Page 1

PTX10003-80C and PTX10003-160C

Published

2019-10-03

Fixed Packet Transport Router Hardware

Guide

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

PTX10003-80C and PTX10003-160C Fixed Packet Transport Router Hardware Guide

Copyright © 2019 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

About the Documentation | xi

Documentation and Release Notes | xi

Using the Examples in This Manual | xi

Merging a Full Example | xii

Merging a Snippet | xiii

Documentation Conventions | xiii

Documentation Feedback | xvi

Requesting Technical Support | xvi

Self-Help Online Tools and Resources | xvii

Creating a Service Request with JTAC | xvii

iii

Overview

PTX10003 System Overview | 21

Benefits of the PTX10003 | 21

PTX10003-160C | 22

PTX10003-80C | 23

PTX10003 System Architecture | 24

PTX10003 System Software | 24

PTX10003 Fixed-Configuration Router Specifications | 25

PTX10003 Port Panel | 26

PTX10003-160C Port Panel | 26

PTX10003-80C Port Panel | 27

Understanding QSFP-DD Interfaces and Configurations | 28

Allowable QSFP-DD Interface Configurations for the PTX10003-160C | 29

Allowable QSFP-DD Interface Configurations for the PTX10003-80C | 30

Examples of PTX10003 QSFP-DD Configurations | 30

Example: Using Network Ports as 10 Gbps or 40 Gbps Ethernet Interfaces | 31

Example: Using Network Ports as 100 Gbps Ethernet Interfaces | 32

Example: Using Network Ports as 200 Gbps Ethernet Interfaces | 32

Example: Using Network Ports as 1x400 Gbps Ethernet Interfaces | 33

Page 4

PTX10003 Port LEDs | 34

Channelizing Interfaces on PTX10003 Routers with Junos OS Evolved | 35

PTX10003 Field-Replaceable Units Panel | 36

PTX10003-160C FRU Panel | 37

PTX10003-80C FRU Panel | 39

PTX10003 Management Panel | 40

PTX10003 Management Panel Components | 41

PTX10003 Management Panel LEDs | 42

PTX10003 Cooling System Description and Airflow | 46

PTX10003 Fan Modules | 46

PTX10003 Chassis Airflow | 47

Fan Module Status and LED Description | 48

iv

PTX10003 Power System | 50

PTX10003 AC/HVDC Power Supply Description | 50

PTX10003 AC/HVDC Power Supply LED | 52

PTX10003 AC/HVDC Power Specifications | 56

PTX10003 AC Power Cord Specifications | 56

PTX10003 DC Power Supply Description | 59

PTX10003 DC Power Supply LED | 61

PTX10003 DC Input Current Selector (DIP Switch) | 62

PTX10003 DC Power Redundancy | 63

PTX10003 Input DC Voltage Specification | 63

PTX10003 DC Power Cables | 64

PTX10003 DC Power Lugs | 64

Viewing Power Statistics | 65

Page 5

Site Planning, Preparation, and Specifications

2

PTX10003 Site Preparation Checklist | 71

PTX10003 Site Guidelines and Requirements | 72

PTX10003 Environmental Requirements and Specifications | 73

General Site Guidelines | 74

PTX10003 Chassis Grounding Cable and Lug Specifications | 74

PTX10003 Clearance Requirements for Airflow and Hardware Maintenance | 75

PTX10003 Chassis Physical Specifications | 76

PTX10003 Rack Requirements | 76

PTX10003 Network Cable and Transceiver Planning | 78

Determining Transceiver Support for the PTX10003 | 78

Cable and Connector Specifications for MX and PTX Series Devices | 79

v

12-Fiber MPO Connectors | 79

24-Fiber MPO Connectors | 83

LC Duplex Connectors | 84

Understanding Fiber-Optic Cable Signal Loss, Attenuation, and Dispersion | 85

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable | 85

Attenuation and Dispersion in Fiber-Optic Cable | 86

Calculating Power Budget and Power Margin for Fiber-Optic Cables | 86

Calculating Power Budget for Fiber-Optic Cable | 87

Calculating Power Margin for Fiber-Optic Cable | 87

PTX10003 Management Cable Specifications and Pinouts | 89

PTX10003 Cable Specifications for Console and Management Connections | 89

PTX10003 Management Port Connector Pinouts | 90

PTX10003 Console Port Connector Pinouts | 90

PTX10003 SFP Port Connector Pinouts | 91

PTX10003 SFP+ Port Connector Pinouts | 92

PTX10003 QSFP+ and QSFP28 Port Connector Pinouts | 93

PTX10003 USB Port Specifications | 95

Page 6

Initial Installation and Configuration

3

PTX10003 Installation Overview | 99

Overview of Installing the PTX10003 | 99

PTX10003 Installation Safety Guidelines | 100

General Installation Safety Guidelines | 100

Chassis Lifting Guidelines | 100

Unpacking and Mounting the PTX10003 | 101

Unpacking the PTX10003 | 101

Mounting the PTX10003 in a Rack | 103

Before You Begin Mounting the PTX10003 | 103

Mounting the PTX10003 | 105

Connect the PTX10003 to Power | 109

vi

Connecting the PTX10003 to Ground | 110

Connecting AC Power to the PTX10003 | 112

Connecting DC Power to the PTX10003 | 114

Connecting the PTX10003-80C to External Devices | 120

Connecting the PTX10003-80C to a Management Ethernet Device | 120

Connecting the PTX10003-80C to a Management Console | 121

Registering Products—Mandatory for Validating SLAs | 122

Performing the Initial Software Configuration for the PTX10003 | 123

Powering Off the PTX10003 | 125

Powering Off the AC-Powered PTX10003 | 126

Powering Off the DC-Powered PTX10003 | 127

Page 7

Maintaining Components

4

5

6

Maintaining the PTX10003 Fan Modules | 131

Removing a Fan Module from the PTX10003 | 131

Installing a Fan Module in the PTX10003 | 132

Maintaining the PTX10003 Power Supplies | 134

Replacing an AC/HVDC Power Supply in the PTX10003 | 134

Remove the AC/HVDC Power Supply from the PTX10003 | 135

Install the AC/HVDC Power Supply in the PTX10003 | 137

Replacing an DC Power Supply in the PTX10003 | 139

Remove the DC Power Supply from the PTX10003 | 139

Install the DC Power Supply in the PTX10003 | 141

Maintaining Transceivers and Fiber-Optic Cables on the PTX10003-80C | 143

vii

Removing a Transceiver from the PTX10003-80C | 143

Installing a Transceiver in the PTX10003-80C | 146

Disconnecting a Fiber-Optic Cable from a PTX10003-80C | 148

Connecting a Fiber-Optic Cable to a PTX10003-80C | 149

Maintaining Fiber-Optic Cables | 150

Uninstalling the PTX10003 | 151

Troubleshooting Hardware

Troubleshooting the PTX10003 | 155

PTX10003 Troubleshooting Resources Overview | 155

PTX10003 Alarm Messages Overview | 156

PTX10003 System Alarm Messages and Recommended Actions | 156

Contacting Customer Support and Returning the Chassis or Components

Contacting Customer Support | 163

Returning the PTX10003 Chassis or Components | 163

Locating the Serial Number on a PTX10003 Chassis or Component | 164

Listing the PTX10003 Chassis and Component Details by Using the CLI | 164

Locating the PTX10003 Chassis Serial Number ID Label | 167

Page 8

Locating the Serial Number ID Labels on PTX10003 Components | 167

7

Returning a PTX10003 or Component for Repair or Replacement | 169

Contacting Customer Support to Obtain Return Material Authorization | 170

Packing a PTX10003 Chassis or Component for Shipping | 171

Packing a PTX10003 Chassis for Shipping | 171

Packing a PTX10003 Component for Shipping | 172

Safety and Compliance Information

General Safety Guidelines and Warnings | 175

Definitions of Safety Warning Levels | 176

Qualified Personnel Warning | 178

Warning Statement for Norway and Sweden | 179

Fire Safety Requirements | 179

viii

Fire Suppression | 179

Fire Suppression Equipment | 179

Installation Instructions Warning | 181

Chassis and Component Lifting Guidelines | 181

Restricted Access Warning | 183

Ramp Warning | 185

Rack-Mounting and Cabinet-Mounting Warnings | 185

Grounded Equipment Warning | 190

Laser and LED Safety Guidelines and Warnings | 190

General Laser Safety Guidelines | 191

Class 1 Laser Product Warning | 192

Class 1 LED Product Warning | 193

Laser Beam Warning | 194

Page 9

Radiation from Open Port Apertures Warning | 195

Maintenance and Operational Safety Guidelines and Warnings | 196

Battery Handling Warning | 197

Jewelry Removal Warning | 198

Lightning Activity Warning | 200

Operating Temperature Warning | 201

Product Disposal Warning | 203

General Electrical Safety Guidelines and Warnings | 204

Action to Take After an Electrical Accident | 205

Prevention of Electrostatic Discharge Damage | 205

AC Power Electrical Safety Guidelines | 207

ix

AC Power Disconnection Warning | 208

DC Power Electrical Safety Guidelines | 209

DC Power Copper Conductors Warning | 210

DC Power Disconnection Warning | 211

DC Power Grounding Requirements and Warning | 213

DC Power Wiring Sequence Warning | 215

DC Power Wiring Terminations Warning | 218

Multiple Power Supplies Disconnection Warning | 221

TN Power Warning | 222

PTX10003 Regulatory Standard Compliances | 222

PTX10003 Agency Approvals | 223

Compliance Statements for the PTX10003 Routers | 225

Canada | 225

European Community | 226

Israel | 226

Japan | 226

Korea | 226

Page 10

Taiwan | 227

United States | 227

x

Page 11

About the Documentation

IN THIS SECTION

Documentation and Release Notes | xi

Using the Examples in This Manual | xi

Documentation Conventions | xiii

Documentation Feedback | xvi

Requesting Technical Support | xvi

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the PTX10003-80C and PTX10003-160C Fixed Packet Transport Router. Once you

complete installation and perform the basic configuration procedures covered in this guide, refer to the

Junos OS documentation for information about further software configuration.

