Page 1

Desiccant Pack

Installation Instructions

Why Install a Desiccant Pack into the Allegro?

The Allegro is waterproof when the baery and PC card doors are

properly closed. However, the unit is built with a micro-pore lter

in the wall of the Allegro, which allows for a balance of atmospheric

pressure between the inside and outside of the case. This can allow

the passage of atmospheric gases, comprised mostly of nitrogen and

oxygen as well as the minor elements such as carbon dioxide and

water vapor.

In higher humidity environments, water vapor may collect inside

the case to a level sucient to cause condensation inside the case

when the Allegro is subjected to colder conditions. This condition

appears as fog inside of the touchscreen covering the display. Placing

a desiccant pack in the Allegro case can reduce the possibility of

condensation on the inside of the touchscreen.

Included Items

When you order a desiccant pack, you

receive two desiccant packs in a small, airtight, resealable plastic bag. Each desiccant

pack is shipped with two small pieces of

Velcro. The rst piece is aached to the

desiccant pack, and the other is aached to

the rst piece of Velcro.

Page 2

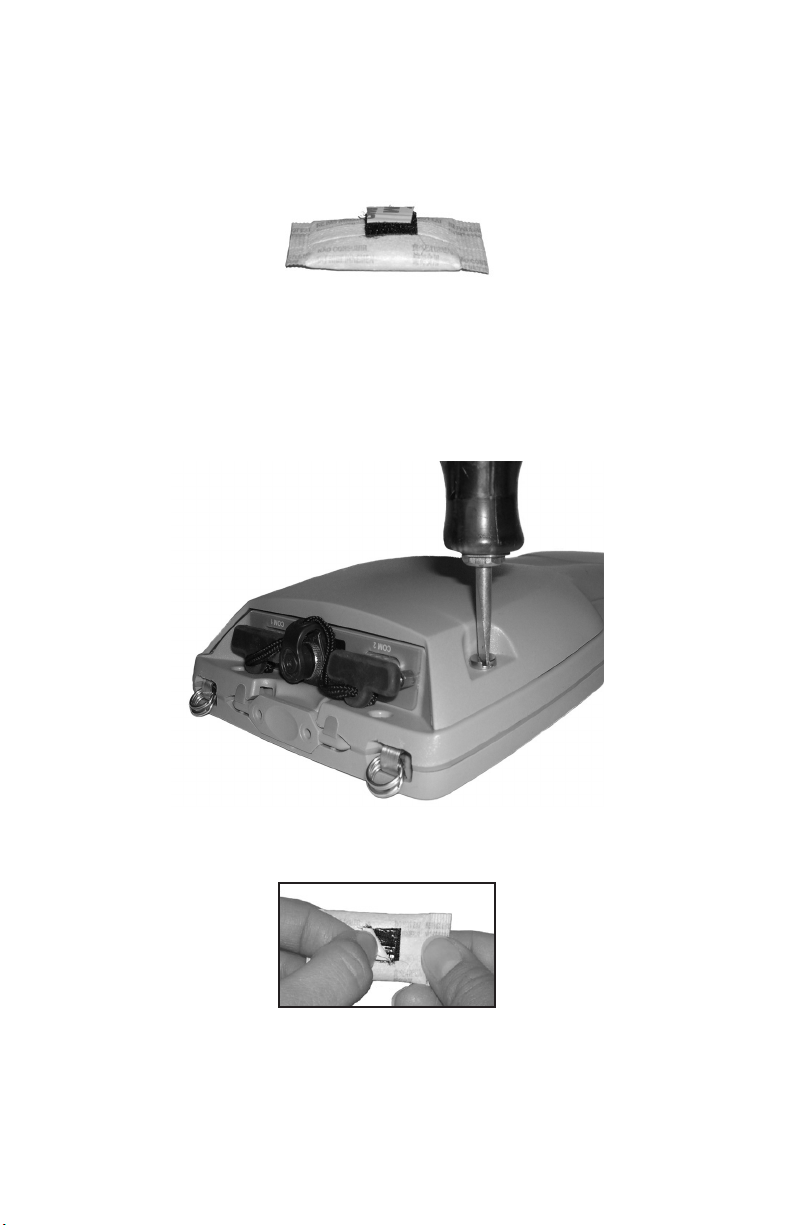

Items Needed

• Desiccant pack with two pieces of Velcro aached (included)

• Small athead screwdriver

Velcro with adhesive to attach to Allegro

Velcro attached to desiccant pack

Installation Instructions

To install a desiccant pack in the Allegro, complete the following steps:

1. Using a small athead screwdriver (or coin), turn the screws on the

PC Card door ¼ turn to the le to unlock the latches.

2. Remove the adhesive backing from the piece of Velcro aached to

the Velcro that is aached to the desiccant pack.

3. Aach the desiccant pack with the aached Velcro pieces so it is

about ¼ inch below the upper gasket rim and centered between the

PC card door holder tabs. Make sure the lower edge of the desiccant

pack sits directly above the PC Card holder tabs.

