Page 1

PTX3000 Packet Transport Router Quick Start

March 2017

Part Number: 530-069280

Revision 01

This document describes how to install the Juniper Networks®PTX3000 Packet Transport Router.

1

Contents

Quick Start Description | 3

Step 1: Prepare the Site for the PTX3000 | 3

Rack-Mounting Requirements | 3

Tools Required to Unpack and Install the PTX3000 | 6

Step 2: Unpack the PTX3000 | 7

Step 3: Install the PTX3000 Mounting Hardware | 7

Install Cage Nuts, If Needed | 7

Install the Mounting Shelf | 8

Step 4: Install the PTX3000 | 9

Step 5: Connect the PTX3000 Grounding Cable | 15

Step 6: Connect External Devices and PIC Cables to the PTX3000 | 17

Connect the PTX3000 to a Console or Auxiliary Device | 17

Connect the PTX3000 to a Network for Out-of-Band Management | 18

Connect PIC Cables to the PTX3000 | 20

Page 2

Step 7: Connect the PTX3000 to Power | 23

Connect AC Power to the PTX3000 AC Power Supply Modules | 24

Connect Nonredundant AC Power to the PTX3000 AC Power Supply Modules | 24

Connect Redundant AC Power to the PTX3000 AC Power Supply Modules | 24

Connect DC Power to the PTX3000 DC Power Supply Modules | 27

Connect Nonredundant DC Power to the PTX3000 DC Power Supply Modules | 27

Connect Redundant DC Power to the PTX3000 DC Power Supply Modules | 27

Step 8: Power On the PTX3000 | 32

Power On the AC-Powered PTX3000 | 32

Power On the DC-Powered PTX3000 | 34

Step 9: Install the Front Doors on the PTX3000 | 36

Step 10: Perform the PTX3000 Initial Software Configuration | 37

Enter Configuration Mode | 38

Configure User Accounts and Passwords | 38

2

Configure System Attributes | 39

Commit the Configuration | 40

Safety Warnings | 42

PTX3000 Compliance Statements for NEBS | 44

Compliance Statements for EMC Requirements | 44

Canada | 44

European Community | 44

Israel | 45

Japan | 45

United States | 45

Junos OS Documentation and Release Notes | 46

Requesting Technical Support | 46

Self-Help Online Tools and Resources | 46

Creating a Service Request with JTAC | 47

Revision History | 48

Page 3

Quick Start Description

This Quick Start contains information you need to install and configure the PTX3000. For complete

installation instructions, see the PTX3000 Packet Transport Router Hardware Guide at

https://www.juniper.net/documentation/.

WARNING: This Quick Start contains a summary of safety warnings in “Safety Warnings”

on page 42. For a complete list of warnings for the PTX3000, including translations, see

the PTX3000 Packet Transport Router Hardware Guide at

https://www.juniper.net/documentation/.

The PTX3000 is shipped in a wooden crate. A wooden pallet forms the base of the crate. The chassis is

bolted to this pallet. The shipping crate also contains an accessory box and this Quick Start

3

Step 1: Prepare the Site for the PTX3000

IN THIS SECTION

Rack-Mounting Requirements | 3

Tools Required to Unpack and Install the PTX3000 | 6

Before installing the PTX3000, make sure that the site meets all the power, environmental, and clearance

requirements. See the site preparation guidelines in the PTX3000 Packet Transport Router Hardware Guide.

Rack-Mounting Requirements

You can install the PTX3000 in many types of racks, including a four-post rack or cabinet or an open-frame

rack:

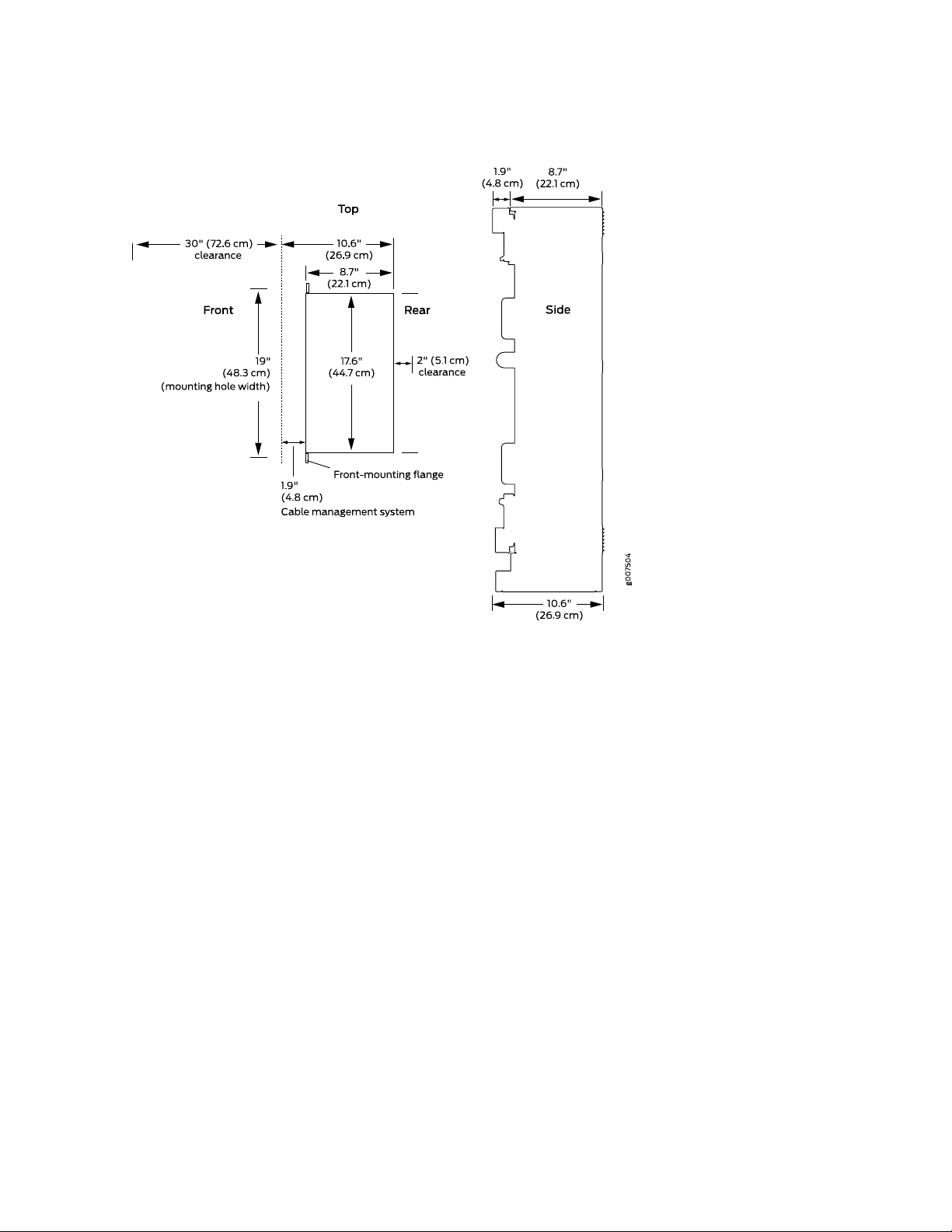

The rack rails must be spaced widely enough to accommodate the chassis's external dimensions: 38.5 in.

•

(97.8 cm) high, 8.7 in. (22.1 cm) deep, and 17.6 in. (44.7 cm) wide. The cable management system on the

Page 4

front of the chassis adds 1.9 in. (4.8 cm) to the depth, for a total depth of 10.6 in. (26.9 cm). The outer

edges of the mounting brackets extend the width to 19 in. (48.3 cm).

The rack must be strong enough to support the weight of the fully configured PTX3000, up to about

•

310 lb (140.6 kg).

You must allow sufficient clearance around the rack:

For the cooling system to function properly, the airflow around the chassis must be unrestricted.

•

For service personnel to remove and install hardware components, there must be adequate space at the

•

front of the chassis. At least 24 in. (61.0 cm) is required in front of the PTX3000. NEBS GR-63 recommends

that you allow at least 30 in. (72.6 cm) in front of the rack.

Additional clearance is required to accommodate the depth of the cable management system:

•

1.9 in. (4.8 cm) additional depth in the front of the chassis.

The compact form-factor of the chassis allows up to four PTX3000 routers to be installed in a single

•

four-post rack. For all configurations, there must be at least 10 in. (25.4 cm) between the PTX3000 and

neighboring devices to the side, and there must be no obstruction above the chassis that prevents airflow.

Depending on your installation, the required clearance at the rear of the chassis varies:

4

A standalone PTX3000 requires 2 in. (5.1 cm) of clearance at the rear (see Figure 1 on page 5).

