Page 1

M10i Multiservice Edge

Router

Hardware Guide

Published: 2010-10-28

Copyright © 2010, Juniper Networks, Inc.

Page 2

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

This productincludes the Envoy SNMP Engine, developed by EpilogueTechnology,an Integrated Systems Company. Copyright ©1986-1997,

Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed at private expense, and no part

of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation

and software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright ©

1979, 1980, 1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through

release 3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s

HELLO routing protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD

software copyright © 1988, Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D.

L. S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, Junos, Steel-Belted Radius, NetScreen, and ScreenOS are registered trademarks of Juniper Networks, Inc. in the United

States and other countries. The Juniper Networks Logo, the Junos logo, and JunosE are trademarks of Juniper Networks, Inc. All other

trademarks, service marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are

owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312,

6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

M10i Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Writing: Charissa Fleischer, Elizabeth Gardner, Jerry Isaac

Editing: Stella Hackell, Joanne McClintock

Illustration: Faith Bradford Brown

Cover Design: Edmonds Design

Revision History

August 2010—Corporate rebranding.

May 2010—Updated VCCI Class B compliance for Japan. Corrected grounding, power, and management port topics.

October 2009—Corrected maximum aggregate throughput and updated information about CompactFlash cards.

August 2009—Corrected rear fan tray figure.

July 2009—Updated product names.

10 April 2009—530-017393-01. Revision 4. Revised sections into modular topics for easier customer access.

6 February2009—530-017393-01. Revision 3. Added Enhanced CompactForwarding Engine Board(CFEB-E) support.Added high availability

information. Updated troubleshooting and power sections.

20 March 2007—530-017393-01. Revision 2. Corrected the input operating voltage range for DC power supplies and AC power supplies.

Corrected clearance requirements. Updated the mounting hardware installation procedure.

20 October 2006—530-017393-01. Revision 1. Added European Community EMC Declaration of Conformity.

28 June 2006—530-014302-01. Revision 4. Added torque limits for securing cable lugs to the DC power supplies.

30 May 2006—530-014302-01. Revision 3. Corrected maximum aggregate throughput. Added AC power cord warning in Japanese. Added

Lithium battery statement.

13 April 2006—530-014302-01. Revision 2.Deleted notes thaterroneously stated powersupplies must be installed in specific slots. Clarified

DC power supply requirements for full system power redundancy. Updated Junos OS Release recommendation for graceful switchover.

Copyright © 2010, Juniper Networks, Inc.ii

Page 3

14 September 2005—530-014302-01. Revision 1.

9 November 2004—530-011255-01. Revision 2.

18 March 2004—530-011255-01. Revision 1.

The information in this document is current as of the date listed in the revision history.

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. The Junos OS has no known time-related limitations through

the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

iiiCopyright © 2010, Juniper Networks, Inc.

Page 4

END USER LICENSE AGREEMENT

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE.

BY DOWNLOADING, INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS

CONTAINED HEREIN, YOU (AS CUSTOMER OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO

BIND THE CUSTOMER) CONSENTTO BEBOUND BY THISAGREEMENT. IF YOUDO NOTOR CANNOT AGREE TO THE TERMS CONTAINED

HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE, AND (B) YOU MAY CONTACT JUNIPER NETWORKS

REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are (i) Juniper Networks, Inc. (if the Customer’s principal office is located in the Americas) or

Juniper Networks (Cayman) Limited(if the Customer’s principal office islocated outside the Americas) (suchapplicable entitybeing referred

to herein as “Juniper”), and (ii) the person or organization thatoriginally purchased fromJuniper oran authorizedJuniper reseller the applicable

license(s) for use of the Software (“Customer”) (collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, for

which Customer has paid the applicable license or support fees to Juniper or an authorized Juniper reseller, or which was embedded by

Juniper in equipment which Customer purchased fromJuniper or an authorized Juniper reseller. “Software” also includes updates, upgrades

and new releases of such software. “Embedded Software” means Software which Juniper has embedded in or loaded onto the Juniper

equipment and any updates, upgrades, additions or replacements which are subsequently embedded in or loaded onto the equipment.

3. License Grant. Subject to payment ofthe applicablefees andthe limitationsand restrictions set forth herein, Juniper grants to Customer

a non-exclusive and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the

following use restrictions:

a. Customer shall use Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by

Customer from Juniper or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units

for which Customer has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey Access

Client software only, Customer shall use such Software on a single computer containing a single physical random access memory space

and containing any number of processors. Use of the Steel-Belted Radius or IMS AAA software on multiple computers or virtual machines

(e.g., Solaris zones) requires multiple licenses, regardless of whether such computers or virtualizations are physically contained on a single

chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may

specify limitsto Customer’s use of the Software. Such limitsmay restrict use to a maximumnumber of seats,registered endpoints, concurrent

users, sessions, calls, connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the purchase of

separate licenses to use particular features, functionalities, services, applications, operations, or capabilities, or provide throughput,

performance, configuration, bandwidth, interface, processing, temporal, or geographical limits. In addition, such limits may restrict the use

of the Software to managing certain kinds of networks or require the Software to be used only in conjunction with other specific Software.

Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable licenses.

d. For any trial copy of the Software, Customer’s right to use the Software expires 30 days after download, installation or use of the

Software. Customer may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer may not

extend or create an additional trial period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer’s

enterprise network. Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the

Steel-Belted Radius software to support any commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase

the applicable license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees

not to and shall not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized

copies of the Software (except as necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the

Software,in any form, to any third party;(d) remove any proprietary notices, labels, or markson or in any copy ofthe Softwareor any product

in which the Software is embedded; (e) distribute any copy of the Software to any third party, including as may be embedded in Juniper

equipment sold in the secondhandmarket; (f) use any‘locked’ or key-restricted feature, function, service,application, operation,or capability

without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even if such feature, function, service, application,

operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper to any third party; (h) use the

Copyright © 2010, Juniper Networks, Inc.iv

Page 5

Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper reseller; (i)

use Embedded Software on non-Juniper equipment; (j) use Embedded Software (or make it available for use) on Juniper equipment that

the Customer did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking

of the Software to any third party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly

provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper,

Customer shall furnish such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper.

As such, Customer shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence,

which at a minimum includes restricting access to the Software to Customeremployees and contractors having a need to use the Software

for Customer’s internal business purposes.

7. Ownership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to

the Software, associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance

of any right, title, or interest in the Software or associated documentation, or a sale of the Software, associated documentation, or copies

of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty

statementthat accompanies theSoftware(the “Warranty Statement”). Nothingin this Agreementshall give riseto any obligation tosupport

the Software. Support services may be purchased separately. Any such support shall be governed by a separate, written support services

agreement. TO THE MAXIMUM EXTENT PERMITTED BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA,

OR COSTSOR PROCUREMENTOF SUBSTITUTE GOODSOR SERVICES,OR FORANY SPECIAL, INDIRECT,OR CONSEQUENTIALDAMAGES

ARISING OUTOF THIS AGREEMENT,THE SOFTWARE, ORANY JUNIPEROR JUNIPER-SUPPLIED SOFTWARE. INNO EVENT SHALLJUNIPER

BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY JUNIPER OR JUNIPER-SUPPLIED SOFTWARE.

EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY LAW, JUNIPER DISCLAIMS ANY

AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE), INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES

JUNIPER WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT

ERROR OR INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’

or licensors’ liability to Customer, whether in contract, tort (including negligence), breach of warranty, or otherwise, exceed the price paid

by Customer for the Software that gave rise to the claim, or if the Software is embedded in another Juniper product, the price paid by

Customer for such other product. Customer acknowledges and agrees that Juniper has set its prices and entered into this Agreement in

reliance upon the disclaimers of warranty and the limitations of liability set forth herein, that the same reflect an allocation of risk between

the Parties (including the risk that a contract remedy may fail of its essential purpose and cause consequential loss), and that the same

form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination

of the license granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related

documentation in Customer’s possession or control.

10. Taxes. All license fees payable under this agreement are exclusive of tax. Customer shall be responsible for paying Taxes arising from

the purchase of the license, or importation or use of the Software. If applicable, valid exemption documentation for each taxing jurisdiction

shall be provided to Juniper prior to invoicing, and Customer shall promptly notify Juniper if their exemption is revoked or modified. All

payments made by Customer shall be net of any applicable withholding tax. Customer will provide reasonable assistance to Juniper in

connection with such withholding taxes by promptly: providing Juniper with valid tax receipts and other required documentation showing

Customer’s payment of any withholding taxes; completing appropriate applications that would reduce the amount of withholding tax to

be paid; and notifying and assisting Juniper in any audit or tax proceeding related to transactions hereunder. Customer shall comply with

all applicable tax laws and regulations, and Customer will promptly pay or reimburse Juniper for all costs and damages related to any

liability incurred by Juniper as a result of Customer’s non-compliance or delay with its responsibilities herein. Customer’s obligations under

this Section shall survive termination or expiration of this Agreement.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any

applicable foreign agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such

restrictions, laws or regulations, or without all necessary approvals. Customer shall be liable for any such violations. The version of the

Software supplied to Customer may contain encryption or other capabilities restricting Customer’s ability to export the Software without

an export license.

vCopyright © 2010, Juniper Networks, Inc.

Page 6

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use,

duplication, or disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS

227.7201 through 227.7202-4, FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information. To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer

with the interface information needed to achieve interoperability between the Software and another independently created program, on

payment of applicable fee, if any. Customer shall observe strict obligations of confidentiality with respect to such information and shall use

such information in compliance with any applicable terms and conditions upon which Juniper makes such information available.

14. Third Party Software. Any licensor of Juniper whose software is embedded inthe Software and any supplier of Juniper whose products

or technology are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement,

and such licensor or vendor shall have the right toenforce this Agreement in its own name as if it were Juniper. In addition, certain third party

software may be provided with the Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent

portions of the Software are distributed under and subject to open source licenses obligating Juniper to make the source code for such

portions publicly available (such as the GNU General Public License (“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper

will make such source code portions (including Juniper modifications, as appropriate) available upon request for a period of up to three

years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194 N. Mathilda Ave., Sunnyvale, CA

94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a copy of the LGPL

at http://www.gnu.org/licenses/lgpl.html .

