Page 1

MX104 3D Universal Edge Routers

Quick Start

April 2016

Part Number: 530-062013

Revision 02

This document describes how to install the Juniper Networks®MX104 3D Universal Edge

Router.

Contents

MX104 Quick Start Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 1: Prepare the Site for MX104 Router Installation . . . . . . . . . . . . . . . . . . . . . . . 4

Step 2: Install the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tools Required to Install the Router in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install the MX104 Router in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Step 3: Ground the MX104 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tools Required to Ground the MX104 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connect the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 4: Connect External Devices and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connect the Router to a Network for Out-of-Band Management . . . . . . . . . 10

Connect the Router to a Management Console Device . . . . . . . . . . . . . . . . . . 10

Connect MIC Cables to the MX104 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Step 5: Connect Power to the MX104 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect AC Power to an AC-Powered MX104 Router . . . . . . . . . . . . . . . . . . . 13

Connect DC Power to a DC-Powered MX104 Router . . . . . . . . . . . . . . . . . . . . 14

Step 6: Perform Initial Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Enter Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure User Accounts and Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure System Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Commit the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Compliance Statements for NEBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Compliance Statements for EMC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

European Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Israel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1Copyright © 2016, Juniper Networks, Inc.

Page 2

MX104 3D Universal Edge Routers Quick Start

Junos OS Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Copyright © 2016, Juniper Networks, Inc.2

Page 3

MX104 Quick Start Description

g007602

17 16 15 1314 12

31 54 10 1198762

This Quick Start contains information you need to install and configure the router quickly.

For complete installation instructions, see the MX104 3D Universal Edge Router Hardware

Guide at http://www.juniper.net/techpubs/.

WARNING: This Quick Start contains a summary of safetywarnings in “Safety

Warnings” on page 21. For a completelist of warnings for this router,including

translations, see the MX104 3D Universal Edge Router Hardware Guide at

http://www.juniper.net/techpubs/.

The router is environmentally hardened and is 3.5 rack units (U; that is 6.125 in., or 15.55

cm) tall. Several routers can be stacked in a single floor-to-ceiling rack, for increased

port density per unit of floor space. The chassis installs in standard 11.81 in. (30 cm)-deep

(or larger) enclosed cabinets, 19-in. equipment racks, or telco open-frame racks.