•

Two PTX3000 routers installed back-to-back require 4 in. (10.2 cm) of clearance between the routers

•

at the rear.

Four PTX3000 routers installed back-to-back and stacked in a single rack require 10 in. (25.4 cm) of

•

clearance between the routers at the rear (see Figure 2 on page 6).

NOTE: These requirements have been designed to provide adequate cooling in deployments

with ambient temperatures up to 104°F (40°C).

Page 5

Figure 1: Chassis Dimensions and Clearance Requirements

5

Page 6

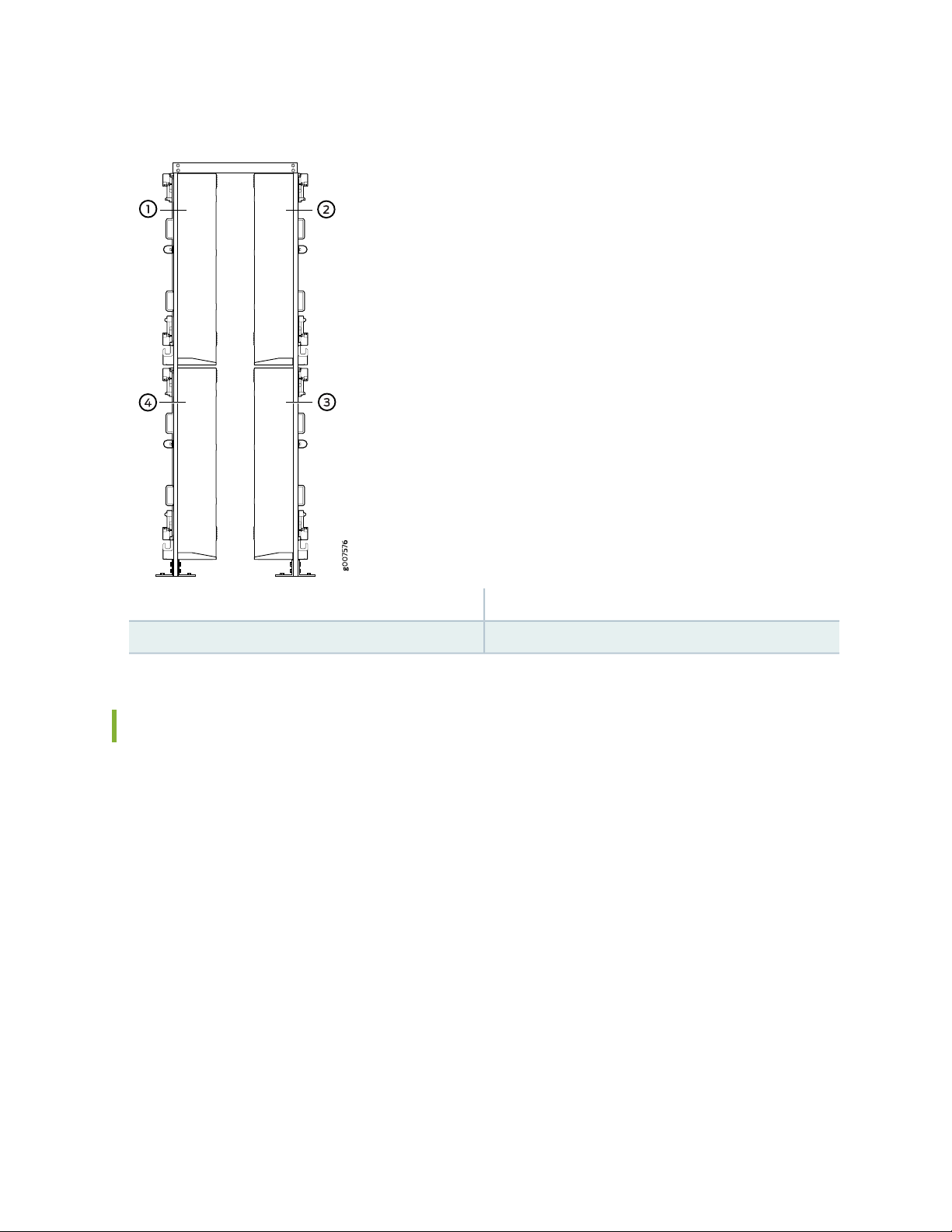

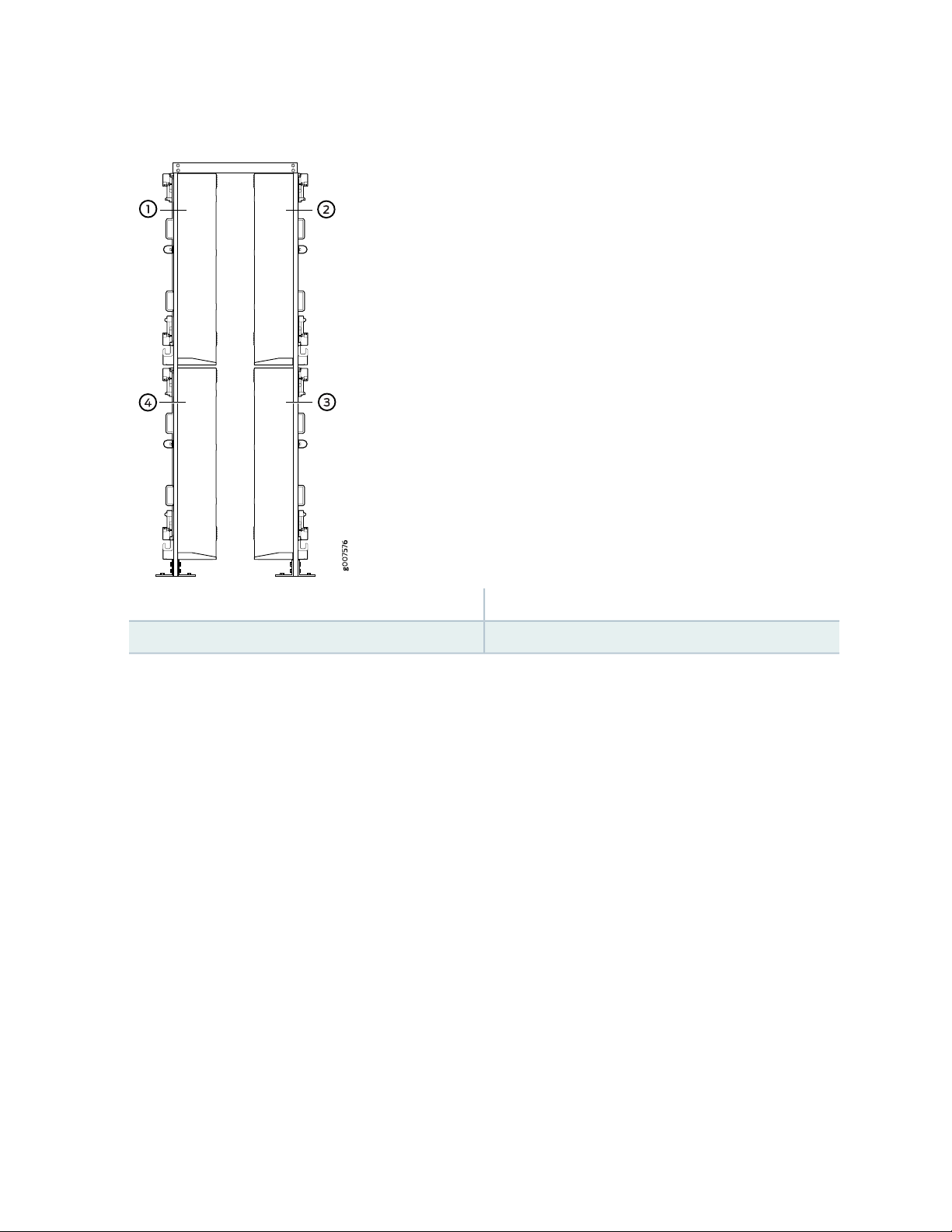

Figure 2: Four Routers Installed Back-to-Back

6

3—1— Lower chassis 1Upper chassis 1

4—2— Lower chassis 2Upper chassis 2

Tools Required to Unpack and Install the PTX3000

Gather the tools required to unpack the PTX3000:

Phillips (+) screwdriver, number 2

•

1/2-in. or 13-mm open-end or socket wrench to remove bracket bolts from the shipping pallet

•

Gather the tools and parts required to install the PTX3000 in a rack:

Mechanical lift

•

Screwdriver appropriate for your mounting screws (a number 1 Phillips (+) screwdriver is required for

•

the mounting screws included in the accessory box

Mounting screws appropriate for your rack (ten mounting screws are included in the accessory box)

•

Cage nuts (if required for your rack or cabinet)

•

Page 7

Step 2: Unpack the PTX3000

For detailed instructions on how to unpack the shipping crate and verifying the parts received, see the

PTX3000 Packet Transport Router Hardware Guide.

