Page 1

High-Capacity

GrainGage Quick

Reference Sheet

FRS Main Menu

1. Collect

2. Maps

3. Setup

4. Diagnostics

Collect

1. Spatial

2. Form

3. List

4. Navigation

5. Map Traits

6. Map Identiers

Maps

1. Add

2. Edit

3. Delete

4. View

Setup

1. System

2. Traits

Management

3. Database Tools

4. Hardware Setup

Diagnostics

1. Load Cells

2. Moisture

3. Test Weight

4. Level Detect

Sensor

5. Actuators

6. Version

Information

7. Print Calibrations

System

1. Manage Devices

2. Dene Standard Units

3. Dene Backup Location

4. Label Printer

5. Preferences

6. About

Traits Management

1. Master Traits List

2. Trait Template

Database Tools

1. Export data to CSV

2. Import data from CSV

Hardware Setup

1. Weight Calibration

a. Load Cell

b. Edit Weight Calibration

c. Slope and Motion

d. Set Tare Warning

2. EM Sensor/Test Weight

3. Level Sensor

4. Timers

5. Actuators

6. Setup File

7. GPS Setup

Harvest Setup

1. Select desired Activity – Harvest Plot or

Harvest Strip.

2. Select desired Field Map.

3. Select desired harvest Trait Template.

4. Select Collect.

5. Select desired Moisture Curve.

6. Select Form or Nav.

7. Select Navigation Type – Serpentine, Sequential, Circular, or Random.

8. Select the Left Range and Left Row (starting plot).

9. Select the primary and secondary Direction of Travel.

10. Select Save.

11. Select Form.

12. Start harvesting.

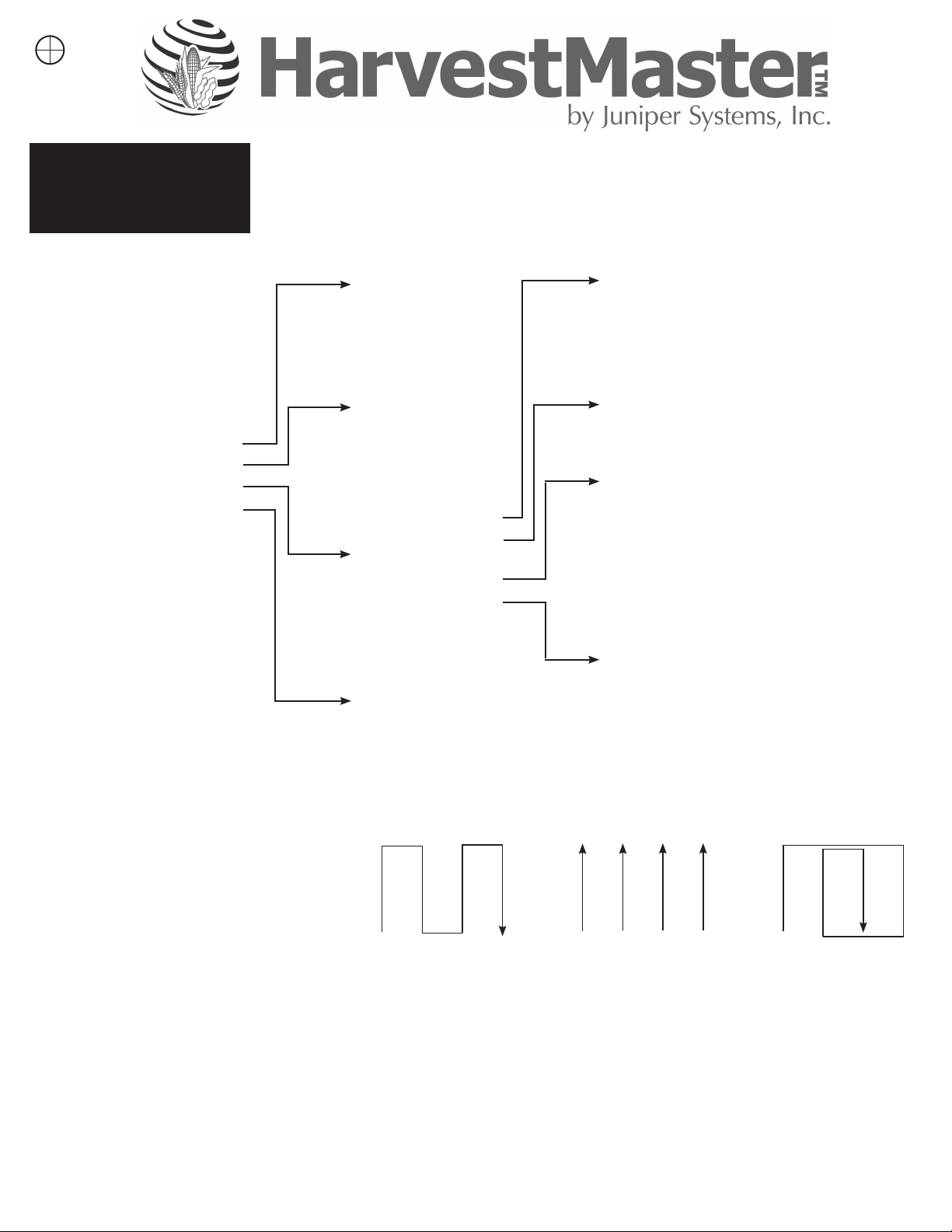

401 402 403 404 401 402 403 404 401 402 403 404

301 302 303 304 301 302 303 304 301 302 303 304

201 202 203 204 201 202 203 204 201 202 203 204

101 102 103 104 101 102 103 104 101 102 103 104

Serpentine Sequential Circular

Page 2

HCGG System Calibrating Guide

Load Cells—Calibration

1. Select Setup > Hardware Setup > HCGG Setup > Weight Calibration

Slope and Motion Sensor needs to be turned OFF during calibration.

2. Follow instructions on handheld screen.

EM Sensor/Test Weight Coecient Calibration

1. Select Setup (F3) > Hardware Setup > HCGG Setup > EM Sensor > Test Weight Coefcients.

* DO NOT ADJUST Coefcient V (CoefV) and Coefcient F (CoefF). Values have been optimized.

2. To adjust your test weight reading, determine the actual test weight of the grain sample.

3. Enter the diagnostics screen by selecting Diag (F3) to see the measured test weight and then pour the grain sample into the weigh bucket

