Page 1

Juniper Networks

G10 CMTS

Getting Started

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, CA 94089

USA

408-745-2000

www.juniper.net

Part Number: 530-008005-01, Revision 1

Page 2

•

•

Copyright © 2002, Juniper Networks, Inc. All rights reserved. Juniper Networks is registered in the U.S. Patent and Trademark Office and in other countries

•

as a trademark of Juniper Networks, Inc. Broadband Cable Processor, G10, Internet Processor, JUNOS, JUNOScript, M5, M10, M20, M40, M40e, M-series,

M160, ServiceGuard, T640, and T-series are trademarks of Juniper Networks, Inc. All other trademarks, service marks, registered trademarks, or registered

•

service marks are the property of their respective owners. All specifications are subject to change without notice.

•

•

Products made or sold by Juniper Networks (including the M5, M10, M20, M40, M40e, and M160 routers, T640 routing node, and the JUNOS software) or

•

components thereof might be covered by one or more of the following patents that are owned by or licensed to Juniper Networks: U.S. Patent Nos.

5,473,599, 5,905,725, and 5909,440.

•

•

Juniper Networks G10 CMTS Getting Started

•

Copyright © 2002, Juniper Networks, Inc.

All rights reserved. Printed in USA.

•

•

Writer: Jerry Isaac

•

Illustrations: Paul Gilman

•

Covers and template design: Edmonds Design

•

Revision History

•

17 June 2002—First Edition.

•

•

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer, or

otherwise revise this publication without notice.

•

•

The DOCSIS Module performs encryption that is subject to U.S. Customs and Export regulations. A DOCSIS Module shall not be exported, sold or transferred

•

to a country outside the USA and Canada without an appropriate export license from the U.S. Government. The specific Regulations governing exports of

encryption products are set forth in the Export Administration Regulations, 15 C.F.R. (Code of Federal Regulations), Parts 730-774.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

ii

Page 3

Table of Contents

About This Manual

Purpose .................................................................................................................ix

Organization..........................................................................................................ix

Document Conventions ..........................................................................................x

Notes, Cautions, and Warnings........................................................................x

G10 CMTS Document Set.......................................................................................xi

Chapter 1

Chapter 2

Chapter 3

G10 CMTS Hardware Overview ........................................................................1

G10 CMTS Installation ..........................................................................................9

Tools and Equipment Required for Installation.......................................................9

Installation Preparation.........................................................................................10

Notices..................................................................................................................11

Rack Mounting......................................................................................................12

Installing Power Supplies ......................................................................................14

Installing a Front-Loaded Module..........................................................................17

Installing a Rear-Loaded Module ...........................................................................19

Cabling an HFC Connector Module .......................................................................21

Cabling a Chassis Control Module.........................................................................23

Cabling a NIC Module ...........................................................................................25

Cabling a NIC Access Module................................................................................28

Attaching a PC to the Chassis Control Module.......................................................31

Connecting to Power Sources ...............................................................................32

AC Power.......................................................................................................32

DC Power ......................................................................................................33

G10 CMTS Configuration ...................................................................................35

Powering On the G10 CMTS .................................................................................35

Powering On and Configuring the PC ...................................................................39

Logging In and Out of the G10 CMTS.............................................................39

Configuring the G10 CMTS....................................................................................40

Cable Interface Assignment...........................................................................40

Creating Usernames and Passwords..............................................................42

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Table of Contents

iii

Page 4

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Index

Index ..............................................................................................................................47

Configuring Miscellaneous Parameters..........................................................42

Viewing and Saving Running Configuration...................................................42

Configuring Downstream Channel Parameters..............................................43

Configuring Upstream Channel Parameters...................................................44

Configuring Fast Ethernet Interfaces .............................................................45

Configuring Gigabit Ethernet Interfaces.........................................................45

Configuring a Management Interface.............................................................46

Juniper Networks G10 CMTS Getting Started

iv

Page 5

List of Figures

List of Figures

Figure 1: Front View of Fully-Configured Chassis ................................................2

Figure 2: Front View of Partially-Configured Chassis............................................3

Figure 3: Rear View of Fully-Configured Chassis..................................................4

Figure 4: Rear View of Partially-Configured Chassis.............................................5

Figure 5: Top View of Chassis Midplane ..............................................................6

Figure 6: Bottom of Chassis...............................................................................13

Figure 7: Front and Rear Views of Midplane......................................................16

Figure 8: Power Supply Installation ...................................................................17

Figure 9: Front-Loaded Module Installation .......................................................19

Figure 10: Rear-Loaded Module Installation ........................................................20

Figure 11: Example of Allocation of Multiple Channels Per Port ..........................21

Figure 12: HFC Connector Module Rear Panel.....................................................22

Figure 13: Chassis Control Module and CCM Access Module Front Panels...........24

Figure 14: NIC Module and NIC Access Module Panels ........................................26

Figure 15: NIC Module Cabling – Front View.......................................................27

Figure 16: NIC Access Module Cable Connections ...............................................30

Figure 17: AC Power Cord and Retainer Clip .......................................................33

Figure 18: DC Power Transition Module ..............................................................34

Figure 19: DOCSIS Module and Chassis Control Module Front Panels..................37

Figure 20: NIC Module and NIC Access Module Panels ........................................38

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Figures

v

Page 6

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Figures

Juniper Networks G10 CMTS Getting Started

vi

Page 7

List of Tables

List of Tables

Table 1: Power Supply Guideline......................................................................18

Table 2: NIC Access Module Wiring Plan ..........................................................31

Table 3: Downstream Channel Assignment......................................................41

Table 4: Upstream Channel Assignment (8-Channel DOCSIS Module)..............41

Table 5: Upstream Channel Assignment (16-Channel DOCSIS Module) ............41

Table 6: Downstream Channel Parameter Ranges............................................43

Table 7: Upstream Channel Parameter Ranges.................................................44

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Tables

vii

Page 8

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

List of Tables

Juniper Networks G10 CMTS Getting Started

viii

Page 9

About This Manual

This section describes important information about the design of this document.

Purpose

The purpose of the Juniper Networks G10 CMTS Getting Started manual is to provide

experienced personnel the procedures required to properly install and configure the G10

Cable Modem Termination System (CMTS).

If you do not have experience with the installation and configuration of CMTS equipment in

cable headends, or if you need more details regarding the installation, configuration, or

upgrading of the G10 CMTS, then it is recommended that you follow the procedures

provided in the companion manual Juniper Networks G10 CMTS Installation and Configuration

for more detailed information.

Additional instructions and details regarding the subsequent and on-going operation of the

CMTS can be found in the documents listed in “G10 CMTS Document Set” on page xi.

Organization

Juniper Networks G10 CMTS Getting Started is organized as follows:

Chapter 1, “G10 CMTS Hardware Overview” – Provides a hardware overview of the G10

Chapter 2, “G10 CMTS Installation” – Provides the procedures that must be followed to

Chapter 3, “G10 CMTS Configuration” – Describes the configuration procedure for the

CMTS.

install the G10 CMTS in the headend.

G10 CMTS.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

About This Manual

ix

Page 10

Document Conventions

•

Document Conventions

•

•

The following document conventions are used in this manual:

•

•

•

•

General

Conventions

•

Italic font Denotes a) emphasis, b) first use of a new term, or c) a document title.

Screen Name font Denotes a) the on-screen name of a window, dialog box or field, or b) keys on a

•

•

•

•

Software

Conventions

•

Computer font Font denotes code or messages displayed on-screen.

Computer Bold font Font denotes literal commands and parameters that you enter exactly as shown.

•

•

<Computer Italic> font Font denotes parameter values that require a user-defined input.

•

•

•

•

•

•

•

•

•

•

[parameter] Square brackets denote optional parameters.

{parameter} Braces denote required parameters.

| Vertical bars separate parameters in a group from which you must choose only one.

↵ Return symbol indicates pressing the Enter key at the end of a command line.

•

•

•

Notes, Cautions, and Warnings

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

keyboard.

The value strings are enclosed in angle brackets <...>.

A note indicates information that might be helpful in a

particular situation, or information that might otherwise

be overlooked.

A caution indicates a situation that requires careful

attention. Failure to observe a cautionary note could result

in injury or discomfort to yourself, or serious damage to

the product.

A warning is intended to alert the user of the presence of

uninsulated dangerous voltage within the product’s

enclosure that may present a risk of electric shock.

