SRX1500 Services Gateway Hardware

Published

2020-11-10

Guide

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

SRX1500 Services Gateway Hardware Guide

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Table of Contents

1

About the Documentation | viii

Documentation and Release Notes | viii

Using the Examples in This Manual | viii

Merging a Full Example | ix

Merging a Snippet | x

Documentation Conventions | x

Documentation Feedback | xiii

Requesting Technical Support | xiii

Self-Help Online Tools and Resources | xiv

Creating a Service Request with JTAC | xiv

iii

Overview

SRX1500 Services Gateway Overview | 16

SRX1500 Services Gateway Overview | 16

SRX1500 Services Gateway Field Replaceable Units Overview | 17

Benefits of the SRX1500 Services Gateway | 17

SRX1500 Chassis | 18

SRX1500 Services Gateway Chassis Overview | 18

SRX1500 Services Gateway Front Panel | 18

Management Port LEDs | 22

Network Port LEDs | 22

HA Port LEDs | 23

SRX1500 Services Gateway Back Panel | 23

SRX1500 Cooling System | 24

SRX1500 Power System | 25

SRX1500 Services Gateway Power Supply | 25

SRX1500 Services Gateway Supported AC Power Cords | 27

SRX1500 Services Gateway AC Power Supply Electrical Specifications | 28

SRX1500 Services Gateway DC Power Supply Electrical Specifications | 28

SRX1500 Services Gateway DC Power Cable Specifications | 29

Site Planning, Preparation, and Specifications

2

3

Site Preparation Checklist for the SRX1500 Services Gateway | 31

SRX1500 Site Guidelines and Requirements | 33

SRX1500 Services Gateway General Site Installation Guidelines | 33

SRX1500 Services Gateway Environmental Specifications | 34

SRX1500 Services Gateway Electrical Wiring Guidelines | 34

SRX1500 Services Gateway Grounding Specifications | 36

SRX1500 Services Gateway Physical Specifications | 36

SRX1500 Services Gateway Clearance Requirements for Airflow and Hardware

Maintenance | 37

Rack Requirements | 39

Cabinet Requirements | 39

SRX1500 Transceiver Specifications and Pinouts | 40

iv

SRX1500 Transceiver Support | 40

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Ethernet Port | 41

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Console Port | 41

Mini-USB Connector Pinouts for the SRX1500 Services Gateway Console Port | 42

Initial Installation and Configuration

SRX1500 Services Gateway Installation Overview | 45

Unpacking and Mounting the SRX1500 | 45

Unpacking the SRX1500 Services Gateway | 46

Verifying Parts Received with the SRX1500 Services Gateway | 46

Preparing the SRX1500 Services Gateway for Rack-Mount Installation | 48

Installing the SRX1500 Services Gateway in a Rack | 48

Connecting the SRX1500 to Power | 50

Required Tools and Parts for Grounding the SRX1500 Services Gateway | 50

Connecting the SRX1500 Services Gateway Grounding Cable | 50

Installing an AC Power Supply on the SRX1500 Services Gateway | 52

Connecting the SRX1500 Services Gateway to an AC Power Supply | 53

Installing a DC Power Supply on the SRX1500 Services Gateway | 54

Connecting the SRX1500 Services Gateway to a DC Power Supply | 57

Powering On the SRX1500 Services Gateway | 58

4

Powering Off the SRX1500 Services Gateway | 59

Connecting the SRX1500 to External Devices | 60

Required Tools and Parts for Connecting the SRX1500 Services Gateway | 60

Connecting the SRX1500 Services Gateway to a Network for Out-of-Band Management | 60

Connecting the SRX1500 Services Gateway to a Management Console | 61

Configuring Junos OS on the SRX1500 | 62

SRX1500 Services Gateway Software Configuration Overview | 63

Understanding SRX1500 Services Gateway Factory-Default Settings | 63

Viewing SRX1500 Services Gateway Factory-Default Settings | 63

Accessing J-Web on the SRX1500 Services Gateway | 64

Configuring the SRX1500 Services Gateway Using J-Web | 64

Configuring Root Authentication and the Management Interface from the CLI | 65

v

Configuring Interfaces, Zones, and Policies with J-Web | 66

Accessing the CLI on the SRX1500 Services Gateway | 69

Connecting to the SRX1500 Services Gateway from the CLI Remotely | 70

Configuring the SRX1500 Services Gateway Using the CLI | 70

Maintaining Components

Maintaining the SRX1500 Components | 78

Required Tools and Parts for Maintaining the SRX1500 Services Gateway | 78

Routine Maintenance Procedures for the SRX1500 Services Gateway | 78

Maintaining the SRX1500 Power System | 79

Maintaining the SRX1500 Services Gateway Power Supply | 79

Required Tools and Parts for Replacing the SRX1500 Services Gateway Components | 79

Replacing an AC Power Supply on the SRX1500 Services Gateway | 80

Disconnecting an AC Power Cord from the SRX1500 Services Gateway | 80

Removing an AC Power Supply from the SRX1500 Services Gateway | 80

Replacing a DC Power Supply on the SRX1500 Services Gateway | 82

Removing a DC Power Supply Cable from the SRX1500 Services Gateway | 82

Removing a DC Power Supply on the SRX1500 Services Gateway | 83

Troubleshooting Hardware

5

6

7

Troubleshooting the SRX1500 | 86

Troubleshooting Resources for the SRX1500 Services Gateway Overview | 86

Troubleshooting Chassis and Interface Alarm Messages on the SRX1500 Services Gateway | 86

Troubleshooting the Power System on the SRX1500 Services Gateway | 88

Using the RESET CONFIG Button on the SRX1500 Services Gateway | 90

Contacting Customer Support and Returning the Chassis or Components

Returning the SRX1500 Chassis or Components | 92

Contacting Customer Support | 92

Returning a SRX1500 Services Gateway Component to Juniper Networks | 93

Locating the SRX1500 Services Gateway Chassis Serial Number and Agency Labels | 93

Listing the SRX1500 Services Gateway Component Details with the CLI | 94

vi

Required Tools and Parts for Packing the SRX1500 Services Gateway | 95

Packing the SRX1500 Services Gateway for Shipment | 95

Packing SRX1500 Services Gateway Components for Shipment | 96

Safety and Compliance Information

Definitions of Safety Warning Levels | 99

General Safety Guidelines and Warnings | 102

Restricted Access Warning | 104

Qualified Personnel Warning | 107

Prevention of Electrostatic Discharge Damage | 107

Fire Safety Requirements | 109

Fire Suppression | 109

Fire Suppression Equipment | 109

Laser and LED Safety Guidelines and Warnings | 110

General Laser Safety Guidelines | 110

Class 1 Laser Product Warning | 111

Class 1 LED Product Warning | 112

Laser Beam Warning | 113

Radiation from Open Port Apertures Warning | 114

Maintenance and Operational Safety Guidelines and Warnings | 115

Battery Handling Warning | 116

Jewelry Removal Warning | 117

Lightning Activity Warning | 119

Operating Temperature Warning | 120

Product Disposal Warning | 122

Action to Take After an Electrical Accident | 123

General Electrical Safety Guidelines and Warnings | 123

Safety Guidelines and Warnings | 123

Grounded Equipment Warning | 124

Backplane Energy Hazard Warning | 124

vii

Multiple Power Supplies Disconnection Warning | 125

Power Disconnection Warning | 126

TN Power Warning | 127

Copper Conductors Warning | 128

AC Power Electrical Safety Guidelines | 129

DC Power Electrical Safety Guidelines | 130

DC Power Electrical Safety Guidelines | 130

DC Power Disconnection Warning | 132

DC Power Grounding Requirements and Warning | 134

DC Power Wiring Sequence Warning | 136

DC Power Wiring Terminations Warning | 139

SRX1500 Services Gateway Agency Approvals | 141

SRX1500 Services Gateway Acoustic Noise Compliance Statements | 142

SRX1500 Services Gateway EMC Requirements | 143

Canada | 143

European Community | 143

Israel | 143

Japan | 144

United States | 144

About the Documentation

IN THIS SECTION

Documentation and Release Notes | viii

Using the Examples in This Manual | viii

Documentation Conventions | x

Documentation Feedback | xiii

Requesting Technical Support | xiii

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the SRX1500 Services Gateway. After completing the installation and basic configuration

procedures covered in this guide, refer to the Junos OS documentation for information about further

software configuration.

viii

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

ix

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

x

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

Table 1 on page xi defines notice icons used in this guide.

Table 1: Notice Icons

xi

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

Table 2 on page xi defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Table 2: Text and Syntax Conventions (continued)

xii

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Table 2: Text and Syntax Conventions (continued)

xiii

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

xiv

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

1

CHAPTER

Overview

SRX1500 Services Gateway Overview | 16

SRX1500 Chassis | 18

SRX1500 Cooling System | 24

SRX1500 Power System | 25

SRX1500 Services Gateway Overview

IN THIS SECTION

SRX1500 Services Gateway Overview | 16

SRX1500 Services Gateway Field Replaceable Units Overview | 17

Benefits of the SRX1500 Services Gateway | 17

SRX1500 Services Gateway Overview

Juniper Networks SRX1500 Services Gateway expands the SRX Series family of security platforms. The

SRX1500 Services Gateway is a mid-range dynamic services gateway that consolidates security functionality

and uncompromised performance for small to medium enterprises. With advanced security and threat

mitigation capabilities, the SRX1500 Services Gateway provides campus edge Integrated Security Appliance

(ISA) support.

16

The SRX1500 Services Gateway has a modular 1U chassis with twelve 1G Ethernet ports, four 1G SFP

ports, and four 10G SFP+ ports. It contains two slots for WAN Physical Interface Modules (PIMs), one slot

for an SSD device, and two slots for power supplies.

