Page 1

Optical Inline Amplifier Hardware Guide

Published

2020-10-30

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

Optical Inline Amplifier Hardware Guide

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

About the Documentation | ix

Documentation and Release Notes | ix

Using the Examples in This Manual | ix

Merging a Full Example | x

Merging a Snippet | xi

Documentation Conventions | xi

Documentation Feedback | xiv

Requesting Technical Support | xiv

Self-Help Online Tools and Resources | xv

Creating a Service Request with JTAC | xv

iii

Overview

Optical ILA System Overview | 17

Optical Inline Amplifier Description | 17

Front Panel | 18

FRU Panel | 19

Optical ILA Hardware Component Overview | 19

Optical ILA Component Redundancy | 20

Optical ILA Field-Replaceable Units | 20

Optical ILA Chassis | 21

Optical ILA Chassis Description | 22

Optical ILA Front Panel and FRU Panel | 22

Front Panel | 22

FRU Panel | 23

Optical ILA Chassis Status LEDs | 24

Optical ILA Management Panel | 26

Optical ILA Management Port LEDs | 28

Optical ILA Cooling System Description | 29

Fan Modules | 30

Page 4

Optical ILA Power System | 31

2

Optical ILA AC Power Supply Description | 31

Optical ILA DC Power Supply Description | 32

Optical ILA Power Supply LEDs | 34

Optical ILA AC Power Specifications | 36

Optical ILA AC Power Cord Specifications | 36

Optical ILA DC Power Specifications | 37

Optical ILA DC Power Cable and Lugs Specifications | 38

DC Power Cables | 38

DC Power Connector | 39

Optical ILA Chassis Grounding Cable and Lug Specifications | 39

Site Planning, Preparation, and Specifications

Optical ILA Site Preparation Checklist | 42

iv

Optical ILA Site Guidelines and Requirements | 43

Optical ILA Environmental Requirements and Specifications | 44

Optical ILA Clearance Requirements for Airflow and Hardware Maintenance | 45

Optical ILA Physical Specifications | 46

Optical ILA Rack Requirements | 46

Optical ILA Cabinet Requirements | 47

Optical Specifications for the Optical ILA | 48

Optical ILA Management Cable Specifications and Pinouts | 49

Cable Specifications for Console and Management Connections for the Optical ILA | 49

Management Port Connector Pinouts for the Optical ILA | 50

Console Port Connector Pinouts for the Optical ILA | 51

Page 5

Initial Installation and Configuration

3

Overview of Installing the Optical ILA | 53

Unpacking and Mounting the Optical ILA | 54

Unpacking the Optical ILA | 54

Mounting an Optical ILA in a Rack or Cabinet | 55

Before You Begin Mounting the Optical ILA | 56

Mounting the Optical ILA | 57

Connecting the Optical ILA to External Devices | 58

Connecting the Optical ILA to a Management Ethernet Device | 58

Connecting the Optical ILA to a Management Console | 59

Connecting the Optical ILA to the Network and External Devices | 60

Connecting the Optical ILA to Power | 61

v

Connecting the Optical ILA Grounding Cable | 62

Connecting AC Power to an Optical ILA | 63

Connecting DC Power to an Optical ILA | 66

Configuring the Software on the Optical ILA | 69

Performing Initial Software Configuration for the Optical ILA | 69

Optical ILA Modes of Operation | 70

Optical ILA CLI System Commands | 71

Optical ILA CLI show Commands | 72

Optical ILA CLI Configuration Commands | 78

Optical ILA CLI Upgrade Commands | 85

Optical ILA CLI Debug Commands | 86

Powering Off an Optical ILA | 88

Page 6

Maintaining Components

4

5

6

7

Maintaining the Optical ILA Cooling System | 92

Removing a Fan Module from an Optical ILA | 92

Installing a Fan Module in an Optical ILA | 93

Maintaining Power Supplies | 95

Removing a Power Supply from an Optical ILA | 95

Installing a Power Supply in an Optical ILA | 97

Maintaining the Optical ILA Fiber-Optic Cables | 99

Disconnect a Fiber-Optic Cable | 99

Connect a Fiber-Optic Cable | 100

How to Handle Fiber-Optic Cables | 101

Removing an Optical ILA from a Rack or Cabinet | 102

vi

Troubleshooting Hardware

Troubleshooting the Optical ILA | 105

Troubleshooting Resources Overview | 105

Optical ILA Alarm Messages Overview | 105

Contacting Customer Support and Returning the Chassis or Components

Returning the Optical ILA Chassis or Components | 112

Contacting Customer Support | 112

Locating the Serial Number on an Optical ILA Chassis or Component | 113

Listing the Chassis and Component Details by Using the CLI | 113

Locating the Chassis Serial Number ID Label on an Optical ILA | 115

Locating the Serial Number ID Labels on FRU Components | 115

How to Return a Hardware Component to Juniper Networks, Inc. | 116

Guidelines for Packing Hardware Components for Shipment | 117

Packing an Optical ILA Chassis or Component for Shipping | 118

Packing an Optical ILA for Shipping | 118

Safety and Compliance Information

General Safety Guidelines and Warnings | 122

Definitions of Safety Warning Levels | 123

Page 7

Fire Safety Requirements | 126

Fire Suppression | 126

Fire Suppression Equipment | 126

Qualified Personnel Warning | 127

Warning Statement for Norway and Sweden | 128

Installation Instructions Warning | 128

Chassis and Component Lifting Guidelines | 129

Restricted Access Warning | 130

Rack-Mounting and Cabinet-Mounting Warnings | 132

Grounded Equipment Warning | 138

Laser Safety Warnings for Class 1M Juniper Networks Devices | 139

vii

General Laser Safety Guidelines | 139

Class 1M Laser Product Warning | 140

Class 1 LED Product Warning | 141

Laser Beam Warning | 142

Radiation from Open Port Apertures Warning | 143

Maintenance and Operational Safety Guidelines and Warnings | 144

Battery Handling Warning | 145

Jewelry Removal Warning | 146

Lightning Activity Warning | 148

Operating Temperature Warning | 149

Product Disposal Warning | 151

General Electrical Safety Guidelines and Warnings | 152

Action to Take After an Electrical Accident | 153

Prevention of Electrostatic Discharge Damage | 153

AC Power Disconnection Warning | 155

Optical ILA DC Power Electrical Safety Guidelines | 155

DC Power Copper Conductors Warning | 157

Page 8

DC Power Disconnection Warning | 158

DC Power Grounding Requirements and Warning | 160

DC Power Wiring Sequence Warning | 162

DC Power Wiring Terminations Warning | 165

Multiple Power Supplies Disconnection Warning | 168

Site Electrical Wiring Guidelines for Juniper Networks Devices | 169

Distance Limitations for Signaling | 169

Radio Frequency Interference | 169

Electromagnetic Compatibility | 169

Agency Approvals and Compliance Statements | 170

Optical ILA Agency Approvals | 171

viii

Compliance Statements for EMC Requirements | 172

Canada | 172

European Community | 172

Israel | 172

Japan | 173

United States | 173

Compliance Statements for Environmental Requirements | 173

Compliance Statements for NEBS | 173

Optical ILA Compliance Statements for Acoustic Noise | 174

Page 9

About the Documentation

IN THIS SECTION

Documentation and Release Notes | ix

Using the Examples in This Manual | ix

Documentation Conventions | xi

Documentation Feedback | xiv

Requesting Technical Support | xiv

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the Optical Inline Amplifier.

ix

After completing the installation and basic configuration procedures covered in this guide, refer to the

PTX3000 Integrated Photonic Line System user guide for information about further software configuration.

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

Page 10

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

x

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Page 11

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

xi

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

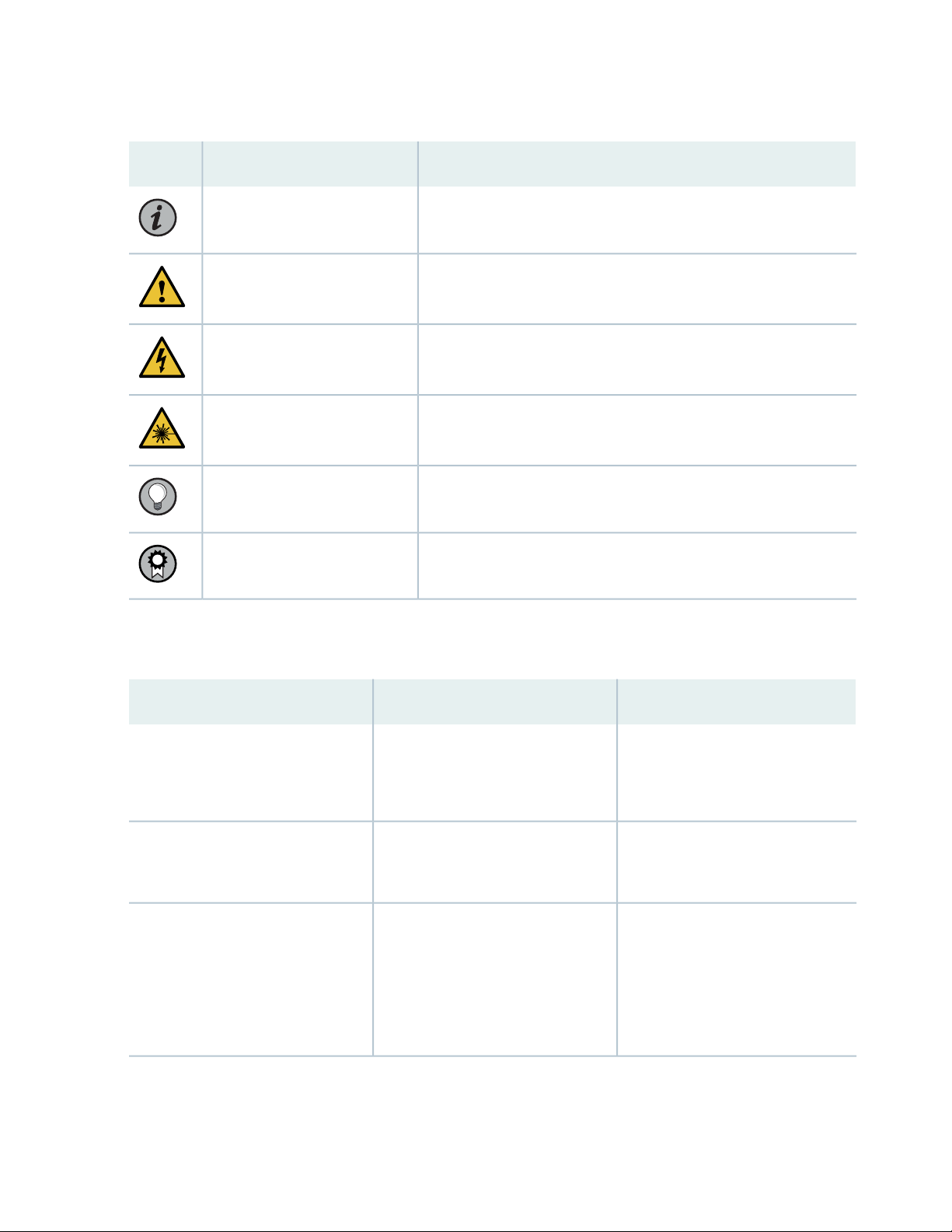

Table 1 on page xii defines notice icons used in this guide.

Page 12

Table 1: Notice Icons

xii

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

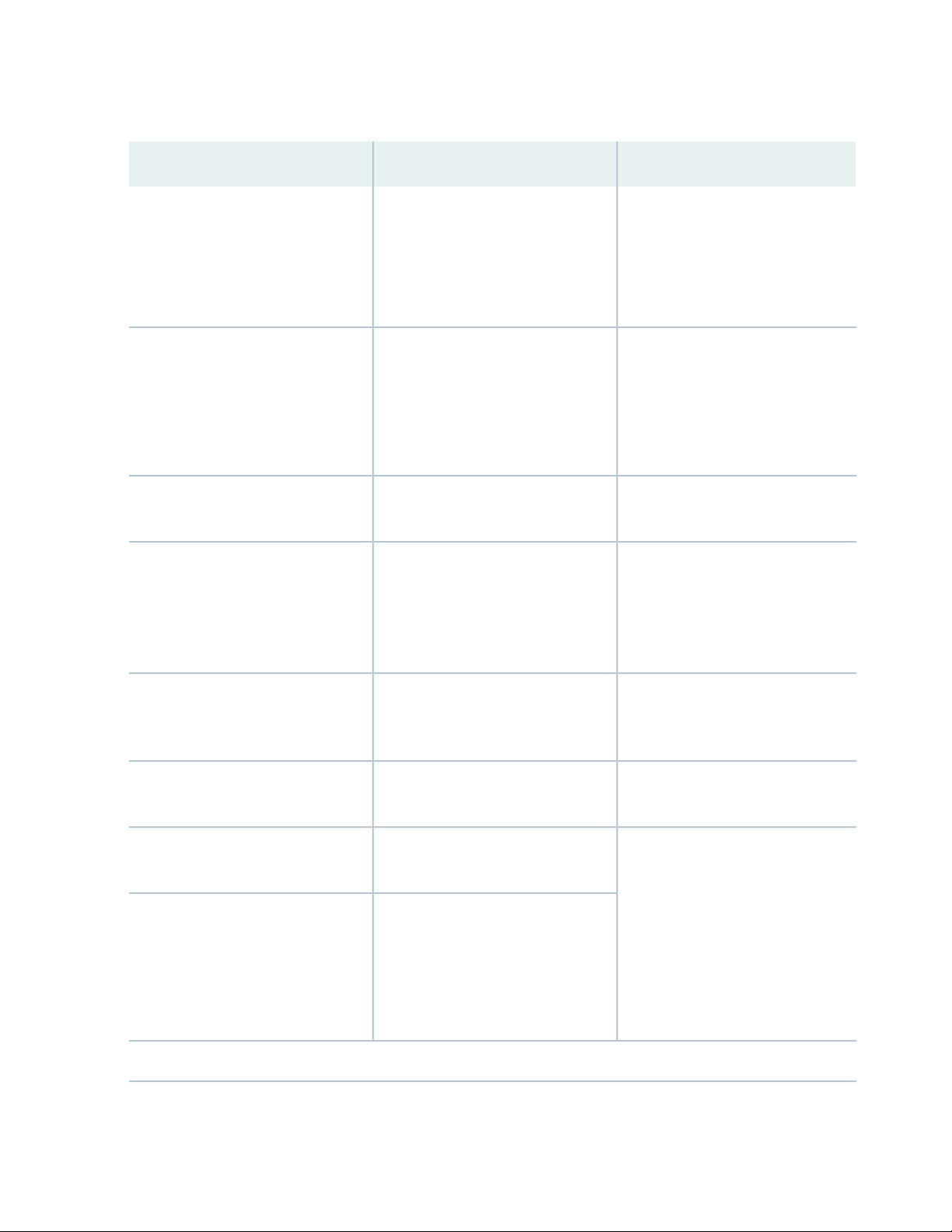

Table 2 on page xii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Page 13

Table 2: Text and Syntax Conventions (continued)

xiii

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Page 14

Table 2: Text and Syntax Conventions (continued)

xiv

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

Page 15

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

xv

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 16

1

CHAPTER

Overview

Optical ILA System Overview | 17

Optical ILA Chassis | 21

Optical ILA Cooling System Description | 29

Optical ILA Power System | 31

Page 17

Optical ILA System Overview

IN THIS SECTION

Optical Inline Amplifier Description | 17

Optical ILA Hardware Component Overview | 19

Optical ILA Component Redundancy | 20

Optical ILA Field-Replaceable Units | 20

Optical Inline Amplifier Description

17

IN THIS SECTION

Front Panel | 18

FRU Panel | 19

The Juniper Networks Optical Inline Amplifier is a stand-alone erbium-doped fiber amplifier (EDFA) with

dual AC or DC power supplies. The optical inline amplifier (ILA) supports bidirectional optical inline

amplification. The optical ILA provides periodic amplification of a dense wavelength-division multiplexing

