Page 1

INSTRUCTIONS FOR INSTALLATION AND USE

MONTAGE- UND GEBRAUCHSANWEISUNG

INSTRUCTIONS POUR L'INSTALLATION ET L’UTILISATION

ISTRUZIONI PER L'INSTALLAZIONE E L’USO

INSTRUCCIONES PARA INSTALACIÓN Y USO

INSTRUÇÕES DE INSTALAÇÃO Y UTILIZAÇÃO

AANWIJZING VOOR GEBRUIK EN INSTALLATIE

Page 2

ENGLISH

DESCRIPTION

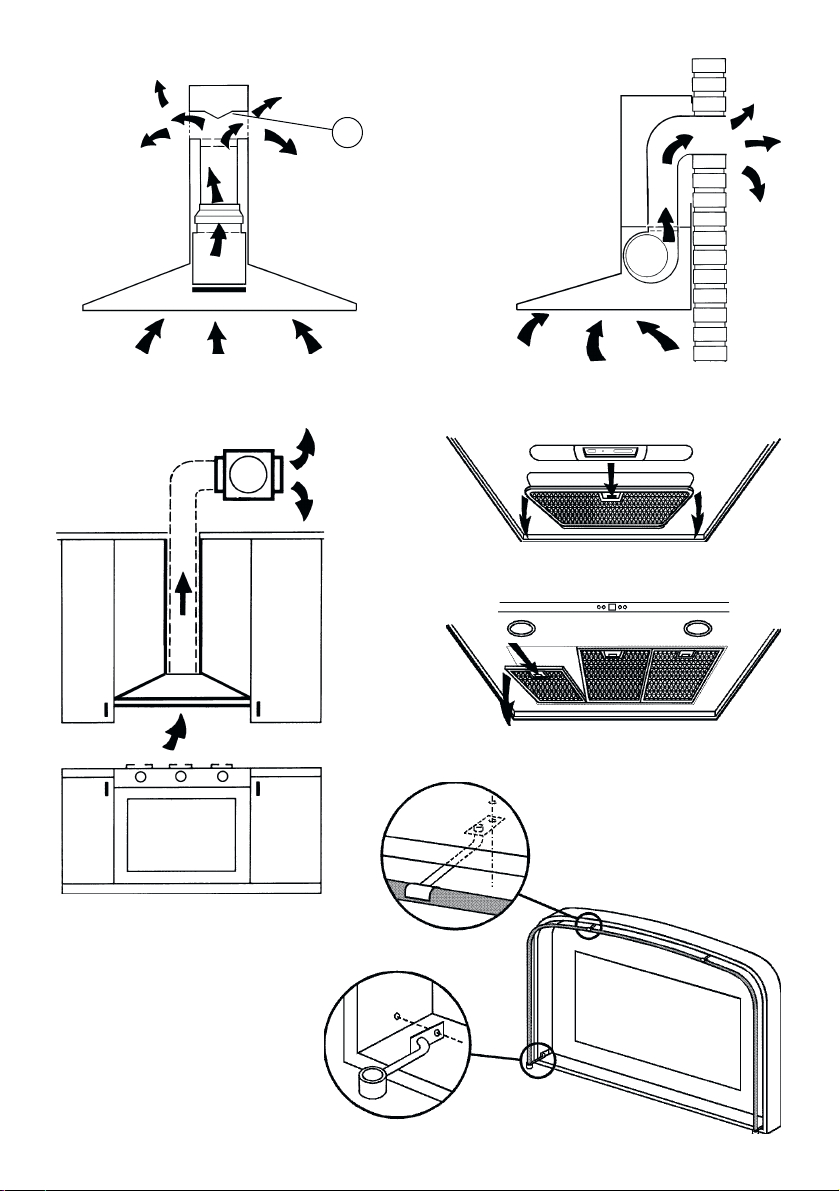

The unit can be found in filtering hoods, exhaust hoods or in hoods with an outside motor. In the Filtering hoods (Fig. 1)

the air and steam taken up by the unit are purified with carbon filters and returned to the environment through the aeration

grids on the side of the flue. WARNING: When using filtering hoods, both carbon filters and an air deflector must be used.

Located in the upper part of the pipe, this deflector recycles the air to the environment (Fig. 1A). In the Exhaust hoods (Fig

.2) an exhaust duct conveys the steam and cooking odors directly outside through the wall/ceiling. Therefore they do not

require carbon filters. In the hoods with an outside motor (Fig. 3), a vacuum suction unit must be connected; this exhaust

will operate separately, conveying the exhaust air through the unit. Only use vacuum units suggested in the original

catalogue.

INSTALLATION

To facilitate installation, before starting remove the grease filter/s: press inward on the clamp at the handle and pull the

filter downward (Fig. 4/5).

Installation of a utensil holder (upon request): See Figure 6A or 6B depending on the model purchased. Install the utensil

holder with 4 flathead screws (supplied). Secure the 2 supports (C) to the hood, one on the left and one on the right; insert

the utensil holder into these supports. Keep a good grip on it until you have installed, and secured, at least one of the 2

supports (D) at the top of the hood.

Installation on the wall (Fig. 7): Using the special drilling template, drill the required holes in the wall. As previously

specified in the chapter “Warning” remember there must be a minimum of 650 mm between the bottom edge of the hood

and the stop of the stove. Secure the metal bracket (B) to the wall using the screws and plugs (bracket, screws and plugs

are all supplied with the unit). Use the 2 triangles cut into the bracket to position it precisely along the vertical axis of the

hood. Then set the hood onto the bracket. Adjust the horizontal position, shifting the hood to the right or left as needed

lining it up with the wall units. If the height of the hood also requires adjustment, use the special regulation screws (V)

(supplied). Once regulation has been completed, finish securing the hood with 4 more screws (M): mark the points for the

4 holes on the wall, remove the hood and drill (8mm diameter holes); then use the plugs and screws to complete installation.