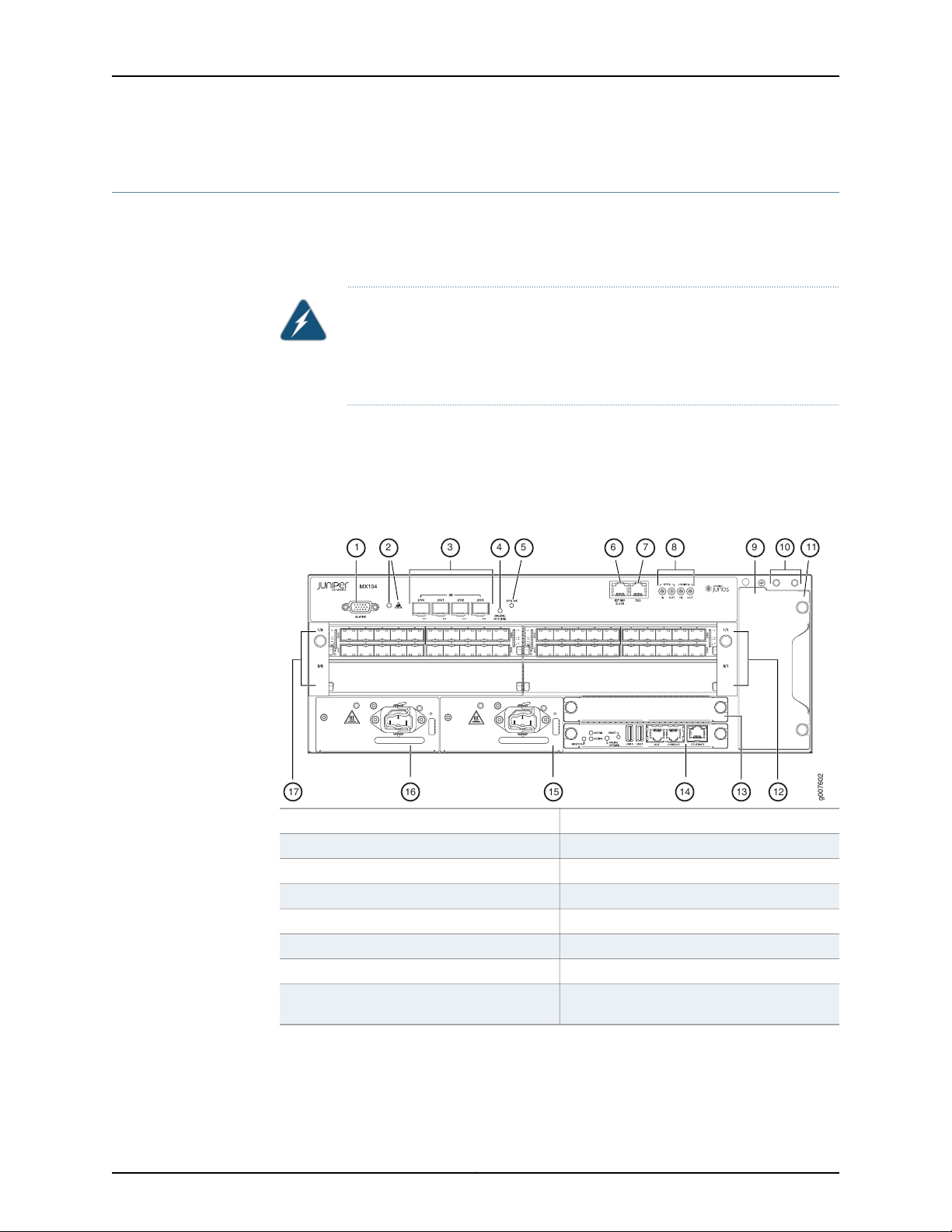

MX104 Quick Start Description

Figure 1: Front View of the MX104 Router

9—1— ESD pointAlarm input and output contacts

10—2— Grounding terminalsAlarm LEDs

11—3— Fan tray10-Gigabit Ethernet SFP+ ports

12—4— MIC slots 0/1 and 1/ 1ONLINE/OFFLINE button

13—5— Routing EnginesSystem status LED

14—6— Power supplies (AC or DC)External reference clocking port

8—1-PPS and 10-MHz GPS input and output

ports

15—7— MIC slots 0/0 and 1/0Time-of-day (TOD) port

3Copyright © 2016, Juniper Networks, Inc.