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws

principles. The provisions of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes

arising under this Agreement, the Parties hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal

courts within Santa Clara County, California. This Agreement constitutes the entire and sole agreement between Juniper and the Customer

with respect to the Software, and supersedes all prior and contemporaneous agreements relating to the Software, whether oral or written

(including any inconsistent terms contained in a purchase order), except that the terms of a separate written agreement executed by an

authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict with terms contained

herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in writing

by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity

of the remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the

Parties agree that the English version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de

même que tous les documents y compris tout avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that

this Agreement and all related documentation is and will be in the English language)).

Copyright © 2010, Juniper Networks, Inc.vi

Page 7

Table of Contents

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Junos OS Documentation and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Requesting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Self-Help Online Tools and Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Opening a Case with JTAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Part 1 Overview of the M10i Multiservice Edge Router

Chapter 1 Overview of the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M10i Router Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M10i System Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AC System Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DC System Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

M10i Chassis Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

M10i Midplane Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

M10i Flexible PIC Concentrators (FPCs) Description . . . . . . . . . . . . . . . . . . . . . . . . 8

M10i PICs Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

M10i PIC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M10i Compact Forwarding Engine Board (CFEB) and Enhanced Compact

Forwarding Engine Board (CFEB-E) Description . . . . . . . . . . . . . . . . . . . . . . . 10

CFEB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

M10i CFEB and CFEB-E LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

M10i Routing Engine Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

M10i Routing Engine Interface Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

M10i Routing Engine 400 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

M10i Routing Engine 400 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M10i Routing Engine 850 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M10i Routing Engine 850 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

M10i High-Availability Chassis Manager (HCM) Description . . . . . . . . . . . . . . . . . . 21

M10i HCM LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

M10i HCM Alarm LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

M10i Power Supplies Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

M10i Power System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

M10i AC Power Supply Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

viiCopyright © 2010, Juniper Networks, Inc.

Page 8

M10i Multiservice Edge Router Hardware Guide

M10i DC Power Supply Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

M10i Power Supply LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

M10i Fan Tray Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

M10i Cable Management System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3 M10i System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

M10i System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

M10i Packet Forwarding Engine Architecture Overview . . . . . . . . . . . . . . . . . . . . . 32

Data Flow Through the Packet Forwarding Engine . . . . . . . . . . . . . . . . . . . . . 32

M10i Routing Engine Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Routing Engine Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Part 2 Setting Up the M10i Router

Chapter 4 Preparing the Site for M10i Router Installation . . . . . . . . . . . . . . . . . . . . . . . . 39

M10i Router Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

M10i Rack Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

M10i Rack Size and Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Spacing of Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connection to Building Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Clearance Requirements for Airflow and Hardware Maintenance . . . . . . . . . . . . . 43

Chapter 5 Overview of M10i Router Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Overview of M10i Router Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 6 Unpacking the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Tools and Parts Required to Unpack the M10i Router . . . . . . . . . . . . . . . . . . . . . . . 47

Unpacking the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Verifying the M10i Router Parts Received . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 7 Installing the M10i Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . 51

Moving the Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Installing the M10i Cable Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 8 Installing the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Tools and Parts Required to Install the M10i Router Into a Rack . . . . . . . . . . . . . . 55

Installing the M10i Router into a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 9 Grounding the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Grounding the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 10 Connecting the M10i Router to External Devices . . . . . . . . . . . . . . . . . . . . . . . 61

Tools and Parts Required to Connect the M10i Router to External Devices . . . . . . 61

Connecting to a Management Console or Auxiliary Device . . . . . . . . . . . . . . . . . . 62

Connecting to a Network for Out-of-Band Management . . . . . . . . . . . . . . . . . . . 62

Connecting M10i PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 11 Providing Power to the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connecting Power on an AC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . . . 65

Powering On an AC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Disconnecting Power on an AC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . 67

Connecting Power on an DC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . . . 67

Copyright © 2010, Juniper Networks, Inc.viii

Page 9

Table of Contents

Powering On a DC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Disconnecting Power on an DC-Powered M10i Router . . . . . . . . . . . . . . . . . . . . . . 70

Powering Off an M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 12 Configuring Junos OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Initially Configuring the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 13 Maintaining M10i Router Hardware Components . . . . . . . . . . . . . . . . . . . . . . 79

Routine Maintenance Procedures for the M10i Router . . . . . . . . . . . . . . . . . . . . . . 79

Maintaining the M10i CFEB and CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Maintaining the M10i Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maintaining the M10i PICs and PIC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Maintaining the M10i Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Maintaining the M10i Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Chapter 14 Troubleshooting M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . 87

M10i Hardware and Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Troubleshooting the M10i HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Troubleshooting the M10i Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Troubleshooting the M10i CFEB and CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Troubleshooting the M10i Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Troubleshooting the M10i PICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Troubleshooting the M10i Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting the M10i Power System When LEDs on All Power Supplies

Are Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Troubleshooting the M10i Power System When the LED on One Power

Supply Is Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Chapter 15 Replacing M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

M10i Field-Replaceable Units (FRUs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Tools and Parts Required to Replace M10i Hardware Components . . . . . . . . . . . 100

Replacing an M10i Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Removing an M10i Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Installing an M10i Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Replacing, Upgrading, or Downgrading an M10i CFEB or CFEB-E . . . . . . . . . . . . 103

Removing an M10i CFEB or CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Installing an M10i CFEB or CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Upgrading or Downgrading an M10i CFEB or CFEB-E . . . . . . . . . . . . . . . . . . 106

Replacing an M10i HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Removing an M10i HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Installing an M10i HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Replacing an M10i PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Removing an M10i PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Installing an M10i PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Replacing an M10i PIC Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Removing an M10i PIC Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Installing an M10i PIC Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

ixCopyright © 2010, Juniper Networks, Inc.