Installation with rear panel (Fig. 8): The rear panel is positioned at the top of the stove, flush against the wall. Rest the

lower edge of the panel behind the stove and anchor the upper edge to the wall using the two holes found on the panel.

Insert the screws and plugs provided (A). The unit is secured to the rear panel as though it were being installed on the wall:

use the supplied metal bracket (B) and the screws and plugs supplied with the panel.

Securing the extension pipes:

by the decorative piping. – If your unit is installed in an Exhaust hood or in a hood with outside motor, prepare the air exhaust

hole.

When installing exhaust hoods and hoods with outside motor, to achieve the best possible conditions use an air exhaust

pipe that : i) is as short as possible, ii) has a minimum of curves (maximum angle: 90°), iii) is made of a material that

complies with the standards (which vary from nation to nation) and iv) is smooth on the inside. It is also advisable to avoid

any drastic changes in pipe section (diameter: 150 mm).

Adjust the width of the extension pipe support bracket (W) using screws A indicated in Fig. 9. Then use the plugs and

screws provided to secure it to the ceiling. Make certain it is aligned with the hood. For filtering hoods, the air exhaust grids

are positioned in the upper part (Fig. 10). For exhaust hoods, turn the upper pipe over so that the air exhaust grid is in the

lower section (Fig. 11).

Be very careful when handling the telescopic pipes, especially when resting these on the hood body, to

prevent scratching.

Exhaust hoods and hoods with outside motors: Connect the hood flange to the exhaust hole in the wall/ceiling using a

flexible pipe. Only for models with outside motor (Fig. 12): plug the hood into the outside control unit using the special

terminal block: remove wire clamp A and lid B from the wiring junction box. Secure the wire connecting the control unit

to terminal C. Then replace wire clamp A and lid B on the wiring junction box. The other end of the wire is secured to the

terminal block on the outside control unit. Plug in the hood. Insert the extension pipes setting them on the hood; extend

the upper pipe to the ceiling and secure with the 2 screws (G) - Fig. 13.

Filtering hood: Secure the deflector to the upper pipe using the 4 special screws (provided) – Fig. 14; hook up the flexible

pipe (diameter: 125) to the deflector. Install the reduction (provided) on the hood air outlet point (Fig. 15). Take the 2

assembled extension pipes and set them on the hood; extend the upper pipe to the ceiling and secure with the 2 screws

(G) - Fig. 13. Extend the lower pipe taping it in place and then connect the flexible pipe to the hood reduction. Plug in the

hood. Extend the lower pipe downward setting it against the hood. Install the carbon filters by pressing the 2 tabs on the

filter down into the special housing (Fig. 16) and rotating upward.

Basic installation requirements: – Set the electrical power supply within the space covered

OPERATION

Depending on the model, the unit is equipped with the following commands:

Commands shown in Fig. 17: Button A = turns the lights on/off. Button B = turns the TIMER on/off: press once to turn

the timer on, therefore, after 5 minutes, the motor cuts out (at the same time the selected speed blinks on the display); the

timer remains on if the motor speed is changed. Display C = - indicates the selected motor speed (from 1 to 4); - indicates

Timer On when the number blinks; - indicates Filter Alarm when the central segments is on or blinking.

Page 3

Button D = makes the motor work (at the last speed selected); pushing the button again, the speeds of the motor are

sequentially selected from 1 to 4; keeping this button pressed for about 2 seconds shuts down the motor.

Button R = resets the grease filters or carbon filters; when the filter alarm appears (i.e. when the central segment on the

display goes on), the grease filters must be cleaned (30 hours of operation); when the central segment starts blinking, the

grease filters must be cleaned and the carbon filters replaced (120 hours of operation). Obviously, if the hood is not a

filtering model and does not have a carbon filter, clean the grease filters both when the central segment goes on and when

it starts blinking. The filter alarm can be seen when the motor is off and for about 30 seconds. To reset the hour counter,

keep the button pressed for 2 seconds while the alarm can be seen.

Commands shown in Fig. 18/19: Switch A: LIGHT; position 0: light off; position 1: light on. Switch B: MOTOR SPEED:

makes it possible to select the motor operating speed; position 0: motor off. C : Motor on light.

Commands shown in Fig. 20: A = light switch. B = first speed motor ON/OFF switch. C = second speed switch.

D = third speed switch. E = motor on light.

Pay special attention to the grease filters:

must be cleaned approximately once every 30 hours of operation (when the central segment on the display goes on or starts

blinking). To remove the filters: press inward on the clamps at the handles and pull the filter downward. Wash out the filter

by hand or in the dishwasher using a neutral soap. Once the cleaned filters are reinstalled, keep button R (Reset) pressed

for two seconds to reset the counter. For further information, see the Commands in Fig. 17 in the paragraph entitled

“Operation”.

periodically: exactly how often depends on use (at least once every other month). To remove the filter: push inward on the

clamp at the handle and pull the filter downward. Wash out the filter by hand or in the dishwasher using a neutral soap.

Replacing the carbon filters: If the unit is a filtering hood, the carbon filters must be replaced: to remove them press

inward on the clamp (Fig. 16) and rotate the filter downward until the 2 tabs can be removed from the housing.