Page 4

MX104 3D Universal Edge Routers Quick Start

Step 1: Prepare the Site for MX104 Router Installation

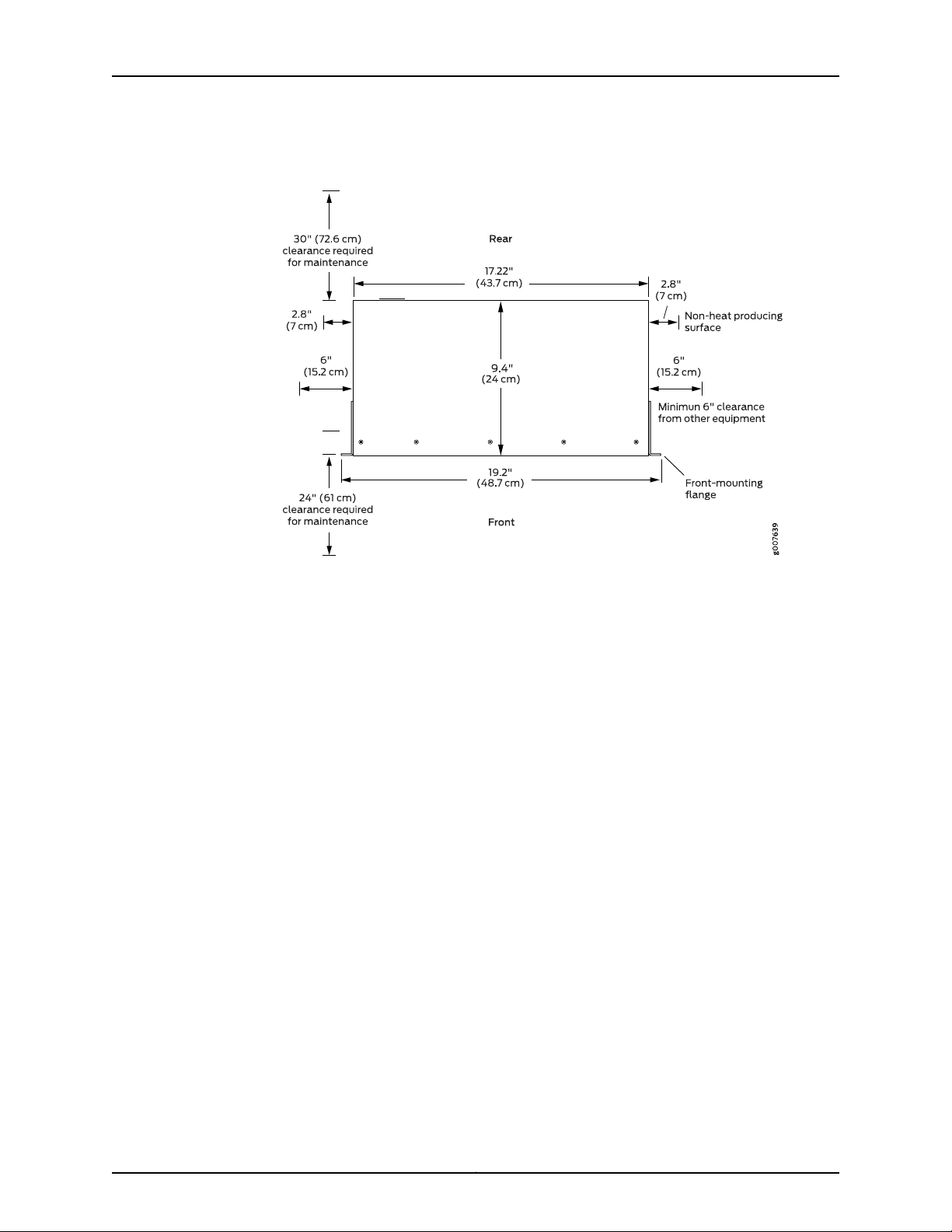

Prepare your site for MX104 installation by observing the following guidelines:

•

You can install the router in a four-post rack or cabinet or an open-frame rack.

•

The rack rails must be spaced widely enough to accommodate the chassis's external

dimensions: 6.125 in. or (15.55 cm) high, 9.5 in. (24.13 cm) deep, and 17.5 in. (44.5 cm)

wide. The outer edges of the mounting brackets extend the width to 19.2 in. (48.7 cm).

•

One person must be available to lift the router while another secures the router to the

rack.

•

The rack must be strong enough to support the weight of the fully configured router,

up to 32 lb (14.5 kg).

•

For the cooling system to function properly, the airflow around the chassis must be

unrestricted. Allow at least 6 in. (15.2 cm) of clearance between side-cooled devices.

Allow 2.8 in. (7 cm) between the side of the chassis and any non-heat-producing

surface such as a wall.

•

For service personnel to remove and install hardware components, there must be

adequate space at the front and back of the router. Allow at least 30 in. (76.2 cm) in

front of the router and 24 in. (61 cm) behind the router.

•

The rack or cabinet must have an adequate supply of cooling air.

•

Ensure that the cabinet allows the chassis hot exhaust air to exit from the cabinet

without recirculating into the router.

•

You must install the router into a rack that is secured to the building structure.

•

Mount the router at the bottom of the rack if it is the only unit in the rack.

•

When mounting the router in a partially filled rack, load the rack from the bottom to

the top with the heaviest component at the bottom of the rack.

•

Install the router only in restricted areas, such as dedicated equipment rooms and

equipment closets, in accordance with Articles 110-16, 110-17,and 110-18 of the National

Electrical Code, ANSI/NFPA 70.

Copyright © 2016, Juniper Networks, Inc.4

Page 5

Step 1: Prepare the Site for MX104 Router Installation

Figure 2: MX104 Rack Clearance and Chassis Dimensions

5Copyright © 2016, Juniper Networks, Inc.

Page 6

MX104 3D Universal Edge Routers Quick Start

Step 2: Install the Router

•

Tools Required to Install the Router in a Rack on page 6

•

Install the MX104 Router in the Rack on page 6

Tools Required to Install the Router in a Rack

To install the router in a rack, you need the following tools:

•

Phillips (+) screwdriver, number 2

•

ESD grounding wrist strap

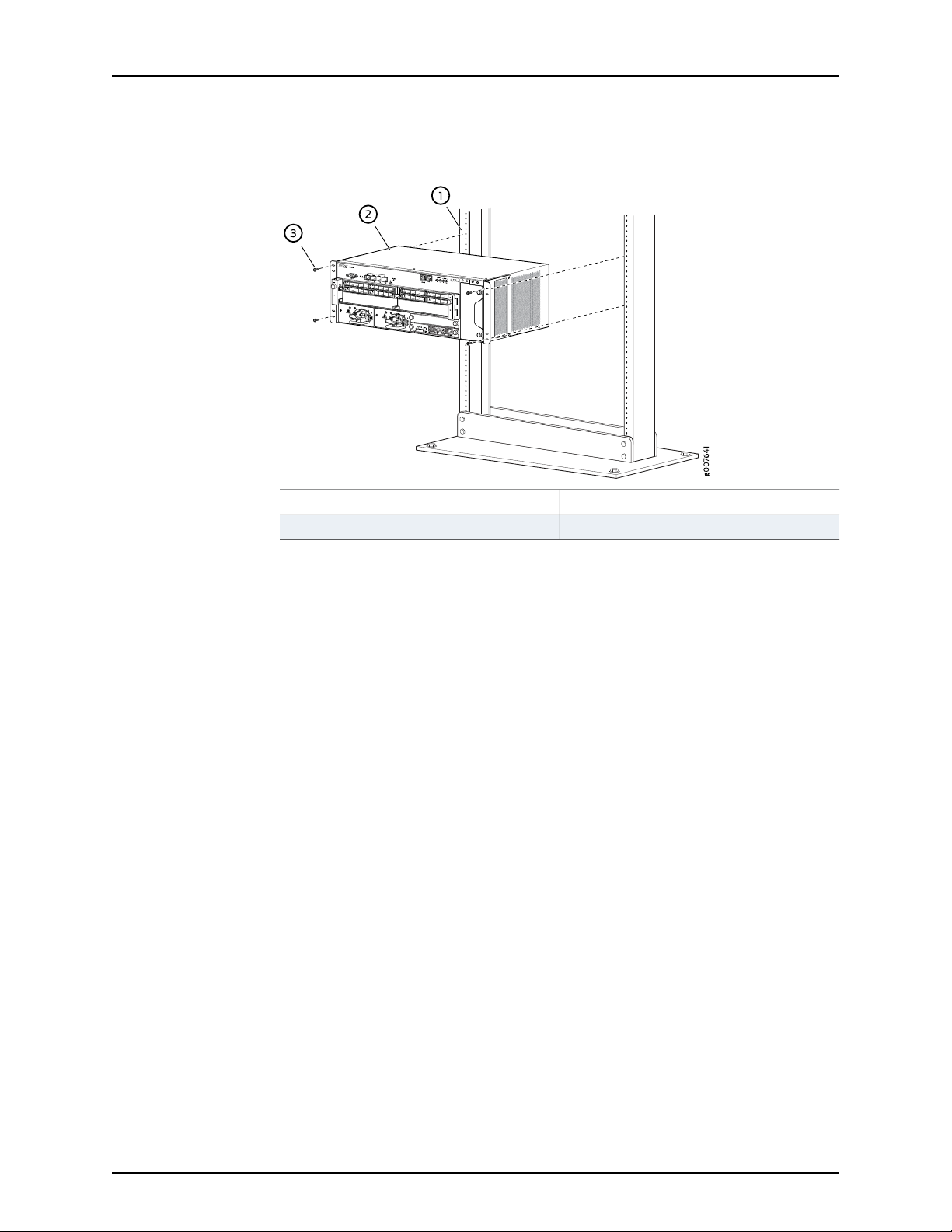

Install the MX104 Router in the Rack

The router can be installed horizontally in a rack or cabinet.

Two people are required to install the MX104 router. The chassis weighs approximately

32 lb (14.5 kg). To install the chassis (see Figure 3 on page 7):

1. Ensure that the rack is in its permanent location and is secured to the building. Ensure

that the installationsite allows adequateclearance for both airflow and maintenance.

2. Position the router in front of the rack or cabinet.

3. Have one person grasp both sides of the router, lift the router, and position it in the

rack, aligning the mounting bracket holes with the threaded holes in the rack rails.

Make sure the chassis is level.

4. Have the second person install a mounting screw into each of the open mounting

holes aligned with the rack, starting from the bottom.

5. Visually inspect the alignment of the router. If the router is installed properly in the

rack, all the mounting screws on one side of the rack should be aligned with the

mounting screws on the opposite side, and the router should be level.

Copyright © 2016, Juniper Networks, Inc.6

Page 7

Install the MX104 Router in the Rack

Figure 3: Installing the Front-Mounted Router in the Rack

3—1— Mounting screwsRack

2—MX104 router

7Copyright © 2016, Juniper Networks, Inc.

Page 8

MX104 3D Universal Edge Routers Quick Start

Step 3: Ground the MX104 Router

•

Tools Required to Ground the MX104 Router on page 8

•

Connect the Grounding Cable on page 8

Tools Required to Ground the MX104 Router

To ground the router, you need the following tools:

•

Phillips (+) screwdriver, number 2

•

ESD grounding wrist strap

•

Two SAE 10-32 screws and washers

•

Grounding lug, Panduit LCD10-10-L

•

Grounding cable, use 14-AWG (2.08 mm2) 90°C wire for AC (not provided)

•

Grounding cable, use 6-AWG (13.3 mm2) 60°C wire for 24V DC (not provided)

Connect the Grounding Cable

You ground the router by connecting a grounding cableto earth ground and then attaching

it to the chassis grounding points on the front of the router. To ground the router:

1. Verify that a licensed electrician has attached the cable lug provided with the router

to the grounding cable.

2. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect

the strap to an approved site ESD grounding point. See the instructions for your site.

3. Ensure that all grounding surfaces are clean and brought to a bright finish before

grounding connections are made.

4. Connect the grounding cable to a proper earth ground.

5. Detach the ESD grounding strap from the site ESD grounding point.

6. Attach an ESD grounding strap to your bare wrist and connect the strap to one of the

ESD points on the chassis.

7. Place the grounding cable lug over the grounding points on the front of the chassis

(see Figure 4 on page 9).

8. Secure the grounding cable lug with the washers and screws. The holes are sized for

SAE 10-32 screws. Apply 4.34 lb-in. (0.49 Nm) of torque to each screw. Do not

overtighten the screw. (Use a number 2 Phillips screwdriver.)