The SRX1500 Services Gateway is available in two models:

SRX1500 (AC)–SRX1500 Services Gateway with a 120 GB SSD (with 100 GB usable space) and AC

•

power supply

SRX1500 (DC)–SRX1500 Services Gateway with a 120 GB SSD (with 100 GB usable space) and DC

•

power supply

The SRX1500 Services Gateway runs the Junos operating system (Junos OS) and supports the following

features:

Firewall support with key features such as IPsec and VPN

•

Advanced security services (IPS, AppID, UTM) and threat mitigation capabilities

•

High availability

•

QoS

•

Secure boot

•

Juniper Sky Advanced Threat Prevention (Juniper SkyATP)

•

The services gateway runs the Junos OS and can be managed using the CLI, Junos Space, and J-Web.

SRX1500 Services Gateway Field Replaceable Units Overview

Field-replaceable units (FRUs) are components that you can replace at your site. The power supplies are

the only FRUs on the SRX1500 Services Gateway. The power supplies (if redundant) are hot-swappable.

You can remove and replace the power supply without powering off the services gateway or disrupting

the services gateway functions.

SEE ALSO

Required Tools and Parts for Replacing the SRX1500 Services Gateway Components | 79

Replacing an AC Power Supply on the SRX1500 Services Gateway | 80

Replacing a DC Power Supply on the SRX1500 Services Gateway | 82

17

Benefits of the SRX1500 Services Gateway

High performance—The SRX1500 supports up to 9-Gbps of firewall throughput and is suited for enterprise

•

campus and data center edge deployments.

Simplified deployment with minimal manual intervention—The Zero Touch Provisioning (ZTP) feature

•

enables you to provision and configure the SRX1500 automatically, thereby reducing operational

complexity and simplifying the provisioning of new sites.

Advanced threat protection—The SRX1500 supports the intrusion prevention system (IPS), Juniper Sky

•

Advanced Threat Prevention (Juniper Sky ATP), antivirus, and antispam features, which protect against

potential vulnerabilities. Juniper Sky ATP protects against zero-day attacks and other unknown threats.

RELATED DOCUMENTATION

SRX1500 Services Gateway Installation Overview | 45

SRX1500 Chassis

IN THIS SECTION

SRX1500 Services Gateway Chassis Overview | 18

SRX1500 Services Gateway Front Panel | 18

SRX1500 Services Gateway Back Panel | 23

SRX1500 Services Gateway Chassis Overview

The SRX1500 Services Gateway chassis is a rigid sheet metal structure that houses all the other hardware

components. The chassis weighs 15 lb. and measures 1.75 in. high, 17.5 in. wide, and 18.2 in. deep. The

chassis installs in standard 600-mm deep (or larger) enclosed cabinets or 19-in. equipment racks.

18

CAUTION: Before removing or installing components of a functioning services

gateway, attach an electrostatic discharge (ESD) strap to an ESD point and place the

other end of the strap around your bare wrist. Failure to use an ESD strap could result

in damage to the device.

The services gateway must be connected to earth ground during normal operation. The protective earthing

terminal on the rear of the chassis is provided to connect the services gateway to ground. Additional

grounding is provided to an AC-powered services gateway when you plug its power supply into a grounded

AC power receptacle.

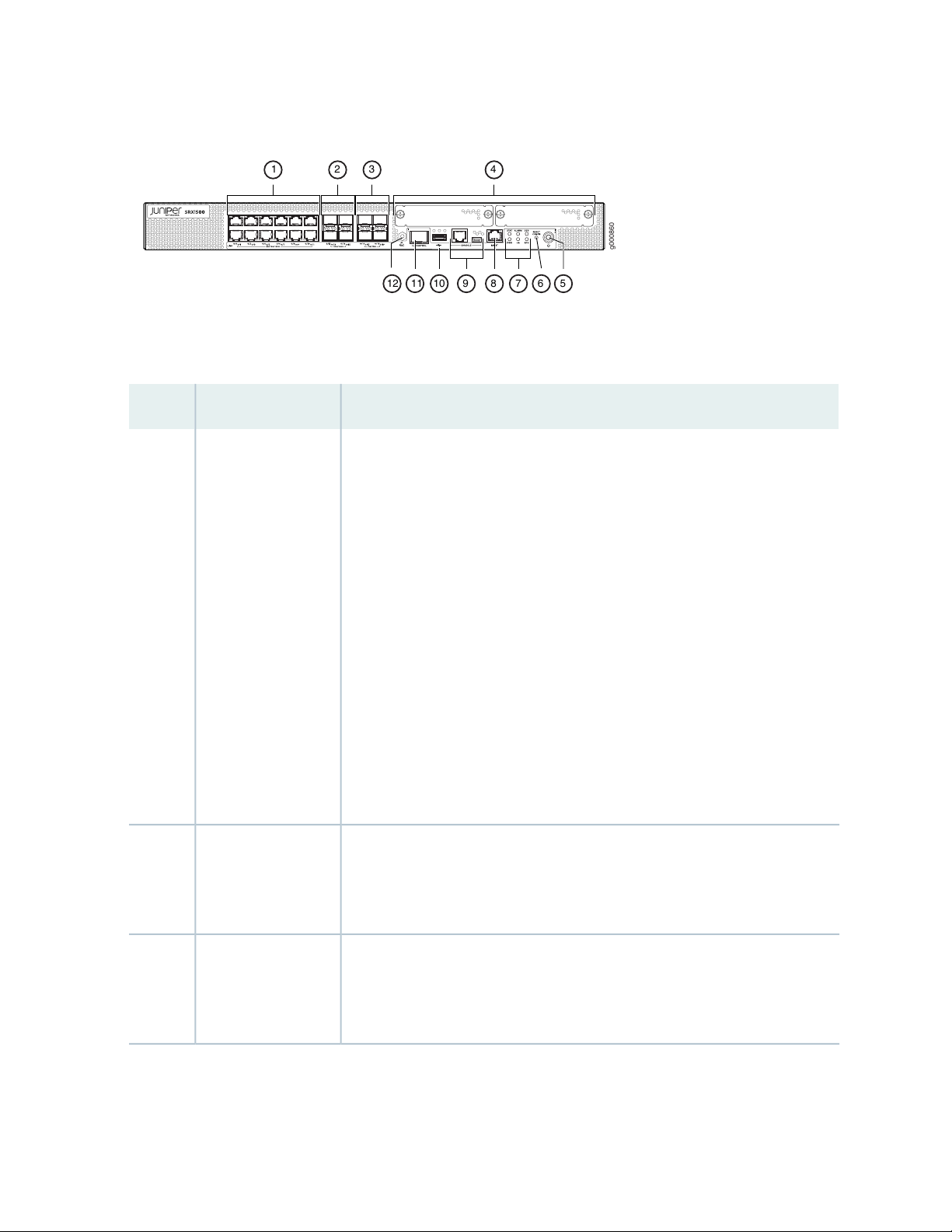

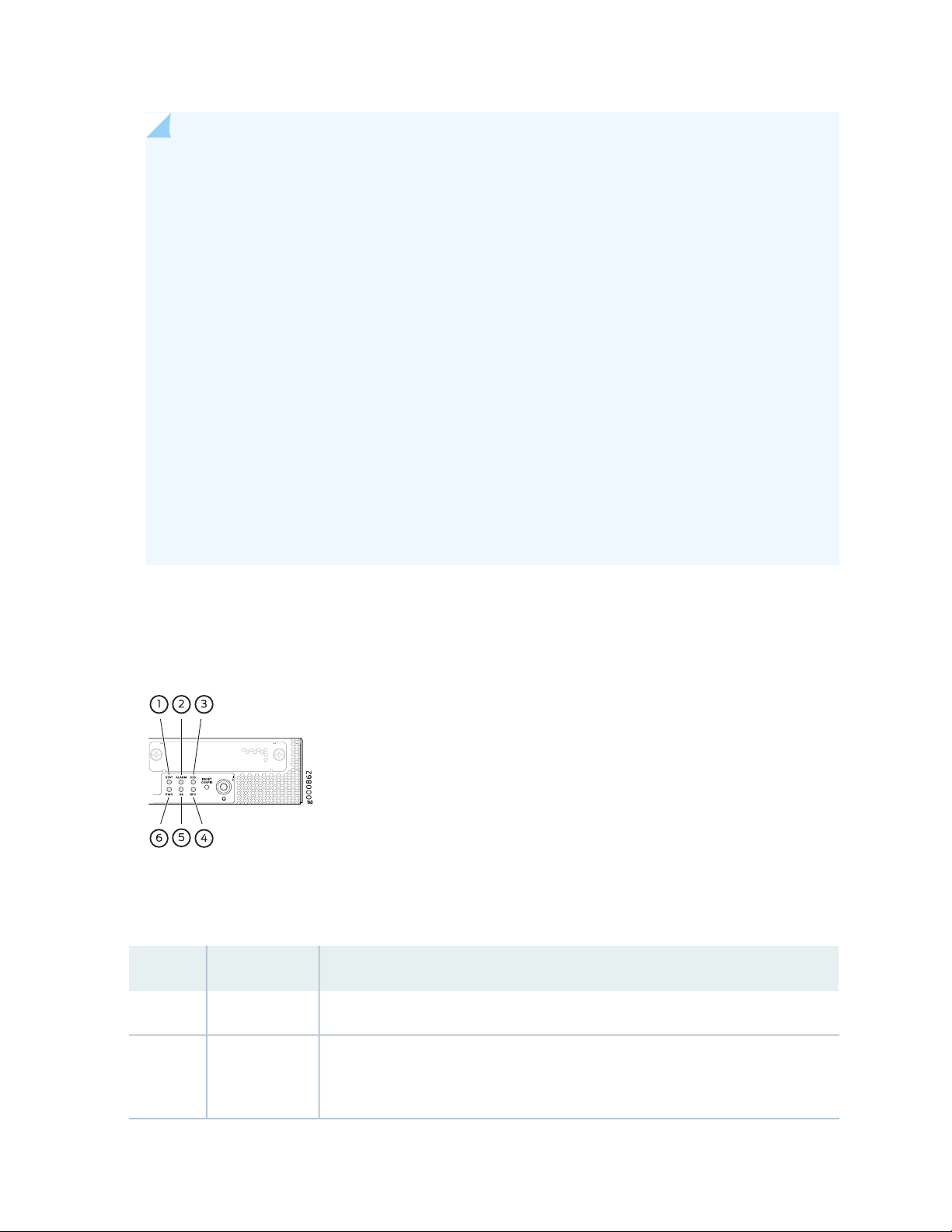

SRX1500 Services Gateway Front Panel

Figure 1 on page 19 shows the front panel of the SRX1500 Services Gateway. The front panel contains

LEDs, Power and Reset Config buttons, and various ports.