(DWDM) signal to enable long-distance transmission as it propagates along the fiber-optic cable. Optical

ILAs are typically placed between 50 miles (80 km) and 62 miles (100 km) apart along the length of the

fiber. They are used in conjunction with the integrated photonic line cards (IPLCs) that are installed in the

Juniper Networks PTX3000 Packet Transport Routers. An optical ILA connects to an IPLC through the

LINE IN and LINE OUT LC port connectors on the front panel. It also connects to other optical ILAs through

the same LC port connectors.

The optical ILA operates with redundant hot-swappable pluggable power supplies that are either AC or

DC. The optical ILA can be managed by using Connectivity Services Director (CSD), or by using the CLI

console commands. The optical ILA does not run the Juniper Networks Junos operating system (Junos

OS).

Starting with Junos OS release 17.1, you can control and manage optical inline amplifiers (ILA) over the

optical supervisory channel (OSC) of the PTX3000 integrated photonic line system. For information about

Page 18

managing the ILAs over the OSC of the the IPLCs, see the Integrated Photonic Line Card (IPLC) System User

Guide.

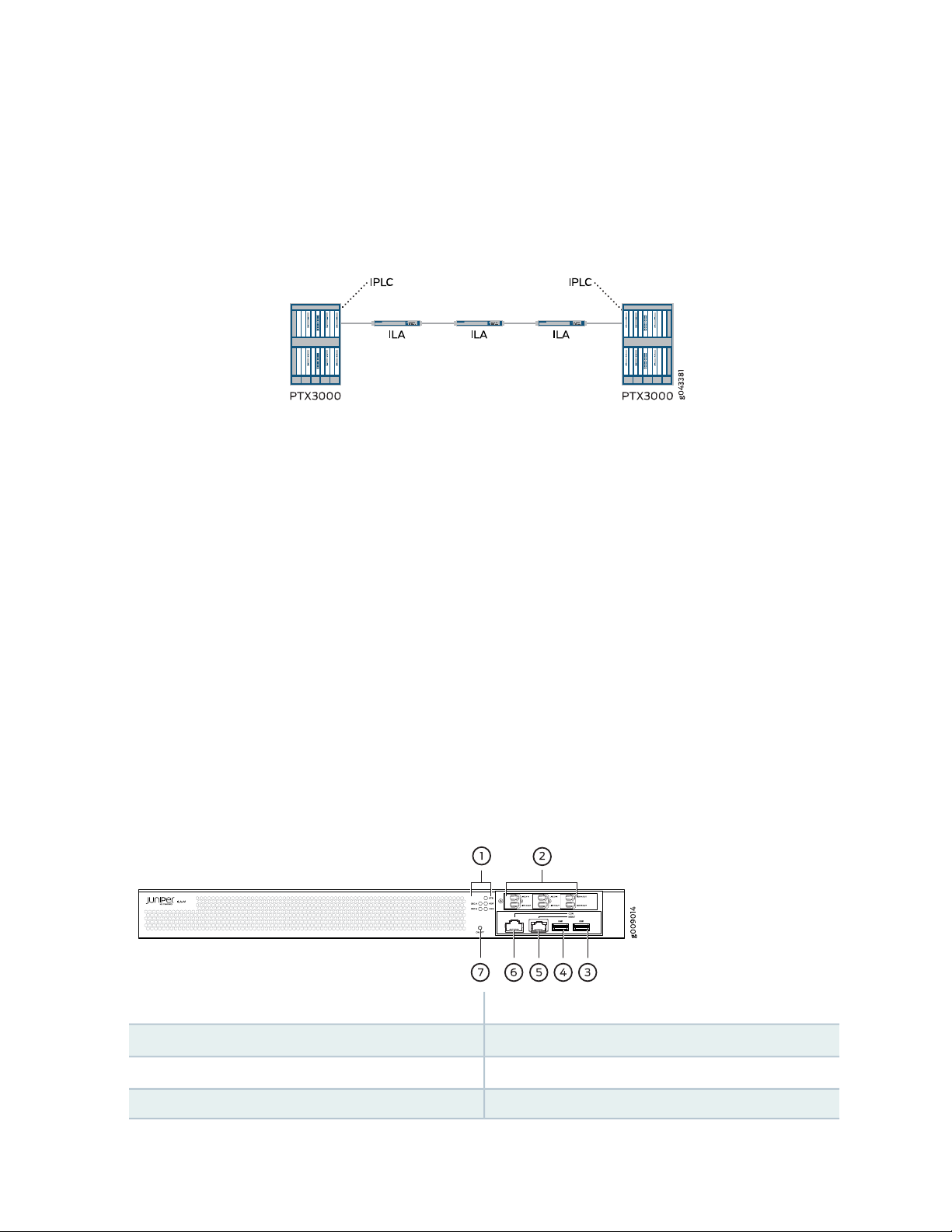

Figure 1 on page 18 shows a point-to-point configuration with the optical ILA and IPLC.

Figure 1: Point-to-Point Configuration

In this example, the optical ILA is connected to the IPLC in the PTX3000 chassis, which is connected to

compatible PICs in the same chassis through the add and drop ports. The multiplexed wavelengths from

the IPLC are amplified and transmitted in a single fiber toward the line (through the Line OUT port on the

IPLC), which is connected to the optical ILA (through the LINE IN port on the ILA). Based on the distance,

you can have multiple ILAs connected. In this example, there are three ILAs to enable long-distance

transmission.

18

For more information about the IPLCs, see the PTX3000 Packet Transport Router Hardware Guide. For

information about configuring the IPLCs, see the Integrated Photonic Line Card (IPLC) System User Guide.

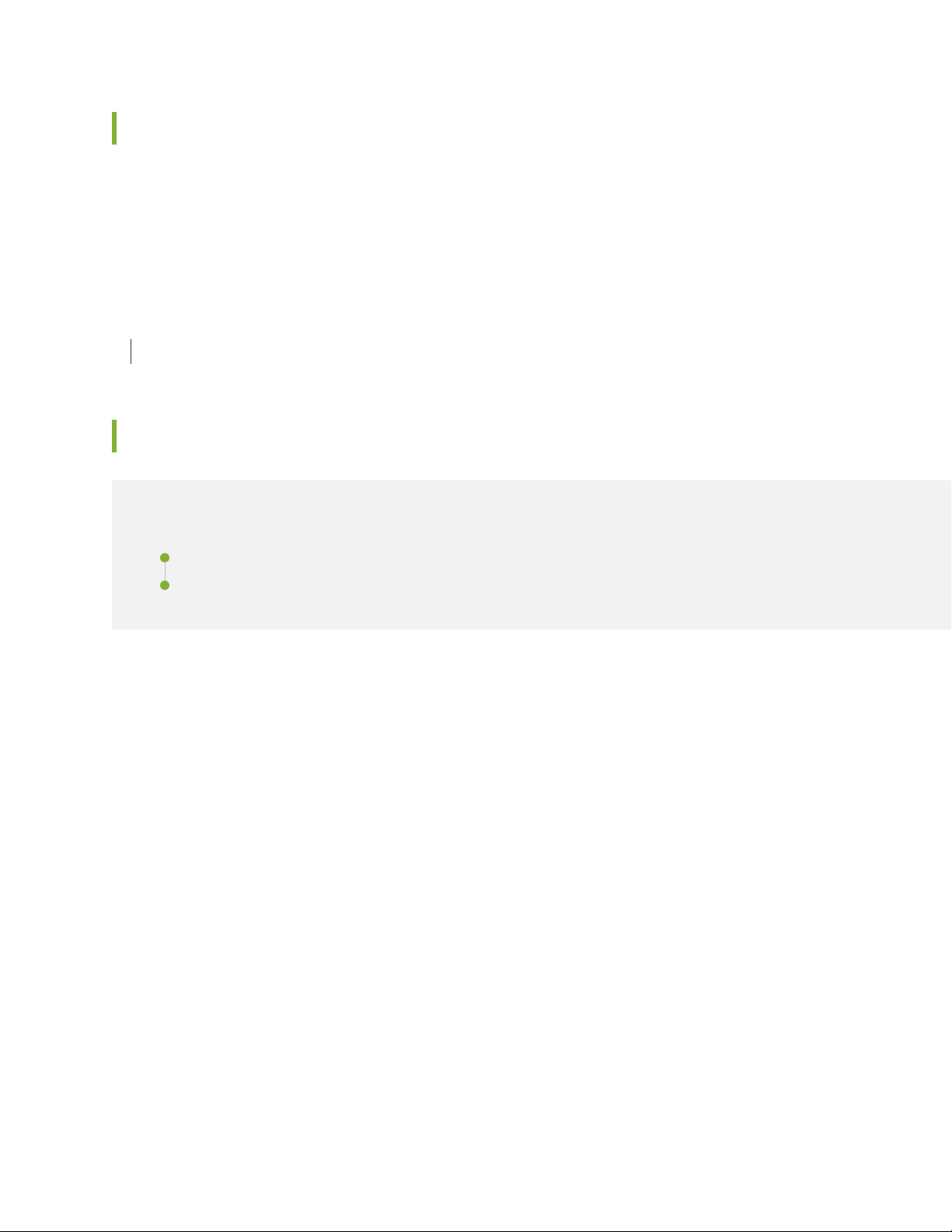

Front Panel

The front panel of the optical ILA contains six LC port connectors, the ON/OFF button, the console and

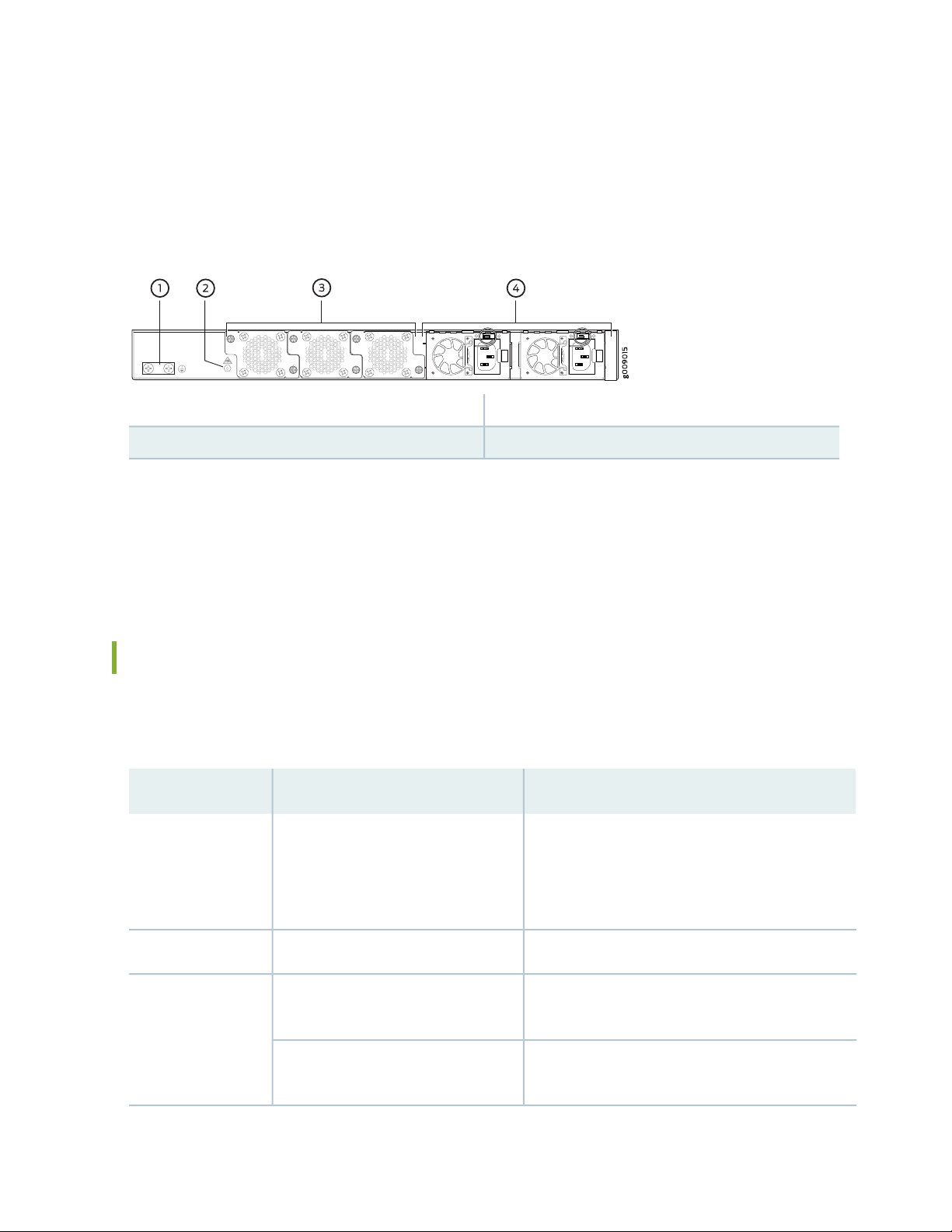

management ports, the system status LEDs, and the USB ports. Figure 2 on page 18 shows the front panel

of the optical ILA.