If the model purchased has the commands shown in Figure 17, the carbon filters must be replaced whenever the central

segment of the display starts blinking (i.e. every 120 hours of operation). If the model purchased has the commands shown

in Figure 18/19/20, the carbon filters must be replaced according to use: on the average once every 6 months.

Lighting: Depending on the model purchased, see Fig.21, Fig.22 or Fig. 23.

Fig. 21: to remove the halogen lamps, turn the locknut counter-clockwise. Replace with the same type of lamp.

Fig. 22: to replace the incandescent light bulbs, remove the grease filters so as to be able to access the inside of the

unit; remove the screw securing the light fitting and then, working from inside the hood, push the light fitting pin towards

the inside of the unit. Replace with light bulbs of the same type.

Fig. 23: if your appliance has the same kind of lights as in the figure 23, to replace the incandescent light bulbs open the

anti-grease grille and remove it; replace with light bulbs of the same type.

If the model purchased has the commands shown in Figure 18/19/20: the grease filter must be replaced

if the model purchased has the commands shown in Figure 17: the grease filters

DEUTSCH

BESCHREIBUNG

Das Gerät kann in Filterversion, in Aspirationsversion und in der Version mit externem Motor geliefert werden. In der

Filterversion (Abb. 1) werden die durch das Gerät geleitete Luft und der Dampf durch Kohlefilter gereinigt und dann über

die seitlichen Lüftungsgitter der Haube wieder in Zirkulation gebracht. ACHTUNG! Beim Einsatz der Filterversion müssen

die Kohlefilter zusammen mit einem Luftablenker eingesetzt werden, der in den oberen Rohrabschnitt montiert wird und

die Rezirkulation der Luft und Ableitung in die Umgebung ermöglicht (Abb. 1A). In der Aspirationsversion (Abb. 2)

werden die Dämpfe und Küchengerüche direkt über eine Evakuationsöfffnung in der Wand oder Decke nach außen

abgezogen. Daher sind keine Kohlefilter notwendig. In der Version mit externem Motor (Abb. 3) ist das Gerät mit einer

Aspirationszentrale zu verbinden, die getrennt arbeitet und das Gerät als Verbindungsbasis für die abzuleitende Luft

benutzt. Bitte verwenden Sie nur eine der im Originalkatalog vorgeschlagenen Zentralen.

INSTALLATION

Vor den Montageoperationen muß/müssen zur leichteren Handhabung des Geräts der/die Antifettfilter entfernt werden:

Den Festhalter in der Nähe des Griffs nach innen drücken und den Filter nach unten ziehen (Abb. 4/5).

Montage des Kochlöffelhalters (auf Anfrage): Studieren Sie je nach dem von Ihnen erworbenen Modell Abbildung 6A

oder 6B. Zur Montage des Kochlöffelhalters werden 4 Schrauben mit flachem Kopf (im Lieferumgang inbegriffen)

verwendet. Befestigen Sie die 2 Träger (C) an der Haube, einen rechts und den anderen links: Bringen Sie den

Kochlöffelhalter dazwischen an und halten sie ihn, bis mindestens einer der 2 Träger (D) montiert ist, die an der Vorderseite

der Haube zu befestigen sind.

Befestigung an der Wand (Abb. 7): Bohren Sie mit der mitgelieferten Bohrschablone die Löcher an den jeweiligen Stellen

an der Wand. Wie bereits im Kapitel “Montage und Gebrauchsanweisung” beschrieben ist darauf zu achten, daß der

Abstand zwischen dem unteren Rand der Haube und der Kochfläche mindestens 650 mm beträgt. Den Metallbügel (B)

mit Schrauben und Dübeln (Bügel, Schrauben und Dübel werden mitgeliefert) befestigen. Benutzen sie die beiden auf

dem Bügel ausgesparten Dreiecke, um diesen ganz in Richtung auf die Längsachse der Haube hin auszurichten. Dann

die Haube mit dem Bügel verhaken. Die horizontale Position regulieren, indem die Haube in Übereinstimmung mit der

Anordnung der Hängeschränke nach rechts oder nach links verschoben wird. Soll die Haube auch in der Höhe reguliert

werden, so nimmt man auf die Regulierschrauben (V) (m Lieferumfang inbegriffen) Einfluß. Nach erfolgter Regulierung

wird die Haube definitiv mit 4 Schrauben (M) befestigt: Markieren Sie die 4 zu bohrenden Löcher auf der Wand, entfernen

Page 4

1

3

2

A

4

5

D

6A

C

Page 5

6B

7

M

D

C

V

B

8

A

B

Page 6

9

12

X

X

A

W

10 11

13

G

14

C

B

A

Page 7

15 16

17

A B D RC

19

A

18

A BC

20

A B

BC

C D E

Page 8

21

22

23

Page 9

04306506/1 - Kbasse sen.nor.

Page 10

WARNING - HINWEIS - ATTENTION - AVVERTENZE - ADVERTENCIA

ADVERTENCIAS - OPGELET

ENGLISH

WARNING

The distance between the supporting surface for the cooking

vessels on the hob and the lower part of the hood must be at

least 65 cm. If the instructions for installation for the hob

specify a greater distance, this has to be taken into account.

The air collected must not be conveyed into a duct used to

blow off smokes from appliances fed with an energy other

than electricity (central heating systems, thermosiphons,

water-heaters, etc.).

Comply with the official instructions provided by the competent

authorities in merit when installing the disposal duct. In

addition, exhaust air should not be discharged into a wall

cavity, unless the cavity is designed for that purpose.

The room must be well aerated in case a hood and some

other heat equipment fed with an energy other than electricity

(gas, oil, coal heaters, etc) operate at the same time.