Page 10

M10i Multiservice Edge Router Hardware Guide

Replacing an M10i SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Removing an M10i SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Installing an M10i SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Replacing M10i Power System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Replacing an M10i AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Replacing an M10i AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Replacing an M10i DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Replacing an M10i DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Replacing M10i Routing Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Replacing the M10i Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Removing and Inserting the PC Card from an M10i Routing Engine . . . . . . . 135

Replacing the CompactFlash Card in an M10i Routing Engine . . . . . . . . . . . . 137

Configuring the CompactFlash Card on an M10i Routing Engine . . . . . . . . . 138

Replacing an SDRAM Module on an M10i Routing Engine . . . . . . . . . . . . . . . 139

Replacing an M10i Ethernet Management Cable . . . . . . . . . . . . . . . . . . . . . . 141

Replacing an M10i Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . . . . . 141

Removing an M10i AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Installing an M10i AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Removing an M10i AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Installing an M10i AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Removing an M10i DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Installing an M10i DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Removing a DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Installing a DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Removing the M10i Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Installing the M10i Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Removing the PC Card from an M10i Routing Engine . . . . . . . . . . . . . . . 135

Inserting the PC Card in an M10i Routing Engine . . . . . . . . . . . . . . . . . . . 136

Removing the CompactFlash Card from an M10i Routing Engine . . . . . 137

Installing the CompactFlash Card in an M10i Routing Engine . . . . . . . . . 137

Removing an SDRAM Module from an M10i Routing Engine . . . . . . . . . 139

Installing an SDRAM Module in an M10i Routing Engine . . . . . . . . . . . . 140

Removing a Management Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . 141

Installing a Management Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . 141

Removing an M10i Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . 142

Installing an M10i Console or Auxiliary Cable . . . . . . . . . . . . . . . . . . . . . 142

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the M10i Router . . . . 145

Definition of Safety Warning Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

General Safety Guidelines for M Series, MX Series, and T Series Routers . . . . . . 147

Copyright © 2010, Juniper Networks, Inc.x

Page 11

Table of Contents

General Safety Warnings for M Series, MX Series, and T Series Routers . . . . . . . 148

Qualified Personnel Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Restricted Access Area Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Preventing Electrostatic Discharge Damage to an M10i Router . . . . . . . . . . . . . . 150

M10i Router Installation Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . 151

M10i Chassis Lifting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Installation Safety Warnings for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Installation Instructions Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Rack-Mounting Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . 152

Ramp Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Laser and LED Safety Guidelines and Warnings for the M10i Router . . . . . . . . . . 156

General Laser Safety Guidelines for M10i Routers . . . . . . . . . . . . . . . . . . . . . 157

M10i Laser and LED Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Class 1 Laser Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Class 1 LED Product Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Laser Beam Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Radiation from Open Port Apertures Warning . . . . . . . . . . . . . . . . . . . . 159

Fire Safety Requirements for M Series, MX Series, and T Series Routers . . . . . . . 160

General Fire Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Fire Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Fire Suppression Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Maintenance and Operational Safety Warnings for M Series, MX Series, and T

Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Battery Handling Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Jewelry Removal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Lightning Activity Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Operating Temperature Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Product Disposal Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Electrical Safety Guidelines and Warnings for the M10i Router . . . . . . . . . . . . . . 166

In Case of an Electrical Accident . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

General Electrical Safety Guidelines and Warnings Electrical Codes for the

M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

General Electrical Safety Guidelines and Electrical Codes for M10i

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

General Electrical Safety Warnings for M Series, MX Series, and TSeries

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

TN Power Warning for M10i Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

M10i AC Power Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Japanese AC Power Cord Warning for M Series and MX Series Routers . . . . 172

M10i DC Power Electrical Safety Guidelines and Warnings . . . . . . . . . . . . . . 173

M10i DC Power Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . 173

DC Power Electrical Safety Warnings for M Series, MX Series, and T

Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

xiCopyright © 2010, Juniper Networks, Inc.

