Page 1

ANLEITUNG ZUM GEBRAUCH - INSTRUCTION BOOKLET

DE

GAS COOKERS

JGS 1000

JGS 1010

JGS 3010

JGS 5010

JGS 5110

GASHERDE

2

Page 2

ENGLISH

DISPOSAL OF PACKING

HINTS ON THE DISPOSAL OF PACKING

In case of not making use thereof we recommend to put:

Except for wooden material, packing and auxiliary

material of Juno Major Appliances are recyclable and on

principle should be handed over to recycling stations.

- After delivery to your premises packing of major

appliances may be returned to our contract forwarders.

Same will then initiate forwarding on for reuse or disposal.

Only recyclable plastics are

allowed by Juno as auxiliary

packing material, e.g.:

02**

05 06

PE PP PS

INSTRUCTIONS FOR USE

IMPORTANT HINTS

● The connection of the gas cooker must be carried out

by an approved gas fitter, only.

● When connecting electric appliances to sockets

in the near of a cooker make sure that connecting

leads will not get in touch with hot open burners

or get jammed by the hot oven door.

● Overheated fats and oils may rapidly flare up on

the hot open burners. Dishes with fat or oil, such

as French fries must therefore be prepared under

control, only.

- paper, cardboard and corrugated board as well as

- plastic packing material and

- metal packing material

into the collecting bins provided for this purpose. As long

as same are not existing in your living area, add the

material to your rubbish.

The samples read:

PE for polyethylene**02 = PE-HD:04 PE-LD

PP for polypropylene

PS for polystyrene

● In case of any trouble do shut off the supply of

energy! Call the after-sales-service!

● To maintain the safety of the appliance make sure

that repairs, in particular of live gas conducting

components, are exclusively carried out by expert

gas fitters. With any trouble call the after-salesservice.

● Do carefully keep the instructions for installation

and use!

● Do neither line the oven with aluminium foil nor place

any baking/roasting vessels direct on the oven

bottom. The heat accumulation resulting thereby

may destroy the enamel. Such damages of enamel

are not covered by our guarantee.

● Do not use the gas burners for space heating!

● When operating the oven do always fold up the

top lid.

● The typeplate can be seen after opening of the

oven door at the right side.

The present instruction for use is valid only for countries the abbreviation of which is shown on

the front page of the instructions as well as on the appliance.

During the operation the oven door is slightly

heated up because of the structure of the

oven door crystal and of the adjacent parts.

Do make sure, therefore, that playing children

will not approach the oven. If there be a socket

in the direct vicinity of the oven, make sure

that cables

of electric appliances will not get in touch

with hot open burners or jammed in the oven

door.

