Page 1

T640 Core Router Quick Start

January 2015

Part Number: 530-062015

Revision 01

This document describes how to install the Juniper Networks®T640 Core Router.

Contents

T640 Quick Start Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 1: Preparing the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rack-Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tools Required to Unpack and Prepare the T640 Router for Installation . . . . . 5

Step 2: Installing the Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Mounting Hardware for a Four-Post Rack or Cabinet . . . . . . . . . 7

Installing Cage Nuts, If Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Large Mounting Shelf and Spacer Bars . . . . . . . . . . . . . . . . 8

Installing the Small Mounting Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing the Center-Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Mounting Hardware in an Open-Frame Rack . . . . . . . . . . . . . . . 9

Installing Cage Nuts if Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the Large Mounting Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Removing the Spacer Bars and Center-Mounting Brackets . . . . . . . . . . . 11

Step 3: Installing the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Router Using a Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Router Without a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . . 13

Removing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting the Router into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reinstalling Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 4: Connecting the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 5: Connecting External Devices and PIC Cables . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting a Management Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting to a Network for Out-of-Band Management . . . . . . . . . . . . . . . . 21

Connecting the PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1Copyright © 2015, Juniper Networks, Inc.

Page 2

T640 Core Router Quick Start

Step 6: Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting Power to a T640 Router with Two-Input 160-A DC Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting Power to a T640 Router with Three-Input 240-A DC Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting the Input Mode Switch on a Three-Input 240-A DC Power

Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacingthe Cable Restrainton a Three-Input 240-A DC Power Supply

(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the DC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting Power to a T640 Router with Four-Input 160-A DC Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting Power to a T640 Router with Six-Input DC Power Supplies . . . . 30

Connecting Power to a T640 Router with Three-Phase Delta AC Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting Power to a T640 Router with Three-Phase Wye AC Power

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Step 7: Powering On the T640 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Powering On the DC-Powered Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Powering On the AC-Powered Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Step 8: Performing the Initial Software Configuration . . . . . . . . . . . . . . . . . . . . . . 42

Entering Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring User Accounts and Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configuring System Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Committing the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Compliance Statements for NEBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Compliance Statements for EMC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

European Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Israel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Junos OS Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Copyright © 2015, Juniper Networks, Inc.2

Page 3

T640 Quick Start Description

This Quick Start contains information you need to install and configure the router quickly.

For complete installation instructions, see the T640 Core Router Hardware Guide at

http://www.juniper.net/techpubs/hardware/.

WARNING: This Quick Start contains a summary of safetywarningsin “Safety

Warnings” on page47. For a complete list of warnings for this router, including

translations, see the T640 Core Router Hardware Guide at

http://www.juniper.net/techpubs/hardware/.

The router is shipped in a wooden crate. A wooden pallet forms the base of the crate.

The router chassis is bolted to this pallet. The shipping crate also contains an accessory

box and a Quick Start (this document).

T640 Quick Start Description

3Copyright © 2015, Juniper Networks, Inc.

Page 4

T640 Core Router Quick Start

Step 1: Preparing the Site

Before installing the router, make sure that the site meets all the power, environmental,

and clearance requirements. See the site preparation guidelines in the T640 Core Router

Hardware Guide.

•

Rack-Mounting Requirements on page 4

•

Tools Required to Unpack and Prepare the T640 Router for Installation on page 5

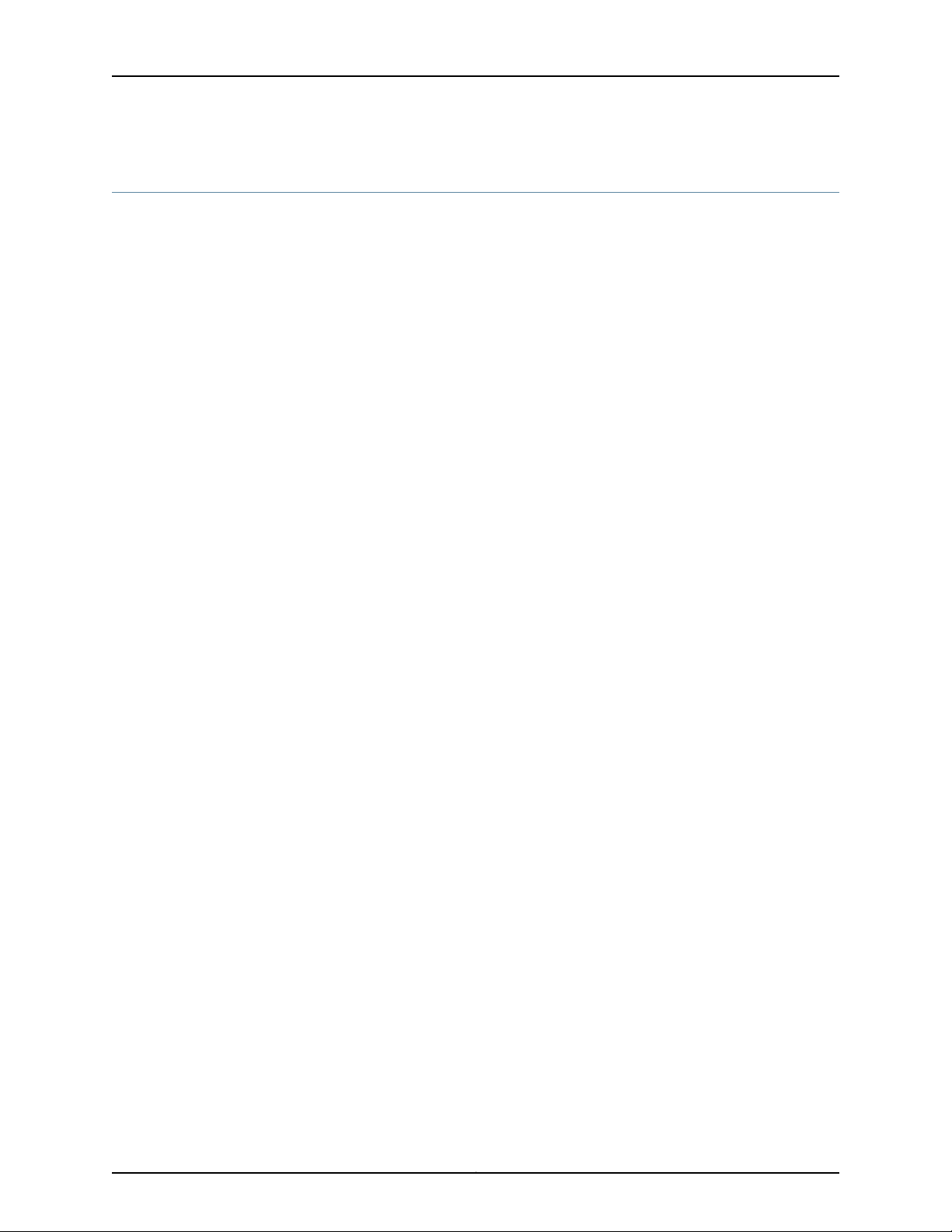

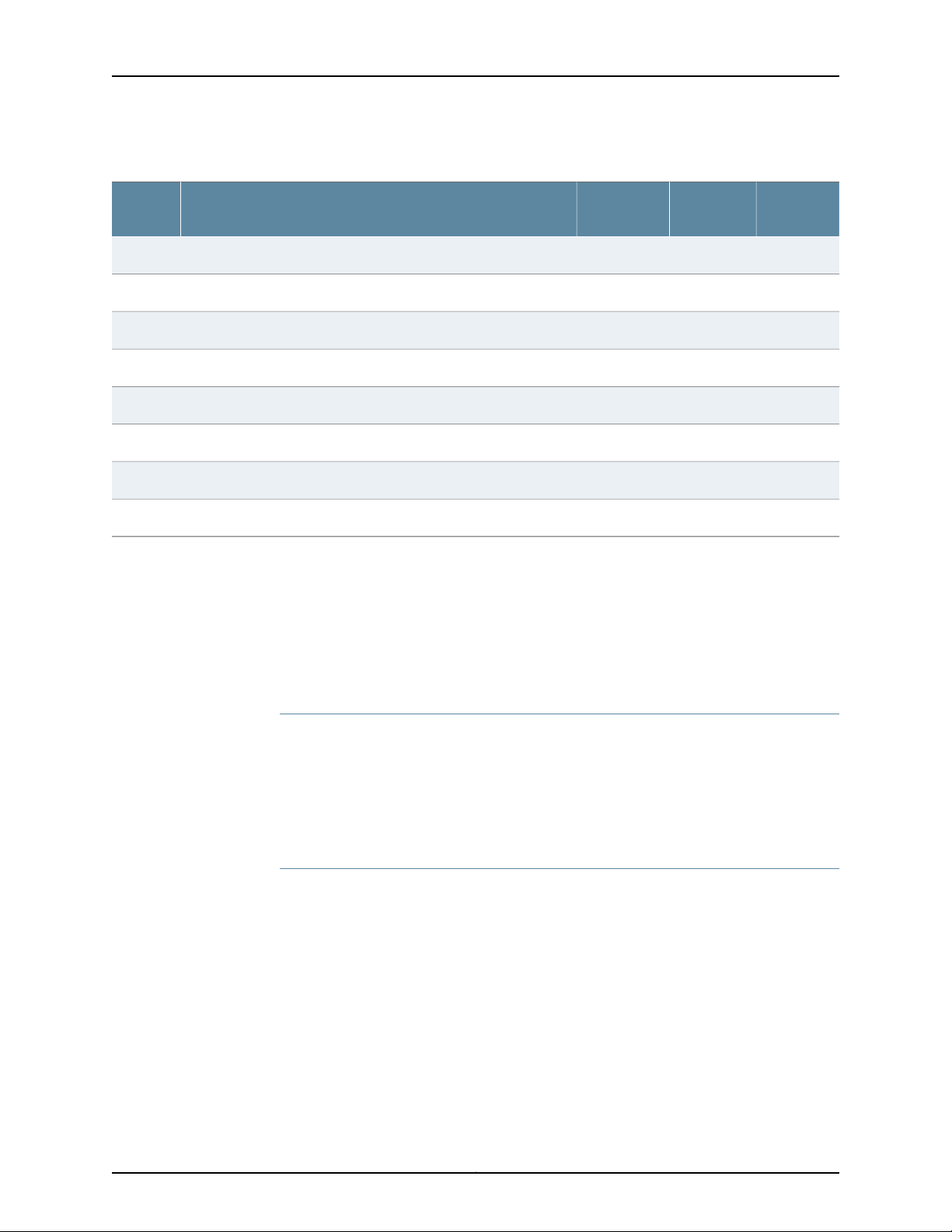

Rack-Mounting Requirements

•

You can install the router in many types of racks, including a four-post rack or cabinet

or an open-frame rack.

•

The rack rails must be spaced widely enough to accommodate the router chassis's

external dimensions: 37.45 in. (95.6 cm) high, 31 in. (78.7 cm) deep, and 17.43 in. (44.3

cm) wide. The mounting brackets extend the width to fit into standard 19-in. (48.3

cm) racks.

•

The rack must be strong enough to support the weight of the fully configured router,

up to about 565 lb (256.3 kg). If you mount two routers in one rack, it must be capable

of supporting a combined weight of over 1100 lb (499 kg).