Make sure the transparent window is facing out so the color indicator is

visible.

Page 3

Upper Gasket Seal Rim

PC Card Holder Tabs

Note: If a piece of Velcro is already aached to the inside of the Allegro’s PC

card door, remove the piece on the new pack that has the removable adhesive

cover and throw it away. Aach the desiccant pack to the piece of Velcro that is

already aached to your Allegro.

4. Close the door slowly while inspecting the newly installed desiccant

pack. Make sure the edges of the packet are far enough away from

the gasket so that it is not pinched by the PC Card door when it is

closed.

Caution: If the edge of the packet is pinched between the gasket and seal rim,

the door may not fully seal, thus compromising the waterproof integrity of the

Allegro.

5. Using a small athead screwdriver (or coin), turn the screws a ¼

turn to the right to lock the latches on the PC Card door.

6. Replace the desiccant pack periodically as needed.

Indicating Silica Gel

We use an indicating silica gel that has been washed with a

concentration of cobalt chloride (a heavy metal salt). The cobalt

chloride is a deep blue color when it is dry and turns from blue to

purple to pink as it becomes saturated with moisture. Typically, the

color changes as the desiccant goes past 8% moisture levels (by weight)

and indicates it is time to replace the desiccant.

Page 4

If the indicator is pink, heat the bag according to the following

instructions:

Dry the bag in a cool, convection, circulating, forced air oven set at

245 degrees F. Be sure the bag has sucient airow around it.

Warning: Do not exceed 245 degrees. Failure to do so could melt the

desiccant.

Leave the bag in the oven for 24 hours. Once done, seal the bag in the

included air-tight bag or a small air-tight glass jar for cooling.

For detailed instructions, please see the white paper Mil-Spec

Desiccant Regeneration on our website.

If the color changes from pink back to blue, it is reusable. If the color

does not change, contact Juniper Systems for more information.

Color indicator

Storage

You must store the unused desiccant packs in the sealable plastic

bag in which the packs were shipped until you are ready to use

them. Storing the desiccant packs in containers that are not air tight

shortens the useful life of the desiccant pack.

Ordering Information

Replacement packs of two desiccant packs (part number 20391) can

be purchased from Juniper Systems, Inc. at js@junipersys.com or by

calling (435) 753-1881.

a Campbell Scientic Company

1132 West 1700 North

Logan, UT 84341, USA

Tel +1 435.753.1881

Fax +1 435.753.1896

Email js@junipersys.com

Web www.junipersys.com

Mobile Field Computers and Mobile GIS/GPS

HarvestMaster™ Brand Data Collection Tools for Agriculture

Part # 20393-02

Released May 2011

Page 5

MIL-SPEC DESICCANT REGENERATION

Regeneration of Tyvek desiccant bags or brown paper bags can be accomplished

by the following method:

•

Arrange the bags on a wire tray in a single layer to allow for adequate

airflow around the bags during the drying process. The oven’s inside

temperature should be room or ambient (77o F – 85o F.) A CONVECTION,

CIRCULATING, FORCED AIR TYPE OVEN IS RECOMMENDED FOR THIS

REGENERATION PROCESS. SEAL FAILURES MAY OCCUR IF ANY OTHER

TYPE OF HEATING UNIT OR APPLICANCE IS USED.

•

When placed in a forced air, circulating air, or convection oven, allow a

minimum of 1.5 to 2.0 inches of air space between the top of the bags and

the next metal tray above the bags. If placed in a radiating exposed infrared

element type oven, shield the bags from direct exposure to the heating

element, giving the closes bags a minimum of 16 inches clearance from the

heat shield. Excessive surface film temperature due to infrared radiation

will cause the Tyvek material to melt and/or the seals to fail.

•

Seal failure may also occur if the temperature is allowed to increase

rapidly. This is due to the fact that the water vapor is not given sufficient

time to diffuse through the Tyvek material, thus creating internal pressure

within the bag, resulting in a seal rupture. Temperature should not increase

faster than 0.25o to 0.50o F per minute.

•

Set the temperature of the oven to 245o F, and allow the bags of desiccant

to reach equilibrium temperature. WARNING: Tyvek has a melt temperature

of 250o F – 260o F. (NON MIL-D-3464E, activation or reactivation of both

silica gel and Bentonite clay can be achieved at temperatures of 220o F).

•

Desiccant bags should be allowed to remain in the oven at the assigned

temperature for up to 24 hours. At the end of the time period, the bags

should be immediately removed and placed in a desiccator jar or dry (0%

relative humidity) airtight container for cooling. (LPTG01 foil ziplock bags

are ideal) If this procedure is not followed precisely, any water vapor driven

off during reactivation may be re-absorbed during cooling and/or handling.

•

After the bags of desiccant have been allowed to cool in an airtight

desiccator, they may be removed and placed in either an appropriate type

polyliner tightly sealed to prevent moisture absorption, or a container that

prevents moisture from coming into contact with the regenerated

desiccant.

Loading...

Loading...