Step 3: Install the PTX3000 Mounting Hardware

To install the mounting hardware, perform the following procedures:

1.

Install Cage Nuts, If Needed | 7

2.

Install the Mounting Shelf | 8

7

Install Cage Nuts, If Needed

Insert cage nuts on the front rack rails, if needed. The hole distances are relative to the standard U division

on the rack that is aligned with the bottom of the mounting shelf.

To install cage nuts on the front rack rails:

1. Insert cage nuts in the holes specified for the mounting shelf (see Table 1 on page 7).

NOTE: A mounting shelf is not required to install the PTX3000.

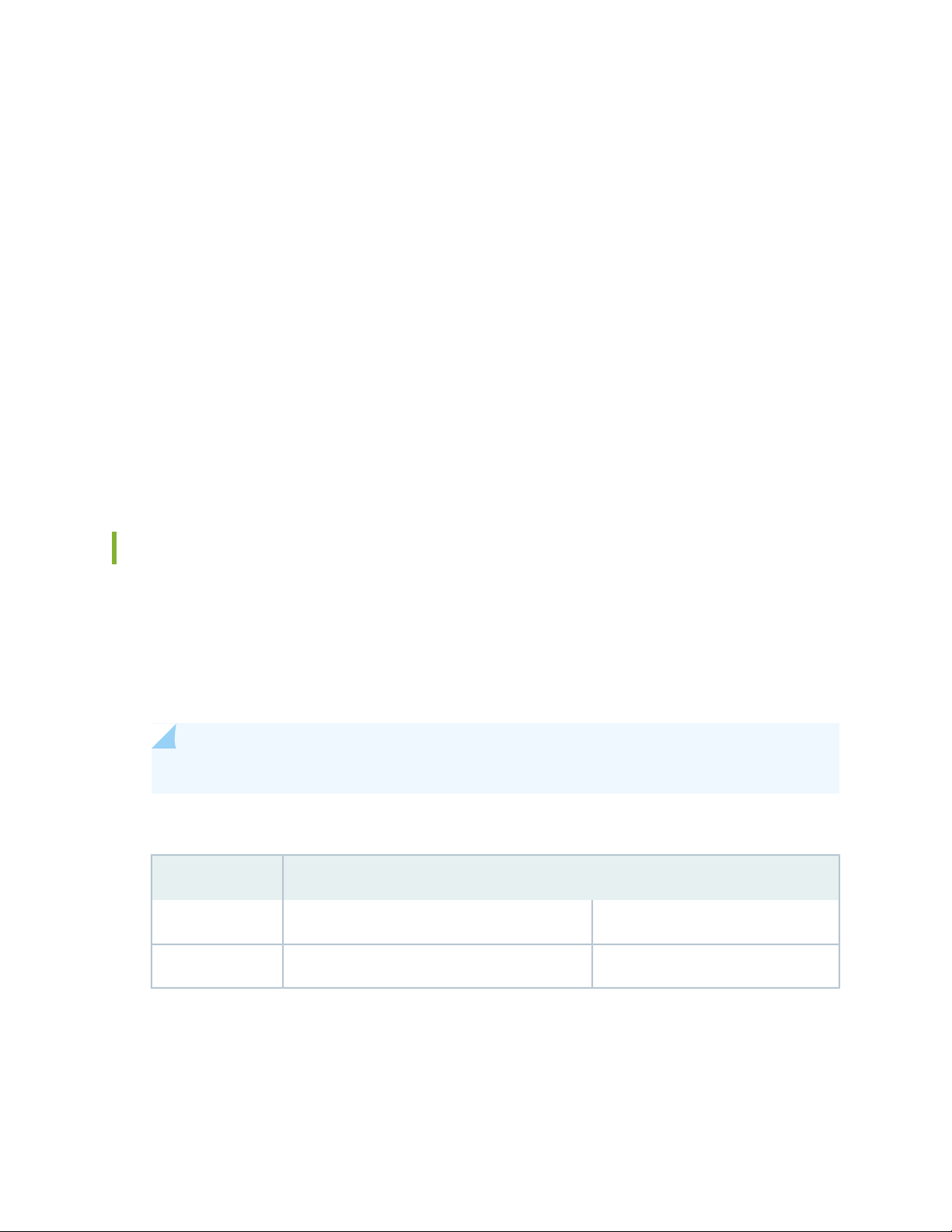

Table 1: Mounting-Hole Locations for Installing a PTX3000 Mounting Shelf

Distance Above U DivisionHole

0.01 U0.02 in. (.06 cm)1

0.08 U0.2 in. (0.4 cm)2

2. Insert cage nuts in the holes specified for mounting the chassis (see Table 2 on page 8).

Page 8

Table 2: Mounting-Hole Locations for Installing a Chassis

Distance Above U DivisionHole

2.8 U4.9 in. (12.5 cm)1

8.8 U15.4 in. (39.1 cm)2

17.1 U29.9 in. (76.0 cm)3

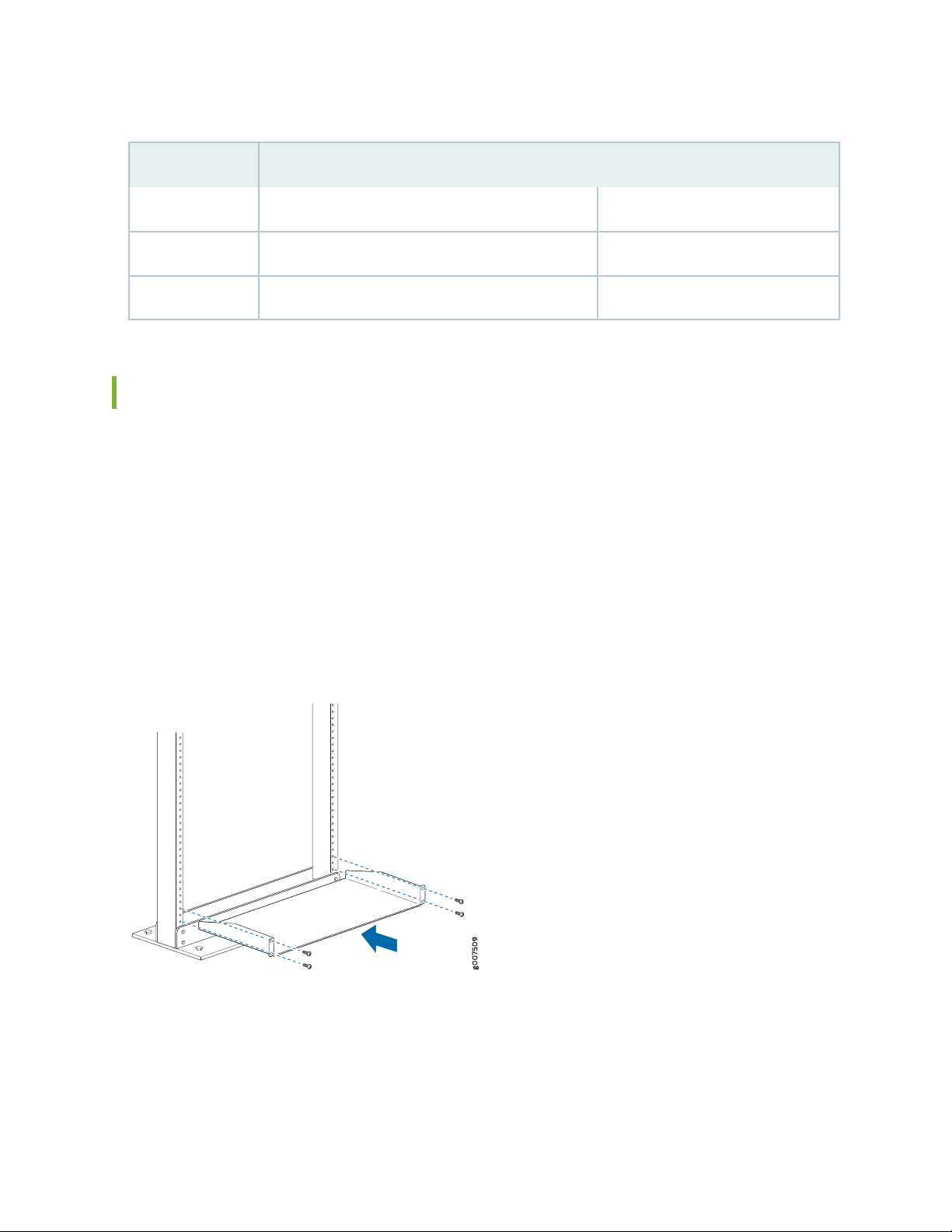

Install the Mounting Shelf

Optionally, you can install the mounting shelf before mounting the chassis in the rack. To install the

mounting shelf (see Figure 3 on page 8):

1. Align the mounting shelf with the mounting holes on the rack rail.

8

2. Partially insert a mounting screw appropriate for your rack into the holes specified in Table 1 on page 7.

3. Tighten all the screws completely to secure the mounting shelf to the rack rails.

Figure 3: Installing the Mounting Hardware

Page 9

Step 4: Install the PTX3000

CAUTION: Before installing the PTX3000 router:

Verify that a mechanical lift is available for the installation.