35

Page 3

10

7

6

5

4

3

2

1

9

8

TABLE OF CONTENTS

Description of the appliance Page 36

Control panel Page 37

Technical data Page 38

Instructions for use Page 39

Open burners Page 39

Oven Page 40

Use of the electric grill Page 42

Hints on the use Page 42

Chart with cooking times Page 45

Cleaning and care Page 46

Installation instructions Page 48

Connection to the mains Page 50

Conversion to other type of gas Page 51

What to do, if ... Page 56

After-sales-service and spareparts Page 57

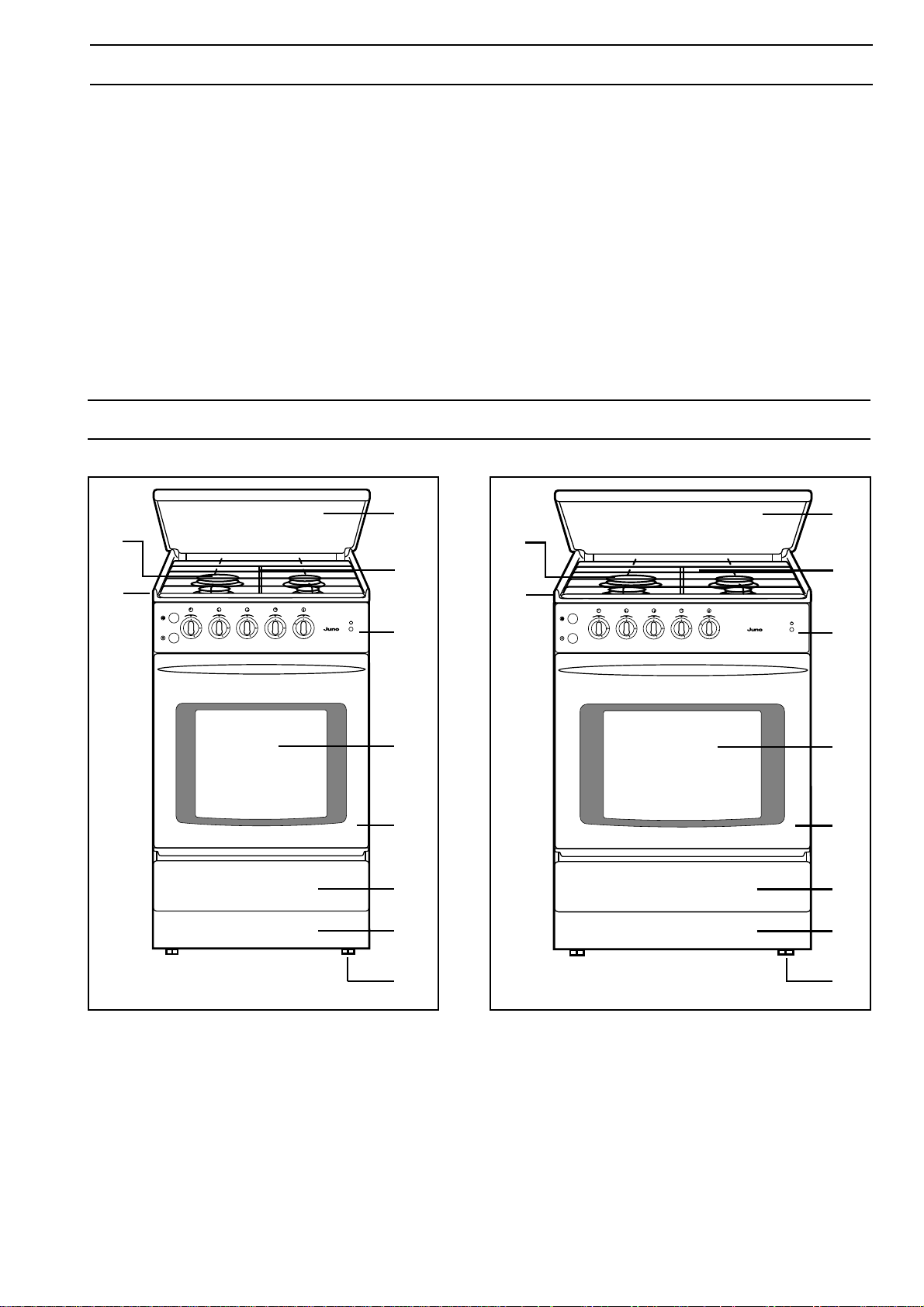

DESCRIPTION OF THE APPLIANCE

5

3

4

2

3

2

5

4

JGS 1000 - JGS 1010

JGS 3010 - JGS 5010

1

2

10

3

9

4

8

5

7

6

1

6

7

8

9

10

1

6

7

8

9

10

Fig. 1 Fig. 2

JGS 5110

1. Control panel

2. Hob unit

3. Open burner

4. Pot rest

5. Top lid

36

6. Oven

7. Oven door with window

8. Utensils drawer

9. Cover plate

10. Leveling leg

Page 4

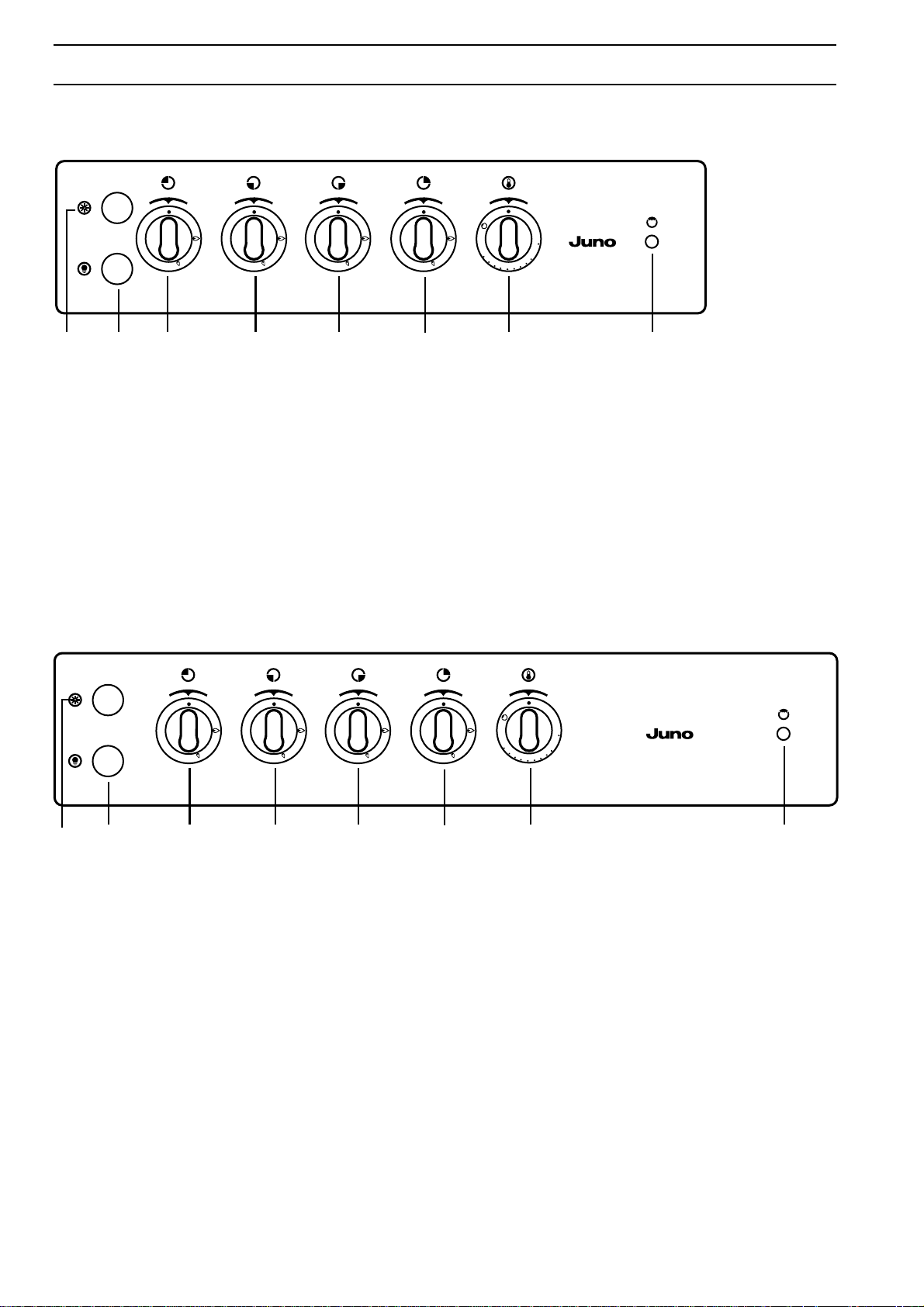

CONTROL PANEL

MOD. JGS 1000-1010-3010-5010

1

2

10

3

9

4

8

5

7

6

1234567 8

1. Electronic ignition of open burners and oven - with model JGS 5010, only

2. Oven light (except for models JGS 1000/1010)

3. Knob for rear left open burner - heavy-duty burner

4. Knob for front left open burner - standard burner

5. Knob for front right open burner - cooking burner

6. Knob for rear right open burner - standard burner (except for models JGS 1000)

7. Knob for oven burner (and electric grill in model JGS 5010)

8. Indicator lamp (with model JGS 5010, only)

Fig. 3

MOD. JGS 5110

1

2

10

3

9

4

8

5

7

6

1234567 8

Fig. 4

1. Electronic ignition of open burners and oven

2. Oven light

3. Knob for rear left open burner - heavy-duty burner

4. Knob for front left open burner - standard burner

5. Knob for front right open burner - cooking burner

6. Knob for rear right open burner - standard burner

7. Knob for oven burner

8. Indicator lamp

37

Page 5

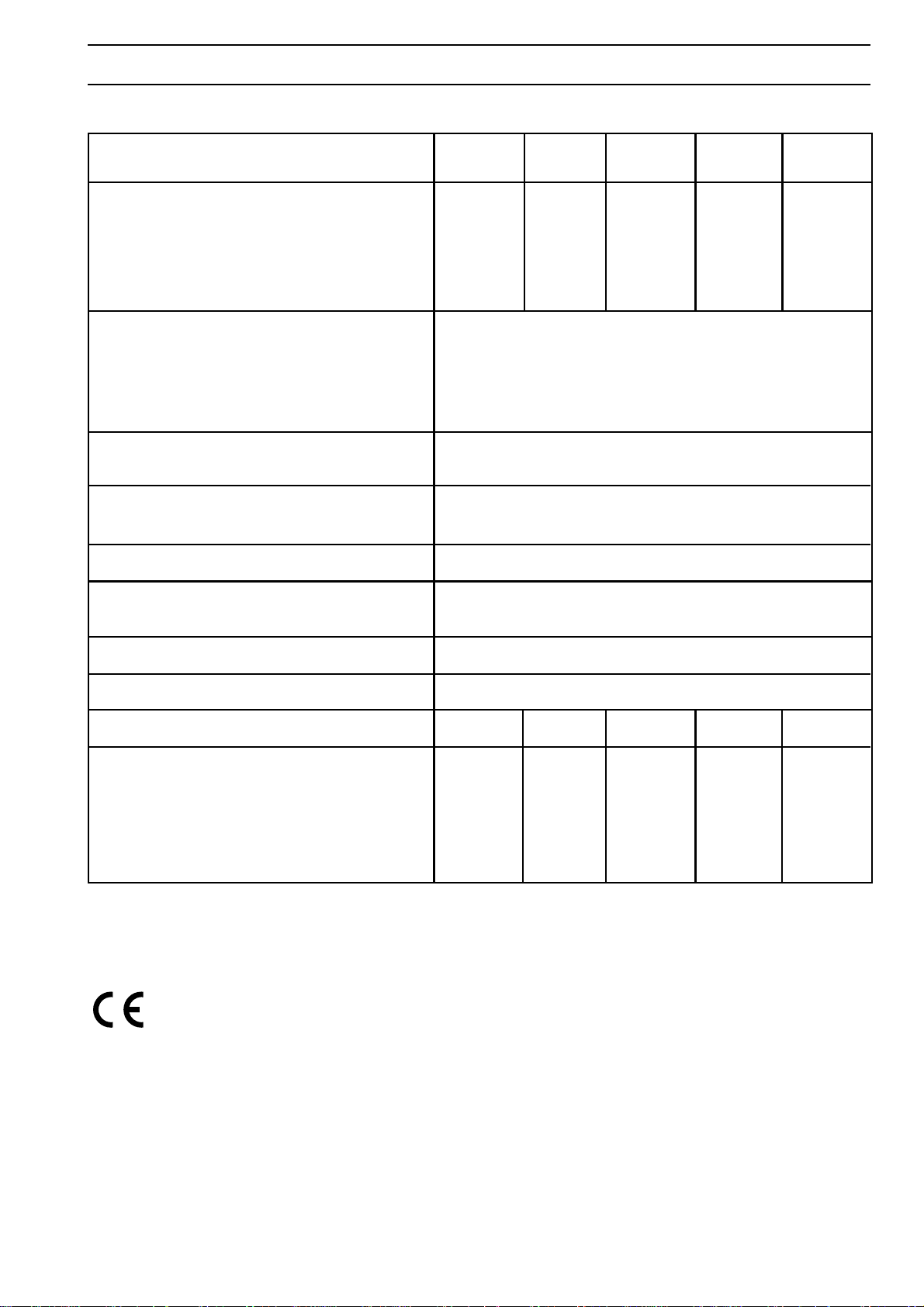

TECHNICAL DATA

MODELL JGS 1000 JGS 1010 JGS 3010 JGS 5010 JGS5110

Sizes: H = mm 850 850 850 850 850

W = mm 500 500 500 500 600

D = mm 600 600 600 600 600

with top lid closed H = mm 870 870 870 870 870

with top lid opened H = mm 1430 1430 1430 1430 1430

height adjustable by mm 15 15 15 15 15

Output of gas burners

Heavy-duty burner W 3000

Standard burner W 2000

Cooking burner W 1000

Oven burner W 3000

Operation Natural gas LPG

Maximum output Natural gas E 1.05 m3/h

LPG 800 g/h

Connection to gas supply R 1/2“