CAUTION: Ensure that each grounding cable lug seats flush against the

surface of the grounding points as you are tightening the screws. Ensure

that each screw is properly threaded into the grounding points. Applying

installation torque to the screw when improperly threaded may result in

damage to the terminal.

Copyright © 2016, Juniper Networks, Inc.8

Page 9

Connect the Grounding Cable

CAUTION: The maximum torque rating of the grounding screws on the

router is 4.34 lb-in. (0.49 Nm). The grounding screws may be damaged if

excessive torque is applied. Use only a torque-controlled driver to tighten

screws.Use an appropriately sized driver, with a maximum torque capacity

of 5 lb-in. or less. Ensure that the driver is undamaged and properly

calibrated and that you have been trained in its use. You may wish to use

a driver that is designed to prevent overtorque when the preset torque

level is achieved.

9. Dress the grounding cable, and verify that it does not touch or block access to router

components, and that it does not drape where people could trip on it.

Figure 4: Grounding Points on the MX104 Router

2—1— ScrewsGrounding cable lug

9Copyright © 2016, Juniper Networks, Inc.

Page 10

g006425

Management PC

MGMT

port

Management

network

MX104 3D Universal Edge Routers Quick Start

Step 4: Connect External Devices and Cables

•

Connect the Router to a Network for Out-of-Band Management on page 10

•

Connect the Router to a Management Console Device on page 10

•

Connect MIC Cables to the MX104 Router on page 11

Connect the Router to a Network for Out-of-Band Management

1. Turn off the power to the management device.

2. Plug one end of the Ethernet cable into the ETHERNET port on the Routing Engine.

(Figure 5 on page 10 shows the connector. Figure 6 on page 10 shows the port.)

3. Plug the other end of the cable into the network device.

Figure 5: Ethernet Cable Connector

Figure 6: Ethernet Port

Connect the Router to a Management Console Device

1. Turn off the power to the console or auxiliary device.

2. Plug the RJ-45 end of the serial cable into the CONSOLE port on the Routing Engine

(Figure 7 on page 11 shows the connector. Figure 8 on page 11 shows the ports.)

3. Plug the female DB-9 end into the device's serial port.

NOTE:

For console devices, configure the serial port to the following values:

•

Baud rate—9600

•

Parity—N

•

Data bits—8

•

Stop bits—1

•

Flow control—none

Copyright © 2016, Juniper Networks, Inc.10

Page 11

Figure 7: Routing Engine Console Cable Connector

g006423

Console Server

PC

CONSOLE/AUX

port

Figure 8: Console Connections

Connect MIC Cables to the MX104 Router

1. Have ready a length of the type of cable used by the component. For MIC cable

specifications, see the MX Series Interface Module Reference.

2. Remove the rubber safety plug from the cable connector port.

Connect MIC Cables to the MX104 Router

WARNING: Do not look directly into a fiber-optic transceiver or into the

ends of fiber-optic cables. Fiber-optic transceivers and fiber-optic cable

connected to a transceiver emit laser light that can damage your eyes.

CAUTION: Do not leave a fiber-optic transceiver uncovered except when

inserting or removing cable. The safety cap keeps the port clean and

prevents accidental exposure to laser light.

3. Insert the cable connector into the cable connector port on the faceplate.

NOTE: The XFP cages and optics on the components are industry standard

parts that have limited tactile feedback for insertion of optics and fiber.

You need to insert the optics and fiber firmly until the latch is securely in

place.

4. Use the equipment frame to support cables and prevent them from dislodging or

developing stress points. Secure the cable so that it is not supporting its own weight

as it hangs to the floor. Place excess cable out of the way in the cable routing channel.

CAUTION: Avoid bending fiber-optic cable beyond its minimum bend

radius. An arc smaller than a few inches in diameter can damage the cable

and cause problems that are difficult to diagnose.

11Copyright © 2016, Juniper Networks, Inc.

Page 12

MX104 3D Universal Edge Routers Quick Start

CAUTION: Do not let fiber-optic cable hang free from the connector. Do

not allow fastened loops of cable to dangle, which stresses the cable at

the fastening point.

Copyright © 2016, Juniper Networks, Inc.12

Page 13

Step 5: Connect Power to the MX104 Router

Depending on your configuration, your router uses either AC or DC power supplies. Perform

the appropriate procedures for each power supply in your router.

WARNING: You must ground the router before connecting the router to power.

•

Connect AC Power to an AC-Powered MX104 Router on page 13

•

Connect DC Power to a DC-Powered MX104 Router on page 14

Connect AC Power to an AC-Powered MX104 Router

To connect power to the AC-powered router, you need the following tools:

•

AC power cords with C15 plugs

•

ESD grounding wrist strap

Step 5: Connect Power to the MX104 Router

1. Locate power cords that have a plug appropriate for your geographical location. For

more information, see the MX104 3D Universal Edge Router Hardware Guide.

