Page 1

M320 Multiservice Edge Router Hardware Guide

Modified: 2015-05-20

Copyright © 2015, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Copyright © 2015, Juniper Networks, Inc. All rights reserved.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

M320 Multiservice Edge Router Hardware Guide

Copyright © 2015, Juniper Networks, Inc.

All rights reserved.

The information in this document is current as of the date on the title page.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related limitations through the

year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with) Juniper Networks

software. Use of such software is subject to the terms and conditions of the End User License Agreement (“EULA”) posted at

http://www.juniper.net/support/eula.html. By downloading, installing or using such software, you agree to the terms and conditions of

that EULA.

Copyright © 2015, Juniper Networks, Inc.ii

Page 3

Table of Contents

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Supported Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Part 1 Overview

Chapter 1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M320 Router Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M320 Component Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 M320 Router Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Outstanding Issues with the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Errata with the M320 Router Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 3 Chassis Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

M320 Chassis Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

M320 Midplane Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M320 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

M320 Cable Management System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

M320 Connector Interface Panel (CIP) Description . . . . . . . . . . . . . . . . . . . . . . . . 13

CIP Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Routing Engine Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Alarm Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

M320 Craft Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

M320 Craft Interface Alarm LEDs and ACO/LT Button . . . . . . . . . . . . . . . . . . . . . . 16

M320 Craft Interface LED Display and Navigation Buttons . . . . . . . . . . . . . . . . . . 16

M320 Craft Interface Host Subsystem LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

M320 Craft Interface FPC LEDs and Online/Offline Buttons . . . . . . . . . . . . . . . . . 18

M320 Craft Interface Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M320 Craft Interface SIB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 4 Cooling System Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 21

M320 Cooling System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 5 Host Subsystem Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . 23

M320 Host Subsystem Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

M320 Routing Engine Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

iiiCopyright © 2015, Juniper Networks, Inc.

Page 4

M320 Multiservice Edge Router Hardware Guide

M320 Routing Engine 600 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

M320 Routing Engine 1600 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

M320 Routing Engine 2000 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

M320 RE-A-1800 Routing Engine Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Routing Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Routing Engine Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

RE-A-1800 Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Routing Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Supported Routing Engines by Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

M7i Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

M10i Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

M40e Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

M120 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

M320 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MX104 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MX240 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MX480 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

MX960 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MX2010 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MX2020 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

PTX3000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

PTX5000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

T320 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

T640 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

T1600 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

T4000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TX Matrix Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TX Matrix Plus Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TX Matrix Plus (with 3D SIBs) Routing Engines . . . . . . . . . . . . . . . . . . . . . . . 44

M320 Control Board (CB) Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

M320 Control Board (CB) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 6 Line Card Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

M320 Flexible PIC Concentrator (FPC) Description . . . . . . . . . . . . . . . . . . . . . . . . 49

M320 FPC Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

M320 FPCs Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

M320 PIC Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

M320 PICs Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

M320 End-of-Life PICs Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

M320 PIC Combination Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

M320 PIC/FPC Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

PIC/FPC Compatibility (Type 1 FPCs and Type 1 PICs) . . . . . . . . . . . . . . . . . . 67

PIC/FPC Compatibility (Type 2 FPCs and Type 2 PICs) . . . . . . . . . . . . . . . . . 70

PIC/FPC Compatibility (Type 3 FPCs and Type 3 PICs) . . . . . . . . . . . . . . . . . . 71

Chapter 7 Power System Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 73

M320 Power System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

M320 AC Power Supplies Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Copyright © 2015, Juniper Networks, Inc.iv

Page 5

Table of Contents

M320 DC Power Supplies Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Nonisolated DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Isolated DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Components Powered by Each Power Supply Slot . . . . . . . . . . . . . . . . . . . . . 75

DC Power Supply Load Sharing and Fault Tolerance . . . . . . . . . . . . . . . . . . . 76

M320 Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Chapter 8 Switch Fabric Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 79

M320 SIB Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

M320 Performance for Different SIB Configurations . . . . . . . . . . . . . . . . . . . . . . . 80

M320 SIB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Part 2 Site Planning, Preparation, and Specifications

Chapter 9 Preparation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

M320 Site Preparation Checklist Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

M320 Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Rack Requirements for the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

M320 Cabinet Size and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 88

M320 Cabinet Airflow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

M320 Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

M320 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

M320 Chassis Grounding Cable and Lug Specifications . . . . . . . . . . . . . . . . . . . . 94

Site Electrical Wiring Guidelines for Juniper Networks Devices . . . . . . . . . . . . . . . 95

Distance Limitations for Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Radio Frequency Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

M320 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

M320 RJ-48 Connector Pinouts for the Control Board External Clock Inputs . . . 98

M320 Fuse Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chapter 10 AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

M320 AC Power Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

M320 AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Chapter 11 DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

M320 DC Power Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

DC Power System Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Nonisolated DC Power Supply Electrical Specifications . . . . . . . . . . . . . . . . 106

Isolated DC Power Supply Electrical Specifications . . . . . . . . . . . . . . . . . . . 106

M320 DC Power Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

M320 DC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

DC Power Circuit Breaker for M320 Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 12 Network Cable and Transceiver Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Understanding Fiber-Optic Cable Signal Loss, Attenuation, and Dispersion . . . . . 111

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable . . . . . . . . . . . . 111

Attenuation and Dispersion in Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . . 111

Calculating Power Budget and Power Margin for Fiber-Optic Cables . . . . . . . . . . 112

Calculating Power Budget for Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . . 112

Calculating Power Margin for Fiber-Optic Cable . . . . . . . . . . . . . . . . . . . . . . . 113

vCopyright © 2015, Juniper Networks, Inc.