Nominal pressure Natural gas 20 mbar

LPG 50 mbar

Oven thermostat from 150°C to 260°C

Connection to the mains (50 cycles) 230 V

Output of electric grill kW - - - 1,8 1,8

Accessories Plate for Plate for Plate for Plate for Plate for

pastry pastry pastry pastry pastry

Pot rest Pot rest Pot rest Pot rest Pot rest

Protective Protective

screen for screen for

knobs knobs

The gas hob is registered acc. to German Standard DIN-DVGW.

CATEGORY II 2 ELL 3 B/P

This appliance corresponds to the

following

E.E.C. regulations:

- 73/23 - 90/683 (low voltage guideline):

- 89/336 (EMC guideline):

- 90/396 (gas guideline):

- 93/68 (general instructions):

and subsequent changes.

PRODUCER: ELECTROLUX HAUSGERÄTE

Rennbahnstraße 72-74

60528 Frankfurt

38

Page 6

INSTRUCTIONS FOR USE

OPEN BURNERS

● The open burners are thermoelectrically secured in

a way that the feed of gas will automatically be shut

off when the flame goes out.

● Lay the burner caps always exactly on the burner

chalice.

● The slots of the burner chalice must not be obstructed.

● The burner caps are enamelled

● Operate the open burners with items to be cooked

put on, only!

PUTTING INTO OPERATION

OF THE OPEN BURNERS

To ignite the gas burner bring a flame (matchstick,

lighter or igniter) to the desired burner, with that push

the corresponding rotary knob quite in and turn it

counterclockwise up to the position for maximum temperature. As soon as the burner is ignited, set the gas

flame as required.

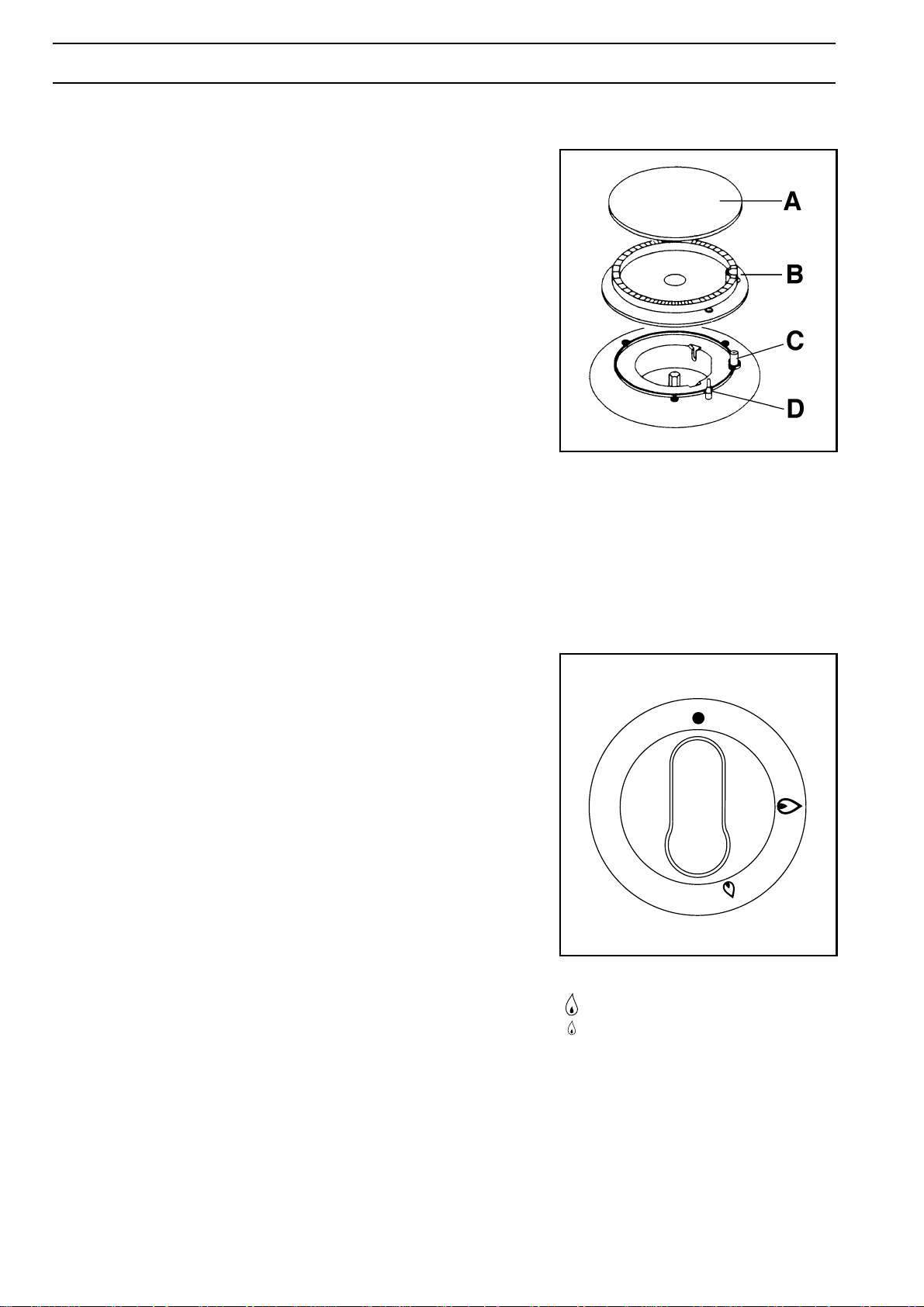

Fig. 5

FO 0204

Open burner

A Burner cap

B Flame distributor crown

C Spark plug

D Temperature sensor

In case of models with integrated automatic ignition

push the ignition button, which is marked by a small

spark symbol, at the same time quite push in the

corresponding rotary knob and turn it counterclockwise

up to the position for maximum temperature.

Because of pushing the ignition knob an ignition spark

will jump over to the burner and ignite it. After ignition of

the flame keep the rotary knob pushed in for about 5

seconds; this time is required to heat up the „temperature sensor“ (fig. 5, letter D) and to switch off the safety

valve, that otherwise would interrupt the feed of

gas. Afterwards check whether the flame is uniform and

turn the rotary knob to the desired strength.

In case the burner will in spite of several trials not ignite,

make sure that the flame distributor crown (fig. 5, letter

B) and the burner cap (fig. 5, letter A) are correctly laid

on.