•

For service personnel to remove and install hardware components, there must be

adequate space at the front and back of the router. Allow at least 24 in. (61.0 cm) both

in front of and behind the router.

•

The rack or cabinet must have an adequate supply of cooling air.

•

In a closed cabinet, there must be a minimum of 6 in. (15.2 cm) of unobstructed airflow

behind the router, or airflow baffles must be installed to prevent recirculation of hot

air and overheating.

•

If the router is the only unit in the rack, mount it at the bottom.

•

When mounting the router in a partially filled rack, load the rack from the bottom to

the top, with the heaviest component at the bottom of the rack.

Copyright © 2015, Juniper Networks, Inc.4

Page 5

Tools Required to Unpack and Prepare the T640 Router for Installation

Figure 1: Rack Clearances and Router Dimensions

Tools Required to Unpack and Prepare the T640 Router for Installation

•

A mechanical lift—recommended

•

1/2-in. or 13-mm open-end or socket wrench to remove bracket bolts from the shipping

pallet

•

Phillips screwdrivers, numbers 1 and 2

•

DC-powered routers: 7/16-in. (11 mm) hexagonal-head external drive nut driver, with

a torque range between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm), for tightening nuts

to terminal studs on each power supply on a DC-powered router

•

AC-powered router:

•

Phillips (+) screwdriver, number 2 to access the metal AC wiring compartment

5Copyright © 2015, Juniper Networks, Inc.

Page 6

T640 Core Router Quick Start

•

1/4-in. slotted screwdriver to attach the ground wire and input terminal wires of the

AC power cord.

•

Wire cutters

•

Cage nuts, if needed for your rack or cabinet

•

Electrostatic discharge wrist strap

•

Antistatic mat

•

Blank panels to cover any slots not occupied by a component

Copyright © 2015, Juniper Networks, Inc.6

Page 7

Step 2: Installing the Mounting Hardware

To install the mounting hardware:

•

Installing the Mounting Hardware for a Four-Post Rack or Cabinet on page 7

•

Installing the Mounting Hardware in an Open-Frame Rack on page 9

Installing the Mounting Hardware for a Four-Post Rack or Cabinet

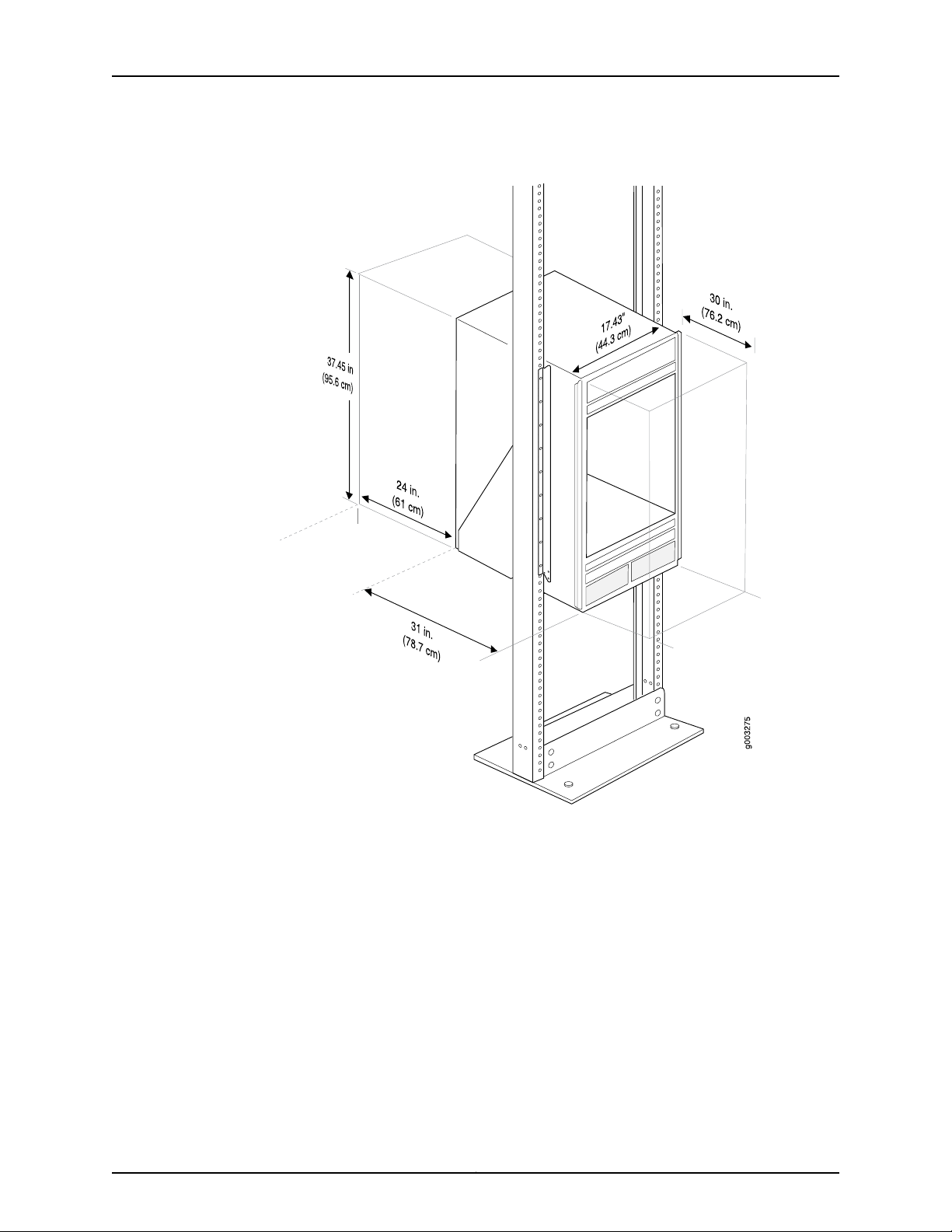

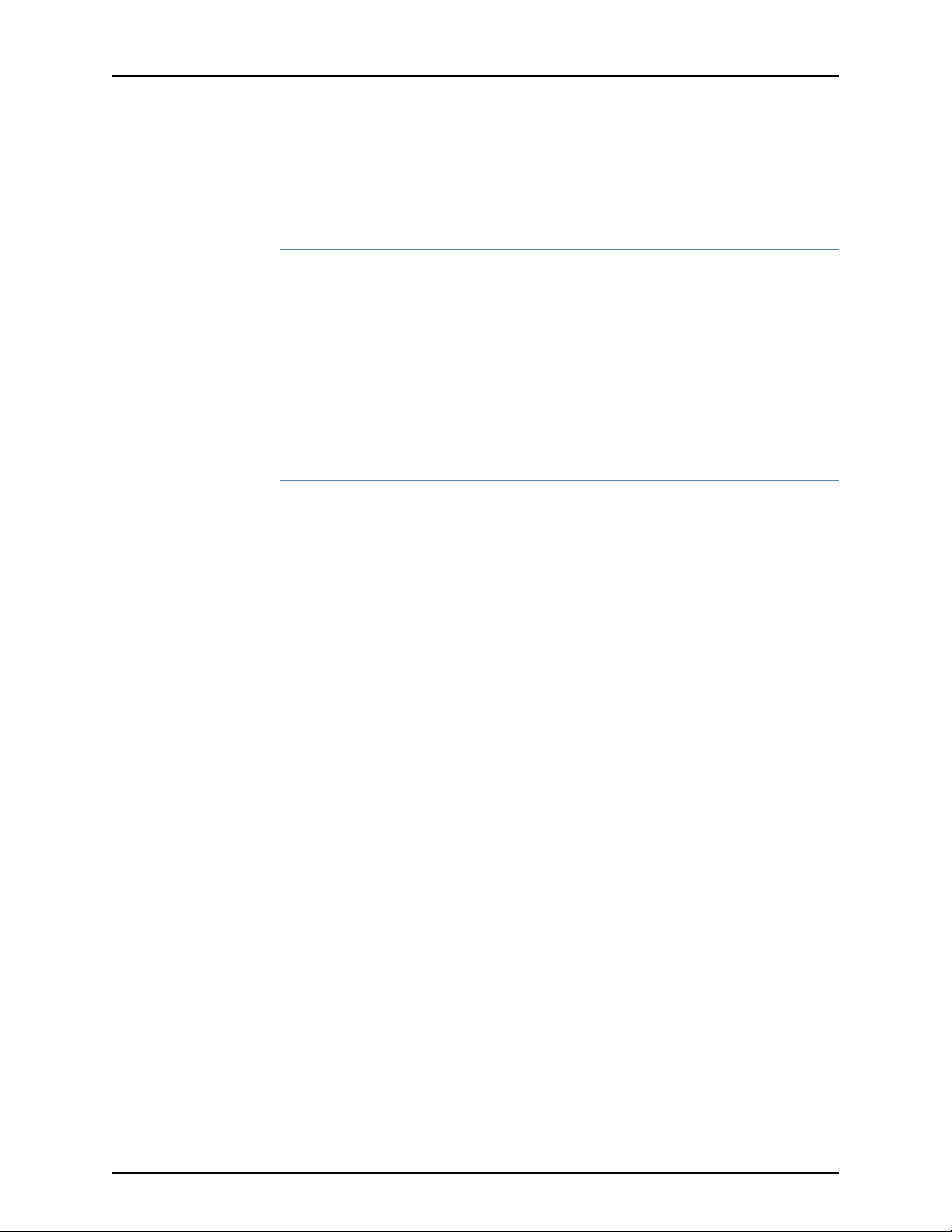

Figure 2: Mounting Hardware for a Four-Post Rack or Cabinet

Step 2: Installing the Mounting Hardware

An x in Table 1 on page 7 indicates a mounting hole location.

Table 1: Four-Post Rack and Cabinet Mounting Hole Locations

Spacer

BarsLarge ShelfDistance Above “U” DivisionHole

Small

Shelf

–x–19.86 U34.75 in. (88.3 cm)60

–x–16.86 U24.26 in. (61.6 cm)51

–x–13.86 U24.26 in. (61.6 cm)42

7Copyright © 2015, Juniper Networks, Inc.

Page 8

T640 Core Router Quick Start

Table 1: Four-Post Rack and Cabinet Mounting Hole Locations (continued)

To install the mounting hardware for a four-post rack or cabinet:

•

Installing Cage Nuts, If Needed on page 8

•

Installing the Large Mounting Shelf and Spacer Bars on page 8

•

Installing the Small Mounting Shelf on page 9

•

Removing the Center-Mounting Brackets on page 9

Spacer

BarsLarge ShelfDistance Above “U” DivisionHole

Small

Shelf

–x–10.86 U19.01 in. (48.3 cm)33

–x–7.86 U13.76 in. (34.9 cm)24

xx–4.86 U8.51 in. (21.6 cm)15

x––3.86 U6.76 in. (17.1 cm)12

x––4.86 U5.01 in. (12.7 cm)9

xx–1.86 U3.26 in. (8.3 cm)6

x––0.86 U1.51 in. (3.8 cm)3

––x0.5 U0.88 in. (2.2 cm)2

Installing Cage Nuts, If Needed

For racks without threaded holes, you must install cage nuts in the locations specified in

Table 1 on page 7:

•

On each front rack rail, install cage nuts for the large shelf and spacer bars.