Juniper Networks G10 CMTS Getting Started

x

Page 11

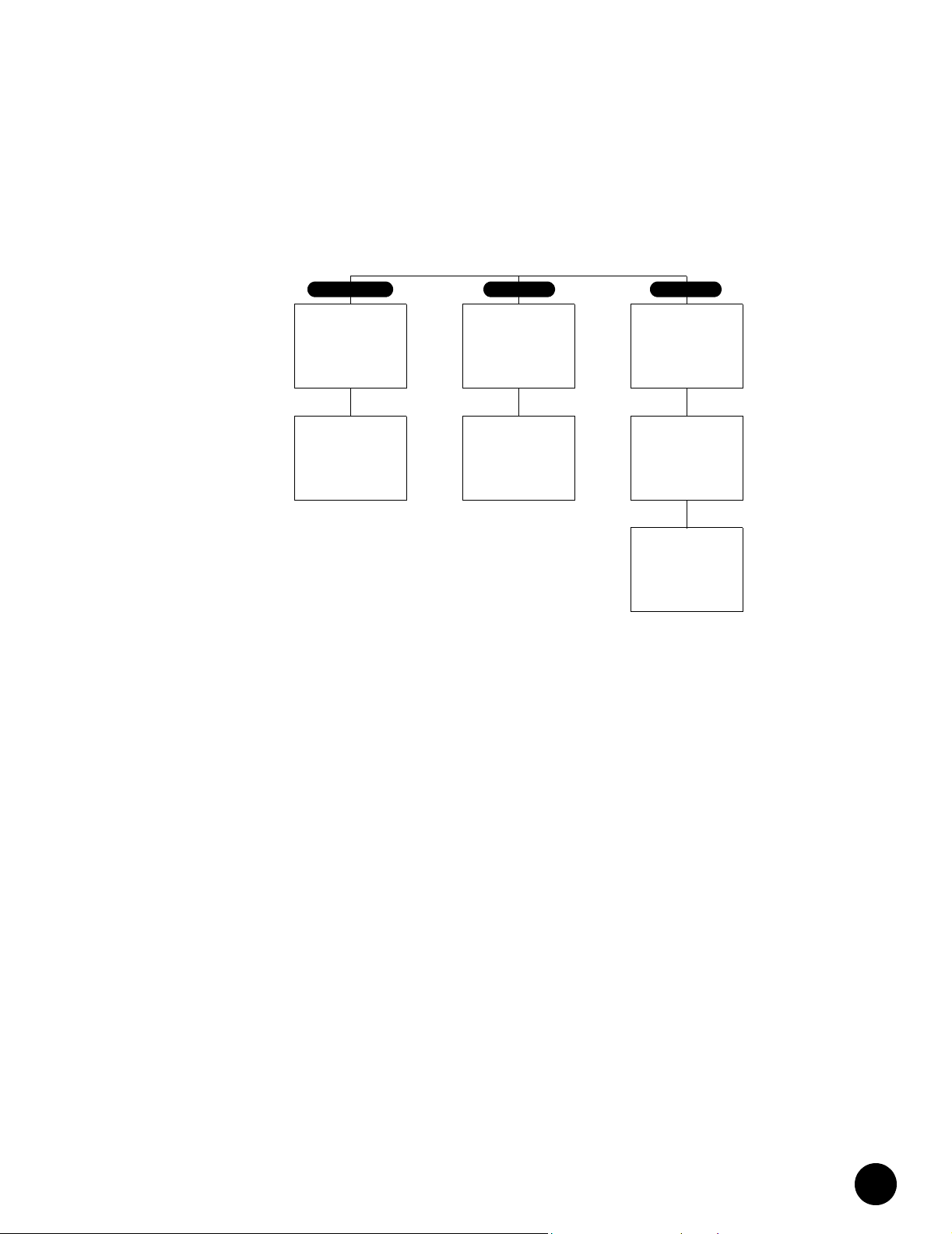

G10 CMTS Document Set

G10 CMTS Document Set

PREPARATION

Pre-Installation

530-008003-01

Installation and

Configuration

Guide

OPERATION

Getting Started

Operation and

Maintenance

REFERENCE

Functional

Description

530-008007-01530-008005-01

SNMP and

Enterprise MIB

Specification

530-008008-01530-008004-01530-008002-01

CLI Reference

530-008006-01

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

About This Manual

xi

Page 12

G10 CMTS Document Set

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Juniper Networks G10 CMTS Getting Started

xii

Page 13

Chapter 1

G10 CMTS Hardware Overview

This chapter provides an overview of the modules and various hardware components of the

G10 Cable Modem Termination System (CMTS), and where they reside within the chassis.

This overview presents material that is specific to the installation and configuration of the

G10 CMTS. For more details and specifications regarding these assemblies, refer to the

Juniper Networks G10 CMTS Functional Description.