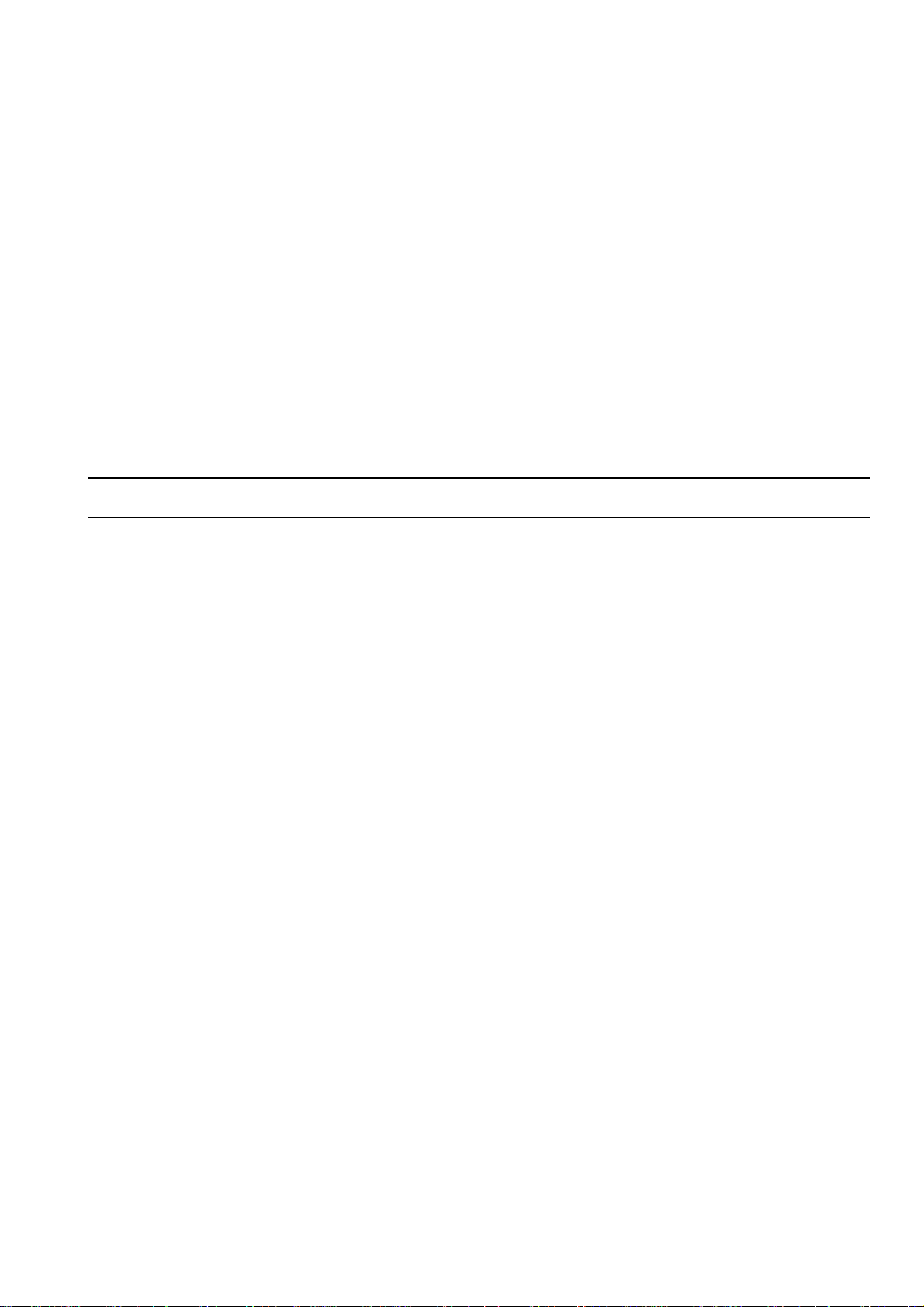

To interrupt the gas feed turn turn the rotary knob in

clockwise direction up to position „●„.

When using fat or oil you must not leave it out of

visual control during the cooking procedure, as it

may flare up when being heated.

Fig. 6

●

Gas feed closed

High-burner

Low-burner

39

Page 7

COOKING ON THE OPEN BURNERS

PRESERVATION

When switching on the open burners for first-boiling/

frying, start at first with a big flame, and

afterwards set back to a small flame for cooking on. The

pot size must be chosen in a way that the flames will not

exceed the pot rim. You may use pots of at least 240 to

260 mm diameter with the

heavy-duty burner, pots of at least 200 to 220 mm

diameter with a standard burner, and pots of about 160

mm diameter and smaller with the auxiliary burner.

Always put the dishes in the middle of the open burner.

OVEN

● The oven burner is thermoelectrically secured in a

way that the feed of gas will automatically be cut off

if the flame goes out.

Most convenient is preserving in a water bath in a big

preserving pot on the heavy-duty burner.

Prepare the glasses in the usual manner. Make use of

commercial preserving glasses with rubber ring and

glass lid. Glasses with screw cap or bayonet catch and

metal boxes must not be used.

Put the glasses in the water bath, not, however, on the

pot bottom, but e.g. on a wire shelf. The glasses should

be about ∫ of the height in the water bath

Upon reaching the boiling of the water set the flame

smaller in a way that the water keeps on slightly boiling.

In preserving pots without a thermometer the firstboiling time is calculated from the start of boiling of the

water.

● The oven temperature is thermostatically controlled.

After ignition the oven burner performs with full

output until reaching the temperature set. Afterwards

the thermostat reduces the output to the value

required for keeping the temperature set.

● This control is effective with the door closed, only.

● The oven bottom can be removed for cleaning.

PRIOR TO FIRST USE

● Remove all accessories from the oven.

● Clean eneamel and glass surfaces with a wet cloth.

● After connection of the appliance operate the oven

for about 1 hour at max. temperature setting (see

paragraph: Putting into operation of the oven burner).

The smell resulting thereby will be safe if the room is

adequately ventilated.

● Afterwards wipe out the oven with a wet cloth and

dry.

40

Page 8

PUTTING INTO OPERATION

OF THE OVEN BURNER

● Attention! When operating the oven burner the

ceiling slide must be pushed in against stop.

● The oven burner is ignited with the door opened.

● Turn the oven control knob to the left in porition 10,

push in against stop, and ignite the gas flowing out.

After ignition keep the control knob pushed in for

about 5 more seconds until the temperature sensor

is sufficiently heated and the flame remains stable.

Afterwards the control knob can be set to the position

desired between 1 and 10.

● Watch the flame picture. If the flame goes out, repeat

the ignition procedure.

Models with integrated automatic ignition

● Push in the knob for oven/electric grill, turn from the

right to the left up to highest marking and keep the

knob pushed in.

● At the same time one pushes the button for the

electronic ignition in order to generate sparks. Keep

the knob pushed in until appearance of the flame

(one spark will be generated after each second).

● To switch off the burner turn the knob to position

„●„ (OFF)

Abb. 7

1

10

9

8

7

6

〈 Closed position (off)