•

On each rear rack rail, install cage nuts for the small shelf.

Installing the Large Mounting Shelf and Spacer Bars

1. On the front side of each front rail, partially insert a mounting screw into the lowest

hole specified in Table 1 on page 7 for the large shelf.

2. Install the large shelf on the front side of the front rack rails. Rest the bottom slot in

each flange on one of the mounting screws.

3. Tighten all the screws completely.

4. Place one spacer bar over a flange of the large shelf.

5. Partially insert a mounting screw into each of the nonthreaded holes in the recesses

of the spacer bar.

Copyright © 2015, Juniper Networks, Inc.8

Page 9

Installing the Small Mounting Shelf

6. Repeat Step 4 and Step 5 for the other spacer bar.

7. Tighten all the screws completely.

Installing the Small Mounting Shelf

The small shelf installs on the back of the rear rails, extending toward the center of the

rack. See Table 1 on page 7.

1. Partially insert a mounting screw into the lowest hole specified in Table 1 on page 7.

2. Install the small shelf on the back of the rear rack rails. Rest the bottom slot on each

flange on one of the mounting screws.

3. Partially insert screws into the open holes in the ears of the small shelf.

4. Tighten all the screws completely.

Removing the Center-Mounting Brackets

The router is shipped with a spacer bar attached to the back of each front-mounting

flange, and two center-mounting brackets attached to the chassis. Remove the center

mounting brackets from the chassis by loosening the screws at the top and bottom of

each bracket.

Installing the Mounting Hardware in an Open-Frame Rack

To install the mounting hardware for an open frame rack:

•

Front-mount: Attach the large mounting shelf on the back of the rails. Remove the

center-mounting brackets from the chassis.

•

Center mount: Attach the large mounting shelf on the back of the rails. You do not

have to remove the center-mounting brackets from the chassis.

The small mounting shelf is not needed for open-frame racks.Table 2 on page 10 specifies

the holes in which you insert mounting screws, and cage nuts if needed.

9Copyright © 2015, Juniper Networks, Inc.

Page 10

T640 Core Router Quick Start

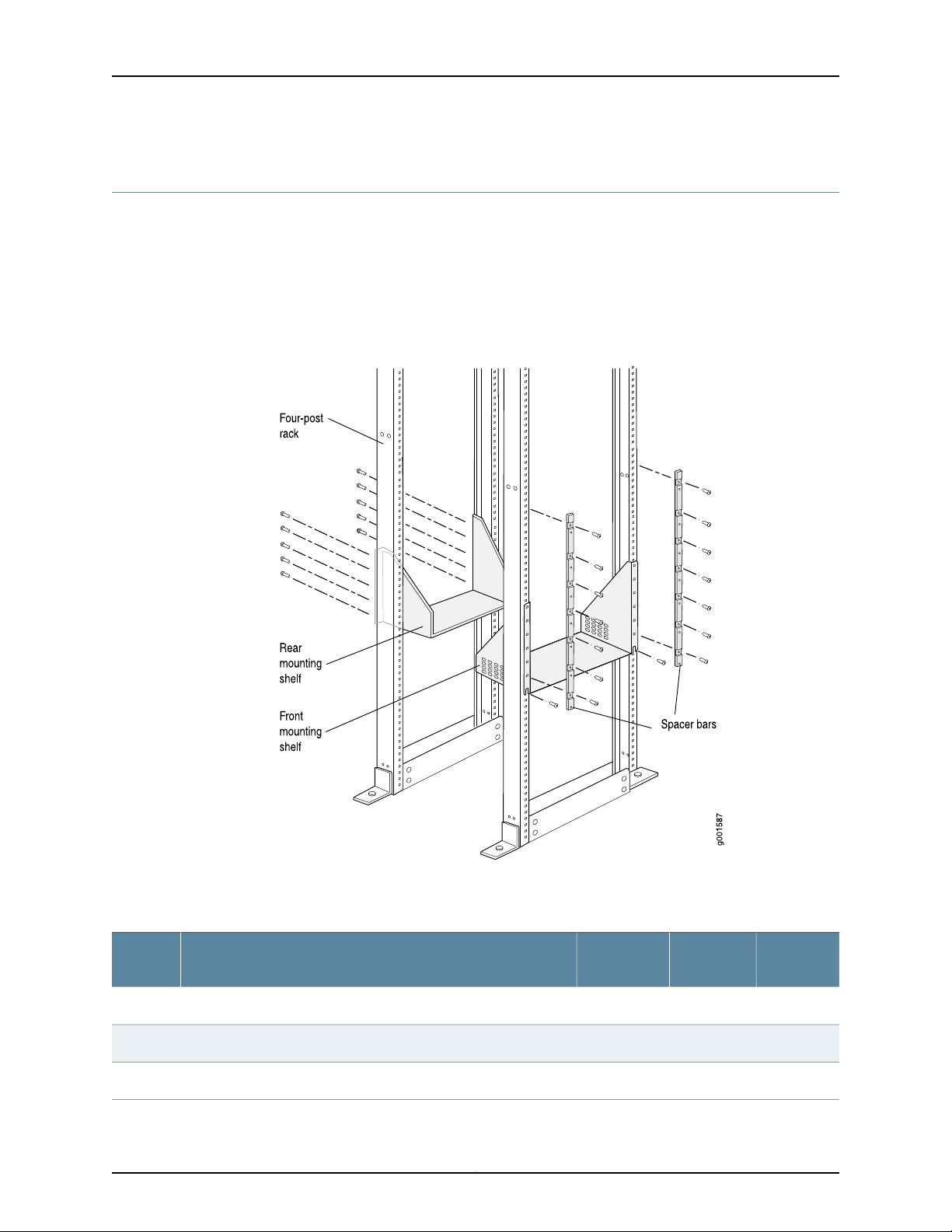

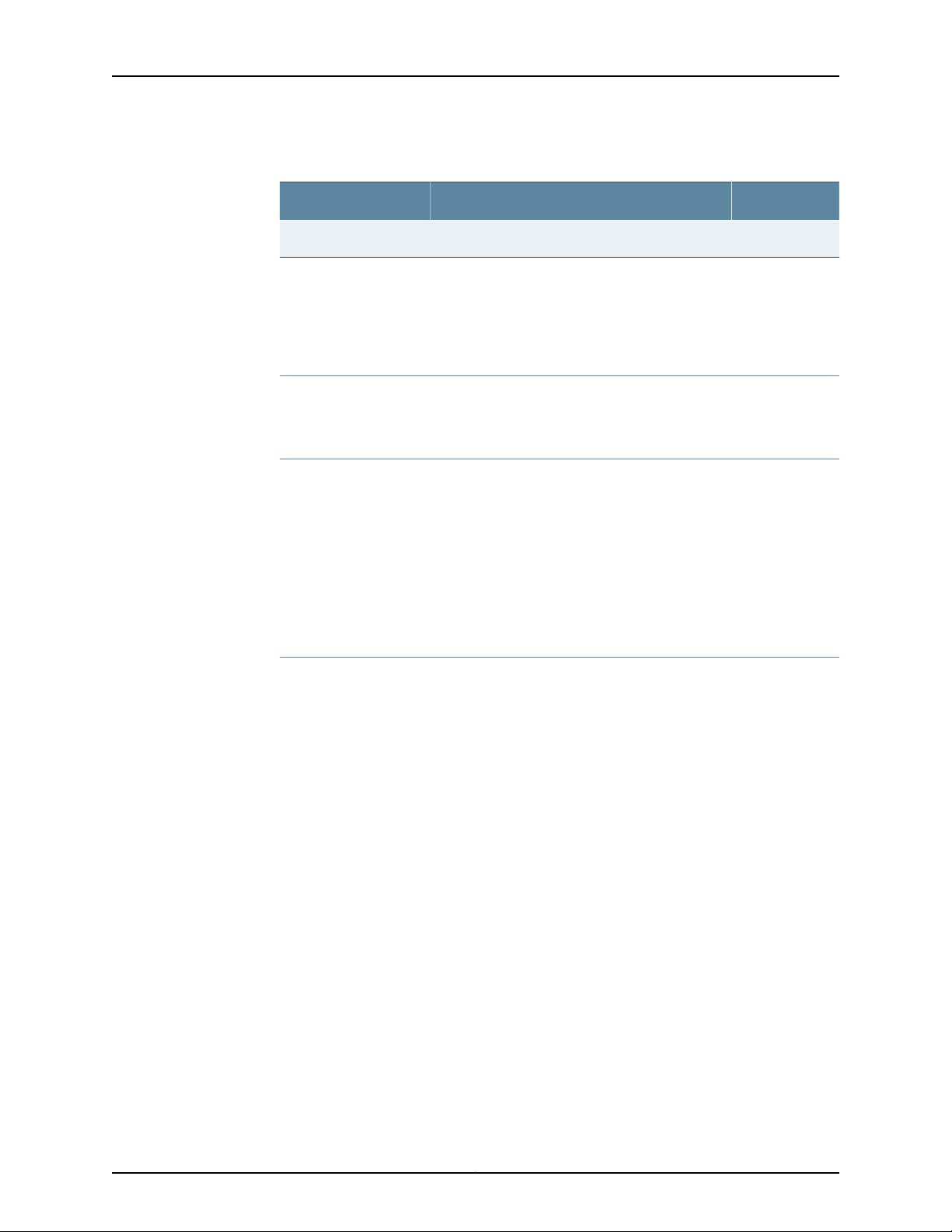

Figure 3: Mounting Hardware for an Open-Frame Rack

An x in Table 2 on page 10 indicates a mounting hole location.

Table 2: Open-Frame Rack Mounting Hole Locations

Large ShelfDistance Above U DivisionHole

x19.5 U34.13 in. (86.7 cm)59

x17.5 U30.63 in. (77.8 cm)53

x16.5U28.88 in. (73.3 cm)50

x14.5 U25.38 in. (64.5 cm)44

x13.5 U23.63 in. (60.0 cm)41

x11.5 U20.13 in. (51.1 cm)35

x10.5 U18.38 in. (46.7 cm)32

Copyright © 2015, Juniper Networks, Inc.10

Page 11

Installing Cage Nuts if Needed

Table 2: Open-Frame Rack Mounting Hole Locations (continued)

Large ShelfDistance Above U DivisionHole

x10.14 U17.75 in. (45.1 cm)31

•

Installing Cage Nuts if Needed on page 11

•

Installing the Large Mounting Shelf on page 11

•

Removing the Spacer Bars and Center-Mounting Brackets on page 11

Installing Cage Nuts if Needed

Install cage nuts, if needed. On the back of the rack rails, install cage nuts for the large

shelf in the mounting holes specified in Table 2 on page 10.

Installing the Large Mounting Shelf

1. On the rear of each rack rail, partially insert a mounting screw in the lowest hole

specified in Table 2 on page 10.

2. Install the shelf on the rack. Rest the bottom slot in each flange on one of the installed

mounting screws.