•

Have a qualified technician verify that the rack is strong enough to support the chassis

•

weight and is adequately supported at the installation site.

Ensure that the rack is in its permanent location and is secured to the building.

•

Ensure that the installation site allows adequate clearance for both airflow and

•

maintenance.

NOTE: A mounting shelf is not required to install the PTX3000.

9

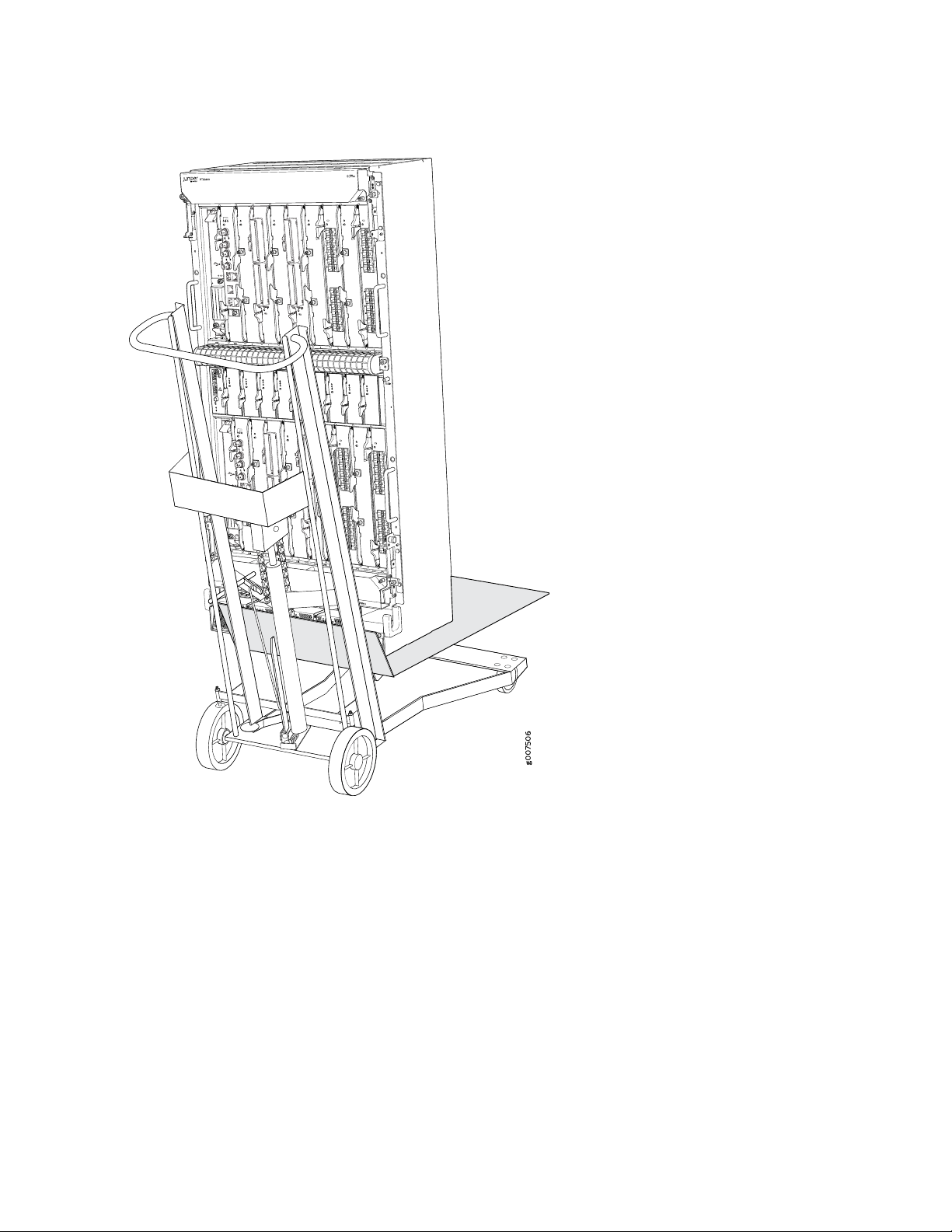

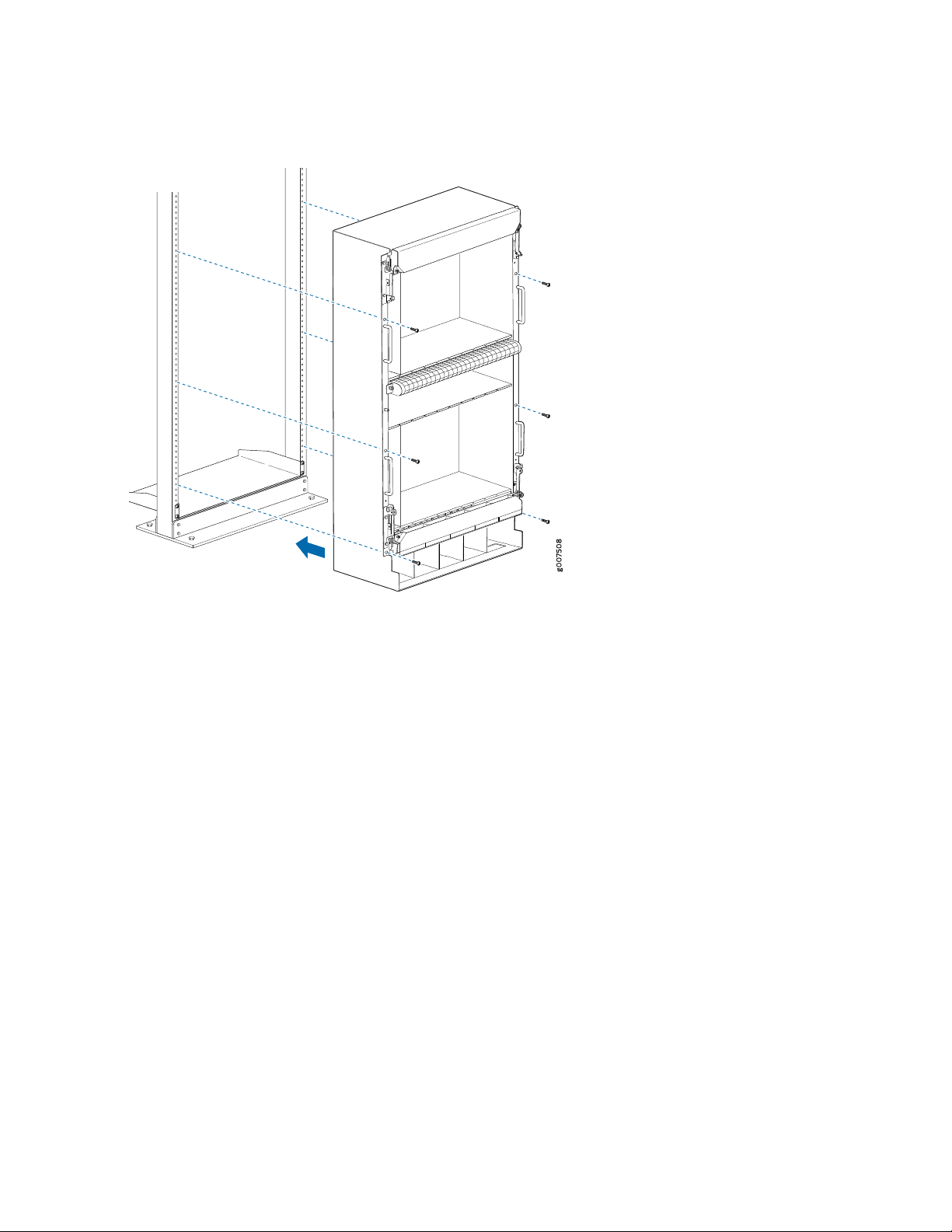

To install the PTX3000 by using a lift (see Figure 4 on page 11 and Figure 5 on page 12):

1. Load the PTX3000 onto the lift, making sure the PTX3000 rests securely on the mechanical lift.

CAUTION: Do not lift the PTX3000 by using the handles on the front-mounting

flanges. Use these handles only to help position the PTX3000.