xi

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

Page 12

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

xii

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Page 13

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

xiii

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

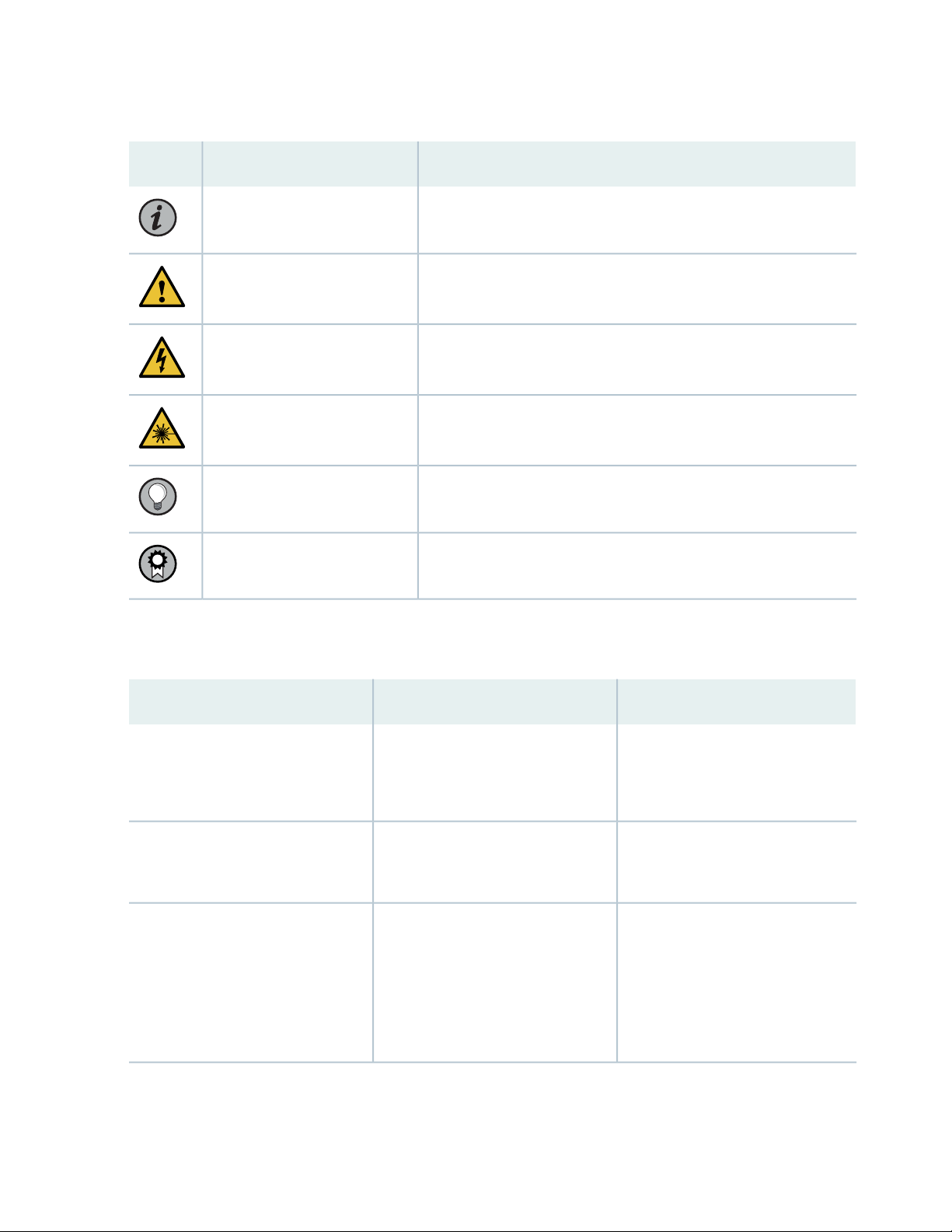

Table 1 on page xiv defines notice icons used in this guide.

Page 14

Table 1: Notice Icons

xiv

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

Table 2 on page xiv defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Page 15

Table 2: Text and Syntax Conventions (continued)

xv

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Page 16

Table 2: Text and Syntax Conventions (continued)

xvi

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

Page 17

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

xvii

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 18

1

CHAPTER

Overview

PTX10003 System Overview | 21

PTX10003 Port Panel | 26

PTX10003 Field-Replaceable Units Panel | 36

PTX10003 Management Panel | 40

PTX10003 Cooling System Description and Airflow | 46

PTX10003 Power System | 50

Page 19

Page 20

PTX10003 System Overview

IN THIS SECTION

Benefits of the PTX10003 | 21

PTX10003-160C | 22

PTX10003-80C | 23

PTX10003 System Architecture | 24

PTX10003 System Software | 24

PTX10003 Fixed-Configuration Router Specifications | 25

21

Occupying only 3 U, the PTX10003 is the industry’s first fixed-configuration core router to support 400 GbE.

The PTX10003 is easy to deploy in space constrained Internet exchange locations, remote central offices,

and embedded peering points throughout the network, including cloud-hosted services. It uniquely addresses

power-constrained environments by providing unprecedented power efficiency of 0.2 watts/Gbps. The

PTX10003 delivers high density 10 GbE, 26 GbE, 40 GbE, 100 GbE, 200 GbE, and 400 GbE and inline

MACsec with no compromise in throughput or latency. Two models with differing capacities are available.

The PTX10003-160C supports 16 Tbps throughput and the PTX10003-80C supports 8 Tbps

throughput—each in a compact 3 U footprint.

TIP: For information about features supported on PTX Series routers, see Feature Explorer.

Benefits of the PTX10003

Juniper Networks ExpressPlus™ Silicon: The PTX10003 is powered by our custom ExpressPlus silicon,

•

providing predictable IP/MPLS packet performance and functionality, along with inline AES-256 MACsec

encryption on all interfaces.

Peering Scale: To match the expanding traffic demands, the PTX10003 delivers a peering scale of up to

•

3 million Forwarding Information Base (FIB) routes and up to 20 million Routing Information Base (RIB)

routes, also known as forwarding and routing tables, respectively.

QSFP-DD: The PTX10003 supports universal multi-rate QSFP-DD optics, quadrupling aggregate switch

•

bandwidth while maintaining port density. QSFP-DD supports continuing growth in network bandwidth

Page 21

demand and data center traffic. Systems designed with QSFP-DD are backwards compatible, allowing

them to support existing QSFP optical modules and provide flexibility for end users and system designers.

Juniper Networks Junos OS Evolved: The PTX10003 operates on Junos OS Evolved, Juniper Networks

•

next-generation Junos OS. Junos OS Evolved has the same CLI user interface, the same code base for

applications and features, and the same management and automation tools as Junos OS. However, the

Junos OS Evolved infrastructure is entirely modernized, delivering the high availability, portability, faster

innovation, and simplified upgrades you need.

Interoperability: The PTX10003 provides seamless interoperability with existing Juniper routing

•

deployments.

PTX10003-160C

The PTX10003-160C scales to 16 Tbps in a single chassis. Operating in a fixed core router configuration,

the PTX10003-160C has flexible interface configuration options, with universal multirate QSFP-DD for

100 GbE/400 GbE/FlexE to support 320 (QSFP +) 10 GbE ports, 80 (QSFP +) 40 GbE ports, 160 (QSFP28)

100 GbE ports, 64 (QSFP28-DD) 200 GbE ports, or 32 (QSFP56-DD) 400 GbE ports. Refer to

Figure 1 on page 22.

22

Figure 1: PTX10003-160C Port Panel

NOTE: 200 Gbps and 400 Gbps data rates are supported on Juniper Junos OS Evolved release

19.3R1 and later.

The FRU panel for the PTX10003-160C has four power supplies, five fan modules, two chassis grounding

points, and an ESD grounding point. Refer to Figure 2 on page 23.

Page 22

Figure 2: PTX10003-160C FRU Panel (AC/HVDC Power Supplies)

For more information about the components on the FRU panel, see “PTX10003 Field-Replaceable Units

Panel” on page 36.

PTX10003-80C

23

The PTX10003-80C scales to 8 Tbps in a single chassis. Operating in a fixed core router configuration,

the PTX10003-80C has flexible interface configuration options, with universal multirate QSFP-DD for

100GE/400GE/FlexE to support 160 (QSFP +) 10 GbE ports, 40 (QSFP +) 40 GbE ports, 80 (QSFP28)

100 GbE ports, 32 (QSFP28-DD) 200 GbE ports, or 16 (QSFP56-DD) 400 GbE ports. Refer to

Figure 3 on page 23.

Figure 3: PTX10003-80C

NOTE: 200 Gbps and 400 Gbps data rates are supported on Juniper Junos OS Evolved release

19.3R1 and later.

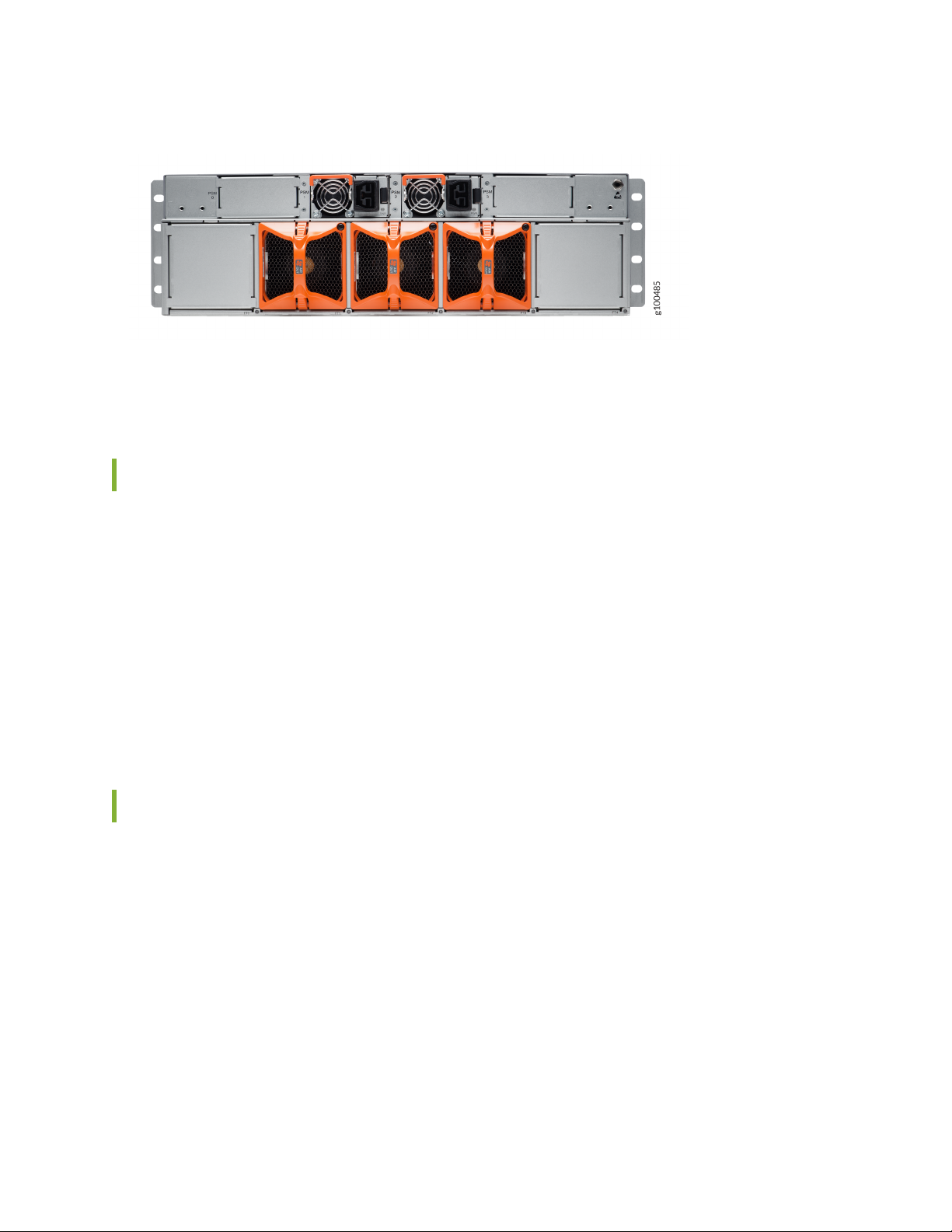

The FRU panel for the PTX10003-80C has two power supplies, three fan modules, two chassis grounding

points, and an ESD grounding point. Refer to Figure 4 on page 24.