3. Partially insert screws into the open holes in the flanges of the large shelf.

4. Tighten all the screws completely.

Removing the Spacer Bars and Center-Mounting Brackets

The router is shipped with a spacer bar attached to the back of each front-mounting

flange, and two center-mounting brackets attached to the chassis.

•

If you plan to front-mount the router in an open-frame rack:

1. Remove the spacer bars by loosening the screws that fasten the spacer bars to the

front-mounting flanges.

2. Remove the center-mounting brackets from the chassis by loosening the screws

at the top and bottom of each bracket.

•

If you plan to center-mount the router in an open-frame rack, leave the center-mounting

brackets attached to the chassis. Optionally, you can remove the spacer bars.

11Copyright © 2015, Juniper Networks, Inc.

Page 12

T640 Core Router Quick Start

Step 3: Installing the Router

Because of the router's size and weight, we recommend that you install the router using

a mechanical lift. If a lift is unavailable, see the instructions for installing the rack without

a mechanical lift.

•

Installing the Router Using a Lift on page 12

•

Installing the Router Without a Mechanical Lift on page 13

Installing the Router Using a Lift

CAUTION: Do not lift the router using the installation handle or the handles

on the sides of the chassis. Use these handles only to help position the router.

1. Make sure the rack is properly secured to the building in its permanent location.

2. Remove the power supplies from the router as described in the T640 Core Router

Hardware Guide.

3. Insert the captive screws of the installation handle into the holes previously occupied

by the captive screws of the power supplies. Attach the installation handle, tightening

the captive screws firmly to secure it to the chassis.

4. Load the router onto the lift, making sure it rests securely on the lift platform.

5. Using the lift, position the router in front of the rack or cabinet, centering it in front of

the large mounting shelf.

6. Carefully lower the router onto the shelf. The shelf ensures that the holes in the

mounting brackets align with the holes in the rack rails.

7. With one person pulling on the installation handle from the rear of the rack or cabinet

while another person pushes on the front-mounting flanges:

•

Four-post rack or cabinet: Slide the chassis onto the mounting shelves until the

front-mounting flanges contact the spacer bars.

•

Front-mounting in an open-frame rack: Slide the chassis onto the large mounting

shelf until the front-mounting flanges contact the rack rails.

•

Center-mounting in an open-frame rack: Slide the chassis onto the large mounting

shelf until the center-mounting brackets contact the rack rails.

8. Move the lift away from the rack.

9. Install the mounting screws:

•

Four-post rack or cabinet: Install a mounting screw into each of the holes aligned

with the threaded holes in the spacer bars.

•

Open-frame rack: Install a mounting screw into each of the open mounting holes

aligned with the rack, starting from the bottom.

10. Reinstall the power supplies as described in the T640 Core Router Hardware Guide.

Copyright © 2015, Juniper Networks, Inc.12

Page 13

Figure 4: Loading the Router onto the Lift

Installing the Router Without a Mechanical Lift

Installing the Router Without a Mechanical Lift

To install the router without a mechanical lift:

•

Removing Components on page 13

•

Lifting the Router into the Rack on page 16

•

Reinstalling Components on page 18

Removing Components

NOTE: For complete instructions on removing router components, see the

T640 Core Router Hardware Guide.

13Copyright © 2015, Juniper Networks, Inc.

Page 14

T640 Core Router Quick Start

Before lifting the router, you must remove the following components (see

Figure 5 on page 15 and Figure 6 on page 16:

•

Power supplies

•

Cable management system

•

Switch Interface Boards (SIBs)

•

Control Boards (CBs)

•

SONET Clock Generators (SCGs)

•

Fan trays

•

Flexible PIC Concentrators (FPCs)

To remove the components from the router:

1. Slide each component out of the chassis evenly so that it does not become stuck or

damaged.

2. Label each component as you remove it so you can reinstall it in the correct location.

3. Immediately store each removed component in an electrostatic bag.

4. Do not stack removed components. Lay each one on a flat surface.

Copyright © 2015, Juniper Networks, Inc.14

Page 15

Removing Components

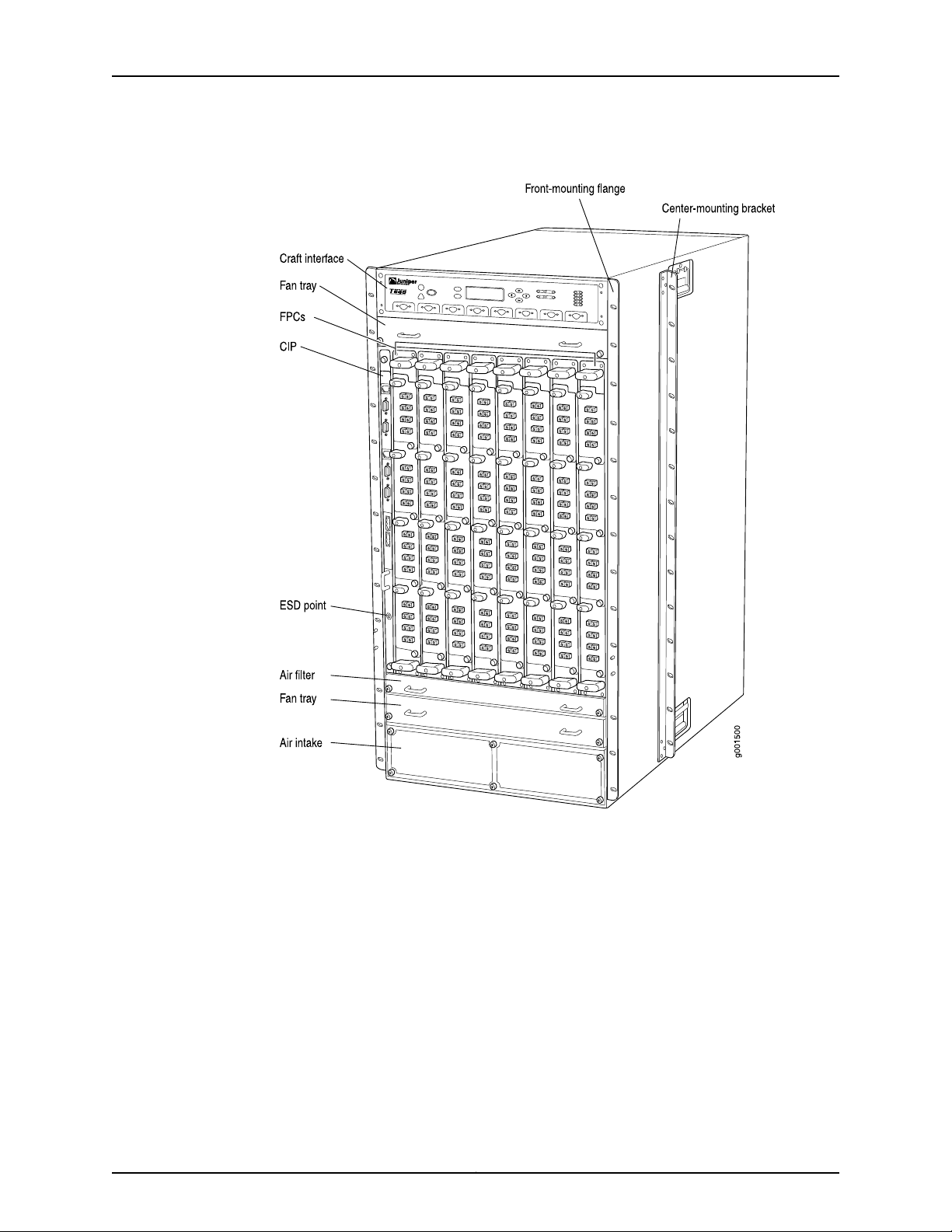

Figure 5: Components to Remove from the Front of the Router

15Copyright © 2015, Juniper Networks, Inc.

Page 16

T640 Core Router Quick Start

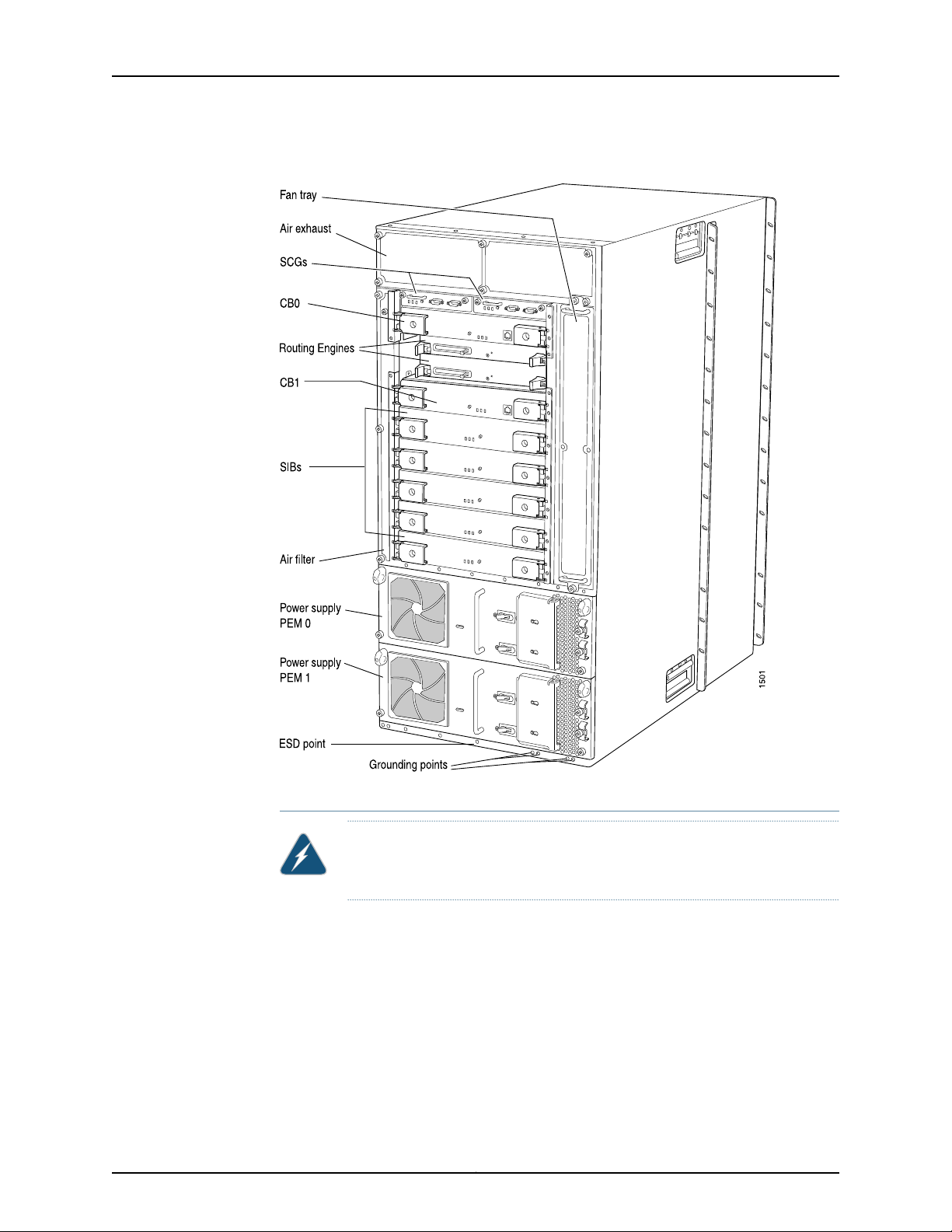

Figure 6: Components to Remove from the Rear of the Router

Lifting the Router into the Rack

WARNING: Do not lift the router using the installation handle or the handles

on the sides of the chassis. Use these handles only to help position the router.