2. Using the lift, position the PTX3000 in front of the rack. Lift the chassis slightly above the position you

plan to install it, and position it as close as possible to the rack.

3. With two people in front, push the front-mounting flanges to slide the PTX3000 into the rack until the

front-mounting flanges contact the rack rails. The front-mounting flanges of the chassis align with the

holes in the rack rails.

4. Install a mounting screw into each of the mounting holes aligned with the rack, starting from the bottom

(see Table 3 on page 10). Use an appropriate screwdriver to tighten all the screws completely.

Visually inspect the alignment of the PTX3000. If the PTX3000 is installed properly in the rack, all the

mounting screws on one side of the rack should be aligned with the mounting screws on the opposite

side, and the PTX3000 should be level.

Page 10

5. Move the lift away from the rack.

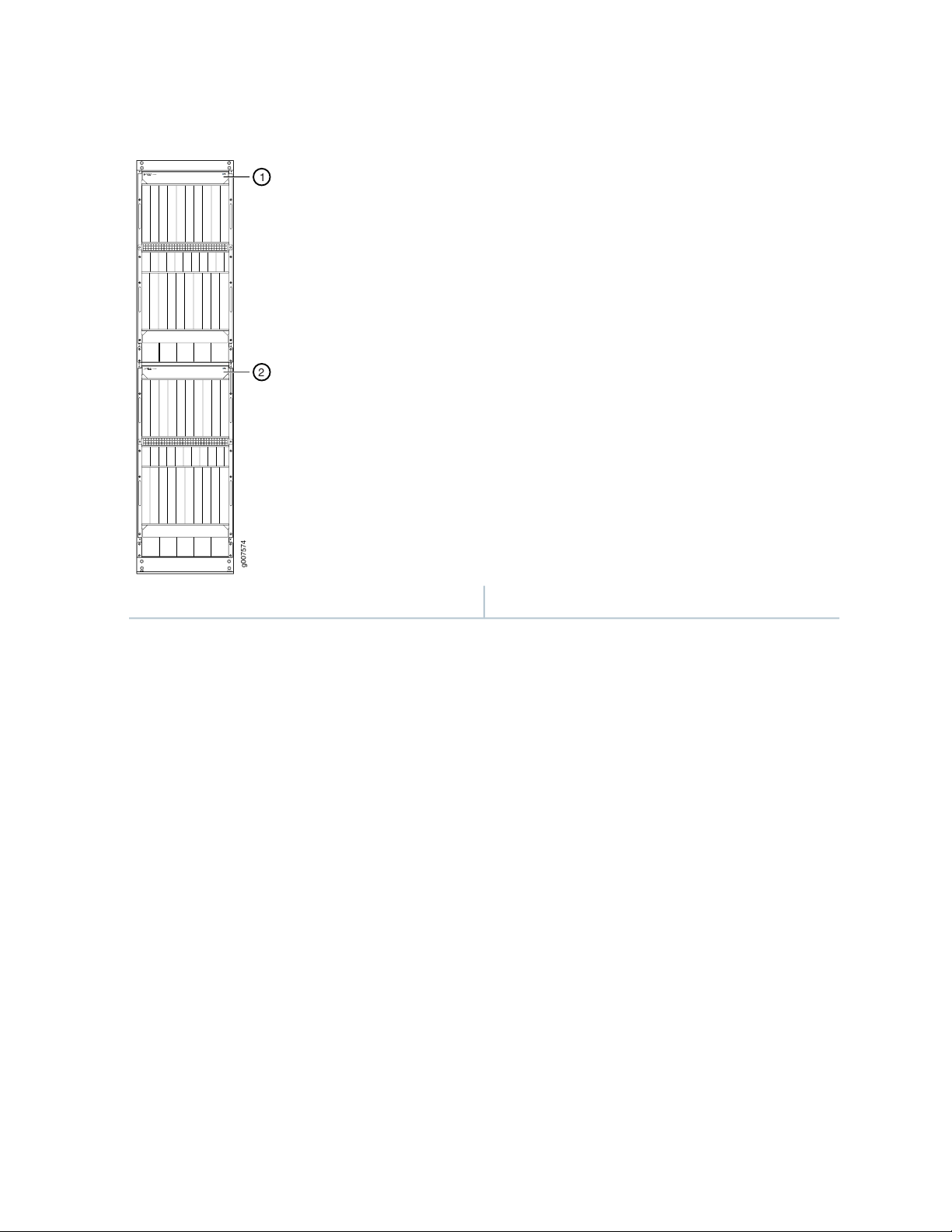

6. If you are installing two to four routers in the rack, repeat this procedure for each router. See

Figure 6 on page 13 and Figure 7 on page 14 for examples of multiple routers installed in a single rack.

Table 3: Mounting-Hole Locations for Installing a Chassis in a Rack

Distance Above U DivisionHole

2.8 U4.9 in. (12.5 cm)1

8.8 U15.4 in. (39.1 cm)2

17.1 U29.9 in. (76.0 cm)3

10

Page 11

Figure 4: Loading the PTX3000 onto the Lift

11

Page 12

Figure 5: Installing the PTX3000 in a Rack

12

Page 13

Figure 6: Installing Two Routers in a Rack (Front View)

PTX3000

PTX3000

g007574

1

2

13

2—1— Lower chassisUpper chassis

Page 14

Figure 7: Installing Four Routers in a Rack (Side View)

14

3—1— Lower chassis 1Upper chassis 1

4—2— Lower chassis 2Upper chassis 2

Page 15

Step 5: Connect the PTX3000 Grounding Cable

You ground the PTX3000 by attaching a grounding cable to the chassis. You must provide the grounding

cable. A 4-AWG cable lug is supplied with the PTX3000 for grounding the router. See PTX3000 Chassis

Grounding Cable and Lug Specifications in the PTX3000 Packet Transport Router Hardware Guide for more

information.

To ground the PTX3000:

1. Gather the tools and parts required to ground the router:

Electrostatic discharge (ESD) grounding wrist strap

•

Grounding cable (which you must provide)

•

Grounding lug (one 4-AWG lug for grounding the router is provided with the PTX3000)

•

Two acorn nuts with washers (three acorn nuts are provided with the PTX3000)

•

15

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to an approved site ESD

grounding point. See the instructions for your site.

3. Connect the grounding cable to a proper earth ground.

4. Verify that a licensed electrician has attached the cable lug provided with the PTX3000 to the grounding

cable.

5. Ensure that grounding surfaces are clean and brought to a bright finish before you connect the grounding

cable.

6. Place the grounding cable lug over the grounding points (Figure 8 on page 16).

7. Secure the grounding cable lug to the grounding points, first with the washers, then with the acorn

nuts.

8. Verify that the grounding cabling is correct, that the grounding cable does not touch or block access

to the PTX3000 components, and that it does not drape where people could trip on it.

Page 16

Figure 8: Connecting the Grounding Cable

g0 0 750 7

16

Page 17

Step 6: Connect External Devices and PIC Cables to the PTX3000

IN THIS SECTION

Connect the PTX3000 to a Console or Auxiliary Device | 17

Connect the PTX3000 to a Network for Out-of-Band Management | 18

Connect PIC Cables to the PTX3000 | 20

To connect external devices and PIC cables, perform the following procedures:

17

Connect the PTX3000 to a Console or Auxiliary Device

Attach one or more management console or auxiliary devices to the Routing Engine ports on each Control

Board or Routing and Control Board (RCB) for management and service operations (see Figure 9 on page 18).

To connect the cables to a management console or auxiliary device:

1. To connect the PTX3000 to external devices, you need an electrostatic discharge (ESD) grounding

wrist strap (provided in the accessory box).

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to the ESD point on the chassis.

CAUTION: During the initial installation before the chassis is grounded, you must

connect the wrist strap to an approved site ESD point. See the instructions for your

site.

3. If necessary, turn off power to the console or auxiliary device.

4. Plug one end of a copper cable with RJ-45 connectors into the CON or AUX port on the Control Board

or RCB in slot CB0 (Figure 9 on page 18).

5. Attach the other end of the cable to the console or auxiliary device.

Page 18

6. Plug one end of another copper cable with RJ-45 connectors into the CON or AUX port on the Control

g0 0 7560

Board or RCB in slot CB1.