Page 12

M10i Multiservice Edge Router Hardware Guide

Agency Approvals and Compliance Statements for the M10i Router . . . . . . . . . . 177

Agency Approvals for M10i Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Compliance Statements for NEBS for M Series, MX Series, and T Series

Compliance Statements for EMC Requirements for M Series, MX Series,

Compliance Statements for EMC Requirements for M Series, MX Series,

Compliance Statements for EMCRequirements for M10i Routers (European

Compliance Statements for Environmental Requirements for M Series, MX

Compliance Statements for Acoustic Noise for M10i Routers . . . . . . . . . . . . 181

Appendix B M10i Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

M10i Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Appendix C M10i Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 185

M10i Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Appendix D Power Guidelines, Requirements, and Specifications for the M10i

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

M10i Chassis Grounding Cable and Lug Specifications . . . . . . . . . . . . . . . . . . . . . 187

M10i Router Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

M10i Router AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

M10i AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

M10i Router AC Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 191

M10i Router DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

M10i Router DC Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 191

M10i DC Power Cable and Lug Specifications . . . . . . . . . . . . . . . . . . . . . . . . 192

Site Electrical Wiring Guidelines for M Series, MX Series, and T Series

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Appendix E Cable and Wire Guidelines and Specifications for the M10i Router . . . . . . 195

Network Cable Specifications for M10i Routers . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Fiber-Optic and Network Cable Specifications for M10i Routers . . . . . . . . . 195

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable for M10i

Attenuation and Dispersion in Fiber-Optic Cable on M Series, MX Series,

Calculating Power Budget for Fiber-Optic Cable for M Series, MX Series,

Calculating Power Margin for Fiber-Optic Cable for M Series, MX Series, and

Routing Engine Interface Cable and Wire Specifications for M10i Routers . . . . . 200

Appendix F M10i Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

RJ-45 Connector Pinouts for the M10i Routing Engine MGMT Port . . . . . . . . . . . 201

DB-9 Connector Pinoutsfor the M10i Routing EngineAUX/MODEM and CONSOLE

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

RJ-48 Cable Pinouts for E1 and T1 PICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

and T Series Routers (Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

and T Series Routers (United States) . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Community) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Series, and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

and T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

T Series Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Copyright © 2010, Juniper Networks, Inc.xii

Page 13

Table of Contents

Appendix G Contacting Customer Support and Returning M10i Hardware . . . . . . . . . . 207

Locating M10i Component Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Displaying M10i Router Components and Serial Numbers . . . . . . . . . . . . . . 207

M10i CFEB and CFEB-E Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . 209

M10i HCM Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

M10i PIC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

M10i Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . 211

M10i Routing Engine Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . 211

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Returning a Hardware Component to Juniper Networks, Inc. . . . . . . . . . . . . . . . . 213

Tools and Parts Required to Remove Components from an M10i Router . . . . . . 214

Packing the M10i Router for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Guidelines for Packing M10i Components for Shipment . . . . . . . . . . . . . . . . . . . . 215

Part 5 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

xiiiCopyright © 2010, Juniper Networks, Inc.

Page 14

M10i Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.xiv

Page 15

List of Figures

Part 1 Overview of the M10i Multiservice Edge Router

Chapter 2 M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1: Front of Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2: Rear of Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3: Midplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4: M10i PIC Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5: CFEB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6: CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7: Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8: M10i High-Availability Chassis Manager . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9: M10i High-Availability Chassis Manager . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10: M10i Router Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 11: AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12: DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13: Airflow Through the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 14: Cable Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 3 M10i System Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 15: System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 16: Packet Forwarding Engine Components and Data Flow . . . . . . . . . . . . 33

Figure 17: Routing Engine Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 18: Control Packet Handling for Routing and Forwarding Table

Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Part 2 Setting Up the M10i Router

Chapter 4 Preparing the Site for M10i Router Installation . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 19: Typical Open-Frame Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 20: Chassis Dimensions and Clearance Requirements . . . . . . . . . . . . . . . . 44

Chapter 6 Unpacking the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 21: Unpacking the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 7 Installing the M10i Router Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 22: Moving the Mounting Brackets on the Chassis . . . . . . . . . . . . . . . . . . . . 52

Figure 23: Installing the Cable Management System . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 8 Installing the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 24: Installing the Chassis into a Open-Frame Rack . . . . . . . . . . . . . . . . . . . 57

Figure 25: Installing the Chassis into a Four-Post Rack . . . . . . . . . . . . . . . . . . . . . 58

Chapter 9 Grounding the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

xvCopyright © 2010, Juniper Networks, Inc.

Page 16

M10i Multiservice Edge Router Hardware Guide

Figure 26: Connecting the Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 10 Connecting the M10i Router to External Devices . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 27: Console and Auxiliary Serial Port Connector . . . . . . . . . . . . . . . . . . . . . 62

Figure 28: Routing Engine Management Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 29: Routing Engine Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 30: Routing Engine Management Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 31: Attaching Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 11 Providing Power to the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 32: Connecting DC Power Cables to a DC Power Supply . . . . . . . . . . . . . . 69

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 15 Replacing M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 33: Removing a Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 34: Installing a Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 35: CFEB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 36: Removing a CFEB or CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 37: Installing a CFEB or CFEB-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 38: Removing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 39: Removing an HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 40: Installing the HCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 41: Installing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 42: Removing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 43: Installing a PIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 44: Connecting Fiber-Optic Cable to a PIC . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 45: Small Form-Factor Pluggable (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 46: Small Form-Factor Pluggable (SFP) . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 47: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 48: Installing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 49: Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 50: Installing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 51: Connecting DC power cables to a DC Power Supply . . . . . . . . . . . . . . . 128