Lifting the chassis and mounting it into a rack requires four people to lift and a fifth person

to secure the mounting screws. The empty chassis weighs over 205 lbs (64.7 kg).

1. Make sure the rack is in its permanent location and is secured to the building.

2. Insert the captive screws of the installation handle into the holes previously occupied

by the captive screws of the power supplies.

3. Move the router as close as possible to the rack. Use a pallet jack if one is available.

4. With two people in the front and two people in the back, hold the bottom of the chassis

and carefully lift it onto the large and small (if installed) mounting shelves.

Copyright © 2015, Juniper Networks, Inc.16

Page 17

Lifting the Router into the Rack

5. With one person pulling on the installation handle from the back of the rack or cabinet

while two people push on the front-mounting flanges, slide the router onto the

mounting shelf or shelves:

•

Four-post rack or cabinet: Slide the router onto the mounting shelves until the

front-mounting flanges contact the spacer bars.

•

Front-mounting in an open-frame rack: Slide the router onto the large mounting

shelf until the front-mounting flanges contact the rack rails.

•

Center-mounting in an open-frame rack: Slide the router onto the large mounting

shelf until the center-mounting brackets contact the rack rails.

6. If you are installing the router in a four-post rack or cabinet, install a mounting screw

and a cage nut into each of the holes aligned with the threaded holes in the spacer

bars. If you are installing the router into an open-frame rack, install a mounting screw

into each of the open mounting holes aligned with the rack, starting from the bottom.

Figure 7: Lifting the Router into the Rack

17Copyright © 2015, Juniper Networks, Inc.

Page 18

T640 Core Router Quick Start

Reinstalling Components

NOTE: For complete instructions on reinstalling router components after

you have installed the router without a mechanical lift, see the T640 Core

Router Hardware Guide.

1. Slide each component into the chassis evenly so that it does not become stuck or

damaged.

2. Tighten the captive screws for each component.

3. Make sure that all empty slots are covered with a blank panel before operating the

router.

Step 4: Connecting the Grounding Cable

You ground the router by connecting a grounding cable to earth ground and then attaching

it to the chassis grounding points with two screws. You must provide the grounding cable

(a cable lug is supplied with the router). To connect the grounding cable (see

Figure 8 on page 19):

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Make sure that grounding surfaces are clean and brought to a bright finish before

grounding connections are made.

3. Connect the grounding cable to a proper earth ground.

4. Verify that a licensed electrician has attached the cable lug provided with the router

to the grounding cable.

5. Attach an electrostaticdischarge(ESD)grounding strap to your bare wrist, and connect

the strap to one of the ESD points on the chassis.

6. Place the grounding cable lug over the grounding points. The left pair is sized for M6

screws, and the right pair is sized for UNC 1/4-20 screws.

7. Secure the grounding cable lug to the grounding points, first with the washers, then

with the screws.

8. Verify that the grounding cabling is correct, that the grounding cable does not touch

or block access to router components, and that it does not drape where people could

trip on it.

Copyright © 2015, Juniper Networks, Inc.18

Page 19

Figure 8: Connecting the Grounding Cable

g006254

Grounding points

(on chassis)

Step 4: Connecting the Grounding Cable

19Copyright © 2015, Juniper Networks, Inc.

Page 20

T640 Core Router Quick Start

Step 5: Connecting External Devices and PIC Cables

Figure 9: Connecting External Devices and PIC Cables

To connect external devices and PIC cables:

•

Connecting a Management Device on page 20

•

Connecting to a Network for Out-of-Band Management on page 21

•

Connecting the PIC Cables on page 21

Connecting a Management Device

1. Locate the appropriate cable and connector.

2. Turn off the power switch on the management device.

Copyright © 2015, Juniper Networks, Inc.20

Page 21

3. Plug the female end of the RS-232 serial connector into the CONSOLE port or AUX

port on the Connector Interface Panel (CIP).

4. Plug the other end of the cable into the management device.

5. Tighten the screws on the connector.

Connecting to a Network for Out-of-Band Management

NOTE: Before you can use the Ethernet management port to connect to a

network for out-of-band management, you must perform the initial Junos

OS configuration after the router has been powered on. See “Step 8:

Performing the Initial Software Configuration” on page 42

1. Locate the appropriate cable and connector.

2. Plug one end of the Ethernet cable into the ETHERNET port on the CIP.

3. Plug the other end into the networking device.

Connecting to a Network for Out-of-Band Management

Connecting the PIC Cables

1. Identify the appropriate cable to be connected to each PIC.

WARNING: Do not look directly into the fiber-optic transceivers or into the

ends of fiber-optic cables.Fiber-optic transceiverscontainlaser light sources

that can damage your eyes.

CAUTION: To prevent damage to fiber-optic transceivers and fiber-optic

cables, observe the following precautions:

•

Do not leave a fiber-optic transceiver uncovered except when inserting or

removing cable. The safety cap keeps the port clean and prevents

accidental exposure to laser light.

•

Do not bend fiber-optic cable beyond its maximum bend radius. An arc

smaller than a few inches in diameter can damage the cable and cause

problems that are difficult to diagnose.

•

Do not let fiber-optic cable hang free from the connector. Do not allow

fastenedloopsof cable to dangle which stresses the cable at the fastening

point.

2. Insert the appropriate cable connector into the PIC cable receptacle.

3. Drape the cable over the bobbins of the cable management system to protect them

from bending past their recommended bend radius.

21Copyright © 2015, Juniper Networks, Inc.

Page 22

T640 Core Router Quick Start

Step 6: Connecting Power

For all other power supplies and connecting six 60-A input feeds to six inputs, see the

following topics for connection procedures.

•

Connecting Power to a T640 Router with Two-Input 160-A DC Power

Supplies on page 22

•

Connecting Power to a T640 Router with Three-Input 240-A DC Power

Supplies on page 24

•

Connecting Power to a T640 Router with Four-Input 160-A DC Power

Supplies on page 28

•

Connecting Power to a T640 Router with Six-Input DC Power Supplies on page 30

•

Connecting Power to a T640 Router with Three-Phase Delta AC Power

Supplies on page 34

•

Connecting Power to a T640 Router with Three-Phase Wye AC Power

Supplies on page 36

CAUTION:

See the T640 Core Router Hardware Guide for special considerations and

connection proceduresforthe followingpowerconfigurations for the six-input

power supply:

•

Five 60-A input feeds connecting to five inputs

•

Four 60-A input feeds connecting to four inputs

Connecting Power to a T640 Router with Two-Input 160-A DC Power Supplies

To connect DC power cables to the router:

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Switch off the customer site circuit breakers. Make sure that the voltage across the

DC power source cable leads is 0 V and that there is no chance that the cable leads

might become active during installation. Follow your site's instructions for safety.

3. Verify that a licensed electrician has attached the cable lugs provided with the router

to the DC power cables.

4. Verify that the router is properly grounded.

5. Detach the ESD grounding strap from the approved site ESD grounding point, and

connect the strap to one of the ESD points on the chassis.

6. Verify that the circuit breakers on the power supply faceplate are in the OFF (O)

position.

7. Remove the clear plastic cover protecting the terminal studs on the power supply

faceplate.

Copyright © 2015, Juniper Networks, Inc.22

Page 23

Connecting Power to a T640 Router with Two-Input 160-A DC Power Supplies

8. Remove the nut and washer from the power terminal studs for INPUT O and INPUT 1.

9. Attach each power cable lug to the correct terminal stud on the power supply

faceplate, and secure the cable lug first with washer, then with the nut. Use a 7/16-in.

(11 mm) nut driver or wrench to tighten the nut. Apply between 23 lb-in. (2.6 Nm) and

25 lb-in. (2.8 Nm) of torque to each nut. (See Figure 10 on page 23, Figure 14 on page 28,

or Figure 15 on page 30.

CAUTION: You must use an appropriate torque-controlled tool to tighten

the nuts. Applying excessive torque damages the terminal studs and the

power supply. The absolute maximum torque that may be applied to this

nut is 45 in-lb (5.0 Nm).

a. Attach and secure the positive (+) cable lugs to the RTN (return) terminals.

b. Attach and secure the negative (–) cable lugs to the -48V (input) terminals.

10. Verifythatthe positive and negative power cables are connected to the correctterminal

studs.

11. Route the DC power cables through the cable restraint or restraints.

12. Tighten the cable restraint captive screw or screws to hold the power cables in place.

13. Replace the clear plastic cover on the power supply.

14. Repeat the procedure for the remaining power supply.

Figure 10: Connecting Power to a Two-Input 160-A DC Power Supply

23Copyright © 2015, Juniper Networks, Inc.

Page 24

T640 Core Router Quick Start

Connecting Power to a T640 Router with Three-Input 240-A DC Power Supplies

1.

Setting the Input Mode Switch on a Three-Input 240-A DC Power Supply on page 24

2.

Replacing the Cable Restraint on a Three-Input 240-A DC Power Supply

(Optional) on page 25

3.

Connecting the DC Power Cables on page 27

Setting the Input Mode Switch on a Three-Input 240-A DC Power Supply

NOTE: Do not set the input mode switch if the power supply is installed in

the chassis. If the power supply is already installed, you must disconnect all

cables and remove the power supply before setting the input mode switch.

To set the input mode switch (see Figure 11 on page 25):

1. Using a screwdriver, loosen the captive screw holding the metal cover over the input

mode switch (see Figure 11 on page 25).

2. Rotate the metal cover away from the input mode switch to expose the switch.

3. Check the setting of the input mode switch. Use a flashlight, if necessary. In 2-INPUT

mode, the switch must be positioned all the way to the right.

4. If the input mode switch is not set correctly, use a sharp, nonconductive object to slide

the switch all the way to the right to set the power supply to 2-INPUT mode.

CAUTION: Do not use a pencil, because fragments can break off and cause

damage to the power supply.

5. Rotate the metal cover over the input mode switch, and use a screwdriver to tighten

the captive screw.

Copyright © 2015, Juniper Networks, Inc.24

Page 25

Replacing the Cable Restraint on a Three-Input 240-A DC Power Supply (Optional)

Figure 11: Three-Input 240-A DC Power Supply in 2-INPUT Mode

Replacingthe CableRestraintona Three-Input 240-A DC Power Supply (Optional)

Each three-input 240-A DC power supply is shipped with the standard cable restraint

shown in Figure 12 on page 26. Two optional cable restraints are shipped in the accessory

box.

If your DC power cables are too large or inflexible to fit into the standard cable restraint,

we recommend that you remove the standard cable restraint and install the optional

cable restraint (see Figure 13 on page 26) on each three-input 240-A DC power supply.