Figure 2: Optical ILA Front Panel

5—1— Management (MGMT) Ethernet portStatus LEDs

6—2— Console (CON) portLC port connectors

4—USB (USB) port

7—3— On/off button (ON/OFF)USB (USB) port

Page 19

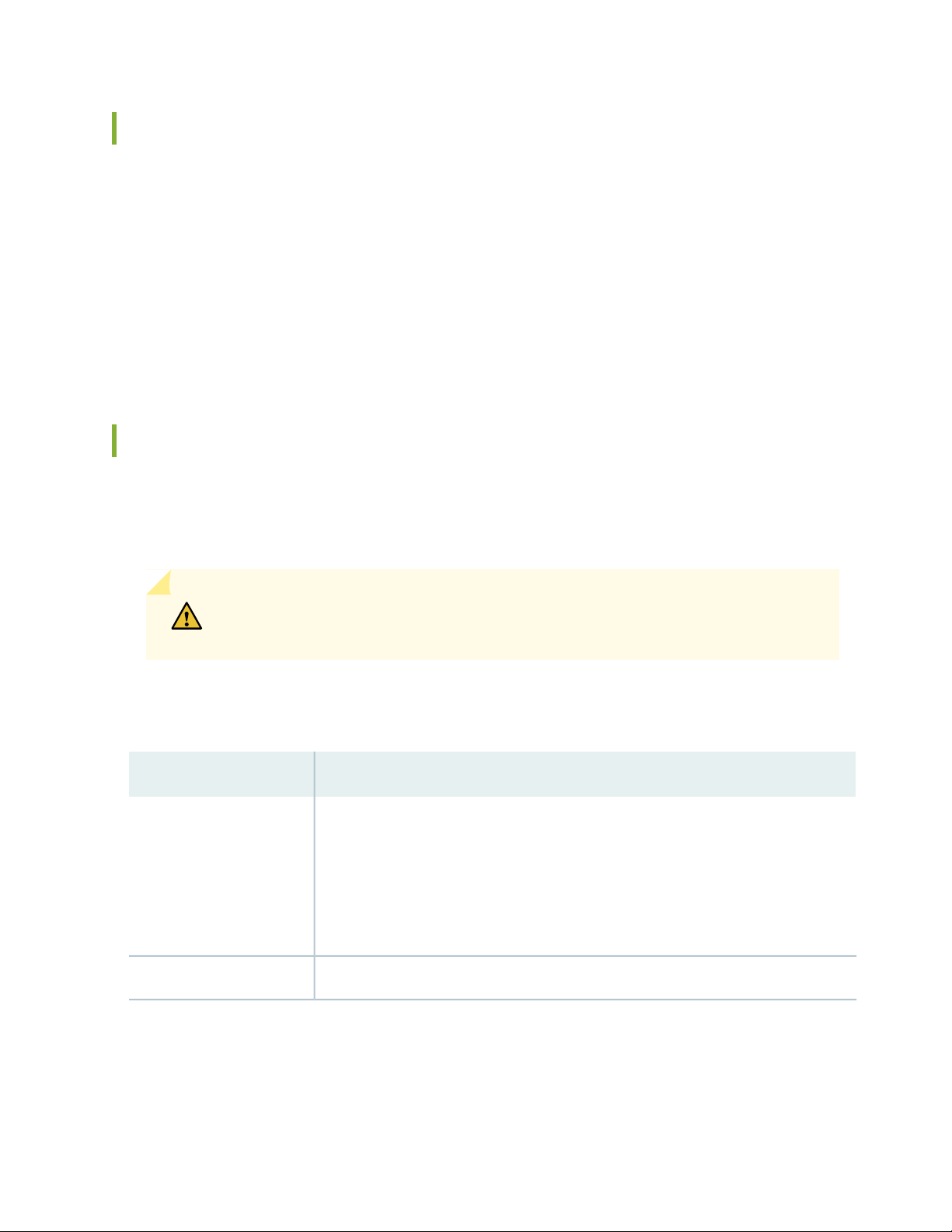

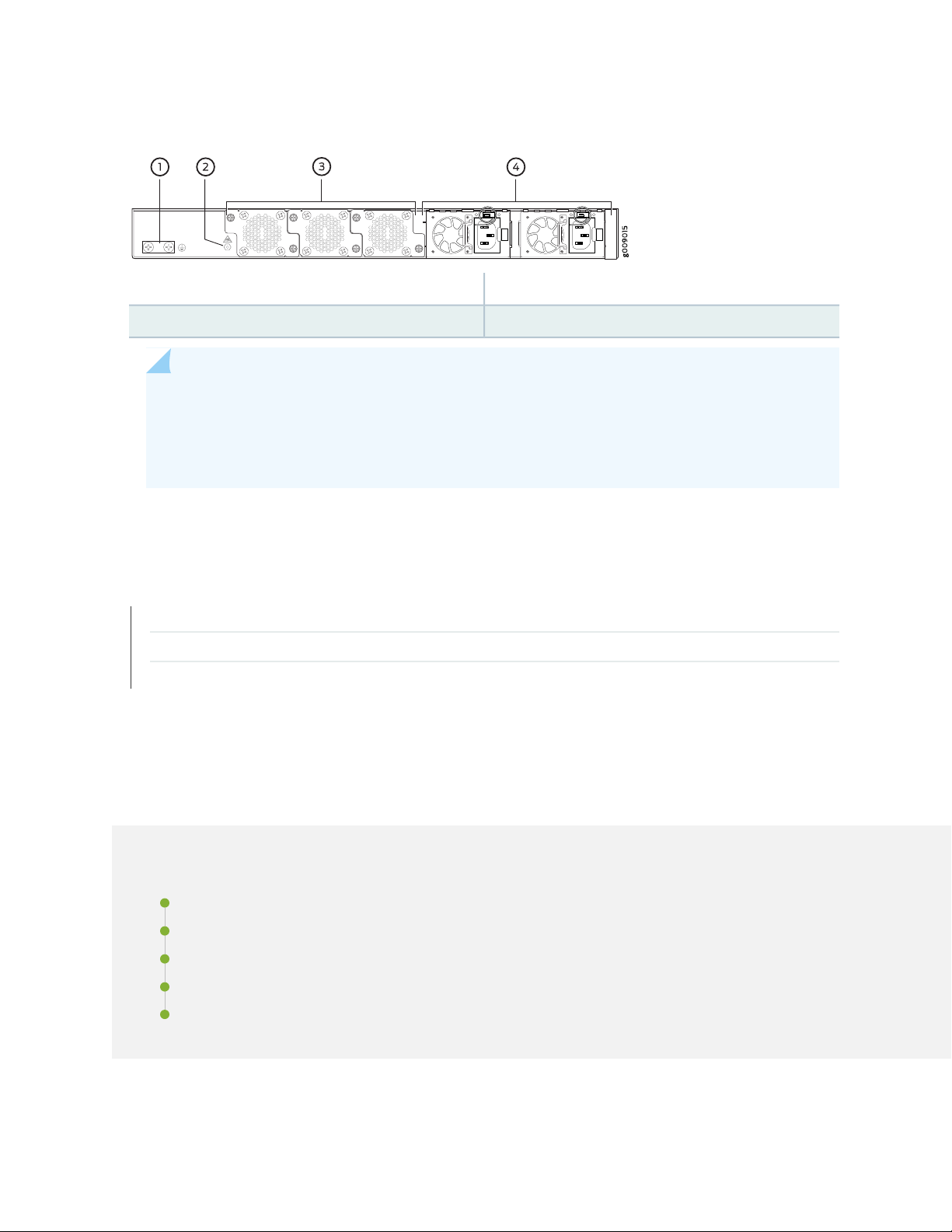

FRU Panel

The field-replaceable unit (FRU) panel of the optical ILA contains the fan modules and power supplies for

the optical ILA. Figure 3 on page 19 shows the FRU panel on the optical ILA.

Figure 3: Optical ILA FRU Panel

3—1— Fan modulesGrounding points

4—2— Power suppliesESD point

The cooling system in an optical ILA consists of three 12.4-W fan modules. These fan modules can be

hot-swapped—you do not need to power off the optical ILA or disrupt the functioning of the optical ILA

to replace a fan module. The optical ILA has two 150-W power supplies, either AC or DC depending on

your configuration. The power supplies need to be both AC or both DC. Only one power supply is required

to power the device, while the second power supply provides redundancy.

19

Optical ILA Hardware Component Overview

Table 3 on page 19 describes the hardware components of the optical ILA.

Table 3: Optical ILA Hardware Components

DescriptionSpare Model NumberComponent

Chassis

PTX-ILA-M-DC

PTX-ILA-M-CHAS

JPSU-150-AC-AFOPower supplies

JPSU-150-DC-AFO

“Optical ILA Chassis Description” on page 22PTX-ILA-M-AC

“Optical ILA Cooling System Description” on page 29FAN-ILA-SFan module

“Optical ILA AC Power Supply Description” on

page 31

“Optical ILA DC Power Supply Description” on

page 32

Page 20

Optical ILA Component Redundancy

The following hardware components provide redundancy on the optical ILA models:

Cooling system—The optical ILA has three fan modules. Each fan module is a redundant unit containing

•

one fan. If a fan module fails and the remaining fan modules are unable to keep the optical ILA within

the desired temperature thresholds, chassis alarms are raised and the optical ILA can shut down.

The optical ILA ships with two power supplies that provide 1+1 redundancy. If one power supply fails

•

or is removed, the second power supply balances the electrical load without interruption and still provides

1+1 redundancy while the failing power supply is replaced.

Optical ILA Field-Replaceable Units

Field-replaceable units (FRUs) are components that you can replace at your site. The optical ILA FRUs are

hot-removable and hot-insertable—you can remove and replace them without powering off the optical

ILA or disrupting the optical ILA function.

20

CAUTION: Replace a failed fan module with a new fan module within 30 seconds of

removal to prevent chassis overheating.

Table 4 on page 20 lists the FRUs for the optical ILA and actions to take before removing them.

Table 4: Required Actions Before Removing a FRU from the Optical ILA

Required Actions Before RemovalFRU

Power supplies (2)

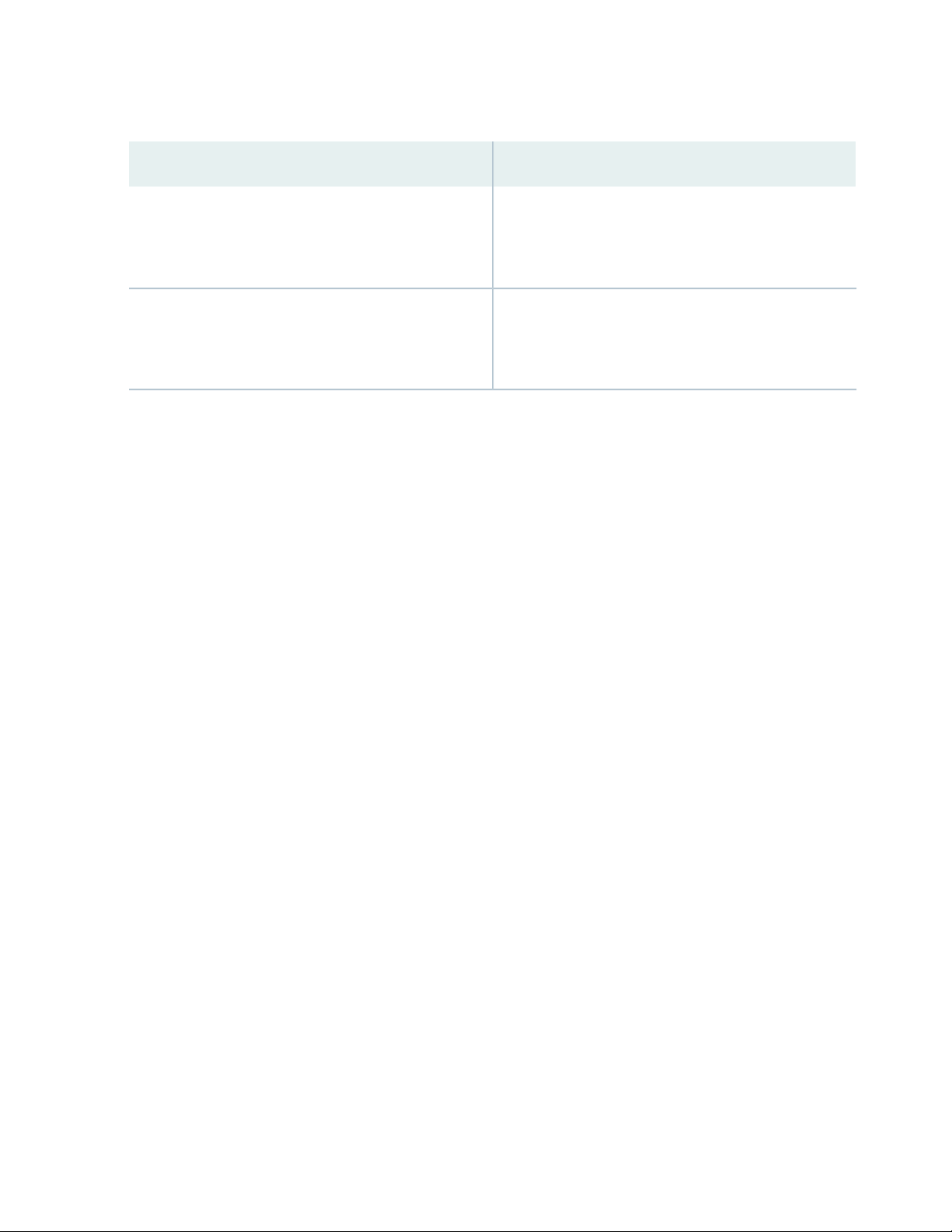

Figure 4 on page 21 shows the FRU panel on an optical ILA.