In fact the intake hood, disposing of air, could create a

vacuum in the room. The vacuum should not exceed 0,04mbar.

This prevents the gas exhausted by the heat source from

being intaken again. It is therefore advisable to ensure the

room contains air taps able to ensure a steady flow of fresh

air.

Check the data label inside the appliance; if the symbol

( ) is printed, read the following: this appliance has

such technical particulars that it belongs to class II

insulation, therefore it must not be earthed.

The following warning is valid in the United Kingdom only: in

case your cable is not furnished with a plug, read the following

instructions; as the colours of the wires in the mains lead of

this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows: –

the wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black;

– the wire which is coloured brown must be connected to the

terminal which is marked with the letter L or coloured red. –

terminal of a three-pin plug.

Check the data label inside the appliance; if the symbol

) is NOT printed, read the following: ATTENTION:

(

This appliance must be earthed. When making the electrical

connections, check that the current socket has a ground

connection.

The following warning is valid in the United Kingdom only: in

case your cable is not furnished with a plug, read the following

instructions; as the colours of the wires in the mains lead of

this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows:

– the wire which is coloured green and yellow must be

connected to the terminal in the plug which is marked with the

letter E or by the earth symbol [

green and yellow; – the wire which is coloured blue must be

connected to the terminal which is marked with the letter N or

coloured black; – the wire which is coloured brown must be

connected to the terminal which is marked with the letter L or

coloured red.

When making the electrical connections, check that the

voltage values correspond to those indicated on the data

plate inside the appliance itself. In case your appliance is not

furnished with a non separating flexible cable and has no

plug, or has not got any other device ensuring omnipolar

disconnection from the electricity main, with a contact opening

distance of at least 3 mm, such separating device ensuring

disconnection from the main must be included in the fixed

installation. If your unit features a power lead and plug,

position this so the plug is accessible.

Always switch off the electricity supply before carrying out

any cleaning or servicing operations on the appliance.

], or coloured green or

USE

Avoid using materials which could cause spurts of flame

(flambées) near the appliance.

When frying, take particular care to prevent oil and grease

from catching fire. Already used oil is especially dangerous in

this respect. Do not use uncovered electric grates.

To avoid possible risks of fire always comply with the indicated

instructions when cleaning anti-grease filters and when

removing grease deposits from the appliance.

MAINTENANCE

Thorough servicing guarantees correct and long-lasting

operation.

Any fat deposits should be removed from the appliance

periodically depending on amount of use (at least every 2

months). Avoid using abrasive or corrosive products. To

clean painted appliances on the outside, use a cloth dipped

in lukewarm water and neutral detergent. To clean steel,

copper or brass appliances on the outside, it is always best

to use specific products, following the instructions on the

products themselves. To clean the inside of the appliance,

use a cloth (or brush) dipped in denatured ethyl alcohol.

DEUTSCH

HINWEIS

Der Mindestabstand zwischen der Topf-Trägerfläche auf der

Kochmulde und dem unteren Teil der Abzughaube muss 65

cm betragen. Geben die Installationsanleitungen der

Kochmulde einen höheren Abstand an, so ist dieser

einzuhalten.

Ein Anschluss der Abluftleitungen an Verbrennungsabgaskamine (zum Beispiel Zentralheizung, Heizgeräte,

Badezimmeröfen usw.) ist nicht gestattet.

In jedem Fall sind bei der Ableitung der Abluft die behördlichen

Vorschriften zu beachten. Desweiteren darf die Abluft nur

dann durch ein Loch in der Wand geleitet werden, wenn

dieses für diesen Zweck bestimmt ist.

Achtung! Bei gleichzeitigem Betrieb einer AbluftDunstabzugshaube und einer raumluftabhängigen

Feuerstätte (wie z. B. gas-, öl- oder kohlebetriebene

Heizgeräte, Durchlauferhitzer, Warmwasserbereiter) ist

Vorsicht geboten, da beim Absaugen der Luft durch die

Dunstabzugshaube dem Aufstellraum die Luft entnommen

wird, die die Feuerstätte zur Verbrennung benötigt. Ein

gefahrloser Betrieb ist möglich, wenn bei gleichzeitigem

Betrieb von Haube und raumluftabhängiger Feuerstätte im

Aufstellraum der Feuerstätte ein Unterdruck von höchstens

0,04 mbar erreicht wird und damit ein Rücksaugen der

Feuerstättenabgase vermieden wird. Daher den Raum mit

Lüftungsanschlüssen versehen, die einen konstanten Zustrom

von Frischluft gewährleisten.

Das Typenschild im Innern des Geräts kontrollieren: Den

folgenden Anweisungen folgen, falls das Symbol ( )

erscheint; dieses Gerät weist konstruktive technische

Details auf, die unter die Isolierungsklasse II fallen und

deshalb muss es nicht geerdet werden.

Das Typenschild im Innern des Geräts kontrollieren: den

folgenden Anweisungen folgen, falls das Symbol ( )

NICHT erscheint; ACHTUNG: dieses Gerät muss geerdet

werden. Beim elektrischen Anschluss sicherstellen, dass die

Steckdose eine Erdung aufweist.

Beim elektrischen Anschluss muss überprüft werden, ob die

Spannungswerte des Stromnetzes mit den Werten auf dem

im Innern des Gerätes angebrachten Typenschilds

übereinstimmen. Falls Ihr Gerät nicht mit einem fest

angeschlossenem Kabel mit Stecker oder einer sonstigen

Page 11

Vorrichtung, die eine allpolige Unterbrechung mit einer

Kontaktöffnung von mindestens 3 mm versehen ist, so müssen

die entsprechenden Trennvorrichtungen bei der festen

Installation vorgesehen werden. Das Gerät so aufstellen,

dass der Stecker zugänglich ist, falls Ihr Gerät mit einem

Netzkabel mit Stecker ausgestattet ist.

