Page 1

Montagevorschrift und Gebrauchsanleitung

für die Dunstabzüge

Prescriptions de montage et mode d’emploi de la hotte aspirante

Instruction on mounting and use of the cooker hood

Istruzioni di montaggio e d’uso della cappa aspirante-filtrante

JDK 8420 E, JDK 9420 E

Der Umwelt zuliebe auf

Recycling-Papier gedruckt

Imprimé sur papier recycle

For this instruction manual has

been used recycled paper

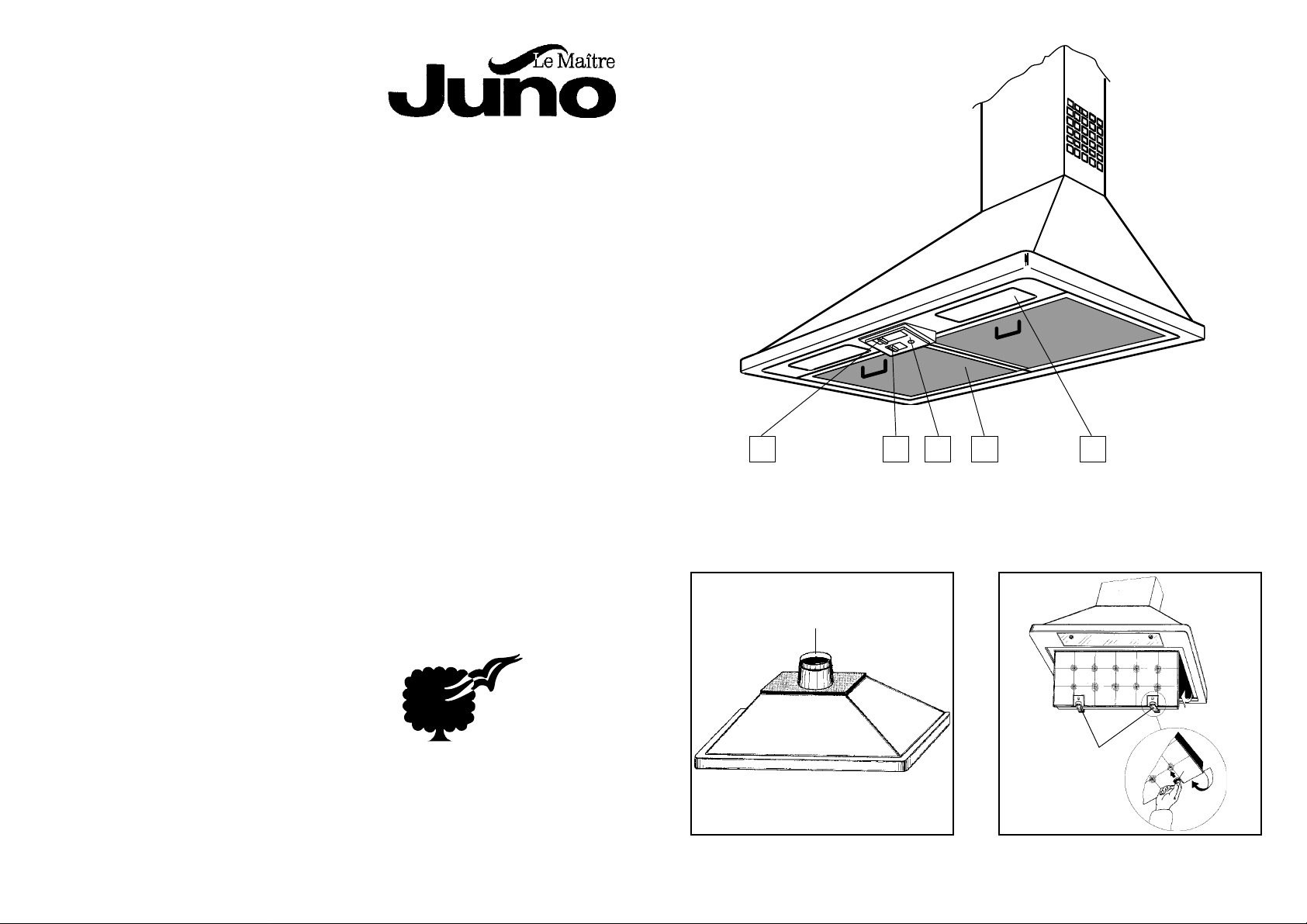

3

12

A

4

5

Questo libretto è stato

stampato su carta riciclata

L 383 Ed. 09/93

Fig. 1

B

B

Fig. 2

Page 2

Ø5-20

5x45

E

Fig. 3

G (2,9x13)

Ø 8

F (2,9x9,5)

3,5x16

I

C

D

Fig. 4

Fig. 6 Fig. 7

F (2,9x9,5)

E

L

P

M

2,9x13

G

(Ø 2,9 x 13)

Fig. 8 Fig. 9

Fig. 5

Schalter für die Leistungsregelung des Lüfters

KontrollLeuchte

Schalter für die Beleuchtung

Fig. 10 Fig. 11

SS

Page 3

vis fournies (Fig. 9).