To replace the cable restraint on a three-input 240-A DC power supply:

•

Removing the Standard Cable Restraint from a Three-Input 240-A DC Power

Supply on page 25

•

Installing the Optional Cable Restraint on a Three-Input 240-A DC Power

Supply on page 26

Removing the Standard Cable Restraint from a Three-Input 240-A DC Power Supply

The cable restraint is located on the right edge of the power supply faceplate. To remove

the standard cable restraint:

1. Loosen the captive screw on the standard cable restraint.

2. Remove the cable restraint from the power supply.

25Copyright © 2015, Juniper Networks, Inc.

Page 26

T640 Core Router Quick Start

Figure 12: Standard Cable Restraint on a Three-Input 240-A DC Power

Supply

Installing the Optional Cable Restraint on a Three-Input 240-A DC Power Supply

To install the optional cable restraint:

1. Align the two captive screws on the optional cable restraint with the two threaded

holes located at the right edge of the power supply faceplate.

2. Fasten the captive screws.

Figure 13: Optional Cable Restraint on a Three-Input 240-A DC Power

Supply

Copyright © 2015, Juniper Networks, Inc.26

Page 27

Connecting the DC Power Cables

Connecting the DC Power Cables

To connect DC power cables to the router:

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Switch off the customer site circuit breakers. Make sure that the voltage across the

DC power source cable leads is 0 V and that there is no chance that the cable leads

might become active during installation. Follow your site's instructions for safety.

3. Verify that a licensed electrician has attached the cable lugs provided with the router

to the DC power cables.

4. Verify that the router is properly grounded.

5. Detach the ESD grounding strap from the approved site ESD grounding point, and

connect the strap to one of the ESD points on the chassis.

6. Verify that the circuit breakers on the power supply faceplate are in the OFF (O)

position.

7. Remove the clear plastic cover protecting the terminal studs on the power supply

faceplate.

8. Remove the nut and washer from the power terminal studs for INPUT O and INPUT 1.

NOTE: For a three-input 240-A DC power supply,INPUT2 is not supported

for the router and should not be connected.

9. Attach each power cable lug to the correct terminal stud on the power supply

faceplate, and secure the cable lug first with washer, then with the nut. Use a 7/16-in.

(11 mm) nut driver or wrench to tighten the nut. Apply between 23 lb-in. (2.6 Nm) and

25 lb-in. (2.8 Nm) of torque to each nut. (See Figure 10 on page 23, Figure 14 on page 28,

or Figure 15 on page 30.

CAUTION: You must use an appropriate torque-controlled tool to tighten

the nuts. Applying excessive torque damages the terminal studs and the

power supply. The absolute maximum torque that may be applied to this

nut is 45 in-lb (5.0 Nm).

a. Attach and secure the positive (+) cable lugs to the RTN (return) terminals.

b. Attach and secure the negative (–) cable lugs to the -48V (input) terminals.

10. Verifythatthe positive and negative power cables are connected to the correctterminal

studs.

11. Route the DC power cables through the cable restraint or restraints.

12. Tighten the cable restraint captive screw or screws to hold the power cables in place.

27Copyright © 2015, Juniper Networks, Inc.

Page 28

T640 Core Router Quick Start

13. Replace the clear plastic cover on the power supply.

14. Repeat the procedure for the remaining power supply.

Figure 14: Connecting Power to the Three-Input 240-A DC Power Supply

Connecting Power to a T640 Router with Four-Input 160-A DC Power Supplies

To connect DC power cables to the router:

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Switch off the customer site circuit breakers. Make sure that the voltage across the

DC power source cable leads is 0 V and that there is no chance that the cable leads

might become active during installation. Follow your site's instructions for safety.

3. Verify that a licensed electrician has attached the cable lugs provided with the router

to the DC power cables.

4. Verify that the router is properly grounded.

5. Detach the ESD grounding strap from the approved site ESD grounding point, and

connect the strap to one of the ESD points on the chassis.

6. Verify that the circuit breakers on the power supply faceplate are in the OFF (O)

position.

Copyright © 2015, Juniper Networks, Inc.28

Page 29

Connecting Power to a T640 Router with Four-Input 160-A DC Power Supplies

7. Remove the clear plastic cover protecting the terminal studs on the power supply

faceplate.

8. Remove the nut and washer from the power terminal studs for INPUT O, INPUT 1,

INPUT 2, and INPUT 3.

NOTE: For a four-input 240-A DC power supply, all four inputs are

connected.

9. Attach each power cable lug to the correct terminal stud on the power supply

faceplate, and secure the cable lug first with washer, then with the nut. Use a 7/16-in.

(11 mm) nut driver or wrench to tighten the nut. Apply between 23 lb-in. (2.6 Nm) and

25 lb-in. (2.8 Nm) of torque to each nut. (See Figure 10 on page 23, Figure 14 on page 28,

or Figure 15 on page 30.

CAUTION: You must use an appropriate torque-controlled tool to tighten

the nuts. Applying excessive torque damages the terminal studs and the

power supply. The absolute maximum torque that may be applied to this

nut is 45 in-lb (5.0 Nm).

a. Attach and secure the positive (+) cable lugs to the RTN (return) terminals.

b. Attach and secure the negative (–) cable lugs to the -48V (input) terminals.

10. Verifythatthe positive and negative power cables are connected to the correctterminal

studs.

11. Route the DC power cables through the cable restraint or restraints.

12. Tighten the cable restraint captive screw or screws to hold the power cables in place.

13. Replace the clear plastic cover on the power supply.

14. Repeat the procedure for the remaining power supply.

29Copyright © 2015, Juniper Networks, Inc.

Page 30

g004661

Terminal studsCable lug

Locking

washer

Nut

T640 Core Router Quick Start

Figure 15: Connecting Power to the Four-Input 240-A DC Power Supply

Connecting Power to a T640 Router with Six-Input DC Power Supplies

You connect DC power to the router by attachingpowercablesfrom the DC power sources

to the terminal studs on the power supply faceplates. You must provide power cables

(the cable lugs are supplied with the router).

CAUTION: All connected inputs on the DC power supply in slot PEM0 must

be powered by dedicatedpowerfeedsderived from feed A, and all connected

inputs on the DC power supply in slot PEM1 must be powered by dedicated

power feeds derived from feed B. This configuration provides the commonly

deployed A/B feed redundancy for the system.

NOTE: We recommend that the positive (+) DC source power cables for the

RTN (return) terminals be 2.6 in. (6.6 cm) longer than the negative (–) DC

source power cables for the –48 V (input) terminals.

CAUTION: You must use an appropriate torque-controlled tool to tighten

the nuts. Applying excessive torque damages the terminal studs and the

power supply. The absolute maximum torque that may be applied to this nut

is 45 lb-in. (5.0 Nm).

Copyright © 2015, Juniper Networks, Inc.30

Page 31

Connecting Power to a T640 Router with Six-Input DC Power Supplies

CAUTION: You must ensure that power connections maintain the proper

polarity. The power source cables might be labeled (+) and (–) to indicate

their polarity. There is no standard color coding for DC power cables. The

color coding used by the external DC power source at your site determines

the color coding for the leads on the power cables that attach to the terminal

studs on each power supply.

To connect DC source power cables to the router, follow this procedure for each DC

power supply:

1. Verify that a properly rated customer site circuit breaker for each DC power cable has

been installed. See the DC power electrical safety guidelines for your router for more

information.

2. Switch off the customer site circuit breakers. Ensure that the voltage across the DC

power source cable leads is 0 V and that there is no chance that the cable leads might

become active during installation.

3. Verify that a licensed electrician has attached appropriate cable lugs to the DC power

cables. See the DC power cable and lug specifications for your router for more

information.

4. Switch the power switch on the power supply faceplate to the standby position.

5. Remove the clear plastic cover protecting the terminal studs on the faceplate.

6. Remove the nut and washer from each power terminal stud to be connected. If no

washers and nuts are already installed, they should be in the accessory box.

7. Removethe captive screws on all three cable restraints on the right edge of the power

supply faceplate (using a Phillips (+) screwdriver, number 2).

8. Route the negative (–) DC source power cables for INPUT 0, INPUT 1, INPUT 3, and

INPUT 4 over the smallest cable restraint on the far right. The cable restraint is marked

as follows top to bottom: INPUT 0, INPUT 1, INPUT 3, and INPUT 4.

NOTE: You must route the cables in the locations as marked to be able

to replace the clear plastic cover over the terminal studs.

Attach the negative (–) DC source power cable lugs INPUT 0, INPUT 1, INPUT 3, and

INPUT 4 to the –48 V (input) terminals on the right. Secure the cable lugs to the

terminal studs, first with the washers, then with the nuts. Using a 7/16-in. (11 mm) nut

driver, tighten the nuts. Apply between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of

torque to each nut.

31Copyright © 2015, Juniper Networks, Inc.

Page 32

g006353

Terminal studs

Cable lug

Locking

washer

Nut

g006358

T640 Core Router Quick Start

Figure 16: Connecting DC Power Cables

Figure 17: Connecting Negative(–) DC Power Cables to INPUT 0, INPUT 1,

INPUT 3, and INPUT 4

9. Replace the smallest cable restraint on the far right, and tighten the captive screw to

hold the power cables for INPUT 0, INPUT 1, INPUT 3, and INPUT 4 in place.

10. Route the negative (–) DC source power cables for INPUT 2 and INPUT 5 through the

middle cable restraint. The middle cable restraint is marked as follows from top to

bottom: INPUT 2, RTN 2, RTN 5, and INPUT 5.

NOTE: You must route the cables in the locations as marked to be able

to replace the clear plastic cover over the terminal studs.

Attach the negative (–) DC source power cable lugs to the –48 V (input) terminals

on the right. Secure the cable lugs to the terminal studs, first with the washers, then

with the nuts. Using a 7/16-in. (11 mm) nut driver, tighten the nuts. Apply between 23

lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of torque to each nut.

Copyright © 2015, Juniper Networks, Inc.32

Page 33

g006354

Connecting Power to a T640 Router with Six-Input DC Power Supplies

Figure 18: Connecting Negative (–) DC Power Cables to INPUT 2 and

INPUT 5

11. Route the positive (+) DC source power cables for RTN 2 and RTN 5 over the middle

cable restraint. The middle cable restraint is marked as follows from top to bottom:

INPUT 2, RTN 2, RTN 5, and INPUT 5.

NOTE: You must route the cables as marked to be able to replace the

clear plastic cover over the terminal studs.

Attach the positive (+) DC source power cable lugs RTN 2 and RTN 5 to the RTN

(return) terminals on the left. Secure the cable lugs to the terminal studs, first with

the washers, then with the nuts. Using a 7/16-in. (11 mm) nut driver, tighten the nuts.

Apply between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of torque to each nut.

12. Replace the middle cable restraint, and tighten the captive screw to hold the power

cables for INPUT 2, INPUT 5, RTN 2, and RTN 5 in place.

13. Route the positive (+) DC source power cables for RTN 0, RTN 1, RTN 3, and RTN 4

over the largest cable restraint on the left. The left cable restraint is marked as follows

from top to bottom: RTN 0, RTN 1, RTN 3, and RTN 4.

NOTE: You must route the cables as marked to be able to replace the

clear plastic cover over the terminal studs.