7. Attach the other end of the cable to the console or auxiliary device.

Figure 9: Connecting to the Console or Auxiliary Port on the Control Board or RCB

18

Connect the PTX3000 to a Network for Out-of-Band Management

To connect the management Ethernet ports on each Control Board or Routing and Control Board (RCB)

to a network for management of the PTX3000, connect a UTP Category 5 Ethernet cable with an RJ-45

connector to the HOST/ETHERNET port on a Control Board, or the MGT port on an RCB.

NOTE: For PTX3000 routers with two host subsystems, we recommend that you connect both

host subsystems to a network. One cable is provided in the accessory box. To connect another

cable to the management Ethernet ports on the second Control Board or RCB, you must provide

an additional cable.

To connect a cable to a network device:

1. To connect the PTX3000 to external devices, you need an electrostatic discharge (ESD) grounding

wrist strap (provided in the accessory box).

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to the ESD point on the chassis.

Page 19

CAUTION: During the initial installation before the chassis is grounded, you must

connect the wrist strap to an approved site ESD point. See the instructions for your

site.

3. Plug one end of a UTP Category 5 Ethernet cable (Figure 10 on page 19 shows the connector) into the

management Ethernet port on the Control Board or RCB in slot CB0 (see Figure 11 on page 19).

NOTE: The management Ethernet port is labeled HOST/ETHERNET on a Control Board. The

port is labeled MGT on an RCB.

4. Plug the other end of the cable into the network device.

19

5. Plug one end of another UTP Category 5 Ethernet cable into the management Ethernet port on the

Control Board or RCB in slot CB1.

6. Plug the other end of the cable into the network device.

Figure 10: Routing Engine Ethernet Cable Connector

Figure 11: Connecting to the Management Ethernet Port on the Control Board or RCB

Page 20

Connect PIC Cables to the PTX3000

The PTX3000 supports PICs and IPLCs that use various kinds of network cable, including multimode and

single-mode fiber-optic cable. For information about the type of cable used by each PIC, see the PTX Series

Interface Module Reference.

You connect the IPLCs to compatible PICs/MICs (see PTX Series IPLC Compatibility), or to other IPLCs, or

to the optical inline amplifier (ILA).

You connect PICs to the network by plugging in network cable. To connect cable to compatible PICs or

IPLCs (see Figure 12 on page 21):

1. To connect the PTX3000 to external devices, you need the following:

The required length of the type of cable used by the PIC. See the PTX Series Interface Module Reference.

•

Number 1 Phillips (+) screwdriver to loosen the captive screws on the cable management system.

•

Electrostatic discharge (ESD) grounding wrist strap (provided in the accessory box).

•

20

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to the ESD point on the chassis.

CAUTION: During the initial installation before the chassis is grounded, you must

connect the wrist strap to an approved site ESD point. See the instructions for your

site.

3. If the PIC cable connector port is covered by a rubber safety plug, remove the plug. The IPLC ports

have an attached cover for the connector.

WARNING: Do not look directly into a fiber-optic transceiver or into the ends of

fiber-optic cable. Fiber-optic transceivers and fiber-optic cable connected to a

transceiver emit laser light that can damage your eyes.

CAUTION: Do not leave a fiber-optic transceiver uncovered except when inserting

or removing cable. The safety cap keeps the port clean and prevents accidental

exposure to laser light.

4. Insert the cable connector into the cable connector port on the PIC or IPLC faceplate. See

Figure 12 on page 21 and Figure 13 on page 22.

Page 21

5. Using a number 1 Phillips (+) screwdriver, loosen the two inner captive screws on the upper or lower

cable management system. Move the cover of the upper cable management system up

(Figure 14 on page 22). Move the cover of the lower cable management system down

(Figure 15 on page 22).

6. Arrange the cable in the cable management system to prevent it from dislodging or developing stress

points (Figure 16 on page 23). Secure the cable so that it is not supporting its own weight as it hangs

to the floor.

CAUTION: Avoid bending fiber-optic cable beyond its minimum bend radius. An arc

smaller than a few inches in diameter can damage the cable and cause problems that

are difficult to diagnose.

CAUTION: Do not let fiber-optic cable hang free from the connector. Do not allow

fastened loops of cable to dangle, which stresses the cable at the fastening point.

21

7. Move the cover of the upper cable management system down, and secure the two inner captive screws

on the upper cable management system by using a number 1 Phillips (+) screwdriver. Move the cover

of the lower cable management system up, and secure the two inner captive screws on the lower cable

management system by using the screwdriver.

Figure 12: Connecting PIC Cables

Page 22

Figure 13: Connecting IPLC Cables with LC Connectors

Figure 14: Upper Cable Management System

22

Figure 15: Lower Cable Management System

Page 23

Figure 16: Routing the PIC Cables in the Cable Management System

23

NOTE: The IPLC cables are arranged similar to the PIC cables shown in Figure 16 on page 23.

Step 7: Connect the PTX3000 to Power

IN THIS SECTION

Connect AC Power to the PTX3000 AC Power Supply Modules | 24

Connect DC Power to the PTX3000 DC Power Supply Modules | 27

Page 24

Connect AC Power to the PTX3000 AC Power Supply Modules

IN THIS SECTION

Connect Nonredundant AC Power to the PTX3000 AC Power Supply Modules | 24

Connect Redundant AC Power to the PTX3000 AC Power Supply Modules | 24

Connect Nonredundant AC Power to the PTX3000 AC Power Supply Modules

To connect nonredundant power, see Connecting Nonredundant AC Power to the PTX3000 AC Power Supply

Modules in the PTX3000 Packet Transport Router Hardware Guide.

Connect Redundant AC Power to the PTX3000 AC Power Supply Modules

24

To connect the AC power cables to both AC PSM inputs for redundant power:

1. Gather the following tools and parts:

Electrostatic discharge (ESD) grounding wrist strap.

•

AC power cords, which must have a plug appropriate for your geographical location. See PTX3000

•

AC Power Cord Specifications in the PTX Series Interface Module Reference for more information.

Phillips (+) screwdriver, number 2.

•

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to one of the ESD points on

the chassis.

3. Switch the power switch on the PSM faceplate to the standby position ( ).

4. Loosen the captive screw on the PSM, using the screwdriver if necessary.

5. Grasp the PSM, and pull it out to remove it from the chassis.

Page 25

Figure 17: Removing an AC PSM

g0 0 7541

6. Set the input switches for redundant power by setting both switches for input 1 and 2 to the on position

(ON).

25

Figure 18: Setting the Input Switches for Redundant Power

2—1— Input 2 switch ONInput 1 switch ON

7. Insert the AC power cord couplers into input 1 and input 2 on the PSM (see Figure 19 on page 26).

CAUTION: One input on each AC PSM must be powered by a dedicated power feed

derived from feed A, and the other input on each PSM must be powered by dedicated

power feed derived from feed B.

This configuration provides the commonly deployed A/B feed redundancy for the

system. For example, you can connect input 1 on each AC PSM to feed A, and input

2 on each AC PSM to feed B.

Page 26

Figure 19: Connecting the AC Power Cords to a PSM

g0 0 7542

8. Insert the power cord plug into an external AC power receptacle.

26

9. Reinstall the PSM into the chassis (see Figure 20 on page 26), and tighten the captive screw to secure

it.

Figure 20: Installing an AC PSM

10. Repeat the procedure for the remaining PSMs.

11. Verify that the AC power cords do not drape where people could trip on them.

Page 27

Connect DC Power to the PTX3000 DC Power Supply Modules

IN THIS SECTION

Connect Nonredundant DC Power to the PTX3000 DC Power Supply Modules | 27

Connect Redundant DC Power to the PTX3000 DC Power Supply Modules | 27

Connect Nonredundant DC Power to the PTX3000 DC Power Supply Modules

To connect nonredundant power, see Connecting Nonredundant DC Power to the PTX3000 DC Power Supply

Modules in the PTX3000 Packet Transport Router Hardware Guide.

Connect Redundant DC Power to the PTX3000 DC Power Supply Modules

27

WARNING: You must ground the router before connecting the router to power.

To connect the DC source power cables to both DC PSM inputs for redundant power:

1. Gather the following tools and parts:

Electrostatic discharge (ESD) grounding strap

•

10-mm nut driver, for tightening nuts to the terminal studs

•

CAUTION: You must use an appropriate torque-controlled tool to tighten the nuts.

Applying excessive torque damages the terminal studs. The maximum torque that

may be applied to this nut is 24 lb-in. (2.7 Nm).

Phillips (+) screwdriver, number 1

•

DC power cables, which you must provide

•

DC power lugs

•

2. Ensure that the voltage across the DC power source cable leads is 0 V and that there is no chance that

the cable leads might become active during installation.