Figure 1: SRX1500 Services Gateway Front Panel

g000860

1 2 3 4

56789101112

Table 3 on page 19 provides information about the front panel components of the services gateway.

Table 3: SRX1500 Services Gateway Front Panel Components

DescriptionComponentCallout

19

1

10/100/1000 Base-T

ports

100/1000 SFP ports2

Twelve 10/100/1000 Base-T ports.

Top: 0/0, 0/2, 0/4, 0/6, 0/8, and 0/10

Bottom: 0/1, 0/3, 0/5, 0/7, 0/9, and 0/11

The ports have the following characteristics:

Use an RJ-45 connector.

•

Operate in full-duplex and half-duplex modes.

•

Support flow control.

•

Support autonegotiation.

•

The ports can be used to:

Function as front-end network ports.

•

Provide LAN and WAN connectivity to hubs, switches, local servers, and

•

workstations.

Forward incoming data packets to the services gateway.

•

Receive outgoing data packets from the services gateway

•

Four 1-Gigabit Ethernet small form-factor pluggable (SFP) ports for network

traffic

Top: 0/12 and 0/14

Bottom: 0/13 and 0/15

1G/10G SFP+ ports3

Four 1-Gigabit Ethernet/10-Gigabit Ethernet enhanced small form-factor

pluggable (SFP+) ports for network traffic

Top: 0/16 and 0/18

Bottom: 0/17 and 0/19

Table 3: SRX1500 Services Gateway Front Panel Components (continued)

DescriptionComponentCallout

20

WAN PIM slots4

Power button5

LEDs7

Console port9

Two WAN PIM slots.

WAN PIMs are used to add WAN interfaces to the services gateway.

NOTE: The WAN PIMs are currently not available for ordering.

Use the Power button to shut down the services gateway. On a services gateway

that has been previously shut down using the Power button, when the power

button is pressed again the services gateway starts up.

Returns the services gateway to the factory-default configuration.Reset config button6

Indicate component and system status and troubleshooting information at a

glance. See Table 4 on page 21.

Use the management (MGMT) port to connect to the device over the network.Management port8

Serial—Connects a laptop to the services gateway for CLI management. The

•

port uses an RJ-45 serial connection, is configured as DTE, and supports the

RS-232 (EIA-232) standard.

USB—Connects a laptop to the services gateway for CLI management through

•

a USB interface. The port accepts a Mini-B type USB cable plug. A USB cable

with Mini-B and Type A USB plugs is supplied with the services gateway. To

use the mini-USB console port, you must download a USB driver to the

management device from the Silicon Labs page.

The services gateway has one USB port that accepts a USB storage device.USB port10

HA control port11

ESD point12

Dedicated Gigabit Ethernet SFP port to synchronize data and maintain state

information in a chassis cluster setup.

For personal safety, while working on the services gateway, use the ESD outlet

to plug in an ESD grounding strap to prevent your body from sending static

charges to the services gateway.

NOTE: For information on supported transceivers, see the Hardware Compatibility Tool. Note

that the HA control port supports only the following transceivers:

EX-SFP-1GE-LH

•

EX-SFP-1GE-LX

•

EX-SFP-1GE-SX

•

EX-SFP-1GE-SX-ET

•

QFX-SFP-1GE-LX

•

QFX-SFP-1GE-SX

•

SRX-SFP-1GE-LH

•

SRX-SFP-1GE-LX

•

SRX-SFP-1GE-LX-ET

•

SRX-SFP-1GE-SX

•

21

SRX-SFP-1GE-SX-ET

•

Figure 2 on page 21 shows the SRX1500 Services Gateway LEDs.

Figure 2: SRX1500 Services Gateway Front Panel LEDs

Table 4 on page 21 lists the SRX1500 Services Gateway LEDs.

Table 4: SRX1500 Services Gateway LEDs

DescriptionLEDCallout

Solid green—operating normallySTAT1

•

ALARM2

Solid amber—noncritical alarm

•

Solid red—critical alarm

•

Off—no alarms

•

Table 4: SRX1500 Services Gateway LEDs (continued)

DescriptionLEDCallout

22

SSD3

RPS4

HA5

PWR6

Management Port LEDs

Blinking green—the services gateway is transferring data to or from the SSD

•

storage device

Off—SSD storage device not present

•

Solid green—the redundant power supply is operating normally

•

Solid red—the redundant power supply is not operating normally

•

Off—no redundant power supply

•

Off—HA is disabled.

•

Solid green—all HA links are available.

•

Solid amber—some HA links are unavailable.

•

Solid red—device is inoperable due to a monitor failure

•

Solid green—receiving power

•

Blinking green—receiving power. The services gateway is in the bootup phase

•

before OS initialization.

Solid red—power supply unit failure

•

The management port has two LEDs that indicate link activity and status of the management port.

Table 5 on page 22 describes the LEDs.

Table 5: Management Port LEDs

DescriptionLED

Link (LED on the left)

Activity (LED on the

right)

Solid green—A link is established.

•

Off—There is no link established.

•

Blinking green—There is activity on the link.

•

Off—There is no link activity.

•

Network Port LEDs

The SFP and Ethernet ports have two status LEDs, LINK and ACT, located above the port.

Table 6: Network Port LEDs

g000861

DescriptionLED

23

LINK (LED on the left)

ACT (LED on the right)

Solid green—A link is established.

•

Off—There is no link established.

•

Blinking green—There is activity on the 1 G link.

•

Off—There is no link activity.

•

HA Port LEDs

The HA port has two LEDs located above the port to indicate status.

Table 7: HA Port LEDs

DescriptionLED

Link (LED on the left)

Activity (LED on the

right)

Solid green—A link is established.

•

Off—There is no link established.

•

Blinking green—There is activity on the link.

•

Off—There is no link activity.

•

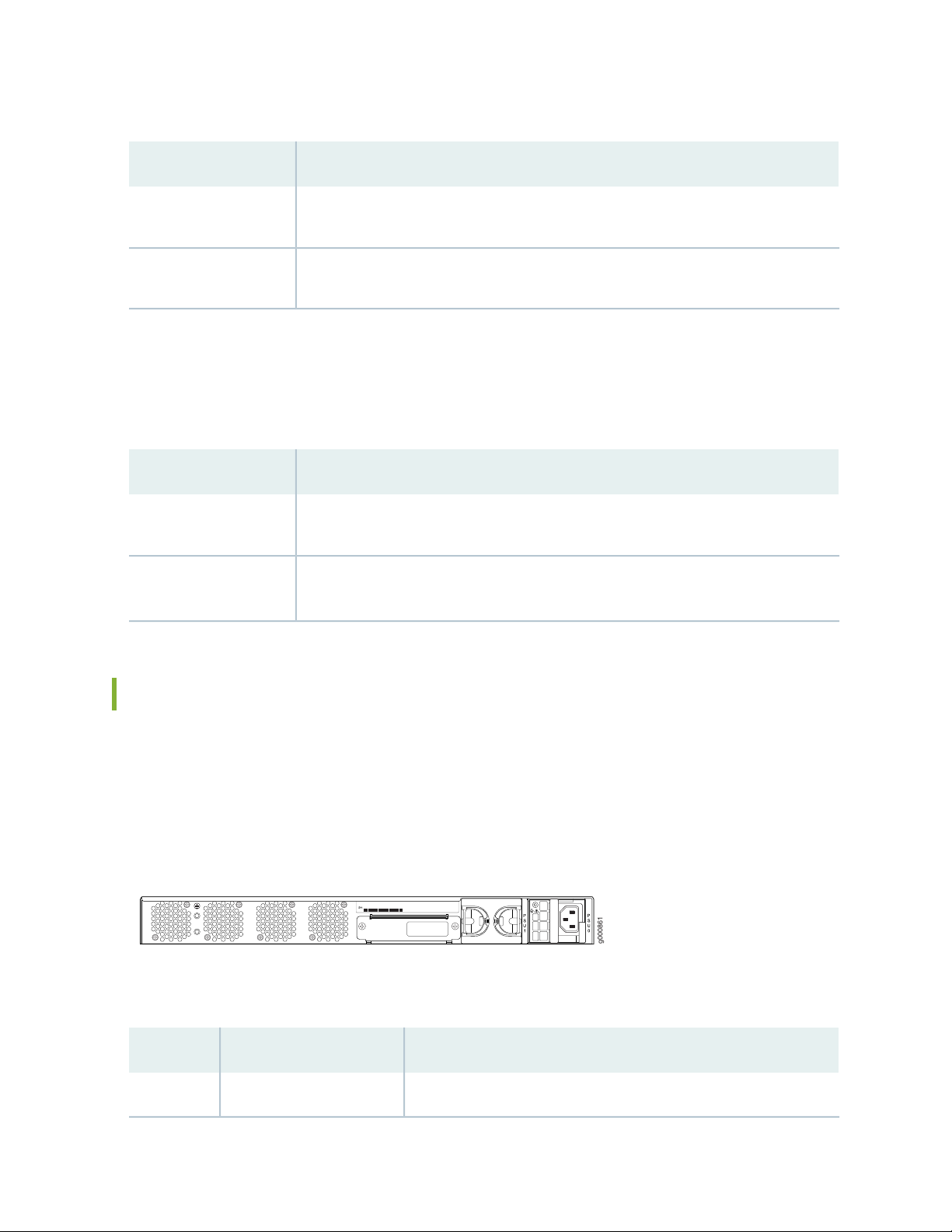

SRX1500 Services Gateway Back Panel

Figure 3 on page 23 shows the back panel of the SRX1500 Services Gateway and Table 8 on page 23 lists

the back panel components.