Page 23

Figure 4: PTX10003-80C FRU Panel

For more information about the components on the FRU panel, see “PTX10003 Field-Replaceable Units

Panel” on page 36.

PTX10003 System Architecture

24

Using Juniper Networks custom ExpressPlus silicon, the PTX10003 system architecture cleanly separates

control operations from packet forwarding operations. This design eliminates processing and traffic

bottlenecks, permitting the PTX10003 to achieve high performance.

Control operations are performed by the Routing Engine, which runs Junos OS Evolved. The Routing

Engine handles routing protocols, traffic engineering, policy, policing, monitoring, and configuration

management. Junos OS Evolved is pre-installed on the PTX10003 internal solid-state drives (SSDs).

Forwarding operations are performed by the Packet Forwarding Engines (PFE) to deliver inline MACsec

on all ports and high density high density 10 GbE, 40 GbE, 100 GbE, 200 GbE, and 400 GbE.

PTX10003 System Software

The PTX10003 runs Junos OS Evolved, which provides Layer 2 and Layer 3 switching, routing, and security

services. Junos OS Evolved runs natively on Linux, giving it direct access to all the Linux utilities and

operations. It is designed to be modular, allowing for upgrades to be done on a component-by-component

basis without a system reboot. Only those components changed are restarted. Junos OS Evolved is easily

portable and minimal work is required to make it work on any platform. It has the same CLI user interface,

the same code base for applications and features, and the same management and automation tools as

Junos OS. However, the Junos OS Evolved infrastructure is entirely modernized, giving you the high

availability, portability, faster innovation, and simplified upgrades you need. Junos OS Evolved software

is installed on the PTX10003 200 GB internal NAND solid state flash drive.

For information about which features are supported on PTX Series devices, see Feature Explorer.

Page 24

PTX10003 Fixed-Configuration Router Specifications

Table 3: PTX10003 Specifications

PTX10003-80CPTX10003-160CHardware

8 Tbps16 TbpsSystem Throughput

Up to 5.3 BppsUp to 10.6 BppsForwarding Capacity

25

Dimension (WxHxD)

17.4 x 5.25 x 31 in (44.2 x 13.3 x 78.7

cm)

17.4 x 5.25 x 31 in (44.2 x 13.3 x 78.7

cm)

3 U3 URack units

88 lb (40 kg)110 lb (50 kg)Weight

Intel Broadwell CPU with 12 CoresIntel Broadwell CPU with 12 CoresCPU

64 Gigabit SDRAM64 Gigabit SDRAMRAM

200 GBx2200 GBx2SSD

~2500 W (AC,HVDC), 8525 BTU/hr~4000 W (AC.HVDC), 13640 BTU/hrMaximum power draw

~1600 W (AC,HVDC), 5456 BTU/hr~3100W (AC,HVDC), 10571 BTU/hrTypical power draw

2x3000 watts (AC/HVDC)4x3000 watts (AC/HVDC)Power supply

3 hot-swappable fans5 hot-swappable fansCooling (front-to-back fan)

64 Gb128 GbPacket buffer

2.5 μs within PFE, 5 μs between PFEs2.5 μs within PFE, 5 μs between PFEsLatency

0.20.2Power Efficiency (watts/Gbps)

24Power Supply Slots

2.5 KW4 KWPower Rating AC

2.5 KW4 KWPower Rating HVDC

Page 25

PTX10003 Port Panel

IN THIS SECTION

PTX10003-160C Port Panel | 26

PTX10003-80C Port Panel | 27

Understanding QSFP-DD Interfaces and Configurations | 28

Allowable QSFP-DD Interface Configurations for the PTX10003-160C | 29

Allowable QSFP-DD Interface Configurations for the PTX10003-80C | 30

Examples of PTX10003 QSFP-DD Configurations | 30

PTX10003 Port LEDs | 34

Channelizing Interfaces on PTX10003 Routers with Junos OS Evolved | 35

26

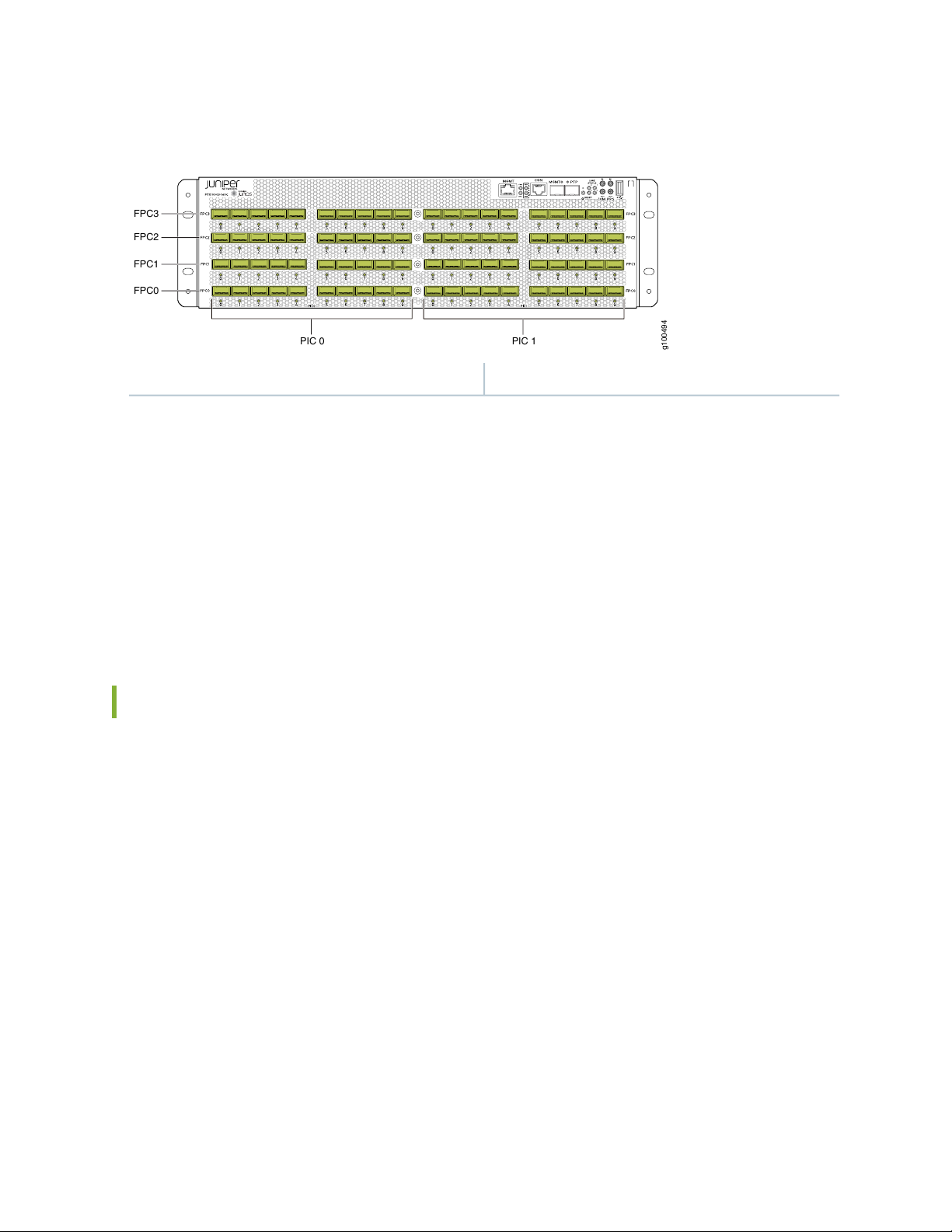

PTX10003-160C Port Panel

Operating in a fixed core router configuration, the PTX10003-160C features flexible interface configuration

options with universal multi-rate double-density Quad Small Form-factor Pluggable (QSFP-DD) optics.

The port panel has 80 optical interfaces which support data rates of 10 Gbps, 25 Gbps, 40 Gbps, 100 Gbps,

200 Gbps, and 400 Gbps. Each of the 16 Juniper Networks 1 Tbps ExpressPlus ASICs in the PTX10003-160C

connect to a group of five QSFP-DD ports. You can configure different data rates for each port group as

long as the total throughput for the group does not exceed 1 Tbps. For more details, see “Understanding

QSFP-DD Interfaces and Configurations” on page 28.

Figure 5 on page 27 illustrates the PTX10003-160C port panel.

Page 26

Figure 5: PTX10003-160C Port Panel

g100494

021

3

B

PIC 0

FPC3

FPC2

FPC1

FPC0

PIC 1

1—80 optical interfaces with 80 port LEDs

As illustrated in Figure 5 on page 27, the interfaces for the PTX10003-160C are divided into logical FPCs,

logical PICs, and physical optical ports as follows:

FPCs: The PTX10003-160C has four FPCs, numbered 0, 1, 2, and 3 from the bottom up in the chassis.

•

PICs: Each FPC has two logical PICs, numbered 0 and 1 from left to right.

•

27

Ports:: Each PIC controls 10 QSFP-DD optical interfaces, numbered 0 through 9 from left to right.

•

The 10 QSFP-DD optical interfaces are divided into two groups of five ports.

•

Each port group is controlled by two PFEs.

•

PTX10003-80C Port Panel

Operating in a fixed core router configuration, the PTX10003-80C features flexible interface configuration

options with universal multi-rate double-density Quad Small Form-factor Pluggable (QSFP-DD) optics.