Option: montage des étagères

(Fig. 7)

Sur les meubles adjacents, fixer les 4

supports latéraux I aux dimension voulues

et poser les étagères.

Fonctionnement

Les hottes JDK 8420 et JDK 9420 sont

fournies d’un moteur à plusieurs vitesses.

Pour un bon rendement, on conseille

d’utiliser les basses vitesses en conditions

normales et les vitesses plus élevées en

cas de hautes concentrations d’odeurs et

de vapeurs.

Nous vous recommandons de mettre

l’appareil en marche avant de procéder à la

cuisson d’un plat quelconque et de laisser

fonctionner l’appareil pendant 10 minutes

encore après la cuisson, jusqu’à ce que

toute odeur ait disparu.

Entretien

Débrancher l’appareil du réseau électrique

avant de procéder à toute opération d

entretien.

Filtre à graisse

La hotte est munie d'un filtre à graisse

métallique.

Il sert à retenir les particules de graisses en

suspension.

En cas d'utilisation normale, le filtre à graisse

doit être lavé une fois par mois au lavevaisselle ou bien avec un peu de savon

dissout dans de l'eau tiède; bien laisser

sécher le filtre avant de le remonter.

Pour le démonter, le pousser vers l’arrière

et l’enlever en le tirant vers le bas (fig. 8).

Filtre à charbon

Ce filtre élimine les odeurs et les vapeurs

qui se forment pendant la cuisson.

En conditions d’usage normal, il faut le

remplacer tous les 6-8 mois.

Pour le commander, s’adresser au

fournisseur Ne jamais le laver.

Pour le démonter, enfoncer les touches B

vers l’intérieur et le tirer vers le bas (fig. 2).

Attention

Le non respect des normes d’entretien de

l’appareiI et de remplacement et nettoyage

des filtres comporte des risques d’incendie.

Nous recommandons donc vivement de

respecter ces instructions.

Remplacement de la lampe

—Débrancher l’appareil du réseau

électrique.

— Ouvrir le plafonnieres L en tournant les

verrous et remplacer l’élément

défectueux, par une élément identique

(40 W-max. E14) (fig. 8).

— Si l’éclairage ne marche pas et au cas ou

l’on désirerait s’adresser au service

après-vente, il faudra d’abord contrôler

le montage correct de la lampe.

Nettoyage

Pour le nettoyage extérieur de la hotte,

utiliser un chiffon imbibé d’alcool ou des

détergents liquides neutres. Eviter l’usage

de tout produit abrasif.

Cet appareil est conforme aux normes

87/308/EWG concernant les antiparasites.

GB

Hood Description

1) Motor speed button

2) Light button

3) Operating light

4) Exhaust grate

5) Work-light

Use

The hood may be used as follows:

— Exhausting version

— Recycling version

Exhausting version

The air is vented outdoors by a duct which

must be connected to the coupling ring A

(Fig. 1).

For JDK 9420 hood only:

Check if the internal shutters S are opened

before using the hood (Fig. 11).

Choosing the exhausting pipe

The coupling ring A has a diameter of

120mm.

We suggest to use Ø 120 mm exhausting

pipe.

Recycling version

The air is filtered through a carbon filter and

recirculated into the room through the grating

on the lower chimney part.

This version is used when there is no exhaust

duct for venting outdoors or when it is

impossible to install one.

To use the hood in this version, proceed as

follows:

— If no carbon filter is supplied with the

hood, ask the technical assistance

service or the manufacturing company

for one and specify the hood model.

— Dismount the metal grease filters.

— To install the carbon filter, fit it in the seat

at the back and fasten it at the front with

the two hooks B (Fig. 2).

— Re-fit the metal grease filters.

For JDK 9420 hood only:

Attention! Close the shutters S before using

the hood in this version.

Installation

When installed, the hood must be not less

than 65 cm. above electric burners or 75

cm. above gas or mixed-fuel burners.

(h,Fig.3).

Warning!

— If the hood is run at the same time as a

burner or fireplace that depend on

ambient air (for example gas, Diesel,

coal or wood heaters, water heaters,

etc.) be careful, because the hood, when

it exhausts the air, removes the ambient

air required by the burner or fireplace for

combustion.