Figure 3: SRX1500 Services Gateway Back Panel

Table 8: SRX1500 Services Gateway Back Panel Components

DescriptionComponentCallout

Connects the services gateway chassis to earth ground.Grounding point1

Table 8: SRX1500 Services Gateway Back Panel Components (continued)

DescriptionComponentCallout

Contains the SSD storage device.SSD slot2

24

Power supply3

RELATED DOCUMENTATION

SRX1500 Services Gateway Installation Overview | 45

Two power supply slots. Each power supply contains a power cord

outlet. One 400 W AC or 650 W DC power supply is provided with

the services gateway.

Four fans for cooling the services gateway and its components.Fans4

SRX1500 Cooling System

The services gateway has a single fan tray that contains four fixed fans. The fan controller constantly

monitors the temperature of the services gateway and its components. Under normal operating conditions,

the fans function at lower than full speed.

If any one of the four fans fails, the services gateway generates a warning but keeps the system running.

If the temperature keeps rising, the services gateway lowers the power consumption by reducing the

performance or shutting down some of the chassis components. However, if the ambient maximum

temperature exceeds the warning level and the system cannot be adequately cooled, then the services

gateway shuts down the system and hardware components completely.

RELATED DOCUMENTATION

SRX1500 Services Gateway Clearance Requirements for Airflow and Hardware Maintenance | 37

SRX1500 Power System

IN THIS SECTION

SRX1500 Services Gateway Power Supply | 25

SRX1500 Services Gateway Supported AC Power Cords | 27

SRX1500 Services Gateway AC Power Supply Electrical Specifications | 28

SRX1500 Services Gateway DC Power Supply Electrical Specifications | 28

SRX1500 Services Gateway DC Power Cable Specifications | 29

SRX1500 Services Gateway Power Supply

25

The power supplies are located on the rear of the chassis. The SRX1500 Services Gateway uses either one

AC or one DC power supply unit.

A second AC or DC power supply can be used with its matching type of power supply to provide redundancy.

Each power supply provides power to all components in the services gateway. When two power supplies

are present, they share power almost equally within a fully populated system. The two power supplies

provide power redundancy. If one power supply fails or is removed, the remaining power supply redistributes

the electrical load without interruption. The services gateway reassesses the power required to support

its configuration and issues errors if the available power is insufficient.

Each power supply is cooled by its own internal cooling system.

NOTE: Only redundant power supplies (AC or DC) support hot-swappable functionality.

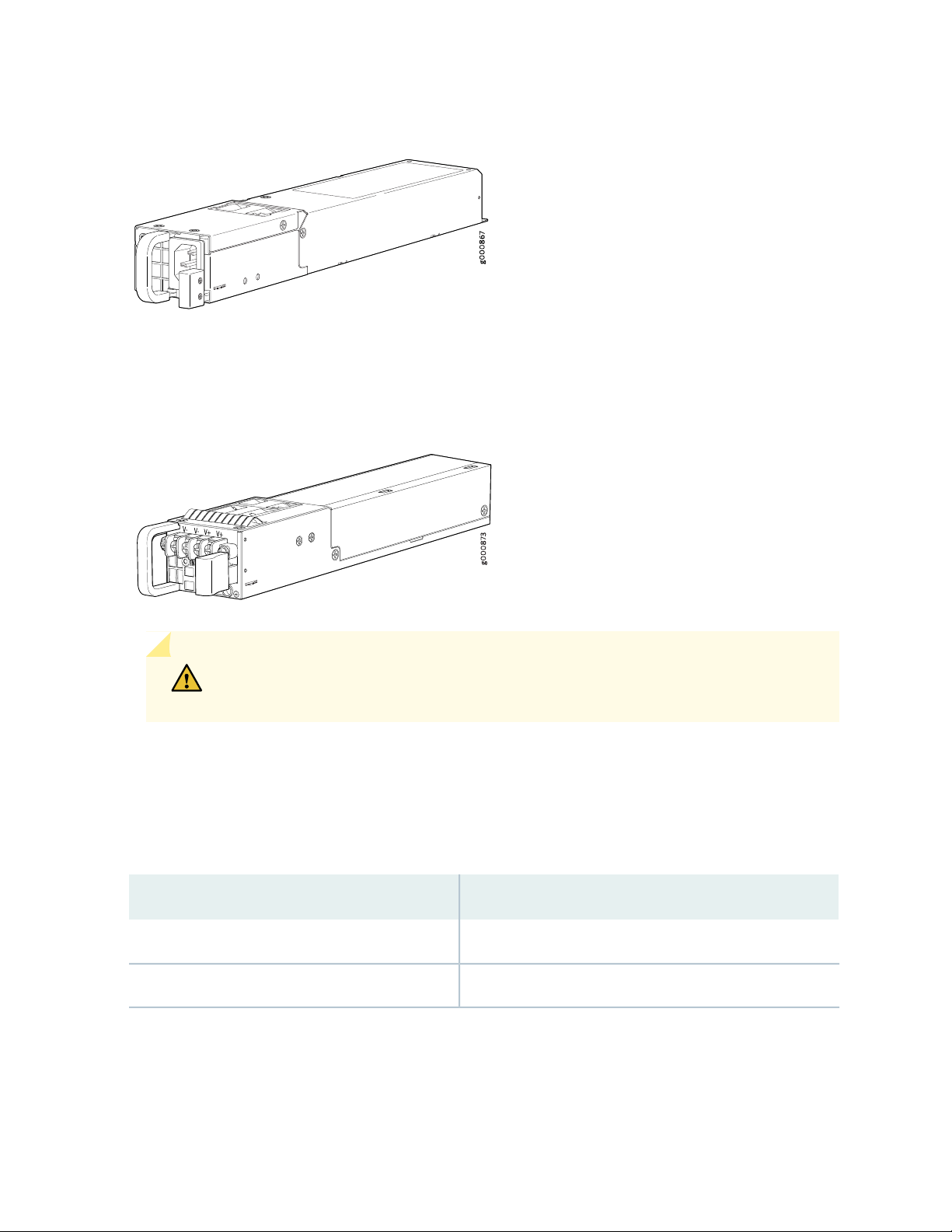

Figure 4 on page 26 shows the AC power supply.

Figure 4: AC Power Supply for the SRX1500 Services Gateway

Figure 5 on page 26 shows the DC power supply.

Figure 5: DC Power Supply for the SRX1500 Services Gateway

26

CAUTION: Do not mix AC and DC power supplies within the same services gateway.

Damage to the device might occur.

The power supplies produce and distribute different output voltages to the services gateway components

according to their voltage requirements.

Table 9 on page 26 lists the power consumption values for the power supplies.