Page 6

M320 Multiservice Edge Router Hardware Guide

Chapter 13 Management Cable and Transceiver Specifications and Pinouts . . . . . . . . 115

M320 Routing Engine Interface Cable and Wire Specifications . . . . . . . . . . . . . . . 115

M320 RJ-45 Connector Pinouts for the Routing Engine ETHERNET Port . . . . . . . 116

M320 DB-9 Connector Pinouts for the Routing Engine AUX and CONSOLE

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Part 3 Initial Installation and Configuration

Chapter 14 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

M320 Router Installation Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Chapter 15 Unpacking the M320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Tools and Parts Required to Unpack the M320 Router . . . . . . . . . . . . . . . . . . . . . 123

Unpacking the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Verifying the M320 Router Parts Received . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter 16 Installing the Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Installing the M320 Mounting Hardware for a Four-Post Rack or Cabinet . . . . . . 127

Installing Cage Nuts (If Needed) for M320 Four-Post Racks or Cabinets . . . 127

Installing the Large Mounting Shelf for M320 Four-Post Racks or

Installing the Small Mounting Shelf for M320 Four-Post Racks or

Removing the Adjustable Center-Mounting Brackets for M320 Four-Post

Installing the M320 Mounting Hardware for Open-Frame Racks . . . . . . . . . . . . . 130

Installing Cage Nuts (If Needed) for M320 Open Frame Racks . . . . . . . . . . . 131

Installing the Large Mounting Shelf for the M320 Open-Frame Racks . . . . . 132

Installing the Small Mounting Shelf for the M320 Open-Frame Racks . . . . . 132

Moving the Adjustable Center-Mounting Brackets for M320 Open-Frame

Chapter 17 Installing the M320 With a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Overview of Installing the M320 Chassis Using a Mechanical Lift . . . . . . . . . . . . 135

Tools Required to Install the M320 Chassis Using a Mechanical Lift . . . . . . . . . . 136

Installing the M320 Chassis Using a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . 136

Attaching the Installation Handle to the M320 Chassis . . . . . . . . . . . . . . . . 136

Mounting the M320 Chassis Using a Mechanical Lift . . . . . . . . . . . . . . . . . . 138

Removing the M320 Installation Handle and Reinstalling the Power

Installing the M320 Cable Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Chapter 18 Installing the M320 Without a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . 143

Tools and Parts Required to Install the M320 Chassis Without a Mechanical

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Removing M320 Components from the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Removing the M320 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Removing the M320 SIBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Removing the M320 CBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Removing the M320 Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Racks or Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Copyright © 2015, Juniper Networks, Inc.vi

Page 7

Table of Contents

Removing the M320 Cable Management System . . . . . . . . . . . . . . . . . . . . . 148

Removing the M320 Front Fan Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Removing the M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Installing the M320 Chassis in the Rack Manually . . . . . . . . . . . . . . . . . . . . . . . . . 151

Reinstalling M320 Components in the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Reinstalling an M320 Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Reinstalling the M320 CBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Reinstalling the M320 SIBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Reinstalling the M320 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Reinstalling the M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Reinstalling M320 Front Fan Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Reinstalling the M320 Cable Management System . . . . . . . . . . . . . . . . . . . . 159

Installing the M320 Cable Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Chapter 19 Connecting the M320 to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Tools and Parts Required to Ground the M320 Router . . . . . . . . . . . . . . . . . . . . . 161

Connecting the M320 Router Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Chapter 20 Connecting the M320 to External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Tools and Parts Required for M320 Router Connections . . . . . . . . . . . . . . . . . . . 163

Overview of Connecting the M320 Router to Management and Alarm

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Connecting the M320 Router to a Management Console or Auxiliary Device . . . 165

Connecting the M320 Router to a Network for Out-of-Band Management . . . . 166

Connecting the M320 Router to an External Alarm-Reporting Device . . . . . . . . . 168

Connecting the M320 Router to an External Clocking Device . . . . . . . . . . . . . . . 168

Connecting PIC Cables to the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 21 Providing Power to the M320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Connecting Power to an AC-Powered M320 Router . . . . . . . . . . . . . . . . . . . . . . . 173

Connecting Power to a DC-Powered M320 Router . . . . . . . . . . . . . . . . . . . . . . . . 174

Powering On the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Powering Off the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Chapter 22 Configuring the Junos OS Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Initially Configuring the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Part 4 Installing and Replacing Components

Chapter 23 Overview of Installing and Replacing Components . . . . . . . . . . . . . . . . . . . 185

M320 Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Tools and Parts Required to Replace the M320 Hardware Components . . . . . . . 186

viiCopyright © 2015, Juniper Networks, Inc.