The port panel has 40 optical interfaces which support data rates of 10 Gbps, 25 Gbps, 40 Gbps, 100 Gbps,

200 Gbps, and 400 Gbps. Each of the eight Juniper Networks 1 Tbps ExpressPlus ASICs in the

PTX10003-80C connect to a group of five QSFP-DD ports. You can configure different data rates for each

port group as long as the total throughput for the group does not exceed 1 Tbps. See “Understanding

QSFP-DD Interfaces and Configurations” on page 28 for more details.

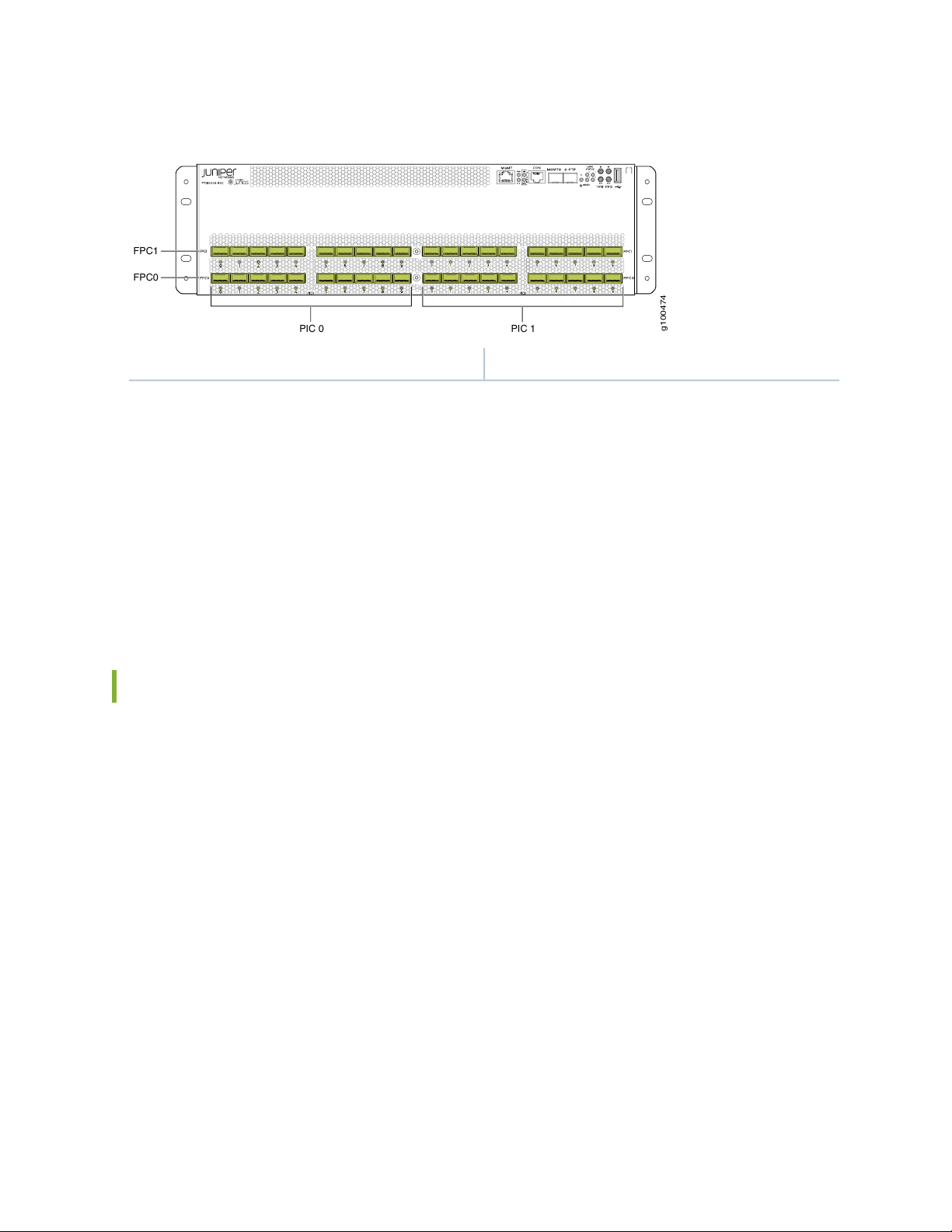

Figure 6 on page 28 illustrates the PTX10003-80C port panel.

Page 27

Figure 6: PTX10003-80C Port Panel

g100474

021

3

B

PIC 0

PIC 1

FPC1

FPC0

1—40 optical interfaces with 40 port LEDs

As illustrated in Figure 6 on page 28, the interfaces for the PTX10003-80C are divided into logical FPCs,

logical PICs, and physical optical ports as follows:

FPCs: The PTX10003-80C has two FPCs, numbered 0 and 1 from the bottom up in the chassis.

•

PICs: Each FPC has two logical PICs, numbered 0 and 1 from left to right.

•

28

Ports:: Each PIC controls 10 QSFP-DD optical interfaces, numbered 0 through 9 from left to right.

•

The 10 QSFP-DD optical interfaces are divided into two groups of five ports.

•

Each port group is controlled by two Packet Forwarding Engines (PFE).

•

Understanding QSFP-DD Interfaces and Configurations

Each Juniper Networks 1 Tbps ExpressPlus ASIC contains two logically independent PFEs which can

provide 400 Gbps throughput. Each QSFP-DD port group is controlled by two PFEs with the middle

QSFP-DD interface (port 2 and port 7) being shared by the PFEs.

Any port can be used as a 100-Gigabit Ethernet interface, 40-Gigabit Ethernet interface, or 10-Gigabit

Ethernet interface. You choose the speed by plugging in the appropriate optical transceiver. You can also

channelize the 100 Gbps and 200 Gbps ports to create multiple independent 25 Gbps interfaces. You can

channelize the 40 Gbps ports to create multiple independent 10 Gbps ports. See Channelizing Interfaces

on PTX10003 Routers for more details.

Given the design of the Juniper Networks ExpressPlus ASIC and chassis level thermal considerations, there

are certain limitations for some QSFP-DD interfaces and configurations. Each QSFP-DD port group can

be configured to achieve the maximum 1 Tbps throughput with the following limitations:

Page 28

Only the interfaces at the outer edge of each QSFP-DD group can be configured for 1x400 Gbps (using

•

QSFP56-DD optics).

The middle QSFP-DD port that is shared across two PFE’s (port 2 and port 7) cannot support a data rate

•

of 1x200 Gbps. These ports can only support 2x100 Gbps (QSFP28-DD).

The highest QSFP-DD data rate that can be used across all QSFP-DD groups is 200 Gbps (2x100 Gbps).

•

This provides 16 Tbps throughput for the PTX10003-160C, and 8 Tbps throughput for the

PTX10003-80C.

Aside from running all interfaces with 2x100 Gbps optics, there are other ways to attain the maximum

•

system throughput. The 400 Gbps optics can be used in combination with 100 Gbps optics and 200 Gbps

optics as shown in the following examples.

Allowable QSFP-DD Interface Configurations for the PTX10003-160C

Assuming the limitations described previously, Table 4 on page 29 lists the allowable interface configurations

for the PTX10003-160C.

29

Table 4: PTX10003-160C Port Density per Optical Interface

QSFP2880

4x25 Gbps

Maximum Number of InterfacesData RateQSFP TransceiverNumber of Ports

320 10 Gbps4x10 GbpsQSFP+80

80 40 Gbps1x40 Gbps

80 100 Gbps1x100 Gbps or

64 200 Gbps1x200 Gbps or 8x25GbpsQSFP28-DD64

160 100 Gbps2x100 Gbps80

32 400 Gbps1x400 GbpsQSFP56-DD32

128 100 Gbps4x100 Gbps

Page 29

Allowable QSFP-DD Interface Configurations for the PTX10003-80C

Assuming the limitations described previously, Table 5 on page 30 lists the allowable interface configurations

for the PTX10003-80C.

Table 5: PTX10003-80C Port Density per Optical Interface

Maximum Number of InterfacesData RateQSFP TransceiverNumber of Ports

160 10 Gbps4x10 GbpsQSFP+40

40 40 Gbps1x40 Gbps

30

QSFP2840

4x25 Gbps

QSFP28-DD32

8x25 Gbps

40 100 Gbps1x100 Gbps or

32 200 Gbps1x200 Gbps or

80 100 Gbps2x100 Gbps40

16 400 Gbps1x400 GbpsQSFP56-DD16

64 100 Gbps4x100 Gbps

Examples of PTX10003 QSFP-DD Configurations

By default, all PTX10003 QSFP-DD interfaces are configured for a data rate of 2x100 Gbps. You can

change the port configuration to achieve different throughput using the following Junos OS Evolved

command:

set chassis fpc slot-number pic pic-number port port-number number-of-subports [1 | 2 | 4 |8] speed [10G

| 25G | 40G | 100G | 200G |400G] command.

For example, to configure the second port in the first port group as a 4x10 Gbps interface, use the set

chassis fpc 0 pic 0 port 1 number-of-subports 4 speed 10g command. After you commit this configuration,

the second port in PIC 0 will operate at 4x10 Gbps.