1-10 Operating position of oven burner

2

3

4

5

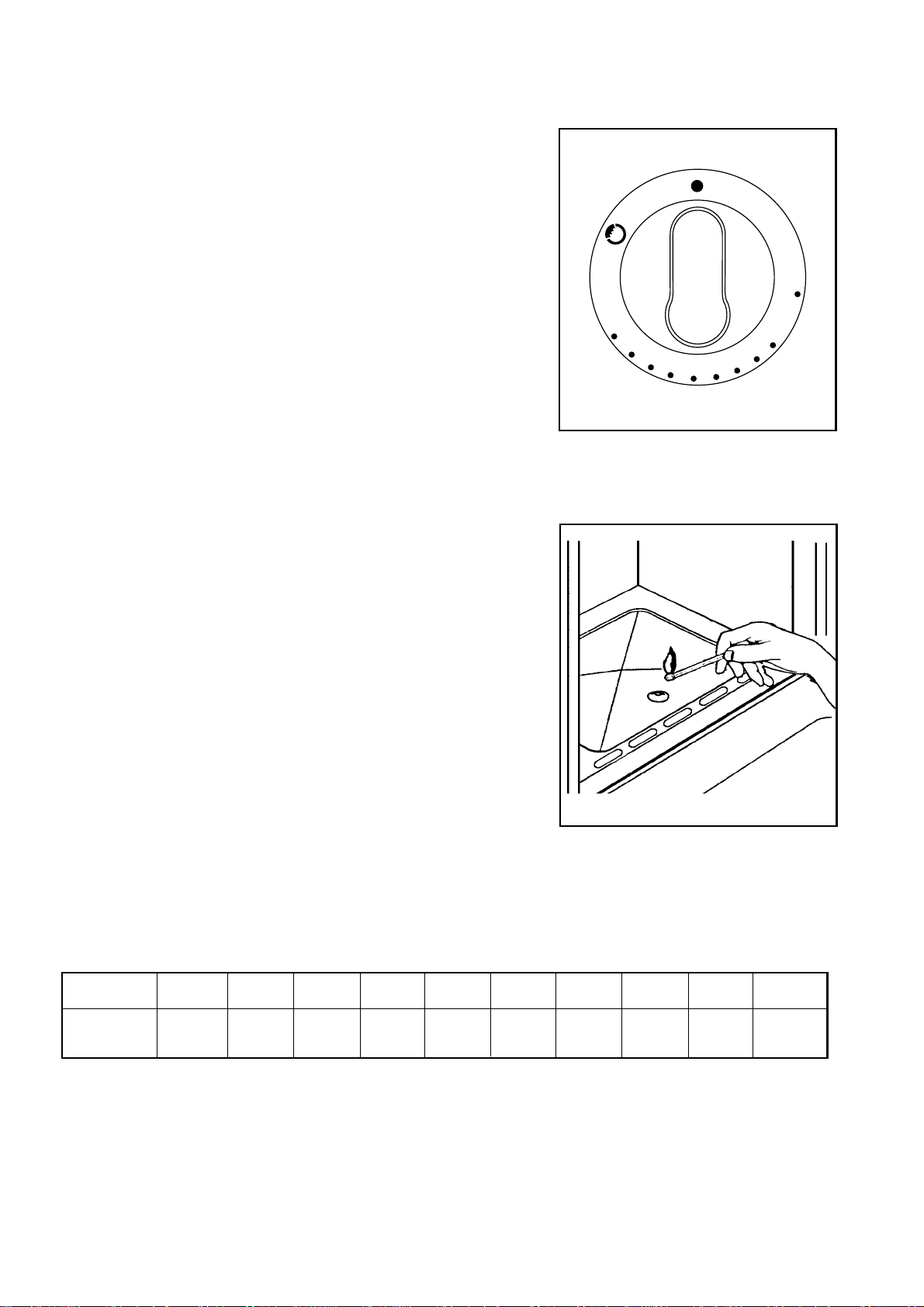

Fig.. 8

TEMPERATURE SETTING

In correspondence with the items to be baked/roasted

and after ignition turn the oven knob to the required

temperature setting from 1 to 10

Position 1 2 3 4 5 6 7 8 9 10

Temperature

140°C 150°C 160°C 180°C 190°C 200°C 220°C 230°C 240°C 260°C

FO 1079

Ignition of the oven burner

41

Page 9

USE OF THE ELECTRIC GRILL

Attention:

● When using the electric grill the accessible parts

can be hot. Keep children off the appliance.

● The electric grill is used with half opened door.

The protective screen must also be installed.

To switch on the electric grill push in the oven control

knob and turn clockwise to marking .

When grilling direct on the wire shelf (grilling food), push

the fat collector into the rails under the grill.

INDICATOR LAMP FOR ELECTRIC GRILL

This lamp is located at the right of the control panel and

comes on when the electric grill is switched on.

In case of models with gas oven and during grill operation

leave the oven door open a crack and mount the

protective strip for the knobs (Fig. 8).

USE OF ACCESSORIES

The oven bottom sheet must always be pushed in

during operation.

The drip pan or the baking sheet must always be pushed

against the rear wall. With that the slots of the drip pan

must show to the rear.

Fig. 8

FO 2124

4

3

2

1

When roasting on the wire shelf insert the drip pan into

the lowest runner

42

Fig. 9

FO 0019

Details on the use of the runner levels are to

be taken from the baking/roasting chart.

Page 10

PREHEATING

If need be, preheat the oven acc. to the instructions in

the baking/roasting chart.

BAKING IN THE OVEN

Cakes on the baking sheet or in the drip pan are

baked on the middle shelf level, only. With that

always insert only one baking sheet.

Put cakes in a baking tin always on the wire shelf.

With that the baking tin should not protrude over the

rear rim of the wire shelf. Several baking tins can also

be put on the wire shelf. Dark tins are not

recommended; they absorb too much of the heat

radiated by the oven. Recommended are bright tins.

Prepare baked goods acc. to recipes. The temperature setting values, the shelf level as well as the

corresponding baking times required for the items to

be baked are to be taken from the baking chart.

Same refers to preheating requirements.

On principle the shorter duration of baking should

always be referred to. A cake baking too quickly from

top will not rise or collapse because of not enough

baking out of humidity.

Before switching off the oven stick a small wooden

rod into the baked goods. When pulling out again it

has to be dry and free from adhering traces of dough.

Turning over of the roast is only necessary when

roasting at higher temperatures.

The gravy ingredients for the perfection of taste such as chopped garlic, omions, roots, mush-rooms

or tomatoes, with lean meat also bacon and other fat

- are added into the drip pan with short roasting time

just in the beginning, and with longer roasting time

about during the last hour. Hot water (1/2 to 1 liter) is

added acc. to the desired degree of browning of the

roast and of the gravy ingredients. An earlier addition

of water will delay the effect of browning and the

gravy becomes too bright.

The temperature setting values required for the

individual roast are to be taken from the roasting

chart.

The roasting time is dependent on the size of the

meat. Considered in general are 12 - 15 min of

roasting time per centimeter height of meat.

By „spoon pressure“ you may check the state of

cooking of the roast; a well-done roast will resist to

the spoon pressure.

The meat juice of quite well-done meat is gray.

By measuring the core temperature inside the roast

by meanns of a commercial meat probe one may find

out when the meat roast will be ready. Dependent on

the sort of meat the core temperature can be taken

from the following chart.

With some dough remaining on the rod switch off the

oven and make use of the residual heat for about 5

minutes.

After the baking have the cake stand in the tin for 5 to

10 minutes. Afterwards loosen from the tin or from

the sheet and have it cool down on a cake grid.

Before making the first cut the items baked must be

quite cold.

ROASTING IN THE OVEN

An economical preparation is recommended only with

at least 1 kg of meat. Smaller roasts should then be

prepared on the open burner.

The meat must be well hung. Remove tendons, wash

and dry. Bones should be removed from roasts

before. This will reduce the roasting time and the

roast can better be carved. Only short before the

insertion of the roast salt and season, or brush it

about 10 minutes before the end of roasting time with

a pickle of water or oil, salt, paprica, pepper, etc.

Depending on the sort of meat the roast can be

prepared on the wire shelf, in the open (drip pan) or

closed vessel.

The prepared meat is placed on the wire shelf with

the „serving side“ or the fat side resp. to the top; the

crackling cut in squares. Lean meat is brushed with

oil or coated with slices of bacon.

The drip pan and the wire shelf with the meat are

together inserted into the oven.

MEAT ROAST CORE TEMPERATURE

Roast Core temp. at the

end of cooking in °C

Beef filet 45 - 55 English

Beef filet 55 - 65 pink

Beef filet 65 - 75 well-done

Beef roast 80 - 90 The lower core

temperature is

Pork roast 80 - 90 mainly chosen for

firm, juicy meat.

Spareribs 70 - 80 The higher core

temperature is

Roast veal 70 - 90 used for well-

cooked, dry meat

Roast lamb 70 - 85 and for roasts to

be well-cooked to

Roast venison 70 - 85 the inside.

Meat loaf 80 - 90

43

Page 11

POULTRY

Poultry is of high value for nutrition and taste. Preparation

is possible in a fresh or defrosted state. Carefully clean

the poultry, have it drip off and swob dry. Then salt inside

and season. Poultry can also be stuffed just as you like.

Poultry can be prepared in a big roasting vessel, on the

wire shelf, or direct in the drip pan. Have fat roasts cook

on the wire shelf in order to enable the fat to drip off. At

first pour about ˚ l of hot water into the drip pan. At the

end of the roasting time pour a little cold brine over the

roast at highest tempera

ture setting in order to obtain an especially crispy

surface.

GAME

Game is rich of valuable proteins, low-fat and easy to

digest. It stands for high contents of flavoring agents

which are providing the meat with the characteristic

nourishing flavour. Game must be well hung. Deepfrozen pieces of roasts are to be defrosted before

preparation.

Carefully remove the skin from the meat and the tendons.

Remove the fat as it gives off an unpleasant taste. In

particular with roasts of

venison and wild boar. Quickly wash the meat, or wipe

off with a wet cloth, and dry. Only short before roasting

rub salt and spices into the meat. Coat the meat with

slices of bacon or lard.