Disconnect the AC power and remove the AC power cord or cable for the power supply

unit.

Disconnect the DC power and remove the power connector.

NOTE: You need a minimum of one powered power supply for the optical ILA to operate

properly.

None.Fan modules (3)

Page 21

Figure 4: Optical ILA FRU Panel

3—1— Fan modulesGrounding

4—2— Power suppliesESD point

NOTE: If you have a Juniper Care service contract, register any addition, change, or upgrade of

hardware components at https://www.juniper.net/customers/support/tools/updateinstallbase/.

Failure to do so can result in significant delays if you need replacement parts. This note does

not apply if you replace existing components with the same type of component.

21

RELATED DOCUMENTATION

Optical ILA AC Power Supply Description | 31

Optical ILA DC Power Supply Description | 32

Optical ILA Cooling System Description | 29

Optical ILA Chassis

IN THIS SECTION

Optical ILA Chassis Description | 22

Optical ILA Front Panel and FRU Panel | 22

Optical ILA Chassis Status LEDs | 24

Optical ILA Management Panel | 26

Optical ILA Management Port LEDs | 28

Page 22

Optical ILA Chassis Description

The optical ILA chassis is a rigid sheet metal structure that houses all the other hardware components.

The chassis measures 1.72 in. (4.36 cm) high, 9.6 in. (24.4 cm) deep, and 17.24 in. (43.8 cm) wide. The

chassis can be installed in racks or cabinets.

SEE ALSO

Optical Inline Amplifier Description | 17

Optical ILA Front Panel and FRU Panel

22

IN THIS SECTION

Front Panel | 22

FRU Panel | 23

The front panel of the optical ILA contains six LC port connectors, the ON/OFF button, the console and

management ports, the system status LEDs, and the USB ports. The field-replaceable unit (FRU) panel of

the optical ILA contains the fan modules and power supplies for the optical ILA.

Front Panel

Figure 5 on page 23 shows the front panel of the optical ILA.

Page 23

Figure 5: Optical ILA Front Panel

g0 0 90 42

1 2 3 4 5 6

4—USB (USB) port

Figure 6: LC Ports

23

5—1— Management (MGMT) portStatus LEDs

6—2— Console (CON) portLC port connectors

7—3— On/off button (ON/OFF)USB (USB) port

(LINE A OUT)

(LINE B OUT)

The LC ports on the optical ILA have line interfaces toward the optical network (LINE IN and LINE OUT).

The optical ILA is bidirectional—with directions east to west and west to east. There are two optical ports

per direction (two LINE IN ports, two LINE OUT ports, and two (MON) ports for monitoring). See

Figure 6 on page 23.

FRU Panel

Figure 7 on page 24 shows the FRU panel on the optical ILA.

4—1— Input line B (LINE B IN)Output line A—for example, east to west direction

5—2— Monitor output line B (MON B OUT)Input line A (LINE A IN)

6—3— Monitor output line A (MON A OUT)Output line B–for example, west to east direction

Page 24

Figure 7: Optical ILA FRU Panel

3—1— Fan modulesGrounding points

4—2— Power suppliesESD point

The cooling system in an optical ILA consists of three 12.4-W fan modules. The fan modules can be

hot-swapped—you do not need to power off the optical ILA or disrupt the optical ILA function to replace

a fan module.

The optical ILA has two 150-W power supplies, either AC or DC depending on your configuration. The

power supplies need to be both AC or both DC—you cannot mix AC and DC power supplies in the same

chassis. Only one power supply is required to power the device, while the second power supply provides

redundancy. When the optical ILA has both power supplies installed and connected to power, the device

has full power redundancy. If a power supply fails or is removed, another power supply balances the

electrical load without interruption. Each power supply provides 12 VDC output with a standby voltage

of 12 VDC. The power supplies can be hot-swapped—you do not need to power off the optical ILA or

disrupt the optical ILA function to replace a power supply.

24

For more information about the components on the FRU panel, see “Optical ILA Cooling System Description”

on page 29, “Optical ILA AC Power Supply Description” on page 31, and “Optical ILA DC Power Supply

Description” on page 32.

Optical ILA Chassis Status LEDs

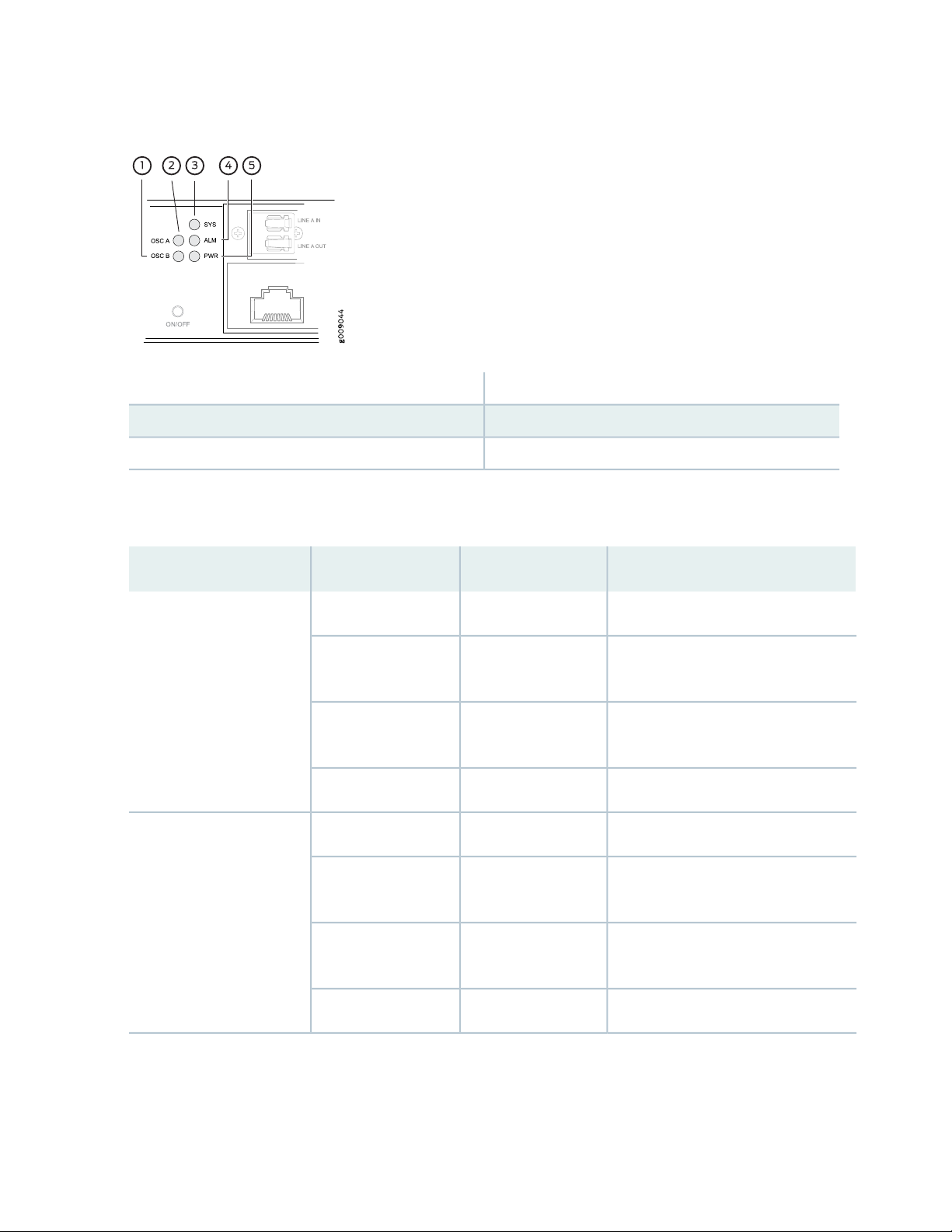

The optical ILA has five status LEDs on the front panel of the chassis (see Figure 8 on page 25)—two optical

supervisory channel (OSC) status LEDs (OSC A and OSC B), a system status LED (SYS), an alarm LED (ALM),

and a power LED (PWR). The OSC is a separate channel that carries overhead information for network

management purposes. The OSC, which is an important section in every DWDM system, is a separate

channel that carries overhead information for network purposes. For instance, it carries data between

sites for monitoring and controlling specifications in the system.

Page 25

Figure 8: Chassis Status LEDs on an Optical ILA

4—1— Alarm (ALM) LEDOSC B status (OSC B) LED

5—2— Power (PWR) LEDOSC A status (OSC A) LED

3—System status (SYS) LED

Table 5 on page 25 describes the chassis status LEDs on an optical ILA.

25

Table 5: Optical ILA Chassis Status LEDs

DescriptionStateColorName

The power is off.OffUnlitOSC A status (OSC A) LED

On steadilyRed

On steadilyAmber

On steadilyRed

On steadilyAmber

No OSC signal is received from the

downstream device.

OSC signal received from the upstream

device indicates a fault.

OSC signal is communicating normally.On steadilyGreen

The power is off.OffUnlitOSC B status (OSC B) LED

No OSC signal is received from the

downstream device.

OSC signal received from the upstream

device indicates a fault.

OSC signal is communicating normally.On steadilyGreen

Page 26

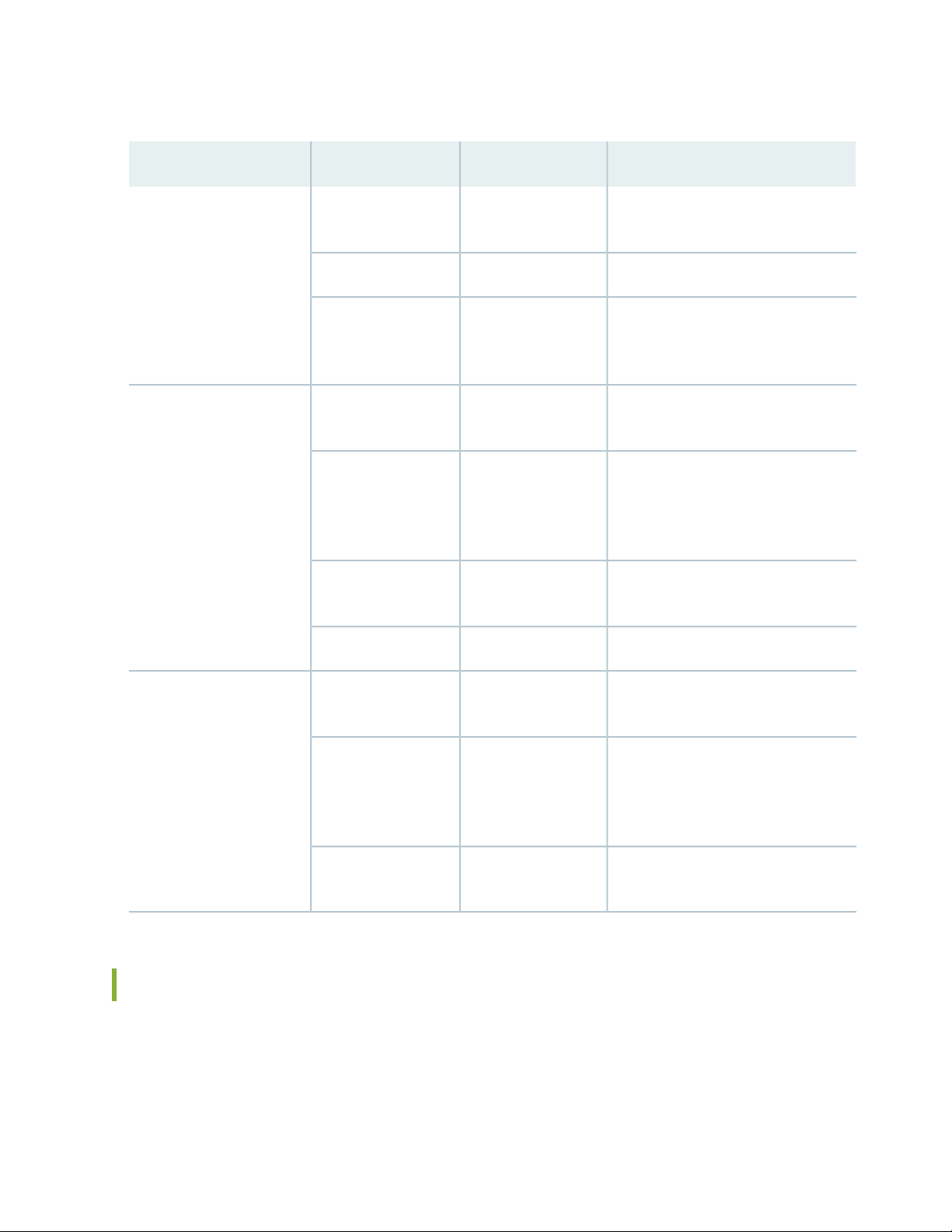

Table 5: Optical ILA Chassis Status LEDs (continued)

26

DescriptionStateColorName

OffUnlitSystem status (SYS) LED

BlinkingGreen

OffUnlitAlarm (ALM) LED

On steadilyRed

On steadilyAmber

The power is off, or the optical ILA is

not connected to any power source.

The optical ILA software has booted.On steadilyGreen

The optical ILA is active and is

communicating with upstream and

downstream network elements.

The optical ILA is off, or there is no

alarm.

A major hardware fault has occurred,

such as a temperature alarm or a power

or pump failure, and the unit has

halted. The CLI is still accessible.

A minor alarm has occurred, such as a

software error.

The optical ILA is operating properly.SolidGreen

OffUnlitPower (PWR)

On steadilyAmber

On steadilyGreen

The optical ILA is powered off or there

is no power to the device.