Figure 52: Connecting DC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 53: Removing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 54: Installing a Routing Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 55: Removing the PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 56: Inserting the PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 57: Removing the CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 58: Inserting the CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 59: Installing the SDRAM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 60: Routing Engine Ethernet Cable Connector . . . . . . . . . . . . . . . . . . . . . . 141

Figure 61: Ethernet Management Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 62: Console and Auxiliary Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Part 4 Appendixes

Appendix A Safety and Regulatory Compliance Information for the M10i Router . . . . 145

Copyright © 2010, Juniper Networks, Inc.xvi

Page 17

List of Figures

Figure 63: Placing a Component into an Electrostatic Bag . . . . . . . . . . . . . . . . . . 151

Figure 64: M10i Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Appendix D Power Guidelines, Requirements, and Specifications for the M10i

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 65: Grounding Cable and Grounding Points . . . . . . . . . . . . . . . . . . . . . . . . 188

Figure 66: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 67: DC Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Appendix G Contacting Customer Support and Returning M10i Hardware . . . . . . . . . . 207

Figure 68: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 69: CFEB or CBEF-E Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 70: HCM Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 71: PIC Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 72: Power Supply Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 73: Routing Engine Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . 212

xviiCopyright © 2010, Juniper Networks, Inc.

Page 18

M10i Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.xviii

Page 19

List of Tables

About the Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Table 1: Notice Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Table 2: Text and Syntax Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Part 1 Overview of the M10i Multiservice Edge Router

Chapter 2 M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3: States for CFEB or CFEB-E LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4: States for Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5: States for Routing Engine LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6: States for HCM LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 7: Alarm LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 8: States for Power Supply LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Part 2 Setting Up the M10i Router

Chapter 4 Preparing the Site for M10i Router Installation . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 9: Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6 Unpacking the M10i Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 10: Parts List for a Fully Configured Router . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 11: Accessory Box Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Part 3 Hardware Maintenance, Troubleshooting, and Replacement

Procedures

Chapter 14 Troubleshooting M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 12: Chassis Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 13: Routing Engine Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 14: CFEB or CFEB-E Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 15: Cooling System Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 16: SONET/SDH Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 17: Power System Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 15 Replacing M10i Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 18: Field-Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 19: Tools and Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Part 4 Appendixes

Appendix B M10i Router Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 20: M10i Chassis Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

xixCopyright © 2010, Juniper Networks, Inc.

Page 20

M10i Multiservice Edge Router Hardware Guide

Appendix C M10i Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Table 21: M10i Router Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . 185

Appendix D Power Guidelines, Requirements, and Specifications for the M10i

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Table 22: Component Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table 23: AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Table 24: Electrical Specifications for AC Power Supply . . . . . . . . . . . . . . . . . . . . 191

Table 25: Electrical Specifications for DC Power Supply . . . . . . . . . . . . . . . . . . . . 192

Appendix E Cable and Wire Guidelines and Specifications for the M10i Router . . . . . . 195

Table 26: Estimated Values for Factors Causing Link Loss . . . . . . . . . . . . . . . . . . 198

Table 27: Cable Specifications for Routing Engine Management Ports . . . . . . . 200

Appendix F M10i Cable Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Table 28: RJ-45 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Table 29: DB-9 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Table 30: RJ-48 Connector to RJ-48 Connector (Straight) Pinout . . . . . . . . . . . 203

Table 31: RJ-48 Connector to RJ-48 Connector (Crossover) Pinout . . . . . . . . . . 203

Table 32: RJ-48 Connector to DB-15 Connector (Straight) Pinout . . . . . . . . . . . 204

Table 33: RJ-48 Connector to DB-15 Connector (Crossover) Pinout . . . . . . . . . . 205

Copyright © 2010, Juniper Networks, Inc.xx

Page 21

About the Documentation

•

Junos OS Documentation and Release Notes on page xxi

•

Objectives on page xxi

•

Audience on page xxii

•

Documentation Conventions on page xxii

•

Documentation Feedback on page xxiii

•

Requesting Technical Support on page xxiv

Junos OS Documentation and Release Notes

For a list of related Junos OS documentation, see

http://www.juniper.net/techpubs/software/junos/ .

If the information in the latest release notes differs from the information in the

documentation, follow the Junos OS Release Notes.

To obtain the most current version of all Juniper Networks®technical documentation,

see the product documentation page on the Juniper Networks website at

http://www.juniper.net/techpubs/.

Objectives

This documentation describes hardware components, installation, basic configuration,

and basic troubleshooting procedures for the Juniper Networks M10i Multiservice Edge

Router. It explains how to prepare your site for router installation, unpack and install the

hardware,power onthe router, perform initial software configuration, andperform routine

maintenance. After completing the installation and basic configuration procedures

covered in this documentation, see the Junos OS configuration guides for information

about further Junos OS configuration.

NOTE: For additional information about Juniper Networks routers and the

Physical Interface Cards (PICs) they support—either corrections to or

informationthat mighthave been omitted from this guide—see the hardware

release notes at http://www.juniper.net/.

xxiCopyright © 2010, Juniper Networks, Inc.

Page 22

M10i Multiservice Edge Router Hardware Guide

Audience

This documentation is designed for network administrators who are installing and

maintaining a Juniper Networks router or preparing a site for router installation. To use

the documentation, you need a broad understanding of networks in general, the Internet

in particular, networking principles, and network configuration. Any detailed discussion

of these concepts is beyond the scope of this hardware documentation.