The meat becomes more tender as a result of laying it

2-3 days before the preparation in a pickle or marinade.

Game is at best to be roasted in a closed vessel in order

to keep it most juicy. When roasting in the drip pan rinse

same at first with water and, if need be, lay out with

stripes of bacon. Loosely

cover the prepared roast with an aluminium foil and fix

it on the rim.

Too high temperatures are unfavourable as the meat

will dry out easily.

HINT

Recipe data as well as hints on the preparation for

boiling, baking and roasting are furthermore to be taken

from cooking and recipe literature as available from

specialist dealers.

PRESERVING IN THE OVEN

● Up to 6 preserving jars of 1 to 1.5 l capacity can be

prepared in the oven.

● As usual prepare the items to be preserved and the

jars.

● Exclusively make use of commercial jars with heatresistant rubber rings. Glasses with screw cap or

bayonet catch and metal boxes must not be used.

● Insert the drip pan into the first shelf level from the

bottom. Put the prepared jars in the drip pan. The

glasses must not touch each other and should be

filled to possibly the same height and with the same

contents and be clamped together. Fill the drip pan

to the half with hot water. Set the temperature control

knob to position 2 or 3.

● Watch the items to be preserved until the liquid in the

glasses will start to pearl (after about 40 - 50 min with

1 l-glasses, after about 60 min with 11/2 l-glasses).

● In case of fruits and pickled gherkins then switch off

the oven, but have the glasses stand in the closed

oven for about 30 more minutes (about 15 more

minutes with delicate fruits, such as strawberries,

about 15-40 more minutes with stone and core fruits)

● In case of vegetable or meat resp. and after reaching

the state of pearling, accordingly set back the temperature and have the jars remain in the closed oven for

about 30 more minutes.

● Then remove the jars at once. Do avoid a slow

cooling down in the oven, as this would support

another new formation of germs.

44

Put the jars on an absorbent cloth, cover them and

protect against draught.

Page 12

CHART ON BAKING / ROASTING / GRILLING

Dishes Weight (g) Shelf level Height Pre-heating Temperature Time

from below setting °C °C (min.)

BAKING

Pastries in moulds

High ring cake 1500 3 yes 170° (3) 60 - 70

Marble cake 1500 3 yes 170° (3) 60 - 70

Cake in oblong tin 1000 3 yes 170° (3) 60 - 70

Cheese cake 1500 3 yes 170° (3) 60 - 70

Sponge cake 750 3 yes 160° (2) 35 - 45

Tart base, stirred dough 750 3 yes 170° (3) 20 - 30

Pastries on baking sheets

Rye bread 1000 3 yes 180° (4) 60 - 70

Yeast plaited loaf 1000 3 yes 170° (3) 35 - 45

´Strudel´ 500 3 yes 170° (3) 50 - 60

Yeast cake with dry topping 750 4 yes 160° (2) 30 - 35

Yeast cake with wet topping 1000 3 yes 160° (2) 45 - 50

Swiss roll 400 3 yes 160° (2) 10 - 15

Small pastries (stirred dough) 300 3 yes 160° (2) 12 - 18

Small pastries (puff paste) 500 4 yes 160° (2) 20 - 30

Rolls 500 4 yes 180° (4) 15 - 25

Cream buns / éclairs 300 4 yes 180° (4) 20 - 30

ROASTING

Meat

Roast pork 1000 3 - 175° (3) 90 - 120

Roastbeef 1000 3 yes 190° (5) 45 - 60

Roast veal, abt. 1 kg 1000 3 - 190° (5) 60 - 90

Poultry

Chicken 1000 3 - 190° (5) 60 - 90

Duck 1700 3 - 190° (5) 120 - 180

Goose 3000 2 or 3 - 180° (4) 150 - 210

Fish

Whole fish (mackerels, etc.) 1000 3 - 185° (4) 40 - 50

Soufflés and gratins

Vegetable soufflé 500 3 - 185 ° (4) 40 - 50

Noodle soufflé 1000 3 yes 205° (6) 40 - 50

Vegetable gratinated 500 3 yes 190° (5) 30 - 40

Dishes Oven switch Shelf level height Grilling time

from below

Pork cutlet 4 10 min per Side

Beef cutlet 3 20 min per Side

Merguez-sausages 4 10 - 15 min

Fish 3 - 4

Chicken portions 3 20 min per Side

10 - 15 min acc. to size or thickness

Hot dishes 3 5 - 10 min

Farinaceous products gratinated 3 5 - 10 min

Fancy meringue 3 5 min

Hot toast with bacon and cheese

Roasted pudding

4 5 min

3 5 min

45

Page 13

CLEANING AND CARE

- For cleaning do not make use of scouring agents,

caustic cleaners and hard objects.

- Do not scratch off burnt-in residues, instead soak them

with a wet cloth or with hot water resp. and remove with

a little cleanser additives.

OPEN BURNERS

For the cleaning of pot rests, hob unit and open burner

sections use hot water with a little cleanser additive;

also clean the temperature sensor with a small soft

brush.

The slots of the burner chalice must be kept clean, too.

Relocate the burner parts correctly. Not correctly

positioned burner caps will make ignition more difficult.

After cleaning do well dry the open burner.

OVEN

FO 0416

Fig. 10

The still warm oven is to be cleaned after every use with

hot water with a little cleanser additive! For better

cleaning of the oven the bottom slide can be removed.

When cleaning make sure that spray will not be sprayed

on the temperature sensor located at the oven ceiling.

Never clean the oven burner by yourself. Have this

cleaning work exclusively be carried out by an expert

fitter. This procedure is only needed where the flames

will not burn at all gas outlets.

After cleaning re-install the bottom slide!

OVEN DOOR REMOVAL

The door can be removed for more efficient cleaning.

Attention! Careless use of the oven will result in

danger of hurts in the area of the door hinges!

Unhooking of the oven door

- Fold the door down in horizontal position.

- Door catches on both sides to be clockwise turned by

30 degrees by means of a screwdriver.

- Slightly lift the door and remove.

Fig. 11

FO 0417

Reinsertion of the oven door

- When re-installing the door lift the lower hinge frame

and on both sides introduce into the openings

provided at the cooker.

- Turn back the door catches.

46

Fig. 12

FO 0967

Page 14

TOP LID REMOVAL AND REINSERTION

For better cleaning the top lid can be removed.

- For removal fold up the lid and remove upward.

- For reinsertion of the lid introduce the pivot pins

vertically into the pin guide.

OVEN LAMP

Prior to replacement the cooker must be

separated from the mains by unscrewing the

fuses or switching off the circuit-breaker!

Unscrew the glass cover in anticlockwise direction and

replace the bulb (socket E 14, 230V, 25 W, 300°C).

Afterwards screw down the glass cover again.

The replacement of the oven lamp is not covered by the

guarantee.

REPLACEMENT OF COOKER

COMPONENTS

In case of damage the customer must replace only parts

removable without the use of tools. The replacement of

parts to be removed with tools must exclusively be

carried out by an approved electrician or gas fitter resp.

● The control knobs for open burners and oven can be

drawn off to the front.

Fig. 13

Fig. 14

FO 0418

FO 0424

● Spareparts can be ordered with the after-salesservice under indication of ordering number and

model name of the appliance

● Trouble

In case of trouble with the gas section or when

smelling gas resp. do at once:

- close the gas tap of the gas feed or direct

at the bottle resp.!

- extinguish the gas burners or all flames

resp., and cigarettes!

- do not switch on any electrical appliance!

- ventilate the room!

- inform the gas fitter!

47

Page 15

MONTAGEANWEISUNG

IMPORTANT HINTS

● The connection of the gas cooker must exclusively

be carried out by an approved gas fitter. This must

happen under adherence to DVGW/ÖVGW

regulations, technical rules, guidelines of federal

building regulations, guidelines and regulations of

gas supply boards as well as to the following

standards:

- DVGW, worksheet G600 (DVGW-TRG, 1986)

- Technical rules for gas installation

- TRF 1988 - Technical rules for LPG

● Prior to installation one must check whether the

indications on the typeplate are in conformity with

the local gas conditions.

● The gas connection must be accessible and provided

with a shutoff device.