Vor jeder Reinigungs- oder Wartungsarbeit muss das Gerät

vom Stromnetz getrennt werden.

GEBRAUCH

In der unmittelbaren Nähe des Geräts die Benutzung von

flammenerzeugenden Materialien (Flambieren) vermeiden.

Beim Frittieren besonders auf die Brandgefahr achten, die

durch Öl und Fette verursacht wird. Besonders gefährlich ist

die Entflammbarkeit von bereits benutztem Öl. Keine offenen

Elektrogrills verwenden.

Zur Vermeidung einer möglichen Brandgefahr die

Anweisungen zur Reinigung der Fettfilter und zur Entfernung

eventueller Fettablagerungen auf dem Gerät beachten.

WARTUNG

Nur eine sorgfältige Pflege garantiert auf Dauer eine gute

Leistung und Funktion des Geräts.

Die Entfernung eventueller Fettablagerungen vom Gerät

erfolgt in regelmäßigen Abständen in Abhängigkeit von der

Benutzung (zumindest alle zwei Monate). Die Verwendung

von scheuernden oder korrosiven Produkten vermeiden. Für

die äußere Reinigung von lackierten Geräten ein mit

lauwarmen Wasser und Neutralreiniger angefeuchtetes Tuch

verwenden; für die äußere Reinigung der Geräte aus Stahl,

Kupfer und Messing wird die Verwendung von Spezialprodukten empfohlen, wobei die auf dem Produkte

angegebenen Anweisungen zu beachten sind; für die innere

Reinigung der Geräte einen in denaturalisierten Äthylalkohol

eingetauchten Lappen (oder Pinsel) verwenden.

FRANCAIS

ATTENTION

La distance minimum entre la surface de support des

casseroles sur le plan de cuisson et la partie inférieure de la

hotte doit être de 65 cm. Si les consignes, pour l’installation

du plan de cuisson, indiquent une plus grande distance, il faut

en tenir compte.

L'air aspiré ne doit pas être canalisé dans un conduit qui est

utilisé pour évacuer les fumées produites par des appareils

alimentés par des sources d'énergies autres que l'énergie

électrique (installations de chauffage central, radiateurs,

chauffe-eau, etc.).

Pour évacuer l'air qui doit être éliminé respectez les

prescriptions des autorités compétentes. De plus l'air qui doit

être évacué ne doit pas être déchargé dans une cavité du

mur, à moins que cette cavité soit prévue pour ce but.

Prévoyez une aération de la pièce adéquate quand une hotte

et des appareils alimentés par une énergie autre que l'énergie

électrique (poêle à gaz, à huile, à charbon etc.) sont utilisés

en même temps. En effet, en évacuant l'air, la hotte pourrait

créer une dépression dans la pièce. La pression négative de

la pièce ne doit pas dépasser 0,04mbar, évitant ainsi que la

source de chaleur provoque un appel des gaz qui doivent être

évacués. Il est donc nécessaire d'équiper la pièce de prises

d'air alimentant un flux d'air frais constant.

Contrôler la plaque des caractéristiques techniques se

trouvant à l’intérieur de l’appareil; si le symbole ( )

figure sur la plaque suivre les instructions suivantes: cet

appareil est construit pour appartenir à la classe

d’isolation II ; il ne doit donc pas être relié à la terre.

Contrôler la plaque des caractéristiques techniques se

trouvant à l’intérieur de l’appareil; si le symbole ( ) NE

figure pas sur la plaque suivre les instructions suivantes:

ATTENTION: cet appareil doit être relié à la terre. Lors du

raccordement électrique s’assurer que la prise de courant est

équipée d’une connexion de mise à la terre.

Lors du raccordement électrique assurez-vous que les valeurs

de tension correspondent à celles qui sont indiquées sur la

plaque des caractéristiques de l’appareil, qui se trouve à

l'intérieur de celui-ci. Si votre appareil, n'a pas de câble

flexible qui ne peut pas être séparé ni de prise, ou bien d'autre

dispositif qui garantisse le débranchement de tous les pôles

du réseau, avec une distance d'ouverture entre les contacts

d'au moins 3 mm, ces dispositifs de séparation du réseau

doivent alors être prévus dans l'installation fixe. Si votre

appareil est muni d’un câble d’alimentation, positionner

l’appareil de manière à ce que la fiche soit accessible.

Avant de procéder à une opération d’entretien ou de nettoyage

quelconque, débranchez l’appareil.

UTILISATION

Evitez d'utiliser des matériaux qui provoquent des flammes à

proximité de l'appareil.

Dans le cas de fritures, faites tout particulièrement attention

au danger d’incendie que représentent les huiles et les corps

gras. A cause de son inflammabilité l’huile usagée est

particulièrement dangereuse. N'utilisez pas de grils électriques

découverts.

Pour éviter des risques d'incendie possibles suivez les

instructions données concernant le nettoyage des filtres à

graisse et sur la façon d'enlever des dépôts éventuels de

graisse sur l'appareil.

ENTRETIEN

Un entretien soigné est une garantie de bon fonctionnement

et de bon rendement de votre appareil dans le temps.