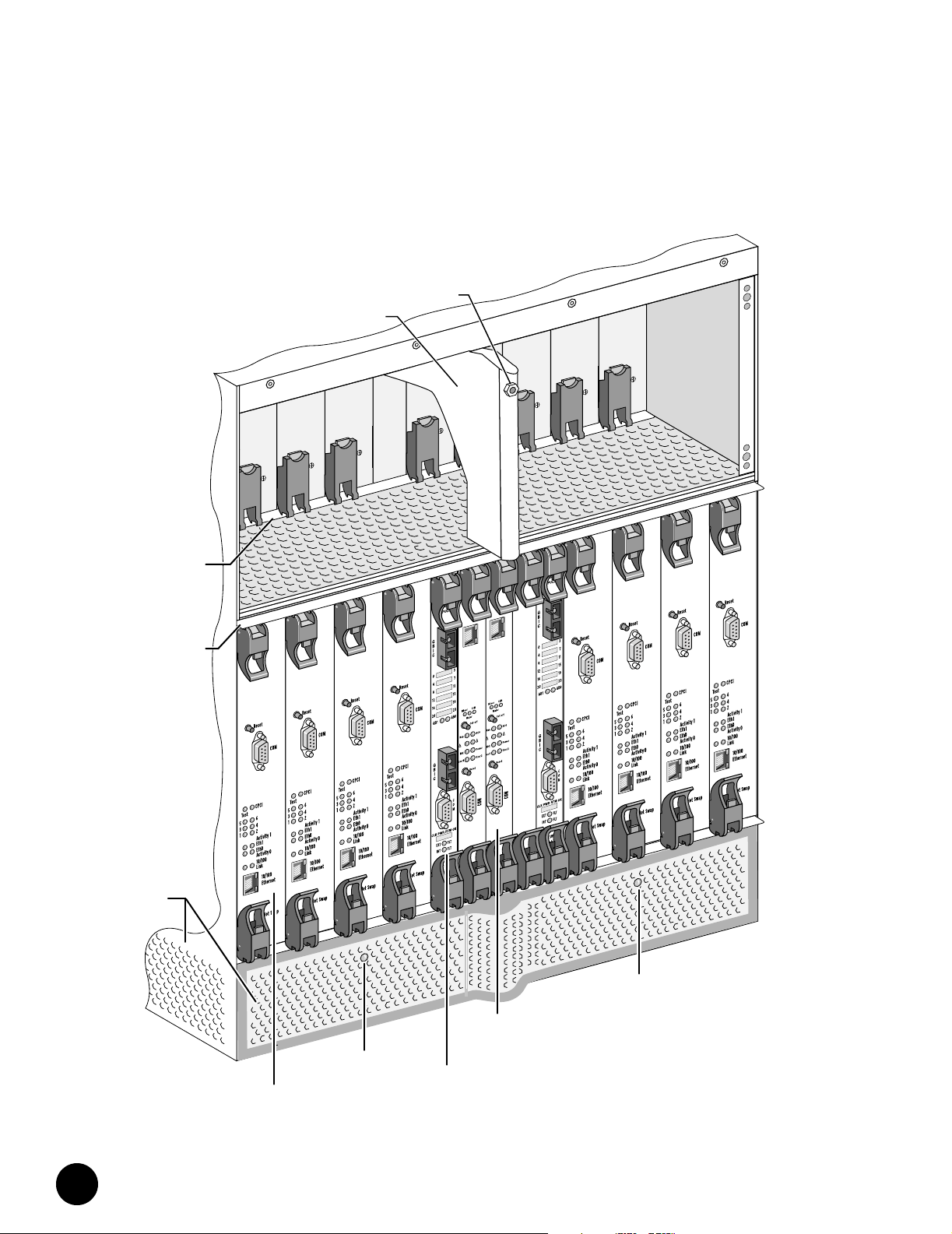

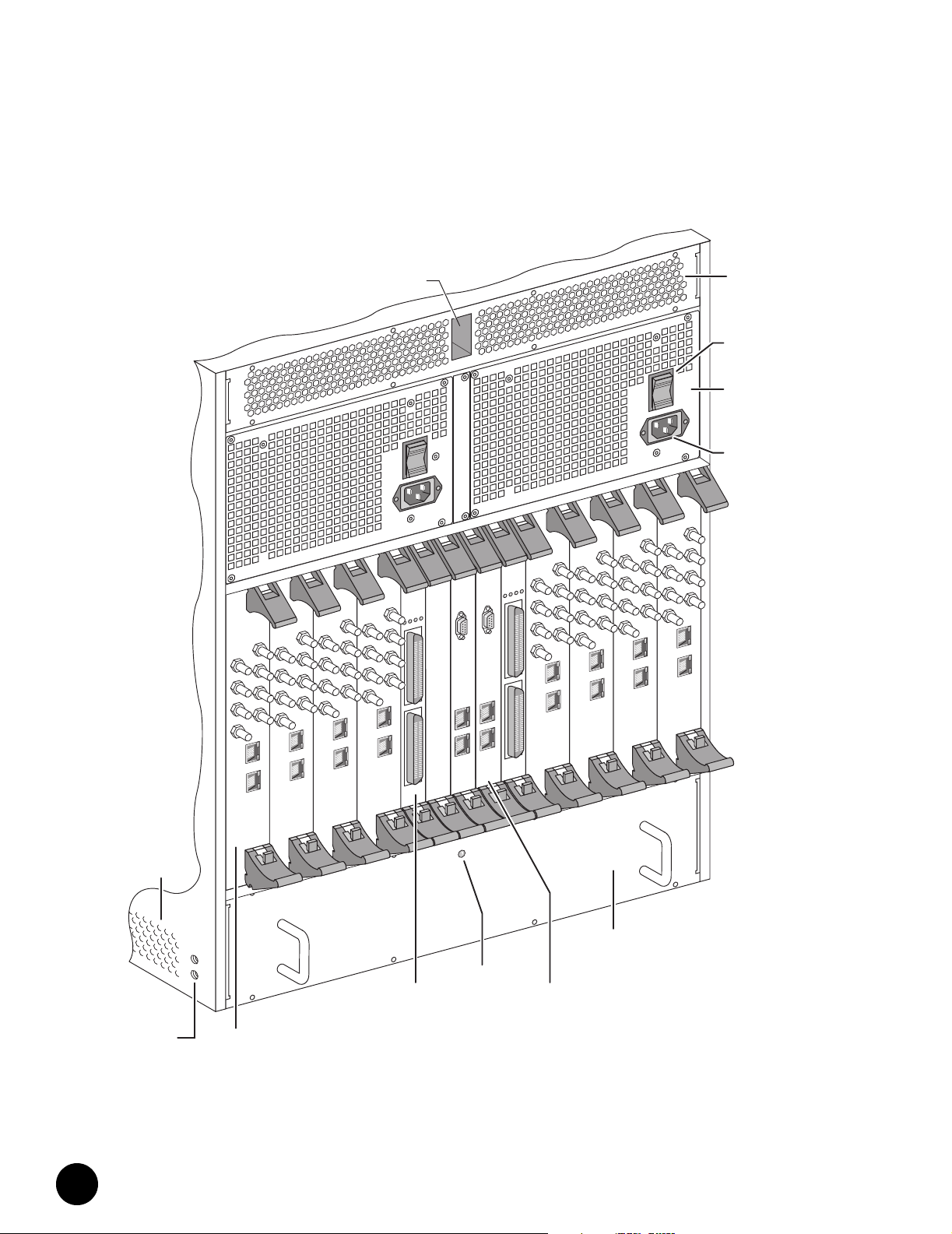

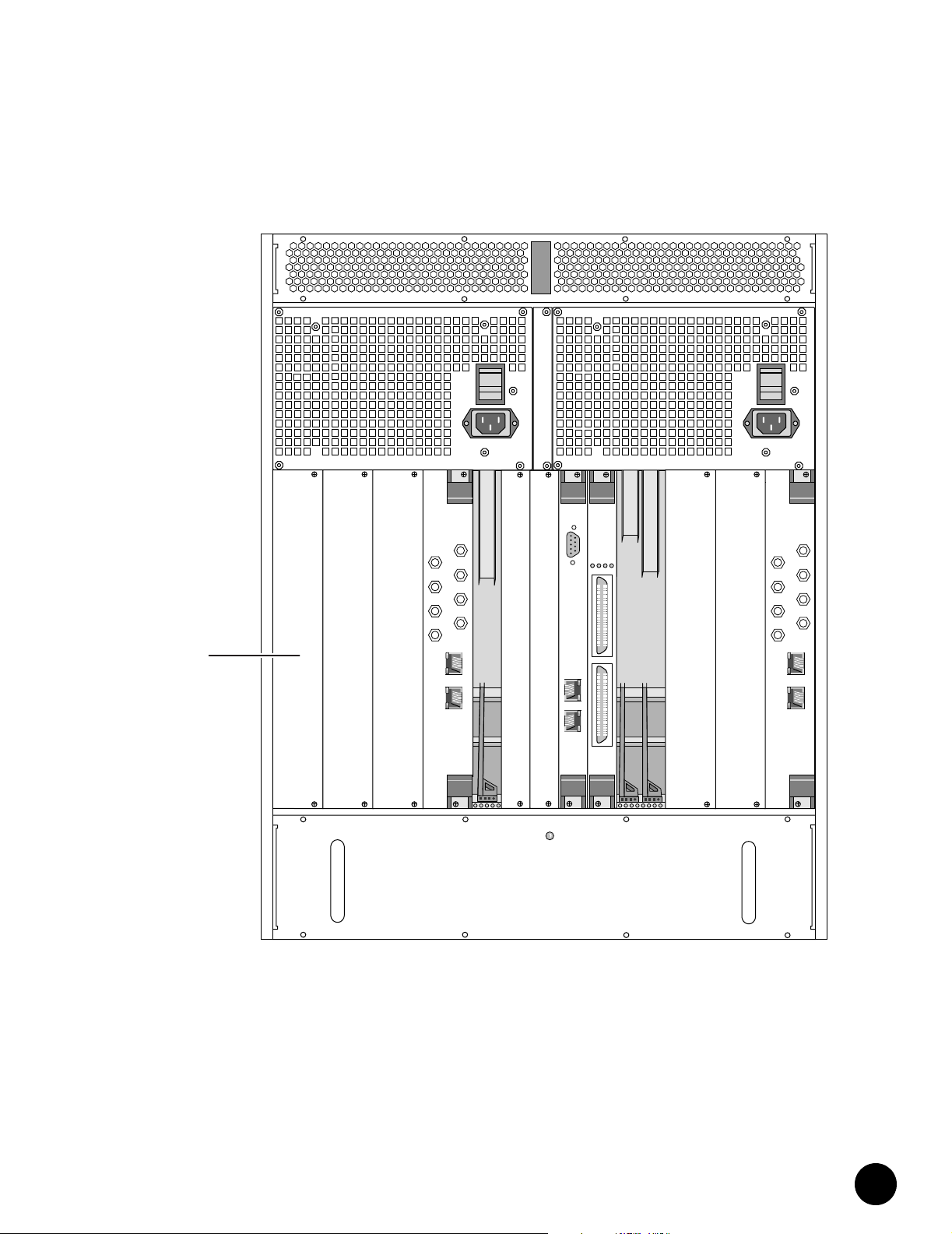

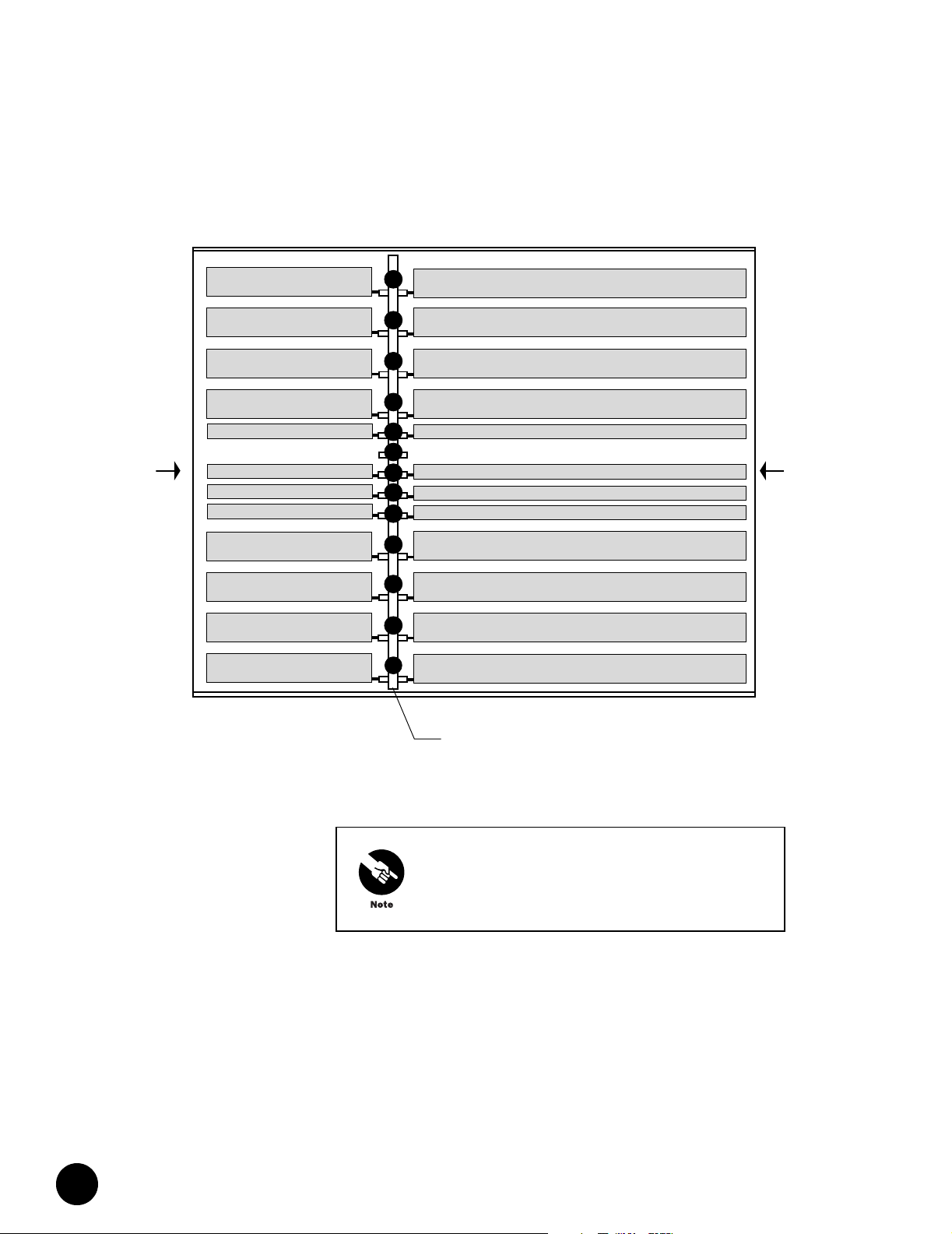

Figure 1 on page 2 illustrates a front view of a fully-configured chassis. Figure 2 on page 3

illustrates a front view of a partially-configured chassis in which DOCSIS Modules, a Chassis