The optical ILA is powered by a single

power supply. The second power

supply is either missing or not

connected to a power source.

The optical ILA is powered with two

redundant power supplies.

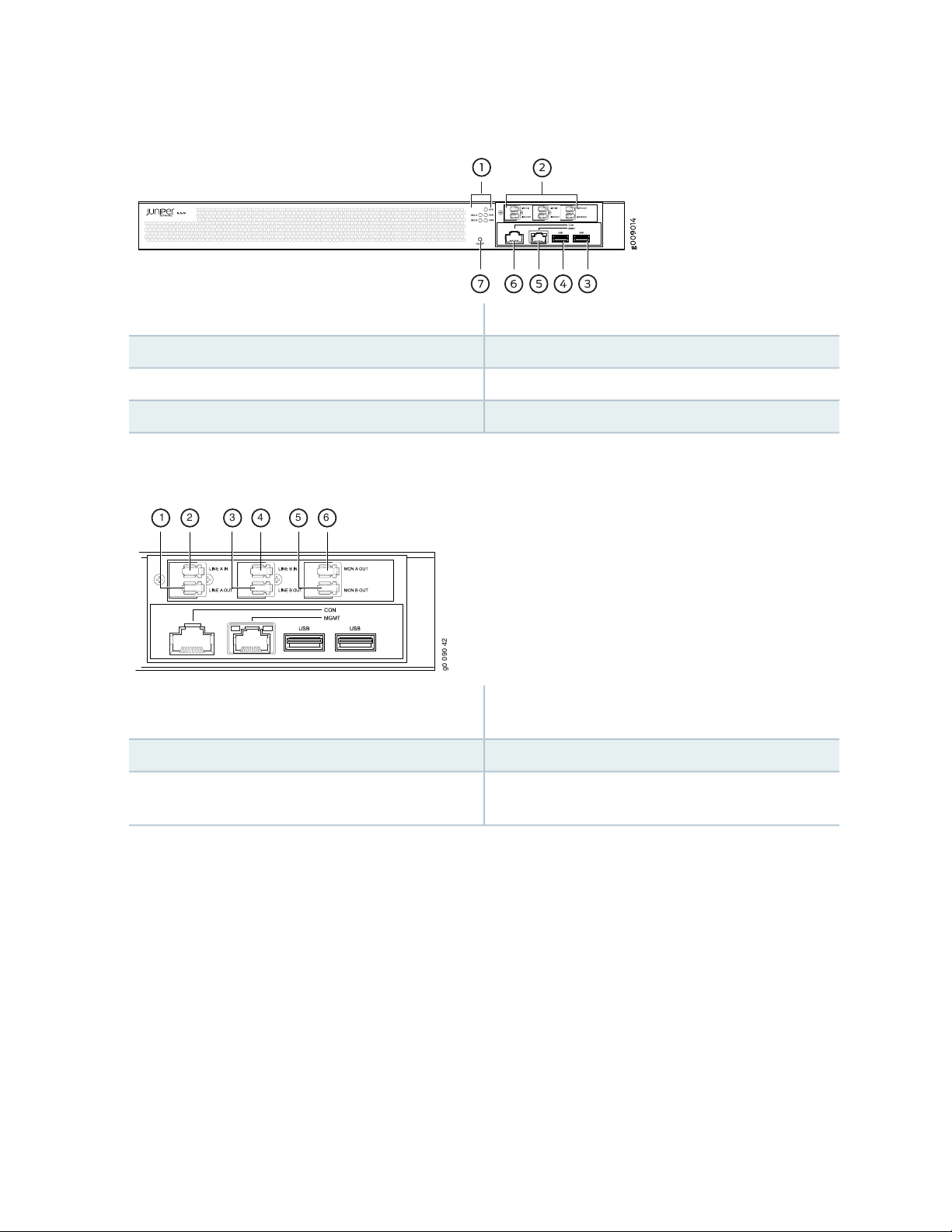

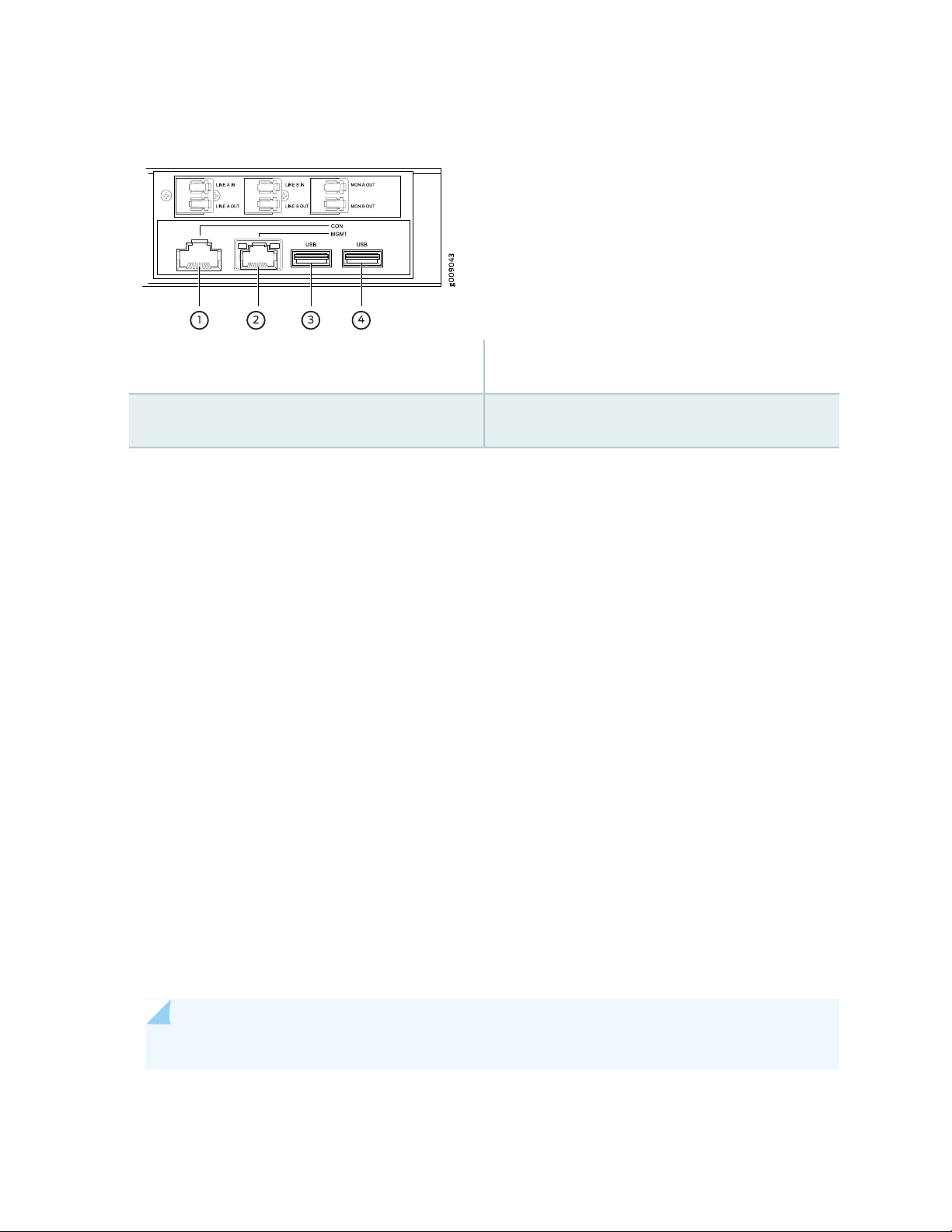

Optical ILA Management Panel

The optical ILA management panel is found on the front panel (see Figure 9 on page 27).

Page 27

Figure 9: Optical ILA Management Panel Components

3—1— USB port (USB). Debug only.RJ-45 console port (CON) to support RS-232 serial

ports.

4—2— USB port (USB). Debug only.RJ-45 (1000BASE-T) management Ethernet port

(MGMT).

You manage the optical ILA by using the command-line interface (CLI), which is accessible through the

console and out-of-band management ports on the management panel. In addition, the front panel has

system status LEDs (see Table 4 in “Optical ILA Chassis Status LEDs” on page 24) that alert you to minor

or major alarms or other issues with the amplifier. Figure 9 on page 27 shows the management panel in

detail.

27

You can also manage the optical ILA through Connectivity Services Director (CSD), which is a Junos Space

application developed to manage the optical functionality provided by optical ILAs and integrated photonic

line cards (IPLCs) that are installed in the PTX3000 routers. CSD is managed over a data communications

network (DCN). CSD presents a topological network view in an intuitive, comprehensive, and cohesive

manner that enables you to visualize optical sites, links, and services and a site view that provides status,

configuration, alarms/faults, and performance monitoring functionality on the optical interfaces. By using

CSD, you can perform the following tasks on an optical ILA:

View the optical interface specifications that are currently applied on the device, such as wavelength

•

and power.

Modify the existing parameters of the optical port to suit your network needs or resolve any alarms

•

caused by certain interface settings.

View the active alarms generated for the optical interface to analyze and resolve the condition that

•

triggered the alarm on the device.

Configure threshold crossing alarms (TCAs) for the optical interface.

•

View the performance monitoring details in statistical and graphical formats for the optical interface.

•

NOTE: See the Connectivity Services Director User Guide for more information.

Page 28

SEE ALSO

Optical ILA CLI System Commands | 71

Optical ILA CLI show Commands | 72

Optical ILA CLI Configuration Commands | 78

Optical ILA CLI Upgrade Commands | 85

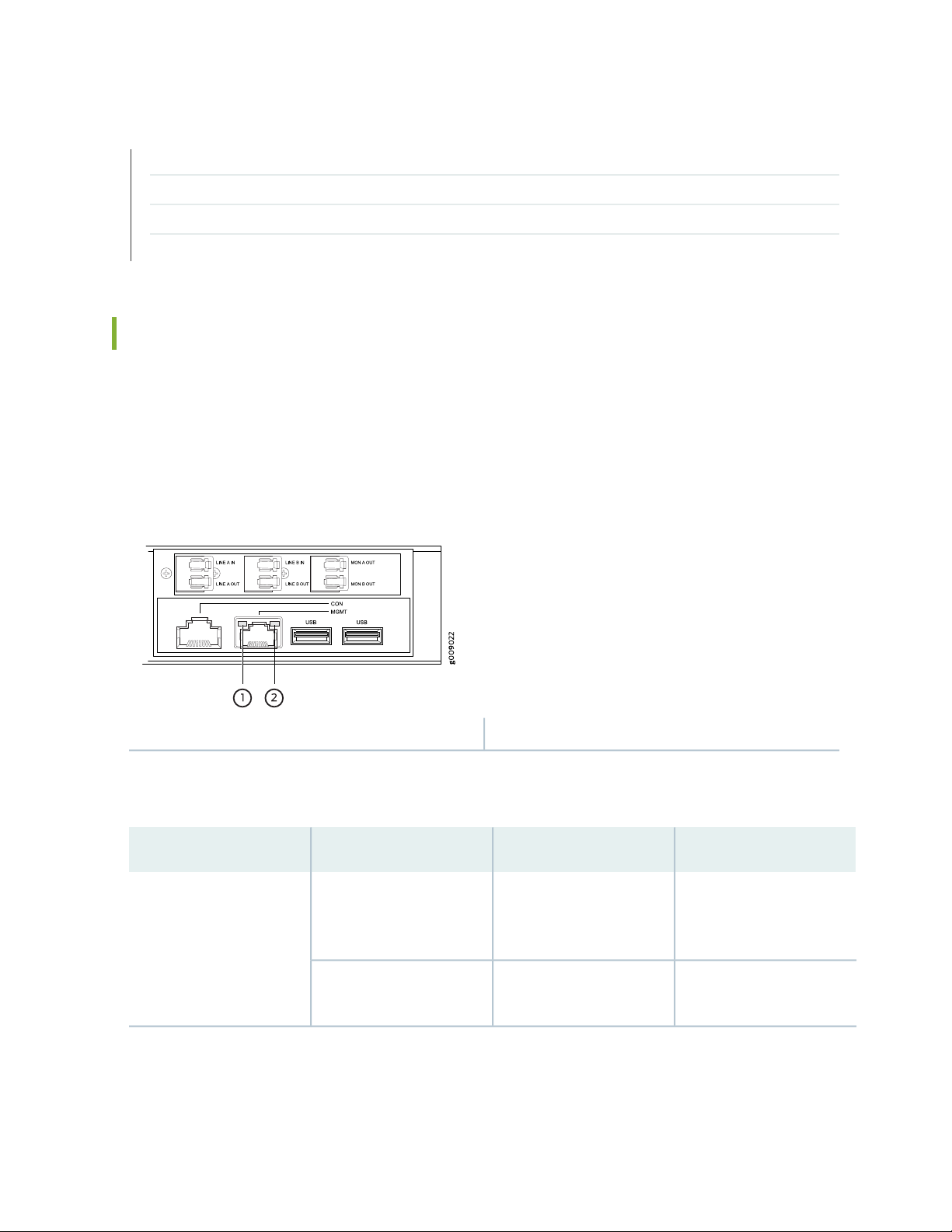

Optical ILA Management Port LEDs

The management port—labeled MGMT—on the optical ILA is located on the management panel.

The management port is an Ethernet port that supports an RJ-45 connector and has separate LEDs for

status and activity. Figure 10 on page 28 shows the location of the LEDs.

Figure 10: Management Port LEDs on the Optical ILA

28

2—1— StatusLink

Table 6 on page 28 describes the RJ-45 management port LEDs.

Table 6: Optical ILA RJ-45 Management Port LEDs

OffUnlitLink

BlinkingYellow

DescriptionStateColorLED

No link is established, there

is a fault, or the link is

down.

A link is established, and

there is link activity.