Table 9: Component Power Output/Consumption

Output/ConsumptionPower Supply

400 W @12 V400 W AC power supply

650 W @12 V650 W DC power supply

SEE ALSO

Powering On the SRX1500 Services Gateway | 58

Powering Off the SRX1500 Services Gateway | 59

SRX1500 Services Gateway Supported AC Power Cords

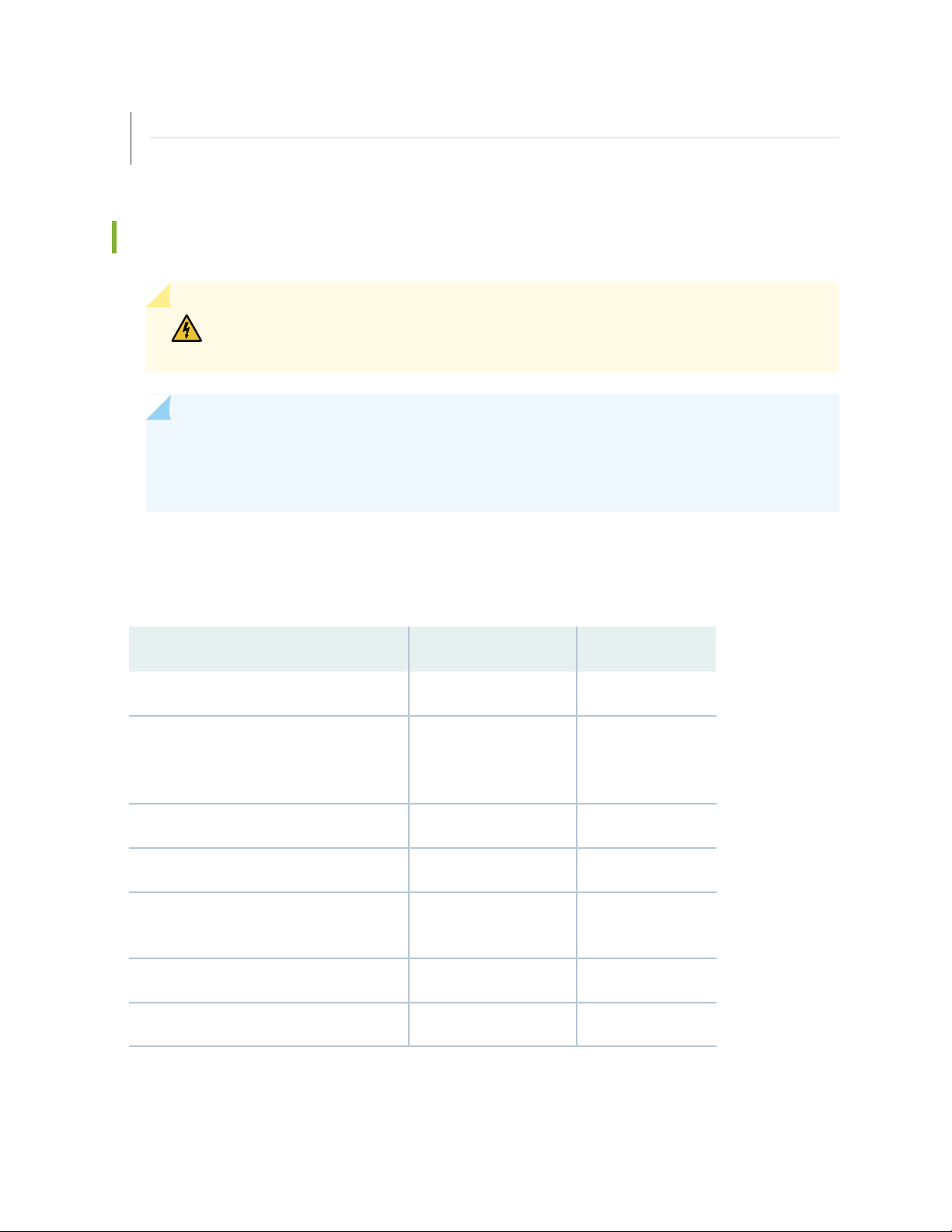

WARNING: The AC power cord for the services gateway is intended for use with the

services gateway only and not for any other use.

NOTE: In North America, AC power cords must not exceed 4.5 m (approximately 14.75 ft) in

length, to comply with National Electrical code (NEC) Section 400-8 (NFPA 75, 5-2.2) and 210-52,

and Canadian Electrical Code (CEC) Section 4-010(3).

27

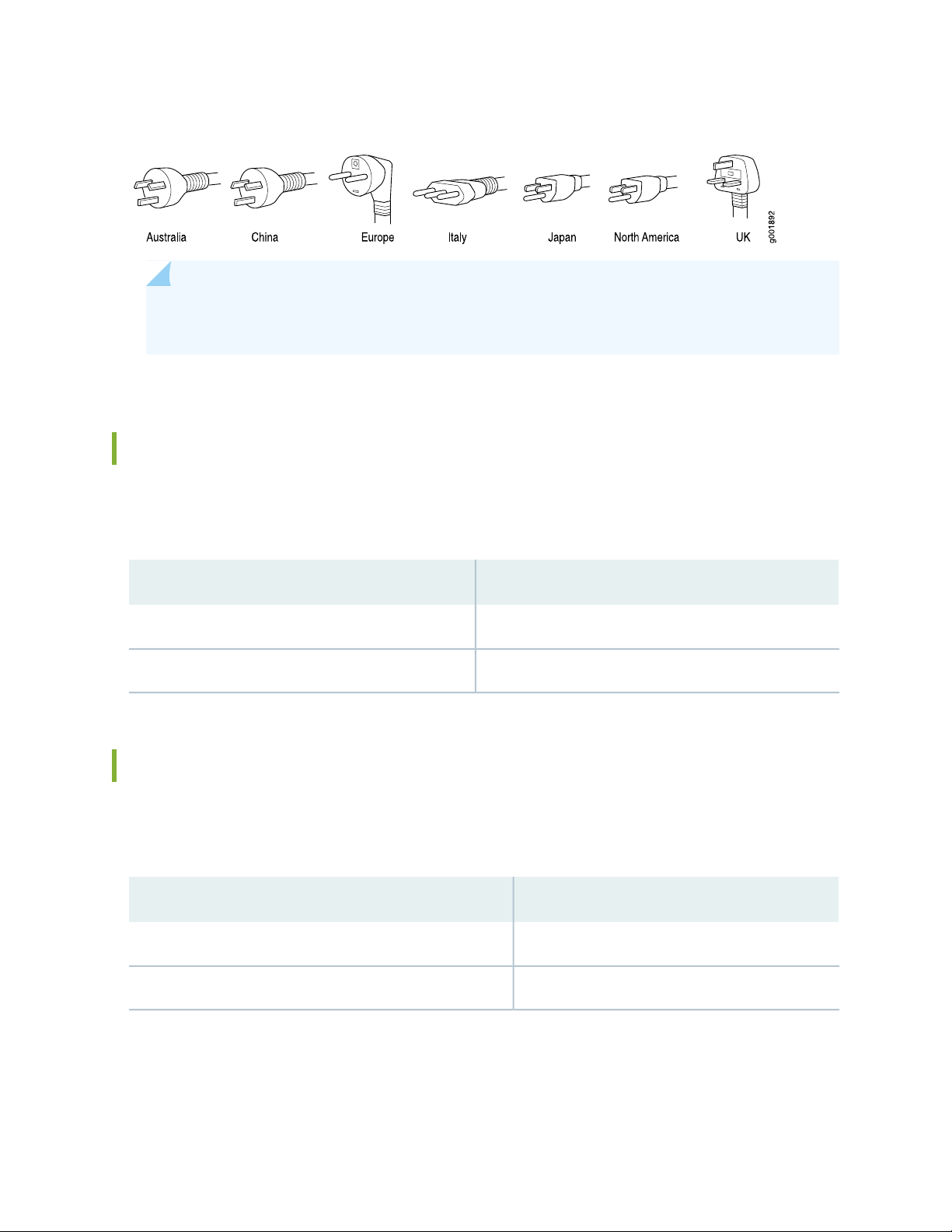

Table 10 on page 27 provides power cord specifications, and Figure 6 on page 28 depicts the plug on the

AC power cord provided for each country or region.

Table 10: AC Power Cord Specifications

Plug StandardsElectrical SpecificationCountry

AS/NZ 3112-1993250 VAC, 10 A, 50 HzAustralia

250 VAC, 10 A, 50 HzChina

Japan

Hz

GB2099.1 1996 and

GB 1002 1996

(CH1-10P)

CEE (7) VII250 VAC, 10 A, 50 HzEurope (except Italy and United Kingdom)

CEI 23-16/VII250 VAC, 10 A, 50 HzItaly

JIS 8303125 VAC, 12 A, 50 or 60

NEMA 5-15125 VAC, 10 A, 60 HzNorth America

BS 1363A250 VAC, 10 A, 50 HzUnited Kingdom

Figure 6: AC Plug Types

NOTE: Power cords and cables must not block access to services gateway components or drape

where people might trip on them.

SRX1500 Services Gateway AC Power Supply Electrical Specifications

Table 11 on page 28 lists the AC power supply electrical specifications for the SRX1500 Services Gateway.

28

Table 11: AC Power Supply Electrical Specifications for the SRX1500 Services Gateway

SpecificationPower Requirement

100 to 127 V ~ 2.5 A, 200 to 240 V ~ 1.3 AAC input voltage

47 to 63 HzAC input line frequency

SRX1500 Services Gateway DC Power Supply Electrical Specifications

Table 12 on page 28 lists the DC power supply electrical specifications for the SRX1500 Services Gateway.

Table 12: DC Power Supply Electrical Specifications for the SRX1500 Services Gateway

SpecificationPower Requirement

–44 to –72 VDCDC input voltage

6.2 A maximumDC system current rating

SRX1500 Services Gateway DC Power Cable Specifications

The DC power supply in slot 0 must be powered by dedicated power feeds derived from feed A, and the

DC power supply in slot 1 must be powered by dedicated power feeds derived from feed B. This

configuration provides the commonly deployed A/B feed redundancy for the system.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the external

DC power source at your site determines the color coding for the leads on the power

cables that attach to the terminal studs on each power supply.

WARNING: For field-wiring connections, use copper conductors only. For other

electrical safety information, see “SRX1500 Services Gateway Electrical Wiring

Guidelines” on page 34.

29

CAUTION: Power cords and cables must not block access to services gateway

components or drape where people could trip on them.

Table 13 on page 29 summarizes the specifications for the power cable(s), which you must supply.

Table 13: SRX1500 Services Gateway DC Power Cable Specification

Quantity and SpecificationCable Type

14-16 AWG, minimum 60° C wire, or as permitted by the local codePower

RELATED DOCUMENTATION

SRX1500 Services Gateway Electrical Wiring Guidelines | 34

2

CHAPTER

Site Planning, Preparation, and

Specifications

Site Preparation Checklist for the SRX1500 Services Gateway | 31

SRX1500 Site Guidelines and Requirements | 33

SRX1500 Transceiver Specifications and Pinouts | 40

Site Preparation Checklist for the SRX1500 Services Gateway

Table 14 on page 31 provides a checklist of tasks you need to perform when preparing a site for installing

the SRX1500 Services Gateway.

Table 14: Site Preparation Checklist for SRX1500 Services Gateway Installation

Performed

ByAdditional InformationItem or Task

Power

NotesDate

31

Measure distance between external power

sources and device installation site.

Locate sites for connection of system

grounding.

Calculate the power consumption and

requirements.

Environment

Verify that environmental factors such as

temperature and humidity do not exceed

device tolerances.

“SRX1500 Services Gateway

Electrical Wiring Guidelines” on

page 34

“Connecting the SRX1500 Services

Gateway Grounding Cable” on

page 50

“SRX1500 Services Gateway AC

Power Supply Electrical

Specifications” on page 28 and

“SRX1500 Services Gateway DC

Power Supply Electrical

Specifications” on page 28

“SRX1500 Services Gateway

Environmental Specifications” on

page 34

Rack Installation

Table 14: Site Preparation Checklist for SRX1500 Services Gateway Installation (continued)

Performed

ByAdditional InformationItem or Task

“Rack Requirements” on page 39Verify that your rack meets the minimum

requirements.