Control Module (CCM), a Network Interface Card (NIC) Module, power supplies, air

management modules, and power supply filler panels have been removed. Figure 3 on

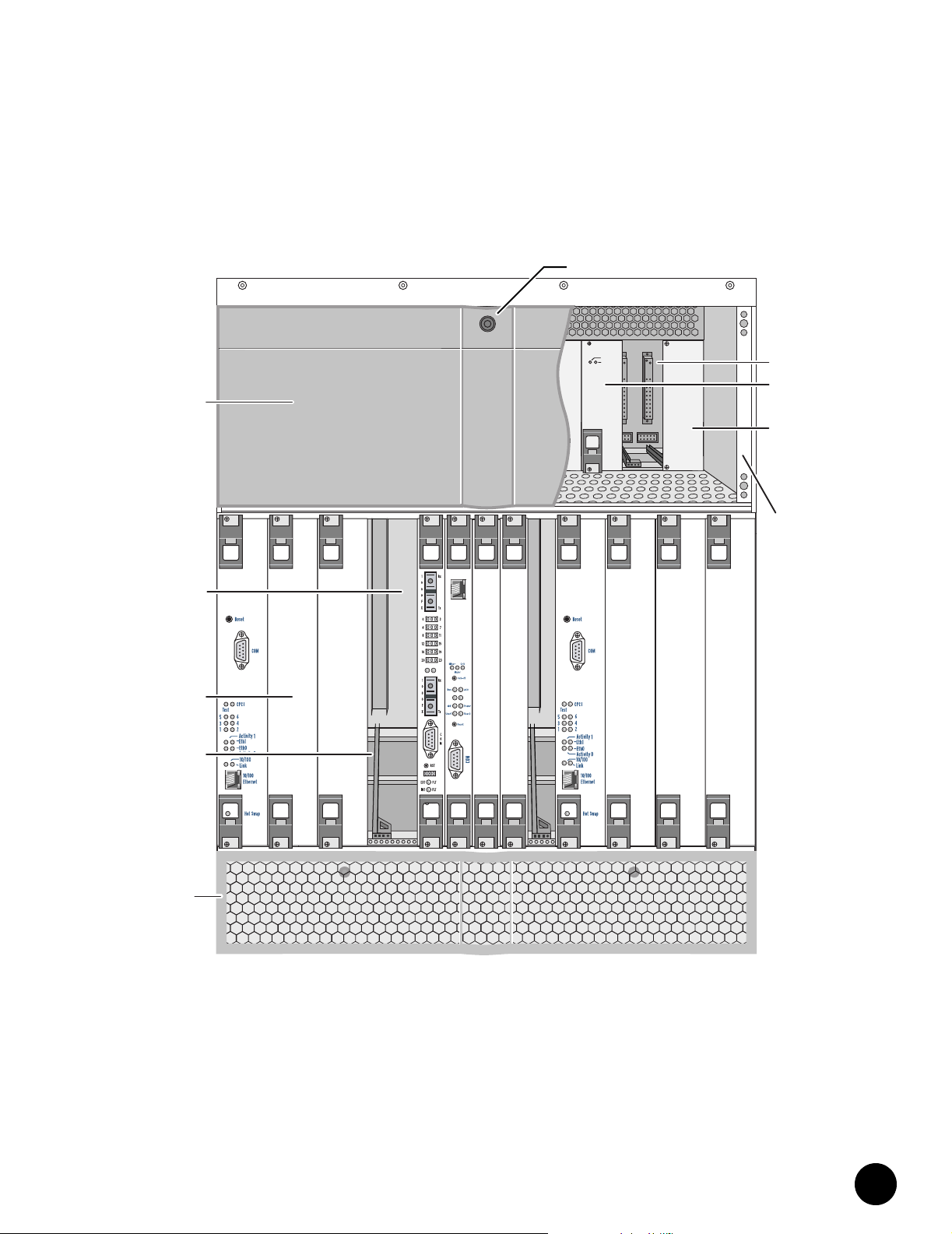

page 4 illustrates a rear view of a fully-configured chassis. Figure 4 on page 5 illustrates the

rear view of the partially-configured chassis in which HFC Connector Modules, a CCM Access

Module, a NIC Access Module, and air management panels have been removed. Figure 5 on

page 6 provides a top view of the chassis midplane showing the slot enumeration and

location of each module.

All of the features of the chassis that are cited in these figures will be referenced in one or

more procedures described in this document.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Hardware Overview

1

Page 14

•

Figure 1: Front View of Fully-Configured Chassis

•

•

•

•

•

•

•

•

•

•

•

•

Po

•

Powe

r

e

w

Fault

Po

r

Fault

•

•

•

•

•

•

•

•

•

•

Power

Supply

Ejector

Rail

•

•

•

•

•

Module

Ejector

Rail

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Air

Intake

•

•

•

•

•

•

•

•

•

•

•

•

DOCSIS

Module

•

•

Cable

Guide

er

w

ult

Fa

Front Fan

Tray LED

ESD

Strap

Jack

Power

Fault

Module

NIC

er

Pow

lt

u

Fa

Eth0

2

1

Chassis

Control

Module

er

Pow

lt

u

er

Pow

er

Pow

Fa

0

h

t

E

2

1

Fa

lt

u

Fa

lt

u

Front Fan

Tray L E D

Juniper Networks G10 CMTS Getting Started

2

Page 15

Figure 2: Front View of Partially-Configured Chassis

Power

Fault

Power

Power

Power

Power

Fault

Fault

Power

Fault

Fault

Supply

Faceplate

Midplane

Air

Management

Module

Card

Guide

Air

Intake

Faceplate

•

•

•

ESD

Strap

Jack

•

•

•

•

•

•

Power

Power

Fault

Power

Power

Fault

Fault

Power

Fault

Supply

Bay

Power

Supply

Power

Supply

Filler

Panel

•

•

•

•

•

•

•

•

•

•

•

Power

Supply

Faceplate

Clip

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Hardware Overview

3

Page 16

•

Figure 3: Rear View of Fully-Configured Chassis

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

S 0

D

0

US

DS 1

1

US 1

S 2

D

2

2

US

DS 3

US 3

•

•

•

•

Eth0

Eth1

0

S

D

US 0

US 0

S 1

D

US 1

1

US

S 2

D

US

2

US

S 3

D

US 3

US 3

Eth0

Eth0

Eth1

Eth1

•

•

•

•

•

Air

Intake

•

•

•

•

•

•

•

•

•

•

•

•

Chassis

Ground

Nuts

HFC

Connector

Module

•

•

•

•

2

S 0

D

DS 1

S 2

D

DS 3

Cable

Channel

DS 0

0

US

S 1

D

US 1

S 2

D

US 2

S 3

D

US 3

Eth0

Eth1

Access

Module

OPERATIONAL

POWER

1

2

NIC

INT FAULT

EXT FAULT

C

O

C

M

O

M

Eth0

Eth0

Eth1

Eth1

Rear Fan

Tray LED

OPERATIONAL

INT FAULT

POWER

1

2

EXT FAULT

0

US

1

US

US 2

US 3

Eth0

Eth1

CCM

Access

Module

S 0

D

S 1

D

S 2

D

DS 3

S 0

D

US 0

DS 1

1

US

S 2

D

2

US

DS 3

US 3

Eth0

Eth1

Rear Fan

Tray

Air

Exhaust

AC Power

Switch

AC Power

Transition

Module

AC Power

Receptacle

DS 0

S 0

D

0

US

S 1

US 0

US 1

2

US

US 3

Eth0

Eth1

D

1

S

D

US 1

2

S

D

DS 2

US 2

S 3

D

S 3

D

US 3

Eth0

Eth1

Juniper Networks G10 CMTS Getting Started

4

Page 17

Figure 4: Rear View of Partially-Configured Chassis

Air

Management

Panel

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

OPERATIONAL

EXT FAULT

INT FAULT

DS 0

US 0

DS 1

US 1

DS 2

US 2

DS 3

US 3

C

POWER

O

M

1

DS 0

US 0

DS 1

US 1

DS 2

US 2

DS 3

US 3

•

•

•

•

•

•

•

•

Eth0

Eth1

Eth0

2

Eth1

Eth0

Eth1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Hardware Overview

5

Page 18

•

Figure 5: Top View of Chassis Midplane

•

•

•

•

•

•

•

HFC Connector Module

•

•

HFC Connector Module

•

•

HFC Connector Module

•

•

•

•

HFC Connector Module

NIC Access Module

•

•

•

Rear

•

•

CCM Access Module

CCM Access Module

NIC Access Module

•

•

HFC Connector Module

•

•

HFC Connector Module

•

•

•

HFC Connector Module

•

•

HFC Connector Module

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

13

12

11

10

9

8

7

6

5

4

3

2

1

Midplane

with logical slot numbers

DOCSIS Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

NIC Module

Front

Chassis Control Module

Chassis Control Module

NIC Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

DOCSIS Module

Module slots 1 through 6 reside in Domain A. Module slots

7, and 9 through 13 reside in Domain B.