Page 30

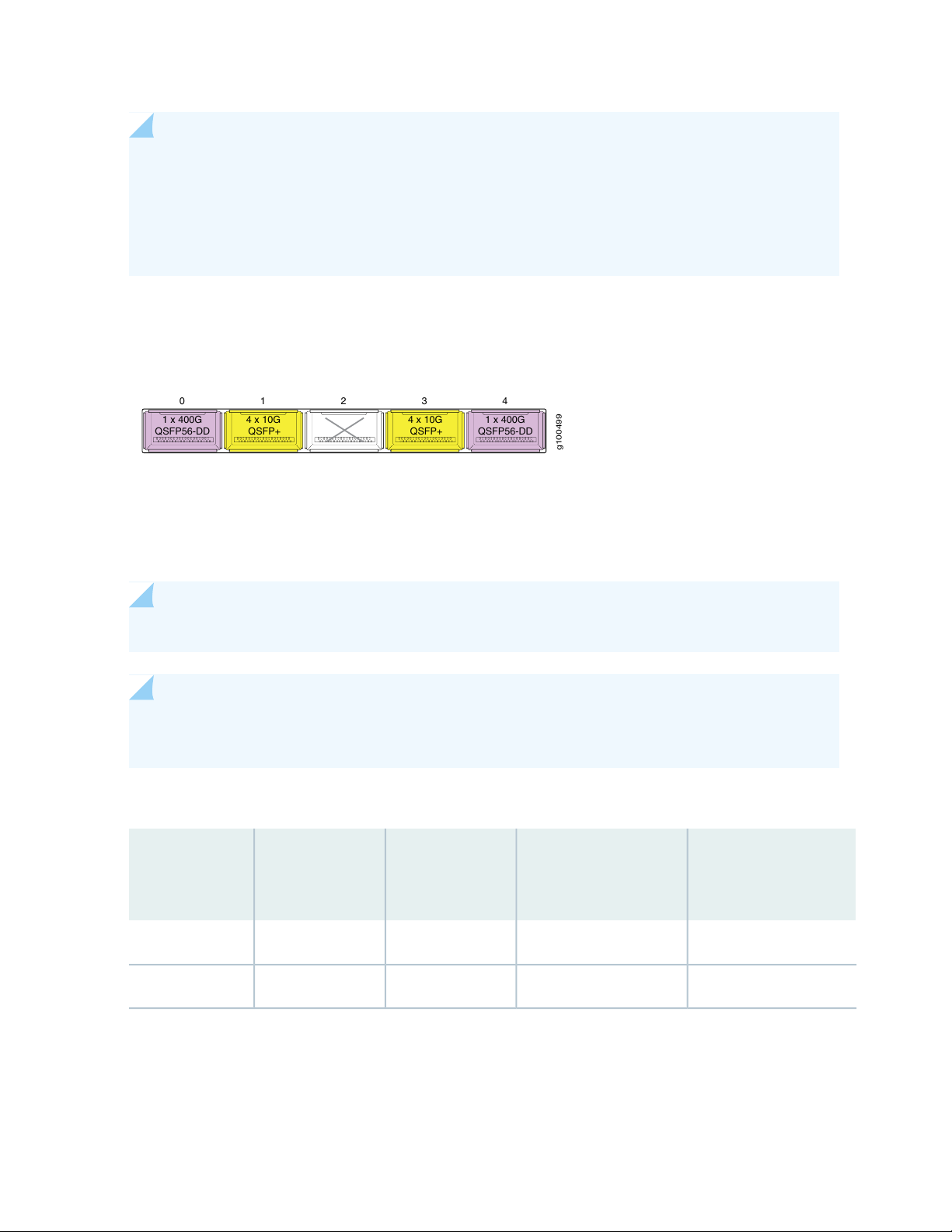

NOTE: When a port speed and sub-port-number are configured, the configured values override

g100499

1 x 400G

QSFP56-DD

4 x 10G

QSFP+

1 x 400G

QSFP56-DD

0 1 2 3 4

4 x 10G

QSFP+

the default port speed for the transceiver. If you try to configure a port speed that is not supported

by the transceiver, the port will be disabled. If there isn’t a port speed configured on a valid optical

port, the PTX10003 uses a default port speed of 2x100 Gbps. Also, if number-of-subports is not

configured, a 1x 40G | 100G |200G |400G] data rate is assumed. A 1x10G sub-port is not supported.

Example: Using Network Ports as 10 Gbps or 40 Gbps Ethernet Interfaces

With QSFP+ transceivers, you can configure 10 Gbps or 40 Gbps interfaces on any port. To attain the

maximum 1 Tbps throughput for a port group, you can configure the 10 Gbps and 40 Gbps ports with

combinations of 1x100 Gbps, 2x100 Gbps, and 400 Gbps, data rates. Refer to Table 6 on page 31.

31

NOTE: 1x10 Gbps and 2x10 Gbps are not supported.

NOTE: Only the ports at the outer edge of each group can be configured for 1x400 Gbps (using

QSFP56-DD transceivers).

Table 6: Using Network Ports as 10 Gbps or 40 Gbps Ethernet Interfaces

Maximum Number of

QSFP

TransceiverData Rate

Allowable Port

Numbers

Ports

(PTX10003-160C)

Maximum Number of

Ports (PTX10003-80C)

1603200-9QSFP+4x10 Gbps

40800-9QSFP+1x40 Gbps

Page 31

Example: Using Network Ports as 100 Gbps Ethernet Interfaces

g100498

2 x 100G

QSFP-DD

2 x 100G

QSFP-DD

2 x 100G

QSFP-DD

0 1 2 3 4

2 x 100G

QSFP-DD

2 x 100G

QSFP-DD

g100497

1 x 200G

QSFP56-DD

2 x 100G

QSFP28-DD

1 x 200G

QSFP56-DD

0 1 2 3 4

1 x 200G

QSFP56-DD

1 x 200G

QSFP56-DD

With QSFP28 and QSFP28-DD transceivers, you can configure a 2x100 Gbps data rate on any port. This

is the default port configuration. To attain the maximum 1 Tbps throughput for a port group using 100 Gbps

interfaces, you can configure combinations of 1x100 Gbps, 2x100 Gbps, and 4x100 Gbps data rates. Refer

to Table 7 on page 32.

Table 7: Using Network Ports as 100 Gbps Interfaces

32

Maximum Number

of Ports

(PTX10003-80C)

Allowable Port

NumbersQSFP TransceiverData Rate

Maximum Number of

Ports

(PTX10003-160C)

40800-9QSFP281x100 Gbps

801600-9QSFP28-DD2x100 Gbps

641280, 4, 5, 9QSFP56-DD4x100 Gbps

Example: Using Network Ports as 200 Gbps Ethernet Interfaces

With QSFP28-DD transceivers, you can configure select ports in each port group as a 1x200 Gbps Ethernet

interface. To attain the maximum 1 Tbps throughput for a port group, you can configure combinations of

1x400 Gbps, 1x100 Gbps, 2x100 Gbps, and 1x200 Gbps data rates. Refer to Table 8 on page 33.

NOTE: The center port in each port group (port 2 and port 7) cannot support 1x200 Gbps. To

configure a 200 Gbps data rate for those ports, you’ll need to configure them as 2x100 Gbps.

Page 32

Table 8: Using Network Ports as 200 Gbps Interfaces

g100584

1 x 400G

QSFP56-DD

1 x 100G

QSFP28

1 x 400G

QSFP56-DD

0 1 2 3 4

1 x 100G

QSFP28

g100582

PIC 0

PIC 1

FPC1

FPC0

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

400G

100G

33

Maximum Number of

Ports

(PTX10003-80C)

Allowable Port

NumbersQSFP TransceiverData Rate

Maximum Number of

Ports

(PTX10003-160C)

32640, 1, 3, 4, 5, 6, 8, 9QSFP28-DD1x200 Gbps

801600-9QSFP28-DD2x100 Gbps

NOTE: 200 Gbps data rates are supported on Juniper Junos OS Evolved release 19.3R1 and later.

Example: Using Network Ports as 1x400 Gbps Ethernet Interfaces

With QSFP56-DD transceivers, you can configure a data rate of 1x400 Gbps on the two outer ports in a

port group. To attain the maximum 1 Tbps throughput, you can configure combinations of 1x400 Gbps,

1x100 Gbps, 2x100 Gbps, and 1x200 Gbps data rates with the following limitations:

Only the ports at the outer edge of each group can be configured for 1x400 Gbps (using QSFP56-DD

•

transceivers).

When ports 0, 4, 5, 9 are configured as 1x400 Gbps, the center ports 2 and 7 must be blank.

•

When configuring a port for 1x200 Gbps, port 1, 3, 6 and 8 must be blank or configured as 1x100 Gbps.

•

Page 33

Table 9: Using Network Ports as 400 Gbps Interfaces

34

Maximum Number

of Ports

(PTX10003-80C)

16320, 4, 5, 9QSFP56-DD1x400 Gbps

641280, 4, 5, 9QSFP56-DD4x100 Gbps

801600-9QSFP28-DD2x100 Gbps

Allowable Port

NumbersQSFP TransceiverData Rate

Maximum Number of

Ports

(PTX10003-160C)

NOTE: 400 Gbps data rates are supported in Juniper Junos OS Evolved release 19.3R1 and later.

PTX10003 Port LEDs

Each PTX10003 port uses a single bi-colored LED to indicate link status and activity. See

Table 10 on page 34 for how to interpret the port LEDs.

NOTE: After you insert an optical transceiver, the LINK UP LED flashes red and green during the

first 60 seconds. This means the link is unstable. It may take up to 60 seconds for the LED to stop

flashing.

Table 10: Network Port LEDs on a PTX10003

DescriptionStateColor

Off—

On steadilyAmber

The transceiver is not present or loopback configuration is

present.

A link is established and all channels are up.On steadilyGreen

One or more channels are up. However, at least one channel

has activity, but not all connections are active.

All channels are down.On steadilyRed

Page 34

Channelizing Interfaces on PTX10003 Routers with Junos OS Evolved

PTX10003 Packet Transport Routers feature flexible interface configuration options with universal multi-rate

double-density Quad Small Form-factor Pluggable (QSFP-DD) optics. The PTX10003-80C port panel has

40 physical ports and the PTX10003-160C port panel has 80 physical ports. The physical ports are in

groups of five QSFP-DD ports. You can configure different data rates for each port group as long as the

total throughput for the group does not exceed 1 Tbps. Any port can be used as a 100-Gigabit Ethernet

interface, 40-Gigabit Ethernet interface, or 10-Gigabit Ethernet interface. You choose the speed by plugging

in the appropriate transceiver.

NOTE: The center port in each port group (port 2 and port 7) cannot support 1x200 Gbps. To

configure a 200 Gbps data rate for those ports, you’ll need to configure them as 2x100 Gbps. For

more details, see “Understanding QSFP-DD Interfaces and Configurations” on page 28.

You can channelize the Gigabit Ethernet interfaces on PTX10003 routers to create multiple independent

Gigabit Ethernet interfaces and then use breakout cables to connect the channelized ports to other servers,

storage devices, and routers. Here’s the allowable channelization configurations for the optical transceivers

supported by the PTX10003:

35

Channelization OptionsNative Port SpeedsQSFP Transceiver

QSFP28-DD

2x100 Gbps

QSFP+

4x10 Gbps

8x25 Gbps1x200 Gbps

4x25 Gbps1x100 GbpsQSFP28

4x10 Gbps1x40 Gbps

NOTE: For more details about supported transceivers and cable specifications, see the PTX10003

Packet Transport Router Hardware Guide .

By default, all PTX10003 QSFP-DD interfaces are configured for a data rate of 2x100 Gbps. The interface

names appear in the et-fpc/pic/port:channel format.

The port speed can be configured at the PIC-level. To view the port speed capability of a logical PIC, issue

the show chassis pic fpc-slot slot-number pic-slot slot-number command.

Page 35

For details on how to channelize a port, see Channelizing Interfaces on PTX10003 Routers.