Page 8

M320 Multiservice Edge Router Hardware Guide

Chapter 24 Replacing Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Replacing the M320 CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Removing an M320 CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Installing an M320 CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Replacing the M320 Alarm Relay Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Replacing an M320 Management Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . 192

Replacing an M320 Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Removing an M320 Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . . 194

Installing an M320 Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . . . 195

Replacing an M320 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Removing an M320 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Installing an M320 Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Replacing an M320 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Chapter 25 Replacing Cooling System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Replacing an M320 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Removing an M320 Front Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Installing an M320 Front Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Removing an M320 Rear Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Installing an M320 Rear Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Replacing an M320 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Removing an M320 Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Installing an M320 Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Removing an M320 Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Installing an M320 Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Chapter 26 Replacing Host Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Taking the M320 Host Subsystem Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Replacing an M320 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Removing an M320 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Installing an M320 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Replacing a Solid-State Disk on an M320 RE-A-1800 Routing Engine . . . . . . . . 218

Removing an Solid-State Disk From an M320 RE-A-1800 Routing

Installing an Solid-State Disk on an M320 RE-A-1800 Routing Engine . . . . 219

Inserting or Removing a PC Card from an M320 Routing Engine . . . . . . . . . . . . . 219

Inserting a PC Card into an M320 Routing Engine . . . . . . . . . . . . . . . . . . . . . 220

Removing an M320 PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Replacing a DIMM Module in an M320 Routing Engine . . . . . . . . . . . . . . . . . . . . . 221

Removing an M320 DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Installing an M320 DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Replacing an M320 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Removing an M320 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Installing an M320 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Copyright © 2015, Juniper Networks, Inc.viii

Page 9

Table of Contents

Chapter 27 Replacing Line Card Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Replacing an M320 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Removing an M320 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Installing an M320 FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Replacing an M320 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Removing an M320 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Installing an M320 PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Replacing M320 PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Removing an M320 PIC Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Installing an M320 PIC Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Replacing an M320 SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Removing an M320 SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Installing an M320 SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Replacing an M320 XENPAK Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Removing an M320 XENPAK Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Installing an M320 XENPAK Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Chapter 28 Replacing Power System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Replacing an M320 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Removing an M320 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Installing an M320 AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Replacing an M320 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Removing an M320 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Installing an M320 DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Replacing an M320 AC Power Supply Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Replacing an M320 DC Power Supply Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Chapter 29 Replacing Switch Fabric Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Replacing an M320 SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Removing an M320 SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Installing an M320 SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Part 5 Maintaining the Chassis and Components

Chapter 30 Routine Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Routine Maintenance Procedures for the M320 Router . . . . . . . . . . . . . . . . . . . . 265

Chapter 31 Maintaining Components and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Tools and Parts Required to Maintain the M320 Hardware Components . . . . . . 267

Maintaining the M320 Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Maintaining the M320 Fan Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Maintaining the M320 Host Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Maintaining M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Holding and Storing M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Holding M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Storing M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Maintaining M320 PICs and PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Maintaining the M320 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Maintaining the M320 SIBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

ixCopyright © 2015, Juniper Networks, Inc.

Page 10

M320 Multiservice Edge Router Hardware Guide

Part 6 Troubleshooting Hardware

Chapter 32 Troubleshooting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

M320 Troubleshooting Resources Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

M320 LED Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Craft Interface LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

M320 Chassis and Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Troubleshooting the M320 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Troubleshooting the M320 FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Troubleshooting the M320 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Troubleshooting the M320 PICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Troubleshooting the M320 Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Part 7 Contacting Customer Support and Returning the Chassis or

Components

Chapter 33 Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Chapter 34 Locating Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Locating M320 Component Serial Numbers Using the CLI . . . . . . . . . . . . . . . . . 299

Locating the M320 Chassis Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . 300

Locating the M320 CIP Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Locating the M320 Craft Interface Serial Number Label . . . . . . . . . . . . . . . . . . . 301

Locating the M320 Routing Engine Serial Number Label . . . . . . . . . . . . . . . . . . . 301

Locating the M320 CB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Locating the M320 FPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Locating the M320 PIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Locating the M320 Power Supply Serial Number Labels . . . . . . . . . . . . . . . . . . . 304

Locating the M320 SIB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Chapter 35 Packing and Returning Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Returning a Hardware Component to Juniper Networks, Inc. . . . . . . . . . . . . . . . . 307

Tools and Parts Required to Remove Components From an M320 Router . . . . 308

Packing the M320 Router for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Packing M320 Router Components for Shipment . . . . . . . . . . . . . . . . . . . . . . . . 310

Part 8 Safety and Compliance Information

Chapter 36 General Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Definition of Safety Warning Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

General Safety Guidelines for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . 315

General Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . . 316

Qualified Personnel Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Restricted Access Area Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

M320 In Case of an Electrical Accident . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Preventing Electrostatic Discharge Damage to an M320 Router . . . . . . . . . . . . . 318