Following is a brief explanation of each feature referenced in Figure 1 through Figure 4:

DOCSIS Module—Module that contains the Broadband Cable Processor ASIC and resides

between the Network Side Interface (NSI) and the Hybrid Fiber/Coax (HFC) interface

NIC Module—Module that provides the Gigabit Ethernet interface and the Fast Ethernet

switching functions for the network side interface

Chassis Control Module—Module that performs management and monitoring functions

Juniper Networks G10 CMTS Getting Started

6

Page 19

Module Ejector Rail—Rail into which a module’s ejector tabs mate when a module is

installed into a slot

ESD Strap Jack—Location in front of chassis where ESD ground strap can be plugged

Chassis Ground Nuts—Location where the earth ground connection to the chassis is

made

Air Intake—Slotted openings along the front (removable) and sides of the chassis where

air is drawn into the chassis for cooling the installed modules and power supplies

Air Intake Faceplate—Slotted removable panel that covers up the two front fan trays

Air Intake Faceplate Clip—Retainer clip used to mount the air intake faceplate

Front Fan Tray—Fan assembly that forces air upward through the front of the chassis

Front Fan Tray LED—LED that represents the status of the front fan tray

Power Supply Ejector Rail—Rail into which the power supply ejector tabs mate when a

power supply is installed into a bay

Midplane—Passive electrical interconnecting device for all modules in the chassis

Air Management Module—Module that is installed into an unused module slot to redirect

the air flow through the chassis

Card Guide—Used to align a module or power supply while it is being inserted into its

slot or bay, respectively

Power Supply—Converts AC or DC power supplied through the power transition modules

into the DC voltages required by the modules

Power Supply Faceplate—Panel that runs along the top of the chassis that covers up the

power supplies

Power Supply Faceplate Clip—Retainer clip used to mount the power supply faceplate

Power Supply Bay—Chassis bay in which a single hot-swappable power supply is

inserted

Power Supply Filler Panel—Panel covering an empty power supply bay

Cable Channel—Channel that runs through the top of the chassis that is used to route

the network cables from the rear of the chassis to the front of the chassis

Cable Guide—Guide in the front of the chassis used to route the network cables between

the cable channel and the lower opening in the power supply faceplate

HFC Connector Module—Module that functions as the DOCSIS Module’s physical access

to both the NSI and the HFC interfaces on the rear of the chassis

NIC Access Module—Module that provides the network connections between the NIC

Modules and the HFC Connector Modules

CCM Access Module—Module that provides Ethernet and serial connector access to the

Chassis Control Module from the rear of the chassis

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Hardware Overview

7

Page 20

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Rear Fan Tray—Fan assembly that forces air upward through the rear of the chassis

Rear Fan Tray LED—LED that represents the status of the rear fan tray

Air Management Panel—Panel that is installed over an unused module slot to redirect

the air flow through the chassis

Air Exhaust—Panel along the top and rear of the chassis where air is exhausted out of

the chassis for cooling purposes

AC Power Transition Module—Rear module that distributes the externally-supplied AC

power to the midplane

AC Power Receptacle—AC power cord receptacle on AC Power Transition Module

AC Power Switch—AC power ON/OFF switch that resides on the AC Power Transition

Module

DC Power Transition Module—Rear module that distributes the externally-supplied DC

power to the midplane

DC Power Receptacle—DC power cord terminal block on DC Power Transition Module

Juniper Networks G10 CMTS Getting Started

8

Page 21

Chapter 2

G10 CMTS Installation

This chapter describes the installation procedure for the G10 CMTS. It is recommended that

the entire installation process in this chapter be read prior to performing the actual G10

CMTS installation.

Tools and Equipment Required for Installation

The following tools are needed to install power supplies and modules, and to rack mount the

G10 CMTS chassis:

M2.5 Phillips torque screwdriver

M2.5 flathead torque screwdriver

M3 Phillips torque screwdriver

M5 Phillips torque screwdriver

#10 Phillips torque screwdriver

#10 flathead torque screwdriver

#12 Phillips torque screwdriver

7/16 in. torque wrench

22-10 AWG crimper/cutter/stripper

In addition, the following supplies may be required:

RF cables and adapters

Ethernet cables with RJ-45 connectors

The following equipment is required to configure the G10 CMTS and verify that the RF

system has been setup properly:

PC with asynchronous terminal emulation

RF spectrum analyzer

RF power meter

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

9

Page 22

Installation Preparation

•

Installation Preparation

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1. Ensure that the procedures and the checklist provided in the Juniper Networks G10 CMTS

Pre-Installation Guide have been successfully completed and approved by the user and

Juniper Networks field engineers.

2. Ensure that all safety precautions and procedures described in the Juniper Networks G10

CMTS Installation and Configuration manual have been followed prior to performing the

procedures presented in this chapter.

High levels of electrical energy are distributed across the

system midplane. Be careful not to contact the midplane

connectors, or any component connected to the midplane,

with any metallic object while hot-swapping or servicing

components installed in the system.

3. Verify that the contents of the shipping cartons and accessory kits are identical to the

contents listed on their corresponding packing lists.

4. Install the power supply faceplate included in the shipment by aligning its four ball studs

with the four power supply faceplate clips and pressing the faceplate towards the

chassis until it snaps into place.

The power supply faceplate must always be installed prior

to powering on the G10 CMTS to ensure that proper air

ventilation occurs throughout the chassis.

5. Install the air intake faceplate included in the shipment by aligning its four ball studs

with the four air intake faceplate clips and pressing the faceplate towards the chassis

until it snaps into place.

Juniper Networks G10 CMTS Getting Started

10

Page 23

Notices

Notices

This equipment is intended only for installation in a

restricted access location within a building.

This equipment is intended for indoor use only.

This equipment does not have a direct copper

connection to the outside plant.

Removal of power supplies or cards will result in

access to hazardous energy.

Each power cord must be connected to an

independent branch circuit.

Product connected to two power sources. Disconnect

both power sources before servicing.

Risk of explosion if battery is replaced by an incorrect

type. Dispose of used batteries according to the

instructions.

This is a Class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

11

Page 24

Rack Mounting.

•

Rack Mounting.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The G10 CMTS chassis must be rack mounted prior to the

installation of any additional power supplies or modules.

Never power on the G10 CMTS without first grounding the

chassis.

1. The G10 CMTS accessory kit contains a two-ring lug connector that must be crimped to

the earth ground strap.

2. Using the two supplied #10 hex bolts, attach the two-ring lug connector of the ground

strap to the chassis using 20 in lb of torque on each bolt. Figure 3 on page 4 shows the

location of the chassis ground nuts on the chassis.

3. Ensure that proper clearance is maintained between the G10 CMTS chassis and its

surroundings to allow adequate air ventilation to flow into the air intakes and out of the

air exhaust:

A minimum of 3 feet (0.91 m) between the front of the chassis and any other object

A minimum of 2 feet (0.61 m) between the rear of the chassis and any other object

A minimum of 3 inches between each side of the chassis and any other object

The G10 CMTS does not require any clearance between

the bottom of the chassis and the floor. Similarly, there are

no clearance requirements between the top of the chassis

and the bottom of another G10 CMTS stacked above it on

the same rack.

4. It is recommended that an equipment shelf be installed into the rack that can support

the maximum weight (140 lb, or 64 kg) and dimensions of the chassis. The chassis

dimensions, when viewed from the bottom, are provided in Figure 6.

Juniper Networks G10 CMTS Getting Started

12

Page 25

Rack Mounting.

Figure 6: Bottom of Chassis

17.3 in (439.4 mm)

18.6 in (472.6 mm)

Front

5. If the chassis will be front-rack mounted, proceed to Step 7. If the chassis will be

mid-rack mounted, proceed to Step 6.

6. Remove the seven screws fastening the mounting brackets to the front of the chassis,

align the brackets with the corresponding hole patterns in the center of the chassis, and

insert the seven screws into the chassis. Apply 20 in lb of torque to each of the seven

screws.

7. Using at least three installers, slowly lift and slide the G10 CMTS onto the equipment

shelf until the flanges of the mounting brackets are flush with the mounting rails of the

rack, and the mounting holes in the mounting brackets are aligned with the

corresponding holes in the mounting rails.

Do not use the handles on the rear fan tray to assist with

lifting the G10 CMTS. These handles are solely for the

purpose of removing the rear fan tray.

8. Using the twelve #12 screws supplied in the accessory kit (six for each mounting

bracket), fasten the chassis to the rack by applying 30 in lb of torque to each of the 12

screws.

9. Attach the ground strap to earth ground.

At this point, the installation of any additional power supplies or modules can be installed in

the chassis as described in “Installing Power Supplies” on page 14 through “Installing a

Rear-Loaded Module” on page 19.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

13

Page 26

Installing Power Supplies

•

Installing Power Supplies

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Before installing a power supply or any module into the

G10 CMTS, attach one end of an ESD ground strap to your

wrist and attach the other end to the ESD strap jack on the

front of the chassis (refer to Figure 2 on page 3).