L’élimination, d’éventuels dépôts de graisse sur l’appareil,

doit être effectuée en fonction de l’utilisation de ce dernier (au

moins tous les 2 mois). Il faut éviter d’utiliser des produits

contenant des abrasifs ou des corrosifs. Pour le nettoyage

extérieur des appareils peints, utiliser un chiffon mouillé avec

de l’eau tiède et un détersif neutre. Pour le nettoyage extérieur

des appareils en acier, en cuivre et en laiton il est conseillé

d’utiliser des produits spécifiques et de suivre les instructions

fournies sur le produit. Pour le nettoyage de l’intérieur de

l’appareil, utiliser un chiffon (ou un pinceau) imbibé d’alcool

dénaturé.

ITALIANO

AVVERTENZE

La distanza minima tra la superficie di supporto delle pentole

sul piano di cottura e la parte inferiore della cappa deve

essere 65 cm. Se le istruzioni per l’installazione del piano di

cottura specificano una distanza maggiore, questa deve

essere tenuta in considerazione.

L'aria raccolta non deve essere convogliata in un condotto

usato per lo scarico di fumi di apparecchi alimentati con

energia diversa da quella elettrica (impianti di riscaldamento

centralizzati, termosifoni, scaldabagni ecc.).

Per lo scarico dell'aria da evacuare rispettare le prescrizioni

delle autorità competenti. Inoltre l'aria da scaricare non deve

essere eliminata attraverso una cavità del muro a meno che

tale cavità non sia destinata a questo scopo.

Prevedere un'adeguata areazione del locale quando una

cappa e apparecchi alimentati con energia diversa da quella

elettrica (stufe a gas, ad olio, a carbone ecc), vengono usati

contemporaneamente. Infatti la cappa aspirante evacuando

l'aria potrebbe creare una pressione negativa nella stanza.

La pressione negativa del locale non deve superare i 0,04

mbar, evitando così il risucchio dei gas di scarico della fonte

di calore. Pertanto attrezzare il locale con delle prese d’aria

che alimentino un flusso costante di aria fresca.

Controllare la targa caratteristiche tecniche posta all'interno dell'apparecchio; se sulla targa compare il simbo-

) seguire le seguenti istruzioni: questo apparec-

lo (

chio presenta accorgimenti tecnici costruttivi tali da

essere annoverato nella classe di isolamento II e pertanto non deve essere collegato a terra.

Controllare la targa caratteristiche tecniche posta all'interno dell'apparecchio; se sulla targa NON compare il

Page 12

simbolo ( ) seguire le seguenti istruzioni: ATTENZIONE: questo apparecchio deve essere collegato a terra.

Nell’operazione di collegamento elettrico assicurarsi che la

presa di corrente sia munita di collegamento di terra.

Nell’operazione di collegamento elettrico verificare che i

valori di tensione corrispondano con quelli indicati nella targa

inserita all’interno dell’apparecchio. Se il Vostro apparecchio

non è provvisto di cavo flessibile non separabile e di spina, o

di altro dispositivo che assicuri la onnipolare disinserzione

dalla rete, con una distanza di apertura dei contatti di almeno

3 mm, allora tali dispositivi di separazione dalla rete devono

essere previsti nell'installazione fissa. Se il Vostro apparecchio è provvisto di cavo alimentazione e di spina, porre

l'apparecchio in modo che la spina sia accessibile.

Prima di procedere a qualsiasi operazione di pulizia o manutenzione è necessario togliere tensione.

USO

Evitare l’uso di materiali che causano fiammate (flambè) nelle

immediate vicinanze dell’apparecchio.

Nel caso di fritture fare particolarmente attenzione al pericolo

di incendio che costituiscono olio e grassi. Particolarmente

pericoloso per la sua infiammabilità è l’olio già usato. Non

usare griglie elettriche scoperte.

Per evitare un possibile rischio di incendio attenersi alle

istruzioni indicate per la pulizia dei filtri antigrasso e la

rimozione di eventuali depositi di grasso sull’apparecchio.

MANUTENZIONE

Un'accurata manutenzione garantisce un buon funzionamento

ed un buon rendimento nel tempo.

La rimozione di eventuali depositi di grasso dall'apparecchio

va effettuata periodicamente in rapporto all'uso (almeno ogni

2 mesi). Evitare l'uso di prodotti contenenti abrasivi o corrosivi. Per la pulizia esterna di apparecchi verniciati adoperare

un panno inumidito con acqua tiepida e detersivo neutro; per

la pulizia esterna di apparecchi in acciaio, rame od ottone è

consigliato l'uso di prodotti specifici, seguendo le istruzioni

indicate sul prodotto; per la pulizia interna dell'apparecchio

usare un panno/pennello imbevuto di alcool etilico denaturato.

ESPAÑOL

ADVERTENCIA

La distancia mínima entre la superficie de soporte de las ollas

sobre la placa de cocción y la parte inferior de la campana

debe ser de 65 cm. Si las instrucciones de instalación de la

placa de cocción indican una distancia mayor, la misma

deberá ser tenida en consideración.

El aire viciado no debe ser absorbido por un tubo o conducto

que sirva al mismo tiempo para la absorción del humo

descargado por otros aparatos que no funcionan con energía

eléctrica (instalaciones de calefacción central, radiadores,

calentadores, etc...).

La descarga del aire viciado debe hacerse según las

prescripciones de las autoridades competentes. Además el

aire de descarga no tiene que ser eliminado a través de una

cavidad de la pared a menos que dicha cavidad esté destinada

a tal fin.