Copyright © 2015, Juniper Networks, Inc.x

Page 11

Table of Contents

Chapter 37 Fire Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Fire Safety Requirements for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . . 321

General Fire Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Fire Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Fire Suppression Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Chapter 38 Installation Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . 323

M320 Installation Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

M320 General Installation Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . 323

M320 Chassis Lifting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Installation Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . 324

Intra-Building Ports Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Installation Instructions Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Rack-Mounting Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . . . . 325

Ramp Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Chapter 39 Laser and LED Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . 331

M320 General Laser Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Laser Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . . . . . . . . . . . 331

Class 1 Laser Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Class 1 LED Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Laser Beam Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Radiation from Open Port Apertures Warning . . . . . . . . . . . . . . . . . . . . . . . . 333

Chapter 40 Maintenance and Operational Safety Guidelines and Warnings . . . . . . . . 335

Maintenance and Operational Safety Warnings for Juniper Networks Devices . . 335

Battery Handling Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Jewelry Removal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Lightning Activity Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Operating Temperature Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Product Disposal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Chapter 41 Electrical Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

General Electrical Safety Warnings for Juniper Networks Devices . . . . . . . . . . . . 341

Grounded Equipment Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Grounding Requirements and Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Midplane Energy Hazard Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Multiple Power Supplies Disconnection Warning . . . . . . . . . . . . . . . . . . . . . 343

Power Disconnection Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

General Electrical Safety Guidelines and Electrical Codes for Juniper Networks

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

M320 AC Power Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

M320 AC Power Electrical Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

M320 DC Power Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

DC Power Electrical Safety Warnings for Juniper Networks Devices . . . . . . . . . . 347

DC Power Copper Conductors Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

DC Power Disconnection Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

DC Power Wiring Terminations Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

xiCopyright © 2015, Juniper Networks, Inc.

Page 12

M320 Multiservice Edge Router Hardware Guide

Chapter 42 Agency Approvals and Compliance Statements . . . . . . . . . . . . . . . . . . . . . . 351

M320 Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Compliance Statements for EMC Requirements for Juniper Networks Devices

(Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

M320 Compliance Statements for EMC Requirements (European

Community) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Compliance Statements for EMC Requirements for Juniper Networks Devices

(Israel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Compliance Statements for EMC Requirements for Juniper Networks Devices

(Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Compliance Statements for EMC Requirements for Juniper Networks Devices

(United States) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Compliance Statements for Environmental Requirements for Juniper Networks

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

M320 Compliance Statements for NEBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

M320 Compliance Statements for Acoustic Noise . . . . . . . . . . . . . . . . . . . . . . . 354

Part 9 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Copyright © 2015, Juniper Networks, Inc.xii

Page 13

List of Figures

Part 1 Overview

Chapter 3 Chassis Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1: Front View of a Fully Configured Router Chassis . . . . . . . . . . . . . . . . . . . . 8

Figure 2: Rear View of a Fully Configured AC-Powered Router Chassis . . . . . . . . . . 9

Figure 3: Rear View of a Fully Configured DC-Powered Router Chassis . . . . . . . . . 10

Figure 4: Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5: Cable Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6: CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7: Front Panel of the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8: LED Display in Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9: LED Display in Alarm Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 4 Cooling System Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10: Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 5 Host Subsystem Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . 23

Figure 11: Routing Engine 1600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12: Routing Engine 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13: RE-A-1800 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14: RE-A-1800x2 Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15: USB Memory Device in an Routing Engine . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16: CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 6 Line Card Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 17: FPC Installed in Router Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 18: FPC1, FPC2, and FPC3 for the M320 Router . . . . . . . . . . . . . . . . . . . . . . 51

Figure 19: Enhanced II FPC1, FPC2, and FPC3 for the M320 Router . . . . . . . . . . . . 52

Figure 20: Enhanced III FPC1, FPC2, and FPC3 for the M320 Router . . . . . . . . . . . 52

Figure 21: FPC Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 7 Power System Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 22: AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 8 Switch Fabric Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 23: SIB-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Part 2 Site Planning, Preparation, and Specifications

Chapter 9 Preparation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 24: Typical Open-Frame Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 25: Airflow Baffle Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 26: Chassis Dimensions and Clearance Requirements . . . . . . . . . . . . . . . . 92

xiiiCopyright © 2015, Juniper Networks, Inc.

Page 14

M320 Multiservice Edge Router Hardware Guide

Figure 27: Typical Open-Frame Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 28: DC Power and Grounding Cable Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 10 AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 29: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 11 DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 30: DC Power Cable Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 31: Typical DC Source Cabling to the Router . . . . . . . . . . . . . . . . . . . . . . . . 108

Part 3 Initial Installation and Configuration

Chapter 15 Unpacking the M320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 32: Contents of the Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Chapter 16 Installing the Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 33: Installing the Mounting Hardware for a Four-Post Rack or Cabinet . . 129

Figure 34: Center-Mounting Bracket Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 35: Installing the Mounting Hardware for a Center-Mount Open-Frame

Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 36: Center-Mounting Bracket Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Chapter 17 Installing the M320 With a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 37: Removing an M320 Power Supply Before Installing the Installation

Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 38: Attaching the M320 Installation Handle . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 39: Installing the M320 Router in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 40: Reinstalling an M320 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 41: Installing the M320 Cable Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Chapter 18 Installing the M320 Without a Mechanical Lift . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 42: Removing a Power Supply Before Installing the Router . . . . . . . . . . . . 144

Figure 43: Removing a SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 44: Removing a CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 45: Removing the Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 46: Removing a Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 47: Removing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Figure 48: Attaching the Installation Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 49: Installing the Router in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 50: Reinstalling the Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 51: Reinstalling a CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 52: Reinstalling a SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 53: Reinstalling a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 54: Reinstalling an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 55: Reinstalling a Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 56: Installing the M320 Cable Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Chapter 19 Connecting the M320 to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 57: Grounding Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Chapter 20 Connecting the M320 to External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Figure 58: Routing Engine Management Ports and Alarm Relay Contacts . . . . . 164

Copyright © 2015, Juniper Networks, Inc.xiv

Page 15

List of Figures

Figure 59: Console and Auxiliary Serial Port Connector . . . . . . . . . . . . . . . . . . . . 166

Figure 60: Console and Auxiliary Ports on the CIP . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 61: Routing Engine Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . 167

Figure 62: ETHERNET Port on the CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 63: Attaching Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 64: Installing the Cable Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Chapter 21 Providing Power to the M320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Figure 65: Connecting AC Power to the M320 Router . . . . . . . . . . . . . . . . . . . . . . 174

Figure 66: Connecting DC Power to the M320 Router . . . . . . . . . . . . . . . . . . . . . . 176

Part 4 Installing and Replacing Components

Chapter 24 Replacing Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 67: Removing the CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 68: Installing a CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 69: Ethernet Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 70: Routing Engine Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . 195

Figure 71: Routing Engine Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . 196

Figure 72: Removing the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 73: Installing the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 74: Fuses in the Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Chapter 25 Replacing Cooling System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 75: Removing the Front Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Figure 76: Replacing the Front Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Figure 77: Installing the Front Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 78: Removing the Rear Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Figure 79: Removing the Rear Air Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Figure 80: Installing the Rear Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 81: Removing a Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 82: Installing a Front Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 83: Removing the Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 84: Installing a Rear Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Chapter 26 Replacing Host Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Figure 85: Removing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Figure 86: Installing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 87: RE-A-1800 Routing Engine SSD Slots . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 88: Installing a PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Figure 89: Removing a PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Figure 90: Installing the DIMM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Figure 91: Removing a CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Figure 92: Installing a CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Chapter 27 Replacing Line Card Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Figure 93: Removing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Figure 94: Installing an FPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Figure 95: Connecting Fiber-Optic Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . 233

Figure 96: Removing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Figure 97: Installing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

xvCopyright © 2015, Juniper Networks, Inc.

Page 16

M320 Multiservice Edge Router Hardware Guide

Figure 98: Connecting Fiber-Optic Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . 240

Figure 99: Small Form-Factor Pluggable (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Figure 100: Removing a XENPAK Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Figure 101: Installing a XENPAK Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Chapter 28 Replacing Power System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 102: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 103: Rear of the Power Supply Showing Midplane Connector . . . . . . . . . 248

Figure 104: Installing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 105: Disconnecting Power Cables from the DC Power Supply . . . . . . . . . . 251

Figure 106: Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Figure 107: Installing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Figure 108: Connecting Power Cables to the DC Power Supply . . . . . . . . . . . . . . 254

Figure 109: Disconnecting or Connecting a Power Cable from a DC Power

Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Chapter 29 Replacing Switch Fabric Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Figure 110: Removing a SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 111: Installing a SIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Part 5 Maintaining the Chassis and Components

Chapter 31 Maintaining Components and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Figure 112: Do Not Grasp the Connector Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figure 113: Do Not Carry an FPC with Only One Hand . . . . . . . . . . . . . . . . . . . . . . 273

Figure 114: Do Not Rest the FPC on an Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 115: Holding an FPC Vertically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Figure 116: Do Not Stack FPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Part 6 Troubleshooting Hardware

Chapter 32 Troubleshooting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 117: Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Figure 118: Fuses in the Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Part 7 Contacting Customer Support and Returning the Chassis or

Components

Chapter 34 Locating Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Figure 119: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Figure 120: M320 Chassis Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Figure 121: CIP Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Figure 122: Craft Interface Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Figure 123: Routing Engine Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 124: CB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Figure 125: FPC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Figure 126: PIC Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Figure 127: AC Power Supply Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . 305

Figure 128: DC Power Supply Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . 305

Figure 129: SIB Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Copyright © 2015, Juniper Networks, Inc.xvi

Page 17

List of Figures

Part 8 Safety and Compliance Information

Chapter 36 General Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Figure 130: Placing a Component into an Electrostatic Bag . . . . . . . . . . . . . . . . . 319

xviiCopyright © 2015, Juniper Networks, Inc.