1. The power supply faceplate must be removed by pulling the flanges on each side of the

faceplate away from the chassis until the faceplate ball studs are removed from the

power supply faceplate clips.

2. Decide the bay in which the power supply will be inserted. As described in the Juniper

Networks G10 CMTS Functional Description, the midplane is partitioned into two

domains—Domain A (slots 1—6) and Domain B (slots 7, 9—13). The AC power supplies

in each domain are supplied from the power source connected to that domain’s AC

power transition module. However, the DC outputs of all ten power supplies in both

domains are interconnected along the midplane. Therefore, if power source redundancy

is not a consideration, adding an AC power supply to either domain will supply

additional power to all of the modules in the chassis. However, if power source

redundancy is desired, the addition of an AC power supply in one domain must be

accompanied with the addition of an AC power supply in the other domain. Within a

domain, a power supply can be installed in any of the available five bays. Figure 7 on

page 16 illustrates the two power supply domains.

Unlike the AC configuration, the DC power transition modules do not operate

independently. Each DC power transition module supports the power supplies in both

domains of the chassis. Therefore, power supply redundancy is independent of the

domain in which a power supply is installed.

3. Remove the power supply filler panel covering the selected bay by loosening the two

self-contained screws.

4. If the power supply’s ejector is locked in the vertical position, press down on the ejector

release while simultaneously pulling the ejector away from the power supply. The

ejector should rest at approximately 45° from the faceplate.

The power supplies and the chassis are mechanically

keyed to ensure that same-type supplies and chassis (AC or

DC) are used together. Do not attempt to remove or

reconfigure the keys.

5. Align the printed circuit board of the power supply with the bay card guides and slowly

slide the power supply into the bay until it comes to a stop with the inside tabs of the

ejector (tabs closest to midplane) resting over the power supply ejector rail (refer to

Figure 8 on page 17).

6. Firmly lift the ejector to the vertical position until the ejector release clicks into position.

7. Tighten the upper and lower retainer screws by applying 3 in lb of torque to each screw.

Juniper Networks G10 CMTS Getting Started

14

Page 27

Installing Power Supplies

8. Replace the power supply faceplate by aligning its four ball studs with the four power

supply faceplate clips and pressing the faceplate towards the chassis until it snaps into

place.

The power supply faceplate must be replaced prior to

powering on the G10 CMTS to ensure that proper air

ventilation occurs throughout the chassis.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

15

Page 28

Installing Power Supplies

•

Figure 7: Front and Rear Views of Midplane

•

•

•

•

•

•

PS1 PS2 PS3 PS4 PS5 PS6 PS7 PS8 PS9 PS10

•

•

•

•

•

•

P5

Pwr Supply Domain A Pwr Supply Domain B

12 34 5678910111213

•

•

•

P4

•

•

P3

•

•

P2

•

•

P1

•

•

cPCI Bus Domain A

•

•

•

•

•

•

•

•

•

•

•

•

•

•

P5

•

•

•

P4

•

•

P3

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Front View

Rear View

cPCI Bus Domain B

Power

Supply

Connectors

Fan

Connectors

Power

Distribution

Connectors

12345678910111213

Fan

Connectors

Juniper Networks G10 CMTS Getting Started

16

Page 29

Installing a Front-Loaded Module

Figure 8: Power Supply Installation

Installing a Front-Loaded Module

This section describes the procedure for installing a DOCSIS Module, a Chassis Control

Module, and a NIC Module. Refer to Figure 7 on page 16 and Figure 5 on page 6 for views of

the front, rear, and top of the chassis midplane.

DOCSIS Modules are installed in front card cage slots 1 through 4 (for Domain A) and

slots 10 through 13 (for Domain B).

Chassis Control Modules are installed in front card cage slot 6 (for Domain A) and slot 7

(for Domain B).

NIC Modules are installed in front card cage slot 5 (for Domain A) and slot 9 (for Domain

B). NIC Modules are shipped from the factory with two Multi-Mode GBIC modules

installed. If you are using a different GBIC module interface, you will need to replace the

Multi-Mode GBIC modules that are shipped with the NIC Module. GBIC module removal

and installation is performed while the NIC Module is installed in the chassis.

r

Powe

t

Faul

1

2

Do not install DOCSIS Modules that support the DOCSIS

standard and DOCSIS Modules that support the

EuroDOCSIS standard within the same G10 CMTS chassis.

DOCSIS Modules that support EuroDOCSIS are labeled as

such on the front panel of the module.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

17

Page 30

Installing a Front-Loaded Module

•

•

•

•

•

•

•

•

•

Table 1: Power Supply Guideline

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

As DOCSIS Modules are installed in your CMTS, ensure the correct number of power supplies

are installed to support your configuration. The Juniper Networks production guideline for the

number of power supplies to install for N+1 power supply redundancy is provided in Table 1.

To implement full power redundancy (power supplies, power transition modules, and input

power), the number of power supplies installed in domain A must also be installed in

domain B.

Number of

DOCSIS Modules

13

24

35

46

57

68

79

810

Number of

Power Supplies

1. If an air management panel is installed in the slot to be populated, remove it from the

card cage.

2. Unlock the ejectors of the module to be installed so that each ejector rests at

approximately 45° away from its locked position.

3. Align the printed circuit board of the module with the card guides and slowly slide the

module into the slot until it comes to a stop with the inside tabs (tabs closest to

midplane) of the upper and lower ejectors resting directly under and over, respectively,

the module ejector rail (refer to Figure 9 on page 19).

4. Simultaneously close the ejectors toward the module faceplate to the vertical position

until each ejector release clicks into position.

5. Tighten the two retainer screws by applying 3 in lb of torque to each screw.

6. If you have installed a NIC Module and you will be using a GBIC module interface other

than Multi-Mode, then you must replace the Multi-Mode GBIC modules that are shipped

with the NIC Module. Remove each Multi-Mode GBIC module from the installed NIC

Module by squeezing the metal clasps at the top and bottom of the GBIC module

towards the module itself, and firmly pull out the module until it is fully removed from

its slot.

7. The GBIC modules that you will be using must now be installed in the NIC Module. With

the label side of the GBIC module facing the right, slide each module into its NIC Module

slot until the metal clasps at the top and bottom of the module click into place.

The GBIC module can only be installed one way. If it is

oriented in its slot incorrectly, it will stop about halfway

into the slot. If this occurs, remove the GBIC module, rotate

it 180°, and reinstall it.

Juniper Networks G10 CMTS Getting Started

18

Page 31

Installing a Rear-Loaded Module

Figure 9: Front-Loaded Module Installation

1

Installing a Rear-Loaded Module

This section describes the procedure for installing an HFC Connector Module, a CCM Access

Module, and a NIC Access Module. Refer to Figure 7 on page 16 and Figure 5 on page 6 for

views of the front, rear, and top of the chassis midplane.

HFC Connector Modules are installed in rear card cage slots 1 through 4 (for domain A)

and slots 10 through 13 (for domain B).

CCM Access Modules are installed in rear card cage slot 6 (for Domain A) and slot 7 (for

Domain B).

NIC Access Modules are installed in rear card cage slot 5 (for Domain A) and slot 9 (for

Domain B).

1. If an air management panel is installed in the slot to be populated, remove it from the

card cage.

•

•

•

•

•

•

•

•

•

•

2

2

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

19

Page 32

Installing a Rear-Loaded Module

•

2. Unlock the ejectors of the module to be installed so that each ejector rests at

•

•

•

•

•

•

•

•

•

•

3. Align the printed circuit board of the module with the card guides and slowly slide the

•

•

•

•

•

4. Simultaneously close the ejectors toward the module faceplate to the horizontal position

•

•

•

5. Tighten the two retainer screws by applying 3 in lb of torque to each screw.

•

•

•

Figure 10: Rear-Loaded Module Installation

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

approximately 45° away from its locked position.

Unlike front-loading modules, the ejectors on rear-loading

modules lock in the horizontal position (90° from the

faceplate) when the module is properly installed into its

card slot.

module into the slot until it comes to a stop with the inside tabs (tabs closest to

midplane) of the upper and lower ejectors resting directly under and over, respectively,

the module ejector rail (refer to Figure 10 on page 20).

until each ejector release clicks into position.

2

0

S

D

0

1

S

S

U

D

1

2

S

S

U

D

3

2

S

S

D

U

3

1

S

U

0

Eth

1

Eth

2

Juniper Networks G10 CMTS Getting Started

20

Page 33

Cabling an HFC Connector Module

Cabling an HFC Connector Module

Prior to inserting a coaxial cable into any of the HFC

Connector Module F-connectors, ensure that the cable

meets the requirements provided in the Juniper Networks

G10 CMTS Installation and Configuration manual.

Each DOCSIS Module— and its corresponding HFC Connector Module—support a total of

four downstream channels, where one channel is assigned to each physical downstream

port. Each DOCSIS Module supports a total of 8 or 16 upstream channels (depending on the

DOCSIS Module model) which can be logically allocated to any one of the four physical

upstream ports. Figure 11 on page 21 illustrates an example where the number of channels

allocated on each port is five, three, seven, and one, respectively. The assignment of a node

to a port, and the allocation of upstream channels per upstream port should be considered

prior to connecting the coaxial cables from the cable plant to the HFC Connector Module.