● Prior to any action stop the feed of gas to the cooker

● The minimum distance between gas cooker and

cooker hood must correspond to the instructions

given by the manufacturer of the hood.

● Prior to the opening or exposure of live parts the gas

cooker must be made dead! Remove fuses or activate

the earthing-pin plug.

Gas

connection

Gas

connection

Fig. 15

FACTORY-SIDED SETTING

● The gas cooker is tested and registered acc. to

German Standard DIN-DVGW.

● The gas cooker is supplied with the sealed gas

setting to natural gas, towns gas, or LPG and

accordingly marked with a label.

● All gas burners are thermoelectrically secured in a

way that the feed of gas will automatically be shut off

when the flame goes out.

● The indications are given on the typeplate of the

cooker. The typeplate is visible after door opening.

● The load and the throughput of gas of the individual

burners are to be seen in chart I.

● A replacement of jets is required for the conversion

to a different type of gas. The indications are given in

chart II to VII.

● With conversion to a different type of gas, with

repairs, or with a damaged sealing (only with natural

gas E 15), the functional parts must be checked acc.

to installation instructions and sealed again.

Functional parts are: high-burner jet, low-burner jet

and for the oven in addition the primary air focusing

sleeve.

Fig. 16

FO 0994

115

400

780

48

Page 16

GAS COOKER INSTALLATION

When installing the gas cooker a safety distance of 15

mm must be kept towards the adjacent furniture. If this

safety distance cannot be kept, a thermal insulation will

have to be located between the side panels and the

furniture.

Align the gas cooker horizontally. For that do horizontally

align the open burners by means of the set screws

mounted in the base and adapt the upper edge of

cooker to the adjacent furniture.

GAS CONNECTION

On the back side (left and right) the cooker is provided

with two gas sockets R 1/2“.

The gas connection must be accessible and provided

with a shutoff device.

Recommended is a safety gas socket. Same should be

located at the right or left, outside the radiation area. The

connection can be carried out rigid or by the use of a

DVGW-approved safety gas hose with socket acc. to

DIN 3383, page 1. In case the gas connection is not to

be carried out at the side prepared, but instead at the

other side, the closure will have to be loosened and

attached on the other side. Always insert a sealing

washer. Afterwards connect to the gas supply at the free

side.

When using the safety gas hose make sure that same is

not guided through hot zones, but freely installed.

After connection subject cooker and connection to a

sealing test.

PUTTING INTO OPERATION

Fig. 17

Fig. 18

FO 0063

A

FO 0605

A Ramp end piece

B Round disk

C Ramp closure

A

B

C

Putting into operation to be carried out acc. to instructions

for use.

Ignite each open burner and check the burning stability

of high-burner and low-burner setting. (see par.: open

burner setting).

Heat up the oven burner for at least 10 minutes at

highest temperature setting. Then turn the oven control

knob to position 1. The burner must burn with a little, but

stable flame (see par.: oven burner setting).

After inspection: user to be instructed, function and

operation to be explained, instructions for use to be

handed over.

49

Page 17

CONNECTION TO THE MAINS

The appliance is designed for the operation with a onephase supply voltage of 230 V.

The electrical connection must be carried out acc. to the

valid standards and the relevant legal prescriptions.

Before the execution of the electrical connection make

sure that

- fuselage and house installation are designed for the

max. load of the appliance (see typeplate);

- the house installation is provided with a correct earthing

that will also correspond to valid standards; socket and two-pole switch will also be easily accessible

if the appliance is switched on.

The connection must be carried out direct, i.e. without

plug connection. For that there must be provided between

appliance and power supply a two-pole switch with a

gap of at least 3 mm between the contacts, which is

designed for the load of the appliance and corresponding

with the valid standards. The yellow-green earthing

cable must, however, not be interrupted by a switch.

The brown phase cable (starting at terminal „L“ on the

terminal board of the cooker) must always be connected

to the power supply phase line. The power supply cable

is to be installed in a way that no position will reach a

temperature exceeding 50°C above room temperature.

If there is need to replace the power supply cable, do

please make use of cable type H05RR-F with a crosssection designed for the load of the appliance. The little

yellow-green earthing cable must be longer by about 2

cm than the phase cable and the neutral conductor (fig.

19).

After completion of the electrical connection check all

heating elements by switching them on for about 3

minutes.

The producer rejects any liability for the case that

the afore-mentioned measures for the prevention of

accidents will not be complied with.

Phase

earthing cable (yellowgreen)

Fig . 19

50

Page 18

CONVERSION TO OTHER TYPE OF GAS

When converting to a different type of gas there is need

for an additional setting of the amount of gas or for a

replacement of jets resp. (see charts I to VII).

CONNECTION TO LPG

A metallically sealed connection piece 8 x 1 mm must be

fitted to the R 1/2“ gas supply socket. When doing so

please focus on leakage testing .

REPLACEMENT OF OPEN BURNER

HIGH-BURNER JETS

- Remove pot rest, burner cap and burner chalice.

- By means of a wrench replace the high-burner jets

acc. to indications and descriptions in charts I to VII.

CONVERSION OR REPLACEMENT

OF LOW-BURNER JET

- Remove pot rests, hob unit covers and burner

chalices.

- Loosen the fastening screws of the hob unit and

remove.

- Loosen the 3 each visible fastening screws of the

open burners. Remove the hob unit.

- Draw off the control knobs to the front.

- Unscrew the fastening screws of the control panel.

- Set or replace resp. the low-burner jet acc. to charts

I to VII.

- Re-install in reverse sequence.

Fig. 20

Fig. 21

FO 0392

FO 0069

low-burner jet

FO 0068

Fig. 22

51

Page 19

REPLACEMENT OF OVEN JET

- Pull out the oven bottom sheet.

- Unscrew the fastening screw and remove the oven

burner

- Turn out the burner jet and insert the jet suitable for

the new type of gas acc. to charts

I to VII.

- Re-install in reverse sequence.

oven burner

OVEN TEMPERATURE CONTROL

Instructions for the adjustment of the by-pass needle

of the oven burner thermostat.

The adjustment of the round head by-pass needle for

models provided with this feature, is carried out as

follows:

- Remove the selector switch;

- Take away the control panel;

- Carry out the adjustment by means of a fine-edged

screwdriver, refer to the figure.

- At first check, whether a quick turning of the tap from

maximum flame to minimum flame would result in

extinguishing the flame.

PERFORMANCE TEST

Carry out a performance test after conversion of the jets

and after maintenance and repair work:

- In accordance with the instructions for use put the

appliance into operation.

- Carry out a sealing test acc. to DVGW-TRGI or TRF

resp.

- In cold and warm state check the burning safety of all

burners.

Fig. 23

Fig. 24

Fig. 25

FO 1132

fastening

screw

FO 1072

oven burner jet

FO 0112

INFORMATION OF THE USER

- Make the user familiar with the operation of the

appliance.

- In particular refer to the fact that structural changes,

which may affect the supply of combustion air, will

have need for a nother performance test.

GREASING OF THE TAPS

If after longer use the taps cannot be actuated at ease,

the sliding faces will have to be greased. Proceed as

follows:

- Shut off the gas supply.

- Put the control knobs in 0-position and pull off.

- Remove the control panel.

- Dismantle the tap caps and pull off the plugs of the

tap.

- Clean and regrease the sealing faces. The tap

grease must be applied very thin, only.

low-burner jet

Fig. 26

Attention!

Never interchange tap housing and plug as otherwise

there will be no guarantee for sealing.