Plan rack location, including required space

clearances.

If a rack is used, secure the rack to the floor

and building structure.

Cabinet Installation

“Cabinet Requirements” on page 39Verify that your cabinet meets the

minimum requirements.

32

NotesDate

Plan the cabinet location, including required

space clearances.

Cables

Acquire cables and connectors.

Review the maximum distance allowed for

each cable. Choose the length of cable

based on the distance between the

hardware components being connected.

Plan the cable routing and management.

RELATED DOCUMENTATION

“SRX1500 Services Gateway

Supported AC Power Cords” on

page 27and “SRX1500 Services

Gateway DC Power Cable

Specifications” on page 29

SRX1500 Services Gateway Installation Overview | 45

SRX1500 Site Guidelines and Requirements

IN THIS SECTION

SRX1500 Services Gateway General Site Installation Guidelines | 33

SRX1500 Services Gateway Environmental Specifications | 34

SRX1500 Services Gateway Electrical Wiring Guidelines | 34

SRX1500 Services Gateway Grounding Specifications | 36

SRX1500 Services Gateway Physical Specifications | 36

SRX1500 Services Gateway Clearance Requirements for Airflow and Hardware Maintenance | 37

Rack Requirements | 39

Cabinet Requirements | 39

33

SRX1500 Services Gateway General Site Installation Guidelines

The following precautions help you plan an acceptable operating environment for your SRX1500 Services

Gateway and avoid environmentally caused equipment failures:

For the cooling system to function properly, the airflow around the chassis must be unrestricted. Allow

•

sufficient clearance between the front and back of the chassis and adjacent equipment. Ensure that

there is adequate circulation in the installation location.

Follow the ESD procedures to avoid damaging equipment. Static discharge can cause components to

•

fail completely or intermittently over time. For more information, see “Prevention of Electrostatic

Discharge Damage” on page 107.

Ensure that the blank panels are installed into empty slots to prevent any interruption or reduction in

•

the flow of air across internal components.

NOTE: Install the services gateway only in restricted areas, such as dedicated equipment rooms

and equipment closets, in accordance with Articles 110–16, 110–17, and 110–18 of the National

Electrical Code, ANSI/NFPA 70.

SRX1500 Services Gateway Environmental Specifications

Table 15 on page 34 provides the required environmental conditions for normal SRX1500 Services Gateway

operations. In addition, the site must be as dust-free as possible because dust can clog air intake vents,

reducing the efficiency of the cooling system.

Table 15: SRX1500 Services Gateway Environmental Specifications

ValueDescription

No performance degradation to 10,000 ft (3048 m)Altitude

34

Relative humidity

Temperature

Normal operation ensured in relative humidity range of 5% to 90%,

noncondensing

Normal operation ensured in temperature range of 32° F (0° C) to 104°

•

F (40° C)

Nonoperating storage temperature in shipping container: –40° F (–40°

•

C) to 158° F (70° C)

614 BTU/hourMaximum thermal output

512 BTU / hourAverage heat dissipation

66.5 dBANoise level

SRX1500 Services Gateway Electrical Wiring Guidelines

Table 16 on page 35 describes the factors you must consider while planning the electrical wiring for the

SRX1500 Services Gateway at your site.

CAUTION: It is particularly important to provide a properly grounded and shielded

environment and to use electrical surge-suppression devices.

Table 16: Site Electrical Wiring Guidelines for the SRX1500 Services Gateway

GuidelineSite Wiring Factor

35

Signaling limitations

Radio frequency

interference (RFI)

Electromagnetic

compatibility (EMC)

To ensure that signaling functions optimally:

Install wires correctly.

•

Improperly installed wires can emit radio interference.

Do not exceed the recommended distances or pass wires between buildings.

•

The potential for damage from lightning strikes increases if wires exceed recommended

distances or if wires pass between buildings.

Shield all conductors.

•

The electromagnetic pulse (EMP) caused by lightning can damage unshielded

conductors and destroy electronic devices.

To reduce or eliminate the emission of RFI from your site wiring:

Use twisted-pair cable with a good distribution of grounding conductors.

•

Use a high-quality twisted-pair cable with one ground conductor for each data signal

•

when applicable, if you must exceed the recommended distances.

Provide a properly grounded and shielded environment and use electrical

surge-suppression devices.

Strong sources of electromagnetic interference (EMI) can cause the following damage:

Destroy the signal drivers and receivers in the device

•

Conduct power surges over the lines into the equipment, resulting in an electrical

•

hazard

TIP: If your site is susceptible to problems with EMC, particularly from lightning or radio

transmitters, you might want to seek expert advice.

WARNING: Some ports are designed for use as intrabuilding interfaces only Type 2

or Type 4 ports, the battery return connection is to be treated as an Isolated DC return

(that is, DC-I), as defined in GR-1089-CORE and require isolation from the exposed

OSP cabling. To comply with NEBS requirements and protect against lightning surges

and commercial power disturbances, the intrabuilding port(s) of the device MUST NOT

be metallically connected to interfaces that connect to the OSP or its wiring. The

intrabuilding port(s) of the device is suitable for connection to intrabuilding or

unexposed wiring or cabling only. The addition of primary protectors is not sufficient

protection to connect these interfaces metallically to OSP wiring.

SRX1500 Services Gateway Grounding Specifications

To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, the

SRX1500 Services Gateway must be adequately grounded before power is connected. You must provide

a grounding lug to connect the services gateway to earth ground.

WARNING: Before you connect power to the services gateway, a licensed electrician

must attach a cable lug to the grounding and power cables that you supply. A cable

with an incorrectly attached lug can damage the services gateway (for example, by

causing a short circuit).

The services gateway chassis has one grounding point on the back panel. The grounding point consists of

two threaded holes spaced 0.625 in. (15.86 mm) apart. The grounding point holes fit M5 screws.

Table 17 on page 36 lists the specifications of the grounding cable used with the device.

36

Table 17: Grounding Cable Specifications for the SRX1500 Services Gateway

SpecificationGrounding Requirement

14 AWG single-strand wire cableGrounding cable

Up to 25AAmperage of grounding cable

Ring-type, vinyl-insulated TV14-6R lug, or equivalentGrounding lug

SEE ALSO

Connecting the SRX1500 Services Gateway Grounding Cable | 50

Powering On the SRX1500 Services Gateway | 58

Powering Off the SRX1500 Services Gateway | 59

SRX1500 Services Gateway Physical Specifications

Table 18 on page 37 lists the physical specifications for the services gateway.

Table 18: Physical Specifications for the SRX1500 Services Gateway

ValuePhysical Specification of Chassis

1.75 in.Height

17.5 in.Width

18.2 in.Depth

15 lb.Weight

SEE ALSO

SRX1500 Services Gateway Overview | 16

SRX1500 Services Gateway Front Panel | 18

37

SRX1500 Services Gateway Back Panel | 23

SRX1500 Services Gateway Clearance Requirements for Airflow and Hardware Maintenance

When planning the installation site for the SRX1500 Services Gateway, you need to allow sufficient

clearance around the rack. Consider the following:

For the cooling system to function properly, the airflow around the chassis must be unrestricted. The

•

fan tray contains four fans and provides front-to-back chassis cooling. Figure 7 on page 38 shows the

direction of airflow through the chassis.

For service personnel to remove and install hardware components, there must be adequate space at the

•

front and back of the services gateway as indicated in Table 19 on page 38.

If you are mounting the services gateway in a rack with other equipment, ensure that the exhaust from

•

other equipment does not blow into the intake vents of the chassis.

Table 19 on page 38 provides information about the clearance requirements for maintaining optimum

airflow and the distances necessary to facilitate easy maintenance of the services gateway.

Table 19: Clearance Requirements for the SRX1500 Services Gateway

g000866

PortsFRUs

Top down view

Recommended

ClearanceLocation

Requirement for Clearance

38

8.7 in. (22 cm)Front of the chassis

17.4 in. (44.2 cm)Rear of the chassis

rack or cabinet edge

6.0 in. (15.24 cm)Between both sides of the chassis and

any non-heat-producing surface such

as a wall or cabinet side

Figure 7 on page 38 shows the airflow through the chassis.

Figure 7: Airflow Through the Chassis

Space for service personnel to remove and

install hardware components

Space for service personnel to remove and

install hardware components

Space for cable management and organization2.5 in. (6.35 cm)Between front-mounting flange and

Space for the cooling system to function

properly and to maintain unrestricted airflow

around the chassis

Rack Requirements

When installing the services gateway in a rack, you must ensure that the rack complies with a 1U (19 in.

or 48.7 cm) rack as defined in Cabinets, Racks, Panels, and Associated Equipment (document number

EIA-310-D), published by the Electronic Industries Alliance (http://www.ecaus.org/eia/site/index.html).

When selecting a rack, ensure that the physical characteristics of the rack comply with the following

specifications:

The outer edges of the mounting brackets extend the width of either chassis to 19 in. (48.3 cm).

•

The front of the chassis extends approximately 0.5 in. (1.27 cm) beyond the mounting ears.

•

Maximum permissible ambient temperature when two devices are placed side by side in a 19 in. rack is

•

40° C.

The spacing of the mounting brackets and flange holes on the rack and device mounting brackets are as

follows:

39

The holes within each rack set are spaced at 1 U (1.75 in. or 4.5 cm).

•

The mounting brackets and front-mount flanges used to attach the chassis to a rack are designed to

•

fasten to holes spaced at rack distances of 1 U (1.75 in.).

The mounting holes in the mounting brackets provided with the device are spaced 1.25 in. (3.2 cm) apart

•

(top and bottom mounting hole).

Always secure the rack in which you are installing the services gateway to the structure of the building. If

your geographical area is subject to earthquakes, bolt the rack to the floor. For maximum stability, also

secure the rack to ceiling brackets.