Figure 11: Example of Allocation of Multiple Channels Per Port

One possible deployment scenario for the upstream is to attach one node per upstream port

and to turn on one upstream channel per node. If one of the nodes reaches capacity due to

high penetration or heavy usage of bandwidth-intensive services, then another channel can

be provisioned on that port.

In the following procedures, a node may represent a single

node, or multiple nodes that are combined.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

21

Page 34

Cabling an HFC Connector Module

•

Figure 12: HFC Connector Module Rear Panel

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

US 0

•

•

•

US 1

•

•

•

US 2

•

•

•

•

US 3

•

•

•

•

•

Eth0

•

•

•

•

•

Eth1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

DS 0

DS 1

DS 2

DS 3

Juniper Networks G10 CMTS Getting Started

22

Page 35

Cabling a Chassis Control Module

The following procedure describes how to connect to the downstream ports (refer to

Figure 12 on page 22 for port labeling):

1. Select the first node(s) in the cable plant for assignment to the first of four downstream

ports. Connect the coaxial cable associated with the first node(s) to the F-connector on

the HFC Connector Module labeled “DS 0”.

2. If applicable, repeat the previous step for the second, third, and fourth nodes for

connection to downstream ports “DS 1”, “DS 2”, and “DS 3”, respectively.

The following procedure describes how to connect to the upstream ports:

3. Select the first node(s) in the cable plant for assignment to the first of four upstream

ports. Connect the coaxial cable associated with the first node(s) to the F-connector on

the HFC Connector Module labeled “US 0”.

4. If applicable, repeat the previous step for the second, third, and fourth nodes for

connection to upstream ports “US 1”, “US 2”, and “US 3”, respectively.

If a NIC Module in not used in the G10 CMTS, connect each of the two 10/100BASE-T

Ethernet RJ-45 ports labeled “Eth0” and “Eth1” to the appropriate network equipment in the

headend (refer to Figure 12 on page 22 for port labeling).

Cabling a Chassis Control Module

The Chassis Control Module contains a 10/100BASE-T Ethernet RJ-45 port labeled “Eth0” on

its front panel (refer to Figure 13 on page 24). This port is used for the management interface

to the G10 CMTS. The following procedure describes how to connect this port to the network:

1. Carefully thread the Ethernet cable into the cable channel from the rear of the chassis

(refer to Figure 3 on page 4) until it extends through the opening of the power supply

faceplate.

2. Plug the RJ-45 connector of the Ethernet cable into the RJ-45 port of the Chassis Control

Module labeled “Eth0.”

3. Attached the other end of the Ethernet cable to its respective network equipment in the

headend.

When connecting nodes to the upstream ports of an HFC

Connector Module, do not split a coaxial cable from one

node and attach it to more than one upstream port. Doing

so prevents using the complete features of a DOCSIS

Module that were designed for supporting four separate

nodes or four groups of nodes that are combined.

The CCM Access Module is not used in this procedure.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

23

Page 36

Cabling a Chassis Control Module

•

Figure 13: Chassis Control Module and CCM Access Module Front Panels

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Eth0

C

O

M

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Eth0

•

•

•

•

Eth1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Juniper Networks G10 CMTS Getting Started

24

Page 37

Cabling a NIC Module

Cabling a NIC Module

The NIC Module contains two full-duplex, 1-Gigabit Ethernet GBIC (Gigabit Interface

Converter) transceiver ports on its front panel. Refer to the Juniper Networks G10 CMTS

Installation and Configuration manual for the specifications of the various types of GBIC

interfaces provided.

The following procedure describes how to connect the network cables to these ports (refer to

Figure 14 on page 26 for port labeling):

1. Carefully thread each of the two cables into the cable channel from the rear of the

2. Connect the transmit/receive pair of each of these cables to the GBIC ports labeled “0”

3. Attached the other end of each cable to its respective network equipment in the

4. Repeat this process if another NIC Module is installed in the chassis.

Figure 15 on page 27 provides the front view of the chassis with the network cables installed

into a NIC Module.

chassis (refer to Figure 3 on page 4) until they extend through the opening of the power

supply faceplate.

and “1” on the NIC Module.

headend.

If using optical cables, take care not to bend the cables too

sharply when threading them through the cable channel.

Both ports on each NIC Module must be connected to the

network if redundancy is desired.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

25

Page 38

Cabling a NIC Module

•

Figure 14: NIC Module and NIC Access Module Panels

•

•

•

•

•

•

•

•

•

•

•

•

PULL

OPERATIONAL

EXT FAULT

G

B

I

C

INT FAULT

POWER

•

•

•

•

•

•

•

•

•

GB1 GB0

1

•

•

•

•

•

•

•

G

B

I

C

•

•

•

•

2

•

•

•

CLK PWR RTM OK

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Juniper Networks G10 CMTS Getting Started

26

Page 39

Cabling a NIC Module

Figure 15: NIC Module Cabling – Front View

Power

Power

Fault

Fault

•

•

•

•

•

•

•

•

Power

Power

Fault

Power

Fault

Fault

Power

Power

Fault

Power

Fault

Fault

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

27

Page 40

Cabling a NIC Access Module

•

Cabling a NIC Access Module

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

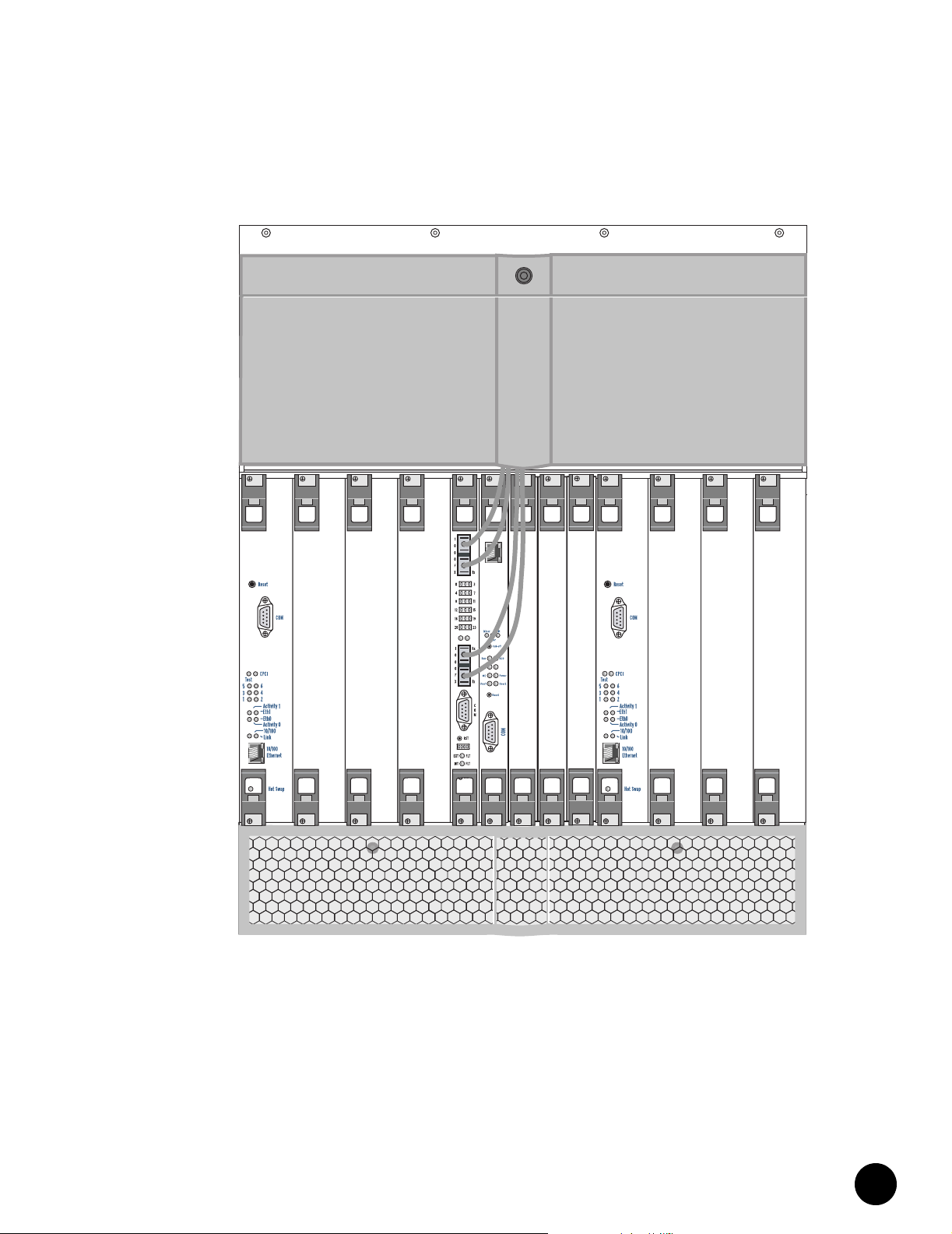

This section describes how to interconnect up to two NIC Access Modules to multiple HFC

Connector Modules in a non-redundant configuration. The procedure assumes that a NIC

Module only supports the DOCSIS Modules installed in the same domain of the chassis.