Documentation Conventions

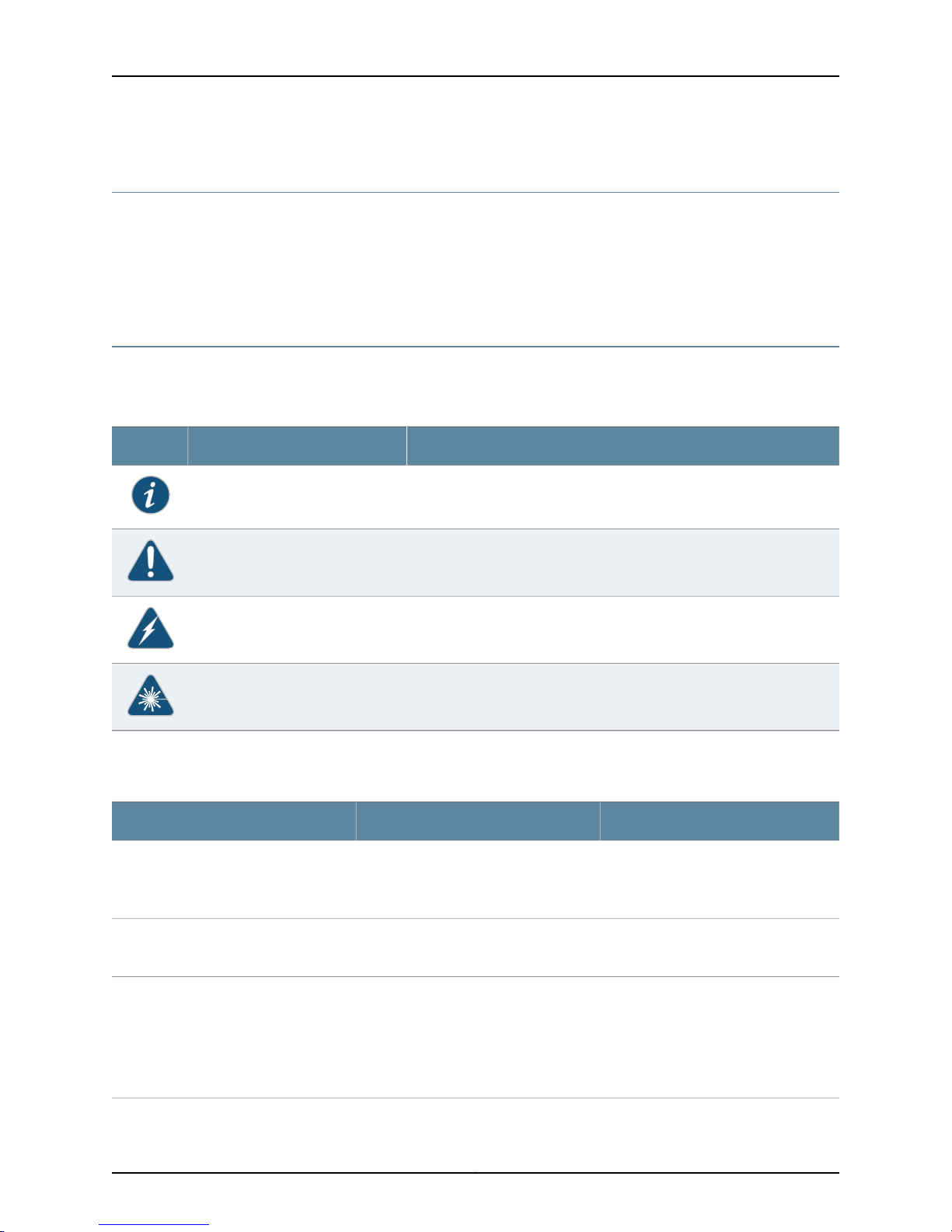

Table 1 on page xxii defines the notice icons used in this guide.

Table 1: Notice Icons

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Table 2 on page xxii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

Represents text that you type.Bold text like this

Fixed-width text like this

Italic text like this

Represents output that appears on the

terminal screen.

•

Introduces important new terms.

•

Identifies book names.

•

Identifies RFC and Internet draft titles.

Indicates a situation that might result in loss of data or hardware damage.Caution

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

ExamplesDescriptionConvention

To enter configuration mode, type the

configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

•

A policy term is a named structure

that defines match conditions and

actions.

•

Junos System Basics Configuration

Guide

•

RFC 1997, BGPCommunities Attribute

Copyright © 2010, Juniper Networks, Inc.xxii

Page 23

Table 2: Text and Syntax Conventions (continued)

About the Documentation

ExamplesDescriptionConvention

Italic text like this

Text like this

| (pipe symbol)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

Represents variables (options for which

you substitute a value) in commands or

configuration statements.

Represents names of configuration

statements, commands, files, and

directories; IP addresses; configuration

hierarchy levels; or labels on routing

platform components.

Indicates a choice betweenthe mutually

exclusivekeywords or variables on either

side of the symbol. The set of choices is

often enclosed in parentheses for clarity.

same lineas theconfiguration statement

to which it applies.