Cabinet Requirements

You can install the services gateway in a 19 in. (48.7 cm) cabinet as defined in Cabinets, Racks, Panels, and

Associated Equipment (document number EIA-310-D) published by the Electronic Industries Alliance

(http://www.ecaus.org/eia/site/index.html). You must mount the services gateway horizontally in the

cabinet using appropriate rack adapters.

When selecting a cabinet, ensure that it meets the following specifications:

The cabinet is at least 1U (3.50 in. or 8.89 cm) and can accommodate the services gateway.

•

The outer edges of the mounting brackets extend the width of either chassis to 19 in. (48.7 cm), and the

•

front of the chassis extends approximately 0.5 in. (1.27 cm) beyond the mounting brackets.

The minimum total clearance inside the cabinet is 30.7 in. (78 cm) between the inside of the front door

•

and the inside of the rear door.

NOTE: A cabinet larger than the minimum required provides better airflow and reduces the

chance of overheating.

When you mount the services gateway in a cabinet, you must ensure that ventilation through the cabinet

is sufficient to prevent overheating. Consider the following when planning for chassis cooling:

Ensure that the cool air supply you provide through the cabinet can adequately dissipate the thermal

•

output of the services gateway.

Install the services gateway as close as possible to the front of the cabinet so that the cable management

•

system clears the inside of the front door. Installing the chassis close to the front of the cabinet maximizes

the clearance in the rear of the cabinet for critical airflow.

Route and dress all cables to minimize the blockage of airflow to and from the chassis.

•

40

SRX1500 Transceiver Specifications and Pinouts

IN THIS SECTION

SRX1500 Transceiver Support | 40

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Ethernet Port | 41

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Console Port | 41

Mini-USB Connector Pinouts for the SRX1500 Services Gateway Console Port | 42

SRX1500 Transceiver Support

You can find information about the pluggable transceivers supported on your Juniper Networks device

by using the Hardware Compatibility Tool. In addition to transceiver and connector type, the optical and

cable characteristics—where applicable—are documented for each transceiver. The Hardware Compatibility

Tool enables you to search by product, displaying all the transceivers supported on that device, or category,

by interface speed or type. The list of supported transceivers for the SRX1500 is located at

https://apps.juniper.net/hct/product/#prd=SRX1500.

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Ethernet Port

The port on the front panel labeled MGMT is an autosensing 10/100/1000-Mbps Ethernet RJ-45 receptacle

that accepts an Ethernet cable for connecting the services gateway to a management LAN (or other device

that supports out-of-band management). Table 20 on page 41 describes the RJ-45 connector pinouts for

the Ethernet port.

Table 20: RJ-45 Connector Pinouts for Services Gateway Ethernet Port

SignalPin

TX+1

TX-2

RX+3

Termination network4

41

Termination network5

RX-6

Termination network7

Termination network8

RJ-45 Connector Pinouts for the SRX1500 Services Gateway Console Port

The SRX1500 Services Gateway has two console ports: an RJ-45 Ethernet port and a mini-USB Type-B

port. The port on the front panel labeled CONSOLE is an asynchronous serial interface that accepts an

RJ-45 connector. Table 21 on page 41 describes the RJ-45 connector pinouts for the console port.

Table 21: RJ-45 Connector Pinouts for the Services Gateway Console Port

DescriptionSignalPin

Request to SendRTS1

Data Terminal ReadyDTR2

Transmit DataTXD3

Table 21: RJ-45 Connector Pinouts for the Services Gateway Console Port (continued)

DescriptionSignalPin

Signal GroundGround4

Signal GroundGround5

Receive DataRXD6

Data Set ReadyDSR/DCD7

Clear to SendCTS8

Mini-USB Connector Pinouts for the SRX1500 Services Gateway Console

42

Port

The SRX1500 Services Gateway has two console ports: an RJ-45 Ethernet port and a mini-USB Type-B

port. If your management device (laptop or PC) does not have a DB-9 plug connector pin or an RJ-45

connector pin, you can connect your management device to the Mini-USB Type-B console port of the

services gateway by using a cable that has a standard Type-A USB connector on one end and a Mini-USB

Type-B (5-pin) connector on the other end. Table 22 on page 42 describes the Mini-USB Type-B connector

pinouts for the console port.

NOTE: By design, the mini-USB console port has higher priority over the RJ-45 console port. If

both mini-USB and RJ-45 console ports are connected, then the mini-USB console port will be

active.

Table 22: Mini-USB Type-B Connector Pinouts for the Services Gateway Console Port

DescriptionCable ColorSignalPin

+5 VDCRedVCC1

Data -WhiteD-2

Data +GreenD+3

Table 22: Mini-USB Type-B Connector Pinouts for the Services Gateway Console Port (continued)

DescriptionCable ColorSignalPin

43

N/CX

RELATED DOCUMENTATION

SRX1500 Services Gateway Front Panel | 18

Could be not connected

(N/C), connected to

ground (GND), or used as

an attached device

presence indicator

GroundBlackGND4

3

CHAPTER

Initial Installation and Configuration

SRX1500 Services Gateway Installation Overview | 45

Unpacking and Mounting the SRX1500 | 45

Connecting the SRX1500 to Power | 50

Connecting the SRX1500 to External Devices | 60

Configuring Junos OS on the SRX1500 | 62

SRX1500 Services Gateway Installation Overview

After you have prepared the site for installation and unpacked the SRX1500 Services Gateway, you are

ready to install the device. It is important to proceed through the installation process in the following order:

1. Review the safety guidelines explained in “General Electrical Safety Guidelines and Warnings” on

page 123.

2. Prepare the services gateway for installation as described in “Preparing the SRX1500 Services Gateway

for Rack-Mount Installation” on page 48.

3. Install the services gateway as described in “Installing the SRX1500 Services Gateway in a Rack” on

page 48.

4. Connect cables to external devices as described in “Connecting the SRX1500 Services Gateway to a

Network for Out-of-Band Management” on page 60 and “Connecting the SRX1500 Services Gateway

to a Management Console” on page 61.

45

5. Connect the grounding cable as described in “Connecting the SRX1500 Services Gateway Grounding

Cable” on page 50.

6. Power on the services gateway as described in “Powering On the SRX1500 Services Gateway” on

page 58.

Unpacking and Mounting the SRX1500

IN THIS SECTION

Unpacking the SRX1500 Services Gateway | 46

Verifying Parts Received with the SRX1500 Services Gateway | 46

Preparing the SRX1500 Services Gateway for Rack-Mount Installation | 48

Installing the SRX1500 Services Gateway in a Rack | 48

Unpacking the SRX1500 Services Gateway

The SRX1500 Services Gateway is shipped in a cardboard carton and secured with foam packing material.

The carton also contains an accessory box and quick-start instructions.

NOTE: The services gateway is maximally protected inside the cardboard carton. Do not unpack

it until you are ready to begin installation.

To unpack the SRX1500 Services Gateway:

1. Move the cardboard carton to a staging area as close to the installation site as possible, where you

have enough room to remove the components from the chassis.

2. Position the cardboard carton with the arrows pointing up.

46

3. Carefully open the top of the cardboard carton.

4. Remove the foam covering the top of the services gateway.

5. Remove the accessory box.

6. Verify the parts received against the lists in “Verifying Parts Received with the SRX1500 Services

Gateway” on page 46.

7. Store the brackets and bolts inside the accessory box.

8. Save the shipping carton and packing materials in case you need to move or ship the services gateway

at a later time.

Verifying Parts Received with the SRX1500 Services Gateway

The SRX1500 Services Gateway shipment package contains a packing list. Check the parts in the shipment

against the items on the packing list. The packing list specifies the part numbers and carries a brief

description of each part in your order.

If any part is missing, contact a customer service representative.

A fully configured services gateway contains the chassis with installed components, listed in

Table 23 on page 47, and an accessory box, which contains the parts listed in Table 24 on page 47.

NOTE: The parts shipped with your services gateway can vary depending on the configuration

you ordered.

Table 23: Parts List for a Fully Configured SRX1500 Services Gateway

QuantityComponent

11U SRX1500 Services Gateway chassis with 12 Gigabit Ethernet LAN ports, four 1G SFP ports,

four 1G/10G SFP ports, two power supply slots, four fans, and one SSD (includes blank covers

for WAN PIM)

1Front-mount rack-mount kit

47

NOTE: The shipment includes one power cord appropriate for your geographical location.

Two power supplies must be installed in the services gateway for redundancy.

Table 24: Accessory/Upgrade Parts List for the SRX1500 Services Gateway

QuantityPart

1RoHS Card

1End User License Agreement

1CAT5E cable

1DB9-to-RJ45 adapter

1USB cable

1Documentation Roadmap and Product Warranty

1400 W AC or 650 W DC power supply

Preparing the SRX1500 Services Gateway for Rack-Mount Installation

You can mount an SRX1500 Services Gateway on four-post (telco) racks, enclosed cabinets, and open-frame

racks. Center-mount racks are not supported.

Before mounting the SRX1500 Services Gateway in a rack:

Verify that the site meets the requirements described in “Site Preparation Checklist for the SRX1500

•

Services Gateway” on page 31.

Verify that you have the following parts available in your rack-mounting kit for the SRX1500 Services

•

Gateway:

Rack-mounting brackets

•

Screws

•

Verify that the racks or cabinets meet the specific requirements described in SRX1500 Services Gateway

•

Rack Requirements.

48

Place the rack or cabinet in its permanent location, allowing adequate clearance for airflow and

•

maintenance, and secure it to the building structure. For more information, see “Cabinet Requirements”

on page 39.

Remove the gateway chassis from the shipping carton. For unpacking instructions, see “Unpacking the

•

SRX1500 Services Gateway” on page 46.