3. Attach an ESD grounding strap to your bare wrist, and connect the strap to the ESD point on the chassis.

Page 28

4. Switch the power switch on the power supply module (PSM) faceplate to the standby position ( ).

5. Loosen the captive screw on the PSM.

6. Grasp the PSM, and pull it out to remove it from the chassis (see Figure 21 on page 28). The DC PSM

weighs 4.6 lb (2.1 kg).

Figure 21: Removing a DC PSM

28

7. Set the switches for input 1 and input 2 to the on position (ON) for redundant power. See

Figure 22 on page 28.

Figure 22: Setting the Input Switches for Redundant Power

2—1— Input 2 switch ONInput 1 switch ON

8. Use a number 1 Phillips (+) screwdriver to loosen the screws on the input terminal cover, and remove

the input terminal cover.

9. Remove the nuts from the DC power terminal studs.

Page 29

10. Connect the positive (+) DC source power cables to input 1 and input 2 RTN (return) input terminals

(Figure 23 on page 30 and Figure 24 on page 30).

CAUTION: One input on each DC PSM must be powered by dedicated power feeds

derived from feed A, and the other input on each PSM must be powered by dedicated

power feeds derived from feed B.

This configuration provides the commonly deployed A/B feed redundancy for the

system. For example, you can connect input 1 on each DC PSM to feed A, and input

2 on each DC PSM to feed B.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the external

DC power source at your site determines the color coding for the leads on the power

cables that attach to the terminal studs on each power supply.

29

Secure the positive (+) DC source power cable lugs to the RTN (return) terminals with a nut for each

terminal. Use a 10-mm nut driver to tighten the nuts.

CAUTION: You must use an appropriate torque-controlled tool to tighten the nuts.

Applying excessive torque damages the terminal studs and power supply. The maximum

torque that may be applied to this nut is 24.0 lb-in. (2.7 Nm).

Page 30

Figure 23: DC PSM Inputs

30

Figure 24: Connecting the Positive DC Source Power Cable Lugs to a PSM

11. Connect the negative (–) DC source power cables to input 1 and input 2 –48V input terminals

(Figure 23 on page 30 and Figure 25 on page 31).

Secure the negative (–) DC source power cable lugs to the –48V input terminals. Use a 10-mm nut

driver to tighten the nuts.

Page 31

Figure 25: Connecting the Negative DC Source Power Cable Lugs to a PSM

31

12. Verify that the source power cables are connected to the appropriate terminal: the positive (+) source

cable to the return terminal (labeled RTN) and the negative (–) source cable to the input terminal (labeled

–48V).

13. Replace the input terminal cover over the DC power cables, and tighten the screws.

14. Verify that both input 1 and input 2 LEDs on the PSM faceplate are lit steadily green, indicating that

the inputs are receiving power.

15. Reinstall the PSM into the chassis (see Figure 26 on page 32), and tighten the captive screw to secure

it.

Page 32

Figure 26: Installing a DC PSM

16. Repeat the procedure for the remaining PSMs.

17. Verify that the DC power cables do not touch or block access to the components, and that they do not

drape where people could trip on them.

32

Step 8: Power On the PTX3000

IN THIS SECTION

Power On the AC-Powered PTX3000 | 32

Power On the DC-Powered PTX3000 | 34

To power on the PTX3000, perform one of the following procedures:

Power On the AC-Powered PTX3000

To power on an AC-powered router:

1. Verify that each power supply module (PSM) is fully inserted in the chassis and that the captive screws

on the PSM faceplates are tightened.

2. Verify that the AC power cords are connected correctly.

Page 33

3. Verify that an external management device is connected to one of the Routing Engine ports on the

Control Board or the Routing and Control Board (RCB). The auxiliary ports are labeled AUX and the

management console ports are labeled CON.

NOTE: The management Ethernet port labeled HOST/ETHERNET on the Control Board and

MGT on the RCB are not available until after the initial software configuration. You can monitor

the startup process during the initial installation by using devices connected to the AUX or CON

ports.

4. Turn on power to the external management device.

5. Switch on the dedicated customer-site circuit breakers to provide power to the AC power cables. Follow

your site’s procedures.

6. Verify that the input 1 and input 2 LEDs on the AC PSM faceplates are lit steadily green for each

connected input, indicating that the power supplies are receiving power.

33

7. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect the strap to

one of the ESD points on the chassis.

8. Switch the power switch on one of the AC PSMs to the on position (|). The OK LED blinks momentarily,

and then is lit steadily.

NOTE: The Routing Engine or the RCB—depending on your configuration—boots as the PSM

completes its startup sequence. If the Routing Engine or RCB finishes booting and you need to

power off the system, see Powering Off the PTX3000 in the PTX3000 Packet Transport Router

Hardware Guide.

After powering on a power supply, you must wait at least 60 seconds before powering it off.

9. Verify that the OK LED on the AC PSM faceplate is lit steadily, indicating that power supply is correctly

installed, functioning properly, and providing power to the outputs.

10. On the external management device connected to the PTX3000, monitor the startup process to verify

that the system has booted properly.

11. Repeat Step 8 and Step 9 for the other PSMs.

Page 34

Power On the DC-Powered PTX3000

To power on a DC-powered PTX3000:

NOTE: After powering off a power supply, you must wait at least 60 seconds before powering it

on again.

1. Verify that the power supply modules (PSMs) are fully inserted in the chassis and that the captive screw

on the faceplate of each PSM is tightened.

2. Verify that the DC power cables are connected correctly.

3. Verify that an external management device is connected to one of the Routing Engine ports on the

Control Board or the Routing and Control Board (RCB). The auxiliary ports are labeled AUX and the

management console ports are labeled CON.

34

NOTE: The management Ethernet port labeled HOST/ETHERNET on the Control Board and

MGT on the RCB are not available until after the initial software configuration. You can monitor

the startup process during the initial installation by using devices connected to the AUX or CON

ports.

4. Turn on the power to the external management device.

5. Switch on the customer-site circuit breakers to provide voltage to the DC power source cables. Follow

your site’s procedures.

6. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect the strap to

the ESD point on the chassis.

7. Verify that the input 1 and input 2 LEDs on the PSM faceplate are lit steadily green, indicating that the

inputs are receiving input voltage.

8. Switch the power switch on one PSM to the on position (|).

Page 35

NOTE: After a PSM is powered on, it can take up to 60 seconds for status indicators—such as

the LEDs on the PSMs and the command output displays—to indicate that the PSMs are

functioning normally. Ignore error indicators that appear during the first 60 seconds.

NOTE: The Routing Engine or the RCB—depending on your configuration—boots as the PSM

completes its startup sequence. If the Routing Engine or RCB finishes booting and you need to

power off the system, see Powering Off the PTX3000 in the PTX3000 Packet Transport Router

Hardware Guide.

After powering on a power supply, you must wait at least 60 seconds before powering it off.

9. Verify that the OK LED on the PSM faceplate is lit steadily and that the LED is off, indicating that

the PSM is correctly installed and is functioning properly.

35

NOTE: If the OK LED is not light steadily, remove the PSM, repeat the cabling procedure, and

reinstall the PSM into the PTX3000.

10. On the external management device connected to the PTX3000, monitor the startup process to verify

that the system has booted properly.

11. Repeat Step 8 and Step 9 for the other PSMs.

Page 36

Step 9: Install the Front Doors on the PTX3000

Front doors are installed over the card cage that contains the components in the chassis. Each PTX3000

is shipped with two front doors, one door for each card cage. Captive thumbscrews secure the door to

the chassis.

To install an upper or lower card front door on a PTX3000 (see Figure 27 on page 37):

1. Gather the following tools:

Electrostatic discharge (ESD) grounding strap

•

Phillips (+) screwdriver, number 2

•

2. Attach an ESD grounding strap to your bare wrist, and connect the strap to the ESD point on the chassis.

CAUTION: During the initial installation before the chassis is grounded, you must

connect the wrist strap to an approved site ESD point. See the instructions for your

site.

36

3. Place the door over the appropriate card cage in the chassis.

4. Using your fingers, loosely tighten the thumbscrews on each side of the door.

5. Tighten the screws completely by using a number 2 Phillips (+) screwdriver to secure the door to the

chassis.

NOTE: If you must return the chassis to Juniper Networks for any reason, you must remove

the front doors from the chassis. See Packing the PTX3000 for Shipment in the PTX3000 Packet

Transport Router Hardware Guide.

Page 37

Figure 27: Installing the Front Doors on the PTX3000

37

Step 10: Perform the PTX3000 Initial Software Configuration

These procedures connect a PTX3000 to the network but do not enable it to forward traffic. For complete

information about enabling the PTX3000 to forward traffic, including examples, see the Junos OS

configuration guides.