Therefore, if five or more DOCSIS Modules are installed in the system, then two NIC Modules

are installed to support them. In addition, the procedure assumes that DOCSIS Modules are

installed in the following slot order: 1, 2, 3, 4, 10, 11, 12, 13.

The NIC Access Module cables are used to interconnect the Fast Ethernet ports of the HFC

Connector Modules to the NIC Access Module. The 12 RJ-45 connectors on the NIC Access

Module cable plugged into the connector labeled “2” on the NIC Access Module can be used

as general purpose switched FastEthernet ports. Refer to Table 1 on page 18 for details.

1. If applicable, remove the protective cover that is inserted into the RJ-21 end of the NIC

2. Firmly insert the RJ-21 end of the cable into the connector labeled “1” on the NIC Access

3. Tighten the two cable retainer screws by applying 4 in lb of torque to each of the screws.

4. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 5” and

5. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 7” and

6. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 9” and

7. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 11” and

In this particular procedure, the RJ-45 ports of the CCM

Access Module labeled “Eth0” and “Eth1” are unused.

It is recommended that the following procedure be

followed to allow for future wiring considerations.

Access Module cable.

Module in slot 5 (refer to Figure 14 on page 26).

“PORT 6” and plug them into the RJ-45 ports of the HFC Connector Module in slot 1

labeled “Eth0” and “Eth1,” respectively (refer to Figure 12 on page 22 for port labeling).

If an HFC Connector Module is installed in slot 2, proceed to Step 5; otherwise, jump

ahead to Step 15.

“PORT 8” and plug them into the RJ-45 ports of the HFC Connector Module in slot 2

labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in slot

3, proceed to Step 6; otherwise, jump ahead to Step 15.

“PORT 10” and plug them into the RJ-45 ports of the HFC Connector Module in slot 3

labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in slot

4, proceed to Step 7; otherwise, jump ahead to Step 15.

“PORT 12” and plug them into the RJ-45 ports of the HFC Connector Module in slot 4

labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in slot

10, proceed to Step 8; otherwise, jump ahead to Step 15.

Juniper Networks G10 CMTS Getting Started

28

Page 41

Cabling a NIC Access Module

8. If you have reached this step in the procedure, then at least five HFC Connector Modules

are installed in the G10 CMTS, in which case a second NIC Access Module and its

corresponding cable are required to complete the interconnection procedure. If

applicable, remove the protective cover that is inserted into the RJ-21 end of the NIC

Access Module cable.

9. Firmly insert the RJ-21 end of the second NIC Access Module cable into the connector

labeled “1” on the NIC Access Module in slot 9 (refer to Figure 14 on page 26).

10. Tighten the two cable retainer screws by applying 4 in lb of torque to each of the screws.

11. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 5” and

“PORT 6” and plug them into the RJ-45 ports of the HFC Connector Module in slot 10

labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in slot

11, proceed to Step 12; otherwise, jump ahead to Step 15.

12. Locate the RJ-45 connectors of the second NIC Access Module cable labeled “PORT 7”

and “PORT 8” and plug them into the RJ-45 ports of the HFC Connector Module in slot

11 labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in

slot 12, proceed to Step 13; otherwise, jump ahead to Step 15.

13. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 9” and

“PORT 10” and plug them into the RJ-45 ports of the HFC Connector Module in slot 12

labeled “Eth0” and “Eth1,” respectively. If an HFC Connector Module is installed in slot

13, proceed to Step 14; otherwise, jump ahead to Step 15.

14. Locate the RJ-45 connectors of the NIC Access Module cable labeled “PORT 11 and

“PORT 12” and plug them into the RJ-45 ports of the HFC Connector Module in slot 13

labeled “Eth0” and “Eth1,” respectively.

15. At this point, all of the Ethernet ports of the HFC Connector Modules should be

connected to the NIC Access Module. Figure 16 on page 30 provides an illustration of

these connections (without the HFC Connector Module coaxial cables shown).

16. All used and unused Ethernet cable wires on either NIC Access Module cable should be

dressed appropriately and routed to avoid obstructing the rear connections of the G10

CMTS.

Table 2 on page 31 summarizes the NIC Access Module wiring plan used in this procedure.

The “Module – Slot / Port” headings specify the module name, the slot in which the module is

installed, and the RJ-45 port label of the module.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

G10 CMTS Installation

29

Page 42

Cabling a NIC Access Module

•

Figure 16: NIC Access Module Cable Connections

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

S 0

D

0

US

DS 1

1

US

S 2

D

US 2

DS 3

US 3

•

•

•

•

Eth0

Eth1

0

S

D

0

US

S 1

D

US 1

S 2

D

2

US

S 3

D

US 3

Eth0

Eth1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

DS 0

S 0

D

US 0

S 1

S 0

D

0

OPERATIONAL

OPERATIONAL

EXT FAULT

INT FAULT

POWER

0

DS

S 0

D

US 0

S 1

0

US

1

US

2

US

US 3

Eth0

Eth1

D

DS 1

1

US

S 2

D

S 2

D

2

US

S 3

D

DS 3

US 3

Eth0

1

Eth

Eth0

Eth

POWER

C

O

C

M

O

M

Eth0

Eth1

1

S 0

D

EXT FAULT

INT FAULT

0

US

S 1

D

1

US

S 2

D

US C

DS 3

D

US

Eth1

Eth2

US

0

US

1

DS

1

US

US 1

S 2

D

US 2

US 2

DS 3

US 3

US 3

Eth0

Eth0

Eth1

Eth2

D

1

S

D

1

US

2

S

D

2

DS

2

US

S 3

D

S 3

D

US 3

Eth0

Eth1

Juniper Networks G10 CMTS Getting Started

30

Page 43

Attaching a PC to the Chassis Control Module

Table 2: NIC Access Module Wiring Plan

NIC Access Module 5

Cable/Port Module – Slot/Port

Cable 1 / PORT 1 Reserved Cable 1 / PORT 1 Reserved

Cable 1 / PORT 2 Reserved Cable 1 / PORT 2 Reserved

Cable 1 / PORT 3 Reserved Cable 1 / PORT 3 Reserved

Cable 1 / PORT 4 Reserved Cable 1 / PORT 4 Reserved

Cable 1 / PORT 5 HFC – 1 / Eth0 Cable 1 / PORT 5 HFC – 10 / Eth0

Cable 1 / PORT 6 HFC – 1 / Eth1 Cable 1 / PORT 6 HFC – 10 / Eth1

Cable 1 / PORT 7 HFC – 2 / Eth0 Cable 1 / PORT 7 HFC – 11 / Eth0

Cable 1 / PORT 8 HFC – 2 / Eth1 Cable 1 / PORT 8 HFC – 11 / Eth1

Cable 1 / PORT 9 HFC – 3 / Eth0 Cable 1 / PORT 9 HFC – 12 / Eth0

Cable 1 / PORT 10 HFC – 3 / Eth1 Cable 1 / PORT 10 HFC – 12 / Eth1

Cable 1 / PORT 11 HFC – 4 / Eth0 Cable 1 / PORT 11 HFC – 13 / Eth0

Cable 1 / PORT 12 HFC – 4 / Eth1 Cable 1 / PORT 12 HFC – 13 / Eth1

Cable 2 / PORT 1 FastEthernet or Unused

Cable 2 / PORT 2 FastEthernet or Unused1Cable 2 / PORT 2 FastEthernet or Unused

Cable 2 / PORT 3 FastEthernet or Unused1Cable 2 / PORT 3 FastEthernet or Unused

Cable 2 / PORT 4 FastEthernet or Unused1Cable 2 / PORT 4 FastEthernet or Unused

Cable 2 / PORT 5 FastEthernet or Unused1Cable 2 / PORT 5 FastEthernet or Unused

Cable 2 / PORT 6 FastEthernet or Unused1Cable 2 / PORT 6 FastEthernet or Unused

Cable 2 / PORT 7 FastEthernet or Unused1Cable 2 / PORT 7 FastEthernet or Unused

Cable 2 / PORT 8 FastEthernet or Unused1Cable 2 / PORT 8 FastEthernet or Unused

Cable 2 / PORT 9 FastEthernet or Unused1Cable 2 / PORT 9 FastEthernet or Unused

Cable 2 / PORT 10 FastEthernet or Unused1Cable 2 / PORT 10 FastEthernet or Unused

Cable 2 / PORT 11 FastEthernet or Unused1Cable 2 / PORT 11 FastEthernet or Unused

Cable 2 / PORT 12 FastEthernet or Unused1Cable 2 / PORT 12 FastEthernet or Unused

1. These ports can be used as general purpose switched Fast Ethernet ports; otherwise, these connectors are unused.

Ports 1–12 on Cable 2 correspond to FastEthernet ports 0–11, respectively, under the interface fastEthernet sub-mode

for the NIC Module.

Attaching a PC to the Chassis Control Module

Initial configuration of the G10 CMTS requires a direct connection between a personal

computer (PC) and the Chassis Control Module. Using the DB-9– to–DB-9 null modem serial

cable supplied in the accessory kit, connect one end of the cable to the RS-232 DB-9 port

labeled COM on the Chassis Control Module front panel (refer to Figure 13 on page 24), and

connect the other end to the serial port on your PC.

An adapter may be needed to connect the DB-9 connector

of the cable to the serial port of your PC (for example,

DB-9–to–DB-25).