Page 29

Table 6: Optical ILA RJ-45 Management Port LEDs (continued)

29

DescriptionStateColorLED

Link is down.OffUnlitStatus

Green

RELATED DOCUMENTATION

Optical ILA AC Power Supply Description | 31

Optical ILA DC Power Supply Description | 32

On steadily

Blinking

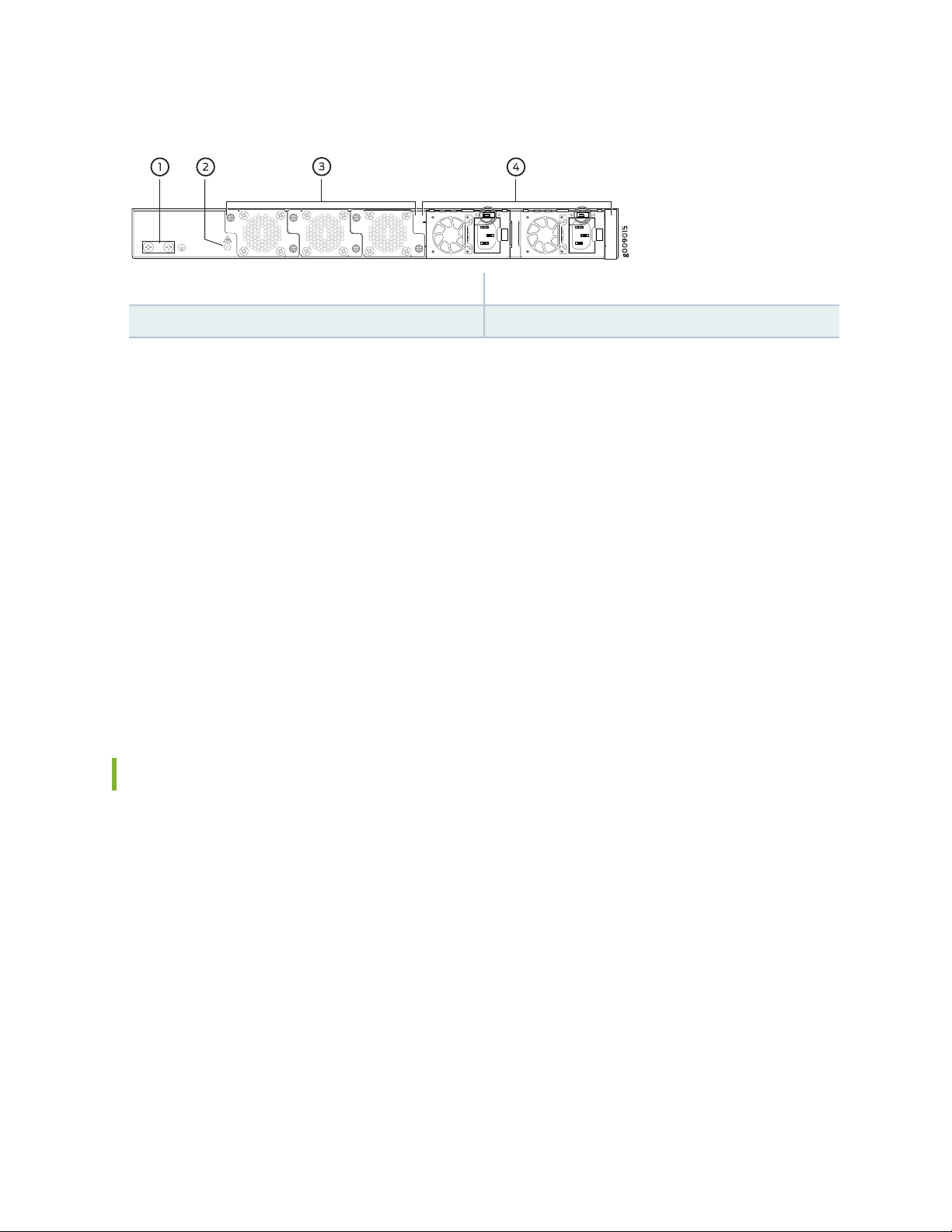

Optical ILA Cooling System Description

IN THIS SECTION

Fan Modules | 30

Link is up.

There is data activity.

The cooling system in an optical ILA consists of three 12.4-W fan modules installed in the field-replaceable

unit (FRU) panel and two counter-rotating fans housed in each of the power supplies.

In the optical ILA's cooling system, cool air enters through the vents in the front panel and hot air exhausts

through the fans in the FRU panel. This type of airflow is known as airflow out or front-to-back airflow.

When installed, the chassis must be positioned so that the FRUs are next to the hot air exhaust.

NOTE: Under normal operating conditions, the fan modules operate at a moderate speed.

Temperature sensors in the chassis monitor the temperature within the chassis. The system

raises an alarm if a fan module fails or if the ambient temperature inside the chassis rises above

the acceptable range.

Page 30

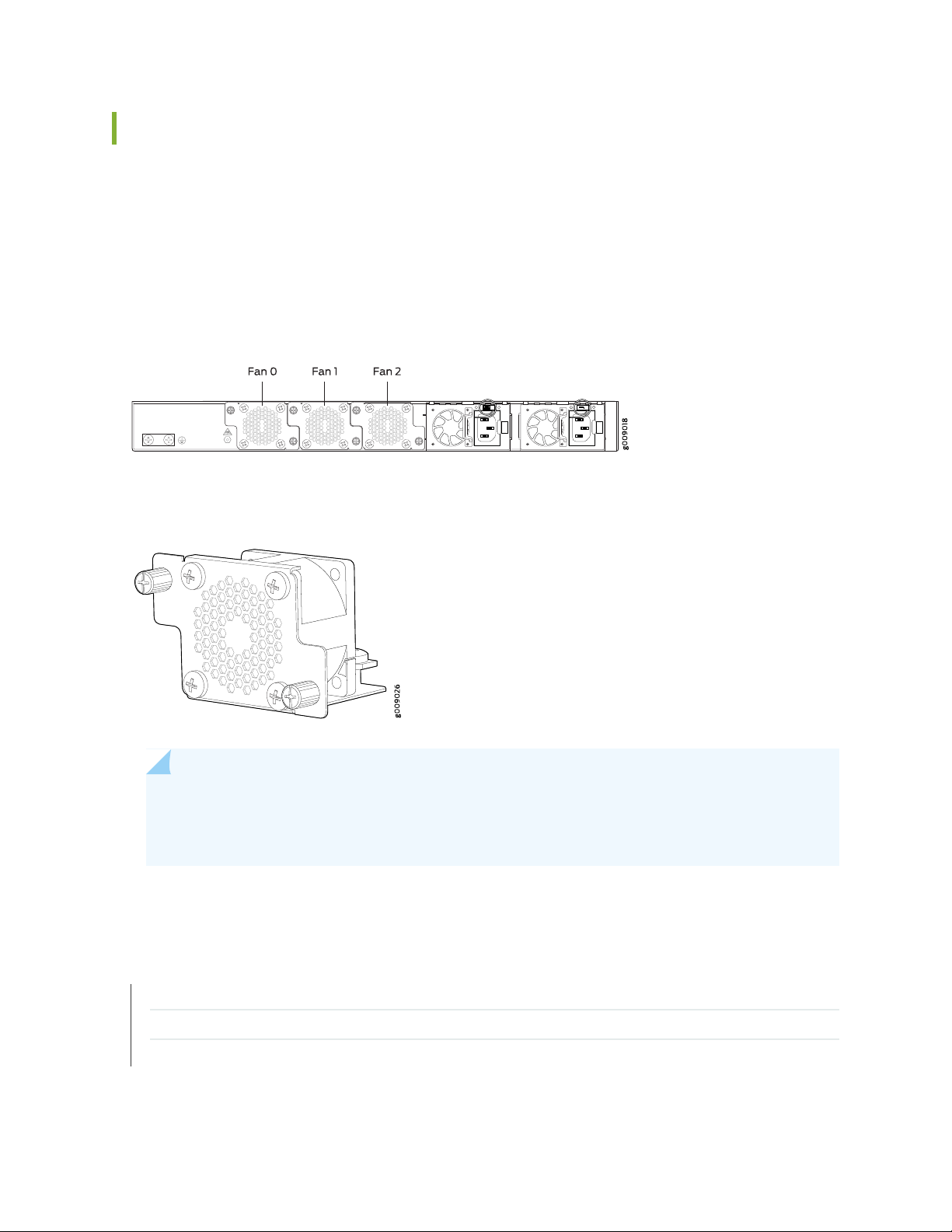

Fan Modules

The fan modules in an optical ILA are hot-removable and hot-insertable FRUs. These fan modules can be

hot-swapped—you do not need to power off the optical ILA or disrupt the optical ILA function to replace

a fan module. The fan module slots are numbered 0 through 2 from left to right when viewing chassis from

the FRU panel side (see Figure 11 on page 30). Figure 12 on page 30 shows the fan module for the optical

ILA. The numbers are located on the top of the chassis.

Figure 11: Fan Numbering

Figure 12: Fan Module

30

NOTE: All three fan modules must be installed for optimal operation of the optical ILA. The

optical ILA continues to operate for a period of 30 seconds during the replacement of the fan

module without thermal shutdown.

RELATED DOCUMENTATION

Prevention of Electrostatic Discharge Damage | 153

Installing a Fan Module in an Optical ILA | 93

Removing a Fan Module from an Optical ILA | 92

Page 31

Optical ILA Power System

IN THIS SECTION

Optical ILA AC Power Supply Description | 31

Optical ILA DC Power Supply Description | 32

Optical ILA Power Supply LEDs | 34

Optical ILA AC Power Specifications | 36

Optical ILA AC Power Cord Specifications | 36

Optical ILA DC Power Specifications | 37

Optical ILA DC Power Cable and Lugs Specifications | 38

Optical ILA Chassis Grounding Cable and Lug Specifications | 39

31

Optical ILA AC Power Supply Description

The AC power supplies in the optical ILA (see Figure 14 on page 32) are hot-removable and hot-insertable

field-replaceable units (FRUs) that you can install without powering off the optical ILA or disrupting the

functioning of the optical ILA. The optical ILA has two AC power supplies. Both the power supplies are

initially installed at the factory. See Figure 13 on page 31 for the power numbering scheme, the power

supply number (0 or 1) is located on the top of the chassis.

Figure 13: Power Supply Numbering

Page 32

Figure 14: AC Power Supply in an Optical ILA

3—1— Power plug connectorPower cord retainer

4—2— Ejector leverHandle

Each of the 150-W power supplies has a single AC input. The power supply provides 12-VDC output with

a standby voltage of 12 VDC. An optical ILA has twice the number of power supplies needed to power all

of the components in the device, which is known as 1+1 redundancy. When the optical ILA has both power

supplies installed and connected to power, the device has full power redundancy. If a power supply fails

or is removed, another power supply balances the electrical load without interruption.

32

The fans in the power supply provide front-to-back airflow, which is also known as airflow out (AFO).

CAUTION: To avoid electrical injury, carefully follow instructions in “Connecting AC

Power to an Optical ILA” on page 63, “Installing an AC Power Supply in an Optical ILA”

on page 98, and “Removing an AC Power Supply from an Optical ILA” on page 96.

NOTE: For more information about power system redundancy, see “Optical ILA Component

Redundancy” on page 20.

Optical ILA DC Power Supply Description

The DC power supplies in the optical ILA (see Figure 15 on page 33) are hot-removable and hot-insertable

field-replaceable units (FRUs) that you can install without powering off the optical ILA or disrupting the

functioning of the optical ILA. The DC version of the optical ILA has two DC power supplies. Both the

power supplies are initially installed at the factory.

Page 33

Figure 15: DC Power Supply in an Optical ILA

3—1— Ejector leverHandle

2—DC terminal

Each of the two 150-W power supplies has a single DC input. The power supply provides 12 VDC output

with a standby voltage of 12 VDC. An optical ILA has twice the number of power supplies needed to power

all of the components in the device, which is known as 1+1 redundancy. When the optical ILA has both

power supplies installed and connected to power, the device has full power redundancy. If a power supply

fails or is removed, the other or second power supply balances the electrical load without interruption.

33

The fans in the power supply provide front-to-back airflow, which is also known as airflow out (AFO).

CAUTION: To avoid electrical injury, carefully follow instructions in “Connecting DC

Power to an Optical ILA” on page 66, “Installing a Power Supply in an Optical ILA” on

page 97, and “Removing a Power Supply from an Optical ILA” on page 95.

NOTE: We recommend that the 48-VDC facility DC source be equipped with a circuit protector

rated at 10 A (–48 VDC) minimum, or as required by local code.

NOTE: We recommend that the 60-VDC facility DC source be equipped with a circuit protector

rated at 5 A (–60 VDC) minimum, or as required by local code.

NOTE: For more information about power system redundancy, see “Optical ILA Hardware

Component Overview” on page 19.

Page 34

Optical ILA Power Supply LEDs

Each optical ILA power supply has two LEDs on the power supply faceplate. Figure 16 on page 34 shows

the location of the LEDs on an optical ILA AC power supply. Figure 17 on page 34 shows the location of

the LEDs on an optical ILA DC power supply.

Figure 16: AC Power Supply LEDs

34

2—1— AC OKDC OK

Figure 17: DC Power Supply LEDs

2—1— DC IN OKDC OUT OK

Use Table 7 on page 35 and Table 8 on page 35 to interpret the state of the power supply LEDs.

Page 35

Table 7: Optical ILA AC Power Supply LED

35

DescriptionStateColorName

There is no power to any of the power supplies.OffUnlitDC OK

The power supply is on standby mode (AC IN present).BlinkingGreen

The power supply is on and operating correctly.On steadily

There is a power supply failure.On steadilyRed

No AC power to this power supply only.Blinking

There is no power to any of the power supplies.OffUnlitAC OK

The power supply output is on and operating correctly.On steadilyGreen

Table 8: Optical ILA DC Power Supply LED

The power supply is on standby mode (AC IN present).On steadily

There is a power supply failure.On steadilyRed

No AC power to this power supply only.Blinking

DescriptionStateColorName

There is no power to the power supplies.OffUnlitDC OUT OK

The power supply is on and operating correctly.On steadilyGreen

The power supply is on standby mode (DC IN present).Blinking

There is a power supply failure.On steadilyRed

There is no DC power to this power supply only.Blinking

Page 36

Table 8: Optical ILA DC Power Supply LED (continued)

Optical ILA AC Power Specifications

36

DescriptionStateColorName

There is no power to the power supplies.OffUnlitDC IN OK

The power supply is on and operating correctly.On steadilyGreen

The power supply is on standby mode (DC IN present).On steadily

There is a power supply failure.On steadilyRed

There is no DC power to this power supply only.Blinking

Table 9 on page 36 describes the AC power specifications for an optical ILA.