Installing the SRX1500 Services Gateway in a Rack

You can front-mount the SRX1500 Services Gateway in a rack. Many types of racks are acceptable, including

four-post (telco) racks, enclosed cabinets, and open-frame racks.

NOTE: If you are installing multiple devices in one rack, install the lowest one first and proceed

upward in the rack.

To install the services gateway in a rack:

1. Position a mounting bracket on each side of the chassis.

2. Use a number 2 Phillips screwdriver to install the screws that secure the mounting brackets to the

chassis.

Figure 8: Installing the Mounting Brackets on the SRX1500 Services Gateway

g000872

3. Have one person grasp the sides of the services gateway, lift it, and position it in the rack.

4. Align the bottom hole in each mounting bracket with a hole in each rack rail, making sure the chassis

is level.

5. Have a second person install a mounting screw into each of the two aligned holes. Use a number 2

Phillips screwdriver to tighten the screws.

49

6. Install the second screw in each mounting bracket.

Figure 9: Installing the SRX1500 Services Gateway in a Rack

7. Verify that the mounting screws on one side of the rack are aligned with the mounting screws on the

opposite side and that the services gateway is level.

Connecting the SRX1500 to Power

IN THIS SECTION

Required Tools and Parts for Grounding the SRX1500 Services Gateway | 50

Connecting the SRX1500 Services Gateway Grounding Cable | 50

Installing an AC Power Supply on the SRX1500 Services Gateway | 52

Connecting the SRX1500 Services Gateway to an AC Power Supply | 53

Installing a DC Power Supply on the SRX1500 Services Gateway | 54

Connecting the SRX1500 Services Gateway to a DC Power Supply | 57

Powering On the SRX1500 Services Gateway | 58

Powering Off the SRX1500 Services Gateway | 59

50

Required Tools and Parts for Grounding the SRX1500 Services Gateway

To ground and to provide power to the services gateway, you need the following tools:

Phillips (+) screwdrivers, numbers 1 and 2

•

Electrostatic discharge (ESD) grounding wrist strap

•

Wire cutters

•

Connecting the SRX1500 Services Gateway Grounding Cable

You ground the services gateway by connecting a grounding cable to earth ground and then attaching it

to the chassis grounding points located on the back panel of the device using two metric M5 x 0.8,

12-mm-long grounding screws.

You must provide the following items:

Two metric M5 x 0.8, 12-mm-long grounding screws

•

Grounding cables

•

Cable lugs (for example, Panduit LCC6-10A-L)

•

CAUTION: Before you connect power to the services gateway, a licensed electrician

must attach a cable lug to the grounding and power cables that you supply. A cable

with an incorrectly attached lug can damage the services gateway (for example, by

causing a short circuit).

To ground the services gateway:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect the strap to

the ESD point on the chassis. For more details, see “Prevention of Electrostatic Discharge Damage” on

page 107.

2. Ensure that all grounding surfaces are clean and brought to a bright finish before grounding connections

are made.

3. Connect the grounding cable to a proper earth ground.

51

4. Place the grounding cable lugs over the grounding points (sized for metric M5 x 0.8, 12-mm-long

grounding screws) on the side of the chassis.

Figure 10: Connecting the Grounding Cable to the SRX1500 Services Gateway

5. Secure the grounding cable lugs to the grounding points, first with the washers, then with the screws.

6. Dress the grounding cable and verify that it does not touch or block access to the services gateway

components and that it does not drape where people could trip on it.

Installing an AC Power Supply on the SRX1500 Services Gateway

To install an AC power supply:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and connect the strap to

one of the ESD points on the chassis. For more information about ESD, see “Prevention of Electrostatic

Discharge Damage” on page 107.

2. Using both hands, slide the power supply straight into the chassis until the power supply is fully seated

in the chassis slot. The power supply faceplate should be flush with any adjacent power supply faceplate

(see Figure 11 on page 52).

Figure 11: Installing an AC Power Supply on the SRX1500 Services Gateway

52

3. Attach the power cord to the power supply. Use a power cord retainer to hold the power cord in place.

Figure 12: Connecting the AC Power Cord on the SRX1500 Services Gateway

4. Attach the power cord to the AC power source, and switch on the dedicated facility circuit breaker for

the power supply. Follow the ESD and connection instructions for your site. If the power supply is

correctly installed and functioning normally, the PWR LED glows steadily.

NOTE: If more than one power supply is being installed, ensure the following:

Connect power cords to both the power supplies.

•

Connect each power supply to a DC power feed.

•

If both power supplies are plugged in and receiving power, the RPS LED glows solid green.

Connecting the SRX1500 Services Gateway to an AC Power Supply

CAUTION: Do not mix AC and DC power supplies within the same services gateway.

Damage to the device might occur.

53

You connect AC power to the services gateway by attaching the power cord from the AC power source

to the AC appliance inlet located on the power supply.

To connect the services gateway to an AC power supply:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect the strap to

the ESD point on the front of the chassis.

2. Insert the appliance coupler end of the power cord into the appliance inlet on the power supply.

3. Insert the power cord plug into an external AC power source receptacle.

NOTE: Each power supply must be connected to a dedicated AC power feed and a dedicated

external circuit breaker. We recommend that you use a 15 A (250 VAC) minimum, or as

permitted by local code.

4. Dress the power cord appropriately. Verify that the power cord does not block the air exhaust and

access to services gateway components or drape where people could trip on it.

NOTE: The services gateway must be connected to earth ground during normal operation. The

protective earthing terminal on the side of the chassis is provided to connect the services gateway

to ground.

CAUTION: We recommend using a surge protector for the power connection.

Installing a DC Power Supply on the SRX1500 Services Gateway

To install a DC power supply:

54

1. Ensure that the voltage across the DC power source cable leads is 0 V and that there is no chance that

the cable leads might become active during installation. To ensure that all power is off, locate the circuit

breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position

(O), and tape the switch handle of the circuit breaker in the OFF position.

2. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and connect the strap to

one of the ESD points on the chassis. For more information about ESD, see “Prevention of Electrostatic

Discharge Damage” on page 107.

3. Orient the power supply so that the locking lever is on the left as shown in Figure 13 on page 54.

Figure 13: Installing a DC Power Supply on an SRX1500 Services Gateway

4. Using both hands, slide the power supply straight into the chassis until the power supply is fully seated

in the chassis slot. The power supply faceplate should be flush with any adjacent power supply faceplate.

5. Tighten the captive screws on the lower edge of the power supply faceplate.

6. Remove the clear plastic cover protecting the terminal studs on the faceplate.

7. Verify that the DC power cables are correctly labeled before making connections to the power supply.

In a typical power distribution scheme where the return is connected to chassis ground at the battery

plant, you can use a multimeter to verify the ohm output of the –48V and RTN DC cables to chassis

ground. The cable with very large resistance (indicating an open circuit) to chassis ground will be –48V

and the cable with very low resistance (indicating a closed circuit) to chassis ground will be RTN.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the

external DC power source at your site determines the color coding for the leads

on the power cables that attach to the terminal studs on each power supply.

55

8. Using a number 2 Phillips screwdriver, remove the screws and square washers from the terminal studs.

9. Secure each power cable lug to the terminal studs, first with the square washer, then with the screw.

Apply between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of torque to each screw.

a. Attach the positive (+) DC source power cable lug to the RTN (return) terminal.

b. Attach the negative (–) DC source power cable lug to the –48V (input) terminal.

Figure 14: Securing the Power Cables

10. Replace the clear plastic cover over the terminal studs on the faceplate.

11. Verify that the power cables are connected correctly, that they are not touching or blocking access to

services gateway components, and that they do not drape where people could trip on them.

12. Remove the tape from the switch handle of the circuit breaker on the panel board that services the

DC circuit and switch the circuit breaker to the ON position (|). Observe the status LEDs on the power

supply faceplate. If the power supply is correctly installed and functioning normally, the POWER LED

glows solid green on the services gateway front panel.

NOTE: If more than one power supply is being installed, turn on all power supplies at the same

time.

If both power supplies are plugged in and receiving AC power, the RPS LED glows solid green.

56

Connecting the SRX1500 Services Gateway to a DC Power Supply

You connect DC power to the services gateway by attaching power cables from the external DC power

sources to the terminal studs on the power supply faceplates.

WARNING: To meet safety and electromagnetic interference (EMI) requirements and

to ensure proper operation, you must properly ground the services gateway chassis

before connecting power. See “Connecting the SRX1500 Services Gateway Grounding

Cable” on page 50 for instructions.

WARNING: Before performing the following procedure, ensure that power is removed

from the DC circuit. To ensure that all power is off, locate the circuit breaker on the

panel board that services the DC circuit, switch the circuit breaker to the OFF position

(0), and tape the switch handle of the circuit breaker in the OFF position.

57

CAUTION: Do not mix AC and DC power supplies within the same services gateway.

Damage to the services gateway might occur.

CAUTION: Before you connect power to the services gateway, a licensed electrician

must attach appropriate cable lugs to the grounding and power cables that you use.

A cable with an incorrectly attached lug can damage the device (for example, by causing

a short circuit).

To connect the DC source power cables to the services gateway for each power supply:

1. Switch off the dedicated facility circuit breakers. Ensure that the voltage across the DC power source

cable leads is 0 V and that there is no chance that the cable leads might become active during installation.

2. Remove the clear plastic cover that protects the terminal studs on the faceplate.

3. Verify that the DC power cables are correctly labeled before making connections to the power supply.

In a typical power distribution scheme where the return is connected to chassis ground at the battery

plant, you can use a multimeter to verify the ohm output of the -48V and RTN DC cables to chassis

ground. The cable with very large resistance (indicating an open circuit) to chassis ground will be -48V,

and the cable with very low resistance (indicating a closed circuit) to chassis ground will be RTN.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the

external DC power source at your site determines the color coding for the leads

on the power cables that attach to the terminal studs on each power supply.