2. Attach an ESD grounding strap to your bare wrist and connect the strap to one of the

ESD points on the chassis.

3. Insert the appliance coupler end of the power cord into the appliance inlet on the

power supply.

4. Insert the power cord plug into an external AC power source receptacle.

NOTE: Each power supply must be connected to a dedicated AC power

feed and a dedicated customer site circuit breaker. We recommend that

you use a dedicated customer site circuit breaker rated for 10 A (100 VAC),

or as required by local code.

5. Secure the power cord with the power cord retainer clip.

6. Dress the power cord appropriately. Verify that the power cord does not block the air

exhaust and access to router components, or drape where people could trip on it.

7. Repeat Step 1 through Step 6 for the remaining power supply.

8. Observe the LED on the power supply. The LED blinks green as it transitions online. If

the power supply is functioning normally, the LED lights green steadily.

If the LED is red or not lit, the power supply is not functioning normally. Repeat the

cabling procedures.

13Copyright © 2016, Juniper Networks, Inc.

Page 14

MX104 3D Universal Edge Routers Quick Start

Figure 9: Connecting an AC Power Cord to an MX104 AC Power Supply

Connect DC Power to a DC-Powered MX104 Router

To connect power to the DC-powered router, you need the following tools:

•

Phillips (+) screwdriver, number 2

•

ESD grounding wrist strap

•

Grounding ring lug with hole sized for an M5 screw

•

M5 nut and washer (one per DC power supply, attached)

•

DC power source cables, minimum 14 AWG or as required by local code (not provided)

•

DC power ring lugs, Panduit PV12-14HDRB-2k (two per DC power supply)

•

M6 screws and washers (two per DC power supply, attached)

•

Grounding cable, use 6-AWG (13.3 mm2) 60°C wire for 24V DC (not provided)

The DC power supply has two terminals on each power supply, covered by a clear plastic

cover.

Table 1: MX104 DC Power System Input Voltage

SpecificationNominal Voltage

Operating range: +18 to +30 VDC+24

Operating range: –39 to –56 VDC–48

Operating range: –39 to –72 VDC–60

Copyright © 2016, Juniper Networks, Inc.14

Page 15

Connect DC Power to a DC-Powered MX104 Router

1. Switchoff the dedicated customer site circuit breakers.Ensure that the voltage across

the DC power source cable leads is 0 V and that there is no chance that the cable

leads might become active during installation.

2. Ground the DC power supply (see Figure 10 on page 15):

a. Remove the nut and washer from the grounding point on the power supply.

b. Secure each grounding cable lug to the grounding point with the washer and nut.

Figure 10: Connecting the Ground Cable to the MX104 DC Power Supply

3. Remove the plastic cover protecting the terminal on the faceplate.

4. Verify that the DC power cables are correctly labeled before making connections to

the power supply. In a typical power distribution scheme where the return is connected

to chassis ground at the batteryplant, you can use a multimeter to verify the resistance

of the –48V and return DC cables to chassis ground:

For –48V and –60V:

a. The cable with very high resistance (indicating an open circuit) to chassis ground

is the DC input cable (-).

b. The cable with very low resistance (indicating a closed circuit) to chassis ground

is the return cable (+).

For +24V:

a. The cable with very low resistance (indicating a closed circuit) to chassis ground

is the DC input cable (-).

b. The cable with very high resistance (indicating an open circuit) to chassis ground

is the return cable (+).

5. Remove the screws and washers from the DC terminals.

6. Secure each power cable lug to the terminal with the washers and screw (see

Figure 11 on page 17). Apply 27.4 lb-in. (3.1 Nm) of torque to each screw. Do not

overtighten the screw. (Use a number 2 Phillips screwdriver.)

15Copyright © 2016, Juniper Networks, Inc.

Page 16

MX104 3D Universal Edge Routers Quick Start

a. Secure the positive DC source power cable lug to the return (+) terminal.

b. Secure the negative DC source power cable lug to the input (–) terminal.

CAUTION: Ensure that each power cable lug seats flush againstthe surface

of the terminal block as you are tightening the screws. Ensure that each

screw is properly threaded into the terminal. Applying installation torque

to the screw when improperly threaded may result in damage to the

terminal.

CAUTION: The maximum torque rating of the terminal screws on the DC

power supply is 27.4 lb-in. (3.1 Nm). The terminal screws may be damaged

if excessive torque is applied. Use only a torque-controlleddriver to tighten

screws on the DC power supply terminals. Use an appropriately-sized

driver, with a maximum torque capacity of 27.4 lb-in. or less. Ensure that

the driver is undamaged and properly calibrated and that you have been

trained in its use. You may wish to use a driver that is designed to prevent

overtorque when the preset torque level is achieved.

7. Replace the plastic cover over the terminals on the faceplate.

8. Connect each DC power cable to the appropriate external DC power source.

NOTE: For information about connecting to external DC power sources,

see the instructions for your site.