You configure the PTX3000 by issuing Junos OS CLI commands, either on a console device attached to

the CON port, or over a Telnet connection to a network connected to the management Ethernet port.

NOTE: These procedures enable you to use the management Ethernet port. For the initial

configuration, use a device attached to the CON port.

1.

Enter Configuration Mode | 38

2.

Configure User Accounts and Passwords | 38

Page 38

3.

Configure System Attributes | 39

4.

Commit the Configuration | 40

Enter Configuration Mode

1. Verify that the network device is powered on.

2. Log in as the root user. There is no password.

Amnesiac <ttyd0>

login: root

3. Start the CLI.

38

root@% cli

root>

4. Enter configuration mode.

root> configure

Entering configuration mode.

[edit]

root#

Configure User Accounts and Passwords

For information about using an encrypted password or an SSH public key string (DSA or RSA), see Configuring

the Root Password and user.

1. Add a password to the root administration user account. Enter a cleartext password.

[edit]

root@host# set system root-authentication plain-text-password

New password: password

Retype new password: password

Page 39

2. Create a management console user account.

[edit]

root@host# set system login user user-name authentication plain-text-password

New Password: password

Retype new password: password

3. Set the user account class to super-user.

[edit]

root@host# set system login user user-name class super-user

Configure System Attributes

39

1. Configure the name of the PTX3000. If the name includes spaces, enclose the name in quotation marks

(“ ”).

[edit]

root@# set system host-name host-name

NOTE: The DNS server does not use the hostname to resolve to the correct IP address. This

hostname is used to display the name of the device in the CLI. For example, this hostname is

displayed on the command-line prompt when the user is logged in to the CLI:

user-name@host-name>

2. Configure the IP address of the DNS server.

[edit]

root# set system name-server address

3. Configure the domain name of the PTX3000.

[edit]

Page 40

root@# set system domain-name domain-name

4. Configure the IP address and prefix length for the PTX3000 router’s management Ethernet interface.

[edit]

root@# set interfaces em0 unit 0 family inet address address/prefix-length

5. Configure the IP address of a backup router. The backup router allows the PTX3000 to install a route

to the management network while the Routing Engine or RCB is booting and before the routing protocol

process (rpd) is up and running. The backup router must be directly connected—that is, on the same

subnet—through the management Ethernet interface.

[edit]

root@# set system backup-router address

40

6. (Optional) Configure the static routes to remote subnets with access to the management port. Access

to the management port is limited to the local subnet. To access the management port from a remote

subnet, you must add a static route to that subnet within the routing table.

[edit]

root@# set routing-options static route remote-subnet next-hop destination-IP retain no-readvertise

7. Configure the Telnet service at the [edit system services] hierarchy level.

[edit]

root@# set system services telnet

Commit the Configuration

1. Display the configuration to verify that it is correct.

[edit]

root@# show

system {

host-name host-name;

domain-name domain-name;

Page 41

backup-router address;

root-authentication {

authentication-method (password | public-key);

}

name-server {

address;

}

}

interfaces {

em0 {

unit 0 {

family inet {

address address/prefix-length;

}

}

}

}

41

2. Commit the configuration to activate it.

[edit]

root@# commit

3. Optionally, configure additional properties by adding the necessary configuration statements. Then

commit the changes to activate them.

[edit]

root@host# commit

4. When you have finished the configuration, exit configuration mode.

[edit]

root@host# exit

root@host>

Page 42

Safety Warnings

WARNING: See installation instructions before connecting the PTX3000. This is a

summary of safety warnings. For a complete list of warnings for the PTX3000, including

translations, see the PTX3000 Packet Transport Router Hardware Guide at

https://www.juniper.net/documentation/.

WARNING: The intrabuilding ports of the equipment or subassembly are suitable for

connection to intrabuilding or unexposed wiring or cabling only. The intrabuilding ports

of the equipment or subassembly MUST NOT be metallically connected to interfaces

that connect to the Outside Plant (OSP) or its wiring. These interfaces are designed for

use as intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089) and

require isolation from the exposed OSP cabling. The addition of Primary Protectors is

not sufficient protection in order to connect these interfaces metallically to OSP wiring.

42

WARNING: The network device has more than one power supply connection. All

connections must be removed completely to remove power from the unit completely.

Attention Cette unité est équipée de plusieurs raccordements d'alimentation. Pour

supprimer tout courant électrique de l'unité, tous les cordons d'alimentation doivent être

débranchés.

CAUTION: Before removing or installing components of a PTX3000, attach an ESD strap

to an ESD point, and place the other end of the strap around your bare wrist. Failure to

use an ESD strap could result in damage to the router.

CAUTION: Use an external surge protective device (SPD) at the AC input of the router.

Only trained and qualified personnel must install or replace the PTX3000.

•

Perform only the procedures described in this Quick Start or in the PTX3000 Packet Transport Router

•

Hardware Guide. Other services must be performed by authorized service personnel only.

Page 43

Read the installation instructions before you connect the PTX3000 to a power source.

•

Before installing the PTX3000, read the guidelines for site preparation in the PTX3000 Packet Transport

•

Router Hardware Guide to make sure that the site meets power, environmental, and clearance requirements

for the router.

For the cooling system to function properly, the airflow around the chassis must be unrestricted.

•

When installing the PTX3000, do not use a ramp inclined more than 10 degrees.

•

Manually installing the PTX3000 without a mechanical lift is not supported.

•

The PTX3000 must be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting the PTX3000 in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

•

PTX3000 in the rack.

When removing or installing an electrical component, always place it component-side up on a flat

•

antistatic surface or in an electrostatic bag.

43

When you install the PTX3000, always make the ground connection first and disconnect it last.

•

Wire the DC power distribution unit by using the appropriate lugs. When connecting power, the proper

•

wiring sequence is ground to ground, +RTN to +RTN, and then –48 V to –48 V. When disconnecting

power, the proper wiring sequence is –48 V to –48 V, +RTN to +RTN, and then ground to ground. Always

connect the ground wire first and disconnect it last.

Do not work on the system or connect or disconnect cables during electrical storms.

•

Before working on equipment that is connected to power lines, remove jewelry, including rings, necklaces,

•

and watches. Metal objects heat up when connected to power and ground and can cause serious burns

or become welded to the terminals.

Failure to observe these safety warnings can result in serious physical injury.

•

AC power cable warning (Japan):

•

WARNING: The attached power cable is only for this product. Do not use the cable

for another product.

Page 44

PTX3000 Compliance Statements for NEBS

The equipment is suitable for installation as part of the Common Bonding Network (CBN).

•

The equipment is suitable for installations in Network Telecommunication Facilities.

•

The equipment is suitable for installation in locations where the National Electrical Code (NEC) applies.

•

The battery return connection is to be treated as an isolated DC return (DC-I), as defined in

•

GR-1089-CORE.

For Juniper systems with AC power supplies, an external surge protective device (SPD) must be used at

•

the AC power source.

Compliance Statements for EMC Requirements

44

IN THIS SECTION

Canada | 44

European Community | 44

Israel | 45

Japan | 45

United States | 45

Canada

CAN ICES-3 (A)/NMB-3(A)

European Community

This is a Class A product. In a domestic environment, this product might cause radio interference in which

case the user might be required to take adequate measures.

Page 45

Israel

Translation from Hebrew—Warning: This product is Class A. In residential environments, the product might

cause radio interference, and in such a situation, the user might be required to take adequate measures.

Japan

45

The preceding translates as follows:

This is a Class A product based on the standard of the Voluntary Control Council for Interference by

Information Technology Equipment (VCCI). If this product is used near a radio or television receiver in a

domestic environment, it might cause radio interference. Install and use the equipment according to the

instruction manual. VCCI-A.

United States

The hardware equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, might cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Page 46

Junos OS Documentation and Release Notes

For a list of related Junos OS documentation, see https://www.juniper.net/documentation/software/junos/.

If the information in the latest release notes differs from the information in the documentation, follow the

Junos OS Release Notes.

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active J-Care or Partner Support Service support contract, or are covered

under warranty, and need postsales technical support, you can access our tools and resources online or

open a case with JTAC.

46

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC Hours of Operation —The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Page 47

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

47

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 48

Revision History

March 2017—Revised weight and clearance requirements and added RCB.

January 2014—Revised to include AC power connection.

November 2013—Initial revision.

48

Copyright © 2019 Juniper Networks, Inc. All rights reserved.

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc.

and/or its affiliates in the United States and other countries. All other trademarks may be property of their respective

owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

Loading...

Loading...