FO 0392

52

Page 20

THERMAL LOAD, THROUGHPUT OF GAS, MARKING OF JETS

Chart I

Cooker setting Burner spot Auxiliary burner Standard burner Heavy-duty Oven burner

burner

high low high low high low high low

Natural gas "E" Thermal load kW 1 0,33 2 0,45 3 0,65 3 0,85

20 mbar

H5 = 37,78 MJ/m3Throughput of gas l/h 95 31 190 43 286 62 286 81

W5 = 50,72 MJ/m

Natural gas "LL" Thermal load kW 1 0,33 2 0,45 3 0,65 3 0,85

20 mbar

H5 = 32,49 MJ/m3Throughput of gas l/h 111 36 221 50 332 72 332 94

W5 = 41,52 MJ/m

LPG Thermal load kW 1 0,33 2 0,45 3 0,65 3 0,85

50 mbar

H5 = 125,81 MJ/m3Throughput of gas l/h 73 24 145 33 218 47 218 62

W5 = 87,33 MJ/m

3

Marking of jets 70 E 96 E 119 E 116 E

3

Marking of jets 74 E 106 E 133 E 128 E

3

Marking of jets 43 23 60 28 75 35 76 40

The term „marking of jets“ is referring to the jet diameter in hundredth of mm. In case of jets marked with

„E“ the nominal values for thermal load and for throughput of gas are achieved by the setting of jets.

CONVERSION TO OTHER TYPE OF GAS

Chart II

Conversion from natural gas E to ...

Open burners

High-burner Low-burner

NATURAL GAS LL Unscrew high-burner jet (fig. 20) and screw No conversion

down the jet for gas LL acc. to chart I

LPG Unscrew high-burner jet (fig. 20) and screw Unscrew low-burner jet (fig. 22) and acc. to chart I

down the jet for LPG acc. to chart I. screw down the setting jet for LPG until stop .

With conversion to a different type of gas fix a corresponding label!

53

Page 21

Conversion from natural gas E to ...

Oven burners

High-burner Low-burner Primary air

NATURAL GAS LL Unscrew high-burner jet (fig. 23, 24, No conversion

25) and screw down the jet for gas

LL acc. to chart I.

Chart III

LPG Unscrew high-burner jet (fig. 23, 24, Unscrew low-burner jet (fig. 26)

No conversion

25) and screw down the jet for LPG and acc. to chart I screw down

acc. to chart I. the setting jet for LPG until stop.

Conversion from LPG to ...

Chart IV

Open burners

High-burner Low-burner

NATURAL GAS E Unscrew high-burner jet (fig. 20) Unscrew low-burner jet (fig. 22)

and screw down the jet for natural gas and acc. to chart I screw down

LL acc. to chart I. the jet for natural gas E until stop.

NATURAL GAS LL Unscrew high-burner jet (fig. 20) Unscrew low-burner jet (fig. 22)

and screw down the jet for natural gas and acc. to chart I screw down

LL acc. to chart I. the jet for natural gas LL until stop.

With conversion to a different type of gas fix a corresponding label.

When setting to natural gas E the high-burner fixed jet, the low-burner setting jet as well as the primary air setting

sleeve will have to be sealed-in again.

Conversion from LPG to ...

Chart V

Oven burners

High-burner Low-burner Primary air

NATURAL GAS Unscrew high-burner jet (fig. 23, 24, Unscrew low-burner jet (fig. 26)

E 25) and screw down the jet for natural and acc. to chart I screw down

gas E acc. to chart I. the setting jet for natural gas E

until stop.

NATURAL GAS Unscrew high-burner jet (fig. 23, 24, Unscrew low-burner jet (fig. 26) No conversion

LL 25) and screw down the jet for natural and acc. to chart I screw down

gas LL acc. to chart I. fthe setting jet for natural gas LL

until stop.

With conversion to a different type of gas fix a corresponding label.

When setting to natural gas E the high-burner fixed jet, the low-burner setting jet as well as the primary air setting

sleeve will have to be sealed-in again.

54

Page 22

Conversion from natural gas LL to ...

Open burners

High-burner Low-burner

NATURAL GAS E Unscrew high-burner jet (fig. 20)

and screw down the jet for natural gas No conversion

E acc. to chart I.

LPG Unscrew high-burner jet (fig. 20) Unscrew low-burner jet (fig. 22)

and screw down the jet for LPG and acc. to chart I screw down

acc. to chart I. the setting jet for LPG until stop.

With conversion to a different type of gas fix a corresponding label!

Chart VI

Conversion from natural gas LL to ...

Oven burners

High-burner Low-burner Primary air

NATURAL GAS E Unscrew high-burner jet (fig. 23, 24, No conversion

25) and screw down the jet for gas

E acc. to chart I.

LPG Unscrew high-burner jet (fig. 23, 24, Unscrew low-burner jet (fig. 26)

25) and screw down the jet for LPG and acc. to chart I screw down

acc. to chart I. the setting jet for LPG until stop.

Chart VII

No conversion

55

Page 23

WHAT TO DO, IF ...

To file an after-sales-service call is not always necessary. In some cases you may cure the problem by yourself.

For this purpose please find some hints below.

Important! Repair work must exclusively be carried out by experts. Inappropriate repairs may result in

considerable danger for the user.

What is, ... Possible cause Remedy

... if a liquid or a highly liquid dough is Appliance not horizontally installed. Align the appliance by means of the

distribuited rather unilaterally? adjustable legs located underneath or check

... if the open burners are irregularly burning Flame picture irregular due to wrong gas Have the gas setting checked.

after installation of the appliance? setting

... if the flame picture of the open burners has Wrongly laid on burner parts. Correctly put the removable burner parts in

changed all of a sudden? place.

... if a cake or pastry gets dark underneath? Baking sheet too close to oven bottom. Insert cake or pastry in a higher shelf level of

wrong shelf level. Or too high temperature. the oven.

the installation.

... if the baking result is not satisfactory? Wrong oven setting. Carry out the oven setting acc. to the baking

... if smoke develops when roasting? Oven temperature too high Set a lower roasting temperature.

Distance not enough between grill element Increase the distance between grill element

and items to be grilled and items to be grilled

... if the oven is heavily soiled during roasting? Oven temperature too high Set a lower roasting temperature.

Wire shelf and drip pan wrongly inserted. Put the wire shelf above the drip pan and

... if the oven burner is continuously going out Wrong gas setting. Have the gas setting checked by the

after installation of the appliance? appliance installer.

... if the oven burner gies out all of a sudden? Quick closing of the oven door (resulting air Slowly close the oven door if the oven is

pressure) in operation.

... if oven door glass pane or window is Waste air opening covered Do not cover the waste air opening by pots,

steamed-up during heating up? pot cloth, etc.

... if oven door must be pushed? Normal appearance, is due to existing Not possible, adequacy will not be impaired.

difference in temperature.

... if the flame goes out after ignition of the Pushed too shortly Knob to be pushed longer

burners?

Pushed not strong enough Knob to be pushed strongly prior to release.

... if the cake gets too bright underneath? Wrong shelf level. Insert the cake in a lower level.

indications given in recipe booklets or in

charts.

insert together in one shelf level.

... if the cake gets too dry? Roasting temperature too low. Slightly increase the roasting temperature.

Baking time too long. Select a shorter baking time.

... if the cake is slippery, doughy inside or Baking or roasting temperature too high. Set baking or roasting temperature slightly

if the meat will not get cooked inside? lower.

Baking or roasting temperature too short. Select a longer baking or roasting time,

Too much liquid in the cake dough. Put less liquid in the cake dough.

Note:

Baking or roasting times cannot be reduced

by higher setting of the oven temperature

(outside cooked, inside raw)

have the dough rise longer

56

Page 24

SERVICE AND SPAREPARTS

The gas cocks must be periodically lubricated to

ensure good working and safety.

Maintenance should be performed as follows:

● Remove the knob and panel after having taken out

fastening screws.

● Loosen the two screws located at the sides of the

cock bar.

● Remove the cone and clean it carefully.

● Then, apply a thin layer of grease non soluble in

water, suitable for gas cocks. Take care not to

obstruct the gas flow holes by an excess of grease.

Reassemble the whole with utmost care performing the

operations described above inversely.

ORIGINAL SPARE PARTS

This machine, before leaving the factory, has been

tested and studied by many experts and specialists, in

order to give you the best results.

Any repair work which needs to be carried out should

be done with the utmost care and attention.

For this reason we reccomend that for any problem you

contact the dealer who sold it to you, or our nearest

authorized Service Centre, specifying the nature of the

problem and the particular model which you own.

Original spareparts, certified by the product manufacturer

and carrying this symbol

are only available at our Service Centre and authorized

spareparts shops.

57

Loading...

Loading...