9. Switch on the external circuit breakers to provide voltage to the DC power source

cable leads.

10. Repeat Step 2 through Step 9 for the remaining power supply.

11. Observe the LED on the power supply. The LED blinks green as it transitions online. If

the power supply is functioning normally, the LED lights green steadily.

If the LED is red or not lit, the power supply is not functioning normally. Repeat the

cabling procedures.

Copyright © 2016, Juniper Networks, Inc.16

Page 17

Connect DC Power to a DC-Powered MX104 Router

Figure 11: Connecting a DC Power Cable to an MX104 DC Power Supply

17Copyright © 2016, Juniper Networks, Inc.

Page 18

MX104 3D Universal Edge Routers Quick Start

Step 6: Perform Initial Software Configuration

This procedure connects the router to the network but does not enable it to forward

traffic. For complete information about configuring the router to forward traffic, including

examples, see the Junos OS configuration guides.

To configure the software:

•

Enter Configuration Mode on page 18

•

Configure User Accounts and Passwords on page 18

•

Configure System Attributes on page 19

•

Commit the Configuration on page 19

Enter Configuration Mode

1. Verify that the router is powered on.

2. Log in as the “root” user. There is no password.

3. Start the CLI.

root# cli

root@>

4. Enter configuration mode.

cli> configure

[edit]

root@#

Configure User Accounts and Passwords

For information about using an encrypted password or an SSH public key string (DSA or

RSA), see the Junos OS Administration Library for Routing Devices.

1. Add a password to the root administration user account. Enter a clear-text password.

[edit]

root# set system root-authentication plain-text-password

New password: password

Retype new password: password

2. Create a management console user account.

[edit]

root# set system login user user-name authentication plain-text-password

New Password: password

Retype new password: password

3. Set the user account class to super-user.

[edit]

root@# set system login user user-name class super-user

Copyright © 2016, Juniper Networks, Inc.18

Page 19

Configure System Attributes

1. Configure the name of the router. If the name includes spaces, enclose the name in

quotation marks (“ ”).

[edit]

root@# set system host-name host-name

2. Configure the router’s domain name.

[edit]

root@# set system domain-name domain-name

3. Configure the IP address and prefix length for the router’s Ethernet interface.

[edit]

root@# set interfaces fxp0 unit 0 family inet address address/prefix-length

4. Configure the IP address of a backup router, which is used only while the routing

protocol is not running.

[edit]

root@# set system backup-router address

Configure System Attributes

5. Configure the IP address of a DNS server.

6. (Optional) Configure the static routes to remote subnets with access to the

management port. Access to the management port is limited to the local subnet. To

access the management port from a remote subnet, you need to add a static route

to that subnet within the routing table. For more information about static routes, see

the Junos OS Administration Library for Routing Devices.

7. Configure the telnet service at the [edit system services] hierarchy level.

Commit the Configuration

1. (Optional) Display the configuration to verify that it is correct.

[edit]

root@# set system name-server address

[edit]

root@# set routing-options static route remote-subnet next-hop destination-IP retain

no-readvertise

[edit]

root@# set system services telnet

[edit]

root@# show

system {

host-name host-name;

domain-name domain-name;

backup-router address;

root-authentication {

authentication-method (password | public-key);

}

name-server {

address;

19Copyright © 2016, Juniper Networks, Inc.

Page 20

MX104 3D Universal Edge Routers Quick Start

}

}

interfaces {

fxp0 {

unit 0 {

}

}

}

2. Commit the configuration to activate it on the router.

[edit]

root@# commit

3. (Optional) Configure additional properties by adding the necessary configuration

statements. Then commit the changes to activate them on the router.

[edit]

root@host# commit

family inet {

address address/prefix-length;

}

4. When you have finished configuring the router, exit configuration mode.

[edit]

root@host# exit

root@host>

Copyright © 2016, Juniper Networks, Inc.20

Page 21

Safety Warnings

Safety Warnings

WARNING: See installation instructions before connecting the router to a

power source. This is a summary of safety warnings. For a complete list of

warnings for this router, including translations, see the MX104 3D Universal

Edge Router Hardware Guide at http://www.juniper.net/techpubs/.

WARNING: The intrabuilding port(s) of the router is suitable for connection

to intrabuilding or unexposed wiring or cabling only. The intrabuilding port(s)

of the router MUST NOT be metallicallyconnectedto interfacesthat connect

to the OSP or its wiring. These interfaces are designed for use as intrabuilding

interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE, Issue

6) and require isolation from the exposed OSP cabling. The addition of primary

protectors is not sufficient protection to connect these interfacesmetallically

to OSP wiring.

CAUTION: Before removing or installing components of a router, attach an

ESD strap to an ESD point, and place the other end of the strap around your

bare wrist. Failure to use an ESD strap could result in damage to the router.