Proveer una adecuada aireación del local si la campana se

usa simultáneamente con otros aparatos que no funcionan

con energía eléctrica (estufas a gas, carbón, queroseno,

etc...). En tal caso la campana extractora, al evacuar el aire,

podría crear una presión negativa en la habitación. La

presión negativa del local no debe superar los 0,04 mbar,

para evitar la reabsorción de los gases de la fuente de calor.

Por lo tanto es necesario proveer el local de tomas de aire

que aseguren un flujo constante de aire puro.

Controlar la placa de características técnicas situada

dentro del aparato; si en la misma se encuentra el

símbolo (

aparato presenta características de construcción tales

que lo incluyen en la classe de aislamiento II y por lo

tanto no debe tener la descarga a tierra.

) proceder de la siguiente manera: Este

Controlar la placa de características técnicas situada

dentro del aparato; si en la misma NO se encuentra el

símbolo (

ATENCIÓN: este aparato debe contar con una descarga

a tierra. En la operación de conexión eléctrica asegurarse

que la toma de corriente tenga un contacto de tierra.

En la operación de conexión eléctrica verificar que los

valores de tensión correspondan con los indicados en la

placa colocada en el interior del aparato. Si vuestro aparato

no está provisto de cable flexible no separable y de enchufe

u otro dispositivo, que asegure la desconección omnipolar de

la instalación eléctrica con una distancia de apertura de los

contactos de al menos 3mm., dicho dispositivo de

desconección deberá preveerse en la instalación fija. Si su

aparato está provisto de cable de alimentación y enchufe,

deberá ser dispuesto de manera que el enchufe quede

accesible.

Antes de proceder a cualquier operación de limpieza o de

mantenimiento es necesario desconectar el aparato.

) proceder de la siguiente manera:

USO

Evitar el uso de materiales o sustancias inflamables cerca del

aparato.

En el caso de freír tener suma atención al peligro de incendio

que constituyen el aceite y las grasas. Particularmente

peligroso por su inflamabilidad es el aceite ya usado. No usar

parrillas eléctricas descubiertas.

Para evitar un posible riesgo de incendio, atenerse a las

instrucciones indicadas respecto a la limpieza de los filtros

antigrasa y a la eliminación de eventuales depósitos de grasa

sobre el aparato.

MANTENIMIENTO

Un cuidadoso mantenimiento garantiza un buen funcionamiento y un buen rendimiento en el tiempo.

La eliminación de los eventuales depósitos de grasa en el

aparato debe ser efectuada periódicamente en base a la

frecuencia de uso (al menos cada 2 meses). Evitar el empleo

de productos abrasivos o corrosivos. Para la limpieza externa

de los aparatos pintados, servirse de un paño humedecido

con agua tibia y detergente neutro; para la de los aparatos de

acero, cobre o latón se aconseja el uso de productos

específicos, siguiendo las instrucciones indicadas en los

mismos. Para la limpieza interna del aparato, usar un paño

o pincel embebido en alcohol etílico de quemar.

PORTOGUÊS

ADVERTENCIAS

A distância mínima entre a superfície de suporte das panelas

na placa do fogão e a parte inferior do exaustor deve ser 65

cm. Se as instruções de instalação da placa do fogão

estabelecerem uma distância superior aos 65 mm indicados,

será essa que deverá ser tida em consideração.

O ar recolhido não deve ser canalizado em um conduto usado

para a descarga de fumaça de aparelhos alimentados com

energia diferente daquela elétrica (instalação de aquecimento

centralizado, radiadores, aquecedores elétricos, etc.).

Para a descarga do ar que deve ser evacuado, respeitar as

prescrições das autoridades competentes. Alem disso o ar

que tem de ser descarregado não deve ser expulsado pela

cavidade no muro a menos que tal cavidade não seja

predisposta com esse fim.

Prever uma adequada areação do local quando uma coifa e

aparelhos alimentados com energia diferente daquela elétrica

(aquecedor a gás. a óleo, a carvão, etc...), forem usados

contemporaneamente. Isso porque a coifa aspirante, evacuando o ar, pode criar uma pressão negativa no local. A

pressão negativa do local não deve superar os 0,04mbar,

evitando assim o redemoinho dos gases de descarga da

fonte de calor. É necessário, portanto, equipar o local com

presas de ar que alimentem um fluxo constante de ar fresco.

Controlar a chapa das características técnicas no interior

do aparelho; se o símbolo ( ) estiver impresso na

Page 13

chapa, seguir as instruções seguintes: Attenção: este

aparelho apresenta características técnicas construtivas

que o inclui na classe de isolamento II e portanto não

deve ser colegado à terra.

Controlar a chapa das características técnicas no interior

do aparelho; se o símbolo (

chapa, seguir as instruções seguintes: ATENÇÃO: Este

aparelho deve ser ligado à terra. Na operação de ligação

eléctrica é necessário assegurar-se de que a tomada de

corrente possui ligação à terra.

Na operação di ligação eléctrica é necessário verificar que os

valores de tensão correspondam aos indicados na placa

colocada no interior do aparelho. Se o seu aparelho não é

equipado com cabos flexíveis não separáveis e com tomada

ou com outro dispositivo que garanta o desligamento de

todos os polos de rede, com uma distância de abertura dos

contatos de pelo menos 3mm, tais dispositivos de separação

da rede devem ser previstos na instalação fixa. Se o seu

aparelho possuir cabo de alimentação e ficha, colocá-lo de

modo a fazer com que a ficha fique acessível.

Antes de proceder a qualquer operação de limpeza ou

manutenção é necessário desligar o aparelho da corrente

eléctrica.

) NÃO estiver impresso na

USO

Evitar o uso de materiais que causam chamas (flambè) nas

imediatas proximidades do aparelho.