Enclose a variable for which you can

substitute one or more values.

Identify a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

Configure the machine’s domain name:

[edit]

root@# set system domain-name

domain-name

•

To configure a stub area, include the

stub statement at the [edit protocols

ospf area area-id] hierarchy level.

•

The console portis labeled CONSOLE.

stub <default-metric metric>;Enclose optional keywords or variables.< > (angle brackets)

broadcast | multicast

(string1 | string2 | string3)

rsvp { # Required for dynamic MPLS onlyIndicates a comment specified on the

community name members [

community-ids ]

[edit]

routing-options {

static {

route default{

nexthop address;

retain;

}

}

}

J-Web GUI Conventions

Bold text like this

> (bold right angle bracket)

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so that we can

improve the documentation. You can send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

Represents J-Web graphical user

interface (GUI) items you click or select.

Separates levels in a hierarchy of J-Web

selections.

•

In the Logical Interfaces box, select

All Interfaces.

•

To cancel the configuration, click

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

xxiiiCopyright © 2010, Juniper Networks, Inc.

Page 24

M10i Multiservice Edge Router Hardware Guide

https://www.juniper.net/cgi-bin/docbugreport/. If you are using e-mail, be sure to include

the following information with your comments:

•

Document or topic name

•

URL or page number

•

Software release version (if applicable)

Requesting Technical Support

Technical product support is available throughthe Juniper Networks Technical Assistance

Center (JTAC). If you are a customer with an active J-Care or JNASC support contract,

or are covered under warranty, and need post-sales technical support, you can access

our tools and resources online or open a case with JTAC.

•

JTAC policies—For a complete understanding of our JTAC procedures and policies,

review the JTAC User Guide located at

http://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf .

•

Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/ .

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day,

7 days a week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online

self-service portal called the Customer Support Center (CSC) that provides you with the

following features:

•

Find CSC offerings: http://www.juniper.net/customers/support/

•

Search for known bugs: http://www2.juniper.net/kb/

•

Find product documentation: http://www.juniper.net/techpubs/

•

Find solutions and answer questions using our Knowledge Base: http://kb.juniper.net/

•

Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

•

Search technical bulletins for relevant hardware and software notifications:

https://www.juniper.net/alerts/

•

Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

•

Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

To verify serviceentitlement by productserial number, useour Serial NumberEntitlement

(SNE) Tool: https://tools.juniper.net/SerialNumberEntitlementSearch/

Copyright © 2010, Juniper Networks, Inc.xxiv

Page 25

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

•

Use the Case Management tool in the CSC at http://www.juniper.net/cm/ .

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, see

http://www.juniper.net/support/requesting-support.html .

About the Documentation

xxvCopyright © 2010, Juniper Networks, Inc.

Page 26

M10i Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.xxvi

Page 27

PART 1

Overview of the M10i Multiservice Edge

Router

•

Overview of the M10i Router on page 3

•

M10i Hardware Components on page 5

•

M10i System Architecture Overview on page 31

1Copyright © 2010, Juniper Networks, Inc.

Page 28

M10i Multiservice Edge Router Hardware Guide

Copyright © 2010, Juniper Networks, Inc.2

Page 29

CHAPTER 1

Overview of the M10i Router

•

M10i Router Description on page 3

•

M10i System Redundancy on page 4

M10i Router Description

The M10i Multiservice Edge Router provides high-speed interfaces for medium and large

networksand networkapplications, such as those supported by Internetservice providers

(ISPs). Application-specific integrated circuits (ASICs), a definitive part of the router

design, enable the router toforwarddata at the high speeds demanded by current network

media.

The M10i router supports up to eight Physical Interface Cards (PICs). The router height

of 34.80 in. (88.4 cm) enables stacked installation of five M10i routers in a single

floor-to-ceiling rack, for increased port density per unit of floor space.

The router’s maximum aggregate throughput is 12.8 gigabits per second (Gbps) simplex

or 6.4 Gbps full duplex. Inserting a combination of PICs with an aggregate higher than

the maximum throughput per FPC is supported, but constitutes oversubscription of the

FPC.

The router architecture cleanly separates control operations from packet forwarding

operations,which helps to eliminateprocessing and trafficbottlenecks.Control operations

in the router are performed by the Routing Engine, which runs Junos OS to handle routing

protocols,traffic engineering, policy, policing, monitoring, and configuration management.

Forwarding operations in the router are performed by the Packet Forwarding Engine,

which consists of hardware, including ASICs, designed by Juniper Networks.

Related

Documentation

M10i System Redundancy on page 4•

• M10i Chassis Description on page 5

• M10i Router Physical Specifications on page 183

• Overview of M10i Router Installation on page 45

3Copyright © 2010, Juniper Networks, Inc.

Page 30

M10i Multiservice Edge Router Hardware Guide

M10i System Redundancy

You can configure the router for system redundancy by using three AC or four DC

load-sharing, fully-redundant power suppliesto distribute powerto theother components.

AC System Redundancy

AC system redundancy requiresthree independentAC power outlets.If one power supply

fails, the other two power supplies provide full power to the router's components

indefinitely.

You can set up increased AC system redundancy by using four AC power supplies. In this