— For secure operation and to prevent

discharged gas from coming back in, the

vacuum must not exceed 0,04 mbr.

This may be done by making sure the air

inlet into the room passes through non-

closing openings such as air recycling

wall boxes, doors, windows or with other

technical measures.

—No food must be cooked flambé

underneath the hood.

14

15

Page 4

The use of an unprotected flame is

dangerous for the filters and could cause

fires.

Therefore, never use an open flame

under the hood. When frying foods, never

leave the pan alone because the cooking

oil could flare up.

— The hood must not be connected to fuel

exhaust flues (boilers, heating systems,

water heaters, etc.).

— Please, keep to the provisions of official

directives regarding the question of fume

discharge.

— The manufacturers refuse to accept any

responsibility for damage to the hood or

its catching on fire because of failure to

observe the above instructions.

Suggestions for the installation and

use of the hood

— The horizontal sections of the pipe must

be slanted slightly upwards (about 10%)

to ensure an easy flow of the air outwards.

— The best performance of the unit is

obtained in the external exhaust model

(suction), therefore in the limits of the

possibilities it is advised to use the

external exhaust (suction) type.

— The best performances are obtained with

short pipes (max. 4 m) and with few

curves.

Electric connection

Before completing any connection, make

sure the house voltage corresponds with

the voltage indicated on the label affixed

inside the hood.

The hood is supplied with a standard plug;

connect it to a correspondingly standard

socket. In the case is intended to connect

the appliance permanently to the mains

after having removed the plug supplied,

must be fitted a two-pole switch conforming

to regulations with an opening distance

between contacts of not less than 3mm.

The manufacturers are not liable for any

problems caused by the user’s failure to

observe the above instructions.

Fastening the hood to the wall

(Fig. 4)

— Position the template in the correct

position and make two 8mm diameter

holes and two 12mm diameter holes.

— Fit the two 8mm diameter plugs in the top

holes.

— Fasten the two hooks C in the bottom

holes.

— Hang the hood on the hooks and level it

with the screws D.

— Secure it in place with the two 5x45 mm

screws and 5-20 mm diameter washers

in the top holes. The screws and washers

are standard equipment.

Installing the duct for exhausting

version (Fig. 5-6)

— Fasten the top support E to the wall close

to the ceiling on the perpendicular of the

bottom connections. To do use the two

8mm diameter screws and plugs supplied

as standard equipment.

Insert the plastic mould P on the duct.

— Take the measure between the ceiling

and the hood top, and adjust the duct to

this height. Fasten it with screws F.

— Insert the duct with the slots downwards

and fasten it with the two top screws and

the two bottom screws G.

Installing the duct for recycling

version

Perform the same operations described in

the preceding paragraph. With screws

supplied, fasten the air conveyor M inside

the duct (Fig. 9).

Fastening of shelves (optional)

(Fig. 7)

Fasten the four side supports I to the adjacent

cabinets and place the shelf on the supports.

Operation

The hoods JDK 8420 and JDK 9420 are

provided with a motor with three speed.

For the best performance, we recommend

using the low speeds in normal conditions

and the high speeds in particular cases of

strong odour and vapour concentration.

We recommend starting up the hood a few

minutes before cooking and keeping it

running until all the odours have been

eliminated.

Maintenance

Before performing any maintenance

operation, disconnect the hood from the

electricity.

Grease filter

This serves to hold the grease particles in

suspension.

To remove the filter, push it towards

the back of the hood and pull it

downwards (Fig. 8).

To clean, wash it in hot water and

biodegradable detergent or in a dishwasher.

Let dry before reinstalling.

Clean it at least once a month.

Carbon filter

This filter dissolves cooking odours.

It should be changed every 6-8 months in

normal use. Ask the technical assistance

service or manufacturing company for a

new one.

The carbon filter must never be washed.

To remove the carbon filter, push the pushbuttons B inwards and pull the filter

downwards (Fig. 2).

Important

Failure to observe the rules for cleaning the

appliance and changing and cleaning the

filters may cause fires.

Therefore, we recommend observing these

instructions.

Changing the neon light and starter

— Disconnect the hood from the electricity.

— Remove the light covers L by unscrewing

the fixing screws (Fig. 8).

— Replace the damaged lamp with one of

equal rating (40W-max. E14).

— Before calling for technical service

because the light fails to work, make

sure the lamps are well screwed.

Cleaning

To clean the outside of the hood use a cloth

moistened with denatured alcohol or neutral

liquid detergents. Never use products

containing abrasive.

This appliance meets 87/308 EWG radio

and television noise Standards

16

17

Loading...

Loading...