Attach the positive (+) DC source power cable lugs to the RTN 0, RTN 1, RTN 3, and

RTN 4 terminals on the left. Secure the cable lugs to the terminal studs, first with the

washers, then with the nuts. Using a 7/16-in. (11 mm) nut driver, tighten the nuts. Apply

between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of torque to each nut.

14. Replacethe left cable restraint,and tighten the captive screw to hold the power cables

for RTN 0, RTN 1, RTN 3, and RTN 4 in place.

33Copyright © 2015, Juniper Networks, Inc.

Page 34

g006355

T640 Core Router Quick Start

Figure 19: Connecting Positive (+) DC Power Cables to RTN 2, RTN 5,

RTN 0, RTN 1, RTN 3, and RTN 4

15. Verify that the power cabling is correct, that the power cables are not touching or

blocking accessto router components, and that they do not drape where people could

trip on them.

16. Replace the clear plastic cover over the terminal studs on the faceplate.

Connecting Power to a T640 Router with Three-Phase Delta AC Power Supplies

You connect AC power to the router with three-phase delta AC power supplies by

connecting the AC power cord from an AC power supply to an AC power source.

To connect an AC power cord to an AC power source:

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Switch off the customer site circuit breakers. Ensure that the voltage across the AC

power source is 0 V and that there is no chance that the voltage might become active

during installation.

3. Detach the ESD grounding strap from the approved site ESD grounding point, and

connect the strap to one of the ESD points on the chassis.

4. Switch the power switch on the power supply faceplate to the standby position.

5. Using a number 2 Phillips (+) screwdriver, unscrew the two captive screws located

on the right side of the metal AC wiring compartment.

6. Open the metal door of the metal AC wiring compartment.

7. Unscrew the retaining nut from the AC power cord.

8. Place the retaining nut inside the metal wiring compartment.

9. Put the wires of the AC power cord through the hole of the metal wiring compartment.

10. Screw the retaining nut onto the AC power cord to secure it to the metal wiring

compartment.

Copyright © 2015, Juniper Networks, Inc.34

Page 35

L1 L2 L3

g004951

L1 L2 L3

Connecting Power to a T640 Router with Three-Phase Delta AC Power Supplies

11. Connect the wires to the AC terminal block on the three-phase delta AC power supply

(Figure 20 on page 35). Loosen the input terminal or grounding point screw, insert

each wire into the grounding point or input terminal, and tighten the screw.

NOTE: The terminal connections have either slottedscrewsor hex screws.

Use a 1/4-in. slotted screwdriver for the slotted screws. Use a 5/32-in

(4-mm) Allen wrench for the 5/ 16-in hex screws.

a. Insert the wire labeled GND into the grounding point labeled GND.

b. Insert the wire labeled L1 into the L1 input terminal.

c. Insert the wire labeled L2 into the L2 input terminal.

d. Insert the wire labeled L3 into the L3 input terminal.

Figure 20: Connecting Power to a Three-Phase Delta AC Power Supply

NOTE: The color of each AC power wire might vary.

12. Verify that the power cable connections are correct.

13. Using a number 2 Phillips (+) screwdriver, tighten the two captive screws on the metal

AC wiring compartment.

14. Use the provided plastic cable tie to fasten the AC power cord to the power supply.

35Copyright © 2015, Juniper Networks, Inc.

Page 36

T640 Core Router Quick Start

15. Verify that the AC power cord is not touching or blocking accessto router components,

and that it does not drape where people could trip on it.

16. Repeat the procedure for the other three-phase delta AC power supply.

Connecting Power to a T640 Router with Three-Phase Wye AC Power Supplies

To connect an AC power cord:

1. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

2. Switch off the customer site circuit breakers. Ensure that the voltage across the AC

power source is 0 V and that there is no chance that the voltage might become active

during installation.

3. Detach the ESD grounding strap from the approved site ESD grounding point, and

connect the strap to one of the ESD points on the chassis.

4. Switch the power switch on the power supply faceplate to the standby position.

5. Using a number 2 Phillips (+) screwdriver, loosen the two captive screws on the metal

AC wiring compartment.

6. Open the metal door of the metal AC wiring compartment.

7. Unscrew the retaining nut from the AC power cord.

8. Place the retaining nut inside the metal wiring compartment.

9. Put the wires of the AC power cord through the hole of the metal wiring compartment.

10. Screw the retaining nut onto the AC power cord to secure it to the metal wiring

compartment.

Copyright © 2015, Juniper Networks, Inc.36

Page 37

L1 L2 L3 N

g004950

g004953

Connecting Power to a T640 Router with Three-Phase Wye AC Power Supplies

11. Connect the wires to the AC terminal block on the three-phase wye AC power supply

(Figure 21 on page 37). Loosen each of the input terminals or grounding point screws,

insert each wire into the grounding point or input terminal, and tighten the screw.

NOTE: The terminal connections have either slottedscrewsor hex screws.

Use a 1/4-in. slotted screwdriver for the slotted screws. Use a 5/32-in

(4-mm) Allen wrench for the 5/ 16-in hex screws.

a. Insert the wire labeled GND into the grounding point labeled GND.

b. Insert the wire labeled L1 into the L1 input terminal.

c. Insert the wire labeled L2 into the L2 input terminal.

d. Insert the wire labeled L3 into the L3 input terminal.

e. Insert the wire labeled N into the N input terminal

Figure 21: Connecting Power to the Three-Phase Wye AC Power Supply

12. Verify that the power cable connections are correct.

13. Using a number 2 Phillips (+) screwdriver, tighten the two captive screws on the metal

AC wiring compartment.

14. Use the provided plastic cable tie to fasten the AC power cord to the power supply.

Figure 22: Fastening the AC Power Cord to the Power Supply

37Copyright © 2015, Juniper Networks, Inc.

Page 38

T640 Core Router Quick Start

15. Verify that the AC power cord is not touching or blocking accessto router components,

and that it does not drape where people could trip on it.

16. Repeat the procedure for the other three-phase wye AC power supply.

Copyright © 2015, Juniper Networks, Inc.38

Page 39

Step 7: Powering On the T640 Router

•

Powering On the DC-Powered Router on page 39

•

Powering On the AC-Powered Router on page 41

Powering On the DC-Powered Router

To power on the router:

1. Verify that the power supplies are fully inserted in the chassis and that the captive

screws on their faceplates are tightened.

2. Verify that the DC power cables are connected to the appropriate terminal —the

positive (+) source cable to the return terminal (labeled RTN) and the negative (–)

source cable to the input terminal (labeled -48V).

3. Verify that an external management device is connected to one of the Routing Engine

ports on the CIP (AUXILIARY or CONSOLE).

Step 7: Powering On the T640 Router

NOTE: The management Ethernet port will not be functional until you

have completed the initial configuration.

4. Turn on the power to the external management device.

5. Switch on the customer site circuit breakers to provide power to the DC power source

cable leads.

6. For a three-input 240-A DC power supply and six-input DC power supply, verify that

the INPUT PRESENT LED is lit steadily, indicating that the power supply is receiving

power.

NOTE: The two-input 160-A power supply does not have an INPUT

PRESENT LED.

7. For two-input 160-A DC power supplies, three-input 240-A DC power supplies, or

four-input 240-A DC power supplies, switch the circuit breakers on one of the power

supplies to the on position (|).

For six-input power supplies, switch the power switch on one of the power supplies

to the ON position (—). The DC OK LED blinks momentarily, then lights steadily.

NOTE: The Routing Engine boots as the power supply completesitsstartup

sequence.

8. For a two-input 160-A DC power supply, three-input 240-A DC power supply, or

four-input 240-A DC power supply, verify that the CB ON LED is lit steadily.

39Copyright © 2015, Juniper Networks, Inc.

Page 40

T640 Core Router Quick Start

NOTE: The six-input DC power supply does not have a CB ON LED.

9. Verify that the DC OK LED lights steadily, indicating that the power supply is correctly

installed and is functioning properly, The DC OK LED blinks momentarily after the

power switch or circuit breakers are switched to the on position, then lights steadily.

NOTE: After a power supply is powered on, it can take up to 60 seconds

for status indicators—suchasthe output status LEDs on the power supply,

the show chassis commands display output, and the messages on the

LCDon the craft interface—to indicatethat the power supply is functioning

normally. Ignore status indicators that appear during the first 60 seconds.

If any of the output status LEDs do not light steadily after a few minutes,

verify that the DC power cables are connected correctly. For three-input

240-A power supplies, verify that the input mode switch is correctly set

to two-input mode (see “Setting the Input Mode Switch on a Three-Input

240-A DC Power Supply” on page 24) and that the DC power cables are

connected to INPUT 0 and INPUT 1 only. If you are unable to correct the

problem, repeat the installation and cabling procedures.

10. Repeat Step 5 through Step 9 for the other power supply.

11. On the external management device connected to the Routing Engine, monitor the

startup process to verify that the system has booted properly.

NOTE: After powering on a power supply, wait at least 60 seconds before

turning it off. If the Routing Engine finishes booting and you need to power

down the router again, first issue the CLI request system haltcommand,

then wait for the following message:

Halt the system ? [yes,no] (no) yes

*** FINAL System shutdown message from root@section2 ***

System going down IMMEDIATELY

Terminated

...

syncing disks... 11 8 done

The operating system has halted.

Please press any key to reboot.

Copyright © 2015, Juniper Networks, Inc.40

Page 41

Powering On the AC-Powered Router

You can use this procedure for a router with either three-phase delta AC power supplies

or three-phase wye AC power supplies. To power on the AC-powered router:

1. Verify that the power supplies are fully inserted in the chassis and that the captive

screws on their faceplates are tightened.

2. Verify that the AC power cords are connected correctly.

3. Verify that an external management device is connected to one of the Routing Engine

ports on the CIP (AUXILIARY or CONSOLE).

NOTE: The management Ethernet port will not be functional until you

have completed the initial configuration.

4. Turn on the power to the external management device.

5. Switch on the dedicated customer site circuit breakers to provide power to the AC

power cables. Follow your site’s procedures.

Powering On the AC-Powered Router

6. Verify that the AC OK LED on both AC power supply faceplates are lit steadily green,

indicating that the power supplies are receiving power.

7. Attachan electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to one of the ESD points on the chassis.

8. Switch the power switch on one of the power supplies to the ON position (|). The DC

OK LED blinks momentarily, then lights steadily.

NOTE: After a power supply is powered on, it can take up to 60 seconds

for status indicators—suchasthe output status LEDs on the power supply,

the command output, and messages on the LCD on the craft interface—to

indicate that the power supply is functioning normally. Ignore error

indicators that appear during the first 60 seconds.

9. Verify that the DC OK LED on the AC power supply faceplate is lit steadily, indicating

that power supply is correctly installed, functioning properly, and providing power to

the DC outputs.

10. On the external management device connected to the Routing Engine, monitor the

startup process to verify that the system has booted properly.

NOTE: If the systemis completely powered off when you power on the power

supply, the Routing Engine boots as the power supply completes its startup

sequence. If the Routing Engine finishes booting, you must power off the

router before powering it on again. After powering on a power supply, wait

at least 60 seconds before turning it off. After powering off a power supply,

wait at least 60 seconds before turning it back on.

41Copyright © 2015, Juniper Networks, Inc.