Table 9: AC Power Specifications for an Optical ILA

SpecificationItem

Operating range: 100–240 VACAC input voltage

50–60 HzAC input line frequency

AC input current rating

3 A at 100–136 VAC

1.5 A at 180–266 VAC

75 WTypical power consumption

115.5 WMaximum power consumption

Optical ILA AC Power Cord Specifications

Detachable AC power cords are shipped with the chassis if you include them as part of your order. The

coupler is type C13 as described by International Electrotechnical Commission (IEC) standard 60320. The

plug end of the power cord fits into the power source outlet that is standard for your geographical location.

Page 37

NOTE: In North America, AC power cords must not exceed 14.75 feet (approximately 4.5 meters)

in length, to comply with National Electrical Code (NEC) Sections 400-8 (NFPA 75, 5-2.2) and

210-52 and Canadian Electrical Code (CEC) Section 4-010(3). The cords that can be ordered for

the optical ILA are in compliance.

Table 10 on page 37 lists AC power cord specifications provided for each country or region.

Table 10: AC Power Cord Specifications for the Optical ILA

Plug TypeElectrical SpecificationModel NumberCountry

AS/NZ 3112–1993250 VAC, 10 A, 50 HzCBL-GP-JX-PWR-AUAustralia

37

250 VAC, 10 A, 50 HzCBL-GP-JX-PWR-CHChina

and United Kingdom)

Optical ILA DC Power Specifications

Table 11 on page 38 describes the DC power specifications for an optical ILA.

GB2099.1 1996 and

GB1002 1996 (CH1-10P)

CEE (7) VII250 VAC, 10 A, 50 HzCBL-GP-JX-PWR-EUEurope (except Italy

IEC60884-1250 VAC, 10 A, 50 HzCBL-GP-JX-PWR-ITItaly

JIS 8303 and 8306125 VAC, 12 A, 50 Hz or 60 HzCBL-GP-JX-PWR-JPJapan

NEMA 5-15P125 VAC, 10 A, 60 HzCBL-GP-JX-PWR-USNorth America

BS1363250 VAC, 10 A, 50 HzCBL-GP-JX-PWR-UKUnited Kingdom

NOTE: We recommend that the 48 VDC facility DC source be equipped with a circuit breaker

rated at 10 A (–48 VDC) minimum, or as required by local code.

We recommend that the 60-VDC facility DC source be equipped with a circuit protector rated

at 5 A (–60 VDC) minimum, or as required by local code.

Page 38

Table 11: DC Power Specifications for the Optical ILA

38

SpecificationsItem

DC input voltage

Operating voltage range: –40 VDC through

–72 VDC

6 A maximumDC input current rating

75 WTypical power consumption

115.5 WMaximum power consumption

Optical ILA DC Power Cable and Lugs Specifications

IN THIS SECTION

DC Power Cables | 38

DC Power Connector | 39

DC Power Cables

You must supply the DC power cables that meet the specifications in Table 12 on page 38, or as required

by the local code, laws, and standards.

Table 12: DC Power Cable Specifications

SpecificationCable

18-AWG (0.8 mm2) minimumMinimum size cable

12-AWG (3.3 mm2)Maximum size cable

WARNING: For field-wiring connections, use copper conductors only.

Page 39

CAUTION: Before optical ILA installation begins, a licensed electrician must attach a

cable lug to the power cables that you supply. A cable with an incorrectly attached lug

can damage the optical ILA.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the external

DC power source at your site determines the color coding for the leads on the power

cables that attach to the terminals on each power supply.

DC Power Connector

39

The accessory box shipped with the optical ILA includes the DC power connector that attaches to the

terminal studs of each power supply.

SEE ALSO

Connecting DC Power to an Optical ILA | 66

Optical ILA DC Power Electrical Safety Guidelines | 155

Optical ILA Chassis Grounding Cable and Lug Specifications

For installations that require a separate grounding conductor to the chassis, the optical ILA must be

adequately grounded before power is connected to ensure proper operation and to meet safety and

electromagnetic interference (EMI) requirements. To ground an optical ILA, connect a grounding cable to

earth ground and then attach it to the chassis grounding points.

WARNING: The device is pluggable type A equipment installed in a restricted-access

location. It has a separate protective earthing terminal provided on the chassis in

addition to the grounding pin of the power supply cord. This separate protective

earthing terminal must be permanently connected to earth ground for installations

that require a separate grounding conductor to the chassis.

Page 40

CAUTION: Before device installation begins, a licensed electrician must attach a cable

lug to the grounding cables that you supply. See “Connecting the Optical ILA Grounding

Cable” on page 62. A cable with an incorrectly attached lug can damage the optical

ILA.

Before connecting the optical ILA to earth ground, review the following information:

A protective earthing terminal bracket is required for connecting the optical ILA to earth ground. This

•

two-holed bracket is attached to the rear of the optical ILA chassis and provides a protective earthing

terminal for the device. The grounding points require two #10-32 UNF screws. The grounding points

are spaced at 0.63 in. (16 mm).

The grounding lug required is a Panduit LCD6-14BH-L or equivalent (not provided). The grounding lug

•

accommodates 14–10 AWG (2–5.3 mm²) stranded wire.

The grounding cable that you provide for an optical ILA must be the same size or heavier than the input

•

wire of each power supply. Minimum recommendations are 14–10 AWG (2–5.3 mm²) stranded wire,

60° C wire, or as permitted by local code.

40

RELATED DOCUMENTATION

Connecting AC Power to an Optical ILA | 63

Connecting DC Power to an Optical ILA | 66

Prevention of Electrostatic Discharge Damage | 153

Page 41

2

CHAPTER

Site Planning, Preparation, and

Specifications

Optical ILA Site Preparation Checklist | 42

Optical ILA Site Guidelines and Requirements | 43

Optical ILA Management Cable Specifications and Pinouts | 49

Page 42

Optical ILA Site Preparation Checklist

The checklist in Table 13 on page 42 summarizes the tasks you need to perform when preparing a site for

an optical ILA installation.

Table 13: Site Preparation Checklist

DatePerformed byFor More InformationItem or Task

Environment

42

Verify that environmental factors such as

temperature and humidity do not exceed the

optical ILA tolerances.

Power

Measure the distance between external power

sources and the optical ILA installation site.

Calculate the power consumption and

requirements.

Rack or Cabinet

Verify that your rack or cabinet meets the

minimum requirements for the installation of

the optical ILA.

“Optical ILA Environmental

Requirements and

Specifications” on page 44

“Optical ILA AC Power

Specifications” on page 36

“DC Power Specifications for

the Optical ILA” on page 38

“Optical ILA Rack

Requirements” on page 46

“Optical ILA Cabinet

Requirements” on page 47

Plan rack or cabinet location, including required

space clearances.

Secure the rack or cabinet to the floor and

building structure.

Cables

“Optical ILA Clearance

Requirements for Airflow and

Hardware Maintenance” on

page 45

Page 43

Table 13: Site Preparation Checklist (continued)

Acquire cables and connectors:

Determine the number of cables needed

•

based on your planned configuration.

Review the maximum distance allowed for

•

each cable. Choose the length of cable based

on the distance between the hardware

components being connected.

Plan the cable routing and management.

RELATED DOCUMENTATION

43

DatePerformed byFor More InformationItem or Task

General Electrical Safety Guidelines and Warnings | 152

Overview of Installing the Optical ILA | 53

Unpacking and Mounting the Optical ILA | 54

Optical ILA Site Guidelines and Requirements

IN THIS SECTION

Optical ILA Environmental Requirements and Specifications | 44

Optical ILA Clearance Requirements for Airflow and Hardware Maintenance | 45

Optical ILA Physical Specifications | 46

Optical ILA Rack Requirements | 46

Optical ILA Cabinet Requirements | 47

Optical Specifications for the Optical ILA | 48

Page 44

Optical ILA Environmental Requirements and Specifications

The optical ILA must be installed in a rack or cabinet. It must be housed in a dry, clean, well-ventilated,

and temperature-controlled environment.

Follow these environmental guidelines:

The site must be as dust-free as possible, because dust can clog air intake vents and filters, reducing the

•

efficiency of the optical ILA cooling system.

Maintain ambient airflow for normal optical ILA operation. If the airflow is blocked or restricted, or if

•

the intake air is too warm, the chassis might overheat, leading to the optical ILA temperature monitor

shutting down the device to protect the hardware components.

Table 14 on page 44 provides the required environmental conditions for normal operation of the optical

ILA .

Table 14: Optical ILA Environmental Tolerances

44

Relative humidity

Temperature

Seismic

ToleranceDescription

No performance degradation up to 6000 feet (1828.8 meters).Altitude

Normal operation ensured in relative humidity range of 5% through 90%,

noncondensing.

Short-term operation ensured in relative humidity range of 5% through

•

93%, noncondensing.

NOTE: As defined in NEBS GR-63-CORE, Issue 3, short-term events can

be up to 96 hours in duration but not more than 15 days per year.

Normal operation ensured in temperature range of 41° F (5° C) through

•

104 F (40° C). Short-term temperature is 23° F (–5° C) through 131 F

(55° C)

Nonoperating storage temperature in shipping container: –40°F (40° C)

•

through 158° F (70° C).

Designed to comply with Zone 4 earthquake requirements per NEBS

GR-63-CORE, Issue 3.

NOTE: Install the optical ILA only in restricted-access areas, such as dedicated equipment rooms

and equipment closets, in accordance with Articles 110-16, 110-17, and 110-18 of the National

Electrical Code, ANSI/NFPA 70.

Page 45

Optical ILA Clearance Requirements for Airflow and Hardware Maintenance

When planning the site for an optical ILA installation, you must allow sufficient clearance around the

installed chassis (see Figure 18 on page 45).

Figure 18: Clearance Requirements for Airflow and Hardware Maintenance for an Optical ILA

45

Follow these guidelines:

For the cooling system to function properly, the airflow around the chassis must be unrestricted. See

•

“Optical ILA Cooling System Description” on page 29 for more information about the airflow through

the chassis.

If you are mounting an optical ILA in a rack or cabinet with other equipment, ensure that the exhaust

•

from other equipment does not blow into the intake vents of the optical ILA chassis.

You must leave at least 24 in. (61 cm) both in front of and behind the optical ILA. For service personnel

•

to remove and install hardware components, you must leave adequate space at the front and back of

the optical ILA. NEBS GR-63 recommends that you allow at least 30 in. (76.2 cm) in front of the rack or

cabinet and 24 in. (61 cm) behind the rack or cabinet.

Page 46

Optical ILA Physical Specifications

Table 15 on page 46 lists the physical specifications for the optical ILA chassis and components.

Table 15: Physical Specifications for the Optical ILA

Model

Numbers

WeightDepthWidthHeightFans and Power

46

PTX-ILA-M-AC

PTX-ILA-M-DC

3 fan modules and 2

AC power supplies

installed

3 fan modules and 2

DC power supplies

installed

1.72 in.

(4.36 cm)

1.72 in.

(4.36 cm)

17.24 in.

(43.8 cm)

17.4 in.

(44.19 cm)

9.6 in. (24.4 cm)

without handles for

fans or power

supplies.

9.8 in. (24.89 cm)

without handles for

fans or power

supplies.

Optical ILA Rack Requirements

The optical ILA chassis is designed to be installed in two-post or four-post racks.

Rack requirements consist of:

Rack type

•

With

field-replaceable

units (FRUs)

installed: 11.7 lb

(5.30 kg)

With FRUs installed:

11.8 lb (5.35 kg)

Mounting bracket hole spacing

•

Rack size and strength

•

Table 16 on page 46 provides the rack requirements and specifications for the optical ILA.

Table 16: Rack Requirements for the Optical ILA

GuidelinesRack Requirement

Rack type: two-post or

four-post

Use a two-post or four-post rack that provides bracket patterns spaced at 1-U (1.75 in.

or 4.45 cm) increments and that meets the size and strength requirements to support the

weight.

A U is the standard rack unit defined in Cabinets, Racks, Panels, and Associated Equipment

(document number EIA-310–D) published by the Electronics Components Industry

Association (http://www.ecianow.org/).

Page 47

Table 16: Rack Requirements for the Optical ILA (continued)

GuidelinesRack Requirement

47

Mounting bracket hole

spacing

Rack size and strength

Rack connection to

building structure

The holes in the mounting brackets are spaced at 1.25 in. (or 3.17 cm), so that the optical

ILA can be mounted in any rack that provides holes spaced at that distance.

Ensure that the rack complies with the standards for a 19-in. or 23-in. rack as defined

•

in Cabinets, Racks, Panels, and Associated Equipment (document number EIA-310–D)

published by the Electronics Components Industry Association

(http://www.ecianow.org/).

Ensure that the rack rails are spaced widely enough to accommodate the optical ILA

•

chassis. The outer edges of the front-mounting brackets extend the width to 19 in.

(48.26 cm).

Ensure that the front and rear rack rails are spaced between 28 in. (71.1 cm) and 36 in.

•

(91.4 cm) front-to-back.

Ensure that the rack is strong enough to support the weight of the optical ILA.

•

Ensure that the spacing of rails and adjacent racks allows for proper clearance around

•

the optical ILA and rack.

Secure the rack to the building structure.

•

If earthquakes are a possibility in your geographical area, secure the rack to the floor.

•

Secure the rack to the ceiling brackets as well as wall or floor brackets for maximum

•

stability.

SEE ALSO

Maintenance and Operational Safety Guidelines and Warnings | 144

Optical ILA Cabinet Requirements

You can mount optical ILA models in a cabinet that contains a two-post 19-in. or four-post rack as defined

in Cabinets, Racks, Panels, and Associated Equipment (document number EIA-310-E) published by the

Electronics Components Industry Association (http://www.ecianow.org/).