SEE ALSO

number-of-sub-ports

speed (Ethernet)

fpc

pic

PTX10003 Field-Replaceable Units Panel

36

IN THIS SECTION

PTX10003-160C FRU Panel | 37

PTX10003-80C FRU Panel | 39

Page 36

The PTX10003 field-replaceable units (FRU) panel contains fan modules, power supply modules, two

g100451

21 1 3

4

grounding points, and an ESD grounding point. The PTX10003 FRUs are hot-removable and

hot-insertable—you can remove and replace them without powering off the PTX10003 or disrupting the

routing function.

NOTE: If you have a Juniper Care service contract, register any addition, change, or upgrade of

hardware components at https://www.juniper.net/customers/support/tools/updateinstallbase/.

Failure to do so can result in significant delays if you need replacement parts. This note does not

apply if you replace existing components with the same type of component.

PTX10003-160C FRU Panel

The FRU panel for the PTX10003-160C has four power supplies, five fan modules, two chassis grounding

points, and an ESD grounding point. Refer toFigure 7 on page 37 (AC/HVDC power supplies) and

Figure 8 on page 38 (DC power supplies).

37

Figure 7: PTX10003-160C FRU Panel with AC/HVDC Power Supplies

3—1— ESD grounding pointChassis grounding points

4—2— Fan modules (5)Power supplies (4)

Page 37

Figure 8: PTX0003-160C FRU Panel with DC Power Supplies

g100452

21 1 3

4

3—1— ESD grounding pointChassis grounding points

4—2— Fan modules (5)Power supplies (4)

Table 11 on page 38 lists the component part numbers for PTX10003-160C FRUs.

38

Table 11: List of PTX10003-160C FRUs

PTX10003-160C-ACPTX10003-160C Base

System (AC)

PTX10003-160C-DCPTX10003-160C Base

System (DC)

JNP10003-160C-CHASPTX10003-160C Chassis

Spare

JNP-3000W-AC-AFOAC Power Supply

DescriptionModel NumberComponent

PTX10003-160C base system with 160 100 GbE ports

or 32 400 GbE ports, 4 3000 W AC power supplies, 4

power cables, and 5 fan trays, with standard tier

right-to-use license.

PTX10003-160C base system with 160 100 GbE ports

or 32 400 GbE ports, 4 3000 W DC power supplies, and

5 fan trays, with standard tier right-to-use license

JNP10003-160C spare chassis with 160 100 GbE ports

or 32 400 GbE ports.

Fan tray for 3 RU 8 T and 16 T fixed platforms.JNP10003-FANFan Tray

AC power supply for JNP10003-160C and JNP10003-80C

fixed platforms.

JNP-3000W-DC-AFODC Power Supply

DC power supply for JNP10003-160C and JNP10003-80C

fixed platforms

Page 38

PTX10003-80C FRU Panel

g100261

2

1

1 3

4

g100262

1

1 3

4

2

The FRU panel for the PTX10003-80C has two power supplies, three fan modules, two chassis grounding

points, and an ESD grounding point. Refer toFigure 9 on page 39 (AC/HVDC power supplies) and

Figure 10 on page 39(DC power supplies).

Figure 9: PTX10003-80C with AC/HVDC Power Supplies

39

3—1— ESD grounding pointChassis grounding points

4—2— Fan modules (3)Power supplies (2)

Figure 10: PTX10003-80C with DC Power Supplies

3—1— ESD grounding pointChassis grounding points

4—2— Fan modules (3)Power supplies (2)

Table 12 on page 40 lists the component part numbers for PTX10003-80C FRUs.

Page 39

Table 12: List of PTX10003-80C FRUs

40

DescriptionModel NumberComponent

(AC)

System (DC)

(Spare)

PTX10003-80C-ACPTX10003-80 Base System

PTX10003-80C-DCPTX10003-80C Base

JNP10003-80C-CHASPTX10003-80C Chassis

JNP-3000W-AC-AFOAC Power Supply

JNP-3000W-DC-AFODC Power Supply

PTX10003-80C base system with 80 100 GbE ports or 16

400 GbE ports, 2 3000 W AC power supplies, 2 power

cables, and 3 fan trays, with standard tier right-to-use

license.

PTX10003-80C base system with 80 100 GbE ports or 16

400 GbE ports, 2 3000 W DC power supplies, and 3 fan

trays, with standard tier right-to-use license.

JNP10003-80C spare chassis with 80 100 GbE ports or

16 400 GbE ports.

Fan tray for 3 RU 8T and 16T fixed platforms.JNP10003-FANFan Tray

AC power supply for JNP10003-160C and JNP10003-80C

fixed platforms.

DC power supply for JNP10003-160C and JNP10003-80C

fixed platforms.

PTX10003 Management Panel

IN THIS SECTION

PTX10003 Management Panel Components | 41

PTX10003 Management Panel LEDs | 42

The PTX10003-8T management panel is in the upper right corner of the port panel (see

Figure 11 on page 41).

Page 40

Figure 11: PTX10003-8T Port Panel and Management Panel

g100260

LANE

STATUS

021

3

B

1

2

2—1— Port panelManagement panel

PTX10003 Management Panel Components

41

You manage the PTX10003 by using the Junos OS Evolved software CLI, which is accessible through the

console and out-of-band management ports on the management panel. The management panel, located

in the upper right corner of the port panel, has system status LEDs that alert you to minor and major alarms,

and other issues with the router. It also has external clock synchronization ports and a USB port to support

software installation and recovery. Figure 12 on page 42 shows the management panel in detail.

Page 41

Figure 12: PTX10003 Management Panel Components

LANE

STATUS

021

3

B

1 2 3 5 6 74 8 9

g100268

10

42

6—1— Beacon LEDRJ-45 Ethernet management port(MGMT)

Power (PWR) Status (STA) and alarm LEDs (MJR=

major alert; MNR=minor alert)

7—2— Four LANE STATUS LEDs numbered 0, 1, 2, 3 for

lane identification of the QSFP channel. The lane ID

LEDs work in conjunction with the activity LEDs that

appear beneath the optics. These optics can support

up to four independent lanes. Since there is only one

LED per QSFP, the lane ID LEDs indicate which

physical QSFP lane corresponds to the LED indicator

that is currently active.

RJ-45 console UART (CON) port. An optional GPS

Time of Day (TOD) is also supported.

8—3— Four co-axial input/output (IN/OUT SMB connectors

for external 1PPS and 5MHz/10MHz simultaneous

I/O bi-directional timing. BITS is not supported.

9—4— USB 2.0 port for connection to the CPUSFP (MGMT) port for 1G system management

10—5— Reset (RESET) push button for resetting the CPUSFP (PTP) port for an IEEE 1588 PTP timing source

PTX10003 Management Panel LEDs

Table 13 on page 42 describes the management panel LEDs on the PTX10003.

Table 13: PTX10003 Management Panel LEDs

Port LED MGMT

DefinitionColor/StateLED Name

Link up, no activityOffRJ-45 10/100/1000 Management

Link up, activityYellow/Blinking

Power is okGreen/OnPower LEDs PWR

Power faultYellow/Blinking

OfflineOff

Page 42

Table 13: PTX10003 Management Panel LEDs (continued)

MGMT

43

DefinitionColor/StateLED Name

Link up, no activityGreenSFP Optic Management Port LED

Link up, activityGreen/Blinking

Link downOff

Link up, no activityGreenPTP Port LED PTP

Link, activityGreen/Blinking

Link downOff

Alarm is activeRed/OnAlarm

MJR

MNR

Green/off, 2x2 LED matrixLANE STATUS

No alarmOff

Alarm is activeYellow/OnAlarm LEDs

No alarmOff

Used as chassis locatorBlue/offBeacon (B)

Indicates which lane of optics

corresponds to LED traffic indicator

beneath optics. Upper left corner LED

corresponds to lane 0, proceeding

clock wise – lane 1,2,3

For power and temperature alarms, use the show chassis environment fpc operational mode command

to get detailed information on the internal state of the chassis. For example:

user@device> show chassis environment fpc

FPC 0 status:

State Online

Temperature 51 degrees C / 123 degrees F

Voltage:

PE0 VDD Core 0.9V 949 mV

PE0 AVDD 1.0V 1000 mV

Page 43

PE0 HMC VDD 0.9V 897 mV

PE0 HMC AVDD 1.2V 1197 mV

PE01 HMC VDD 1.2V 1197 mV

PE1 VDD Core 0.9V 949 mV

PE1 AVDD Core 1.0V 999 mV

PE1 HMC VDD 0.9V 899 mV

PE1 HMC AVDD 1.2V 1197 mV

PE2 VDD Core 0.9V 950 mV

PE2 AVDD Core 1.0V 999 mV

PE2 HMC VDD 0.9V 897 mV

PE2 HMC AVDD 1.2V 1197 mV

PE23 HMC AVDD 1.2V 1197 mV

PE3 VDD Core 0.9V 949 mV

PE3 AVDD Core 1.0V 999 mV

PE3 HMC VDD 0.9V 899 mV

PE3 HMC AVDD 1.2V 1200 mV

PE4 VDD Core 0.9V 949 mV

PE4 AVDD Core 1.0V 999 mV

PE4 HMC VDD 0.9V 899 mV

PE4 HMC AVDD 1.2V 1197 mV

PE45 HMC AVDD 1.2V 1197 mV

PE5 VDD Core 0.9V 949 mV

PE5 AVDD Core 1.0V 1000 mV

PE5 HMC VDD 0.9V 899 mV

PE5 HMC AVDD 1.2V 1200 mV

XMB VDD 3.3V 3316 mV

MAIN VDD 3.3V 3298 mV

RT VDD 1.0V 999 mV

MAIN VDD 2.5V 2502 mV

MAIN PFE 1.5V 1502 mV

PE6 VDD Core 0.9V 949 mV

PE6 AVDD 1.0V 1000 mV

PE6 HMC VDD 0.9V 897 mV

PE6 HMC AVDD 1.2V 1204 mV

PE67 HMC VDD 1.2V 1197 mV

PE7 VDD Core 0.9V 949 mV

PE7 AVDD Core 1.0V 999 mV

PE7 HMC VDD 0.9V 897 mV

PE7 HMC AVDD 1.2V 1197 mV

PE8 VDD Core 0.9V 949 mV

PE8 AVDD Core 1.0V 999 mV

PE8 HMC VDD 0.9V 897 mV

PE8 HMC AVDD 1.2V 1200 mV

PE78 HMC AVDD 1.2V 1197 mV

44

Page 44

PE9 VDD Core 0.9V 950 mV

PE9 AVDD Core 1.0V 999 mV

PE9 HMC VDD 0.9V 897 mV

PE9 HMC AVDD 1.2V 1200 mV

PE10 VDD Core 0.9V 949 mV

PE10 AVDD Core 1.0V 999 mV

PE10 HMC VDD 0.9V 899 mV

PE10 HMC AVDD 1.2V 1200 mV

PE910 HMC AVDD 1.2V 1200 mV

PE11 VDD Core 0.9V 950 mV

PE11 AVDD Core 1.0V 999 mV

PE11 HMC VDD 0.9V 899 mV

PE11 HMC AVDD 1.2V 1200 mV

PF0 VDD Core 0.9V 950 mV

PF0 AVDD Core 1.0V 999 mV

PF1 VDD Core 0.9V 950 mV

PF1 AVDD Core 1.0V 999 mV

XDB VDD 3.3V 3298 mV

XDB RT VDD 1.0V 999 mV

MEZZ VDD 2.5V 2502 mV

MEZZ PFE 1.5V 1502 mV

MEZZ GEX 1.0V 999 mV

VCC 1.0V 1009 mV

VCC 0.85V 862 mV

VDD RAIL 12.0V 0 mV

VCC 1.8V 1793 mV

VDD 1.2V 1215 mV

PCH VCC 1.0V 999 mV

CPU VCC 1.8V 1803 mV

BIAS 1 3.3V 3312 mV

AUX VCC 5.0V 4165 mV

DDR VDD 1.5V 1499 mV

VTT SA CPU 0.8V 803 mV

VTT CPU 1.05V 1048 mV

CORE CPU 1.0V 940 mV

PCH VCC 1.5V 1509 mV

PCH VCC 1.05V 1058 mV

VDD 2.5V 2508 mV

45

SEE ALSO

show chassis alarms

Page 45

PTX10003 Cooling System Description and Airflow

IN THIS SECTION

PTX10003 Fan Modules | 46

PTX10003 Chassis Airflow | 47

Fan Module Status and LED Description | 48

The PTX10003 is cooled front to back with five fan modules (PTX10003-160C) or three fan modules

(PTX10003-80C). Located in the rear of the chassis, the 98.4-W fan modules operate at 164 cubic feet

per minute (CFM) at full speed under zero static pressure. Each fan module is a redundant unit containing

dual counter-rotating fans. The fan modules can be hot-swapped and hot-inserted, meaning that you can

replace a fan module without powering off the router or disrupting the router function.

46

The fan modules pull air through the front panel around the gaps between the optical transceivers. Cooling

for the power supplies is also front to back, utilizing fans inside the power supplies. A separate air plenum

provides air circulation to the power supplies in the entrance at the top of the chassis. There are no air

filters in the PTX10003. Fans are field replaceable but a fan failure must be addressed within one minute

to avoid system shutdown. Access to the fans is from the Field Replaceable Units (FRU) end of the chassis.

Each fan module is composed of two individual fans per tray (10 fans per PTX10003-160C chassis and six

fans per PTX10003-80C chassis). The power requirements of the PTX10003 do not allow for redundant

fan modules.

PTX10003 Fan Modules

The PTX10003 fan modules are hot-removable and hot-insertable FRUs designed for front-to-back airflow.

For the PTX10003-160C, the fan modules are numbered 0 through 4. For the PTX10003-80C, the fan

modules are numbered 1 through 3. Fan modules are installed in fan trays located below the power supplies.

Each fan tray has a fan icon label on the handle.

Figure 13 on page 47 shows a PTX10003 fan module.

Page 46

Figure 13: PTX10003 Fan Module

g100312

Serial number

ID label

You remove and replace a fan module from the FRU end of the chassis. The router continues to operate

for a limited period of time (30 seconds) during the replacement of the fan module without thermal

shutdown.

NOTE: All fan modules must be installed for optimal operation of the router.

47

NOTE: If a fan module fails and the remaining fan modules are unable to keep the PTX10003

within the desired temperature thresholds, chassis alarms are raised and the PTX10003 might shut

down.

SEE ALSO

Maintaining the PTX10003 Fan Modules | 131

PTX10003 Chassis Airflow

In data center deployments, position the router in such a manner that the AIR OUT labels on router

components are next to the hot aisle. Figure 14 on page 48 shows the airflow through the chassis.

Page 47

Figure 14: Front-to-Back Airflow Through the PTX10003 Chassis

g100290

Ports FRUs

Fan Module Status and LED Description

48

You can check the status of fan modules by using the show system alarms or show chassis fan commands

or by looking at the LEDs next to each fan module. For example:

user@device> show chassis fan

Item Status RPM Measurement

Tray 0 Fan 0 Absent

Tray 0 Fan 1 Absent

Tray 1 Fan 0 OK 5000 Spinning at normal speed

Tray 1 Fan 1 OK 4400 Spinning at normal speed

Tray 2 Fan 0 OK 5000 Spinning at normal speed

Tray 2 Fan 1 OK 4400 Spinning at normal speed

Each router has a status LED (labeled ST) for each fan module on the left of the corresponding fan module

slot. The LED indicates the fan module status.

Figure 15 on page 49 shows the location of the LED next to the PTX10003-80C and PTX10003-160C

fan modules.

Page 48

Figure 15: PTX10003 Fan Module LEDs

g100289

1

g100467

1

49

1—Fan module LEDs

Table 14 on page 49 describes the fan module LED states.

Table 14: PTX10003 Fan Module LED

DescriptionStateColor

On steadilyGreen

BlinkingYellow

The fan module is operating normally. The system has

verified that the module is engaged, and that the fan is

operating correctly.

An error has been detected in the fan module. Replace

the fan module as soon as possible. Either the fan has

failed or it is seated incorrectly. To maintain proper airflow

through the chassis, leave the fan module installed in the

chassis until you are ready to replace it.

Under normal operating conditions, the fan modules operate at a moderate speed. Temperature sensors

in the chassis monitor the temperature within the chassis.

The system raises an alarm if a fan module fails or if the ambient temperature inside the chassis rises above

the acceptable range. If the temperature inside the chassis rises above the threshold temperature, the

router shuts down automatically.

Page 49

PTX10003 Power System

IN THIS SECTION

PTX10003 AC/HVDC Power Supply Description | 50

PTX10003 DC Power Supply Description | 59

The PTX10003 is powered by 3000-W redundant AC/HDVC or DC power supplies that are pre-installed

at the factory. The PTX10003-160C is powered by four power supplies for 2+2 redundancy. The

PTX10003-80C is powered by two power supplies for 1 + 1 redundancy. The power supplies are

hot-removable and hot-insertable. If one power supply fails, you can replace it without powering off or

disrupting the routing function. The other power supply balances the electrical load without interruption.

Each power supply has two outputs: 12 V and 12 V standby. Two counter-rotating fans in each power

supply provide front to back cooling. The input voltages are as follows:

50

AC input voltage range: 200—277 V/50—60 Hz

•

DC input voltage range: —40 VDC Min, —72 VDC maximum

•

CAUTION: Do not mix AC/HVDC and DC power supplies in the same chassis.

PTX10003 AC/HVDC Power Supply Description

The input power to the AC/HVDC power supplies can be AC power or HVDC power. The power supplies

automatically detect whether there is AC or HVDC input voltage and manage the power accordingly. AC

power can be 180—305 VAC input voltage and HVDC power can be 190—400 VDC input voltage. Each

3000- W AC/HVDC power supply module has a single AC or HVDC input and provides 12 V power to

the system.

Figure 16 on page 51 shows the location of the AC/HVDC power supplies on the PTX10003-160C FRU

panel, and Figure 17 on page 51 shows the location of the AC/HVDC power supplies on the PTX10003-80C

FRU panel.

Page 50

Figure 16: PTX10003-160C FRU Panel (AC Power Supplies Installed)

g100451

21 1 3

4

g100261

2

1

1 3

4

3—1— ESD grounding pointChassis grounding points (2)

4—2— Fan modules (5)AC/HVDC Power supplies (4)

Figure 17: PTX10003-80C FRU Panel (AC/HVDC Power Supplies Installed)

51

3—1— ESD grounding pointChassis grounding points (2)

4—2— Fan modules (3)AC/HVDC power supplies (2)

Figure 18 on page 52 shows the AC/HVDC power supply components.

Page 51

Figure 18: PTX10003 AC/HVDC Power Supply

g100270

1

3

4 2

g100287

1

CAUTION: To avoid electrical injury, carefully follow the instructions in “Maintaining the

PTX10003 Power Supplies” on page 134.

52

3—1— Ejector leverMale power connector

4—2— Orange handleStatus LED

PTX10003 AC/HVDC Power Supply LED

Each PTX10003 AC/HVDC power supply has a status LED on the power supply faceplate. Refer to

Figure 19 on page 52.

Figure 19: PTX10003 AC/HVDC Power Supply LED

1—Power supply LED

The PTX10003 AC/HVDC power supply uses an amber and green bi—color LED to indicate the operating

state. Refer to Table 15 on page 53.

Page 52

Table 15: PTX10003 AC/HVDC Power Supply States

Possible causes: high temperature, high power, high

current, fan failure

events. Possible conditions: high temp (inlet temperature

is greater than 53 degrees or a hot spot temperature is

greater than 95 degrees), high power, high current, slow

fan (less than 1200 rpm)

53

AmberGreenState

OffOnThe power supply is on and operating properly

OffOffOne or both power supplies do not have AC power

OnOffThe power supply shut down due to a critical event.