Page 42

T640 Core Router Quick Start

Step 8: Performing the Initial Software Configuration

The T640 Core Router is shipped with the Junos OS preinstalled and ready to be

configured when the T640 router is powered on. These procedures connect a router to

the network but do not enable it to forward traffic. For complete information about

enabling the router to forward traffic, including examples, see the Junos OS configuration

guides.

For the initial software configuration, issue Junos OS command-line interface (CLI)

commands on a console device attached to the CONSOLE port on the CIP.

NOTE: These procedures enable you to use the management Ethernet port.

For more information about the commands in this procedure see the Junos OS

Administration Library for Routing Devices.

1.

Entering Configuration Mode on page 42

2.

Configuring User Accounts and Passwords on page 42

3.

Configuring System Attributes on page 43

4.

Committing the Configuration on page 44

Entering Configuration Mode

1. Verify that the network device is powered on.

2. Log in as the root user. There is no password.

Amnesiac <ttyd0>

login: root

3. Start the CLI.

root@% cli

root>

4. Enter configuration mode.

root> configure

Entering configuration mode.

[edit]

root#

Configuring User Accounts and Passwords

For information about using an encrypted password or an SSH public key string (DSA or

RSA), see authentication.

1. Add a password to the root administration user account. Enter a clear-text password.

[edit]

root# set system root-authentication plain-text-password

New password: password

Copyright © 2015, Juniper Networks, Inc.42

Page 43

Retype new password: password

2. Create a management console user account.

[edit]

root# set system login user user-name authentication plain-text-password

New Password: password

Retype new password: password

3. Set the user account class to super-user.

[edit]

root@# set system login user user-name class super-user

Configuring System Attributes

For more information on configuring the backup routing and static routes, see the Junos

OS Administration Library for Routing Devices.

1. Configure the name of the router. If the name includes spaces, enclose the name in

quotation marks (“ ”).

Configuring System Attributes

[edit]

root@host# set system host-name host-name

NOTE: The DNS server does not use the hostname to resolvetothe correct

IP address. This hostname is used to display the name of the routing engine

in the CLI. For example, this hostname shows on the command-line prompt

when the user is logged on to the CLI:

user-name@host-name>

2. Configure the IP address of the DNS server.

[edit]

root# set system name-server address

3. Configure the router’s domain name.

[edit]

root@# set system domain-name domain-name

4. Configure the IP address and prefix length for the router’s management Ethernet

interface.

NOTE: The RE-C1800 Routing Engine (RE-DUO-1800) does not support

the fxp0 interface or the fxp1 and fxp2 internal Ethernet interfaces. Use

the em0 interface for the RE-C1800 Routing Engine, and fxp0 interface

for all other Routing Engines supported for the router.

[edit]

root@# set interfaces fxp0 unit 0 family inet address address/prefix-length

[edit]

root@# set interfaces em0 unit 0 family inet address address/prefix-length

43Copyright © 2015, Juniper Networks, Inc.

Page 44

T640 Core Router Quick Start

5. Configure the IP address of a backup routing engine. The backup routing engine is

used while the local router is booting and if the routing process fails to start. After the

routing process starts, the backup routing engine address is removed from the local

routing and forwarding tables.

[edit]

root# set system backup-router address

6. (Optional) Configure the static routes to remote subnets with access to the

management port. Access to the management port is limited to the local subnet. To

access the management port from a remote subnet, you must add a static route to

that subnet within the routing table.

[edit]

root# set routing-options static route remote-subnet next-hop destination-IP retain

no-readvertise

7. Configure the telnet service at the [edit system services] hierarchy level.

[edit]

set system services telnet

Committing the Configuration

For a chassis with two Routing Engines, commit the configuration changes to both Routing

Engines. When you issue the commit synchronize command, the configuration is shared

between both Routing Engines and committed on both Routing Engines simultaneously.

For a chassis with only one Routing Engine, use the commit command instead of the

commit synchronize command.

1. Display the configuration to verify that it is correct.

root# show

## Last changed: 2008-10-17 18:32:25 UTC

version 9.1R1.8;

groups {

re0 {

system {

host-name spice-re0;

}

interfaces {

fxp0 {

unit 0 {

family inet {

address 192.168.69.155/21;

}

}

}

}

}

re1 {

system {

host-name spice-re1;

}

interfaces {

fxp0 {

Copyright © 2015, Juniper Networks, Inc.44

Page 45

unit 0 {

family inet {

address 192.168.70.72/21;

}

}

}

}

}

global;

}

apply-groups [ re0 re1 ];

system {

domain-name englab.juniper.net;

backup-router 192.168.71.254;

root-authentication {

encrypted-password "xxxxxxxxxxx"; ## SECRET-DATA

}

name-server {

192.168.1.1;

}

login {

user regress {

uid 2001;

class super-user;

authentication {

encrypted-password "xxxxxxxxxxx"; ## SECRET-DATA

}

}

}

services {

telnet;

}

syslog {

user * {

any emergency;

}

file messages {

any notice;

authorization info;

}

file interactive-commands {

interactive-commands any;

}

}

}

routing-options {

static {

/* corporate office */

route 172.16.0.0/12 {

next-hop 192.168.71.254;

retain;

no-readvertise;

}

}

}

Committing the Configuration

45Copyright © 2015, Juniper Networks, Inc.

Page 46

T640 Core Router Quick Start

2. Commit the configuration to activate it, and synchronize the configuration. The commit

synchronize command commits this new configuration on both Routing Engines

simultaneously.

[edit]

root# commit synchronize

re0:

configuration check succeeds

re1:

commit complete

re0:

commit complete

If you receive an error message after you issue the commit statement, you can review

the configuration using the show command to find the errors in your configuration.

You can delete incorrect entries using the delete command. For example, to delete a

hostname from the configuration, issue the following command:

[edit]

root# delete system host-name hostname

3. (Optional) Configure additional properties by adding the necessary configuration

statements. Then commit the changes to activate them.

[edit]

root@host# commit synchronize

4. Exit configuration mode.

[edit]

root@host# exit

Exiting configuration mode

root>

Copyright © 2015, Juniper Networks, Inc.46

Page 47

Safety Warnings

Safety Warnings

WARNING: See installation instructions before connecting the router. This

is a summary of safety warnings. For a complete list of warnings for this

router, including translations, see the T640 Core Router Hardware Guide at

http://www.juniper.net/techpubs/hardware/.

WARNING: The intrabuilding port(s) of the router is suitable for connection

to intrabuilding or unexposed wiring or cabling only.The intrabuilding port(s)

of the router MUST NOT be metallically connected to interfacesthat connect

to the OSP or its wiring. These interfacesare designed for use as intrabuilding

interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE, Issue

4) and require isolation from the exposed OSP cabling. The addition of primary

protectors is not sufficient protection to connect these interfaces metallically

to OSP wiring.

CAUTION: Before removing or installing components of a router, attach an

ESD strap to an ESD point, and place the other end of the strap around your

bare wrist. Failure to use an ESD strap could result in damage to the router.

CAUTION: Use an external surge protective device (SPD) at the AC input of

the router.

•

Only trained and qualified personnel should install or replace the router.

•

Perform only the procedures described in this Quick Start or the T640 Core Router

Hardware Guide. Other services should be performed by authorized service personnel

only.

•

Incorporate an easily accessible disconnect device into the facility wiring. In the United

States and Canada, the –48 VDC facility should be equipped with a circuit breaker

rated a minimum of 125% of the power provisioned for the input in accordance with

the National Electrical Code in the US and the Canadian Electrical Code in Canada.

WARNING: For six-input DC power supplies, failure to provide the required

circuit breaker or current-limiting fuse for each DC power cable can cause

injury or damage to equipment.

For six-input DC power supplies, each 48 VDC facility DC source input power cable

must be equipped with a current-limiting fuse or circuit breaker external to the Juniper

Networksequipment rated at 100 A (–48 VDC) maximum, or as required by local code.

47Copyright © 2015, Juniper Networks, Inc.

Page 48

T640 Core Router Quick Start

The voltage rating of the facility DC source circuit breaker must be 80 V minimum. We

recommend an 80 A circuit breaker or current-limiting fuse rated for each 60 A DC

power cable. We recommend a 100 A circuit breaker or current-limiting fuse rated for

each 80 A DC power cable.

•

Read the installation instructions before you connect the router to a power source.

•

Before installing the router, read the guidelines for site preparation in the T640 Core

Router Hardware Guide to make sure that the site meets power, environmental, and

clearance requirements for the router.

•

For the cooling system to function properly, the airflow around the chassis must be

unrestricted.

•

When installing the router, do not use a ramp inclined more than 10 degrees.

•

Manually installing the router requires four people to lift the chassis. Before lifting the

chassis, remove components as described in the T640 Core Router Hardware Guide.

To prevent injury, keep your back straight and lift with your legs, not your back. Do not

attempt to lift the chassis by the power supply handles.

•

The router should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting the router in a partially filled rack, load the rack from the bottom to

the top with the heaviest component at the bottom of the rack.

•

If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the router in the rack.

•

When removing or installing an electrical component, always place it component-side

up on a flat antistatic surface or in an electrostatic bag.

•

When you install the router, always make the ground connection first and disconnect

it last.

•

Wire the DC power supply using the appropriate lugs. When connecting power, the

proper wiring sequence is ground to ground, +RTN to +RTN, then –48 V to –48 V. When

disconnecting power, the proper wiring sequence is –48 V to –48 V, +RTN to +RTN,

then ground to ground. Always connect the ground wire first and disconnect it last.

•

Do not work on the system or connect or disconnect cables during electrical storms.

•

Beforeworking on equipment that is connected to power lines, remove jewelry, including

rings, necklaces, and watches. Metal objects heat up when connected to power and

ground and can cause serious burns or become welded to the terminals.

•

Failure to observe these safety warnings can result in serious physical injury.

•

AC power cable warning (Japan):

Copyright © 2015, Juniper Networks, Inc.48

Page 49

WARNING: The attached power cable is only for this product. Do not use

the cable for another product.

Compliance Statements for NEBS

•

The equipment is suitable for installation as part of the Common Bonding Network

(CBN).

•

The equipment is suitable for installation in locations where the National Electrical

Code (NEC) applies.

Compliance Statements for NEBS

•

The battery return connection is to be treated as an isolated DC return (i.e. DC-I), as

defined in GR-1089-CORE.

•

For Juniper systems with AC power supplies, an external surge protective device (SPD)

must be used at the AC power source.

Compliance Statements for EMC Requirements

•

Canada on page 49

•

European Community on page 49

•

Israel on page 50

•

Japan on page 50

•

United States on page 50

Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Community

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

49Copyright © 2015, Juniper Networks, Inc.

Page 50

T640 Core Router Quick Start

Israel

Japan

Translation from Hebrew—Warning: This product is Class A. In residential environments,

the product may cause radio interference,and in such a situation, the user may be required

to take adequate measures.

United States

Translation from Japanese—This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be required to take

adequate measures. VCCI-A

The hardware equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Copyright © 2015, Juniper Networks, Inc.50

Page 51

Junos OS Documentation and Release Notes

For a list of related Junos OS documentation, see

http://www.juniper.net/techpubs/software/junos/.