Cabinet requirements consist of:

Cabinet size and clearance

•

Cabinet airflow requirements

•

Table 17 on page 48 provides the cabinet requirements and specifications for the optical ILA.

Page 48

Table 17: Cabinet Requirements for the Optical ILA

GuidelinesCabinet Requirement

48

Cabinet size and clearance

Cabinet airflow requirements

The minimum cabinet size for accommodating an optical ILA is 18 in. (45.7 cm)

deep. Large cabinets improve airflow and reduce the chance of overheating.

NOTE: The DC version of the optical ILA conforms to the ETSI 300 mm

cabinets.

When you mount the optical ILA in a cabinet, ensure that ventilation through

the cabinet is sufficient to prevent overheating.

Ensure that the cool air supply you provide through the cabinet adequately

•

dissipates the thermal output of the optical ILA (and other installed

equipment).

Ensure that the cabinet allows the hot exhaust air of the chassis to exit

•

the cabinet without recirculating into the optical ILA. An open cabinet

(without a top or doors) that employs hot air exhaust extraction from the

top allows the best airflow through the chassis. If the cabinet contains a

top or doors, perforations in these elements assist with removing the hot

air exhaust.

Install the optical ILA in the cabinet in a way that maximizes the open space

•

on the field-replaceable unit (FRU) side of the chassis. This maximizes the

clearance for critical airflow. The optical ILA exhausts hot air through the

fans and power supplies.

Route and dress all cables to minimize the blockage of airflow to and from

•

the optical ILA.

Ensure that the spacing of rails and adjacent cabinets allows for the proper

•

clearance around the optical ILA and cabinet.

Optical Specifications for the Optical ILA

Table 18 on page 48 provides the optical specifications for the optical ILA.

Table 18: Optical Specifications

MaximumMinimumConfigurationsParameter

9.8 dBm–15.2 dBmLoaded system (96 channels)Input power range

–10 dBm–35 dBmSingle channel

Page 49

Table 18: Optical Specifications (continued)

range

49

MaximumMinimumConfigurationsParameter

19.8 dBmLoaded system (96 channels)Signal output power

0 dBmSingle channel

30 dB10 dBOutput gain tilt equal to 0 dBGain range (standard)

Gain range (extended)

0

RELATED DOCUMENTATION

Connecting the Optical ILA Grounding Cable | 62

Unpacking and Mounting the Optical ILA | 54

35 dB30 dBOutput gain tilt not equal to

Optical ILA Management Cable Specifications and Pinouts

IN THIS SECTION

Cable Specifications for Console and Management Connections for the Optical ILA | 49

Management Port Connector Pinouts for the Optical ILA | 50

Console Port Connector Pinouts for the Optical ILA | 51

Cable Specifications for Console and Management Connections for the Optical ILA

Table 19 on page 50 lists the specifications for the cables that connect the optical ILA to a management

device.

Page 50

Table 19: Cable Specifications for Console and Management Connections for the Optical ILA

50

Port on optical

ILA

Console (CON) port

Management

(MGMT) port

RS-232 (EIA-232) serial

cable

Category 5 cable or

equivalent suitable for

1000BASE-T operation

One 7-foot (2.13-meter)-long

RJ-45 patch cable and RJ-45

to DB-9 adapter

One 7-foot (2.13-meter)-long

RJ-45 patch cable

Maximum

LengthCable SuppliedCable Specification

(2.13 meters)

(100 meters)

Device

Receptacle

RJ-457 feet

RJ-45328 feet

Management Port Connector Pinouts for the Optical ILA

The 1000BASE-T management port (labeled MGMT) uses an RJ-45 connector to connect to a management

device for out-of-band management.

Table 20 on page 50 provides the pinout information of the RJ-45 management port connector. An RJ-45

cable is supplied with the optical ILA.

Table 20: RJ-45 Management Port Connector Pinouts for the Optical ILA

DescriptionSignalPin

Transmit/receive data pair 1TRP1+1

Transmit/receive data pair 1TRP1–2

Transmit/receive data pair 2TRP2+3

Transmit/receive data pair 3TRP3+4

Transmit/receive data pair 3TRP3–5

Transmit/receive data pair 2TRP2–6

Transmit/receive data pair 4TRP4+7

Transmit/receive data pair 4TRP4–8

Page 51

Console Port Connector Pinouts for the Optical ILA

The console port (labeled CON) is an RS-232 serial interface that uses an RJ-45 connector to connect to

a console management device. The default baud rate for the console port is 9600 baud.

Table 21 on page 51 provides the pinout information for the RJ-45 console connector. An RJ-45 cable

and RJ-45 to DB-9 adapter are supplied with the optical ILA.

NOTE: If your laptop or PC does not have a DB-9 plug connector pin and you want to connect

your laptop or PC directly to an optical ILA, use a combination of the RJ-45 cable and RJ-45 to

DB-9 adapter supplied with the device and a USB to DB-9 plug adapter. You must provide the

USB to DB-9 plug adapter.

Table 21: Console Port Connector Pinouts for the Optical ILA

51

RELATED DOCUMENTATION

DescriptionSignalPin

ReservedReserved1

Data terminal ready/ReservedReserved2

Transmit dataTxD Output3

Signal groundSignal Ground4

Signal groundSignal Ground5

Receive dataRxD Input6

ReservedReserved7

ReservedReserved8

Management Port LEDs on the Optical ILA | 28

Page 52

3

CHAPTER

Initial Installation and Configuration

Overview of Installing the Optical ILA | 53

Unpacking and Mounting the Optical ILA | 54

Connecting the Optical ILA to External Devices | 58

Connecting the Optical ILA to Power | 61

Configuring the Software on the Optical ILA | 69

Powering Off an Optical ILA | 88

Page 53

Overview of Installing the Optical ILA

To install and connect an optical ILA:

1. Follow the instructions in “Unpacking and Mounting the Optical ILA” on page 54 to determine how

the device is to be mounted and for instructions on how to mount the optical ILA in a rack or cabinet

2. Follow the instructions in:

Connecting the Optical ILA Grounding Cable on page 62

•

Unpacking and Mounting the Optical ILA on page 54

•

Connecting the Optical ILA to External Devices on page 58

•

3. Connect AC or DC power:

Connecting AC Power to an Optical ILA on page 63

•

53

Connecting DC Power to an Optical ILA on page 66

•

4. Configure the device following the instructions in: .

Optical ILA Modes of Operation on page 70

•

Optical ILA CLI System Commands on page 71

•

Optical ILA CLI show Commands on page 72

•

Optical ILA CLI Configuration Commands on page 78

•

Optical ILA CLI Upgrade Commands on page 85

•

RELATED DOCUMENTATION

Rack Requirements for the Optical ILA | 46

Optical ILA Cabinet Requirements | 47

Clearance Requirements for Airflow and Hardware Maintenance for an Optical ILA | 45

Page 54

Unpacking and Mounting the Optical ILA

IN THIS SECTION

Unpacking the Optical ILA | 54

Mounting an Optical ILA in a Rack or Cabinet | 55

Unpacking the Optical ILA

The optical ILA chassis is a rigid sheet-metal structure that houses the hardware components. The optical

ILA is shipped in a cardboard carton, secured with foam packing material. The carton also contains an

accessory kit and quick start instructions.

54

CAUTION: The optical ILA chassis is maximally protected inside the shipping carton.

Do not unpack the optical ILA until you are ready to begin installation.

To unpack an optical ILA:

1. Move the shipping carton to a staging area as close to the installation site as possible, but where you

have enough room to remove the system components.

2. Position the carton so that the arrows are pointing up.

3. Open the top flaps on the shipping carton.

4. Remove the accessory kit and verify the contents against the inventory of components listed in

Table 22 on page 55.

5. Pull out the packing material holding the optical ILA in place.

6. Verify the chassis components received:

Three fan modules

•

Two power supplies

•

7. Save the shipping carton and packing materials in case you need to move or ship the chassis later.

Page 55

Table 22: Inventory of Components Supplied with an Optical ILA

55

QuantityComponent

1Chassis with three fan modules and two power supplies

219-in. mounting brackets attached to the chassis

1Quick start guide

223-in. mounting brackets

1RJ-45 cable and RJ-45 to DB-9 adapter

2AC power cord (only with the AC version)

2DC power connectors (only with the DC version)

SEE ALSO

Overview of Installing the Optical ILA | 53

Mounting an Optical ILA in a Rack or Cabinet

IN THIS SECTION

Before You Begin Mounting the Optical ILA | 56

Mounting the Optical ILA | 57

Page 56

You can mount an optical ILA in a two-post or four-post 19-in. rack or cabinet by using the attached

mounting brackets. (The remainder of this topic uses rack to mean rack or cabinet.)

Before You Begin Mounting the Optical ILA

Before you begin mounting an optical ILA in the rack:

1. Ensure that you understand how to prevent electrostatic discharge (ESD) damage. See “Prevention of

Electrostatic Discharge Damage” on page 153.

2. Verify that the site meets the requirements described in “Optical ILA Site Preparation Checklist” on

page 42.

3. Place the rack in its permanent location, allowing adequate clearance for airflow and maintenance, and

secure it to the building structure.

4. Read “General Safety Guidelines and Warnings” on page 122, and Optical ILA Installation Safety Guidelines.

56

5. Remove the optical ILA from the shipping carton (see “Unpacking the Optical ILA” on page 54).

6. Ensure that you have the following parts and tools available to mount the optical ILA in a rack:

ESD grounding strap (not provided).

•

One pair of 19-inch mounting brackets (attached).

•

One pair of 23-inch mounting brackets.

•

Four screws to secure the chassis and mounting blades to the rack (not provided).

•

Screwdriver appropriate for the rack mounting screws (not provided).

•

CAUTION: If you are mounting multiple devices in a rack, mount the device in the

lowest position of the rack first. Proceed to mount the rest of the devices from the

bottom to the top of the rack to minimize the risk of the rack toppling.

Page 57

Mounting the Optical ILA

To mount the optical ILA on two posts or four posts in a rack by using the provided mounting kit (see

Figure 19 on page 57):

NOTE: The 19-inch brackets are attached to the optical ILA when they are shipped. If you want

to attach the 23-inch brackets, unscrew the 19-inch brackets from the chassis, and attach the

23-inch brackets by using the same screws.

1. Attach the ESD grounding strap to your bare wrist and to a site ESD point.

NOTE: Place the rack in its permanent location, allowing adequate clearance for airflow and

maintenance, and secure it to the building structure. If you are mounting multiple units in the

rack, mount the heaviest unit at the bottom and mount the others from bottom to top in

order of decreasing weight. AC-powered optical ILA version weighs 11.7 lb (5.30 kg) while

the DC-powered optical ILA weighs 11.8 lb (5.35 kg).

57

2. Position the optical ILA in such a manner that the FRUs are next to the hot aisle.

3. Use four mounting screws (and cage nuts and washers if your rack requires them) to attach the brackets

to the rack.

Figure 19: Installing the Optical ILA on a Rack

4. Tighten the screws.

SEE ALSO

Page 58

Connecting the Optical ILA Grounding Cable | 62

Connecting AC Power to an Optical ILA | 63

Connecting DC Power to an Optical ILA | 66

Connecting the Optical ILA to External Devices

IN THIS SECTION

Connecting the Optical ILA to a Management Ethernet Device | 58

Connecting the Optical ILA to a Management Console | 59

Connecting the Optical ILA to the Network and External Devices | 60

58

Connecting the Optical ILA to a Management Ethernet Device

You can monitor and manage the optical ILA by using a dedicated management channel. Use the

management port to connect the optical ILA to a network for out-of-band management.

NOTE: You cannot use the management port to perform the initial configuration of the optical

ILA. You must configure the management ports through the console connection before you can

successfully connect to the optical ILA using the management ports. See “Optical ILA Modes of

Operation” on page 70.

Ensure that you have an appropriate cable available. See “Optical ILA Management Cable Specifications

and Pinouts” on page 49.

To connect an optical ILA to a network for out-of-band management (see Figure 20 on page 59):

1. Connect one end of the cable to the management port (labeled MGMT) on the optical ILA.

2. Connect the other end of the cable to the management network device.

Page 59

Figure 20: Connecting an Optical ILA to a Network for Out-of-Band Management

g020548

Management PC

Management PC

Management PC

Management

Network

To Management Port

(on Device)

MGMT

Connecting the Optical ILA to a Management Console

59

The optical ILA has a console port with an RJ-45 connector. Use the console port to connect the device

directly to a management console, such as a laptop, or to a console server.

Ensure that you have an RJ-45 to DB-9 rollover cable available. An RJ-45 cable with an RJ-45 to DB-9

adapter is provided with the device.

NOTE: If your laptop or PC does not have a DB-9 plug connector pin and you want to connect

your laptop or PC directly to the optical ILA, use a combination of the RJ-45 cable and RJ-45 to

DB-9 adapter supplied with the device and a USB to DB-9 plug adapter. You must provide the

USB to DB-9 plug adapter.

To connect the optical ILA to a management console (see Figure 21 on page 60 or Figure 22 on page 60):

1. Connect one end of the Ethernet cable to the console port (labeled CON).

2. Connect the other end of the Ethernet cable directly to a management console or console server.

Page 60

Figure 21: Connecting the Optical ILA Directly to a Management Console

g050109

Laptop CPU

ETH CRAFT

port (on device)

CON

g050108

Laptop CPU

To Console Port

CON

Figure 22: Connecting the Optical ILA to a Management Console Through a Console Server

60

SEE ALSO

Console Port Connector Pinouts for the Optical ILA | 51

Connecting the Optical ILA to the Network and External Devices

The optical ILA provides signal amplification to boost the dense wavelength-division multiplexing (DWDM)

signal as it propagates along the fiber-optic cable. It is used to connect to trunk fibers to enable long-distance

transmission over many hundreds of kilometers of fiber-optic cable. Two pairs of the LC ports on the front

panel of the chassis are used for this purpose. Typically, either another optical ILA or an IPLC (installed in

a PTX3000 router) is connected at the far end of this trunk fiber, which could be as far as 62 miles (100

km) away depending on the availability and condition of the fiber plant. Additionally, the optical monitor