Page 18

M320 Multiservice Edge Router Hardware Guide

Copyright © 2015, Juniper Networks, Inc.xviii

Page 19

List of Tables

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Table 1: Notice Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Table 2: Text and Syntax Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Part 1 Overview

Chapter 3 Chassis Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3: Alarm LEDs and Alarm Cutoff/Lamp Test Button . . . . . . . . . . . . . . . . . . . 16

Table 4: M320 Host Subsystem LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5: FPC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6: Power Supply LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 7: SIB LEDs on the Craft Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 5 Host Subsystem Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . 23

Table 8: Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 9: Routing Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 10: End-of-Life Routing Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . 33

Table 11: M7i Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 12: M10I Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13: M40e Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14: M120 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 15: M320 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 16: MX104 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 17: MX240 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 18: MX480 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 19: MX960 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 20: MX2010 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 21: MX2020 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 22: PTX3000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 23: PTX5000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 24: T320 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 25: T640 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 26: T1600 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 27: T4000 Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 28: TX Matrix Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 29: TX Matrix Plus Routing Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 30: Routing Engines on TX Matrix Plus with 3D SIBs . . . . . . . . . . . . . . . . . . 45

Table 31: M320 CB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 6 Line Card Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 32: FPCs Supported by the M320 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

xixCopyright © 2015, Juniper Networks, Inc.

Page 20

M320 Multiservice Edge Router Hardware Guide

Table 33: ATM IQ PICs Supported by the M320 Router . . . . . . . . . . . . . . . . . . . . . 55

Table 34: ATM2 IQ PICs Supported by the M320 Router . . . . . . . . . . . . . . . . . . . . 56

Table 35: Channelized PICs Supported by the M320 Router . . . . . . . . . . . . . . . . . 56

Table 36: Channelized IQ PICs Supported by the M320 Router . . . . . . . . . . . . . . . 57

Table 37: Channelized IQE PICs Supported by the M320 Router . . . . . . . . . . . . . . 57

Table 38: Circuit Emulation PICs Supported by the M320 Router . . . . . . . . . . . . . 58

Table 39: DS3, E1, E3, and T1 PICs Supported by the M320 Router . . . . . . . . . . . . 58

Table 40: EIA-530 PIC Supported by the M320 Router . . . . . . . . . . . . . . . . . . . . . 59

Table 41: Fast Ethernet PICs Supported by the M320 Router . . . . . . . . . . . . . . . . 59

Table 42: Gigabit Ethernet PICs Supported by the M320 Router . . . . . . . . . . . . . . 60

Table 43: 10-Gigabit Ethernet PICs Supported by the M320 Router . . . . . . . . . . . 62

Table 44: Service PICs Supported by the M320 Router . . . . . . . . . . . . . . . . . . . . . 62

Table 45: SONET/SDH PICs Supported by the M320 Router . . . . . . . . . . . . . . . . . 63

Table 46: End-of-Life PICs Supported in the M320 Router . . . . . . . . . . . . . . . . . . 64

Table 47: M320 PIC/FPC Compatibility Type 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 48: M320 PIC/FPC Compatibility Type 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 49: M320 PIC/FPC Compatibility Type 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 7 Power System Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 50: Components Powered by Each DC Power Supply Slot . . . . . . . . . . . . . 75

Table 51: Power Supply LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Chapter 8 Switch Fabric Components and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 52: Performance per SIB/FPC Configuration . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 53: SIB LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Part 2 Site Planning, Preparation, and Specifications

Chapter 9 Preparation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 54: Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 55: M320 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 56: Cabinet Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 57: Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 58: Component Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 59: RJ-48 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 60: Fuse Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chapter 10 AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 61: AC Power Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 62: AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 11 DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 63: DC Power System Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . 105

Table 64: Nonisolated DC Power Supply Electrical Specifications . . . . . . . . . . . 106

Table 65: Isolated DC Power Supply Electrical Specifications . . . . . . . . . . . . . . . 106

Table 66: DC Power Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 12 Network Cable and Transceiver Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 67: Estimated Values for Factors Causing Link Loss . . . . . . . . . . . . . . . . . . . 113

Chapter 13 Management Cable and Transceiver Specifications and Pinouts . . . . . . . . 115

Copyright © 2015, Juniper Networks, Inc.xx

Page 21

List of Tables

Table 68: Cable and Wire Specifications for Routing Engine Management and

Alarm Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 69: RJ-45 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 70: DB-9 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Part 3 Initial Installation and Configuration

Chapter 15 Unpacking the M320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Table 71: M320 Router Parts List for a Fully Configured Router . . . . . . . . . . . . . . . 125

Table 72: M320 Router Accessory Box Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Chapter 16 Installing the Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table 73: Four-Post or Cabinet Rack Mounting Hole Locations . . . . . . . . . . . . . . 127

Table 74: Open-Frame Rack Mounting Hole Locations . . . . . . . . . . . . . . . . . . . . . 131

Part 4 Installing and Replacing Components

Chapter 23 Overview of Installing and Replacing Components . . . . . . . . . . . . . . . . . . . 185

Table 75: Field-Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Table 76: Tools and Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Chapter 26 Replacing Host Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Table 77: Effect of Taking the Host Subsystem Offline . . . . . . . . . . . . . . . . . . . . . 213

Part 6 Troubleshooting Hardware

Chapter 32 Troubleshooting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Table 78: M320 Chassis Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Table 79: SONET/SDH Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . 286

xxiCopyright © 2015, Juniper Networks, Inc.