4. Use the formula below to gure out how much to adjust Coefcient Z to create the new Coefcient Z value.

Actual Test Weight – Measured test weight = Coefcient Z adjustment value

Level Detect Settings

1. Select Setup (F3)>Hardware Setup>Classic GrainGage Setup>Level Detect.

2. The Open and Close levels are settings that determine the amount of grain in the hopper needed to trigger the GrainGage to cycle. The

higher the level setting the more grain required to start the cycle sequence. Open and Close Level should never be set lower than 5.0.

HM 800 Default Settings

Open Level – 10.0 Close Level – 10.0 Hopper Delay – 3.0

HCGG Maintenance Checklist

Item Process

Start System

Air Pressure Air pressure should be set 60 –80 psi.

Air Leaks

Cable Connections

Debris

Bucket Clearance

Actuators Cycle Smoothly Make sure all cylinders open and close smoothly.

Weight System

First, start the combine. Next, turn on HarvestMaster System Console (Handheld should turn on

automatically). Finally, load FRS.

If you have a reservoir air tank, turn off the combine after lling the tank. Check for air leaks on all

cylinders and solenoids. Also check solenoid exhaust port plugs for any build-up of oil or debris. If

they are caked in debris, take the exhaust port out and clean with Brake & Parts Cleaner.

Ensure all cable connections are tight and there is not any debris in the connections.

Be careful when reconnecting the cables not to bend or damage any connector pins.

Blow out the Graingage at the end of every day. DO NOT use a high-pressure washer to clean

system.

The plot bucket should be sitting rmly on the load cell tracks. Check to ensure that all cables and

air hoses are not touching the bucket. Also, check the clearance around the bucket.

Place a known weight into the weight bucket. Verify that the system reads the weight accurately.

Remove the weight and verify the system zeros out.

Calibrate Slope and Motion Procedure is in the manual (HCGG pg. 29)

Calibrate Moisture Curve Procedure is in the manual (HCGG pg. 38)

Calibrate Test Weight Coefcient Procedure is in the manual (HCGG pg. 48)

For questions, concerns, or comments

Please contact HarvestMaster:

During Ofce Hours: (435) 753-1881

After Ofce Hours: (435) 757-5354

Email: techsupport@harvestmaster.com

P/N 11524-03

Loading...

Loading...