CAUTION: Use an external surge protective device (SPD) at the AC input of

the router.

•

Only trained and qualified personnel should install or replace the router.

•

Perform only the procedures described in this Quick Start or the MX104 3D Universal

Edge Router Hardware Guide. Other services should be performed by authorized service

personnel only.

•

Before installing the router, read the guidelines for site preparation in the MX104 3D

Universal Edge Router Hardware Guide to make sure that the site meets power,

environmental, and clearance requirements for the router.

•

When installing the router, do not use a ramp inclined more than 10 degrees.

•

To prevent injury, keep your back straight and lift with your legs, not your back.

•

Mount the router at the bottom of the rack if it is the only unit in the rack.

•

When mounting the router in a partially filled rack, load the rack from the bottom to

the top, with the heaviest component at the bottom of the rack.

•

If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the router in the rack.

21Copyright © 2016, Juniper Networks, Inc.

Page 22

MX104 3D Universal Edge Routers Quick Start

•

When removing or installing an electrical component, always place it component-side

up on a flat antistatic surface or in an electrostatic bag.

•

When you install the router, always make the ground connection first and disconnect

it last.

•

Wire the DC power supply using the appropriate lugs.

•

Do not work on the system or connect or disconnect cables during electrical storms.

•

Beforeworking on equipment that is connectedto power lines, remove jewelry, including

rings, necklaces, and watches. Metal objects heat up when connected to power and

ground and can cause serious burns or become welded to the terminals.

•

Failure to observe these safety warnings can result in serious physical injury.

•

AC power cable warning (Japan):

WARNING: The attached power cable is only for this product. Do not use

the cable for another product.

Compliance Statements for NEBS

•

The equipment is suitable for installation as part of the Common Bonding Network

(CBN).

•

The equipment is suitable for installation in locations where the National Electrical

Code (NEC) applies.

•

The battery return connection is to be treated as an isolated DC return (i.e. DC-I), as

defined in GR-1089-CORE.

•

For Juniper Networks systems with AC power supplies, an external surge protective

device (SPD) must be used at the AC power source.

Compliance Statements for EMC Requirements

•

Canada on page 23

•

European Community on page 23

•

Israel on page 23

•

Japan on page 23

•

United States on page 23

Copyright © 2016, Juniper Networks, Inc.22

Page 23

Canada

European Community

Israel

Compliance Statements for EMC Requirements

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

This is a Class A product. In a domestic environment, this product might cause radio

interference in which case the user might be required to take adequate measures.

Japan

United States

Translation from Hebrew—Warning: This product is Class A. In residential environments,

the product might cause radio interference, and in such a situation, the user might be

required to take adequate measures.

The preceding translates as follows:

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this product is used near

a radio or television receiver in a domestic environment, it might cause radio interference.

Install and use the equipment according to the instruction manual. VCCI-A.

The hardware equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction

manual, might cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

23Copyright © 2016, Juniper Networks, Inc.

Page 24

MX104 3D Universal Edge Routers Quick Start

Junos OS Documentation and Release Notes

For a list of related Junos OS documentation, see

http://www.juniper.net/techpubs/software/junos/.

If the information in the latest release notes differs from the information in the

documentation, follow the Junos OS Release Notes.

To obtain the most current version of all Juniper Networks®technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

Requesting Technical Support

Technicalproduct support is availablethrough the Juniper Networks Technical Assistance

Center (JTAC). If you are a customer with an active J-Care or Partner Support Service

support contract, or are covered under warranty, and need postsales technical support,

you can access our tools and resources online or open a case with JTAC.

•

JTAC policies—For a complete understanding of our JTAC procedures and policies,

review the JTAC User Guide located at

http://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

•

Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/.

•

JTAC Hours of Operation —The JTAC centers have resources available 24 hours a day,

7 days a week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with the

following features:

•

Find CSC offerings: http://www.juniper.net/customers/support/

•

Find product documentation: http://www.juniper.net/techpubs/

•

Find solutions and answer questions using our Knowledge Base: http://kb.juniper.net/

•

Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

•

Search technical bulletins for relevant hardware and software notifications:

http://kb.juniper.net/InfoCenter/

•

Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

•

Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

Copyright © 2016, Juniper Networks, Inc.24

Page 25

To verify service entitlement by product serial number, use our Serial Number Entitlement

(SNE) Tool: https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

•

Use the Case Management tool in the CSC at http://www.juniper.net/cm/.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, visit us at

http://www.juniper.net/support/requesting-support.html

Revision History

April 11, 2016—530-062013. Revision 2. Updates grounding information.

January 2015—530-062013. Revision 1. Minor updates.

November 2013—530-053224. Revision 1. Initial release.

Requesting Technical Support

Copyright © 2016, Juniper Networks, Inc. All rights reserved.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

25Copyright © 2016, Juniper Networks, Inc.

Loading...

Loading...