF900 Series Pendant Stem, &

TF21 Electrical Feed Cylinder

11. Thread two nuts on top of stem leaving

space between nuts. Slide top cap onto

stem. Install and tighten bushing onto

stem.

12. Cut two pieces of 10-ga. solid copper

wire to length. Strip one end of each

wire 5/8”. Tightly bind one wire under

each feed cylinder terminal screw.

13. Push wire through stem and screw top

cap onto Feed Cylinder as shown. Pass

assembly through cover.

14. Carefully bend wires at top of stem

90˚ and push assembly onto bracket.

Tighten nuts.

15. Return to step 16 on the previous page.

pg 2 of 3

Page 3

INSTALLATION INSTRUCTIONS

GUIDELINES FOR A TROUBLE-FREE LOW VOLTAGE INSTALLATION

1. IMPROPER WIRE GAUGE OR POOR WIRE CONNECTIONS CAN RESULT IN PRODUCT FAILURE.

These transformers reduce the line voltage by a factor of ten. To achieve the same power levels at the lamp, the output current is increased

by the same factor of ten. To accommodate these high current levels, heavy gauge wire and secure connections are essential, or product

failure can result.

300 WATTS = 120 VOLTS x 2.5 AMPS 300 WATTS = 12 VOLTS x 25 AMPS

2. LAMP VOLTAGE CAN BE AFFECTED BY NUMEROUS FACTORS.

Many factors will affect the voltage delivered to the load. Below is a list of these factors and examples of their affects:

A. Variations in transformer input voltage. 11.8 V @ 120v input 12.4 V @ 126v input (+5%)

B. Use of a dimmer to control the transformer. 11.8 V (no dimmer) 11.2 V (with dimmer set at maximum)

C. The amount of load applied to the transformer. 11.8 V @ 300w 12.0 V @ 150v

D. Length of wire between transformer and trac. 11.5 V @ 5 feet (#10) 10.8 V 20 feet (#10)

E. Transformer operating temperature 11.8 V room temp. 11.5 V max lamp

3. EXCESSIVE LAMP VOLTAGE AND TEMPERATURE CAN DRASTICALLY REDUCE LAMP LIFE.

Lamp life is directly affected by the applied voltage. Excess voltage as little as 1/4 volt over 12 volts can reduce lamp life by as much as 40%.

Some of the factors listed above can be chosen, while others cannot, and therefore must be compensulated for.

TABLE PREDICTING VOLTAGE AT FIRST LAMP FOR VARIOUS WIRE LENGTHS AND LOADS USING TF6300 TRANSFORM

Distance from

Transformer

to 1st Lamp

0’ 12.067 12.000 11.933 11.867 11.800

1’ 12.050 11.975 11.899 11.824 11.749

2’ 12.033 11.949 11.865 11.782 11.698

3’ 12.016 11.924 11.832 11.739 11.647

4’ 11.999 11.898 11.798 11.697 11.596

5’ 11.982 11.873 11.764 11.655 11.546

6’ 11.965 11.847 11.730 11.612 11.495

7’ 11.948 11.822 11.696 11.570 11.444

8’ 11.931 11.796 11.662 11.527 11.393

10’ 11.897 11.746 11.594 11.443 11.291

12’ 11.863 11.695 11.526 11.358 11.189

14’ 11.829 11.644 11.458 11.273 11.087

16’ 11.795 11.593 11.390 11.188 10.986

20’ 11.727 11.491 11.255 11.018 10.782

24’ 11.659 11.389 11.119 10.849 10.578

28’ 11.592 11.287 10.983 10.679 10.375

4. A VOLTMETER SHOULD BE USED TO CONFIRM THAT THE PROPER VOLTAGE IS PRESENT

After the installation is complete, a voltmeter should be used to insure that suggested lamp voltages are not being exceeded. The voltage

should be measured at the first lamp on the trac. Since some of the factors listed above are constantly changing some allowance should be

made for variations in voltage.

12V, 8.33A, 100W 12V, 12.5A, 150W 12V, 16.67A, 200W 12V, 20.83A, 250W 12V, 25A, 300W

The shaded areas represent the suggested operating range of 11.0 to 11.8 volts at the first lamp on the Trac.

120V INPUT

#10 AWGr

ER

WARRANTY

Juno Lighting Group warrants that its products are free from defects in material and workmanship. Juno Lighting Group’s obligation

is expressly limited to repair or replacement, without charge, at Juno Lighting Group’s factory after prior written return authorization has been

granted. This warranty shall not apply to products which have been altered or repaired outside of Juno Lighting Group’s factory. This warranty is

in lieu of all other warranties, expressed or implied, and without limiting the generality of the foregoing phrase, excludes any implied warranty of

merchantability. Also, there are no warranties which extend beyond the description of the product on the company’s literature setting forth terms

of sale.

Product Services Phone (888) 387-2212

1300 South Wolf Road • Des Plaines, IL 60018 • Phone 800-323-5068 • www.junolightinggroup.com

© 2016 Acuity Brands Lighting, Inc. Printed in USA Rev 6/07 P3008 pg 3 of 3

Loading...

Loading...