Page 22

M320 Multiservice Edge Router Hardware Guide

Copyright © 2015, Juniper Networks, Inc.xxii

Page 23

About the Documentation

•

Documentation and Release Notes on page xxiii

•

Supported Platforms on page xxiii

•

Documentation Conventions on page xxiii

•

Documentation Feedback on page xxv

•

Requesting Technical Support on page xxvi

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

If the information in the latest release notes differs from the information in the

documentation, follow the product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject

matter experts. These books go beyond the technical documentation to explore the

nuances of network architecture, deployment, and administration. The current list can

be viewed at http://www.juniper.net/books.

Supported Platforms

For the features described in this document, the following platforms are supported:

•

M320

Documentation Conventions

Table 1 on page xxiv defines notice icons used in this guide.

xxiiiCopyright © 2015, Juniper Networks, Inc.

Page 24

M320 Multiservice Edge Router Hardware Guide

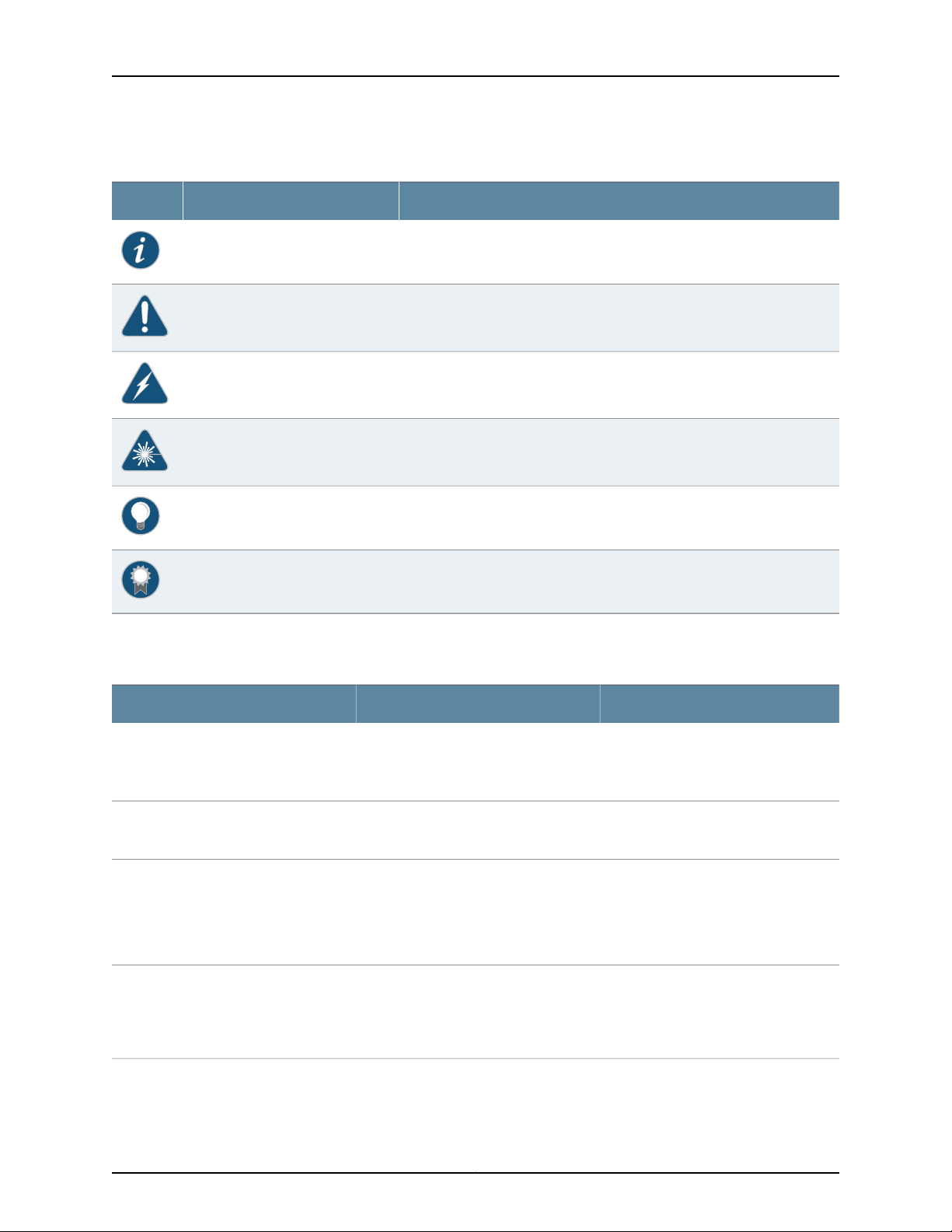

Table 1: Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Table 2 on page xxiv defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

Represents text that you type.Bold text like this

Fixed-width text like this

Italic text like this

Italic text like this

Represents output that appears on the

terminal screen.