Blinking amberOffThe power supply is operating but there are warning

OffBlinkingThere is no input power but the power supply module

from another slot in the same system is on with 12 VSB

active

OnOffThe AC power cord is unplugged

You can get additional information about the status of the power modules using the show chassis power

command and the show chassis power detail command. Here’s some examples of the CLI output:

PTX10003-160C Power with Four AC/HVDC Power Supplies

user@device> show chassis power

Chassis Power Input(V) Used(W)

Total Power 2052

PDU 0 2052

PSM 0

Input 1 226 489

Capacity: 3000 W (maximum 3000 W)

PSM 1

Input 1 227 546

Capacity: 3000 W (maximum 3000 W)

PSM 2

Input 1 226 435

Capacity: 3000 W (maximum 3000 W)

Page 53

PSM 3

Input 1 227 582

Capacity: 3000 W (maximum 3000 W)

user@device> show chassis power detail

Chassis Power Input(V) Used(W)

Total Power 2044

PDU 0 2044

PSM 0

Input 1 226 489

Capacity: 3000 W (maximum 3000 W)

PSM 1

Input 1 227 534

Capacity: 3000 W (maximum 3000 W)

PSM 2

Input 1 226 432

Capacity: 3000 W (maximum 3000 W)

PSM 3

Input 1 227 589

Capacity: 3000 W (maximum 3000 W)

54

Item Used(W)

Routing Engine 0 147

CB 0 382

FPC 0 308

FPC 1 297

FPC 2 290

FPC 3 318

Fan Tray 0 17

Fan Tray 1 13

Fan Tray 2 17

Fan Tray 3 15

Fan Tray 4 12

System:

Zone 0:

Capacity: 12000 W (maximum 12000 W)

Allocated power: 4650 W (7350 W remaining)

Actual usage: 2047 W

Page 54

Total system capacity: 12000 W (maximum 12000 W)

Total remaining power: 7350 W

PTX10003-80C with Two AC/HVDC Power Supplies

user@device> show chassis power

Chassis Power Input(V) Used(W)

Total Power 1498

PDU 0 1498

PSM 1

Input 1 204 798

Capacity: 3000 W (maximum 3000 W)

PSM 2

Input 1 206 700

Capacity: 3000 W (maximum 3000 W)

55

user@device> show chassis power detail

Chassis Power Input(V) Used(W)

Total Power 1497

PDU 0 1497

PSM 1

Input 1 204 802

Capacity: 3000 W (maximum 3000 W)

PSM 2

Input 1 205 695

Capacity: 3000 W (maximum 3000 W)

Item Used(W)

Routing Engine 0 76

CB 0 266

FPC 0 435

FPC 1 443

Fan Tray 1 8

Fan Tray 2 7

Fan Tray 3 8

Page 55

System:

Zone 0:

Capacity: 6000 W (maximum 6000 W)

Allocated power: 2807 W (3193 W remaining)

Actual usage: 1495 W

Total system capacity: 6000 W (maximum 6000 W)

Total remaining power: 3193 W

PTX10003 AC/HVDC Power Specifications

The PTX10003 operates within the AC/HVDC input voltage range listed in Table 16 on page 56.

Table 16: PTX10003 AC/HVDC Power Specifications

MaximumRatedMinimumParameter

56

305 VAC200—277 VAC180 VACInput voltage (AC)

400 VDC240—380 VDC190 VDCInput voltage (HVDC)

63 Hz50—60 Hz47 HzAC input line frequency

PTX10003 AC Power Cord Specifications

Detachable AC power cords are shipped with the chassis if you include them as part of your order. The

plug at the male end of the power cord fits into the power source outlet that is standard for your

geographical location.

NOTE: In North America, AC power cords must not exceed 14.75 feet (approximately 4.5 meters)

in length, to comply with National Electrical Code (NEC) Sections 400-8 (NFPA 75, 5-2.2) and

210-52 and Canadian Electrical Code (CEC) Section 4-010(3). The cords that can be ordered for

the PTX10003 are in compliance.

Table 17 on page 57 lists AC power cord specifications provided for each country or region.

Page 56

Table 17: PTX10003 Power Cord Specifications

g050616

g100342

Spare Juniper

Model NumberPlug StandardsCord Set RatingLocale

57

Graphic

Zealand

Switzerland, and

United Kingdom)

16 A, 250 VACArgentina

CBL-JNP-SG4-ARIRAM 2073 Type

RA/3

CBL-JNP-SG4-AUAS/NZS 441715 A, 250 VACAustralia and New

16 A, 250 VACBrazil

CBL-JNP-SG4-BRNBR 14136 Type

BR/3

CBL-JNP-SG4-CHGB209916 A, 250 VACChina

CBL-JNP-SG4-EUCEE 7/7 STRAIGHT20 A, 250 VACEurope (except Italy,

CBL-JNP-SG4-UKBS136313 A, 250 VAC,Great Britain

Page 57

Table 17: PTX10003 Power Cord Specifications (continued)

g050751

g100341

Spare Juniper

Model NumberPlug StandardsCord Set RatingLocale

CBL-JNP-SG4-SASANS 164/116 A, 250 VACIndia

58

Graphic

16 A, RA, 250 VACIsrael

CBL-JNP-SG4-ILSI 32/1971 Type

IL/3G

CBL-JNP-SG4-ITCEI 23-1616 A, 250 VACItaly

20 A, 250 VACNorth America

CBL-JNP-SG4-C20C20 to Anderson

3-5958p4

16 A, 250 VACNorth America

CBL-JNP-SG4-US-LLocking NEMA

L6-20P

CBL-JNP-SG4-USNEMA 6-20P16 A, 250 VACNorth America

CBL-JNP-SG4-HVACNEMA I7-20P15 A, 277 VNorth America

CG_CBL-APP-400-02IEC 320P6W20 A, 250 VNorth America

CBL-JNP-SG4-SASANS 164/116 A, 250 VACSouth Africa

Page 58

Table 17: PTX10003 Power Cord Specifications (continued)

Table 18: PTX10003 HVDC Cable Specifications (Bare Wire)

Spare Juniper

Model NumberPlug StandardsCord Set RatingLocale

CBL-JNP-SG4-SZCEI 23-5016 A, 250 VACSwitzerland

Spare Juniper Model NumberCord Set RatingLocale

59

Graphic

CBL-PWR2-BARE16 A, 400 VACHVDC power cord

NOTE: The insulation color for wires in the HVDC cables are color coded. Green is ground, black

is line, and white is neutral. For HVDC, the black and white wires are not polarity-sensitive. The

black wire can be positive (+) or neutral (–) and the white wire can be positive (+) or negative (–).

PTX10003 DC Power Supply Description

The PTX10003 DC power supplies are hot-removable and hot-insertable FRUs. Each 3000 W power

supply has a single DC input and provides 12 VDC output with a standby voltage of 12 VDC.

Figure 20 on page 60 shows the location of the DC power supplies on the PTX10003-160C FRU panel,

and Figure 21 on page 60shows the location of the DC power supplies on the PTX10003-80C FRU panel.

Page 59

Figure 20: PTX10003-160C FRU Panel (DC Power Supplies Installed)

g100452

21 1 3

4

g100262

1

1 3

4

2

3—1— ESD grounding pointChassis grounding points (2)

4—2— Fan modules (5)DC power supplies (4)

Figure 21: PTX10003-80C FRU Panel (DC Power Supplies Installed)

60

3—1— ESD grounding pointChassis grounding points (2)

4—2— Fan modules (3)DC power supplies (2)

Figure 22 on page 61 shows the DC power supply components.

CAUTION: Do not mix AC/HVDC and DC power supplies in the same chassis.

Page 60

Figure 22: PTX10003 DC Power Supply

g100275

1 32 54

g100288

1

3—DC input current selector (DIP switch)

61

4—1— HandleEjector lever

5—2— Terminal block coverStatus LED

CAUTION: To avoid electrical injury, carefully follow instructions in “Maintaining the

PTX10003 Power Supplies” on page 134.

PTX10003 DC Power Supply LED

Each PTX10003 DC power supply has a status LED on the power supply faceplate. Refer to

Figure 23 on page 61.

Figure 23: PTX10003 DC Power Supply Status LED

1—Power supply status LED

Page 61

Use Table 19 on page 62 to interpret the state of the power supply status LED.

Table 19: PTX10003 DC Power Supply LED

Power Supply StateLED Color

The power supply is on and in the OK state.Solid green

One or both power supplies do not have DC powerOff

The power supply is in cold redundant stateBlinking green

62

Solid amber

Blinking amber

Solid amber

The DC power cord is unplugged but the second power supply still has DC

power

The power supply is operating but there are warning events. Possible causes:

high temp, high power, high current, slow fan

The power supply shut down due to a critical event. Possible causes: high

temperature, high power, high current, slow fan

The power supply is uploading firmwareBlinking green

PTX10003 DC Input Current Selector (DIP Switch)

The PTX10003 DC power supply can operate with an input current of 80 A or 60 A. You select the input

rating by moving the DC input current selector (DIP switch) to the desired setting. Refer to

Figure 22 on page 61 for the location of the DC input current selector (DIP switch). If you select 60 A, the

power supply limits the output power so that the input current does not exceed 60 A under normal

steady-state operation. If you select 80 A, the power supply limits the output power so that the input

current does not exceed 80 A.

CAUTION: The PTX10003 DC power supply does not support a 60 A power source in

Junos OS Evolved software release 19.1. When installing the PTX10003 DC power supply,

be sure you set the DC input current selector (DIP switch) to 80 A.

Page 62

For example:

63

Then...If you select...

60 A

80 A

The power supply limits the output power to 2200 W at 40 V input and linearly

increases the output power if the input voltage increases. The power supply provides

3000 W output power for input voltage greater than 55 V assuming 92% efficiency.

CAUTION: The PTX10003 DC power supply does not support a 60 A power source

in Junos OS Evolved software release 19.1. When installing the PTX10003 DC power

supply, be sure you set the DC input current selector (DIP switch) to 80 A.

The power supply provides 3000 W output power throughout the input voltage range

from 40 VDC to 72 VDC.

PTX10003 DC Power Redundancy

To provide power redundancy for the PTX10003, the power supply modules must be connected to an

80 A power source and the input current selector (DIP switch) on the power supply must be set to 80 A.

For the PTX10003-80C, the maximum power budget is 3000 W. For the PTX10003-160C, the maximum

output power budget is 4700 W.

CAUTION:

The PTX10003 DC power supply does not support an 60 A power source in Junos OS Evolved software

release 19.1. When installing the PTX10003 DC power supply, be sure you set the input current selector

to 80 A.

PTX10003 Input DC Voltage Specification

The PTX10003 DC power supply modules operate within the DC input voltage range listed in

Table 20 on page 64.

NOTE: Depending on the available input source, Juniper recommends that the 48-VDC facility DC

source be equipped with a circuit breaker rated at a minimum of 60 A (-48 VDC) or 80 A (-48 VDC),

or as required by local code.

Page 63

Table 20: PTX10003 DC Power Specifications

64

Input Switch

Setting

Minimum Input

DC Voltage

Rated Input DC

Voltage

MaximumInput

DC Voltage

Maximum Input

DC Current

Maximum

Output Power

2200 W60 ADC-72 VDC-48 VDC to -60 VDC-40 VDC60 A

3000 W90 ADC-72 VDC-48 VDC to -60 VDC-40 VDC80 A

PTX10003 DC Power Cables

You must supply the DC power cables that meet the specifications required by the local code, laws, and

standards. The insulation color of the wires are color coded. Green is ground, black is line, and white is

neutral. The wires are labeled (+) and (–) to indicate their polarity.

CAUTION: You must ensure that power connections maintain the proper polarity.

WARNING: For field-wiring connections, use copper conductors only.

WARNING: DC Power cables must not block access to PTX10003 components or drape

where people could trip on them.

PTX10003 DC Power Lugs