No caso de frituras prestar especial atenção ao perigo de

incendio constituídos por óleos o gorduras. Especialmente

perigoso pela sua inflamabilidade é o óleo já usado. Não usar

grelhas elétricas descobertas.

Para evitar um possível risco de incêndio, seguir as instruções

indicadas para a limpeza dos filtros anti-gorduras e a remoção

de eventuais depósitos de gordura do aparelho.

MANUTENÇÃO

Una cuidadosa manutenção garante um bom funcionamento

e um bom rendimento no tempo.

A remoção dos depósitos de gordura do aparelho deve ser

efectuada periodicamente, em função do uso (pelo menos de

2 em 2 meses). Evitar a utilização de produtos que contenham

abrasivos ou corrosivos. Para a limpeza externa dos aparelhos

pintados, utilizar um pano humedecido em água morna e

detergente neutro; para a limpeza do exterior dos aparelhos

de aço, cobre ou latão, é aconselhado usar produtos

específicos, seguindo as instruções indicados nos próprios

produtos; para limpar o aparelho por dentro utilizar um pano

(ou um pincel) embebido em álcool etílico desnaturado.

NEDERLANDS

OPGELET

De afstand tussen het draagvlak van de pannen op de

kookplaat en de onderkant van de wasemkap moet minstens

65 cm zijn. Als de instructies voor de installatie van de

kookplaat een grotere afstand specificeren, moet deze in

aanmerking genomen worden.

De luchtafvoer van dit apparaat niet aansluiten op een buis

(pijp) die reeds gebruikt wordt voor de luchtafvoer van niet

elektrische apparatuur (centrale verwarmingsinstallaties,

radiatoren, geiser, enz.).

Voor de lozing van de af te voeren lucht de voorschriften van

de bevoegde autoriteit in acht nemen. Verder moet de af te

voeren lucht niet via een holte in de muur verwijderd worden,

tenminste wanneer deze holte niet voor dit doel bestemd is.

Voorzie de ruimte van een goede ventilatie indien de kap

gelijktijdig wordt gebruikt met andere, niet elektrische

apparaten (gas-, olie, kolenkachels, enz.). De afzuigkap kan

nl. een onderdruk in de ruimte creëren. De onderdruk in de

ruimte mag niet groter worden dan 0,04 mbar., om te

voorkomen dat de afvoergassen van de warmtebron worden

aangezogen. De ruimte moet daarom voorzien zijn van een

rechtstreekse luchttoevoer, die voor een konstante verse

luchtaanvoer zorgt.

Controleer het plaatje met technische gegevens in het

apparaat; als op het plaatje het symbool ( ) afgebeeld

staat, moeten de volgende instructies worden opgevolgd:

dit apparaat vertoont opbouwende technische

omzichtigheden zodat het gerekend kan worden in de

isolatie-klas ll en dus daarom niet geaard gehoeft te

worden.

Controleer het plaatje met technische gegevens in het

apparaat; als op het plaatje NIET het symbool ( )

afgebeeld staat, moeten de volgende instructies worden

opgevolgd: LET OP: Dit apparaat moet geaard worden.

Bij het tot stand brengen van de elektrische aansluiting moet

men zich ervan vergewissen dat het stopcontact geaard is.

Bij het tot stand brengen van de elektrische aansluiting moet

worden gecontroleerd of de spanningswaarden overeenstemmen met de waarden die vermeld staan op het plaatje in het

apparaat. Indien Uw apparaat niet voorzien is van niet

splitsbaar flexibel snoer en stekker, of van een ander

mechanisme dat de eenpoligheid uitschakeling verzekert

van de netspanning, met een openingswijdte tussen de

kontakten van tenminste 3mm., dan moet het apparaat dus

worden voorzien van een soortgelijk netspanningscheidingsmechanisme bij vaste installatie van het apparaat.

Als uw apparaat is voorzien van een snoer en stekker, dient

het apparaat zo te worden geplaatst dat u bij de stekker kunt

komen.

Schakel altijd de spanning over het apparaat uit alvorens met

een schoonmaak- of onderhoudsbeurt te beginnen.

HET GEBRUIK

Vermijd het gebruik van materiaal dat steekvlammen kan

veroorzaken in de nabijheid van het apparaat.

Bij het frituren moet men vooral letten op het brandgevaar dat

bestaat bij het gebruik van olie en vetten. Met name reeds

gebruikte olie is gevaarlijk vanwege hun ontvlambaarheid.

Gebruik geen open elektrische gril.

Ter vermijding van mogelijk brandgevaar, houdt men zich

aan de voorschriften voor het schoonmaken van de antivetfilters en de verwijdering van eventuele vet-aanslag op het

apparaat.

ONDERHOUD

Een nauwkeurig onderhoud garandeert een goede werking

en een lange levensduur.

Eventuele vetafzettingen dienen regelmatig, naar gelang het

gebruik (minstens eenmaal per 2 maanden) van het apparaat

te worden verwijderd. Gebruik geen schurende of corrosieve

middelen. Voor reiniging aan de buitenkant van gelakte

apparaten dient een doek te worden gebruikt die vochtig

gemaakt is in lauw water en een neutraal reinigingsmiddel;

voor reiniging aan de buitenkant van apparaten van staal,

koper of messing wordt het gebruik van specifieke producten

aangeraden, volgens de instructies op het product zelf; voor

de reiniging van de binnenkant van het apparaat moet een

doek (of kwast) worden gebruikt die is ondergedompeld in

gedenatureerde ethylalcohol.

04306466/2- Vol. nor. Cl. I/II

Loading...

Loading...