•

Introduces or emphasizes important

new terms.

•

Identifies guide names.

•

Identifies RFC and Internet draft titles.

Represents variables (options for which

you substitute a value) in commands or

configuration statements.

Alerts you to a recommended use or implementation.Best practice

ExamplesDescriptionConvention

To enter configuration mode, type the

configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

•

A policy term is a named structure

that defines match conditions and

actions.

•

Junos OS CLI User Guide

•

RFC 1997, BGP Communities Attribute

Configure the machine’s domain name:

[edit]

root@# set system domain-name

domain-name

Copyright © 2015, Juniper Networks, Inc.xxiv

Page 25

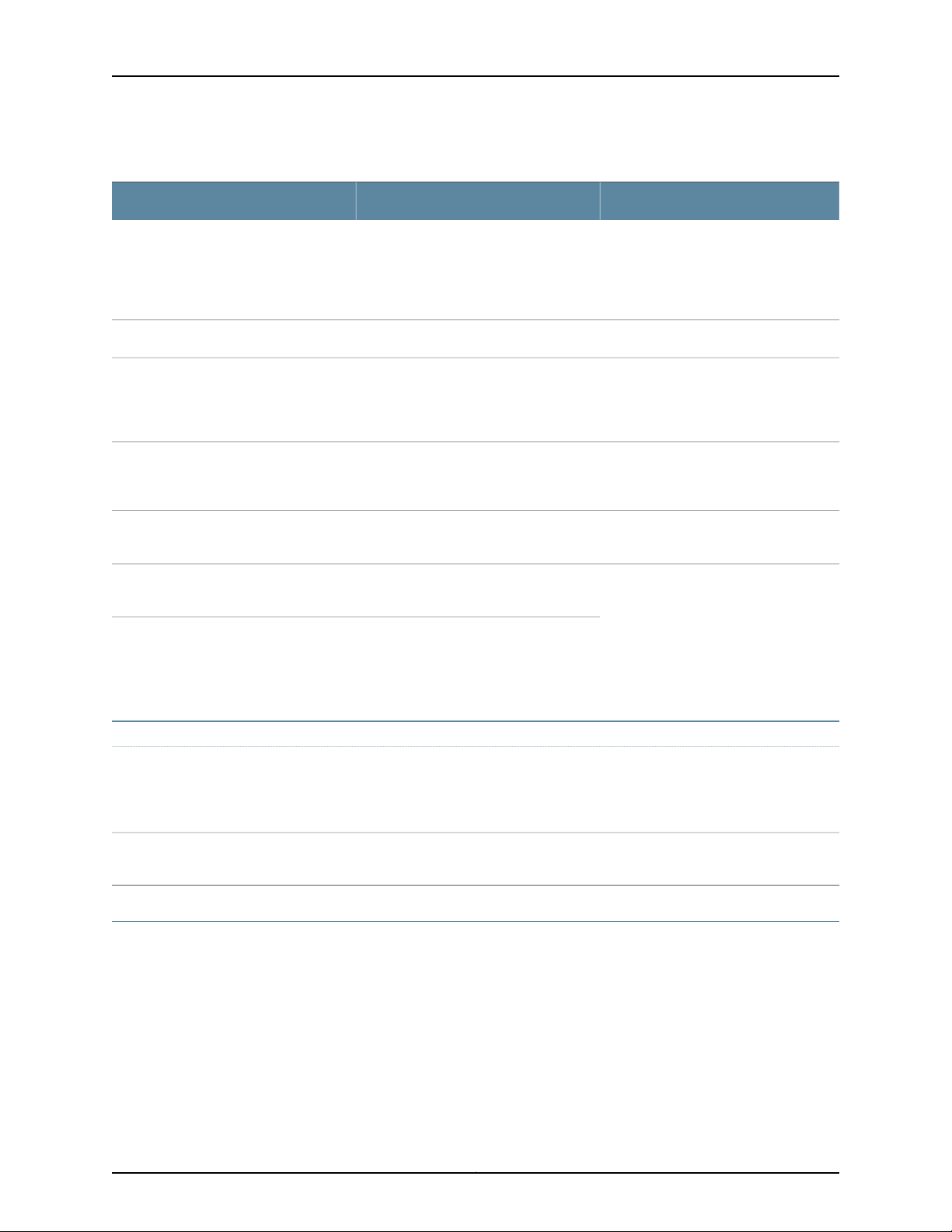

Table 2: Text and Syntax Conventions (continued)

Text like this

Represents names of configuration

statements, commands, files, and

directories;configuration hierarchylevels;

or labels on routing platform

components.

About the Documentation

ExamplesDescriptionConvention

•

To configure a stub area, include the

stub statement at the [edit protocols

ospf area area-id] hierarchy level.

•

The console portis labeled CONSOLE.

stub <default-metric metric>;Encloses optional keywords or variables.< > (angle brackets)

| (pipe symbol)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Bold text like this

Indicates a choice between the mutually

exclusivekeywords or variables on either

side of the symbol. The set of choices is

often enclosed in parentheses for clarity.